94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci., 15 January 2025

Sec. Geochemistry

Volume 12 - 2024 | https://doi.org/10.3389/feart.2024.1525983

This article is part of the Research TopicShale Oil Micro-Migration and Its Effect on Shale Oil Differential EnrichmentView all 7 articles

Wenjun He1

Wenjun He1 Zhiming Li2,3,4*

Zhiming Li2,3,4* Changrong Li3,5

Changrong Li3,5 Jinyi He2,3,4

Jinyi He2,3,4 Junying Leng2,3,4

Junying Leng2,3,4 Zhongliang Sun2,3,4

Zhongliang Sun2,3,4 Deguang Liu1

Deguang Liu1 Sen Yang1

Sen Yang1Hydrocarbon generation patterns are crucial for defining favorable exploration maturity intervals and targets for shale oil. The Permian Fengcheng shale and Lucaogou shale in the Junggar Basin, as significant targets for shale oil exploration, study on their hydrocarbon generation, expulsion, and retention characteristics are insufficient. This study establishes hydrocarbon generation patterns for the Fengcheng shale and Lucaogou shale using a semi-open thermal simulation system, combined with rock pyrolysis, vitrinite reflectance (Ro), total organic carbon (TOC) analysis, carbon isotope analysis, gas chromatography-mass spectrometry (GC-MS), mercury porosimetry, and nitrogen adsorption. Additionally, a multivariate regression model was employed to systematically evaluate the primary controlling factors of hydrocarbon expulsion ratio. Based on these results, favorable exploration maturity intervals and targets for the Fengcheng shale and Lucaogou shale were identified. The results indicate that the hydrocarbon generation potential of Fengcheng shale was superior to that of Lucaogou shale, whether considering gas yield or oil yield. However, Lucaogou shale began the thermal degradation earlier than Fengcheng shale and has a broader degradation window. The corresponding (TR) is slightly higher for Fengcheng shale. The Lucaogou shale exhibited significantly higher hydrocarbon expulsion ratios compared to Fengcheng shale, with a maximum hydrocarbon expulsion ratio 2.1 times that of Fengcheng shale. Mesopore volume and its connectivity were critical factors affecting the hydrocarbon expulsion ratio, whereas oil mobility and macropore volume have relatively limited effects. The optimal maturity interval for shale oil exploration as Ro = 1.0%–1.1% for the Fengcheng shale and Ro = 0.9%–1.1% for the Lucaogou shale. Exploration of the Fengcheng shale should focus on lithofacies assemblages, the dolomitic mixed rock-shale assemblages in the shore-shallow lake facies represent the primary exploration target. Exploration of the Lucaogou shale should focus on source-reservoir assemblages, with a higher reservoir-to-shale thickness ratio being the primary exploration target. These findings provide support for the exploration and development decisions of shale oil in the Junggar Basin.

Shale oil have emerged as a global hotspot for unconventional hydrocarbon exploration and development, attracting widespread attention from petroleum geologists. China has made significant progress in shale oil exploration in several lacustrine sedimentary basins, including the Junggar Basin, Ordos Basin, Bohai Bay Basin, Songliao Basin, and Subei Basin (Hackley and Cardott, 2016; Zhao et al., 2020; Zou et al., 2019; Hu et al., 2024a; Feng et al., 2023). The Mahu Sag and Jimusar Sag, as important petroliferous sags in the Junggar Basin, have made significant breakthroughs in Permian shale oil exploration (Gong et al., 2024). Among them, the Lucaogou Formation shale oil in the Jimusar Sag has established the first national-level lacustrine shale oil demonstration zone in China, with estimated resources of 11.12 × 108 t (Tang et al., 2023). Multiple exploration wells in the Fengcheng Formation of the Mahu Sag have obtained industrial oil flow with a daily output exceeding 100 t, demonstrating its huge potential for shale oil exploration and development (Tang et al., 2021).

Previous research indicates that both the Mahu Sag and Jimsar Sag are saline sub-basins with hydrocarbon source rocks primarily composed of fungi and algae, with cyanobacteria development being distinctive compared to other saline lake basins (Cao et al., 2015). Although the source rocks of the Fengcheng shale and Lucaogou shale are similar, they exhibit marked differences in hydrocarbon generation characteristics and oil content (Zhang et al., 2019). The Fengcheng shale has a relatively low TOC content (approximately 1%) and a hydrocarbon generation potential of about 6 mg HC/g Rock (Dongming et al., 2021). In contrast, the Lucaogou shale has a higher TOC content (exceeding 3%) and a hydrocarbon generation potential greater than 20 mg HC/g TOC. Both shales show extensive lateral continuity in oil distribution (Zhi et al., 2019). However, the Fengcheng shale exhibits vertical continuity, whereas the Lucaogou shale contains two distinct “sweet spot” intervals vertically (Wang et al., 2014). Additionally, the reservoir characteristics of the Fengcheng shale and Lucaogou shale differ. The Fengcheng shale has a high carbonate mineral content, with pore throat radii primarily ranging from 0.01 to 10 μm and an average porosity of approximately 3.3% (Tang et al., 2023). Conversely, the Lucaogou shale has a higher clay mineral content, with pore throat radii ranging from 10 to 100 μm and an average porosity exceeding 9% (Ma et al., 2022). Overall, the differences in source-reservoir characteristics between the Fengcheng and Lucaogou shales are significant. As the source-reservoir assemblage is a critical factor affecting the generation, expulsion, and retention of shale oil (Jia et al., 2014; Schimmelmann et al., 2001; Shao et al., 2020), understanding the hydrocarbon generation and expulsion characteristics of the two set shales is essential for elucidating the enrichment mechanisms and identifying favorable exploration targets in the Junggar Basin.

Thermal simulation experiment is a critical method for studying the generation, expulsion, and retention characteristics of shale oil and have been widely utilized (Zhang C et al., 2022). Combined with basin modeling, these experimental results can be applied to geological conditions to guide shale oil exploration. In this study, we employed a self-developed semi-open thermal simulation apparatus, integrated with various analytical techniques including rock pyrolysis, vitrinite reflectance, total organic carbon (TOC) analysis, carbon isotope analysis, gas chromatography-mass spectrometry (GC-MS), mercury porosimetry, and nitrogen adsorption. The objectives of this study are to (1) determine the TR, product yields, composition, carbon isotopic characteristics, and variations in porosity and morphology for the Fengcheng shale and Lucaogou shale; (2) develop hydrocarbon generation patterns for the Fengcheng shale and Lucaogou shale; (3) identify the differences in hydrocarbon expulsion ratios and controlling factors between the Fengcheng shale and Lucaogou shale; (4) optimize favorable exploration maturity intervals and targets. These findings provide support for the exploration and development decisions of shale oil in the Junggar Basin.

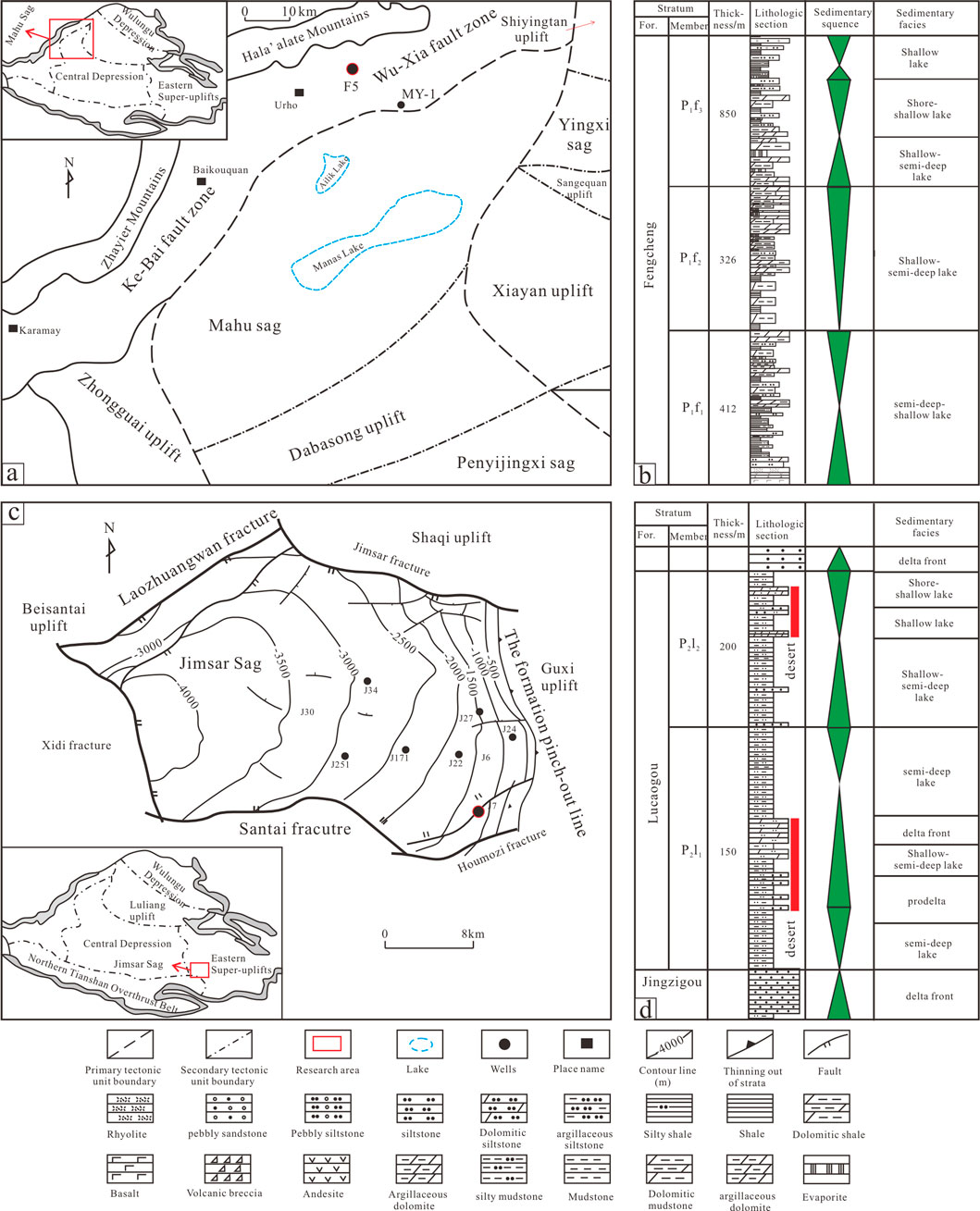

During the Permian, the Junggar Basin developed a complex set of saline lacustrine deposits, which have been confirmed as the main source rocks of the basin (Zhang Y et al., 2022). The Mahu Depression, located in the northwest of the Junggar Basin, covers an area of approximately 5,000 km2 (Jiang et al., 2023) and is classified as a sub-basin with high salinity lacustrine environments influenced by terrigenous freshwater inputs (Fang et al., 2006) (Figure 1A). The depression undergone five evolutionary stages: initial lake development, lake expansion, lake contraction, formation of alkaline lakes, and further lake expansion (Xiao et al., 2021). During the deposition of the Fengcheng Formation (P1f), a fan delta-lacustrine depositional system developed and is further divided into three members (Zhang et al., 2018) (Figure 1B). During the deposition of the first member (P1f1), frequent volcanic activity provided a rich source of organic matter for hydrocarbon generation. During the deposition of the second member (P1f2), the paleoclimate changed to arid and hot, increasing lake salinity and resulting in the formation of dolomitic shales and alkaline minerals such as calcite and nahcolite. During the deposition of the third member (P1f3), the paleoclimate changed to more humid, leading to the development of thick, high-quality shales interbedded with siltstone (Gong et al., 2024).

Figure 1. Geological structure map with well locations, depositional environments, and stratigraphic columns. (A,B) Fengcheng Formation; (C,D) Lucaogou Formation modified from Du et al. (2023), Zhang et al. (2018).

The Jimsar Depression, located in the eastern part of the Junggar Basin, covers an area of 1,278 km2 (Hou et al., 2021) and was a relatively isolated sub-basin formed in the late Middle Permian with high water salinity (Liang et al., 2023). The Jimsar Depression undergone multiple tectonic movements, bounded by faults in the west and overlapping in the east (Figure 1C). The Lucaogou Formation (P2l) primarily developed a lacustrine-delta depositional system and was the main source rock in the Jimsar Depression, with sediment thickness reaching up to 5,000 m in the depositional center (Tang et al., 2024). The P2l was further divided into two members: the first member of Lucaogou Formation (P2l1) and the second member of Lucaogou Formation (P2l2), with sediments mainly comprising siltstone, shale, and carbonates (Figure 1D). Drilling results indicated that the Lucaogou Formation includes two shale oil-rich intervals (Lai et al., 2023). The upper sweet spot was characterized by dolomite with minor siltstone interlayers, while the lower sweet spot features interbedded dolomite and siltstone (Guo et al., 2019).

