- 1Socioeconomics Research Directorate, Oromia Agricultural Research Institute, Asella, Ethiopia

- 2Ethiopian Economics Association, Addis Ababa, Ethiopia

- 3Research Projects Coordinator, International Livestock Research Institute (ILRI), Addis Ababa, Ethiopia

Introduction: Farm mechanization has multi-dimensional impacts on agricultural production systems like economic efficiency and productivity, thereby improving the quality of life in the farming community by reducing work drudgeries. However, these impacts were not studied empirically in Ethiopia. Hence, this research was initiated to estimate the level of economic efficiency, and productivity of wheat and barley, and the impact of farm mechanization on economic efficiency and productivity of wheat and barley.

Methods: The analysis was done for 232 and 257 wheat and barley producer farmers respectively who are selected from the Arsi and West Arsi zones. The stochastic frontier model was used to estimate economic efficiency while augmented inverse probability weighted (AIPW) was used to estimate the impact.

Results and discussion: Based on the result, it is apparent that farm mechanization has a significant positive impact on wheat productivity while the percentage change in average treatment effect for the barley was not statistically significant. Farm mechanization also affects wheat and barley economic efficiency positively. Hence, we recommended the wider use of farm mechanization to improve economic efficiency and productivity. Therefore, policy design should focus on ways to avail farm machinery easily like establishing farm mechanization service centers and facilitating credit services for mechanization service renders.

1 Introduction

The impacts of agricultural mechanization have been estimated for different outcome vary in different regions of the world. Amirani (2001) and Houmy et al. (2013) pointed out that farm mechanization has multi-dimensional impacts in agricultural production system like economic efficiency, and life quality of the farming community by reducing work drudgeries. Its introduction can also increase the productivity of the farming system significantly, especially where agriculture is more dominated by traditional technologies. Mechanization reduces production costs, thereby increasing profit and reducing food costs (Cossar, 2019; Bello, 2012). Farm mechanization has great impacts on factor productivity improvement like labor productivity, land productivity, and capital productivity (Goyal et al., 2014). Moreover, the literature indicated that farm mechanization has an impact on the adoption of technologies like an improved seed, chemical fertilizer, agrochemicals, etc., and crop yields (Takeshima et al., 2013; Benin, 2015; Ma et al., 2018; Paudel et al., 2019; Zhang et al., 2019; Zhou et al., 2020; Zhou and Ma, 2022).

The advantages of farm mechanization can also be explained in terms of acquired or desired work quality and maintained timeliness of work accomplishment which can contribute to production quality (Houmy et al., 2013; Bello, 2012). The level of industrialization and the development of the agricultural economy of a nation are also directly related to farm mechanization (Singh, 2006). In general, agricultural mechanization can contribute to sustainable production and productivity to secure food self-sufficiency through the mitigation of labor shortage, and reduction of drudgery and other production bottlenecks (Wang et al., 2016; Zhou and Ma, 2022). Therefore, estimating the impacts of farm mechanization on productivity and economic efficiency is rational and can generate evidences for policy and development interventions (Hormozi et al., 2012; Singh, 2006).

Recently, there are several studies on impacts of farm mechanization on production efficiency and farm productivity in different parts of the world. For example, Soliman (1992) studied impact of farm mechanization in Egyptian agriculture and found that farm mechanization has significant impact both on productivity and efficiency of all kinds of crops under consideration, i.e., wheat, maize, cotton and rice. The author also found highest and significant impact of mechanization on wheat economic efficiency compared to other crops. Similarly, Min et al. (2021) conducted research on impact of mechanization at different phases on agricultural operation and they found that mechanization has different impact at different phases. Accordingly, they found that mechanization has a positive effect on technical efficiency at the chemical application phase, but does not affect efficiency at the plowing and harvesting phases.

Impact of farm mechanization in rice productivity in Cauvery delta zone of Tamil Nadu state was studied by Chidambaram (2013). Mamman (2015) also studied the influence of agricultural mechanization on crop production in Bauchi and Yobe states of Nigeria. The study by Vortia et al. (2019) also indicated that Mechanization has positive impact and leading to increase productivity and profitability of rice producers in Bangladesh. The above-mentioned studies all identified that farm mechanization has significant effects on productivity and technical, and economic efficiency of farm mechanization on different crops and suggested the importance of the technology in production.

Similarly, introduction of farm mechanization, as kind of technical change in agricultural activities, is expected to have certain impacts on production, productivity and economic efficiency of smallholder farmers in Ethiopia. The findings on impact of farm mechanization in developing countries in the past were not in conformity with each other and lack conclusiveness (Tan, 1981). In order to bridge the gaps, several empirical studies have been conducted in different parts of the developing countries. To this end, a number of empirical and conclusive case studies on impacts of farm mechanization on different outcome variables like productivity (production/hectare) and economic efficiency different countries were conducted. Similar to other developing countries, demonstration and popularization efforts were started since 1970s in Ethiopia (Stahl, 1973; Cohen, 1987) mainly around the central and southern parts of Oromia region. However, there were also similar debates about the impacts of farm mechanization in Ethiopia during 1970s. Research conducted in Chilalo Agricultural Development Unit (CADU) project areas concluded that the expansion of farm mechanization had different negative outcomes to small-holder farmers like the eviction of tenants, high soil erosion, reduction of pastureland and others. Based on the findings, the government decided to ban farm mechanization (Henock, 1972). As a result, farm mechanization was only practiced on limited areas and some state-owned farms in Ethiopia (Mohammed et al., 2000). But there is also recent findings that farm mechanization has positive impacts on yield in Ethiopia (Guush et al., 2017).

However, the government of Ethiopia has recently taken substantial steps to promote farm mechanization through policy supports such as provision of tax-free farm machinery imports, and credit facilities through youth employment opportunities by the Development Bank of Ethiopia under the “machinery lease financing scheme.” The tax-free machinery import was approved by the Ministry of Finance in 2019 for farm machinery and irrigation technologies. The lease financing service is not limited to youths but also other interested potential investors in areas of agriculture to purchase farm machineries including tractors, combine harvesters, irrigation technologies, and livestock husbandry technologies since 2016 (Development Bank of Ethiopia, 2016a, 2016b). These efforts are evidence for the beliefs developed nationally that farm mechanization is more important and contributing to the growth of production, and productivity being attained in Ethiopian agricultural sector. Furthermore, studies indicated that machinery up-take at national level is increasing from time-to-time (Guush et al., 2017). Despite over seven decades of efforts to mechanize Ethiopian agriculture and the multi-dimensional impact of the technologies, studies on these areas are not sufficient (Workneh et al., 2021). On the other side, there are still debates at every corner on the importance and timeliness of farm mechanization. Particularly, there is a dearth of studies on the impacts of farm mechanization on economic efficiency and farm productivity of smallholder farming households in Ethiopia in general and in central and southern Oromia region of Ethiopia in particular. Hence, this research was initiated to fill the gap observed in this area with specific objectives of estimating the impacts of farm mechanization on economic efficiency and farm productivity in central and southern Oromia, Ethiopia. Specifically, the study is aimed at providing and clearly showing the importance and positive impacts that the wider use of farm mechanization can have on regional and national agricultural production and productivity. It can also indicate the way forwards to promote farm mechanization.

