- 1Institute of Food Economics, Nanjing University of Finance and Economics, Nanjing, Jiangsu, China

- 2School of Finance and Accounting, Yellow River Conservancy Technical Institute, Kaifeng, Henan, China

Introduction: One of the best ways to ensure food security is to reduce Food Loss and Waste (FLW). However, China still confronts numerous obstacles in food loss and waste study because of the intricate industrial chain, the wide range of accounting standards, and a lack of data, among other reasons.

Methods: Using the literature analysis method, 119 literatures were collected and analyzed to examine the current status of FLW in China at various stages after food production and throughout the life cycle from the perspectives of time series and research areas.

Results: The study indicates that the rates of FLW in China have been higher than 20% in recent years and are still increasing. Among them, the highest FLW rates were found in the harvesting stage (3–6%), storage stage (8–10%) and consumption stage (10–17%). In addition, FLW results in a huge waste of resource endowments.

Discussion: The environment and resources are profoundly affected by these substantial food losses and wastes, leading to unnecessary depletion of resources. As China’s focus on food loss and waste intensifies, an increasing number of academics are expected to delve into this area, exploring dimensions such as ecological footprint assessment, innovative uses for food waste, and gathering primary data.

1 Introduction

The issue of food security has long been a major global challenge. It is not only related to the basic right to survival of human beings but also poses a constraint on stable socioeconomic development. The challenge of food security has been further exacerbated, especially in recent years, by the global outbreak of COVID-19, the frequency of extreme weather events, and the proliferation of international political and military conflict (Yumnam et al., 2024; Lee et al., 2024). According to FAO, nearly 850 million people were hungry or undernourished globally in 2021, which puts the global food system under great challenge and pressure (FAO, 2022). Combating food insecurity is a complex and systematic project that involves multiple areas of production, distribution, and consumption (Béné et al., 2019). In the realm of agricultural production, enhancing food supply can be accomplished through various strategies, such as elevating yields per unit area, extending the cultivated land, and augmenting technological inputs. However, relying solely on these means to increase food production is becoming increasingly challenging as the scale of production and agricultural technology inputs become saturated (Campi et al., 2021). In addition to enhancing food production, another key measure is to take action at the distribution and consumption end – to reduce food losses and wastage (Parfitt et al., 2010). This strategy proves to be not only cost-efficient but also pivotal in ensuring food security and fostering sustainable development.

Food loss and waste is the reduction in the quantity or quality of food for various reasons during its production, harvest, storage, transport, processing, and consumption, and its eventual failure to be used effectively (Gatto and Chepeliev, 2024). It is divided into two main components, namely, food loss (FL) and food waste (FW). It is important to emphasize that food loss occurs mainly at the pre-consumption stage, while food waste occurs mainly at the consumption stage. Data released by the United Nations show that global food losses and waste exceed 1.3 billion tons per year, representing 13.8% of global food production (FAO, 2009). This means that globally the equivalent of 23% of arable land and 24% of fertilizer use is wasted each year (FAO, 2011a). Kummu et al. (2012) came to a similar conclusion through their calculations that about a quarter of the world’s water resources, arable land, and fertilizers are wasted due to food losses and wastage. This not only leads to a significant waste of resources but also imposes undue environmental stress (FAO, 2013). According to FAO calculations, global food production would have to increase by 60% by 2050 to meet the escalating consumption needs of a growing population, but only a 28% increase would be needed to meet demand if FLW were halved (FAO, 2011b). It is evident that to ensure food safety, strategies aimed at curbing food loss and waste are more effective and practical than merely seeking to boost production.

As the world’s most populous nation, a leading developing country, and the foremost producer and consumer of food, China’s food security issues hold profound implications for the nation’s stability and progress. Despite significant efforts and notable achievements in ensuring domestic food security, China continues to grapple with various challenges (Ghose, 2014).On the one hand, China needs to import large quantities of food every year to meet its demand (Yu et al., 2019). On the other hand, the problem of food loss and waste persists. According to the Chinese Government, 20% of China’s food production, or about 120 Mt. of food per year, is lost and wasted in the supply chain (Li and Mao, 2022). To this end, the Chinese government has actively advocated and implemented the “Clean Plate” campaign over the past ten years, and explicitly proposed food conservation actions in the 14th Five-Year Plan. In 2021, China enacted the “Anti-Food Waste Law” and the “Comprehensive Work Plan for Food Conservation and Reduction of Losses,” aiming to establish a long-term mechanism to promote food conservation and reduce losses.

Although the Chinese government has gradually recognized the importance of the issue of food loss and waste and has made significant progress in the construction of institutions and practical exploration, there is still a gap between the research results of academics and the real needs. Compared with other countries and regions around the world, China’s research in the field of food loss and waste started relatively late, and the attention and research depth of academics on this issue need to be further improved. As a result, the challenges faced by China in the area of food loss and waste are still serious. The objective of this paper is to methodically organize and scrutinize the existing body of research on food loss and waste in China, offering insights that can facilitate the effective resolution of these issues. The paper’s marginal contributions encompass the following three aspects:

Firstly, this paper overcomes the limitations of previous studies that focused solely on a single link or discipline. Instead, it comprehensively examines the current state of food loss and waste in China by considering various stages of post-production, different food varieties, and the entire life cycle. This holistic research methodology furnishes a detailed and enlightening reference framework, conducive to a thorough investigation of the intricate dynamics of food loss and waste in China.

Secondly, previous studies predominantly focus on analyzing food loss from the perspective of volume, yet this approach struggles to align with the contemporary societal imperatives of sustainable development. This paper explores a new research perspective on food loss and waste from the perspective of life cycle and environmental costs, which is complementary to existing studies.

Finally, this paper offers a prospective analysis of research trends about Food Loss and Waste in China. These forecasts serve not only as informative guidance for ongoing research endeavors but also offer significant reference value for policymakers in addressing Food Loss and Waste challenges.

2 Current status of food loss research in China

2.1 Background and current status of research on the occurrence of food losses in China

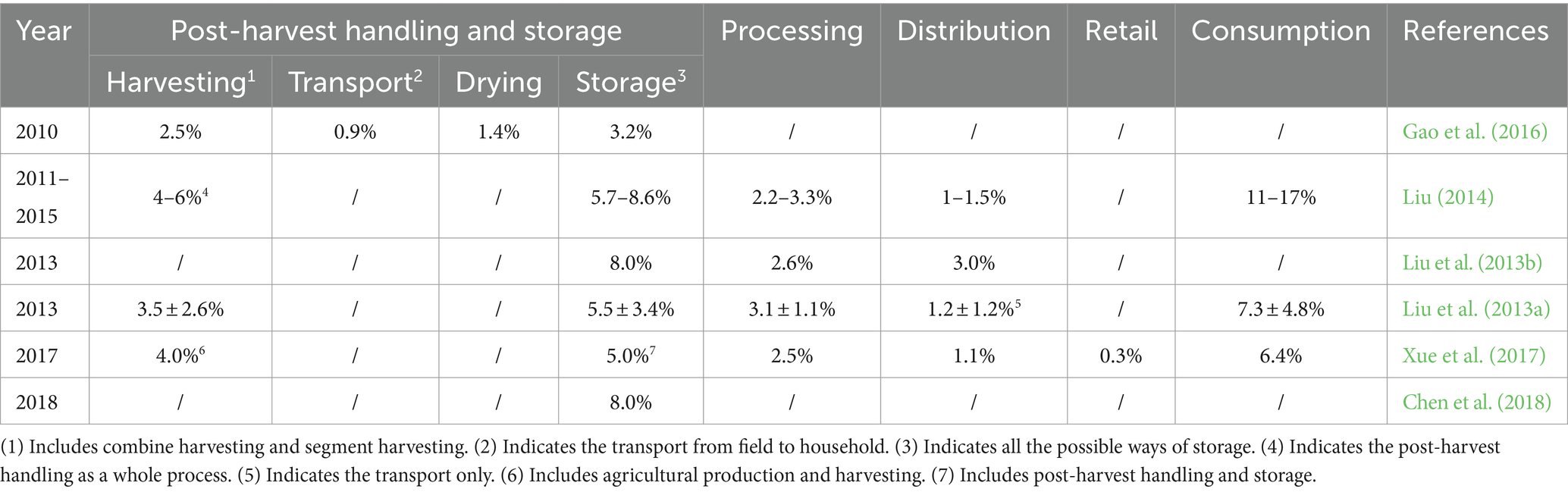

Food security has always been one of the core issues of great concern to the Chinese Government. Since the middle of the twentieth century, China has faced the challenge of food shortages for a long time (Wang and Chern, 1992; Yang, 1999; Yang and Li, 2000). Until the 1990s, with the significant increase in food production, the problem of food loss and waste came to the forefront (Lu et al., 2024). Therefore, since the 1990s, Chinese scholars have begun to conduct systematic research on food loss and waste. However, in contrast, the Food and Agriculture Organisation of the United Nations (FAO), the Association of Southeast Asian Nations (ASEAN), as well as major Western countries, have been focusing on research on post-production impairment of food since the 1970s and even earlier, and have made progress accordingly (Table 1).

In the 21st century, China’s rapid economic growth, significant improvement in people’s living standards, and the deepening of global trade integration have combined to drive China’s population to the best level of food ownership in history (Gandhi and Zhou, 2014). However, the problem of food loss and waste in China has also become increasingly prominent during this period. Research by relevant scholars shows that in 2010, the amount of waste of major foodstuffs in the consumption chain in China reached 62.818 Mt., accounting for 14.5% of total food production (Sun et al., 2018). Between 2011 and 2015, total food losses accounted for 13–20% of total production, with harvest losses ranging from 3.5–6%, storage losses from 5.5–8.6%, and consumption wastage as high as 7–17% (Liu et al., 2013b; Liu, 2014). From 2015 to 2017, China’s post-production crop loss rate ranged from 7 to 11%, and the food waste rate at the consumption stage ranged from 3.8 to 11.1%, with an average of about 10% (Gao et al., 2018). Qi et al. (2020) found that China’s food waste declined gradually from the 1990s, reaching a low in 2006 (16%), but then began to increase gradually, reaching 18%. FAO statistics show that China’s post-production grain loss rate is as high as 14.5% (FAO, 2019). Statistics from the Chinese Academy of Agricultural Sciences and China’s Ministry of Agriculture and Rural Development show that China’s food loss and waste rate will be as high as 22.7% in 2022, total volume of approximately 460 Mt. Among them, the loss and waste rate of grain-based food is 16.4%, and the waste rate in the consumption stage is 9.4%, accounting for 57.3% of the total loss, making it the largest stage of food loss (Fan G. et al., 2023).

These data indicate that China still faces serious challenges in terms of food security and sustainable development and needs to further strengthen the management and control of food loss and waste. To further analyze the situation of food loss and waste in China, this paper analyses the following specifics from the post-production stage of food production.

2.2 Current status of losses in the food harvesting chain and factors affecting them

The harvest stage is the beginning of post-production handling of grain, covering a series of key steps such as harvesting, threshing, and transportation. Available studies have shown that losses at the harvest stage in the 28 provinces of China involved in the cultivation of rice, wheat, and maize accounted for 3.55, 4.41, and 2.58% of the total production, respectively. More than 50% of these losses occur during harvesting and about 30% during threshing and grain cleaning (Luo et al., 2022a). Lu S. et al. (2022), through a field study in 12 provinces in China, found that grain losses at the harvest stage accounted for 7.9% of the total losses, respectively. The study of Yan et al. (2023) further indicated that the loss rate of wheat and maize at the harvest stage is about 7%. Despite the continued efforts of the Government of China to reduce losses at the harvesting stage, the results are not yet significant. Lu S. et al. (2022) suggested that there is still room for significant reductions in loss rates at the harvest stage through improved technical and management practices. Specifically, the loss rate could be reduced by 36% for rice, and 43.8% for wheat, while maize has the potential to reduce the loss rate by 61.3%.

