- 1Department of Food, Bioprocessing, and Nutrition Sciences, North Carolina State University, Raleigh, NC, United States

- 2Department of Food Science and Technology, Oregon State University, Corvallis, OR, United States

Accelerating decarbonization in the food and beverage industry is critical to reducing greenhouse gas (GHG) emissions, as this sector accounts for approximately one-third of total emissions globally. Electrified, non-thermal food processing technologies offer promising alternatives to conventional thermal methods by improving energy efficiency and enabling cross-sectoral decarbonization. However, direct comparisons of their costs and environmental impacts remain limited due to the early-stage development of some technologies and variability in system configurations. This study provides a comprehensive review of four key non-thermal food processing technologies: high-pressure processing (HPP), pulsed electric fields (PEF), cold plasma, and ultraviolet light (UV). Using orange juice production as an illustrative case study, their industrial sustainability was evaluated through life cycle assessment (LCA) and technoeconomic analysis (TEA). Our LCA/TEA results show that, compared to conventional thermal pasteurization, orange juice processed with non-thermal technologies has slightly higher selling prices, with HPP being the most expensive. The carbon footprints of non-thermal processes are comparable to or lower than those of thermal pasteurization. This review offers valuable insights into the sustainability of various non-thermal food technologies, identifies key environmental and economic hotspots for industrial application, and serves as a guide for advancing sustainable practices in the food industry.

1 Introduction

Decisive actions are expected to mitigate the impacts of global climate change. Among industrial sectors, the food and beverage industry has gained growing attention due to its significant contribution to global greenhouse gas (GHG) emissions (Crippa et al., 2021). Given the increasing food demand to meet the growing population by 2050, and the fact that the food industry heavily depends on fossil fuels for heating and cooling in various unit operations (Ladha-Sabur et al., 2019; Searchinger, 2019; DOE, 2022), the need to develop GHG mitigation strategies has never been greater. The food and beverage industry also ranked as the fifth-largest energy consumer among U. S. manufacturing sectors, as reported in 2018 (U.S. Energy Information Administration, 2023). Despite its high energy demand, the food and beverage industry face substantial barriers to improve energy efficiency. According to the U. S. Department of Energy, the total energy losses were up to 60% in food sector (Department of Energy, 2018). These challenges come from both technical and non-technical factors, such as the complexity of food processing systems, the use of energy-intensive equipment, the stringent standards of food quality and safety, and profitability concerns (Clairand et al., 2020). Given that energy efficiency is a foundational and the most cost-effective option for GHG reductions in the near term (DOE, 2022), exploring and implementing energy-efficient strategies for the food and beverage industry is crucial for reducing energy consumption, lowering operational costs, and improving environmental sustainability.

Several approaches have been proposed to improve energy efficiency and sustainability in the food and beverage industry, such as alternative or hybrid drying technologies (Menon et al., 2020), waste heat recovery technologies (Chowdhury et al., 2018), and the adoption of renewable energy (Taibi et al., 2012). Among these proposed approaches, non-thermal food processing technologies have been explored as a sustainable option to conventional energy-intensive thermal processing (Picart-Palmade et al., 2018; Chakka et al., 2021). Non-thermal processes require ambient or lower temperatures than conventional thermal processes, reducing energy demands for both heating and cooling, while maintaining high food quality by minimizing the deleterious effects of heat on sensory properties and nutrition (Pereira and Vicente, 2010). In recent decades, a variety of non-thermal food processing technologies have been explored, with varying technology readiness levels (TRL). Some have achieved commercial success for certain food products (Aganovic et al., 2017). For instance, high pressure processing (HPP) has been used to produce cold-pressed juices with a better retention of flavor (Wu et al., 2012), pulsed electric field (PEF) has been used as a pretreatment for fried potato products to improve frying efficiency and product quality (Corrales et al., 2008), and germicidal ultraviolet C (UV-C) light, with long proven effective for water and surfaces disinfection, has been applied in beverage processing and package sterilization (Rocha et al., 2015). Some technologies, such as cold plasma (CP), are currently at a lower TRL in the food and beverage industry (Dalsgaard and Abbotts, 2003), but have shown significant promise in applications (Sarangapani et al., 2017).

Despite the potential of non-thermal technologies, their adoption in the food industry remains limited. At an industrial scale, these technologies are integrated into specific food processing lines, each with unique process configurations and requirements. Moreover, different non-thermal technologies serve distinct functions depending on the application, further complicating efforts to assess their sustainability. These variations, combined with a lack of primary data, have resulted in limited comprehensive analyses to fully evaluate the sustainability potential of these emerging technologies (Chakka et al., 2021). This review aims to address this research gap by conducting a systematic review of environmental impact assessments of non-thermal food processing technologies published between 2000 and 2023. To further illustrate the potential industry implications, we’ll also perform life cycle assessment (LCA) and technoeconomic analysis (TEA) to evaluate and compare selected non-thermal technologies from both environmental and economic perspectives, using orange juice processing as a representative case study. Specifically, we focused on HPP, PEF, CP, and UV-C, which are selected based on their industrial potential and availability in the literature. Orange juice processing serves as a representative case study due to its relatively abundant data and its relevance to various non-thermal processing techniques. The findings from this review have the potential to provide critical insights into the sustainability of non-thermal food processing technologies, identifying opportunities and barriers to their broader industrial adoption.

