- Socioeconomics Division, Philippine Rice Research Institute, Science City of Muñoz, Philippines

The Laboy tiller was developed to address the challenges of preparing fields with laboy soil conditions. This study uses the scaling ingredients framework developed by PPPlab and CIMMYT to examine how the machine scaled from its initial project in San Luis, Aurora, Philippines. In-depth interviews with farmers (n = 28) and key informants (n = 12) were conducted to address the research questions. The results show a lack of concerted efforts in addressing some of the scaling ingredients, such as collaboration, evidence and learning, leadership and management, and public sector governance. Consequently, the Laboy tiller experienced limited scaling outside of San Luis town. However, it had a profound impact on the farmers of laboy areas in Aurora, where the concept of altruism emerged as a critical scaling ingredient. Altruism facilitated the Laboy tiller’s dissemination through the personal networks of its initial owners, who valued and maintained the machine over time. Recognizing altruism as a key scaling ingredient could enhance the scaling efforts of other innovations by encouraging beneficiaries to actively participate in the continued uptake and sustainability of introduced innovation.

1 Introduction

Rice cultivation is deeply woven into the Filipino social fabric (Manalo et al., 2020). The country has millions of rice farmers, and rice is celebrated as its favored staple. The Philippines is home to diverse rice-growing conditions. It has both favorable and unfavorable environments. Favorable environments are irrigated areas with an ample supply of water and those that meet the photosynthetic requirement for rice. These are also the areas that generate the highest yields in the country. Unfavorable environments prove challenging in growing rice, such as rain-fed areas or those that depend on the onset of rain before farmers can cultivate rice. Laboy fields are among the unfavorable environments for rice growing. Laboy fields are characterized by soft, low-bulk-density soil with deep mud reaching the waist (Regalado and Juliano, 2010). These fields were formed from the clearing of former swampy forests by the Philippine government’s Agrarian Reform Program; hence, they were also referred to as basal by the locals of Aurora. Due to the waterlogged conditions, there is a buildup of organic matter at various stages of decomposition. This bulk of organic matter, peat soil, has a low density and floats in water. An area in San Luis, Aurora, was named ‘yanig’ (tremor) because of the way the laboy soil shakes as one steps on it. As there is a layer of peat floating on water, land preparation was done by manually cutting blocks of this layer and then turning it over to submerge the growing weeds. Traversing the field is difficult as the mud acts like quicksand; hence, the locals kneel to increase surface area as they move through the field.

The laboy soil stores carbon efficiently, where organic matter content is 70% or higher, whereas 5% is already considered high. Because of this high organic matter content, there are deficiencies, such as zinc deficiency and toxicities in the soil. Furthermore, because of the decomposition of the organic matter, the soil is also acidic (Sandro Cañete,1 face-to-face conversation with author, June 8, 2022). Laboy fields are among the most challenging conditions in rice cultivation in the Philippines. On average, rice yield in laboy fields is only approximately 2 t/ha due to the difficulties in land preparation (Regalado and Juliano, 2010). In the early 2000s, there were approximately 15,000 ha of laboy rice fields across the country, with more than 1,000 ha in Aurora alone. Other provinces in the Philippines with laboy conditions include Cagayan, Pampanga, Oriental Mindoro, Samar, Surigao, Agusan del Sur, and North Cotabato (Regalado and Juliano, 2010). To address issues in laboy fields, the Rice Engineering and Mechanization Division (REMD) of the Philippine Rice Research Institute (PhilRice) developed the Laboy tiller in 2003. Sitio Hiwalayan in San Luis, Aurora, was the site for a demonstration of the PalayCheck System, where the PhilRice crew encountered the difficulties of the farmers with their laboy fields. The PalayCheck System is an integrated crop management platform for rice to assist farmers in achieving desired yield increases. Land preparation was performed manually, as heavy machinery would sink in the mud. The land is prepared by cutting the floating soil into blocks and turning them over by hand to bury the weeds. Different types of machinery, such as the Turtle Tiller or the ‘Pagong,’ as well as the hydrotiller from the International Rice Research Institute (IRRI), were introduced earlier in the area to address issues in laboy fields. However, they were unsuccessful as the farmers observed the machines having frequent bog downs (Regalado et al., 2007).

Participatory development followed for the Laboy tiller with REMD through the initiative of Dr. Manuel Jose Regalado, a PhilRice scientist under the REMD and part of the crew in the demonstration of the PalayCheck System mentioned earlier. Some of the farmers tested the prototypes and recorded their observations. Data on the machine performance and farmer’s insights were collected in developing the Laboy tiller. The initial target was a riding-type tiller to address the difficulty of traversing the laboy fields—described by farmers as kneel-walking on land without a hard pan. However, after feedback from the farmers who had tried the prototypes, the riding type was scrapped as they preferred lower fuel consumption and found the machine difficult to maneuver when seated.

This study explores the factors that affected the technology uptake of the Laboy tiller almost two decades after its development. Insights from this study could serve as inputs in developing technologies by agricultural research institutions across the globe. The next section of this study presents the literature review covering information and insights on laboy soil, the level of mechanization in the Philippines relative to other rice-producing countries, and factors affecting technology uptake. The theoretical framework, specifically the 10 scaling ingredients, is presented.

2 Literature review

2.1 Mechanization

Mechanizing rice cultivation is central to the agenda of the Philippine government to make the sector more competitive. The cost reduction from the mechanization of labor-intensive tasks, such as land preparation, crop establishment, and harvesting, has a significant impact on raising the competitiveness of locally produced rice, with labor costs amounting to 37% of the total production cost in Nueva Ecija (Bordey et al., 2016). Compared with the mechanization level of other Asian countries with data from 2011, the Philippines (1.23 hp/ha for all crops; 2.31 hp/ha for rice and corn) is way behind countries like Japan with 18.87 horsepower/hectare (hp/ha), Korea with 9.38 hp/ha, China with 8.42 hp/ha, and Thailand with 4.20 hp/ha (Bautista et al., 2017). Furthermore, in a study validating the modified agricultural mechanization index for lowland rice (MAMIrice), Amongo et al. (2018) found that the computed MAMIrice for the three provinces in their study was way below the ideal theoretical computation of 5.071 hp/ha needed to achieve 6 tons of yield per ha. The computed MAMIrice in the man–machine system in the three provinces in Amongo et al.’s (2018) study using rototilling and combined harvesting operations are only 1.780 hp/ha for Oriental Mindoro, 1.232 hp/ha for Laguna, and 2.505 hp/ha for Quezon.

Bautista et al. (2017) noted that small and irregular landholdings that could be inaccessible during the rainy season are among the key challenges in achieving full farm mechanization in the Philippines. In comparison, countries like Korea and Japan have had some success in consolidating their farmlands, enabling greater mechanization (Bautista et al., 2017; OECD, 2009). Another issue discussed by Bautista et al. (2017) is the high price of machines coupled with the low buying power of farmers that could be circumvented through custom hiring services to give marginal farmers access (Kadhim, 2018; Rawat et al., 2020).

2.2 Adoption

Various studies have been conducted to determine factors affecting agricultural innovation adoption (Connor et al., 2021; Cafer and Rikoon, 2018; Glover et al., 2017; Mottaleb et al., 2016; Obeng Adomaa et al., 2022; Orr, 2018). Orr (2018) finds the importance of market demand and overcoming production and seed delivery constraints for the adoption of improved seeds. Connor et al. (2021) find in their study on sustainable rice that ease of implementation and non-rice income are the main drivers in adopting individual requirements. In a study on small-scale agricultural machinery adoption, Mottaleb et al. (2016) find household assets, credit availability, electrification, and road density as factors that are positively associated with machine ownership. Cafer and Rikoon (2018) also find that cash and capital influence the decision to adopt more than contact with the agricultural innovation system, which shows the importance of addressing resource constraints to enable adoption. The variability and context of the location should also be considered when looking into the factors affecting adoption. Glover et al. (2017, pp. 17–18) discussed the concepts of ‘inscription’ and ‘affordance,’ indicating how innovations could be adapted by the users despite the ‘inscribed’ uses, as designed by developers, through the ‘affordances’ of the innovation or its potential uses. ‘Inscription’ pertains to how the designers and engineers set how innovation is to be used in contrast with ‘affordances,’ which entails the innovation’s potential uses even if it goes against the designer’s intended use (Glover et al., 2017, pp. 17–18). Obeng Adomaa et al. (2022) used these concepts in their study, tracing the pruning practices from research to farms in Ghana’s cocoa sector. They find the importance of unpacking the affordances to better fit the local context, as this will make the process more meaningful for the farmers than the standardized recommendations developed from research (Obeng Adomaa et al., 2022). These concepts shift the focus from how an innovation is adopted to how it could be or is being adapted by the end users to better fit their needs. With respect to the existing literature, this current study contributes by using the 10 scaling ingredients to see how adoption or adaptation takes place in the context of the Laboy tiller. As will be elaborated in the next section, the scaling ingredients provide a better lens and tighter grip on factors that surround the adoption or adaptation of the technology in question.