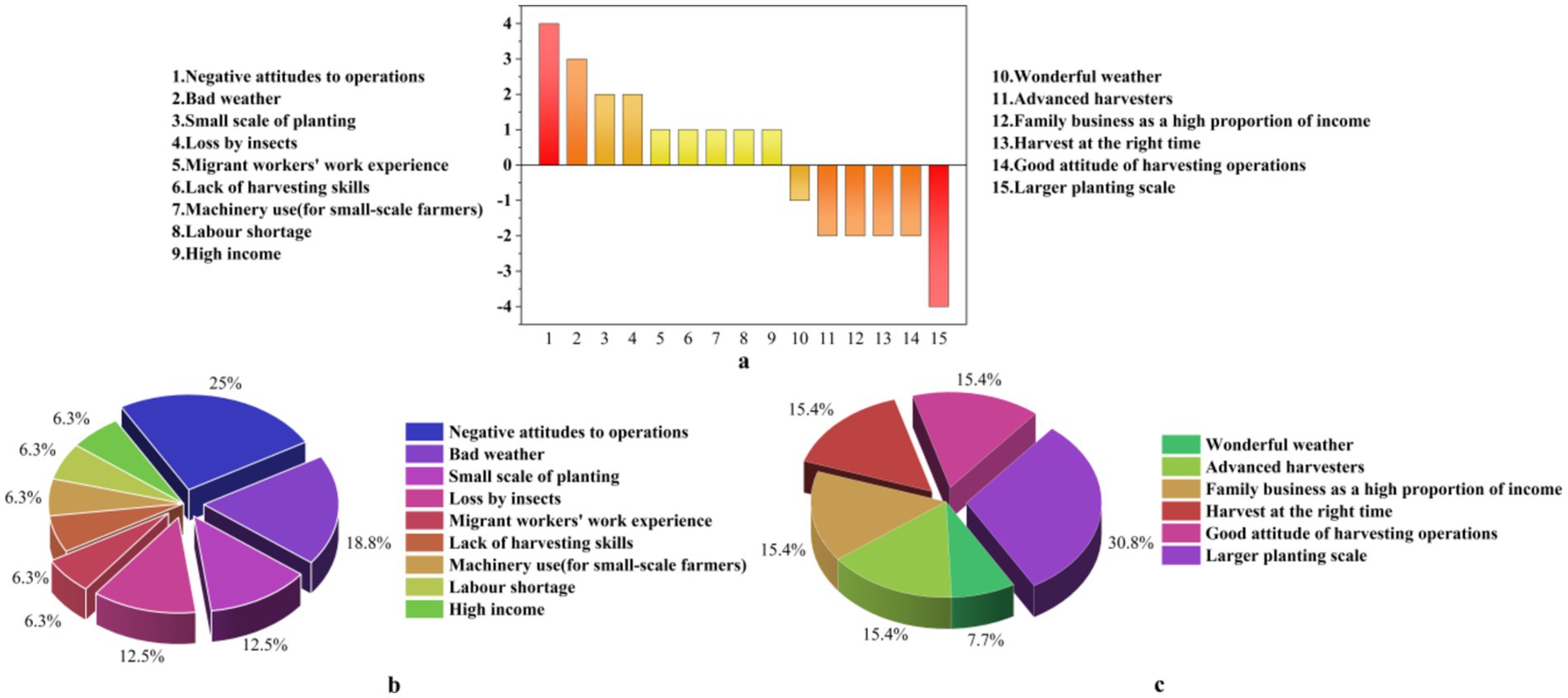

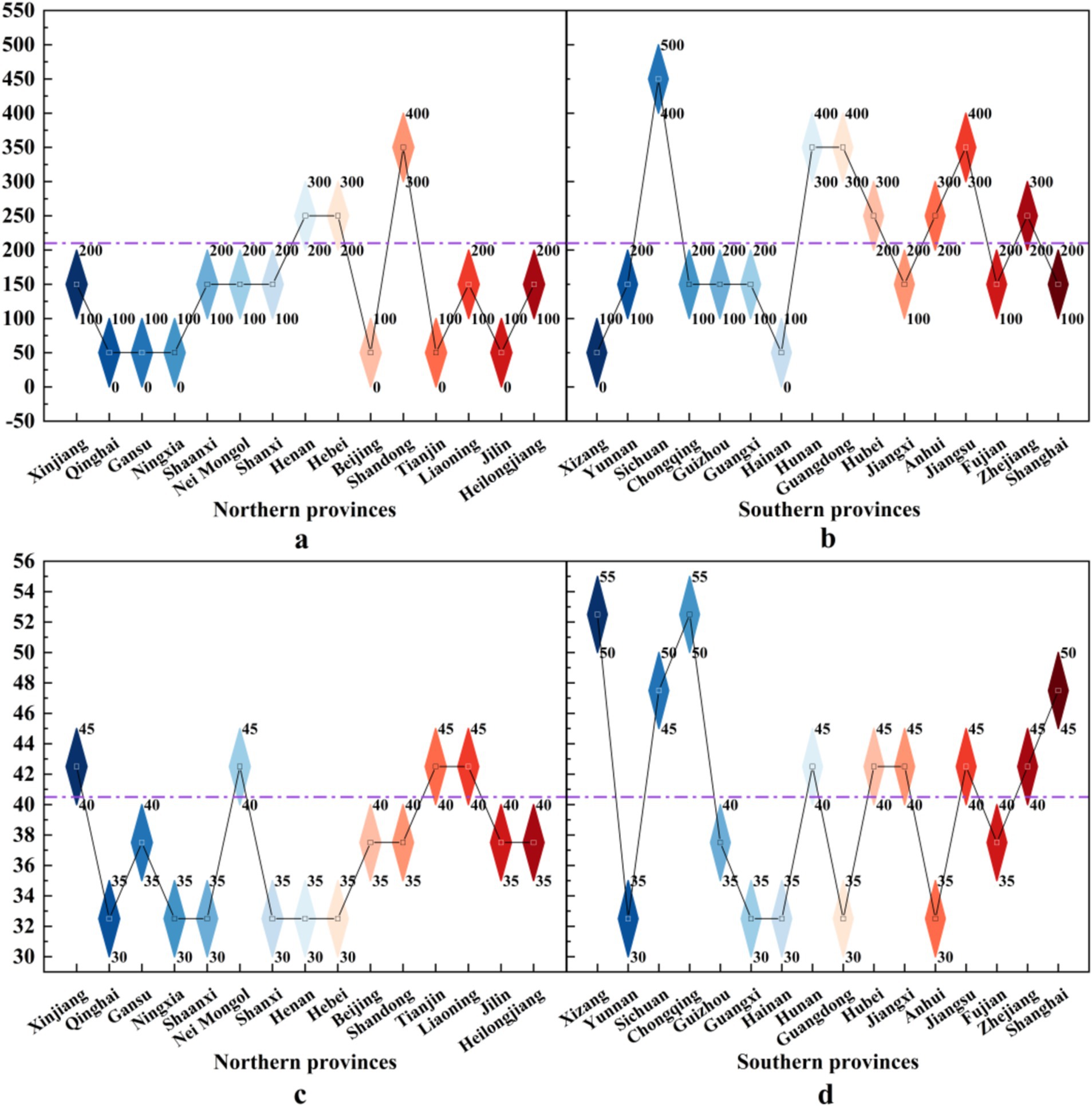

Figure 1 illustrates the frequency of studies on grain losses at the harvest stage by the factor of interest. Positive values in Figure 1a indicate that the factor significantly increased grain losses, while negative values indicate that the factor significantly decreased grain losses. Figure 1b (factors that enhance losses) and Figure 1c (factors that reduce losses) show the proportion of these factors in the total frequency of studies, respectively. The study’s findings indicated that a total of 15 factors impact grain losses during the harvesting process, with 9 factors generally contributing to increased harvest losses and 6 factors aiding in the reduction of such losses.

Figure 1. (a–c) Factors and shares that positively and negatively affect the harvesting stage. These data are derived from the following literature: Qu et al. (2020), Qu et al. (2021a), Qu et al. (2021b), Qu et al. (2021c), Qu et al. (2023), Huang et al. (2017), Wu et al. (2017), and Luo et al. (2022d).

As can be seen from Figure 1b, negative attitude to operations (4 times), bad weather (3 times), small scale of planting (2 times) and losses by insects (2 times) were the top four most frequently studied items, accounting for 68.8% of the total study frequency in Figure 1b. This indicates that they are the key factors that are of general academic interest and widely recognized to enhance losses in the grain harvesting chain. Figure 1c shows that the most effective factor in reducing losses in the grain harvesting chain was a larger planting scale (4 times), followed by a good attitude toward harvesting operations, harvest at the right time, and family business as a high proportion of income (i.e., more income from grain cultivation) and more advanced harvesters, which were confirmed 2 times each. These five factors accounted for 92.4% of the total study frequency in Figure 1c and are the most critical factors in reducing losses in the grain harvesting chain. Of course, most of the influencing factors will have different impacts on enhancing and reducing harvest losses, for example, bad harvest weather significantly increases harvest losses, but good weather does not reduce harvest losses. Another example is that larger acreage may result in lower harvest losses, but too small an acreage is no longer significantly associated with harvest losses.

Beyond the conclusions identified in Figure 1, there is no consensus in the academic community on the factors influencing grain harvest losses. Among these factors, farm machinery services and harvesting methods are by far one of the most controversial. The effectiveness of farm machinery services in curbing harvest losses is subject to the moderating influence of moral hazard (Qu et al., 2023). Studies have demonstrated that among farmers employing mechanical harvesting methods, whether semi-mechanized or fully mechanized, those opting for farm machinery services experience notably reduced grain harvest loss rates. This is attributable to the fact that farm machinery services offer not only essential hardware support but also introduce more advanced operational technology and a wealth of managerial expertise (Qu et al., 2020; Qu et al., 2021c). However, when providers of farm machinery services are providing services to others, too much efficiency can sacrifice a certain amount of harvest finesse, which can lead to increased food losses (Li X. et al., 2020).

Not only do farm machinery services produce different results, but different harvesting methods and varieties also show different results. Qu et al. (2021b) found that farm machinery services increased losses in segmented harvesting but reduced losses in combined harvesting. Manual harvesting of rice has the lowest losses, followed by partially mechanical harvesting, and mechanical harvesting, on the contrary, has the highest losses. Comparatively, the harvesting losses of wheat decreased gradually with the degree of mechanization. Corn, on the other hand, has the lowest losses in partially mechanical harvesting (Luo et al., 2022b; Huang et al., 2018; Li X. et al., 2020). This suggests that the harvesting method, like moral hazard, is a key mediator of the effectiveness of farm machinery services in reducing harvest losses. In addition to the above two factors, regional differences can equally affect losses during grain harvesting. Huang et al. (2018) showed that the combined loss rates in the Northeast Plain, Yangtze River Basin, and Southeast Coast were 3.02, 3.17, and 4.12%, respectively, while the semi-mechanized loss rates were 1.41, 1.81, and 1.76%, respectively, significant variance from expectations. It is evident that a multitude of factors, including agricultural machinery services, harvesting techniques, varietal variations, and regional distinctions, all contribute to grain losses, and these factors may also exhibit interplay with one another. However, how and in what direction these factors affect grain losses at harvest is not yet well-researched, and there is some disagreement in the existing research results.

In summary, in addition to the influences already recognized by the academic community, the harvesting process still involves a high degree of uncertainty. In addition to the aforementioned farm services, harvesting methods, varietal and regional differences, market prices, credit constraints, and work experience also affect losses during the harvesting phase of grain. This suggests that the factors affecting grain harvest losses in China are multidimensional and complex.

2.3 Current status of losses in food drying and factors affecting them

Drying is a key component in ensuring that stored grain does not deteriorate and is resistant to storage. In the case of maize, for example, there is a strong correlation between timely harvesting and a significant reduction in storage losses, due to the high moisture content of immature maize, which makes it vulnerable to insect damage (Stathers et al., 2020).In contrast, mature corn has a lower moisture content and is less susceptible to mold and mildew during storage when it is dried after harvest. In addition, lower moisture content is effective in reducing kernel breakage during handling and transportation, thereby improving overall storage and transportation efficiency. Plett (1994) found that kernel moisture content at the lowest breakage rates was 16.7–22.1%.

It has been shown that the drying method is one of the key factors determining the degree of grain loss. In China, two traditional methods, natural drying, and shade drying, are commonly used by farmers. However, these two methods are susceptible to rodent, mold, and insect infestations, and are also affected by a variety of factors such as drying temperature, time, weather conditions, drying thickness, and the number of times of tumbling (Gao et al., 2016).

Grain depots and grain enterprises usually use mechanical drying, which has higher efficiency, better quality, and lower loss rates than natural drying. However, the effectiveness of mechanical drying is also affected by several factors, including the specific drying technology, the grain variety, and the details of the operation process (Chu et al., 2022). However, in China, the use of mechanical drying is only 10%, while 90% of grain drying still relies on farmers’ traditional natural drying methods. This indicates that mechanical drying technology has huge development potential and room for growth in China.

However, mechanical drying consumes huge amounts of energy and causes serious environmental pollution. Grain drying equipment in the drying process still need to face the challenge of pollution emissions (Zhao et al., 2017). Against this backdrop, solar energy, recognized as a clean and renewable resource, has garnered extensive interest and has been the subject of research and promotion in the drying process. Its capacity to significantly conserve energy and diminish emissions makes it a promising alternative. For example, solar drying technology, heat pump drying technology, and the research and development of drying vehicles are all innovative attempts to utilize solar energy for grain drying, aiming at the greening and sustainable development of the grain drying process.

There is still much room for improvement in terms of research depth and data accumulation in the drying process compared to the harvesting process. Although mechanical drying technology has shown significant potential for reducing losses, there is still insufficient research and practice to increase the proportion of mechanical drying applications in China, optimize the drying process, and tailor more efficient and precise drying solutions for different food crops.

2.4 Current status of losses in food storage and factors affecting them

Compared with drying, storage is relatively well-researched. According to the FAO, reasonable storage losses should not exceed 5%, but China’s storage losses are far greater than that (Rai et al., 2011). Gao et al. (2016) concluded that the storage stage occupies the largest share of 40.3% in the composition of grain losses in China. It has also been concluded that post-harvest handling and storage losses account for 28% of post-production losses in China, this ratio highlights the importance of the storage stage in food loss management (Xue et al., 2021). Thus, the storage stage became a key area for reducing post-production losses.

