- Department of Nutrition and Food Processing, Al-Huson University College, Al-Balqa Applied University, As-Salt, Jordan

The present study evaluated the impact of carob-based coating films on Fat %, moisture %, fat uptake %, moisture retention %, and sensory scores of Kubeh during deep-fat frying. Various coating solutions using carob (seeds, fruit, and a combination of seeds and fruit) were heated to 80°C for 15 min, followed by cooling. The Kubeh samples were then immersed in the coating solutions and allowed to air dry. The treated samples were subsequently subjected to deep-fat frying, and their moisture retention, ash content, and fat absorption were analyzed, also fat uptake and moisture retention were calculated. Additionally, sensory evaluations were conducted to assess the perceived attributes. The results demonstrated that all the carob-based coating treatments exhibited reduced fat absorption during deep-fat frying. Among the different coating films, those derived from carob seeds were the most effective in minimizing fat absorption. The coating films made from carob fruit also demonstrated a significant reduction in fat absorption compared to the control samples. Moreover, the combination of carob seeds and fruit in the coating film exhibited an intermediate level of fat absorption reduction. Furthermore, all the carob-coated Kubeh samples exhibited an improvement in sensory attributes, unlike the control group. The sensory evaluations exhibited a positive impact of carob coatings on the overall sensory experience of Kubeh.

1. Introduction

Kubeh, a traditional culinary delight celebrated in Jordan, Lebanon, Syria, Palestine, and Iraq, boasts diverse variations in form, composition, taste, and preparation methods (Ciezadlo, 2012). This traditional dish manifests diverse forms, compositions, flavors, and methods of preparation and presentation, resulting in a gastronomic tapestry of culinary delights. From succulent grilled Kubeh to the raw and vibrant Kubeh nayyeh, the yogurt-infused Kubeh labaniyye, the artfully plated Kubeh bseniyye, the tangy Kubeh Hamada with a burst of lemon juice, to the crispy and delectable fried Kubeh (Ciezadlo, 2012), each variation reflects a distinct cultural expression. Among these preparations, fried Kubeh has garnered popularity, notably through the technique of deep frying, which bestows upon it an exquisite amalgamation of flavors, a tantalizing texture, and an appealing appearance that delights discerning palates (Angor, 2016).

Carob, the fruit derived from an evergreen tree cultured in the Mediterranean region, possesses remarkable characteristics. The fruit’s pulp constitutes approximately 90% of its composition and is known for its high carbohydrate and tannin content while containing relatively low levels of fat and protein. Carob syrup/powder, derived from the fruit, finds extensive use as an ingredient in various confections such as cakes and cookies and serves as a substitute for chocolate (Makris and Kefalas, 2004). Carob powder is recognized for its abundant carbohydrate content (75.92%) while exhibiting comparatively low levels of protein (6.34%) and fat (1.99%). Moreover, the inclusion of crude fiber in carob powder accounts for 7.30% of its composition (El Batal et al., 2013). Carob powder stands out as an abundant reservoir of crucial nutrients, boasting an impressive array of essential elements including iron (Fe), calcium (Ca), sodium (Na), potassium (K), phosphorus (P), and sulfur (S). Moreover, this remarkable ingredient also harbors significant amounts of vitamins E, D, C, niacin, vitamin B6, and folic acid, making it a highly valuable and comprehensive source of essential micronutrients. Additionally, it also contains 11 phenolic compounds, which contribute to its nutritional profile (Youssef et al., 2013).

The carob powder’s phenolic profile unveils noteworthy variations, with pyrogallol, catechol, chlorogenic, and protocatechuic compounds exhibiting the highest concentrations. Conversely, compounds such as coumarin, ferulic, vanillic, cinnamic, and gallic acid compounds are found in relatively lower quantities. Furthermore, the carob powder oil’s composition encompasses a diverse array of fatty acids, prominently featuring oleic acid (40.45%), linoleic acid (23.19%), palmitic acid (11.01%), and stearic acid (3.08%; Youssef et al., 2013). The nutritional value of carob powder is widely acknowledged due to elevated levels of phenolic compounds and dietary fiber. The soluble fibers present in carob powder play a preventive role against heart disease and aid in the reduction of serum cholesterol levels, further enhancing its nutritional significance (Youssef et al., 2013).

