- 1School of Safety Science and Emergency Management, Wuhan University of Technology, Wuhan, China

- 2China Research Center for Emergency Management, Wuhan University of Technology, Wuhan, China

- 3Guangxi Vocational and Technical College of Market Quality, Nanning, China

Background: Food safety has always been a major concern for people, and frequent food safety incidents pose a serious threat to people’s health and safety. To identify high-risk patterns in the field of food safety and assist regulatory authorities in scientifically managing food safety risks, this study aims to evaluate food safety risks from multiple dimensions and provide a scientific basis for formulating targeted food safety management measures.

Methods: The risk matrix method, along with the Borda method, is used to evaluate food safety risks. Based on the constructed food safety incident database, the risk matrix method is applied for static risk assessment from seven aspects: food categories, years, provinces, incident entities, causes, pollution sources, and links, and for dynamic risk assessment in different provinces.

Results: The top five food categories in risk ranking are meat and meat products, fruits and vegetables, grain and grain products, other category, and aquatic products. Food safety risks show an increasing trend year by year, with the years 2006, 2012-2015 and 2019 having higher risk rankings. The top three provinces in risk ranking are Hunan, Guangdong, and Shaanxi. The top four entities in risk ranking are restaurants, enterprises, households, and canteens. The top four causes in risk ranking are human intention, human error, mismanagement, and production and social environment. The top four pollution sources in risk ranking include chemical pollution, other pollution, biological pollution, and food additives. The top three links in risk ranking include production and processing link, catering link, and agricultural production link. Across provinces, food safety risks in the years 2012-2015 are generally higher compared to other years, with the highest number of high-risk provinces in 2014.

Implication: The findings of this study have significant implications for food safety management in China. By implementing food safety risk prevention and control countermeasures proposed, China can strengthen its food safety management framework, reduce the incidence of food safety incidents, and safeguard the health and well-being of its population.

1 Introduction

Access to adequate amounts of safe and nutritious food is key to sustaining life and promoting health. Food safety is one of the people’s most concerning livelihood issues. The World Health Organization (WHO) defines food safety as the conditions and actions required during the production, processing, storage, distribution, and preparation of food to guarantee that it is secure, healthful, and suitable for human consumption (Engdaw et al., 2023). A sustainable global future should consider food safety to achieve long-term sustainability. In recent years, food safety issues have occurred frequently, and the crisis of public confidence in food safety has become more and more serious. Foods that contain harmful bacteria, viruses, insects or chemicals can cause more than 200 illnesses ranging from diarrhea to cancer. According to WHO, foodborne hazards result in about 600 million cases of illness, 420,000 deaths, and 33 million disabilities (Yenealem et al., 2020). In the world, food safety incidents occur frequently, such as the fipronil incident in 2017 in the Netherlands (Focker et al., 2021), the food poisoning incident on June 17, 2020, in Korean kindergartens, the food poisoning incident in 2023 in Japan’s Ishikawa prefecture, and the food poisoning incident on September 21, 2023, in China’s Ningjin.

Food safety risk refers to the probability of a detriment to human health being introduced over the course of food production, processing, storage, and consumption due to toxic or harmful substances, or technological or management factors during business operations (Gao et al., 2023). No matter what link of the food supply chain, what part of the regulatory agency, what kind of hazard factors, what kind of food, will have different impacts on food safety, resulting in certain risks. All of the above factors constitute a diversity of food safety risks. To protect consumer health, promote fair trade in food, and coordinate food standards globally, the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) jointly established the Codex Alimentarius Commission (CAC) in 1963. In the late 1980s, the Codex Alimentarius Commission proposed to conduct food safety risk assessment, which is used to identify hazards that may affect human health and manage risks in the food decision-making process in advance, providing scientific data support for making and improving food quality supervision decisions. China formally joined the Codex Alimentarius Commission in 1984 and established the China Codex Committee in 1986. In addressing food safety issues, China implemented the agricultural product coding system nationwide in 2007 to achieve traceability of agricultural product quality and safety. In 2009, China enacted the “Food Safety Law” and established the National Food Safety Risk Assessment Expert Committee. Since the implementation of the “Food Safety Law,” China has formulated and promulgated a large number of national food safety standards, taking Codex Alimentarius standards as a reference, utilizing risk assessment as a scientific basis, and considering the healthy development of the food industry. The framework of the food safety standard system established aligns closely with the standards of the Codex Alimentarius Commission. Currently, China is actively involved in the development of various international Codex standards, enhancing its international influence, and facilitating the import and export trade of Chinese food products. Food safety risk assessment can ensure food safety, assess food safety risks, and prevent the recurrence of food safety incidents. Food safety risk assessment is a scientific assessment process to identify hazards in the food supply chain and estimate potential health implications of human exposure to such hazards (Talari et al., 2022). According to the Codex Alimentarius, the term hazard is defined as a biological, chemical or physical agent in food or the condition of food with the potential to cause an adverse health effect (van de Brug et al., 2014). Food safety risk assessment is usually composed of four logically connected sections: hazard identification, hazard characterization, exposure assessment, and risk characterization, and the outputs of the risk assessment can then be used to support the development of risk mitigation strategies (Mahoney, 2022).

Some researchers used statistical analysis methods to describe the characteristics of food safety problems and determine the key points of food safety prevention and control. For example, Pigłowski and Niewczas-Dobrowolska (2023) used data extracted from the Rapid Alert System for Food and Feed (RASFF) notifications’ 1998–2020 public information database to analyze plant-origin products with respect to hazard, year, product, notifying country, origin country, notification type, notification basis, distribution status, and action taken. Park et al. (2017) used media reports to analyze food safety incidents in South Korea that occurred between January 1998 and March 2016 to determine the type of food, the type of hazard, at what link a breakdown in food safety is likely to occur. However, limited by the quantity and reliability of data collection, as well as the lack of theoretical and logical persuasiveness, it is difficult to measure the overall level of food safety risk, which hinders regulatory authorities from allocating regulatory resources based on risk ranking. Therefore, a large number of studies and tests have been carried out on food safety risk assessment methods to gradually develop mature food safety risk assessment methods, mainly including the expert scoring method (Racicot et al., 2019), the analytic hierarchy process (AHP) (Hassna et al., 2023), the catastrophe progression method (Yin et al., 2022), the fault tree analysis (Song et al., 2018), the Bayesian Network (BN) (Marvin et al., 2016), the support vector machine (Zhang, 2020), and the fuzzy method (Davidson et al., 2006).

In order to solve the problem that the traditional single risk assessment model cannot comprehensively assess food safety risks, the food safety risk assessment model composed of multiple methods is proposed to improve the comprehensiveness, accuracy and effectiveness of food safety risk assessment (Han et al., 2023). Ma et al. (2020) proposed an improved analytic hierarchy process integrating quality control analysis method. In terms of the high complexity and temporal characteristics of food detection data, Han et al. (2019) proposed a novel hidden Markov model (HMM) based on gray relational analysis (GRA) (GRA-HMM) to dynamically assess the food quality and safety risk, and used the fuzzy matrix to prove the accuracy and reliability of the risk assessment model. Considering that the sample size of most food data is very small, the training sample data of data-driven risk prediction model are insufficient, the prediction accuracy is not high, and it cannot provide effective prevention and control measures, Geng et al. (2022) proposed a food safety risk prediction model based on the improved random forest prediction method and Monte Carlo algorithm. Later, Geng et al. (2023) successively proposed an improved adaptive particle swarm optimization algorithm (IAPSO) for optimizing the long short-term memory (LSTM) neural network (IAPSO-LSTM).

