95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. Food Syst. , 12 June 2024

Sec. Sustainable Food Processing

Volume 8 - 2024 | https://doi.org/10.3389/fsufs.2024.1403164

This article is part of the Research Topic Sustainable Active Packaging for Food Safety and Preservation: Technological, Consumer, and Environmental Perspectives View all 4 articles

Effective and innovative freshly produced preservation methods are paramount for ensuring safe and sustainable food. Edible coatings for fresh dates can provide an additional protective layer to enhance their shelf life and extend marketability. However, the optimum coating requires a high uniformity of coating layer on the fruit. The ultrasonic coating can achieve a more uniform and consistent coating on the fruit surface. Therefore, this study aimed to design, evaluate, and optimize the process parameters of an innovative ultrasonic coating system (UCS) to enhance the shelf life and quality of fresh date palm fruit utilizing gum Arabic as an edible coating. The response surface methodology (RSM) was conducted using Design-Expert software Version 13. The central composite design was employed to determine the influence of eight independent variables, namely, coating time, air flow rate, liquid height above the ultrasonic transducers, liquid temperature, edible gum Arabic concentration, drying time for coated fruit, drying temperature, and storage temperature on the responses which were fruit shelf life, ripe fruit percentage, color changes, and weight loss. The optimization was conducted to determine the optimal solutions for enhancing fruit shelf life and quality. The optimal optimization outcome with the desirability of 0.90 demonstrated that coating fresh date palm fruits with a gum Arabic concentration of 9.58% at an air flow rate of 1.95 m/s, a height of liquid above the ultrasonic transducer of 0.62 cm, a liquid temperature of 40°C, a drying time of 7.4 min, a drying temperature of 30°C, and a storage temperature of 5°C resulted in extending the shelf life of the stored fruits to 65 days with 3.47 ripening percentage, 7.39 color change, and 4.22% fruit weight loss. The validation experiment conducted at the same independent variable levels indicated that the fruit shelf life extended to 60.2 ± 0.5 days, accompanied by a ripening percentage of 3.4 ± 0.4%, a color change of 10.3 ± 0.9, and a fruit weight loss of 5.4 ± 0.9%. The solutions were validated through rigorous experiments on fresh date palm fruit at the Khalal stage. The findings showed a positive response for fruit shelf life with a slight decrease in the percentage of fruit ripe, color change, and weight loss.

Date palm (Phoenix dactylifera L.), a well-known fruit crop that belongs to the family Arecaceae, is mainly cultivated in arid and semi-arid regions, particularly the Arabian Peninsula and northern Africa (Chao and Krueger, 2007). Among the top date palm-producing countries, Saudi Arabia ranked second with annual production of 1.57 million tons (FAO, 2023). Due to its great nutritional value, numerous health benefits, and several economic, social, and cultural advantages, in addition to its significance in agroecosystems, date palms have gained great importance in many countries (Singh et al., 2022).

Hilali, a common Saudi Arabian date variety, is mainly consumed at a partial maturity stage known as Khalal, where the fruits have a yellow color, crispy texture, and sweety taste. However, the rapid conversion of Hilali date fruits from Khalal to Rutab (soft, brown, and ripe fruits) due to its climacteric nature, as all date palm varieties, represents the major challenge after harvesting and during storage, handling, transportation, and exportation (Alqahtani et al., 2023). Although cold storage represents the most common technology on a commercial scale applied to reduce the quality changes of fresh fruits and vegetables, postharvest changes such as weight loss, shrinking, softening, odor changes, and fruit conversion from Khalal to Rutab are still high (Fawole et al., 2020). Accordingly, cold storage should be accompanied by additional preservation methods to maintain the quality and extend the shelf life of Khalal Hilali dates.

In the last few years, great attention has been focused on applying edible coatings (ECs) as an assistant method for preserving fruits and vegetables as they are safe, eco-friendly, and consistent with the demand for healthy foods (Özden and Bayindirli, 2002). ECs are natural biopolymers that can cover food products with a thin layer to maintain the quality and enhance storage stability by preventing moisture loss and gas movements from fruits’ surfaces (Senturk Parreidt et al., 2018). In the case of fresh fruits and vegetables, ECs are mainly dependent on delaying the ripening processes and other related changes, including moisture loss, weight loss, respiration, softening, discoloration, browning, taste changes, flavor deterioration, and loss of organic acids and nutrients (Ncama et al., 2018).

Coating materials can be divided into three groups: polysaccharides, proteins, lipids, or a combination. Polysaccharide-based coatings (e.g., starch, alginate, pectin, chitosan, and carrageenan) are the most common coating materials as they are inexpensive, environmentally friendly, non-allergic, and biodegradable substances. In addition, they have a lower gas permeability (Panahirad et al., 2021; Yaashikaa et al., 2023). Polysaccharide coatings are majorly applied to packaging and preserving fruits and vegetables. Protein-based coating materials (e.g., gluten, soy, gelatin, and collagen) are excellent in terms of mechanical properties, and they are commonly used in packaging meat, poultry, and seafood products (Yaashikaa et al., 2023). Lipid-based coatings such as waxes (carnauba, bees, paraffin, and candelilla waxes) and vegetable oils have excellent resistance against environmental factors, particularly water permeability, compared with other coating materials due to their hydrophobic nature (Yaashikaa et al., 2023); accordingly, it was effective in minimizing water migration in fruits and vegetables, and therefore, the weight loss was eliminated. However, lipid-based coatings have some drawbacks, including their sensitivity to oxidation, leading to rancidity and unpleasant sensory properties; moreover, their film-forming capability is not the best.

Gum Arabic (GA), a gum formed naturally as solid exudations accumulated on the stems of the Acacia tree (Acacia spp.), is an essential polysaccharide-based coating material with excellent properties as it is an abundant, non-toxic, ecofriendly, biodegradable substance and generally recognized as safe according to the FAO and WHO (Islam et al., 1997; Kawhena et al., 2021; Taher et al., 2022). In addition, GA has a low viscosity with high emulsification properties and strong stability, which can be used as an excellent film-forming material in food and non-food applications, e.g., bakery, beverages, fruits and vegetables, pharmaceuticals, and cosmetics (Kawhena et al., 2021; Taher et al., 2022). The effects of GA as an edible coating on the quality and shelf life of tomato (Ali et al., 2013), summer squash (Bleoanca et al., 2022), plum (Fawole et al., 2020), pomegranate (Kawhena et al., 2021), kaki (Saleem et al., 2023), peach (Taher et al., 2022), apple (Soppelsa et al., 2023), acid lime (Beheiry et al., 2023), strawberries (De Bruno et al., 2023), guava (El-Gioushy et al., 2022), banana (Maqbool et al., 2011), and papaya (Maqbool et al., 2011) have been investigated. The findings of the previous studies revealed that coating with GA delayed the ripening, decreased weight loss, reduced shrivel, postponed microbial spoilage, preserved the antioxidants, lowered browning and chilling damage, and prolonged the shelf life of fruits during storage.

Generally, the coating treatments were conducted in the previous studies by dipping (Ali et al., 2013; Kawhena et al., 2020; El-Gioushy et al., 2022; Pham et al., 2023), spreading (Kumar and Prabhu, 2007; Pham et al., 2023), layer-by-layer deposition method (Pham et al., 2023), and spraying methods (Embuscado and Huber, 2009; Andrade et al., 2012; Pham et al., 2023), which have some drawbacks, (e.g., 1) the heterogeneity of the thickness of the developed film as the higher thickness may negatively affect the fruits’ color and appearance and may lead to anaerobic respiration of fruits with the formation of off-odors while the low thickness may not provide the required protection during storage; (2) the risk of microbial contamination due to the high moisture content around the fruits during the treatment; and the coating solution may be contaminated with microorganisms and dirt from dipped fruits; (3) the consumption of higher amounts of coating solution; and (4) the long time required for dehydration of the developed coatings (Pham et al., 2023).

The experimental design is regarded as a suitable approach grounded in statistical analysis, aimed at reducing the number of experiments, assessing the connections between variables, constructing an empirical model, and, eventually, highlighting the optimal response of the experimental data. The resulting outcome is a mathematical model that predicts outcomes across various parameter configurations (Bezerra et al., 2008). One of the design of experiment (DOE) divisions is response surface methodology (RSM). DOE subdivisions leverage various mathematical and statistical methodologies to formulate a resilient experimental design. Studies have indicated that RSM extensively applies to optimization, particularly within system operation procedures. Response surface methodology (RSM) is a standard multifunctional software that can be employed to design experiments and determine the best processing/operating conditions of a product/process from several experimental runs and many variables (Ali et al., 2016; Chelladurai et al., 2021). RSM describes the obtained results with polynomial equations, provides a comprehensive vision of the relationship between responses and independent variables, and provides statistical conclusions (Ali et al., 2016; Chelladurai et al., 2021). Previous studies employed RSM to optimize edible coating solutions to prolong the shelf life of fruits, for example, dates (Mohammed and Alqahtani, 2022), pear (Nandane et al., 2017), papaya (Hamzah et al., 2013), guava (Murmu and Mishra, 2017), and fresh-cut apples (Chiumarelli and Hubinger, 2012).

Ultrasonic sound waves are defined as waves with a frequency exceeding the human hearing range. Ultrasonics is an energy-efficient, non-thermal technique that can be utilized in various applications, including food processing (Mohammed and Alhajhoj, 2020; Salehi, 2023). The ultrasonic technique is currently used in the sonication processes, particularly in fruit and vegetable processing, for specific roles such as homogenization, extraction, and pretreatment before different processing methods such as drying, non-thermal food processing, and preservation (Akhoundzadeh Yamchi et al., 2022). Ultrasonic techniques can be used alone or supported with other techniques such as osmotic dehydration, microwave, edible coatings, vacuum drying, and humidification for acclimatization systems and cold storage rooms for enhancing stored fruit shelf life (Mohammed et al., 2021, 2023; Salehi, 2023).

Despite advancements in coating application, a significant gap persists in comprehending the impact of various coating application techniques on the efficacy of these coatings. Conventional approaches such as dipping and spraying often yield uneven coating dispersion. Moreover, a lack of research exists regarding the use of ultrasonic coating systems, which are known for producing finer and more uniform droplets, thereby improving the consistency and efficiency of coatings. To the best of our knowledge, no previous studies have been conducted on applying ultrasonic coatings to develop GA-based coatings to preserve Khalal Hilali date fruits during cold storage. This study focuses on using ultrasonic systems for date palm fruit preservation. Variables such as gum Arabic concentration, coating duration, airflow velocity, and temperature are examined to enhance fruit quality through optimized coating. In general, this study is focused on developing GA edible coating as an assistant preservation method besides refrigeration, with enhanced properties using ultrasonic techniques to extend the shelf life of date fruits at the Khalal maturity stage. The specific contribution of this study is to analyze the best conditions for using gum Arabic coatings with an ultrasonic system. Examined factors include coating time, air flow rate, and liquid height to ensure uniform and effective coatings. In addition, it assesses how optimized ultrasonic coating parameters impact the quality attributes of date palm fruit. This includes shelf life, ripening percentage, color difference, and weight loss, illustrating the advantages of this advanced coating technique.