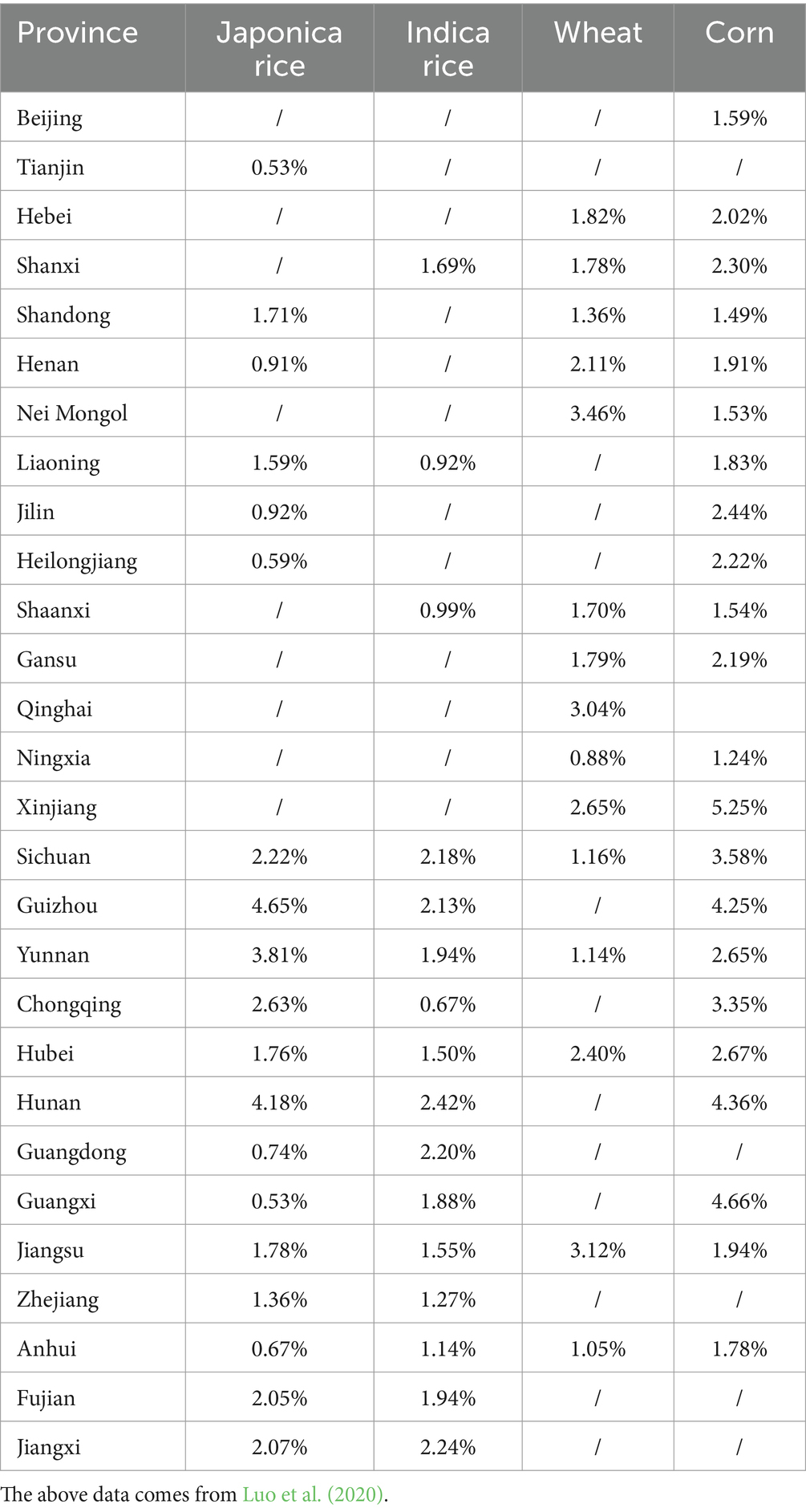

Table 2 presents detailed data on household food storage losses by province in China (Luo et al., 2020). In terms of Japonica rice storage losses, Guizhou (4.65%), Hunan (4.18%) and Yunnan (3.81%) were at the top of the list, while in terms of Indica rice storage losses, Hunan (2.42%), Jiangxi (2.24%) and Guangdong (2.20%) had relatively high loss rates. It is noteworthy that the loss rates for Japonica and Indica rice varieties in the northern provinces were generally lower compared to those in the southern provinces. In terms of wheat storage losses, Inner Mongolia (3.46%), Jiangsu (3.12%), and Qinghai (3.04%) had relatively high loss rates, while in terms of maize storage losses, Xinjiang (5.25%), Guangxi (4.66%) and Hunan (4.36%) had particularly significant loss rates. Comprehensive analysis showed that grain storage loss rates were generally high in all Chinese provinces, with corn having the highest average loss rate. In addition, grain loss rates were generally higher in the southern provinces than in the northern provinces, which may be related to factors such as climatic conditions, storage technology, and management practices.

Liu et al. (2013b) categorized the causes of storage losses into three groups: first, lack of high-quality grain storage facilities; second, lack of efficient and low-toxicity pesticides to control pests, molds, and rodents; and third, lack of scientific knowledge and technology for grain storage. The Government’s food storage system, through the provision of more advanced facilities and management, has a food loss rate of about 1.4%, which is significantly lower than that of farmers’ family farms, which is about 8%. Similar conclusions were reached in a study by Qiu and Jin (2003), who concluded that in China, the loss rate of national grain reserves is about 0.2%, while the loss rate of grain reserves in rural households is as high as 7–13%. These findings emphasize the importance of upgrading grain storage technology and management to reduce grain losses.

Scientific storage methods have been shown to significantly reduce grain losses to low levels of 1–2% (Kumar and Kalita, 2017). Nonetheless, the prevailing grain storage conditions in China indicate that approximately 60% of the grain is held in farmers’ households, a scenario that harbors significant potential for losses (Liu et al., 2013b). Liu (2014) study reveals the pyramid structure of China’s grain reserves: more than half of the grain is stockpiled by farmers, while 25% is stockpiled by large corporations, with 90 billion kg of warehouse volume belonging to older warehouses, which are characterized by poorer hardware, leading to higher loss rates. The remaining grain reserves are the responsibility of local and central governments. Despite the low loss rates reported by government grain warehouses (less than 0.5%), storage losses are still higher for farmers when they store for their use (usually six months to a year) or when they wait for marketing opportunities. Specifically for different regions, the average loss rates of household grain reserves in the Northeast, Northwest, Middle and Lower Yangtze River, and Yellow and Huaihai Plains were 10.2, 8.8, 7.4, and 5%, respectively. In the context of various crops, the national household storage loss rates for corn, rice, and wheat were 11, 6.5, and 4.7%, respectively.

The above data comes from Luo et al. (2020) and Chen et al. (2018).

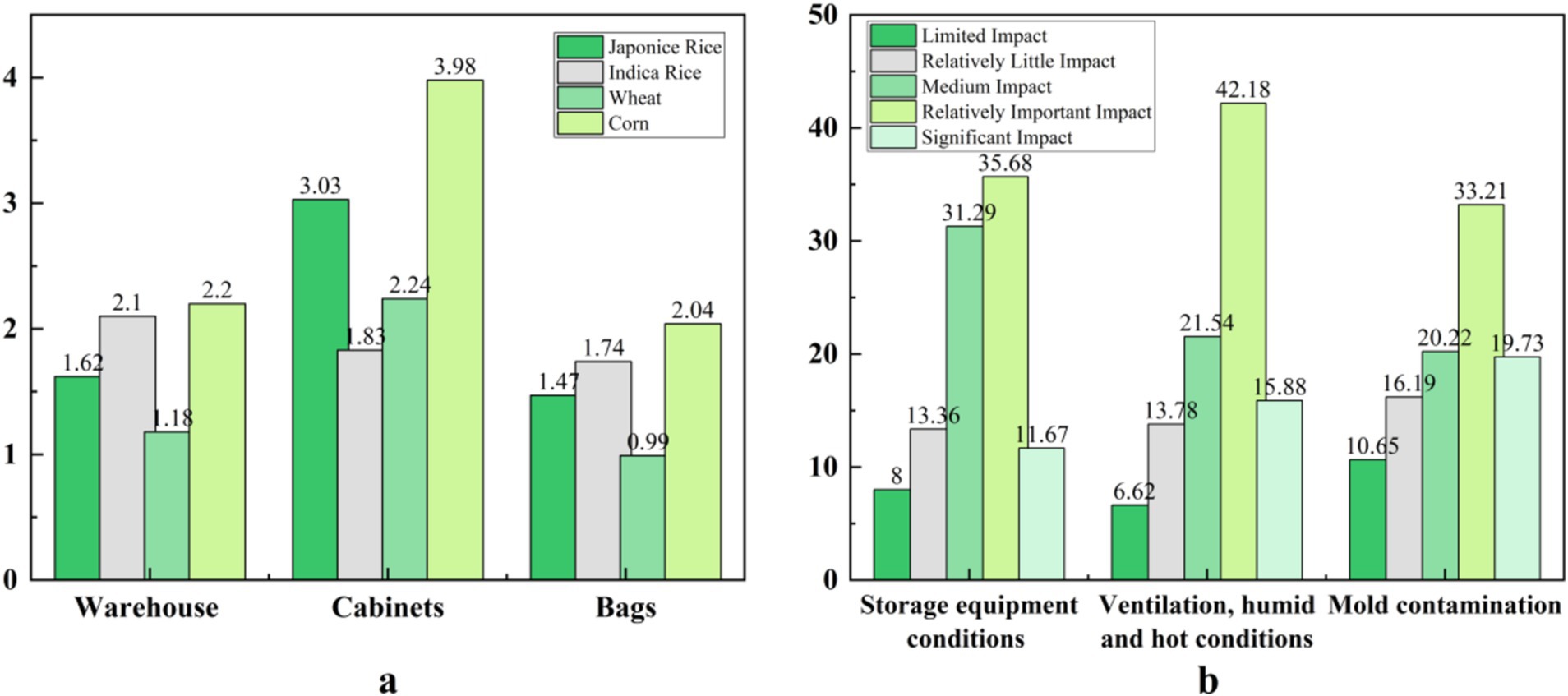

By analyzing Figure 2, it is clear that there are significant differences in the loss rates of the different storage methods, but they are generally at a high level. Specifically, cabinets generally have the highest loss rates, occupying the peak loss rate for almost all crops stored, followed closely by warehouses; in contrast, the bag has a relatively low loss rate. From a crop type perspective, regardless of storage method, maize consistently has the highest loss rate, followed by japonica and indica, and wheat has a relatively low loss rate.

Figure 2. (a,b) Grain loss from different facilities and different factors. (a) Losses in grain storage due to different facilities (%). (b) Factors that affect the extent of grain loss at storage (%).

Differences in the rate of loss of grain in different storage facilities reveal the sensitivity of its hygroscopic and thermal conductivity to the storage environment. These properties make grain vulnerable to environmental, climatic, and precipitation changes during storage, which can lead to mold or quality deterioration (Gitonga et al., 2013). Figure 2b shows farmers’ perceptions of the causes of losses in the grain storage chain, where storage equipment conditions, ventilation and humid and hot conditions, and mold contamination were all considered significant factors by more than 10%, while 35.68, 42.18, and 33.21%, respectively, regarded these three as important factors (Chen et al., 2018). This suggests that in addition to equipment hardware and mold, ventilation and hot and humid environments are important factors in storage losses (Luo et al., 2022b).In addition, apart from the storage facilities themselves, rodents, molds, and pests are key contributors to storage losses, accounting for 49, 30, and 21% of total losses, respectively (Liu, 2014). The study of Luo et al. (2022a) similarly emphasized the importance of rodent infestation in storage losses, which caused more than 50% of the losses. Inadequate protection against pests and rodents during storage promotes the reproduction of pests and rodents, which in turn damages the quality of the grain (Durán-Sandoval et al., 2021). Qiu and Jin (2003) further stated that insect and rodent infestation were the main causes of storage losses in southern China, while losses in northern China were mainly attributed to mold.

The use of metal silos has proved to be a very cost-effective measure in order to minimize the loss of grain stored by farmers. Not only did metal silos significantly reduce farmers’ food losses, helping them to save about 150 to 200 kg of grain per year, but they also extended the storage period by several months, while reducing the rate of grain loss to 43%, thus greatly improving the efficiency and safety of grain storage (Luo et al., 2022c; Luo et al., 2022e).In addition, the use of metal silos has almost completely eradicated the problem of pests and significantly reduced losses due to rodents and mold. Widely spreading the use of metal silos could provide the market with an additional 626,800 tons of rice per year, enough to meet the food needs of 1.39 million people. In addition, the widespread use of metal silos can effectively mitigate market price volatility by reducing the demand for food and stabilizing the supply, providing strong support for the stable development of the food market (Gitonga et al., 2013).

2.5 Status of losses in food transportation and factors affecting them

In addition to storage losses, the impact of the transportation process on post-harvest grain losses should not be overlooked (Chen et al., 2018). The main challenges facing China’s grain transportation system include the fact that it has yet to build an independent and complete transportation system, the relative backwardness of transportation technology, and the imperfections of transportation hardware and software facilities (Zhou and Sun, 2015; Dorward, 2012). From the perspective of transportation service providers, the main causes of losses include management negligence, operational errors, cost control challenges, and inherent industry constraints (Yan et al., 2023). Therefore, an efficient and coordinated transportation system plays a crucial role in reducing post-harvest losses and improving the operational efficiency of the entire supply chain.

However, numerous studies have pointed out that different modes of transportation and different forms of packaging are still the main factors contributing to food losses (Buzby et al., 2011). In China’s grain transportation system, packaged transportation and bulk transportation are the two main modes of transportation. Packaged transportation involves the transportation of grain in linen bags, a method that is still dominant in China despite its high cost. However, packaged transportation has a high loss rate of more than 5%, which is further exacerbated by increased loading and unloading. In contrast, bulk transportation does not rely on packaging, and grain is loaded directly into shipping containers, thus reducing costs and losses. Nonetheless, bulk grain transportation accounts for only about 15% of China’s total grain distribution, while packaged transportation dominates, accounting for about 85% of it (Gao et al., 2016). This proportion is well below the level of many developed countries, where, for example, the proportion of bulk transportation is as high as 90% in some developed countries (Liu et al., 2013b). This indicates that China still has much room for development in modernizing and improving the efficiency of grain transportation methods.