In addition, by applying the concept of risk ranking, different risks can be compared [EFSA BIOHAZ Panel (EFSA Panel on Biological Hazards), 2015]. Risk ranking has been applied to food safety monitoring programs and has shown to increase the efficiency of monitoring and to decrease inspection costs, both in practice and from theoretical calculations (Van der Fels-Klerx et al., 2018). Eygue et al. (2020) developed a structured and transparent framework to evaluate and rank food safety risks associated with emerging dietary practices in France. Wu and Hsiao (2021) used a failure mode and effect analysis (FMEA) approach to evaluate risk in food cold chains. Puertas et al. (2020) proposed the use of three multicriteria decision-making (MCDM) methods—Technique for Order Preference by Similarity to the Ideal Solution (TOPSIS), Elimination et Choix Traduisant la Realité (ELECTRE), and cross-efficiency (CE)—to establish a ranking of non-European Union countries supplying cereals to the European Union in 2012, 2014, and 2016. The risk matrix can be used for ranking and prioritizing risks, in order to aid in determining the risk handling strategy (mitigate, watch, research, accept) and program resources decision priorities (Lengyel et al., 2023). The risk matrix provides a clear risk rating framework by mapping the severity and probability of the occurrence of risk factors to corresponding risk ratings (Zheng et al., 2023). There is no single best method for risk ranking. The risk matrix is widely recognized for its ease of implementation and has been widely applied for risk prioritization in various fields, such as healthcare (Shang et al., 2023), engineering (Spasenic et al., 2023), and chemical (Ibrahim et al., 2022). In the risk matrix, multiple risk factors of the same risk level may not be of the same importance. Therefore, the importance of multiple risk factors is ranked to determine the risk magnitude of different risk factors within the same risk level. The Borda method can enhance the promotion and popularization of the risk matrix approach (Ni et al., 2010). This research combines the risk matrix method with the Borda method to conduct static risk assessment in China from seven aspects, and conduct dynamic risk assessment in different provinces. The objective is to identify the high-risk patterns of food safety, propose countermeasures for preventing and controlling food safety risks in China, and assist the regulatory authorities in making informed decisions regarding the scientific management of food safety risks. The remainder organization of this paper is shown as follows. Section 2 introduces the definition of food safety incidents, the theory of equivalent fatalities, risk matrix method and Borda method. Section 3 presents the construction of the food safety incident database. Section 4 carries out static risk assessment on food safety risks from seven aspects: food categories, years, provinces, incident entities, causes, pollution sources and links, and carries out dynamic risk assessment on food safety risks in different provinces. Section 5 presents the food safety risk prevention and control countermeasures.

2 Theory and method

2.1 Definition of food safety incidents

Food safety is not only a national or regional issue but a global one. A lack of clarity regarding the definition of food safety may lead to fraud-related incidents with public and environmental health related outcomes being subsumed into the general analysis of food safety incidents (Kendall et al., 2019). Therefore, it is crucial to have an accurate definition of food safety incidents. Currently, the definitions of food safety incidents lack a unified opinion, mainly based on the definition of food safety. Motarjemi and Wallace (2014) define food safety incidents as an episode resulting from a deviation from the standard practice or a norm, leading to a substandard product, dissatisfaction of customers/consumers, or regulatory authorities (e.g., due to injury, perceived food safety problems, non-compliance with regulatory norms, or sensory requirements). Barnett et al. (2016) believe that a food safety incident is different from food fraud, which is an unintentional act with unintentional harm. A food safety incident occurs when the safety of the food has been compromised, and actions are required to protect consumers, including food contamination, food adulteration (Soon et al., 2020). However, not all food safety incidents are caused by food fraud or profit pursue, more food safety incidents are caused by unintentional errors or simply ignorance.

According to the definition of food safety incidents, a large number of food-news events reported by the media in recent years are not related to “safety,” many of which do not have health risks and do not belong to the food safety incidents that are harmful to human health or may be harmful. Therefore, this paper defines food safety incidents as conditions where food deviates from standard practice, contains physical, chemical, biological, food additives, or other harmful substances, flows to consumers, and has caused or may cause acute, subacute or chronic harm to human health. Based on a large number of media reports, this paper selects the data of food safety incidents that meet the definition of food safety incidents to carry out research.

2.2 Theory of equivalent fatalities

Currently, research on equivalent fatalities mainly focuses on traffic accidents and work safety accidents. Two common approaches exist: one is based on the comprehensive cost estimates of traffic accidents by the National Safety Council (Liu, 2017), and the other is based on the International Maritime Organization Formal Safety Assessment (Pallis, 2017). There have been no studies on equivalent fatalities of food safety incidents or food poisoning. In China’s “Food Safety Accident Classification Standards and Response Regulations,” a food safety incident with more than 100 poisoning cases and deaths or more than 10 deaths is classified as a Class II (major food safety accident), meaning that 10 poisonings are roughly equivalent to 1 death. In view of the above, the equivalent fatality of food safety incidents is measured by collecting the number of deaths and cases of poisoning (Equation 1). The equation used to determine the equivalent fatality is as follows:

Where denotes the number of equivalent fatalities; denotes the number of fatalities; denotes the number of people poisoned.

2.3 Risk matrix method

The risk matrix method was first proposed by the US Air Force Electronic Systems Center in April 1995 to assess risk over the life cycle of an acquisition project. The risk of a hazard is determined by the probability that it will result in an undesired event and the consequences that such an event would have.