2.3 Framework

With the aim of the study to explore the factors affecting the technology uptake of the Laboy tiller, we were guided by the concepts of German et al. (2006) that propose “a methodology for tracking the ‘fate’ of technological interventions in agriculture.” German et al. (2006) shift away from the paradigm of technology transfer that sees innovation as something static passed on from researcher to the farmers through extension and aims to gain insight into the spontaneous spread and adoption of technologies, recognizing the importance of the continued reinvention of these technologies to better adapt them to the needs of the end-users. The study follows German et al.’s (2006, pp. 2–3) guide questions looking at the uptake of technology:

• “What are the pros and cons of each technology and the primary barriers to more widespread adoption?

• What were the social and farming systems’ “uptake niches” of different technologies?

• What innovations and adaptations were made to the introduced technologies and why?

• Did introduced or modified technologies have any positive or negative impacts on livelihood?

• Did introduced or modified technologies have any impact on agroecosystem resilience?”

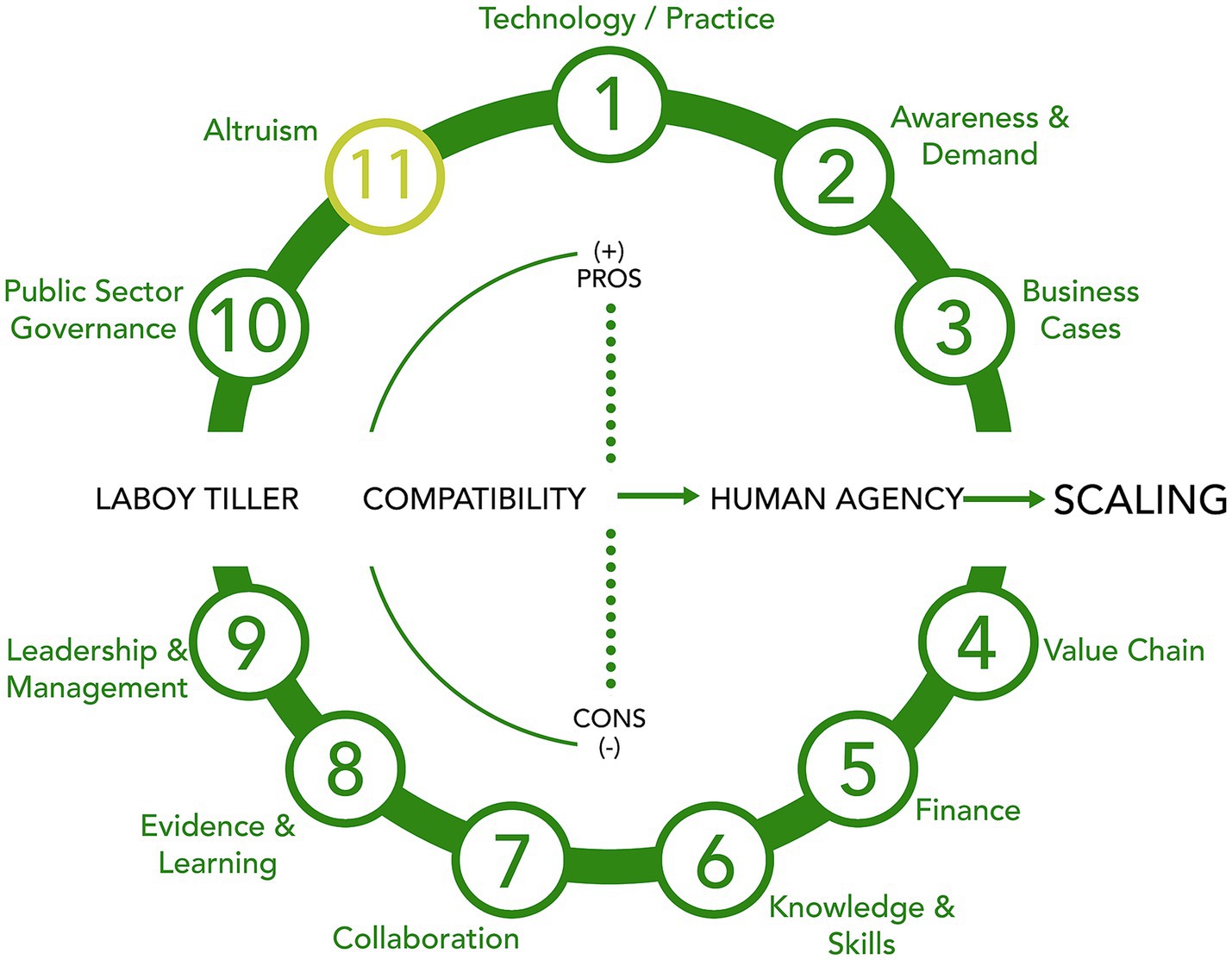

These questions explore how the technology was assessed by its recipients as they exercised their agency to decide if the technology was compatible with them. The findings were then incorporated into the 10 scaling ingredients from Jacobs et al.’s (2018) scaling scan tool as we assessed the technology’s capacity to scale wider. The scaling ingredients, as introduced by Jacobs et al. (2018, pp. 10–14), are:

• Technology/Practice: Asks if the innovation has a relative advantage over other solutions to the issues that the innovation aims to solve

• Awareness and Demand: Ask if the innovation is seen as necessary or desirable and if they have access to information regarding this innovation

• Business Cases: Ask if the business for the innovation is viable across all actors in its value chain

• Value Chain: Asks if the links between the actors are effective in pursuance of their business case

• Finance: Asks if effective financing options are available for users and value chain actors

• Knowledge and Skills: Asks if the intended users can use the innovation

• Collaboration: Asks if relevant actors to the innovation are sufficiently engaged

• Evidence and learning: Ask if evidence is being gathered for the understanding of the scaling of the innovation

• Leadership and Management: Ask if effective coordination toward scaling is followed by relevant actors

• Public Sector Governance: Asks if the government is supportive of the scaling ambition

The study by Manalo IV et al. (2022) may be consulted for a comprehensive discussion of the scaling ingredients.

We also draw from the Unified Theory and Acceptance and Use of Technology (UTAUT) to sharpen our analysis. This theory unifies several established theories from various disciplines to develop a more holistic understanding of technology acceptance and use. The main premise of this theory is that the use and acceptance of technology are guided by behavioral intention. Along this line, there are four key considerations: performance expectancy, effort expectancy, social influence, and facilitating conditions. Performance expectancy pertains to how good a technology is at addressing the key concerns of the user. That is, if a technology is fit for purpose. Effort expectancy is the degree of ease in using the technology, i.e., it should not be too difficult to use. Social influence refers to the perception of the individual that “important others believe that s/he should use the new [technology].” Lastly, facilitating conditions refer to the belief of an individual that there is a supportive organization and technical infrastructure in using the new technology (Venkatesh et al., 2003).

Figure 1 combines the key insights from German et al. (2006), Jacobs et al. (2018), and Venkatesh et al. (2003). Of these three references, the work of Jacobs et al. (2018) provides a good rallying point for the concepts used in this study. For example, question 1 of German et al. (2006) on the pros and cons of the technology and its barriers are captured in the “Technology/practice” scaling ingredient. The same can be said of the impact on livelihood. The other questions are easily subsumed under the different scaling ingredients. The four key elements in the work of Venkatesh et al. (2003) also fall under the 10 scaling ingredients. For example, “facilitating conditions” relate to “leadership and management” and “public sector governance.” “Social influence” in the work of Venkatesh et al. (2003) relates to “altruism” and “awareness and demand.” While Jacobs et al. (2018) provide an all-encompassing theory, we argue that the other two references enhance the explanatory power of the overall theory, which then contributes to sharpening the analysis in this study.