Despite the heterogeneity of shale, the type of organic matter within the same shale formation is relatively consistent. Selecting low-maturity shale samples for thermal simulation experiments is a widely utilized method to reveal the complete process of hydrocarbon generation from organic matter (Hu et al., 2024b). The shales in the northern margin of the Mahu Depression and the southeastern margin of the Jimusar Depression were relatively shallowly buried and exhibited low maturity. Drilling results indicate that the shales in well F5 and well J7 are well-developed with similar thermal evolution context, making them optimize choices for thermal simulation studies (Figure 1).

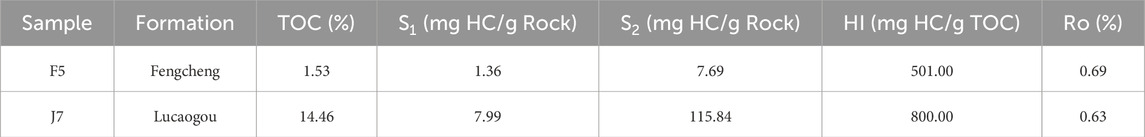

The vitrinite reflectance (Ro) values for the Fengcheng shale and Lucaogou shale samples were 0.69% and 0.63%, respectively, indicating low maturity shale. Both Fengcheng shale and Lucaogou shale were high quality shale with type I kerogen (Du et al., 2023). The basic geochemical information of the samples is presented in Table 1. A total of ∼700 g of samples was used in this study, with each pyrolysis experiment utilizing ∼80 g of samples. To avoid the impact of heterogeneity caused by interbedded organic-rich and organic-poor layers on the hydrocarbon generation and expulsion characteristics of the shale, ∼0.5 cm diameter particulate samples were used instead of powdered samples.

Table 1. Geochemical information of the Fengcheng and Lucaogou shale, including rock-eval pyrolysis, TOC, and Ro.

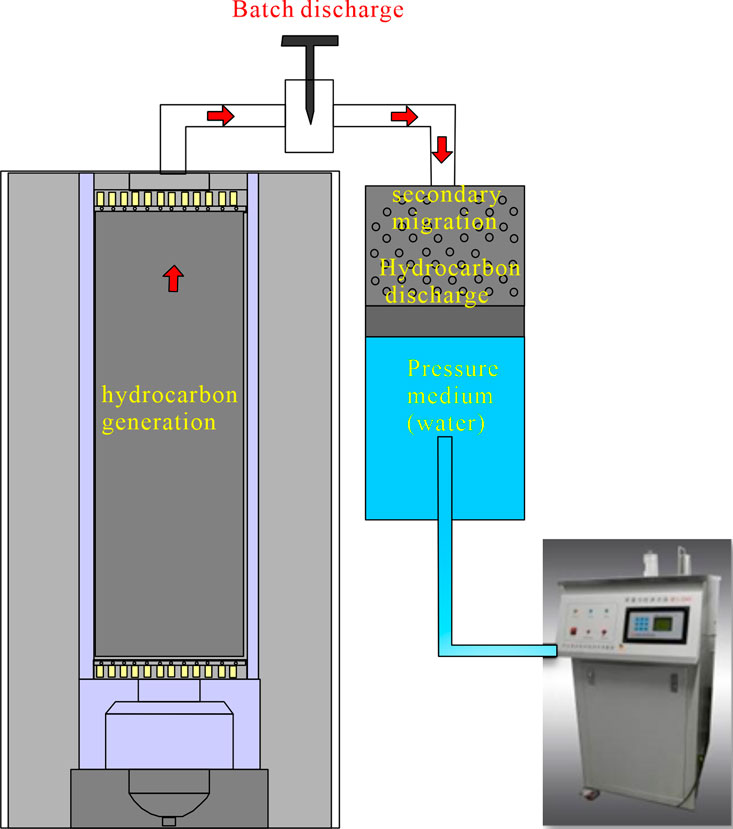

To simulate the hydrocarbon generation, expulsion, and retention evolution of shale under geological conditions, semi-open system pyrolysis experiments were conducted using a formation pore thermo-pressurized hydrocarbon generation simulator IV, independently developed by the Wuxi Petroleum Geology Institute of the Sinopec Exploration and Production Research Institute. The apparatus consists mainly of a high-temperature high-pressure reactor, a pressure-boosting system, and a product collection system (Figure 2). The specific operational procedure includes: (1) loading the shale sample (∼80 g) into the reactor and injecting deionized water to pressurize to the target simulated formation pressure; (2) rapidly heating the system to the target simulated formation temperature and maintaining for 48 h; (3) quickly cooling the reaction system to room temperature and collecting the gas and oil. The mixed products pass through a liquid nitrogen-cooled separator, where the gas is collected in a gas metering tube and the expelled oil is frozen in a liquid collection tube. Subsequently, dichloromethane is used to extract the residual oil from the pyrolyzed shale sample. Finally, the pyrolyzed shale sample is dried, weighed, and sealed for subsequent experimental analysis.

Figure 2. Schematic diagram of formation pore thermo-pressurized hydrocarbon generation simulator IV, showing experiment procedure.

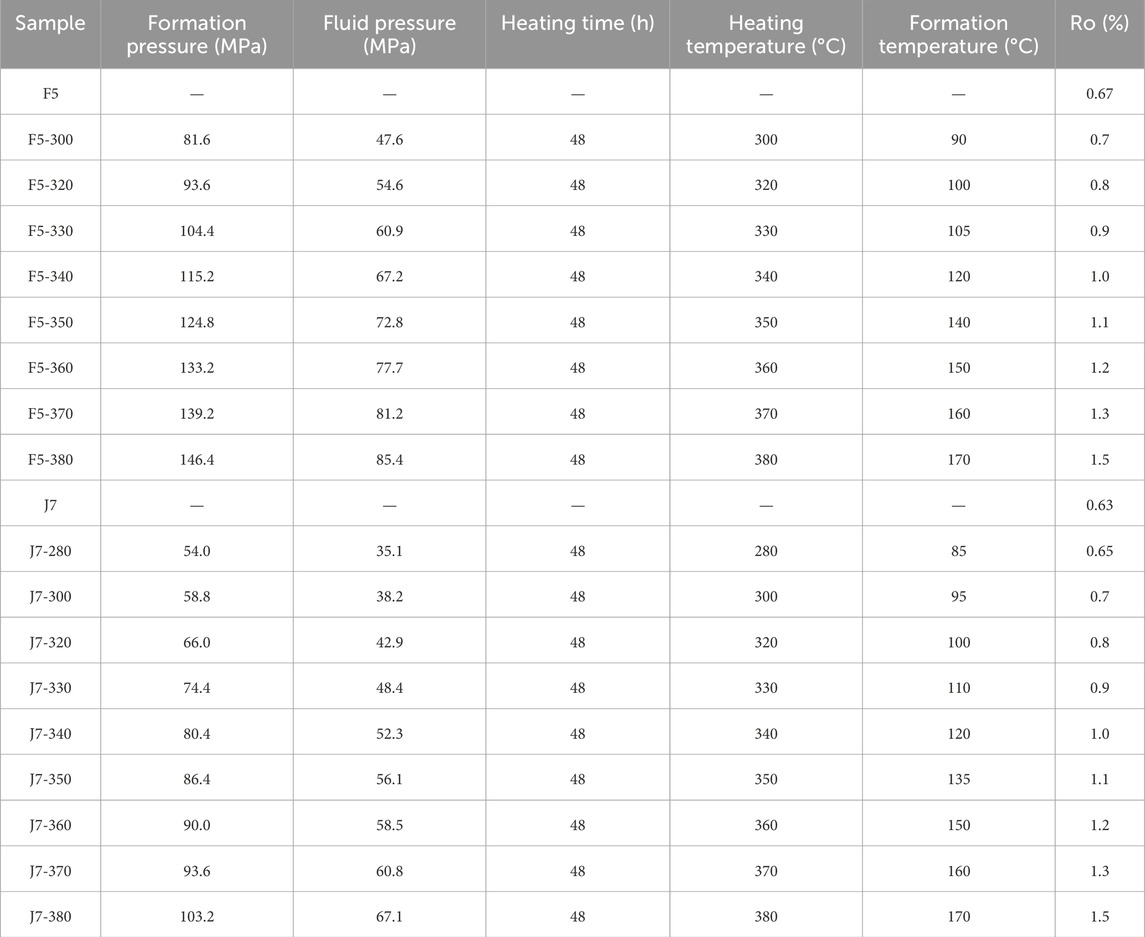

Based on the basin modelling results from the Mahu Depression and Jimsar Depression, the burial history and thermal history of the typical MY1 well and J10025 well penetrated the Fengcheng Formation and Lucaogou Formation were selected to design 8 and 9 sets of pyrolysis experimental parameters for the Fengcheng shale and Lucaogou shale, respectively (Ref.). These parameters included temperature, fluid pressure, and Formation pressure (Table 2). This study systematically characterized the yield and composition of the products from each pyrolysis experiment, carbon isotope characteristics, shale reservoir morphology, and pore physical properties.

Table 2. Thermal simulation experimental parameters of the Fengcheng and Lucaogou shale, including heating temperature, fluid pressure, and formation pressure.

To avoid the loss of light hydrocarbons, the shale was crushed to 100 mesh under liquid nitrogen cooling and then analyzed using the Rock-Eval VI instrument, although some loss of light hydrocarbons during the waiting time in the analysis was unavoidable. Total organic carbon (TOC) of the shale was analyzed using the LECO CS230 carbon/sulfur analyzer. Inorganic carbon in the shale was removed with 5% HCl prior to analysis. Kerogen was separated using HCl and HF (Durand and Nicaise, 1980), and the Ro values were measured with a Leica DM4500P polarized microscope equipped with a photometer. The oil SARA (saturates, aromatics, resins, and asphaltenes) fractions were separated using column chromatography (Ogbonnaya et al., 2024) and quantified with an XP205 balance. Gas components were analyzed using an Agilent 7890-5975C gas chromatograph equipped with an HP-5MS fused silica capillary column (60 m × 0.25 mm × 0.25 μm) and helium as the carrier gas at a flow rate of 1 mL/min. Saturated and aromatic hydrocarbons in the shale oil were analyzed using a tandem TSQ8000 Evo mass spectrometer, with ion peaks identified and quantified using Agilent ChemStation® software. The carbon isotopes of gas and oil SARA fractions were analyzed using a Thermo Delta V Advantage stable carbon isotope ratio mass spectrometer, with m/z peak heights below 204 mV. The micropores, mesopores, and macropores of the shale was determined using a combination of an Autopro 9,520 high-pressure mercury intrusion porosimeter and an ASAP 2460 adsorption analyzer. The porosity of the shale was measured using a QK-98 gas porosimeter. After argon ion polishing, the surface morphology and pore characteristics of the shale samples were observed using a Helios 650 focused ion beam scanning electron microscope.

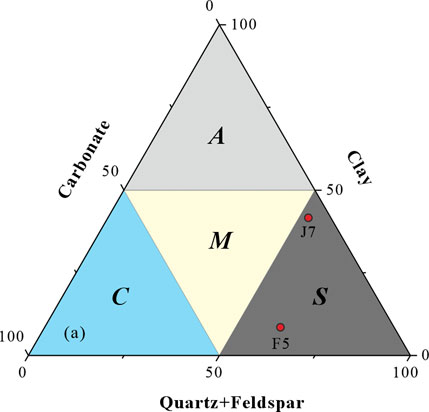

XRD analysis indicates that both Fengcheng shale and Lucaogou shale were the felsic lithofacies, with quartz and feldspar relative abundances exceeding 50%. However, Fengcheng shale is characterized by a high carbonate mineral content, predominantly dolomite (28.2%), whereas Lucaogou shale is characterized by a high clay mineral content, comprising 39.3% (Figure 3).

Figure 3. Lithofacies and mineral composition of Fengcheng shale and Lucaogou shale. A represents clay lithofacies, C represents carbonate lithofacies, S represents felsic lithofacies, and M represents mixed lithofacies.

