94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Sustain. Food Syst. , 27 June 2022

Sec. Agro-Food Safety

Volume 6 - 2022 | https://doi.org/10.3389/fsufs.2022.914254

The edible coating is an environmentally friendly technology that is applied to fresh-cut fruit products. One of the natural ingredients that are potentially applicable is aloe-gel because it contains several functional components. The main advantage of aloe-coating is that additives can be incorporated into the polymer matrix to enhance its properties. Additives tend to improve the safety, nutritional, and sensory attributes of fresh fruits, but in some cases, aloe-coating does not work. Furthermore, particle size determines the effectiveness of the process on fresh-cut fruits. Aloe-gel nano-coating can be used to overcome the difficulty of adhesion on the surface of fresh-cut fruits. However, quality criteria for fresh cut fruit coated with aloe-gel nano-coating must be strictly defined. The fruit to be processed must be of minimal quality so that discoloration, loss of firmness, spoilage ratio, and fruit weight loss can be minimized. This study aims to discuss the use of nano-coating aloe-gel incorporated with additional ingredients to maintain the quality of fresh-cut fruits. It also examined the recent advances in preparation, extraction, stabilization, and application methods in fresh fruits.

Fresh-cut fruits are being grown rapidly and are popular, especially during the pandemic due to the high consumer demand as they are considered fresh, convenient, safe, nutritious, and healthy food. Some of the advantages of fresh-cut fruits are short preparation, reduced household waste, uniform quality, smaller volume, and cheaper transport costs (Suriati et al., 2020b; Chen et al., 2021; Deshi et al., 2021). However, the process of removing the peel causes a rapid reduction in the quality of fresh-cut fruit as well as a shorter shelf life (Awad et al., 2021; Zhao et al., 2021). One of the environmentally friendly ingredients that can be applied is edible coating combined with cold (Maringgal et al., 2020; Basaglia et al., 2021; Bassey et al., 2021; Liu et al., 2021). The advantage of using this method is that some active ingredients can be incorporated into the polymer matrix and consumed with food, to maintain its nutritional and sensory attributes (Rehman et al., 2020; Tabassum and Khan, 2020; Deshi et al., 2021; Ochoa-Velasco et al., 2021). One of the potential natural ingredients applicable as edible coating for fresh-cut fruits is a polysaccharide found in aloe vera gel (Aloe-gel) that contains functional components (Rehman et al., 2020; Shah and Hashmi, 2020; Hasan et al., 2021).

Aloe-gels have the advantages of being biodegradable, permeable to oxygen, antioxidant power, and low toxicity effects (Chauhan and Kumar, 2020; Sánchez et al., 2020; Sonawane et al., 2021). However, in some cases, the edible coating does not maximize its role in maintaining quality and extending the shelf life of the fruit. The stability of aloe-gel also decreases when stored at room temperature and the size of its particles determines the effectiveness of the coating process (Suriati et al., 2020c; Sonawane et al., 2021). Nano edible coating or nano-coating of aloe-gel incorporated with additives can be used to overcome the difficulty of material adhesion on the fresh-cut surface of the fruit (Sánchez et al., 2020; Bassey et al., 2021). Food additives that are applicable include citric and ascorbic acids as well as potassium sorbate as an acidulant, antioxidant, and antimicrobial, respectively (Nascimento et al., 2020; Rodríguez et al., 2020; Tkaczewska, 2020; Manzoor et al., 2021; Suriati et al., 2021a). Quality criteria for fresh cut fruit coated with aloe-gel nano-coating must be strictly defined. The fruit to be processed must be of minimal quality so that discoloration, loss of firmness, spoilage ratio, and fruit weight loss can be minimized. This review discusses the use of nano-coating of Aloe-gel incorporated with additional ingredients to maintain the quality of fresh-cut fruits in cold storage.

The minimal processing of fruits is a preparation and handling effort to maintain natural freshness without degrading quality, and nutrition, as well as extending the shelf-life of products (Suriati et al., 2020d; Sadler et al., 2021; Silvetti et al., 2021). Fruit minimal processing products are also known as fresh-cut fruits (Chen et al., 2021; Yousuf et al., 2021). They are produced through cleaning, washing, trimming/peeling, coring, slicing, shredding, and packaging (Tabassum and Khan, 2020). According to Etemadipoor et al. (2020), García-Pastor et al. (2020), Nourozi and Sayyari (2020), Suriati et al. (2020b), Ali et al. (2021), fresh-cut fruit storage is usually carried out at low temperatures.

Some of their advantages include presenting consumers with a variety of choices in one package, short time of preparation, reducing household waste, directly showing the internal condition of the product, to guarantee the quality compared to the whole fruit, and easy assessment of the quality of the products purchased, uniform and consistent, lower product volume, and cheaper transport costs (Nicolau-Lapeña et al., 2021). Fresh-cut fruits circulated in the market currently include mango, mangosteen, rambutan, jackfruit, melon, watermelon, papaya, durian, orange, pineapple, and fruit mixture (Alves et al., 2017). They are widely found in supermarkets, fast food restaurants, and catering services. Furthermore, some of the considerations needed in handling post-harvest fresh-cut fruit are physiological, physical, and pathological (Wen et al., 2020; Xu et al., 2020; Awad et al., 2021; Deshi et al., 2021). Whole cells and injured or cut cells are be shown in Figures 1A,B. The minimal process also has an impact on product deterioration; hence, handling techniques are needed to maintain quality and extend shelf life as shown in Figure 2. Measures to overcome problems arising from minimal processing include the use of food additives that can extend shelf life, and edible coating as a primary packer to preserve as well as maintain the freshness and quality of the product (Hasan et al., 2021; Ochoa-Velasco et al., 2021; Paidari et al., 2021).

Edible coatings are made from eatable materials and are part of all fresh-cut fruit products (Abu-Shama et al., 2020; Al-Tayyar et al., 2020; Anjum et al., 2020; Suriati and Suardani, 2021; Zhang et al., 2021). They are biodegradable, formed to coat a food, or placed between components that serve as a barrier to chemical, physical, and biological changes (Nicolau-Lapeña et al., 2021) such as mass decay by moisture, oxygen, light, lipids, and solutes, additive carriers, water vapor as well as the exchange of O2 and CO2 gases (Yu et al., 2021). According to Parven et al. (2020), La et al. (2021), Yu et al. (2021), the application of edible coating also serves to improve appearance in the form of bright and shiny colors, retaining moisture, prevent weight loss, as well as antimicrobials.

The use of edible coatings has been widespread since the mid-1980s and is likely to grow along with public awareness of the healthy and safe food benefits (Chottanom et al., 2020; Daniloski et al., 2021; Kuai et al., 2021; Mousavian et al., 2021). They are majorly used to protect products from the outside environment such as gas effects, water, evaporation, odor, microorganisms, dust, shock, vibration, and pressure (Figure 3). Oxygen gas levels must be monitored because it influences certain reactions that affect shelf life including microbial growth, discoloration, oxidation of fats that have an impact on freshness, and fruit maturation (Cheng et al., 2020; Sánchez et al., 2020; Ozturk et al., 2021; Praseptiangga et al., 2021; Rosu et al., 2021). The advantage of using edible coatings is that some active ingredients can be included in the polymer matrix and consumed with food, to maintain its nutrition and sensory attributes (Panahirad et al., 2021).

