94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. Food Syst. , 28 October 2022

Sec. Crop Biology and Sustainability

Volume 6 - 2022 | https://doi.org/10.3389/fsufs.2022.1012410

The cooking quality, especially the pasting properties, is essential in cassava starch applications or successfully utilizing cassava in food industries and at the household level. This study evaluated the cassava roots from the Genetic Gain Assessment trial grown in three locations for dry matter (DM) and the pasting characteristics. Four hundred cassava genotypes were planted under IVS (Dry season in Inland Valley Hydromorphic area) and Upland (rain-fed conditions) trials at IITA Research Farms, Nigeria. The harvested cassava roots (12 months after planting) were analyzed for DM, and the dried-milled roots were analyzed for pasting properties using standard laboratory methods. The DM ranged from 25.04 to 38.72%, with a mean of 31.97 ± 2.41%. The pasting properties (peak, trough, breakdown, setback and final viscosities) ranged from 140.36–570.93 RVU (mean 241.71 ± 38.17), 6.74–173.32 RVU (mean 96.65 ± 23.45), 66.97–482.35 RVU (mean 142.44 ± 30.16), 60.06–231.74RVU (mean 134.42 ± 30.52), and 5.22–135.69 RVU (mean 37.78 ± 12.96), respectively. The genotypes had no significant effect (P > 0.05) on the DM and pasting properties, but the growing location showed a highly significant effect (P < 0.05) on all the parameters studied. The cluster analysis grouped the genotypes into 2 clusters where clusters 1 and 2 had 115 and 285 genotypes, respectively. Knowing the impact of genotype and grown location on the pasting behavior could help the breeders select the best genotypes with excellent qualities that could adapt to different environments and identify the suitable growing area for the best cooking quality.

Cassava (Manihot esculenta Crantz) is a drought-tolerant, staple food crop grown in tropical and subtropical areas. It is a source of calories for most developing countries, especially cassava-consuming countries. Cassava has become a multipurpose crop responding to the challenges of climate change (Sabitha et al., 2016). It has also been earmarked to be a crop that could address the food crisis in Africa because of its efficient production of food, year-round availability, and tolerance to extreme stress conditions (Hahn, 1987). The tuberous roots and the leaves are used as human food, animal feed and industrial products (Adugna, 2019). Starch accounts for about 85% of dry weight (Sánchez et al., 2009; Sayre et al., 2011). However, Cassava root pasting properties are related to the amylose/ amylopectin ratio of the starch component. The amylose component is about 15 to 20% on average; however, the high-amylose mutants with about 30% amylose have been bred (Ceballos et al., 2007). The high percentage of starch in cassava has caused a strong positive correlation between starch content and dry matter on a fresh basis. Sánchez et al. (2009) reported that the starch quality and content are influenced by genetics and growing conditions linked to the environment (such as the soil water availability, temperature, soil type, and soil nutrient status).

Most breeding programs use quantitative and population genetics knowledge to generate and select new genotypes with higher yields and superior traits than the commercial varieties available for cultivation. In cassava, breeders primarily use the vegetative propagation method to promote the hybridizations between contrasting parents and select superior F1 individuals. Moreover, the superior genotypes are always identified and clonally propagated and evaluated in field conditions that usually refer to the clonal evaluation trials. Thus, the ability to select individuals during the early stages to maximize genetic gains and develop new varieties is the primary goal for cassava breeders (Andrade et al., 2019). Ceballos et al. (2004) reported that cassava breeding faces several limitations, including the heterozygous nature of cassava and parental lines used to generate new segregating progenies and has made the breeding mainly based on the mass phenotypic recurrent selection. However, it is known that the breeding objectives always depend on the end use of the crop. For example, breeding for industrial uses of cassava requires a high dry matter and starch contents as the leading quality traits for the roots, whereas breeding for human consumption will emphasize the cooking quality (pasting properties) with excellent pasting properties (Ceballos et al., 2004). Moreover, the breeding teams can make transparent advancement decisions whenever a potential genotype meets all the “must-have” criteria and possess at least one “value-added” trait that differentiates it in the marketplace (Cobb et al., 2019) and give the opportunities for value addition.

The nutrient composition of cassava varies according to the maturity and age of the roots as well as other factors such as climatic condition, soil quality and other environmental factors during cultivation (Montagnac et al., 2009). Farmers prefer high-yielding and marketable varieties which would give high returns on investment; however, most new varieties are either low yielding or not meeting the expectation of consumers and processes in terms of final product qualities. Cassava breeding programs. Therefore, the Collaborative Study of Cassava in Africa (COSCA), working with the International Institute of Tropical Agriculture, is launching a massive campaign to adopt new varieties among farmers and processors (Solomon and Okedo-Okojie, 2016). Pasting is an essential physical measurement demonstrating starch's cooking behavior, which could also be affected by certain processing factors such as fermentation. The effects of duration of fermentation on the pasting properties of cassava starches were investigated (Adegunwa et al., 2011). The authors reported significant differences (p < 0.05) in the pasting properties of the cassava starch except for pasting temperature and breakdown viscosity, irrespective of the length of fermentation.

