- Department of Civil Engineering, Sir Syed University of Engineering and Technology, Karachi, Pakistan

This research aims to develop a sustainable concrete matrix using industrial waste materials, including marble powder, waste glass sludge (WGS), and crumb rubber from tire waste. The mechanical properties of the newly designed concrete mix, such as compressive strength, split tensile strength, and flexural strength, were evaluated. The results showed improvements in compressive strength by 5%, split tensile strength by 4%, and flexural strength by 5%. Besides, a statistical two-way analysis of variance (ANOVA) with a threshold of less than 0.001 was used, and the residual error was found to be low (4.09), both in terms of lack of fit and pure error. This research proposes a new model to assess the sustainable performance of the newly developed concrete matrix. Data was collected from 21 academic professors and structural engineers, and hypotheses were tested using partial least squares structural equation modelling. The Design Expert software was deployed to check its hypothesis, and the Smart PLS software was deployed to measure data validation. The findings demonstrate that a sustainable concrete matrix positively influences sustainable performance. The proposed model offers valuable insights for decision-makers and engineering managers, highlighting the benefits of adopting sustainable materials to enhance overall sustainability performance. Incorporating marble powder, waste glass sludge, and crumb rubber was beneficial in terms of mechanical strengths and microstructure. Overall, this research contributes to the goal of reducing CO2 emissions in the cement industry and provides practical recommendations for incorporating sustainable materials in construction practices.

1 Introduction

The cement industry significantly contributes to 8% of global carbon dioxide (CO2) emissions. The construction industry is a major contributor to global energy consumption, and a key part of carbon emissions is attributed to it. The production of one ton of concrete and one ton of cement generates 0.15 and 1 ton of greenhouse gas emissions, respectively. Given the global annual output of 25 billion tons of concrete, these figures have a significant environmental impact. One way to reduce this impact is through green concrete, which incorporates waste, renewable, or supplementary cementitious materials (SCMs) instead of ordinary Portland cement (OPC) or aggregates. SCMs are finely ground pozzolanic materials that can partially or fully replace OPC in concrete mixtures, improving their fresh and hardened properties (Xiang et al., 2019; Yang et al., 2023; Thomas and Gupta, 2016).

Researchers are investigating various sustainable construction materials to reduce the environmental impact of building and construction projects (Ali et al., 2022; Akbar et al., 2023a; Yang et al., 2023). These sustainable construction materials have been found to perform similarly to traditional cement-based structures (Wang et al., 2019; Chang et al., 2020; Abdelmelek and Lubloy, 2021; Cao et al., 2022; Junaid et al., 2022). Mechanical properties and durability have been extensively studied to ensure the reliability of supplementary cementitious materials (Amin et al., 2020; Ansari and Chang, 2020; Alaloul et al., 2021). Studies have found that replacing a portion of cement with supplementary materials like silica fume (SF) and fly ash (FA) can improve the properties of porous concrete. Up to 5% cement replacement with SF has increased compaction ease, strength, and durability in harsh environments. Combining SF with PVC waste powder as a replacement for ordinary Portland cement (OPC) can also produce concrete with suitable mechanical properties for structural use and be economically and environmentally friendly. Overall, using pozzolanic materials like SF and FA as alternatives to OPC has positively impacted strength and durability in various types of concrete, including geopolymer and self-compacting concrete (Adil et al., 2020; Akbar et al., 2023b; Cao et al., 2023). Similarly, (Umar et al., 2022; Paruthi et al., 2023), concluded that The optimal coal bottom ash dosage for normal-strength concrete was identified to be 10% when combined with WGS, as it resulted in the highest increase in compressive strength after 28 days (Jagadesh et al., 2023; Wang et al., 2017). deduced that the compressive strength was highest when the fly ash replacement was 15%. Additionally, as the pore water saturation increased, the rebound value of the fly ash concrete first increased and then decreased. When the pore water saturation was below 20%, the rebound value continued to increase. However, the rebound value decreased significantly when the pore water saturation was between 20%–60%. Beyond 60% pure water saturation, the rebound value remained relatively stable. The water absorption and corrosion resistance capacity of marble powder-enhanced concrete revealed that the addition of ultra-hydrophobic marble powder decreased the concrete water absorption by 36.42% compared to conventional concrete. Electrochemical experiments revealed that the use of 20% super hydrophobic marble powder increased the polarization resistance of the mortar by 4 × 10⁻⁴ KΩ·cm2 more than ordinary mortar, showing that the marble powder-based concrete could be helpful in offshore concrete structures (Song et al., 2022; Cao et al., 2023). Waste glass sludge, a silica-based industry, is also incorporated in concrete as a supplementary cementitious material. The superior mechanical characteristics of WGS (Waste Glass Sludge) are due to its increased pozzolanic reactivity, increased surface area, smaller particle size, and decreased overall porosity of the resulting concrete. It is important to use WGS with finer particle sizes to achieve optimal properties. The freezing and thawing resistance test results indicate that WGS has high durability, with a durability factor of over 90%. Additionally, the scaling resistance and rapid chloride penetration evaluation showed that WGS-contained concrete showed satisfactory results (Lee et al., 2018; Lu et al., 2019; Umar et al., 2022). Test results concluded by (Deng et al., 2023) showed that using waste glass powder as a replacement for cement in concrete can improve the material’s durability by forming a denser cement matrix through a pozzolanic reaction with lime during the early stages of hydration, resulting in the formation of additional C-S-H gel. Using glass particles in concrete can enhance its microstructure and decrease permeability, resulting in improved resistance to sulfate attacks and freeze-thaw cycles. However, it can also negatively affect carbonation resistance and increase the risk of ASR expansion. The extent of ASR expansion depends on the type, size, and amount of glass particles used. To mitigate the risk of ASR expansion, reducing the size of the glass particles is a simple and efficient solution. Glass particles smaller than 425 mm have been shown not to cause ASR expansion (Guo et al., 2020). Research (Ahmad et al., 2022) has shown that incorporating waste glass into rubberized concrete can significantly improve its mechanical performance, with a maximum improvement of 20% when using a 20% substitution rate. It was discovered that the concrete’s compressive and split tensile strengths were 24% and 30% greater than those of ordinary concrete, respectively (Garg et al., 2023; Zeyad et al., 2020). Waste glass also improves the concrete’s durability, including its resistance to water absorption, dry shrinkage, and acid. Experimental results by (Liu et al., 2016; Saba et al., 2021) confirmed that the strength of crumb rubber concrete made with pretreated rubber and synthetic resin increased by 12% for compressive strength, 40% for splitting tensile strength, and 5% for axial compressive strength. Additionally, the durability of the concrete was improved, as demonstrated by a reduced strength loss ratio of 1.2% after 25 cycles of freezing and thawing. Furthermore, the experimental analysis by (Xu et al., 2018) indicates that an increase in the rubber content of concrete leads to a greater number and longer cracks. This implies that the concrete is becoming more ductile, which allows it to absorb more energy during the collapse, making it more suitable for structures at risk of dangerous collapses (Meshram et al., 2023).