The constituent components of edible coating are divided into three groups namely hydrocolloids such as polysaccharides, proteins, and alginate; lipids including fatty acids, aryl glycerides, waxes, and composites namely protein–protein, polysaccharide–protein, and fat–polysaccharide formulated with the addition of surfactants and plasticizers as shown in Figure 4 (Liu et al., 2021; Ochoa-Velasco et al., 2021; Paidari et al., 2021; Suriati et al., 2021b). The constituent components of edible coating can provide maximum protection in a combined form. The application of coatings in fruits and vegetables is carried out in several ways, namely dipping, foaming, spraying, casting, and controlled testing (Chottanom et al., 2020).

The effectiveness depends on the structure, size of the molecule, and chemical constituents. Special requirements are as follows; water, minimal 1–3% oxygen around the commodity, function as a barrier, permeable against gases, water vapor, volatile compounds, and solutes, form an emulsion, non-sticky, quickly dry, does not interfere with the quality of the fruit and can apply pressure. It must also have low viscosity, be transparent, tasteless, and do not give an unwanted influence on the coated product. The formulation of edible coatings does not contain harmful additives, technology, and the raw materials are relatively cheap (Nasrin et al., 2020; Parven et al., 2020; Tabassum and Khan, 2020; Tkaczewska, 2020; Umaraw et al., 2020; Le et al., 2021; Ozturk et al., 2021; Perdana et al., 2021; Piazzolla et al., 2021).

Edible coatings made from polysaccharides have also been developed to inhibit gas transfer and reduce respiration rates. Plant sources and chemical structures are very suitable as edible coatings, due to their great potential and safety when in contact with food (Ali et al., 2020; Le et al., 2021; Panahirad et al., 2021). Recently, the incorporation of antimicrobial compounds in food packaging has become a concern. Coatings with antimicrobial activity can help control the growth of pathogenic microorganisms and decay (Al-Tayyar et al., 2020; Ochoa-Velasco et al., 2021). Nano-additive antimicrobial coatings are in high demand due to their barrier properties and structural integrity (Das et al., 2020).

The function of edible coatings can also be improved by including antioxidant acidulant agents, and functional ingredients such as minerals and vitamins (Rodríguez et al., 2020; Zhang et al., 2020). Antioxidants are added to protect fruits against oxidation processes, degradation, and discoloration (Rodríguez et al., 2020; Zhang et al., 2020; Chen et al., 2021). For example, citric antioxidants and ascorbic acid are incorporated to control oxygen permeability and reduce the loss of vitamin C in fruit during storage (Nourozi and Sayyari, 2020; Gürbüz and Kahramanoglu, 2021). Several studies also applied edible coatings to preserve whole fruits such as cherry (Sánchez et al., 2020), papaya (Mendy et al., 2019), apple (Liu et al., 2021), grapes (Sellitto et al., 2021), mango (Ebrahimi and Rastegar, 2020), and apricot (Nourozi and Sayyari, 2020).

The ability of edible coatings to maintain the quality of fresh-cut fruits differs depending on the product. Some factors to consider are the level of ripeness, surface coverage, storage conditions, as well as the composition and thickness of the layer (Tkaczewska, 2020; Nicolau-Lapeña et al., 2021; Suriati et al., 2021a). The application of edible coatings must report the problem of the adhesion on the surface of hydrophilic fruit slices (Salgado-Cruz et al., 2021; Suriati et al., 2022).

Furthermore, it aims to provide a modified atmosphere, time transfer inhibitors, reduce moisture and aroma loss, delay discoloration, and improve appearance (Chauhan and Kumar, 2020; Ochoa-Velasco et al., 2021). Another advantage of the edible coating is the reduction of synthetic packing waste because this layer consists of biodegradable raw materials (Yousuf and Qadri, 2020; Kumar S. et al., 2021; Le et al., 2021). Therefore, the potential use of fresh-cut fruit is to reduce the modification of the internal atmosphere, decrease decay, postpone maturation in climacteric fruit, prevent water loss, retain color and taste, increase the appearance, decrease the loss of aroma and moisture exchange between fruit and environmental cranks, as well as improve texture, antioxidant carrier, volatile compounds, and nutrients (Ochoa-Velasco et al., 2021).

One potential natural ingredient as an edible coating on fresh-cut fruit is aloe vera (Sánchez et al., 2020; Liu et al., 2021). Several studies reported that edible coatings can be used as agents to inhibit microbes and reduce the detrimental effects of fresh-cut kiwi (Manzoor et al., 2021), mango (Suriati et al., 2020d), apples (Liu et al., 2021), cherry (Ozturk et al., 2019), guava (Rehman et al., 2020), and papaya (Parven et al., 2020). Aloe gel tends to reduce the rate of respiration, ethylene production, heavy shrinking, and softening. It can be used to extend the shelf life after harvest and maintain the product's sensory capabilities during the storage period (Chauhan and Kumar, 2020; Ehtesham Nia et al., 2021; Hasan et al., 2021).

Aloe vera belonging to the family Liliaceae has been used for thousands of years and is often called the wonder plant (Sánchez-Machado et al., 2017; Rehman et al., 2020). The species that is widely grown in Indonesia is Aloe barbadense Miller, which has the characteristics of bright green leaves with irregular white spots as well as an average weight of about 0.5–1 kg. The harvest period ranges from 10 to 12 months after planting (Chauhan and Kumar, 2020; Suriati et al., 2020a) and the leaf layers are shown in Figure 5.

Aloe vera leaves consist of three parts: the first layer also called Aloe-gel contains parenchyma cells and produces mucilage that is clear and tasteless (Nourozi and Sayyari, 2020). It consists of polysaccharides, minerals, proteins, ß-100 sitosterols, long-chain hydrocarbons, and esters (Liu et al., 2021). The second part is exudate which consists of yellow sap and colorless mucus. Yellow mucus contains various components such as anthraquinone along with its derivatives, aloin, barbaloin, aloe-emodin, and glycosides (Chauhan and Kumar, 2020). Anthraquinone is a phenolic compound that has anti-inflammatory, antioxidant, and antibacterial effects. Furthermore, colorless mucus contains various types of phenolic components, which act as antioxidants to inhibit free radicals, fat peroxidation, and enzymes. The third part is the outer layer or skin consisting of 15–20 cells, has a protective function, and synthesizes carbohydrates as well as proteins.

The chemical composition of aloe-gel is estimated to contain more than 75 chemical compounds (Sánchez et al., 2020). The biological activity of the leaf extract is largely due to the synergy of several compounds. Aloe-gel majorly contains water which ranges from 99 to 99.5% (Suriati et al., 2022), while the other contents are in the form of solids consisting of various compounds that are soluble in air, including fat, vitamin, minerals, enzymes, phenolics, polysaccharides, amino acids, lipids, sterols, and organic acids. Based on the dry weight analysis. Aloe-gel is composed of approximately 55% polysaccharides, 17% sugar, 16% minerals, 7% protein, 4% lipids, and 1% phenolics which have antioxidant and antimicrobial abilities (Farina et al., 2020; Sánchez et al., 2020; Suriati et al., 2022). Furthermore, acemannan (acetylated glucomannan) and glucomannan are the main functional components together with other various organic and inorganic constituents. Ace mannan is a rich polysaccharide unit of mannose located in the protoplasm of the parenchyma cell (Sánchez et al., 2020).

