- 1Perkins&Will, Vancouver, BC, Canada

- 2Food and Agriculture Institute, University of the Fraser Valley, Abbotsford, BC, Canada

- 3Controlled Environment Systems Research Facility, School of Environmental Sciences, University of Guelph, Guelph, ON, Canada

- 4School of Architecture and Landscape Architecture, University of British Columbia, Vancouver, BC, Canada

This paper explores the potential of Building-Integrated Agriculture (BIA) as a strategy to align urban agriculture systems with building lifecycle sustainability goals. BIA systems such as indoor vertical farms, rooftop greenhouses, and soil-based urban farms promise to bolster urban food security and resource circularity. However, their environmental impacts can be further optimized via integration with building resources and strategic design, which requires a standardized framework for evaluating life-cycle metrics. This study develops a cross-industry Life Cycle Assessment (LCA) framework that harmonizes agricultural and building performance indicators, using carbon as a unifying metric to evaluate operational and embodied impacts. The research combines a meta-analysis of existing LCA studies, detailed case study evaluations, and novel paired metrics to quantify energy use, water use, and greenhouse gas emissions within a case study. Key findings identify operational carbon hotspots, infrastructure inefficiencies, and embodied carbon challenges while highlighting opportunities for integrating resource recovery strategies, such as greywater reuse and waste heat recovery. The results reveal trade-offs between productivity and environmental impact, with vertical farms demonstrating high yields but significant energy intensity, while soil-based systems excel in resource efficiency but exhibit lower output. This work introduces a structured methodology for cross-industry data integration and offers actionable insights for designers, growers and developers. By redefining system boundaries and incorporating reciprocal benefits between BIA and host buildings, this framework provides a pathway toward more sustainable urban agricultural practices and resilient urban ecosystems.

Introduction

Urban agriculture has emerged as a promising strategy to bolster urban food security and resilience by providing local fresh produce year-round (Mok et al., 2014). Commercial scale applications in densely populated centres have gained traction, particularly methods like controlled environments agriculture (CEA), including indoor vertical farms (VF) or Rooftop Greenhouses (RG), as well as soil-based urban farms on vacant lands. These systems continue to expand in city centres globally, generating food, income, and employment opportunities (Dorr et al., 2021). While urban agriculture is not a singular solution to agri-food sustainability issues, its increasing presence in and around population centres requires further research to drive optimal outcomes and management approaches.

Cities are increasingly promoting urban food production as part of their sustainability and resiliency agendas to reduce pressures on agricultural land and minimize food miles (Pact, Milan Urban Food Policy, 2024). Moreover, incorporating food production in cities by leveraging underutilized urban spaces has a significant potential for enhancing self-sufficiency in fresh produce, highlighting a meaningful contribution to the local food supply and economies while reducing environmental footprints. In Singapore, for instance, it is estimated that incorporating high-yield Rooftop Greenhouses (RG) in urban residential centers could fulfil 35.5% of domestic vegetable demand (Benis et al., 2018). Similarly, high-yield VF and soil-based farming using vacant spaces in Montreal could fully meet the city’s vegetable needs (Benis et al., 2018). In Europe, implementing RG throughout a city such as Bologna could meet an estimated 77% of the city’s vegetable demand (Benis et al., 2018). These cases underscore the transformative potential of urban agriculture to support efforts toward decentralized food systems and reduce dependence on external food supplies. The need for decentralized food systems has become increasingly critical in futureproofing our cities, particularly in the light of increased global, political and environmental crises, as well as the recent pandemic, which exposed vulnerabilities in our food supply chain (Béné, 2020).

Building-integrated agriculture (BIA) is a unique opportunity to implement individual, community, and commercial urban agriculture systems to optimize space and leverage resource recovery systems between farms and buildings. We define BIA here, also termed zero-acreage or vertical farming (Specht et al., 2015; Specht et al., 2019), as the practice of growing food within, on top of, or beside buildings and the philosophy of pursuing circular agri-food development at a building scale (Benis et al., 2018). This concept extends beyond food production to include waste valorization, water recirculation, and energy symbiosis between buildings and agriculture systems.

While BIA systems hold the potential to bolster urban food security, their environmental impacts remain under scrutiny. These systems are typically energy and resource-intensive, possibly leading to undesirable environmental externalities. Additionally, as research into the sustainability of CEA-integrated models through life-cycle assessment (LCA) within urban contexts is still emerging, comprehensive assessments and standardized metrics for LCA are limited compared to field production, leading to conflicting results. For instance, Goldstein et al. (2016) indicate that BIA may not consistently provide climate benefits over traditional agriculture and, in some cases, may exhibit less efficient resource use. Similarly, Kulak et al. (2013) report that producing strawberries in RG in London could result in a higher carbon footprint than importing greenhouse-grown strawberries from Spain. In contrast, Goldstein et al. (2016) show that the greenhouse gas (GHG) emissions associated with importing tomatoes from Spain or Italy to Austria were half those of locally grown tomatoes in Austria. A critical limitation in these assessments lies in their narrow system boundaries, which fail to account for building efficiencies introduced by BIA applications, such as insulation benefits, waste heat recovery, and reduced stormwater runoff. These building benefits, often treated as externalities, must be integrated into holistic LCA calculations to reflect the full sustainability potential of BIA systems.

The lack of a robust LCA framework and diverse LCA methodologies to assess the environmental impacts of BIA further exacerbates the uncertainty of the environmental impacts of urban BIA, making it difficult to establish consistent trends or draw definitive conclusions. This necessitates the development of a comprehensive, unifying framework to evaluate the environmental impacts of BIA and to allow for effective cross-comparisons of LCA data. When LCA is implemented, distinct metric sets are applied for buildings and urban agriculture. In UA, the environmental impacts are typically expressed on food-based units as kg CO₂e per kg of crop harvested annually, linking environmental impacts directly to food production. In contrast, the building industry uses metrics such as Energy Use Intensity (EUI), Water Use Intensity (WUI) or Greenhouse Gas Intensity (GHGI), which measure resource consumption and emissions per unit area. Although these metrics are essential within their respective sectors, a unified framework for their integration is currently lacking to capture the extent of BIA systems’ efficiency relative to their host buildings.

Besides the metrics used, the framework for evaluating life cycle impacts differs between the UA and building-construction sectors. In UA, the metric kg CO₂-equivalent per kg of crop harvested encompasses the entire life cycle, including upstream (pre-farm), on-farm, and downstream (post-farm) stages. In contrast, the construction industry evaluates life cycle impacts through distinct stages: material extraction and processing (product stage), transportation to the construction site and on-site assembly (construction stage), operational energy and resource use over the building’s life span (use stage), and the disposal or recycling of materials (end-of-life stage). The absence of overlap in these frameworks further limits cross-industry integration. This disparity in metrics and frameworks highlights limits in integrating building performance indicators with the life cycle impacts of UA for BIAs, underscoring the need for a more comprehensive, cross-disciplinary approach to sustainability metrics.

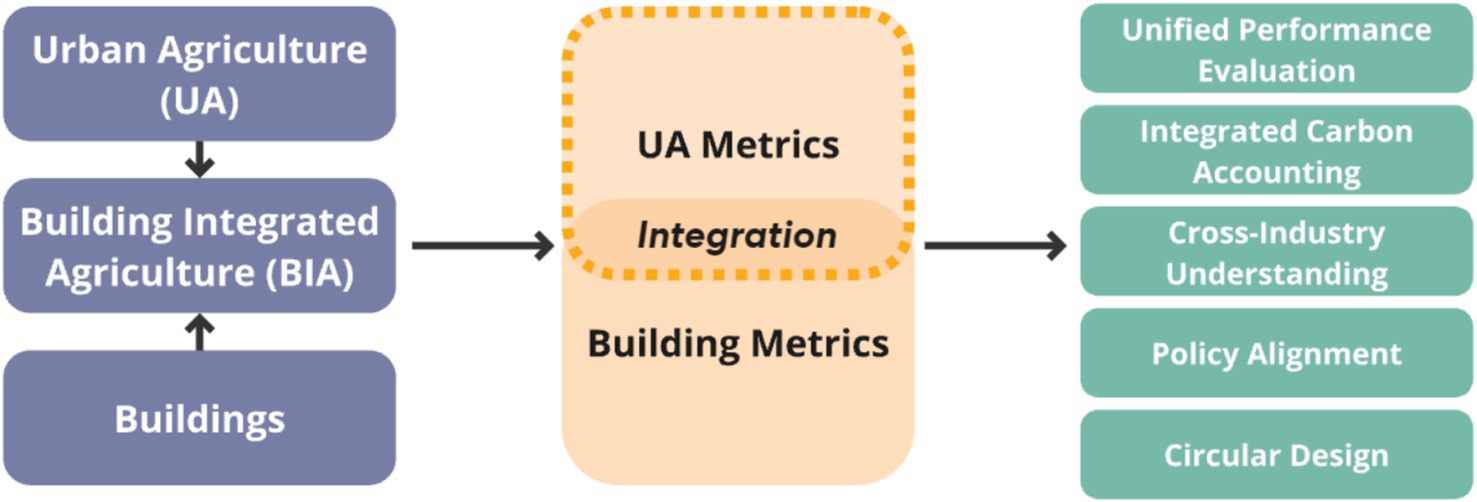

There are several additional benefits to the integration of building and urban agriculture lifecycle metrics, beyond streamlining and standardizing assessments of BIA performance metrics (see Figure 1, rightmost column). Where carbon is increasingly measured, reported, and verified within building certification systems and green building design standards (WBDG, 2024), these conversations and efforts are relatively new in the urban agriculture and BIA space. An integrated framework can support further refinement and development of carbon accounting within BIA systems. Further, as certification systems and design standards are developed, integrated life cycle frameworks afford an opportunity to align urban planning policies centred on sustainability. Finally, and perhaps most practically, the benefits of an integrated framework for BIA life cycle analysis can identify opportunities for circular design principles where hotspots and coldspots of negative environmental performance (across buildings or urban farming systems) may operate synergistically, affording opportunities for resource circularity, recovery, and reuse (see Chowdhury and Asiabanpour, 2024). Examples include redirecting waste heat from buildings to support BIA heating needs, utilizing compost and urine-derived fertilizers, and reusing greywater for irrigation. Such strategies have been successfully implemented in projects such as the PAE building in Portland, Oregon (Thomas, 2022).

Figure 1. This figure denotes the purpose of the research (green boxes) and key steps taken to address the research questions. Carbon-centric evaluation framework outline: Integrating UA and BIA metrics into a unified framework for carbon-centric performance evaluation, carbon accounting, and policy alignment.

Research questions and scope

Considering these challenges, this paper explores the potential for integrating urban agriculture (UA) and buildings LCA metrics to develop a cross-industry framework see Figure 1. The novel framework redefines system boundaries and incorporates reciprocal benefits such as resource recovery and energy exchange strategies between integrated farms and their host buildings. By using carbon as a unifying metric, the framework aims to align performance evaluation, integrated carbon accounting, and policy development across the two sectors.