3 Methodology

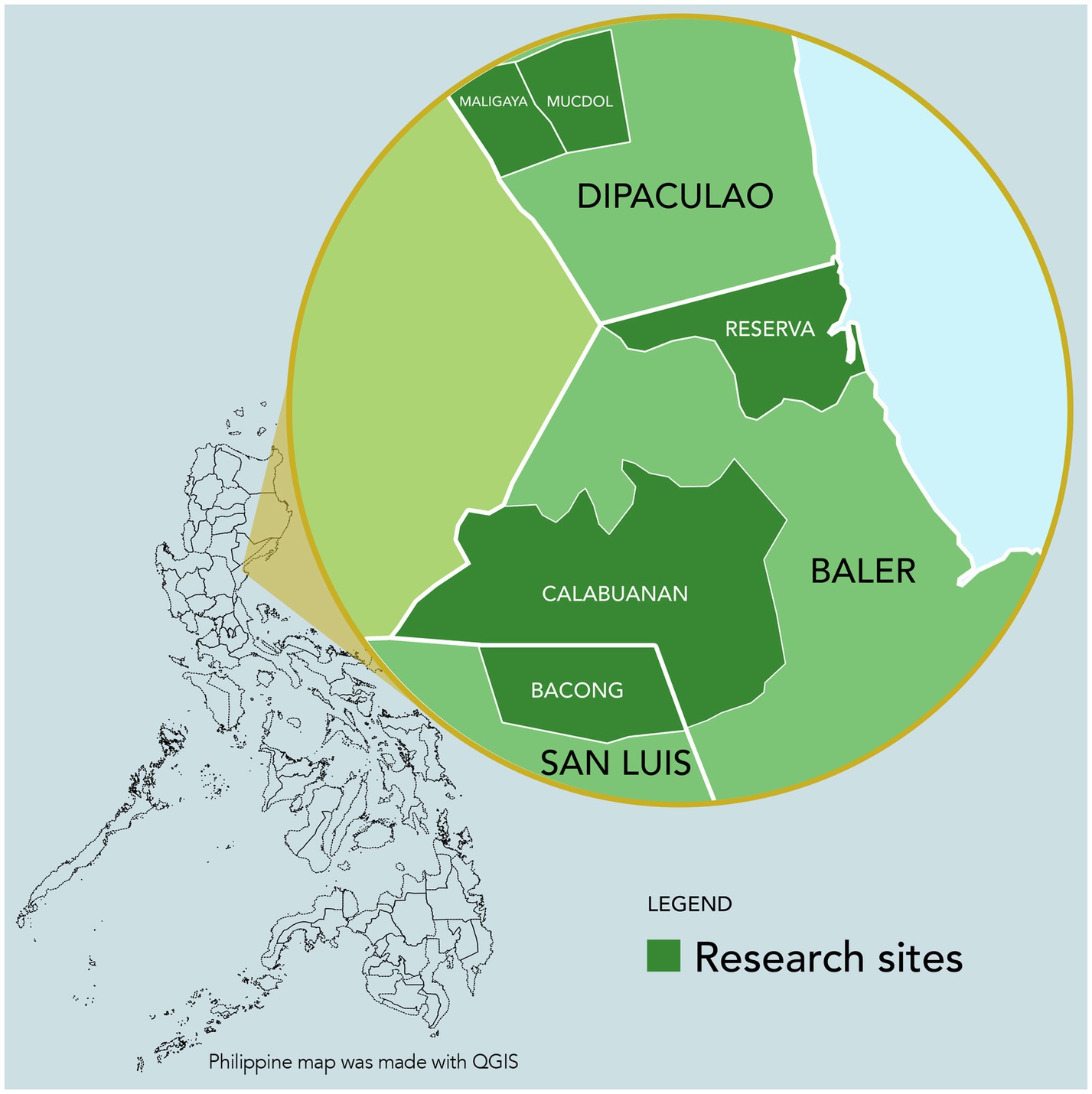

The main site of our inquiry was Sitio Hiwalayan, Barangay (village) Bacong, San Luis, in the province of Aurora, where the development of the Laboy tiller started. Then, nearby areas with laboy soil located in Reserva and Calabuanan in the town of Baler and Mucdol and Maligaya in Dipaculao town were also covered based on the recommendations of farmers from earlier interviews. The municipalities of San Luis, Baler, and Dipaculao are connected, with Bacong and Calabuanan situated adjacent to each other and Reserva, Mucdol, and Maligaya also clustered together.

We conducted in-depth interviews with 28 farmers for this study through face-to-face, semi-structured interviews designed to be flexible with respect to the information and narratives the respondents were willing to share. The first farmer-interviewees were referred to us by Dr. Manuel Jose Regalado, or “Doc Manny,” as the technology developer, and were traced with the help of the officials of the relevant Office of the Municipal Agriculturist (OMAg). The succeeding farmers were either referred to us by officials of the OMAg in San Luis, Aurora, or by the farmers that we had earlier interviewed. This process of selecting samples is called snowball sampling. Further referrals were traced from the suggestion of the succeeding farmers until the suggestions were pointing back to farmers that had been interviewed, and the succeeding interviews returned similar key points suggesting theoretical saturation. Aside from the farmer participants, we also had 12 non-farmer stakeholders that we interviewed to gain vital context about the innovation and the research sites. We interviewed staff members from the local government units (LGUs) (n = 6) that serve the areas where our research sites are located. We also interviewed mechanics (n = 2) referred to us by the farmers we interviewed who avail themselves of services for the maintenance and upkeep of their machines. PhilRice staff members (n = 3) who were involved with the development of the machine were also interviewed, as well as a manufacturer (1), referred by the PhilRice staff members, who are licensed to manufacture the machine. In our analysis, we transcribed all interview recordings, and they were read line by line by the three authors during the coding process. We also had a code guide to ensure reliability and consistency as each author coded the transcripts. The authors compiled the emerging codes in the coding process and deliberated through meetings to decide the final codes that would be used in the code guide. We did informal member checks to enhance the soundness and authenticity of our analysis (Lincoln and Guba, 1985). We also did a formal member-checking session where we presented our findings to the farmers to reduce, if not diminish, errors in the representation of their lived experiences with respect to the Laboy tiller. We alternated inductive and deductive analysis to make sense of our findings. All research participants were anonymized in this study.

4 Results

4.1 Scaling ambition

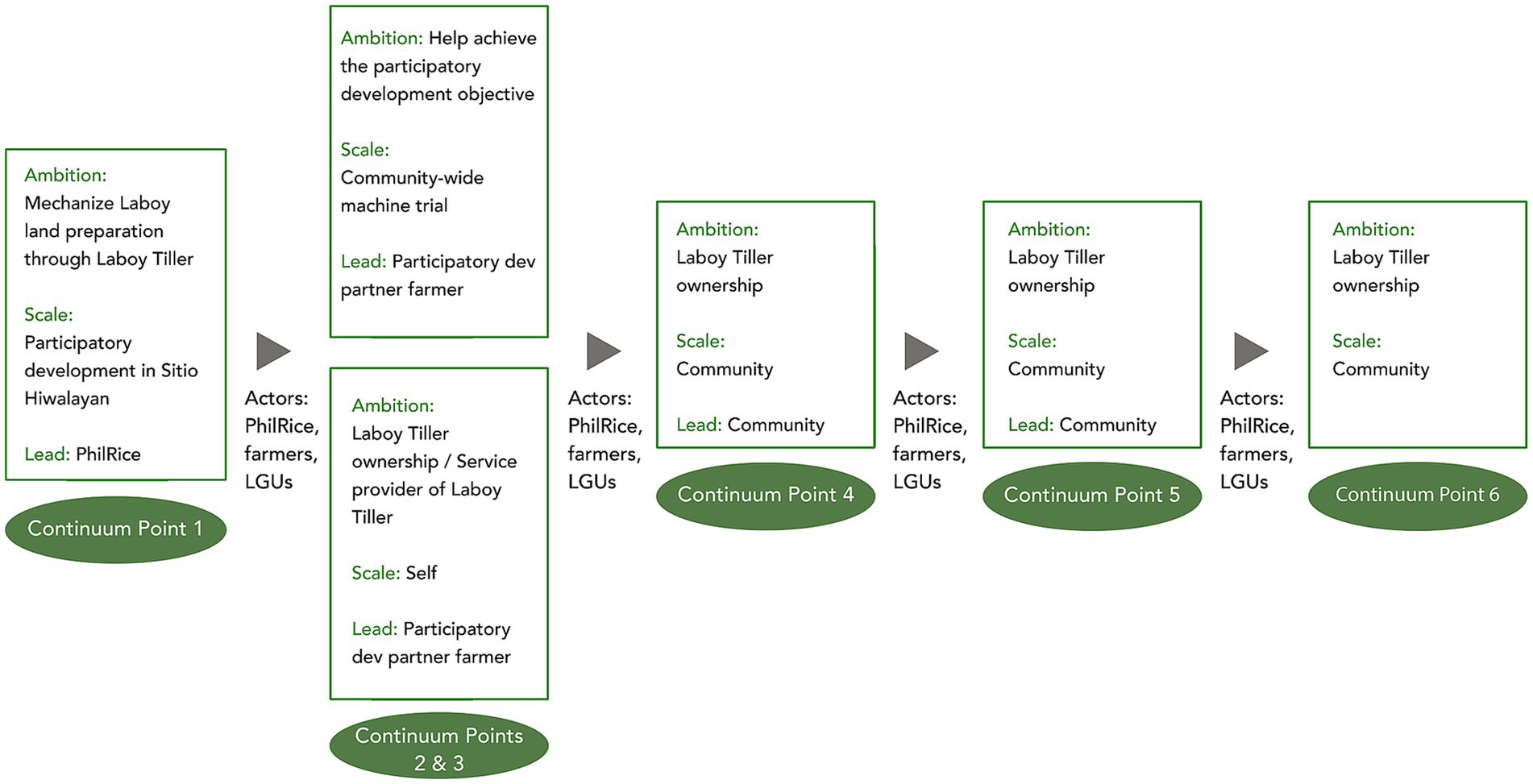

Adopting Jacobs et al.’s (2018) scaling scan tool to formulate the scaling ambition of the Laboy tiller in our research site for the area, we conceptualized a continuum (Figure 2). As there were multiple actors during the period covered by this study, we determined that different scaling ambitions were made at different points in time by different actors. Illustrated in Figure 2 are some of the important points we found in this continuum.