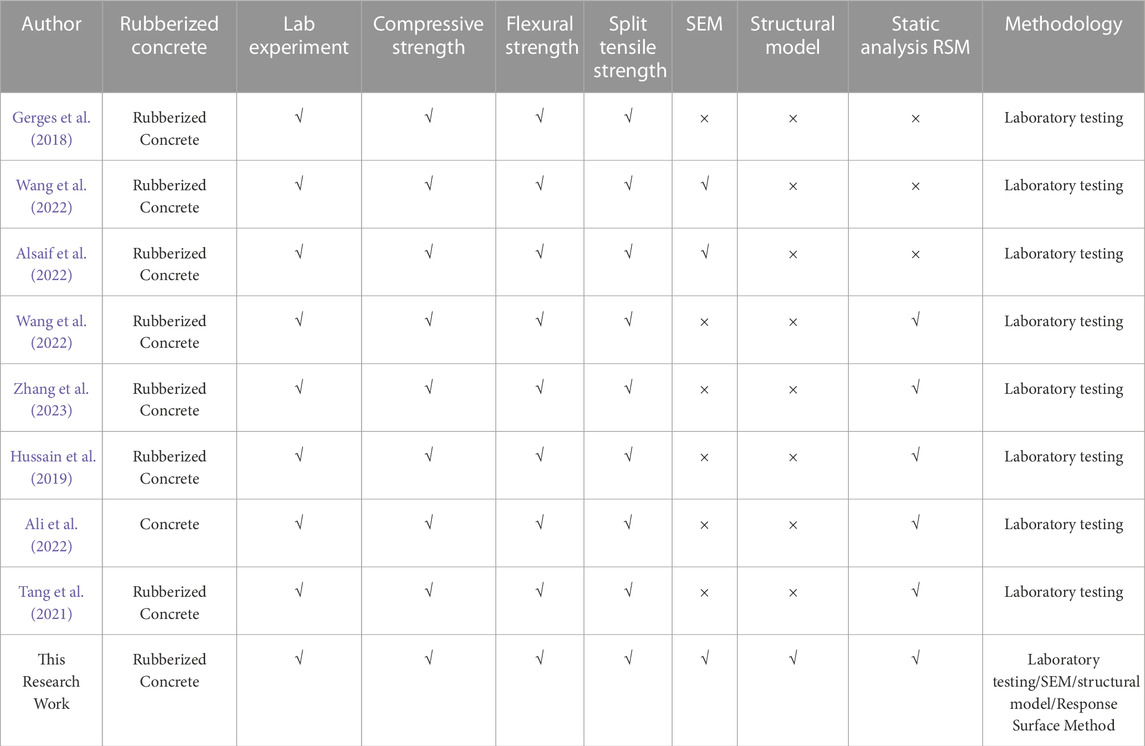

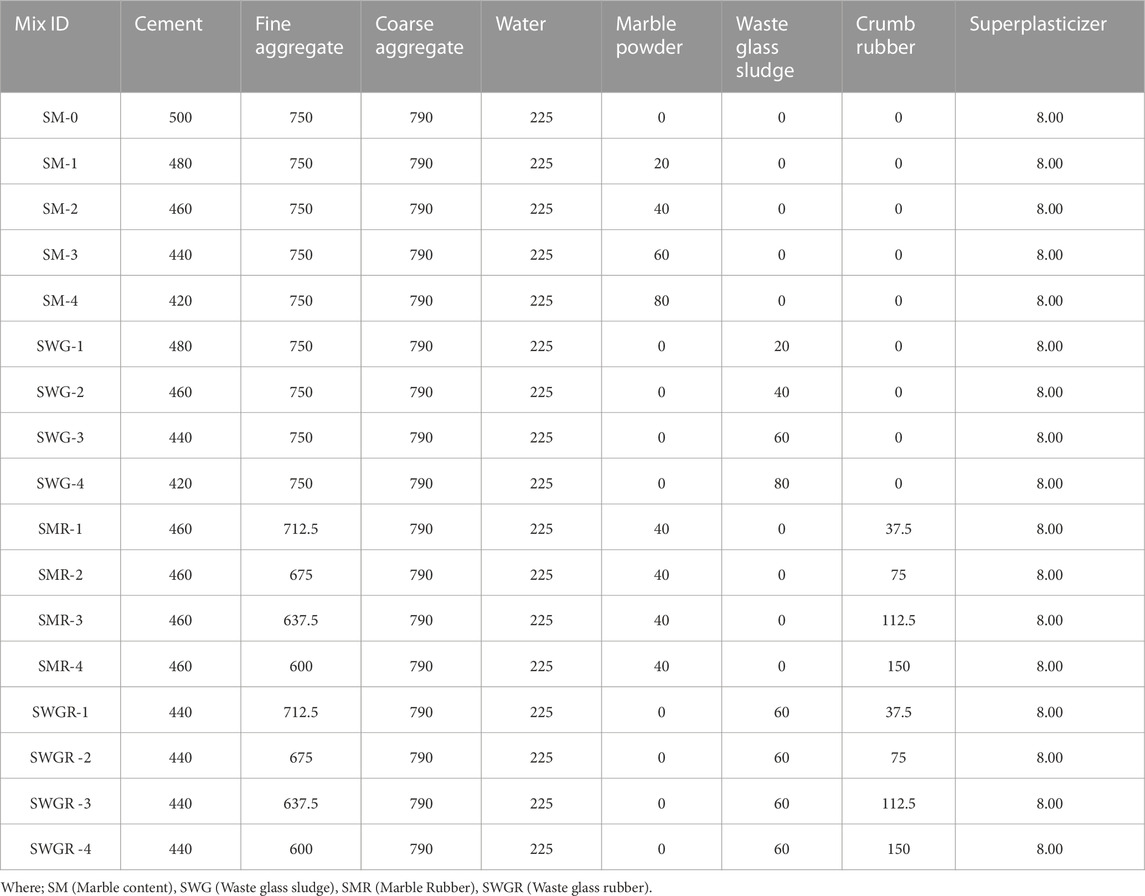

This study demonstrates that industrial waste materials like glass sludge and marble powder can be used as supplementary cementing materials when combined with crumb rubber to replace natural sand. To the authors’ knowledge, this specific combination of three different industrial waste materials has not yet been studied. Using a sustainable performance model, economic and environmental factors were analyzed to determine the environmental impact of conventional concrete. Additionally, an optimization model utilizing the RSM method is presented to validate the study’s findings, showcasing the research’s uniqueness. Parallel to these studies, this research fulfills the research gap by investigating a wide range of factors such as compressive strength, flexural strength, split tensile strength, SEM, structural model; static analysis RSM; of the rubberized concrete (Table 1). Therefore, the researchers assumed the possibility of achieving that goal.

2 Materials and methods

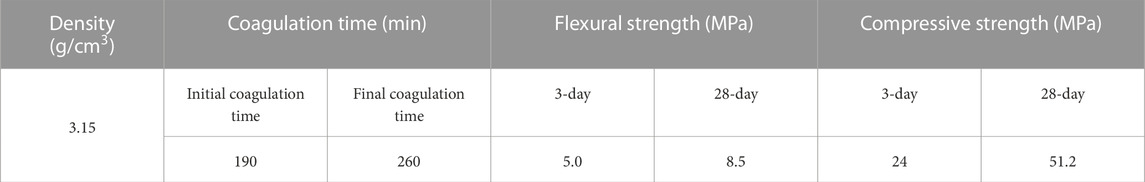

2.1 Cement

Due to the low strength of recycled aggregates, it is necessary to increase the cement grade to improve the overall strength of rubberized concrete. This experiment used PO42.5 ordinary Portland cement, suitable for general industrial and civil buildings, produced by Pioneer Cement Co., Ltd. Its specific physical and mechanical properties are shown in Table 2 (Garg et al., 2023). The cement is a water-hard cementitious material, and the hydration reaction occurs after adding water; the main chemical reactions are the silicate hydration reaction and the aluminate hydration reaction. Cement composition is added in Table 3.

2.2 Reducing agents

To improve the workability of concrete and disperse cement particles more easily during mixing, reducing agents need to be added. This article selects the high-efficiency reducing agent, whose basic performance parameters are shown in Table 4.

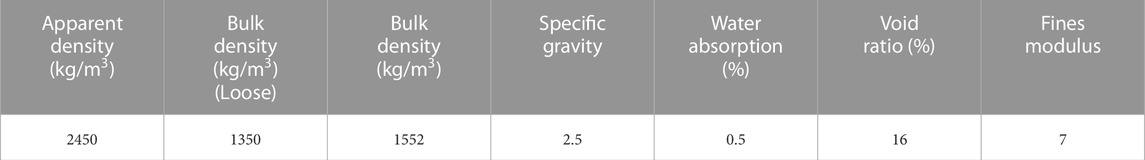

2.3 Coarse aggregate

The coarse aggregate is natural stone. The aggregate surface is uneven with many apertures, and many sizes. Due to the different shapes and sizes of natural stone, the particle size distribution is uneven. Therefore, the coarse aggregate should be crushed and sieved before being mixed with concrete (Liu et al., 2016). The internal porosity of the coarse aggregate is high, and the density is a little bit low. According to the classification standards for aggregates, it belongs to the lightweight aggregate category. The coarse aggregate particle size is graded between 5 and 20 mm and is continuously screened in this paper (Saba et al., 2021); the results are shown in Table 5.

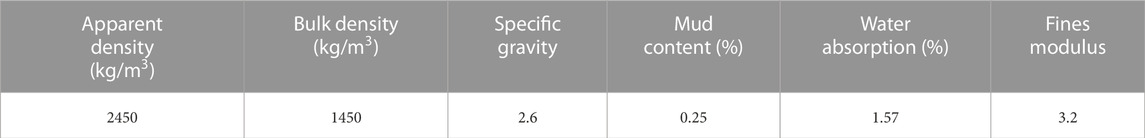

2.4 Fine aggregate

The fine aggregate used in this study is natural sand from the river region of Pakistan. Natural sand has a well-graded particle size distribution, is classified as Zone II sand, and falls under the category of medium sand according to the fineness modulus. The physical properties of the sand used in this study were determined according to the “Experimental Regulations for Concrete” (Xu et al., 2018), with the results presented in Table 6. The rubber used in this study is tier rubber from the waste tier.

2.5 Specimens preparation

The investigation consisted of two phases. Initially, a model was optimized using Response Surface Method (RSM). The optimized results were validated in the second stage through a comprehensive experimental campaign. The study utilized a combination of fine aggregates with a size range of 0–4 mm, coarse aggregates with a size range of 4.75–10 mm, and Ordinary Portland cement (OPC) as the primary materials. In addition, crumb rubber with a size range of 0.221–0.35 mm was used. The mix design used in the experimental campaign is outlined in Table 7. The composition of the cement used is summarized in Table 7. A superplasticizer called Chemrite 520BA was also utilized. The study evaluated the concrete’s compressive, split, and flexural strength by testing at least 3 cylinders (300 × 150 mm) and 3 beams (100 × 100 × 500 mm) for each mix design composition.

2.6 Concrete production and testing phase

A standard concrete mixer was utilized to mix the concrete, and a vibrating Table operating at 350 Hz was employed to compact the concrete. The concrete ingredients were mixed in the following sequence: cement, waste glass sludge (WGS), marble powder, crumb rubber, natural fine aggregates, and coarse aggregates were added and dry mixed for 3 minutes to ensure a homogenous concrete matrix. Next, water and superplasticizer were added and mixed for 5 minutes before casting beams and cylinders. The compressive, split, flexural strength and microstructural analysis was carried out at 28 ± 3 days.

2.7 Response surface methodology

The response surface method (RSM) is an advanced statistical model showing several outcomes and responses for input variables. The proposed method makes a polynomial relationship between the response and the input. This demonstration is helpful in the optimization of the mix design. The prediction models have been helpful for various purposes. For instance, (Rabczuk and Belytschko, 2004), suggested a prediction model for arbitrary cracks that addresses both 2D problems and experimental analysis.

Similarly, (Rabczuk and Belytschko, 2007), presented another 3D model for evaluating large deformations and cracks that help to analyze the available experimental data in 3D. To generate statistical data, it is essential to have relevant experimental data that helps to match the model and test results, which assists in checking the adequacy of the proposed model. Design-Expert v11 is a quantifiable computer program that features test plans, mathematical formulas, analytical research, and response improvement (Noordin et al., 2004; Akbar et al., 2023b). The ANOVA analysis tool is utilized to examine the relationship and effect of input components on the response (Myers et al., 1995).

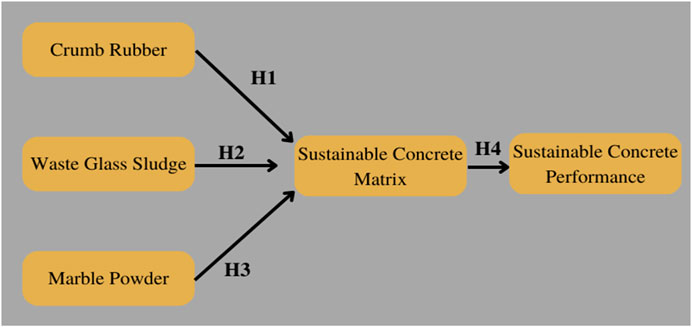

2.8 Sustainable performance research methodology

Due to the increasing expansion of industrial activity, there are issues with waste generation, environmental contamination, resource scarcity, and deterioration of environmental condition (Ma et al., 2022). Construction industry looking for ways to switch from conventional to sustainable construction techniques to meet their economic objectives without causing environmental pollution (Oke et al., 2019). Therefore, we need sustainable materials to ensure sustainable performance. This is due to the growing environmental concerns, rising demand for construction materials, and the shortage of sustainable material supply. One major industry that requires more attention is construction because of its significant resource use, waste production, and environmental impact (Ma et al., 2023). The construction industry has a significant potential for improving the eco-friendly materials and technologies for sustainable performance (Ali et al., 2023). Moreover, Crumb rubber (CR), Waste glass sludge (WGS), and Marble powder (MP) makes a concrete mixture which influence the sustainable material performance. Therefore, reducing waste, improving energy, and resource efficiency are the three fundamental goals of the sustainable material. Based on above discussion and introduction we hypotheses that.