2 Review of selected non-thermal food processing technologies and their sustainability

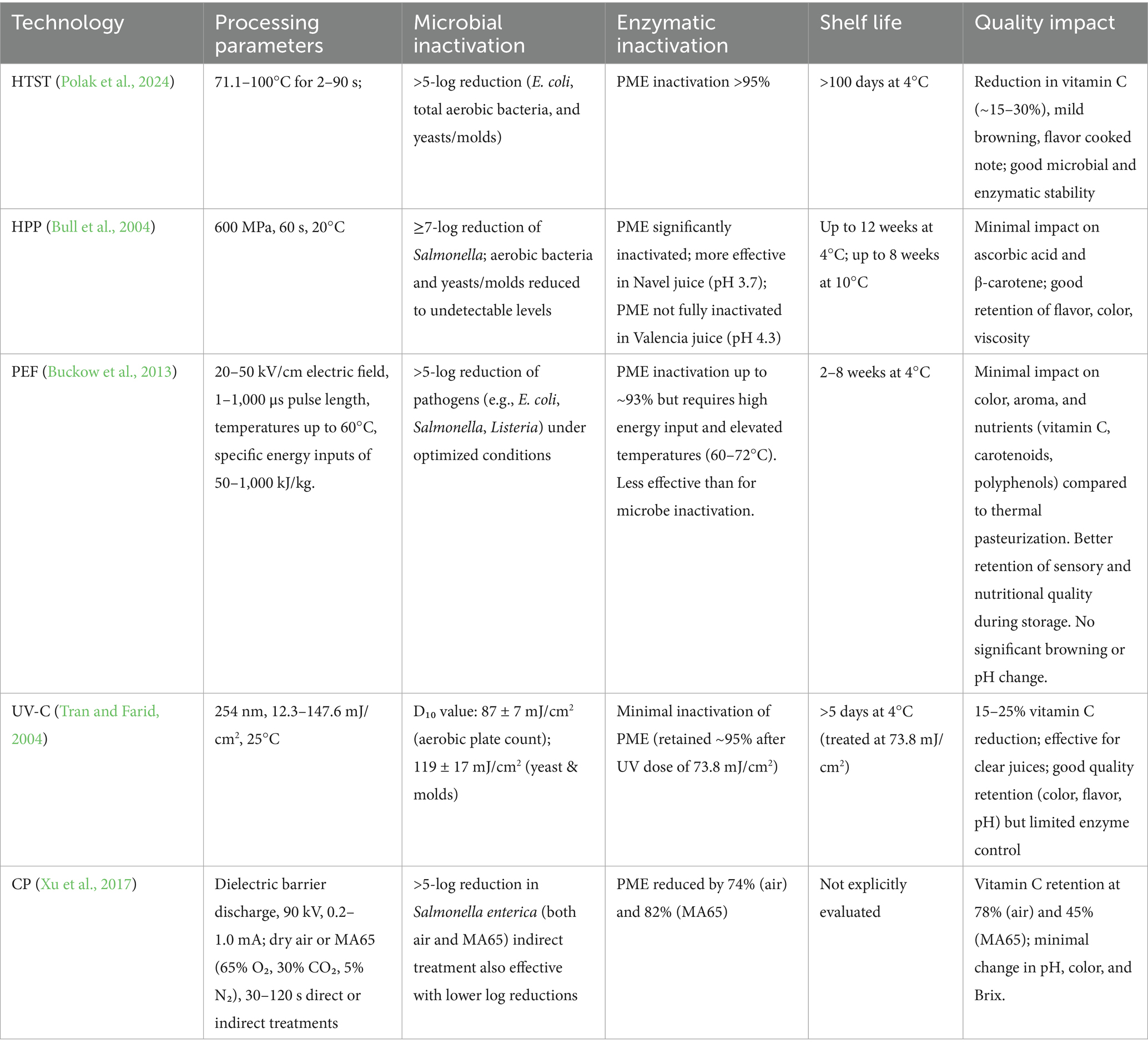

A systematic review was conducted to understand the state-of-art environmental sustainability via life-cycle assessment (LCA) approach of non-thermal food processing technologies. LCA has been widely applied to evaluate environmental sustainability or footprints in emerging fields such as renewable fuels, alternative proteins, and carbon removal (Terlouw et al., 2021; Yoo et al., 2022; Sinke et al., 2023). We selected databases with multidisciplinary coverage such as the Web of Science and specific coverage in agri-food and bioprocessing such as AGRICOLA to assist the screening process for eligible studies. Keyword used in the screening process was: (LCA OR life cycle assessment OR environmental footprint OR environmental impact OR energy consumption) AND (non-thermal food processing OR non-thermal food technology). We then refined the search results by filtering additional search criteria: publication time after the year of 2,000, English only, peer-reviewed research paper, and excluding review articles. After the initial screening, 92 records were identified through the database search. Upon further review, 2 peer-reviewed articles met our inclusion criteria. We further identified 8 additional articles of interests from citation within the previously selected articles. Thus, a total of 10 peer-reviewed research articles published after the year of 2,000 were identified to serve the purpose of this study. Related numerical results of the 10 articles can be found in Table 1. The results from literature screening process indicates that limited studies have been conducted to investigate the environmental sustainability of non-thermal food processing technologies since 2,000. With the 10 published studies, global research community mainly focuses on the application of HPP and PEF in fruit juice preservation.

Table 1. Environmental sustainability studies of non-thermal food processing technologies focusing on carbon footprint and energy consumption (2000–present).

2.1 High pressure processing (HPP)

HPP, also known as high hydrostatic pressure, is a non-thermal food processing method that involves subjecting food products to extremely high pressures. The food product is commonly packed in a high-pressure suitable container and immersed in a pressure-transmitting fluid, usually pure water, held under pressure for certain times until decompression (Balasubramaniam, 2016). It is generally accepted that pressure is transmitted rapidly and uniformly in an isostatic manner throughout the food product. In commercial pasteurization-equivalent food applications, HPP equipment with the vessel capacity of 35–525 L operating in a pressure range of 200–600 MPa at ambient or chilled temperature with holding time from 2 to 5 min is usually applied (Hiperbaric, 2022). Since the process is performed at ambient or lower temperature where thermal load is marginal, it is considered a non-thermal pasteurization-equivalent food application. The high pressure inactivates pathogenic and spoilage microorganisms and enzymes by altering large molecular components, changing cell morphology, and damaging cell membrane permeability (Sehrawat et al., 2021), However, because high pressure has limited effects on covalent bonds, it preserves bioactive compounds and key sensory components, maintaining the food’s nutritional quality and fresh-like attributes (Liu et al., 2023). HPP has been applied in a wide range of food categories, including fresh produce, meats, seafood, eggs, dairy, juices and beverages, and ready-to-eat products such as sauces and dressings, to improve food safety and enhance quality (Rastogi et al., 2007; Oey et al., 2008; Devi et al., 2013). In addition, HPP has been used for developing new food ingredients or products by modifying food’s physical and functional properties (Balasubramaniam, 2021). In the U. S., HPP has been approved by the U. S. Food and Drug Administration (FDA) as an alternative pasteurization technology for microbial inactivation.

HPP is regarded a potentially green technology since it primarily relies on electricity rather than fossil fuels to generate high pressure. Energy consumption for HPP is concentrated in the compression phase of the process; once the target pressure is achieved, no additional energy is required to maintain it (Balasubramaniam, 2021). The process reduces the need for natural gas and other forms of energy by eliminating the need for heating and reducing cooling system requirements. HPP is also considered a waste-free process because pre-sterilization of packaging material using sanitizing agents is unnecessary, limiting wastewater generation. In HPP process, water serves as the pressure transmitting medium and is typically recycled (Balasubramaniam, 2021). However, the GHG emission and energy consumption associated with HPP remain a subject of debate. LCA studies have reported varying impacts of HPP in terms of GHG emissions. For instance, by comparing orange juice processing, it was reported that equivalent CO2 annual emission for HPP was about 773,000 kg, whereas for thermal pasteurization the number was 90,000 kg, significantly lower than HPP. The authors identified that the higher equivalent CO2 emissions of HPP were due to the higher electricity consumption (Sampedro et al., 2014). Conversely, another study reported that HPP processing of Parma ham outperformed conventional thermal treatments in terms of GHG emissions and other environmental impact categories, such as water consumption and fossil resource scarcity (Cacace et al., 2020). A few other studies have indicated no significant differences in environmental impact between HPP, conventional pasteurization, and other selected non-thermal technologies for fruit and vegetable juices (Davis et al., 2010; Aganovic et al., 2017). It is important to recognize that specific energies and environmental impacts are sensitive to equipment design and operation conditions. For example, a theoretical model suggests that the energy performance of HPP improves with larger scale and higher vessel fill ratio (Atuonwu et al., 2019). Process optimization should also be tailored to specific food product. Due to the emerging nature of HPP, the evolving systems, different energy recovery considerations, and the limited number of studies, it is currently difficult to draw general conclusions regarding the overall sustainability of HPP compared to conventional thermal processes.

The appealing properties of HPP have driven its development and successful commercialization. In the past, the potential of HPP for commercial utilization was limited by the capacity of the pressure vessels and the high cost of HPP unit (Torres and Velazquez, 2005). With advancements in technology and reductions in equipment costs, the process has become more accessible for a broader range of products (Aganovic et al., 2021). Despite the decrease in equipment costs, the operational costs associated with HPP remain high. Particularly, the high cost of electricity makes it less economical than gas-powered conventional thermal processing systems. It has been suggested that as the proportion of renewable energy in electricity generation increases, electrically powered innovative technologies such as HPP will become more economically competitive (Atuonwu et al., 2019).

2.2 Pulsed electric field (PEF)

PEF is a non-thermal processing method that uses short (1–100 μs) but high-voltage (typically 20–80 kV/cm) electrical pulses to inactivate microorganisms or enzymes in food products. The process consists of applying an electric field to biological cells to damage the cell membrane, a process named “electroporation,” thereby causing cell death (Arshad et al., 2021). In terms of enzyme inactivation, generally higher energy levels than those required to destroy microorganisms are needed (Martín-Belloso and Elez-Martínez, 2005). Various studies have shown the efficacy of PEF treatment for inactivating a wide range of pathogenic and spoilage microorganisms, though sufficient reduction of microorganisms has been mostly proven in liquid and semi-liquid foods such as juices, beverages, milk, and liquid eggs (Nowosad et al., 2021). Research indicates that PEF pasteurization of plant-based juices at mild temperatures minimizes changes in physicochemical characteristics, including color and flavor, while preserving health-related biomolecules more effectively than conventional thermal processing (Abbas Syed, 2017). Despite its advantages, drawbacks exist such as the potential hazard of metal ion leakage from electrode corrosion and the risk of under- or overtreatment due to uneven electric field distribution (Roodenburg et al., 2005; Roobab et al., 2018). PEF has already been adopted for commercial non-thermal pasteurization of fruit juices in the U. S. since 2005 (Janahar et al., 2022). Beyond its use as a standalone treatment, PEF has been suggested for combination with mild heat to enhance microbial and enzyme inactivation efficacy (Martín-Belloso and Sobrino-López, 2011). In addition to liquid food pasteurization, PEF has been explored for other applications in the food industry, such as improving drying efficiency and extraction of intracellular compounds.