Cooking quality, especially the pasting properties, is essential in cassava starch applications or successfully utilizing cassava starch/cassava roots in food industries and at the household level (Iwe et al., 2017). The knowledge of pasting properties is an essential indicator of the cooking quality of foods and their constituents. The food processors mainly apply this knowledge to optimize the ingredient levels and temperature-pressure-shear limits to achieve the desired product (Maziya-Dixon et al., 2005). Pasting properties are primarily evaluated using pasting curves or Brabender amylograph obtained using Rapid Visco Analyser (RVA). Gelatinization of cassava starch has been defined as breaking down intermolecular bonds of starch molecules in the presence of heat and water (which serves as a plasticizer) that allows the hydrogen bonding sites to absorb more water. It causes the starch granule to dissolve in the water irreversibly. The heating of the starch granules in liquid (like water) absorbs the liquid, then swells and ruptures, leading to increased viscosity (stickiness) of the starch (Iwe et al., 2017; Godswill et al., 2019). The pasting properties of all starchy flours have been found in research influenced by genotype and environmental factors that brought subtle changes in the source materials, such as grains and tubers (Iwe et al., 2017). Various studies reported the impacts of environmental conditions on pasting and the physicochemical properties of cassava flour and starch samples. They indicated the possibility of predicting and controlling cassava flour quality and pasting properties according to the environmental conditions, such as growth temperature, rainfall, and altitude has an enormous impact on starch production and properties (Santisopasri et al., 2001; Karlström et al., 2019; Zhang et al., 2020). Also, it was reported in the literature that the ambient temperature 3 months before harvesting cassava roots had a positive correlation with the paste clarity and pasting temperature (Gu et al., 2013).

Moreover, cassava starch's peak viscosity from plants grown at a low altitude is statistically higher than those grown at an intermediate altitude (Karlström et al., 2019). Unlike this study which used a more significant number of genotypes from different growing environments, all these studies used a few cassava varieties. We hypothesize that the genetic makeup and environmental condition play a vital role in drymatter content and the pasting properties of flours of cassava genotypes from the Genetic Gain Assessment (GGA) multilocation trials. The Genetic Gain Assessment (GGA) trials are all genotypes developed and selected up to the Uniform Yield Trial (UYT) breeding stage. No more selection is made on them but go into multilocation On-farm trials for nomination for National Coordinated Research Project on Cassava (NCRP) trials by the National Root Crops Research Institute (NRCRI)- an agricultural research institute in Nigeria, before official release.

Therefore, evaluating the pasting qualities of most selected materials at the advanced stages, such as genetic gain assessment (GGA) trials, is essential. Much variability exists in the pasting properties of cassava genotypes. The systematic characterization of these genotypes, especially those under final selection for release (as improved varieties), is essential for meeting its food, feed, and industry application requirements in crop breeding programmes. The utilization of these newly developed genotypes depends on their functional properties, and they must be studied and established. Based on this background, this study was conducted to quantify the dry matter and the pasting characteristics of cassava genotypes being evaluated under the GGA trials in different growing environments to establish their genetic variability and the relationship between the dry matter content and pasting properties. The information from this study on the pasting properties of cassava flour from the GGA trial will provide an opportunity for improving the quality and functionality of cassava flour.

A total of 400 cassava genotypes (Supplementary Table 1) were planted under IVS (Dry season in Inland Valley Hydromorphic area) and Upland (rain-fed conditions) trials at 2 locations of IITA Research Farms, Ibadan (IVS and Upland) and Mokwa (Upland) in Nigeria during the 2006 and 2007 cropping seasons. In Mokwa, the dry season is humid and partly cloudy and becomes hot throughout the year. The average annual rainfall ranges from 0.0 to 6.2 inches, while average temperatures range from 63 to 980F, with the highest around March and April. Also, for Ibadan, the average rainfall ranges from 0.3 to 9.1 inches, and the average temperature ranges from 69 to 920F, highest around February and March. The design for the IVS trial was an Augmented Completely Randomized Design with three checks [TME 1 (famous landrace) and 91/02324 and 30572 (improved and officially released varieties)] repeated randomly in each sub-block.

In contrast, the upland trial was an Augmented Completely Randomized Design with checks [TME 1 (famous landrace, and 3,0572 (improved and officially released variety)] repeated randomly in each sub-block. Planting was done on ridges (30 cm high and 1 m apart) as plots. For the IVS trial, each plot consisted of one ridge and five plants per plot spaced 0.5 m between plants and 1 m between ridges. Each plot consisted of one ridge, and ten plants per plot spaced 0.5 m between plants and 1 m between ridges for the Upland trial. No fertilizers or herbicides were applied to both trials. Manual weeding was done as necessary.

The method described by Alamu et al. (2021) was used for the sampling and sample preparation (Figure 1). Five plants per genotype were harvested 12 months after planting (MAP). Three cassava roots of different sizes were randomly selected per genotype and labeled appropriately. The cassava roots were washed with tap water and air-dried on a chux-lined surface. The roots were peeled with a stainless-steel knife and rinsed in deionized water. After that, each root was cut into four longitudinal sections using a stainless-steel knife. One-quarter was removed from each root and chopped into small pieces. The chopped pieces from each root were mixed and sub-sampled for dry matter and pasting properties determinations. However, the samples for dry matter determination were taken directly to the laboratory for analysis. The samples for pasting profiling were placed in a petri dish and dried in an uncorroded convectional oven at 50–60°C for 2 days. The samples were then packed in labeled envelopes for pasting profiling analysis. All samples were run in duplicates in the laboratory.

The DM content of the fresh samples was determined by weighing 100 g of the cassava samples in a cleaned and pre-weighed moisture can and placed in an oven (Fisher Scientific IsotempR Oven model 655 F, Loughborough, United Kingdom) at 105°C for 24 h until the constant weight was obtained (AOAC, 2006). The DM was calculated using the following equation:

The pasting properties of the samples were determined using a Rapid Visco Analyzer (RVA) (model 3C; Newport Scientific Pty Ltd, Sydney, NSW, Australia). Three grams of the flour samples were weighed into a dried empty canister. About 25 mL of distilled water (volume adjusted by the sample's moisture content) was dispensed into the sample's canister. According to the manufacturer's instructions, the mixture was thoroughly stirred, and the canister was fitted into the RVA. The mixture was heated from 50 to 95 °C with a holding time of 2 min followed by cooling to 50°C with a 2 min holding time. The heating and cooling were constant at 11.25°C/min. The pasting properties- Peak viscosity, holding strength, breakdown, final viscosity, set back, peak time, and pasting temperature- were recorded using a computer with Thermocline for Windows Software; Newport Scientific (AOAC, 2006; Alamu et al., 2017).