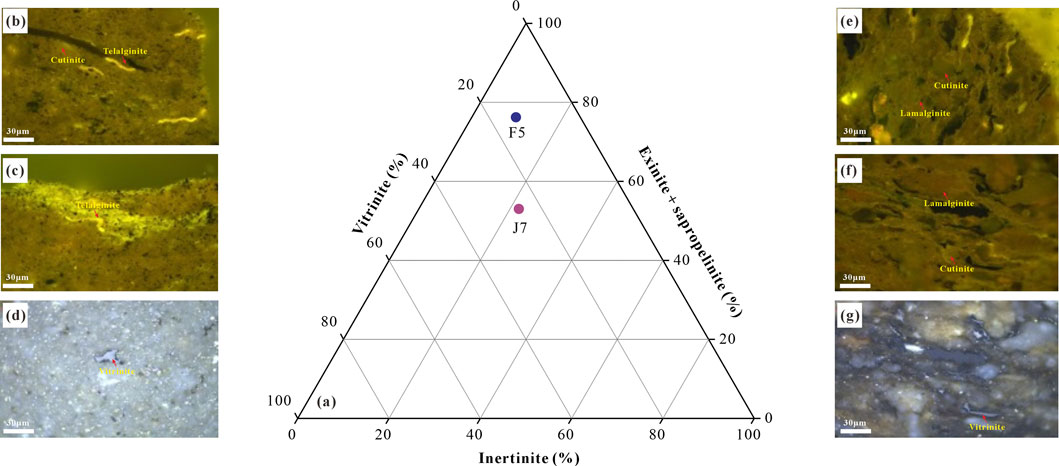

Organic petrology shows that the microscopic components of organic matter in both Fengcheng shale and Lucaogou shale were mainly composed of exinite and sapropelinite (Figure 4A). In comparison, Fengcheng shale featured telalginite and cutinize exhibiting yellow fluorescence (Figures 4B, C), while Lucaogou shale featured lamalginite and cutinize and spores with yellow fluorescence, as well as high contents of cutinite and funginite (Figures 4E, F). Additionally, the vitrinite group in both Fengcheng shale and Lucaogou shale is primarily composed of detrital vitrinite (Figures 4D, G). The TOC values of Fengcheng shale and Lucaogou shale are 1.53% and 14.46%, respectively, with HI values of 501.00 mg HC/g TOC and 800.00 mg HC/g TOC (Table 1), classified as high-quality shale (Welte and Tissot, 1984). Based on organic petrology and pyrolysis results, the organic matter in Fengcheng shale was type II1, whereas that in Lucaogou Shale was type I (Chen et al., 2017).

Figure 4. Organic petrology and microscopic components of Fengcheng shale and Lucaogou shale. (A) ternary diagram showing the relative abundance of microscopic components (B–D) show the organic petrology characteristics of Fengcheng shale, with telalginite and cutinize exhibiting yellow fluorescence, while vitrinite exhibiting gray under white reflected light; (E–G) show the organic petrology characteristics of Lucaogou shale, with lamalginite and cutinize exhibiting yellow fluorescence, while vitrinite exhibiting gray under white reflected light.

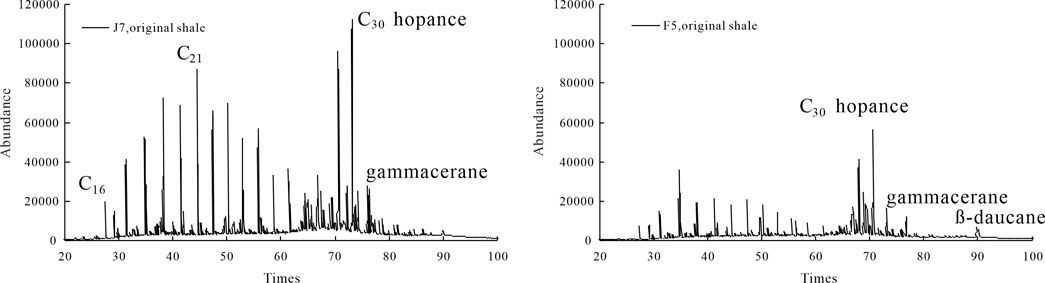

The GC results indicate that although the main peak carbon for saturated hydrocarbons in Lucaogou shale was C21, higher than the main peak carbon C19 in Fengcheng shale, the relative content of saturated hydrocarbons with main peak carbons from C16 to C27 is higher in Lucaogou shale, whereas the relative content of saturated hydrocarbons with main peak carbons from C29 to C35 was higher in Fengcheng shale (Figure 5).

Figure 5. Total ion chromatograms (TIC) of saturated hydrocarbons from Fengcheng and Lucaogou shale samples.

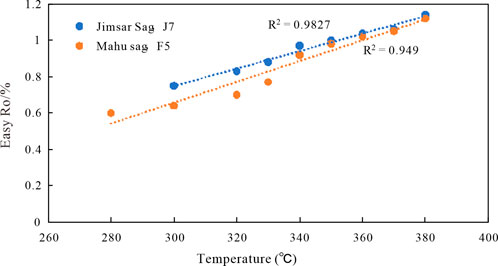

To facilitate the guidance of shale oil exploration, it is necessary to establish a correlation between the simulation experiments timescale and geological timescales. Therefore, the Ro values of Fengcheng shale and Lucaogou shale samples were measured before and after the simulation experiments and calibrated using the Vitrimat Easy Ro model (Sweeney and Burnham, 1990). As shown in the Figure 6, there is a positive linear correlation between the simulation experiment temperature and Ro, consistent with previous studies (Waples, 1980). This correlation provides a basis for applying the shale oil generation, expulsion, and retention models obtained from simulation experiments to actual geological conditions.

Figure 6. Relationship between temperature and Ro in thermal simulation experiment, calibrated using the Vitrimat Easy Ro model (Sweeney and Burnham, 1990).

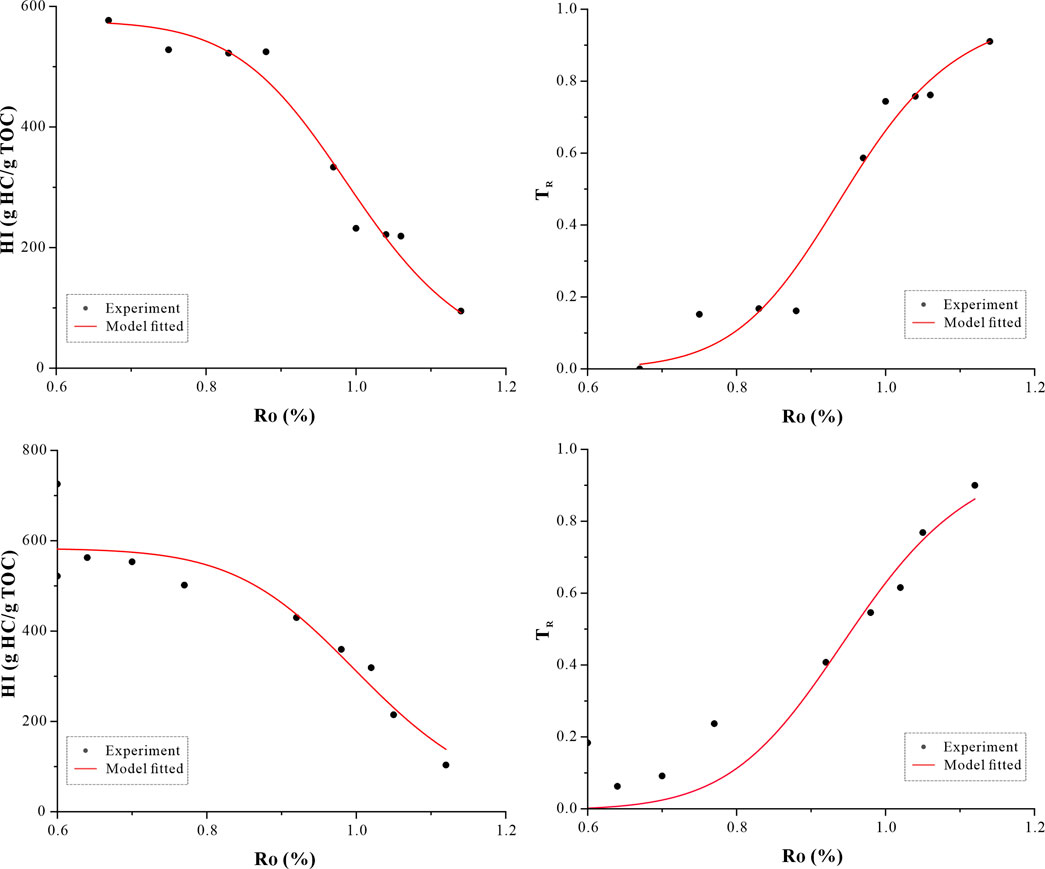

HI is an important indicator for evaluating the hydrocarbon generation potential of shale. This study employs the statistical model proposed by Li E et al. (2020), which is very useful for the quantitative evaluation of shale oil and gas systems, to establish the relationship between HI and Ro for shale samples (Equation 1). Additionally, the TR evaluation method based on the law of mass conservation (Equation 2) is used to assess the degree of shale conversion (Chen and Jiang, 2015).

where HI0 initial hydrogen index, β represents the hydrocarbon generation peak, and θ represents hydrocarbon generation window.

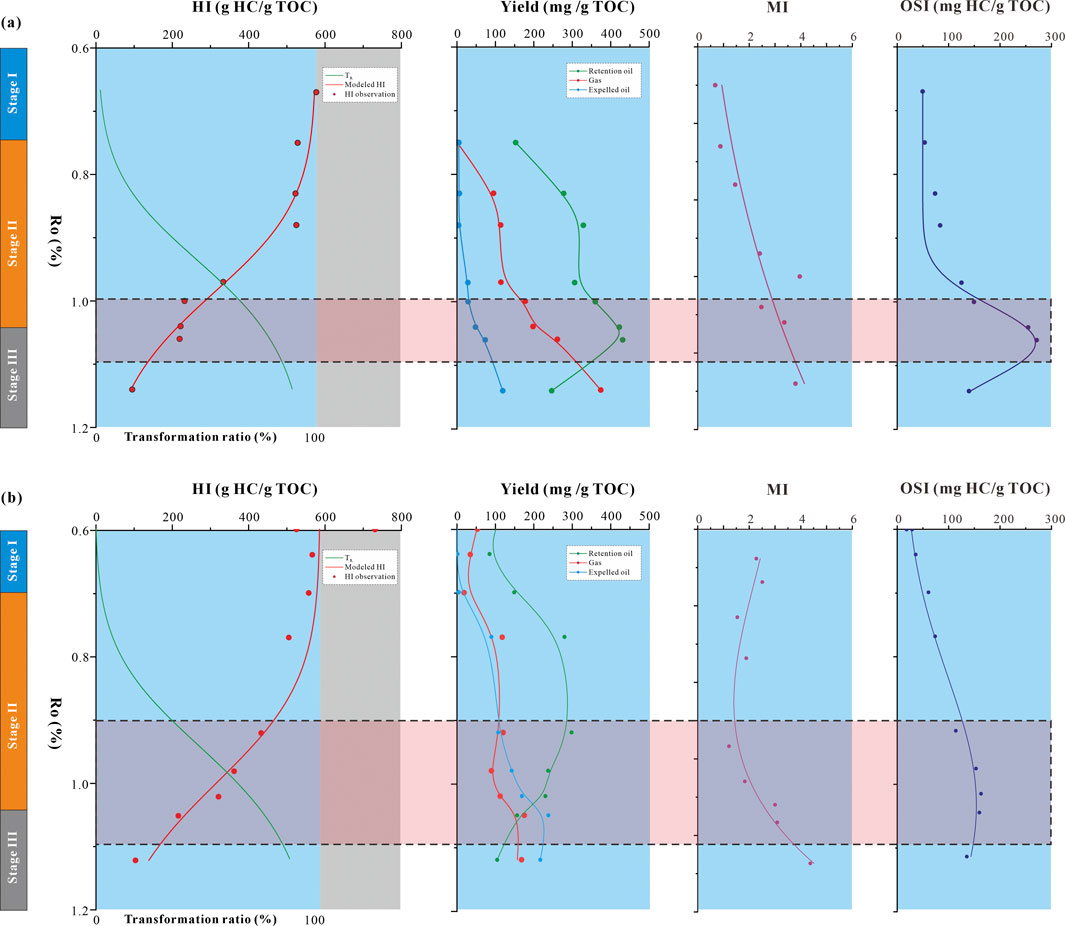

The results indicate that both Fengcheng shale and Lucaogou shale began to degrade at a Ro of 0.65% and 0.6%, respectively. As maturity increases, the HI gradually decreases. The β values for Fengcheng shale and Lucaogou shale were 1.00 and 1.01, respectively, indicating that the degradation peak was reached at Ro values of 1.00% and 1.01%. The θ values were 12.5 and 11.5, respectively, suggesting that the hydrocarbon generation window for Lucaogou shale is wider than that for Fengcheng shale. Additionally, the model shows that, although the TR at the degradation peak is higher for Fengcheng shale than for Lucaogou shale, the TR values converge at 0.91 when the Ro reaches 1.1% (Figure 7).