The research focuses on high-impact Building-Integrated Agriculture (BIA) systems, evaluating operational and embodied carbon perspectives while addressing gaps in existing LCA datasets. Additionally, it examines baseline energy and water consumption, food yield, and associated GHG emissions of common BIA systems. The overall research question informing this work is as follows: How can LCA studies facilitate a cross-industry data comparison by using carbon calculations as a unifying metric to assess the feasibility and impact of BIA systems? To guide this analysis, the following key research questions are explored:

1. Where are common areas of crossover between urban agriculture and building life cycle inventories?

2. What are the baseline energy and water requirements as well as food yield estimations of various BIA systems?

3. What are the systems’ associated operational and embodied carbon emissions?

Methodology

Overview

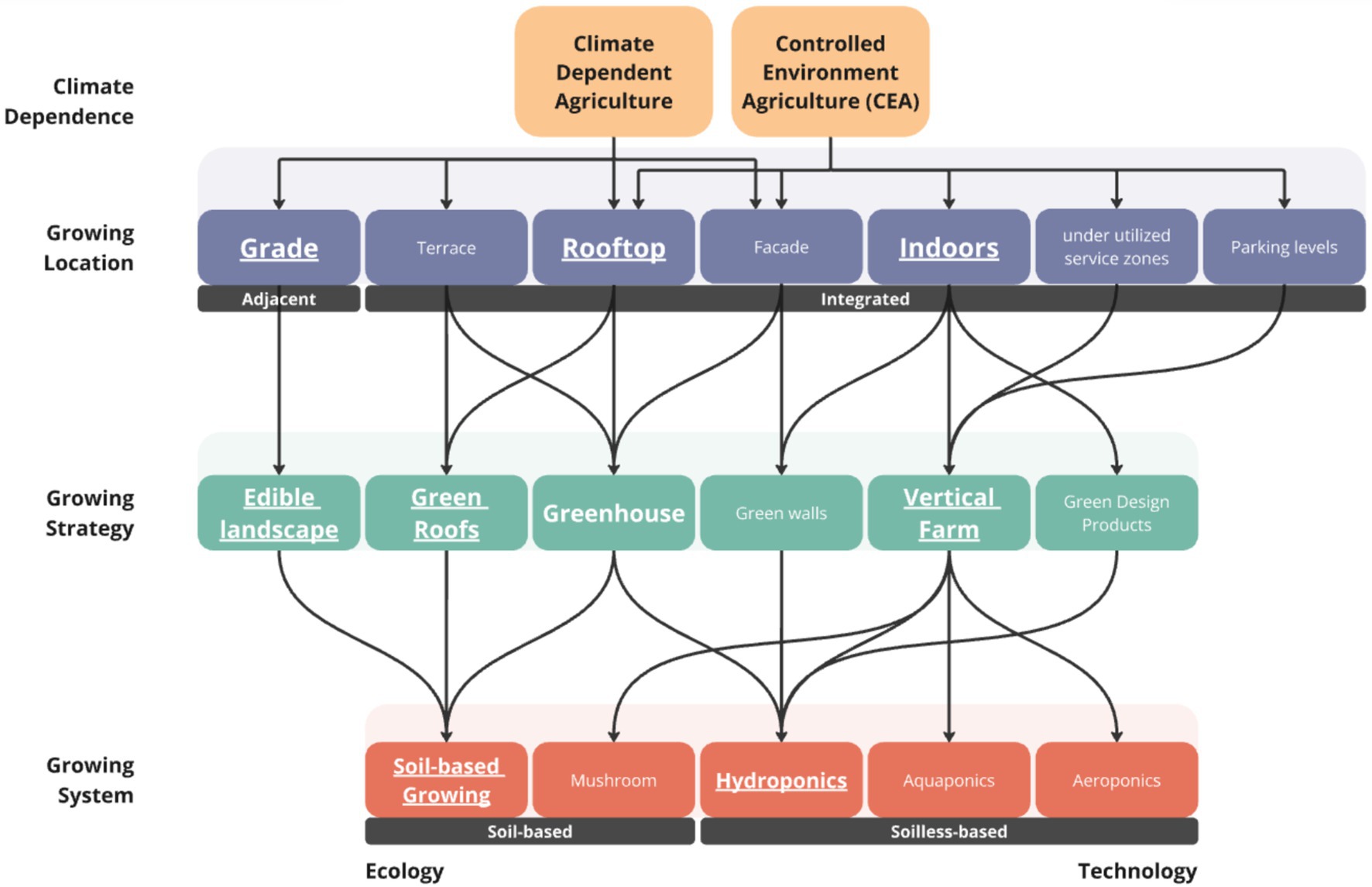

BIA systems’ research and deployment continue to grow in various cities globally, allowing for identifying high-impact systems based on their practical use, research focus, industry support, and associated crop yield, see Figure 2. This study prioritizes these high-impact cases by selecting the most common systems and production-types currently available at-scale, in most cities. Meta-studies by Dorr et al. (2021) and Benis et al. (2018) identify the most implemented systems as (1) climate-dependent soil-based farms (SB), (2) Rooftop Greenhouses, and (3) Hydroponic Indoor Vertical Farms (VF). Similarly, the most cultivated crops in these settings are (1) Leafy greens (lettuce), (2) Herbs (Basil), and (3) Vining crops (Tomatoes), as classified by FAOSTAT—a global database maintained by the food and agriculture organization (FAO) that provides comprehensive agriculture statistics, including crop classifications, production, and trade (FAOSTAT, 2024). These crops are selected for their short growth cycles, high yield potential and suitability for controlled environment systems (Benis et al., 2018).

Figure 2. Contextualized high-impact BIA systems and crops: BIA systems classified by climate dependence, growing location, strategy, and system, highlighting their interconnected design and diversity. Bold and underlined classifications indicate those that are adopted in this research.

While LCA has been widely applied in the construction industry, its use in agriculture, particularly BIA systems, is still developing. The study focuses on LCA as its holistic approach enables the evaluation of the environmental impacts of a product or system throughout its life cycle, accounting not only for farm activities but also for pre-farm and post-farm stages. Existing studies often focus on conventional agriculture, and the current literature on BIA LCA shows inconsistencies in methodology (Caffrey and Veal, 2013).

Although carbon sequestration is often excluded from LCA due to data uncertainties on CO2e uptake before harvest (Dorr et al., 2017; Al-Qubati et al., 2024), modelled carbon sequestered from compost in the substrate, potting soil, and amendments in a UA urban farm, estimating that the sequestered carbon represents 0.2–3% of the farm’s GHG emissions. This can be a starting point to build the sequestration data set.

The research focuses on developing a structured framework to evaluate the efficiency of BIA systems relative to their host buildings. Through a literature review and case study analysis, the objectives are to assess the common BIA systems, best practices, and data availability, focusing on the quantitative intersection of energy consumption, water use, and food yield using carbon calculations as a unifying metric to assess feasibility and impact. Data was obtained through desktop research of peer-reviewed journals and farm operation specification sheets that were publicly available or secured via email with business representatives. Research data and approaches were partially validated by examining existing BIA life cycle analysis meta-reviews and informal conversations with stakeholders such as architects, building operators, developers, and urban farmers with knowledge of project environmental impacts.

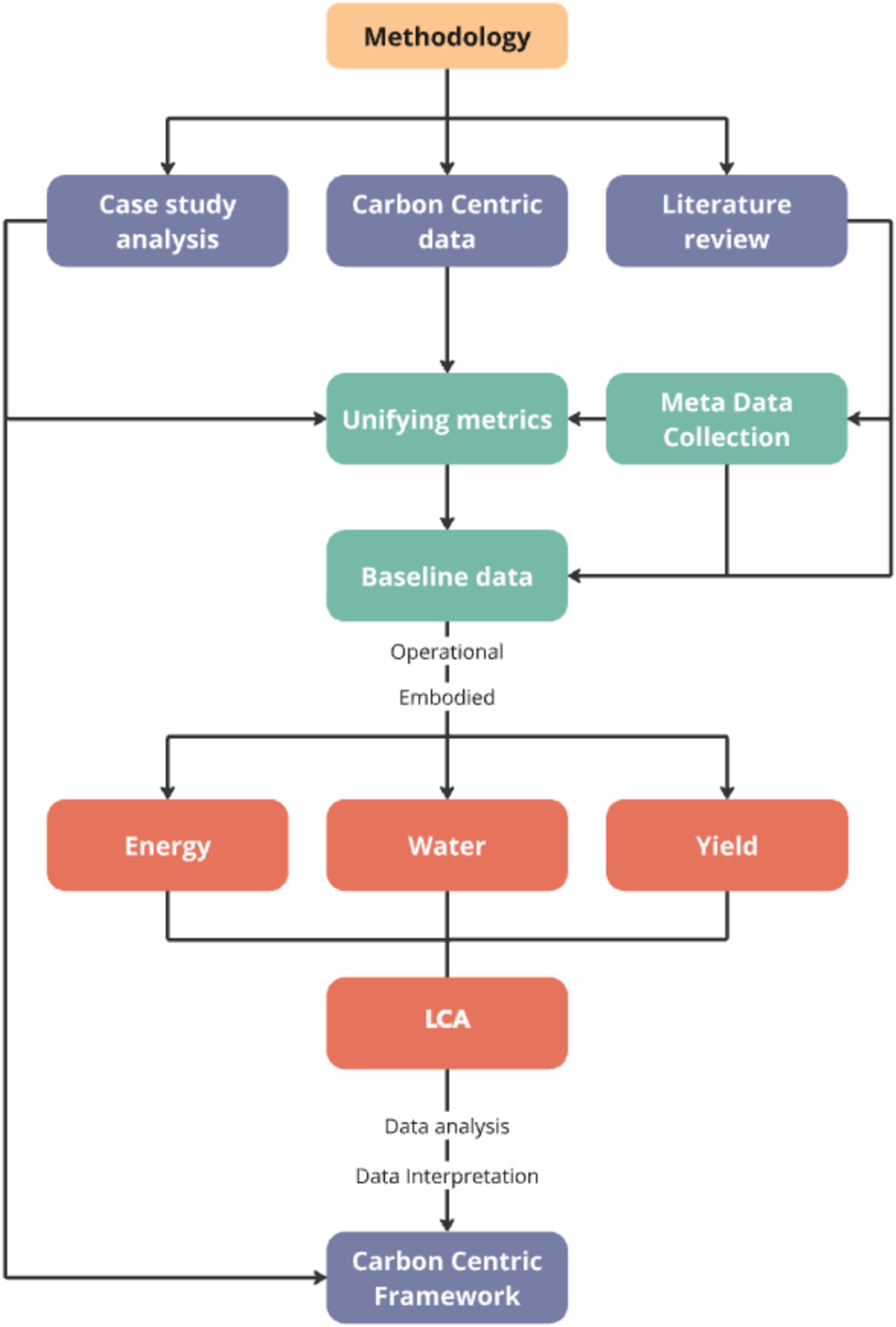

Case study analysis, literature review, and carbon centric data collection

BIA case study identification

A robust data pool of BIA Life Cycle Assessment (LCA) is essential to support the application and verification of the proposed framework’s usability. This section aims to collect and standardize carbon equivalent data between urban farming and the buildings that house them. To support future analyses where live, on-farm energy, water, and food yield data is available within new developments, it is necessary to establish working, practical assumptions of baseline operational and embodied carbon present across urban agriculture operations, particularly in the high impact systems outlined from the literature review of farm type (soil based, greenhouse, vertical farms) and crop type (leafy greens, herbs, vining crops).

The initial step involves identifying relevant case studies that exemplify BIA. A preliminary review of over 150 BIA projects globally was conducted to validate the most common systems, technologies, scales, and crops identified in the literature. Cases were identified from a combination of existing knowledge of projects from the research team, dialogue with colleagues within the firm Perkins&Will, project collaborators, and Google search. From this pool, 48 case studies were selected for detailed analysis based on technology reliability (i.e., the BIA technology is currently used in projects), evidence of resource recovery strategy integration, and geographic and climatic diversity. Data was collected through desktop research, operational specification sheets, and informal conversations with the architects, operators and developers involved in these projects. Energy use values by infrastructure type (HVAC, lighting, equipment, and gas broiler) were gathered and reported through this case study data collection process.

To supplement this dataset, performance data for 41 projects were extracted from peer-reviewed LCA studies with publicly available inventory data and performance benchmarks. To identify relevant papers, the review undertook keyword searches within key databases, specifically Web of Science and Scopus. Urban farming infrastructure, including stationed structures such as greenhouses and mobile infrastructure such as hydroponic vertical farm racks, were assumed to have a 60-year design life.