The XLSTAT (Addinsoft, 2021) was used for the data analysis, such as the analysis of variance (ANOVA) and descriptive statistics. Also, the means were separated using Fisher's protected least significant difference (LSD) test at P < 0.05. In addition, principal component analysis (PCA) and hierarchical cluster analysis (HCA) were also applied.

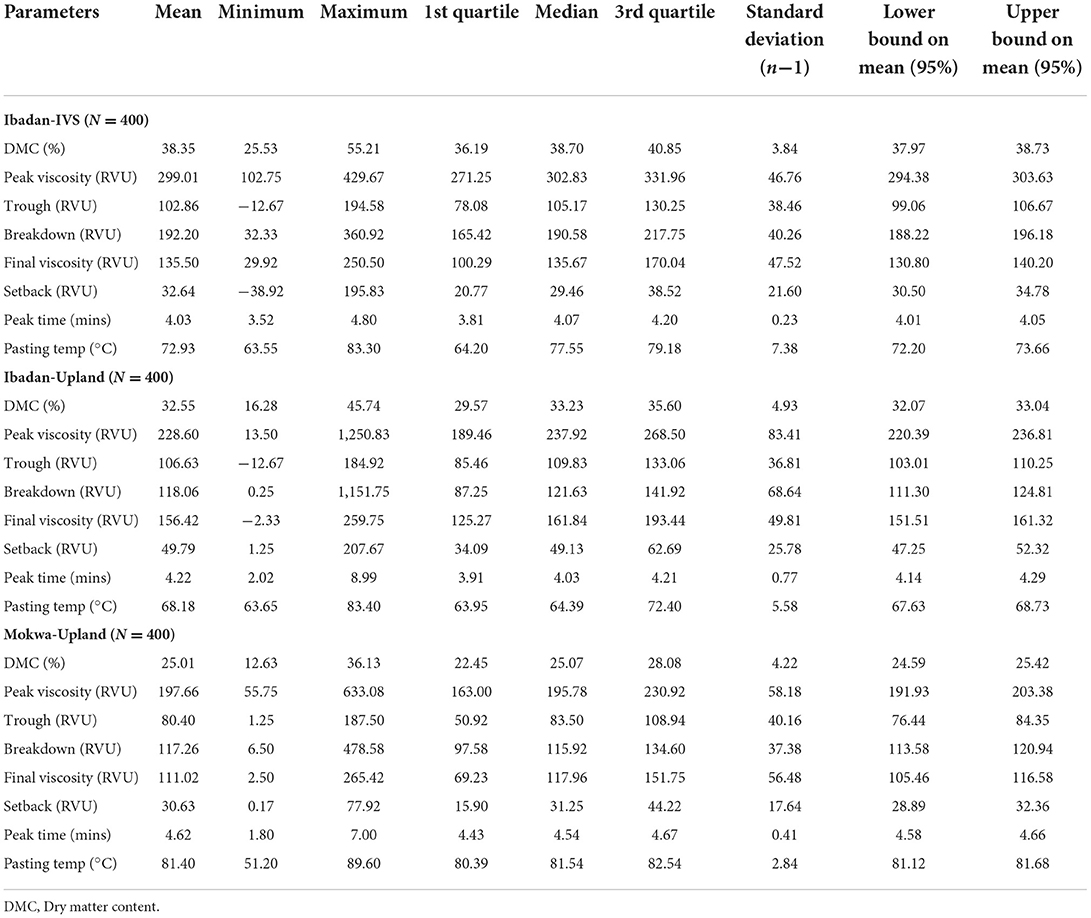

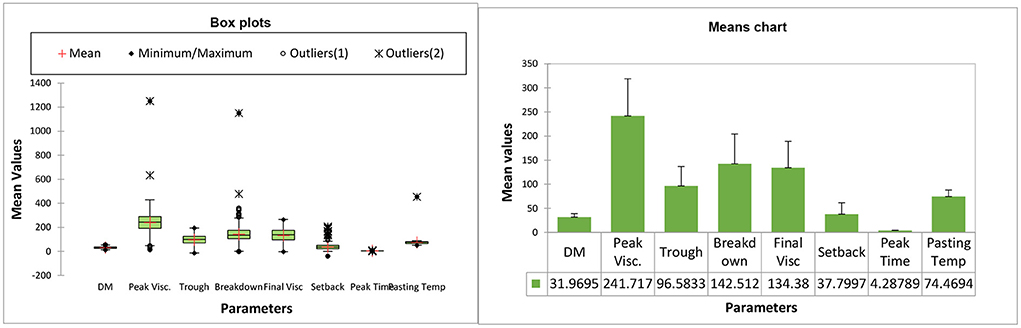

The DM of the fresh roots and pasting properties of the flours from the GGA cassava genotypes across the growing locations and conditions are shown in Table 1, Figure 2 and Supplementary Table 2. The DM ranged between 25.04 and 38.72%, with a mean of 31.97 ± 2.41%, with the equivalent moisture content ranging from 61.28 to 74.96%. The DM indicates the total organic and inorganic matter level in the root, and the higher the DM, the less the water/moisture content (MC) and the better the genotype. This aggress with the results reported by various studies that the average MC of fresh cassava roots ranges from 60 to 80% and that of the quality cassava flour could be between 9 and 12% (Charles et al., 2005; Shittu et al., 2007; Zvinavashe et al., 2011; Adugna, 2019). MC is an essential property in cassava flour storage and preservation, and flour with MC of >12% would promote the proliferation of microbes. It implies that low levels of MC in cassava flour elongate its shelf life (Alamu et al., 2017; Adugna, 2019). The breeder and consumer prefer cassava roots with high dry matter content (Ceballos et al., 2021). Thus, most of the GGA genotypes investigated in the present study showed a high average DM of 31.97 ± 2.41% and could be advanced to the released breeding stage. The pasting properties (peak, trough, breakdown, setback, and final viscosities) ranged from 140.36 to 570.93 RVU (mean 241.71 ± 38.17), 6.74–173.32 RVU (mean 96.65 ± 23.45), 66.97–482.35 RVU (mean 142.44 ± 30.16), 60.06–231.74RVU (mean 134.42 ± 30.52) and 5.22–135.69 RVU (mean 37.78 ± 12.96), respectively. However, the peak time and pasting temperature ranged between 3.27 and 5.95 min (mean 4.29 ± 0.30) and 59.72–83.71°C (mean 74.17 ± 3.34°C). Thus, the genotypes showed a high peak viscosity value and good peak time and pasting temperature. The pasting temperature indicated the minimum temperature required for flour cooking. Pasting properties are critical in utilizing and applying starch in making food products. The pasting characteristics of cassava flour play a key role in its cooking and baking quality determinations (Onyeneke, 2019). The peak viscosity of cassava flour is described as the ability of starch to swell freely that precedes the physical breakdown. It indicates the product's final quality (Alamu et al., 2017). However, applying a constant shearing (160 rpm) of the swollen starch granules and at a high temperature (95°C), the granules disrupt into small fragments and break into dispersed molecules. The process results in a decrease in viscosity, referred to as “breakdown” in the pasting profile. However, the trough viscosity is the minimum value at the pasting profile's constant temperature, indicating the paste's capacity to resist breaking down during cooling. The ability of the flour sample to form a gel while processed is measured by the final viscosity value and indicates the strength of the cooked paste (Sanni et al., 2006; Adeniji et al., 2010; Alamu et al., 2017). Most of the genotypes studied showed excellent DM and pasting characteristics that could be advanced for release as improved varieties.