Figure 7. Statistical models of (A, C) HI vs. Ro, and (B, D) TR vs. Ro for Fengcheng shale and Lucaogou shale.

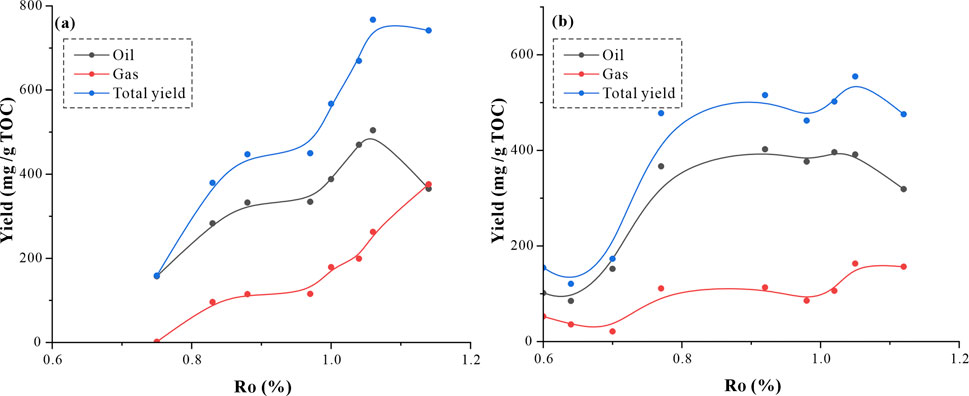

Thermal simulation experiment results indicate that the yield of Fengcheng shale can be divided into four stages (Figure 8A). In the first stage (Ro = 0.75%–0.88%), the products were mainly oil. Both the total yield and oil yield increase with temperature, from 158.88 mg/g TOC and 157.23 mg/g TOC to 447.38 mg/g TOC and 332.6 mg/g TOC, respectively. The gas yield was relatively low at this stage, increasing from 1.65 mg/g TOC to 114.78 mg/g TOC. In the second stage (Ro = 0.88%–0.97%), both oil and gas products increase slowly, with oil and gas yields increasing by only 1.84 mg/g TOC and 0.6 mg/g TOC, respectively. In the third stage (Ro = 0.97%–1.06%), there was a rapid secondary increase in oil and gas products, reaching peak yields of 767.09 mg/g TOC and 504.31 mg/g TOC. In the fourth stage (Ro = 1.06%–1.14%), the total yield remained stable, with the secondary cracking oil yield decreasing to 365.44 mg/g TOC and the corresponding gas yield increasing to 376.08 mg/g TOC (Figure 8A).

Figure 8. Oil, gas, and total yields at different maturities for (A) Fengcheng shale and (B) Lucaogou shale.

The yield of Lucaogou shale can also be divided into four stages (Figure 8B). In the first stage (Ro = 0.60%–0.64%), the degradation rate of organic matter was slow, with low oil and gas yields of 84.95 mg/g TOC and 35.88 mg/g TOC, respectively. In the second stage (Ro = 0.64%–0.77%), the oil yield increases rapidly to 366.59 mg/g TOC, while the gas yield increases slowly to 111.21 mg/g TOC. In the third stage (Ro = 0.77%–1.05%), the oil and gas yields remain stable, reaching peak values of 402.28 mg/g TOC and 113.38 mg/g TOC at a Ro of 0.92%. In the fourth stage (Ro = 1.05%–1.12%), secondary cracking of oil leads to a decrease in oil yield to 318.87 mg/g TOC. Continued degradation of organic matter results in an increase in gas and total yields, reaching peak values of 163.25 mg/g TOC and 554.57 mg/g TOC, respectively (Figures 7, 8).

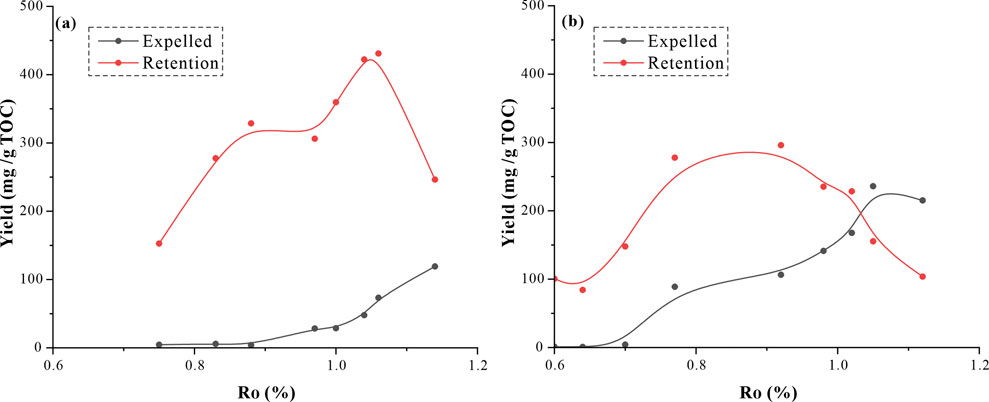

The expulsion and retention oil yields of Fengcheng shale can also be divided into four stages (Figure 9A). In the first stage (Ro = 0.75%–0.88%), the generated oil mainly accumulates within the shale, with the residual oil yield rapidly increasing to 328.67 mg/g TOC, while the expelled oil yield is relatively low at 3.93 mg/g TOC (Figure 9A). The retained oil was characterized by a relatively high abundance of stable C30 compounds and saturated hydrocarbons with a dominant carbon number of C21, similar to the initial sample. In contrast, the discharged oil contained heavier saturated hydrocarbons with a predominant carbon number of C23 (Figure 10). In the second stage (Ro = 0.88%–0.97%), the residual oil yield remains stable, and the expelled oil yield increases to 28.3 mg/g TOC (Figure 9A). During this stage, the retained oil underwent a significant compositional change, with a decrease in large molecules like C30 hopanes and a corresponding increase in C21 saturated hydrocarbons. The discharged oil exhibited a shift in hydrocarbon distribution, with an enrichment of C15-C19 saturated hydrocarbons and a depletion of C21-C23 saturated hydrocarbons (Figure 10). In the third stage (Ro = 0.97%–1.06%), further degradation of organic matter leads to a rapid increase in residual oil yield to a peak of 430.97 mg/g TOC, and the expelled oil yield increases to 73.34 mg/g TOC (Figure 9A). The content of large molecules, such as C30 hopanes, in the retained oil continued to decrease during this stage, the content of C20-C24 saturated hydrocarbons continues to increase. Similarly, C14-C19 saturated hydrocarbons dominated the discharged oil (Figure 10). In the fourth stage (Ro = 1.06%–1.14%), secondary cracking causes the residual oil yield to decrease rapidly to 246.27 mg/g TOC, while the expelled oil yield continues to increase, reaching a maximum of 119.18 mg/g TOC (Figure 9A). The composition of the retention oil remained stable during this stage, The continued expulsion of retained oil results in an increase in the content of C20-C24 saturated hydrocarbons in the expelled oil (Figure 10).

Figure 9. Expulsion and residual oil yields at different maturities for (A) Fengcheng shale and (B) Lucaogou shale.

The expulsion and retention oil yields of Lucaogou shale can be divided into five stages (Figure 9B). In the first stage (Ro = 0.60%–0.64%), the oil mainly accumulates within the shale, with the residual oil yield being low at 100.66 mg/g TOC, and the expelled oil yield at only 1.02 mg/g TOC (Figure 9B). The main peak carbon of saturated hydrocarbons in the retained oil was C21, along with stable biomarker compounds at C30, showing no significant difference from the initial samples. During this stage, the saturated hydrocarbons in the expelled oil were primarily light hydrocarbons, with the initial main peak carbon C16. As maturity increased, hydrocarbons with main peak carbons of C23-C25 expelled (Figure 11). In the second stage (Ro = 0.64%–0.77%), the residual oil yield rapidly increases to 277.74 mg/g TOC, while the expelled oil yield also rapidly increases to 88.85 mg/g TOC (Figure 9B). During this stage, the content of large molecular compounds such as C30 hopanes in the retained oil decreases rapidly, while the saturated hydrocarbons with a main peak carbon of C20 increase. Simultaneously, the content of saturated hydrocarbons with main peak carbons of C23-C25 in the expelled oil continues to increase (Figure 11). In the third stage (Ro = 0.77%–0.92%), the residual oil yield slowly increases to a peak of 295.94 mg/g TOC, while the expelled oil continues to increase to 106.34 mg/g TOC (Figure 9B). During this stage, large molecular compounds such as C30 hopanes in the retention oil almost disappear, and the content of light hydrocarbons with main peak carbons below C22 increased. The content of C20-C24 saturated hydrocarbons in the expelled oil increased (Figure 11). In the fourth stage (Ro = 0.92%–1.05%), secondary cracking causes the residual oil yield to decrease rapidly to 155.3 mg/g TOC, while the expelled oil continues to increase to a peak of 236.02 mg/g TOC (Figure 9B). The expelled oil was mainly composed of saturated hydrocarbons ranging from C14 to C18, with the main peak carbon decreasing to C16 (Figure 11). In the fifth stage (Ro = 1.05%–1.12%), as the degree of cracking increases, both the residual oil and expelled oil yields decrease to 103.67 mg/g TOC and 215.2 mg/g TOC, respectively (Figure 9B). The composition of the retention oil remained stable during this stage, while the content of hydrocarbons with peak carbons more than C19 in the discharged oil increased slightly (Figure 11).