H1. Crumb rubber (CR) positively and significantly impacts the making of the sustainable concrete matrix (SCM)

H2. Waste glass sludge (WGS) positively and significantly impacts the making of sustainable concrete matrix (SCM)

H3. Marble powder (MP) positively and significantly impacts the making of sustainable concrete matrix (SCM)

H4. Sustainable concrete matrix (SCM) positively and significantly impacts sustainable material performance (SMP)

2.8.1 Data collection and procedure

The current research used a survey research design. A questionnaire was created to gather information and test hypotheses. To measure each concept, the questions from earlier literature are adopted. The survey questionnaire was examined for content validity, conformance to theoretical definitions, and redundancy by 21 academic professors and structural engineers with experience working on materials. Utilizing several techniques, the questionnaire’s validity and reliability were guaranteed. Different portions of the questionnaire were used to represent the items for each construct. Each item is evaluated on a Likert scale of 1–7 points. In this study, the experts have experience working for organizations engaged in sustainable concrete and serve as the unit of analysis. Due to the target informant’s excellent observations of sustainable concrete implementation in construction, a sample approach like this one was employed. The researchers selected a representative sample size of 21 for the statistical analysis. Figure 1 explain the structure model.

2.8.2 Measures and validation

For this study, the survey was divided into two portions. In the first part, fourteen items related to three dimensions of the sustainable concrete matrix: crumb rubber, waste glass sludge, and marble powder. The crumb rubber was measured using four items. We adopt items for these parts from (Akbar et al., 2023b). The waste glass sludge was measured using five items. We adopt items for these parts from (Umar et al., 2022). Marble powder was measured using five items. We adopt items for these parts from (Ali et al., 2022). The final part calculated sustainable performance using environmental and economic dimensions. The environmental performance was measured using three items, and economic performance was measured using three items. The constructs for this part were derived from research (Li et al., 2019).

2.8.3 Data analysis

This study uses smart-PLS version 4 and partial least squares structural equation modelling (PLS-SEM). PLS-SEM is an effective method for examining intricate models. The study aims to identify endogenous variables contributing the least amount of variance to the model. PLS-SEM can simultaneously manage the structural and measurement models (Hair et al., 2019). The proposed model is tested with PLS-SEM. According to Hair (Hair et al., 2019), the measurement and structural models were explicitly approximated to produce reliable results, because this technique is most recommended when the goal of the study is to examine and predict the dependent variables in order to account for the maximum variance.

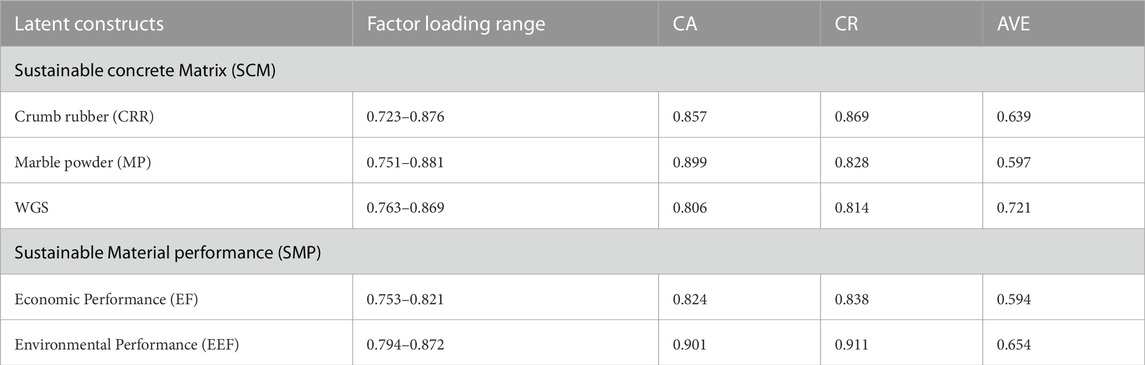

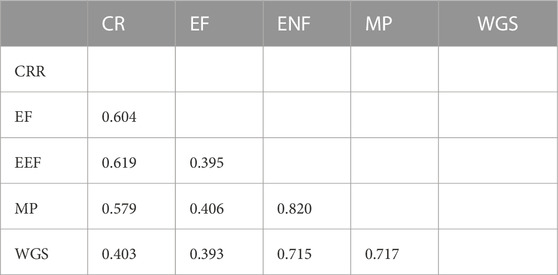

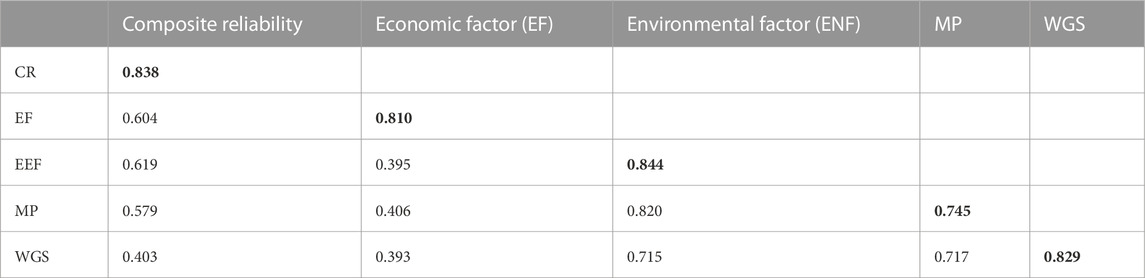

2.8.4 Measurement model analysis

We applied the validity and reliability tests Hair (Hair et al., 2019) recommended to evaluate the measurement model. Results above the 0.70 threshold were obtained when composite reliability and Cronbach alpha (CA) were used to evaluate the reliability of all constructs (Hair et al., 2019). The full results for AVE, CA, and CR values are shown in Table 8. To confirm the construct’s validity, Petter advised computing first-order constructs’ VIF and outer weight values (Petter et al., 2007). The outer and inner VIF values were less than 5.0, demonstrating the lack of multicollinearity in our data (Sarstedt et al., 2017; Fornell and Larcker, 1981) Additionally, the Heterotrait-Monotrait ratio (HTMT) and Fornell-Larcker criteria were used to evaluate the discriminant validity (DV) (Hair et al., 2019). Using a conventional approach, Fornell (1981) discovered that the AVE’s root square value exceeded the correlation values in columns and rows. The HTMT is a more recent method of calculating DV; data indicates that all HTMT values were less than 0.85 (Henseler et al., 2015). As a result, the investigation’s DV is unaffected. Tables 8 and, Tables 9 & Tables 10 present the complete collection of findings.

2.8.5 Structural model analysis

The structural model (Hussain et al., 2018) confirmed the underlying associations between independent and dependent variables (Hair et al., 2019). The study model was examined using its explanatory power (

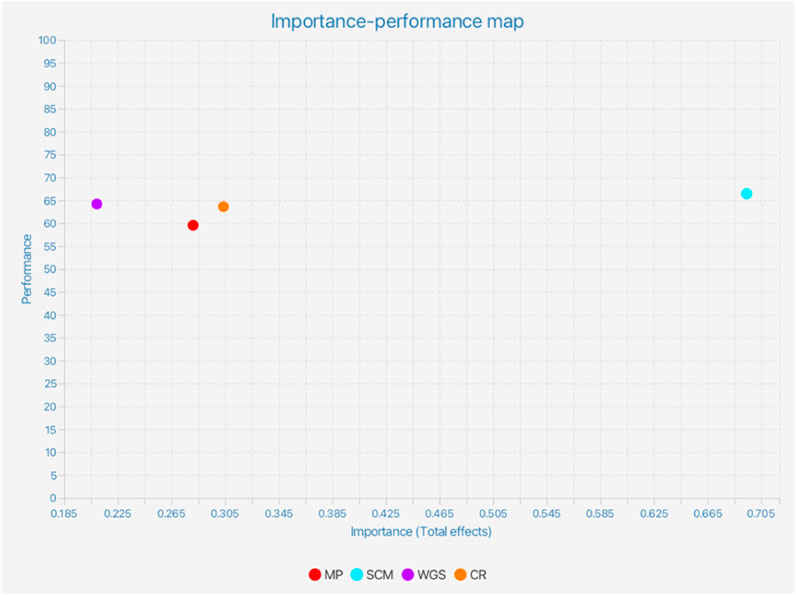

Finally, the GOF model measures how well the outer and inner measurement models predict the model’s empirical results (Ansari et al., 2022). The formula used to compute the GOF is GOF = ; PLS models have a global validation cutoff range of 0–1, which yields GOF big 0.36, medium 0.25, and tiny 0.1, respectively (Wetzels et al., 2009). The model’s GOF is 0.510, which indicates that it has excellent predictive power and is a good fit for the data. SMP is a dependent variable in our model, with the following four antecedents predicting its occurrence: CR, WGS, MP, and SCM. SCM has a performance value of 65.774 and an importance value of 0.688, as shown in Figure 2. MP, CR, and WGS have performance values of 59.839, 64.016, and 64.709, respectively, and importance values of 0.282, 0.310, and 0.287.