2 Methodology of the research

2.1 Description of the study area

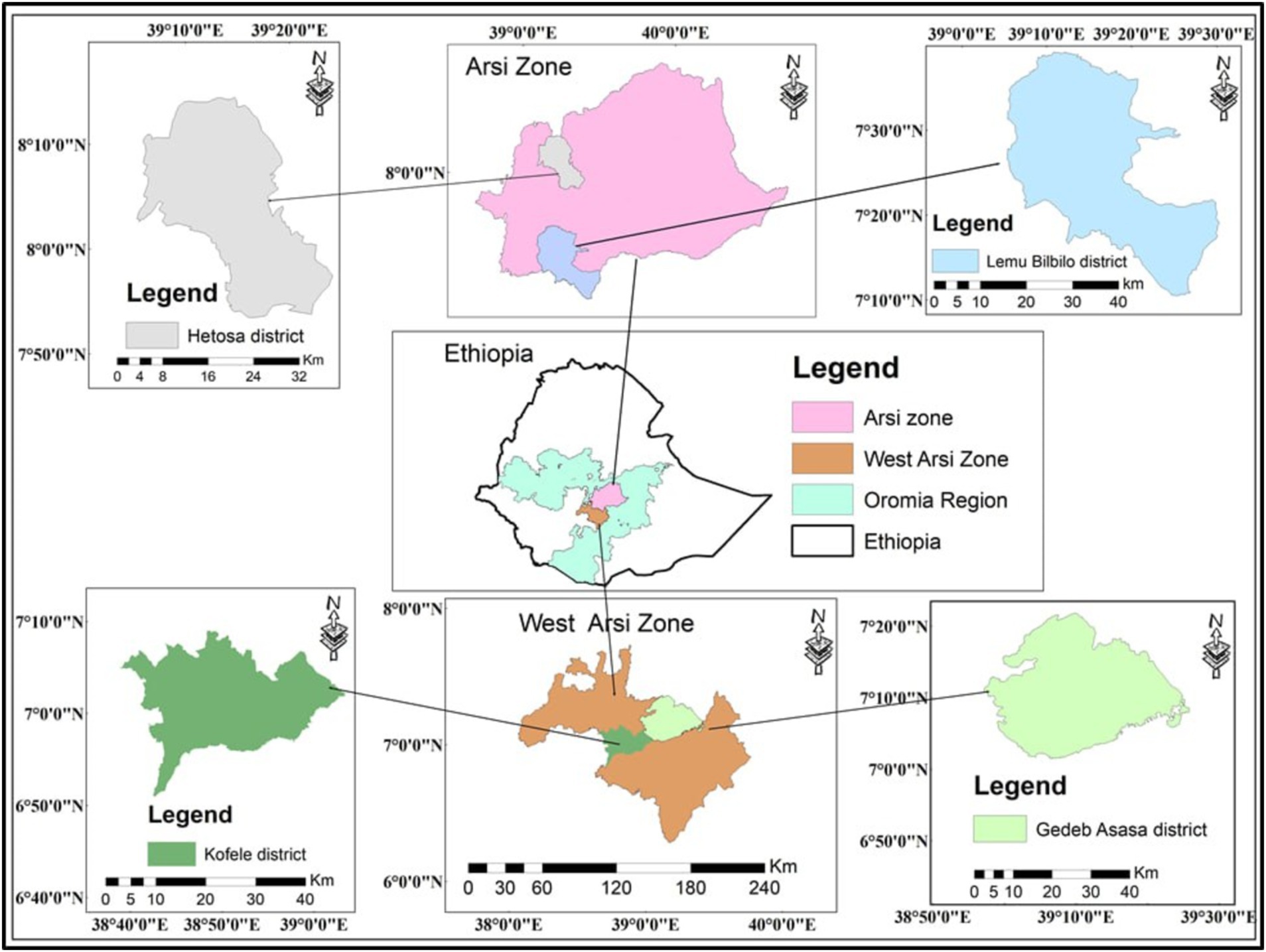

This study was conducted in two selected zones of central and southeast part of Oromia regional state. The region is located 3°24′20″ North to 10°23′26″ North latitudes (extending for about 7o north to south and 34°7′37″ East to 42°58′51″ East longitudes (extending for about 9o west to east) in tropical zone. In terms of both population size and land mass, Oromia is the largest regional state in Ethiopia by occupying approximately 34, and 37% of land and populations, respectively. Even though it varies from study to study, its average estimated area is about 363,375 km2 (BoFED, RD and ICP, 2012). Based on the CSA (2013) projection, its population by 2025 is estimated to jump over 42millions. In terms of spatial coverage of its temperature, more than 99% of the area of the region is suitable for crop growth. The region receives annual rainfall of 1,600-2400 mm in highland part and less than 400 mm in lowland parts of the region (MoA, 2000). The lion-share of national crop cultivated land is also from Oromia region. For instance, in 2020/21 production season, the region’s total all crop cultivated land accounts for 46.24% of total national crop cultivated area (CSA, 2021).

The two zones, selected for this study Arsi and West Arsi, are in central and southeastern part of Oromia region, respectively. The geographical locations of the four sampled districts are indicated in study map (Figure 1). There are two reasons for the area limitation of this study. The first and foremost reason is that the area has more exposure to farm mechanization technologies and it is easy to get respondents who are experiencing the technologies for the analysis of impacts. The second reason is due to the limitation of time and resource to cover wider geography of the nation. Arsi zone geographically lies between 6°45′N to 8°58′N latitude and 38,032′E to 40°50′ E longitude while West Arsi zone extends from 6,012′29″ to 7,042′55″ latitude and 38,004′04″ to 39,046′08″ longitude (Oromia Bureau of Finance and Economic Development (OBOFED), 2011; Tamrat et al., 2019).

Crop-livestock mixed farming is practiced in the area. Livestock are sources of traction forces and manure for agricultural activities and biomass fuel and income sources in the area. Barley and wheat are among widely grown crops in the two zones. While Oromia covers 52.51% of total wheat cultivated land of Ethiopia, the two zones together covered 33.24 and 17.45% of total wheat grown land of Oromia and Ethiopia, respectively. Similarly, major barely production of the region and the country as a whole is from these two zones. Accordingly, in 2020/21 production season, 47.59% of barley grown land was from Oromia where Arsi and West Arsi alone covered 37.67% of Oromia and 17.93% of national barley farm (CSA, 2021). In nutshell, these two zones are among the zones that are surplus producers in Oromia region.

2.2 Data types, data collection method, and target groups

Data used in this study was both qualitative and quantitative primary data that have been collected from farm households in the study area. Data related to households’ socioeconomic characteristics, crop production system, inputs use intensity, household off-farm and farm income, and other related were collected using a structured questionnaire. Additional qualitative data to enrich the quantitative data was collected by using focus group discussion at each kebele. Data collection was conducted from April to May 2022 by trained enumerators from Asella Agricultural Engineering Research Center under the full supervision of the researchers. A Census and Survey Processing System (CSPro) software was employed for data collection. CSPro is a software package for entry, editing, tabulation, and dissemination of census and survey data. It is commonly used to conduct surveys in agriculture and economic among others (Ponnusamy, 2012).

2.3 Sampling frame and sampling procedures

A stratified multi-stage sampling procedure was employed to sample respondent households. In the first stage, Arsi and West Arsi zone were purposively selected as representatives for the central and southern parts of Oromia region and where adoption of farm mechanization is considerably high. Due to similarity in terms of agroecological zones and farming systems, the two zones were highly homogenous and sampling of districts and kebeles were designed accordingly. The study mainly focused on highland and midland districts of the study area where adoption of farm mechanization is relatively high. Districts having better practices of farm mechanization were first identified and listed. Then, at the second stage, from the identified districts with better farm mechanization practices, two districts from each zone, i.e., Hetosa and Lemu-bilbilo from Arsi and Kofele and Gedeb-Hasasa districts from West Arsi were also selected randomly. Thirdly, a total of eight kebeles (the lowest administrative unit), two from each district, were selected randomly. The number of households from each kebele was determined based on probability proportional to the size of the district’s household population size. The final sample size was determined using Kothari’s (2004) formula which gives us the maximum proportional sample size.

Where N is the desired sample size; Z is the standard cumulative distribution that corresponds to the level of confidence with the value of 1.96; e is desired level of precision; p is the estimated proportion of an attribute present in the population with the value of 0.5 as suggested by Israel (1992) to get the desired minimum sample size of households at 95% confidence level and ±5% precision; q = 1 − p. Accordingly, a sample of 385 was proposed and finally, 397 household heads were selected and interviewed using random sampling technique by adding 12 respondents for contingency purpose.

The sample households producing wheat and barley are not mutually exclusive. Hence, since there are households who are producing wheat but not barley; and there are producing barley but not producing wheat; economic efficiency estimation was only calculated for only 262 wheatproducer and 257 barley-producer farmers.

2.4 Methods of data analysis and synthesis

Information and data related to the impacts of farm mechanization on economic efficiency, and farm productivity were analyzed and synthesized using different statistical and econometric tools. Descriptive statistics like mean and inferential statistics were largely employed to analyze and summarize demographic and socioeconomic variables. An estimator for average treatment effects (ATEs) known as the augmented-inverse-propensity-weighted (AIPW) estimator method was used to analyze the impacts of the level of farm mechanization on those outcome variables (Glynn and Quinn, 2010).