Table 1. Descriptive statistics of the dry matter content (DMC) and pasting properties of cassava genotypes from the GGA trial by the growing locations.

Figure 2. Box plots and means chart for DM and pasting properties of GGA cassava genotypes from three locations (IVS, Mokwa Upland).

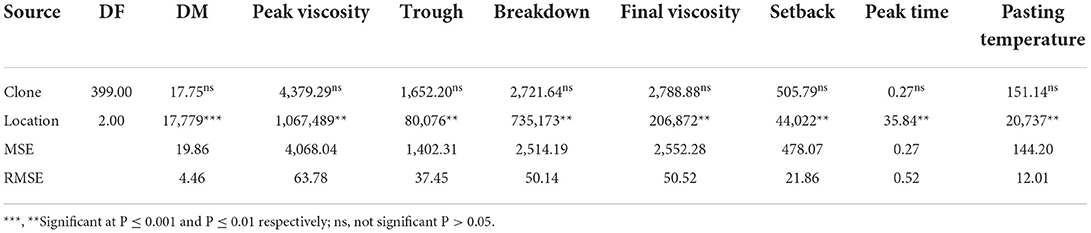

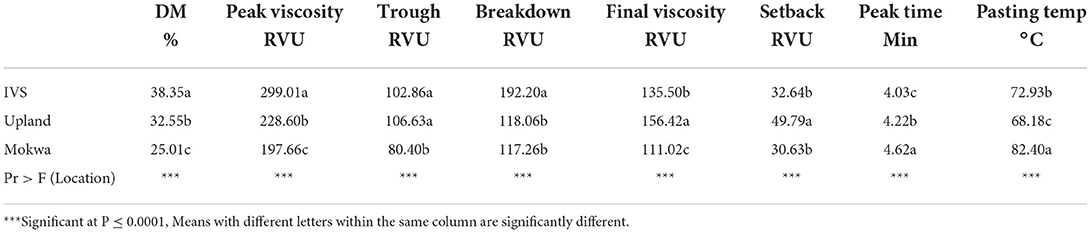

Table 2 shows the analysis of the variance of drymatter and pasting properties of cassava genotypes from GGA trails across the three locations. The genotypes had no significant effect (P > 0.05) on the DM and pasting properties, but the growing location showed a highly significant effect (P < 0.05) on all the parameters studied. Table 3 shows the means of the DM and pasting properties by location. There was a significant (P < 0.05) difference in the mean values for DM, peak viscosity, final viscosity, and peak time across the three locations. There were significant differences in the trough mean value for IVS and Upland genotypes and the breakdown mean value for Upland and Mokwa. However, the genotypes from the IVS location had the highest mean value for DM (38.35%), peak viscosity (299.01 RVU) and breakdown viscosity (192.20 RVU), followed by the upland genotypes. In contrast, the mean values of the trough (106.63 RVU), setback (49.79 RVU), and final viscosity (156.42 RVU) for genotypes from Upland were the highest. The excellent pasting values indicate the processing quality of the genotypes. However, genotypes from Mokwa had the lowest DM (25.01%) and pasting properties, except for the peak time (4.62 min) and pasting temperature (82.4°C), which were the highest. The lowest peak time and highest peak viscosity for genotypes from the IVS location showed the best quality as they achieved gelatinization within the shortest time. In comparison, genotypes from Mokwa showed the poorest quality because of the highest peak time and pasting temperature. It implies that these Mokwa's genotypes would take the longest time to cook and requires the highest energy. Genotype and environmental factors have influenced the pasting properties of cassava starch and flour (Sánchez et al., 2010; Gu et al., 2013; Zhang et al., 2020), as found in this study. Although, there was no significant effect (P > 0.05) of growing locations on the GGA cassava genotypes investigated in this study. It could be because the GGA trials used for this study comprised all genotypes selected up to the Uniform Yield Trial (UYT) breeding stage, categorized as an advanced breeding stage. Moreover, various studies reported that environmental conditions such as temperature, rainfall, and altitude influenced starch production and properties of cassava that controlled the cassava flour quality and pasting properties (Gu et al., 2013; Karlström et al., 2019; Mohan et al., 2019; Zhang et al., 2020). In a separate study, Zeeman et al. (2002) reported that factors such as season and location could impact the pasting behavior of rice flour. Knowing the impact of these factors on the pasting behavior could help the breeders select the best genotypes with excellent qualities that could adapt to different environments and identify the suitable growing location for the best cooking quality.