The various contents of aloe-gel depend on process, growth, soil, climate, and other geographical conditions. It can be used as a bio preservative and create a wax-like coating to increase shelf life (Ehtesham Nia et al., 2021). Moreover, aloe-gel is easy to apply, able to maintain moisture, and will produce maximal effects when used in fresh conditions (Suriati and Utama, 2019). According to Suriati et al. (2020a), the constituent enzyme is very active as it affects the bonds of compounds as well as the viscosity of the gel. When it is diluted, the viscosity decreases drastically close to that of water under a storage condition at room temperature for 24–36 h (Farina et al., 2020) due to the hydrolysis of polysaccharides (Li et al., 2021). Furthermore, aloin which is bound as a glycoside in the presence of enzyme activity can form a free structure. Adlakha et al. (2021) stated that quinone and anthrax in Aloe-gel in the presence of light will cause a change in color. Aside from the discoloration, they also cause unpleasant flavors and loss of amino acids (Chauhan and Kumar, 2020; Yang et al., 2021).

Gel extraction from leaves is an important step due to its applications in the food, drug, and cosmetic industries (Chauhan and Kumar, 2020). The fresh gel can be harvested directly from aloe vera leaves and stored for further use. The new aloe-gel extract is colorless, thick, slimy, and clear with connective tissues, while the quality is determined by species and growing state, including climate, amount of water, fertilization, as well as harvest time, and the extraction method (Liu et al., 2021). Furthermore, the extraction often involves several stages of processing such as crushing, grinding, and pressing the entire leaf, or fileting to remove the outer leaves and grinding the gel to produce juice followed by various filtration and stabilization steps. One of the main factors that affect the functional properties of Aloe-gel is the handling of leaves after harvest.

The freshness of the leaves is relatively fixed when stored at a cold temperature of 8°C for 6 h after harvest before going to the processing unit. The leaves are washed with a disinfectant to remove dirt and bacteria on the surface. At the fileting stage, a thick green outer layer is removed to produce a gel filet. Fileting surgery must be completed within 36 h after the leaves are harvested. The gel is further processed through the stages of filtration, sterilization, and stabilization (Hasan et al., 2021). It is reported that the enzyme glucose oxidase can be added to remove oxygen and inhibit the growth of aerobic bacteria (Kornecki et al., 2020). Moreover, ultraviolet (UV) irradiation followed by ultra-filtration is an effective way to sterilize Aloe-gel (Bassey et al., 2021). Gel extraction from leaves is sometimes carried out by adding cellulose, treating it with activated carbon for purification, as well as removing aloin and anthraquinones that have a laxative effect. Centrifugation methods have also been found to be effective in the Aloe-gel extraction process. The centrifugal action breaks the chain of sugar molecules surrounded by gel molecules, producing a gel without more fiber (Rehman et al., 2020).

Aloe-gel extraction must be followed by sterilization and stabilization measures because the processing stage can alter the properties of polysaccharides, affect the original structure, as well as cause changes in the physiological and pharmacological properties. Measures that can be taken to avoid changes in the physicochemical properties are to be stored in a dark and cold place as well as chemically stabilizing with additives (Rehman et al., 2020; Suriati et al., 2020a; Sonawane et al., 2021).

The stability of Aloe-gel is greatly affected by air, light, heat, and microbes when it is not immediately stored in the refrigerator. When the gel comes into direct contact with air and light, its color is pink and eventually becomes brown. Heat and light greatly catalyze this reaction which is also affected by the sugar content. The older the age of the aloe plant, the more sugar content is reduced, thereby turning into a less active polysaccharide (Sánchez et al., 2020). The stabilization process can be carried out with proper processing, heating treatment, and the addition of preservatives and other additives such as sodium benzoate, potassium sorbate, citric acid, and vitamin E. Some other chemicals that have a supporting function include ascorbic acid which potentially reduces the activity of polyphenol oxidase, potassium sorbate as an antimicrobial, or the addition of calcium chloride to improve texture (Nascimento et al., 2020; Rodríguez et al., 2020; Tkaczewska, 2020; Manzoor et al., 2021).

Stabilization of aloe-gel can also be performed with the addition of ascorbic acid ranging from 0.05–0.5% followed by one or more standardization ingredients. Among others are citric acid (0.01–0.5)%, sorbitol powder 1–6%, sodium benzoate (0.05–0.5)%, acetyl alcohol (0.001–0.05)%, and color stabilizers such as tocopherol or vitamin E (0.006–0.01)%. The addition of citric acid and ascorbic acid tends to reduce the activity of polyphenol oxidase, while potassium sorbate acts as an antimicrobial (Ochoa-Velasco et al., 2021; Ong et al., 2021). Aloe-gel must be stored in a dark-colored glass container to avoid the influence of light on sensitive bioactive agents (Suriati et al., 2020c). The capacity to form coatings and biodegradable capabilities make aloe-gel an important alternative to petroleum-based materials that are used as food packers. Furthermore, the barrier capability, mechanical resistance, and thermal properties of polymers are important characteristics to explain their potential use as food-packing materials. Time, temperature, and sterilization are also important for maintaining the bioactive molecules of aloe vera (Cui et al., 2020; Deshi et al., 2021).

Additives are ingredients that are intentionally added to food in small amounts, to improve appearance, taste, and texture, as well as extend shelf life. Additionally, it can increase the nutritional value such as proteins, minerals, and vitamins but must not affect the texture, taste, and aroma of the final product (Galus et al., 2021; Ochoa-Velasco et al., 2021; Salgado-Cruz et al., 2021). One of the additives that have the potential to be incorporated with edible coatings is citric acid which is a crystalline or white powder-shaped organic compound with the chemical formula C6H8O7 (2-hydroxy acid 1,2,3-tricarboxylate) (Marghmaleki et al., 2021). The properties include: being easily soluble in water, odorless, tasting very acidic, and tending to melt when decomposed. Citric acid is a deflating agent that inhibits tanning because it can complex copper ions which act as catalysts, lower the pH to inactivate the enzyme polyphenol oxidase (PPO) (Díaz-Montes and Castro-Muñoz, 2021; Kumar N. et al., 2021). Besides, it is a natural preservative that is safe to consume and the acid content serves to prevent the growth of bacteria and fungi (Bhat T. A. et al., 2021; Galus et al., 2021; Xu Y. et al., 2021). Citric acid can also be used to regulate acidity or food preservatives, as well as to prevent tanning in fruits (Marghmaleki et al., 2021).

Meanwhile, ascorbic acid is one of the chemical compounds in the form of whitish-yellow crystal powder that is soluble in water and has antioxidant properties. Soaking apples in solution on ascorbates can reduce the activity of polyphenol oxidase (Marghmaleki et al., 2021). Manzoor et al. (2021), reported that fresh-cut kiwi treated with an ascorbic acid solution effectively prevents browning during storage, while Liguori et al. (2021) argued that it can maintain the quality of strawberries during cold storage. Xu L. et al. (2021) also stated that ascorbic acid can control enzymatic browning in green food and conventional apples in China. The results showed that ascorbic acid was more effective at reducing browning. A study was also conducted to evaluate the potential of citric and ascorbic acid as anti-browning ingredients in fresh-cut kiwi fruit (Bhat T. A. et al., 2021). At higher concentrations, ascorbic acid is more effective in maintaining fruit quality than citric and can reduce browning.