The efficacy of inactivating microbial by PEF treatment is highly associated with the generated electric field strength: the higher electric-field strength, the higher lethality of this treatment (Heinz and Knorr, 2000; Heinz et al., 2003). Hence, relative to conventional thermal processing, PEF treatment often requires high capital investment and operating costs for the generation of high electric field strength (Sampedro et al., 2013). In terms of energy consumption, studies reported that PEF treatment can either result in energy savings or require higher energy input depending on food processing conditions. For example, PEF treatment can enhance extraction yield in olive processing and shorten maceration time in grape winemaking, thereby reducing electricity consumption during these stages. However, the overall energy savings across the entire wine production life cycle remain minimal (Ferreira et al., 2019). In tomato juice pasteurization, higher energy uptake were reported for PEF (0.12 kWh/L of juice) than conventional thermal processing (0.04 kWh/L of juice) for achieving the same level of microbial inactivation (Heinz et al., 2003). Combining with other treatments such as heat and antimicrobial, the energy required for generating electric field strength by PEF could be lowered while still achieving desired level of lethality (Chemat et al., 2017). When increasing PEF treatment temperature from 20–30°C to 55–65°C, Heinz et al. (2003) found that the specific energy consumption can be reduced from above 100 kJ/kg to <40 kJ/kg of juice, mainly due to synergetic effects of PEF and temperature. In addition, studies have suggested the potential of PEF to reduce energy consumption in mass transfer processes such as extraction or pressing. For instance, PEF-treated carrots showed an increase in juice yield from 60.15 to 66.4% compared with untreated samples, indicating that PEF could possibly lower the energy required for juice pressing (Toepfl et al., 2006). In another study where PEF was applied as a pre-treatment for drying chicken meat, total energy consumption was significantly reduced, with the most efficient results observed at 60°C. This effect was attributed to accelerated dewatering of PEF-treated meat products (Ghosh et al., 2020). Compared to other non-thermal technologies such as HPP, Aganovic et al. (2017) reported that while PEF demonstrated slightly lower energy consumption and life cycle impact for watermelon and tomato juice pasteurization, the differences were minor (Aganovic et al., 2017). Davis et al. (2010) highlighted that when considering the entire supply chain from “farm to gate,” the GHG emissions from PEF and HPP processing were relatively small compared to the impacts of other stages, such as fruit production, PET bottle manufacturing, and transportation (Davis et al., 2010).

2.3 Cold plasma (CP)

Plasma is partially ionized gas containing atoms or molecules in a metastable state with a roughly zero net electrical charge (Misra et al., 2019). CP, also referred to as low-temperature plasma, is plasma generated under low-pressure or atmospheric pressure without high temperature conditions (< 60°C). In recent years, CP has attracted growing interests in the food sector as a non-thermal technology due to its effectiveness against major foodborne pathogenic microorganisms (Pankaj et al., 2018). Extensive studies have been conducted to explore ways to apply this emerging technology for the food and beverage industry. So far, the promising application of CP has been mostly limited to surface decontamination, on food contact surfaces or food surfaces, to improve the safety of product, reduce cross-contamination, and extend product shelf life (Ucar et al., 2021). The decontamination of CP is particularly effective for even and smooth surfaces, while treatment of foods with rough, irregular surfaces needs further studies to improve efficacy due to the limited travel distances of the short-lived reactive species (Bhide et al., 2017). CP contains a variety of reactive species, including positive and negative ions, free radicals, electrons, photons, and gas molecules, that work synergistically for microbial inactivation by damaging multiple targets of microbial cells such as nucleic acids, lipids, and enzymes (Ucar et al., 2021). Most studies claimed that CP treatment does not cause significant quality changes in the treated food products within their treatment conditions. However, defining the appropriate dosage of CP remains challenging due to variations in CP system and the compositions of the reactive species generated. As a result, comparing the effectiveness of CP and optimizing processes for specific product is difficult (Misra et al., 2016). Recently, some studies have explored the use of CP for liquid food treatment, such as juices and milk (Pohl et al., 2022). However, since CP is a relatively new technology, its safety implications for food components, particularly potential toxicological concerns related to generated ozone, nitric oxide, and other reactive species, remain insufficiently studied. Regulatory agencies have not yet approved CP as a food safety process (Food Safety News, 2024).

Although research on the sustainability of CP technology is limited, several studies suggest it is energy efficient (Bourke et al., 2018; Chakka et al., 2021). One key advantage of CP is its operation at ambient temperature, making it suitable for heat-sensitive food products while reducing energy consumption (Niemira, 2012; Obileke et al., 2022; Thirumdas et al., 2015). After CP treatment, minimal residues are expected, as the short-lived reactive species generated during the process quickly recombine and revert to their original gaseous state under optimal conditions (Chizoba Ekezie et al., 2017; Obileke et al., 2022). Additionally, CP requires minimal water consumption, and its energy input can be adjusted based on system configuration (Misra et al., 2016). When used as a sanitizer, plasma-activated water (water exposed to CP) in fresh produce washing can potentially be reused and recycled, as plasma continuously generates reactive species to eliminate contaminants (Patange et al., 2019). However, the capital cost of CP varies depending on the system and intended application, making it difficult to generalize. Detailed cost analyses also remain limited (Chakka et al., 2021; Lee et al., 2005; Niemira, 2012).

2.4 Ultraviolet light (UV)

UV light is a well-established, non-ionizing radiation widely used for the disinfection of surface, water, and air (Koutchma, 2009). Depending on the wavelengths on the electromagnetic spectrum, UV can be classified into UV-A (315–400 nm), UV-B (280–315 nm), and UV-C (200–280 nm). Of these, UV-C light is the most effective for microbial inactivation due to its wavelength range aligns with the peak absorption range of nucleic acids in microorganisms (Kesavan and Sagripanti, 2013). In the food industry, UV is one of the most researched non-thermal technologies and has been commercially utilized for multiple purposes, including disinfection of solid and liquid foods and food contact surfaces. The United States Food and Drug Administration (FDA) has approved UV treatment for food processing and handling under safe conditions (FDA, 2000). Key advantages of UV treatment in the food industry include its chemical-free process, minimal waste generation, minimal loss of food nutrients and quality attributes, cost-effectiveness, ease of implementation and maintenance, and low energy requirements (Pereira and Vicente, 2010). The low penetration depth and to dose distribution is its major limitation. UV light cannot reach microorganisms embedded within opaque or solid products. In liquid treatment, particles in turbid fluids can scatter the light and reduce its effectiveness. As a result, UV treatment is primarily limited to surface applications and clear liquids. Even in surface treatments, complex or irregular surfaces can create shadowing effects, preventing microorganisms from receiving the necessary UV dose and ultimately lowering the treatment efficacy. Combining UV light with other food processing techniques as a treatment, such as chemical sanitizers, may be a way to overcome its limitations and enhance overall effectiveness (Singh et al., 2021).

UV treatment is generally considered an environmentally friendly non-thermal technology due to its energy efficiency, waterless application, lack of chemical residues, ease of operation, and cost advantages over other approaches, although they may vary depending on the UV light source (Bintsis et al., 2000). While traditional mercury-based UV lamps are effective, they pose a potential food safety risk of introducing toxic mercury if broken. UV light emitting diodes (UV LEDs) are gaining popularity in the food industry due to their mercury-free design, flexible sizes, high efficiency, long lifespan, and ability to switch on and off instantly. Despite these advantages, UV LEDs may require improved electrical efficiency and optimized reactor designs to match the microbial reduction performance of conventional UV lamps (Beck et al., 2017). Krypton-chloride excimer lamps (also known as far-UV with a typical wavelength at 222 nm) is another mercury free alternative. Excimer lamps are reported as effective as conventional UV-C (254 nm) lamps, having a longer life span, and are considered safer for human exposure (Eadie et al., 2022). However, they are more expensive, and their efficacy against certain microorganisms requires further valuations.

