94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

POLICY AND PRACTICE REVIEWS article

Front. Sustain. Food Syst. , 27 March 2023

Sec. Agro-Food Safety

Volume 7 - 2023 | https://doi.org/10.3389/fsufs.2023.1059058

This article is part of the Research Topic Food Safety in Low and Middle Income Countries View all 25 articles

Edible offals comprise those parts of the animal considered fit for human consumption apart from the skeletal muscle, fat and attached skin. Edible offals form an important source of affordable animal protein and a delicacy for the larger Kenyan market. The offals are mainly traded in the informal markets which supplies at least 80% of the domestic market and where hygiene levels are low. The Meat Control Act Chapter 356, Laws of Kenya (Revised 2012) requires that offals be obtained from an officially declared food animal that has been slaughtered in a licensed slaughterhouse and declared fit for human consumption. According to the Meat Control Act, slaughterhouses in Kenya are classified as either export or local. The latter is subdivided into categories A, B, and C depending on their daily capacity, land size and the area they are authorized to supply meat and meat products. Each export slaughterhouse, category A and B slaughterhouses require a minimum of three meat inspectors to carry out inspection of carcasses and offals. The Directorate of Veterinary Services is the main regulator in Kenya on matters concerning safety of meat at the slaughterhouses. The Director of Veterinary Services appoints meat inspectors and veterinary officers who are responsible for ascertaining the safety of meat and meat products from the slaughterhouses. The meat inspectors also verify that slaughter facilities, staff, processes and equipment conform to food safety requirements. Offals, like carcass meat, should be handled under utmost hygiene conditions to minimize contamination or excessive growth of microorganisms. The current practices in slaughterhouses is that each set of edible offals is packaged separately in either polythene bags, plastic containers, meat transport containers or carriers and dispatched to the market. In some instances, stomachs and intestines are packaged for dispatch together with the lungs and hearts for transportation to distances over 50 km in either refrigerated or non-refrigerated containers or carriers. Some of these practices could compromise the safety of the offals. In this paper, we review the challenges faced in maintaining safety of edible offals especially at the slaughterhouses, distributors and retailers level from regulators' point of view.

Offals are often defined as the edible, non-muscular parts of the carcasses of livestock including heart, kidney, liver, tongue, brain and intestines. Tails, feet, heads, and skin may also be considered offal (Codex, 2021). Many types of offals are nutrient dense, containing more iron and vitamin B12 than lean muscle meat, and historically were widely consumed worldwide. However, offals became less popular in high-income countries (HICs), possibly because it was more difficult to prepare, associated with lower status, induced feelings of disgust by some consumers, and because of changes in value chains and concerns about health hazards such as heavy metals or diseases such as bovine spongiform encephalopathy (Hicks et al., 2018). In low- and middle-income countries (LMIC), offals remain widely consumed, and there are increasing efforts to promote their consumption in HICs as their consumption reduces food waste. In 2021, Kenyan exports of meat and edible offal was worth US$ 75.09 Million (Trading Economics, 2022).

The Kenya Standards-Offal Specification (DKS 2716:2017) categorizes offals into three namely: green offals (digestive tract organs i.e., rumen, reticulum, omasum, abomasum, small intestines, large intestines and colon), red offals (lungs, trachea, liver, hearts, kidneys, spleen, tongue, and pancreas) and white offals (brain, spine, bone marrow, testicles, pizzles, and udder). They are also loosely referred to as the “fifth quarter”. Most of the green and red offals constitute edible offals in Kenya. Of the edible offals, the liver, kidney, gizzards and “matumbo” (rumen, reticulum, omasum, and abomasum) are most traded in the formal markets targeting high- and middle-income consumers. In the informal markets, traders sell intestines and tongue in addition to what is sold to the high- and middle-income consumers targeting low-income earners (Kenya Markets Trust, 2019).