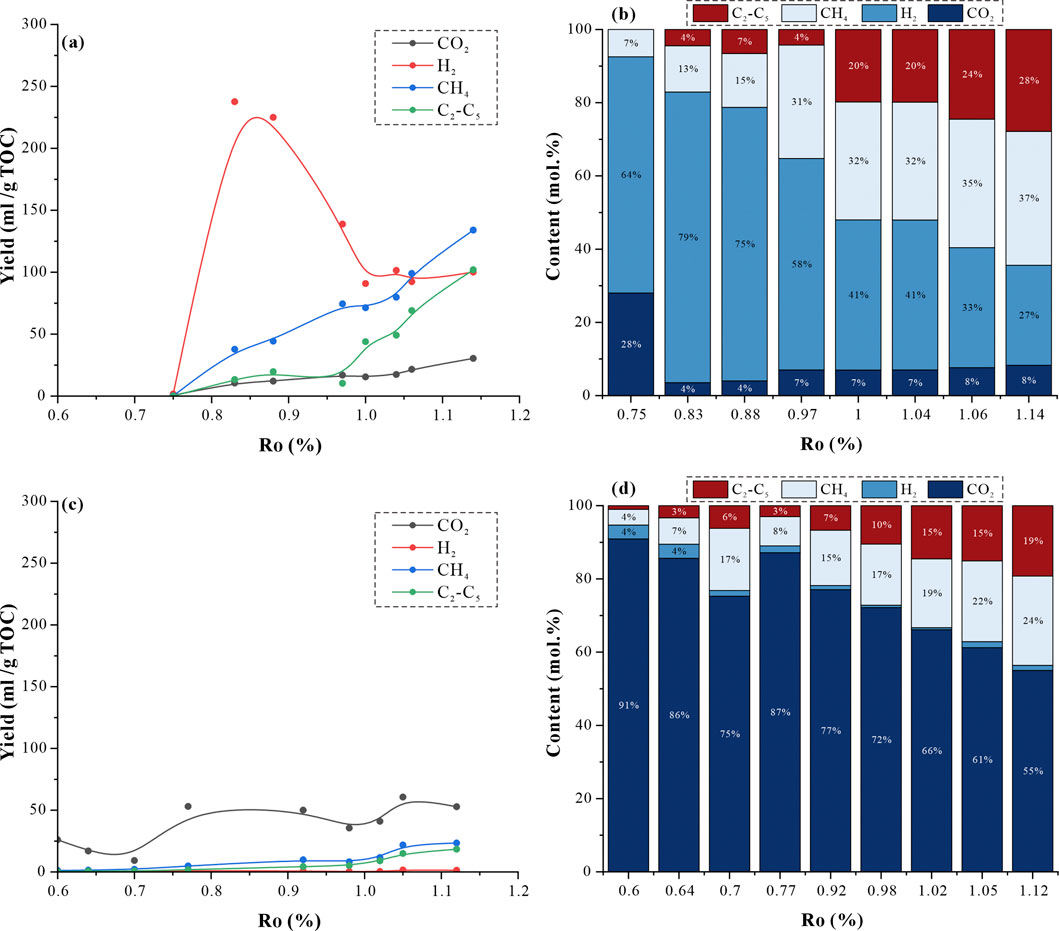

Thermal simulation experiments revealed that the predominant gaseous products from Fengcheng and Lucaogou shales were CO2, H2, and hydrocarbon compounds (Figure 12). The gas composition from the Fengcheng shale at the early stage of organic matter degradation (Ro = 0.75%) was characterized by extremely low yields and a dominance of H₂ (64%) and CO₂ (28%), with CH4 representing only 7% (Figures 12A, B). As maturity increased (Ro = 0.75%–0.83%), the H₂ yield exhibited a significant increase of 237.61 mL/g TOC. In contrast, the CO₂ and CH₄ yields increased at a slower rate, reaching 10.55 mL/g TOC and 37.75 mL/g TOC, respectively. Notably, heavier hydrocarbon gases (C₂-C₅) began to form during this stage, with a yield of 13.32 mL/g TOC. H₂ dominated the gas product, accounting for a substantial 79%, followed by CH₄ at 13% (Figures 12A, B). As Ro increased to 0.83%–1.0%, the H₂ yield decreased sharply to 90.85 mL/g TOC. In contrast, the yields of CH₄ and C₂-C₅ heavy hydrocarbons increased significantly, with relative abundances increasing by 18% and 16%, respectively. The CO₂ yield increased slowly, with a relative abundance increase of only 3% (Figures 12A, B). As Ro increased to 1.0%–1.14%, the H₂ yield plateaued at approximately 90.85 mL/g TOC. In contrast, the yields of CO₂, CH₄, and C₂-C₅ heavy hydrocarbons continued to rise, reaching 30.39 mL/g TOC, 133.98 mL/g TOC, and 101.93 mL/g TOC, respectively. As a result, the relative abundance of H₂ decreased to 27% (Figures 12A, B).

Figure 12. Gas yields (A, C) and relative content (B, D) of gas components in Fengcheng and Lucaogou shales.

The gas production rates of various components in the Lucaogou shale were relatively low. The CO₂ production rate was the highest, but only 60.33 mL/g TOC, and the H₂ production rate was the lowest, averaging only 0.84 mL/g TOC. In the early stage of organic matter degradation (Ro = 0.6%–0.64%), CO₂ dominated, with a relative abundance of 86%–91% (Figures 12C, D). With increasing maturity, the production rates of CH₄ and C₂-C₅ heavy hydrocarbons gradually increased, and the relative abundance of CO₂ decreased accordingly. When Ro reached 1.12%, the relative abundances of CH₄ and C₂-C₅ heavy hydrocarbons reached 24% and 19%, respectively, while the relative abundance of H₂ stabilized at about 1.44% (Figures 12C, D).

Carbon isotope analysis shows that with increasing maturity, the δ1³C values of CO₂ and light hydrocarbons (C₁-C₄) in Fengcheng shale gas exhibit an initial increase followed by a decrease, reaching a minimum at a Ro value of 0.97%. In contrast, the δ1³C values of light hydrocarbons (C₅) show an opposite trend, reaching a maximum at a Ro value of 0.97%. Similarly, δ1³C values of saturates, aromatics, resins, and asphaltenes in the oil phase also show a decrease-increase trend, with a minimum at Ro value of 0.97% (Table 3). The δ1³C values of saturated hydrocarbons, aromatics, resins, and asphaltenes in the Lucaogou shale oil generally showed a negative shift. In contrast, the δ1³C values of light hydrocarbons (C1-C5) exhibited a positive shift. The δ1³C values of CO₂ showed a more complex variation, with a relative enrichment of 1³C at a vitrinite reflectance (Ro) of 0.77%–1.02%, with an average δ1³C value of −1.2‰, followed by a trend towards depletion (Table 3).

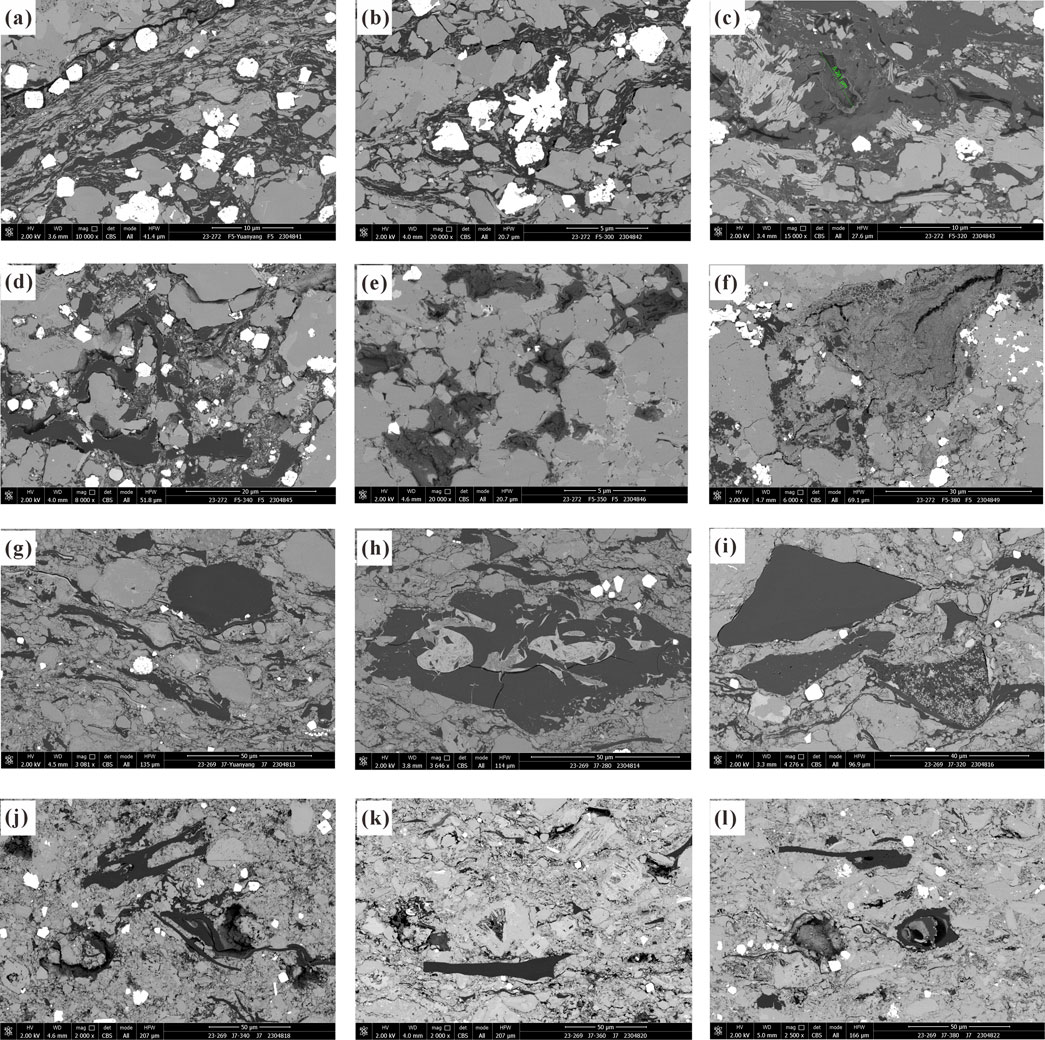

SEM results indicate that the pores in shale primarily consist of inorganic matrix pores, organic pores, and fractures (Loucks et al., 2012). Organic matter in Fengcheng shale is uniformly distributed in both banded and massive forms. The shale is characterized by bitumen-filled fractures, well-developed intergranular inorganic pores, but a lack of organic pores (Figure 13A). At the low maturity stage (Ro = 0.62%–0.73%), the preliminary degradation of organic matter and bitumen leads to the formation of fractures at the boundaries between organic matter and minerals in shale. A small number of pores develop within the bitumen, but overall, organic pores remain underdeveloped (Figures 13B, C). With further increases in maturity (Ro = 0.83%–0.97%), intense thermal degradation of organic laminae and pore-filling bitumen led to a significant increase in the number of pores and fractures (Figures 13D, E). When the Ro value reached 1.12%, refractory plant fragments were observed coexisting with bitumen in the pores and fractures, although the increase in the number of fractures was not significant (Figure 13F). Overall, the pore evolution characteristics of Lucaogou shale were similar to those of Fengcheng shale. Intergranular pores in clay minerals and fractures were observed in the initial Lucaogou shale samples (Figure 13G). At the low maturity stage (Ro = 0.60%–0.70%), intergranular pores and fractures increased (Figures 13H, I). At the moderate maturity stage (Ro = 0.92%–1.12%), intense degradation of organic matter led to an increase in fractures, intergranular mineral pores, and organic pores in the shale, resulting in a loosening of the shale matrix and enhanced pore connectivity (Figures 13J–L).

Figure 13. Scanning electron microscope (SEM) images of shale samples. (A) Initial Fengcheng shale; (B) Fengcheng shale, Ro = 0.62%; (C) Fengcheng shale, Ro = 0.73%; (D) Fengcheng shale, Ro = 0.88%; (E) Fengcheng shale, Ro = 0.97%; (F) Fengcheng shale, Ro = 1.06%; (G) initial Lucaogou shale; (H) Lucaogou shale, Ro = 0.60%; (I) Lucaogou shale, Ro = 0.70%; (J) Lucaogou shale, Ro = 0.92%; (K) Lucaogou shale, Ro = 1.02%; (L) Lucaogou shale, Ro = 1.12%.

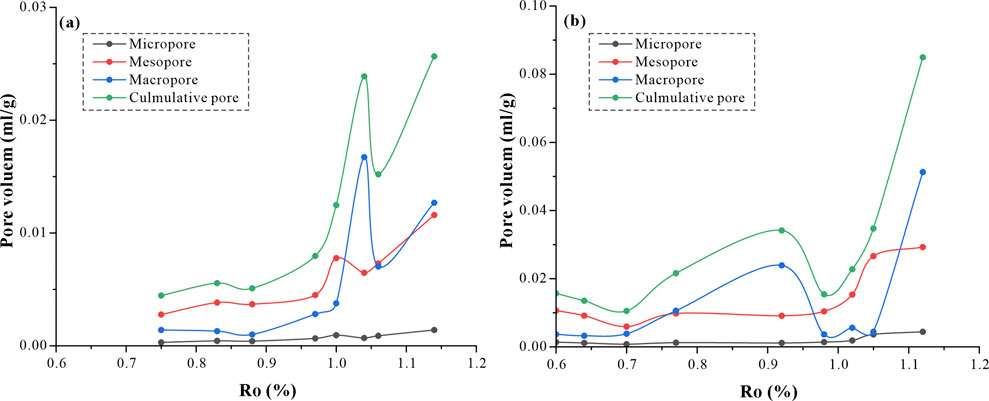

This study classifies macropores, mesopores, and micropores according to IUPAC standards (Ougier-Simonin et al., 2016; Sing, 1985). High-pressure mercury intrusion and nitrogen adsorption results indicate that with increasing organic maturity, the pore volume of both Fengcheng and Lucaogou shales generally increases. Notably, macropores and mesopores contribute most significantly to the total pore volume (Figure 14). The maximum pore volume of Fengcheng shale is 0.026 mL/g, which is markedly lower than the 0.085 mL/g observed for Lucaogou shale. Interestingly, both Fengcheng and Lucaogou shales show a phase of decreased pore volume at Ro values of 1.04% and 0.98%, respectively, which may be related to pore closure caused by hydrocarbon expulsion (Figure 14).

Figure 14. Total pore volume, macropore volume, mesopore volume, and micropore volume of (A) Fengcheng shale and (B) Lucaogou shale.