Accordingly, the objectives of the present research could be summarized as follows: (1) the development of an ultrasonic coating system for applying GA edible coating onto fresh Hilali date palm fruit, (2) the evaluation of the impact of the operating parameters on the fruit shelf life, ripe fruit percentage, color changes, and weight loss of fruits during cold storage, (3) optimization of the conditions of the coating process using desirability function as an optimization tool, and (4) validation of the optimized selected solutions.

The ultrasonic coating system was developed to adjust the uniformity and amount of coating on fruit to enhance the shelf life and quality of fresh date palm fruit utilizing gum Arabic as an edible coating. The ultrasonic coating system comprised several components, such as a stainless-steel basket for samples, tubes, an air blower with a DC motor of 12 V, air purifiers, floats, a reservoir for aqueous solution with gum Arabic, ultrasonic transducers, 24 V DC power supply for ultrasonic transducers, and control unit. Figure 1 shows a schematic diagram detailing the components of the developed ultrasonic coating system. Figure 2 visually represents the assembled ultrasonic coating system. The reservoir is constructed from plastic containers safe for food in a size of 25 × 25 × 36 cm3. It held up to 2 L of aqueous solution with gum Arabic. The aqueous solution with gum Arabic was transformed into droplets by ultrasonic transducers under the main reservoir. The aqueous solution with gum Arabic is filled in the ultrasonic coating system reservoir using a centrifugal 12 V pump and an electric solenoid valve with a 1.25 cm inlet diameter. The reservoir has a stainless-steel float sensor, and the solenoid valve is controlled using a water-level electronic circuit. Once the reservoir reaches its maximum capacity, the electronic water-level circuit closes the electric valve and the pump motor. Ten ultrasonic transducers (2,600 kHz with 2 Ω resonance impedance) were placed centrally at the base of the system reservoir. The liquid level above the ultrasonic transducers was controlled between 0.5 and 1.0 cm to obtain optimal droplet generation.

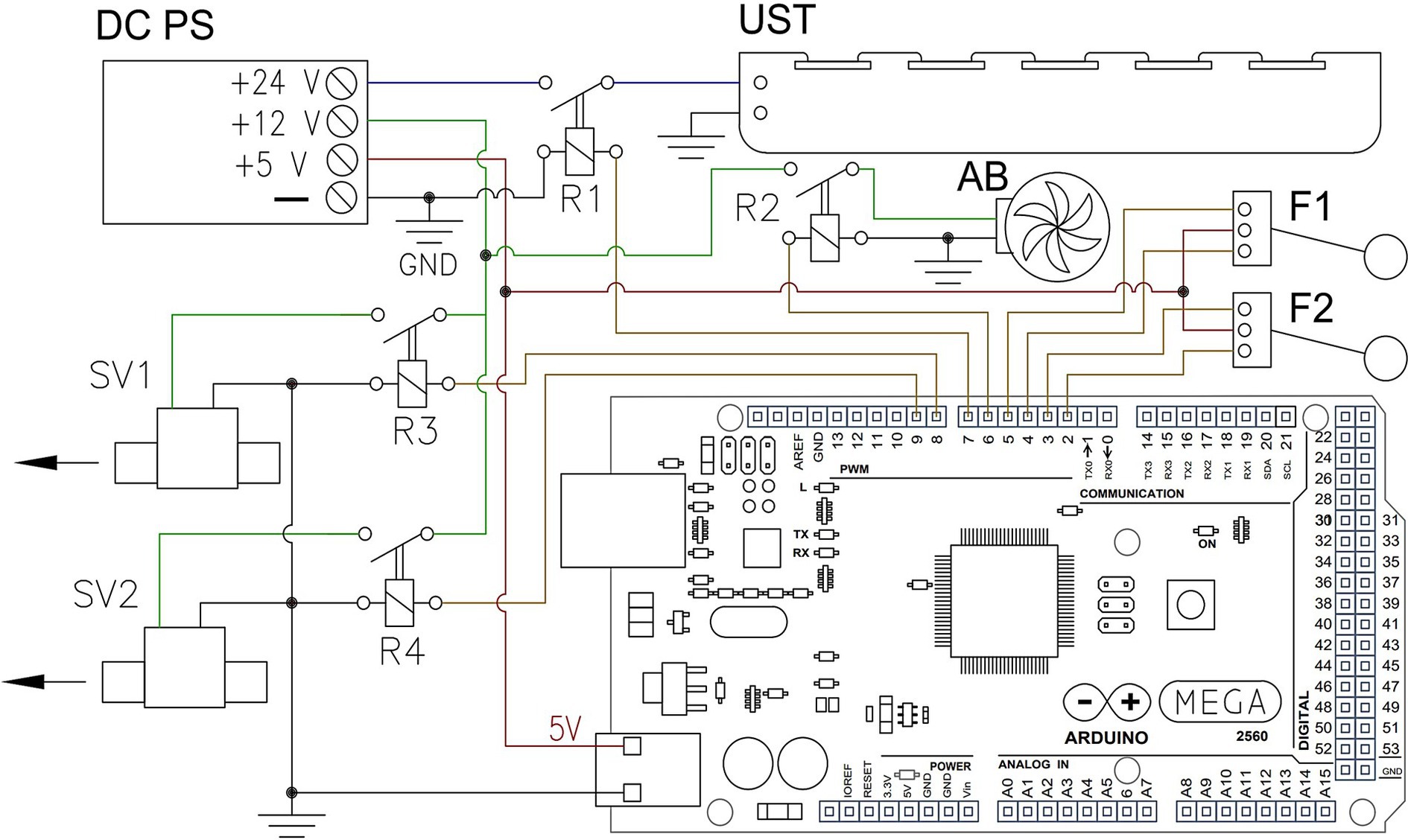

Figure 3 shows the main components of the circuit used to implement the control algorithm for the ultrasonic coating system. This circuit interfaces multiple components with the ATmega328P Arduino Mega board Microchip (Microchip Technology Inc., W Chandler Blvd, Chandler, AZ, United States) to control the coating process. The float sensor (F1) detects the main reservoir’s minimum and maximum liquid levels. The float sensor (F2) detects the minimum and top liquid levels above the ultrasonic transducers, and this information is forwarded to the Arduino Mega. R1, R2, R3, and R4 relays control the power connection for the ultrasonic transducers (UST), air blower (AB) DC motor, and solenoid valve of the main reservoir (SV1), and the solenoid valve of the liquid level above the ultrasonic transducers (SV2), respectively, based on the Arduino Mega output signal.

Figure 3. The control circuit diagram for the designed ultrasonic coating system, the DC PS is the direct current power supply, the UST is the ultrasonic transducer unit, the AB is the air blower, the FI is the float sensor of the main reservoir, the F2 is the float sensor of liquid level above the ultrasonic transducer, the R1, R2, R3, and R4 are the control relays, and the SV1 and SV 2 are the solenoid valves.

Figure 4 shows the basic control algorithm outline of the ultrasonic coating system. The initial parameters of the target minimum and maximum liquid level, ultrasonic power, air blower speed, and ultrasonic transducer safety thresholds are set in the first. In the main loop, the system continuously loops, monitors, and controls the coating process. The float sensors detect the actual liquid level in the reservoir and then send signals to the Arduino Mega board to record the liquid level in the main reservoir and above the ultrasonic transducer. The Arduino controller compares the liquid level acquired from the float sensors with the desired level minimum and maximum setpoints during initialization. This comparison decides whether the liquid level is below or above the target level. Suppose the liquid level is above the target minimum level. In that case, the controller sends a signal to the ultrasonic relay (R1) to connect the power to the ultrasonic transducer unit from the DC power supply (DC PS) to atomize the aqueous solution with gum Arabic. In addition, the air blower DC motor relay (R2) will work to remove the air with the atomized droplets for fruit coating. Electronic liquid inlet valve relays (R3 and R4) are opened to refill the liquid as required. If the liquid level is below the targeted level, the controller shuts down the R1 and R2 power to save the transducers from damage. Suppose the actual liquid level is above the target maximum level. In that case, electronic liquid in-let valves are closed to prevent overfilling. By following this control algorithm, the ultra-sonic coating system effectively controlled the liquid level in the reservoir to ensure accurate and efficient gum Arabic solution coating while maintaining the safety and reliability of the ultrasonic transducers.

Fresh date palm fruits (Helali cv.) were selected for this study at the Khalal stage due to their susceptibility to quick spoilage after harvesting at this stage. The fruits in this stage have high moisture content and water activity low total soluble solids and are yellow with a crunchy texture. Once the fruits reached the Khalal stage, the free defect samples were harvested manually from the experimental farm (25.268° N, 49.708° E) of the Date Palm Research Center of Excellence (DPRC), King Faisal University, SA. The harvested fruits were packaged in perforated plastic crates of 0.50 × 0.40 × 0.25 m with approximately 25 kg of fresh fruits. The crates were immediately transported to the DPRC storage room at 22°C for 3 h to decrease the initial temperature of the fruits and reach the ambient temperature of the laboratory. The initial physicochemical characteristics of the samples were measured before the treatments. Then, the samples were sorted for uniformity of color before the treatments, and 1 kg of the sorted fruits was used for each coating treatment.

The organic edible gum Arabic used in this study was purchased from the local market in Al-Ahsa, Saudi Arabia, sourced from Abnaa Sayed Elobied Agro-Export, Khartoum State, Sudan. This gum was harvested from the dried, hardened sap of acacia trees in Sudan. This natural GA was cleaned and crushed into a fine powder, and then, the powder was sieved using stainless steel fine mesh strainers (200 mesh with a nominal aperture size of 53 μm). Different weights of GA powder, conforming to the different concentrations selected (% w/v), were dissolved in 1,000 mL of distilled water for 60 min at 25°C for 1 h on a hot plate magnetic stirrer, and then, GA coating solution was filtered through a cheesecloth. Immediately before using the GA coating solution at the appropriate concentration, it was homogenized at 3,000 rpm for 10 min using an overhead stirrer.

The influence of treatment conditions on the shelf life and quality of fresh date palm fruits utilizing the proposed ultrasonic coating was evaluated using response surface methodology (RSM) implemented in Design Expert software (version DX 13.0.5.0, Stat-Ease, Inc., Minneapolis, MN, United States). The central composite design (CCD) has eight independent variables. CCD is a type of experimental design typically employed in statistical modeling and optimization, and it is the fractional factorial design that is most commonly used in the RSM model. The CCD has three design points, i.e., center points, factorial points, and star/axial points. The first two-point categories of factorial and center points help estimate the main, linear, interaction, and quadratic effects. The axial/star points help improve the symmetry of the design to achieve flexibility in rotatability across the center points. Supplementary Figure S1 shows the types of points involved in a typical CCD. A description outlining the typical features of each point in the CCD is given below. The independent variables were analyzed at five levels coded as –α, −1, 0, 1, and +α. The determination of the values for “–α/+α” depends on the type of CCD chosen for the study, whether a face-centered or rotatable design. The value of α is contingent upon the number of factorial points within the factorial portion of the CCD. The number of experimental runs is illustrated as a polynomial model, as shown in Eq. 1. Uncoded values of axial/star points were determined according to Eq. 2.

where is the number of experimental runs, K is the number of factors, 2K is the number of factorial points, 2K is the number of star/axial points, n is the number of center points, uncoded value of axial points, α is the coded value of at axial points, is the high value of the factor expressed in real units, and is the value of the center point expressed in real units.