Using the tool by Jacobs et al. (2018), we were able to (re)construct the initial scaling ambition as follows:

By the end of the participatory development on the Laboy tiller, the PhilRice Rice Engineering and Mechanization Division (REMD) wants to see increased uptake of the Laboy tiller stemming from their earlier work in Sitio Hiwalayan. The overarching goal was to do away with manual land turning and hence make their land preparation labor easier and more efficient.

Continuum points 1–3 refer to the conceptualization of the Laboy tiller until it has reached some level of acceptability on the part of the farmers in the study sites. At this juncture, the Laboy tiller has become known in the community, and there is demand for more Laboy tiller units (continuum point 4), opening up for the remaining ingredients on the supply chain, financial cases, knowledge and skills, and collaboration (continuum point 5). After the second wave of unit provision and training, PhilRice REMD’s engagement with the community regarding the Laboy tiller was also terminated. The remaining ingredients of evidence and learning, leadership and management, and public sector governance become more discernible once the community is left on its own (continuum point 6).

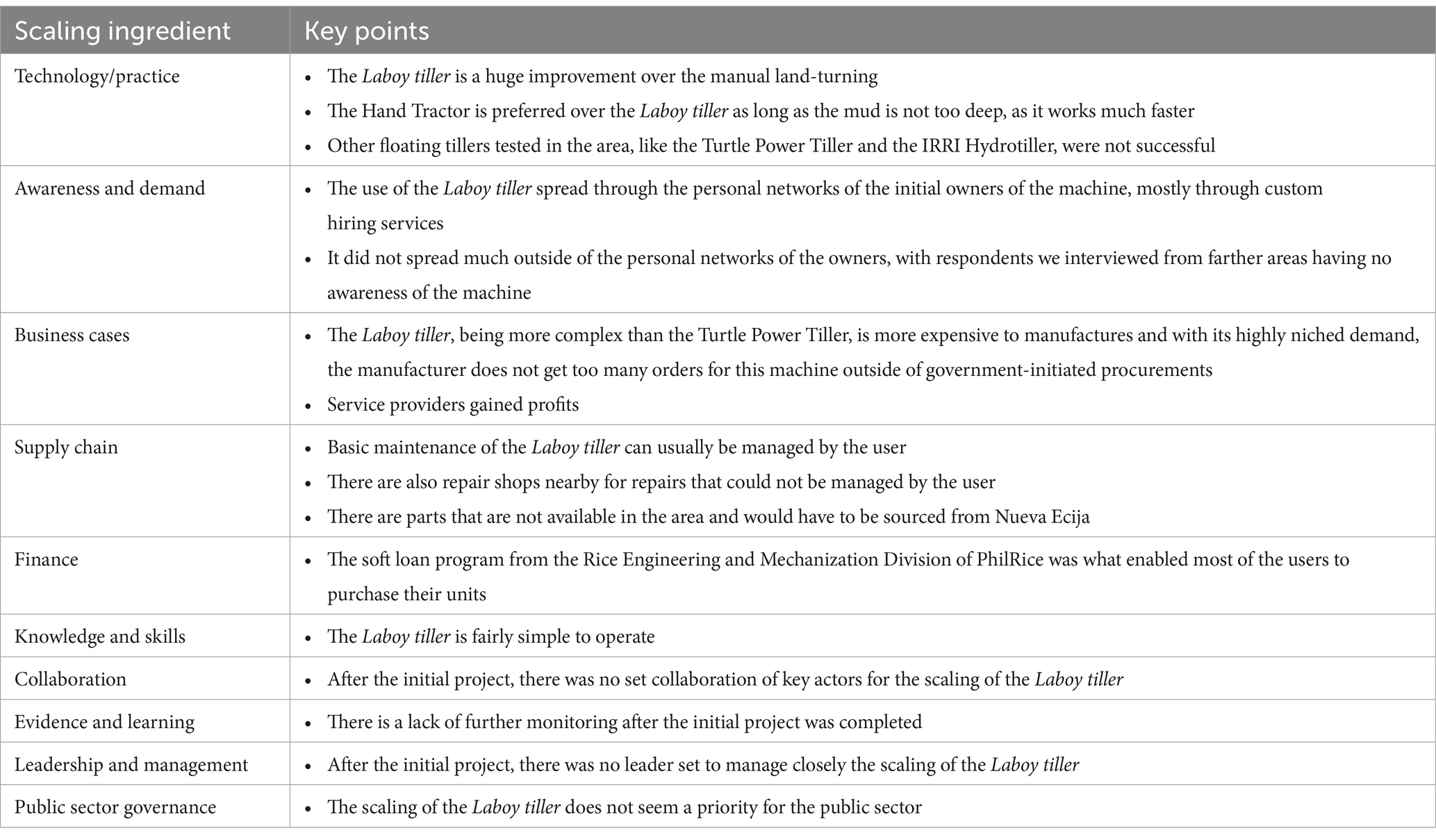

4.2 Scaling ingredients

Jacobs et al.’s (2018) scaling scan tool proposes 10 different ingredients representing fields that need attention for the success of the scaling ambition. In the following paragraphs, the state of each scaling ingredient concerning the uptake of the Laboy tiller is discussed. Key points regarding each ingredient are summarized in Table 1.

4.2.1 Technology/practice and knowledge and skills

The practice when the Laboy tiller was being developed was manual land turning. As reflected in our interviews, this practice is tedious and may also be ineffective. The weeds are still rooted in the soil; some may still grow back. This gives the Laboy tiller a high relative advantage.

“The technology they practice is manual. They just turned over the weeds before. When weeds grow when no crop is planted, they turn it over manually. Alas, the weeds are surely still alive since they just turned it over.2”

[LGU official from Bacong]

Other comparable technologies are floating tillers, such as the Turtle Power Tiller and the IRRI Hydrotiller. However, they had often bogged down; hence, these floating tillers did not gain a following in the area. In comparison, the Laboy tiller reliably floats (Figure 3). Furthermore, regarding the Turtle Power Tiller, the interviewees shared that among their difficulties with it is that it has little traction to go forward once the weeds have been mulched up. It works fine on the first passing as it gains traction from the weeds, but the operator will have to expend much effort to push it through for a second passing. In comparison, the Laboy tiller has cross paddles attached to the cage wheel to facilitate forward movement (Figure 4). This feature is among the results of the participatory development activity.

Figure 4. Diagram of Laboy tiller with the cross paddles incorporated into the puddling rotor. Reproduced from Regalado and Juliano (2010); with permission from PhilRice.

“It [Turtle Tiller] won’t move forward because it can’t find traction, it wants to always have something to grab on. Unlike the floater [Laboy tiller], even without anything to grab on, it will run.3”

[Farmer from Bacong, M, 60]

The Hand Tractor has become popular in recent years due to the changing landscape of the area. This shift can be attributed to the canalet-digging initiative undertaken by farmers with support from local government units. By digging canalets around their fields to drain water, the laboy fields gradually solidified over time, leaving only a few deep areas. This transformation paved the way for the increased use of Hand Tractors. On shallow land, Hand Tractors operate much faster than the Laboy tiller, making them the preferred option when deep areas are minimal. Additionally, innovations have been introduced to enable Hand Tractors to navigate deep areas. One such innovation involves bridging the tractor over these areas using bamboo. Another strategy employs cage wheels, which are wide enough to remain unaffected by sudden dips in the field. To further enhance their efficiency, the sides of the cage wheels can be covered to prevent soft mud from entering and obstructing the Hand Tractor.

In terms of speed, the Hand Tractor is much faster. One of our interviewees advances that the Laboy tiller can prepare the land better as the spikes of its cage wheels ensure that the weeds are cut up. In contrast, the Hand Tractor with cage wheels cannot have spikes, as the engine may be unable to handle the added load due to the added resistance. Furthermore, they usually modify it to be wider to still find footing with narrower deep areas, which adds significant load to the engine. Also, a stronger and heavier engine cannot be used as the Hand Tractor may just sink if it becomes too heavy.

“Interviewer: What is this spike? Is it better if it has spikes, or like…

Interviewee: That is what’s nice

Interviewer: It could really crush the…

Interviewee: Yes, it could really crush the stalks and weeds. Because what we use before doesn’t have [spikes], it just topples the stalks and weeds4”

[Excerpt of Interview of Farmer from Mucdol, M, 58]

“Interviewee: It is also hard. The engine will be overburdened because it is big.

Interviewer: If it is bigger, the engine becomes overburdened? Why so?

Interviewee: You also can’t put a bigger engine as you’ll be heavier5”

[Excerpt of interview with a farmer from Mucdol, M, 58]

Recognizing the pros and cons of the two machines, some farmers innovated by combining them. During one of our visits, we witnessed a land preparation activity where the farmers alternated Laboy tiller and Hand Tractor on the same field so that the two machines complemented each other.