Antimicrobial ingredients such as sorbic acid can be used to prevent microbes on fresh-cut fruit. This is because sorbic acid is odorless and tasteless up to a usage rate of 0.3%. It is chemically known as 2,4-hexadecenoic acid and is commonly used in the form of potassium sorbic salts, has a broad spectrum of inhibiting yeast, but is not effective in inhibiting bacteria. Furthermore, potassium sorbate is classified as an unsaturated fatty acid used to inhibit the growth of mold (Cheng et al., 2020; Abdollahzadeh et al., 2021; Wangprasertkul et al., 2021). It is powdery and the granules are white or slightly yellowish-brown, and odorless. A rise in potassium sorbate concentration will increase the inhibitive force of microbial growth, hence, organic acids are formed slightly. The use of sorbic acid and salt varies depending on the type of food (Abdollahzadeh et al., 2021).

Calcium chloride (CaCl2) is a salt that is white, odorless, colorless, inflammable, and stored in an airtight container due to its hygroscopic nature (Sathiyaseelan et al., 2021; Sultan et al., 2021). The properties include great solubility and a source of calcium ions in solutions. CaCl2 can maintain the quality of fresh-cut fruit as well as suppress the process of ripening or the treatment of sugar into organic acids. Furthermore, the immersion treatment in the solution preserves the firmness of the fruit tissue and extends shelf life. It also stiffens the structure of the cell wall of lamella by slowing the activity of polygalacturonate, as well as maintaining the structural and functional integrity of the membrane system (Bhat V. G. et al., 2021; Díaz-Montes and Castro-Muñoz, 2021; Mohd Suhaimi et al., 2021; Sultan et al., 2021). The ions bind to pectic and galactosemic acids to form calcium pectin cross-bonds that strengthen molecular bonds between constituents and maintain the firmness of the fruit cell wall (Muñoz-Almagro et al., 2021). CaCl2 exogenous slurs can also delay the tanning and softening reaction of logan fruit as well as increase apple's fresh-cut firmness during cold temperature storage.

Nanotechnology is a science that has become quite popular and attract massive attention in the last few decades. Meanwhile, nanoparticles include the design, characterization, production, and application of a material, tool, or system at the nanoscale of 0.1–100 nm (Kehinde et al., 2021; Lu et al., 2021). They have received significant attention in the food sector, including nano ingredients, nano-emulsions, and nano-coatings (Sathiyaseelan et al., 2021). The advantages of using nano-coatings are:

1) Antimicrobial ability: Nano-coatings can interact directly with microbial cells, penetrate cell membranes, oxidize cell components, or produce secondary products that cause damage (Lu et al., 2021). They are also used to extend the shelf life of food that are easily damaged by microbial activity such as meat and its processed products, as well as minimally processed foods, etc. (Hu et al., 2020; Prakash et al., 2020).

2) Improvement of mechanical properties such as flexibility, durability, temperature, and humidity. This is related to the interaction between nano-coating additives and the matrix, the movement of air and gas is increasingly difficult because of the tortuous path (Praseptiangga et al., 2021). Nano-coating mechanism tends to also reduce matrix (Salgado-Cruz et al., 2021).

3) Improved emulsion system. The advantage of nano-coating is that the droplets are much smaller which causes a decrease in the gravitational force, and prevents sedimentation, cream formation, and flocculation to improve the emulsion system. Tools commonly used include high-pressure homogenizer, ultrasonic disruptor, and high-speed blender (Prakash et al., 2020; Wang et al., 2020).

4) Bioavailability: Nano-coating is expected to increase bioavailability to improve the absorption of bioactive components. The very fine and small size of the material causes an increase in the higher solubility rate and even dispersal (Suriati et al., 2022).

The use of nano-coating for aloe-gel has great potential to provide new, innovative, and better results in horticultural productivity, post-harvest, processing efficiency, packaging, food quality, and safety through the detection of microbes that are harmful to human health (Ghasemi and Niakousari, 2020; Hu et al., 2020). Currently, the application in food products makes a significant contribution to the delivery of bioactive compounds. This is because nano-coating of Aloe-gel can increase the bioavailability and control the release of active ingredients, as well as inhibit chemical reactions thereby reducing the impact on the sensory properties of the product. Nano-coating of Aloe-gel mechanism on fresh-cut fruit as Figure 6.

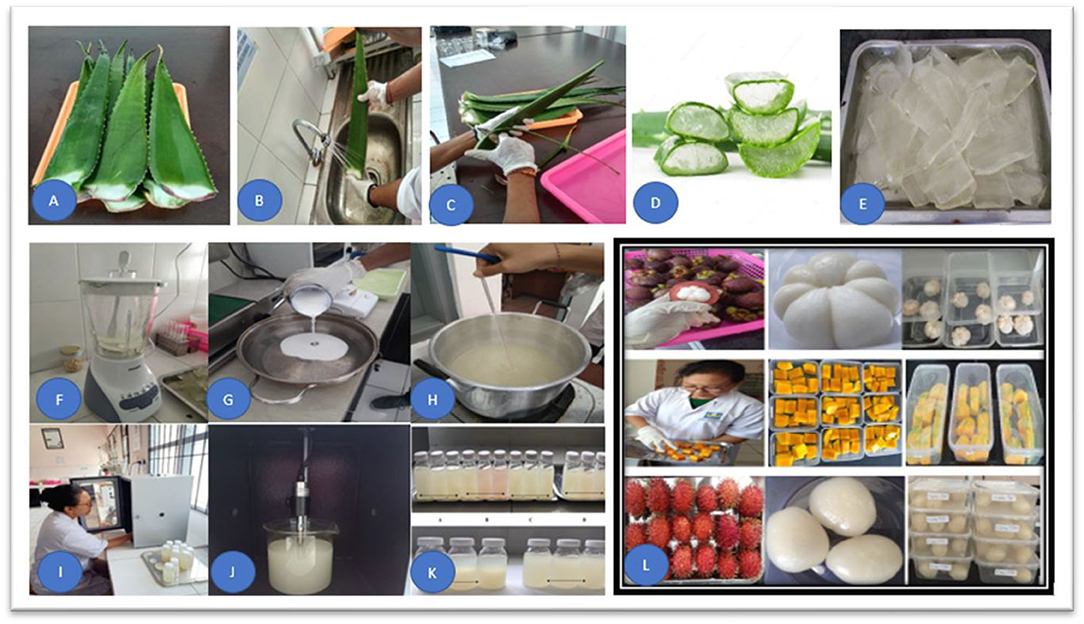

Nano-coating of aloe-gel produces a larger surface area which has the potential to increase the solubility, absorption, and availability of biologically active compounds as well as controlled release. Subsequently, the small particle size culminates in new physicochemical properties, such as surface area, reactivity, and color, which are very different from conventional-sized materials. Several studies reported that nano-coating of Aloe-gel is used for a wide variety of products. According to Suriati et al. (2020c) and Salgado-Cruz et al. (2021), it can be applied to fresh handling, processing, preservation, and improving the functional properties of food to maintain the physical quality or freshness, and chemical quality of a product. Moreover, nano-coating has been widely developed and applied to the surface of fresh fruit to maintain its quality and shelf life. Wang et al. (2020) showed that the active application of chitosan nano-composite can maintain the nutritional content of the coating material as well as extend shelf life, produce a better appearance, and prevent mold growth. The extraction, formulation, and application of aloe vera gel on fresh-cut mangosteen, mango, and rambutan fruits are presented in Table 1, Figures 7, 8.