The objective of this paper is to describe the red meat offal value chain in Kenya and challenges in maintaining food safety at different levels of the value chain from regulators' point of view following the structure below:

i The meat sector in Kenya: production, slaughter and retail line.

ii The yield of red meat offal in Kenya both from domestic and export sectors plus an estimate of the amount of red meat offal from the domestic sector.

iii Regulatory framework for meat safety in Kenya.

iv Offal handling practices.

v Offal condemnation.

Kenya is administratively divided into forty seven counties and has a huge livestock resource base comprising 13.6 million heads of traditional/beef cattle, 2.2 million heads of dairy cattle, 19.3 million sheep, 28 million goats, 38.8 million poultry, 4.6 million camels, 1.2 million donkeys, and 0.4 million pigs (KNBS, 2019). About 60% of the livestock population is found in arid and semi-arid areas where it employs over 90% of the population (MOA, 2020). Beef, mutton, goat and camel meat comprise over 80% of meat consumed locally at a per capita meat consumption of 15 kg (Kenya Markets Trust, 2019). In 2018, meat production was as follows: 652,000 MT (beef), 25,271 MT (sheep and goat meat), 25,000 MT (pork) and 72,780 MT (camel meat) (FAOSTAT, 2018). The main market for the meat is domestic while a small proportion is sold internationally, mostly to Middle East countries, which are a major export destination for chilled sheep and goat carcasses. The main challenge in accessing other markets has been fulfilling the importing countries' sanitary standards particularly conditions on transboundary animal diseases and food safety.

In Kenya, slaughterhouses are classified as either export or local. There are several export slaughterhouses namely: Farmers Choice for pigs slaughter and Kenchic for chicken slaughter, whereas Choice Meats, Neema, Quality Meat Packers, KenMeat, Juja, and Kenya Meat Commission are mainly for slaughter of cattle, sheep and goats. Local slaughterhouses are over 2000 in number and are divided into: (1) Category A which is a large slaughterhouse with a daily capacity to process over 40 heads of cattle and is authorized to supply meat to any part of the country; (2) category B which is a medium slaughterhouse with a daily processing capacity of 6- 39 heads of cattle and is authorized to supply meat to towns or urban centers within 50 kilometers radius from its locality; (3) category C also called slaughter slabs, which processes less than 5 heads of cattle daily and is allowed to supply meat within its locality [Meat Control (local slaughterhouse) regulations, 2010 (Revised 2012)]. The slaughterhouses are further required to provide adequate land for each specific category to cater for slaughter stock holding area, location of auxiliary slaughterhouse facilities such as incinerator/condemnation pits, manure shed, waste water pre-treatment and changing rooms/ ablution. The primary aim of the slaughterhouses is to produce wholesome, healthy and clean meat and meat products (Ahmed et al., 2019).

The meat sector in Kenya is an important contributor to its economy. In 2020, the country exported 1,076 MT of beef valued at US$ 4,695,000; 12,508 MT of goat meat and mutton valued at US$ 55,790,000. In that year, 674,975 cattle, 2,634,766 goats, and 761,042 sheep were slaughtered. A small proportion of these was destined for the export market that mainly demands for whole carcass meat without offals. This left quite a significant quantity of offals to be handled and sold in the domestic market with a small proportion of this going for export. In 2020, Kenya exported edible offals worth US$ 1.45 million to Vietnam and Hong Kong making it the 64th largest exporter of edible offal in the world (OEC, 2023).

A high demand for ruminant offals is evident locally and is steadily growing owing to increased urban population coupled by expected doubling of red meat consumption by 2030. In Nairobi, Kenya's capital city, where the majority of export and large local slaughterhouses are located, the marketing channels for sale of offals are well established and known. The channels are distributed in formal (supermarkets and butcheries) and informal markets (street vendors, kiosks, and a popular chain of urban meat eateries). Kenya's informal sector is large and is increasingly expanding creating 8 out of 10 all new jobs outside the agricultural sector (KLMIS, 2021). The sector comprises enterprises that are not registered by the Registrar of Companies and are not covered by the government social security scheme and other employment related government regulations (KLMIS, 2021). Informal markets are the main channels for distribution of offals. In areas where these are located, some county governments have tried to establish prerequisites for food safety such as running water, public toilets, waste disposal and electricity. However, hygiene controls in these markets are still inadequate and there is a need to build capacity of food business operators (FBOs) on hygiene responsibility and perform regular check-ups to enforce hygiene regulations.