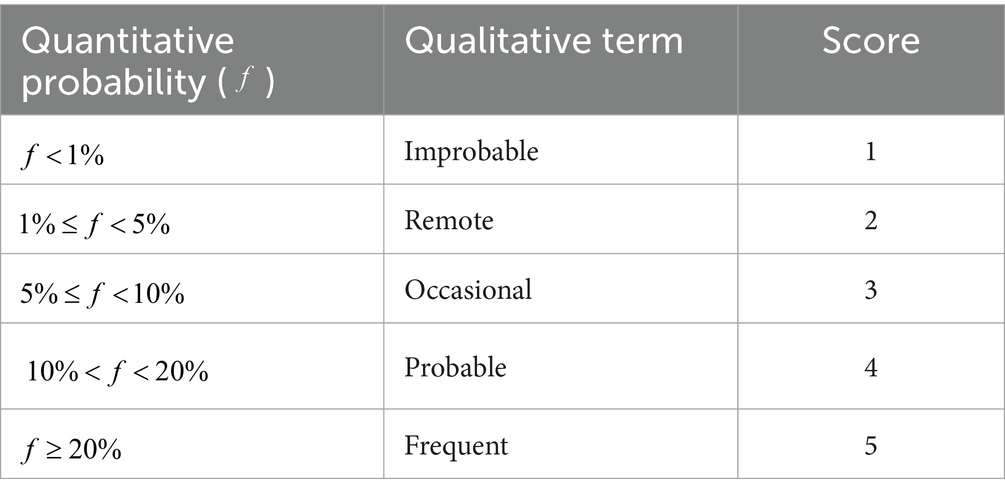

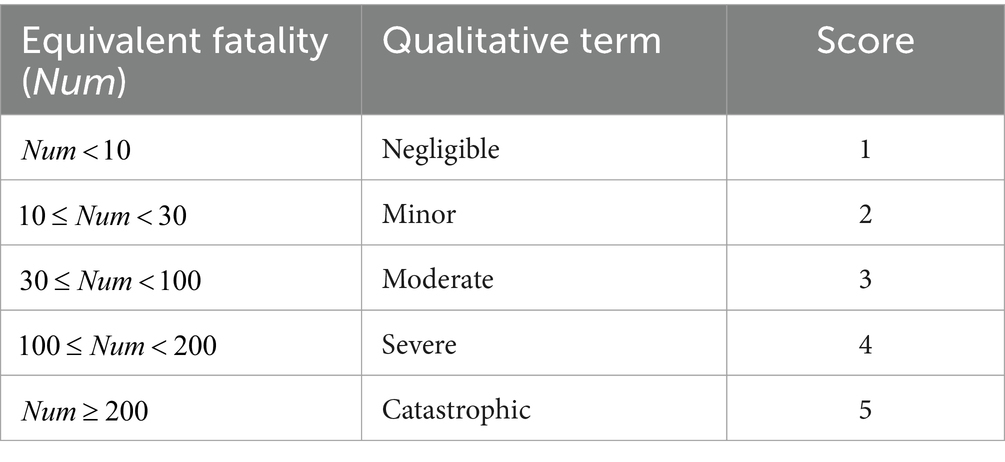

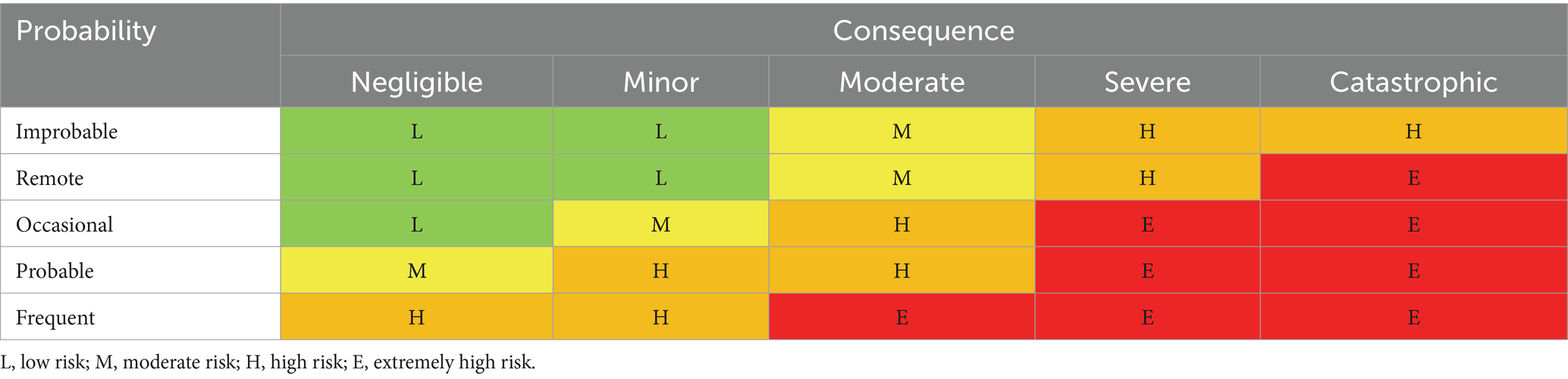

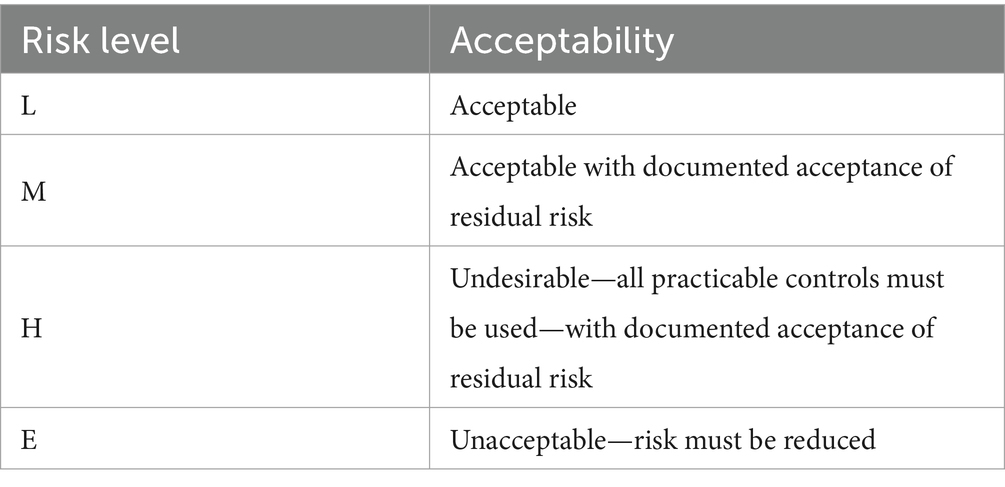

The two variables, probability and consequence, may be classified by qualitative terms or quantitative values (Donohue, 2001). However, there is no standardized way to define these categories (Kim et al., 2023). Accordingly, the occurrence frequency of a certain food safety risk is taken as the probability and divided into five different levels in Table 1. The equivalent fatalities caused by a certain food safety risk is taken as the measuring standard of consequences and divided into five different levels in Table 2. The risk matrix is constructed by combining the classification of probabilities and consequences, as shown in Table 3, and the corresponding risk acceptability criteria is shown in Table 4.

2.4 Borda method

Borda method was used to rank the food safety risks. The Borda point is calculated based on the score of probability and the score of consequence (Equation 2). The equation used to determine the Borda point is as follows:

Where denotes the Borda point for the i-th risk, the higher the Borda point, the higher the food safety risk; denotes the i-th risk. denotes the evaluation criteria (probability, consequence); denotes the number of (generally =2); denotes the number of risk to be evaluated; denotes the number of risk with a higher level than risk i under evaluation criterion .

3 Construction of food safety incident database

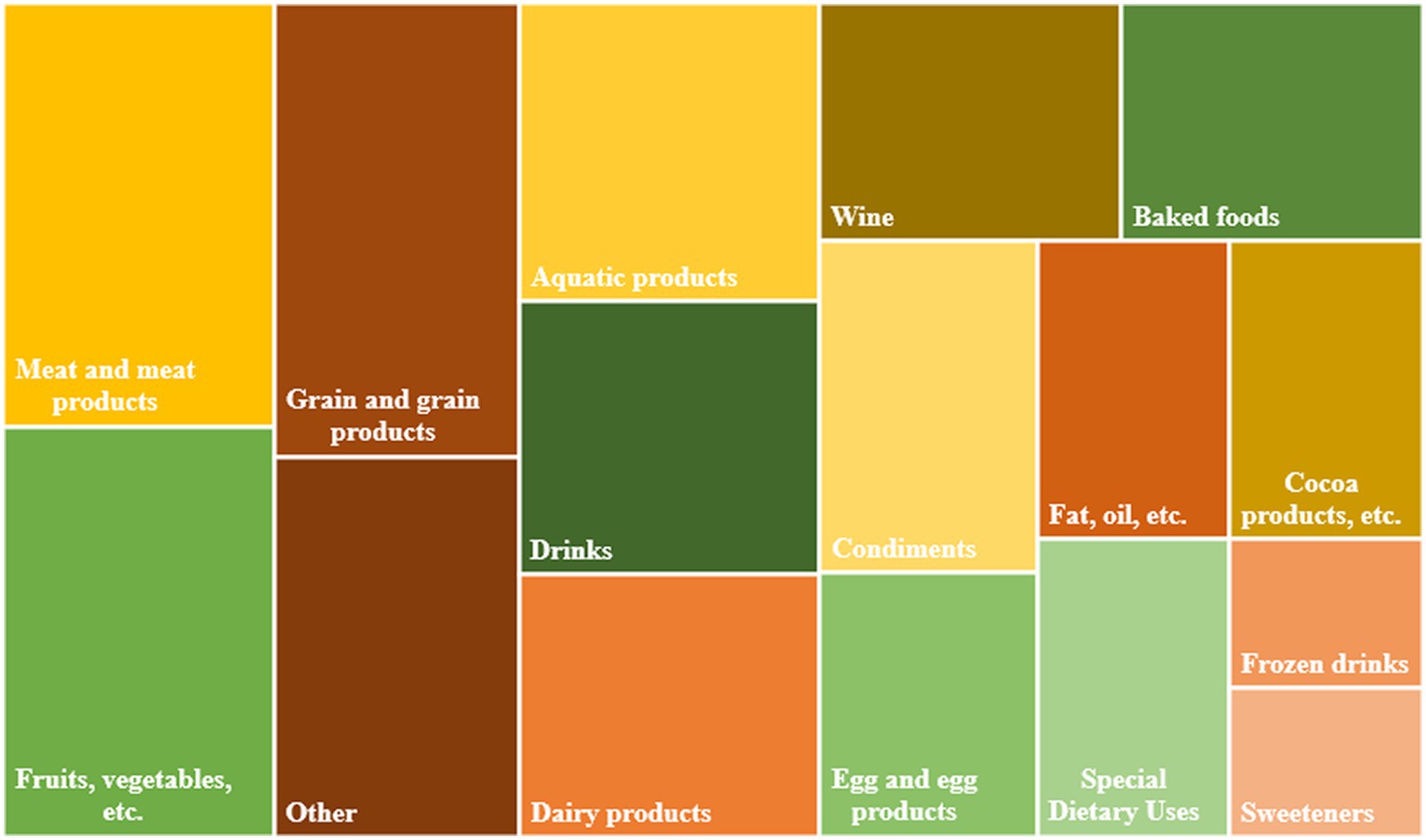

In order to avoid including news events that do not belong to food safety accidents into food safety risk assessment (Surareungchai et al., 2022), based on a certain search strategy, the descendant collector was used to automatically collect food news events from 2003 to 2019. Based on the definition of food safety incidents, the collected news events were manually screened, and the missing values and duplicate values were deleted by data cleaning to build a text corpus of food safety incidents. According to the connotation and characteristics of food safety incidents, the crisp number was used as the attribute value of the indicator to construct food safety incident indicator system, as shown in Table 5. In this system, food categories are classified into 16 major categories according to China’s “National Food Safety Standard for the Use of Food Additives (GB 2760–2014).” The incident entities are classified into 25 types based on China’s food safety operation and management regulations, combined with the constructed text corpus. Based on accident causation theory and the constructed text corpus, the causes are categorized into 8 types. Furthermore, based on the impact modes and characteristics of hazardous substances on food safety, combined with the constructed text corpus, pollution sources are divided into 8 types. Finally, links are classified into 13 types based on the divisions of the food supply chain, combined with the constructed text corpus. A food safety incident database was further constructed, with a total of 5,354 effective food safety incident cases. Because it is tedious to list the attribute values of all food safety incident cases, Table 6 presents only part of the food safety incident database. The food categories and regions of the incidents are completely random, and there is no emphasis on one aspect. Therefore, the collected incidents can basically reflect the food safety situation at that time.