Table 2. Mean squares of the analysis of variance (ANOVA) of drymatter content (DMC) and pasting properties of cassava genotypes from the GGA trial.

Table 3. Means of the drymatter content (DMC) and pasting properties of cassava genotypes from GGA trial by the growing locations.

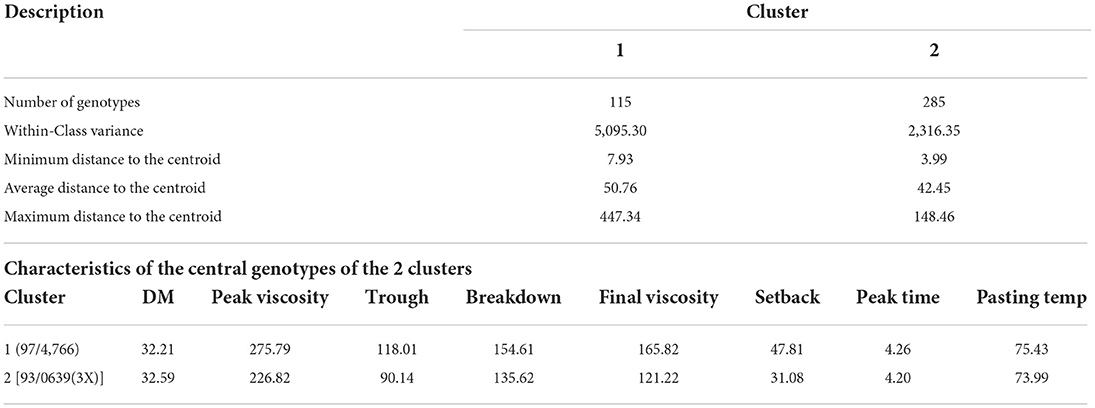

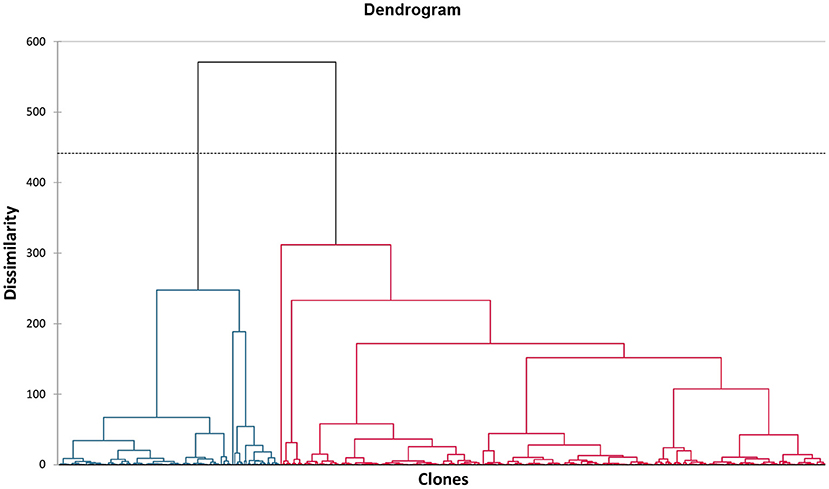

Table 4 and Figure 3 show the clusters of cassava genotypes from the Genetic Gain Assessment Trials across the location based on their dissimilarity for the DM and pasting properties studied. The cluster analysis grouped the genotypes into 2 clusters where clusters 1 and 2 had 115 and 285 genotypes, respectively. Euclidean distance for dissimilarity and Ward's method was used as the agglomeration method, and the variance explained by each trait is shown in Figure 3 (Alamu et al., 2021). The list of genotype names in each Cluster is presented in Supplementary Table 3. Figure 4 shows the profile of the two clusters. All genotypes in Cluster 1 had higher DM and pasting parameters than Cluster 2 genotypes, except for peak time and pasting temperature. All the genotypes in cluster 1 were better than those in cluster 2 regarding DM and pasting characteristics. Cluster 1 genotypes had lower peak time and pasting temperature, indicating the low cooking time and low energy required for cooking. It is imperative to note that the check (control) samples were grouped into cluster 1, and it implies that all the genotypes found in cluster 1 are compared favorably with the famous landrace (TME 1) and improved and officially released varieties (91/02324 and 30,572). Also, the central genotype 97/4,766 for cluster 1 had higher pasting properties than the central genotype 93/0639(3X) for cluster 2. However, both central genotypes had similar dry matter content above 32%. It shows that genotypes with excellent cooking and pasting properties should be from Cluster 1, although they had the lowest number of genotypes (115). The dendrogram depicts noticeable dissimilarities/differences among genotypes in clusters 1 and 2 (Figure 2).

Table 4. Cluster analysis of cassava genotypes from Genetic Gain Assessment trials across locations.

Figure 3. Dendrogram (Ward's minimum variance clusters) from the cluster analysis of GGA cassava genotypes across three locations (IVS, Mokwa Upland).