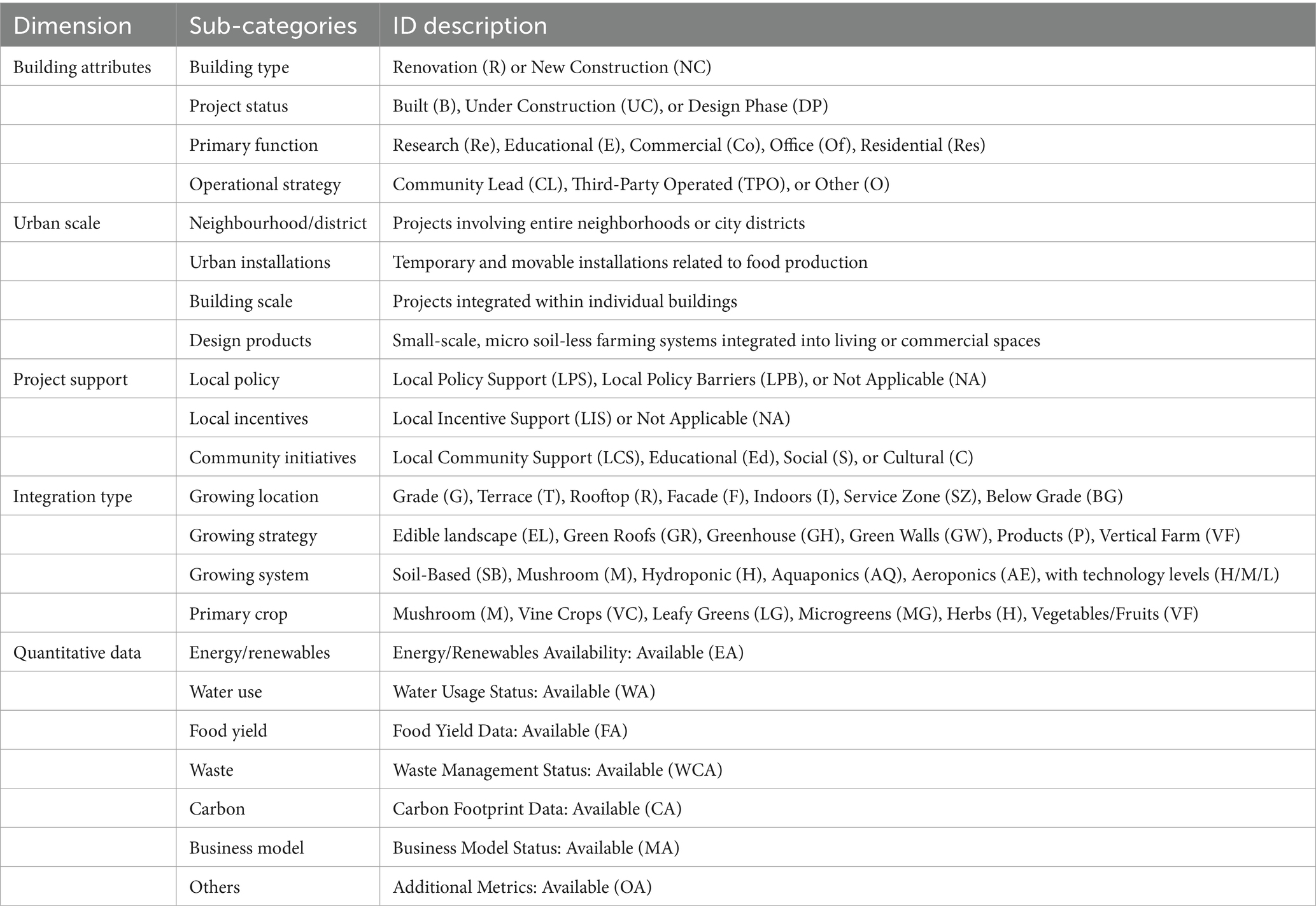

The classification strategy for BIA case studies is designed to allow the systematic organization and evaluation of BIA initiatives based on specific criteria. The strategy encompasses five primary dimensions: building type, urban scale, project support, integration type, and quantitative data. Each dimension is divided into sub-categories, each assigned an ID for clarity and consistency, as shown in the table and figure below. This classification aims to identify high-impact BIA types and categorize findings from the literature review (Dorr et al., 2021) (see Figure 3; Table 1).

Figure 3. Methodology outline: process flow for developing a carbon-centric framework, incorporating case study analysis, data collection, unifying metrics, and LCA.

Table 1. Case study data classification method: sub-categories and ID descriptions are used to classify case studies, including building attributes, urban scale, integration type, and quantitative data metrics.

Developing the framework and applying relevant carbon data

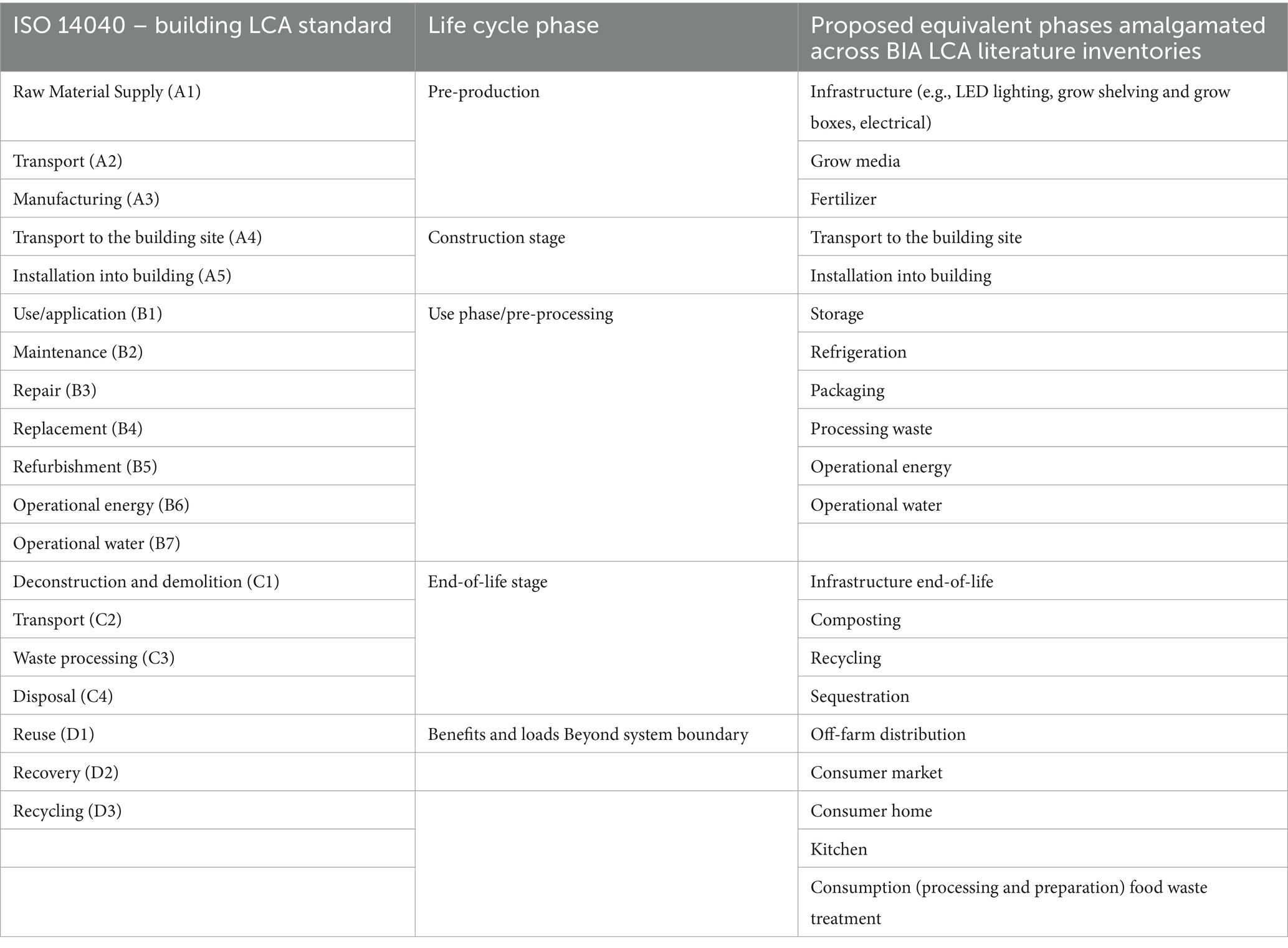

To answer research question 1 and develop the cross-comparison framework, this study first establishes the benchmark to compare and standardize BIA life cycle inventories. The researchers selected ISO 14040 as the benchmark to which BIA studies would be standardized. These standards are globally recognized, adopted, and intended to measure buildings’ environmental footprint and associated products.

The initial step in this research involved collecting and recording inventories from diverse urban farming studies to match and compare how they stack against these building LCA phase standards. Then, these inventories and associated value chains were mapped and compared against ISO 14040, an overarching standard encompassing all phases of LCA addressing quantitative assessment methods for environmental aspects of a product in its entire life cycle stages. This provides the necessary framework for comparing building and BIA life cycle studies, including identifying gaps in data and hotspots that demonstrate potential for resource circularity.

To address research questions 2 and 3 and cross-industry correlation challenges, the data collection and synthesis extracted metrics for operational energy, water, and GHG emissions, utilizing metric pairs to enable conversions across domains. From the captured case study pool, the team was able to extract operational data and embodied carbon data within the grow system infrastructures and upstream inventories from the literature review of LCA studies focused on urban farming operations. After selecting relevant papers, the supplementary data files and tables were extracted and analyzed using the life cycle phase typology developed to compare building and urban agriculture LCAs. We have also included data from Dorr et al. (2021) meta-review of life cycle papers to add robustness to the number of reviewed papers and to ensure the accuracy of our data collection and yield, water, and energy use calculations.

With the framework developed and operation/embodied carbon data extracted from case study review, operational carbon data between a hypothetical building and values from the BIA case study analysis were integrated. This was facilitated by standardizing operational carbon by functional unit (kg of farm-gate crop produced annually at the farm gate) and by area (per square meter of production space) to provide a comprehensive assessment framework. This approach evaluates the area occupied by BIA systems and the resulting food yield, with metrics designated by subscripts ‘a’ for agriculture and ‘b’ for building (see Table 2).

Table 2. The metric pairs framework illustrates the focus on EUI, WUI, and GHGI for both the farm designated by subscript “a” and building “b”.

Another key metric is the building’s Gross Floor Area (GFA) that houses BIA. Different design scenarios can be established to calculate standard building industry metrics such as EUI, WUI, and GHGI, incorporating BIA-related energy, water, and food yield data. For instance, if food yield (kg) is the primary design factor, and the designer wants to assess the energy impact and required space for the BIA system, calculations are as follows:

Alternatively, if the available space within a building to house BIA is the primary factor and the designer needs to determine energy impact and food yield potential:

The same logic extends to WUI and GHGI calculations. The paired metrics (a and b) enable effective translation and resolution of stakeholder queries within the building design process.

From an environmental impact perspective, building design also considers embodied carbon. While operational carbon metrics (e.g., EUI, WUI, and GHGI) can be directly translated into performance impacts for agricultural ‘a’ and building ‘b’ contexts, embodied carbon in BIA refers to the carbon associated with constructing and maintaining the agricultural systems. This carbon is integrated with the building’s overall embodied carbon through a Life Cycle Assessment (LCA) study, quantifying the combined impact. The 48 selected LCA studies are grouped by farm type and analyzed by inventory to collate data on embodied carbon across multiple life cycle phases. This section focuses on upstream inputs (infrastructure, supplies) and downstream end-of-life and materials disposal, bounded at the farm gate, see Figure 4. Further work is required to model and compare downstream and post-farmgate consumption and waste. Similar to operational carbon, embodied carbon is reported as kgCO₂e per functional unit (FU): kg of crop for agriculture (a) and kgCO₂e per m2 for building (b).