4 Food safety risk assessment

Based on the food safety incident database, the risk matrix method combined with Borda method was used to conduct static risk assessment from seven aspects and dynamic risk assessment in different provinces. The assessment results of risk matrix method are shown in Annex 1.

4.1 Food safety risk assessment of food categories

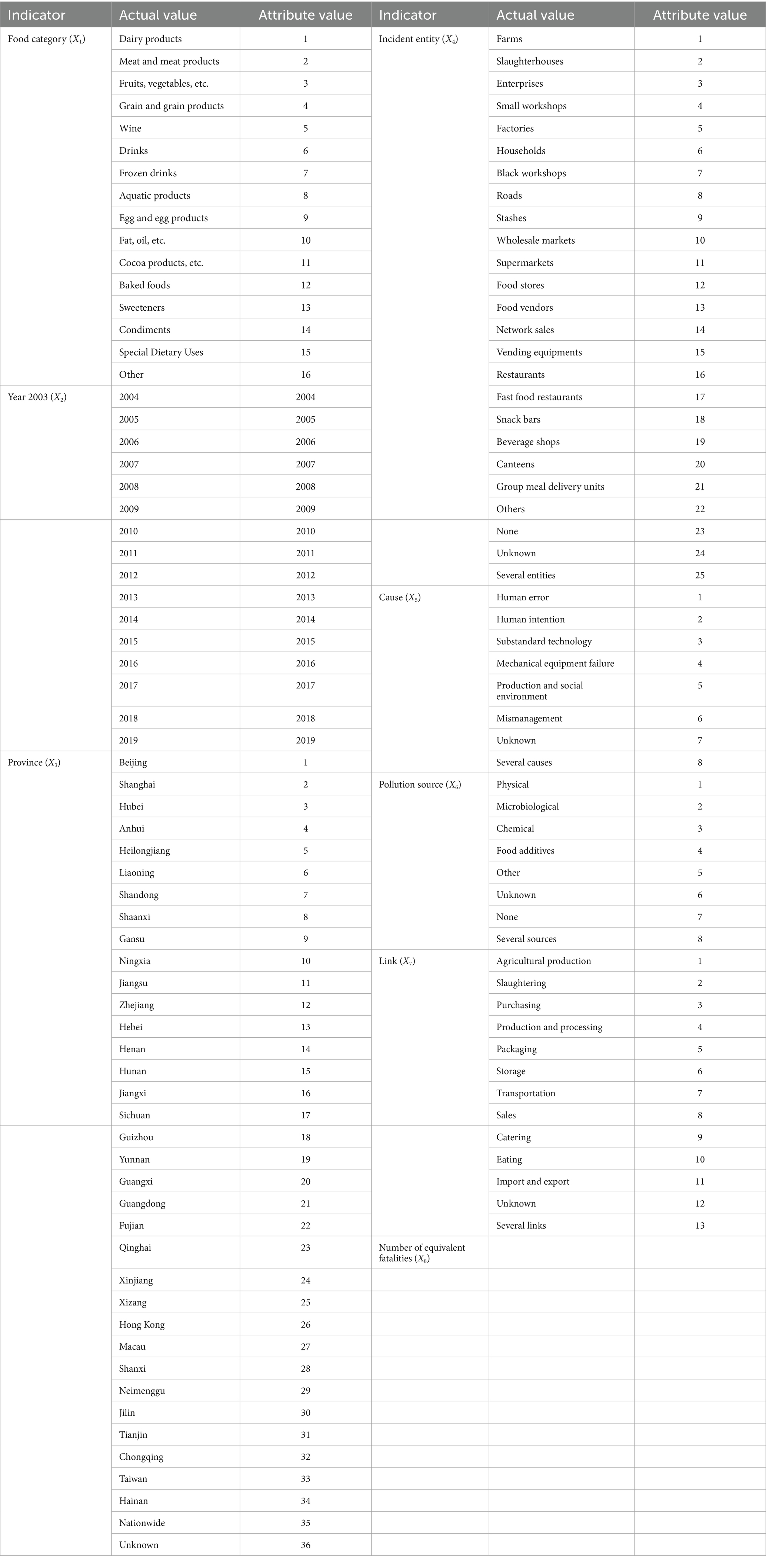

Borda points and risk levels of different food categories were calculated, and the food safety risk matrix was constructed according to Borda points, as shown in Figure 1. The size of color blocks represents the Borda point of the food category.

Meat and meat products have the highest Borda points and the highest food safety risks, followed by fruits and vegetables, grain and grain products, other type and aquatic products. The risk level of these five food categories is extremely high risk (E), and risk prevention and control measures need to be taken immediately. The risk level of drinks and dairy products is high risk (H), and food safety supervision departments need to pay attention to prevention and control.