The process of deep frying food has been associated with an increase in fat content, which in turn can contribute to various health issues, including elevated cholesterol levels, obesity, heart disease, atherosclerosis, and hepatic steatosis. Addressing this concern, researchers have focused on developing healthier food products that minimize the absorption of fat during deep frying. One approach involves applying edible coating films to the food before frying (Mellema, 2003). Several edible coating materials have been explored for this purpose, including starch, whey protein, whey protein isolate, corn zein, carrageenan, gelatin, powdered bread crumbs, soy protein films, and carob (Bourtoom, 2008). The application of such coatings holds promise as a viable strategy to reduce oil absorption and enhance the nutritional profile of fried food products (Ngadi et al., 2007).

Nevertheless, a significant research gap exists regarding the utilization of carob solutions as coating materials, encompassing carob seeds, fruit, and a combination of seeds and fruit to reduce fat absorption and enhance moisture retention during the process of deep-fat frying of Kubeh. To address this gap, the present study investigates the impact of various carob solutions as coating films for Kubeh during deep-fat frying, with a specific focus on evaluating the extent of fat absorption and examining the sensory properties of the fried product. By exploring the potential of carob-based coatings in this context, this study contributes to the understanding of novel approaches to enhance the nutritional quality and sensory attributes of fried Kubeh. The findings from this research will shed light on the effectiveness of carob solutions as coating materials, providing valuable insights for the development of healthier fried food products.

2. Materials and methods

2.1. Materials

Kubeh samples were procured from a reputable local market (Nabil Trading Company, Jordan) to serve as the basis for this experimental study. The coating materials employed in the study consisted of carob solutions derived from carob seeds, carob fruit, and a combination of both seeds and fruit. Additionally, glycerin and sunflower oil obtained from Al-Hasad Trading Company, Jordan were utilized as supplementary components in the coating formulations (Al-Hasad, Trading Company, Jordan).

2.2. Preparing the coating solution

To prepare the coating materials, three distinct solutions were created for each carob component. Carob seeds were ground and processed to form the first solution, while the second solution was prepared by grinding carob fruit. The third solution involved grinding both carob seeds and fruit together. Subsequently, these solutions were heated at 80°C for 15 min and subsequently left at room temperature to get cooled. To enhance the flexibility and plasticity of the coatings, glycerin was incorporated into the solutions at a concentration of 4% w/v, acting as a plasticizer (Angor, 2014).

The Kubeh samples underwent a coating process by submerging them in the respective coating solutions for 5 s, followed by air drying facilitated by a fan for 5 min. To achieve consistent and uniform coating coverage on the Kubeh products, the dipping and drying process was meticulously repeated, ensuring that each Kubeh piece received an even application of the coating film. As a control group, Kubeh samples were subjected to the same treatment procedure without the utilization of any coating materials.

2.3. Frying

The frying process was conducted using a commercial electrical deep-fat fryer (Emjoi power, Model UEDL-206, China) comprising 2 liters of sunflower oil, maintained at 180°C for 5 min. To ensure precise control of the oil temperature, a digital thermocouple (K-type, APPA-51, Taiwan) was employed (Angor, 2016). Following each frying procedure, the oil was replaced to maintain consistent frying conditions (Angor, 2016). Each frying batch consisted of 12 Kubeh samples, which were placed in a frying basket with hot oil. After frying, the samples were transferred to paper towels carefully and allowed to rest for 5 min. This brief cooling period was implemented to minimize oil absorption (Angor et al., 2013). Following the frying process, the fried Kubeh samples were cooled for an hour at room temperature. During this cooling period, a portion of the fried Kubeh was set aside for sensory evaluation, where trained evaluators assessed various sensory attributes. Simultaneously, some of the fried Kubeh was reserved for comprehensive physical and chemical analysis.