Figure 8. Extraction, formulation and application nano coating of aloe-gel on fresh-cut mangosteen, mango and rambutan fruits. (A) Aloe vera leaf, (B) washing aloe vera leaves, (C) gel on aloe vera leaf, (D) aloe vera leaf peeling, (E) aloe vera gel, (F) blending aloe vera gel, (G) slurry aloe vera gel, (H) warming up aloe vera gel, (I) nano coating manufacturing process, (J) sonicate probe, (K) nano-coating aloe vera gel, and (L) application process of aloe vera gel nano coating on fresh-cut mangosteen, mango, and rambutan.

The packaging system in the future is expected to effectively close the small pores and have a good response to the environment such as changes in temperature, air, and humidity. Additionally, future packaging trends must be biodegradable and have antimicrobial capabilities. Nano-coating of aloe-gel can be used as an alternative packaging material and is expected to increase the added value of food products as shown in Figure 9. They are applied to control the ripening process of fruit, maintain freshness and safety, as well as to detect contaminants/pathogens, and food expiration dates (Singh et al., 2020).

The edible coating is the future and environmentally friendly alternative to synthetic packaging because it is biodegradable, exists in the form of a thin layer that is edible, safe for health, inhibits physical, biological and chemical changes, improves the appearance, acts as a barrier of gas exchange, as well as maintains moisture and antimicrobial abilities. Meanwhile, aloe-gel consists of polysaccharides, namely acemannan and glucomannan, that contain several bioactive components applicable as edible coatings. The characteristics include transparent, thick, slimy, clear, biodegradable, permeable to O2, antioxidant, low toxicity, forms layers, affordable, as well as easy to apply and obtain. The easy-to-dilute weakness can also be overcome by the process of stabilization, sterilization, the addition of antioxidants and fillers, control of the extraction process, odorization, modification of the atmosphere, and storage temperature. Furthermore, the size of the particle determines the effectiveness of the coating process on the fresh-cut fruit. Nano-coating can be used to overcome the difficulty in the adhesion of coating materials on surfaces of fresh-cut fruits. Based on the results, there is a need to develop simple and efficient processing techniques to improve the quality of the product, as well as maintain all-natural bioactive chemical components to increase the quality and ability of an edible coating. Quality criteria for fresh-cut fruits processed with nano-coating must be determined rigorously and monitored throughout the storage period. The use of aloe-gel nano-coating incorporated with additives can maintain the quality of fresh-cut fruits.

Written informed consent was obtained from the individual(s) for the publication of any potentially identifiable images or data included in this article.

The author confirms being the sole contributor of this work and has approved it for publication.

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The author was grateful to the Rector of Warmadewa University for supporting this research. The author was also grateful to all colleagues for their assistance.

Abdollahzadeh, E., Nematollahi, A., and Hosseini, H. (2021). Composition of antimicrobial edible films and methods for assessing their antimicrobial activity: a review. Trends Food Sci. Technol. 110, 291–303. doi: 10.1016/j.tifs.2021.01.084

Abu-Shama, H. S., Abou-Zaid, F. O. F., and El-Sayed, E. Z. (2020). Effect of using edible coatings on fruit quality of Barhi date cultivar. Scientia Horticulturae 265, 262. doi: 10.1016/j.scienta.2020.109262

Adlakha, K., Koul, B., and Kumar, A. (2021). Value-added products of Aloe species: panacea to several maladies. South Afric. J. Bot. 22, 1–12. doi: 10.1016/j.sajb.2020.12.025

Ali, S., Anjum, M. A., Ejaz, S., Hussain, S., Ercisli, S., Saleem, M. S., et al. (2021). Carboxymethyl cellulose coating delays chilling injury development and maintains eating quality of ‘Kinnow' mandarin fruits during low temperature storage. Int. J. Biologic. Macromol. 168, 77–85. doi: 10.1016/j.ijbiomac.2020.12.028

Ali, S., Anjum, M. A., Nawaz, A., Naz, S., Ejaz, S., Sardar, H., et al. (2020). Tragacanth gum coating modulates oxidative stress and maintains quality of harvested apricot fruits. Int. J. Biologic. Macromol. 163, 2439–2447. doi: 10.1016/j.ijbiomac.2020.09.179

Al-Tayyar, N. A., Youssef, A. M., and Al-Hindi, R. R. (2020). Edible coatings and antimicrobial nanoemulsions for enhancing shelf life and reducing foodborne pathogens of fruits and vegetables: a review. Sustain. Mater. Technol. 26, 215. doi: 10.1016/j.susmat.2020.e00215

Alves, M. M., Gonçalves, M. P., and Rocha, C. M. R. (2017). Effect of ferulic acid on the performance of soy protein isolate-based edible coatings applied to fresh-cut apples. LWT - Food Sci. Technol. 80, 409–415. doi: 10.1016/j.lwt.2017.03.013

Anjum, M. A., Akram, H., Zaidi, M., and Ali, S. (2020). E. Scientia. Horticulturae 271, 506. doi: 10.1016/j.scienta.2020.109506

Awad, A. H. R., Parmar, A., Ali, M. R., El-Mogy, M. M., and Abdelgawad, K. F. (2021). Extending the shelf-life of fresh-cut green bean pods by ethanol, ascorbic acid, and essential oils. Foods 10, 5. doi: 10.3390/foods10051103

Basaglia, R. R., Pizato, S., Santiago, N. G., Maciel de Almeida, M. M., Pinedo, R. A., and Cortez-Vega, W. R. (2021). Effect of edible chitosan and cinnamon essential oil coatings on the shelf life of minimally processed pineapple (Smooth cayenne). Food Biosci. 41, 6. doi: 10.1016/j.fbio.2021.100966

Bassey, E. J., Cheng, J. H., and Sun, D. W. (2021). Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 112, 137–148. doi: 10.1016/j.tifs.2021.03.045

Bhat, T. A., Rather, A. H., Hussain, S. Z., Naseer, B., Qadri, T., and Nazir, N. (2021). Efficacy of ascorbic acid, citric acid, ethylenediaminetetraacetic acid, and 4-hexylresorcinol as inhibitors of enzymatic browning in osmo-dehydrated fresh cut kiwis. J. Food Measure. Characteriz. 17, 2. doi: 10.1007/s11694-021-01017-2

Bhat, V. G., Narasagoudr, S. S., Masti, S. P., Chougale, R. B., and Shanbhag, Y. (2021). Hydroxy citric acid cross-linked chitosan/guar gum/poly(vinyl alcohol) active films for food packaging applications. Int. J. Biologic. Macromolecul. 177, 166–175. doi: 10.1016/j.ijbiomac.2021.02.109