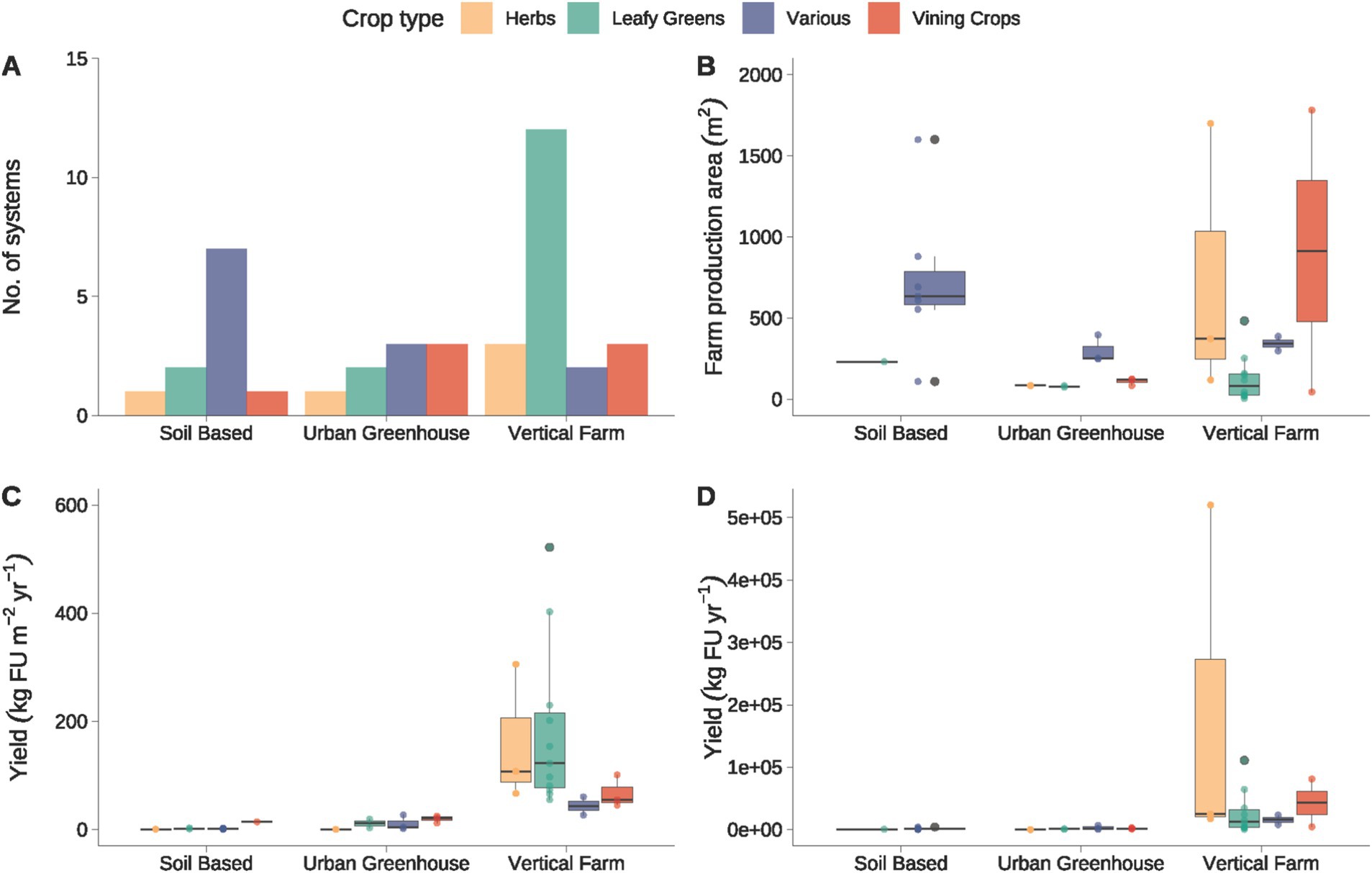

Figure 4. Descriptive data regarding life cycle studies reviewed, including number of farm operation systems from which yield, grow area, and total production volumes were collected. Figure parts are defined as follows, across all reviewed life cycle studies: (A) system type; (B) total grow area; (C) production volume by area; (D) total production volume per year.

Study limitations

There are several limitations to the methodology presented here. Data collection presents a challenge when projects span different regions with varying data availability and quality. Operational and embodied environmental performance values are highly location specific. This is crucial to acknowledge for metrics like energy consumption and carbon emissions, which depend on local grid emissions (Ferguson, 2023). Additionally, collecting detailed information on technology, performance, and sustainability practices often requires close collaboration with stakeholders with potential for confidentiality issues. However, this was not an appropriate approach for this study which required ranges of values.

Data for the study were aggregated from relevant case studies and published peer-reviewed literature. Due to reliance on publicly available data from the case studies, there is a chance of incorrect or misleading data from these websites and conversations with project practitioners, absent verified and published life cycle assessments. Until further case study data is verified and in the public domain, there are few ways to mitigate this challenge. The researchers substantiated the data with peer-reviewed literature to mitigate this issue, yet still it is important to acknowledge this limitation to the protocol.

Results

Case study analysis

The following sections discuss the trends identified across the reviewed 48 case studies, capturing geographic, climate zone, system type, and attribute diversity. This case study data provides a robust dataset to establish ranges of operational characteristics for various farm types (i.e., rooftop farming, soil-based urban farming, and indoor vertical farming), including grow areas and yields. This dataset also provides a foundation to capture relevant life cycle inputs and outputs – inventory items that are required to develop the carbon-centric framework for building and urban farming life cycle integration.

Descriptive data

The case studies span nine different climate zones, demonstrating the adaptability of BIA systems to varying environmental conditions. A significant concentration of projects is in marine climates (4C and 5A), with 20 projects, while mixed-humid climates (4A) account for another 9. Other climate zones include cold climates (6A) with two projects and very cold climates (7A) with three projects. The projects are distributed across 15 countries, with the highest concentration in British Columbia, Canada (8 projects). Other prominent locations include the Netherlands (6 projects), the USA (5 projects), and France (3 projects). Other projects are in Spain, Denmark, the UK, Belgium, Italy, Poland, Germany, Sweden, Thailand, China and Japan. The case studies are split primarily between renovation (20 projects) and new construction (20 projects), with a few projects classified as an add-on structure. Most of the projects are fully built (36 projects), with a smaller number still under construction (2 projects) or in the design phase (3 projects). The primary functions of the projects vary, with commercial applications being the most common (23 projects). Many projects also serve research (11 projects) or educational purposes (13 projects), and several combine multiple functions, such as residential (10 projects) and office spaces (6 projects).

BIA systems are implemented across various locations within the case study buildings, with rooftops (19 projects), at grade (20 projects), and interiors (22 projects) being the most common. Other integration types are more complex locations like below grade (9 projects) and service zones (6 projects). Various growing strategies are used in these case studies, with indoor vertical farms being the most popular (26 projects), followed by greenhouses (14 projects) and green roofs (12 projects). Some projects also employ green walls (6 projects). Additionally, the case studies include a combination of low (L), medium (M), and high-tech (H) growing systems, with the most prevalent being soil-based systems (L) (24 projects). Hydroponic systems (M) are also widely used (23 projects), along with aquaponics (H) (7 projects), aeroponics (H) (5 projects), and mushroom cultivation (7 projects). The most common crops grown in these systems are leafy greens and herbs (33 and 30 projects, respectively), followed by microgreens and vine crops (22 projects each). Mushrooms are also grown in 8 projects. This validates the findings of the literature review and charts a strong correlation to focus on (1) soil-based, (2) greenhouse, and (3) hydroponic vertical farming, focusing on (1) vining crops (tomatoes), (2) Leafy greens (lettuce), and (3) Herbs (Basil) as the most frequently studied systems, and crops which indicates their common utilization in the market.

Soil-based urban farming demonstrates the largest growing area requirements, with consistent values across crop types (Median = 231 m2). Vertical farming, in contrast, shows a more diverse range for leafy greens (Median = 101 m2), herbs (Median = 119 m2), and vining crops (Median = 45 m2). The vining crop lower area is due to the facility type capturing this crop as a testing research facility and is not necessarily representative of this crop type area needs. Greenhouses exhibit relatively smaller grow areas with less variation between leafy greens (Median = 80 m2), herbs (Median = 84 m2), and vining crops (Median = 104 m2). This differentiation underscores the land efficiency of vertical farming and greenhouse systems, which maintain relatively consistent space requirements across crop types. Notably, the vertical farming area captured from the case studies does not capture tray stacking within the farm (i.e., they are based on grow area footprint); thus, vertical farming reflects higher land use efficiencies with respect to the other farm types.

Figure 4 compares yield with total annual yield per kg crop and meters squared, highlighting system compactness. Vertical farms produce the highest yield and total crop yield per year due to stacking, year-long production, as well as controlled environmental conditions for leafy greens (Median = 110 kg/m−2), herbs (Median = 108 kg/m−2), and vining crops (Median = 55 kg/m−2) respectively. Regarding total production, leafy greens perform best in vertical farms, yielding up to 7,376 kg, followed by herbs at 25,000 kg and vining crops at 4,550 kg. In greenhouses, tomatoes have the highest yield at 1,445 kg, followed by leafy greens (963 kg) and herbs (34 kg), indicating the optimization of greenhouses for vining crop production. Finally, soil-based systems reflect a large range in total yearly production, at 357 and 54,106 for leafy greens and vining crops, respectively. No data was available for soil-based systems producing herbs.

As a comparative benchmark, we examined FAOSTAT data from 2018–2022 for traditional farming of the same crops in Canada. The average yield of leafy greens (lettuce) and vining crops (tomatoes) was 23 and 83 kg crop m2 (full data set included in the Supplementary Material). These values indicate a higher yield in optimized traditional farming than climate-dependent, soil-based urban farms, with traditional methods yielding approximately 10 times more. However, traditional farming yields are notably lower than those achieved through indoor vertical farming (up to 5 times higher yields), with a reduction in land use.

BIA system integration – application

Table 3 proposes a cross-comparison framework between ISO 14040 building LCA standards and inventory items within BIA LCA literature. While individual LCA inventory items differ between building and BIA systems, their common life cycle phases allow for cross-comparison between each system.

Table 3. Integrating BIA LCA inventory items into the comparative framework with building LCA EN 14040.

We include infrastructure, grow media, and fertilizer as pre-production inputs. BIA LCA studies capture raw material extraction, transportation, and manufacturing of these infrastructural components within embodied carbon values. Construction stage phases are common between building and BIA systems; however, no studies reviewed in this paper included embodied carbon values related to their installation. Most use-phase and pre-processing inventory items vary substantially between buildings and BIA LCA, where BIA systems include quality control measures for products stored and processed on-site and packaging materials. Other than energy use, water use, and packaging, there were insufficient data points to report embodied carbon values from storage, refrigeration, and processing waste, given that farms may not process products on-site and/or may only account for performance data in their physical production spaces. End-of-life inventory items in BIA LCA include consideration of both infrastructure and organic materials.

Baseline operational data and embodied carbon

The paired metrics framework for farm operations was calculated using literature review data, including EUIa, EUIb, WUIa, WUIb, GHGIa, and GHGIb. Importantly, all operational values, irrespective of location-specific energy mixes, have been reported as is and are thus not standardized. Furthermore, the framework approach allows for adjusting and scaling embodied carbon values from each study. Detailed inventory data was recorded for embodied carbon emissions, focusing on infrastructure (input materials and end-of-life carbon), packaging, grow media, fertilizers/seeds, and waste. Most studies were conducted in Europe (especially Spain and Sweden); however, we suggest that the findings are broadly applicable, as upstream inputs and end-of-life embodied carbon is less regionally variable than operational emissions, which are influenced by local energy grids and climate factors. Emerging research has noted that energy grids play a large role in the potential sustainability of vertical farming (Blom et al., 2022).