Table 1 shows the coded and actual values of the independent variables. The value of α was chosen here as 1.68 to fulfill the rotatability and orthogonality in the CCD.

In the current study, the independent factors such as ultrasonic coating time (Ct), air flow rate (AFR), height liquid height (HOL) above the ultrasonic transducers, liquid temperature (LT), edible gum Arabic concentration (GAC), drying time (Dt) for coated fruit, drying temperature (DT), and storage temperature (ST) after processing at three levels were utilized. These factor effects were evaluated on the dependent variables [fruit shelf life (SL), ripening percentage (Rp), weight loss (WL), and color change (ΔE*)]. The number of center points was 5. Based on Eq. 1, the full number of CCD points is 277 (256 factorial, 16 axial points, and 5 center points). However, due to the limited availability of fresh date fruits at the Khalal stage, we employed a “Min-run resolution V design” in Design Expert software for experimental design with 3 replicates for the factorial and star points and 5 replicates for the center points. This selected design aimed to minimize the total number of experimental runs needed, and three replicates enhanced the precision and reliability of the results. Therefore, the total runs were 143 (122 factorial points, 16 axial points, and 5 center points). Supplementary Table S1 shows the experimental runs for the design along with their corresponding coding values, excluding replicates using the Min-run resolution V design.

The coating process optimization for extending fruit shelf life at optimal combination treatments was implemented using RSM and Design Expert software. The optimization procedure goal was to maximize the fruit shelf life by minimizing fruit ripening, weight loss, and color change, considering various independent variables related to the operation of the proposed ultrasonic coating system and storage conditions. The maximum shelf life value of the treated fruits was determined using different optimization criteria, according to the study’s variables, to maximize their shelf life under optimal conditions. Table 2 shows constraints placed on the independent variables under different optimization criteria for optimizing fruit shelf life.

Validation experiments were performed to validate the obtained model under optimization conditions with three replicates. The experimental results for the observed fruit shelf life (R1: SL), Ripe percentage (R2: Rp), color changes (R3: ΔE*), and weight loss (R4: WL) under the different treatments of optimization criteria were compared with the predicted results obtained by the quadratic regression models to validate their practicality and accuracy. Furthermore, as part of the validation experiment, the physicochemical attributes of treated date fruits were assessed upon reaching the end of their shelf life. The quality parameters of treated fruits under the optimization criteria were compared with fresh fruits at the Khalal stage (control).

The shelf life of the treated fruits was estimated according to the non-destructive method described by Mohammed et al. (2023). A multispectral sensor with an AS7265x chipset was employed to capture the spectral reflectance of the tested fruits at wavelengths from 410 nm to 940 nm. A tiny ML-based model was employed to estimate shelf life using data collected from the multispectral sensor using Arduino Nano33 BLE sense–Cortex M4 microcontroller and the Edge Impulse Cloud MLOPs engine. The estimation model utilized reflected light data corresponding to fruit shelf life, which was captured by the AS7265x sensor. It estimated the fruit’s quality and ripening stages, i.e., Khalal, Rutab, or spoiled. The decline in the shelf life of fresh date fruits initiates as they convert from the Khalal stage to the Rutab stage and concludes upon their beginning of rotting or ripening into the Tamr stage (Srinivasagan et al., 2023). The percentage of Rutab and the decay fruits was estimated every 3 days. The criterion for assessing the expiration of treated fruit shelf life was set when the percentage of Rutab fruits reached 10% or when there were 5% of spoiled fruits. The Rutab and decay fruit percentages were determined using Eqs. 3, 4:

where is the Rutab fruits percentage and is the decay percentage. Ff is the fresh fruit in the sample before coating treatment.

The coated fruit was considered ripe when fully converted to Rutab or Tamr fruit. After a storage period of 45 days, the percentage of ripe fruits was determined according to Eq. 5:

Rp is the percentage of the ripe fruit and Rf is the ripe fruits after a storage period of 45 days. Ff is the fresh fruit in the sample before coating treatment.

The color parameters of fresh date fruits were measured according to the Hunter and Harold (1987) method using a portable digital color meter (Hunter lab Color Quest-4500 LAV, Hunter Associates Laboratory, Inc., Reston, Virginia, United States) as International Commission on Illumination (CIE) lab L*, a*, and b* values. The color meter was calibrated using the white primary tile they supplied. The average of three readings was recorded for each of the 10 randomly selected fruits per sample, both before and after a storage period of 45 days. The color changes in the coated fruit relative to their initial color were determined according to CIE lab using Eq. 6:

where ∆E* is the fruit color difference, L* is the fruit lightness, a* is the fruit greenness/redness, b* is the fruit blueness/yellowness, subscripts “b” and “a” denote the color parameter value before and after a storage period of 45 days, respectively.

Fruit weight loss (WL) during storage can be attributed to several factors, such as moisture loss, respiration, and decay processes occurring within the fruits over time, impacting their quality and shelf life. The percentage of WL for the coated fruits after a storage period of 45 days relative to their initial weight was determined using Eq. 7.

where is the initial weight of the coated fruits before storage and is the final weight of the coated fruits after 45 days of cold storage.

The multiple regression analysis was used to determine the relationship between the independent and dependent variables. The multiple regression equation was employed using the experimental data to construct a quadratic polynomial model. The response value (y) was obtained by regression Eq. 8:

where y is the response or the dependent variable, are the regression coefficients, and and are the independent variables. K is the number of factors, and ε is the error component.

The regression coefficients of individual linear, quadratic, and interaction terms were estimated, the analysis of variance (ANOVA) was conducted to assess the effect of the independent variables on the dependent variables in the developed models, response surface graphs were plotted, and optimization procedures were performed using Design Expert software version 13.0.5.0. The fit statistics for the models of the responses using the evaluation metrics of Std. Dev., C.V. %, coefficient of determination (R2), adjusted R2, predicted R2, adequate precision, and lack of fit p-value were determined using Design Expert software. In addition, ANOVA at p < 0.05 used the commercial statistical package IBM SPSS software (SPSS version 26, Inc., Chicago, IL, United States) to analyze the data on physicochemical properties in the validation experiment. Subsequently, comparisons were made between the means of different treatments using the Tukey test, with a significant level set at 0.05. The optimization solutions were evaluated by comparing them with the actual data obtained from the validation experiment, utilizing the calculated R2, the root mean square error (RMSE), and the mean absolute percentage error (MAPE) according to the following Eqs. 9–11:

where RSS is the residual sum of squares, TSS is the total sum of squares, is the observed value of the dependent variable for observation i, is the value predicted by the model, is the mean of the observed values of the dependent variable, n is the total number of observations, is the is the actual value for observation i, and Pi is the predicted value of the dependent variable.

The experimental data obtained according to the experimental plan for the responses, i.e., fruit shelf life (R1: SL), ripe percentage (R2: Rp), color changes (R3: ΔE*), and weight loss (R4: WL) to coating treatments influenced by studied variables, i.e., ultrasonic coating time (A: Ct), air flow rate (B: AFR), height of liquid (C: HOL) above the ultrasonic transducers, liquid temperature (D: LT), edible gum Arabic concentration (E: GAC), drying time (F: Dt) for coated fruit, drying temperature (G: DT), and storage temperature (H: ST) are shown in Table 3. This table shows the factors’ uncoded values and the responses’ mean values.

Coefficients of quadratic polynomial equations were obtained from experimental data to model the impact of dependent variables on the experimental data analysis. The coefficients of final equations in terms of coded factors and their p-value from the ANOVA for fruit SL, Rp, ΔE*, and WL are shown in Table 4. Table 5 shows the fit statistics for the models of the responses using the evaluation metrics of standard deviation, C.V. %, R2, adjusted R2, predicted R2, adequate precision, and lack of fit p-value. The model evaluation indicated that the obtained regression models could sufficiently fit the dependent variable values. The model F-value of 117.11 for the SL implies that the model is significant. The ANOVA results for the SL model indicated that A, B, D, E, F, G, H, AB, AC, AD, AE, AF, AG, AH, BC, BD, BE, BF, BH, CD, CF, DF, DG, DH, EF, EG, EH, FG, FH, GH, A2, B2, C2, D2, E2, F2, G2, and H2 were significant model terms (p < 0.05). However, SL model terms C, BG, CE, CG, CH, and DE were not statistically significant (p > 0.05). The lack of fit F-value of 0.75 indicated that the lack of fit was insignificant relative to the pure error. The predicted R2 of 0.96 is in reasonable agreement with the adjusted R2 of 0.97, i.e., the difference is less than 0.2. The adequate precision of 48.49 indicates an adequate signal, and the model can be used to navigate the design space.

The model F-value of 78.1 for the Rp implies that the model is significant. The ANOVA results for the Rp model indicated that A, B, D, E, G, H, AC, AE, AF, AG, AH, BC, BD, BF, BH, CD, CF, DF, DG, DH, EF, EG, EH, FG, FH, A2, B2, C2, D2, E2, F2, G2, and H2 were significant model terms (p < 0.05). However, model terms C, F, AB, AD, BE, BG, CE, CG, CH, DE, DE, and GH were not statistically significant (p > 0.05). The lack of fit F-value of 1.3 indicated that the lack of fit was insignificant relative to the pure error. The predicted R2 of 0.94 is in reasonable agreement with the adjusted R2 of 0.95, i.e., the difference is less than 0.2. The adequate precision of 39.19 indicates an adequate signal, and the model can be used to navigate the design space.

The model F-value of 30.20 for the ΔE* implies that the model is significant. The ANOVA results for the ΔE* model indicated that A, D, E, F, G, H, AB, AH, BC, DF, DG, DH, FG, A2, B2, D2, E2, F2, G2, and H2 were significant model terms (p < 0.05). However, model terms B, C, AD, AF, AG, BD, BE, BF, BG, BH, CD, CE, CF, CG, CH, DE, FH, and GH were not statistically significant (p > 0.05). The lack of fit F-value of 0.87 indicated that the lack of fit was insignificant relative to the pure error. The predicted R2 of 0.85 is in reasonable agreement with the adjusted R2 of 0.90, i.e., the difference is less than 0.2. The adequate precision of 24.33 indicates an adequate signal, and the model can be used to navigate the design space.

The model F-value of 35.17 for the ΔE* implies that the model is significant. The ANOVA results for the ΔE* model indicated that A, B, D, E, F, G, H, AB, AC, AE, AH, BC, BE, DF, DG, DH, EF, EH, FG, A2, B2, C2, D2, E2, F2, G2, and H2 were significant model terms (p < 0.05). However, model terms H, AD, AF, AG, BD, BF, BG, BH, CD, CE, CF, CG, CH, EG, FH, and GH were not statistically significant (p > 0.05). The lack of fit F-value of 0.11 indicated that the lack of fit was insignificant relative to the pure error. The predicted R2 of 0.87 is in reasonable agreement with the adjusted R2 of 0.91; i.e., the difference is less than 0.2. The adequate precision of 28.22 indicates an adequate signal, and the model can navigate the design space. The error parameters suggested that the model efficiently predicted fruit SL, Rp, ΔE*, and WL.