2.4. Chemical methods

The Kubeh samples underwent comprehensive analyses to determine their moisture, ash, and fat content, following the protocols outlined by the Association of Official Analytical Chemists (AOAC, 2000). The moisture content was evaluated utilizing an oven-drying method. To achieve constant weight, the Kubeh samples were kept in dishes at an oven temperature of 102°C for 3 h. The ash content was evaluated through a furnace burning method, involving the placement of 2–3 grams of Kubeh samples in a crucible and subsequent exposure to a temperature of 550°C for 2 h. For the assessment of fat content, the Soxhlet method was employed. This technique involved the continuous vaporization and condensation of diethyl ether via a moisture-free sample (10–12 g) housed in an extraction thimble covered with cotton wool. Following 5 h of extraction, the obtained extract was subjected to distillation, resulting in the collection of crude fat. This fat was subsequently dried and weighed for further analysis.

The fat and moisture numbers were compared by calculating the percent relation variation in fat uptake (FU%) and moisture retention (MR%) in the coated treatment product compared to the uncoated treatment product, using the following formula stated by Angor (2023):

2.5. Sensory evaluations

A sensory evaluation was conducted on the samples from each treatment, involving the participation of a panel comprising 20 members from the Department of Nutrition and Food Technology at Al-Balqa’a Applied University, representing both genders and various age groups. Before the evaluation, the panelists were provided with detailed instructions regarding the testing procedure and were acquainted with the rating system employed for the assessment (Al-Abdullah et al., 2011).

Each sample underwent a comprehensive evaluation encompassing appearance, flavor, color, taste, and overall acceptability. A 5-point hedonic scale was employed, wherein a rating of 5 showed strong preference (“like very much”), while a rating of 1 showed strong aversion (“dislike very much”). To mitigate potential carryover effects and eliminate any lingering tastes between sample evaluations, a small quantity of water was used to cleanse the palate between each sample.

2.6. Data analysis

The obtained data were entered into Statistical Package for the Social Sciences (SPSS) software, version 15 (SPSS Inc., Chicago, IL, United States) for conducting the analysis. To investigate the impact of the different treatments on the variables including Fat %, Ash %, moisture %, fat uptake %, moisture retention %, and sensory scores, a Completely Randomized Design (CRD) was employed. To determine the significance of mean differences among the treatments, the Least Significant Difference (LSD) method was utilized.