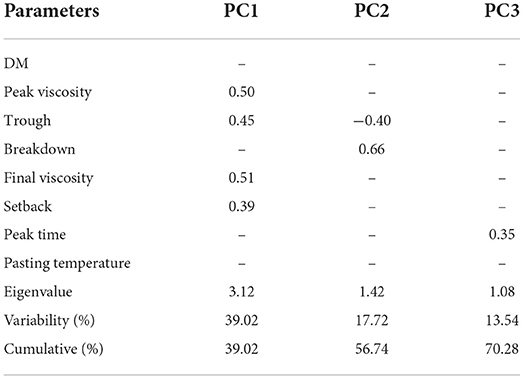

The principal component analysis of the DM and pasting properties of the cassava genotypes from the GGA trials across the growing locations were presented in Table 5. The Eigenvalues ≤ 1.08 were selected as the logical cut-off to identify the essential axis that explains the dataset's variation, and 0.35 for the eigenvector. With this in view, the first three axes were selected, and the three of them accounted for 70.28% of the total variation (PC1 = 39.02%, PC2 = 17.72% and PC3 = 13.54%). With this cut-off, the trait interpretation will be based on the first PC1, PC2, and PC3 with eigenvalues of 3.12, 1.42, and 1.08, respectively. The peak viscosity, trough, final viscosity, and setback were loaded on PC 1 and positively correlated. However, the trough and breakdown were loaded on the PC2, but the trough is negatively correlated with the breakdown. DM, peak time and pasting temperature were loaded on the PC3, and they were all positively correlated. However, final viscosity had the highest eigenvector of 0.51 on PC1 and setback had the lowest (0.39) on PC1. For PC2, the breakdown had the highest vector (0.66) and trough with the lowest (-0.40). Also, pasting temperature showed the highest vector (0.74) and peak time the lowest (0.35) for PC3. It implies that final viscosity, breakdown and pasting temperature showed the strongest strength for PC1, PC2, and PC3. Also, the variations observed within the dataset were driven by PC1 parameters (peak viscosity, trough, final viscosity, and setback) that accounted for 39% of the total variation (71%).

Table 5. Principal component analysis of cassava genotypes from Genetic Gain Assessment trials across growing locations.

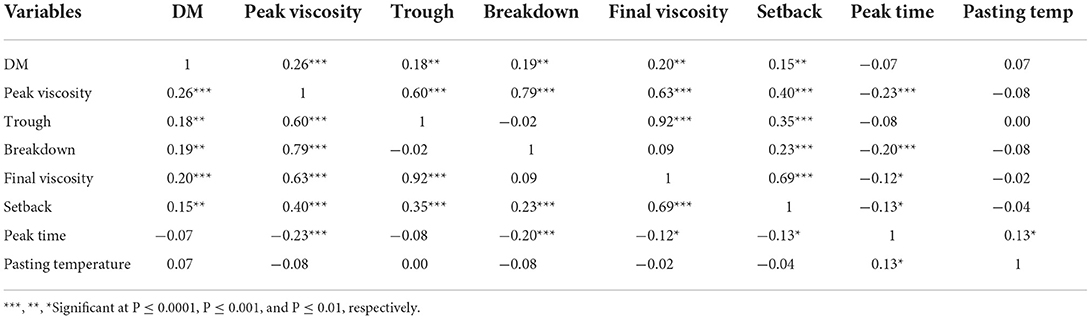

Table 6 shows the Pearson correlation coefficients of dry matter content (DM) and pasting properties of cassava genotypes from GGA trials grown in different locations. There were strong significant (P < 0.001) but weak and positive correlations between DM and pasting properties except for the peak time (r = −0.07) and pasting temperature (r = 0.07), which was non-significant(P > 0.05) with a very low correlation. It implies that high DM means high pasting properties, and thus, breeders can use DM to select genotypes with good pasting characteristics except for peak time and pasting temperature. Peak viscosity had significant (P < 0.0001), positive, strong correlations between the trough (r = 0.60), breakdown(r = 0.79), final viscosity (r = 0.63), and setback (r = 0.40) but showed negative correlation with peak time (P < 0.0001, r = −0.23) and pasting temperature (P > 0.05, r = −0.08). Thus, peak viscosity could describe other pasting properties except pasting temperature. Pasting temperature showed low non-significant (P > 0.05) and negative correlations with other pasting properties except peak time (P < 0.01, r = 0.13).

Table 6. Correlation matrix (Pearson) of dry matter content (DM) and pasting properties of cassava genotypes from GGA trials.

This observation looks logical that the higher the time required to cook the sample, the higher the energy required. DM could be a valuable parameter for selecting the genotype directly with suitable peak viscosity. Because of the correlation of peak viscosity with other pasting properties (such as trough, breakdown, and final viscosity), DM could be indirectly used for these properties.

This study provides information on the dry matter content and the pasting characteristics of cassava genotypes evaluated under the GGA trials in different growing environments. Thus, most of the GGA genotypes studied showed a high DM and excellent pasting features that could be advanced for release as improved varieties. The genotypes had no significant impact on the DM and pasting properties, but growing location influenced the DM content and the pasting behavior. The genotypes from the IVS location had the best pasting properties, but genotypes from Mokwa showed the poorest quality. Knowing the impact of these factors (genotypes and growing location) on the pasting behavior could help the breeders select the best genotypes with excellent attributes that could adapt to different environments and identify the suitable growing area for the best cooking quality. The check (control) samples were grouped into cluster 1, and it implies that all the genotypes found in cluster 1 are compared favorably with the famous landrace (TME 1) and improved and officially released varieties (91/02324 and 30,572). DM can be a parameter to select a genotype with suitable peak viscosity directly and indirectly for other pasting properties (trough, breakdown, and final viscosity). However, for future study will include to investigate the effects of different agronomic practices on the pasting properties of selected varieties. The limitations of this study include inability to collect soil samples and detailed weather information during the planting of the trials.