Previous studies have demonstrated that the degradation of organic matter in shale exhibits distinct stages (Tissot and Espitalie, 1975). Based on Ro, the degradation process can be divided into four stages: biogeochemical gas generation stage (Ro < 0.6%), thermal cracking oil and gas generation stage (Ro = 0.6%–1.3%), thermal cracking wet gas generation stage (Ro = 1.3%–2.0%), and high-temperature cracking dry gas generation stage (Ro > 2.0%) (Schmoker, 1996). However, the heterogeneity of lacustrine shale is significant, and the thermal degradation processes of organic matter in different basins or strata vary greatly (Chen and Jiang, 2015). Based on the results of the above simulation experiments, this study establishes the hydrocarbon generation patterns of the Fengcheng shale and the Lucangou shale, respectively, aiming to provide more accurate guidance for shale oil exploration in these two areas of the Junggar Basin.

Previous studies have indicated that the Fengcheng shale in the Mahu Sag is rich in algal and bacterial organic matter, with a wide hydrocarbon generation window and a predominance of oil generation over gas generation (Cao et al., 2015). However, the results of this simulation experiment indicate that at the low maturity stage, gas yield is relatively low. As maturity approaches the high maturity stage, gas becomes the dominant product. When the Ro value reaches 1.14%, gas yield surpasses oil yield (Figures 8A, 15A).

Combining the results of previous studies, this study divides the degradation process of organic matter in Fengcheng shale into three stages, as shown in Figure 15A. (1) Stage I (Ro < 0.75%): due to the relatively low thermal degradation temperature (<300°C), a small portion of organic matter initially degrades into macromolecular compounds, which remain trapped within the pores and fractures (Figures 13B, C). At this stage, the TR value of Fengcheng shale reaches only 5%, with no gas generation or hydrocarbon expulsion (Figure 15A). (2) Stage II (Ro = 0.75%–1.04%): As the temperature increases, organic matter and macromolecular bitumen gradually degrade, producing gases such as H₂ and hydrocarbons, as well as a significant amount of light hydrocarbons with a predominant carbon peak around C24 (Figures 11A, 12A). Therefore, a negative shift of carbon isotopes in gas and oil components was observed (Bjorøy et al., 1991). Some of these products were expelled from the shale, leading to a gradual increase in hydrocarbon expulsion (Figure 15A). This stage shows two peaks in the oil generation rate, which may be attributed to the increased pore pressure in the shale, leading to pore compaction and closure after hydrocarbon expulsion (Zhang Y et al., 2022). (3) Stage III (Ro = 1.04%–1.14%): as the organic matter TR increases from 80% to 91%, the yield of retained oil decreases (Figure 15A). This may relate to two factors: first, the further degradation of organic matter leads to an increased proportion of C20-C24 saturated hydrocarbons (Figure 11), which enhances the fluidity of the oil and results in greater hydrocarbon expulsion; second, some of the retained oil undergoes secondary cracking, converting into gas (Wang et al., 2022).

Figure 15. Hydrocarbon generation patterns of (A) Fengcheng shale and (B) Lucaogou shale, illustrating the favorable maturity interval for shale oil accumulation.

In contrast, Lucaogou shale contains lower amounts of exinite and sapropelinite groups, while it has higher amounts of vitrinite and inertinite groups (Figure 4A). The lower hydrocarbon potential of the vitrinite and inertinite groups (Welte and Tissot, 1984) may contribute to the significantly lower yield in Lucaogou shale compared to Fengcheng shale (Figure 15A). In contrast to the Fengcheng shale, the gas product of the Lucangou shale is primarily CO2 (Figure 12D). This is likely due to the higher content of carboxylic and carbonyl functional groups in its organic matter (Li et al., 2024).

This study also divides the degradation process of organic matter in Lucaogou shale into three stages, as shown in Figure 15B. (1) Stage I (Ro < 0.7%): as temperatures below 300°C, only a small portion of organic matter in Fengcheng shale degrades into macromolecular bitumen, which remains trapped in the pores and fractures of the shale (Figures 13H, I). During this stage, the organic matter conversion ratio is low, with a TR of only 2.5%. Despite this, the gas yield is relatively high, due to the lower energy required for the degradation of carbonyl and carboxyl groups, resulting in substantial CO₂ generation (Smirnov et al., 2024). (2) Stage II (Ro = 0.7%–1.05%): The hydrocarbon generation potential of the organic matter rapidly decreases to 214.7 mg HC/g TOC, leading to the production of gas and light hydrocarbons with a peak carbon number below C24 (Figure 11B). This results in a negative migration of carbon isotopes in hydrocarbon gases and oil components (Bjorøy et al., 1991). The Lucangou shale reached its oil generation peak when Ro reached 0.92%. Subsequently, continued hydrocarbon expulsion leads to a decrease in retained oil yield and a corresponding increase in expelled oil yield. Additionally, gas yield slowly rises during this stage, predominantly as hydrocarbon gases (Figure 15B). (3) Stage III (Ro = 1.05%–1.12%): secondary cracking led to a decrease in both expelled oil and residual oil yields, while the yield of hydrocarbon gases continued to increase. During this stage, the TR of the Lucangou shale reached a high of 82% (Figure 15B).

In summary, the hydrocarbon generation potential of Fengcheng shale is superior to that of Lucaogou shale, whether considering gas yield or oil yield. However, Lucaogou shale began the thermal degradation earlier than Fengcheng shale and has a broader pyrolysis degradation window. The corresponding TR is slightly higher for Fengcheng shale. However, at the high maturity stage, their TR converge. Additionally, the yield of expelled oil of Lucaogou shale is higher than that of Fengcheng shale.

Based on whether hydrocarbons were expelled from the shale, lacustrine shale oil was classified into two categories: layered shale oil and shale-type shale oil (He et al., 2023; Jin et al., 2021) The characteristics of shale oil occurrence, evaluation parameters for the “sweet spot” intervals, and development methods differ between these two types (Zhao et al., 2018; Zou et al., 2019). Exploration results have shown that the Fengcheng shale is classified as shale-type shale oil, while the Lucaogou shale is classified as layered shale oil (Gong et al., 2024). Investigating the differences in hydrocarbon expulsion ratio and their controlling factors between these two shale layers is crucial for evaluating and selecting favorable development intervals for shale oil in the Junggar Basin.

Previous studies have indicated that the hydrocarbon expulsion efficiency of shale is related to factors such as organic matter type, maturity, mineral composition, pore characteristics, and oil properties (Eseme et al., 2012; Liu et al., 2023; Zhao et al., 2023). Thermal simulation experiments demonstrated that Lucaogou shale commenced hydrocarbon expulsion at an earlier maturity stage, with a Ro value of 0.6% (Figures 15, 16A). This indicates that during stage I of organic matter degradation, the hydrocarbon expulsion ratio is primarily determined by the organic matter type, with shales rich in easily degradable organic material exhibiting higher hydrocarbon expulsion ratio. Although the hydrocarbon generation potential of the Lucaogou shale was lower than that of the Fengcheng shale, during stages II-III, where maturity and TR were similar, Lucaogou shale exhibited significantly higher hydrocarbon expulsion ratios compared to Fengcheng shale, with a maximum hydrocarbon expulsion ratio 2.1 times that of Fengcheng shale (Figure 16A). This suggests that the characteristics of the shale reservoir and the mobility of the oil may be the most important factors influencing the hydrocarbon expulsion ratio. As shown in Figure 16B, the hydrocarbon expulsion ratio of both the Fengcheng shale and the Lucaogou shale exhibits a positive correlation with porosity. Due to higher porosity, the Lucaogou shale has a significantly higher hydrocarbon expulsion ratio compared to the Fengcheng shale.

Figure 16. (A) Hydrocarbon expulsion ratio vs. Ro for the Fengcheng shale and Lucaogou shale; (B) hydrocarbon expulsion ratio vs. porosity for the Fengcheng shale and Lucaogou shale.

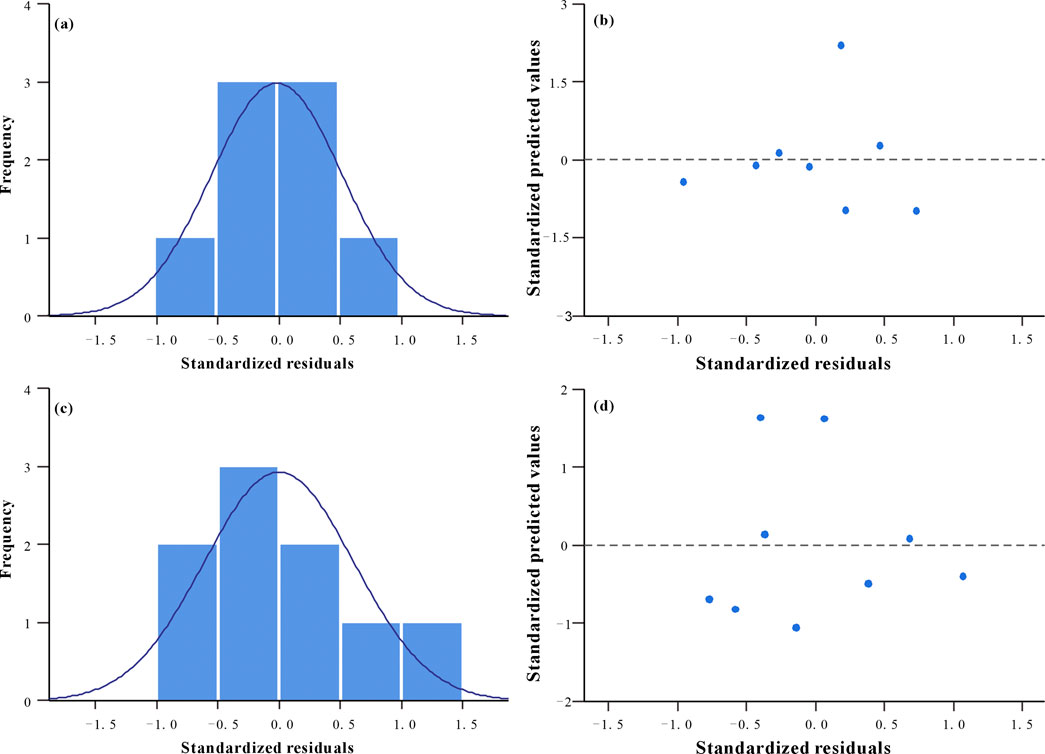

Furthermore, this study developed a multiple regression model to quantitatively assess the influence of porosity, mesopore volume, specific surface area, and MI on the hydrocarbon expulsion ratio and to predict the hydrocarbon expulsion ratio. The model parameters are detailed in Table 4. To mitigate the impact of multicollinearity, only macropore and mesopore volume was selected as the parameter for pore volume. The high R2 value, normally distributed standardized residuals, and standardized predicted values distributed around zero in the regression model all confirm the reliability of the model (Table 4; Figure 17).

Figure 17. (A, C) standardized residual distribution for Fengcheng and Lucaogou shales; (B, D) Standardized residual vs. predicted values for Fengcheng and Lucaogou shales.

Model results indicate that both macropore volume and mesopore volume contribute positively to the hydrocarbon expulsion ratio. According to the standardized regression coefficients, mesopore volume is the primary factor affecting the hydrocarbon expulsion ratio in both the Fengcheng shale and the Lucaogou shale (Table 4). Specifically, a larger mesopore volume, which implies better connectivity, correlates with a higher hydrocarbon expulsion ratio (Figures 13, 14). In contrast, macropore volume has a significantly greater impact on the hydrocarbon expulsion ratio in the Lucaogou shale compared to the Fengcheng shale. This is primarily because macropores or fractures in the Fengcheng shale are often filled with large molecular asphalt, resulting in poor connectivity. Conversely, the micrometer-scale macropores or fractures formed by organic matter degradation in the Lucaogou shale provide excellent connectivity, facilitating hydrocarbon expulsion (Figure 13). Additionally, the standardized regression coefficient for the MI of the oil is negative, indicating that oil mobility has a limited or negative contribution to the hydrocarbon expulsion ratio in both the Fengcheng shale and the Lucaogou shale (Table 4). For instance, although the maximum MI in the Fengcheng shale is comparable to that in the Lucaogou shale, its hydrocarbon expulsion ratio is only 50% of that of the Lucaogou shale. During stage I, the Lucaogou shale has a high MI but the lowest hydrocarbon expulsion ratio, while during stage II, the hydrocarbon expulsion ratio increases despite the lowest MI (Figure 15). In summary, mesopore volume and its connectivity are critical factors affecting the hydrocarbon expulsion ratio, whereas oil mobility and macropore volume have relatively limited effects.