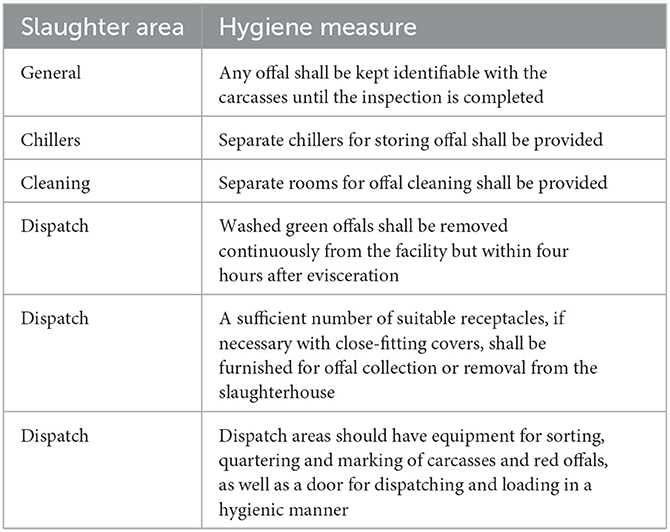

In Kenya, various laws including Public Health Act Chapter 242, Food, Drugs, and Chemical Substances Act Chapter 254, and Meat Control Act Chapter 356 as well as the Kenya standards adopted from international organizations such as Codex Alimentarius Commission and International Standards Organization regulate meat safety. These laws and standards aim at protecting meat consumers from various health hazards arising from consumption of unsafe meat. Slaughterhouses or abattoirs in Kenya are encouraged to implement food safety management systems and are licensed by the Director of Veterinary Services based on compliance to the regulations outlined in the Meat Control Act Chapter 356 of the Laws of Kenya (Law, 2012). Emanating from this Act are regulations governing local slaughterhouses, export slaughterhouses, poultry meat inspection, transport of meat and licensing of meat transport carriers and containers. The Meat Control (local slaughterhouse) regulations of 2010 outlines minimum requirements for hygienic handling of offals (Table 1).

Table 1. Summary of requirements for hygienic handling of offals as outlined in the meat control (local slaughterhouse) regulations of 2010.

Besides the Meat Control Act, the Animal Diseases Act Chapter 364 is applicable in the Meat regulatory framework as it guides in animal disease management and livestock movement. Livestock movement is key in livestock traceability and thus meat product traceability from the farm to the fork. The Prevention of Cruelty to Animals Act, Chapter 360, guides on animal welfare practices for slaughter stock at the farm, during transportation and at slaughter. Upholding animal welfare practices for slaughter stock has a positive correlation with the keeping quality for the meat. Further, it prevents injuries including bruises and fractures on the slaughter stock that leads to economic loss. Kenya as an exporting country to several Middle Eastern countries has conformed to the sanitary conditions imposed by these countries. These sanitary conditions, which are generally outlined in the Health Attestation of the Export Certificates, contribute toward the regulatory framework of the Meat sector in Kenya.

To obtain offals, after stunning and bleeding the slaughter animal, hooves are removed and placed in a receptacle. Flaying is then done to remove the hide. The head is then removed and is placed on the inspection rack for post-mortem inspection. The testicles and pizzles are left on the hide to be removed in the hides and skins room and packaged for dispatch. Evisceration is then undertaken whereby the gastrointestinal tract is removed, post-mortem inspection is conducted, and afterwards they are cleaned and packaged ready for dispatch. The remaining offals are then removed and moved to the inspection area for post-mortem inspection after which they are packaged for dispatch. The kidney remains on the carcass for removal after inspection of the carcass. It is then collated with the other offals and dispatched. For dispatch, packaging is done separately for each set of offals in polythene bags or metal containers.