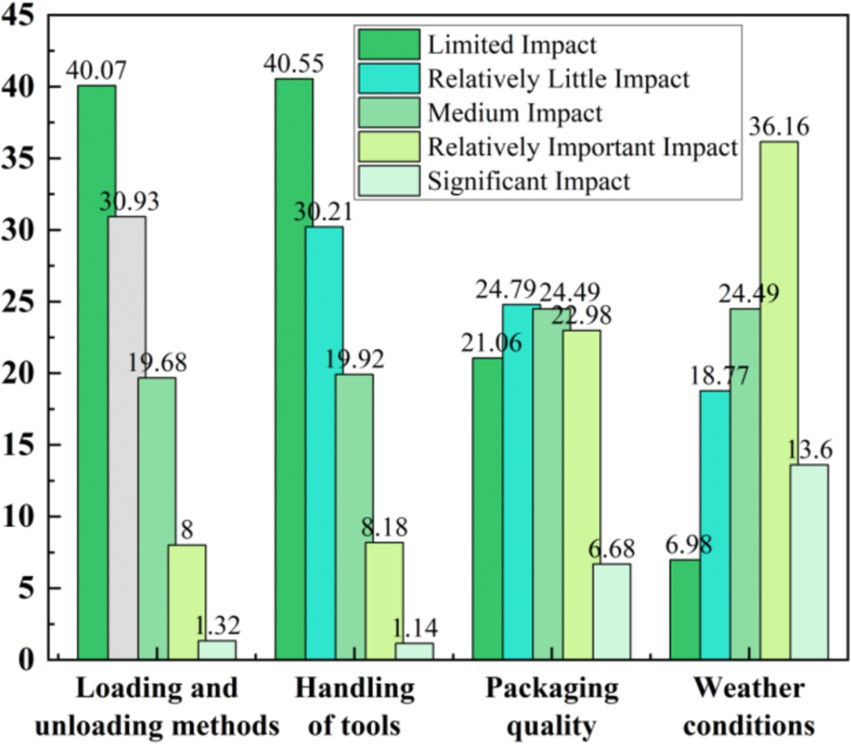

In addition to the reasons mentioned above, the lagging development of the cold chain industry, lack of infrastructure, transportation distances, inclement weather that prolongs the transportation time, and manual transportation in the field also affect the losses in the transportation chain (Zhao et al., 2018; Qu et al., 2021b). As shown in Figure 3, about 50% of the farmers considered weather conditions to be the key factor affecting losses in the transportation chain, while about 30% of the farmers considered packaging quality to be the main factor (Chen et al., 2018).

Figure 3. Factors affecting food losses during transport (%). The above data comes from Chen et al. (2018).

2.6 Status of losses in food processing and distribution (retail) and factors affecting them

Losses in the processing and distribution of grain are likewise a problem that cannot be ignored. Of China’s total grain production, losses in processing account for about 2.6%, while losses in distribution account for 3%. These losses are mainly attributable to imperfections in infrastructure and related technical equipment, as well as room for improvement in technical mastery and operation (Gary, 2009; Quested et al., 2011; Chen et al., 2018). In addition, the decentralized nature of China’s agricultural production system exacerbates the problem of food losses (Liu et al., 2013a).

In contrast, excessive milling during grain and oil processing likewise exacerbates grain loss. As China’s standard of living rises, consumers are increasingly demanding refined flour, refined rice, and refined cooking oil, as well as higher demands on the appearance and color of food products (Loebnitz and Grunert, 2015). This trend has been further exacerbated by the increase in market access standards, which has led to the elimination of non-compliant products from the market (WFP, 2009). As a result, the processing industry has over-pursued finishing, leading to higher raw material costs and lower processing efficiency (Fang et al., 2019).In the case of China’s state-owned grain and oil processing enterprises, for example, the rice yield is only about 65%, the oil production rate of rice bran is less than 10%, and the refining process significantly reduces the ratio of final products to raw materials, leading to low resource utilization. These elements collectively contribute to escalating grain losses at the processing stage, consequently impacting the edible rate of China’s grain and maintaining it at a persistently low level (Liu et al., 2013b).

Sub-species studies show that over-processing is more prominent in wheat and rice. In rice processing, each polishing reduces the yield by 1%, while in wheat it is even more serious, with a 2% reduction. Overpolishing has resulted in significant nutrient loss and waste (Yang et al., 2021). Approximately 75% of maize production is used for feed and 15% for food rations and food processing, which also incur significant losses due to technical and equipment limitations.

In contrast to the above not-so-abundant research on processing, Chinese research on losses at the distribution (retail) level is even more scarce, and research on this stage is essentially non-existent. This is the weakest link in the entire post-production process of grain, and it will require great attention in the future to make up for the lack of research findings.

3 Status of food waste research in China

3.1 Current status of food waste research in China

In China, waste in the food consumption chain are the most serious part of food waste. From a food supply chain perspective, the consumption stage generates the most waste, estimated at 35% of the total (FAO, 2013). In a study by Barrera and Hertel (2021), food losses in China’s consumption chain grew from 5% in 1992 to 27% in 2013. It is projected that by 2050, China will have more food waste than South Asia, Central Asia, and Sub-Saharan Africa combined. In 2010–2019, China wasted an average of 45.7 Mt of wheat per year, alone, during the consumption stage (Jiang et al., 2023). China’s catering industry produces about 17–18 Mt. of food waste annually, accounting for about 20% of the total loss, this huge amount of loss can not be ignored (Zhou et al., 2021).

Before going any further, this study must clarify the definition of food waste in China. Although most studies on food waste in China have focused on grain, a portion of the studies have covered meat, vegetables, and a variety of by-products. Given this, if the proportion of grain waste in total food waste is too low, then this study may not fully reflect the overall situation of grain waste, thus affecting the comprehensiveness and depth of the study. Therefore, it is necessary to emphasize that the research in the section 3 still focuses on grain waste.

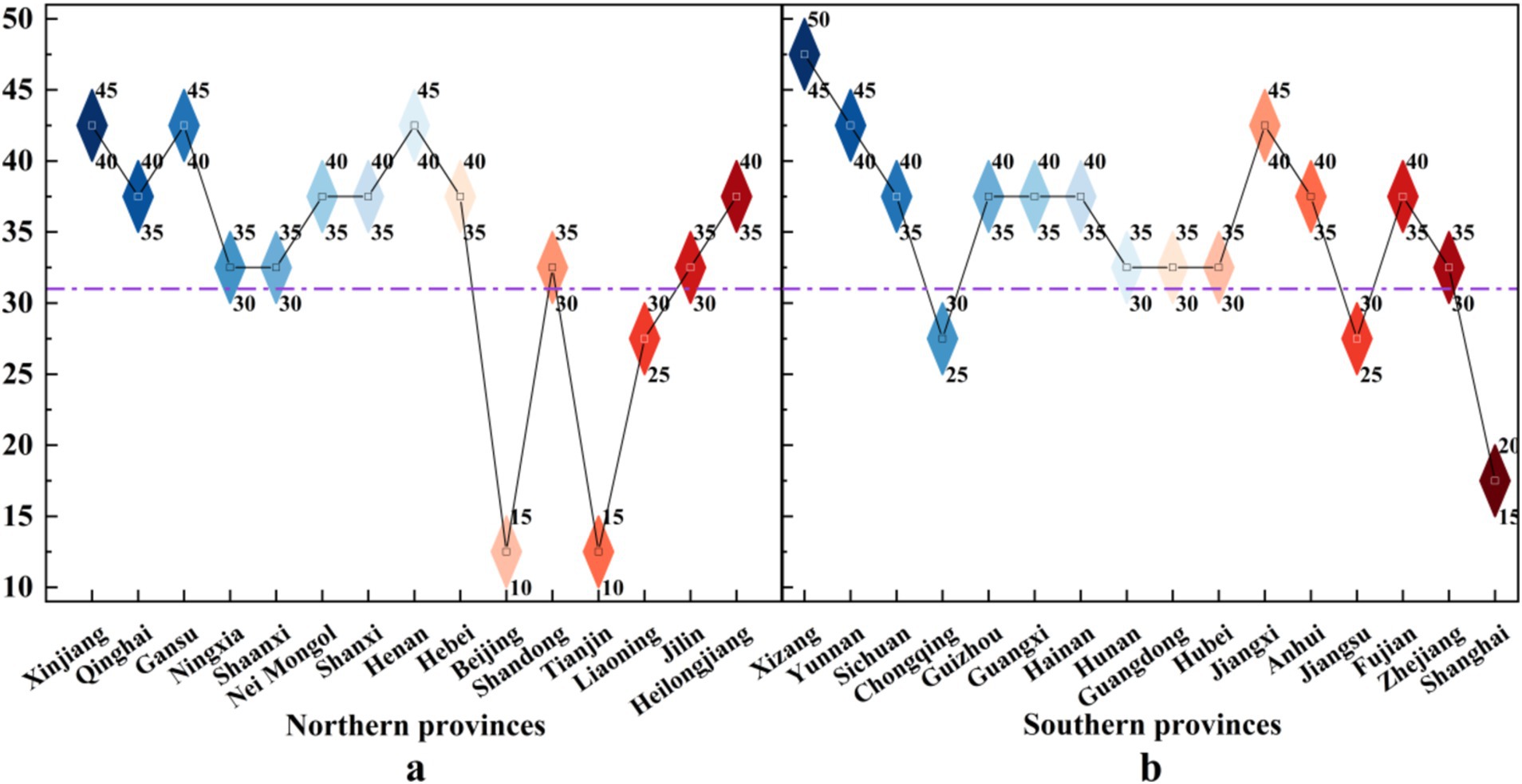

Figure 4 reveals that the share of grain waste in total food waste is significant in most provinces in China, in the vast majority of provinces, the proportion of grain waste is above 30%, and in more than half of the provinces the proportion is above 40%. For example, the proportion of grain waste in Tibet is even close to 50%. This suggests that grain waste accounts for a significant proportion of total food waste in China, a finding that is supported by several studies (Jiang et al., 2024). Song et al. (2015) research further highlights that China’s significant proportion of grain waste, when combined with its vast population, results in an enormously large aggregate volume of waste. In Shenzhen, for example, the proportion of avoidable household food waste was 56% in 2015, and the total amount of avoidable household food waste per year grew from 549 (±45) kilotons to 1,673 (±144) kilotons from 2001 to 2015, with an average annual growth rate of 8%. Among these, grain waste constitutes the largest segment, totaling 514 ± 180 kilotons (Zhang et al., 2018). Therefore, it is important to be clear that the study below will still focus on grain waste, but will also include a small portion of other types of food (although they are not the focus of this study).

Figure 4. (a,b) Share of grain in total FW (%). The above data comes from Sun et al. (2018).

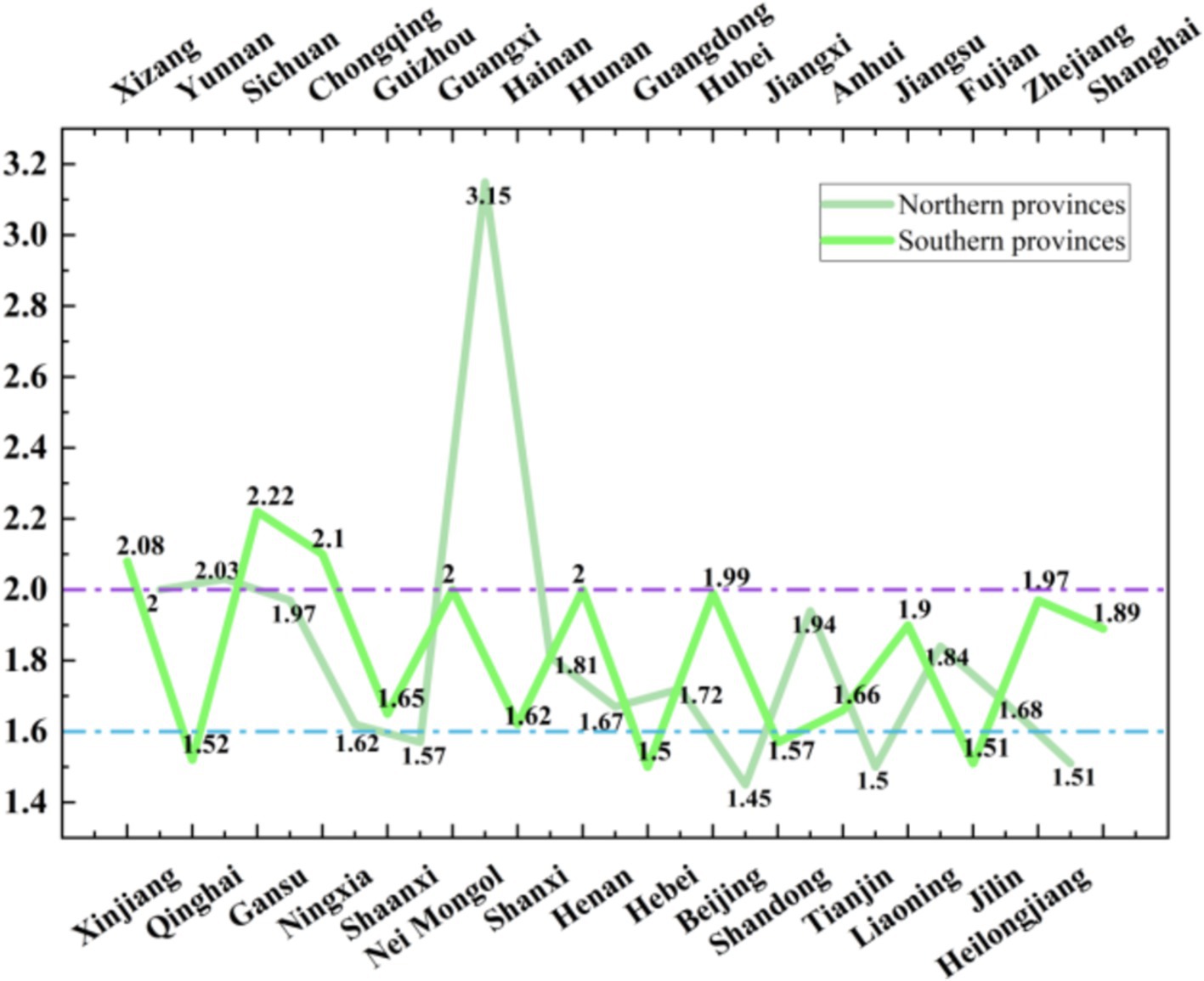

Figure 5 illustrates the overall situation of food waste in China. It can be found that the highest and average values of total food waste in the southern provinces are higher than those in the northern provinces. Similarly, the total amount of food waste in the eastern provinces is higher than that in the western provinces. This may be related to the spatial distribution of China’s population.