3 Case study: sustainability assessment of orange juice processing

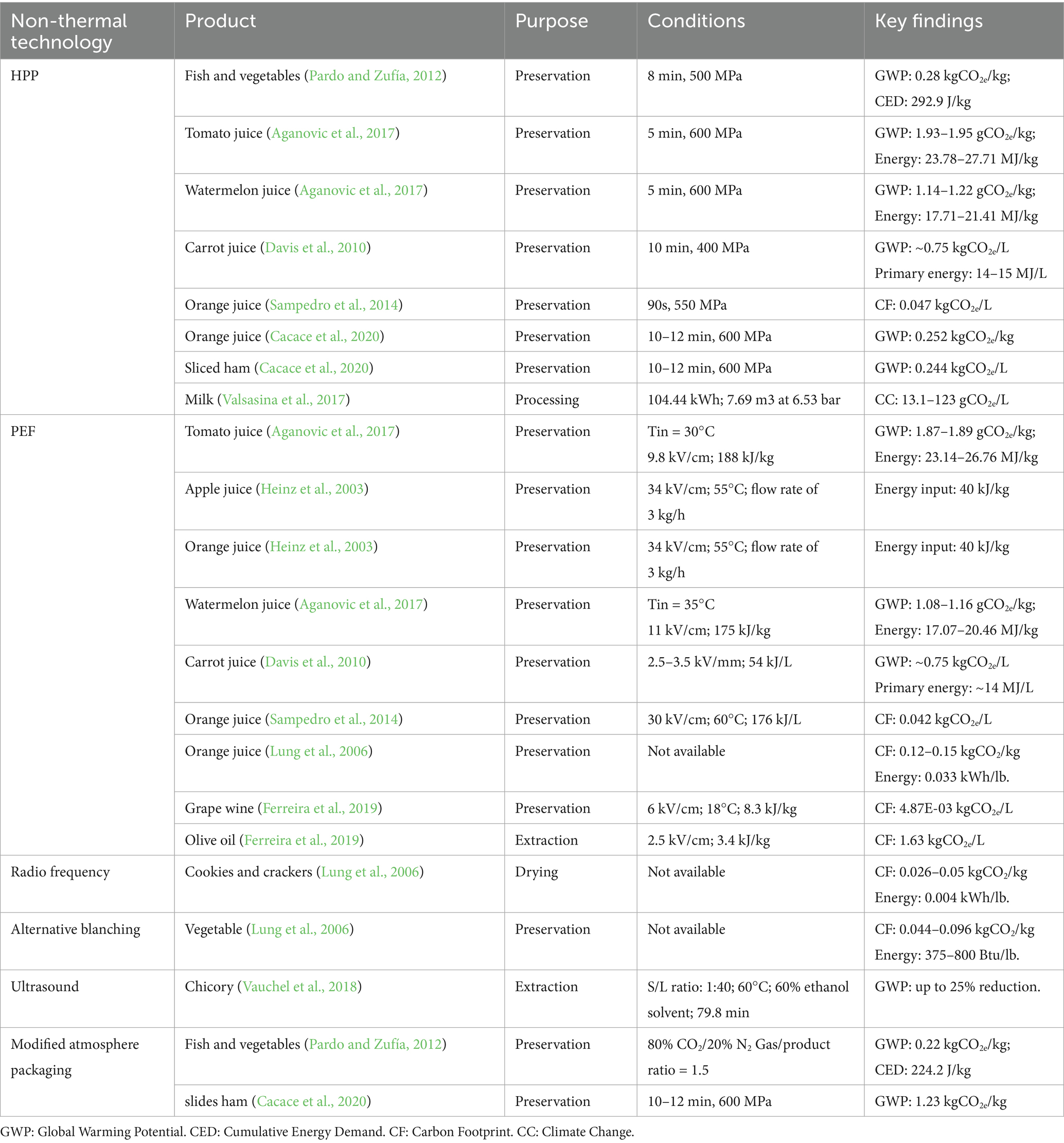

Although non-thermal food processing technologies are labeled as environmentally friendly, green and sustainable, our critical review reveals that comprehensive sustainability assessments have been conducted for only a few of these technologies, let alone direct and straightforward sustainability comparisons among different technologies. Without numerical data, tracking sustainability progress in this emerging field is challenging. To address this gap, we conducted a life-cycle assessment (LCA) and technoeconomic analysis (TEA) to evaluate both the environmental sustainability and cost feasibility of key non-thermal food processing technologies, including high-pressure processing (HPP), pulsed electric field (PEF), cold plasma (CP), and ultraviolet (UV) treatment. As a benchmark for comparison, we also modeled conventional high-temperature and short-time (HTST) pasteurization of orange juice with the conditions for HTST to be 90°C for 60 s (Intelligen, 2023). We carefully selected the reported conditions of the non-thermal technologies (NTTs) (HPP, PEF, UV, and CP) based on recent and reliable data available in peer-reviewed articles. Selection criteria include data source of articles, the year of the published work, target food item, microbial deactivation effect, and completeness of dataset. In selecting conditions for the modeled scenarios, we assumed that the juice products resulting from non-thermal processes are pasteurization-equivalent, i.e., achieving microbial stability and shelf-life comparable to thermally pasteurized juice, not to shelf-stable juice. This assumption was based on peer-reviewed studies reporting that HPP and PEF treatments can meet microbial safety targets and offer refrigerated shelf-life ranging from 1 to 3 months, depending on process parameters and juice characteristics (Carbonell et al., 2013; Daher et al., 2017; Fabroni et al., 2024; Timmermans et al., 2011; Zulueta et al., 2013). UV commonly offers a shelf life shorter than the other commercialized treatment (5–14 days) depending on the clarity of the juice (Tran and Farid, 2004). CP, while less commercially mature, has shown promising microbial inactivation and shelf-life extension under experimental conditions (Dzimitrowicz et al., 2022; Xu et al., 2017). All selected NTT scenarios target refrigerated juice products with fresh-like attributes, aligned with the market category for HTST-treated juice. Representative quality properties of orange juice products pasteurized through HTST and selected NTTs are summarized in Table 2. Simplified process flow diagram of orange juice production using these NTTs can be found in Figure 1. Detailed description on treatment parameters, process modeling, TEA and LCA can be found in the Supplementary materials.

Figure 1. Simplified process flow diagram of orange juice production using 4 non-thermal food processing technologies. HPP conditions and related process parameters were adopted from Cacace et al. (2020) and Sampedro et al. (2014); PEF conditions from Sampedro et al. (2013); CP conditions from Xu et al. (2017); UV conditions from Tran and Farid (2004).