4.2 Food safety risk assessment of years

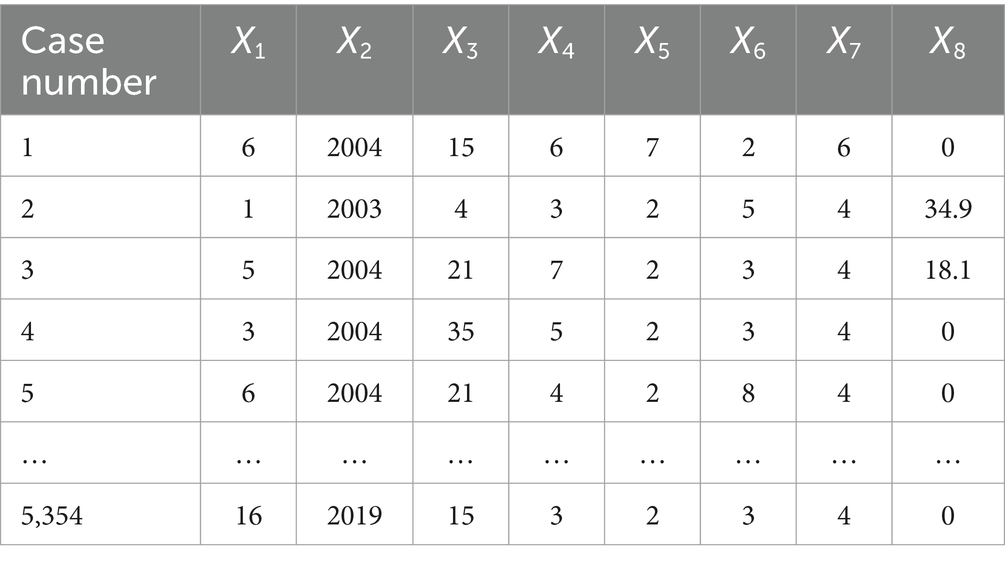

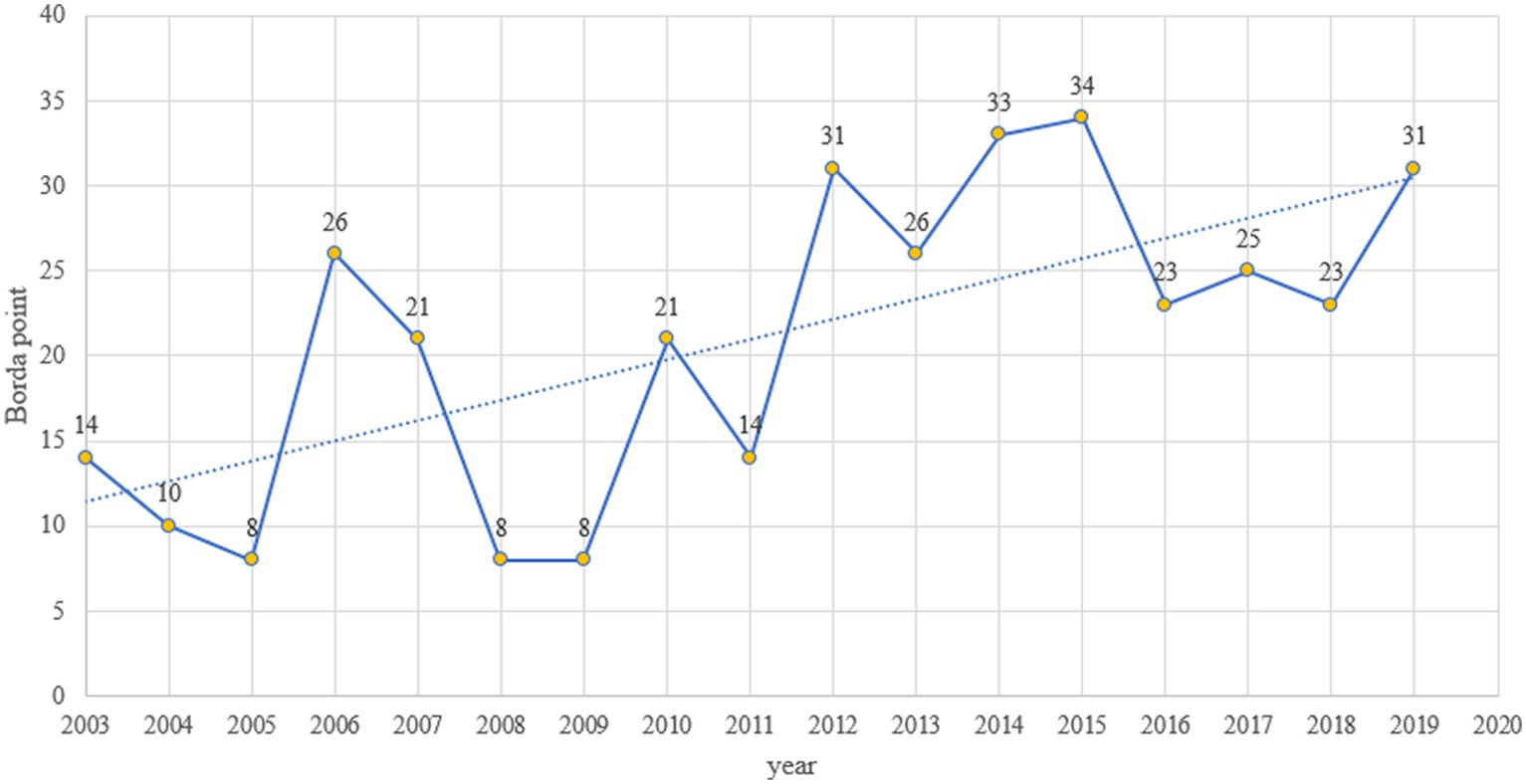

Borda points and risk levels of different years were calculated, and the line chart of food safety risks over time was drawn according to Borda points, as shown in Figure 2.

Food safety risks show an increasing trend year by year. Among them, 2015 has the highest Borda point and the highest food safety risk, followed by 2014, 2012, 2019, 2006, and 2013. The risk level of these five years is extremely high risk (E), and risk prevention and control measures need to be taken immediately. The risk level of 2007, 2010, 2016, 2017 and 2018 is high risk (H), and food safety supervision departments need to pay attention to prevention and control.

4.3 Food safety risk assessment of provinces

Borda points and risk levels of different provinces were calculated, and the food safety risk matrix was constructed according to Borda points, as shown in Figure 3. The size of color blocks represents the Borda point of the province.

Hunan and Guangdong have the highest Borda points and the highest food safety risks, followed by Shaanxi. The risk level of these three provinces is extremely high risk (E), and risk prevention and control measures need to be taken immediately. The risk level of Shandong, Anhui, Jiangsu, Zhejiang, Sichuan, Yunnan, Guangxi, Fujian and Taiwan is high risk (H), and food safety supervision departments need to pay attention to prevention and control.

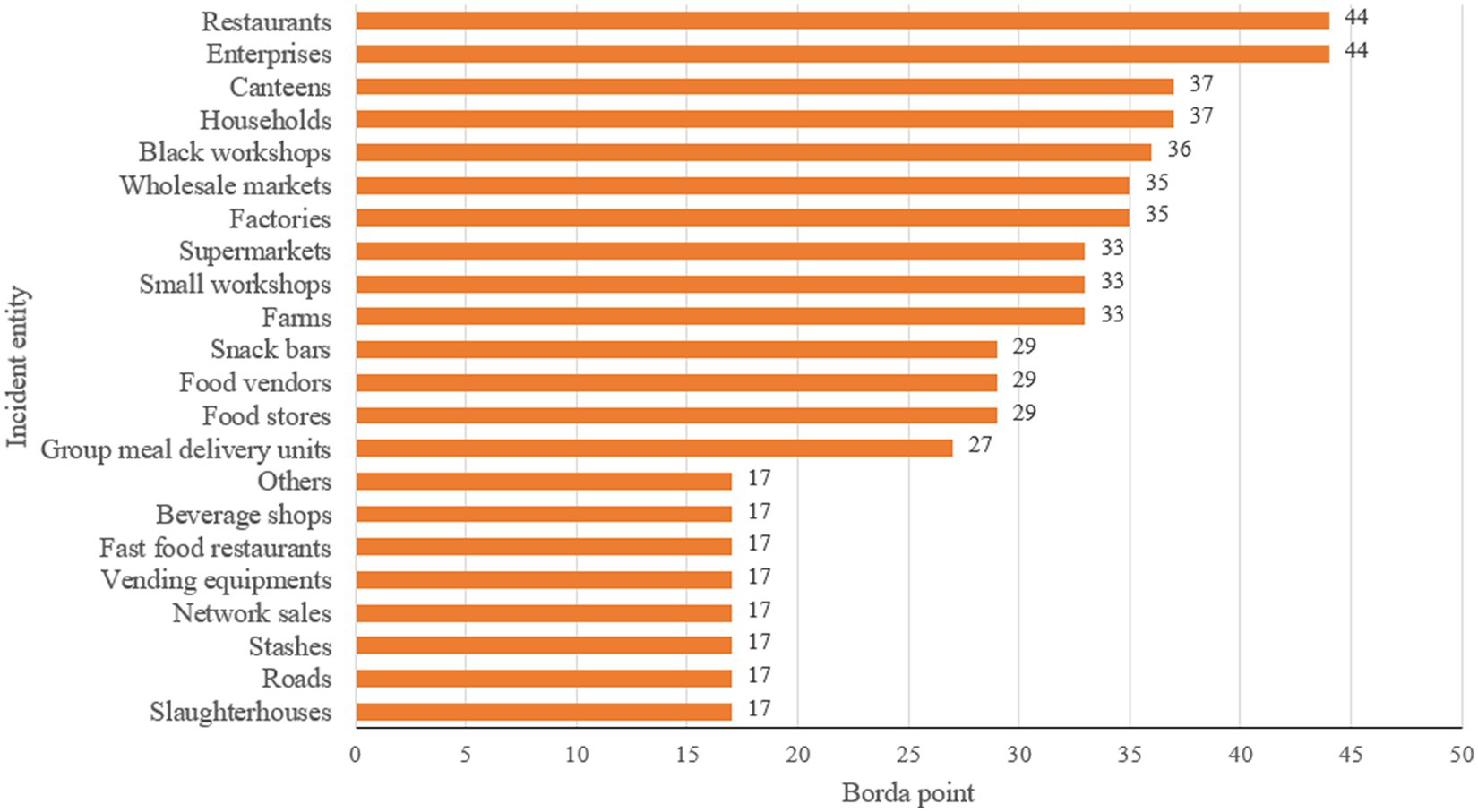

4.4 Food safety risk assessment of incident entities

Borda points and risk levels of different incident entities were calculated, and the bar chart of incident entities was drawn according to Borda points, as shown in Figure 4.

Restaurants and enterprises have the highest Borda points and the highest food safety risks, followed by households and canteens. The risk level of these four incident entities is extremely high risk (E), and risk prevention and control measures need to be taken immediately. The risk level of farms, factories, black workshops, wholesale markets and group meal delivery units is high risk (H), and food safety supervision departments need to pay attention to prevention and control.