Figure 5. Food waste in different regions in China. (a,b) Total food waste in 2015 (Mt). (c,d) Food waste per capita in 2015 (kg). The above data comes from Li B. et al. (2020).

Turning to per capita food waste, it remains lower in the northern provinces than in the southern provinces. However, per capita food waste in the western provinces is significantly higher than in the eastern provinces. Per capita food waste reaches 50–55 kg in Tibet and Chongqing, and 45–50 kg in Sichuan. This phenomenon contrasts with the distributional characteristics of total food waste. The possible reason for this is that the eating habits of the residents of the western provinces and their relatively backward economic conditions lead to a higher proportion of staple foods in their daily diets, which coincides with the findings of the first graph. Nonetheless, the population size of the western provinces is much lower than that of the eastern and southern provinces, and thus the total amount of food wasted per capita is relatively low despite the higher amount. The exception is Sichuan, where high per capita food waste and a large population result in relatively high total food waste.

The results of the previous analysis are further confirmed in Figure 6, where PMR (proportion of plant food to animal food wasted) is a measure of the extent of wastage of plant food to animal food in the daily diet, with a higher ratio indicating a relatively higher wastage of plant food, and vice versa, a higher wastage of animal food. PMR values exceeding 2 are deemed high, whereas those below 1.6 are regarded as low. From the figure, it can be seen that the western provinces, both in the north and the south, generally have a high PMR, with nearly half of them having a PMR value of more than 2 and only a few having a PMR value of less than 1.6. In contrast, the eastern provinces generally have a low PMR, with nearly half of them having a PMR value of less than 1.6, and no province having a PMR value of more than 2. This indicates that China’s western provinces exhibit a relatively elevated PMR in dietary patterns, with waste being more predominantly composed of plant-based foods, in contrast to the eastern provinces, which have a lower proportion of such waste.

Figure 6. The plant-to-animal food waste ratio (PMR). The above data are obtained from Li B. et al. (2020).

3.2 Analysis of factors affecting food waste in China

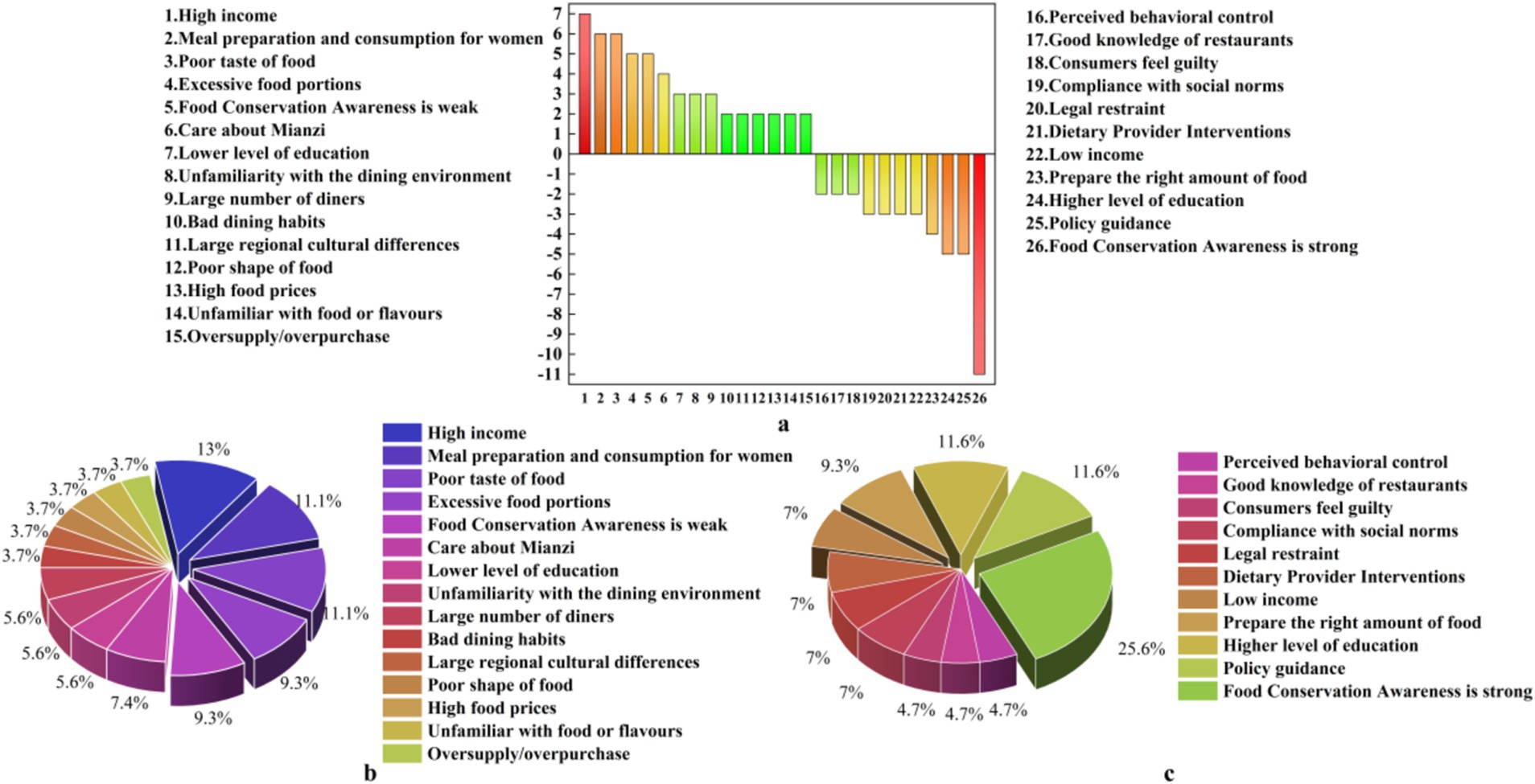

Figure 7 illustrates the key factors influencing food waste (GW) at the consumption stage and how often they have been studied. Figure 7a illustrates the frequency of occurrence of influences with clear conclusions across all studies. Positive values indicate that the factor significantly increases food waste at the consumption stage, while negative values indicate that it decreases FW at the consumption stage (ignoring factors whose direction of influence is not clear or whose significance is not clear). The results of the study showed that a total of 26 factors had a significant increasing or decreasing effect on FW at the consumption stage, a number that far exceeded any single link in the food distribution chain. High income, Meal preparation and consumption for women, and Poor taste of food are the top three factors that increase the level of FW. This is followed by Excessive food portions, Food Conservation Awareness, and Care about Mianzi, which also have a significant impact on FW. The frequency of these six factors accounted for 61.2% of the total frequency (as shown in Figure 7b) and were the main causes of FW. In addition to this, nine other factors were confirmed to significantly increase FW. These findings provide a more nuanced perspective for understanding the causes of food waste at the consumption stage and a more comprehensive basis for developing targeted strategies.

Figure 7. (a–c) Factors and shares that positively and negatively affect the consumption stage. The above data comes from these literatures: Lu J. et al. (2022), Lin et al. (2022), Long et al. (2023), Wu et al. (2023), Qian et al. (2024), Jia et al. (2022), Fan H. et al. (2023), Ma et al. (2023), Chen F. et al. (2022), and Zhang et al. (2022).

Among the above factors that increase food waste, the most Chinese is care about Mianzi. In China, Mianzi (face culture) plays a unique and important role in restaurant consumption, reflecting the decency and generosity of Chinese people in interpersonal interactions. To show the hospitality of their hosts, people often tend to order more food than they need, a behavior that is particularly common in restaurants, leading to a food waste rate of up to 19% (Wang et al., 2016). By contrast, dining in cafeterias results in a relatively low waste rate of 5 to 7%, as the sharing system eliminates the need for entertaining guests. When dining in restaurants, consumers usually invite their friends and relatives and tend to order more food to save face, thus increasing food wastage (Liao et al., 2018). When food is viewed as a tool for social interaction rather than merely a delicacy or necessity, food waste is often the least of people’s concerns. This phenomenon is particularly evident in large restaurants, where consumers are more concerned with social relationships than with the food itself (Wang et al., 2017).

Apart from the “Mianzi” factor, the impact of other factors on food waste should not be overlooked. For example, as China’s GDP per capita rises, so does the amount of food wasted per household (Xue et al., 2017).Increases in per capita disposable income and personal consumption expenditures are also key factors influencing changes in food balances in different provinces (Niu et al., 2022). In addition, the level of education also has an impact on food waste. The average food waste of Beijing University students is 73.7 g/meal, which is 76.4% lower than that of Beijing secondary school students, even though staple food accounts for more than 40% of the food. Among the surveyed groups, doctoral students exhibited an average food waste rate that was 25.1% lower than that of undergraduates and 19.7% lower than that of master’s students. These data suggest that both income level and education are important factors in food waste (Wu et al., 2019).

In addition, some scholars have pointed out that the level of food waste may be influenced by observable social factors such as national culture, consumption habits, food storage techniques, household structure, and physical activity levels. For example, a smaller number of household members may be associated with higher levels of food waste (Li and Wang, 2020). The combination of these factors contributes to the formation of food waste, reflecting the profound influence of socio-economic contexts and lifestyles on food consumption behaviors.

In Figure 7, in addition to listing the factors that elevate food waste at the consumption stage, a variety of factors that significantly reduce FW at the consumption stage are shown (Figure 7c). At the top of the list is Food Conservation Awareness is strong, i.e., strong environmental and conservation awareness has a significant effect on individuals’ behavioral attitudes, subjective norms, and behavioral control (Tsai et al., 2020). Closely followed by Policy guidance and Higher level of education, and Preparing the right amount of food. The frequency of these first four categories of factors accounted for 58.1% of the total frequency, indicating that enhancing the implementation and improvement of these factors has a significant positive effect on reducing FW.

Moreover, not only can these factors influence FW independently, but they may also be interrelated. For example, specific implementations of Intervention in consumer behavior include Policy guidance and Legal restraint. Zhang et al.’s (2012) study points out that interventions in consumer behavior are needed to reduce FW, and that specific measures include increasing the number of policy instruments with guided. Nonetheless, there is currently little academic research on the interactions between these factors, and future research could further explore the interrelationships between these factors with a view to understanding and reducing food waste more fully.

3.3 Characteristics of food waste in different regions of China

China is a country with rich topography, variable climate, and diverse economic conditions, and this diversity has given rise to a unique and colorful food culture (Carter and Lohmar, 2002). For example, the preferred staple food of the inhabitants of the South is rice, and the preferred staple food of the inhabitants of the North is wheat. Qian et al. (2022a) study showed significant differences in food waste between southern residents who eat rice-based diets and northern residents who eat wheat-based diets. In addition, food waste rates between urban and rural areas and between different regions also show significant variability, reflecting the diversity of eating habits and consumption patterns across China. Given this, this paper will next delve into the geographical differences in food waste in China.

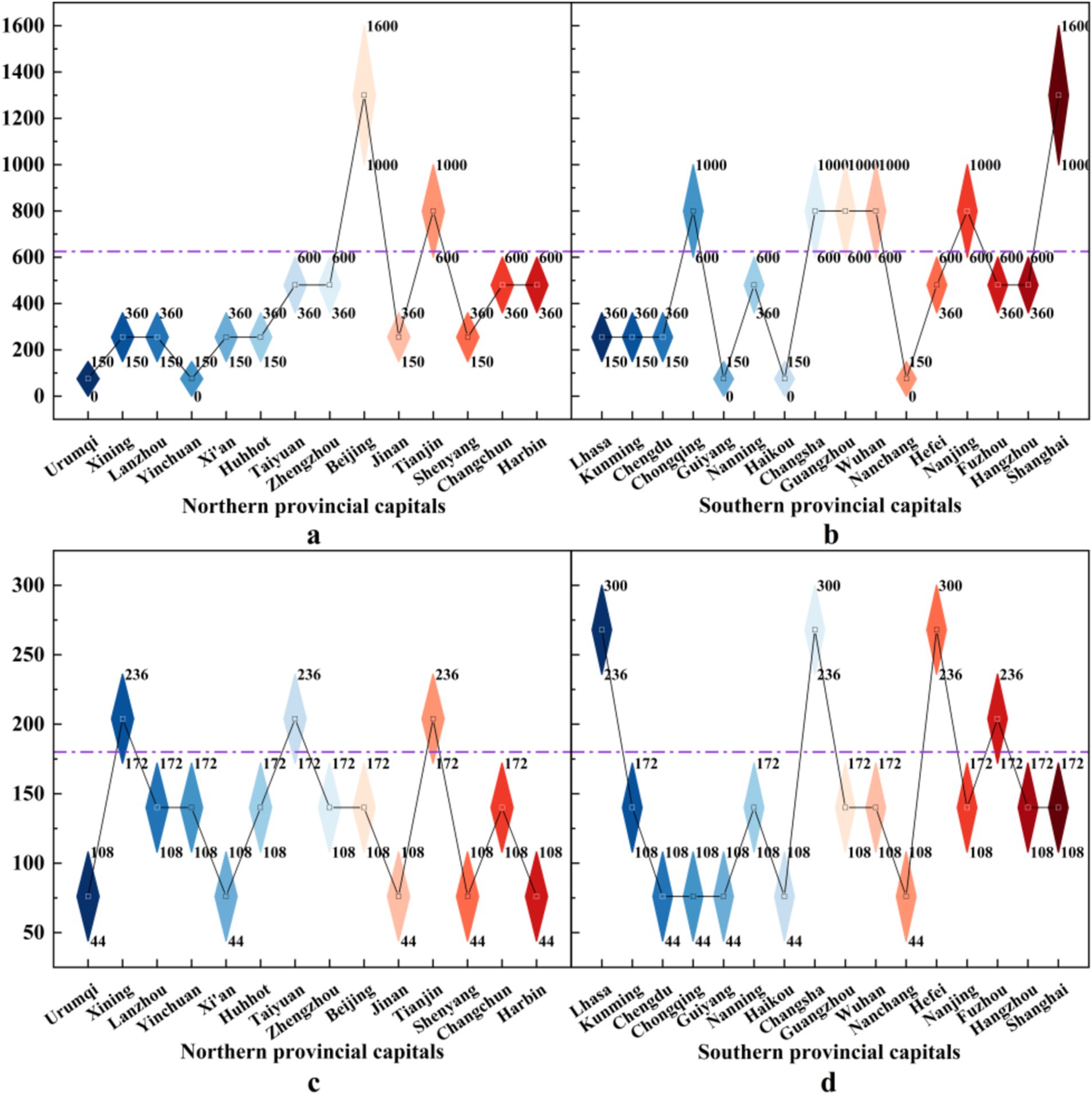

Using provincial capitals as representatives of the urban sector, Figure 8 shows the current status of food waste in the catering sector in different regions of China. In terms of aggregate volume, waste in the northern provincial capitals is notably lower, with the majority recording under 360 tons and only two exceeding 600 tons. Conversely, waste in the southern provincial capitals is considerably higher, with most surpassing 360 tons and six exceeding 600 tons, a figure significantly exceeding that of the northern counterparts. In addition, the total amount of waste in eastern provincial capitals is generally higher than that in western provincial capitals, both in the north and in the south.