The observed significance could be ascribed to the function of gum Arabic in establishing a resilient layer that effectively diminishes moisture loss, oxidation, and microbial activity, thereby prolonging SL and preserving the quality of the fruits. DT and ST factors demonstrated significant positive relationships with Rp, ∆E, and WL, along with a marked negative correlation with SL (p < 0.01). Elevated temperatures typically hasten biochemical processes, resulting in accelerated ripening, noticeable color changes, and increased WL, thus elucidating their statistical significance. Variables that did not achieve statistical significance may have lacked a substantial effect size or consistent impact throughout the dataset to reach statistical significance.

The experimental conditions under scrutiny may not accurately reflect real-world scenarios’ complex and multifaceted realities, potentially introducing uncertainty and unpredictability into the outcomes of the study. The diversity in fruit types utilized, the diverse range of environmental conditions under which the experiment is conducted, and the varying approaches to handling and processing the fruits have the potential to exert considerable influence on the observed results, mainly when extrapolated and applied to disparate settings.

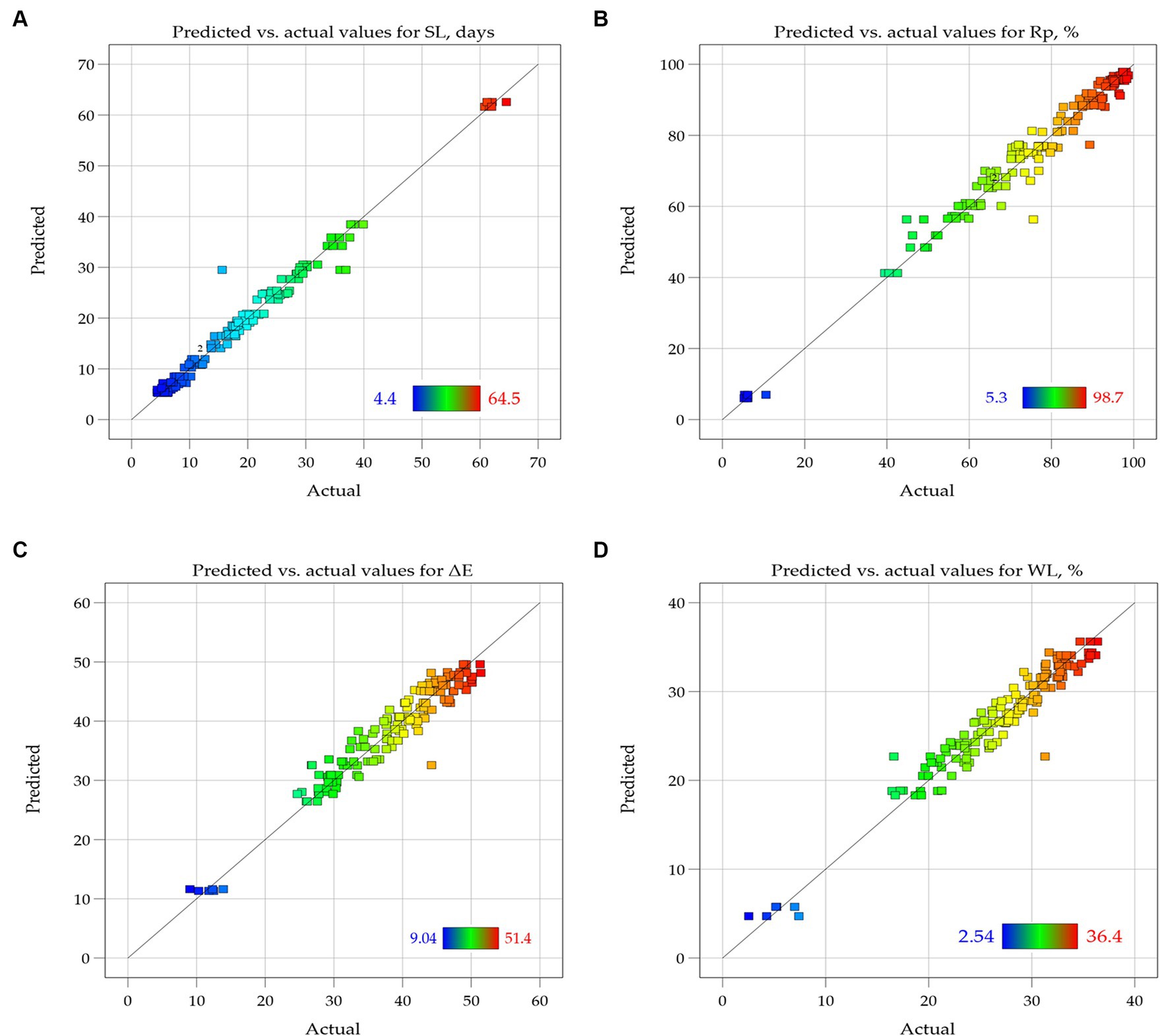

Figures 5A–D display scatter plots comparing the predicted values against the actual experimental values obtained from the developed models for the responses, representing SL (Figure 5A), Rp (Figure 5B), ΔE* (Figure 5C), and WL (Figure 5D). This figure indicates that the predicted values of the responses closely align with the observed values. This shows that the CCD design adequately represents the responses SL, SL, Rp, ΔE*, and WL based on the selected runs. The regression lines are presented in Figures 5A–D, representing predicted versus actual values for all responses, closely approximate the 1:1 line (y = x + 0).

Figure 5. Scatter plots of the predicted versus the actual values of the fruit shelf life (graph A), percentage of ripe fruits (graph B), color changes of the fruits (graph C), and percentage of weight loss (graph D).

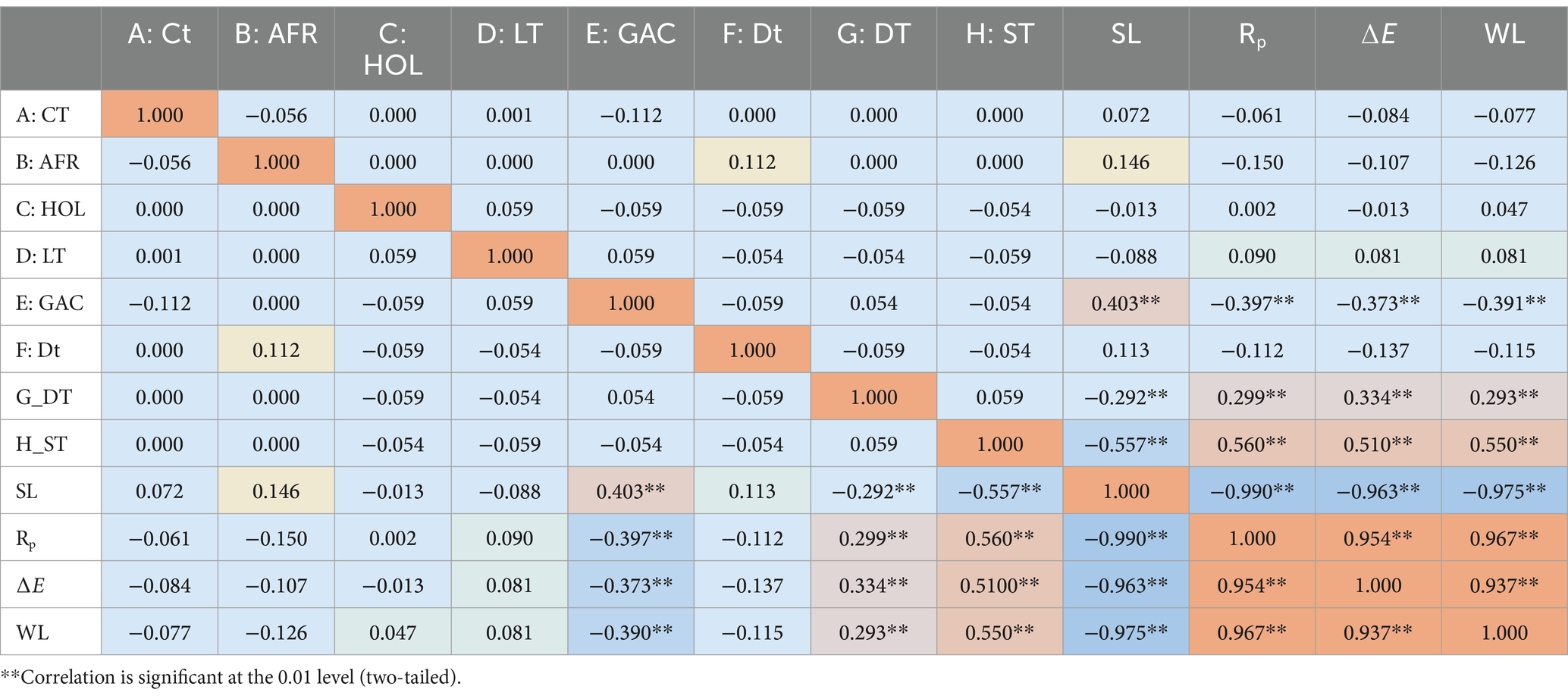

Table 6 shows the correlation coefficients between eight independent variables (Ct, AFR, HOL, LT, GAC, Dt, DT, and ST) and four dependent variables (SL, Rp, ∆E, and WL). The correlation coefficient value close to 0 indicates little or no correlation, a coefficient close to 1 indicates a strong positive correlation, and a coefficient close to −1 indicates a strong negative correlation. GAC shows the strongest negative (p < 0.01) correlations with the dependent variables such as Rp, ∆E, and W and a significant positive correlation with fruit SL. DT and ST show the strongest positive (p < 0.01) correlations with dependent variables such as the Rp, ∆E, and W and a significant negative correlation with fruit SL. Dt and LT show moderate correlations with the dependent variables but are not as strong as GAC and ST. All dependent variables are highly correlated with each other. However, the independent variables are not highly correlated with each other (p > 0.01). This indicates they are not highly interrelated or collinear in the data.

Table 6. Correlation coefficients matrix for independent variables of coating process/storage parameters including ultrasonic coating time (Ct), air flow rate (AFR), height liquid height (HOL) above the ultrasonic transducers, liquid temperature (LT), edible gum Arabic concentration (GAC), drying time (Dt) for coated fruit, drying temperature (DT), and storage temperature (ST) and dependent variables including fruit shelf life (SL), ripening percentage (Rp), color difference (∆E), and weight loss (WL) of coated fruit.