2.4.1 Farm mechanization use impact pathways

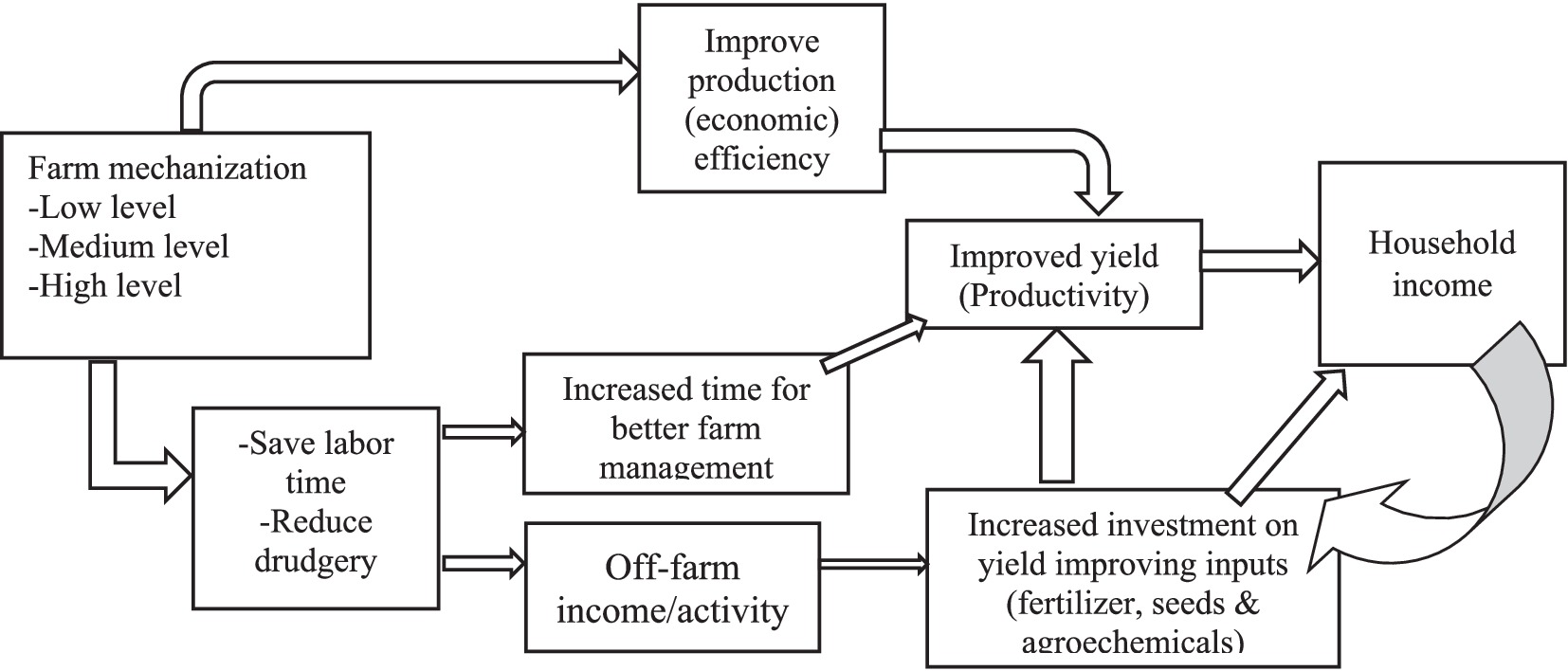

A farm household can adopt farm mechanization at different levels (low, medium, and high levels) categorized based on the mechanization index (MI) calculated based on per hectare expense of household to use farm mechanization as it is done by different authors (Wang et al., 2018; Singh, 2006). Figure 2 depicts the impact pathways for different levels of farm mechanization and how it affects different outcome variables and ultimately the household’s income. According to the literature, farm mechanization directly affects farm productivity, and overall production efficiency (economic efficiency) through timeliness of production operations, overcoming seasonal labor shortages, and reducing wastages and inefficiency of input applications and ultimately the household income (Zhou and Ma, 2022; Hormozi et al., 2012; Abass et al., 2017; Paudel et al., 2019; SHI et al., 2021).

On the other way, the adoption of farm mechanization can improve productivity and income by reducing work drudgery, increasing labor productivity, and saving time for leisure and off-farm and non-farm income-generating activities. For instance, Sang et al. (2023) found that the use of farm mechanization in rural China has a significant impact on improving nonfarm income. Furthermore, the use of farm mechanization can also improve productivity and household income by optimizing agricultural inputs like chemical fertilizers and agrochemicals (Zhang et al., 2019; Zhou et al., 2020; Su et al., 2022; Afridi et al., 2020; Kirui, 2019). For instance, the use of precision agriculture in fertilizer and agrochemicals application can optimize the gain from those inputs by reducing wastage. The use of mechanization technologies can also bring impacts on productivity and production by appropriate placement and rate of application.

2.4.2 Specification of stochastic frontier cost function and cost efficiency

Prior to the estimation of the impact of farm mechanization level on the economic efficiency of a household, the economic efficiency of wheat and barley producer farmers was estimated using Farm mechanization -Low level -Medium level -High level Improve production (economic) efficiency Improved yield (Productivity) Household income -Save labor time -Reduce drudgery Increased time for better farm management Off-farm income/activity Increased investment on yield improving inputs (fertilizer, seeds, and agroechemicals) stochastic frontier cost function and cost efficiency estimation methods. The stochastic frontier function method is preferred over the non-stochastic method like data envelopment analysis (DEA) as it accounts for measurement errors due to the absence of farm records and agricultural variability due to climatic hazards, plant pathology, insect and pests (Battese and Coelli, 1995). Hence, the assumption of DEA which accounts for all deviation from the frontier to inefficiency is not logical in agricultural production. Accordingly, the SFA model is selected and specified as follows (Equation 1):

Where is the production of the farmer, is a vector of inputs used by the farmer, is a vector of unknown parameters, is a random variable which is assumed to be , and is independent of the which is a non-negative random variable assumed to account for technical inefficiency in production.

2.5 Production efficiency estimation

A Cobb–Douglas production function form which describes the transformation relationship from input to output (Kumbhakar et al., 2015) is employed. Cobb–Douglas production is a widely used production function in agricultural production (Zhang et al., 2015; Imad et al., 2019; Min et al., 2021) mainly due to its simplicity over translog function. A translog function has problems of multicollinearity and degrees of freedom that can arise due to a substantial number of parameters to be estimated. Hence, the use of the translog function especially with input variables of more than three is difficult for computation. Moreover, parameters are not directly interpreted because of the second-order terms involved in the function, and additional calculations are needed to get the partial outputs elasticities of individuals. Hence, the Cobb–Douglas production function for wheat/barley crops is preferred and defined as follows (Equation 2):

Where ln is the natural logarithm; is the production of the farmer; represents land (ha), labor (man-days), number of oxen (oxen-days), seed (Kg), agrochemicals (litters), chemical fertilizer (Kg), land plowed by tractor (ha) and grain harvested by combine harvesters (qt); and are parameters to be estimated. Similarly, vi is a random disturbance that captures the stochastic noise in the production and is independent of the inefficiency term, and distributed normally. Ui is also a non-negative random variable that represents the technical inefficiency of production. It is independently and identically distributed as half-normal . Economic efficiency is more important than technical and allocative efficiencies to understand the efficiency of wheat and barley producers. Hence, a dual cost efficiency frontier of the Cobb–Douglas production function is specified following Kumbhakar and Lovell (2000) as follows (Equation 3):

Where Ci is minimum cost a household incurred in wheat/barley production; is total wheat/barley production adjusted for noise; represents price of land, labor, oxen-days, chemicals, seed, fertilizer, tractor rent and combine rent, respectively, and s are parameters to be estimated. Furthermore, a self-dual cost frontier parameter that is associated with dual production function parameters can be expressed algebraically as follows (Equations 4 and 5):

Where is the cost (expenditure) incurred by wheat/barley producer i, is a vector of maximum output (wheat/barley) produced by producer i, is a vector of input prices that wheat/barley producer i faced, is the cost frontier that is common to all wheat/barley producers, and are vectors of technology and inefficiency parameters, respectively to be estimated, is a positive error term which captures cost inefficiency, is a statistical noise or a random error term that is symmetrically distributed and assumed to be independent of . Cost efficiency is given as (Equation 6):

In Equation 2, the function is an equation relating cost inefficiency ( ) to a set of explanatory variables ( that are hypothesized to influence cost efficiency, is the vector of unknown parameters to be estimated from the cost inefficiency model, and is the random error term associated with it.

2.5.1 Specification of augmented inverse propensity weighted estimator

In our research, the first step to analyzing farm mechanization impact was to estimate the level of farm mechanization by using the mechanization index. There are different methods to determine level of farm mechanization used so far by different authors. The pioneer work of Nowacki (1974) expressed level of farm mechanization for a given field as ratio of works done by machineries to total works done on the field during the whole production period. Others used descriptive ways of expressing level of farm mechanization (Wawire et al., 2016; Özpınar, 2020). Zangeneh et al. (2010) also defined Mechanization Index (MI) and level of mechanization for a given province as ratio of total energy power (Kwh or MJha−1) that has been exerted by use of tractors and other machines to total land cultivated in each area relative to the domain like country or region. Almasi et al. (2000) and Maheshwari and Tripathi (2019) also calculated level of farm mechanization as the ratio of total energy power (Kwh or MJha−1) that has been exerted by use of tractors and other machines to total land cultivated in the study area. Machinery Energy Ratio (MER) is also another method used by Collado and Calderón (2000) which indicates the investment in machinery energy in comparison with the other input energy sources required for crop production. However, all above mentioned methods to determine level of farm mechanization are not appropriate due to lack of information on types and size of machineries, number and working hours on a given field. Hence, the level of farm mechanization in this study was determined by using Mechanization Index (MI) following Singh’s (2006) and Wang et al., 2018 method as follows (Equation 7):

Where, MI is the mechanization index expressed in percentage; CMi, CHi, and CAi are costs of using machinery, human labor, and animal power by ith household per hectare, respectively for wheat and barley crop production. For ease of this activity, we first convert the continuous treatment variable into multivalued treatment by taking the 30th percentile and 70th percentile and categorizing the whole sample as low-mechanized, medium-level mechanized, and high-level mechanized farms based on the index of farm mechanization value so that we can employ multivalued treatment effects (MVTE) estimation methods.

It is assumed that households are free to select themselves into different levels of farm mechanization based on their demographic and socioeconomic characteristics (Takeshima, 2017; Ma et al., 2018; Amoozad-Khalili et al., 2020; Tesfaye et al., 2021; Zhou and Ma, 2022). And this situation will lead to a sample selection bias to estimate effects of farm mechanization on outcome variables under this study. Self-selection and other measurement errors are common problems of observational data that have been tried to be overcome by PS matching methods like pscore, IPW, and others. However, these estimators are neither robust nor consistent. Hence, an estimator known as augmented inverse probability weighted (AIPW) was developed (Robins et al., 1994; Robins, 1999; Scharfstein et al., 1999) and applied recently by social researchers (Glynn and Quinn, 2010; Linden et al., 2016; Ma et al., 2018; Zhou and Ma, 2022).