Chauhan, P., and Kumar, A. (2020). Development of a microbial coating for cellulosic surface using aloe vera and silane. Carbohydrat. Polym. Technol. Applicat. 1, 100015. doi: 10.1016/j.carpta.2020.100015

Chen, C., Jiang, A., Liu, C., Wagstaff, C., Zhao, Q., Zhang, Y., et al. (2021). Hydrogen sulfide inhibits the browning of fresh-cut apple by regulating the antioxidant, energy and lipid metabolism. Postharv. Biol. Technol. 175, 87. doi: 10.1016/j.postharvbio.2021.111487

Cheng, J. H., Lv, X., Pan, Y., and Sun, D. W. (2020). Foodborne bacterial stress responses to exogenous reactive oxygen species (ROS) induced by cold plasma treatments. Trends Food Sci. Technol. 103, 239–247. doi: 10.1016/j.tifs.2020.07.022

Chottanom, P., Amornsin, A., Yodthava, N., and Wunnapong, S. (2020). Effect of edible coating on antioxidants and certain properties of dried jerusalem artichoke. Pakist. J. Biol. Sci. 23, 271–277. doi: 10.3923/pjbs.2020.271.277

Cui, K., Shu, C., Zhao, H., Fan, X., Cao, J., and Jiang, W. (2020). Preharvest chitosan oligochitosan and salicylic acid treatments enhance phenol metabolism and maintain the postharvest quality of apricots (Prunus armeniaca L.). Scientia Horticulturae 267, 334. doi: 10.1016/j.scienta.2020.109334

Daniloski, D., Petkoska, A. T., Lee, N. A., Bekhit, A. E. D., Carne, A., Vaskoska, R., et al. (2021). Active edible packaging based on milk proteins: A route to carry and deliver nutraceuticals. Trends Food Sci. Technol. 111, 688–705. doi: 10.1016/j.tifs.2021.03.024

Das, S., Vishakha, K., Banerjee, S., Mondal, S., and Ganguli, A. (2020). Sodium alginate-based edible coating containing nanoemulsion of Citrus sinensis essential oil eradicates planktonic and sessile cells of food-borne pathogens and increased quality attributes of tomatoes. Int. J. Biol. Macromol. 162, 1770–1779. doi: 10.1016/j.ijbiomac.2020.08.086

Deshi, V., Homa, F., Tokala, V. Y., Mir, H., Aftab, M. A., and Siddiqui, M. W. (2021). Regulation of pericarp browning in cold-stored litchi fruit using methyl jasmonate. J. King Saud Univ. Sci. 33, 5. doi: 10.1016/j.jksus.2021.101445

Díaz-Montes, E., and Castro-Muñoz, R. (2021). Edible films and coatings as food-quality preservers: an overview. Foods. 10:249. doi: 10.3390/foods10020249

Ebrahimi, F., and Rastegar, S. (2020). Preservation of mango fruit with guar-based edible coatings enriched with Spirulina platensis and Aloe vera extract during storage at ambient temperature. Scientia Horticulturae 265, 109258. doi: 10.1016/j.scienta.2020.109258

Ehtesham Nia, A., Taghipour, S., and Siahmansour, S. (2021). Pre-harvest application of chitosan and postharvest Aloe vera gel coating enhances quality of table grape (Vitis vinifera L. cv. ‘Yaghouti') during postharvest period. Food Chem. 347:129012. doi: 10.1016/j.foodchem.2021.129012

Etemadipoor, R., Mirzaalian Dastjerdi, A., Ramezanian, A., and Ehteshami, S. (2020). Ameliorative effect of gum arabic, oleic acid and/or cinnamon essential oil on chilling injury and quality loss of guava fruit. Scientia Horticulturae 266, 255. doi: 10.1016/j.scienta.2020.109255

Farina, V., Passafiume, R., Tinebra, I., Scuderi, D., Saletta, F., Gugliuzza, G., et al. (2020). Postharvest application of Aloe vera gel-based edible coating to improve the quality and storage stability of fresh-cut papaya. J Food Qual. 2020:8303140. doi: 10.1155/2020/8303140

Galus, S., Mikus, M., Ciurzy'nska, A., Ciurzy'nska, C., Domian, E., Kowalska, J., et al. (2021). The effect of whey protein-based edible coatings incorporated with lemon and lemongrass essential oils on the quality attributes of fresh-cut pears during storage. Coatings. 11:745. doi: 10.3390/coatings11070745

García-Pastor, M. E., Serrano, M., Guillén, F., Zapata, P. J., and Valero, D. (2020). Preharvest or a combination of preharvest and postharvest treatments with methyl jasmonate reduced chilling injury, by maintaining higher unsaturated fatty acids, and increased aril color and phenolics content in pomegranate. Postharv. Biol. Technol. 20, 167. doi: 10.1016/j.postharvbio.2020.111226

Ghasemi, A., and Niakousari, M. (2020). Superwettability-based systems: basic concepts, recent trends and future prospects for innovation in food engineering. Trends Food Sci. Technol. 104, 27–36. doi: 10.1016/j.tifs.2020.07.027

Gürbüz, R., and Kahramanoglu, I. (2021). Possibility of using leaf extracts of tree-of-heaven (Ailanthus altissima (Mill.) Swingle) for the postharvest quality preservation of fresh apricot fruits. Physiologic. Mol. Plant Pathol. 21, 113. doi: 10.1016/j.pmpp.2020.101594

Hasan, M. U., Riaz, R., Malik, A. U., Khan, A. S., Anwar, R., Rehman, R. N. U., et al. (2021). Potential of aloe vera gel coating for storage life extension and quality conservation of fruits and vegetables: an overview. J. Food Biochemistr. 45, 4. doi: 10.1111/jfbc.13640

Hu, X., Saravanakumar, K., Sathiyaseelan, A., and Wang, M. H. (2020). Chitosan nanoparticles as edible surface coating agent to preserve the fresh-cut bell pepper (Capsicum annuum L. var. grossum (L.) Sendt). Int. J. Biologic. Macromol. 165, 948–957. doi: 10.1016/j.ijbiomac.2020.09.176

Kehinde, B. A., Sharma, P., and Kaur, S. (2021). Recent nano-, micro- and macrotechnological applications of ultrasonication in food-based systems. Critic. Rev. Food Sci. Nutri. 61, 599–621. doi: 10.1080/10408398.2020.1740646

Kornecki, J. F., Carballares, D., Tardioli, P. W., Rodrigues, R. C., Berenguer-Murcia, Á., Alcántara, A. R., et al. (2020). Catalysis Science and Technology MINI REVIEW Enzyme production of D-gluconic acid and glucose oxidase: successful tales of cascade reactions. Cite This: Catal. Sci. Technol 10, 5740. doi: 10.1039/D0CY00819B

Kuai, L., Liu, F., Chiou, B., Sen Avena-Bustillos, R. J., McHugh, T. H., and Zhong, F. (2021). Controlled release of antioxidants from active food packaging: a review. Food Hydrocolloids 120, 92. doi: 10.1016/j.foodhyd.2021.106992