Operational data

Water use

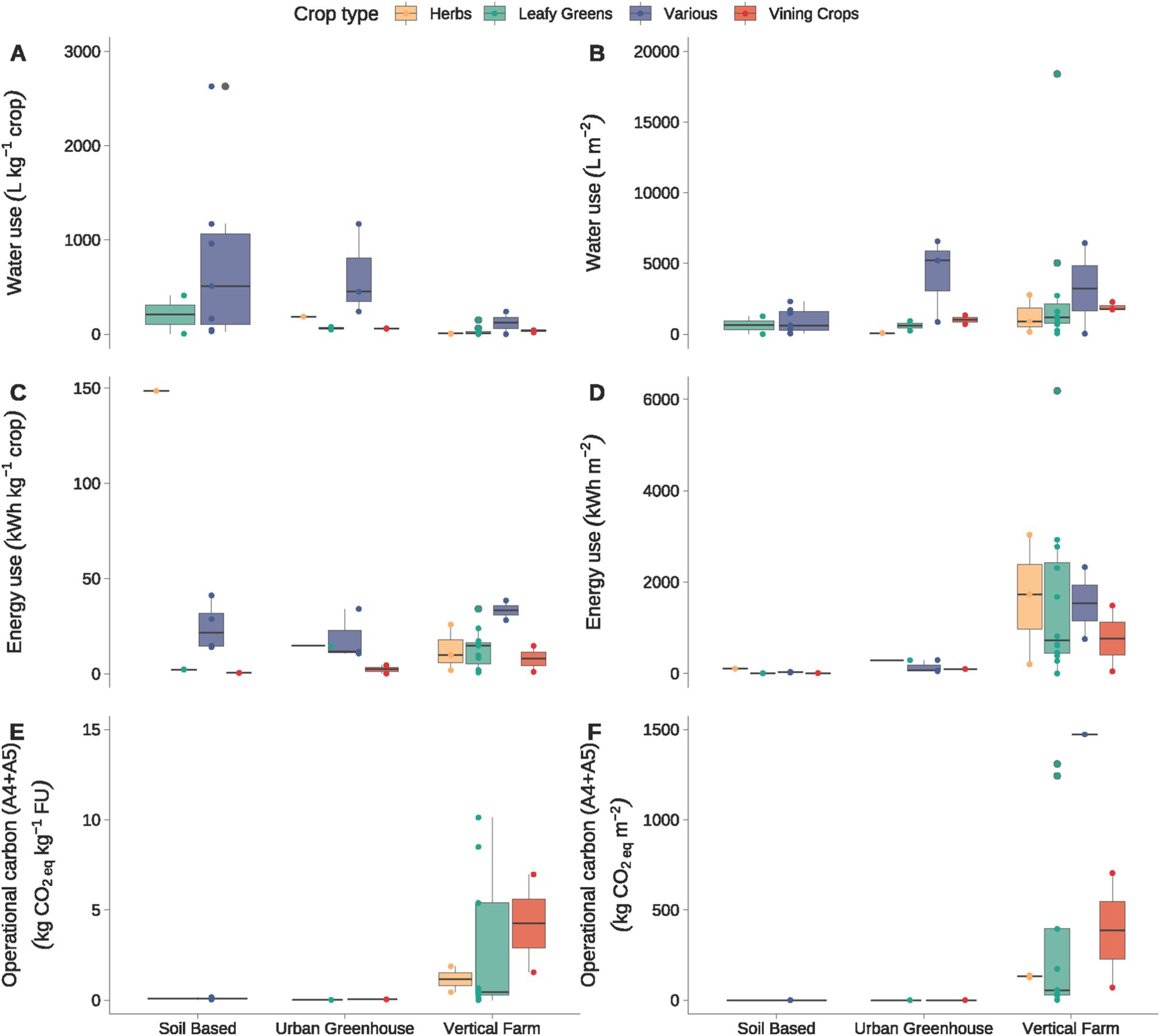

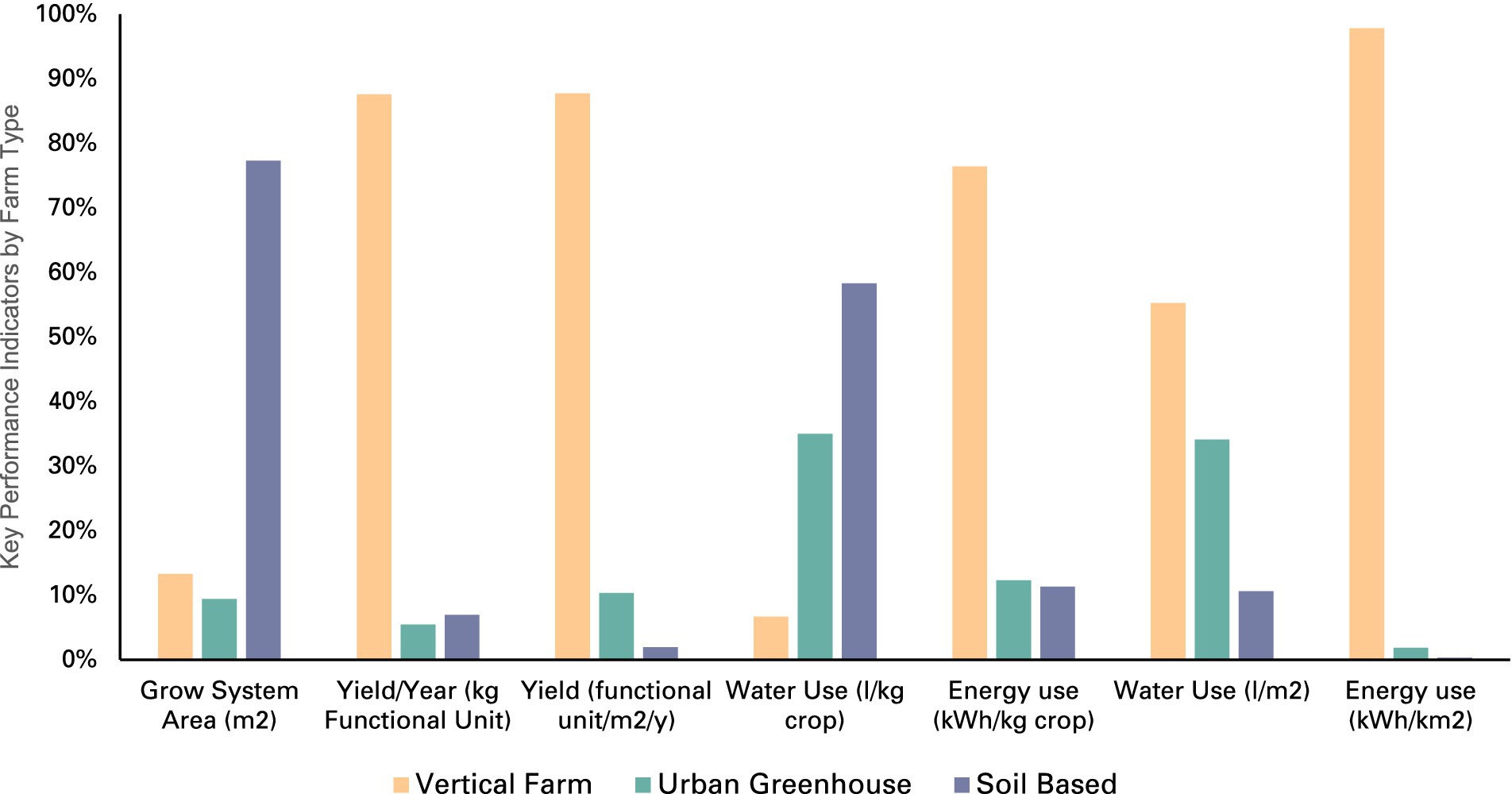

Operational values are reported in Figures 5, 6, synthesized from the life cycle analysis literature review. Values for Figure 7 were sourced from the case study analysis process. The vertical farming system is the most water efficient across all crop types (Median = 21 litres/kg crop), followed by the greenhouse system’s leafy greens crop (Median = 62 litres/kg crop). In contrast, due to climate dependency and system inefficiencies, soil-based systems require far more water for the same leafy greens crop (Median = 2017 litres/kg crop). Vertical farms use much more water per land area; however, this is due to higher biomass production. Notably, this measure does not account for resource circularity practices, such as water recycling or distinguishing between blue and green (rainwater harvested) water (Sanyé-Mengual et al., 2015; Dorr et al., 2021).

Figure 5. Energy, water use, and operational carbon values are reported per functional unit and square meter. Figure parts are defined as follows, across all reviewed life cycle studies: (A) water use by production volume; (B) water use by area; (C) energy use by production volume; (D) energy use by area; (E) operational carbon by production volume; (F) operational carbon by area.

Figure 6. Relative performance indicators by each farm type, adjusted as a percentage of the total (i.e., the percentage of farm type/sum of values across all farm types).

Energy use

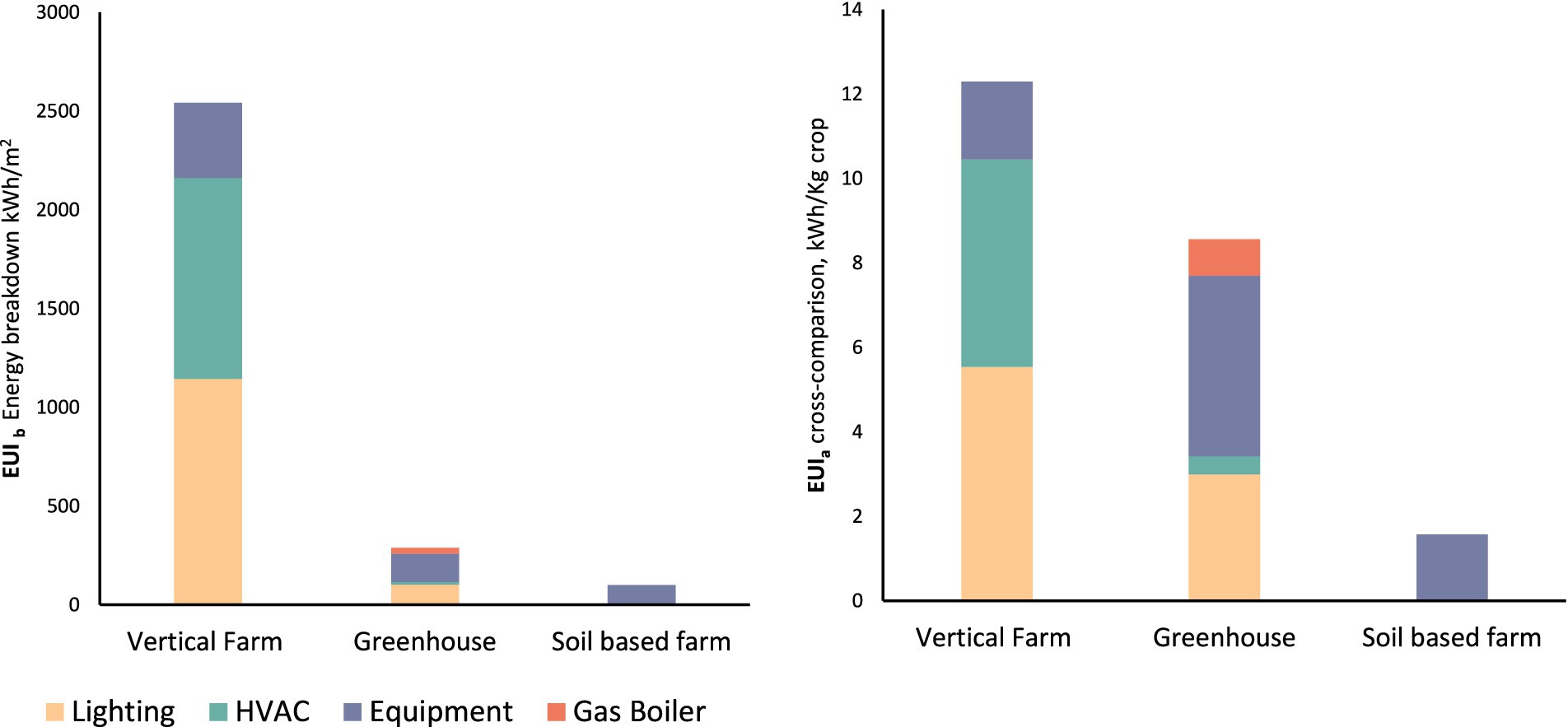

EUI is the key performance metric where vertical farms exhibit significantly higher energy demands compared to greenhouse or soil-based farms. Vertical farms, on average, require the highest amount of energy (Median = 814 kWh/m2) to maintain year-round production, compared to greenhouses (Median = 97 kWh/m2) and soil-based systems (Median = 20 kWh/m2). When adjusted for yield kWh per kg crop, the high productivity of indoor vertical farming helps to reduce its energy consumption relative to other farming types (i.e., it is only 1.05 to 1.32 times more energy intense per unit of crop than soil-based and greenhouse systems, respectively). These values vary substantially based on the constitution of energy grids in different world regions, with high energy requirements for cooling and heating in warm and cool climate regions. Overall energy use was highest in vertical farming operations. Results also suggest that lighting is the largest contributor to energy use values within these operations (Figure 7).