Figure 8. Food loss in different provincial capitals of China. (a,b) Total food waste in catering industries (t/d). (c,d) Food waste per capita in catering industries (g/capita/d). The above data comes from Gao et al. (2013).

Analyzed from the perspective of the amount of food wasted per capita, none of the provincial capitals in the North reached the level of 236 g or more, while three provincial capitals in the South exceeded this standard, which indicates that the South is relatively high in terms of the upper limit of the amount of food wasted per capita. In addition, the distribution of food waste per capita did not show a clear pattern. Among the trio of provincial capitals in the South with the highest food waste, Lhasa is particularly noteworthy. Located in the heart of the Tibetan Plateau, Lhasa attracts many tourists as a well-known tourist destination despite its limited number of residents. The high level of food waste in Lhasa does not stem from the consumption behavior of residents, but rather from the wasteful behavior of tourists (Li Y. et al., 2020).In addition, many factors such as gender, age, family status, education, dietary preferences, dietary satisfaction, purpose of travel, and location of meals also had a significant impact on the amount of food wasted (Wang et al., 2021).

3.4 Characteristics of food waste at different dining places in China

In China, food waste is mainly concentrated in the catering industry (42%), household food waste (29%), and school canteens (21%), which together account for 92% of the total food waste (Li et al., 2022). As the world’s largest emerging economy, food waste in China’s commercial catering sector is becoming increasingly serious, with waste accounting for as much as 11–17% of supply. For example, in Chengdu, food waste in the restaurant industry reached 26.7% in 2011, And the amount of food wasted per person per day in restaurants in Beijing (0.3 kg) is much higher than the amount of food wasted per person per day in Beijing households in 2008 (0.07 kg). Although the problem of school food waste is already quite serious, it is still 4.3% lower than the food waste in Beijing restaurants (Wang et al., 2017). In addition, serious food waste is also prevalent at official receptions, weddings, funerals, and banquets in China.

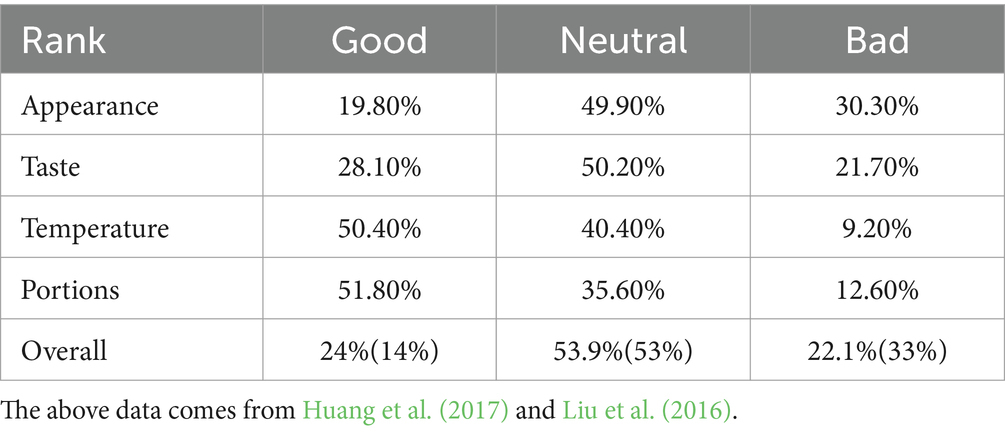

In addition to the commercial catering industry, the food waste problem in Chinese school cafeterias cannot be ignored. According to a study by Qian et al. (2021), 74% of college students generated plate waste while dining in the cafeteria, with wheat and rice accounting for 25.78 and 20.36% of the waste, respectively. Through the analysis of Table 3, we found that only half of the students were satisfied with the temperature and portion size of the food, while the others considered it fair or unsatisfactory; for the appearance and taste of the food, the percentage of students who were satisfied was less than 20 and 30%, and most of the students considered it fair or unsatisfactory. Overall satisfaction with the food was even lower than 25%. For example, Huang et al. (2017) study on the nutritional intake of primary and secondary school students in Shanghai showed that the main causes of food waste included excessive portion sizes and poor taste. These data reveal the severity of food waste in school canteens and point to the need for improved food quality and portion size management to reduce food waste and increase the efficiency of food utilization.

In addition to the factors mentioned above, there are a variety of factors that influence students’ satisfaction with food. Dietary preferences and appetite are the main considerations for students when choosing a meal, and this is closely related to the quality and quantity of food provided in the university cafeteria (Wu et al., 2019). The impact of food supply patterns on food waste should not be overlooked, for example, the amount of waste from packaged meals (216 g/meal) is much higher than from set meals (109 g/meal) or buffets (63 g/meal). Regarding the knowledge of food production, 57% of the students had limited understanding and 16% even had no understanding at all. In addition, 14% of students believe that there is no longer a problem with food supply in China, and 18% believe that table waste is not a problem (Liu et al., 2016).

4 Current status of research on food loss and waste from a life cycle perspective

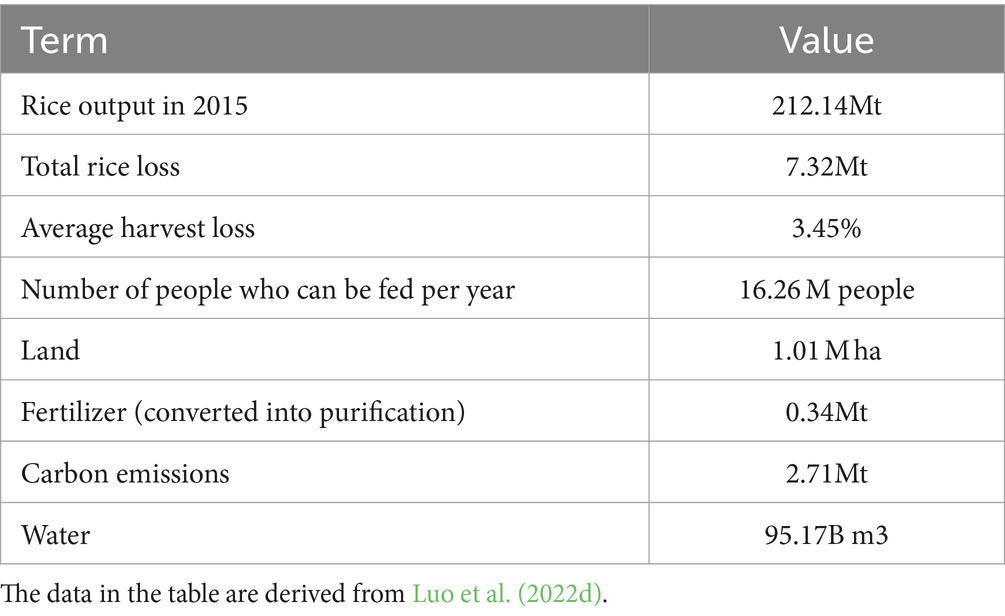

The production of food is a comprehensive process involving many complex systems. From field to table, all post-production links work in synergy to realize the transfer of finished food products in time and space, fulfilling the mission of the whole process of food from production to consumption. At the same time, the production process of food requires inputs such as land (ecological footprint), water resources, fertilizers (nutrients), and other key elements, which are essential to ensure food security and sustainable production. Food consumption also inevitably generates a carbon footprint and carbon emissions, which are environmental challenges that need to be faced and addressed in the food production and consumption process (El-Ramady et al., 2022). Food circulates in the resource and energy dimensions during production and consumption and constitutes another complex system. However, the needless losses in this system are equally huge. Using Table 4 as an illustration, the resource allocation corresponding solely to the food wasted at a specific post-production stage of a particular staple food is already an immense figure, sufficient to sustain 16.26 million people for an entire year. It is therefore very important to sort out the current state of research on the ecological cycle of food loss and waste as well.

4.1 Nutritional loss study of food loss and waste

Although some scholars have studied the nutrients required by the human body that can be provided by food (Popkin et al., 2010), however, the number of studies targeting food is very small, with existing studies mainly targeting phosphorus and nitrogen. According to statistics, phosphorus losses across the food supply chain reached 424,400 tons in 2015 (Li B. et al., 2020). Then in 2018, China’s phosphorus losses from food waste alone rose again to 540,000 tons (5.12% of phosphorus fertilizer consumption), and 3.58 Mt. of nitrogen losses (10.43% of nitrogen fertilizer consumption) (Niu et al., 2022).

Total reactive nitrogen emissions from the food system in the Beijing-Tianjin-Hebei region increased between 1978 and 2017, it was only gradually reduced until 2004, but the share of emissions from food loss and waste in the total increased by 22% over the study period (Chen D. et al., 2022). Crop production accounted for 44.03% of reactive nitrogen inputs in 2019. However, the efficiency of reactive nitrogen utilization is less than 20%. Minimizing food loss and waste can reduce reactive nitrogen emissions by 17.9% (Xing et al., 2023).

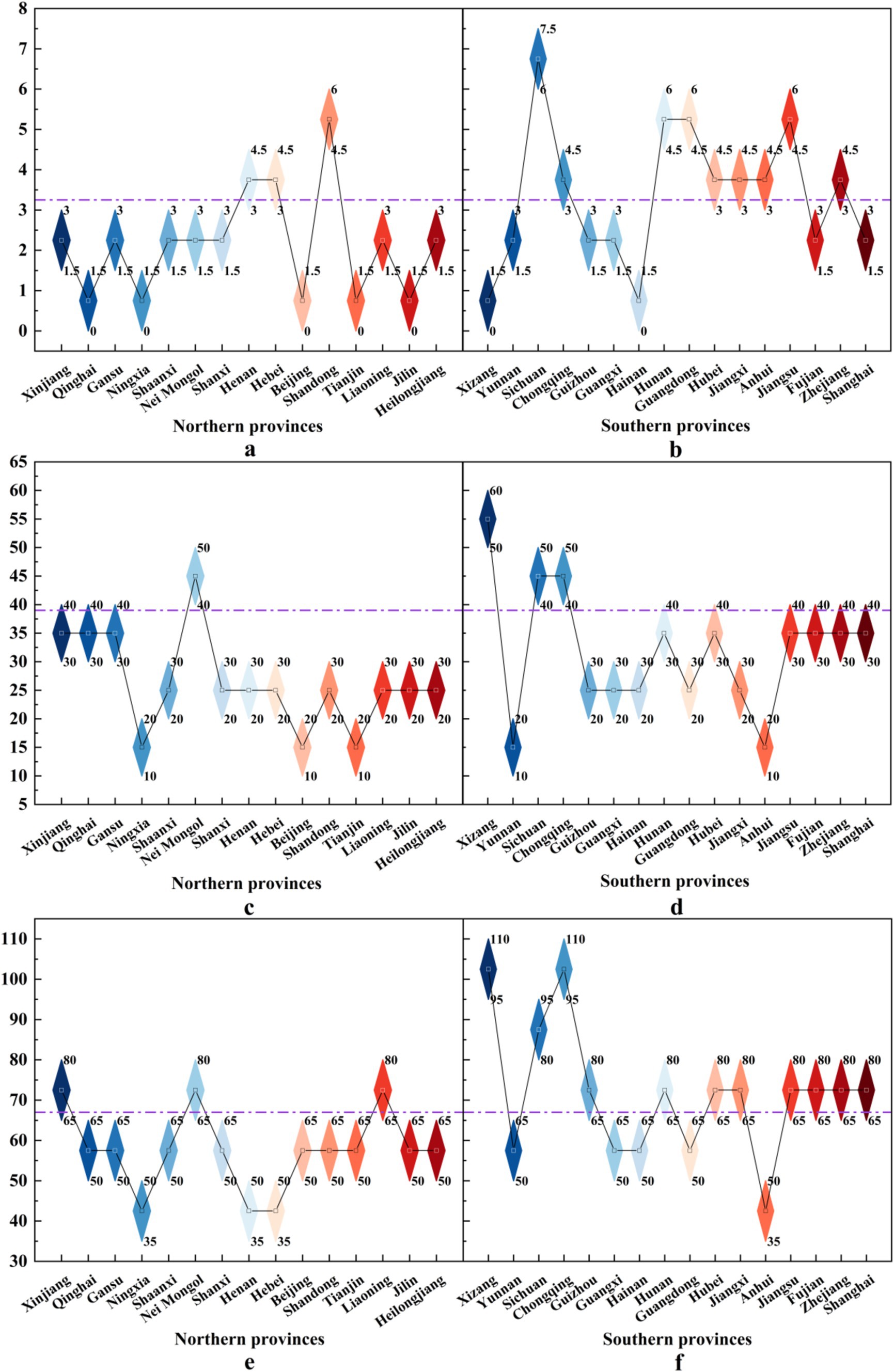

Figure 9 illustrates the phosphorus footprint due to FW in each province, the proportion of elemental phosphorus to FW, and the average edible phosphorus content. Similar to the previous characterization, the average phosphorus footprint of each province is lower in the North than in the South, and lower in the West than in the East. However, the proportion of phosphorus in FW and the average edible phosphorus content are significantly higher in the West than in the East. This is related to the degree of economic development and dietary habits in the Western region (the proportion of food consumption is higher for Western residents). It is also related to the waste caused by the tourist population in the western region (Li B. et al., 2020). After all, the process of traveling generates just as much waste.