It is assumed that offals are dispatched from the slaughterhouses while safe after having been inspected. However, there are challenges that pose increased risk of contamination of the offals thereby a risk of exposure to pathogens by slaughterhouse workers and local consumers that include, inter alia: (i) Inadequate knowledge to support good slaughtering practices, (ii) Lack of, or inadequate proper equipment such as aprons, boilers, cold storage facility and detention rooms, (iii) Water shortages that can compromise adequate cleaning of the products especially the “matumbo,” (iv) Use of untreated water in the slaughterhouses, (v) Improper elimination of condemned slaughterhouse materials, (vi) Lack of value addition for extending the shelf life of the offals, and (vii) Lack of adherence to procedures for maintenance and hygiene of the slaughterhouses including meat transport containers and trucks.

Distributors source edible offals directly from slaughterhouses to distribute to formal and informal markets. The Meat Control Act Chapter 356 requires that the offals be transported in a hygienic manner in licensed meat carriers or containers. The following are the key challenges in maintaining edible offal safety at distributor's level: (i) Weak enforcement of offal transportation regulations as per the Meat Control Act Chapter 356. There is minimal use of licensed meat carriers or containers or poor maintenance of the licensed ones, (ii) Practice of mixing red and green offals poses a risk of cross contamination, (iii) Long distance transportation in non-refrigerated containers to the markets, (iv) Inadequate or lack of monitoring product temperatures during transport and (v) Inadequate system for tracking and tracing the offal distribution system.

The key challenges in maintaining edible offal safety at retailer's level include: (i) Hygiene of the retail areas is occasionally overlooked if sold to informal markets as compared to formal ones such as butcheries, restaurants or hotels, (ii) Lack of industry association creating a barrier for access to capital to improve their infrastructure for hygiene, (iii) Lack of product traceability systems and (iv) Inadequate or lack of cold chain facilities.

Meat inspection in slaughterhouses refers to the expert supervision of the whole process of producing meat products with the objective of providing wholesome meat for human consumption and preventing danger to public health (Herenda et al., 1994).

The main reasons for condemnation of offals at the slaughterhouses include but not limited to parasitic conditions such as fascioliasis, hydatidosis, pimply gut/oesophagostomiasis; inflammatory conditions such as peritonitis, gastritis, enteritis, and pulmonary blood aspiration. A variety of internal parasites affect animals such as worms or helminths predominantly roundworms (nematodes), which are primarily parasites of the gastrointestinal tract with lung included, and the flat worms (trematodes) including liver flukes and tapeworms. Parasites often lead to abnormal conditions such as fascioliasis, peritonitis, hydatidosis and emphysema in livestock (Mareko et al., 2018). In a slaughterhouse survey in Ethiopia, out of 384 animals' slaughtered, postmortem inspection led to condemnation of 18.8% liver, 6.5% lung, 4.4% heart, 4.7% kidneys, and 4.7% tongue. The main causes for condemnation were fascioliasis (33.3%), calcification (16.7%), abscess (16.7%), and hydatid cysts (12.5%) (Ahmed et al., 2019).

A study in Kisumu County, Kenya conducted by Kanyari et al., (2012) revealed that in 2007 and 2008, a total of 12,332 and 10,509 cattle were slaughtered, respectively. Of these, 664 and 738 livers were condemned in 2007 and 2008. Of these, 52.04% and 56.4% for year 2007 and 2008 respectively were condemned due to fascioliasis. In 2007, the total monetary loss from liver fluke infections was KES 926,600 (US$ 12,034) while in 2008, this figure was KES 1,032,800 (US$ 13,413). On a monthly basis, the losses ranged from US$ 436 in February 2008 to US$ 13,413 in December of the same year (Kanyari et al., 2012). Regarding heart condemnations, in 2007 and 2008, the losses were KES 26,800 [US$ 348] and 10,780 [US$140] respectively. In 2007, all months recorded losses from cases of bovine muscular cysticercosis while in 2008, some months had very low or no cases at all (as observed in October). Between January and August, losses from heart condemnation fluctuated between the two years without a clear difference but from August, losses were consistently higher in 2007 compared to 2008. This somehow coincided with the higher losses being recorded from liver condemnations (Kanyari et al., 2012).