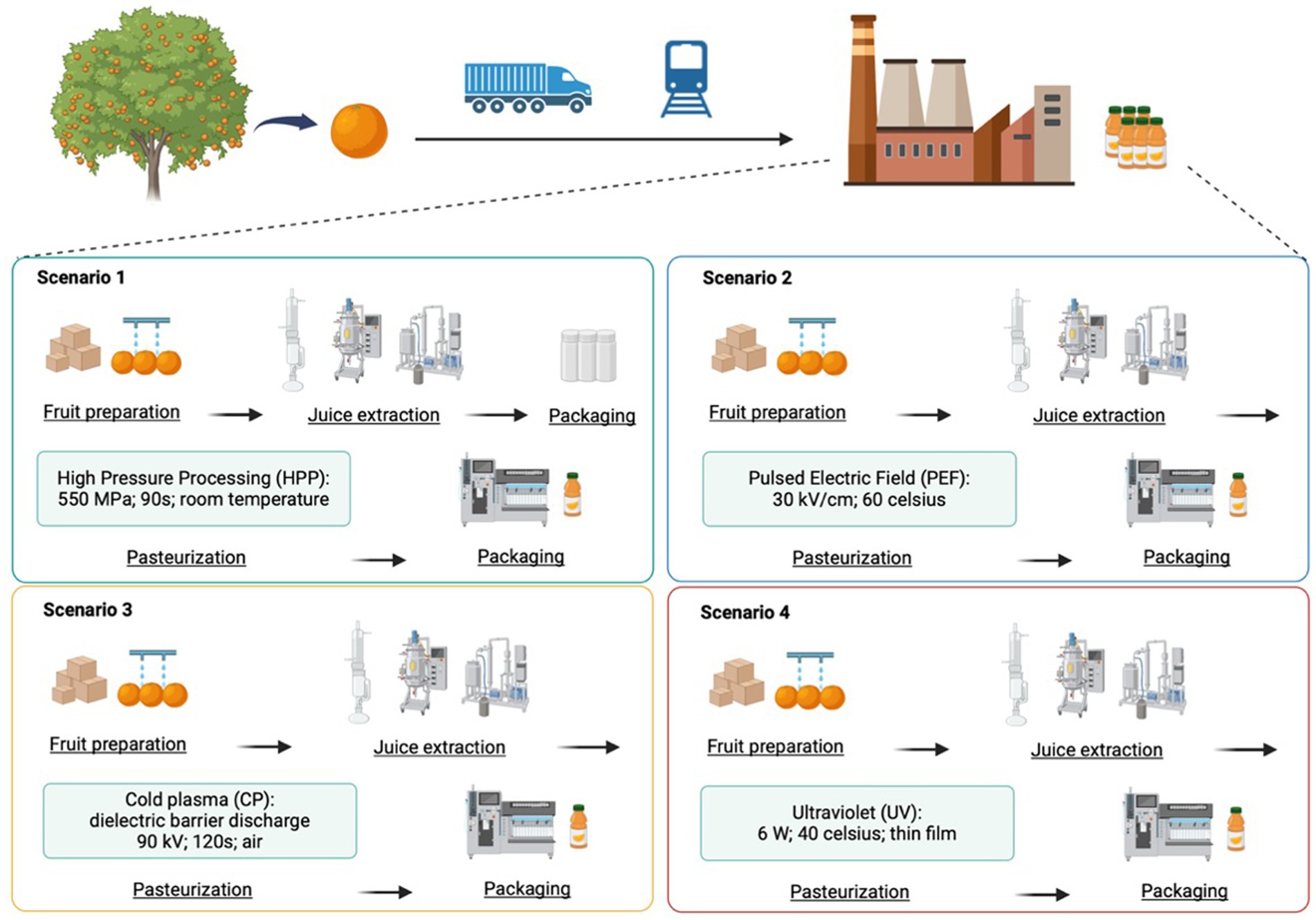

TEA results indicate that for all NTT scenarios, the costs are comparable or higher relative to the base case thermal processing. In the base case, the MSP of orange juice is found to be $1.62/kg using HTST. Switching to HPP, the MSP increases to $1.66/kg mainly due to the high equipment cost of HPP unit. PEF pasteurization is slightly lower than HPP, but still higher than that of HTST ($1.64/kg). As for CP and UV pasteurization, the MSPs are similar to thermal processing, about $1.63/kg and $1.62/kg, respectively. These are mainly due to their low equipment costs and operating costs. Figure 2A provides a cost contribution for these 4 NTT scenarios in orange juice production plant. Regardless of the NTT scenario, feedstock (raw orange) cost is the largest cost contributors to the final MSPs. Among these 4scenarios, cost contribution from using HPP for pasteurization is the highest, followed by the PEF due to their high capital investments. CP and UV require less CAPEX and OPEX investments. Comparing with other published studies in this field, we find similar cost trends for these NTTs. Chakka et al. (2021) performed a literature review on the sustainability of different NTT technologies, and reported that CP has low equipment and operational costs, and PEF has high capital costs.

Figure 2. TEA and LCA results of orange juice produced using 4 non-thermal food processing technologies. HPP, high pressure processing; PEF, pulsed electric field; CP, cold plasma; UV, ultraviolet.

It is worth noting that, although four NTTs discussed in the case study are in the early stage of development, CP is the most nascent and has not yet been applied for commercial pasteurization. This contributes to relatively high uncertainty associated with MSPs than other NTTs. Given the premature nature of CP in large-scale food industry applications and lack of process optimization and standardization, ideal assumptions are made in this study for sustainability analysis. For instance, during plasma generation, we assume no GHG emission was associated with it; however, depending on the generating gas such as air or nitrogen, indirect emissions like N2O could be observed. Besides, the equipment cost may vary among the diverse CP systems. The chemical safety aspect of CP treated juices also remains unclear (Ozen and Singh, 2020).

As for carbon footprint, the results follow the same trend to costs: relative comparable to or higher than that of base case thermal processing. Regardless of the NTT scenarios, the orange cultivation in CA and transportation emissions stay the same. The largest emission differences among 4 NTTs come from the energy consumption in the juice processing stage. HPP requires the highest energy use, followed by PEF, resulting in high carbon footprints than those generated by UV or CP (see Figure 2B for carbon footprint results). Despite higher energy consumption for HPP and PEF to deliver comparable shelf-life of juices relative to base case thermal processing, their advantage is widely recognized in their potential to deliver products with an improved quality comparable to their thermal counterparts (Aganovic et al., 2017). As for CP, the primary energy consumption mainly comes from the generation of plasma, which is minimum compared to HPP or PEF. Similarly, using energy-efficient UV lamps help to reduce energy consumption, leading to less GHG emissions.

In this study, we assume the orange is produced in California and the juice plant is in North Carolina. If sourcing Valencia orange nearby from Florida, the transportation distance reduces from ~2,400 miles from CA to NC to ~660 miles. However, the transportation emissions associated with FL-NC scenario increase largely to 0.25 kg CO2e/kg of orange due to the use of truck. For comparison, the CA-NC scenario relies on rail, resulting in 0.16 kg CO2e/kg of orange in transportation sector. Besides, growing orange in FL is reported to have a higher GHG emissions (0.24 kg CO2e/kg orange) relative to that from CA (0.2 kg CO2e/kg orange). Hence, sourcing foods nearby or locally may reduce the cost burden on transportation, the overall environmental impacts may suggest that sourcing foods from a greener option is preferable, even if it involves longer transportation distances (Supplementary Figure 2). In addition to the scenarios based on orange production places, we also explored the potential of adopting bioplastic for juice packaging because of the ongoing discussion around plastic packaging and the growing advocacy for alternative options as greener and more sustainable options. Consistent with other studies, switching to bio-PET bottles could largely reduce the life-cycle carbon footprint, making it comparable to or lower relative to that of the base case thermal processing using petro-based PET bottles, especially in the CP and UV pasteurization processes. This scenario analysis highlights another critical strategy to lower the life-cycle environmental footprint within the food industry (Supplementary Figure 2).

4 Discussion

LCA and TEA are widely used to evaluate the environmental, technical, and economic feasibilities of emerging technologies in field such as renewable energy. However, comprehensive sustainability data on food processing technologies remains limited, and challenges exist, which demands significant efforts in future research. As most of the studies on innovative technologies in food processing have been performed only at the lab scale, we recognize that the results obtained may be difficult to scale-up and generalize in real-world settings. For instance, in most studies, energy consumption is calculated based on internal thermal transfer or reaction-based heating, rather than direct measurements from industrial processes as primary data. In case where scale-up studies have been conducted, there is a lack of detailed public dataset or information. The diversity in equipment used, lack of dosimetry standardization, and the wide variation in processes, products, and recipes further complicate comparison in sustainability assessment such as energy consumption across different food technologies. Additionally, mass and/or energy consumption data of individual facility sites are rarely available due to nondisclosure agreements, and similar restrictions apply to data on single unit operations. This lack of transparency further exacerbates the difficulty of compiling reliable process-based inventory lists for food processing technologies and poses significant challenges to robust and accurate sustainability assessment.

While we carefully selected the reliable experimental data available for the sustainability models, a key limitation of this study is the assumption that the five processing scenarios produce comparable juice products. Although literature supports that the selected non-thermal treatments can achieve microbial inactivation and refrigerated shelf-life similar to thermal pasteurization, direct comparative data under standardized conditions are lacking. The results of our case study may not be generalizable to other juice plants or processing conditions, as variations in juice composition, equipment design, energy sources, and local environmental factors can all influence process performance and sustainability outcomes. Despite these limitations, our study provides valuable new insights into the environmental sustainability and cost feasibility of existing non-thermal food processing technologies. By conducting sustainability assessment at an early stage of the emerging food processing technologies, we offer a foundation for future research and emphasize the need for more detailed, case-specific data collection and modeling before these technologies become widely adopted. This review will support a more comprehensive understanding of how non-thermal technologies can be optimized for sustainability in food industries.

Author contributions

MY: Conceptualization, Data curation, Formal analysis, Funding acquisition, Visualization, Writing – original draft, Writing – review & editing. QW: Conceptualization, Funding acquisition, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work is supported by the Research Capacity Fund (HATCH), project award no. 7005027, from the USDA NIFA and Oregon State University Agricultural Experimental Station.