Kumar, N., Pratibha, Neeraj, Ojha, A., Upadhyay, A., Singh, R., and Kumar, S. (2021). Effect of active chitosan-pullulan composite edible coating enrich with pomegranate peel extract on the storage quality of green bell pepper. LWT 138, 110435. doi: 10.1016/j.lwt.2020.110435

Kumar, S., Basumatary, I. B., Sudhani, H. P. K., Bajpai, V. K., Chen, L., Shukla, S., et al. (2021). Plant extract mediated silver nanoparticles and their applications as antimicrobials and in sustainable food packaging: a state-of-the-art review. Trends Food Sci. Technol. 112, 651–666. doi: 10.1016/j.tifs.2021.04.031

La, D. D., Nguyen-Tri, P., Le, K. H., Nguyen, P. T. M., Nguyen, M. T. H. D. B., Vo, A. T. K., et al. (2021). Effects of antibacterial ZnO nanoparticles on the performance of a chitosan/gum arabic edible coating for post-harvest banana preservation. Progr. Organic Coat. 151, 106057. doi: 10.1016/j.porgcoat.2020.106057

Le, K. H., Nguyen, M. D. B., Tran, L. D., Nguyen Thi, H. P. H. P., Tran, C., Van Tran, K., et al. (2021). A novel antimicrobial ZnO nanoparticles-added polysaccharide edible coating for the preservation of postharvest avocado under ambient conditions. Progr. Organic Coat. 158, 106339. doi: 10.1016/j.porgcoat.2021.106339

Li, L., Yi, P., Li, C., Xin, M., Sun, J., He, X., et al. (2021). Influence of polysaccharide-based edible coatings on enzymatic browning and oxidative senescence of fresh-cut lettuce. Food Sci Nut. 9:888–99. doi: 10.1002/fsn3.2052

Liguori, G., Gaglio, R., Settanni, L., Inglese, P., D'anna, F., and Miceli, A. (2021). Effect of Opuntia ficus-indica mucilage edible coating in combination with ascorbic acid, on strawberry fruit quality during cold storage. J Food Qual. 2021:9976052. doi: 10.1155/2021/9976052

Liu, H., Liu, S., Du, B., Dong, K., Wang, Y., and Zhang, Y. (2021). Aloe vera gel coating aggravates superficial scald incidence in ‘Starking' apples during low-temperature storage. Food Chemistr. 339, 128151. doi: 10.1016/j.foodchem.2020.128151

Lu, W., Chen, M., Cheng, M., Yan, X., Zhang, R., Kong, R., et al. (2021). Development of antioxidant and antimicrobial bioactive films based on Oregano essential oil/mesoporous nano-silica/sodium alginate. Food Packag. Shelf Life 29, 691. doi: 10.1016/j.fpsl.2021.100691

Luh Suriati, I., Putu Candra, I., and Komang, S. (2021). Aloe-gel coating for delaying physicochemical change of fresh-cut mango. SEAS 5, 58–65. doi: 10.22225/seas.5.1.3302.58-65

Manzoor, S., Gull, A., Wani, S. M., Ganaie, T. A., Masoodi, F. A., Bashir, K., et al. (2021). Improving the shelf life of fresh cut kiwi using nanoemulsion coatings with antioxidant and antimicrobial agents. Food Biosci. 41, 101015. doi: 10.1016/j.fbio.2021.101015

Marghmaleki, S. N., Mohammad, S., Mortazavi, H., Saei, H., and Mostaan, A. (2021). The effect of alginate-based edible coating enriched with citric acid and ascorbic acid on texture, appearance and eating quality of apple fresh-cut. Int. J. Fruit Sci. 21, 40–51. doi: 10.1080/15538362.2020.1856018

Maringgal, B., Hashim, N., Amin Tawakkal, I. S. M., Muda Mohamed, M. T., Hazwan Hamzah, M., Ali, M. M., et al. (2020). Kinetics of quality changes in papayas (Carica papaya L.) coated with Malaysian stingless bee honey. Scientia Horticulturae 267, 20. doi: 10.1016/j.scienta.2020.109321

Mendy, T. K., Misran, A., Mahmud, T. M. M., and Ismail, S. I. (2019). Application of Aloe vera coating delays ripening and extend the shelf life of papaya fruit. Scientia Horticulturae 246, 769–776. doi: 10.1016/j.scienta.2018.11.054

Mohd Suhaimi, N. I., Mat Ropi, A. A., and Shaharuddin, S. (2021). Safety and quality preservation of starfruit (Averrhoa carambola) at ambient shelf life using synergistic pectin-maltodextrin-sodium chloride edible coating. Heliyon 7, e06279. doi: 10.1016/j.heliyon.2021.e06279

Mousavian, D., Mohammadi Nafchi, A., and Nouri, L. (2021). Effect of active packaging based on polyethylene/propylene films containing thymol on the quality attributes and shelf life of season salad. J. Food Sci. Technol. 18, 116. doi: 10.52547/fsct.18.116.67

Muñoz-Almagro, N., Villamiel, M., Wilde, P. J., Gunning, A. P., and Montilla, A. (2021). Effect of sucrose substitution with stevia and saccharin on rheological properties of gels from sunflower pectins. Food Hydrocolloids 120, 106910. doi: 10.1016/j.foodhyd.2021.106910

Nascimento, J. I. G., Stamford, T. C. M., Melo, N. F. C. B., Nunes, I., dos, S., Lima, M. A. B., et al. (2020). Chitosan–citric acid edible coating to control Colletotrichum gloeosporioides and maintain quality parameters of fresh-cut guava. Int. J. Biologic. Macromol. 163, 1127–1135. doi: 10.1016/j.ijbiomac.2020.07.067

Nasrin, T. A. A., Rahman, M. A., Arfin, M. S., Islam, M. N., and Ullah, M. A. (2020). Effect of novel coconut oil and beeswax edible coating on postharvest quality of lemon at ambient storage. J. Agricult. Food Res. 2, 100019. doi: 10.1016/j.jafr.2019.100019

Nicolau-Lapeña, I., Aguiló-Aguayo, I., Kramer, B., Abadias, M., Viñas, I., and Muranyi, P. (2021). Combination of ferulic acid with Aloe vera gel or alginate coatings for shelf-life prolongation of fresh-cut apples. Food Packag. Shelf Life 27, 100620. doi: 10.1016/j.fpsl.2020.100620

Nourozi, F., and Sayyari, M. (2020). Enrichment of Aloe vera gel with basil seed mucilage preserve bioactive compounds and postharvest quality of apricot fruits. Scientia Horticulturae 262, 109041. doi: 10.1016/j.scienta.2019.109041

Ochoa-Velasco, C. E., Pérez-Pérez, J. C., Varillas-Torres, J. M., Navarro-Cruz, A. R., Hernández-Carranza, P., Munguía-Pérez, R., et al. (2021). Starch edible films/coatings added with carvacrol and thymol: In vitro and in vivo evaluation against colletotrichum gloeosporioides. Foods 10, 1. doi: 10.3390/foods10010175

Ong, G., Kasi, R., and Subramaniam, R. (2021). A review on plant extracts as natural additives in coating applications. Progr. Organic Coat. 151, 106091. doi: 10.1016/j.porgcoat.2020.106091