In addition, a cross sectional study conducted by Achollah et al. (2019) in Siaya County, Kenya revealed that 75 out of 112 cattle slaughtered, each had one or more organs condemned. Of the condemned organs, 51.8% had fascioliasis, 25% showed pimply gut and 0.9% had hepatic hydatidosis. Because of these condemnations, a total of US$ 935 in losses were incurred. The study concluded that many organs were condemned at slaughter due to controllable parasitic conditions and defects associated with poor slaughtering techniques. This causes wastage of edible organs and heavy economic losses for the livestock industry. The occurrence of hepatic fascioliasis and hydatidosis suggested an increased risk of transmission of the zoonotic agents to humans. However, World Health Organization Foodborne Disease Burden Epidemiology Reference Group ranked helminths as low-risk pathogens in Africa having been predicted to produce 105 illnesses per 100,000 population, respectively (WHO, 2015).

Kanyari et al. (2012) postulates that malnutrition is a major cause of human mortalities in Sub-Saharan Africa and every effort must be made to conserve the available sources of protein for human wellbeing. Utilization of animal by-products such as the edible offals for human consumption contributes to conservation of animal source proteins and provision of key nutrients thereby combatting malnutrition especially in LMIC. Availability of these meats may be hampered by diseases such as the parasitic ones that constitute a major impediment to livestock production in Sub-Saharan Africa owing to the direct and indirect losses they cause. For example, it has been estimated that fascioliasis in Kenya leads to losses estimated at ₤7 million annually, through a combination of poor productivity, death of stock and condemnation of infected livers (Kanyari et al., 2012).

Offal handling practices by slaughterhouses, distributors and retailers affects the safety of offals either positively or negatively. Adherence to Meat Control Act regulations and generally improved sanitary conditions by these value chain actors will go a long way in improving the safety of meat and offals. Hygienic handling and adequate cooking of these meats by consumers will decrease the likelihood of meat borne diseases, bacterial or parasitic, being conveyed to human beings. The Directorate of Veterinary Services (DVS) has put in place measures to improve safety of meat in Kenya that include improving meat inspection services by introducing risk-based controls for better prioritization of resources and improving uniformity of inspections countrywide through developing guiding principles and values for inspectors. The DVS aims to regularly capacity build county veterinary services on matters veterinary public health including slaughterhouse inspections. Furthermore, the DVS has developed the veterinary public health bill which when enacted into Veterinary Public Health Act will repeal the current Meat Control Act. The envisaged Veterinary Public Health Act will bestow the responsibility for food safety to FBOs. The FBOs will be required to implement immediate and safe disposal of condemned offals to break the cycle of parasites, promote value addition of offals to extend their shelf life and to promote investment in cold chain and monitoring of temperature of products throughout the value chain.

We conclude that continuous education on production of quality and safe meat along the value chain, coupled with strict enforcement of the legal framework, is inevitable so as to build consumer confidence on safety of these products.

AS and AM conceptualized the review topic and outline. AS and EM drafted the first manuscript with inputs from all co-authors. AS helped revise the manuscript after reviews. All authors approved the final manuscript.