3 Results and discussion

3.1 Compressive strength of marble powder, waste glass sludge and crumb rubber-based concrete

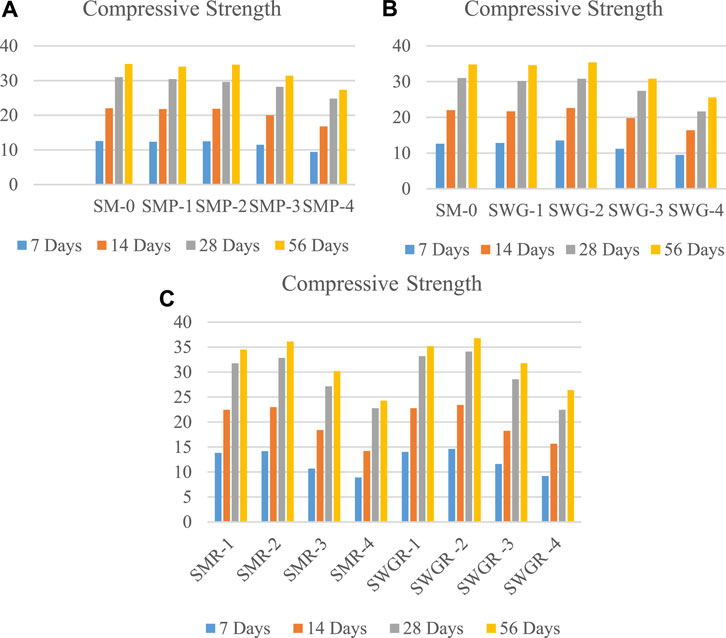

The compressive strength of concrete was evaluated with varying amounts of marble powder and compared to a control mix to determine the impact of marble powder on the concrete. Testing was conducted at ages 7, 14, 28, and 56 days. The results suggest a positive influence of marble powder at various ages. Marble powder replaced cement at dosages of 20, 40, 60, and 80 kg/m3. Figure 3 reveals compressive strength improved with cement replacement with marble powder up to 40 kg/m3. The maximum compressive strength, 34.6 MPa, was achieved at 56 days with the mix SMP-2, nearly equal to the control mix strength of 34.8 MPa. On the 28th day, the strength of SMP-2 showed a different pattern compared to the control and previous mix designs, which showed a slight decrease in strength, possibly due to a slower hydration process with marble powder. However, a decrease in strength was observed when the amount of marble powder was increased. At 56 days, mix designs SMP-3 and SMP-4 had strengths of 31.4 MPa and 27.3 MPa, respectively. During cement hydration, the growth of crystals on particle surfaces decreases cracks and pores. The particle size of marble powder impacts the microstructure of the hydration process. A large particle size provides structural support, while smaller particles can enter interior pores to enhance hydration. The results suggest that the proposed mix designs incorporating different percentages of marble powder are suitable for various concrete applications, minimizing the high dosage of cement (Santos et al., 2020; Wang et al., 2022).

FIGURE 3. Compressive strength of the concrete (A) Marble-based concrete (B) Waste Glass Sludge concrete (C) Marble Powder, Waste Glass Sludge, and Rubber Concrete.

Concrete made with waste glass sludge had a higher compressive strength than that made with marble powder, as shown in Figure 3B. The strength improved gradually until a WGS replacement of 40 kg/m3 was used, but it declined beyond that point. The highest strength was observed at 40 kg/m3 WGS on the 56th day. The pozzolanic reaction in waste glass concrete was slower but increased over time and reached its maximum strength at a later stage.

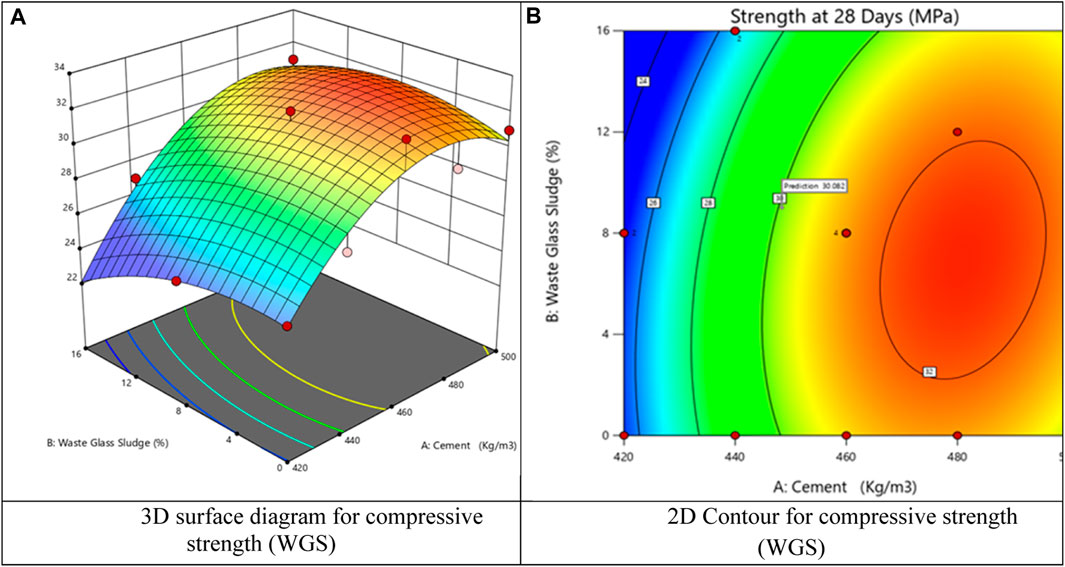

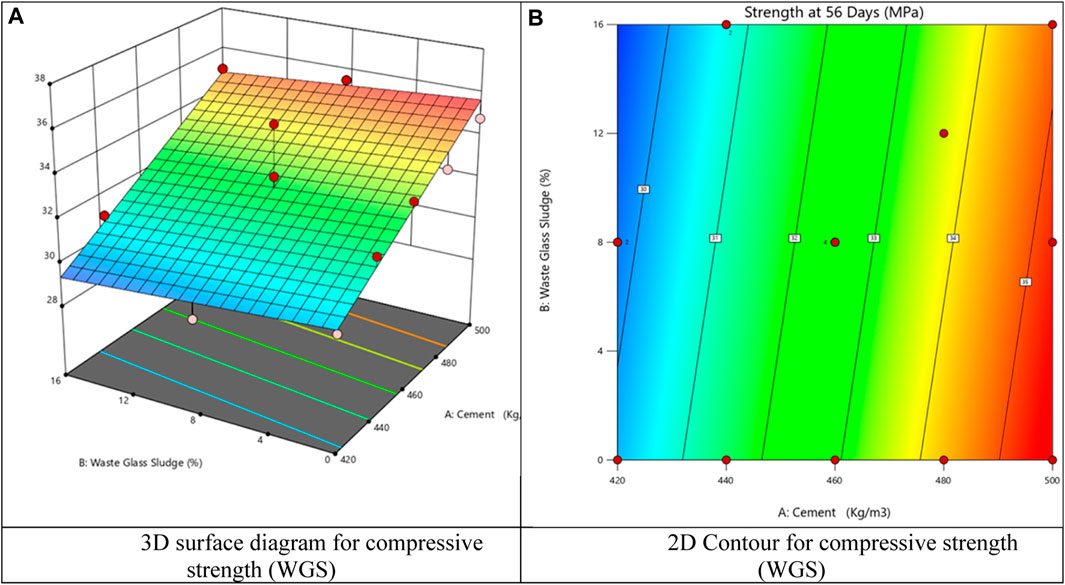

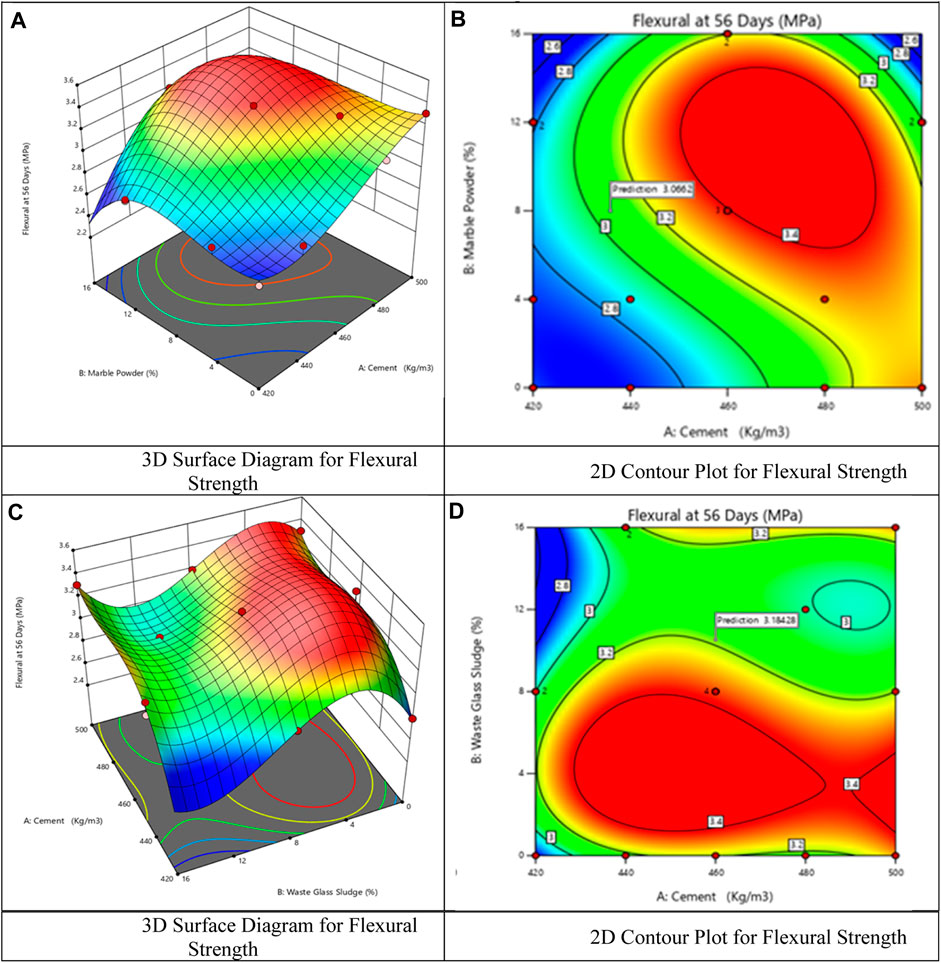

Rubber, an inert material, doesn't participate in pozzolanic activities. However, rubber plays its role as a filler material. Figure 3C shows that concrete containing marble powder and crumb rubber improves the overall compressive strength. Replacing fine aggregate with crumb rubber up to 75 kg/m3 improves the compressive strength to 32.82 MPa. Existing natural fine aggregates and crumb rubber played a better-filling role, improving the concrete matrix. For the higher content of crumb rubber, the strength of concrete is reduced, showing a disadvantage of a higher percentage of crumb rubber. However, the concrete strength of a later age improved due to the marble powder’s slow hydration process. Waste glass sludge (WGS) and crumb rubber-based concrete outperformed the marble powder and crumb rubber-based concrete specimens for the 28th and 56th days. This is because of the better pozzolanic activities of waste glass sludge than marble powder. SWGR-2, containing a waste glass sludge of 60 kg/m3 and a crumb rubber of 75 kg/m3, had a compressive strength of 36.8 MPa, the highest among all combinations. The 2D and 3D diagrams predicted by the RSM method suggested similar trends, as shown in Figures 4, 5.