Figure 9. Phosphorus waste corresponding to food waste in China. (a,b) Phosphorus loss from FW (kt). (c,d) Rate of phosphorus loss due to FW (%). (e,f) Average at-table phosphorus (g). The above data comes from Li B. et al. (2020).

4.2 Water footprint study of food loss and waste

The loss of water resources due to food waste (blue water plus green water) is 605.02 Bm3, accounting for more than 10% of China’s total water consumption (Sun et al., 2018). In 2018, the water loss caused by food waste alone was 120.25 billion tons (3.06 times the amount of water stored in the Three Gorges Reservoir) (Niu et al., 2022). Curbing food waste is crucial for alleviating undue strain on the environment and natural resources, notably water.

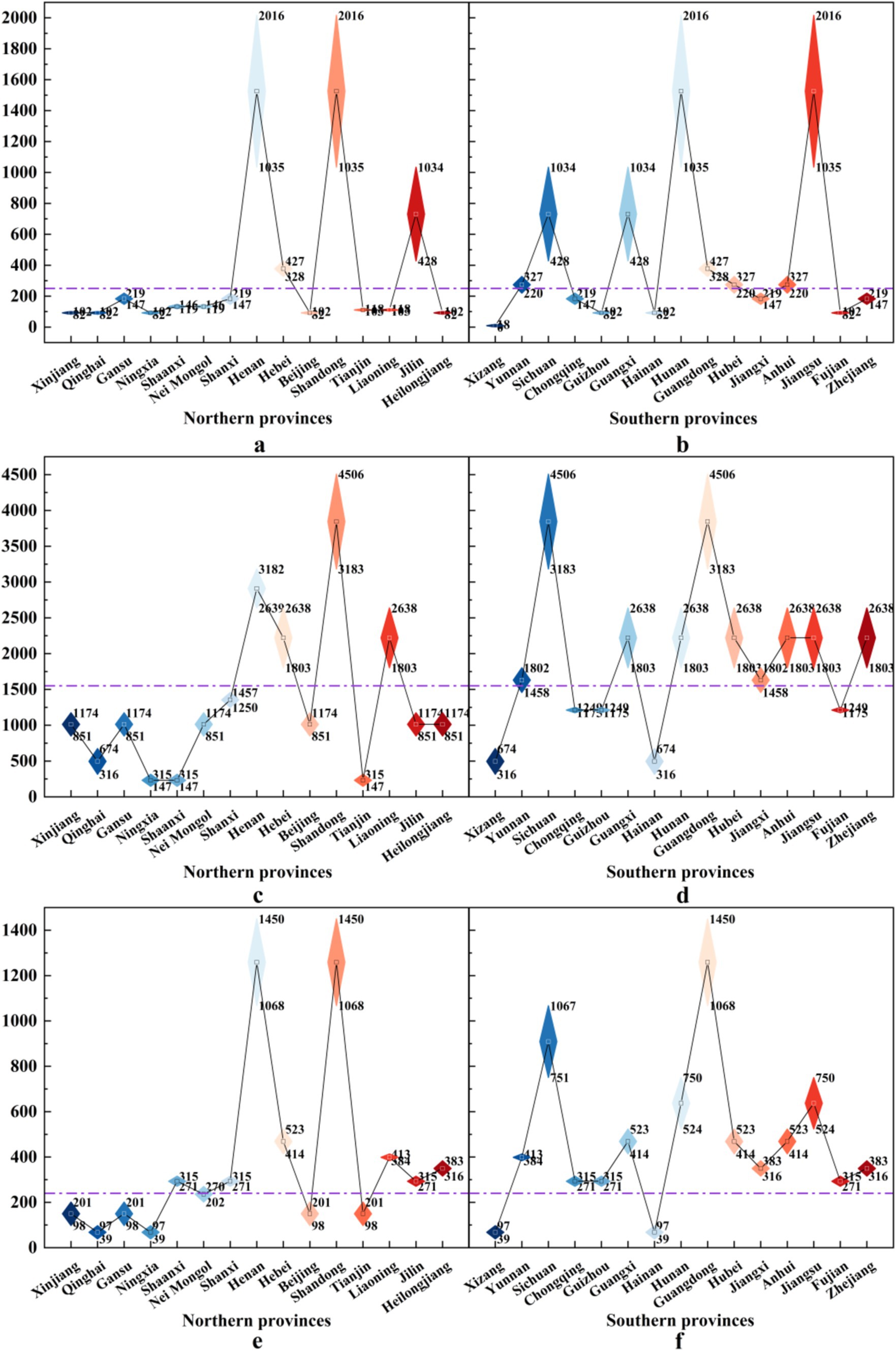

Figure 10 illustrates the superfluous blue, green, and gray water footprints associated with FLW across various provinces. First of all, the blue water footprint is mainly distributed in the range of 100–300 Mm3, but the blue water footprints of Jilin, Sichuan, and Guangxi are extremely high, reaching 700 Mm3 on average, and the blue water footprints of Henan, Shandong, Hunan, and Jiangsu are even twice as high as those of these provinces, reaching 1,500 Mm3 on average, which makes the water loss of these six provinces extremely serious. The green water footprint is still highest in Henan and Shandong in the north, and very high in the south, except for Tibet and Hainan. The gray water footprint is highest in Henan, Shandong, Sichuan, Hunan, Guangdong, and Jiangsu.

Figure 10. Water footprint of FLW in China. (a,b) Blue water wastage (M·m3). (c,d) Green water wastage (M·m3). (e,f) Grey water wastage (M·m3). The above data comes from Sun et al. (2018).

4.3 Carbon footprint study of food loss and waste

After discussing the resource input of the whole food industry chain, we will face the unnecessary carbon emission caused by FW in the consumption chain. As the world’s largest developing country, China cannot afford to ignore the problem of minimizing carbon emissions before carbon peaking and carbon neutrality are completed. Of course, the excessive waste of food also makes it more difficult to reduce carbon emissions and lower carbon footprint. At this stage, the carbon footprint caused by food waste is 168.07 Mt. CO2eq, accounting for 1.44% of China’s total greenhouse gas emissions (Niu et al., 2022). The carbon footprint of consumer food waste ranges from 30 to 96 kg of CO2eq per year in nine representative provinces in China (Song et al., 2018).

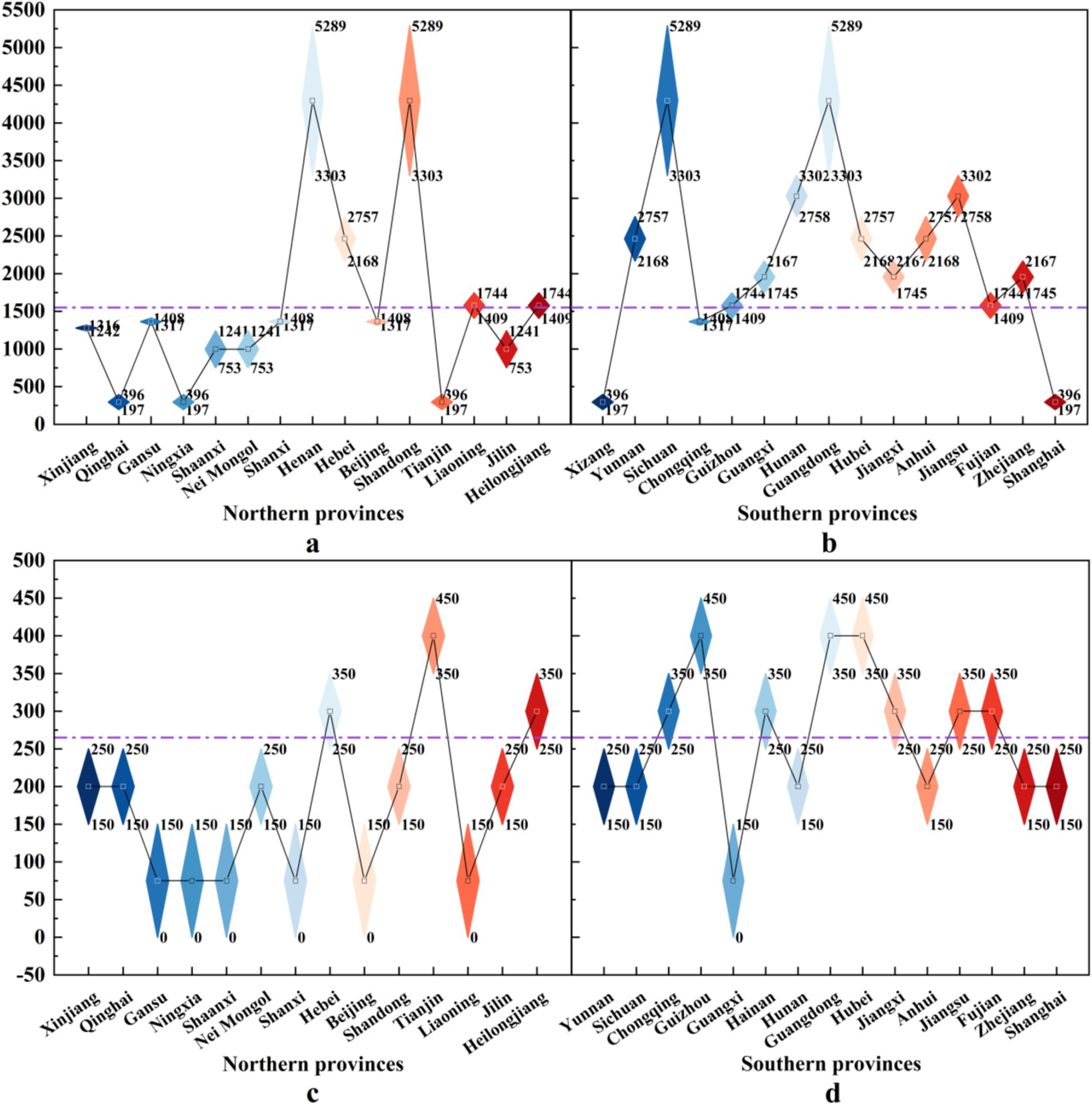

Carbon emissions are again examined spatially. Figures 11a,b shows the total carbon emissions from food waste by province in 2010 (Sun et al., 2018). Among the northern provinces, except for Henan, Hebei, and Shandong, the rest of the provinces are at 1500 Mkg and below, which is in sharp contrast to the southern provinces. In the South, except for Tibet and Shanghai, whose carbon emissions are well below 1,500 Mkg, the rest of the provinces are greater than this level, most of these values range between 1,500–3,000 Mkg, significantly exceeding the average level observed in the northern regions. Overall Henan, Shandong, Sichuan, and Guangdong have the largest carbon emissions, averaging 4,250 Mkg.

Figure 11. Carbon emissions from food loss and waste in China by province. (a,b) Carbon emissions caused by food waste (M·kg). (c,d) Carbon footprint of university plate waste (g CO2eq/d). (c,d) Missing data for Henan and Xizang.

Due to the lack of data on household and restaurant food waste, studies at this stage underestimate the amount of waste and total carbon emissions. In China, however, the school cafeteria has been a presence that cannot be ignored. It is a non-home dining environment and the results are easy to count, making it a link that cannot be bypassed in Chinese food waste research. It is estimated that the total food waste in Chinese universities in 2018 was 1.55 Mt. In terms of food waste components, food waste ranked second, accounting for about 36.23% (560,000 tons). The carbon footprint reached 2.51 Mt. of CO2eq, with a daily per capita carbon footprint of 233 g CO2eq (Qian et al., 2022b).In 2019, the total amount of food waste in the canteens of 22,000 university students in three canteens of Taiyuan University of Technology was 246.75 tons, and the carbon footprint caused by food waste was 539.28 tons of CO2eq for 4,729,900 yuan. Among them, the amount of grain waste was the largest, accounting for about 46.14% of the total amount of waste (Li et al., 2021).

Figures 11c,d shows the carbon emissions caused by the waste of each meal in the university cafeteria. The average value of carbon emission in the northern provinces is lower than that in the southern provinces. Among the northern provinces, the carbon emission in the eastern region is higher than that in the western region, but there is no obvious pattern in the southern provinces. Because they are both public dining environments, the characteristics of school cafeterias and the restaurant industry are relatively similar. Overall, both the total carbon emissions and the carbon emissions caused by food waste are much higher than the international average emissions.