Operational carbon

Similarly, vertical farms’ operational carbon emissions (energy and water use, GHGIa) are substantially higher (Median = 1.1 kgCO2/kg crop) than for greenhouses (Median = 0.036 kgCO2/kg crop) and soil-based farms (Median = 0.079 kgCO2/kg crop). In comparison, greenhouses (Median = 0.51 kgCO2/m2) and soil-based farms (Median = 0.10 kgCO2/m2) have much lower GHGIb values than vertical farms (Median = 132 kgCO2/m2), see Figure 5.

Embodied carbon data

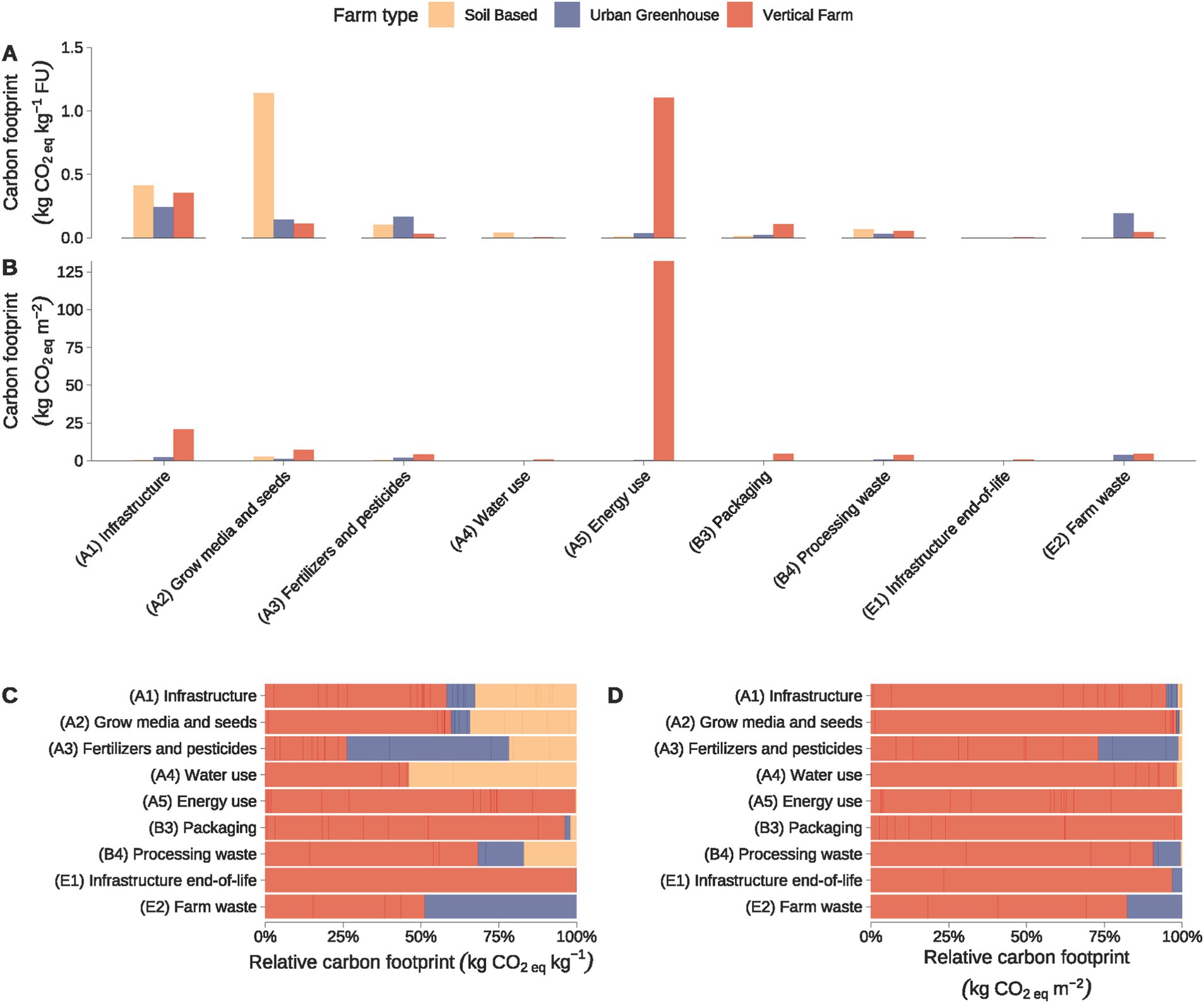

Drawing upon the data gathered from the LCA literature review data, Figure 8 shows the range of embodied emissions impact per life cycle phase. Overall, each BIA system has differing impacts per phase and highlights the opportunities for system optimizations depending on the project application, location, and grid intensity. Embodied carbon in VF is largely driven by energy use (factoring in energy grid constitution) and end-of-life impacts from infrastructure. For soil-based farms, grow media significantly contributes to embodied carbon due to the high carbon intensity of large soil volumes, unlike the hydroponic grow media often used in greenhouses and vertical farms. The high yield of indoor vertical farms also increases the carbon intensity of packaging and high operational energy demands. Both energy and packaging impacts offer substantial optimization potential. Figure 9 illustrates the relative resource flows across each phase, recognizing data gaps in BIA LCA literature via greyed-in flows.

Figure 8. Carbon emission equivalents by life cycle phase across farm type. Figure parts are defined as follows: (A) median carbon footprint by farm type and production volume, across life cycle stage; (B) median carbon footprint by farm type and area, across life cycle stage; (C) relative carbon footprint by farm type and production volume, across life cycle stage; (D) relative carbon footprint by farm type and area, across life cycle stage.

Figure 9. The BIA system boundary notes that grey zones are excluded from the study due to a lack of data. Data for transportation post-farmgate was not quantitatively captured or analyzed in this study, which is in line with the integrated building and BIA LCA framework defined in Table 3 and the complexity of diverse possible post-farmgate supply chains. The size of each arm of the Sankey diagram represents relative carbon emission equivalent flows.

BIA system integration – framework and application

The research presents in the following section an application of the framework of paired metrics to compare BIA and building systems. This application is based on a confidential commercial example from the research team (and so specific details regarding location and structure are omitted), and it compares building metrics total thermal energy use (TEUI) with crop-related metrics such as EUIa, WUIa, and GHGIa. Crop-related metrics are reported by area (b) to enable rapid conversion when integrating BIA systems into buildings, enabling quick performance mapping. To illustrate this integration, the case study below applies BIA-paired metrics to building design, demonstrating how BIA can be incorporated into overall building performance at the early design stage (and with what possible energy and greenhouse gas emissions implications) to inform decision-making regarding crop and farm type.

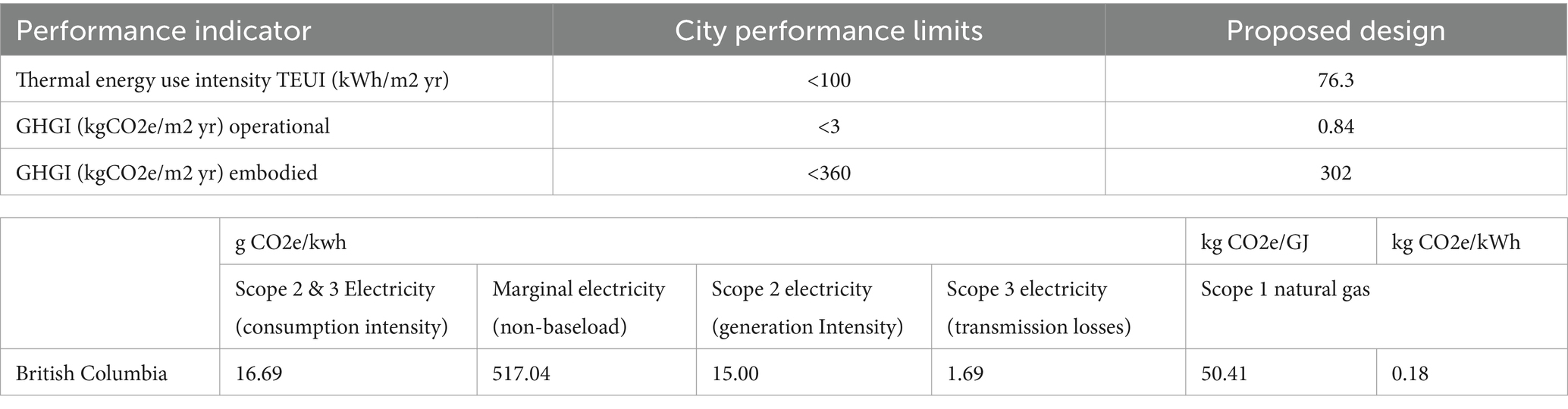

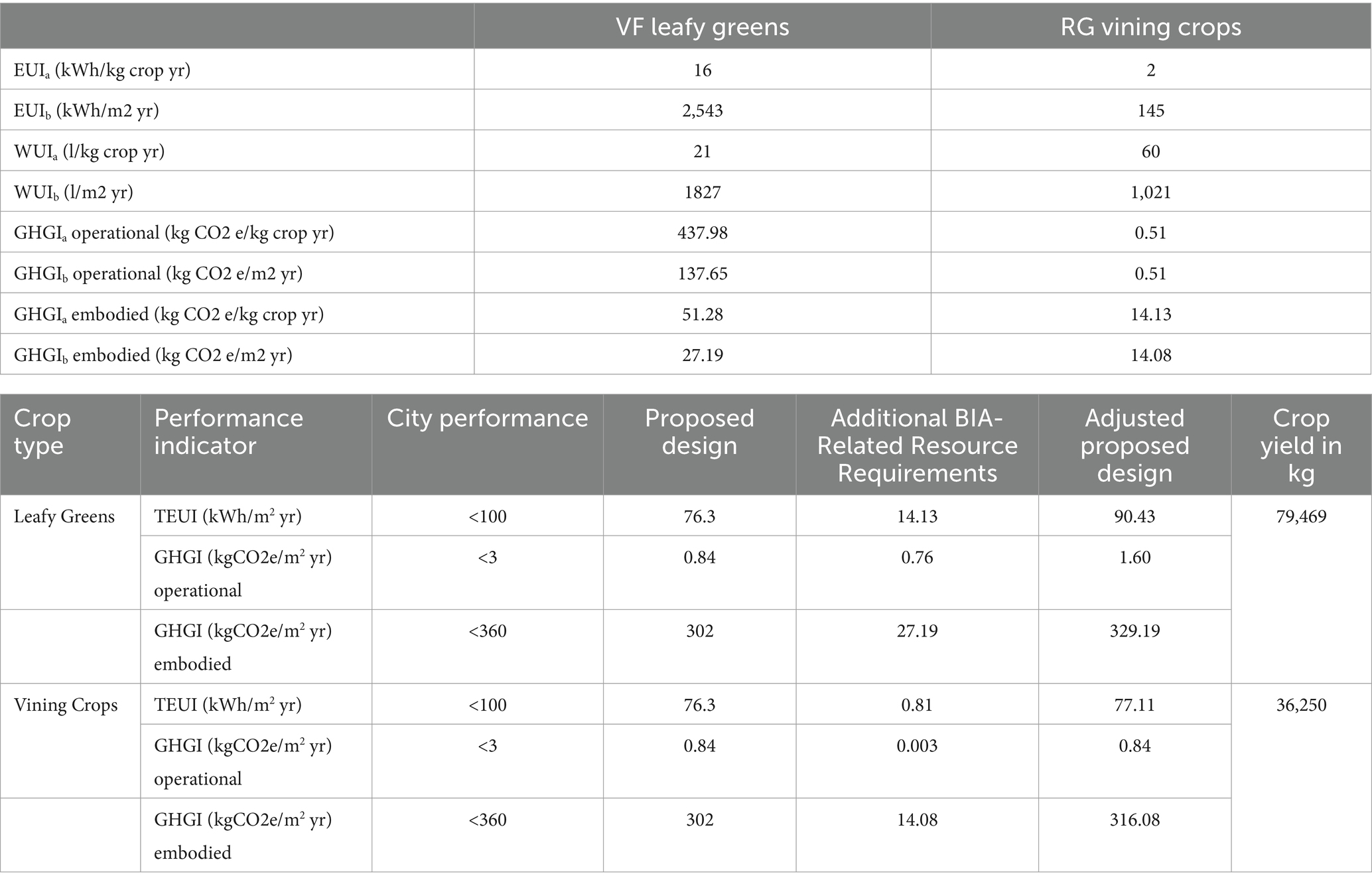

The project is a high-rise multi-unit residential building (MURB) in Vancouver, BC, with a total modelled floor area of approximately 90,000 m2 (see Figure 10). As part of Vancouver’s rezoning requirements, the project must meet specific energy intensity and GHG emission limits. An energy modeller conducted an energy simulation, and the results are presented in Table 4, associated with conversion rates for operational energy based on the energy grid for Vancouver, BC.