“Yes, it is still being used because if you know that it’s deep, [SIC] you shouldn’t use the Hand Tractor over it. Instead, go around it and finish it with the Floating Tiller6”

[Farmer from Bacong, M, 60]

Furthermore, the machine is easy enough to use and operates similarly to a Hand Tractor. According to one of the farmers we interviewed, if you know how to use the Hand Tractor, then you already know how to use the Laboy tiller.

“If you already know how to use the Hand Tractor, you already know how to use it, too7”

[Farmer from Bacong, M, 60]

4.2.2 Awareness and demand

The term ‘Laboy tiller’ did not gain popularity among the farmers, resulting in some confusion. In our interviews, the Laboy tiller was referred to by the general term ‘Floating Tiller’ and sometimes also called ‘Pagong’ or ‘Turtle Tiller,’ which confuses it with the actual Turtle Power Tiller, especially with those who only had experience with the machine through service providers, those who own the machine that is hired to work on the fields of others. The negative experiences of others with the Turtle Power Tiller, such as its often being bogged down, are also attached to the Laboy tiller, as some thought that it was the same as the Turtle Power Tiller. During the interviews, we utilized a printout of the pictures of the different machines to ensure accuracy. Nevertheless, regardless of the term, it is still quite easy in Bacong to find a service provider for laboy fields because of the personal network of the people there. It is a place where everybody knows everybody. However, farmers from areas farther from Bacong, such as in Dipaculao, are unaware of the machine.

The changing situation of their farmlands decreases the demand for the Laboy tiller. With their fields drained, more can be prepared faster with the Hand Tractor. The issue comes in the areas where the canalets are ineffective, such as in low areas where the canalets cannot drain the water. Furthermore, if there is a huge amount of rainfall, their canalets may be overburdened, essentially turning back their fields into laboy. This is further exacerbated in areas with infrastructure development, such as highways, which trap the drained water and the rainwater. The service provider that we interviewed also said that sometimes he has to turn down requests as he is already fully booked, indicating that there is demand for the Laboy tiller that has not been fully met.

“Interviewee: Ma’am, if the rainy season is too… it easily gets flooded and the soil floats

Interviewer: During [SIC] rainy season

Interviewee: Yes, also in the sunny season, whenever it rains too much, it floats, like organic soil that floats because it is light8”

[Excerpt of Interview with Farmer from Bacong, M, 63]

“When the road was developed, the laboy areas further increased9”

[Farmer from Mucdol, M, 58]

4.2.3 Business cases and finance

The more complex design of the Laboy tiller, compared with the Turtle Power Tiller, means that it would also cost more to manufacture. According to a manufacturer interviewed, the Turtle Power Tiller is preferred because it is simpler to manufacture. Furthermore, because of the COVID-19 pandemic, he also notes that it is much harder for farmers to build capital to invest in more expensive machines. Moreover, the fact that Laboy tiller serves a niche demand does not help build the business case of the manufacturer.

With limited demand from private farmers, most of the Laboy tiller orders were drawn from government procurement efforts. However, a business case based on government procurements may be difficult for small manufacturers, given highly bureaucratic processes. Smaller manufacturers who mainly sell a small number of units per order cannot participate in bigger procurement biddings even if they have the capacity for it. Furthermore, payment of government orders, in general, often takes too long to complete, necessitating bigger capital funds to continue functioning the business while waiting for the payment from a big order that costs a huge amount of money to manufacture. In addition, manufacturers pay some fees to renew their accreditation.

In terms of financing, the soft loan program of the REMD enabled some farmers to avail themselves of their units since December 2006. However, after REMD’s involvement in the area, there were no longer any financing programs to help the farmers procure the machines. The last recorded purchase through the soft loan program was in June 2010.

There is a more promising business case on the side of the service providers. As we discussed earlier, the service provider we interviewed had to turn down some requests. Thus, more service providers can establish their business in the area. Furthermore, another farmer we interviewed who was also a service provider shared that he only gave up being a service provider because of his old age.

The farmers rely on their social network to avail themselves of the services of people who own a Laboy tiller. The promotion of the Laboy tiller also heavily depended on these personal connections. Personal connections have been vital, from the developers establishing rapport with farmers in their participatory approach to the farmers relaying their contacts through their social network. The farmers also passed on their units through their connections. However, as the promotion of the Laboy tiller mostly depended on these personal connections, the unit’s usage did not spread widely. In Calabuanan, a neighboring village of Bacong, there remain people who have contacts with service providers of the unit from San Luis. However, in other research sites, such as Reserva, Mucdol, and Maligaya, we did not find anyone familiar with the Laboy tiller. For context, these are just surrounding villages, as shown in Figure 5.

4.2.4 Supply chain

It is difficult to purchase a unit from Aurora, as the nearest manufacturer will come from Nueva Ecija, approximately 80 km away. For context, the road network connecting Nueva Ecija and Aurora has only recently been paved. However, for the post-purchase servicing, the farmers could usually handle the basic repair and maintenance of the machine as they also have some tools for it. There are also auto repair shops where they bring the unit if they cannot handle the needed repairs. Even so, some specific parts may be unavailable and could only be sourced generally from manufacturers like the one in Nueva Ecija. They also have some modifications done on their units, such as on the handle to make it longer and on the engine bracket to fit different engines.

4.2.5 Collaboration, evidence and learning, leadership and management, and public sector governance

There was a strong sense of collaboration between the engineers who developed the machine and the farmers who participated in the development of the Laboy tiller. During the creation of the Laboy tiller, the farmer-cooperators diligently documented their experiences and evaluated the prototypes, as agreed with the developers, before involving them in the trials. However, collaboration between key actors diminished after the initial project, and regular monitoring was infrequent.

After the project, no key leadership or management was set up to focus on the scaling of the machine. The machine was promoted and procured for farmers through other PhilRice projects, which proved useful. However, there was no concerted effort to sustainably establish it in new areas. Furthermore, the LGU mostly works through procurement of what is needed as farmers requested in terms of machinery aid, where the scaling out and active promotion of units is not the priority. Given that farther areas are unaware of this technology, it would be logical to think that this machine would also not be requested.

4.2.6 New scaling ingredient

Scrutinizing the findings above, it becomes apparent that with all the imperfections of the machines and the innovation ecology, Laboy tiller seems to have withstood the test of time. While it did not go very far in terms of scaling, it also did not die down. In the words of a farmer-adopter, it remains the best machine in their town in dealing with laboy soils, i.e., after 19 years since it was introduced in San Luis, Aurora. Many reasons could explain why this is the case. From our data, we argue for the role of ‘altruism’ in the technology uptake and the near-scaling process.

Broadly, altruism is defined and understood as the “disinterested and selfless concern for the well-being of others” (Bhuvana et al., 2021, p. 706). However, Kraut (2020) also expounds that acts could have a mixture of motives but remain altruistic, differentiating between mixed motives and ‘pure’ altruism. Returning to the scaling ambition described in Figure 1, we argue that altruism is interwoven in the process. Firstly, Laboy tiller’s development could very easily be considered an altruistic gesture (continuum point 1 in Figure 2), stemming from the desire to do something about the land preparation situation. For context, researchers can choose to tackle any research question or technology they wish to pursue, given the available resources, as long as it aligns with organizational priorities. Choosing to address the “laboy” issue was not imposed on the researchers but was a decision based on their judgment and capacity to address. It should also be mentioned that the original intent in going to Aurora was to do a demonstration for the PalayCheck, which is the Philippines’ key platform to assist farmers in achieving decent yields. It was not meant to focus on the Laboy tiller or the laboy fields, which do not merit investment if seen from a business perspective. This shows that the act of choosing to work on the ‘laboy’ issue could be read as an altruistic move.

As the participatory development rolled out, at the machine trialing phase, one farmer-partner was identified to steward it when the machine was left in the community, “model” it, and record observations. The scale of trialing expanded when this partner enjoined other farmers in the exercise (continuum point 2 in Figure 2). The first act of altruism had its first ripple effect here. Going back to the framework, the inclusion of the farmer as a co-developer aligns with ‘performance expectancy.’ Here, the REMD team of Dr. Regalado was trying to show that the technology can address a pressing issue.

By the end of the participatory development period, Doc Manny proposed to the farmer-partner that if he would like to buy the machine, he should be paid in tranches within the farmer’s capacity to pay (hulug-hulugan). Had the farmer agreed to pay in tranches, Doc Manny would have to pay in case the farmer is unable to pay his dues. To highlight Doc Manny’s gesture, it should be noted that Laboy tiller was not yet commercialized. The business aspect was not yet in the picture, as PhilRice is not into manufacturing. It is a purely research-for-development organization. Mass production is done by a private entity. Doc Manny was just after collecting some data to establish the machine’s efficiency. This was the second altruistic gesture. It was favorable for the farmer partner, who had also realized the prospect of a servicing business (continuum point 3 in Figure 2).