FIGURE 4. 3D surface diagram for compressive strength (WGS) (B) 2D Contour for compressive strength (WGS).

FIGURE 5. 3D surface diagram for compressive strength (WGS) (B). 2D Contour for compressive strength (WGS).

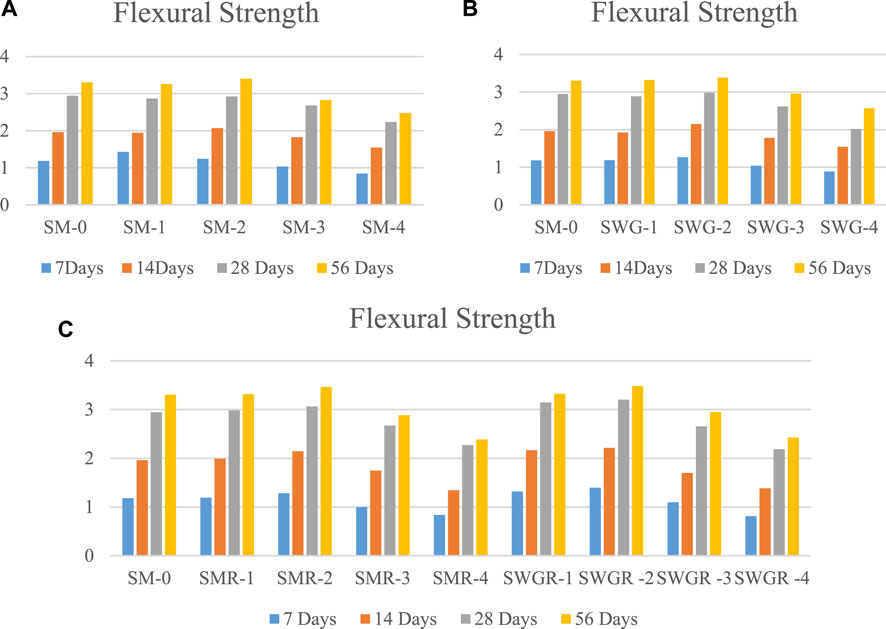

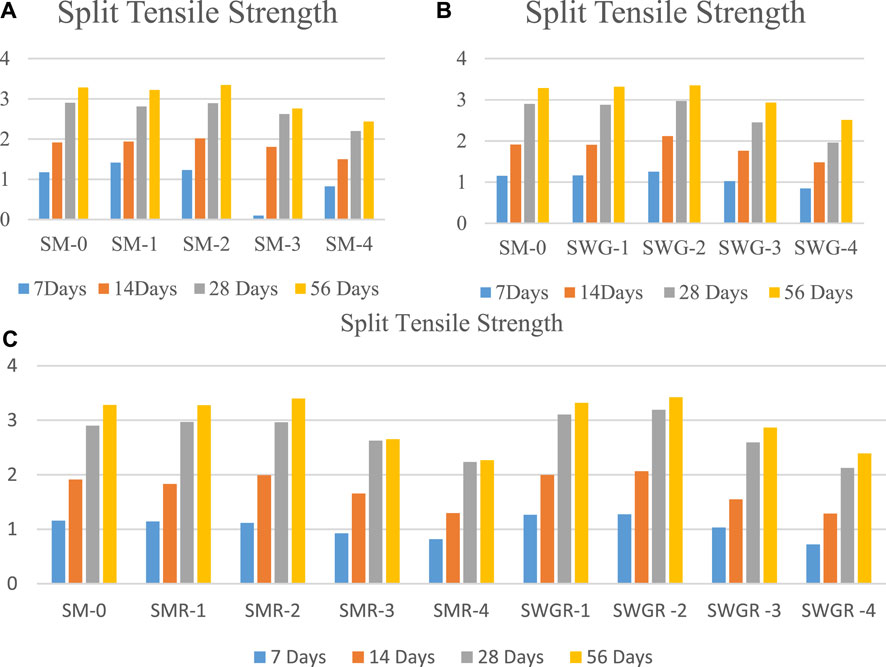

3.2 Flexural and split tensile strength

The flexural strength of the concrete matrix is shown in the figure. Generally speaking, the flexural strength of concrete mainly depends on the conventional reinforcement or fibres, which helps to increase the flexural strength (Zaid et al., 2021). Besides, the reinforcement of the bonding of the concrete matrix also plays an important role. Glass powder, with its cementitious properties, showed promising results. In moderate incorporation, it has improved the mechanical strength of concrete (Mafalda and Sousa-coutinho, 2012). The test result of the current study shows similar results; a partial replacement of cement with marble powder and waste glass sludge showed better mechanical performance. At 56 days, the flexural strength of marble powder-based concrete reached a maximum of 3.4 MPa, while waste glass sludge-based concrete exhibited a maximum flexural strength of 3.38 MPa. Likewise, crumb rubber and crumb rubber-based concrete achieved a flexural strength of 3.4 MPa.

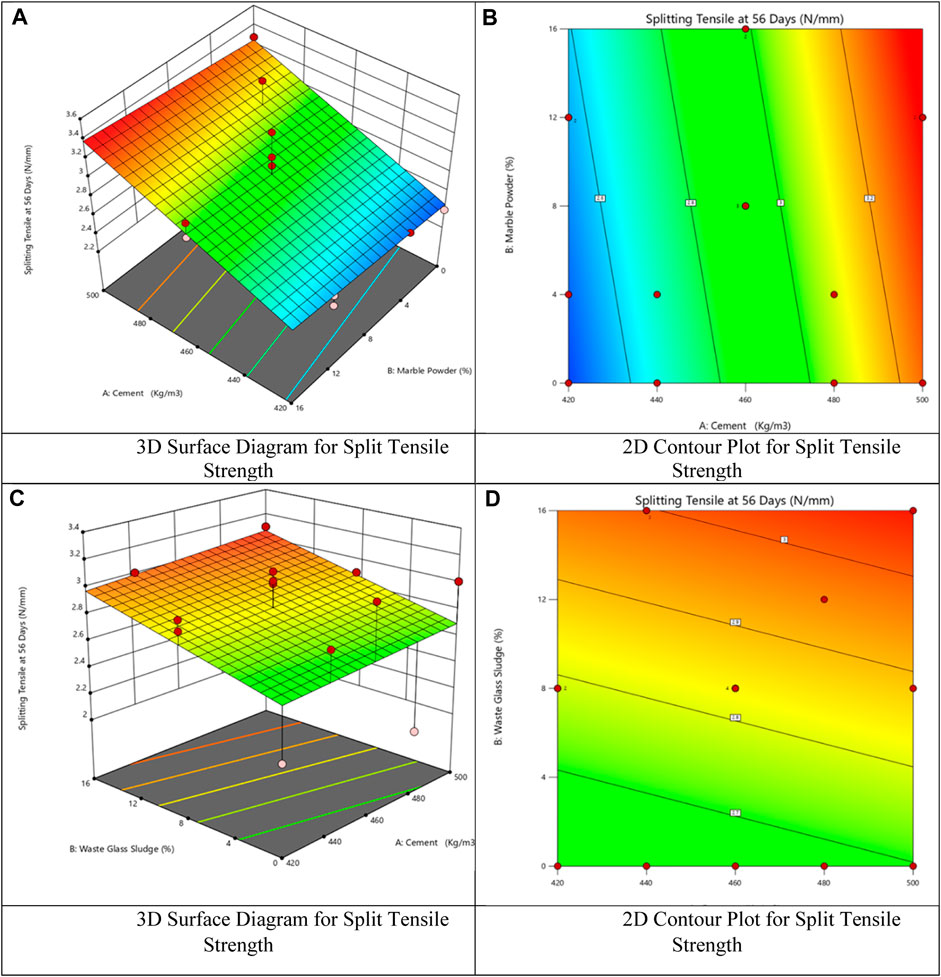

In contrast, waste glass sludge-based rubber concrete demonstrated a maximum flexural strength of 3.48 MPa at the same age of 56 days, as shown in Figure 6. The split tensile strength of concrete had similar trends, as shown in Figure 7. The 3D contour diagrams suggested by RSM predicted similar results, as shown in Figures 8, 9. The flexural and split tensile strength did not impact because of the addition of the supplementary cementitious materials. This indicates that cement can be partially replaced with marble powder and waste glass sludge. One of the fundamental reasons behind the enhanced strength properties of concrete with marble powder and waste glass sludge lies in their pozzolanic activity. Both marble powder and waste glass sludge contain high amounts of amorphous silica and alumina, which exhibit pozzolanic behaviour when in contact with calcium hydroxide (CH) released during cement hydration. This reaction forms additional calcium silicate hydrates (C-S-H) gel, filling the voids and pore spaces within the concrete matrix which ultimately decreases the porosity of concrete.

FIGURE 6. Flexural strength of concrete (A) Marble-based concrete (B) Waste Glass Sludge concrete (C) Marble Powder, Waste Glass Sludge and Rubber Concrete.

FIGURE 7. Split tensile strength of concrete (A) Marble concrete, (B) Waste Glass Sludge based concrete, (C) Marble Powder, Waste Glass Sludge and Rubber Concrete.

FIGURE 8. (A). 3D surface diagram for flexural strength (B). 2D contour plot for flexural strength (C). 3D surface diagram for flexural strength (D). 2D contour plot for flexural strength.

FIGURE 9. (A). 3D surface diagram for split tensile strength (B). 2D contour plot for split tensile strength (C). 3D surface diagram for split tensile strength (D). 2D contour plot for split tensile strength.

Consequently, the densification of the microstructure contributes to improved flexural and split tensile strength. The fine particles of these waste materials enhance the packing density of the concrete matrix, resulting in reduced porosity and increased interfacial transition zone (ITZ) density. This densification improves load transfer mechanisms and hinders crack propagation, leading to higher flexural and split tensile strength. Waste glass sludge typically contains alkaline components, such as sodium oxide and potassium oxide, which can act as chemical activators, promoting the early-age strength development of concrete.

Additionally, the presence of these chemical admixtures can improve the homogeneity of the mix and reduce water demand, resulting in enhanced workability and subsequent strength gain. Marble powder and waste glass sludge incorporation can induce microstructural modifications within the concrete matrix. The fine particles of waste materials fill the gaps between cement particles, reducing the average pore size and enhancing the interconnectivity of the pore network. This microstructure refinement leads to increased strength, improved crack resistance, and a more durable concrete matrix. RSM results verify the experimental results, as shown in Figures 8, 9.