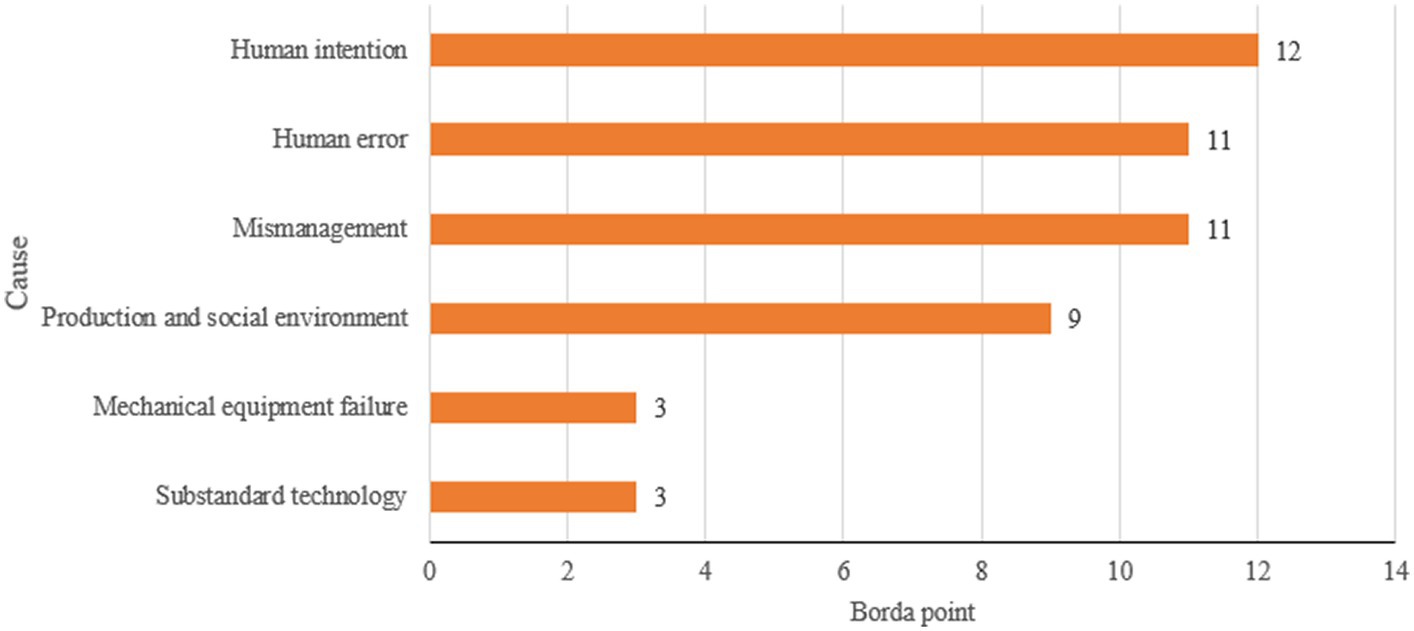

4.5 Food safety risk assessment of causes

Borda points and risk levels of different causes were calculated, and the bar chart of causes was drawn according to Borda points, as shown in Figure 5.

Human intention has the highest Borda point and the highest food safety risk, followed by human error, mismanagement, and production and social environment. The risk level of these four causes is extremely high risk (E), and risk prevention and control measures need to be taken immediately.

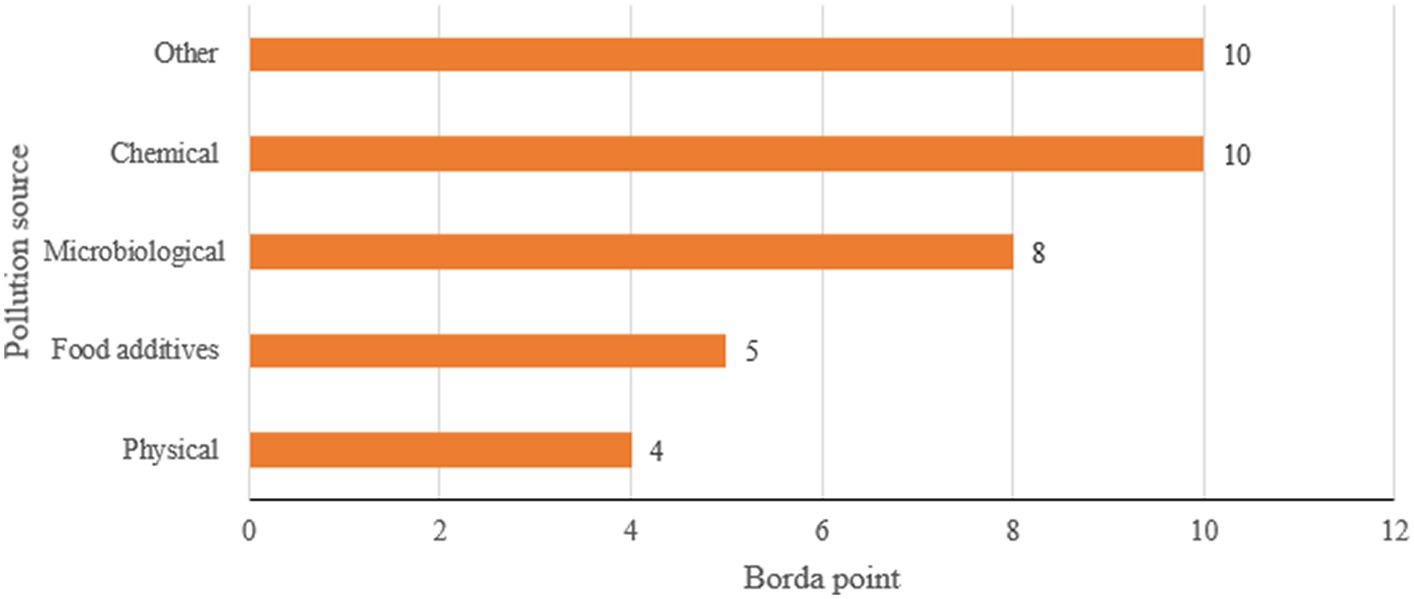

4.6 Food safety risk assessment of pollution sources

Borda points and risk levels of different pollution sources were calculated, and the bar chart of pollution sources was drawn according to Borda points, as shown in Figure 6.

Chemical pollution and other pollution have the highest Borda points and the highest food safety risks, followed by microbiological pollution and food additives. The risk level of these four pollution sources is extremely high risk (E), and risk prevention and control measures need to be taken immediately. The risk level of physical pollution is high risk (H), and food safety supervision departments need to pay attention to prevention and control.

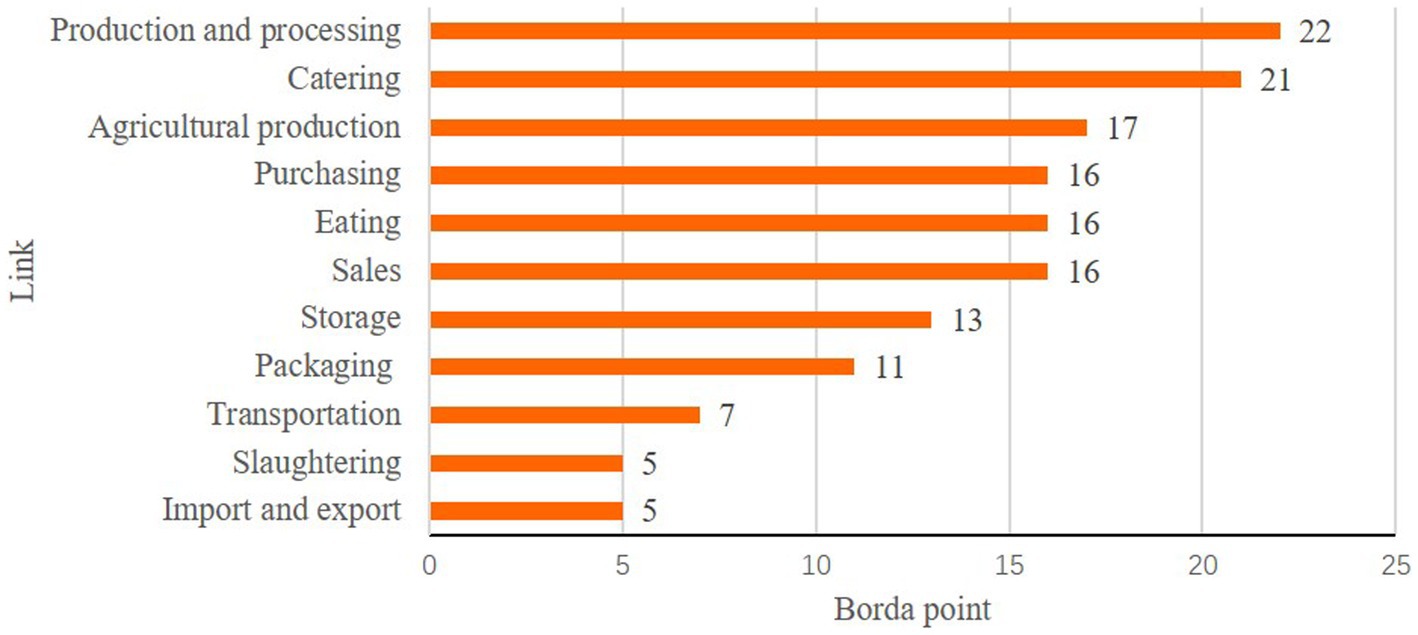

4.7 Food safety risk assessment of links

Borda points and risk levels of different links were calculated, and the bar chart of links was drawn according to Borda points, as shown in Figure 7.

Production and processing link has the highest Borda point and the highest food safety risk, followed by catering link, and agricultural production link. The risk level of these three links is extremely high risk (E), and risk prevention and control measures need to be taken immediately. The risk level of purchasing link, sales link and eating link is high risk (H), and food safety supervision departments need to pay attention to prevention and control.