AIPW estimator instead of modeling either the outcome, like regression adjustment (RA), or the treatment probability, like inverse probability weight (IPW), models both the outcome and the treatment probability. An interesting part of this estimator is that only one of the two models must be correctly specified to consistently estimate the treatment effects, a property known as “doubly robust” (Robins et al., 2000). However, the model is not without limitations where it does not address the unobserved endogeneity problem. However, since it minimizes most shortcomings of other models mentioned above, and this problem is rarely raised, the model is preferred over the others. The property of “double robustness” is that it is consistent (i.e., it converges in probability to the true value of the parameter) for the ATE if either the propensity score model or the outcome model is correctly specified. It also solves the problem of poor performance in IPW especially with smaller data size (Raad et al., 2020). This enables it to combine aspects of regression adjustment and inverse-probability-weighted methods. It accepts a continuous, binary, count, fractional, or nonnegative outcome and allows a multivalued treatment.

The three-step approach to estimating treatment effects in AIPW are: 1. estimate the parameters of the treatment model and compute IPW. 2. estimate separate regression models of the outcome for each treatment level and obtain the treatment-specific predicted outcomes for each subject. 3. compute the weighted means of the treatment-specific predicted outcomes, where the weights are the inverse-probability weights computed in step 1. The contrasts of these weighted averages provide the estimates of the ATEs. In AIPW estimation we are interested in three parameters: the potential-outcome mean (POM) , 2. the average treatment effect (ATE), and 3. the average treatment effect on the treated (ATET) .

Under a normal risk-free situation, a household is assumed to choose one of the three mechanization levels (low, medium, or high) in order to maximize its utility from farm mechanization. Hence, a household’s decision to use a different level of farm mechanization can be modeled using the multinomial logit (MNL) model as follows (Equation 8):

Where is the probability of a household can choose to adopt either of the three levels of farm mechanizations. is a set of demographic and socioeconomic characteristics, and is a set of parameters to be estimated. At this stage a maximum likelihood method will be employed to estimate those parameters and also generalized propensity scores (GPS) will be generated automatically and saved.

The other value in MVTE model to estimate as mentioned above is ATE of the use of the different levels of farm mechanization on the outcome variables which are labor amount, chemical fertilizer, agrochemical amount, productivity, and household income in our cases (Equation 9).

Where is the potential outcome of the low-level group and refers to the potential outcome of either medium or high-level farm mechanization? For the test of model validity, the covariate balance test and treatment effect overlap check were also conducted. The first assumption implies that the distribution of each potential outcome y(j) is independent of the random treatment t(j), conditional on the covariates X and it is mathematically specified as (Equation 10):

where “⊥” means “independent of” and “|” denotes “conditional on.” The second assumption of ignorability states that for every possible X in the population, there is a strictly positive probability that someone with that covariate pattern could be assigned to each treatment level and mathematically expressed as (Equation 11):

Both assumptions, covariate balance, and treatment effect overlap, were checked by using “tebalance” and “teoverlap” commands, respectively, and the model was appropriate for this data (Appendix 1; Figure 2). Finally, a statistical software STATA version 17.0 was employed to analyze the data.

3 Result and discussion

3.1 Postestimation test for model validity

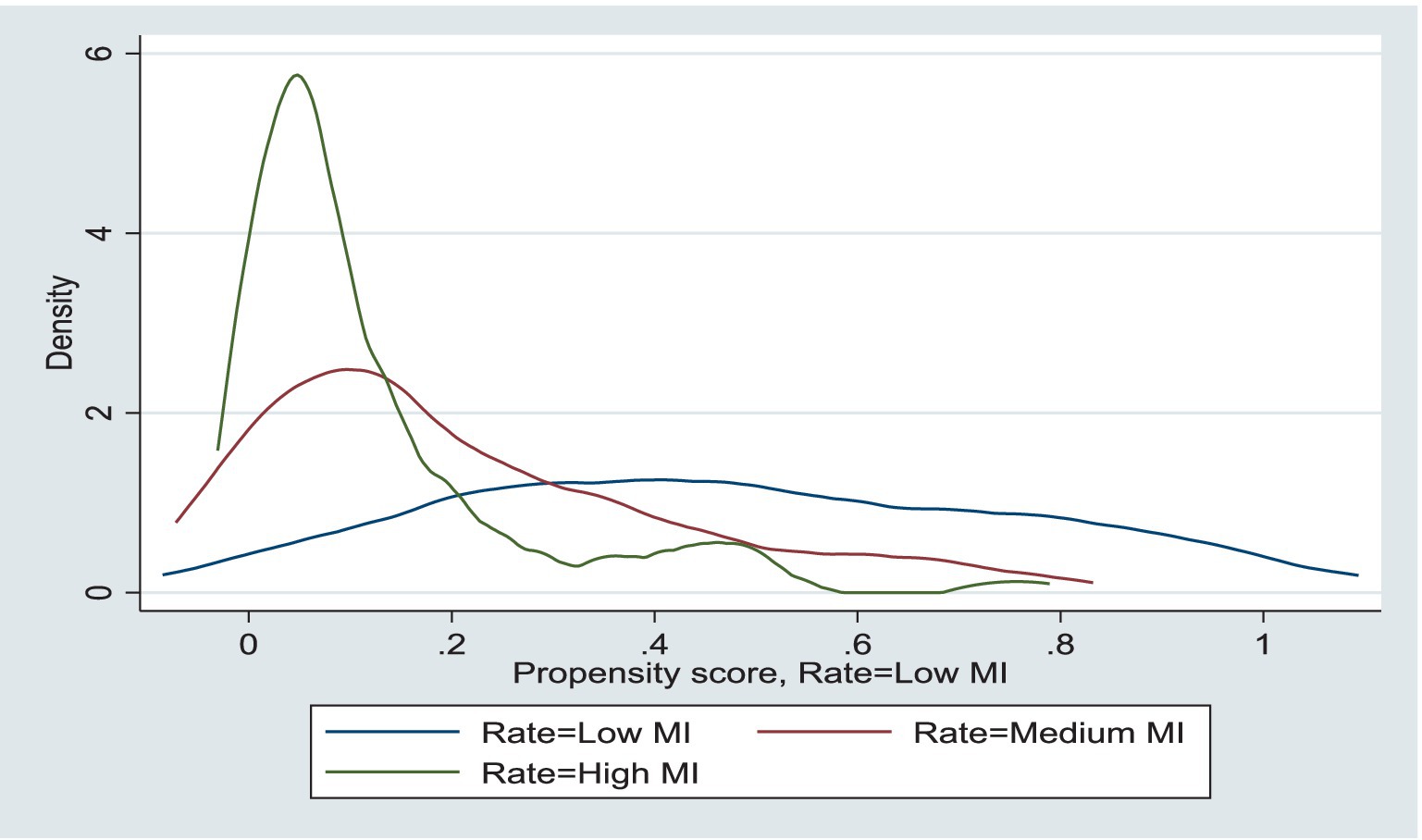

The overlap assumption that states “each individual has a positive probability of receiving each treatment Level” was tested by “teoverlap” command on STATA version 17. The “teoverlap,” a post-estimation command, that plots the estimated densities of the probability of getting each treatment level is used to inspect whether the assumption is violated as shown in Figure 3.

The figure depicted that neither plot indicates too much probability mass near 0 or 1, and the three estimated densities have most of their respective masses in regions in which they overlap each other. Hence, there is no evidence that the overlap assumption is violated in our data.