Previous studies have shown that low to medium maturity and medium to high maturity continental shale oils exhibit significant differences in geological characteristics related to hydrocarbon generation, expulsion, and retention, as well as in exploration strategies, technologies, and evaluation criteria (Eseme et al., 2012; Liu et al., 2023; Zhao et al., 2023). Therefore, selecting the optimal maturity interval is crucial for decision-making in the exploration and development of lacustrine shale oil (Hackley and Cardott, 2016; Wang et al., 2022b; Hu et al., 2025). Currently, oil content and mobility are key factors in determining the favorable maturity interval for shale oil exploration (Donmoyer et al., 2023; Li et al., 2019). However, for layered shale oil, the yield of expelled oil or hydrocarbon expulsion ratio is the primary factor influencing its oil content (Jin et al., 2021). Therefore, this study aims to identify the favorable maturity interval for shale oil exploration in the Fengcheng shale and Lucaogou shale, based on the established hydrocarbon generation patterns, combined with assessments of oil content, oil mobility, and hydrocarbon expulsion ratio.

The pyrolysis parameter S1 was used to characterize the oil content of shale, with S1 values generally exceeding 2.0 mg HC/g Rock in the “sweet spot” intervals of lacustrine shales where exploration breakthroughs have been achieved in China (Javie, 2012; Li et al., 2023). Given that S1 may be influenced by the micro-migration of shale oil, this study also employed the OSI to assess shale oil content (Wang et al., 2022a). Exploration results indicate that shales with OSI values greater than 100 mg HC/g TOC typically exhibit high oil content and high mobility (Javie, 2012; Wang et al., 2022a), findings consistent with the results of the thermal simulation experiments conducted in this study (Figure 15). Although the multiple regression model suggests that the MI has a limited impact on the hydrocarbon expulsion ratio (Table 4), MI is crucial for shale oil extraction. Generally, higher concentrations of saturated and aromatic hydrocarbons correlate with lower crude oil viscosity, facilitating the dispersion of asphaltenes and preventing their adsorption onto mineral surfaces due to their strong polarity (Brunauer et al., 1938). Consequently, a higher MI value indicates greater oil mobility, which is advantageous for shale oil extraction. Therefore, this study identifies the optimal maturity interval for shale oil exploration as Ro = 1.0%–1.1% for the Fengcheng shale and Ro = 0.9%–1.1% for the Lucaogou shale (Figure 15).

The Fengcheng Formation in the Mahu Sag was classified as shale-type shale oil. Despite its high TR values and hydrocarbon yields, most of the oil residual within the shale. In the optimal maturity interval, the hydrocarbon expulsion ratio is below 20% (Figures 15, 16). The depositional environment of the Mahu Sag was highly variable, resulting in centimeter-scale lithofacies assemblages, including combinations such as sandstone-shale, dolomitic mixed rock-shale, volcanic clastic-shale, and alkaline mineral mixed rock-shale (Tang et al., 2024). Among these, the dolomitic mixed rock-shale and volcanic clastic-shale assemblages in the shore-shallow lake facies, as well as combinations with a higher proportion of sandstone, are more favorable for hydraulic fracturing and represent the primary lithofacies assemblages for future exploration. The Lucaogou Formation in the Jimsar Sag was classified as interlayer-type shale oil. Although its hydrocarbon generation potential is lower than that of the Fengcheng shale, the Lucaogou shale exhibits a higher hydrocarbon expulsion ratio due to its high porosity and connectivity, with an hydrocarbon expulsion ratio exceeding 40% within the optimal maturity interval (Figures 13, 15, 16). However, the high clay content in the Lucaogou shale is unfavorable for hydraulic fracturing (Figure 3), necessitating a focus on source-reservoir assemblages during exploration. The confirmed “sweet spot” intervals typically have oil saturations exceeding 85%, predominantly composed of meter-scale sandstones (Zhi et al., 2019). Combinations with a higher reservoir-to-shale thickness ratio exhibit higher hydrocarbon expulsion ratios (Li C et al., 2020) and should be the primary targets for exploration.

(1) The degradation process of the Fengcheng shale and Lucaogou shale can be divided into 3 stages: Stage I, the initial degradation of organic matter; Stage II, the rapid degradation of organic matter; and Stage III, the secondary cracking of organic matter. The hydrocarbon generation potential of Fengcheng shale is superior to that of Lucaogou shale, whether considering gas yield or oil yield. However, Lucaogou shale began the thermal degradation earlier than Fengcheng shale and has a broader pyrolysis degradation window. The corresponding TR is slightly higher for Fengcheng shale. However, at the high maturity stage, their TR converge. Additionally, the yield of expelled oil of Lucaogou shale is higher than that of Fengcheng shale.

(2) During stage I, the hydrocarbon expulsion ratio is primarily determined by the organic matter type, with shales rich in easily degradable organic material exhibiting higher hydrocarbon expulsion ratio. During stages II-III, where maturity and TR were similar, Lucaogou shale exhibited significantly higher hydrocarbon expulsion ratios compared to Fengcheng shale, with a maximum hydrocarbon expulsion ratio 2.1 times that of Fengcheng shale. Mesopore volume and its connectivity are critical factors affecting the hydrocarbon expulsion ratio, whereas oil mobility and macropore volume have relatively limited effects.

(3) The optimal maturity interval for shale oil exploration as Ro = 1.0%–1.1% for the Fengcheng shale and Ro = 0.9%–1.1% for the Lucaogou shale. Exploration of the Fengcheng shale should focus on lithofacies assemblages, the dolomitic mixed rock-shale assemblages in the shore-shallow lake facies represent the primary exploration target. Exploration of the Lucaogou shale should focus on source-reservoir assemblages, with a higher reservoir-to-shale thickness ratio being the primary exploration target.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

WH: Conceptualization, Supervision, Writing–original draft, Writing–review and editing. ZL: Conceptualization, Supervision, Writing–original draft, Writing–review and editing. CL: Conceptualization, Writing–original draft, Writing–review and editing. JH: Investigation, Writing–original draft, Writing–review and editing. JL: Investigation, Writing–original draft, Writing–review and editing. ZS: Investigation, Writing–original draft, Writing–review and editing. DL: Investigation, Writing–original draft, Writing–review and editing. SY: Investigation, Writing–original draft, Writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The authors would like to acknowledge the funding supports from National Natural Science Foundation of China (No. 42090020).

Authors WH, DL, and SY were employed by Xinjiang Oilfield Company, PetroChina. Authors ZL, JH, JL, and ZS, were employed by SINOPEC.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Bjorøy, M., Hall, K., Gillyon, P., and Jumeau, J. (1991). Carbon isotope variations in n-alkanes and isoprenoids of whole oils. Chem. Geol. 93, 13–20. doi:10.1016/0009-2541(91)90061-U

Brunauer, S., Emmett, P. H., and Teller, E. (1938). Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 60, 309–319. doi:10.1021/ja01269a023

Cao, J., Lei, D., Li, Y., Tang, Y., Chang, Q., and Wang, T. (2015). Ancient high-quality alkaline lacustrine source rocks discovered in the lower permian Fengcheng Formation, Junggar Basin. Acta Pet. Sin. 36, 781–790. doi:10.7623/syxb201507002

Chen, Z., Guo, Q., Jiang, C., Liu, X., Reyes, J., Mort, A., et al. (2017). Source rock characteristics and rock-eval-based hydrocarbon generation kinetic models of the lacustrine chang-7 shale of triassic yanchang formation, Ordos Basin, China. Int. J. Coal Geol. 182, 52–65. doi:10.1016/j.coal.2017.08.017

Chen, Z., and Jiang, C. (2015). A data driven model for studying kerogen kinetics with application examples from Canadian sedimentary basins. Mar. Pet. Geol. 67, 795–803. doi:10.1016/j.marpetgeo.2015.07.004

Dongming, Z., Yong, T., Wenjun, H., Xuguang, G. U. O., Zheng, M., and Huang, L. (2021). Orderly coexistence and accumulation models of conventional and unconventional hydrocarbons in lower permian Fengcheng Formation, Mahu sag, Junggar Basin. Pet. Explor. Dev. 48, 43–59. doi:10.1016/s1876-3804(21)60004-6

Donmoyer, S., Agrawal, V., Sharma, S., and Hakala, J. A. (2023). Effect of oxidative breakers on organic matter degradation, contaminant mobility and critical mineral release during shale-fracturing fluid interactions in the Marcellus Shale. Fuel 331, 125678. doi:10.1016/j.fuel.2022.125678

Du, X., Jin, Z., Zeng, L., Liu, G., He, W., Ostadhassan, M., et al. (2023). Formation of natural fractures and their impact on shale oil accumulation in the Mahu Sag, Junggar Basin, NW China. Int. J. Coal Geol. 279, 104385. doi:10.1016/j.coal.2023.104385

Durand, B., and Nicaise, G. (1980). Procedures for kerogen isolation, Kerogen: insoluble organic matter from sedimentary rocks. Paris: Technip.

Eseme, E., Krooss, B. M., and Littke, R. (2012). Evolution of petrophysical properties of oil shales during high-temperature compaction tests: implications for petroleum expulsion. Mar. Pet. Geol. 31, 110–124. doi:10.1016/j.marpetgeo.2011.11.005

Fang, S. H., Jia, C. Z., Guo, Z., Song, Y., Xu, H. M., and Liu, L. J. (2006). New view on the Permian evolution of the Junggar Basin and its implications for tectonic evolution. Earth Sci. Front. 13, 108–121.

Feng, Y., Xiao, X.-M., Wang, E.-Z., Gao, P., Lu, C.-G., and Li, G. (2023). Gas storage in shale pore system: A review of the mechanism, control and assessment. Pet. Sci. 20, 2605–2636. doi:10.1016/j.petsci.2023.05.012

Gong, D., Zeyang, L. I. U., Wenjun, H. E., Chuanmin, Z., Zhijun, Q. I. N., Yanzhao, W. E. I., et al. (2024). Multiple enrichment mechanisms of organic matter in the Fengcheng Formation of Mahu sag, Junggar Basin, NW China. Pet. Explor. Dev. 51, 292–306.

Guo, X. G., He, W., Yang, S., Wang, J. T., Feng, Y. L., Jia, X. Y., et al. (2019). Evaluation and application of key technologies of “sweet area” of shale oil in Junggar Basin: case study of permian Lucaogou Formation in jimusar depression. Nat. Gas. Geosci. 30, 1168–1179.

Hackley, P. C., and Cardott, B. J. (2016). Application of organic petrography in North American shale petroleum systems: a review. Int. J. Coal Geol. 163, 8–51. doi:10.1016/j.coal.2016.06.010

He, W., Zhu, R., Cui, B., Zhang, S., Meng, Q., Bai, B., et al. (2023). The geoscience frontier of gulong shale oil: revealing the role of continental shale from oil generation to production. Eng. S2095809922008128 28, 79–92. doi:10.1016/j.eng.2022.08.018

Hou, L., Luo, X., Zhao, Z., and Zhang, L. (2021). Identification of oil produced from shale and tight reservoirs in the permian Lucaogou shale sequence, jimsar sag, Junggar Basin, NW China. ACS Omega 6, 2127–2142. doi:10.1021/acsomega.0c05224

Hu, T., Jiang, F., Pang, X., Liu, Y., Wu, G., Zhou, K., et al. (2024a). Identification and evaluation of shale oil micro-migration and its petroleum geological significance. Pet. Explor. Dev. 51, 127–140. doi:10.1016/S1876-3804(24)60010-8

Hu, T., Jing, Z., Zhang, Q., Pan, Y., Yuan, M., and Li, M. (2025). Shale oil micro-migration characterization: key methods and outlook. Adv. Geo-Energy Res. 15, 5–12.

Hu, T., Liu, Y., Jiang, F., Pang, X., Wang, Q., Zhou, K., et al. (2024b). A novel method for quantifying hydrocarbon micromigration in heterogeneous shale and the controlling mechanism. Energy 288, 129712. doi:10.1016/j.energy.2023.129712

Javie, D. M. (2012). Shale resource systems for oil and gas: part I—shale gas resource systems. Part II—shale oil resource systems. Shale reservoirs-giant resources for the 21st century. AAPG Mem. 97, 69–87.