Figure 10. Sankey diagram demonstrating relative resource flows and inputs/outputs for BIA systems, denoting pre- and post-farmgate stages. The BIA system boundary notes that grey zones are excluded from the study due to a lack of data. Data for transportation post-farmgate was not quantitatively captured or analyzed in this study, which is in line with the integrated building and BIA LCA framework defined in Table 3 and the complexity of diverse possible post-farmgate supply chains. The size of each arm of the Sankey diagram represents relative carbon emission equivalent flows.

Table 4. Building energy model results of case study and conversion rates for operational energy for Vancouver, full list in Supplementary Material.

Given its scale, the project also falls under the Sustainable Large Developments Policy, which requires the inclusion of three diverse food assets on-site (City of Vancouver, 2024). The client has expressed strong support for integrating a BIA system into the unused areas of the underground parking facility alongside traditional soil-based urban agriculture. This case study also includes a hypothetical greenhouse to assess the three BIA systems discussed in this paper comprehensively.

Based on the BIA systems requirements and building constraints, a 500 m2 area has been allocated for each BIA system: vertical farm, soil-based, and greenhouse. While the client expressed support for BIA systems, the client did question the additional energy requirements for these agricultural systems and the overall impact on the project’s performance.

Table 5 summarizes the paired metrics calculated for the vertical farm system. These metrics are extracted from averages of the LCA analysis outlined in this research, and the full data set is included in the Appendix Tables 5, 6. These data points can provide insights that address the client’s questions and connect the BIA system to the building’s overall performance at this design stage.

Table 5. Paired metrics for indoor vertical farms (IVF) and rooftop greenhouse (RG) extracted from case study averages, followed by the paired metrics calculation results.

Since the available space for BIA, is the known driving factor (500m2), the calculations are expressed as:

Table 5 also outlines the energy and operational carbon impacts of integrating a vertical farm into the building. It shows that all adjusted EUI and GHGI values remain within the city’s performance limits. Estimated crop yields are also included, enabling the client to understand the additional benefit of integrating such a system into an urban development.

This example illustrates a single design scenario for quantifying and incorporating BIA into building performance at the early design stage. By preparing paired metrics, as shown here, vendors can provide ready-to-use specifications, easing cross-industry integration for designers. Multiple scenarios can be created based on client needs and design constraints, but this case highlights how BIA can be integrated into building design and underscores the importance of collaboration between BIA vendors and the building design industry.

Discussion

This paper aimed to establish cross-industry integration of BIA and building life cycle data. Through a review of BIA lifecycle inventories, the researchers mapped common inventory items across these studies against a common and established building LCA standard ISO 14040. We found that most BIA inventory items from pre-production to farm-gate map neatly against building life cycle phases from pre-production to end-of-life. Post-farmgate (i.e., as products exist farms into supply chains), comparisons with building standards become challenging, given the scale and complexity of agri-food supply chains.

The paper also reviewed performance metrics for three urban agriculture types—soil-based, greenhouse, and indoor vertical farms—through the literature review, case study analysis, and discussions with urban farming and technology providers. The findings reveal key operational and embodied carbon hotspots and trade-offs in each farm type’s food yield, energy use, and water use. The following sections discuss opportunities for addressing these trade-offs across urban agriculture and building systems.

The results indicate that embodied carbon values are highly yield-dependent. When assessed per kg of market-ready product and discounting operational carbon phases (A4 and A5), soil-based urban farms (worst case) hold the highest values due to grow media and infrastructure requirements. In contrast, vertical farms have lower embodied carbon for these phases but report higher values when adjusted for yield, i.e., embodied carbon per square meter, for their high infrastructure and packaging needs. This data suggests trade-offs between production volume (where indoor vertical farming excels) and embodied carbon emissions. Comparing KPIs across farm types reveals distinct strengths and challenges. Indoor vertical farms, for example, are highly productive and may be the best choice when the goal is to maximize yield in a minimal floor area. Higher yields, however, come with additional impacts, including increased operational energy (and associated carbon emissions), as well as embodied carbon in packaging, and grow media. Conversely, while soil-based systems have lower yields, they may be well-suited to settings where rainwater collection is feasible and where limited indoor space restricts vertical or greenhouse infrastructure use.

This study raises critical questions for future research within a holistic food systems context. For example, while environmental impacts per kg of market-ready crop serve as a useful metric for cross-comparison between each system type, this approach does not account for relative food yield losses in lower-yield systems. Where the goal is to increase total food production in a city, losses in yield through greenhouse or soil-based systems, with respect to vertically grown products, would have to be made up through conventional agriculture production. Where some recent work has undertaken comparative life cycle methodologies (see Blom et al., 2022), future work is required to compare total production impacts using diverse urban farming solutions, while accounting for these yield discrepancies.

Additionally, substantial variation exists in KPIs across each farm type. This variability presents both a challenge and an opportunity. It can complicate definitive predictions for operational KPIs and embodied carbon for any proposed farm; however, it also highlights the potential for significant improvements in individual farm operations. Notably, areas like packaging and grow media—easily adjusted inputs—offer greater flexibility for optimization than infrastructure, which is expensive and less adaptable.

This research identifies energy use, end-of-life infrastructure, and packaging as key improvement areas for vertical farming systems. Energy efficiency can be enhanced by design adjustments connecting BIA systems to building waste streams and establishing a framework for resource recovery, such as passive lighting and waste heat recovery (Gentry, 2019). For soil-based systems, infrastructure and grow media offer high-priority opportunities for embodied carbon efficiency gains.

Across all farm types, pre-production infrastructure inputs (A1) and packaging (B3) are major contributors to embodied carbon. They represent the two life cycle phases with the highest embodied carbon, regardless of whether measured per kg of product or by grow area. Future work is required to identify strategies to reduce embodied carbon across each life cycle phase, where the highest possible beneficial impacts may be realized.

Given the relatively small dataset of life cycle analyses used (n = 41) to generate these results, it is essential to interpret the findings with context. The urban greenhouse data relies primarily on greenhouse LCA analysis by Sanjuan-Delmás et al. (2018) and Rufí-Salís et al. (2021), and the vertical agriculture studies vary widely in size from small-scale grow units (e.g., Martin et al., 2024) to larger scale plant factories (e.g., Martin et al., 2024). Although this is a limitation, data availability remains challenging until more life cycle studies are completed and publicly accessible. Dorr et al. (2021), a further data limitation was reliance on self-reported key performance indicators from companies, via the case study analysis. Absent publicly available life cycle analyses or grow trial data, the researchers could not assess the accuracy of these reported values. Finally, most case studies informing the data for this study are from Europe, North America, and some parts of Asia. There is strong need for life cycle analysis data to be captured from additional national contexts in Asia, Oceania, and across the continents of Africa and South America, reflecting diverse climates, crops, energy grids and, therefore, varied operational and embodied values. Paucek et al. (2023) found, for example, strong differences in suitability for vertical farming across 54 different African states.

Analyzing BIA case studies presents unique challenges. BIA projects vary widely in scale, from small urban installations to large neighbourhood initiatives, and incorporate various technologies and practices (Kalantari et al., 2017; Glaros et al., 2024). This diversity complicates the development of a standardized analytical framework that can adapt to each project’s specific characteristics and goals. For instance, this paper reports infrastructure values in the aggregate, but infrastructure inventories differ considerably across studies; some include rainwater harvesting equipment alongside grow infrastructure (e.g., Sanjuan-Delmás et al., 2018), while others report only grow system infrastructure.

The multi-faceted goals of BIA projects add further complexity to the analysis. BIA initiatives often address diverse issues, including food security, heat island reduction, and sustainability. Balancing these objectives requires integrating multiple performance metrics and sustainability indicators. This diversity is evident in the data where some projects, like large-scale vertical farms (e.g., Martin et al., 2019), prioritize yield, while others, such as soil-based urban farms, focus on community building (Hawes et al., 2024).

These challenges underscore the need for a methodical, adaptable approach to BIA case study analysis, which allows for identifying innovative solutions and developing effective urban sustainability strategies. The approach outlined in this paper offers a replicable framework that can be refined as more data becomes publicly available.

Opportunities and future directions

Introducing resource recovery measures between building and farm offers a promising pathway to improve KPIs and lower embodied carbon emissions across all farm types. For example, grow media for plant production can be sourced from local building or business waste, treating and repurposing organic materials as substrates in hydroponic systems (Molari et al., 2024). This approach reduces end-of-life emissions by extending waste materials’ lifecycles and lowering input-related carbon emissions.

Energy use remains the primary contributor to operational emissions in vertical farms. Energy reductions can be achieved through waste heat reuse for climate control, passive solar integration to offset artificial lighting demands and green energy adoption where local grids are not already low carbon. Studies show that integrating vertical farms into buildings can reduce VF energy consumption by 12–51% (Blom et al., 2023). Additionally, situating indoor vertical farms in business parks, industrial zones or within heat-sharing systems offers further opportunities to reduce climate control energy needs (Gentry, 2019). Infrastructure impacts can also be minimized by designing for equipment and material reuse from the concept stage and carrying through this vision to project completion.

The data from this research suggests that resource recovery strategies – integrating BIA with redirected building waste streams like heat, CO2, and nutrients – can reduce energy demands associated with climate control. Supplementary natural lighting for glazed VF could also lower artificial lighting requirements, enhancing connectivity between the farm and users, though this may impact yield optimization. Further research should examine these opportunities to guide growers, developers, and designers in effective resource use.

Among promising approaches for reducing energy use and embodied carbon across all grow systems, especially vertical farming, is hybridizing standard farming systems. Rather than treating each system type as isolated, combining the efficiencies of multiple systems can yield more impactful BIA designs. For example, stacking crops within greenhouse infrastructure, rather than fully indoors, allows passive solar heating and lighting, offsetting some environmental impacts of vertical farming. Aquaponics—integrating fish with hydroponic vegetable cultivation—is a widely adopted, effective example of such hybridization (Forchino et al., 2017).

Studies have only recently begun to explore the potential of hybridizing BIA systems. For instance, waste from vertical farming can be repurposed through soil-based composting—a significant source of embodied carbon emissions in these systems compared to soil-based or greenhouse farming. One study integrated a simulated hydroponic vertical farm with a vermicompost system and secondary seaweed/halophyte production to form a circular system (Chowdhury and Asiabanpour, 2024). Another rooftop agriculture case study demonstrated the potential to repurpose tomato stems as grow media for lettuce production, which could occur within indoor vertical farming environments (Manríquez-Altamirano et al., 2020). Hybridizing BIA systems can help reconcile diverse food, energy, and water trade-offs across farm types. Future research should focus on designing, modelling, and implementing these hybrid systems to optimize key performance metrics and support building design.

Effective project design requires robust data collection to minimize environmental impacts. Data collection may be more straightforward in automated systems, such as vertical agriculture, where sensors and instruments already manage ongoing maintenance and functionality. However, the BIA sector has limitations regarding transparent, high-quality socio-economic and environmental data availability. There is a need to facilitate standardized data collection between farm types. Frameworks such as that proposed in this paper can facilitate the process, but further work is required via legislation, policy, and guidelines to create an interoperable and integrated BIA impact monitoring system in practice.