3. Results and discussion

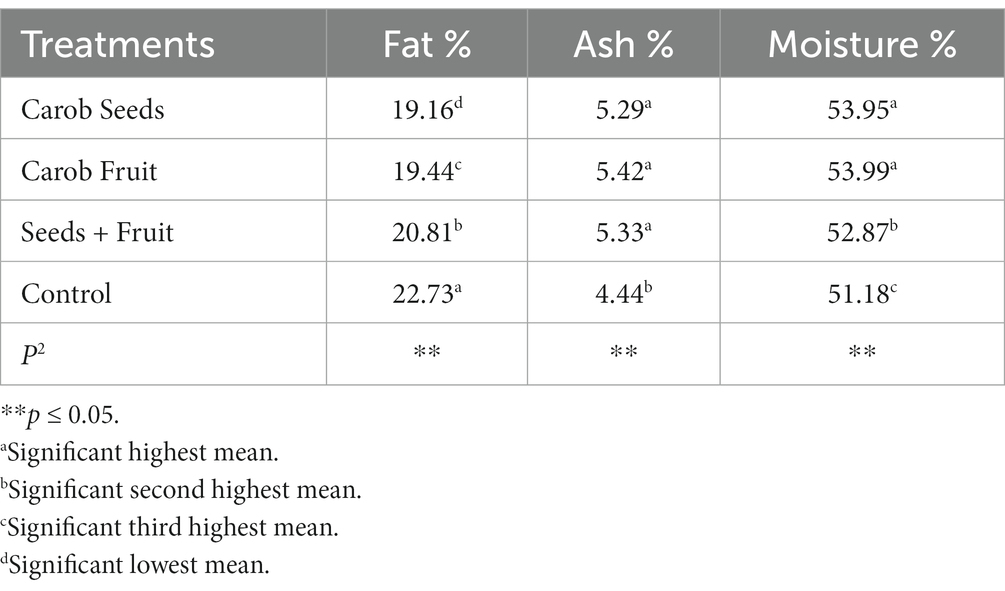

Table 1 presents the analysis of fat, ash, and moisture content in deep-fried Kubeh coated with various Carob solutions (seeds, fruit, seeds, and fruit together). The data demonstrate the effectiveness of all Carob solutions to reduce the fat percentage unlike the uncoated Kubeh (control). Notably, the Kubeh coated with Carob seed solution exhibited the lowest fat content at 19.16%, which was significantly lower as compared to other coated samples (p ≤ 0.05). Conversely, the Kubeh coated with a combination of Carob seeds and fruit displayed the highest fat content at 20.81%. In comparison, the uncoated Kubeh (control) exhibited a fat percentage of 22.73%. Regarding ash content, the sample coated with Carob fruit exhibited the highest percentage at 5.42%, while the uncoated Kubeh (control) had the lowest ash content at 4.44%. The moisture content of the Kubeh coated with different Carob solutions ranged from 51.18% to 53.99% across all samples. Notably, the lower fat content in these coated samples corresponded to higher moisture content. These findings are consistent with the results reported by Angor (2014), which demonstrated reduced fat absorption and improved moisture retention in potato pellets chips when using various edible coating films.

Table 1. Fat, ash, and moisture content of deep-fried Kubeh coated with different solutions of carob (seeds, fruit, seeds, and fruit together).

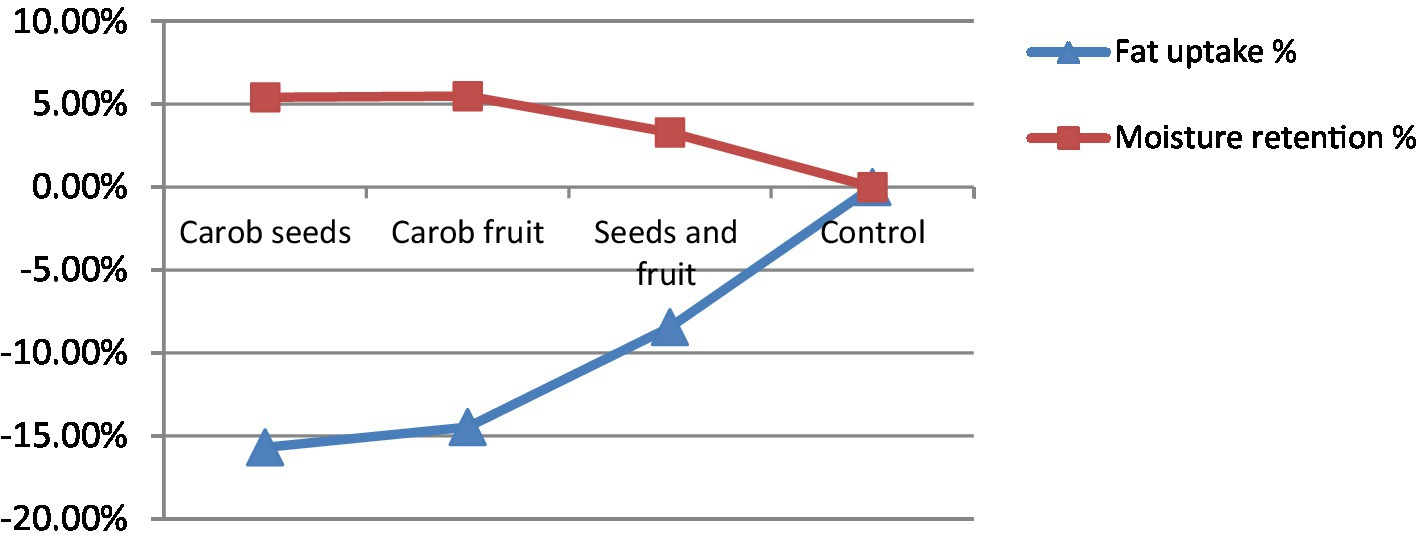

Figure 1 shows the fat uptake and moisture-retention percent related with carob (seeds, fruit, and a combination of seeds and fruit) used for coating Kubeh during deep frying. The fat uptake is lower in coated samples compared to uncoated samples (control) because the coating reduces the fat content. In this work, the highest fat uptake observed for Kubeh coated with carob seeds solution (−15.70%), followed by Kubeh coated with carob fruit solution (−14.47%). The lowest fat uptake observed for Kubeh coated with solution of seeds and fruit together (−8.45%). These results are in agreement with those of Jafarin and Mohammadnejad (2020) and Liu et al. (2021), who reported that the use of gum coating treatments reduces the fat absorption of deep-fried foods. The most effective reduction in fat uptake was Kubeh coated with carob seeds solution.

Figure 1. Fat uptake % and moisture retention % of deep-fried Kubeh coated with different solutions of carob (seeds, fruit, seeds, and fruit together).

The impact of different treatments of Carob (Seeds, fruit, seeds and fruit together) as coating films on the reduction in fat absorption run to increased retention of moisture in the deep-fried Kubeh. Coated treatment samples had higher moisture content than uncoated samples (controls), resulting in positive moisture retention for each coating film made of carob (seeds, fruit, and a combination of seeds and fruit) used for coating Kubeh during deep frying. The highest moisture retention observed for Kubeh coated with carob fruit solution (5.49%), followed by Kubeh coated with carob seeds solution (5.41%). The lowest moisture retention observed for Kubeh coated with solution of seeds and fruit combination (3.30%).

Angor (2016) reported that the formation of a protective film on the surface of treatment samples during the early stages of frying due to thermal gelation run to a reduction in fat uptake and an increase in moisture retention. Fat absorption is strong-minded by the food’s moisture content because the vapor created during heating leaves voids into which fat can subsequently enter (Oke et al., 2018). However, the Carob (Seeds, fruit, seeds, and fruit together) films form a layer of gel, which reduces the penetration of fat and, thus, the evaporation of water. Angor (2016) reported the effectiveness of pectin in falling fat content when used as a constituent of coatings films.

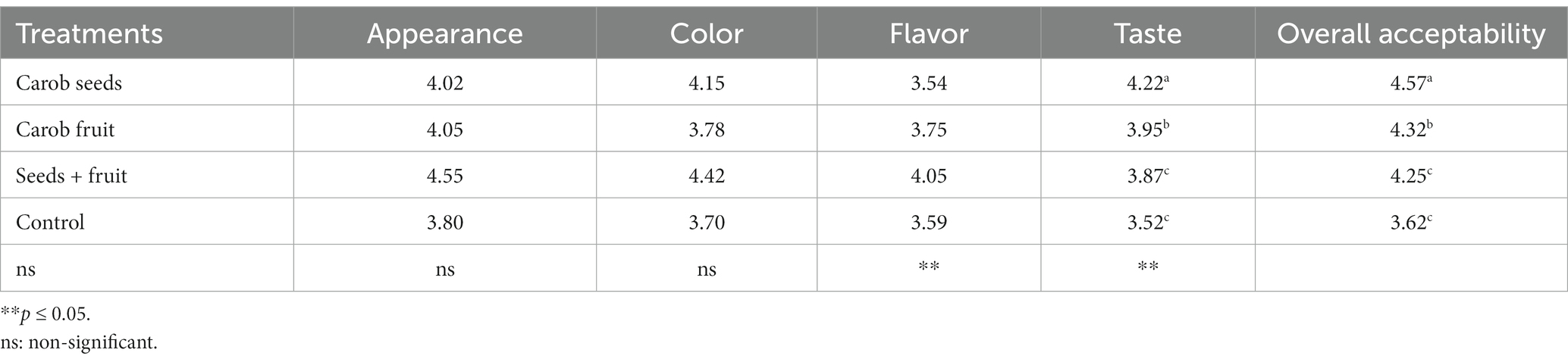

Table 2 displays the mean hedonic scores for the appearance, flavor, color, taste, and overall acceptability of the fried Kubeh coated with different Carob solutions (seeds, fruit, seeds, and fruit together). The data revealed no significant differences between all treatments and the control group in terms of appearance, color, and flavor (p ≤ 0.05). These findings are consistent with the results reported by Angor et al. (2013) in their study on starchy coating films with potato pellets chips. However, significant improvements (p ≤ 0.05) were observed in taste and overall acceptability for all treatments, unlike the control group. These results align with the findings of Angor (2016), who demonstrated the enhanced taste and overall acceptability of potato pellets chips coated with Carboxymethyl Cellulose (CMC) coating films.

Table 2. Sensory evaluation mean scores of deep-fried Kubeh coated with carob (seeds, fruit, seeds and fruit together) different solutions.

The study findings have some significant implications for the development of healthier and more appealing fried Kubeh products. The use of Carob solutions as coating materials for deep-fried Kubeh resulted in reduced fat absorption and improved sensory attributes, specifically taste and overall acceptability. These results indicate that Carob coatings can enhance the quality and consumer appeal of fried Kubeh. The significance of these findings lies in addressing the health concerns associated with deep-fried foods, such as increased fat content contributing to various health problems including high cholesterol levels, obesity, and cardiovascular diseases. By reducing fat absorption during deep-frying, Carob coatings offer a promising approach to developing healthier food products. Furthermore, the sensory improvements observed in taste and overall acceptability highlight the potential of Carob coatings to enhance the sensory experience of fried Kubeh. This is crucial in ensuring consumer satisfaction and market acceptance of healthier food options.

4. Conclusion

In conclusion, the utilization of Carob seeds, Carob fruit, and a combination of Carob seeds and fruit as coating films for Kubeh before deep-fat frying demonstrated a reduction in fat absorption. The results indicated that all Carob-coated samples exhibited a decrease in fat absorption, with the most significant reduction observed in the Carob seeds coating film, followed by Carob fruit, and Carob seeds and fruit together. These findings highlight the effectiveness of Carob seeds as a coating material in reducing fat absorption during the frying process. Furthermore, there is the significant importance of sensory evaluation in assessing the quality attributes of fried Kubeh products. The sensory analysis revealed that all coated treatments resulted in sensory improvements, particularly in taste and overall acceptability, unlike the uncoated control. However, there were no significant effects observed in terms of appearance, color, and flavor among the different coated samples and the control.

Overall, this study emphasized the positive effects of Carob coatings in reducing fat absorption and improving the sensory qualities of fried Kubeh. The findings offer promising prospects for the development of healthier and more appealing deep-fried food products. Continued exploration and refinement of Carob coating techniques can pave the way for the production of novel and nutritious food options that cater to consumer demands for healthier food choices. The study provides valuable insights into the potential application of Carob coatings to enhance the nutritional profile and sensory attributes of deep-fried Kubeh. Future research directions could focus on optimizing the formulation of Carob coatings to achieve an even greater reduction in fat absorption while simultaneously enhancing other quality attributes, such as texture and shelf life. Additionally, investigating the effect of Carob coatings on the oxidative stability and sensory stability of fried Kubeh over an extended storage period would contribute to a more comprehensive understanding of their potential in practical applications.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the author, without undue reservation.

Author contributions

MA: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft, Writing – review & editing.