Acknowledgments

We would like to thank Tyler Hill (North Carolina State University) and Mammonhand Meer (Oregon State University) for supporting data collection during literature review process.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2025.1585467/full#supplementary-material

References

Abbas Syed, Q. (2017). Pulsed electric field technology in food preservation: a review. J. Nutr. Health Food Eng. 6:219. doi: 10.15406/jnhfe.2017.06.00219

Aganovic, K., Hertel, C., Vogel, R. F., Johne, R., Schlüter, O., Schwarzenbolz, U., et al. (2021). Aspects of high hydrostatic pressure food processing: perspectives on technology and food safety. Compr. Rev. Food Sci. Food Saf. 20, 3225–3266. doi: 10.1111/1541-4337.12763

Aganovic, K., Smetana, S., Grauwet, T., Toepfl, S., Mathys, A., Van Loey, A., et al. (2017). Pilot scale thermal and alternative pasteurization of tomato and watermelon juice: an energy comparison and life cycle assessment. J. Clean. Prod. 141, 514–525. doi: 10.1016/j.jclepro.2016.09.015

Arshad, R. N., Abdul-Malek, Z., Roobab, U., Munir, M. A., Naderipour, A., Qureshi, M. I., et al. (2021). Pulsed electric field: a potential alternative towards a sustainable food processing. Trends Food Sci. Technol. 111, 43–54. doi: 10.1016/j.tifs.2021.02.041

Atuonwu, J. C., Leadley, C., Bosman, A., and Tassou, S. A. (2019). High-pressure processing, microwave, ohmic, and conventional thermal pasteurization: quality aspects and energy economics. J. Food Process Eng. 43:e13328. doi: 10.1111/jfpe.13328

Balasubramaniam, V. M. (2016). High pressure processing of food: Principles, technology and applications (food engineering series). 1st Edn. Cham: Springer.

Balasubramaniam, V. M. (2021). Process development of high pressure-based technologies for food: research advances and future perspectives. Curr. Opin. Food Sci. 42, 270–277. doi: 10.1016/j.cofs.2021.10.001

Beck, S. E., Ryu, H., Boczek, L. A., Cashdollar, J. L., Jeanis, K. M., Rosenblum, J. S., et al. (2017). Evaluating UV-C LED disinfection performance and investigating potential dual-wavelength synergy. Water Res. 109, 207–216. doi: 10.1016/j.watres.2016.11.024

Bhide, S., Salvi, D., Schaffner, D. W., and Karwe, M. V. (2017). Effect of surface roughness in model and fresh fruit systems on microbial inactivation efficacy of cold atmospheric pressure plasma. J. Food Prot. 80, 1337–1346. doi: 10.4315/0362-028X.JFP-17-064

Bintsis, T., Litopoulou-Tzanetaki, E., and Robinson, R. K. (2000). Existing and potential applications of ultraviolet light in the food industry - a critical review. J. Sci. Food Agric. 80, 637–645. doi: 10.1002/(SICI)1097-0010(20000501)80:6<637::AID-JSFA603>3.0.CO;2-1

Bourke, P., Ziuzina, D., Boehm, D., Cullen, P. J., and Keener, K. (2018). The potential of cold plasma for safe and sustainable food production. Trends Biotechnol. 36, 615–626. doi: 10.1016/j.tibtech.2017.11.001

Buckow, R., Ng, S., and Toepfl, S. (2013). Pulsed electric field processing of orange juice: a review on microbial, enzymatic, nutritional, and sensory quality and stability. Compr. Rev. Food Sci. Food Saf. 12, 455–467. doi: 10.1111/1541-4337.12026

Bull, M. K., Zerdin, K., Howe, E., Goicoechea, D., Paramanandhan, P., Stockman, R., et al. (2004). The effect of high pressure processing on the microbial, physical and chemical properties of Valencia and navel orange juice. Innov. Food Sci. Emerg. Technol. 5, 135–149. doi: 10.1016/j.ifset.2003.11.005

Cacace, F., Bottani, E., Rizzi, A., and Vignali, G. (2020). Evaluation of the economic and environmental sustainability of high pressure processing of foods. Innov. Food Sci. Emerg. Technol. 60:102281. doi: 10.1016/j.ifset.2019.102281

Carbonell, J. V., Navarro, J. L., Izquierdo, L., and Sentandreu, E. (2013). Influence of high pressure homogenization and pulp reduction on residual pectinmethylesterase activity, cloud stability and acceptability of lane late orange juice: a study to obtain high quality orange juice with extended shelf life. J. Food Eng. 119, 696–700. doi: 10.1016/j.jfoodeng.2013.06.041

Chakka, A. K., Sriraksha, M. S., and Ravishankar, C. N. (2021). Sustainability of emerging green non-thermal technologies in the food industry with food safety perspective: a review. LWT 151:112140. doi: 10.1016/j.lwt.2021.112140

Chemat, F., Rombaut, N., Meullemiestre, A., Turk, M., Perino, S., Fabiano-Tixier, A.-S., et al. (2017). Review of green food processing techniques. Preservation, transformation, and extraction. Innov. Food Sci. Emerg. Technol. 41, 357–377. doi: 10.1016/j.ifset.2017.04.016

Chizoba Ekezie, F.-G., Sun, D.-W., and Cheng, J.-H. (2017). A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Technol. 69, 46–58. doi: 10.1016/j.tifs.2017.08.007

Chowdhury, J. I., Hu, Y., Haltas, I., Balta-Ozkan, N., Matthew, G. J., and Varga, L. (2018). Reducing industrial energy demand in the UK: a review of energy efficiency technologies and energy saving potential in selected sectors. Renew. Sust. Energ. Rev. 94, 1153–1178. doi: 10.1016/j.rser.2018.06.040

Clairand, J.-M., Briceno-Leon, M., Escriva-Escriva, G., and Pantaleo, A. M. (2020). Review of energy efficiency technologies in the food industry: trends, barriers, and opportunities. IEEE Access 8, 48015–48029. doi: 10.1109/ACCESS.2020.2979077

Corrales, M., Toepfl, S., Butz, P., Knorr, D., and Tauscher, B. (2008). Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: a comparison. Innov. Food Sci. Emerg. Technol. 9, 85–91. doi: 10.1016/j.ifset.2007.06.002

Crippa, M., Solazzo, E., Guizzardi, D., Monforti-Ferrario, F., Tubiello, F. N., and Leip, A. (2021). Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2:225. doi: 10.1038/s43016-021-00225-9

Daher, D., Le Gourrierec, S., and Pérez-Lamela, C. (2017). Effect of high pressure processing on the microbial inactivation in fruit preparations and other vegetable based beverages. Agriculture 7:72. doi: 10.3390/agriculture7090072

Dalsgaard, H., and Abbotts, A. W. (2003). “Improving energy efficiency” in Environmentally-friendly food processing. eds. B. Mattson and U. Sonesson, 116–129.

Davis, J., Moates, G., and Waldron, K. (2010). “The environmental impact of pulsed electric field treatment and high pressure processing: the example of carrot juice” in Case studies in novel food processing technologies. ed. C. J. Doona (Amsterdam: Elsevier), 103–115.

Department of Energy (2018). 2018 manufacturing static energy Sankey diagrams. Available online at: https://www.energy.gov/eere/iedo/2018-manufacturing-static-energy-sankey-diagrams (accessed November 14, 2023).

Devi, A. F., Buckow, R., Hemar, Y., and Kasapis, S. (2013). Structuring dairy systems through high pressure processing. J. Food Eng. 114, 106–122. doi: 10.1016/j.jfoodeng.2012.07.032

Dzimitrowicz, A., Pohl, P., Caban, M., Jamroz, P., Cyganowski, P., Bykowski, M., et al. (2022). How does direct current atmospheric pressure glow discharge application influence on physicochemical, nutritional, microbiological, and cytotoxic properties of orange juice? Food Chem. 377:131903. doi: 10.1016/j.foodchem.2021.131903

Eadie, E., Hiwar, W., Fletcher, L., Tidswell, E., O’Mahoney, P., Buonanno, M., et al. (2022). Far-UVC (222 nm) efficiently inactivates an airborne pathogen in a room-sized chamber. Sci. Rep. 12:4373. doi: 10.1038/s41598-022-08462-z

Fabroni, S., Platania, G. M., Amenta, M., Ballistreri, G., Galvano, F., Nges, I. A., et al. (2024). Pulsed electric field as a mild treatment for extended shelf-life and preservation of bioactive compounds in blood orange juice. Appl. Sci. 14:7275. doi: 10.3390/app14167275

FDA (2000). CFR - code of Federal Regulations Title 21. Available online at: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=179.39 (accessed December 20, 2023).