In addition to traditional consumption methods, a few studies have also focused on emerging consumption methods in China, namely online food ordering (Xu et al., 2024). This burgeoning industry not only contributes to water pollution but also leads to increased solid waste pollution, resource consumption, and air pollution. On average, 118.5 grams of solid waste and 0.68 kg of CO2eq are generated per trip, of which packaging manufacturing and packaging handling account for 45 and 50%, respectively, which hurts carbon footprints (Li C. et al., 2020; Sun and Zhang, 2024). In addition to the above conclusions, other studies on this link are currently mainly at the theoretical stage (Yang et al., 2024).

5 Discussion

Our research delves into the prevailing state of Food Loss and Waste (FLW) in China to a significant degree. Previously, while certain scholars have investigated global Agricultural Food Waste (AFW), there has been a notable scarcity of comprehensive overviews that examine the entire process, the entire industry chain, the entire region, the holistic perspective, and the full spectrum of varieties about China’s FLW issue (Wang et al., 2024). Our work fills the gap in this field to some extent. We discovered that research on FLW in China is relatively sparse, with a noticeable uptick in studies emerging only over the past five years. But in general, it is still in the stage of stating the current situation and identifying problems. The specific approach is to explain the phenomenon through empirical studies or research, and seldom conduct theoretical studies to explain the principles. As a result, most of the identified deficiencies do not have effective solutions or are not implemented.

Of all the post-production links, the one with more complete research conclusions is the storage link. There are fewer factors affecting losses in storage, and the main influences have largely been studied, with clearer conclusions, but implementation is difficult (e.g., depositing more grain in central reserves or popularizing metal silos). Some results in the research conclusions are in the harvesting stage and consumption stage. There are a large number of factors influencing FLW in these two stages, and existing research identifies some of these factors, but it is not clear why they occur and how they can be improved. Harvesting is very difficult to improve, while consumption has not yet received enough attention, and measures to save food and reduce losses have not been effectively implemented. The weakest findings are in the drying, transportation, processing, and distribution (retail) stages. Despite the fewer influences of Food Loss (FL) observed in the aforementioned stages, it remains challenging to pinpoint the primary factors and the underlying causes of their emergence. If the theoretical foundation of FLW research in China is to be strengthened, it is necessary to focus on the drying, transportation, processing, and distribution (retail) stages, and to continue to improve the research on the harvesting stage and consumption stage.

All the research on FLW and the life cycle of food crops is summarized in one sentence: “The unnecessary waste of resources is extremely serious and the unnecessary carbon emissions are very large.” However, while strategies to diminish and enhance the situation are broadly outlined, there is a lack of precise conclusions and targeted measures that effectively address the core issues. The practicality and guidance are very low. Ultimately, the measures should be implemented to optimize and improve the post-production processes of food. However, the research on each link is very weak, and naturally, no effective conclusions and recommendations can be obtained.

These are all the studies on FLW in China. It is easy to find that the studies in the post-production chain are mainly about the current situation of FLW and the factors affecting the formation of loss and waste, while the studies in the life cycle are even fewer, mainly describing the current situation. Fewer theoretical studies are addressing FLW formation. Even in the studies that account for a high proportion of the available research and address the influencing factors, the existing perspective is too narrow and many aspects are not addressed. For example, the influence of beliefs on FLW (Zamri et al., 2020)、Factors affecting grain losses at the retail link, or a study of the whole chain as a whole (Chirsanova and Calcatiniuc, 2021; Principato et al., 2021). Even when the research aimed to extend and broaden the scope across the entire industry chain, it ultimately concentrated on a single stage, failing to truly encompass the entire chain (Zhao et al., 2023; Gao et al., 2021). At the same time, both post-production and life cycle studies rarely mention how to improve FLW at the macro level, and at the micro level, although some suggestions for improvement have been made, they have rarely been put into practice. Furthermore, the findings from studies focusing on the same research subject are inconsistent, and in some cases, there exists a significant disparity between the conclusions drawn. While some scholars have recently started employing advanced techniques like machine learning to enhance research precision, the application of these methods is still in its infancy and has yet to achieve widespread adoption (Li and Mao, 2022).

Take the most typical example of consumption. China has been promoting food conservation and low-carbon consumption in recent years, such as through the eight provisions in 2012 the restriction of official consumption in 2013, and the enactment of a law in 2021 that restricts food waste in various ways and guides localities and industries to develop appropriate laws or rules to reduce waste. In absolute terms, there has been a certain degree of impact, yet when considering the percentage, there remains ample opportunity for enhancement. And compared to Europe, whose legislation provides detailed strategies, China’s laws lack specificity and guidance in nature. Meanwhile, the theoretical research on the mechanism of food waste behavior is also very imperfect. Consumer food waste behavior falls under the micro-level domain, characterized as a subjective act driven by a blend of self-interest and altruistic intentions. Therefore, the fundamental solution to food waste is to let consumers take the subjective initiative to avoid food waste by themselves. However, the corresponding theoretical research is also scarce. In a word, the existing research only solves the problem of “what phenomena affect FLW,” but not “why these phenomena occur” and “how to avoid these phenomena.”

6 Research constraints

6.1 Lack of primary data

The primary impediment to quantifying FLW is the absence of comprehensive data. Objective estimation of FLW is the basis of research on this issue. However, the vast majority of existing FLW studies use qualitative analysis, and less than 20% of the data used in quantitative analysis studies comes from first-hand sources. The vast majority of studies rely on data from secondary literature, such as FAO reports, World Bank reports, and related research literature, to which this paper also belongs. The adoption of secondary data is prevalent in the academic community, owing to its benefits of reduced cost, enhanced feasibility, and time efficiency. However, these outdated data may not be able to explain the current problems scientifically and there are large uncertainties.

6.2 Lack of harmonized accounting standards

The concept of FLW in China is not consistent with the international. International research focuses on FLW, or food loss and waste, but the concept of food in China has long been at odds with the international concept of food. The Chinese conceptualization of food generally refers only to cereals, legumes, and potatoes, whereas the international conceptualization of food has a broader range of food attributes. This results in a smaller scope and less applicability of Chinese studies on FLW. Because the findings of existing FLW studies are too few to support the research in this paper, this paper delves deeper into the subject of FLW. This is the drawback of the existing studies in China, which mainly study grains and seldom study other foods, which has been completely out of touch with the current dietary habits and dietary structure of Chinese people.

6.3 The research perspective is too microscopic and every link is not equally emphasized

Most of the existing research perspectives are limited to the FLW status of a region, a stage, or a crop, and this single FLW accounting is a micro perspective. In reality, however, FLW accounting for non-single links is more complex. Taking the transportation link as an example, the transportation link exists in the whole process of post-production of food, and the transportation loss at a single time stage cannot represent the loss of the whole post-production system of food. However, in the existing literature, the accounting of FLW in the transportation link is often limited to a certain stage or a certain link, which is neither practical nor scientific.

Overall, it is extremely important to accurately assess the overall status of FLW and improve it accordingly. Consequently, it is of paramount importance to synthesize the data from each stage from a macroscopic perspective. The academic community should adopt an interdisciplinary and systematic scientific research perspective to construct an FLW accounting framework that connects different stages. This approach will facilitate the acquisition of comprehensive and precise primary data, enabling a scientific evaluation of the extent of FLW at each stage and across the entire system.

7 Conclusion

With the improvement of China’s urbanization level and residents’ living standards, as well as the continuous extension of the food industry chain, if the control of the food industry chain is not strengthened, the loss rate of food and other food in the circulation process will be higher and higher. We conducted our research through the methods of literature review and classification analysis and obtained the following conclusions.

First, the phenomenon of FLW in China is very common and getting more and more serious, with the rate of FLW in China being higher than 20% in 2022. FL mainly occurs in the harvest-to-retail chain, and FW mainly occurs in the consumption chain. Existing research on FLW in China exhibits three main characteristics: fragmentation (research focusing on one stage, one species, and one region), research imbalance (a large gap in the number of studies in each stage), and inconsistency between the concept of FLW in China and that in the international arena (existing studies in China focus more on grain loss and waste than on food loss and waste). Fragmentation and research imbalance have resulted in existing research findings being too micro and too few findings in vulnerable stages to draw accurate conclusions at the macro level, and the inconsistency of the FLW concept with the international level has resulted in a smaller scope and less applicability of research in China.

Second, among all the post-production stages of food, the average loss rates at the harvesting stage (3–6%), the storage stage (8–10%), and the average waste rate at the consumption stage (10–17%) are very high, while the loss rates at the remaining stages (1–3%) are relatively low. The harvesting stage (15 influencing factors) and the consumption stage (26 influencing factors) have the most influencing factors and are the most researched, while the other stages are very poorly researched. It was found that there are certain factors at each stage that significantly influence the increase in FLW. However, except for the storage stage and consumption stage, most of them did not propose effective improvement measures. Moreover, it is difficult to implement improvement measures in the storage stage on a large scale in a short period, while improvement measures (enactment of laws and implementation of policies) in the consumption stage are largely not effectively implemented.

Third, research on FLW about the life cycle of food crops is more sparse than research on the post-production aspects of food production. Nevertheless, the evidence is sufficient to demonstrate that FLW in China has led to an extraordinarily extensive squandering of resource endowments, including land (ecological footprint), water, and fertilizers (nutrients), along with substantial and unnecessary carbon emissions. However, there is a large gap between the conclusions of the studies. There is a great lack of valid conclusions on how to improve the uncontrolled consumption of resources caused by FLW in the future.

Fourth, whether it is the various post-production stages of FLW (mainly focusing on the consumption stage), the meaningless depletion of resource endowments caused by FLW, or the needless carbon emissions caused by FLW, these studies show some commonalities. First, at the macro level, the amount of waste is greater in the South than in the North, and in the East than in the West. Overall, it gradually decreases from the developed regions in the southeast to the less developed regions in the northwest, so the priority area for improving FLW is to improve FLW in the southeastern provinces. After all, public attention to anti-waste laws is positively correlated with local economic development (Huang et al., 2023), the government will also get better results by enacting new laws and implementing new policies. Secondly, the six provinces of Henan and Shandong in the north and Sichuan, Hunan, Guangdong, and Jiangsu in the south are extremely high in terms of both food loss, waste, and depletion of resource endowment or carbon emissions. Another focus for improving FLW is in the above six provinces. Finally, China’s cities and villages have great structural differences in FLW because of the influence of living habits, income levels, and other factors. In the future, more instructive research should be conducted on the urban–rural dichotomy separately.

The above conclusions are only a stage-by-stage summary of past research, and there are still a large number of research gaps that require more in-depth analysis and research in the future. The first is to improve the research on the drying stage, transportation stage and distribution stage. The second is to strengthen the research on government functions and management measures. Thirdly, research on improving residents’ awareness of conservation and dietary knowledge. The fourth is a study on the secondary utilization of the food waste generated. All of the above research directions contribute to the reduction or reuse of FLW, but there are few existing studies. More attention and research are needed in the future.

In summary, the exploration of the formation mechanism and specific ways to improve FLW in China has only just begun. We summarize previous research results through this study to provide directions and references for subsequent studies. Scholars should strengthen interdisciplinary cooperation, adopt a systems science research perspective, expand the conceptual scope of FLW (Grain loss and waste) to FLW, and construct a theoretical analytical framework connecting the production, processing, distribution, and consumption stages, as well as a theoretical analytical framework of the life cycle. Data collection and standardization should be increased, and research methods combining qualitative and quantitative, macro and micro should be adopted to comprehensively assess the FLW of different stages, regions, and varieties, identify key influencing factors, and propose reasonable measures to improve the FLW situation in China.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

PX: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. KS: Formal analysis, Investigation, Methodology, Resources, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Barrera, E. L., and Hertel, T. (2021). Global food waste across the income spectrum: implications for food prices, production and resource use. Food Policy 98:101874. doi: 10.1016/j.foodpol.2020.101874

Béné, C., Oosterveer, P., Lamotte, L., Brouwer, I. D., de Haan, S., Prager, S. D., et al. (2019). When food systems meet sustainability – current narratives and implications for actions. World Dev. 113, 116–130. doi: 10.1016/j.worlddev.2018.08.011

Buzby, J. C., Hyman, J., Stewart, H., and Wells, H. F. (2011). The value of retail- and consumer-level fruit and vegetable losses in the United States. J. Consum. Aff. 45, 492–515. doi: 10.1111/j.1745-6606.2011.01214.x

Campi, M., Dueñas, M., and Fagiolo, G. (2021). Specialization in food production affects global food security and food systems sustainability. World Dev. 141:105411. doi: 10.1016/j.worlddev.2021.105411

Carter, C. A., and Lohmar, B. (2002). Regional specialization of China’s agricultural production. Am. J. Agric. Econ. 84, 749–753. doi: 10.1111/1467-8276.00332

Chen, F., Gu, X., and Hou, J. (2022). Research on the formation mechanism of individual food waste behavior from the perspective of image construction. Food Secur. 11:1290. doi: 10.3390/foods11091290

Chen, D., Wang, C., and Liu, Y. (2022). Investigation of the nitrogen flows of the food supply chain in Beijing-Tianjin-Hebei region, China during 1978–2017. J. Environ. Manag. 314:115038. doi: 10.1016/j.jenvman.2022.115038

Chen, X., Wu, L., Shan, L., and Zang, Q. (2018). Main factors affecting post-harvest grain loss during the sales process: A survey in nine provinces of China. Sustain. For. 10:661. doi: 10.3390/su10030661

Chirsanova, A., and Calcatiniuc, D. (2021). The impact of food waste and ways to minimize IT. J. Soc. Sci. 4, 128–139. doi: 10.52326/jss.utm.2021.4(1).15

Chu, Z., Bo, M., Lu-lu, L., Jun, X., Wan-xu, Z., Liang-yu, H., et al. (2022). Dynamics of maize grain drying in the high latitude region of Northeast China. J. Integr. Agric. 21, 365–374. doi: 10.1016/S2095-3119(20)63434-7