4.8 Dynamic risk assessment of food safety

A dynamic food safety risk assessment was conducted for 34 provinces and autonomous regions in China from 2003 to 2019 to analyze the changes of food safety risks in different provinces over time. The dynamic risk matrix of food safety is constructed by combining the risk matrix with Borda method, as shown in Figure 8.

The food safety risks in all provinces and autonomous regions were generally higher from 2012 to 2015 than in other years, and the number of provinces and autonomous regions with high risks in 2014 was the most, indicating a challenging situation for national food safety during this period. With the revision of the Food Safety Law in 2015, the overall national food safety risks have eased, indicating that the food safety law is an effective means to control food safety risks.

The SPSS software was used to conduct one-way ANOVA for the classification of all probabilities and consequences in this chapter, and the significance was all less than 0.05, reaching the significance level, indicating that the classification was effective.

5 Food safety risk prevention and control countermeasures

Through the assessment of food safety risks, the key points of food safety risk prevention and control are obtained, and targeted risk prevention and control countermeasures are put forward.

1. Risk prevention and control countermeasures should be taken immediately to improve the safety hazards investigation and risk identification in meat and meat products, fruits and vegetables, grain and grain products, other category and aquatic products. Additionally, supervision and punishment for food safety violations should be increased. Simultaneously, supervision departments should also focus on preventing and controlling risks associated with drinks and dairy products. According to the “one strategy for one category of food” principle, lists of risks, measures and responsibilities for key food categories should be established, and the formulation of norms and standards for these key foods should be improved.

2. Food safety risks show an increasing trend year by year. The prevention and control management of emerging food safety risks should be strengthened, the formulation of food rapid testing equipment, reagents and other related standards should be improved, and the development of food rapid inspection product certification and food rapid inspection methods should be encouraged. New resource foods should be used according to standard specifications, and the supervision mechanism for recurring food safety risks should be strengthened.

3. Hunan, Guangdong and Shaanxi provinces should immediately take risk prevention and control countermeasures according to local conditions; Food safety supervision departments in Shandong, Anhui, Jiangsu, Zhejiang, Sichuan, Yunnan, Guangxi, Fujian and Taiwan provinces should pay attention to risk prevention and control. Financial support policies should be adopted to strengthen food safety guarantees, enhance the manpower, materials, and equipment of food safety regulatory departments. Various regulatory measures and advanced technologies, such as big data and artificial intelligence, should be used to improve the efficiency of food safety supervision. Lists of risks, measures, and responsibilities for key regions should be established to strengthen food safety risk prevention.

4. The sampling inspection and safety hazard investigation of restaurants, enterprises and other food production and supply units should be strengthened, the business qualification of households and other places should be strictly checked, the publicity of residents’ food safety awareness should be strengthened, and the sampling inspection of the collective unit canteens and the health supervision of cooking operations should be strengthened; Food safety supervision departments should pay attention to the prevention and control of risks of farms, factories, black workshops, wholesale markets, group meal delivery units and other places. The risk list for key food producers and operators should be established and the evaluation and assessment of key food producers and operators should be strengthened. In addition, food producers and operators should cultivate a sense of social responsibility, optimize production management and control measures to ensure food safety.

5. The punishment of intentional violations of food safety behavior should be strengthened, food safety training for food practitioners should be regularly carried out, enterprises and other management units should be urged to seriously implement the responsibility system of the main person in charge, the health protection of food production and processing environment should be strengthened, and the basic health environment of food from farms should be ensured. Public should be educated to have correct awareness of food safety, and encouraged to actively participate in food safety supervision, to raise the standard for food quality, thus promoting the development of the entire food industry.

6. Control over the use of chemical substances in food should be strengthened, rapid detection technology for chemical hazards should be improved, the promotion of awareness about harmful food should be enhanced, and the risk of other pollution should be reduced. The risk of biological pollution should be strictly controlled in accordance with the requirements of production and processing, transportation, and storage environmental. Sales channels and regulations on the use of food additives should be strictly controlled. At the same time, attention should be paid to regulating the circulation of genetically modified and radioactive foods, and food processing and production should be strictly implemented in accordance with the management regulations.

7. The risks of production and processing link, catering link, agricultural production link should be strengthened, and risk prevention and control countermeasures should be taken immediately in view of weak points of risk prevention and control; At the same time, food safety supervision departments should pay attention to the prevention and control of risks of raw material procurement link, sales link, and eating link. Due to the complexity of the food supply chain, it is necessary to ensure the seamless connection between the supervision of food production and processing, distribution, and consumption. It is important to strictly fulfill the responsibilities of food safety supervision to detect food safety issues at an early stage and prevent any adverse impacts.

8. At the national level, the revision and improvement of the food safety law should be strengthened, and targeted prevention and control management procedures should be formulated according to the development of food science and technology and risk characteristics; At the local level, the food safety management regulations in various provinces and autonomous regions should be standardized to prevent unnecessary risks caused by food circulation.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

HY: Data curation, Methodology, Writing – original draft, Writing – review & editing. YS: Funding acquisition, Supervision, Writing – review & editing. WL: Conceptualization, Methodology, Supervision, Writing – original draft. DL: Formal analysis, Supervision, Writing – review & editing. HH: Conceptualization, Supervision, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research was supported by the National Social Science Foundation of China [grant number 15ZDB168], Science and Technology Plan Project of Guangxi Zhuang Autonomous Region Administration for Market Regulation [grant number GXSJKJ2023-22], and the Fundamental Research Funds for the Central Universities of China [grant number 2019-YB-037].

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2024.1351826/full#supplementary-material

References

Barnett, J., Begen, F., Howes, S., Regan, A., McConnon, A., Marcu, A., et al. (2016). Consumers' confidence, reflections and response strategies following the horsemeat incident[J]. Food Control 59, 721–730. doi: 10.1016/j.foodcont.2015.06.021

Davidson, V. J., Ryks, J., and Fazil, A. (2006). Fuzzy risk assessment tool for microbial hazards in food systems. Fuzzy Sets Syst. 157, 1201–1210. doi: 10.1016/j.fss.2005.12.018

Donohue, A. M. (2001). The design of hazard risk assessment matrices for ranking occupational health risks and their application in mining and minerals processing. Occup. Med. 51, 118–123. doi: 10.1093/occmed/51.2.118

EFSA BIOHAZ Panel (EFSA Panel on Biological Hazards) (2015). Scientific opinion on the development of a risk ranking toolbox for the EFSA BIOHAZ panel[J]. EFSA J. 13:3939. doi: 10.2903/j.efsa.2015.3939

Engdaw, G. T., Tesfaye, A. H., and Worede, E. A. (2023). Food handlers' practices and associated factors in public food establishments in Gondar, Ethiopia 2021/2022. Heliyon. 9:e15043. doi: 10.1016/j.heliyon.2023.e15043

Eygue, M., Richard-Forget, F., Cappelier, J. M., Pinson-Gadais, L., and Membré, J. M. (2020). Development of a risk-ranking framework to evaluate simultaneously biological and chemical hazards related to food safety: application to emerging dietary practices in France. Food Control 115:107279. doi: 10.1016/j.foodcont.2020.107279

Focker, M., van den Borne, B. H. P., Fischer, M., Schuh, E., Mader, A., Andersson, M. G., et al. (2021). Interactions between risk assessors and risk managers during three major food incidents in Europe. J. Food Sci. 86, 3611–3627. doi: 10.1111/1750-3841.15824

Gao, H. Y., Dai, X. T., Wu, L. H., Zhang, J. X., and Hu, W. Y. (2023). Food safety risk behavior and social co-governance in the food supply chain. Food Control 152:109832. doi: 10.1016/j.foodcont.2023.109832

Geng, Z. Q., Duan, X. Y., Li, J. T., Chu, C., and Han, Y. M. (2022). Risk prediction model for food safety based on improved random forest integrating virtual sample. Eng. Appl. Artif. Intell. 116:105352. doi: 10.1016/j.engappai.2022.105352

Geng, Z. Q., Wang, X. T., Jiang, Y. G., Han, Y. M., Ma, B., and Chu, C. (2023). Novel IAPSO-LSTM neural network for risk analysis and early warning of food safety. Expert Syst. Appl. 230:120747. doi: 10.1016/j.eswa.2023.120747

Han, Y. M., Cui, S. Y., Geng, Z. Q., Chu, C., Chen, K., and Wang, Y. J. (2019). Food quality and safety risk assessment using a novel HMM method based on GRA. Food Control 105, 180–189. doi: 10.1016/j.foodcont.2019.05.039