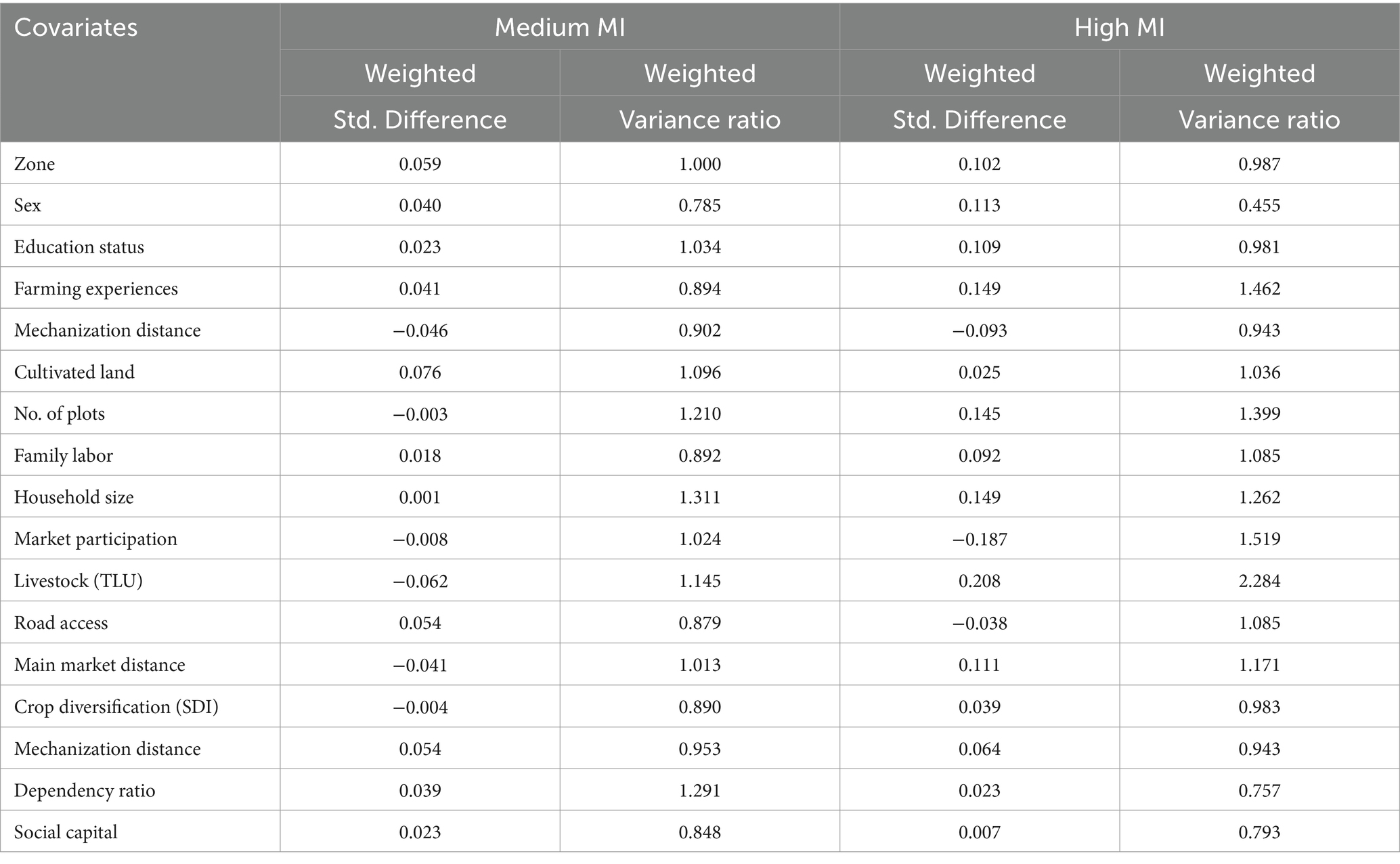

Second, a command known as “tebalance summarize” is employed to test whether a “teffects” estimate command has balanced the covariates over treatment levels. According to Austin (2009) the covariates are said to be balanced if the covariate has a weighted standardized difference of equal or closest to zero and a weighted variance ratio of one or nearer to one. The result for covariate balance is given in Annex 1 and except for minor cases, the covariates are balanced for the matching of the three MI levels.

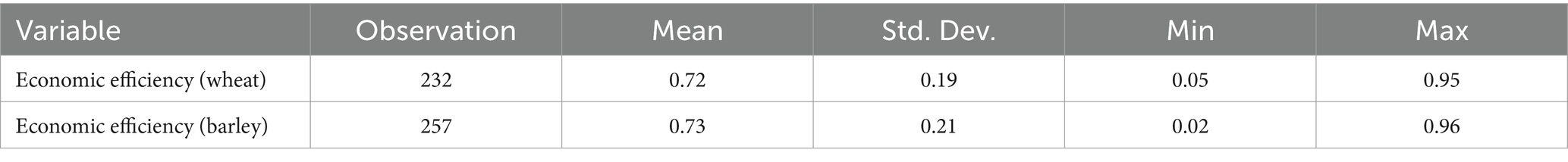

3.2 Economic efficiency of wheat and barley producers

The mean economic efficiency of wheat producers is found to be 72% with values ranging from 5 to 95%. The reason for low value (5%) of the minimum value could be crop failure for the individual observation. The overall loss in producing wheat due to economic inefficiency ranges from 95 to 5%. The findings of similar works done in Arsi and other parts of Ethiopia also reported the closest results (Milkessa et al., 2019; Mesay et al., 2013) to our findings. Similarly, the mean economic efficiency of barley producers is 73% with values ranging from 2 to 96% indicating a wider difference among individual producers. The result also showed that there is a huge inefficiency cost in barley production both in technical and economic inefficiency. According to this result, the loss of production in producing barley due to economic inefficiency ranges from 98 to 4% which is consistent with other findings (Sime et al., 2022; Mustefa and Jema, 2020). Hence, increasing economic efficiency of wheat and barley producers can increase productivity by 28 and 27%, respectively, (Table 1).

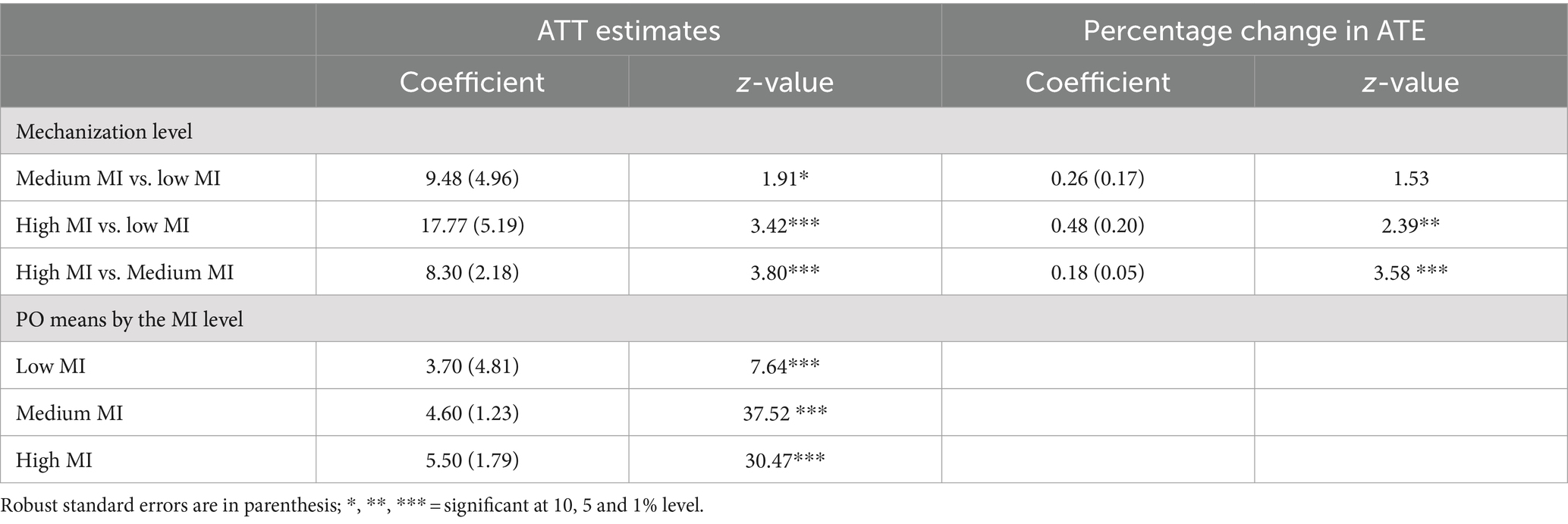

3.3 Farm mechanization impact on wheat and barley farm productivity

As stated before, farm mechanization can significantly affect farm productivity through different factors like improving labor productivity, land productivity, postharvest loss reduction etc. The econometric model results also showed that potential yield of wheat for farmers with low, medium, and high mechanization index is 3.68, 4.60 and 5.50 tons per hectare, respectively, (Table 2). As it is hypothesized, the result showed that the level of farm mechanization has positive and significant impacts on the productivity of the wheat farm. According to the model output, compared to low-level mechanized farms, both relatively medium-level and high-level mechanized farms are more productive. This finding is consistent with other studies in Ethiopia who found that farmers using combine harvester were more productive compared to those threshing using traditional methods of threshing (Guush et al., 2017) and from other parts of the world (Zhou and Ma, 2022; Mather and Belton, 2018; Belton et al., 2021; Kirui, 2019; Roy et al., 2022; Peng et al., 2022; Feryanto et al., 2022), as well as with evidence from our focus group discussion and key informant interview in these areas. The result further shows that relative to the low mechanized farm, adoption of the medium mechanization level increases wheat farm productivity by 26%. Relative to the low-mechanized farm, the high-level mechanized farm is more productive by 48%. Similarly, relative to medium level MI, the high-level MI farms are more productive by 18%.