3.3 Structural model

In this study, a conceptual model (Hussain et al., 2018) that examines the relationship between sustainable concrete matrix and SMP is developed, which has received little prior study. We collected this study’s information from the Pakistani construction industry to examine the hypothesis. According to empirical data, the sustainable concrete matrix inspired SMP to implement environmental and economic protection approaches. Our findings show that CR, WGS and MP significantly impact SCM with t-values (17.650, 15.190, and 13.223) which validate our hypotheses H1, H2, and H3. Finally, the sustainable concrete matrix significantly and positively affects SMP (ß = 0.479), validating hypothesis H4 (as shown in Table 12).

According to the results of this study, the sustainable concrete matrix is a valuable material that allows construction projects (Hussain et al., 2019) to achieve SD objectives by strengthening materials’ economic and environmental influence. The findings of this research show that a sustainable concrete matrix improves SMP. As a result, we need to consider how important a sustainable concrete matrix is for accomplishing SMP.

3.3.1 Practical implications

The local cultural and ecological environment is under much pressure due to sustainable materials. To the best of our knowledge, this research is one of the first to analyze the influence of sustainable concrete matrix on sustainable material performance (SMP) comprehensively. It is remarkable that one of the sustainable initiatives, the sustainable concrete matrix, can, directly and indirectly, improve SMP. Therefore, structural engineers need to consider the positive impact of sustainable concrete matrix on sustainable delivery in a modest manner.

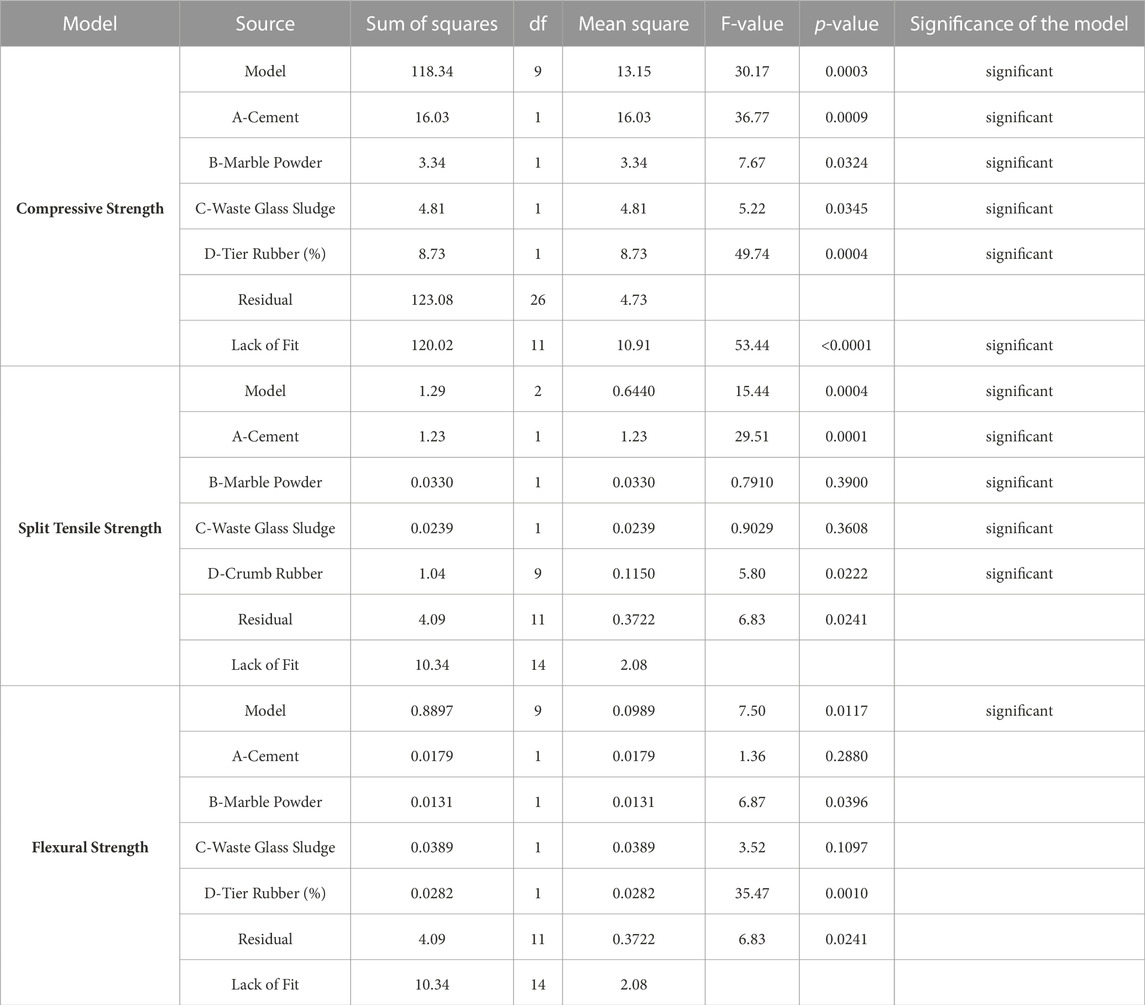

4 ANOVA analysis

This study examines the impact of three distinct variables, namely, a composite of 8% MP (B), 12% WGS (C), and 15% CR (D), on the strength of concrete (A). The statistical technique of analysis of variance (ANOVA) was previously employed to determine the significance of the model. The statistical analysis reveals that the model’s compressive strengths, measured at 36.8 MPa and 36.1 MPa, exhibit a significant difference with a p-value of 0.0003. The corresponding flexural strengths for the samples were 3.48 MPa and 3.42 MPa, while the split tensile strengths were 3.42 MPa and 3.29 MPa, respectively, as presented in Table 13. A statistical significance level, represented by a low p-value, indicates the suitability and pertinence of the model. The tabulated outcomes suggest that each of the models exhibits statistical significance. The probability of noise affecting the p-value of the model is 0.0003. Models that possess F-values below 30.17 are deemed indispensable. Table 7 presents the results.

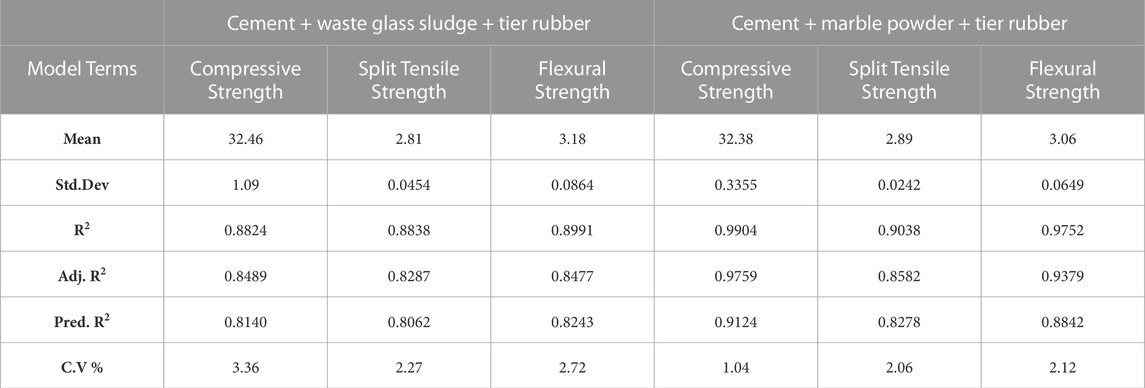

To determine the validity of the models, the coefficient of determination, also known as R-squared (R2), must lie within the range of 0.8824–0.9904. Both models exhibit a variance of less than 0.1 for both adjusted R2 and projected R2. This implies a reasonable level of consistency between the modified R2 and the projected R2. The signal-to-noise ratio measurement is deemed a prerequisite for achieving optimal accuracy. Table 6 demonstrates that all models can traverse the design space. A method for model validation involves generating a 2D contour plot from a 3D surface diagram. It has been observed that when the points are nearly parallel to the normal line, the predicted value yields more precise outcomes than anticipated (Akbar et al., 2023a). The model’s validity and ability to select optimal extraction parameters based on response outcomes are determined using normal residual plots.

Using response surface method (RSM), the interaction of three factors, marble powder, glass sludge, and rubber particles, on mechanical strength was modelled. When all data from the first mixture has been successfully collected, 21 distinct mixture designs are developed based on the first RSM mixture design and re-entered into the RSM to verify their efficacy, resulting in the final model, as shown in Table 14. The comparative outcomes indicate that the results obtained from the experiment and Response Surface Method (RSM) are comparable and satisfactory. The study reveals that the desired value is 0.592, which suggests that 36.8 MPa and 36.1 compressive strengths can be realized by utilizing 12% WGS, 15% rubber, and 8% MP. The flexural strength values for the samples were 3.48 MPa and 3.42 MPa, while the split tensile strength values were 3.42 MPa and 3.29 MPa, respectively.

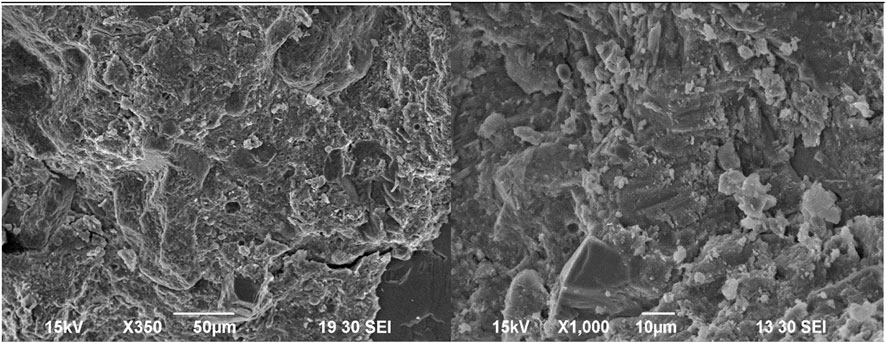

5 Microstructure analysis

Marble powder contains calcium carbonate mineral content equivalent to ground limestone reactivity found in cement. Its presence in the concrete mix increases early compressive and flexural strength gains via internal curing effects caused by the hydrolysis reaction of free lime leaching out of the calcined powder. Improvements extend beyond the matrix to reinforced structural elements where bond efficiency can improve due to advanced interfacial transition zone behavior between steel bars and their surroundings now containing reactive marble fragments as nonmetric secondary particles dispersed homogeneously within the paste. Consequently, applying marble dust results in stronger hardened concrete. The higher compressive strength was due to the better filling capacity of marble waste powder. The reactivity at different hydration days is shown in Figure 10 of marble powder. By focusing on Figure 10, it is evident that marble powder acts as a filler, and its pozzolanic reactivity is efficient. After 28 days of hydration, the surface of the concrete matrix becomes dense by agglomeration of crystals (Wang et al., 2022). The marble powder fills the voids in the concrete matrix and thus acts as micro fillers. These micro fillers mix results in higher densities, low workability, and higher compressive strengths. However, their high dosage can result in lower density and porous microstructure as compared to conventional concrete. The glass sludge showed pozzolanic behaviour as silica present in glass can react with calcium hydroxide, finally giving calcium silicate hydrate gel (C-S-H). This pozzolanic reactivity Leads to increased compressive strength (Zheng, 2016).