Han, Y. M., Liu, J. X., Li, J. T., Jiang, Z. Y., Ma, B., Chu, C., et al. (2023). Novel risk assessment model of food quality and safety considering physical-chemical and pollutant indexes based on coefficient of variance integrating entropy weight. Sci. Total Environ. 877:162730. doi: 10.1016/j.scitotenv.2023.162730

Hassna, B., Namany, S., Alherbawi, M., Elomri, A., and Al-Ansari, T. (2023). Decision making approaches to improve resilience in food supply chains and enhance food security against climate change risks. Comp. Aid. Chem. Eng. 52, 89–94. doi: 10.1016/B978-0-443-15274-0.50015-9

Ibrahim, N. A., Alwi, S. R. W., and Kidam, K. (2022). Risk matrix approach of extreme temperature and precipitation for renewable energy systems in Malaysia. Energy 254:124471. doi: 10.1016/j.energy.2022.124471

Kendall, H., Clark, B., Rhymer, C., Kuznesof, S., Hajslova, J., Tomaniova, M., et al. (2019). A systematic review of consumer perceptions of food fraud and authenticity: a European perspective[J]. Trends Food Sci. Technol. 94, 79–90. doi: 10.1016/j.tifs.2019.10.005

Kim, D. J., Sur, J. M., and Cho, H. U. (2023). A long term expected risk estimation of maritime accidents through Markov chain approach and probabilistic risk matrix. Asian J. Ship. Logist. 39, 1–12. doi: 10.1016/j.ajsl.2023.04.002

Lengyel, D. M., Mazzuchi, T. A., and Vesely, W. E. (2023). Establishing risk matrix standard criteria for use in the continuous risk management process. J. Space Saf. Eng. 10, 276–283. doi: 10.1016/j.jsse.2023.05.001

Liu, Y. Z. (2017). Safer or cheaper? Traffic safety, vehicle choices and the effect of new corporate average fuel economy standards. Resour. Energy Econ. 49, 99–112. doi: 10.1016/j.reseneeco.2017.04.002

Ma, B., Han, Y. M., Cui, S. Y., Geng, Z. Q., Li, H. D., and Chu, C. (2020). Risk early warning and control of food safety based on an improved analytic hierarchy process integrating quality control analysis method. Food Control 108:106824. doi: 10.1016/j.foodcont.2019.106824

Mahoney, D. (2022). Safety and risk mitigation risk assessment in dairy processing-importance of food safety in the dairy processing sector. Encycl. Dairy Sci., 776–784. doi: 10.1016/B978-0-12-818766-1.00139-2

Marvin, H. J. P., Bouzembrak, Y., Janssen, E. M., van der Fels-Klerx, H. J., van Asselt, E. D., and Kleter, G. A. (2016). A holistic approach to food safety risks: food fraud as an example[J]. Food Res. Int. 89, 463–470. doi: 10.1016/j.foodres.2016.08.028

Motarjemi, Y., and Wallace, C. A., (2014). Chapter 40- incident management and root cause analysis. Food Safety management: a practical guide for the food industry. 1017–1036.

Ni, H. H., Chen, A., and Chen, N. (2010). Some extensions on risk matrix approach[J]. Saf. Sci. 48, 1269–1278. doi: 10.1016/j.ssci.2010.04.005

Pallis, P. L. (2017). Port risk Management in Container Terminals. Transp. Res. Proc. 25, 4411–4421. doi: 10.1016/j.trpro.2017.05.337

Park, M. S., Kim, H. N., and Bahk, G. J. (2017). The analysis of food safety incidents in South Korea, 1998–2016. Food Control 81, 196–199. doi: 10.1016/j.foodcont.2017.06.013

Pigłowski, M., and Niewczas-Dobrowolska, M. (2023). Hazards in products of plant origin reported in the rapid alert system for food and feed (RASFF) from 1998 to 2020. Sustain. For. 15:8091. doi: 10.3390/su15108091

Puertas, R., Marti, L., and Garcia-Alvarez-Coque, J. M. (2020). Food supply without risk: multicriteria analysis of institutional conditions of exporters[J]. Int. J. Environ. Res. Public Health 17:3432. doi: 10.3390/ijerph17103432

Racicot, M., Zanabria, R., Paradis, M. È., Gaucher, M. L., Arsenault, J., Leroux, A., et al. (2019). Identification of risk factors to be considered for food establishments’ risk assessment models[J]. Microb. Risk Anal. 11, 1–10. doi: 10.1016/j.mran.2018.01.004

Shang, W. J., Jing, W. Z., Liu, J., and Liu, M. (2023). Global epidemic of Ebola virus disease and the importation risk into China: an assessment based on the risk matrix method. Biomed. Environ. Sci. 36, 86–93. doi: 10.3967/bes2023.008

Song, Y. H., Yu, H. Q., and Lv, W. (2018). Risk analysis of dairy safety incidents in China. Food Control 92, 63–71. doi: 10.1016/j.foodcont.2018.04.007

Soon, J. M., Brazier, A., and Wallace, C. A. (2020). Determining common contributory factors in food safety incidents – a review of global outbreaks and recalls 2008–2018[J]. Trends Food Sci. Technol. 97, 76–87. doi: 10.1016/j.tifs.2019.12.030

Spasenic, Z., Makajic-Nikolic, D., and Benkovic, S. (2023). Integrated FTA-risk matrix model for risk analysis of a mini hydropower plant's project finance. Energy Sustain. Dev. 70, 511–523. doi: 10.1016/j.esd.2022.08.024

Surareungchai, S., Borompichaichartkul, C., Rachtanapun, C., Pongprasert, N., Jitareerat, P., and Srilaong, V. (2022). Comparison of risk assessment schemes in GHPs and HACCP, FSMA preventive controls for human food, ISO 22000, and GFSI recognized standards with risk scoring guidance in general use with fresh produce. Horticulturae 8:181. doi: 10.3390/horticulturae8020181

Talari, G., Cummins, E., McNamara, C., and O'Brien, J. (2022). State of the art review of big data and web-based decision support systems (DSS) for food safety risk assessment with respect to climate change. Trends Food Sci. Technol. 126, 192–204. doi: 10.1016/j.tifs.2021.08.032

van de Brug, F. J., Lucas Luijckx, N. B., Cnossen, H. J., and Houben, G. F. (2014). Early signals for emerging food safety risks: from past cases to future identification. Food Control 39, 75–86. doi: 10.1016/j.foodcont.2013.10.038

Van der Fels-Klerx, H. J., Van Asselt, E. D., Raley, M., Poulsen, M., Korsgaard, H., Bredsdorff, L., et al. (2018). Critical review of methods for risk ranking of food-related hazards, based on risks for human health[J]. Crit. Rev. Food Sci. Nutr. 58, 178–193. doi: 10.1080/10408398.2016.1141165

Wu, J., and Hsiao, H. (2021). Food quality and safety risk diagnosis in the food cold chain through failure mode and effect analysis. Food Control 120:107501. doi: 10.1016/j.foodcont.2020.107501

Yenealem, D. G., Yallew, W. W., and Abdulmajid, S. (2020). Food safety practice and associated factors among meat handlers in Gondar town: a cross-sectional study. J. Environ. Public Health 2020, 7421745–7421747. doi: 10.1155/2020/7421745

Yin, Z. Q., Li, B., Gu, D. Y., Huang, J., and Zhang, L. X. (2022). Modeling of Farmers' vegetable safety production based on identification of key risk factors from Beijing China. Risk Anal. 42, 2089–2106. doi: 10.1111/risa.13843

Zhang, Y. (2020). Food safety risk intelligence early warning based on support vector machine. J. Intell. Fuzzy Syst. 38, 6957–6969. doi: 10.3233/JIFS-179774

Keywords: food safety, risk matrix method, Borda method, database, risk assessment, countermeasures

Citation: Yu H, Song Y, Lv W, Liu D and Huang H (2024) Food safety risk assessment and countermeasures in China based on risk matrix method. Front. Sustain. Food Syst. 8:1351826. doi: 10.3389/fsufs.2024.1351826

Edited by:

Vasco Augusto Pilão Cadavez, Agricultural College of Bragança, PortugalReviewed by:

Soheila Abachi, University of Missouri, United StatesQingli Dong, University of Shanghai for Science and Technology, China

Copyright © 2024 Yu, Song, Lv, Liu and Huang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wei Lv, d2VpbEB3aHV0LmVkdS5jbg==

Huiqin Yu

Huiqin Yu Yinghua Song1,2

Yinghua Song1,2 Wei Lv

Wei Lv