The strong negative correlation observed with Rp, ∆E*, and WL suggests that higher gum Arabic concentrations significantly reduce the rate of ripening, color change, and fruit weight loss. This implies that gum Arabic aids in preserving the fruit’s firmness and visual appeal, possibly by forming a robust, protective barrier that diminishes moisture loss and oxidative alterations. The positive relationship identified with fruit SL implies that an increase in gum Arabic concentration effectively prolongs the fruit’s shelf life by retarding deterioration processes. From a practical standpoint, augmenting the concentration of gum Arabic in the coating solution emerges as a viable approach to elongate the SL and uphold the quality of fresh date palm fruit.

The positive correlation with Rp, ∆E*, and WL indicates that elevated drying and storage temperatures hasten ripening, intensify color changes, and increase fruit weight loss. These outcomes likely stem from the heightened metabolic and respiratory activities facilitated by higher temperatures. Conversely, the notable negative correlation with SL underscores that heightened drying and storage temperatures curtail the fruit’s SL by hastening degradation processes. Regulating drying and storage temperatures is pivotal for safeguarding the quality and extending the shelf life of fresh date palm fruit. Lower temperatures during drying and storage operations can decelerate ripening and curtail quality deterioration.

The moderate correlations displayed by the variables with the dependent variables signify their influence on the quality and SL of the fruit, albeit not as prominently as GAC and ST, indicating that while Dt and LT hold significance, their impacts are secondary compared with GAC and storage conditions. Regarding practical implications, fine-tuning drying time and liquid temperature can increase the efficiency of the coating process. Striking a balance and optimum level between these parameters can aid in achieving the desired quality attributes without compromising the structural integrity of the coating.

The substantial correlation among SL, Rp, ∆E*, and WL indicates interconnectedness among these quality attributes. Enhancements in one attribute (e.g., reduced WL) are likely to yield positive effects on others (e.g., prolonged SL and decreased ripening rate). In practical terms, strategies that enhance a single quality attribute are poised to have favorable repercussions on others.

The absence of significant collinearity among some independent variables (p > 0.01) implies that each variable contributes autonomously to the observed results. This independence permits a more precise optimization of each parameter without the complicating influence of multicollinearity. In practical terms, the capacity to independently optimize each independent variable offers flexibility in tailoring the coating process to specific requirements, facilitating the attainment of desired quality outcomes and unintended interactions.

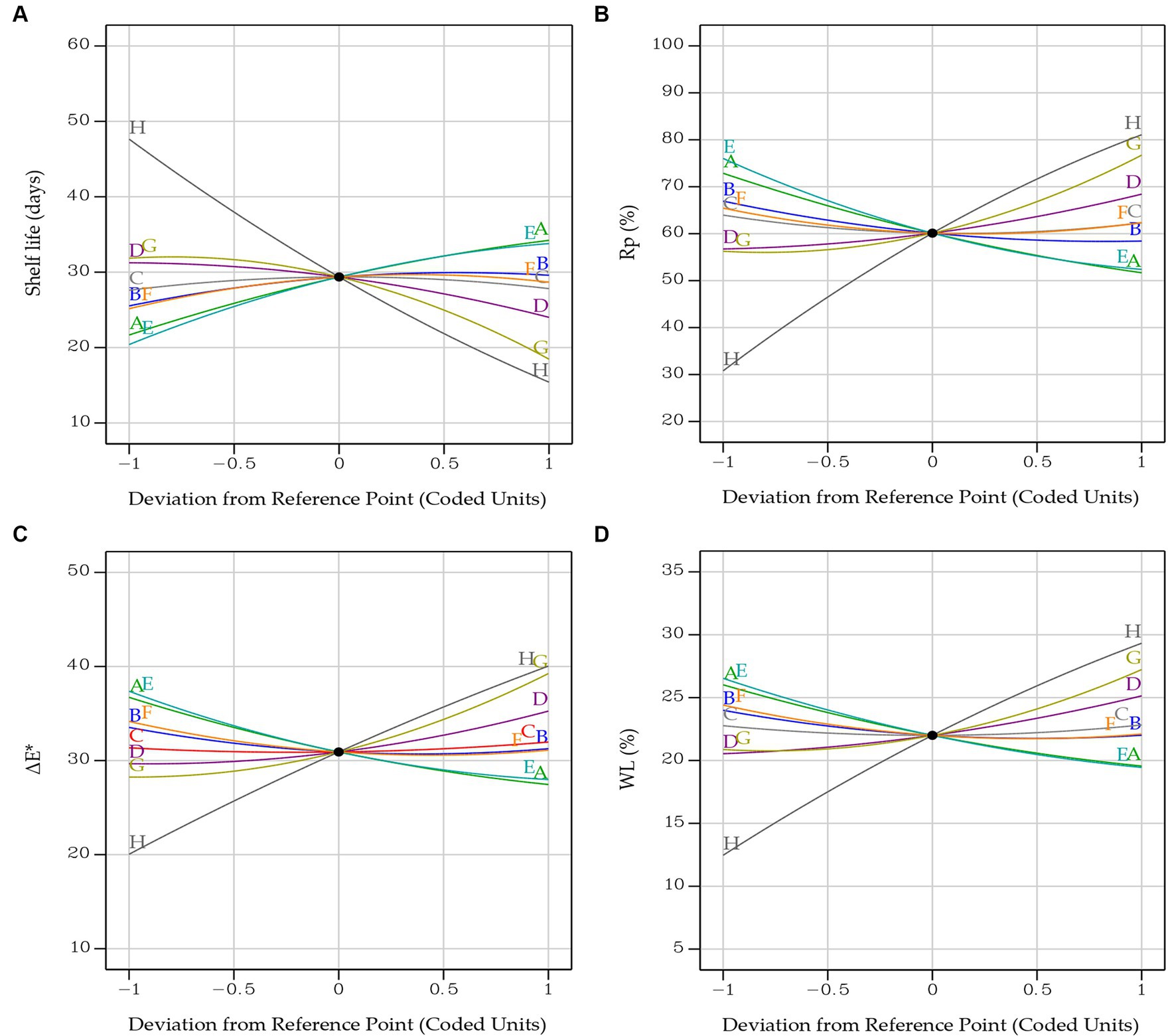

Figures 6A–D show the influence of the main and interactive effects of the independent variables on the fruit SL, Rp, ΔE*, and WL using the perturbation. The perturbation plot shows the main effects of A–H factors on SL (Figure 6A), Rp (Figure 6B), ΔE* (Figure 6C), and WL (Figure 6D). This figure indicates that the H factor significantly affects the fruit SL and quality due to its impact on increasing the fruits’ Rp, ΔE*, and WL, followed by the G and D factors with the same effect. The A and E factors have a moderate positive effect on the fruit SL and fruit quality and an adverse impact on the Rp, ΔE*, and WL fruits, followed by B and F factors, which have a slight positive effect on the fruit SL and a small deserve impact on the Rp, ΔE*, and WL. Factor C had the most minor effect on all responses, and this is because all levels applied were within the adequate working range for ultrasonic atomization. However, Table 4 indicated that the interaction of the B factor with other factors was significant. This table also suggested that the interaction between all factors from A to H was significant (p < 0.05) in most cases.

Figure 6. Perturbation plot for the main effect of coating time (factor A), air flow rate (factor B), height of liquid above the ultrasonic transducers (factor C), liquid temperature (factor D), edible gum Arabic concentration (factor E), drying time for coated fruit (factor F), drying temperature (factor G), and storage temperature (factor H) on fruit shelf life (graph A), percentage of ripe fruits (graph B), color changes of the fruits (graph C), and percentage of weight loss (graph D).