FDA (2024). CFR - code of Federal Regulations Title 21. Available online at: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=173.315 (accessed June 24, 2024).

Food Safety News. Cold plasma processing for food safety [WWW Document]. (2024). Available online at: https://www.foodsafetynews.com/2024/06/cold-plasma-processing-for-food-safety/#:~:text=Like%20all%20new%20food%20processing,of%20plant%20related%20food%20products.%E2%80%9D (Accessed December 17, 2024).

Ferreira, V. J., Arnal, Á. J., Royo, P., García-Armingol, T., López-Sabirón, A. M., and Ferreira, G. (2019). Energy and resource efficiency of electroporation-assisted extraction as an emerging technology towards a sustainable bio-economy in the Agri-food sector. J. Clean. Prod. 233, 1123–1132. doi: 10.1016/j.jclepro.2019.06.030

Ghosh, S., Gillis, A., Levkov, K., Vitkin, E., and Golberg, A. (2020). Saving energy on meat air convection drying with pulsed electric field coupled to mechanical press water removal. Innov. Food Sci. Emerg. Technol. 66:102509. doi: 10.1016/j.ifset.2020.102509

Heinz, V., and Knorr, D. (2000). Effect of pH, ethanol addition and high hydrostatic pressure on the inactivation of Bacillus subtilis by pulsed electric fields. Innov. Food Sci. Emerg. Technol. 1, 151–159. doi: 10.1016/S1466-8564(00)00013-8

Heinz, V., Toepfl, S., and Knorr, D. (2003). Impact of temperature on lethality and energy efficiency of apple juice pasteurization by pulsed electric fields treatment. Innov. Food Sci. Emerg. Technol. 4, 167–175. doi: 10.1016/S1466-8564(03)00017-1

Hiperbaric. (2022). From lab-scale to industrial HPP units: Implications for R&D. Available online at: https://www.hiperbaric.com/en/from-lab-scale-to-industrial-hpp-units-implications-for-rd/ (accessed November 29, 2023).

Janahar, J., Jin, Z. T., and Balasubramaniam, V. M. (2022) Pulsed electric field processing applications in the food industry, Ohioline. Available online at: https://ohioline.osu.edu/factsheet/fst-fabe-1002#:~:text=PEF%20processing%20is%20used%20for,solid%20volume%20(sludge)%20of%20wastewater (Accessed December 16, 2024).

Kesavan, J. S., and Sagripanti, J. (2013). “Disinfection of airborne organisms by ultraviolet-c radiation and sunlight” in Aerosol science: Technology and applications. eds. I. Colbeck and M. Lazaridis (New York, NY: Wiley), 417–439.

Koutchma, T. (2009). Advances in ultraviolet light technology for non-thermal processing of liquid foods. Food Bioprocess Technol. 2, 138–155. doi: 10.1007/s11947-008-0178-3

Ladha-Sabur, A., Bakalis, S., Fryer, P. J., and Lopez-Quiroga, E. (2019). Mapping energy consumption in food manufacturing. Trends Food Sci. Technol. 86, 270–280. doi: 10.1016/j.tifs.2019.02.034

Lee, K.-Y., Joo Park, B., Hee Lee, D., Lee, I.-S. O., Hyun, S., Chung, K.-H., et al. (2005). Sterilization of Escherichia coli and MRSA using microwave-induced argon plasma at atmospheric pressure. Surface and Coatings Technology 193, 35–38. doi: 10.1016/j.surfcoat.2004.07.034

Liu, H., Lin, Y., Sun, M. Y., Zhang, X. W., and Zhao, X. X. (2023). The effects of high-pressure processing on the nutritional quality of sprouts: a review. Food Biosci. 56:103384. doi: 10.1016/j.fbio.2023.103384

Lung, R., Masanet, E., and McKane, A., (2006). The role of emerging technologies in improving energy efficiency: Examples from the food processing industry. Lawrence Berkeley National Laboratory. Available online at: https://escholarship.org/uc/item/43c841xs

Martín-Belloso, O., and Elez-Martínez, P. (2005). “Enzymatic inactivation by pulsed electric fields” in Emerging technologies for food processing. ed. D. W. Sun (Amsterdam: Elsevier), 155–181.

Martín-Belloso, O., and Sobrino-López, A. (2011). Combination of pulsed electric fields with other preservation techniques. Food Bioprocess Technol. 4, 954–968. doi: 10.1007/s11947-011-0512-z

Menon, A., Stojceska, V., and Tassou, S. A. (2020). A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 100, 67–76. doi: 10.1016/j.tifs.2020.03.014

Misra, N. N., Schlüter, O., and Cullen, P. J. (2016). “Plasma in food and agriculture” in Cold plasma in food and agriculture. eds. N. N. Misra, O. Schlüter, and P. J. Cullen (Amsterdam: Elsevier), 1–16.

Misra, N. N., Yadav, B., Roopesh, M. S., and Jo, C. (2019). Cold plasma for effective fungal and mycotoxin control in foods: mechanisms, inactivation effects, and applications. Compr. Rev. Food Sci. Food Saf. 18, 106–120. doi: 10.1111/1541-4337.12398

Niemira, B. A. (2012). Cold plasma decontamination of foods. Annu. Rev. Food Sci. Technol. 3, 125–142. doi: 10.1146/annurev-food-022811-101132

Nowosad, K., Sujka, M., Pankiewicz, U., and Kowalski, R. (2021). The application of PEF technology in food processing and human nutrition. J. Food Sci. Technol. 58, 397–411. doi: 10.1007/s13197-020-04512-4

Obileke, K., Onyeaka, H., Miri, T., Nwabor, O. F., Hart, A., Al-Sharify, Z. T., et al. (2022). Recent advances in radio frequency, pulsed light, and cold plasma technologies for food safety. J. Food Process Eng. 45. doi: 10.1111/jfpe.14138

Oey, I., Lille, M., Van Loey, A., and Hendrickx, M. (2008). Effect of high-pressure processing on colour, texture and flavour of fruit- and vegetable-based food products: a review. Trends Food Sci. Technol. 19, 320–328. doi: 10.1016/j.tifs.2008.04.001

Ozen, E., and Singh, R. K. (2020). Atmospheric cold plasma treatment of fruit juices: a review. Trends Food Sci. Technol. 103, 144–151. doi: 10.1016/j.tifs.2020.07.020

Pankaj, S. K., Wan, Z., and Keener, K. M. (2018). Effects of cold plasma on food quality: a review. Food Secur. 7:4. doi: 10.3390/foods7010004

Pardo, G., and Zufía, J. (2012). Life cycle assessment of food-preservation technologies. J. Clean. Prod. 28, 198–207. doi: 10.1016/j.jclepro.2011.10.016

Pereira, R. N., and Vicente, A. A. (2010). Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res. Int. 43, 1936–1943. doi: 10.1016/j.foodres.2009.09.013

Patange, A., Lu, P., Boehm, D., Cullen, P. J., and Bourke, P. (2019). Efficacy of cold plasma functionalised water for improving microbiological safety of fresh produce and wash water recycling. Food Microbiol. 84:103226. doi: 10.1016/j.fm.2019.05.010

Picart-Palmade, L., Cunault, C., Chevalier-Lucia, D., Belleville, M. P., and Marchesseau, S. (2018). Potentialities and limits of some non-thermal technologies to improve sustainability of food processing. Front. Nutr. 5:130. doi: 10.3389/fnut.2018.00130

Pohl, P., Dzimitrowicz, A., Cyganowski, P., and Jamroz, P. (2022). Do we need cold plasma treated fruit and vegetable juices? A case study of positive and negative changes occurred in these daily beverages. Food Chem. 375:131831. doi: 10.1016/j.foodchem.2021.131831