Focusing on Figure 11, waste glass sludge incorporation of cement-based materials concludes to be a very dense structure. This dense structure is mostly due to the formation of calcium silicate hydrate gel (C-S-H) (Umar et al., 2022). CSH gel comprises amorphous primary phases. However, glass sludge has a drawback: it reduces density and can result in a porous matrix. This matrix can be solved by incorporating crumb rubber and marble powder fillers. Besides, waste glass and marble powder both work as densification. Crumb rubber, marble powder, and waste glass are filler materials. By incorporating crumb rubber, we reduce the need to extract new raw materials and decrease waste sent to landfills.

Additionally, producing new concrete without crumb rubber means less greenhouse gas emissions related to transporting and processing construction materials (Xu et al., 2018). Therefore, SCM samples have optimum crumb rubber, marble powder, and waste glass sludge incorporation. Which ultimately leads to sustainable concrete matric having high tensile, compressive, and flexural strengths. The better mechanical strengths, densification, and packed structure manifest its sustainable concrete performance, and thus, the name is given as a sustainable concrete matrix.

6 Conclusion and recommendations

This study examined the mechanical characteristics of environmentally friendly rubberized concrete produced using marble powder, waste glass sludge, and crumb rubber. In the experiment, a portion of the fine aggregates was substituted with crumb rubber (CR), and the cement was replaced with marble powder and waste glass sludge. The findings lead to the following conclusions.

• Test results show the positive influence of the marble powder and waste glass sludge incorporation in the concrete matrix as it helps in the formation of C-S-H and also acts as a filler material. Adding marble powder, waste glass sludge, and crumb rubber positively impacted compressive, flexural, and split tensile strength.

• This analysis conducted a two-way ANOVA with a significance of the model of less than 0.001. The residual error resulting from the lack of fit and pure error was found to be minimal. The predictive model accurately captures the relationship between the variables and the response.

• The RSM model for determining sustainable concrete’s compressive, split tensile, and flexural strengths yielded satisfactory results. However, further investigation is required to establish a regression relationship between aggregates and rubber concrete. This relationship would enable the RSM model to make accurate predictions in future applications.

• To tackle the environmental concerns associated with crumb rubber derived from waste tires, utilizing automobile tires and replacing cement with marble powder and waste glass sludge in concrete can be an effective solution. This approach not only enhances the durability of concrete but also proves to be cost-effective, aligning with the United Nations’ Sustainable Development Goals. Additionally, substituting crumb rubber waste tires for natural fine aggregate and replacing cement with marble powder and waste glass sludge aids in reducing cement consumption, thereby contributing to a decrease in carbon emissions.

• This sustainability model contributes to knowledge by exploring the link between sustainable concrete matrix (SCM) and sustainable development (SD) in construction. Hypotheses were tested using SEM, and existing literature informed the study’s framework. Findings emphasize the significance of SCM for achieving sustainable materials goals, aiding organizational excellence, and SD in the construction industry. Besides, it helps minimize cement-based industries’ environmental impacts by incorporating supplementary cementitious materials.

6.1 Recommendations

The results presented in this study indicate that refuse glass slurry and marble powder are more dependable predictors of potential mechanical properties of concrete, particularly sustainable concrete, which is the primary objective of environmentally friendly concrete. Nevertheless, its utilization ought to be approached with prudence and in conjunction with established dependable calibrations. According to the findings, mechanical properties and RSM provide greater statistical confidence than conventional concrete. A mixture of 8% marble granules and 12% refuse glass slurry by weight can be utilized effectively in place of cement. 15% of the natural sediment is substituted with crumb rubber to produce sustainable concrete.

Data availability statement

Publicly available datasets were analyzed in this study. This data can be found here: Shall be provided upon request.

Author contributions

MAk: Methodology, Software, Writing–review and editing. ZH: Conceptualization, Data curation, Formal Analysis, Writing–original draft. MI: Formal Analysis, Data curation, Software, Supervision, Writing–review and editing. SB: Investigation, Project administration, Writing–review and editing. MAn: Conceptualization, Formal Analysis, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdelmelek, N., and Lubloy, E. (2021). Flexural strength of silica fume, fly ash, and metakaolin of hardened cement paste after exposure to elevated temperatures. J. Therm. Anal. Calorim. 147, 7159–7169. doi:10.1007/s10973-021-11035-3

Adil, G., Kevern, J. T., and Mann, D. (2020). Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 247, 118453. doi:10.1016/j.conbuildmat.2020.118453

Ahmad, J., Zhou, Z., and Martínez-García, R. (2022). A study on the microstructure and durability performance of rubberized concrete with waste glass as binding material. J. Build. Eng. 49, 104054. doi:10.1016/j.jobe.2022.104054

Akbar, M., Hussain, Z., Huali, P., Imran, M., and Thomas, B. S. (2023b). Impact of waste crumb rubber on concrete performance incorporating silica fume and fly ash to make a sustainable low carbon concrete. Struct. Eng. Mech. 2, 275–287. doi:10.12989/sem.2023.85.2.000

Akbar, M., Umar, T., Hussain, Z., Pan, H., and Ou, G. (2023a). Effect of human Hair fibers on the performance of concrete incorporating high dosage of silica fume. Appl. Sci. 13, 124. doi:10.3390/app13010124

Alaloul, W. S., Musarat, M. A., Haruna, S., Law, K., Tayeh, B. A., Rafiq, W., et al. (2021). Mechanical properties of silica fume modified high-volume fly ash rubberized self-compacting concrete. Sustain 13, 5571. doi:10.3390/su13105571

Ali, A., Hussain, Z., Akbar, M., Elahi, A., Bhatti, S., Imran, M., et al. (2022). Influence of marble powder and polypropylene fibers on the strength and durability properties of self-compacting concrete (SCC). Adv. Mater. Sci. Eng. 2022, 1–12. doi:10.1155/2022/9553382

Ali, A., Li, M., Shahzad, M., Musonda, J., and Hussain, S. (2023). How various stakeholder pressure influences mega-project sustainable performance through corporate social responsibility and green competitive advantage. Environ. Sci. Pollut. Res. doi:10.1007/s11356-023-29717-w

Alsaif, A., Albidah, A., Abadel, A., Abbas, H., and Al, Y. (2022). Development of metakaolin—based geopolymer rubberized concrete : fresh and hardened properties. Arch. Civ. Mech. Eng. 22 (3), 112. doi:10.1007/s43452-022-00464-y

Amin, M., Tayeh, B. A., and Agwa, I. S. (2020). Effect of using mineral admixtures and ceramic wastes as coarse aggregates on properties of ultrahigh-performance concrete. J. Clean. Prod. 273, 123073. doi:10.1016/j.jclepro.2020.123073

Ansari, W. S., and Chang, J. (2020). Influence of fine cement sand paste in preparation of cementitious materials. Constr. Build. Mater. 230, 116928. doi:10.1016/j.conbuildmat.2019.116928

Ansari, W. S., Chang, J., ur Rehman, Z., Nawaz, U., and Junaid, M. F. (2022). A novel approach to improve carbonation resistance of Calcium Sulfoaluminate cement by assimilating fine cement-sand mix, Constr. Build. Mater. 317, 125598. doi:10.1016/j.conbuildmat.2021.125598

Ansari, W. S., Thaheem, M. J., and Khalfan, M. M. A. (2016). Use of offsite construction techniques in Pakistan. J. Manag. 3, 218. doi:10.1504/mejm.2016.10000653

Ansari, W. S., Ur Rehman, Z., and Thaheem, M. J. (2015). A statistical review of offsite construction techniques in Pakistan. Sci. Int. (Lahore). 27, 5069–5074.

Cao, H., Wu, Q., Akbar, M., Yang, N., and Hussain, Z. (2023). Protective performance of coated reinforcement in coral concrete under dry/wet cycling. Materials 16, 4037–4113. doi:10.3390/ma16114037

Cao, Q., Nawaz, U., Jiang, X., and Ansari, W. S. (2022). Effect of air-cooled blast furnace slag aggregate on mechanical properties of ultra-high-performance concrete. Case Stud. Constr. Mater. 16, e01027. doi:10.1016/j.cscm.2022.e01027

Chang, J., Gu, Y., and Ansari, W. S. (2020). Mechanism of blended steel slag mortar with CO2 curing exposed to sulfate attack. Constr. Build. Mater. 251, 118880. doi:10.1016/j.conbuildmat.2020.118880

Deng, Z., Yang, Z., and Pan, X. (2023). Synergetic effects of recycled crumb rubber and glass cullet on the engineering properties of geopolymer mortar. Cem. Concr. Compos. 137, 104907. doi:10.1016/j.cemconcomp.2022.104907

Fornell, S., and Larcker, D. F. (1981). Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 18, 39–50. doi:10.2307/3151312

Garg, R., Garg, R., Eddy, N. O., Khan, M. A., Khan, A. H., Alomayri, T., et al. (2023). Mechanical strength and durability analysis of mortars prepared with fly ash and nano-metakaolin. Case Stud. Constr. Mater. 18, e01796. doi:10.1016/j.cscm.2022.e01796

Gerges, N. N., Issa, C. A., and Fawaz, S. A. (2018). Case studies in construction materials rubber concrete : Mechanical and dynamical properties. Case Stud. Constr. Mater. 9, e00184. doi:10.1016/j.cscm.2018.e00184

Guo, P., Meng, W., Nassif, H., Gou, H., and Bao, Y. (2020). New perspectives on recycling waste glass in manufacturing concrete for sustainable civil infrastructure. Constr. Build. Mater. 257, 119579. doi:10.1016/j.conbuildmat.2020.119579