During the interviews for this current study, the first farmer-cooperator speaks of his interaction with the research team as though it happened just recently, even after approximately two decades since he participated in the development of the Laboy tiller in 2003. In his narrative, the farmer would repeatedly mention the warmth and sincerity that he felt when the machine was being introduced to them – first as part of the participatory machine development addressing their laboy production concern and second as an arbitrary gesture of kabutihang loob (kindness) post-research. In Filipino culture, showing goodness to others is valued highly. Hence, we are inclined to think that the altruistic gestures may have resulted in the farmer valuing the machine developed specifically to address their main concern.

“What Doc Manny (Dr. Manuel Jose Regalado) has done for me is, he left the Floating Tiller, then he told me that I just need to record all that I do with it, how many passes, how much gasoline, that’s what I report to him, but, no payment. He won’t charge me for payment. Ergo, that’s just what he says to me, ‘How many days have I done’, ‘How many passes have I done’, ‘How much gasoline have I used’, ‘How many people were we’. Questions like that are what he asks me. So, in the end, he said that maybe if I wanted, I could pay in installments, and what happened was, the very first Floating Tiller that came here in Baler, Aurora, became mine.10”

[Farmer from Bacong, M, 60]

“I have no bad comments, only good ones! The Laboy tiller is very helpful!“11” [Farmer from Bacong, M, 60]

Seen in this light, we argue that the Filipino value of ‘utang na loob’ may have also played its part as a product of the altruistic gesture. Utang na loob is a key concept in Filipino culture that has been the subject of various studies (Agaton, 2017; Gundran et al., 2021; Kaut, 1961; Pe-Pua and Protacio-Marcelino, 2000; Rungduin et al., 2015). The academically dissected concept built upon (Kaut, 1961; Gundran et al., 2021) emphasizes utang na loob as a cycle of obligations and voluntary paying back to the donor. There are both positive and negative implications of this cycle of obligations, whereas one may take advantage of the system and offer a gift to someone to obligate them to give back something greater. On the other hand, it could also foster a strong relationship when, in the series of back and forth, both parties feel equally indebted to each other (Agaton, 2017; Kaut, 1961). Rungduin et al.’s (2015) study analyzed the utang na loob concept based on the meanings ascribed to it by their study participants, which helped them understand the contemporary meaning of the term. They synthesized three themes ascribed to the meaning of ‘utang na loob’: acknowledgment, reciprocity, and social responsibility. With altruistic acts (seen as kagandahang-loob) resulting in indebtedness and the need to pay back (utang na loob), we find that this social aspect can help in the farmers’ willing adoption of presented technologies if the altruistic ideals are sincere and clearly shown. Sincerity, we argue, in this case, has to be felt by the recipient of the action. The developer’s sincerity and purity of intent may have positively influenced the uptake and long-term use of the technology.

For this reason, we propose including altruism as among the scaling ingredients. Despite all the challenges, the Laboy tiller has remained and is regarded as an important machine in dealing with laboy fields. For a technology to scale, it has to first stay. In the case of this study, altruism is a key ingredient in why the Laboy tiller has since stayed. This proposal sits well with the calls relating to humanizing agricultural extension and considering social aspects often neglected in agricultural extension, usually dominated by discourses on technological determinism (Vanclay, 2004; Cook et al., 2021).

5 Discussion

The use of the Laboy tiller had spread throughout Bacong, mostly due to the service providers and the personal network of the people in the area. This parallels Stræte et al.’s (2022) discussion on the importance of networking as a social integration mechanism that strengthens a group’s absorptive capacity. Through bonding and bridging social capital, the service providers can easily access their social groups and other nearby social groups (Cofré-Bravo et al., 2019). In the framework, this relates to “social influence” or the belief that important others believe that farmers should use the technology.

Group involvement through these social groups facilitates the spread of awareness regarding the relative advantages of this innovation (Kuehne et al., 2011). However, due to weak linkages with other social groups in surrounding areas, awareness is largely confined to Bacong. This limitation is evident, as awareness of the machine is mostly restricted to areas near Bacong, while more distant locations, such as Dipaculao, remain largely unaware in the absence of connections between their social groups and those of the service providers. Moreover, many farmers with small areas of laboy soil, having dug canalets to drain water and worked the fields to aid decomposition, do not perceive the issue as significant enough to seek better solutions than those already available. However, the problem escalates during frequent rains, which overwhelm their canalets and cause the soil to revert to laboy conditions. At such times, demand increases, and the existing service providers are unable to meet the needs of all farmers.

The custom hiring service of the service providers is also an important part of a positive business case, as the machine is quite complex and expensive to manufacture, making it cost-prohibitive for a single farmer to invest in. Being able to earn from their clients’ fields through service provision helps justify the investment as it increases the efficiency of the return on investment (Houssou et al., 2015). Furthermore, a better understanding of how the demand shifts could solidify the business case for prospective service providers. However, regardless of the possible returns, credit availability is still an important factor for the machine’s uptake, which the soft loan facility of REMD provided (Cafer and Rikoon, 2018; Mottaleb et al., 2016; Verkaart et al., 2019). The adoption process could have scaled wider if there had been more focus on awareness and capability building among service providers of the surrounding areas of Bacong, like Dipaculao and Baler, which share similar conditions, seeing that these service providers are best positioned to profit from the relative advantage of the innovation should the constraints in awareness and up-front costs be bridged (Kuehne et al., 2011).

After the initial project, however, there had been no major concerted efforts for the scaling of the machine, where the scaling ingredients for collaboration, evidence and learning, leadership and management, and public sector governance are found to be lacking, which results in the machine not scaling widely enough, emphasizing the need for the involvement of other stakeholders in the agricultural innovation systems to realize scaling ambitions (Klerkx et al., 2012). Even so, we still find the machine in use today, due in part to another ingredient, altruism, that we find helps the innovation in scaling deeply that affects culture, shared norms and values, social relations, and trust with their roles in sustainable technology uptake (Carolan, 2006; Palis, 2006). Overall, these findings relate to the need for “facilitating conditions” for a technology to be accepted and used and, in the context of this research, to scale. As stated, the facilitating conditions do not seem highly favorable.

Looking at it more broadly, what is the implication of altruism in the larger uptake of agricultural technologies? The most obvious response is that farmers or end-users generally value relationships in addition to all the technical requisites of a machine. Farmers, at least in the case of the research participants, value human interaction, goodwill, and everything that is attached to it for them to embrace technology. This is an important point, as oftentimes, the promotion of machines is done routinely, with extension workers or any rural development workers completely detached from their intended technology recipients. The human dimension in agriculture should never be put on the back burner. The second important point is that altruism affects scaling in the sense that once the farmers have embraced the technology and are convinced of the altruistic acts of the developer or the extension worker, they will champion its use. Scaling will be an organic process that will be orchestrated by the farmers themselves. This argument is supported in the literature (e.g., Kiptot and Franzel, 2014; Nyanga, 2012; Akresh et al., 2011; Moore, 2015).

Going back to the framework, this finding on altruism could be seen in the light of ‘social influence.’ As reported, Doc Manny and his team frequently visited the farmers in Aurora and even worked with the farmers, so the latter acted as co-developers of the technology. With this, it is not difficult to think that Dr. Regalado became an ‘important other’ among the farmers in the area, especially with respect to his gesture of loaning the machine to the farmers even though they could not make any promise of repayment. As explained, these acts are important in Filipino culture, especially with the widely known value of ‘utang na loob’ (cycle of obligations). With Doc Manny becoming an ‘important other’ among farmers, his championing of the technology certainly had an influence on them.

In UTAUT, Venkatesh et al. (2003) note that the effect of “social influence” is significant if the use of the technology is mandated. Hence, people may use the technology out of compliance. In the context of this research, the use of the technology was not mandated. The farmers, being research participants, could easily opt out of the research. More so, the farmers could easily abandon the machine after the research. Nevertheless, as we have reported, the machine remains in use and is considered the best technology in laboy fields more than 2 decades after its introduction. Hence, it strengthens the case of altruism as a key ingredient for their continued use of the machine.

To close this discussion, another aspect that needs explaining if one were to buy our proposal on altruism as another scaling ingredient is: why did the farmers trust Doc Manny and his team of researchers? In addition to Doc Manny being an ‘important other’ in the technology uptake, we argue that his approach to working with them facilitated the success of the process. As mentioned in the quote above, the farmers felt the warmth and kindness extended to them by a then stranger. The initial agenda of going to Aurora for the Palaycheck demonstration evolved to a second purpose of addressing the local concern on laboy production through participatory development, culminating in an unexpected altruistic gesture post-research agenda. As evidence that the gesture was no longer a research agenda when the Laboy tiller was left to be owned by the farmer, there is no monitoring record. This research only revisited the machine’s life thereafter, two decades later. Kindness and warmth are highly valued in Filipino culture and even outside it. Brülhart and Usunier (2004) argue that perceived kindness matters.