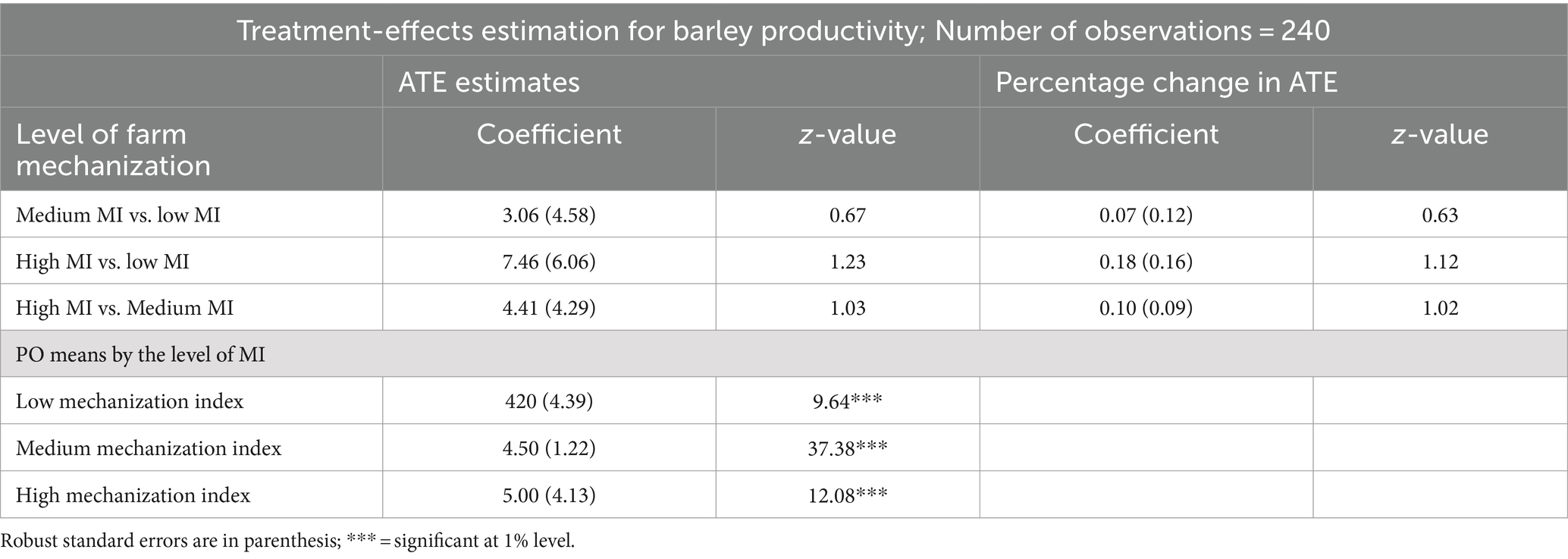

The result in Table 3 further shows that the potential outputs mean of barley are 4.20, 4.50 and 5.00 tons per hectare for low, medium, and high levels of farm MIs, respectively. The result showed that farm productivity is increasing with an increase in the level of farm mechanization implying a direct relationship between the level of mechanization and productivity, but the result is not statistically significant. The insignificant result may be due to the fact that combine harvesting, which is the main contributor in increasing productivity by reducing postharvest losses, is not widely used in barley production.

3.4 Farm mechanization impact on the economic efficiency of wheat and barley producers

Farm mechanization level impact on the economic efficiency of households is estimated for wheat and barley farmers separately. Three observations are found to have propensity scores below the minimum overlap of the common region while four got above the maximum overlap of the common support region hence a total of seven observations were excluded from the analysis.

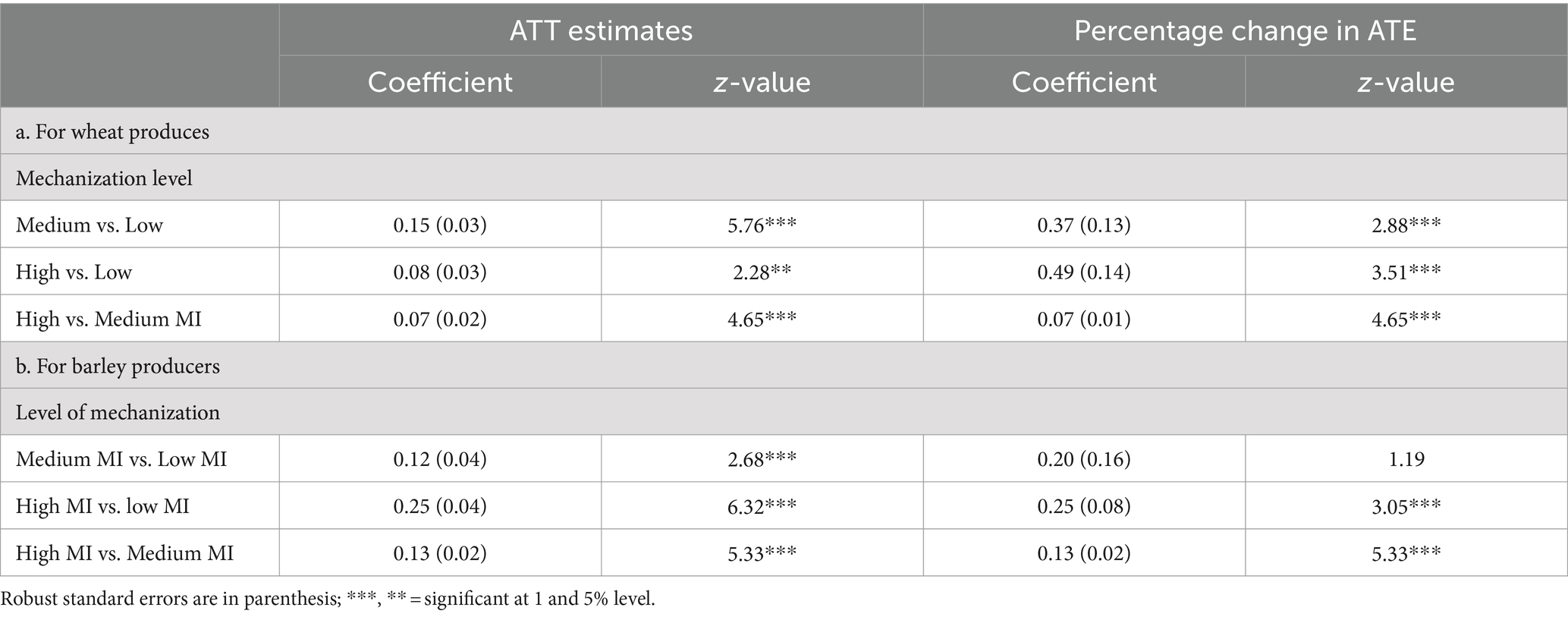

Table 4 presents the result of treatment effects on wheat and barley economic efficiency. The results revealed that wheat farmers who are in the category of medium and a higher level of farm mechanization are economically more efficient than those having a low MI. Relative to the low level of MI, medium-level MI, and high-level MI are more economically efficient by 37 and 49%, respectively. Similarly, relative to medium-level MI, farmers with high-level of MI are more efficient by 7% economically. Similarly, barley producer farmers with higher farm MI are also more efficient. Accordingly, compared to farmers with low MI, medium and high MI farms are more efficient by 20 and 25%, respectively. Relative to the medium farm mechanization level, farmers with high MI are more efficient by 13%. This finding is also consistent with other findings somewhere in the world that show farm mechanization has positive and significant impacts on the economic efficiency (Vortia et al., 2019; Min et al., 2021; Soliman, 1992).

4 Conclusion and recommendation

This research was initiated with the objectives of estimating impacts of farm mechanization on wheat and barley producers’ agricultural productivity and economic efficiency in central and southern Oromia region in Ethiopia. According to the result, the mean economic efficiency of wheat was 94 and 72%, respectively. The values for minimum and maximum economic efficiency were 5 and 95%, respectively. Similarly, the mean economic efficiency for barley producers was 73% with minimum and maximum of values 21 and 96%, respectively.

Consistent with other authors’ results, the econometric model results also showed that farm mechanization has significant positive impacts on wheat and barley producers’ economic efficiency where economic efficiency of wheat producer household increases by 37 and 49% as a farmer’s level of farm mechanization increases from lower to medium and from lower to higher, respectively. Similarly, the farm mechanization impact on productivity level of wheat is positive and significant but even though it has positive impact on barley producers’ farm productivity, the result was not statistically significant. Hence, in general the use of farm mechanization such as tractors and combine harvester has positive significant impacts on wheat and barley production and productivity. This could be by alleviating labor shortage that is happening due to mass urban migration or due to on time operations by farm machineries. Therefore, wider utilization (application) of the technology should be planned in the future both by farmers and policy maker. The farmers would also plan to for further mechanization. Furthermore, ways to popularize the technologies to scale-out the adoption for the realization of the impacts of farm mechanization shall be designed by development practitioners like extension system and non-governmental organizations working on this area.

Different options of farm mechanizations technologies like small-power tractors (where it is applicable), irrigation technologies, small-scale harvesting and threshing technologies shall be included in the plan. Given the financial capacity of the smallholders in the area, it is difficult for the farmers to have farm mechanization technologies at an individual level. The in-depth interview and focus group discussion also reveals that all households are using farm mechanization technologies by renting from service providers in and around the areas. Hence, farm policy design and development interventions should consider such issues to strengthen and motivate the already started support to interested service provider individuals through credit and technical supports. In addition to this government owned mechanization service providing enterprises can be taken as an option. To this end, establishment of mechanization service provider centers and maintenance centers shall be planned. Promotion and implementation of cluster farming can also facilitate mechanization of fragmented farms of Ethiopia as a whole.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

Written informed consent was obtained from the individual(s) for the publication of any potentially identifiable images or data included in this article.