Polak, N., Kalisz, S., and Kruszewski, B. (2024). High-temperature short-time and ultra-high-temperature processing of juices, nectars and beverages: influences on enzyme, microbial inactivation and retention of bioactive compounds. Appl. Sci. 14:8978. doi: 10.3390/app14198978

Rastogi, N. K., Raghavarao, K. S., Balasubramaniam, V. M., Niranjan, K., and Knorr, D. (2007). Opportunities and challenges in high pressure processing of foods. Crit. Rev. Food Sci. Nutr. 47, 69–112. doi: 10.1080/10408390600626420

Rocha, A. B. O., Honório, S. L., Messias, C. L., Otón, M., and Gómez, P. A. (2015). Effect of UV-C radiation and fluorescent light to control postharvest soft rot in potato seed tubers. Sci. Hortic. 181, 174–181. doi: 10.1016/j.scienta.2014.10.045

Roobab, U., Aadil, R. M., Madni, G. M., and Bekhit, A. E. D. (2018). The impact of nonthermal technologies on the microbiological quality of juices: a review. Compr. Rev. Food Sci. Food Saf. 17, 437–457. doi: 10.1111/1541-4337.12336

Roodenburg, B., Morren, J., Berg, H. E., and de Haan, S. W. H. (2005). Metal release in a stainless steel pulsed electric field (PEF) system. Innovative Food Sci. Emerg. Technol. 6, 327–336. doi: 10.1016/j.ifset.2005.04.006

Sampedro, F., McAloon, A., Yee, W., Fan, X., and Geveke, D. J. (2014). Cost analysis and environmental impact of pulsed electric fields and high pressure processing in comparison with thermal pasteurization. Food Bioproc. Technol. 7, 1928–1937. doi: 10.1007/s11947-014-1298-6

Sampedro, F., McAloon, A., Yee, W., Fan, X., Zhang, H. Q., and Geveke, D. J. (2013). Cost analysis of commercial pasteurization of orange juice by pulsed electric fields. Innov. Food Sci. Emerg. Technol. 17, 72–78. doi: 10.1016/j.ifset.2012.10.002

Sarangapani, C., O'Toole, G., Cullen, P. J., and Bourke, P. (2017). Atmospheric cold plasma dissipation efficiency of agrochemicals on blueberries. Innov. Food Sci. Emerg. Technol. 44:12. doi: 10.1016/j.ifset.2017.02.012

Searchinger, T. (2019). Creating a sustainable food future. Washington, DC: World Resource Institute.

Sehrawat, R., Kaur, B. P., Nema, P. K., Tewari, S., and Kumar, L. (2021). Microbial inactivation by high pressure processing: principle, mechanism and factors responsible. Food Sci. Biotechnol. 30, 19–35. doi: 10.1007/s10068-020-00831-6

Singh, H., Bhardwaj, S. K., Khatri, M., Kim, K.-H., and Bhardwaj, N. (2021). UVC radiation for food safety: an emerging technology for the microbial disinfection of food products. Chem. Eng. J. 417:128084. doi: 10.1016/j.cej.2020.128084

Sinke, P., Swartz, E., Sanctorum, H., van der Giesen, C., and Odegard, I. (2023). Ex-ante life cycle assessment of commercial-scale cultivated meat production in 2030. Int. J. Life Cycle Assess. 28, 234–254. doi: 10.1007/s11367-022-02128-8

Taibi, E., Gielen, D., and Bazilian, M. (2012). The potential for renewable energy in industrial applications. Renew. Sust. Energ. Rev. 16, 735–744. doi: 10.1016/j.rser.2011.08.039

Terlouw, T., Bauer, C., Rosa, L., and Mazzotti, M. (2021). Life cycle assessment of carbon dioxide removal technologies: a critical review. Energy Environ. Sci. 14, 1701–1721. doi: 10.1039/D0EE03757E

Thirumdas, R., Sarangapani, C., and Annapure, U. S. (2015). Cold Plasma: A novel Non-Thermal Technology for Food Processing. Food Biophys. 10, 1–11. doi: 10.1007/s11483-014-9382-z

Timmermans, R. A. H., Mastwijk, H. C., Knol, J. J., Quataert, M. C. J., Vervoort, L., Van der Plancken, I., et al. (2011). Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice. Part I: impact on overall quality attributes. Innov. Food Sci. Emerg. Technol. 12, 235–243. doi: 10.1016/j.ifset.2011.05.001

Toepfl, S., Mathys, A., Heinz, V., and Knorr, D. (2006). Review: potential of high hydrostatic pressure and pulsed electric fields for energy efficient and environmentally friendly food processing. Food Rev. Int. 22, 405–423. doi: 10.1080/87559120600865164

Torres, J. A., and Velazquez, G. (2005). Commercial opportunities and research challenges in the high pressure processing of foods. J. Food Eng. 67, 95–112. doi: 10.1016/j.jfoodeng.2004.05.066

Tran, M. T. T., and Farid, M. (2004). Ultraviolet treatment of orange juice. Innov. Food Sci. Emerg. Technol. 5, 495–502. doi: 10.1016/j.ifset.2004.08.002

U.S. Energy Information Administration. (2023). Use of energy in industry. Available online at: https://www.eia.gov/energyexplained/use-of-energy/industry.php (accessed November 13, 2023).

Ucar, Y., Ceylan, Z., Durmus, M., Tomar, O., and Cetinkaya, T. (2021). Application of cold plasma technology in the food industry and its combination with other emerging technologies. Trends Food Sci. Technol. 114, 355–371. doi: 10.1016/j.tifs.2021.06.004

Valsasina, L., Pizzol, M., Smetana, S., Georget, E., Mathys, A., and Heinz, V. (2017). Life cycle assessment of emerging technologies: the case of milk ultra-high pressure homogenisation. J. Clean. Prod. 142, 2209–2217. doi: 10.1016/j.jclepro.2016.11.059

Vauchel, P., Colli, C., Pradal, D., Philippot, M., Decossin, S., Dhulster, P., et al. (2018). Comparative LCA of ultrasound-assisted extraction of polyphenols from chicory grounds under different operational conditions. J. Clean. Prod. 196, 1116–1123. doi: 10.1016/j.jclepro.2018.06.042

Wu, Z., Zhang, M., and Adhikari, B. (2012). Application of high pressure argon treatment to maintain quality of fresh-cut pineapples during cold storage. J. Food Eng. 110, 395–404. doi: 10.1016/j.jfoodeng.2011.12.032

Xu, L., Garner, A. L., Tao, B., and Keener, K. M. (2017). Microbial inactivation and quality changes in orange juice treated by high voltage atmospheric cold plasma. Food Bioprocess Technol. 10, 1778–1791. doi: 10.1007/s11947-017-1947-7

Yoo, E., Lee, U., and Wang, M. (2022). Life-cycle greenhouse gas emissions of sustainable aviation fuel through a net-zero carbon biofuel plant design. ACS Sustain. Chem. Eng. 10, 8725–8732. doi: 10.1021/acssuschemeng.2c00977

Zulueta, A., Barba, F. J., Esteve, M. J., and Frígola, A. (2013). Changes in quality and nutritional parameters during refrigerated storage of an orange juice–milk beverage treated by equivalent thermal and non-thermal processes for mild pasteurization. Food Bioprocess Technol. 6, 2018–2030. doi: 10.1007/s11947-012-0858-x

Keywords: food sustainability, life-cycle assessment (LCA), technoeconomic analysis (TEA), non-thermal processing, decarbonization, juice processing

Citation: Yang M and Wang Q (2025) Carbon footprint and cost analysis of non-thermal food processing technologies: a review with a case study on orange juice. Front. Sustain. Food Syst. 9:1585467. doi: 10.3389/fsufs.2025.1585467

Edited by:

Annalisa Serio, University of Teramo, ItalyReviewed by:

Simona Fabroni, Council for Agricultural Research and Economics - Research Center for Olive, Fruit and Citrus Crops, ItalyGiovanna Ferrari, University of Salerno, Italy

Copyright © 2025 Yang and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Minliang Yang, bWlubGlhbmdfeWFuZ0BuY3N1LmVkdQ==; Qingyang Wang, cWluZ3lhbmcud2FuZ0BvcmVnb25zdGF0ZS5lZHU=

Minliang Yang

Minliang Yang Qingyang Wang2*

Qingyang Wang2*