Additionally, in the larger scholarship on ‘trust,’ “friendliness, openness, flexibility, and generosity” (Dent, 2005, p. 110) are among the key factors that build trust. Based on the narration above, these were all shown by Doc Manny and his team in their dealings with farmers. Thirdly, according to Dent (2005), trust is enhanced through socializing, and “communications of good will increase cooperation” (p. 107). As mentioned, Doc Manny and his group went back and forth to Aurora for several months, and they had productive conversations with farmers. Summing up the interaction between Doc Manny and the farmers, we argue that there was positive reciprocity on the part of the farmers. Brülhart and Usunier (2004) note that positive reciprocity combines trust and trustworthiness.

In the rural development literature, what Doc Manny and his team did could be said to be a part of the ‘trust-building’ phase. It could be. Nonetheless, whether it was a part of trust-building as a phase in rural development work or not, it is cogent that Doc Manny’s gesture was felt deeply and positively by the farmer participants. To this end, we argue that the altruism proposal stands. Altruism is value-laden and multi-faceted. It could be seen either from the doer’s perspective or the action’s recipient.

6 Conclusion

We have seen that the Laboy tiller significantly impacted the lives of farmers in laboy areas. However, its highly specific niche, combined with the lack of concerted efforts addressing some key scaling ingredients, such as collaboration, evidence and learning, leadership and management, and public sector governance, placed much of the responsibility for scaling the innovation onto the beneficiaries themselves. This reliance limited the reach of the innovation to the boundaries of their social networks. Nevertheless, this situation also highlighted the critical role of altruism in the acceptance, sharing, and continued use of introduced innovations.

Going beyond the prescribed duties and obligations of a typical technology transfer relationship holds immense value. Altruistic intentions foster reciprocal tendencies among beneficiaries, often directed toward the benefactor. This elicits a relationship built on respect and trust, as beneficiaries reciprocate altruistic sentiments. Such a relationship, founded on mutual goodwill, enhances the productivity of their interactions, with the benefactor as an intervention implementer and the beneficiary as a farmer partner. Furthermore, when the transfer of innovation is grounded in goodwill, beneficiaries are more motivated to care for the received innovation, demonstrating their acknowledgment and respect for the benefactor’s altruism.

Altruistic actions also extend beyond the direct benefactor-beneficiary relationship. Beneficiaries may feel a social responsibility to act altruistically toward their peers, thereby becoming benefactors themselves. This cascading effect enables the innovation to reach further audiences, albeit still within the constraints of the farmer-partner’s social network. By fostering a culture of reciprocity and mutual support, altruism contributes meaningfully to the scaling and sustained adoption of innovations.

7 Notes

1. Sandro D. Cañete is a PhilRice agronomist.

2. Original in Filipino

“Technology nila noon mano mano. Ibinabaliktad lang noon ang damo. Dadamuhin hano pag walang tanim manual po yan na binabaliktad nila. Edi syempre buhay pa rin yung damo sa loob kasi binabaliktad lang nila.”

1. Original in Filipino.

“Ayaw na umabante kasi wala na po syang mahawakan ang gusto po nya meron syang kinakabig lagi. Di katulad nung floater (Laboy tiller) kahit wala na syang kinakabig na matigas o makunat tatakbo sya.”

1. Original in Filipino.

“Interviewer: Ano po ito yung spike. Parang maganda po ba na may spike or parang…

Interviewee: Yan nga maganda.

…

Interviewer: Parang madurog talaga yung.

Interviewee: Oo madurog nya yung mga dayami at damo. Kasi ang dating gamit namin wala parang tutumbahin lang yung kwan tutumba lang nya yung dayami saka damo.”

1. Original in Filipino.

“Interviewee: mahirap din nga. Mahirapan kasi ang kwan dyan kasi malaki sya mahirapan ang makina.

…

Interviewer: kung mas malaki po sya parang mas mahirap bakit po mahirapan yung makina?

Interviewee: e maliban kung yung makina e lagyan mo ng mas malaki edi mas mabigat ka na naman.”

1. Original in Filipino

“Oo nagamit pa rin kasi pag yong alam mo naman yung lugar na malalim wag mo na padaanan ng handtractor paikutan mo na lang yon iwasan mo at pagka yung floating tiller na ang pifinish doon.”

1. Original in Filipino

“Pag marunong kang maghandtractor talaga marunong ka na rin.”

1. Original in Filipino.

“Interviewee: Maam kasi yung pagka masyadong maano yung tag ulan e yung kwan madali po kasi syang pag natubigan e lumulutang yung lupa.

Interviewer: Pag tag ulan.

Interviewee: Oo. Kahit na tag araw basta po umulan ng malakas umaangat sya parang organic ganon na parang bulok na lupa na magaan ganon.”

1. Original in Filipino.

“Nang nagawa na ng kalsada dumami na ulit ang laboy.”

1. Original in Filipino.

“Ang ginawa sakin ni Doc Manny iniwan nya yung floating tiller tapos irecord ko lang daw kung ano yung ginawa ko kung ilang pasada kung ilang gasolina yon ang irereport ko sa kanya pero walang bayad hindi nya ko sisingilin ng bayad kumbaga yung lang ang sasabihin nya sakin na nakailang araw ka nakailang padaan yung ginawa mo ganon ilang gasoline naubos mo. Ilang tao kayo mga ganon ang tinatanong nya sa akin. Kaya nung bandang huli baka gusto mo sabi nya hulug hulugan mo nalang e ang nangyari napunta sakin yung kauna unahang floating tiller na dumating dito sa Baler sa Aurora.”

1. Original in Filipino.

“Walang masamang komento puro magaganda kasi nakatulong nga basta nakatulong talagang laboy napaani naman nila kahit papano.”

Data availability statement

The datasets presented in this article are not readily available because of the participants’ identifiable data embedded in the recordings. Requests to access the datasets should be directed to b3JjdWxsb2xvdWllZ2VyYXJkQGdtYWlsLmNvbQ==.

Ethics statement

Written informed consent was obtained from the individual(s) for the publication of any potentially identifiable images or data included in this article.

Author contributions

JM: Conceptualization, Investigation, Methodology, Supervision, Writing – original draft, Writing – review & editing. LO: Conceptualization, Investigation, Methodology, Writing – original draft, Writing – review & editing. TL: Conceptualization, Investigation, Methodology, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The authors thank PhilRice for providing the funding for the conduct of this research under SED-232.

Acknowledgments

The authors would like to thank Ms. Camille C. Dumale and Mr. Mark Joseph R. Zuñiga for taking part in the data collection, as well as the Municipal Agriculture Office of San Luis, Aurora, for assisting in coordinating the data collection with the participants of the study.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Agaton, S. I. (2017). Vantage points of Utang na Loob tuba culture in the province of Leyte. Social Ethics Soc. J. Appl. Philos. 3, 59–77. Available at: https://www.researchgate.net/publication/348729589

Akresh, R., Chen, J. J., and Moore, C. (2011). “Altruism, cooperation, and efficiency: agricultural production in polygynous households.” IZA DP No. 6265. Available at: https://www.iza.org/publications/dp/6265/altruism-cooperation-and-efficiency-agricultural-production-in-polygynous-households (Accessed December 19, 2024).

Amongo, R. M. C., Onal, M. K. S., Larona, M. V. L., Fajardo, A. L., Ilao, C. I. L., Lalap, G. N. L., et al. (2018). Level of agricultural mechanization in Oriental Mindoro, Laguna and Quezon, Philippines using the modified agricultural mechanization index for lowland Rice. Philipp. J. Agric. Biosyst. Eng. 14, 55–70.

Bautista, E. G., Kim, J., Kim, Y., and Panganiban, M. E. (2017). Farmer’s perception on farm mechanization and land reformation in the Philippines. J. Korean Soc. Int. Agric. 29, 242–250. doi: 10.12719/KSIA.2017.29.3.242

Bhuvana, M., Pavithra, M., and Suresha, D. (2021). Altruism, an attitude of unselfish concern for others – an analytical cross sectional study among the medical and engineering students in Bangalore. J. Family Med. Prim. Care 10, 706–711. doi: 10.4103/jfmpc.jfmpc_834_20

Bordey, F. H., Moya, P. F., Beltran, J. C., and Dawe, D. C. (Eds.) (2016). Competitiveness of Philippine rice in Asia. Science City of Muñoz (Philippines) and Manila (Philippines): Philippine Rice Research Institute and International Rice Research Institute, 172.

Brülhart, M., and Usunier, J. C. (2004). Verified trust: Reciprocity, altruism, and noise in trust games. Altruism and noise in trust games (November 2004).