Author contributions

TG: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. MK: Supervision, Validation, Visualization, Writing – review & editing, Conceptualization. AS: Conceptualization, Supervision, Validation, Visualization, Writing – review & editing. GF: Conceptualization, Supervision, Validation, Visualization, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

Researchers from Asella Agricultural Engineering Research center who participated in data collection process, respondent (interviewed) farmers who participated in data collection processes, development agents and respective district’s agriculture office leaders are duly acknowledged. The authors also acknowledge the small financial support for data collection by Oromia Agricultural Research Institute (IQQO).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abass, A., Amaza, P., Bachwenkizi, B., Wanda, K., Agona, A., and Cromme, N. (2017). The impact of mechanized processing of cassava on farmers’ production efficiency in Uganda. Appl. Econ. Lett. 24, 102–106. doi: 10.1080/13504851.2016.1167817

Afridi, F., Bishnu, M., and Mahajan, K. (2020). Gendering technological change: evidence from agricultural mechanization. IZA – Institute of Labor Economics, Discussion paper series IZA DP No. 13712.

Almasi, M., Kiani, S., and Loui-mi, N. (2000). Principles of Agricultural Mechanization. Ma’soumeh (PBUH) Publication. Ghom, Iran. 19–40.

Amirani, E. . (2001). Economic factors and their relationship with the promotion of agricultural mechanization. Jihad Scientific Monthly. No. 239–238, April and May 2001.30.

Amoozad-Khalili, M., Rostamian, R., Esmaeilpour-Troujeni, M., and Kosari-Moghaddam, A. (2020). Economic modeling of mechanized and semi-mechanized rainfed wheat production systems using multiple linear regression model. Inf. Process Agric. 7, 30–40. doi: 10.1016/j.inpa.2019.06.002

Austin, P. C. (2009). Balance diagnostics for comparing the distribution of baseline covariates between treatment groups in propensity-score matched samples. Stat. Med. 28, 3083–3107. doi: 10.1002/sim.3697

Battese, G. E., and Coelli, T. J. (1995). A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empir. Econ. 20, 325–332. doi: 10.1007/BF01205442

Bello, S. R. (2012). Agricultural Machinery & Mechanization: Basic concepts. USA: DPS Dominion Publishing Services.

Belton, B., Win, M. T., Xiaobo Zhang, X., and Filipski, M. (2021). The rapid rise of agricultural mechanization in Myanmar. Food Policy 101:102095. doi: 10.1016/j.foodpol.2021.102095

Benin, S. (2015). Impact of Ghana’s agricultural mechanization services center program. Agric. Econ. 46, 103–117. doi: 10.1111/agec.12201

BoFED, RD and ICP . (2012). The National Regional State of Oromiya: Oromiya National Regional State in Brief, Part IV. Available at: https://oromiabofed.org/images/stories/rstatistics/Oromiya_In_Brie_%20Part_IV.pdf (Accessed June 13, 2023).

Chidambaram, M. (2013). Impact of farm mechanization in rice productivity in Cauvery Delta zone of Tamil Nadu state-an economic analysis. Coimbatore: Tamil Nadu Agricultural University.

Cohen, J. M. (1987). Integrated rural development: The Ethiopian experience and the debate. Uppsala, Sweden: The Scandinavian Institute of African Studies.

Collado, M., and Calderón, E. (2000). Energía de utilizada para la producción agrícola en el estado de Guanajuato: Cuantificación y análisis. Memorias del III Congreso Latinoamericano de Ingeniería Agrícola. Guanajuato. México. (In Spanish).

Cossar, F . (2019). “Impact of mechanization on smallholder agricultural production: evidence from Ghana.” in Contributed Paper prepared for presentation at the 93rd Annual Conference of the Agricultural Economics Society, University of Warwick, England. 15–17 April 2019.

CSA (2021). Agricultural sample survey 2020 / 2021 (2013 E.C.) (September – December 2020/2021) volume III report on farm management practices (private peasant holdings, Meher season).

CSA . (2013). Population Projections for Ethiopia: 2007-2037. Addis Ababa, Ethiopia. (The Federal Democratic Republic of Ethiopia Central Statistical Agency).

Feryanto, Herawati, Rifin, A., and Tinaprilla, N, (2022). “Does mechanization have an impact on increasing the productivity and income of narrow-land corn farmers in Indonesia?” in 2nd International Conference on Environmental Ecology of Food Security: IOP Conf. Series: Earth and Environmental Science, 1107 (2022) 012054.

Glynn, A. N., and Quinn, K. M. (2010). An introduction to the augmented inverse propensity weighted estimator. Polit. Anal. 18, 36–56. doi: 10.1093/pan/mpp036

Goyal, S.K., Singh, S.R., Rai, J.P, and Singh, S.N. (2014). Agricultural mechanization for sustainable agricultural and rural development in eastern U. P. - A review

Guush, B., Mekdim, D., Bart, M., and Seneshaw, T. (2017). The rapid – but from a low base – uptake of agricultural mechanization in Ethiopia: Patterns, implications and challenges.

Henock, K. (1972). Investigations on mechanized and its effects on peasant agriculture. CADU publication No. 74.

Hormozi, A. A., Mohammad Amin Asoodar, M. A., and Abdeshahi, A. (2012). Impact of mechanization on technical efficiency: a case study of rice farmers in Iran. Int. Conf. Appl. Econ. Proc. Econ. Finan. 1, 176–185. doi: 10.1016/S2212-5671(12)00021-4

Houmy, K., Clarke, L.J., John, E., and Ashburner, JE., and Kienzle, J. (2013). Agricultural mechanization in sub-Saharan Africa: Guidelines for preparing a strategy. Integrated crop management (22): 2013. Plant production and protection division. Food and Agriculture Organization of the United Nations. Rome, 2013.

Imad, A., Huo, X. X., Imran, K., Hashmat, A., Khan, B., and Sufyan, U. K. (2019). Technical efficiency of hybrid maize growers: a stochastic frontier model approach. J. Integr. Agric. 18, 2408–2421.

Israel, G.D. (1992). Sampling the evidence of extension program impact. Program evaluation and organizational development, IFAS, University of Florida, PEOD-5.

Kirui, K.O . (2019). The agricultural mechanization in Africa: micro-level analysis of state, drivers and effects. Sixth international conference, September 23–26, 2019, Abuja, Nigeria 295819, African Association of Agricultural Economists (AAAE).

Kothari, C. R. (2004). Research methodology: Methods and techniques. 2nd Edn. New Delhi, India: New Age International.

Kumbhakar, S. C., and Lovell, C. A. K. (2000). Stochastic frontier analysis. Cambridge: Cambridge University Press.

Kumbhakar, S. C., Wang, H., and Horncastle, A. P. (2015). A Practitioner’s guide to stochastic frontier analysis using Stata. Cambridge: Cambridge University Press.

Linden, A., Uysal, S. D., Ryan, A., and Adams, J. L. (2016). Estimating causal effects for multivalued treatments: a comparison of approaches. Stat. Med. 35, 534–552. doi: 10.1002/sim.6768

Maheshwari, T. K., and Tripathi, A. (2019). Quantification of Agricultural Mechanization Status for Etawah District of Uttar Pradesh, India. Int J Curr Microbiol Appl Sci. doi: 10.20546/ijcmas.2019.805.077

Mamman, I. S. A. (2015). Influence of agricultural mechanization on crop production in Bauchi and Yobe states, Nigeria. An unpublished M.S. thesis submitted to the Department of Vocational and Technical Education, Ahmadu Bello University, Zaria.

Mather, D., and Belton, B. (2018). Mechanization and crop profitability, productivity and labor use in Myanmar’s dry zone. Research paper 103. July 2018. East Lansing, Michigan State University.

Ma, W., Renwick, A., and Grafton, Q. (2018). Farm machinery use, off-farm employment and farm performance in China. Aust. J. Agric. Resour. Econ. 62, 279–298. doi: 10.1111/1467-8489.12249

Mesay, Y., Tesafye, S., Bedada, B., Fekadu, F., Tolesa, A., and Dawit, A. (2013). Source of technical inefficiency of smallholder wheat farmers in selected waterlogged areas of Ethiopia: a translog production function approach. Afr. J. Agric. Res. 8, 3930–3940.

Milkessa, A., Endrias, G., and Fikadu, M. (2019). Economic efficiency of smallholder farmers in wheat production: the case of Abuna Gindeberet District, Oromia National Regional State, Ethiopia. Int. J. Environ. Sci. Nat. Resour. 6, 41–51.

Min, S., Paudel, K. P., and Feng-bo, C. (2021). Mechanization and efficiency in rice production in China. J. Integ. Agric. 20, 1996–2008.

Mohammed, Hassena, Regassa, Ensermu, Mwangi, W., and Verkuijl, H. (2000). A comparative assessment of combine harvesting Vis-à-Vis conventional harvesting and threshing in Arsi region, Ethiopia. International maize and wheat improvement center (CIMMYT) and Ethiopia agricultural research organization (EARO), Mexico, D. F.

Mustefa, B., and Jema, H. (2020). Economic efficiency in barely production: the case of Chole District, east Arsi zone, Oromia National Regional State, Ethiopia. J. Resour. Dev. Manag. 66, 25–36.