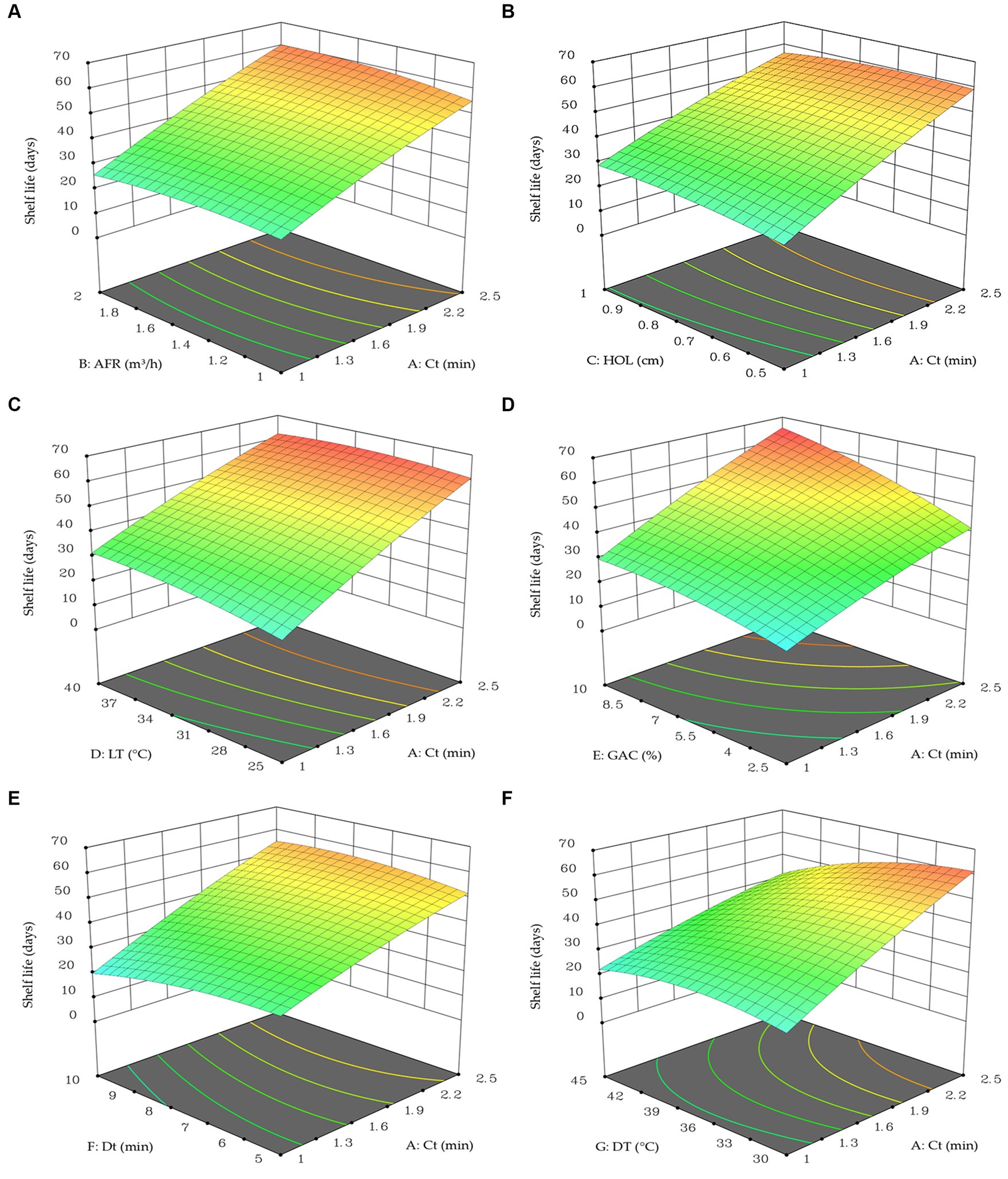

The interaction effect of the Ct with AFR, HOL, LT, GAC, Dt, DT, and ST on the fruit shelf life was plotted based on response surface 3D plots using Design Expert software, as shown in Figure 7. The 3D response surface plots were plotted as a function of the interaction of two factors while keeping the other factors at the center point levels for AFR, HOL, LT, GAC, Dt, and DT factors and at the 5°C ST. The purpose of these 3D response surface plots is to elucidate the interaction effects between Ct and the other factors on various dependent variables related to fruit quality, including fruit SL (Figure 7), Rp of the fruit (Supplementary Figure S2), color change (ΔE*) after storage (Supplementary Figure S3), and percentage of WL (Supplementary Figure S4). Graph A in these figures shows the response surface plots based on quadratic equations of the selected model for the interaction effect of factor A: Ct with factors B: AFR on the Rp, ΔE*, and WL, respectively, at C: HOL = 0.75 cm, D: LT = 32.5°C, E: GAC = 6.52%, F: Dt = 7.5 min, G: DT = 37.5°C, and H: ST = 5°C. Graph B shows the response surface plots for the interaction effect of factor A: Ct with factors C: HOL on the Rp, ΔE*, and WL, respectively, at B: AFR = 1.5 m3/h, D: LT = 32.5°C, E: GAC = 6.52%, F: Dt = 7.5 min, G: DT = 37.5°C, and H: ST = 5°C. Graph C shows the response surface plots for the interaction effect of factor A: Ct with factors D: LT on the Rp, ΔE*, and WL, respectively, at B: AFR = 1.5 m3/h, C: HOL = 0.75 cm, E: GAC = 6.52%, F: Dt = 7.5 min, G: DT = 37.5°C, and H: ST = 5°C. Graph D shows the response surface plots for the interaction effect of factor A: Ct with factors E: GAC on the Rp, ΔE*, and WL, respectively, at B: AFR = 1.5 m3/h, C: HOL = 0.75 cm, D: LT = 32.5°C, F: Dt = 7.5 min, G: DT = 37.5°C, and H: ST = 5°C. Graph E shows the response surface plots for the interaction effect of factor A: Ct with factors F: Dt on the Rp, ΔE*, and WL, respectively, at B: AFR = 1.5 m3/h, C: HOL = 0.75 cm, D: LT = 32.5°C, E: GAC = 6.25%, G: DT = 37.5°C, and H: ST = 5°C. Graph F shows the response surface plots for the interaction effect of factor A: Ct with factors G: DT on the Rp, ΔE*, and WL, respectively, at B: AFR = 1.5 m3/h, C: HOL = 0.75 cm, D: LT = 32.5°C, E: GAC = 6.25%, G: Dt = 7.5°C, and H: ST = 5°C.

Figure 7. 3D response surface plots representing the combined effect of coating time factor (A: Ct) with air flow rate (B: AFR) (graph A), height of liquid (C: HOL) (graph B), liquid temperature (D: LT) (graph C), gum Arabic concentration (E: GAC) (graph D), drying time (F: Dt) (graph E), and drying temperature (G:DT) (graph F) at 5°C storage temperature on coated fresh fruit shelf life.

In the current study, optimization actions focused on refining the coating operating and storage parameters to improve the quality and shelf life of the fruits. Therefore, the primary aim was to achieve optimal response, characterized by the long shelf life of coated fruits, minimal ripe fruits, color change, and weight loss of the treated fruits. Employing the desirability function approach facilitated the analysis of experiments in which multiple responses, namely, SL, Rp, ΔE*, and WL percentage, needed simultaneous optimization at the optimum levels of the independent variables. Adapting the coating operating and storage condition parameters using appropriate numerical optimization methods efficiently achieved the optimal response values. To maintain fresh fruit quality, the SL value was desired to be as long as possible, with a decrease in the Rp, ΔE*, and WL percentages. Therefore, the SL, Rp, ΔE*, and the fruit WL were optimized together. Once the regression models had been created and assessed to evaluate their adequateness, the optimization criteria were specified to determine the optimum conditions for the operating parameters of the ultrasonic coating system and storage temperature. This optimization used three criteria to optimize the target responses, as shown in Table 3. Table 7 illustrates the results for SL, Rp, ΔE*, and the fruit WL at the optimal configurations based on the selected constraints of the optimization criteria to determine the best solutions for fulfilling the target optimization criteria. The solutions under criterion 1 exhibit parameters adjusting to optimize fruit shelf life, and the other parameters with desirability are consistently rated at 0.9. Criterion 2 emphasizes different parameter configurations, resulting in slightly lower desirability values of 0.8 while focusing on achieving optimal processing outcomes. Similarly, Criterion 3 introduces parameter adjustments, aiming to minimize energy consumption by increasing storage temperature while maximizing fruit quality, which is reflected in desirability scores of 0.7.

The optimized parameters (e.g., GAC, DT, and ST) were consistently effective in multiple trials, demonstrating their reliability in maintaining fruit quality and prolonging their SL. This consistency demonstrates robustness in applying these parameters under controlled experimental conditions. Conducting a sensitivity analysis indicated that minor deviations from the optimized parameters did not significantly affect the outcomes. This suggests that the optimized parameters are robust to slight variations, which is crucial for practical applications where exact conditions may vary slightly. While the optimized parameters provide a stable basis, they can be fine-tuned to accommodate specific fruit varieties and environmental conditions. This flexibility enhances their practical applicability and effectiveness in diverse settings. The robustness and generalizability of the optimized parameters make them suitable for scaling up from laboratory to industrial production.

The validation experiments were conducted to validate the optimization solutions under the target criteria for SL, Rp, ΔE*, and the fruit WL. They were conducted with three replicates using the parameter combinations obtained through the optimization criteria. Table 8 shows the details of the experiments and the results of the validation experiments. The predicted values of solutions were achieved based on the R2, MAPE, and RMSE evaluation metrics, as shown in Table 8. The high value of R2 and low values of RMSE and MAPE indicate greater agreement between observed and predicted values. The experimental outcomes validate the efficacy and precision of the response surface predictive models in determining optimal operating coating parameter combinations. Accordingly, these regression predictive models are deemed reliable and accurate tools for predicting fruit shelf life (SL), ripe fruit percentage (Rp), color change (ΔE*), and fruit weight loss (WL) using the designed ultrasonic coating system.

Ultrasonic techniques offer versatility and reliability in different applications by adjusting to various coating solutions and operation conditions. Several critical factors, including the coating techniques, influence the robustness and generalizability of optimized parameters for edible coatings. Dipping and spraying are commonly utilized to ensure consistent coverage, as evidenced by fine-tuning soaking durations and concentrations in optimizing pineapple peel extract and Arabic gum-based coatings for tomatoes, aiming to enhance shelf life and delay ripening (Tsague Donjio et al., 2023). However, traditional coating methods exhibit various drawbacks when juxtaposed with ultrasonic coating techniques. The immersion process frequently yields an irregular coating, which is attributed to the formation of bubbles and erratic paint dispersion. Using soaking techniques may result in extended processing durations and increased expenses due to the requirement for lengthy drying intervals and possible rework to rectify coating imperfections (Nigmetzyanov et al., 2023). Such inconsistencies have the potential to undermine the overall quality and longevity of the coating. Ultrasonic coating methods have advantages for delicate applications such as coating fresh dates. They ensure uniform, bubble-free coating by preventing air entrapment and promoting even distribution of coating material. This method enhances adhesion properties due to the cavitation effect, effectively cleaning and preparing the surface. Ultrasonic coating is efficient, reducing processing time and costs while improving coating layer quality (Toda, 1997). Therefore, the ultrasonic coating is particularly beneficial for fresh dates as it is a non-thermal process that preserves the dates’ nutritional quality and natural flavor. In addition, the precision and control offered by ultrasonic methods also minimize waste and ensure consistent application, making it a superior choice for coating fresh fruits.

The current study developed an ultrasonic coating system, optimized the operation parameters, and evaluated four dependent variables during storage: fruit shelf life, ripe fruit percentage, color changes, and weight loss of Khalal Hilali dates. As mentioned in the materials and methods section, the SL of date fruits ended when 10% of the fruits turned to Rutab or 5% spoiled. The SL of fresh Hilali dates of different treatments ranged from 4.4 to 64.53 days. Based on correlation analysis, GAC, DT, and ST revealed significant effects (p < 0.01) on the SL, whereas other independent variables (Ct, AFR, HOL, LT, and Dt) showed insignificant effects (p > 0.01). The SL was positively influenced by GAC and negatively affected by DT and ST. As GAC increased, the accumulated amount of coating material on fruits’ surfaces increased, resulting in an increase in coating thickness, an improvement in the barrier properties, and an extension of the SL. Moreover, it could be suggested that the decrease in DT and ST may slow down the respiration rate and other related metabolic processes such as water loss, texture degradation, nutrient decomposition, and color changes, besides its role in retarding or delaying the microbial growth resulting in extending the SL.

The GA coating developed with the ultrasonic system may be responsible for extending the SL of Khalal Hilali dates as follows: (1) it may delay the ripening process of date fruits through retarding gas movements from fruits’ surface, reducing the respiration rate, decreasing enzymatic activity, and minimizing metabolic processes; (2) it may prevent microbial spoilage through forming a protective layer on fruits’ surface; (3) it is worth mentioning that yeasts and molds are the most common microorganisms causing fruits’ spoilage and they are obligatory aerobic microorganisms; accordingly, the GA coating developed with ultrasonic system may create anaerobic conditions inside the fruits, which, in turn, prevent the growth of yeasts and molds and, therefore, extend the SL. Generally, edible coatings decrease the fruits’ surface permeability to gases, which may change the internal gas composition, decreasing oxidative metabolism and extending the fruits’ SL (El-Gioushy et al., 2022). It could be expected that the use of an ultrasonic system in the coating development process may convert the coating solution into a mist with unique physical properties, i.e., the mist is formed of microparticles, which, in turn, can accumulate slowly on the surface of the treated fruits, resulting in a uniform coating with improved barrier properties. Such developed coating can decrease the respiration rate, minimize enzymatic activity, prevent microbial penetration, and delay the ripening process. Accordingly, it may be responsible for extending the shelf life of treated fruits. Salehi et al. (2023) investigated the potential of using ultrasonic coating with guar gum as a pretreatment for the dehydration process of quince slices using RSM and they found that the optimum condition was found to be sonication time = 5 min and guar gum concentration = 0.05%. Matching with our results, Meng et al. (2014) reported that nano-ZnO coating supported with ultrasound treatment could be a promising approach to increase the fresh-cut kiwi fruit’s shelf life.