We acknowledge colleagues working at the veterinary headquarters and slaughterhouses who provided information for this paper.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Achollah, A. M., Karanja, D. N., Ng'ang'a, C. J., and Bebora, L. C. (2019). Causes of organ condemnations in cattle at slaughter and associated financial losses in Siaya County, Kenya. J. Vet. Med. Anim. Heal. 12, 27–35. doi: 10.5897/jvmah2019.0779

Ahmed, S., Fentahun, S., Bihonegn, T., Tintagu, T., Alemu, B., and Yilak, N. (2019). Study on major causes of organs condemnation and financial loss in cattle slaughtered at hayik municipal abattoir. J. Anim. Res. 9, 201–207. doi: 10.30954/2277-940x.01.2019.28

Codex (2021). REP21/RVDF. Joint FAO/WHO Food Standards Programme. Codex Alimentarius Commission. 44th Session. (Rome: Food and Agriculture Organization of the United Nations: World Health Organization), 8–13 November 2021.

FAOSTAT (2018). FAO Trade Statistics (Rome: Food and Agriculture Organization of the United Nations).

Herenda, D., Chambers, P. G., Ettriqui, A., Seneviratna, P., and da Silva, T. J. P. (1994). Manual on Meat Inspection for Developing Countries. Rome, Italy: Food and Agriculture Organization of the United Nations (FAO).

Hicks, T. M., Knowles, S. O., and Farouk, M. M. (2018). Global provisioning of red meat for flexitarian diets. Front. Nutr. 5, 1–11. doi: 10.3389/fnut.2018.00050

Kanyari, P., Kagira, J., Mhoma, J., and Omemo, P. (2012). Parasitic causes of liver and heart condemnation and their economic effects in the Lake Victoria Basin: a retrospective abattoir survey in Kisumu Municipality, Kenya. Sci. Parasitol. 13, 139–143.

Kenya Markets Trust (2019). A Study on Meat End Market Trends in Kenya (Nairobi: Kenya Markets Trust).

KLMIS (2021). Kenya Labour Market Information System. Nairobi: The Informal Sector in Kenya, Key Facts.

KNBS (2019). 2019 Kenya Population and Housing Census. Kenya National Bureau of Statistics, Nairobi, Kenya.

Law, K. (2012). Meat Control Act Chapter 356 [WWW Document]. Available online at: http://kenyalaw.org:8181/exist/kenyalex/actview.xqlactid=CAP.~356 (accessed September 20, 2022).

Mareko, M. H. D., Masitha, E., and Raditshane, B. L. (2018). Beef edible red offal condemnations in Kgatleng slaughter facilities, south eastern Botswana in a wet and dry season period. Int. J. Livest. Prod. 9, 318–325. doi: 10.5897/IJLP2018.0499

MOA (2020). Sessional Paper No. 3 of 2020 on The Livestock Policy. Nairobi: Ministry of Agriculture, Kenya.

OEC (2023). Edible Offal - The Observatory of Economic Complexity [WWW Document]. Available online at: https://oec.world/en/profile/hs/edible-offal (accessed January 7, 2023).

Trading Economics (2022). Kenya Exports of meat and edible meat offal - 2023 Data 2024 Forecast 1992–2021 Historical [WWW Document]. Trading Econ. Available online at: https://tradingeconomics.com/kenya/exports/meat-edible-meat-offal#:~:text=Kenya Exports of meat and edible meat offal was US, updated on January of 2023 (accessed January 7, 2023).

Keywords: offals, food safety, regulations, slaughterhouses, hygiene

Citation: Sirma A, Muthuma E, Kariuki J, Maina A, Thaiya J and Njagi O (2023) Using a value chain framework for food safety assessment of edible offals in Nairobi, Kenya. Front. Sustain. Food Syst. 7:1059058. doi: 10.3389/fsufs.2023.1059058

Received: 30 September 2022; Accepted: 10 March 2023;

Published: 27 March 2023.

Edited by:

Bassirou Bonfoh, Swiss Centre for Scientific Research, Côte d'IvoireReviewed by:

Pablo Pérez-Akaki, Monterrey Institute of Technology and Higher Education (ITESM), MexicoCopyright © 2023 Sirma, Muthuma, Kariuki, Maina, Thaiya and Njagi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Anima Sirma, amFuaW1zeUBnbWFpbC5jb20=

†These authors have contributed equally to this work

‡These authors share last authorship

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.