Furthermore, additional research is required to capture missing life cycle data, particularly from post-farmgate stages to consumer waste. BIA systems’ proximity to consumers offers unique opportunities to reduce food waste compared to conventional supply chains, which face significant losses at farms and households (Caldeira et al., 2019). Finally, current yield metrics focus primarily on mass (kg of crops). However, CEA and BIA systems may produce crops with higher nutrient density or other quality factors, suggesting that yield could also be expressed in terms of nutritional content or crop value. Research into well-calibrated lighting, nutrients, and water inputs is essential to better quantify and compare yield outputs beyond mass alone.

Conclusion

The cross-industry framework outlined in this paper can advance the application of Life Cycle Assessment in Building-Integrated Agriculture. By bridging urban agriculture and building metrics, this framework empowers designers, growers, and developers to evaluate Building-Integrated Agriculture impacts through specific Key Performance Indicators, whether area-based or yield-based. Key benefits of this framework include:

a. Unified performance evaluation: by merging urban agriculture and building metrics, this framework facilitates a comprehensive assessment of environmental impacts across both domains. Integrated carbon accounting provides a holistic profile of a project’s performance, allowing for better decision-making in design and policy.

b. Policy alignment: integrating UA metrics into building terms ensures that BIA projects align with evolving sustainability regulations on energy, water, and emissions. This alignment strengthens the integration of urban agriculture within urban planning and policy frameworks.

c. Cross-industry understanding: translating UA metrics into building-specific terms enhances collaboration across disciplines, making BIA projects more accessible to architects, engineers, investors, and policymakers. This shared understanding fosters partnerships and innovation in urban development.

Author contributions

MI: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. AG: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Writing – original draft, Writing – review & editing. CC: Conceptualization, Methodology, Writing – original draft, Writing – review & editing. AD: Data curation, Investigation, Resources, Validation, Visualization, Writing – original draft, Writing – review & editing. AB: Writing – original draft, Writing – review & editing. RF: Investigation, Resources, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was supported by funding from the Government of Canada through the Agricultural Clean Technology (ACT) Program Research and Innovation Stream, Perkins&Will, and the BC Centre for Agritech Innovation (BCCAI).

Acknowledgments

The research team would also like to thank the following organizations for their valuable advisory support: Quanto Tech Ltd. and the University of the Fraser Valley. Their contributions were integral to the success of this project.

Conflict of interest

MI, CC, and AB were employed by Perkins & Will.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that Gen AI was used in the creation of this manuscript. We have used Grammarly tool for editorial support.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2025.1533433/full#supplementary-material

References

Al-Qubati, A., Zhang, L., and Forkel, M. (2024). Urban and peri-urban agriculture under climate change: a review on carbon emissions and sequestration. Sustain. Cities Soc. 115:105830. doi: 10.1016/j.scs.2024.105830

Béné, C. (2020). Resilience of local food systems and links to food security—a review of some important concepts in the context of COVID-19 and other shocks. Food Sec. 12, 805–822. doi: 10.1007/s12571-020-01076-1

Benis, K., Gashgari, R., Alsaati, A., and Reinhart, C. (2018). Urban Foodprints (UF) – establishing baseline scenarios for the sustainability assessment of high-yield urban agriculture. Int. J. Design Nat. Ecodyn. 13, 349–360. doi: 10.2495/DNE-V13-N4-349-360

Blom, T., Jenkins, A., Pulselli, R. M., and van den Dobbelsteen, A. A. J. F. (2022). The embodied carbon emissions of lettuce production in vertical farming, greenhouse horticulture, and open-field farming in the Netherlands. J. Clean. Prod. 377:134443. doi: 10.1016/j.jclepro.2022.134443

Blom, T., Jenkins, A., and van den Dobbelsteen, A. (2023). Synergetic integration of vertical farms and buildings: reducing the use of energy, water, and nutrients. Front. Sustain. Food Syst. 7, 1–16. doi: 10.3389/fsufs.2023.1227672

Caffrey, K. R., and Veal, M. W. (2013). Conducting an agricultural life cycle assessment: challenges and perspectives. Sci. World J. 2013:472431. doi: 10.1155/2013/472431

Caldeira, C., De Laurentiis, V., Corrado, S., van Holsteijn, F., and Sala, S. (2019). Quantification of food waste per product group along the food supply chain in the European Union: a mass flow analysis. Resour. Conserv. Recycl. 149, 479–488. doi: 10.1016/j.resconrec.2019.06.011

Chowdhury, H., and Asiabanpour, B. (2024). A circular economy integration approach into vertical farming with computer-based simulation model for resource optimization and waste reduction. J. Clean. Prod. 470:143256. doi: 10.1016/j.jclepro.2024.143256

City of Vancouver. (2024). "Rezoning policy for sustainable large developments." City of Vancouver Land Use and Development Policies and Guidelines. 04 01. Available at: https://guidelines.vancouver.ca/policy-rezoning-sustainable-large-developments.pdf

Dorr, E., Goldstein, B., Horvath, A., Aubry, C., and Gabrielle, B. (2021). Environmental impacts and resource use of urban agriculture: a systematic review and meta-analysis. Environ. Res. Lett. 16, 1–28. doi: 10.1088/1748-9326/ac1a39

Dorr, E., Sanyé-Mengual, E., Gabrielle, B., Grard, B. J.-P., and Aubry, C. (2017). Proper selection of substrates and crops enhances the sustainability of Paris rooftop garden. Agron. Sustain. Dev. 37, 1–11. doi: 10.1007/s13593-017-0459-1

FAOSTAT. (2024). Emissions totals. Accessed 10 24, 2024. Available online at: https://www.fao.org/faostat/en/?#data/GT

Ferguson, C. (2023). Controlled Environment Agriculture vs. Conventional Agriculture: The Break-Even Point. Dissertations & Theses at RRU. Available at: https://www.viurrspace.ca/items/e2b4990d-0070-4140-8ff2-8d374f129f25

Forchino, A. A., Lourguioui, H., Brigolin, D., and Pastres, R. (2017). Aquaponics and sustainability: the comparison of two different aquaponic techniques using the life cycle assessment (LCA). Aquac. Eng. 77, 80–88. doi: 10.1016/j.aquaeng.2017.03.002

Gentry, M. (2019). Local heat, local food: integrating vertical hydroponic farming with district heating in Sweden. Energy 174, 191–197. doi: 10.1016/j.energy.2019.02.119

Glaros, A., Newell, R., Benyam, A., Pizzirani, S., and Newman, L. L. (2024). Vertical Agriculture's potential implications for food system resilience: outcomes of focus groups in the Fraser Valley, British Columbia. Ecol. Soc. 29, 14547–290112. doi: 10.5751/ES-14547-290112

Goldstein, B., Hauschild, M., Fernández, J., and Birkved, M. (2016). Urban versus conventional agriculture, taxonomy of resource profiles: a review. Agron. Sustain. Dev. 36, 1–19. doi: 10.1007/s13593-015-0348-4

Hawes, J., Goldstein, B., Newell, J., Dorr, E., Caputo, S., Fox-Kämper, R., et al. (2024). Comparing the carbon footprints of urban and conventional agriculture. Nat. Cities 1, 164–173. doi: 10.1038/s44284-023-00023-3

Kalantari, F., Mohd Tahir, O., Mahmoudi, L., and Kaltantari, S. (2017). A review of vertical farming technology: a guide for implementation of building integrated agriculture in cities. Adv. Eng. Forum 24, 76–91. doi: 10.4028/www.scientific.net/AEF.24.76

Kulak, M., Graves, A., and Chatterton, J. (2013). Reducing greenhouse gas emissions with urban agriculture: a life cycle assessment perspective. Landsc. Urban Plan. 111, 68–78. doi: 10.1016/j.landurbplan.2012.11.007

Manríquez-Altamirano, A., Sierra-Pérez, J., Muñoz, P., and Gabarrell, X. (2020). Analysis of urban agriculture solid waste in the frame of circular economy: case study of tomato crop in integrated rooftop greenhouse. Sci. Total Environ. 734:139375. doi: 10.1016/j.scitotenv.2020.139375

Martin, M., Bustamante, M. J., Zauli, I., and Orsini, F. (2024). Environmental life cycle assessment of an on-site modular cabinet vertical farm. Front. Sustain. Food Syst. 8:1403580. doi: 10.3389/fsufs.2024.1403580

Martin, M., Poulikidou, S., and Molin, E. (2019). Exploring the environmental performance of urban Symbiosis for vertical hydroponic farming. Sustain. For. 11:6724. doi: 10.3390/su11236724

Mok, H. F., Williamson, V., Grove, J., Burry, K., Barker, F., and Hamilton, A. (2014). Strawberry fields forever? Urban agriculture in developed countries: a review. Agron. Sustain. Dev. 34, 21–43. doi: 10.1007/s13593-013-0156-7

Molari, M., Dominici, L., and Comino, E. (2024). Experimenting growing media through local bio-resources valorisation: a design-oriented approach for living walls. J. Clean. Prod. 436:140446. doi: 10.1016/j.jclepro.2023.140446

Pact, Milan Urban Food Policy. (2024). About. Accessed October 2024. Available online at: https://www.milanurbanfoodpolicypact.org/#

Paucek, I., Durante, E., Pennisi, G., and Quaini, S. (2023). A methodological tool for sustainability and feasibility assessment of indoor vertical farming with artificial lighting in Africa. Scientificreports 13:2109. doi: 10.1038/s41598-023-29027-8

Rufí-Salís, M., Petit-Boix, A., Villalba, G., Gabarrell, X., and Leipold, S. (2021). Combining LCA and circularity assessments in complex production systems: the case of urban agriculture. Resources, Conservation and Recycling. 166:105359. doi: 10.1016/j.resconrec.2020.105359

Sanjuan-Delmás, D., Llorach-Massana, P., Nadal, A., Ercilla-Montserrat, M., Muñoz, P., Montero, J. I., et al. (2018). Environmental assessment of an integrated rooftop greenhouse for food production in cities. J. Clean. Prod. 177, 326–337. doi: 10.1016/j.jclepro.2017.12.147

Sanyé-Mengual, E., Oliver-Solà, J., Montero, J. I., and Rieradevall, J. (2015). An environmental and economic life cycle assessment of rooftop greenhouse (RTG) implementation in Barcelona, Spain. Assessing new forms of urban agriculture from the greenhouse structure to the final product level. Int. J. Life Cycle Assess. 20, 350–366. doi: 10.1007/s11367-014-0836-9

Specht, K., Siebert, R., Thomaier, S., Freisinger, U. B., Sawicka, M., Dierich, A., et al. (2015). Zero-acreage farming in the City of Berlin: an aggregated stakeholder perspective on potential benefits and challenges. Sustain. For. 7, 4511–4523. doi: 10.3390/su7044511

Specht, K., Zoll, F., Schümann, H., Bela, J., Kachel, J., and Robischon, M. (2019). How will we eat and produce in the cities of the future? From edible insects to vertical farming—a study on the perception and acceptability of new approaches. Sustain. For. 11:4315. doi: 10.3390/su11164315

Thomas, M. A. (2022). The PAE building: Developer-led, nature-inspired. Seattle: Ecotone Publishing.

WBDG. (2024). Green building standards and certification systems. Accessed 01 11, 2025. Available online at: https://www.wbdg.org/resources/green-building-standards-and-certification-systems

Keywords: building integrated agriculture, life cycle assessment, urban food security, resource circularity, operational carbon emission, embodied carbon

Citation: Imam M, Glaros A, Chen C, Dsouza A, Brander A and Ferguson R (2025) A carbon-centric evaluation framework for building-integrated agriculture: a comparison of three farm types and building standards. Front. Sustain. Food Syst. 9:1533433. doi: 10.3389/fsufs.2025.1533433

Edited by:

Martí Rufí-Salís, 2.-0 LCA consultants, SpainReviewed by:

Pablo Torres-Lima, Metropolitan Autonomous University, MexicoMohammad Reza Khalilnezhad, University of Birjand, Iran

Copyright © 2025 Imam, Glaros, Chen, Dsouza, Brander and Ferguson. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mohamed Imam, bW9oYW1lZC5pbWFtQHBlcmtpbnN3aWxsLmNvbQ==

Mohamed Imam

Mohamed Imam Alesandros Glaros

Alesandros Glaros Cheney Chen1

Cheney Chen1