Cafer, A. M., and Rikoon, J. S. (2018). Adoption of new technologies by smallholder farmers: the contributions of extension, research institutes, cooperatives, and access to cash for improving tef production in Ethiopia. Agric. Hum. Values 35, 685–699. doi: 10.1007/s10460-018-9865-5

Carolan, M. S. (2006). Social change and the adoption and adaptation of knowledge claims: whose truth do you trust in regard to sustainable agriculture? Agric. Hum. Values 23, 325–339. doi: 10.1007/s10460-006-9006-4

Cofré-Bravo, G., Klerkx, L., and Engler, A. (2019). Combinations of bonding, bridging, and linking social capital for farm innovation: how farmers configure different support networks. J. Rural. Stud. 69, 53–64. doi: 10.1016/j.jrurstud.2019.04.004

Cook, B. R., Satizábal, P., and Curnow, J. (2021). Humanising agricultural extension: a review. World Dev. 140:105337. doi: 10.1016/j.worlddev.2020.105337

Connor, M., Guia, A. H., de Pustika, A. B., Sudarmaji,, Kobarsih, M., and Hellin, J. (2021). Rice Farming in Central Java, Indonesia—Adoption of Sustainable Farming Practices, Impacts and Implications. Agronomy, 11, 881. doi: 10.3390/agronomy11050881

Dent, G. W. (2005). "Race, trust, altruism, and reciprocity". Faculty Publications 673. Available at: https://scholarlycommons.law.case.edu/faculty_publications/673 (Accessed May 29, 2024).

German, L., Mowo, J., Kingamkono, M., and Nuñez, J. (2006). “Technology spillover: a methodology for understanding patterns and limits to adoption of farm-level innovations.” AHI Methods Guide A1. Available at: http://apps.worldagroforestry.org/programmes/african-highlands/pdfs/mgs/Methods%20Guide%20A1.pdf (Accessed September 25, 2022).

Glover, D., Venot, J., and Maat, H. (2017). “On the movement of agricultural technologies: packaging, unpacking and situated reconfiguration” in Agronomy for development: The politics of knowledge in agricultural research. ed. J. Sumberg. 1st ed (London: Routledge), 14–30.

Gundran, A. M. P., Manalo, J. R. J., Soriano, P. A. S., Cagsawa, R. L. O., and Manguiat, G. C. (2021). The concept of Utang na Loob in the Philippines: Utang na loob scale. ANTORCHA 8:1. Available at: https://www.ejournals.ph/article.php?id=17184

Houssou, N., Asante-Addo, C., Diao, X., and Kolavalli, S.. (2015). “Big tractors, but small farms: Tractor hiring services as a farmer-owner’s response to an under-developed agricultural machinery market.” GSSP Working Paper 39. Washington, DC and Accra, Ghana: International Food Policy Research Institute (IFPRI). Available at: http://ebrary.ifpri.org/cdm/singleitem/collection/p15738coll2/id/129173.

Jacobs, F., Ubels, J., and Woltering, L.. (2018). “The scaling scan - a practical tool to determine the strengths and weaknesses of your scaling ambition.” PPPLab and CIMMYT.

Kadhim, Z. (2018). Custom hiring versus ownership of agricultural machinery services in rice production farms in Alnajaf Al-Ashraf province. Iraqi J. Agric. Sci. 49, 1060–1072. doi: 10.36103/ijas.v49i6.142

Kaut, C. (1961). Utang na loob: a system of contractual obligation among Tagalogs. Southwest. J. Anthropol. 17, 256–272. doi: 10.1086/soutjanth.17.3.3629045

Kiptot, E., and Franzel, S. (2014). Voluntarism as an investment in human, social and financial capital: evidence from a farmer-to-farmer extension program in Kenya. Agric. Hum. Values 31, 231–243. doi: 10.1007/s10460-013-9463-5

Klerkx, L., van Mierlo, B., and Leeuwis, C. (2012). Evolution of systems approaches to agricultural innovation: concepts, analysis and interventions. In: Darnhofer, I., Gibbon, D., Dedieu, B. (eds) Farming Systems Research into the 21st Century: The New Dynamic. Springer, Dordrecht. doi: 10.1007/978-94-007-4503-2_20

Kraut, R. (2020) “Altruism", the Stanford encyclopedia of philosophy (fall 2020 edition), edited by E. N. Zalta. Available at: https://plato.stanford.edu/archives/fall2020/entries/altruism/ (Accessed December 19, 2024).

Kuehne, G., Llewellyn, R. S., Pannell, D. J., Wilkinson, R., Dolling, P., and Ewing, Michael A., (2011). ADOPT: a tool for predicting adoption of agricultural innovations,” 2011 Conference (55th), February 8-11, 2011, Melbourne, Australia 100570, Australian Agricultural and Resource Economics Society. doi: 10.22004/ag.econ.100570

Manalo, J. A. IV, Orcullo, L. G. F., de Leon, T. J. P., and Baltazar, M. A. M. (2022). What happened to PhilRice's microtiller? A scaling study. Asian J. Agric. Dev. 19, 35–49. doi: 10.37801/ajad2022.19.2.p2

Manalo, J. A., van de Fliert, E., and Fielding, K. (2020). Rice farmers adapting to drought in the Philippines. Int. J. Agric. Sustain. 18, 594–605. doi: 10.1080/14735903.2020.1807301

Moore, C. A. (2015). “The role of altruism and fatalism in economic development.” Master’s Thesis, University of Arizona. Available at: https://economics.arizona.edu/role-altruism-and-fatalism-economic-development (Accessed December 6, 2022).

Mottaleb, K. A., Krupnik, T. J., and Erenstein, O. (2016). Factors associated with small-scale agricultural machinery adoption in Bangladesh: census findings. J. Rural. Stud. 46, 155–168. doi: 10.1016/j.jrurstud.2016.06.012

Nyanga, P. H. (2012). Factors influencing adoption and area under conservation agriculture: a mixed methods approach. Sustain. Agric. Res. 1:27. doi: 10.5539/sar.v1n2p27

Obeng Adomaa, F., Sietze, V., Slingerland, M., and Asare, R. (2022). The adoption problem is a matter of fit: tracing the travel of pruning practices from research to farm in Ghana’s cocoa sector. Agric. Hum. Values 39, 921–935. doi: 10.1007/s10460-021-10292-0

Orr, A. (2018). Markets, institutions and policies: A perspective on the adoption of agricultural innovations. Outlook on Agriculture, 47, 81–86. doi: 10.1177/0030727018776433

Palis, F. G. (2006). The role of culture in farmer learning and technology adoption: a case study of farmer field schools among rice farmers in Central Luzon, Philippines. Agric. Hum. Values 23, 491–500. doi: 10.1007/s10460-006-9012-6

Pe-Pua, R., and Protacio-Marcelino, E. (2000). Sikolohiyang Pilipino (Filipino psychology): A legacy of Virgilio G. Enriquez. Asian J. Soc. Psychol. 3, 49–71. doi: 10.1111/1467-839X.00054

Rawat, S., Jaiswal, M., Bhalave, K., Vani, D. K., and Rahangdale, C. P. (2020). Assessment study on custom hiring centers (CHCs) and its services for farmers in Khandwa District of Madhya Pradesh. Asian J. Agric. Ext. Econ. Sociol. 38, 178–184. doi: 10.9734/ajaees/2020/v38i1230516

Regalado, M. J. C., and Juliano, A. S.. (2010). “Laboy tiller: improving deep muddy and swampy rice lands.” Rice Technology Bulletin

Regalado, M. J. C., Juliano, A. S., Moliñawe, L. B., Ramos, J. A., and Cruz, R. T. (2007). Re-engineered floating tiller: key to reduced drudgery and improved productivity in deep-mud rice areas. Philippine Agric. Eng. J. 36, 1–7.

Rungduin, T. T., Rungduin, D. C., Joshua, A., Catindig, R. B. Jr., and Gallogo, L. (2015). The Filipino character strength of utang na loob: exploring contextual associations with gratitude. Int. J. Res. Stud. Psychol. 5, 13–23. doi: 10.5861/ijrsp.2015.1322

Stræte, E. P., Hansen, B. G., Ystad, E., and Kvam, G. T. (2022). Social integration mechanisms to strengthen absorptive capacity in agricultural advisory service organisations. J. Agric. Educ. Ext. 29, 395–416. doi: 10.1080/1389224X.2022.2117214

Vanclay, F. (2004). Social principles for agricultural extension to assist in the promotion of natural resource management. Aust. J. Exp. Agric. 44, 213–222. doi: 10.1071/EA02139

Venkatesh, V., Morris, M., and Davis, G. B. (2003). User acceptance of information technology: toward a unified view. MIS Q. 27:425. doi: 10.2307/30036540

Keywords: altruism, technology adoption, technology adaptation, Laboy tiller, farm machine

Citation: Manalo JA, Orcullo LGF and de Leon TJP (2025) Altruism as a scaling ingredient: an exploration of the adoption of the Laboy tiller in Aurora. Front. Sustain. Food Syst. 9:1380248. doi: 10.3389/fsufs.2025.1380248

Edited by:

Julie Ingram, University of Gloucestershire, United KingdomReviewed by:

Callum Eastwood, DairyNZ, New ZealandM. Lisa Yeo, University of California, Merced, United States

Copyright © 2025 Manalo, Orcullo and de Leon. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Louie Gerard F. Orcullo, b3JjdWxsb2xvdWllZ2VyYXJkQGdtYWlsLmNvbQ==

Jaime A. Manalo IV

Jaime A. Manalo IV Louie Gerard F. Orcullo

Louie Gerard F. Orcullo Teresa Joi P. de Leon

Teresa Joi P. de Leon