Moreover, one of the critical goals of any crop breeding program is to obtain high rates of genetic gain for traits of interest while maintaining genetic diversity to sustain a high adoption rate of improved varieties by the end users. The breeding program, generally in recent times, is aligning its breeding objectives to include key quality traits that drive the acceptability and adoption of new varieties. Understanding the preferences of the consumers or farmers is an important stage for breeders to guide decisions on the quality attributes to integrate into other agronomics traits. Consumers have specific quality traits that influence their acceptability and adoption of new varieties. These traits are linked to the final food product qualities, such as the texture and cooking quality of the product. Some biochemical characteristics are related to these attributes, such as the pasting properties of the crop. It is recommended that breeders put all efforts into integrating quality traits into their breeding objectives and screen for quality traits during their early-stage selections.

The original data contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

EA conceived and drafted the paper. EA and BM-D were involved with laboratory analysis, data cleaning, analysis, and interpretation. AD and BM-D provided the resources. EA, AD, and BM-D contributed to the manuscript by performing a critical interpretation of results and finalized the paper. All authors read and approved the manuscript and were aware of its submission.

This research and the APC were funded by the CGIAR Research Program on Roots, Tubers, and Bananas (RTB) and the Bill & Melinda Gates Foundation (BMGF) through OPP1019962.

The authors acknowledged the support from the HarvestPlus, CGIAR Research Program on Roots, Tubers, and Bananas (RTB), the entire staff of Food and Nutrition Sciences Laboratory, and the Cassava Breeding Unit, IITA, Ibadan, Nigeria, especially Peter Kulakow (PhD) and Parkes Elizabeth (PhD).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2022.1012410/full#supplementary-material

Addinsoft (2021). XLSTAT Statistical and Data Analysis Solution. New York, NY. Available online at: https://www.xlstat.com/en (accessed February 11, 2022).

Adegunwa, M. O., Sanni, L. O., and Maziya-Dixon, B. (2011). Effects of fermentation length and varieties on the pasting properties of sour cassava starch. Afr. J. Biotechnol. 10, 8428–8433. doi: 10.5897/AJB10.1711

Adeniji, T. A., Hart, A. D., Tenkouano, A., Barimakg, I. S., and Sanni, L. O. (2010). Comparative study of pasting properties of improved plantain, banana and cassava varieties with emphasis on industrial application. Afr. J. Food Agric. Nutr. Dev. 10. doi: 10.4314/ajfand.v10i5.56342

Adugna, B. (2019). Review on nutritional value of cassava for use as a staple food. Sci. J. Anal. Chem. 7, 83–91. doi: 10.11648/j.sjac.20190704.12

Alamu, E. O., Maziya-Dixon, B., and Dixon, G. A. (2017). Evaluation of proximate composition and pasting properties of high-quality cassava flour (HQCF) from cassava genotypes (Manihot esculenta Crantz) of β-carotene-enriched roots. LWT Food Sci. Technol. 86, 501–506. doi: 10.1016/j.lwt.2017.08.040

Alamu, E. O., Maziya-Dixon, B., Lawal, O., and Dixon, G. A. (2021). Assessment of chemical properties of yellow-fleshed cassava (Manihot esculenta) roots as affected by genotypes and growing environments. AGRIVITA J. Agric. Sci. 43, 409–421. doi: 10.17503/agrivita.v43i2.2804

Andrade, L. R. B., Sousa, M. B., Oliveira, E. J., Resende, M. D. V., and Azevedo, C. F. (2019). Cassava yield traits predicted by genomic selection methods. PLoS ONE 14, e0224920. doi: 10.1371/journal.pone.0224920

AOAC. (2006). Official Methods of Analysis. 18th Edn. Washington, DC: Association of Official Analytical Chemists.

Ceballos, H., Hershey, C., Iglesias, C., and Zhang, X. (2021). Fifty years of a public cassava breeding program: evolution of breeding objectives, methods, and decision-making processes. Theor. Appl. Genet. 134, 2335–2353. doi: 10.1007/s00122-021-03852-9

Ceballos, H., Iglesias, C. A., Pérez, J. C., and Dixon, A. G. O. (2004). Cassava breeding: opportunities and challenges. Plant Mol. Biol. 56, 503–516. doi: 10.1007/s11103-004-5010-5

Ceballos, H., Sánchez, T., Denyer, K., Tofiño, A. P., Rosero, E. A., Dufour, D., et al. (2007). Induction and identification of a small-granule, high-amylose mutant in cassava (Manihot esculenta Crantz). J. Agric. Food Chem. 56, 7215–7222. doi: 10.1021/jf800603p

Charles, A. L., Sriroth, K., and Huang, T. C. (2005). Proximate composition, mineral contents, hydrogen cyanide and phytic acid of five cassava genotypes. Food Chem. 92, 615–620. doi: 10.1016/j.foodchem.2004.08.024

Cobb, J. N., Juma, R. U., Biswas, P. S., Arbelaez, J. D., Rutkoski, J., Atlin, G., et al. (2019). Enhancing the rate of genetic gain in public-sector plant breeding programs: lessons from the breeder's equation. Theoretical and Applied Genetics 132, 627–645. doi: 10.1007/s00122-019-03317-0

Godswill, C., Somtochukwu, V., and Kate, C. (2019). The functional properties of foods and flours. Int. J. Adv. Acad. Res. Sci. 5, 2488–9849.