The ripening percentage (Rp) of the tested date samples of different treatments varied between 5.9 and 98.7%. As date palm is a climacteric crop, the fruits, after harvesting, are subjected to a series of maturity stages, including chemical and physiological changes, besides the production of the ethylene hormone, which is the main factor responsible for the ripening process (Alqahtani et al., 2023). As shown in the correlation analysis, GAC, DT, and ST exhibited significant effects (p < 0.05) on the Rp, whereas Ct, AFR, HOL, LT, and Dt revealed insignificant effects (p > 0.05). Generally, the Rp decreases with increasing GAC and increases with increasing DT and ST. It could be suggested that the GA coating developed with the ultrasonic system at the optimum operating conditions may prevent gas movements from fruits’ surface, minimizing the respiration rate and other related metabolic processes resulting in lower Rp. Similarly, Mahfoudhi and Hamdi (2015) reported that the delay in the ripening of sweet cherry fruits coated with GA could be due to the reduction in respiration rate, which maintained the physicochemical properties of coated samples. It is worth noting that the developed coating using the ultrasonic system is formed of microparticles accumulated on the surface of date fruits. Such coating with improved barrier properties may minimize the gas movement through the fruit surface, decreasing the respiration rate, decreasing the metabolic processes, and delaying the ripening process. Low storage temperature plays a crucial role in delaying the ripening of stored fruits, as the enzymes responsible for ripening and other related metabolic activities cannot work properly under lower temperatures. Our results are in harmony with Mahfoudhi and Hamdi (2015) and Ali et al. (2013), who reported that coating with GA delayed the ripening process of sweet cherry and tomato fruits, respectively.

Color represents a key parameter affecting consumers’ behavior toward a food product, mainly fruits and vegetables. The color changes (ΔE*) of Khalal Hilali dates of different treatments during storage varied between 9.04 and 50.1. In general, ΔE* was significantly affected (p < 0.05) by GAC, DT, and ST and insignificantly influenced (p < 0.05) by Ct, AFR, HOL, LT, and Dt, according to the correlation analysis. It could be observed that GAC had a negative relationship with ΔE*, whereas DT and ST had a positive effect. However, the changes in color of dates during storage could be illustrated as follows: (1) the natural ripening processes of dates (the conversion from Khalal to Rutab and Tamr stage) include an increase in CO2 and ethylene production, which can lead to degradation of natural pigments and formation of a dark color (Alqahtani et al., 2023); (2) with prolonged storage, the conversion of sucrose to reducing sugars due to natural ripening process may contribute to the change in fruits’ color into light brown (Siddiq et al., 2013); (3) the oxidative enzymes such as polyphenol oxidase, peroxidase, and catalase could be responsible for the discoloration and browning through the oxidation of endogenous phenols into quinones (Ghafoor et al., 2022; Taher et al., 2022). In the present study, the minor changes in ΔE* observed in coated samples with an optimized ultrasonic system reflect a delay in ripening, which could be due to the improved barrier properties of the developed coating and its ability to modify the respiration and ethylene production rates of dates, which, in turn, slowed down the fruit’s metabolism (Asgarian et al., 2023).

Moreover, the lower temperatures applied during drying and storage can minimize the respiration rate and other metabolic and catabolic reactions, consequently decreasing color changes. Our findings are compatible with those reported by Eftekhari et al. (2023), who reported that the ultrasonication process improved the barrier properties of basil seed and guar gum coatings and minimized the color changes of dried orange slices stored at ambient temperature. Similar preservative effects of edible coatings on fruits’ color have been reported by Asgarian et al. (2023) and Taher et al. (2022) for plums and peach fruits, respectively.

WL is an important quality parameter of stored fruits and vegetables and reflects the physicochemical changes that occur during storage, particularly moisture loss and metabolic activity associated with tissue senescence (Kawhena et al., 2020). Generally, the acceptable limit of WL of stored fruits and vegetables is 4–6% of initial weight (Kawhena et al., 2020). In the current study, the WL of all treatments ranged from 4.28 to 36.4 at the end of storage. As mentioned in the correlation analysis, GAC, DT, and ST revealed significant impacts (p < 0.05) on the WL, whereas Ct, AFR, HOL, LT, and Dt showed insignificant effects (p > 0.05). Generally, WL decreases with increasing GAC and increases with increasing DT and ST. It could be suggested that coating with GA using an optimized ultrasonic system can form an excellent physical barrier around the fruit surface, which could decrease water loss and minimize WL of treated samples. Moreover, the hydrophobic nature of GA can reduce water and oxygen penetration when applied to fruits, which, in turn, can prevent moisture loss and decrease WL of coated samples (Kawhena et al., 2020). In addition, Taher et al. (2022) ascribed the barrier properties of GA to its higher content of arabinogalactan (80–90%), which, in turn, can prevent water loss during storage. Moreover, GA-based coating can prevent moisture migration from the fruits’ surface into the environment, decreasing WL (Kawhena et al., 2021). During the storage period, besides water loss, metabolic activities (e.g., transpiration, respiration, ethylene production, ripening, and metabolic and catabolic reactions) are other factors responsible for WL of stored fruits (El-Gioushy et al., 2022). In a previous study conducted by Muñoz-Labrador et al. (2018) on the quality changes during cold storage of strawberries, they observed that pectin-based edible coatings prepared with ultrasonic technique minimized the WL of cold stored strawberry samples, which could be attributed to the beneficial effects of ultrasonic on improving the barrier properties of the developed coatings. Moreover, our findings are in harmony with the previous studies, which confirmed the protective effect of GA coating against WL of pomegranate arils (Kawhena et al., 2020), peach (Taher et al., 2022), and guava (El-Gioushy et al., 2022) during storage.

Matching with our findings, Kumar et al. (2023) confirmed that the ultrasonic technique is an effective method for developing soybean aqueous extract-based composite films. These authors reported that the developed films showed excellent barrier and mechanical properties with less opacity, a uniform structure, and improved rheological properties. The enhancement in the film’s properties could be attributed to the acoustic cavitation effect of the ultrasonic technique, leading to an optimum homogenization of the film-forming components. In addition, Muñoz-Labrador et al. (2018) reported that the application of ultrasonic technique in the preparation of citrus pectin gels as an edible coating improved the barrier properties of the developed coating and minimized the moisture loss and decreased the color changes during storage of strawberry fruits in cold storage.

The current study presents an innovative ultrasonic coating system for enhancing fresh date palm fruit’s shelf life and quality. Process parameters were optimized through experimentation and optimization using response surface methodology. The findings indicated that edible coating with gum Arabic at specific concentrations of 9.58%, at an airflow rate of 1.95 m/s, a height of liquid above the ultrasonic transducer of 0.62 cm, a liquid temperature of 40°C, a drying time of 7.4 min, a drying temperature of 30°C, and a storage temperature of 5°C resulted in extending the shelf life of the stored fruits to 65 days with minimal ripening, color changes, and weight loss. Validation experiments confirmed the optimized parameters’ effectiveness, reinforcing the findings’ reliability. This study illustrates the substantial potential of ultrasonic edible coatings in enhancing the longevity and quality of fresh date palm fruit. The ultrasonic coating system promoted superior distribution and attachment of the active constituents in the coating solutions, optimizing their efficacy. Applying ultrasonic coatings extended the shelf life of date fruits by mitigating moisture loss and postponing the initiation of decay. Using ultrasonic technology for coating purposes presents a promising approach for the fresh produce sector, potentially reducing postharvest wastage and ameliorating product marketability. The findings pave the way for future studies executing ultrasonic coating systems for other fresh fruits to enhance food safety, reduce waste, and improve food security.

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

MM: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing. NA: Conceptualization, Funding acquisition, Project administration, Resources, Writing – original draft, Writing – review & editing. SA: Conceptualization, Investigation, Methodology, Writing – original draft, Writing – review & editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This study was supported by the Deanship of Scientific Research, Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (Grant A202).

The authors gratefully acknowledge the Date Palm Research Center of Excellence, King Faisal University, Saudi Arabia, for the logistic support and equipment availability in the engineering laboratories of the precision engineering technologies program.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2024.1403164/full#supplementary-material

Akhoundzadeh Yamchi, A., Yeganeh, R., and Kouchakzadeh, A. (2022). Effect of ultrasonic pretreatment on drying kinetics and physio-mechanical characteristics of peach slices. J. Food Process Eng. 45:e14053. doi: 10.1111/jfpe.14053

Ali, A., Maqbool, M., Alderson, P. G., and Zahid, N. (2013). Effect of gum Arabic as an edible coating on antioxidant capacity of tomato (Solanum lycopersicum L.) fruit during storage. Postharvest Biol. Technol. 76, 119–124. doi: 10.1016/j.postharvbio.2012.09.011

Ali, S., Singh, B., and Sharma, S. (2016). Response surface analysis and extrusion process optimisation of maize-mungbean-based instant weaning food. Int. J. Food Sci. Technol. 51, 2301–2312. doi: 10.1111/ijfs.13186

Alqahtani, N. K., Alnemr, T. M., and Ali, S. A. (2023). Effects of pomegranate peel extract and/or lactic acid as natural preservatives on physicochemical, microbiological properties, antioxidant activity, and storage stability of Khalal Barhi date fruits. Foods 12:1160. doi: 10.3390/foods12061160

Andrade, R. D., Skurtys, O., and Osorio, F. A. (2012). Atomizing spray systems for application of edible coatings. Compr. Rev. Food Sci. Food Saf. 11, 323–337. doi: 10.1111/j.1541-4337.2012.00186.x

Asgarian, Z. S., Palou, L., Souza, R. F., Quintanilla, P. G., Taberner, V., Karimi, R., et al. (2023). Hydroxypropyl methylcellulose and gum Arabic composite edible coatings amended with geraniol to control postharvest brown rot and maintain quality of cold-stored plums. Foods 12:2978. doi: 10.3390/foods12152978

Beheiry, H. R., Hasanin, M. S., Abdelkhalek, A., and Hussein, H. A. (2023). Potassium spraying preharvest and nanocoating postharvest improve the quality and extend the storage period for acid lime (Citrus aurantifolia Swingle) fruits. Plan. Theory 12:3848. doi: 10.3390/plants12223848

Bezerra, M. A., Santelli, R. E., Oliveira, E. P., Villar, L. S., and Escaleira, L. A. (2008). Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76, 965–977. doi: 10.1016/j.talanta.2008.05.019

Bleoanca, I., Lanciu, A., Patrașcu, L., Ceoromila, A., and Borda, D. (2022). Efficacy of two stabilizers in nanoemulsions with whey proteins and thyme essential oil as edible coatings for zucchini. Membranes 12:326. doi: 10.3390/membranes12030326

Chao, C. T., and Krueger, R. R. (2007). The date palm (Phoenix dactylifera L.): overview of biology, uses, and cultivation. HortScience 42, 1077–1082. doi: 10.21273/HORTSCI.42.5.1077

Chelladurai, S. J. S., Murugan, K., Ray, A. P., Upadhyaya, M., Narasimharaj, V., and Gnanasekaran, S. (2021). Optimization of process parameters using response surface methodology: a review. Mater. Today: Proc. 37, 1301–1304. doi: 10.1016/j.matpr.2020.06.466

Chiumarelli, M., and Hubinger, M. D. (2012). Stability, solubility, mechanical and barrier properties of cassava starch—carnauba wax edible coatings to preserve fresh-cut apples. Food Hydrocoll. 28, 59–67. doi: 10.1016/j.foodhyd.2011.12.006

De Bruno, A., Gattuso, A., Ritorto, D., Piscopo, A., and Poiana, M. (2023). Effect of edible coating enriched with natural antioxidant extract and bergamot essential oil on the shelf life of strawberries. Foods 12:488. doi: 10.3390/foods12030488

Eftekhari, A., Salehi, F., Gohari Ardabili, A., and Aghajani, N. (2023). Effects of basil seed and guar gums coatings on sensory attributes and quality of dehydrated orange slices using osmotic-ultrasound method. Int. J. Biol. Macromol. 253:127056. doi: 10.1016/j.ijbiomac.2023.127056

El-Gioushy, S. F., Abdelkader, M. F., Mahmoud, M. H., Abou El Ghit, H. M., Fikry, M., Bahloul, A. M., et al. (2022). The effects of a gum Arabic-based edible coating on guava fruit characteristics during storage. Coatings 12:90. doi: 10.3390/coatings12010090

Embuscado, M. E., and Huber, K. C. (2009). Edible films and coatings for food applications. New York, NY, USA: Springer.