Nowacki, T . (1974). Examples of technical and economic analysis of mechanized processes in various agro-technical conditions. AGRI/MECH Report (UN)(ECE). 32

Oromia Bureau of Finance and Economic Development (OBOFED) . (2011). Physical and Socio Economic Profile of Arsi Zone and Districts. The National Regional Government of Oromia, Bureau of Finance and d Economic Development –Regional Data and Information Core Process.

Özpınar, S. (2020). Mechanization and agricultural farm structure in the agricultural area of the Dardanelles region. International Journal of Agriculture Environment and Food sciences. doi: 10.31015/jaefs.2020.1.6

Paudel, G. P., KC, D. B., Rahut, D. B., Justice, S. E., and McDonald, A. J. (2019). Scale-appropriate mechanization impacts on productivity among smallholders: evidence from rice systems in the mid-hills of Nepal. Land Use Policy 85, 104–113. doi: 10.1016/j.landusepol.2019.03.030

Peng, J., Zhao, Z., and Liu, D. (2022). Impact of agricultural mechanization on agricultural production, income, and mechanism: evidence from Hubei Province, China. Front. Environ. Sci. 10:838686. doi: 10.3389/fenvs.2022.838686

Ponnusamy, P. (2012). Using CSPro (census and survey processing system) experience from large scale surveys in India. Int. J. Sci. Res. Publ. 2, 1–2.

Raad, H., Cornelius, V., Chan, S., Williamson, E., and Cro, S. (2020). An evaluation of inverse probability weighting using the propensity score for baseline covariate adjustment in smaller population randomized controlled trials with a continuous outcome. BMC Med. Res. Methodol. 20:70.

Robins, J.M. (1999). “Robust estimation in sequentially ignorable missing data and causal inference models.” in Proceedings of the American Statistical Association Section on Bayesian Statistical Science. pp. 6–10.

Robins, J. M., Rotnitzky, A., and van der Laan, M. (2000). Comment. J. Am. Stat. Assoc. 95, 477–482.

Robins, J. M., Rotnitzky, A., and Zhao, L. P. (1994). Estimation of regression coefficients when some Regressors are not always observed.J. Am. Stat. Assoc. 89, 846–866. [86,87,88,89,91]. doi: 10.1080/01621459.1994.10476818

Roy, P., Hansra, B. S., Burman, R. R., Bhattacharyya, S., Roy, T., and Rouf Ahmed, R. (2022). Can farm mechanization enhance small farmers’ income? Lessons from lower Shivalik Hills of the Indian Himalayan region. Curr. Sci. 123, 667–676. doi: 10.18520/cs/v123/i5/667-676

Sang, X., Luo, X., Razzaq, A., Huang, Y., and Sahar Erfanian, S. (2023). Can agricultural mechanization services narrow the income gap in rural China? Heliyon 9:e13367. doi: 10.1016/j.heliyon.2023.e13367

Scharfstein, D. O., Andrea, R., and Robins, J. M. (1999). Rejoinder to adjusting for non- ignorable drop-out using semiparametric nonresponse models. J. Am. Stat. Assoc. 94, 1135–1146.

Shi, M., Paudel, K. P., and Chen, F. (2021). Mechanization and efficiency in rice production in China. J. Integr. Agric. 20, 1996–2008. doi: 10.1016/S2095-3119(20)63439-6

Sime, S., Jema, H., Mengistu, K., and Million, S. (2022). Technical, allocative, and economic efficiency of malt barley producers in Arsi zone, Ethiopia. Cogent Food Agric. 8:2115669. doi: 10.1080/23311932.2022.2115669

Singh, G. (2006). Estimation of a mechanisation index and its impact on production and economic factors-a case study in India. Biosyst. Eng. 93, 99–106. doi: 10.1016/j.biosystemseng.2005.08.003

Soliman, I. (1992). “Agricultural mechanization and economic efficiency of agricultural production in Egypt.” in International Conference on Agricultural Engineering & Rural Development Beijing China, Beijing University of Agricultural Enginireeing. October, 1992, Volume I.

Stahl, M. (1973). Contradictions in agricultural development: a study of three minimum package projects in southern Ethiopia. Research report no. 14, the Scandinavian Institute of African Studies, Uppsala.

Su, M., Heerink, N., Oosterveer, P., and Feng, S. (2022). Upscaling farming operations, agricultural mechanization and chemical pesticide usage: a macro-analysis of Jiangsu Province, China. J. Clean. Prod. 380:135120. doi: 10.1016/j.jclepro.2022.135120

Takeshima, H. (2017). Custom-hired tractor services and returns to scale in smallholder agriculture: a production function approach. Agric. Econ. 48, 363–372. doi: 10.1111/agec.12339

Takeshima, H., Nin-Pratt, A., and Diao, X. (2013). Mechanization and agricultural technology evolution, agricultural intensification in sub-Saharan Africa: typology of agricultural mechanization in Nigeria. Am. J. Agric. Econ. 95, 1230–1236. doi: 10.1093/ajae/aat045

Tamrat, G. C., Aman, N. T., and Ashebir, T. M. (2019). Farming System Characterization of Arsizone: Case of Small-Scale Farming. American Journal of Environmental and Resource Economics, 4, 12–24. doi: 10.11648/j.ajere.20190401.12

Tan, Y. L. (1981). The impact of farm mechanization on small-scale rice production. UPLB: Unpublished. MS Thesis.

Tesfaye, W., Blalock, G., and Tirivayi, N. (2021). Climate-smart innovations and rural poverty in Ethiopia: exploring impacts and pathways. Am. J. Agric. Econ. 103, 878–899. doi: 10.1111/ajae.12161

Vortia, P., Nasrin, M., Bipasha, S. K., and Islam, M. M. (2019). Extent of farm mechanization and technical efficiency of rice production in some selected areas of Bangladesh. Geo J. 86, –742. doi: 10.1007/s10708-019-10095-1

Wang, X., Yamauchic, F., and Huang, J. (2016). Rising wages, mechanization, and the substitution between capital and labor: evidence from small scale farm system in China. Agric. Econ. 47, 309–317. doi: 10.1111/agec.12231

Wang, X., Yamauchi, F., Huang, J, and Rozelle, S. (2018). What constrains mechanization in Chinese agriculture? Role of farm size and fragmentation. China Econ Review. (October. 2017:1–9).

Wawire, N. W., Bett, C., Ruttoh, R. C., Wambua, J., Omari, F. G., and Kisilu, R. (2016). The status of agricultural mechanization in Kenya. KALRO, RDA.

Workneh, W. A., Ujiie, K., and Matsushita, S. (2021). Farmers’ agricultural tractor preferences in Ethiopia: a choice experiment approach. Discov. Sustain. 2, 1–15.

Zangeneh, M., Omid, M., and Akram, A. (2010). Assessment of machinery energy ratio in potato production by means of artificial neural network. Afr. J. Agric. Res. 5, 993–998. doi: 10.5897/AJAR09.051

Zhang, C., Shi, G. M., Shen, J., and Hu, R. F. (2015). Productivity effect and overuse of pesticide in crop production in China. J. Integr. Agric. 14, 1903–1910. doi: 10.1016/S2095-3119(15)61056-5

Zhang, J., Wang, J., and Zhou, X. (2019). Farm machine use and pesticide expenditure in maize production: health and environment implications. Int. J. Environ. Res. Public Health 16:1808. doi: 10.3390/ijerph16101808

Zhou, X., and Ma, W. (2022). Agricultural mechanization and land productivity in China. Int. J. Sustain. Dev. World Ecol. 29, 530–542. doi: 10.1080/13504509.2022.2051638

Zhou, X., Ma, W., Li, G., and Qiu, H. (2020). Farm machinery use and maize yields in China: an analysis accounting for selection Bias and heterogeneity. Aust. J. Agric. Resour. Econ. 64, 1–26.

Appendix 1

Annexes. Covariate balance summary.

Keywords: augment inverse probability weight, economic efficiency, farm mechanization, impact, stochastic frontier analysis

Citation: Gebiso T, Ketema M, Shumetie A and Feye GL (2024) Impact of farm mechanization on crop productivity and economic efficiency in central and southern Oromia, Ethiopia. Front. Sustain. Food Syst. 8:1414912. doi: 10.3389/fsufs.2024.1414912

Edited by:

Folorunso Mathew Akinseye, International Crops Research Institute for the Semi-Arid Tropics (ICRISAT), KenyaReviewed by:

Erhan Akça, Adiyaman University, TürkiyeMohd. Muzamil, Sher-e-Kashmir University of Agricultural Sciences and Technology, India

Shadrack Kwadwo Amponsah, CSIR Crops Research Institute, Ghana

Copyright © 2024 Gebiso, Ketema, Shumetie and Feye. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tamrat Gebiso, Z2ViaXNvY2hhbGxhQGdtYWlsLmNvbQ==

†ORCID: Tamrat Gebiso, http://orcid.org/0000-0002-9870-8626

Tamrat Gebiso

Tamrat Gebiso Mengistu Ketema

Mengistu Ketema Arega Shumetie

Arega Shumetie Getachew Legese Feye3

Getachew Legese Feye3