Hair, J. F., Risher, J. J., Sarstedt, M., and Ringle, C. M. (2019). When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 31, 2–24. doi:10.1108/EBR-11-2018-0203

Henseler, J., Ringle, C. M., and Sarstedt, M. (2015). A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 43, 115–135. doi:10.1007/s11747-014-0403-8

Hussain, S., FangWei, Z., and Ali, Z. (2019). Examining influence of construction projects’ quality factors on client satisfaction using partial least squares structural equation modeling. J. Constr. Eng. Manag. 145, 1–12. doi:10.1061/(asce)co.1943-7862.0001655

Hussain, S., Fangwei, Z., Siddiqi, A. F., Ali, Z., and Shabbir, M. S. (2018). Structural equation model for evaluating factors affecting quality of social infrastructure projects. Sustainability 10, 1415–1425. doi:10.3390/su10051415

Jagadesh, P., Ramachandramurthy, A., Rajasulochana, P., Hasan, M. A., Murugesan, R., Khan, A. H., et al. (2023). Effect of processed sugarcane bagasse ash on compressive strength of blended mortar and assessments using statistical modelling. Case Stud. Constr. Mater. 19, e02435. doi:10.1016/j.cscm.2023.e02435

Junaid, M. F., ur Rehman, Z., Kuruc, M., Medveď, I., Bačinskas, D., Čurpek, J., et al. (2022). Lightweight concrete from a perspective of sustainable reuse of waste byproducts, Constr. Build. Mater. 319, 126061. doi:10.1016/j.conbuildmat.2021.126061

Lee, H., Hanif, A., Usman, M., Sim, J., and Oh, H. (2018). Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 170, 683–693. doi:10.1016/j.jclepro.2017.09.133

Li, Y., Ding, R., Cui, L., Lei, Z., and Mou, J. (2019). The impact of sharing economy practices on sustainability performance in the Chinese construction industry. Resour. Conserv. Recycl. 150, 104409. doi:10.1016/j.resconrec.2019.104409

Liu, H., Wang, X., Jiao, Y., and Sha, T. (2016). Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Mater. (Basel) 9, 172. doi:10.3390/ma9030172

Lu, J. X., Zhou, Y., He, P., Wang, S., Shen, P., and Poon, C. S. (2019). Sustainable reuse of waste glass and incinerated sewage sludge ash in insulating building products: functional and durability assessment. J. Clean. Prod. 236, 117635. doi:10.1016/j.jclepro.2019.117635

Ma, L., Ali, A., Shahzad, M., and Khan, A. (2022). Factors of green innovation: the role of dynamic capabilities and knowledge sharing through green creativity. Kybernetes. doi:10.1108/K-06-2022-0911

Ma, L., Musonda, J., and Ali, A. (2023). MSR influence on environmental & ecological balance: mediating effect of environmental regulations & strategies. J. Clean. Prod. 386, 135817. doi:10.1016/J.JCLEPRO.2022.135817

Mafalda, A., and Sousa-coutinho, J. (2012). Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 36, 205–215. doi:10.1016/j.conbuildmat.2012.04.027

Meshram, S., Raut, S. P., Ansari, K., Madurwar, M., Daniyal, M., Khan, M. A., et al. (2023). Waste slags as sustainable construction materials: a compressive review on physico mechanical properties. J. Mater. Res. Technol. 23, 5821–5845. doi:10.1016/j.jmrt.2023.02.176

Myers, R. H., Draper, N. R., and Montgomery, D. C. (1995). Response surface methodology: process and product optimization using designed experiments. New York: Wiley, 185–186.

Noordin, M. Y., Venkatesh, V. C., Sharif, S., Elting, S., and Abdullah, A. (2004). Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J. Mater. Process. Technol. 145, 46–58. doi:10.1016/S0924-0136(03)00861-6

Oke, A., Aghimien, D., Aigbavboa, C., and Musenga, C. (2019). Drivers of sustainable construction practices in the Zambian construction industry. Energy Procedia 158, 3246–3252. doi:10.1016/j.egypro.2019.01.995

Paruthi, S., Rahman, I., Husain, A., Hasan, M. A., and Khan, A. H. (2023). Effects of chemicals exposure on the durability of geopolymer concrete incorporated with silica fumes and nano-sized silica at varying curing temperatures. Mater. (Basel) 16, 6332. doi:10.3390/ma16186332

Petter, S., Straub, D., and Rai, A. (2007). Specifying formative constructs in information systems research. MIS Q. 31, 623–656. doi:10.2307/25148814

Rabczuk, T., and Belytschko, T. (2004). Cracking particles: a simplified meshfree method for arbitrary evolving cracks. Int. J. Numer. Methods Eng. 61, 2316–2343. doi:10.1002/nme.1151

Rabczuk, T., and Belytschko, T. (2007). A three-dimensional large deformation meshfree method for arbitrary evolving cracks. Comput. Methods Appl. Mech. Eng. 196, 2777–2799. doi:10.1016/j.cma.2006.06.020

Saba, A. M., Khan, A. H., Akhtar, M. N., Khan, N. A., Rahimian Koloor, S. S., Petru, M., et al. (2021). Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 12, 1380–1390. doi:10.1016/j.jmrt.2021.03.066

Santos, T., Gonçalves, J. P., and Andrade, H. M. C. (2020). Partial replacement of cement with granular marble residue: effects on the properties of cement pastes and reduction of CO2 emission. SN Appl. Sci. 2, 1605–1612. doi:10.1007/s42452-020-03371-0

Sarstedt, M., Ringle, C. M., and Hair, J. F. (2017). Partial least squares structural equation modeling marko. Handbook of Market Research.

Song, W., Wang, Q., Qu, L., Li, X., and Xu, S. (2022). Study of water absorption and corrosion resistance of the mortar with waste marble powder. Constr. Build. Mater. 345, 128235. doi:10.1016/j.conbuildmat.2022.128235

Tang, Y., Feng, W., Chen, Z., Nong, Y., Guan, S., and Sun, J. (2021). Fracture behavior of a sustainable material : Recycled concrete with waste crumb rubber subjected to elevated temperatures. J. Clean. Prod. 318, 128553. doi:10.1016/j.jclepro.2021.128553

Thomas, B. S., and Gupta, R. C. (2016). A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 54, 1323–1333. doi:10.1016/j.rser.2015.10.092

Umar, T., Yousaf, M., Akbar, M., Abbas, N., Hussain, Z., and Ansari, W. S. (2022). An experimental study on non-destructive evaluation of the mechanical characteristics of a sustainable concrete incorporating industrial waste. Mater. (Basel) 15, 7346. doi:10.3390/ma15207346

Wajahat Sammer Ansari, Z. U. R. (2017). A statistical review of offsite construction techniques in Pakistan. LAP Lambert Academic Publishing.

Wang, D., Chang, J., and Ansari, W. S. (2019). The effects of carbonation and hydration on the mineralogy and microstructure of basic oxygen furnace slag products. J. CO2 Util. 34, 87–98. doi:10.1016/j.jcou.2019.06.001

Wang, W., Lu, C., Yuan, G., and Zhang, Y. (2017). Effects of pore water saturation on the mechanical properties of fly ash concrete. Constr. Build. Mater. 130, 54–63. doi:10.1016/j.conbuildmat.2016.11.031

Wang, Y., Xiao, J., and Zhang, J. (2022). Effect of waste marble powder on physical and mechanical properties of concrete. J. Renew. Mater. 10, 2623–2637. doi:10.32604/jrm.2022.019381

Wetzels, M., Odekerken-Schröder, G., and Van Oppen, C. (2009). Using PLS path modeling for assessing hierarchical construct models: guidelines and empirical illustration. MIS Q. Manag. Inf. Syst. 33, 177–195. doi:10.2307/20650284

Xiang, R., Li, Y., Li, S., Xue, Z., He, Z., Ouyang, S., et al. (2019). The potential usage of waste foundry sand from investment casting in refractory industry. J. Clean. Prod. 211, 1322–1327. doi:10.1016/j.jclepro.2018.11.280

Xu, J., Fu, Z., Han, Q., Lacidogna, G., and Carpinteri, A. (2018). Micro-cracking monitoring and fracture evaluation for crumb rubber concrete based on acoustic emission techniques. Struct. Heal. Monit. 17, 946–958. doi:10.1177/1475921717730538

Yang, N., Akbar, M., Wu, Q., Hussain, Z., and Ansari, W. S. (2023). Microstructural analysis of corrosion products of steel rebar in coral aggregate seawater concrete. Seawater Concr. 35, 1–11. doi:10.1061/JMCEE7.MTENG-16193

Zaid, O., Ahmad, J., Siddique, M. S., Aslam, F., Alabduljabbar, H., and Khedher, K. M. (2021). A step towards sustainable glass fiber reinforced concrete utilizing silica fume and waste coconut shell aggregate. Sci. Rep. 11, 12822–12914. doi:10.1038/s41598-021-92228-6

Zeyad, A. M., Khan, A. H., and Tayeh, B. A. (2020). Durability and strength characteristics of high-strength concrete incorporated with volcanic pumice powder and polypropylene fibers. J. Mater. Res. Technol. 9, 806–818. doi:10.1016/j.jmrt.2019.11.021

Zhang, Y., Zhang, S., Jiang, X., Zhao, W., Wang, Y., Zhu, P., et al. (2023). Uniaxial tensile properties of multi-scale fiber reinforced rubberized concrete after exposure to elevated temperatures. J. Clean. Prod. 389, 136068. doi:10.1016/j.jclepro.2023.136068

Keywords: sustainable concrete, marble powder, waste glass sludge, crumb rubber, rsm, structural model

Citation: Akbar M, Hussain Z, Imran M, Bhatti S and Anees M (2024) Concrete matrix based on marble powder, waste glass sludge, and crumb rubber: pathways towards sustainable concrete. Front. Mater. 10:1329386. doi: 10.3389/fmats.2023.1329386

Received: 28 October 2023; Accepted: 12 December 2023;

Published: 10 January 2024.

Edited by:

Afzal Husain Khan, Jazan University, Saudi ArabiaReviewed by:

Fahid Aslam, Prince Sattam Bin Abdulaziz University, Saudi ArabiaBlessen Thomas, National Institute of Technology Calicut, India

Copyright © 2024 Akbar, Hussain, Imran, Bhatti and Anees. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zahoor Hussain, dutian17@outlook.com

Muhammad Akbar

Muhammad Akbar