FAO. (2023). Available at: https://www.fao.org/faostat/en/#data/QCL (Accessed November 28, 2023).

Fawole, O. A., Riva, S. C., and Opara, U. L. (2020). Efficacy of edible coatings in alleviating shrivel and maintaining quality of Japanese plum (Prunus salicina Lindl.) during export and shelf life conditions. Agronomy 10:1023. doi: 10.3390/agronomy10071023

Ghafoor, K., Al-Juhaimi, F. Y., Babiker, E. E., Mohamed Ahmed, I. A., Shahzad, S. A., and Alsawmahi, O. N. (2022). Quality attributes of refrigerated Barhi dates coated with edible chitosan containing natural functional ingredients. Foods 11:1584. doi: 10.3390/foods11111584

Hamzah, H. M., Osman, A., Tan, C. P., and Mohamad Ghazali, F. (2013). Carrageenan as an alternative coating for papaya (Carica papaya L. cv. Eksotika). Postharvest Biol. Technol. 75, 142–146. doi: 10.1016/j.postharvbio.2012.08.012

Hunter, R. S., and Harold, R. W. (1987). “The measurement of appearance” in Physics today (New York, NY, USA: John Wiley & Sons).

Islam, A., Phillips, G., Sljivo, A., Snowden, M., and Williams, P. (1997). A review of recent developments on the regulatory, structural and functional aspects of gum Arabic. Food Hydrocoll. 11, 493–505. doi: 10.1016/S0268-005X(97)80048-3

Kawhena, T. G., Opara, U. L., and Fawole, O. A. (2021). Optimization of gum Arabic and starch-based edible coatings with lemongrass oil using response surface methodology for improving postharvest quality of whole “wonderful” pomegranate fruit. Coatings 11:442. doi: 10.3390/coatings11040442

Kawhena, T. G., Tsige, A. A., Opara, U. L., and Fawole, O. A. (2020). Application of gum Arabic and methyl cellulose coatings enriched with thyme oil to maintain quality and extend shelf life of “Acco” pomegranate arils. Plants 9:1690. doi: 10.3390/plants9121690

Kumar, G., and Prabhu, K. N. (2007). Review of non-reactive and reactive wetting of liquids on surfaces. Adv. Colloid Interf. Sci. 133, 61–89. doi: 10.1016/j.cis.2007.04.009

Kumar, V. A., Pravitha, M., Yadav, A., Pandiselvam, R., and Srivastav, P. P. (2023). Influence of ultrasonic application on soybean aqueous extract based composite edible film: characterization and their food application. Food Hydrocoll. 135:108210. doi: 10.1016/j.foodhyd.2022.108210

Mahfoudhi, N., and Hamdi, S. (2015). Use of almond gum and gum Arabic as novel edible coating to delay postharvest ripening and to maintain sweet cherry (Prunus avium) quality during storage. J. Food Process. Preserv. 39, 1499–1508. doi: 10.1111/jfpp.12369

Maqbool, M., Ali, A., Alderson, P. G., Mohamed, M. T. M., Siddiqui, Y., and Zahid, N. (2011). Postharvest application of gum Arabic and essential oils for controlling anthracnose and quality of banana and papaya during cold storage. Postharvest Biol. Technol. 62, 71–76. doi: 10.1016/j.postharvbio.2011.04.002

Meng, X., Zhang, M., and Adhikari, B. (2014). The effects of ultrasound treatment and nano-zinc oxide coating on the physiological activities of fresh-cut kiwifruit. Food Bioprocess Technol. 7, 126–132. doi: 10.1007/s11947-013-1081-0

Mohammed, M., and Alhajhoj, M. (2020). “Importance and applications of ultrasonic technology to improve food quality” in Food processing (London, UK: IntechOpen).

Mohammed, M., and Alqahtani, N. K. (2022). Design and validation of automated sensor-based artificial ripening system combined with ultrasound pretreatment for date fruits. Agronomy 12:2805. doi: 10.3390/agronomy12112805

Mohammed, M., Alqahtani, N., and El-Shafie, H. (2021). Development and evaluation of an ultrasonic humidifier to control humidity in a cold storage room for postharvest quality management of dates. Foods 10:949. doi: 10.3390/foods10050949

Mohammed, M., Munir, M., and Ghazzawy, H. (2023). Design and evaluation of a smart ex vitro acclimatization system for tissue culture plantlets. Agronomy 13:78. doi: 10.3390/agronomy13010078

Mohammed, M., Srinivasagan, R., Alzahrani, A., and Alqahtani, N. K. (2023). Machine-learning-based spectroscopic technique for non-destructive estimation of shelf life and quality of fresh fruits packaged under modified atmospheres. Sustainability 15:12871. doi: 10.3390/su151712871

Muñoz-Labrador, A., Moreno, R., Villamiel, M., and Montilla, A. (2018). Preparation of citrus pectin gels by power ultrasound and its application as an edible coating in strawberries. J. Sci. Food Agric. 98, 4866–4875. doi: 10.1002/jsfa.9018

Murmu, S. B., and Mishra, H. N. (2017). Optimization of the Arabic gum based edible coating formulations with sodium caseinate and tulsi extract for guava. LWT 80, 271–279. doi: 10.1016/j.lwt.2017.02.018

Nandane, A. S., Dave, R. K., and Rao, T. V. R. (2017). Optimization of edible coating formulations for improving postharvest quality and shelf life of pear fruit using response surface methodology. J. Food Sci. Technol. 54, 1–8. doi: 10.1007/s13197-016-2359-9

Ncama, K., Magwaza, L. S., Mditshwa, A., and Tesfay, S. Z. (2018). Plant-based edible coatings for managing postharvest quality of fresh horticultural produce: a review. Food Packag. Shelf Life 16, 157–167. doi: 10.1016/j.fpsl.2018.03.011

Nigmetzyanov, R. I., Sundukov, S. K., Fatyukhin, D. S., Sukhov, A. V., and Simonov, D. S. (2023). Ultrasonic preparation of coating surfaces. E3S Web Conf. 398:01041. doi: 10.1051/e3sconf/202339801041

Özden, Ç., and Bayindirli, L. (2002). Effects of combinational use of controlled atmosphere, cold storage and edible coating applications on shelf life and quality attributes of green peppers. Eur. Food Res. Technol. 214, 320–326. doi: 10.1007/s00217-001-0448-z

Panahirad, S., Dadpour, M., Peighambardoust, S. H., Soltanzadeh, M., Gullón, B., Alirezalu, K., et al. (2021). Applications of carboxymethyl cellulose-and pectin-based active edible coatings in preservation of fruits and vegetables: a review. Trends Food Sci. Technol. 110, 663–673. doi: 10.1016/j.tifs.2021.02.025

Pham, T. T., Nguyen, L. L., Dam, M. S., and Baranyai, L. (2023). Application of edible coating in extension of fruit shelf life: review. AgriEngineering 5, 520–536. doi: 10.3390/agriengineering5010034

Saleem, M. S., Ejaz, S., Mosa, W. F., Ali, S., Sardar, H., Ali, M. M., et al. (2023). Biocomposite coatings delay senescence in stored Diospyros kaki fruits by regulating antioxidant defence mechanism and delaying cell wall degradation. Horticulturae 9:351. doi: 10.3390/horticulturae9030351

Salehi, F. (2023). Recent advances in the ultrasound-assisted osmotic dehydration of agricultural products: a review. Food Biosci. 51:102307. doi: 10.1016/j.fbio.2022.102307

Salehi, F., Goharpour, K., and Razavi Kamran, H. (2023). Optimization of sonication time, edible coating concentration, and osmotic solution °brix for the dehydration process of quince slices using response surface methodology. Food Sci. Nutr. 11, 3959–3975. doi: 10.1002/fsn3.3382

Senturk Parreidt, T., Müller, K., and Schmid, M. (2018). Alginate-based edible films and coatings for food packaging applications. Foods 7:170. doi: 10.3390/foods7100170

Siddiq, M., Aleid, S. M., and Kader, A. A. (2013). Dates: postharvest science, processing technology and health benefits. Hoboken, NJ, USA: John Wiley & Sons.

Singh, V., Aggarwal, P., Kaur, S., and Kaur, N. (2022). Intermediate moisture date (Phoenix dactylifera L.) based dessert with natural sugars: Phytonutritional profile, characterization, sensory quality, and shelf-life studies. J. Food Process. Preserv. 46:e17237. doi: 10.1111/jfpp.17237

Soppelsa, S., Van Hemelrijck, W., Bylemans, D., and Andreotti, C. (2023). Essential oils and chitosan applications to protect apples against postharvest diseases and to extend shelf life. Agronomy 13:822. doi: 10.3390/agronomy13030822

Srinivasagan, R., Mohammed, M., and Alzahrani, A. (2023). TinyML-sensor for shelf life estimation of fresh date fruits. Sensors 23:7081. doi: 10.3390/s23167081

Taher, M. A., Lo’ay, A. A., Gouda, M., Limam, S. A., MFM, A., Osman, S. O., et al. (2022). Impacts of gum Arabic and polyvinylpyrrolidone (PVP) with salicylic acid on peach fruit (Prunus persica) shelf life. Molecules 27:2595. doi: 10.3390/molecules27082595

Tsague Donjio, R., Aghofack Nguemezi, J., Anoumaa, M., Tafre Phounzong, E., Kenfack, J. O., and Fonkou, T. (2023). Using response surface methodology to optimize edible coating formulations to delay ripening and preserve postharvest quality of tomatoes. J. Food Qual. 2023, 1–8. doi: 10.1155/2023/1019310

Keywords: edible coatings, date fruits, food safety, gum Arabic, postharvest technology, quality control, response surface methodology, sustainable food preservation

Citation: Mohammed M, Alqahtani NK and Ali SA (2024) Development, RSM-based modeling, and process optimization of an ultrasonic coating system for extending the storage life of fresh fruits. Front. Sustain. Food Syst. 8:1403164. doi: 10.3389/fsufs.2024.1403164

Received: 26 March 2024; Accepted: 29 May 2024;

Published: 12 June 2024.

Edited by: