- 1Department of Economics, University for Development Studies, Tamale, Ghana

- 2International Institute of Tropical Agriculture, Accra, Ghana

- 3International Institute of Tropical Agriculture, Tamale, Ghana

- 4Department of Agricultural and Food Economics, University for Development Studies, Tamale, Ghana

This paper assessed the conditions contributing to the success of smallholder farmer groups in northern Ghana using mechanical maize shellers (MMS) based on a collective business model. A sample of 156 farmers from 18 intervention communities was analyzed using qualitative comparative analysis (QCA) to examine the conditions necessary to increase usage of MMS. The results revealed a single configuration for achieving high group MMS usage, observed in about 24 percent of the cases. This configuration comprises five sufficient conditions: high cooperation, good relationships among members, payment of financial contributions, provision of prior notice for group meetings, and obedience to group rules. Additionally, two necessary conditions identified were low conflict and reduced use of manual maize shelling. When these core conditions coexist within the farmer groups, the MMS is more likely to be highly utilized. These findings suggest that group leaders and members should encourage mutual understanding, respect individual differences, value diverse opinions, and share responsibilities to improve cooperation, foster better relationships, and reduce conflicts among members. This approach can encourage both existing and new members to utilize the services of mechanical sheller groups, ensuring sustainability. Future research should utilize alternative econometric procedures to evaluate the configurations identified by the QCA analysis, aiming to enhance the reliability and confidence of empirical findings.

1 Introduction

Agricultural mechanization is a necessary condition for agricultural intensification and modernization since it improves production capacity and land output rates (Devkota et al., 2020; Peng et al., 2022). Mechanization transforms the traditional labor-based agriculture to modern technology-based agriculture and improves input-use efficiency (Kusz, 2014; Devkota et al., 2020). Fischer et al. (2021) and Zhang et al. (2017) reported that mechanization creates a division of labor, enhances specialization and reduces drudgery. Others have argued that mechanization also stimulates smallholder farmers to scale up their production activities for commercialization and competition (Pingali, 2007; Li et al., 2021; Liao et al., 2022).

Maize is one of the dominant crops in Ghana in terms of area cultivated and volume of production (MoFA, 2022) which has attracted the attention of researchers, development practitioners, and policy makers with regards to mechanization (Houssou et al., 2013; Diao et al., 2014; Darfour and Rosentrater, 2016). Mostly contributed by smallholder farmers, Ghana’s annual maize production has reached over 3 million metric tons since 2019 (MoFA, 2022) which has been difficult to achieve without mechanization. However, the maize value chain is mostly mechanized in pre-harvest activities such as land preparation while postharvest activities have been given marginal attention (Houssou et al., 2013; Diao et al., 2014; Darfour and Rosentrater, 2016). While maize shelling is the most power-intensive postharvest activity which entails mechanization, it is often done manually (using hand and sticks; Darfour and Rosentrater, 2016). The most challenging aspect of manual maize shelling is that it is laborious and time-consuming while labor is getting scarcer among smallholder farmers in SSA (Pingali, 2007; Baudron et al., 2019; Fischer et al., 2021). Moreover, manual shelling reduces grain quantity and quality (Gebeyehu, 2023), causes burning sensation in the palm and fingers as well as impaired functioning of some arm muscles and joints and may affect the body posture due to continuous sitting, thereby leading to a poor musculoskeletal health (Joshi et al., 2018).

Despite these limitations of the manual maize shelling method and the potential of mechanization to address those issues, smallholder farmers have limited access to mechanization services (Fischer et al., 2021; Gebeyehu, 2023; Kotu et al., 2023). While mobile commercial service providers for maize shelling operate in limited locations of farming communities in northern Ghana, mostly they target large and medium scale maize farmers due to better economies of scale. Moreover, smallholder farmers are not attractive customers for commercial shelling service providers because of their small quantities of produce and financial constraints to pay for rental services.

Collective action is one way to overcome the limited resource constraint confronting smallholders and the diseconomies of scale associated with small volumes of production among smallholders (Poteete and Ostrom, 2004; Fraser et al., 2019). Collective action helps farmers to pull their resources, talents, skills, knowledge and power to fulfill goals that cannot be achieved individually (Poteete and Ostrom, 2004; Fraser et al., 2018; Ureña et al., 2019). Collective action also increases recognition and feelings of self-worth and reduces exclusion (Dong et al., 2018). Nevertheless, some collective actions may also lead to negative sociocultural consequences, such as humiliation and conflict, especially in groups with poor group dynamics or cohesiveness (Ureña et al., 2019; Van de Brake et al., 2020). For instance, the unequal ability of group members to contribute to collective tasks, free-riding and appointment of ineffective leaders may reduce cohesiveness and lead to potential conflict (Gençer, 2019; Bakir et al., 2020).

The success, vis-a-vis the sustainability, of collective action groups depend on the set of principles or institutions guiding the interaction of participants and associated factors including member characteristics and institutional support (Bowles and Gintis, 2002; Rodrik et al., 2004; Skoog, 2005; Bartolini and Santolini, 2017). Ombogoh et al. (2018) observed among smallholder farmers in Kenya and Uganda that farmer groups that practiced the ‘inclusive decision making’ principle were less likely to collapse. This model of decision making includes all members’ views and opinions in decision making, which in turn increases their self-worth. Ochieng et al. (2018) found in Central Africa that farmers’ groups that adopted the ‘participatory market research’ principle had high market performance due to their abilities to penetrate high-value markets. In Japan, working in small groups and having frequent meetings were the two leading factors that enhanced the success of collectively managed irrigation systems (Takayama et al., 2018). While most of the group principles are often organized locally by group leaders and their members, sometimes other rules are devised at the higher level by government agencies. An example is Ghana’s ‘Plants and Fertilizer Act’, which presented farmer groups and individual farmers, especially maize farmers, an unlimited choice of improved seed varieties (Poku et al., 2018).

Despite acknowledging the importance and potential benefits of collective action in overcoming resource constraints and achieving better economies of scale, there is a scarcity of empirical evidence and comprehensive studies focusing on the conditions essential for the success of these collective initiatives, particularly in the domain of agricultural mechanization within smallholder farming communities. The existing literature provides insights into the advantages of mechanization in transforming agriculture and highlights the challenges faced by smallholder farmers in accessing mechanization services (Houssou et al., 2013; Diao et al., 2014; Fischer et al., 2021; Hodjo et al., 2021; Peng et al., 2022; Kotu et al., 2023). However, the specific factors that contribute to the success or failure of collective efforts in adopting mechanized maize shellers among these farmers remain underexplored. This gap in research hampers the comprehensive understanding needed to design effective interventions and support mechanisms for enhancing agricultural mechanization within smallholder farming contexts, limiting the development of sustainable collective business models in this domain.

The objective of this study was to examine the collective action efforts of smallholder farmers with regard to mechanical maize shellers and the conditions that contribute to their successes. Based on the theory of collective action and the qualitative comparative analysis (QCA), the study identified the possible contextual factors that can enhance the success of the group business model adopted by smallholder farmers in northern Ghana. The cases considered are farmers’ groups which were organized and supported by the Africa RISING project1 around mechanical maize shellers (MMS) (see details of MMS groups in Section 3.1). The MMS were organized based on the assumption that, in the presence of financial scarcity among smallholder farmers in northern Ghana and the low scale production by these farmers, the group business model would be attractive to more farmers than the individual business model. This assumption is supported by studies elsewhere in Africa (Fischer et al., 2021; Kotu et al., 2023). For instance, Kotu et al. (2023) found that about 65% of smallholder farmers in their sample were willing to invest in mechanized maize shelling within the group business model while only about 10% of them would like to do so within the individual business model.

The study contributes to the limited evidence around business models in smallholder agriculture in general and agricultural mechanization in particular. From a managerial perspective, this research contributes to stakeholders recognizing the aspects necessary and sufficient to achieving better group goals in a collective action, given the empirical results from the MMS groups. Furthermore, our study adds to the few but growing applications of the QCA in empirical studies in Agriculture (Florea et al., 2019; Ndimbo et al., 2023) which is useful to make scientifically valid comparisons of cases in the context of small sample size (Ragin, 2000; Rihoux and Ragin, 2009; Blackman, 2013).

2 Theoretical framework

This study adopts Olson (1965) theory of collective action to explain the conditions under which a smallholder maize farmer would participate in a mechanical maize sheller (MMS) group, with the willingness to shell a greater percentage, if not all, of the harvested produce using the group’s mechanized sheller instead of any other service, and ensure its sustainability. The hypothesis is that a farmer incurs cost (C) by joining the MMS group. This cost consists of a fixed cost of the sheller (A), variable cost for operating and maintaining the sheller (B) and the rate (r) corresponding to quantity of maize shelled by the farmer. The total cost per person is thus a function of the rate:

Further, the study assumes that the only benefit to the farmer is r. Therefore, total group benefit ( ) depends on the group size ( ), such that . The share of benefit for the farmer ( ) is the ratio of the farmer’s benefit ( ) to the total group benefit . A rational farmer will consider his/her individual absolute advantage, , and if it is positive, the farmer will join the MMS group. A profit-maximizing farmer will compare changes in the individual’s absolute advantage to changes in the rate , as specified in (1) below:

Thus, a profit-maximizing farmer will join the MMS group up to the point where the additional benefit of shelling an extra unit of maize equals the additional cost, as specified in (2) below.

The sustainability of the MMS group depends on the additional collective benefit with respect to the extra unit of maize shelled. Noting that in (2), , the expression becomes as specified in (3) below.

Therefore, the MMS group will be utilized and sustained if the additional collective benefit of the group is equal to times the additional cost of joining the group (i.e., at an optimal condition). The group will also be sustainable if the ratio of collective benefit to the cost is greater than the ratio of collective benefit to individual benefit (increasing condition). More members patronizing the group sheller implies a greater group benefit, including higher revenue to run and maintain the group sheller. For high usage to happen, there should be a set of conditions that foster collective action in the MMS group.

3 Methodology

3.1 Farmers’ groups on mechanical maize sheller

In December 2018, the Africa RISING project demonstrated small-scale mechanical maize shellers (MMS) to farmers in 18 communities of Northern, Upper West and Upper East regions of northern Ghana (Kizito et al., 2018). The MMS had a four horsepower (hp) engine capacity which could shell up to 1.5ton of maize per hour.2 Realizing that farmers were highly motivated during the demonstration events to mechanize maize shelling and that they had severe financial constraints to purchase MMS, the management of the Project decided to donate the shellers to the farmers on condition that they (1) form groups (each group having 15–25 members), (2) jointly mobilize starting operating capital from registered members (Ghs800 = $156 = 25% of the shellers’ market value), (3) develop self-written constitutions,3 (4) operate and maintain the shellers according to the self-written constitutions, (5) ensure a gender balance in leadership (Odhong, 2019). The machines were transferred to 18 farmers’ groups (one per community) in October 2019 after checking the fulfillment of these conditions. Following the transfer of the machines, selected group members were trained on basic repair and maintenance. Moreover, the groups were linked to local artisans so that they could get professional supports on maintenance, customization of the machines to their needs, and repair services, if required.4 As indicated in their written constitutions, most of the groups agreed to provide two types of services to their members including shelling services at payment and loan services to those who need. In addition, they agreed to provide shelling services to non-member farmers to generate more income.

3.2 Data source

This study used survey data collected in March 2021 by the International Institute of Tropical Agriculture (IITA) in the intervention communities regarding the mechanized maize shelling.5 The sampling frame consisted of all individual members (about 320) of maize sheller groups organized in 18 communities. To obtain adequate representation from each maize sheller group, 50% of the total members from each group were selected from members’ lists using the simple random sampling method, resulting in a sample size of 162 farmers. This sample size was slightly above the statistically required sample size (i.e., 147 farmers) following Cochran (1977).6 The sample size per farmers’ group ranged from 5 to 12 with an average of 9.7 A semi-structured questionnaire was used to collect the data from the sampled farmers. Interviews with individual members focused on their household resources, maize produce, methods of shelling before and after the introduction of the group sheller, use of group services, knowledge of group rules and participation in decision making process, member interactions (conflicts and cooperation), perception regarding how maize sheller should be managed. After data cleaning, 156 responses were used for the analysis due to missing information from the remaining 6 farmers.

3.3 Empirical strategy: understanding factors influencing MMS usage

The sustainability of the MMS group depended on farmers’ usage of the sheller, making it crucial to examine the conditions collectively leading to increased usage, as underutilization of the machine would lead to undesirable cost and revenue implications. These conditions were expected to represent various causal pathways affecting the MMS group, with some being necessary and others being sufficient. We used the Qualitative Comparative Analysis (QCA) methodology to analyze the data. The QCA was selected as it is useful to make scientifically valid comparisons of cases in the context of small sample size like ours (Ragin, 2000; Rihoux and Ragin, 2009; Blackman, 2013). Eight key variables or conditions were considered in the study, which are detailed below.

3.3.1 Usage of group sheller (Y)

This is the outcome variable, representing the proportion of maize harvest shelled using the group sheller machine. A higher value indicates greater utilization, typically if the proportion was larger than 0.5. Conversely, a lower value denotes underutilization.

3.3.2 Cooperation (D)

This variable signifies the level of cooperation among group members. A value of 1 indicates perceived cooperation among members, while 0 implies the opposite.

3.3.3 Quantity of maize output shelled manually (E)

This variable represents the extent of maize shelled manually. A higher proportion (e.g., > 0.5) implied manual shelling was present; otherwise, it is marked as absent.

3.3.4 Rule obedience (F)

It reflects farmers’ perceptions regarding the adherence of group members to constitutional rules. A value of 1 indicates perceived obedience, while 0 implies the opposite.

3.3.5 Group relationship after machine (G)

This variable indicated farmers’ perceptions of improved relationships among group members following the introduction of the mechanized sheller. It is marked as 1 if there was perceived improvement and 0 otherwise.

3.3.6 Info received prior to group decision-making (H)

It represents whether members were informed before group decision-making processes. A value of 1 denotes pre-information, while 0 signifies otherwise.

3.3.7 Contribution to group decision-making (I)

This variable assesses the active participation of members in group decision-making. If a member contributed, it is marked as 1; otherwise, it is 0.

3.3.8 Group contribution (J)

It signifies whether a farmer fulfilled financial obligations within the group. A value of 1 denotes meeting these obligations, while 0 signifies not doing so.

3.3.9 Conflict in group (L)

This variable indicates whether farmers observed conflicts among group members. A value of 1 represents observed conflict, while 0 indicates its absence.

These variables/conditions can be grouped into two sets, namely: the crisp set and the fuzzy set. The crisp set represented binary variables, indicating either membership (1) or non-membership (0). These variables distinctly fit into clear-cut categories without any intermediate degrees. For example, whether a member actively contributed to group decision-making (1 if yes, 0 if not) is a crisp set. The fuzzy set included variables which do not fit into a clear-cut category, but have varying degrees of membership with values lying between 0 and 1. For instance, the proportion of maize output manually shelled might be represented as a fuzzy set. A value closer to 1 implies a higher proportion shelled manually, while closer to 0 indicates a lower proportion.

Using the QCA, the relationships between the eight conditions (i.e., D, E,…, L) and the outcome (Y) were analyzed. QCA labels the sets conventionally using lower and upper cases. In crisp sets, uppercases represented a value of 1 (i.e., full membership) and lowercases represented a value of 0 (i.e., full non-membership). With fuzzy sets, uppercases showed the degree of set membership (e.g., the value of D) and lowercases showed the degree of set non-membership (e.g., 1 minus the value of D). Accordingly, QCA identified different combinations of variables (e.g., D*E, D*e, d*E, d*e in the case cooperation and quantity of maize output shelled manually) to assess their impact on the outcome (Y). In the crisp-set case, the relationship between the predictors and the outcome were evaluated using conditional probabilities (e.g., Pr(Y|D*E), where higher conditional probabilities implied the statement “D*E was a subset of Y,” or, in logical terms, “if D*E, then Y”). In the fuzzy-set case, individuals were considered more or less a member of a particular set (e.g., 0.33 would indicate “more out than in, but still somewhat in” the set, whereas 0.7 would signify “more in than out, but not entirely in” the set). To combine fuzzy sets into configurations, the minimum operator, e.g., D*E = min(D, E), or d*E = min[(1 − D), E] was used.

The analysis evaluated these combinations, considering both crisp and fuzzy sets due to the presence of continuous and binary variables in the dataset, to identify configurations significantly contributing to higher or lower usage levels. The goal was to identify the optimal combination of factors that impact MMS usage. To evaluate this relationship, an inclusion ratio or consistency score was calculated following Ragin (2006) as follows:

Sufficient configurations were then condensed to a more concise solution, assessed based on coverage, the degree to which the solution explained the outcome. Based on Ragin (2006), coverage ( ) was computed as specified in (5) below.

This equation computes the coverage, indicating the extent to which the solution (X) explains the outcome (Y). A higher value implies that more of Y is covered or explained by X.

4 Results

4.1 Framers’ socio-demographic characteristics and shelling methods used

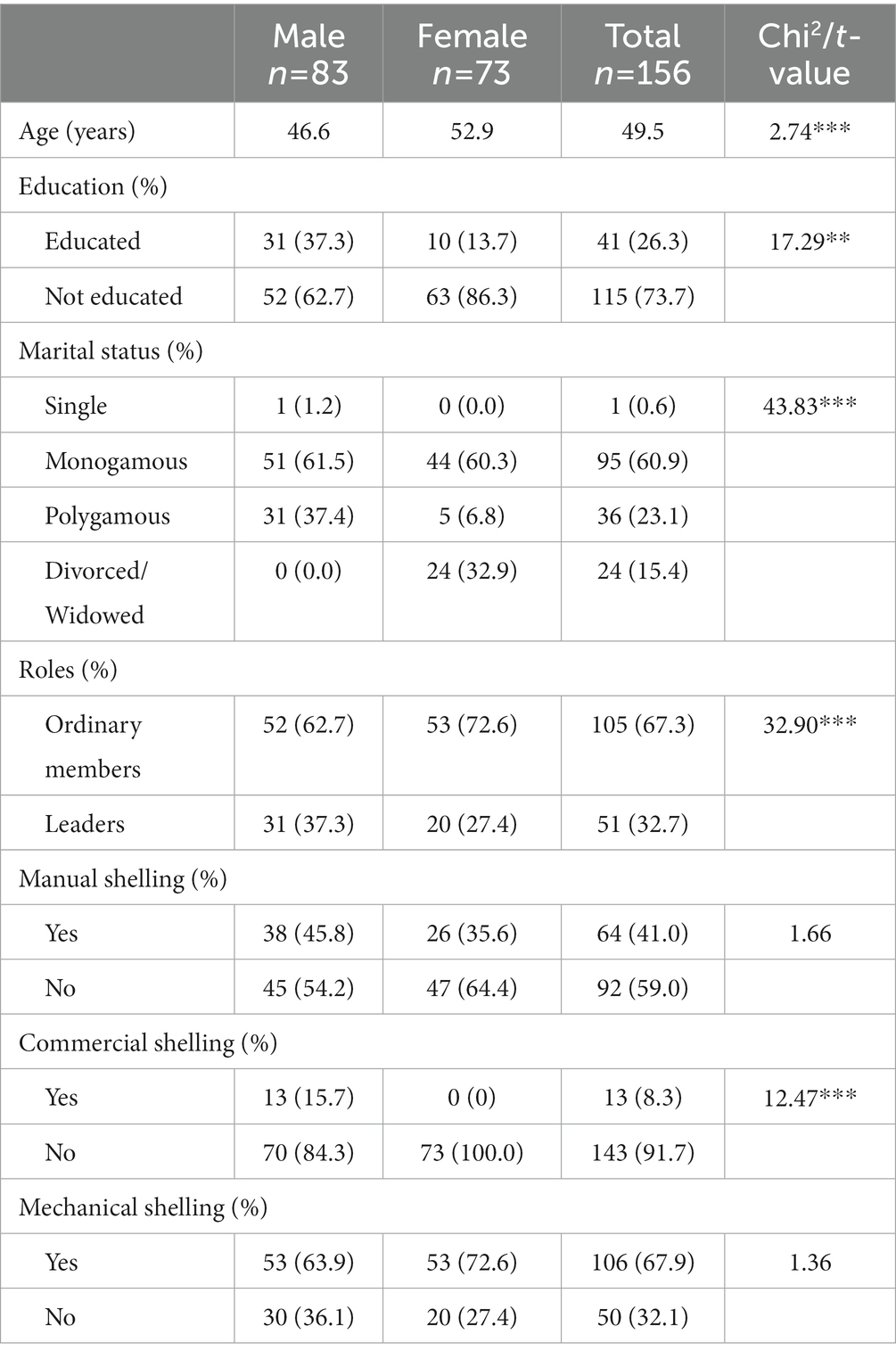

Table 1 displays descriptive results on some basic variables. About 53 and 47% of male and female farmers were, respectively, sampled for the study. In rural Ghana, men are more involved in agricultural production (GSS, 2021b). However, women are more engaged in post-harvest activities (FAO, 2018). The average female farmer (52.9 years) in the sample is about 6 years older than the average male farmer (46.6 years). About 74% of farmers have no formal education, indicating high illiteracy rate in the study area. According to the GSS (2021a), educational attainment among the aged in rural Ghana is low, as rural areas lack appropriate infrastructure and face other institutional rigidities (Barrett et al., 2019).

Furthermore, the results show the presence of a substantial difference between male and female farmers in terms of formal education, i.e., 37% of male farmers and 14% of female farmers have formal education, which confirms the evidence that females are disadvantaged in terms of access to education (Senadza, 2012). About 61% of farmers are monogamously married. More male sample farmers are in polygamous marriages compared to female farmers, while more female farmers are also divorced or widowed compared to male farmers. The dominance of Islamic religion in northern Ghana allows men to have more than one wife while women find it difficult to remarry even after divorce or after the demise of their husbands. The majority of farmers (67.9%) used the group mechanical shellers provided by Africa RISING. Even though more female farmers use the group sheller machines than their male counterparts, the difference is not statistically significant. About 41% of farmers shell their maize manually, while about 8% of the farmers shelled their maize using commercial shelling services. While about 16% of male farmers use commercial maize shelling services none of the female farmers do so.

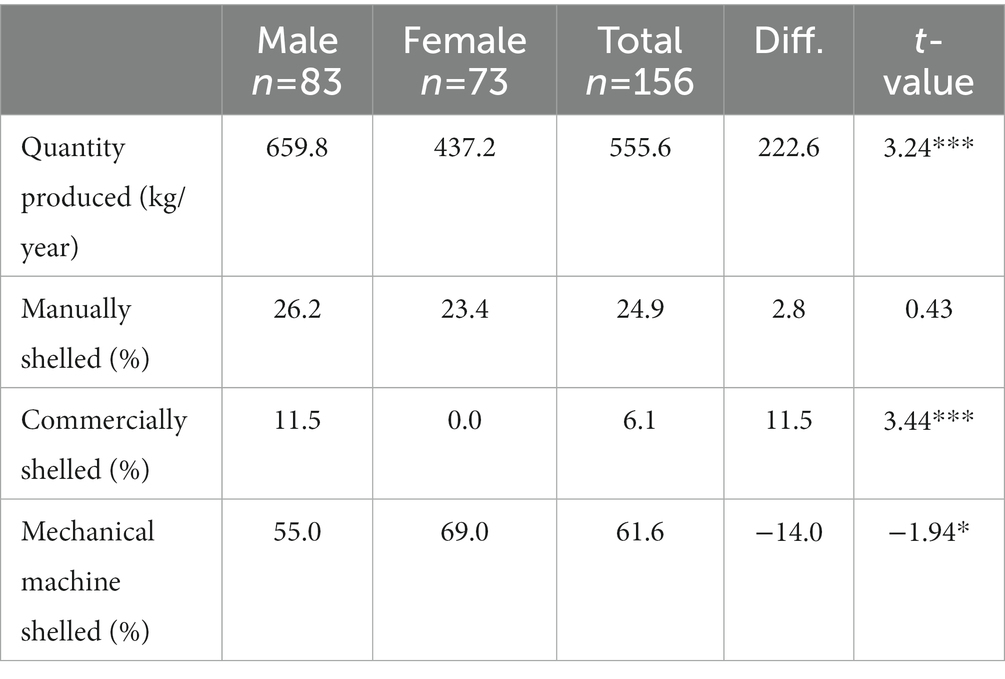

4.2 Maize quantity produced and proportion shelled by different shelling methods

Table 2 displays quantity of maize produced in 2020 cropping season and the shelling methods used by farmers. Farmers harvested an average of output about 556 kg. In most rural areas, especially in northern Ghana, men have more physical access to land compared to women, making male farmers more likely to cultivate larger acreages of land and produce higher output than female farmers. This was the case in the study, where the average male maize farmer produced about 223 kg more than the average female maize farmer. In terms of shelling, the average farmer shelled about 25% of the total maize produced manually and 6% using commercial services. Male farmers shell about 12% of their total maize production using commercial services, but no female farmer accessed commercial shelling services. With the MMS group machine, farmers used it to shell about 62% of their total maize output in 2020. Female farmers significantly shelled a higher proportion (69%) of the total maize produce with the MMS compared to male farmers (55%). Women perform more household chores than men in Africa (Chahalis et al., 2021). This means that women are more likely to embrace a technology that helps them to save labor time, as in the case of the mechanical maize sheller. Therefore, it is not surprising that women shelled a greater proportion of their maize using the group machine.

4.3 Factors associated with group sheller usage

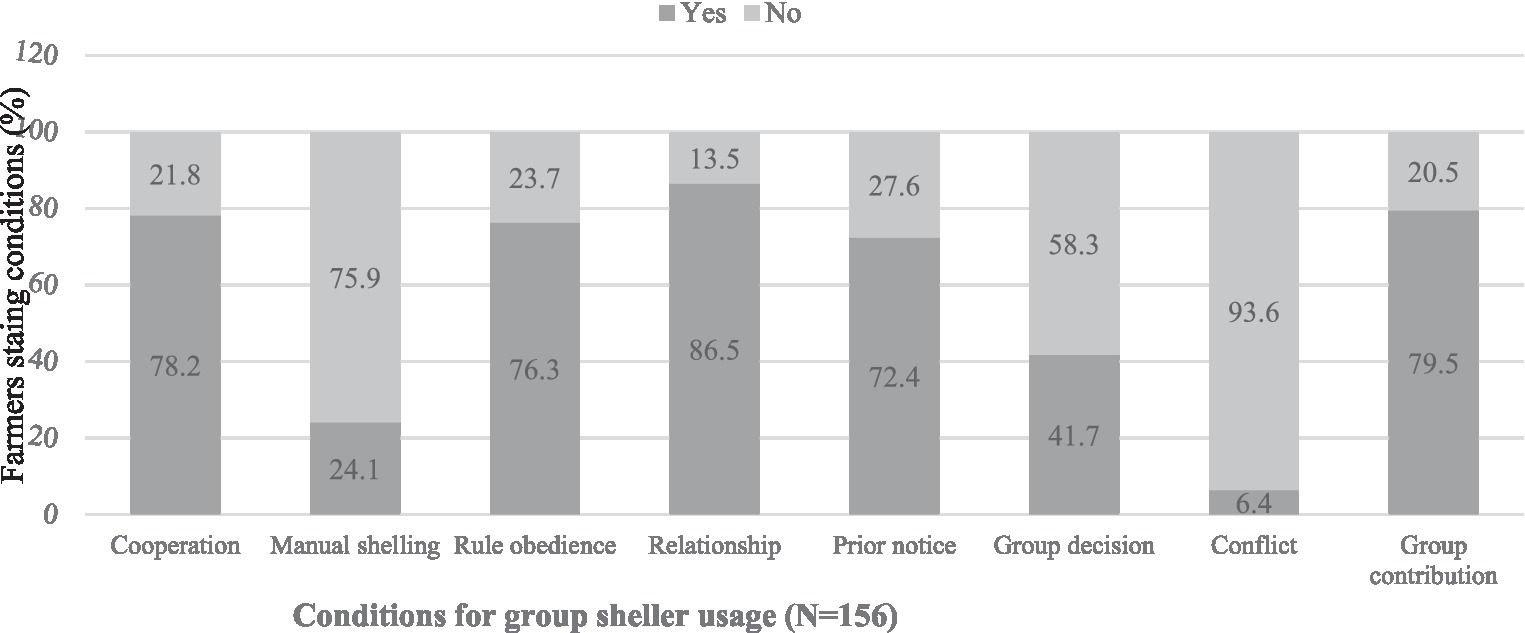

The most important elements to ensuring sustainability in collective action are cooperation and good relationship (Bakir et al., 2020). From the results in Figure 1, about 78% of participants affirmed that there is high cooperation within their groups, while about 87% of participants perceived that members have better relationships within their groups. Due to this, there is very low conflict in the groups; only about 6% reported that they were aware of conflicts in their groups. Rural people often exhibit a high level of social solidarity and unity, which makes them work collectively and effectively (Gongbuzeren et al., 2021), leading to better relationship and cooperation. The high level of cooperation and relationship among participants highlight the advantages of well-organized collective action (Dong et al., 2018). With the availability of mechanical shellers, farmers will be less motivated to shell their maize manually. Therefore, most participants shelled larger proportions of their maize with the mechanical group shellers. Responses from some of the participants reveal that a few of them shelled their maize manually due to low output or the sheller was malfunctioned when they wanted to shell.

In terms of group rules, majority of participants (76.3%) stated that members obey the group rules. In addition, about 80% of participants fulfill their financial obligations. According to Reina et al. (2021), decision-making is complex and may lead to conflict; however, effective decision ensures the success of a collective action. In the sample, about 72% of the participants revealed that they are usually pre-informed before group decisions are made, while about 42% contribute actively to group decision-making.

4.4 Conditions for increasing group sheller usage and enhancing sustainability

4.4.1 Possible configurations and best-fit solution

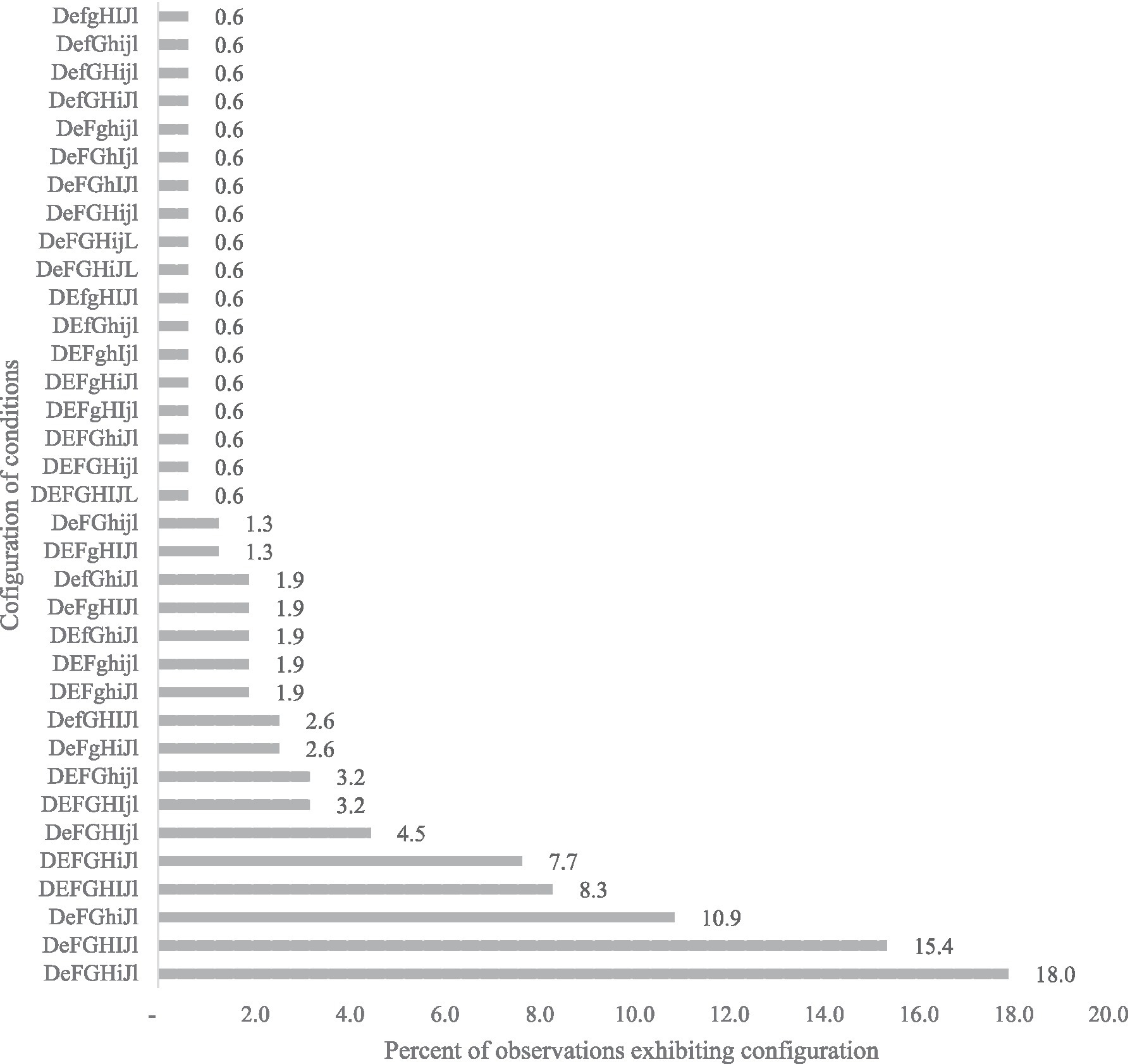

The key initial step in QCA is to ascertain the configuration that contains the highest number of individuals through best-fit solutions. The best fit solution is used to assess the combination of causal conditions and how they are distributed across the cases (farmers). With eight causal conditions, there are 2k (28 = 256) logically possible configurations. Figure 2 reports 35 of these 256 combinations of conditions that have at least one case (farmer) with greater than 0.50 membership.

Figure 2. Configurations with greater than 0.50 membership. D, high cooperation; d, low cooperation; E, high proportion of harvest shelled manually; e, low proportion of harvest shelled manually; F, perception that members obey constitutional rules; f, perception that members disobey group constitutional rules; G, perception of good relationship among group members; g, perception of poor relationship among group members; H, members are pre-informed of group meetings; h, members are not pre-informed of group meetings; I, members actively contribute to group decision-making; i, members do not actively contribute to group decision-making; J, members honor their financial obligations; j, members do not honor financial obligations; L, high conflicts among group members; l, low conflicts among members.

The results show that only 1 farmer (0.64%) is likely to experience all of the independent measures at above-mean levels (DEFGHIJL). The most common configuration is DeFGHiJl, with approximately 18% of the sample best fitting it. This configuration corresponds to high group cooperation, less manual shelling of produce, high rules obedience, better within-group relationships, frequent or consistent prior notice to meetings, low participation in group decision-making, high commitment to group contributions and low levels of conflict within the group.

4.4.2 Overlap between conditions and mechanized maize sheller usage

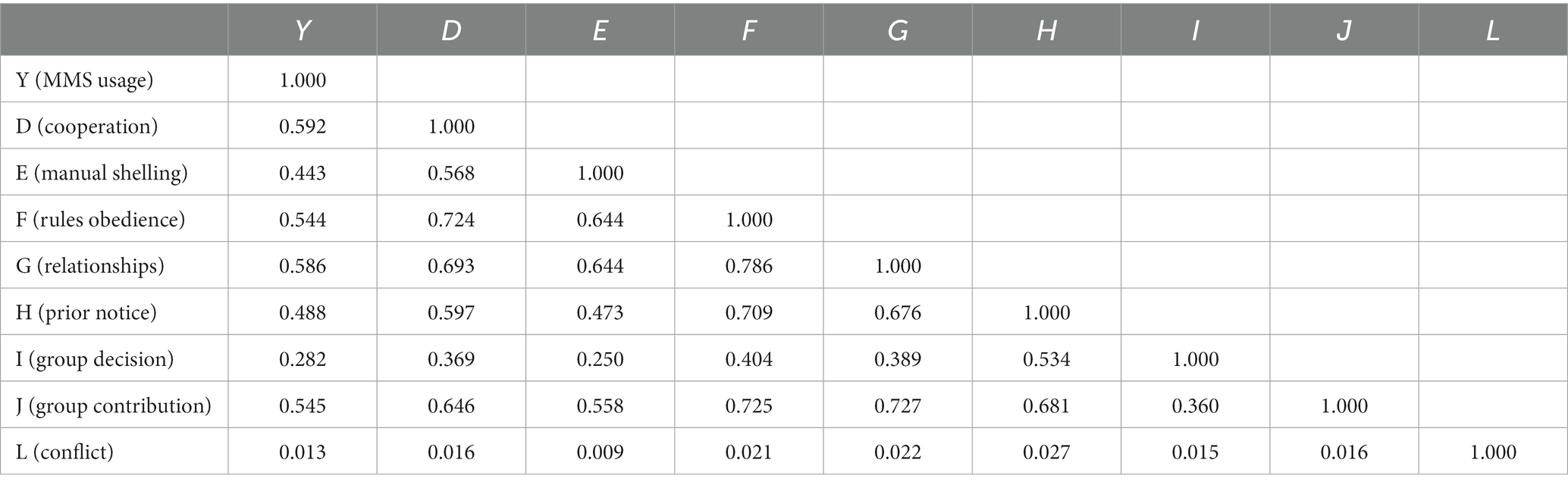

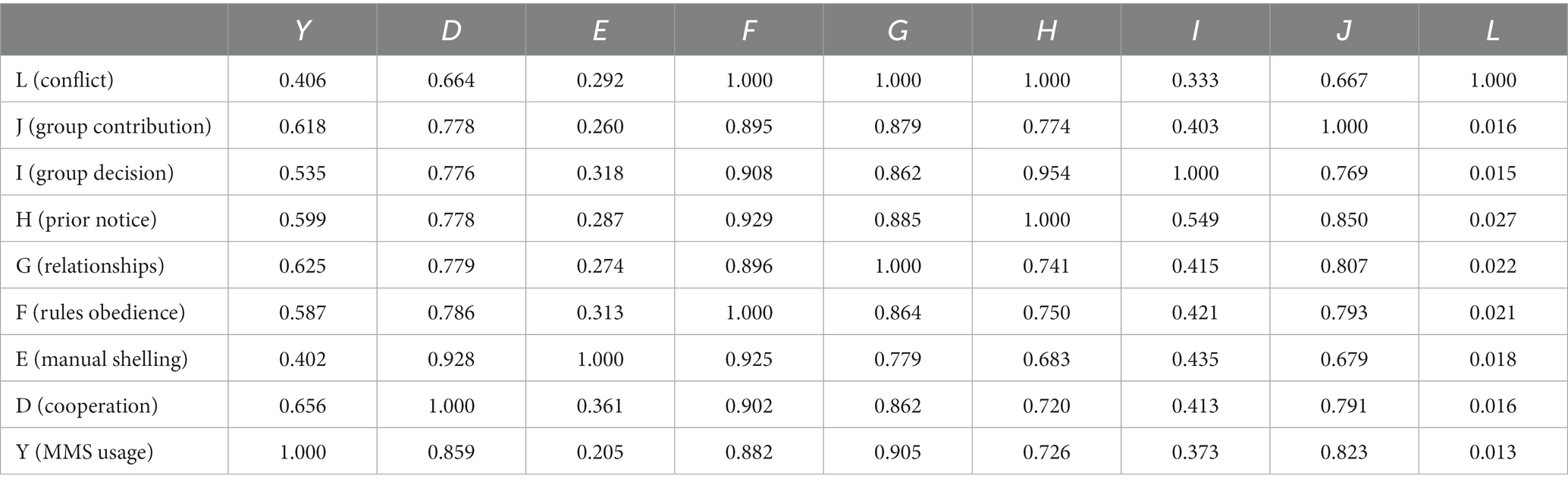

Next, the relationship between the various conditions and group sheller usage were examined through the coincidence matrix, which helps to understand the relationship between the conditions by measuring the amount of overlap or coincidence between the two sets or configurations. The outcomes are reported in Table 3. The results show that the high cooperation and high MMS usage set overlap by 59% of their possible shared area, as shown by their 0.592 coincidence score.

High conflict and high MMS usage sets overlap the least, by only about 1.3% as indicated by the coincidence score of 0.013. There are also high degrees of overlap between the condition sets, implying that these conditions can combine to produce high MMS usage, to be confirmed in subsequent analysis.

4.4.3 Necessity and sufficiency of conditions in predicting mechanized maize sheller usage

Next, the sufficiency and necessity of the conditions were examined, which help to determine the relationship between individual sets with each other and with the outcome. QCA was used to generate consistency scores for these two conditions. According to Ragin (2006), consistency is a measure of the degree to which a relation of necessity or sufficiency between a causal condition (or combination of conditions) and an outcome is met within a given data set. The upper diagonal of Table 4 represents the consistency scores for sufficiency while its lower diagonal reports that for necessity.

The scores show that high cooperation (D) is the single set that–alone–is most sufficient for predicting the outcome (consistency = 0.656). Better relationship within the sheller groups follows next with a high consistency score of 0.625 and group contribution by 0.618. Regarding necessity, better relationships within groups is the single set that–alone–is most necessary for predicting the MMS usage (consistency = 0.905). This is again followed by rules obedience (0.882) and cooperation (0.859). What these results tell is that cooperation, better relationships and group contributions are core conditions which in existence can contribute to higher usage of the group MMS.

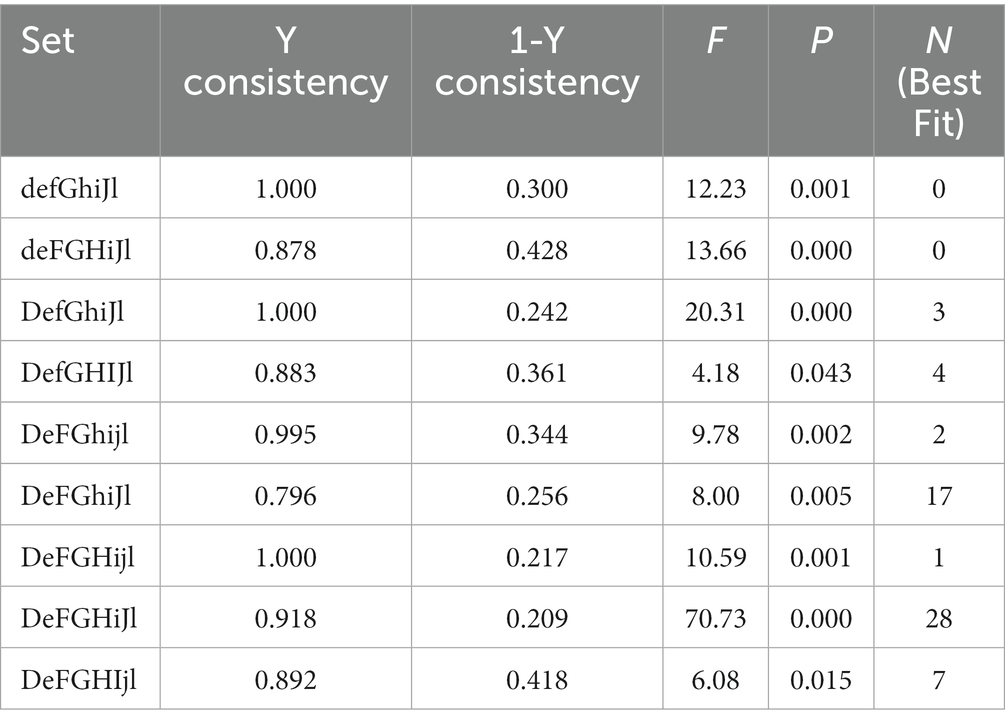

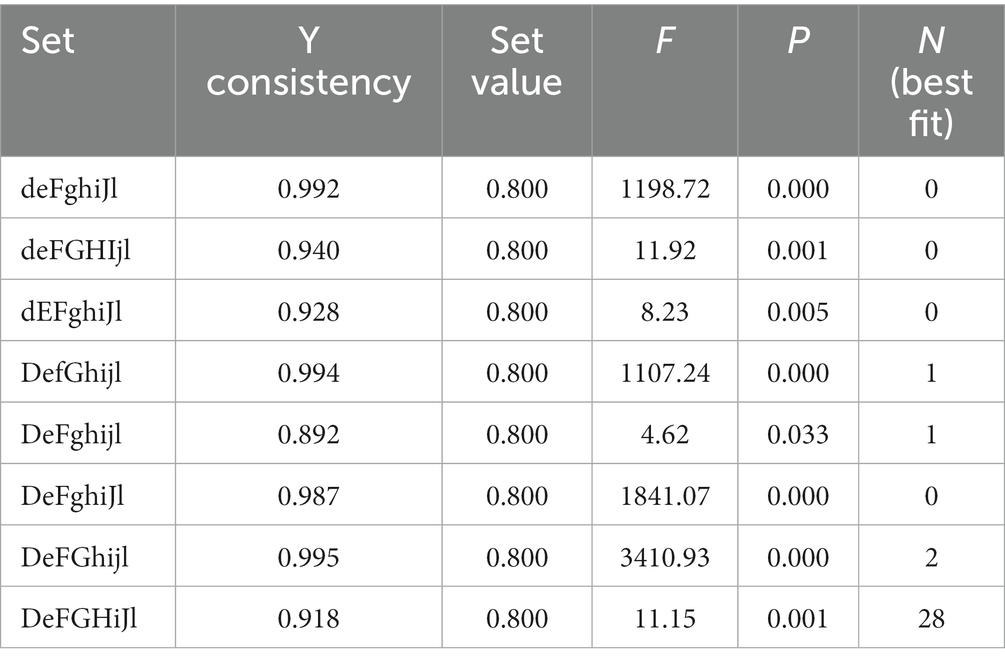

The preceding results all confirm that the condition sets are related, hence the next exercise is to examine their resulting configurations’ sufficiency with the group MMS usage variable. In Tables 5, 6, the consistency scores for the retained configurations that satisfy minimum conditions and a set value (0.8) are reported. According to Ragin (2006), a consistency score lower than 0.75 indicates an obvious departure from the set-theoretic relation in question. A significant value of p means that the inclusion in Y consistency and the inclusion not-in Y consistency of a particular configuration are statistically different for all configurations in the solution. Each configuration’s consistency is displayed, as well as the resulting test against 0.800 set value. The results indicate that eight configurations are significantly more consistent with high MMS usage than 0.800 at the 0.05 significance level. Table 5 for instance indicates that the configuration DeFGHiJl has the highest number of cases (28 farmers) fitting it, while DeFGhijl has the highest Y consistency score but with only two cases. It is possible though that these configurations may logically overlap.

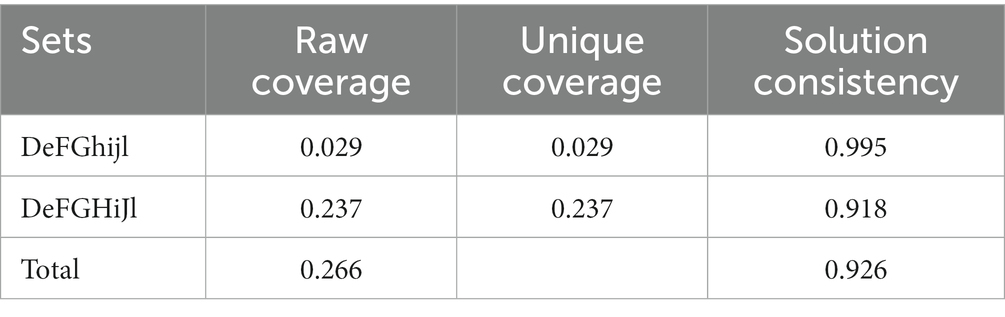

4.4.4 Final reduction test and consistent solution

To find a consistent solution, the reduction test was reported. The results for the reduction test in Table 7 show that the eight initial configurations have been collapsed into just two, which are DeFGhijl and DeFGHiJl. Based on the reduction test, there are two causal pathways to higher usage of the group sheller. The first causal pathway consists of high cooperation (D), low manual shelling (e), high rules obedience (F), better relationships within groups (G), low prior notice (h), low contribution to group decisions (i), low group contribution (j), and low levels of conflicts (l). The second causal pathway consists of high cooperation (D), low manual shelling (e), high rules obedience (F), better relationships within groups (G), high prior notice (H), low contribution to group decisions (i), high group contribution (J), and low levels of conflicts (l).

The six conditions that are key to higher usage of the mechanized group sheller, vis-a-vis its sustainability, are high cooperation within the sheller groups (H), low usage of manual shelling (e), obedience to rules in the constitutions (F), maintaining better relationships within groups (G) low contribution to group decisions (i) and low level of conflicts within groups (l). When these base sets exist, usage of the group sheller is likely to be high. The conditions sets relating to prior notice (H) and group contribution (J) seem to be not so crucial, as the presence or absence of these sets combined with the base sets still produce the same outcome. These two conditions can thus be considered as necessary but not sufficient for high usage of the group sheller.

Based on the coverage parameters in Table 7, there is low coverage (0.029) for the first configuration (DeFGhijl), which indicates that the cases (number of farmers) exhibiting this causal condition only form about 3 % of the sample and do not represent a large proportion of the cases exhibiting the outcome (high group MMS usage). On the other hand, the second configuration (DeFGHiJl) exhibits relatively high coverage of about 24 percent, indicating that the cases exhibiting this causal condition represent a large proportion of the cases that exhibit high group MMS usage. Thus, the second configuration is more plausible to generate higher usage of the group sheller for a large proportion of farmers than the first.

5 Discussion

The arduous task of manual maize shelling prompts farmers to seek mechanized solutions through collective action (Fischer et al., 2021; Kotu et al., 2023). Factors influencing collective action success are intricate; some conditions aiding success in one context may lead to failure in another (Poteete and Ostrom, 2004). For instance, Gavrilets (2015) discusses free-riding problems and within group heterogeneities, while others point to the adverse implications of group size on collective action success (Ostrom, 1986; Esteban and Ray, 2001; Fujiie et al., 2005). Contextual aspects, such as demographics, collective goals, and guiding institutions, shape collective action outcome (Abdul-Rahaman and Abdulai, 2020; Zang et al., 2022). This study assesses contextual factors for sustaining a mechanical maize sheller intervention among smallholder farmers in northern Ghana using QCA. The study’s main hypothesis centered on MMS usage as pivotal for sustainability, generating funds for operational costs and future investments.

Five key conditions–group cooperation, member relationships, individual contributions, rule adherence, and meeting notifications–emerged as essential pathways to increase usage of the group sheller. These findings support existing literature emphasizing cooperation’s significance in collective action success (Dong et al., 2018; Ureña et al., 2019; Nayak et al., 2020; Van de Brake et al., 2020).

High levels of cooperation often stem from a strong sense of trust among group members, and this remains crucial for successful collective action (Bakir et al., 2020). Cooperation encourages active participation in group activities, including the use of the group sheller for maize processing. This synergy innures to learning among group members, as argued by Orsi et al. (2017), and demonstrates effective collaboration and inclusive decision-making, valuing diverse opinions and shared responsibilities (Bakir et al., 2020). Conversely, low cooperation, as noted by Jagers et al. (2020), can lead to defection and negative impacts on group performance. Moreover, positive member relationships foster a sense of belonging, motivating individuals toward collective goals rather than individual gains (Fraser et al., 2019).

Group financial contributions play a pivotal role in boosting group funds and maintaining the operational efficiency of the mechanical group sheller, thereby ensuring sustained functionality and productivity. Regular maintenance of the sheller prevents frequent breakdowns, mitigating farmer disillusionment and discouragement from utilizing the group sheller, potentially resorting to manual shelling. Willer (2009) notes that groups reward an individual’s financial sacrifices to the group, while Fischer and Qaim (2014) concludes that reciprocity motivates individuals to contribute to group goals. Individuals acknowledging the value of their contributions to group capital formation is essential for group capital formation, providing instrumental capacity to the group’s sheller maintenance.

Compliance with constitutional rules within the group context plays a pivotal role in stimulating various aspects that are fundamental to sustained collective action. As highlighted by Markelova et al. (2009), adherence to these rules increases group security by establishing a structured framework that promotes orderliness, consistency, and predictability within the group’s operations. By strengthening credibility, obedience to group rules increases the trust and reliability members have in the group’s functioning, thereby consolidating their commitment to collective initiatives such as the utilization of the group sheller. Moreover, observing these rules fosters uniformity among members, creating a common ground and shared understanding of expected behaviors and responsibilities. This harmonization of conduct cultivates a cohesive environment where members are aligned in their approaches and actions, ultimately contributing to the pursuit of collective objectives. In essence, general adherence to group rules not only signifies a high level of cooperation but also acts as a catalyst for promoting harmonious interactions, facilitating equitable access to shared resources, and consolidating efforts toward achieving collective goals within the group context.

Providing advance information to members about forthcoming group meetings is a crucial factor in nurturing increased usage of the group sheller. Poteete and Ostrom (2004) highlight the significance of adequate information dissemination, emphasizing that a lack of such communication tends to impede coordination and obstruct the attainment of shared objectives within collective endeavors. Offering advance notice of meetings underscores the value placed on members’ participation and contributions to collective decision-making aimed at achieving common goals. This proactive communication serves as a foundation for fostering an inclusive environment where each member feels valued and engaged in the collective decision-making process. By informing members beforehand, it acknowledges their importance and encourages active involvement in shaping the direction of the group’s initiatives. Consequently, this practice not only cultivates a sense of ownership and accountability among participants but also reinforces a shared commitment toward the group’s objectives, such as sustaining the use of the group sheller. Ultimately, prior information dissemination plays a pivotal role in enhancing collaboration, cohesion, and the collective success of the group’s endeavors (Poteete and Ostrom, 2004).

In human interactions, conflict can scarcely be ruled out (Rahim, 2023). The absence of conflict within the group setting emerges as a significant factor encouraging the utilization of the group sheller. Conflict, as highlighted by Roskosa and Rupniece (2016), tends to undermine cooperative efforts, ultimately impeding the group’s ability to effectively execute shared tasks. Therefore, a low level of conflict becomes a necessary condition for fostering an environment conducive to utilizing the group sheller. Reduced conflict levels signify an atmosphere characterized by mutual respect, peace, and cooperation among group members. This harmonious environment promotes a sense of belonging and unity, motivating individuals to engage positively and actively in collective activities, such as utilizing the group sheller. As the saying goes, “you go where you are celebrated rather than tolerated,” indicating that a conflict-free environment encourages active participation and support for shared initiatives.

Furthermore, while individual contributions to group decisions indicate an interest in achieving collective goals, an excessive number of contributions, particularly those that are repetitive or irrelevant are costly (Zhang et al., 2019) and may impede progress. It may lead to extended meeting durations, hindering the establishment of cohesive and forward-moving collective goals within stipulated timeframes. In response, members might choose to limit their active participation in decision-making processes, allowing the constitutional rules to guide proceedings, thereby streamlining discussions and ensuring productive outcomes within the group. Hence, the absence of conflict, balanced participation in group decisions, and a reduction in manual shelling of maize emerge as essential conditions that promote a conducive environment for the successful utilization of the group sheller among the collective.

The necessity of reducing manual shelling of produce cannot be overstated in ensuring the sustainability of the intervention. The continuous reliance on manual shelling practices poses a significant threat to the viability of the group maize sheller. Should farmers persist in manually shelling their produce, the maize sheller within the collective could lose its relevance or even face potential disuse. Consequently, the identification of a low proportion of total output being shelled manually as a vital condition for high utilization of the group sheller is reassuring. Low reliance on manual shelling signifies a higher adoption rate of the mechanized sheller among group members (Kotu et al., 2023). This increased utilization is pivotal as it directly influences the efficiency and cost-effectiveness of the shelling machine. When a substantial portion of produce is manually shelled, it compromises the efficiency gains offered by the shelling machine. This situation may hamper the generation of sufficient funds required for servicing and maintaining the sheller. Ultimately, this could lead to a decrease in the quantity shelled by the machine, further exacerbating the sustainability concerns surrounding its functionality within the collective.

Summarizing, the crucial combination of conditions that collectively ensure high usage of the group sheller, thereby securing its sustainability, includes several key factors: strong group cooperation, minimized manual shelling of produce, adherence to constitutional rules by members, fostering positive relationships within groups, limited contributions to group decisions by members, and reduced conflicts within groups. With these conditions coexisting, the future prospects for the sustainability and potential expansion of the group sheller intervention appear promising.

While the results underscore the impacts of certain conditions on group sheller usage and sustainability, one caveat is the failure of QCA to clarify correlation between variables, hence its inability to quantify how changes in the independent variable (i.e., the causal conditions) affect the dependent variable (Cunha et al., 2023). Nevertheless, QCA explains the logical relationships between the conditions, determining whether they are necessary or sufficient to produce the outcome. Secondly, due to low case counts in the QCA methodology, subjectivity in case selection, conditions and indicator choices could exist (Rihoux et al., 2013). This study preselected cases from the collective action groups, thus precluding theory-based case selection. Accordingly, the claims for generalizability cannot be guaranteed. Nevertheless, the survey design was adequately informed by the collective action theory. The study sample was also randomly generated, thus reducing the risk of subjectivity. Additionally, a 156-farmers sample is comparatively large in QCA context. These strategies are expected to minimize the subjectivity and small sample size risks potentially affecting the results. While QCA does not establish direct cause-and-effect relationships in the traditional sense, its ability to identify necessary and sufficient conditions offers a nuanced understanding of the complex interplay of factors contributing to observed outcomes within specific contexts. This depth of analysis provides valuable insights into the multifaceted nature of social phenomena, contributing to a more holistic understanding of causal mechanisms.

6 Conclusion and recommendation

This paper uses the qualitative comparative analysis (QCA) methodology and data from the Africa RISING project to highlight the contextual conditions that enhance the success of smallholder maize shelling mechanization through a collective business model. The study used the proportion of maize output harvested in 2020 cropping season that was shelled using the mechanized maize sheller as the explained variable, and eight other causal conditions as the explanatory variables. Findings of the study indicate that group cooperation is the single most important sufficient condition that can foster increased usage of the group MMS. Additionally, good relationships among members, payment of financial contributions, provision of prior notice to group meetings and obedience to group rules are important complementary sufficient conditions.

These findings suggest that group members need to understand and respect individual differences, value the opinions of other members and assume shared responsibilities in order to improve cooperation and establish better relationship for a sustainable collective action. Also, the fulfillment of financial obligations is key in augmenting group capital that can be used for maintenance of the mechanized sheller and onboarding of other important interventions that may strengthen their membership and foster the sustainability of the group.

The role of proactive leadership in collective action is key; therefore, it is important that group leaders take proactive steps to always provide prior notice to all members before major group decisions. Further, reduced manual shelling is very necessary for group sheller usage. Hence, leaders must ensure that the mechanical maize sheller remains in well-functioning modes to discourage farmers from manually shelling their produce, as this would retard group success in terms of usage of the group sheller. Finally, as the findings reveal that the absence of conflict enhances success and sustainability of collective action, it is further suggested that group leaders as well as members desist from engaging in actions that may generate conflicts.

In addition to the caveats already outlined, this study requires further cross-validation to improve the reliability and confidence of the empirical findings. Currently, studies addressing this topic are limited, which restricted the depth of discussion. A complementary study applying econometric procedures to assess the QCA-identified configurations might allow the results to be comprehensively scrutinized. These limitations notwithstanding, this study provides valuable insights into the factors influencing group sheller usage. Future research should consider the importance of socioeconomic variables and explore other analytical procedures that can help increase the understanding of the collective actions and their outcomes.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

The studies involving humans were approved by International Institute of Tropical Agriculture. The studies were conducted in accordance with the local legislation and institutional requirements. The ethics committee/institutional review board waived the requirement of written informed consent for participation from the participants or the participants’ legal guardians/next of kin because most of the participants in the interviews were illiterate to provide written consents. However, they have provided oral consents.

Author contributions

IA: conceptualization, methodology, formal analysis, writing–original draft, and writing–review and editing. BK: conceptualization, data curation, and writing–review and editing. BB: data curation and writing–review and editing. JB: writing–review and editing and formal analysis. All authors contributed to the article and approved the submitted version.

Funding

The study was funded by United States Agency for International Development within the Africa RISING program and the Mixed Farming Systems Initiative of the Consultative Group for International Agricultural Research (CGIAR). The authors are grateful for the financial support.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2023.1228382/full#supplementary-material

Footnotes

1. ^Africa RISING is a research-for-development project which was sponsored by the United States Agency for International Development with the aim of reducing poverty among smallholder farmers through innovating and scaling of sustainable agricultural practices and technologies. It was operational in six countries (i.e., Ghana, Mali, Tanzania, Malawi, Ethiopia, and Zambia) from 2012 to 2022 involving several international and national research institutions, development NGOs, and the private sector (visit https://africa-rising.net/ for more info).

2. ^The machine comprises three main parts: diesel engine, concave-shaped chamber where the shelling takes place, and a hopper. The shelling chamber houses a shelling drum on which a narrow beating ridge is mounted, a coarse screen, and collecting pan. In operation, the diesel engine powers a shaft that rotates the shelling drum [see Supplementary Figure A1 in the Annex; also refer to Mutungi et al. (2022) for more description, benefits and procedures of using the machine].

3. ^The farmers were trained on how to develop a written constitution.

4. ^More information on the trainings can be found on these links: https://cgspace.cgiar.org/handle/10568/16926; https://africa-rising.net/no-technician-no-problem-africa-rising-releases-35-vernacular-diy-videos-on-maintenance-of-maize-shelling-machines-for-use-by-farmers-in-ghana/.

5. ^The survey process was reviewed and approved by the Institutional Review Board of the International Institute of Tropical Agriculture.

6. ^Sample size =  = 147, assuming 5% marginal error (e), 1.65 z-score (z), 50% population proportion (P), and 320 population size (N) (Cochran, 1977).

7. ^Although the farmers were advised to organize their groups within the range of 15 to 25 group size, farmers in one of the communities in Upper East region could mobilize only 10 farmers for membership. The group was considered for project support as a special case.

References

Abdul-Rahaman, A., and Abdulai, A. (2020). Farmer groups, collective marketing and smallholder farm performance in rural Ghana. J. Agribus. Dev. Emerg. Econ. 10, 511–527. doi: 10.1108/JADEE-07-2019-0095

Bakir, N., Humpherys, S., and Dana, K. (2020). Students’ perceptions of challenges and solutions to face-to-face and online group work. Inf. Syst. Educ. J. 18, 75–88.

Barrett, P., Treves, A., Shmis, T., Ambasz, D., and Ustinova, M. (2019). The impact of school infrastructure on learning: A synthesis of the evidence. Washington, DC: World Bank.

Bartolini, D., and Santolini, R. (2017). Political institutions behind good governance. Econ. Syst. 41, 68–85. doi: 10.1016/j.ecosys.2016.05.004

Baudron, F., Misiko, M., Getnet, B., Nazare, R., Sariah, J., and Kaumbutho, P. (2019). A farm-level assessment of labor and mechanization in eastern and southern Africa. Agron. Sustain. Dev. 39:563. doi: 10.1007/s13593-019-0563-5

Blackman, T. (2013). Exploring explanations for local reductions in teenage pregnancy rates in England: an approach using qualitative comparative analysis. Soc. Policy Soc. 12, 61–72. doi: 10.1017/S1474746412000358

Bowles, S., and Gintis, H. (2002). The inheritance of inequality. J. Econ. Perspect. 16, 3–30. doi: 10.1257/089533002760278686

Chahalis, E., McGhie, J., Mulokozi, G., Barham, S., Chappell, C., Schenk, C., et al. (2021). Tanzanian men’s engagement in household chores is associated with improved antenatal care seeking and maternal health. BMC Pregnancy Childbirth 21, 1–8. doi: 10.1186/s12884-021-04147-z

Cunha, P., Verschoore, J., and Monticelli, J. (2023). The interaction between cooperatives and startups. A qualitative comparative analysis in the context of open innovation. J. Technol. Manag. Innov. 18, 3–13. doi: 10.4067/S0718-27242023000100003

Darfour, B., and Rosentrater, K. A. (2016). Maize in Ghana: an overview of cultivation to processing. In: 2016 ASABE annual international meeting. American Society of Agricultural and Biological Engineers, p. 1.

Devkota, R., Pant, L. P., Gartaula, H. N., Patel, K., Gauchan, D., Hambly-Odame, H., et al. (2020). Responsible agricultural mechanization innovation for the sustainable development of Nepal’s hillside farming system. Sustainability 12:374. doi: 10.3390/su12010374

Diao, X., Cossar, F., Houssou, N., and Kolavalli, S. (2014). Mechanization in Ghana: emerging demand, and the search for alternative supply models. Food Policy 48, 168–181. doi: 10.1016/j.foodpol.2014.05.013

Dong, Y., Zha, Q., Zhang, H., Kou, G., Fujita, H., Chiclana, F., et al. (2018). Consensus reaching in social network group decision making: research paradigms and challenges. Knowl. Based Syst. 162, 3–13. doi: 10.1016/j.knosys.2018.06.036

Esteban, J., and Ray, D. (2001). Collective action and the group size paradox. Am. Polit. Sci. Rev. 95, 663–672. doi: 10.1017/S0003055401003124

FAO. (2018). National Gender Profile of agriculture and rural livelihoods–Ghana. In: Country gender assessment series, Accra. Available at: https://www.fao.org/3/i8639en/i8639en.pdf (Accessed December 13, 2023).

Fischer, E., and Qaim, M. (2014). Smallholder farmers and collective action: what determines the intensity of participation? J. Agric. Econ. 65, 683–702. doi: 10.1111/1477-9552.12060

Fischer, G., Kotu, B., and Mutungi, C. (2021). Sustainable and equitable agricultural mechanization? A gendered perspective on maize shelling. Renew. Agric. Food Syst. 36, 396–404. doi: 10.1017/s1742170521000016

Florea, A. M., Bercu, F., Radu, R., and Stanciu, S. (2019). A fuzzy set qualitative comparative analysis (fsQCA) of the agricultural cooperatives from south east region of Romania. Sustainability 11:5927. doi: 10.3390/su11215927

Fraser, S. L., Hordyk, S. R., Etok, N., and Weetaltuk, C. (2019). Exploring community mobilization in northern Quebec: motivators, challenges, and resilience in action. Am. J. Community Psychol. 64, 159–171. doi: 10.1002/ajcp.12384

Fraser, S., Vrakas, G., Laliberte, A., and Mickpegak, R. (2018). Everyday ethics of participation: a case study of a CBPR in Nunavik. Glob. Health Promot. 25, 82–90. doi: 10.1177/1757975917690496

Fujiie, M., Hayami, Y., and Kikuchi, M. (2005). The conditions of collective action for local commons management: the case of irrigation in the Philippines. Agric. Econ. 33, 179–189. doi: 10.1111/j.1574-0862.2005.00351.x

Gavrilets, S. (2015). Collective action problem in heterogeneous groups. Philos. Trans. R. Soc. B 370:20150016. doi: 10.1098/rstb.2015.0016

Gebeyehu, S. G. (2023). Developing appropriate business model for maize shelling technologies in small holder farmers in north West Ethiopian districts. Cogent Eng. 10:199. doi: 10.1080/23311916.2023.2165199

Gençer, H. (2019). Group dynamics and behaviour. Univ. J. Educ. Res. 7, 223–229. doi: 10.13189/ujer.2019.070128

Gongbuzeren, G., Wenjun, L., and Yupei, L. (2021). The role of community cooperative institutions in building rural–urban linkages under urbanization of pastoral regions in China. Front. Sustain. Food Syst. 5:2207. doi: 10.3389/fsufs.2021.612207

GSS. (2021a). General report volume 3D: Literacy and education. Ghana 2021 population and housing census. Ghana Statistical Service, December 2021. Available at: https://census2021.statsghana.gov.gh/gssmain/fileUpload/reportthemesub/2021%20PHC%20General%20Report%20Vol%203D_Literacy%20and%20Education.pdf (Accessed December 13, 2023).

GSS. (2021b). General report volume 3E: Economic activity. Ghana 2021 population and housing census. Ghana Statistical Service, December 2021. Available at: https://statsghana.gov.gh/gssmain/fileUpload/pressrelease/2021%20PHC%20General%20Report%20Vol%203E_Economic%20Activity.pdf (Accessed December 13, 2023).

Hodjo, M., Schwab, B., Kere, M., Millogo, V., and Srivastava, A. (2021). Demand for agriculture mechanization in the Hauts- Bassins region in Burkina Faso. J. Agribus. 39, 39–64.

Houssou, N., Diao, X., Cossar, F., Kolavalli, S., Jimah, K., and Aboagye, P. O. (2013). Agricultural mechanization in Ghana: is specialized agricultural mechanization service provision a viable business model? Am. J. Agric. Econ. 95, 1237–1244. doi: 10.1093/ajae/aat026

Jagers, S. C., Harring, N., Lofgren, A., Sjostedt, M., Alpizar, F., Brulde, B., et al. (2020). On the precondition for large-scale collective action. Ambio 49, 1282–1296. doi: 10.1007/s13280-019-01284-w

Joshi, K., Pandey, B. M., Khulbe, R. K., and Pattanayak, A. (2018). Women’s drudgery and maize sheller intervention: a case of tribes of Jaunsar region of Uttarakhand. Indian J. Hill Farm. 1, 96–100.