Gu, B., Yao, Q., Li, K., and Chen, S. (2013). Change in physicochemical traits of cassava roots and starches associated with genotypes and environmental factors. Starch-Stärke 65, 253–263. doi: 10.1002/star.201200028

Hahn, S. K. (1987). An overview of traditional processing and utilization of cassava in Africa. Outlook Agri. 18, 110–118. doi: 10.1177/003072708901800303

Iwe, M. O., Michael, N., Madu, N. E., Obasi, N. E., Onwuka, G. I., et al. (2017). Physicochemical and pasting properties high quality cassava flour (HQCF) and wheat flour blends. Agrotechnology 6, 167. doi: 10.4172/2168-9881.1000167

Karlström, A., Belalcazar, J., Sánchez, T., Lenis, J. I., Moreno, J. L., Pizarro, M., et al. (2019). Impact of environment and genotype-by-environment interaction on functional properties of amylose-free and wildtype cassava starches. Starch-Stärke 71, 1700278. doi: 10.1002/star.201700278

Maziya-Dixon, B., Adebowale, A. A., Onabanjo, O. O., and Dixon, A. G. O. (2005). Effect of variety and drying methods on physico-chemical properties of high quality cassava flour from yellow cassava roots. Afr. Crop. Sci. Conf. Proc. 7, 635–641.

Mohan, G., Raju, J., Shiny, R., Abhilash, P. V., and Soumya, S. (2019). Biochemical, mineral and proximate composition of Indian cassava varieties Biochemical, mineral and proximate composition of Indian cassava varieties. Int. J. Chem. Stud. 7, 1059–1065.

Montagnac, J. A., Davis, C. R., and Tanumihardjo, S. A. (2009). Nutritional value of cassava for use as a staple food and recent advances for improvement. Comprehen. Rev. Food Sci. Food Saf. 8, 181–194. doi: 10.1111/j.1541-4337.2009.00077.x

Onyeneke, E.-B. (2019). Functional and pasting properties of products of white and yellow cassava. J. Agric. 17. doi: 10.4314/jafs.v17i1.1

Sabitha, S., Byiu, G., and Sreekumar, J. (2016). Projected changes in mean temperature and total precipitation and climate suitability of cassava (Manihot esculenta Crantz) in major growing environment of India. Indian J. Agric. Sci. 86, 647–653.

Sánchez, T., Dufour, D., Moreno, I. X., and Ceballos, H. (2010). Comparison of pasting and gel stabilities of waxy and normal starches from potato, maize, and rice with those of a novel waxy cassava starch under thermal, chemical, and mechanical stress. J. Agric. Food Chem. 58, 5093–5099. doi: 10.1021/jf1001606

Sánchez, T., Salcedo, E., Ceballos, H., Dufour, D., Mafl a, G., Morante, N., et al. (2009). Screening of starch quality traits in cassava (Manihot esculenta Crantz). Starch 61, 12–19. doi: 10.1002/star.200800058

Santisopasri, V., Kurotjanawong, K., Chotineeranat, S., Piyachomkwan, K., Sriroth, K., and Oates, C. G. (2001). Impact of water stress on yield and quality of cassava starch. Ind Crops Prod. 13, 115–29. doi: 10.1016/S0926-6690(00)00058-3

Sayre, R., Beeching, J. R., Cahoon, E. B., Egesi, C., Fauquet, C., Fellman, J., et al. (2011). The BioCassava plus program: biofortification of cassava for sub-Saharan Africa. Annu. Rev. Plant Biol. 62, 251–272. doi: 10.1146/annurev-arplant-042110-103751

Shittu, T. A., Sanni, L. O., Awonorin, S. O., Maziya-Dixon, B., and Dixon, A. (2007). Use of multivariate techniques in studying the flour making properties of some CMD resistant cassava clones. Food Chem. 101, 1606–1615. doi: 10.1016/j.foodchem.2006.04.017

Solomon, O. E., and Okedo-Okojie, D. (2016). Economics of cassava farmers' adoption of improved varieties in Isoko North lga, Delta State. J. Agric. Food Sci. 14. doi: 10.4314/jafs.v14i1.4

Zeeman, S., Tiessen, A., Pilling, E., Kato, L., Donald, A., and Smith, A. (2002). Starch synthesis in arabidopsis. Granule synthesis, composition, and structure. Plant Physiol 129,516–529.

Zhang, Y., Nie, L., Sun, J., Hong, Y., Yan, H., Li, M., et al. (2020). Impacts of environmental factors on pasting properties of cassava flour mediated by its macronutrients. Front. Nutr. 7, 598960. doi: 10.3389/fnut.2020.598960

Zvinavashe, E., Elbersen, H. W., Slingerland, M., Kolijn, S., and Sanders, J. P. M. (2011). Cassava for food and energy: exploring potential benefits of processing of cassava into cassava flour and bio-energy at farmstead and community levels in rural mozambique: biofuels, bioproducts and biorefining. J. Dairy Sci. 11, 3405–3415. doi: 10.1002/bbb.272

Keywords: cassava roots, genotypes, dry matter, pasting properties, cooking quality

Citation: Alamu EO, Maziya-Dixon B and Dixon AG (2022) Evaluation of the pasting characteristics of cassava roots grown in different locations in Nigeria from the Genetic Gain Assessment trial. Front. Sustain. Food Syst. 6:1012410. doi: 10.3389/fsufs.2022.1012410

Received: 05 August 2022; Accepted: 14 October 2022;

Published: 28 October 2022.

Edited by:

Samuel Ayofemi Olalekan Adeyeye, Hindustan University, IndiaReviewed by:

Emmanuel Amagu Echiegu, University of Nigeria, Nsukka, NigeriaCopyright © 2022 Alamu, Maziya-Dixon and Dixon. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Emmanuel Oladeji Alamu, oalamu@cgiar.org

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.