Acknowledgments

The author was thankful to all the associated personnel who contributed to this study by any means.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Al-Abdullah, B. M., Angor, M. M., Al-Ismail, K. M., and Ajo, R. Y. (2011). Reducing fat uptake during deep-frying of minced chicken meat-balls by coating them with different materials, either alone or in combination. Ital. J. Food Sci. 23

Angor, M. M. (2014). Application of whey protein and whey protein isolate as edible coating films on potato pellets chips to reduce oil uptake during deep frying. Contemp Eng Sci 7, 1839–1851. doi: 10.12988/ces.2014.410194

Angor, M. M. (2016). Reducing fat content of fried potato pellet chips using carboxymethyl cellulose and soy protein isolate solutions as coating films. J. Agric. Sci. 8, 162–168. doi: 10.5539/jas.v8n3p162

Angor, M. M. (2023). Reducing oil absorption of falafel balls by using edible coating films containing dried orange-albedo powder or dried apple peel during deep frying. Front Sustain Food Syst 7, 1–5. doi: 10.3389/fsufs.2023.1156316

Angor, M. M., Ajo, R., Al-Rousan, W., and Al-Abdullah, B. (2013). Effect of starchy coating films on the reduction of fat uptake in deep-fat fried potato pellet chips. Ital J. Food Sci. 25

AOAC. (2000). Official methods of analysis, 17th Edn., In: Titratable acidity of fruit products, 942.15. Association of Official Analytical Chemists International, Gaithersburg

Bourtoom, T. (2008). Edible films and coatings: characteristics and properties. Int. Food Res. J. 15, 237–248.

El Batal, H., Hasib, A., Ouatmane, A., Boulli, A., Dehbi, F., and Jaouad, A. (2013). Yield and composition of carob bean gum produced from different Moroccan populations of carob (Ceratonia siliqua L.). J Mater Environ Sci 4, 309–314.

Jafarin, S., and Mohammadnejad, P. (2020). Effect of propolis coating on oil uptake and quality properties of fried potato (Solanum tuberosum) strips. Asian Food Sci. J. 15:18. doi: 10.9734/afsj/2020/v15i130139

Liu, Y., Tan, J., Duan, Z., Li, J., and Fan, L. (2021). Effect of oil surface activity on oil absorption behavior of potato strips during frying process. Food Chem. 365:130427. doi: 10.1016/j.foodchem.2021.130427

Makris, D. P., and Kefalas, P. (2004). Carob pods (Ceratonia siliqua L.) as a source of polyphenolic antioxidants. Food Technol. Biotechnol. 42, 105–108.

Mellema, M. (2003). Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci. Technol. 14, 364–373. doi: 10.1016/S0924-2244(03)00050-5

Ngadi, M., Li, Y., and Oluka, S. (2007). Quality changes in chicken nuggets fried in oils with different degrees of hydrogenation. LWT Food Sci. Technol. 40, 1784–1791. doi: 10.1016/j.lwt.2007.01.004

Oke, E., Idowu, M., Sobukola, O., Adeyeye, S., and Akinsola, A. (2018). Frying of food: a critical review. J. Culin. Sci. Technol. 16, 1–21. doi: 10.1080/15428052.2017.1333936

Keywords: coating films, carob, deep-fat frying, fat reduction, Kubeh, sensory properties

Citation: Angor M (2023) Investigating fat reduction absorption and sensory properties for Kubeh during deep frying using carob as coating films. Front. Sustain. Food Syst. 7:1253280. doi: 10.3389/fsufs.2023.1253280

Edited by:

Raul Avila-Sosa, Benemérita Universidad Autónoma de Puebla, MexicoReviewed by:

Seyed-Hassan Miraei Ashtiani, Dalhousie University, CanadaNutsuda Sumonsiri, Teesside University, United Kingdom

Copyright © 2023 Angor. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Malak Angor, ZHIuYW5nb3JtYWxha0BiYXUuZWR1Lmpv

Malak Angor

Malak Angor