Kizito, F., Abdul Rahman, N., Boyubie, B., and Kotu, B. (2018). Photo Report on Africa RISING West Africa: Highlights of small scale maize-shelling machines in Northern Ghana 11-18 December 2018. Ibadan, Nigeria: IITA. Available at: https://cgspace.cgiar.org/handle/10568/100727 (Accessed December 27, 2023).

Kotu, B. H., Manda, J., Mutungi, C., Fischer, G., and Gaspar, A. (2023). Farmers' willingness to invest in mechanized maize shelling and potential financial benefits: evidence from Tanzania. Agribusiness 39, 854–874. doi: 10.1002/agr.21801

Kusz, D. (2014). Modernization of agriculture vs sustainable agriculture. Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development, 14, pp. 171–178.

Liao, W., Zeng, F., and Chanieabate, M. (2022). Mechanization of small-scale agriculture in China: lessons for enhancing smallholder access to agricultural machinery. Sustainability 14:7964. doi: 10.3390/su14137964

Li, F., Feng, S., Lu, H., Qu, F., and D’Haese, M. (2021). How do non-farm employment and agricultural mechanization impact large-scale farming? A spatial panel data analysis from Jiangsu Province, China. Land Use Policy 107:105517. doi: 10.1016/j.landusepol.2021.105517

Markelova, H., Meinzen-Dick, R., Hellin, J., and Dohrn, S. (2009). Collective action for smallholder market access. Food Policy 34, 1–7. doi: 10.1016/j.foodpol.2008.10.001

MoFA (2022). Ministry of Food and Agriculture. Facts and Figures: Agriculture in Ghana, 2021. September 2022. Available at: https://mofa.gov.gh/site/publications/research-reports/442-agriculture-in-ghana-facts-and-figures-2021

Mutungi, C., Abass, A., Fischer, G., and Kotu, B. (2022). “Improved technologies for reducing post-harvest losses” in Sustainable agricultural intensification: A handbook for practitioners in east and southern Africa. eds. M. Bekunda, I. Hoeschle-Zeledon, and J. Odhong (Wallingford, UK: CABI International), 91–105.

Nayak, A. K., Panigrahi, P. K., and Swain, B. (2020). Self-help groups in India: challenges and a roadmap for sustainability. Soc. Responsibil. J. 16, 1013–1033. doi: 10.1108/SRJ-02-2019-0054

Ndimbo, G. K., Yu, L., and Buma, A. A. (2023). ICTs, smallholder agriculture and farmers’ livelihood improvement in developing countries: evidence from Tanzania. Inf. Dev. 2023:11652. doi: 10.1177/02666669231165272

Ochieng, J., Knerr, B., Owuor, G., and Ouma, E. (2018). Strengthening collective action to improve marketing performance: evidence from farmer groups in Central Africa. J. Agric. Educ. Ext. 14:964. doi: 10.1080/1389224X.2018.1432493

Odhong, J. (2019). Establishing shared prosperity: Farmers’ groups in northern Ghana set ground rules for using maize shellers. Online article available at: https://africa-rising.net/establishing-shared-prosperity-farmers-groups-in-northern-ghana-set-ground-rules-for-using-maize-shellers/ (Accessed December 27, 2023).

Olson, M. (1965). The logic of collective action: Public goods and the theory of groups. Cambridge and MA: Harvard University Press.

Ombogoh, D. B., Tanui, J., McMullin, S., Muriuki, J., and Mowo, J. (2018). Enhancing adaptation to climate variability in the east African highlands: a case for fostering collective action among smallholder farmers in Kenya and Uganda. Clim. Dev. 10, 61–72. doi: 10.1080/17565529.2016.1174665

Orsi, L., De Noni, I., Corsi, S., and Marchisio, L. V. (2017). The role of collective action in leveraging farmers' performances: lessons from sesame seed farmers' collaboration in eastern Chad. J. Rural. Stud. 51, 93–104. doi: 10.1016/j.jrurstud.2017.02.011

Ostrom, E. (1986). An agenda for the study of institutions. Public Choice 48, 3–25. doi: 10.1007/BF00239556

Peng, J., Zhao, Z., and Liu, D. (2022). Impact of agricultural mechanization on agricultural production, income, and mechanism: evidence from Hubei Province, China. Front. Environ. Sci. 10, 1–15. doi: 10.3389/fenvs.2022.838686

Pingali, P. (2007). “Agricultural mechanization: adoption patterns and economic impacts” in Handbook of agricultural economics. eds. R. Enanson and P. Pingali, vol. 3 (Amsterdam, Netherlands: Elsevier), 2780–2803.

Poku, A.-G., Birner, R., and Gupta, S. (2018). Why do maize farmers in Ghana have a limited choice of improved seed varieties? An assessment of the governance challenges in seed supply. Food Secur. 10, 27–46. doi: 10.1007/s12571-017-0749-0

Poteete, A. R., and Ostrom, E. (2004). Heterogeneity, group size and collective action: the role of institutions in Forest management. Dev. Chang. 35, 435–461. doi: 10.1111/j.1467-7660.2004.00360.x

Ragin, C. C. (2006). “The limitations of net-effects thinking” in Innovative comparative methods for policy analysis. eds. B. Rihoux and H. Grimm (Boston, MA: Springer), 13–41.

Reina, A., Ferrante, E., and Valentini, G. (2021). Collective decision-making in living and artificial systems: editorial. Swarm Intell. 15, 1–6. doi: 10.1007/s11721-021-00195-5

Rihoux, B., Marx, A., Benoît, R., Axel, M., Charles, C. R., Priscilla, Á.-C., et al. (2013). QCA, 25 years after “the comparative method”: mapping, challenges, and innovations–Mini-symposium. Polit. Res. Q. 66, 167–235. doi: 10.1177/1065912912468269

Rihoux, B., and Ragin, C. C. (2009). Configurational comparative methods: Qualitative comparative analysis (QCA) and related techniques. Thousand Oaks, CA: Sage Publications, Inc.

Rodrik, D., Subramanian, A., and Trebbi, F. (2004). Institutions rule: the primacy of institutions over geography and integration in economic development. J. Econ. Growth 9, 131–165. doi: 10.1023/B:JOEG.0000031425.72248.85

Roskosa, A., and Rupniece, D. (2016). Advantages and drawbacks of using group work in translator training. Procedia. Soc. Behav. Sci. 231, 244–250. doi: 10.1016/j.sbspro.2016.09.098

Senadza, B. (2012). Education inequality in Ghana: gender and spatial dimensions. J. Econ. Stud. 39, 724–739. doi: 10.1108/01443581211274647

Skoog, G. E. (2005). Supporting the development of institutions–formal and informal rules: an evaluation theme basic concepts. UTV working paper 2005:3. Department for Evaluation and Internal Audit, Swedish International Development Cooperation Agency (SIDA). Available at: https://cdn.sida.se/publications/files/sida23418en-supporting-the-development-of-institutions---formal-and-informal-rules-an-evaluation-theme-basic-concepts.pdf (Accessed December 13, 2023).

Takayama, T., Matsuda, H., and Nakatani, T. (2018). The determinants of collective action in irrigation management systems: evidence from rural communities in Japan. Agric. Water Manag. 206, 113–123. doi: 10.1016/j.agwat.2018.04.031

Ureña, R., Kou, G., Dong, Y., Chiclana, F., and Herrera-Viedma, E. (2019). A review on trust propagation and opinion dynamics in social networks and group decision-making frameworks. Inf. Sci. 478, 461–475. doi: 10.1016/j.ins.2018.11.037

Van de Brake, H. J., Walter, F., Rink, F. A., Essens, P. J. M. D., and van der Vegt, G. S. (2020). Benefits and disadvantages of individuals’ multiple team membership: the moderating role of organizational tenure. J. Manag. Stud. 57, 1502–1530. doi: 10.1111/joms.12539

Willer, R. (2009). Groups reward individual sacrifice: the status solution to the collective action problem. Am. Sociol. Rev. 74, 23–43. doi: 10.1177/000312240907400102

Zang, L., Wang, Y., Ke, J., and Su, Y. (2022). What drives smallholders to utilize socialized agricultural services for farmland scale management? Insights from the perspective of collective action. Land 11:930. doi: 10.3390/land11060930

Zhang, H., Kou, G., and Peng, Y. (2019). Soft consensus cost models for group decision making and economic interpretations. Eur. J. Oper. Res. 277, 964–980. doi: 10.1016/j.ejor.2019.03.009

Keywords: maize-sheller, qualitative comparative analysis, group business model, collective action, Ghana

Citation: Ansah IGK, Kotu BH, Boyubie BE and Bonney JE (2024) Enhancing smallholder maize shelling mechanization through the collective business model: the case of Northern Ghana. Front. Sustain. Food Syst. 7:1228382. doi: 10.3389/fsufs.2023.1228382

Edited by:

Francis Kumi, University of Cape Coast, GhanaReviewed by:

Shadrack Kwadwo Amponsah, CSIR Crops Research Istitute, GhanaEmmanuel Wisgtos Inkoom, University of Cape Coast, Ghana

Mohd. Muzamil, Sher-e-Kashmir University of Agricultural Sciences and Technology, India

Adewale Sedara, Iowa State University, United States

Copyright © 2024 Ansah, Kotu, Boyubie and Bonney. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bekele Hundie Kotu, Yi5rb3R1QGNnaWFyLm9yZw==

ORCID: Isaac Gershon K. Ansah, https://orcid.org/0000-0001-5071-6224

Bekele Hundie Kotu, https://orcid.org/0000-0002-5488-8426

Joseph Ekow Bonney, https://orcid.org/0000-0001-6785-0550

Isaac Gershon K. Ansah

Isaac Gershon K. Ansah Bekele Hundie Kotu

Bekele Hundie Kotu Benedict Ebito Boyubie

Benedict Ebito Boyubie Joseph Ekow Bonney

Joseph Ekow Bonney