Jia, W., Wang, Q., Liu, J., Peng, P., Li, B., and Lu, J. (2014). The effect of oil expulsion or retention on further thermal degradation of kerogen at the high maturity stage: a pyrolysis study of type II kerogen from Pingliang shale, China. Geochem. 71, 17–29. doi:10.1016/j.orggeochem.2014.03.009

Jiang, C., Wang, G., Song, L., Huang, L., Wang, S., Zhang, Y., et al. (2023). Identification of fluid types and their implications for petroleum exploration in the shale oil reservoir: a case study of the Fengcheng Formation in the Mahu Sag, Junggar Basin, Northwest China. Mar. Pet. Geol. 147, 105996. doi:10.1016/j.marpetgeo.2022.105996

Jin, Z., Zhu, R., Liang, X., and Shen, Y. (2021). Several issues worthy of attention in current lacustrine shale oil exploration and development. Pet. Explor. Dev. 48, 1471–1484. doi:10.1016/S1876-3804(21)60303-8

Lai, J., Bai, T., Li, H., Pang, X., Bao, M., Wang, G., et al. (2023). Geological and engineering ‘sweet spots’ in the permian Lucaogou Formation, jimusar sag, Junggar Basin. Acta Geol. Sin. - Engl. Ed. 97, 1214–1228. doi:10.1111/1755-6724.15065

Li, C., Jin, Z., Zhang, L., and Liang, X. (2024). Thermodynamic and microstructural properties of the lacustrine Chang-7 shale kerogen: implications for in-situ conversion of shale. Int. J. Coal Geol. 283, 104447. doi:10.1016/j.coal.2024.104447

Li, C., Pang, X., Huo, Z., Wang, E., and Xue, N. (2020). A revised method for reconstructing the hydrocarbon generation and expulsion history and evaluating the hydrocarbon resource potential: example from the first member of the Qingshankou Formation in the Northern Songliao Basin, Northeast China. Mar. Pet. Geol. 121, 104577. doi:10.1016/j.marpetgeo.2020.104577

Li, M., Chen, Z., Ma, X., Cao, T., Qian, M., Jiang, Q., et al. (2019). Shale oil resource potential and oil mobility characteristics of the eocene-oligocene Shahejie Formation, Jiyang super-depression, Bohai Bay Basin of China. Int. J. Coal Geol. 204, 130–143. doi:10.1016/j.coal.2019.01.013

Li, Z., Liu, Y., He, J., Sun, Z., Leng, J., Li, C., et al. (2023). Limits of critical parameters for sweet-spot interval evaluation of lacustrine shale oil. Oil Gas. Geol. 44, 1453–1467.

Liang, C., Zhang, J., Zhu, J., Wang, W., Guo, H., Tan, Q., et al. (2023). The influence of continental mixosedimentite sedimentation on shale oil sweet spot: a case study on the permian Lucaogou Formation in the jimsar sag of the Junggar Basin, NW China. Front. Earth Sci. 10. doi:10.3389/feart.2022.929768

Li E, E., Xiang, B., Liu, X., Ni, Z., Pan, C., and Mi, J. (2020). Study on the genesis of shale oil thickening in Lucaogou Formation in jimsar sag, Junggar Basin. Nat. Gas. Geosci. 31, 250–257.

Liu, X., Wang, Q., Jia, W., Song, J., and Peng, P. (2023). Pyrolysis of an organic-rich shale containing type II kerogen before and after oil generation and expulsion: implications for the generation of late hydrocarbon and hydrogen gases. J. Anal. Appl. Pyrolysis 173, 106105. doi:10.1016/j.jaap.2023.106105

Loucks, R. G., Reed, R. M., Ruppel, S. C., and Hammes, U. (2012). Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 96, 1071–1098. doi:10.1306/08171111061

Ma, K., Hou, J., and Dong, H. (2022). Pore throat characteristics of fine-grained mixed deposits in shale oil reservoirs and their control on reservoir physical properties: a case study of the Permian Lucaogou Formation, Jimsar Sag, Junggar Basin. Oil Gas. Geol. 43, 1194–1205.

Ogbonnaya, O., Suriamin, F., Shiau, B., and Harwell, J. H. (2024). Enhanced oil recovery formulations for liquid-rich shale reservoirs. Fuel 368, 131573. doi:10.1016/j.fuel.2024.131573

Ougier-Simonin, A., Renard, F., Boehm, C., and Vidal-Gilbert, S. (2016). Microfracturing and microporosity in shales. Earth-Sci. Rev. 162, 198–226. doi:10.1016/j.earscirev.2016.09.006

Schimmelmann, A., Boudou, J.-P., Lewan, M. D., and Wintsch, R. P. (2001). Experimental controls on D/H and 13 C/12 C ratios of kerogen, bitumen and oil during hydrous pyrolysis. Org. Geochem. 32, 1009–1018. doi:10.1016/S0146-6380(01)00059-6

Schmoker, J. W. (1996). A resource evaluation of the bakken formation (Upper Devonian and Lower Mississippian) continuous oil accumulation, Williston Basin, North Dakota and Montana. Mt. Geol.

Shao, X., Pang, X., Li, M., Qian, M., Hu, T., Li, Z., et al. (2020). Hydrocarbon retention in lacustrine shales during thermal maturation: insights from semi-open system pyrolysis. J. Pet. Sci. Eng. 184, 106480. doi:10.1016/j.petrol.2019.106480

Sing, K. S. W. (1985). Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 57, 603–619. doi:10.1351/pac198557040603

Smirnov, I. V., Biriukov, K. O., Shvydkiy, N. V., Perekalin, D. S., Afanasyev, O. I., and Chusov, D. (2024). Air-stable arene manganese complexes as catalysts for the syngas-assisted direct reductive amination, cyanation of aldehyde, and CO2 fixation by epoxide with high functional groups tolerance. J. Org. Chem. 89, 10338–10343. doi:10.1021/acs.joc.4c00842

Sweeney, J. J., and Burnham, A. K. (1990). Evaluation of a simple model of vitrinite reflectance based on chemical kinetics. AAPG Bull. 74, 1559–1570. doi:10.1306/0c9b251f-1710-11d7-8645000102c1865d

Tang, Y., Cao, J., He, W.-J., Guo, X.-G., Zhao, K.-B., and Li, W.-W. (2021). Discovery of shale oil in alkaline lacustrine basins: the late paleozoic Fengcheng Formation, Mahu sag, Junggar Basin, China. Pet. Sci. 18, 1281–1293. doi:10.1016/j.petsci.2021.04.001

Tang, Y., He, W., Jiang, Y., Fei, L., Shan, X., Zhao, Y., et al. (2023). Enrichment conditions and exploration direction of Permian saline lacustrine shale oil and gas in Junggar Basin. Acta Pet. Sin. 44, 125.

Tang, Y., Wang, X., Wang, T., Hei, C., Liang, S., and Cheng, H. (2024). Reconstruction of sedimentary paleoenvironment of Permian Lucaogou Formation and its implications for the organic matter enrichment in south-eastern Junggar Basin, China. Front. Earth Sci. 18, 526–537. doi:10.1007/s11707-022-1070-6

Tissot, B., and Espitalie, J. (1975). L’evolution thermique de la matière organique des sédiments: applications d’une simulation mathématique. Potentiel pétrolier des bassins sédimentaires de reconstitution de l’histoire thermique des sédiments. Rev. Inst. Francais Pet. 30, 743–778. doi:10.2516/ogst:1975026

Wang, C. Y., Kuang, L. C., Gao, G., Cui, W., Kong, Y. H., Xiang, B. L., et al. (2014). Difference in hydrocarbon generation potential of the shaly source rocks in Jimusar Sag, Permian Lucaogou Formation. Acta Sedimentol. Sin. 32, 385–390.

Wang, E., Feng, Y., Guo, T., and Li, M. (2022a). Oil content and resource quality evaluation methods for lacustrine shale: a review and a novel three-dimensional quality evaluation model. Earth-Sci. Rev. 232, 104134. doi:10.1016/j.earscirev.2022.104134

Wang, E., Li, C., Feng, Y., Song, Y., Guo, T., Li, M., et al. (2022b). Novel method for determining the oil moveable threshold and an innovative model for evaluating the oil content in shales. Energy 239, 121848. doi:10.1016/j.energy.2021.121848

Wang, Y., Han, X., Gao, Z., and Jiang, X. (2022). Thermal cracking of the large molecular alcohols in shale oil by experimental study and kinetic modeling. J. Anal. Appl. Pyrolysis 168, 105749. doi:10.1016/j.jaap.2022.105749

Waples, D. W. (1980). Time and temperature in petroleum formation: application of Lopatin’s method to petroleum exploration. AAPG Bull. 64, 916–926. doi:10.1306/2f9193d2-16ce-11d7-8645000102c1865d

Xiao, Z., Chen, S., Liu, C., Lu, Z., Zhu, J., and Han, M. (2021). Lake basin evolution from early to Middle permian and origin of triassic baikouquan oil in the western margin of Mahu sag, Junggar Basin, China: evidence from geochemistry. J. Pet. Sci. Eng. 203, 108612. doi:10.1016/j.petrol.2021.108612

Zhang, C., Liu, D.-D., Jiang, Z.-X., Song, Y., Luo, Q., and Wang, X. (2022). Mechanism for the formation of natural fractures and their effects on shale oil accumulation in Junggar Basin, NW China. Int. J. Coal Geol. 254, 103973. doi:10.1016/j.coal.2022.103973

Zhang, J., Cao, J., Xiang, B., Zhou, N., Ma, W., and Li, E. (2019). Fourier-transform infrared proxies for oil source and maturity: insights from the early permian alkaline lacustrine system, Junggar Basinbasin (NW China). Energy fuels. 33, 10704–10717. doi:10.1021/acs.energyfuels.9b02586

Zhang Y, Y., Hu, S., Shen, C., Liao, Z., Xu, J., and Zhang, X. (2022). Factors influencing the evolution of shale pores in enclosed and semi-enclosed thermal simulation experiments, Permian Lucaogou Formation, Santanghu Basin, China. Mar. Pet. Geol. 135, 105421. doi:10.1016/j.marpetgeo.2021.105421

Zhang, Z., Yuan, X., Wang, M., Zhou, C., Tang, Y., Chen, X., et al. (2018). Alkaline-lacustrine deposition and paleoenvironmental evolution in permian Fengcheng Formation at the Mahu sag, Junggar Basin, NW China. Pet. Explor. Dev. 45, 1036–1049. doi:10.1016/S1876-3804(18)30107-1

Zhao, W., Hu, S., and Hou, L. (2018). Connotation and strategic role of in-situ conversion processing of shale oil underground in the onshore China. Pet. Explor. Dev. 45, 563–572. doi:10.1016/S1876-3804(18)30063-6

Zhao, W., Hu, S., Hou, L., Yang, T., Li, X., Guo, B., et al. (2020). Types and resource potential of continental shale oil in China and its boundary with tight oil. Pet. Explor. Dev. 47, 1–11. doi:10.1016/S1876-3804(20)60001-5

Zhao, W., Bian, C., Li, Y., Liu, W., Dong, J., Wang, K., et al. (2023). Organic matter transformation ratio, hydrocarbon expulsion efficiency and shale oil enrichment type in Chang 73 shale of Upper Triassic Yanchang Formation in Ordos Basin, NW China. Pet. Explor. Dev. 50, 14–26. doi:10.1016/S1876-3804(22)60366-5

Zhi, D. M., Tang, Y., Yang, Z. F., Guo, X. G., Zheng, M. L., Wan, M., et al. (2019). Geological characteristics and accumulation mechanism of continental shale oil in Jimusaer sag, Junggar Basin. Oil Gas. Geol. 40, 524–534.

Keywords: shale oil, Fengcheng shale, lucaogou shale, Junggar Basin, thermal simulation

Citation: He W, Li Z, Li C, He J, Leng J, Sun Z, Liu D and Yang S (2025) Hydrocarbon generation, expulsion, and retention characteristics of the Permian Fengcheng shale and Lucaogou shale in the Junggar Basin: implications for the exploration of lacustrine shale oil. Front. Earth Sci. 12:1525983. doi: 10.3389/feart.2024.1525983

Received: 11 November 2024; Accepted: 20 December 2024;

Published: 15 January 2025.

Edited by:

Tao Hu, China University of Petroleum, Beijing, ChinaReviewed by:

Yue Feng, PetroChina Changqing Oilfield Company, ChinaCopyright © 2025 He, Li, Li, He, Leng, Sun, Liu and Yang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhiming Li, lizm.syky@sinopec.com

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.