Ozturk, B., Karakaya, O., Yildiz, K., and Saracoglu, O. (2019). Effects of Aloe vera gel and MAP on bioactive compounds and quality attributes of cherry laurel fruit during cold storage. Scientia Horticulturae 249, 31–37. doi: 10.1016/j.scienta.2019.01.030

Ozturk, S., Zhang, J., Singh, R. K., and Kong, F. (2021). Effect of cellulose nanofiber-based coating with chitosan and trans-cinnamaldehyde on the microbiological safety and quality of cantaloupe rind and fresh-cut pulp. Part 2: Quality attributes. LWT 21, 147. doi: 10.1016/j.lwt.2021.111519

Paidari, S., Zamindar, N., Tahergorabi, R., Kargar, M., Ezzati, S., shirani, N., et al. (2021). Edible coating and films as promising packaging: a mini review. J. Food Measure. Characteriz. 21, 7. doi: 10.1007/s11694-021-00979-7

Panahirad, S., Dadpour, M., Peighambardoust, S. H., Soltanzadeh, M., Gullón, B., Alirezalu, K., et al. (2021). Applications of carboxymethyl cellulose- and pectin-based active edible coatings in preservation of fruits and vegetables: a review. Trends Food Sci. Technol. 110, 663–673. doi: 10.1016/j.tifs.2021.02.025

Parven, A., Sarker, M. R., Megharaj, M., and Md. Meftaul, I. (2020). Prolonging the shelf life of Papaya (Carica papaya L.) using Aloe vera gel at ambient temperature. Scientia Horticulturae 265, 109228. doi: 10.1016/j.scienta.2020.109228

Perdana, M. I., Ruamcharoen, J., Panphon, S., and Leelakriangsak, M. (2021). Antimicrobial activity and physical properties of starch/chitosan film incorporated with lemongrass essential oil and its application. LWT 141, 34. doi: 10.1016/j.lwt.2021.110934

Piazzolla, F., Amodio, M. L., Pati, S., and Colelli, G. (2021). Evaluation of quality and storability of “Italia” table grapes kept on the vine in comparison to cold storage techniques. Foods 10, 5. doi: 10.3390/foods10050943

Prakash, A., Baskaran, R., and Vadivel, V. (2020). Citral nanoemulsion incorporated edible coating to extend the shelf life of fresh cut pineapples. LWT 118, 108851. doi: 10.1016/j.lwt.2019.108851

Praseptiangga, D., Mufida, N., Panatarani, C., and Joni, I. M. (2021). Enhanced multi functionality of semi-refined iota carrageenan as food packaging material by incorporating SiO2 and ZnO nanoparticles. Heliyon 7, 5. doi: 10.1016/j.heliyon.2021.e06963

Rehman, M. A., Asi, M. R., Hameed, A., and Bourquin, L. D. (2020). Effect of postharvest application of aloe vera gel on shelf life, activities of anti-oxidative enzymes, and quality of “gola” guava fruit. Foods 9, 1–16. doi: 10.3390/foods9101361

Rodríguez, G. M., Sibaja, J. C., Espitia, P. J. P., and Otoni, C. G. (2020). Antioxidant active packaging based on papaya edible films incorporated with Moringa oleifera and ascorbic acid for food preservation. Food Hydrocoll. 20, 103. doi: 10.1016/j.foodhyd.2019.105630

Rosu, L., Mustata, F., Rosu, D., Varganici, C. D., Rosca, I., and Rusu, T. (2021). Bio-based coatings from epoxy resins crosslinked with a rosin acid derivative for wood thermal and anti–fungal protection. Progr. Organ. Coat. 21, 151. doi: 10.1016/j.porgcoat.2020.106008

Sadler, C. R., Grassby, T., Hart, K., Raats, M., Sokolovi,ć, M., and Timotijevic, L. (2021). Processed food classification: conceptualization and challenges. Trends Food Sci. Technol. 112, 149–162. doi: 10.1016/j.tifs.2021.02.059

Salgado-Cruz, M., de la, P., Salgado-Cruz, J., García-Hernández, A. B., Calderón-Domínguez, G., Gómez-Viquez, H., et al. (2021). Chitosan as a coating for biocontrol in postharvest products: a bibliometric review. Membranes 11, 421. doi: 10.3390/membranes11060421

Sánchez, M., González-Burgos, E., Iglesias, I., and Gómez-Serranillos, M. P. (2020). Pharmacological update properties of aloe vera and its major active constituents. Molecules 25, 6. doi: 10.3390/molecules25061324

Sánchez-Machado, D. I., López-Cervantes, J., Sendón, R., and Sanches-Silva, A. (2017). Aloe vera: ancient knowledge with new frontiers. Trends Food Sci. Technol. 61, 94–102. doi: 10.1016/j.tifs.2016.12.005

Sathiyaseelan, A., Saravanakumar, K., Mariadoss, A. V. A., Ramachandran, C., Hu, X., Oh, D. H., et al. (2021). Chitosan-tea tree oil nanoemulsion and calcium chloride tailored edible coating increase the shelf life of fresh cut red bell pepper. Progr. Organ. Coat. 151, 106010. doi: 10.1016/j.porgcoat.2020.106010

Sellitto, V. M., Zara, S., Fracchetti, F., Capozzi, V., and Nardi, T. (2021). Microbial biocontrol as an alternative to synthetic fungicides: Boundaries between pre-and postharvest applications on vegetables and fruits. Fermentation 7, 2. doi: 10.3390/fermentation7020060

Shah, S., and Hashmi, M. S. (2020). Chitosan–aloe vera gel coating delays postharvest decay of mango fruit. Horticult. Environ. Biotechnol. 61, 279–289. doi: 10.1007/s13580-019-00224-7

Silvetti, T., Pedroni, M., Brasca, M., Vassallo, E., Cocetta, G., Ferrante, A., et al. (2021). Assessment of possible application of an atmospheric pressure plasma jet for shelf life extension of fresh-cut salad. Foods 10, 1–13. doi: 10.3390/foods10030513

Singh, M., Singh, V., and Kaur, D. (2020). “Research trends in food technology and nutrition,” in Research Trends in Food Technology and Nutrition (Issue January).

Sonawane, S. K., Gokhale, J. S., Mulla, M. Z., Kandu, V. R., and Patil, S. (2021). A comprehensive overview of functional and rheological properties of aloe vera and its application in foods. J. Food Sci. Technol. 58, 1217–1226. doi: 10.1007/s13197-020-04661-6

Sultan, M., Hafez, O. M., Saleh, M. A., and Youssef, A. M. (2021). Smart edible coating films based on chitosan and beeswax-pollen grains for the postharvest preservation of Le Conte pear. RSC Adv. 11:9572–85. doi: 10.1039/d0ra10671b

Suriati, L. (2021). Differences in Physicochemical Characters of Fresh-Cut Mango, Mangosteen and Rambutan Due to Calcium Chloride Application. Food Sci. Nutri. 7, 1–6. doi: 10.24966/FSN-1076/100107

Suriati, L., Made Supartha Utama, I., Admadi Harsojuwono, B., and Bagus Wayan Gunam, I. (2020c). Incorporating additives for stability of Aloe gel potentially as an edible coating. AIMS Agricul. Food 5, 327–336. doi: 10.3934/agrfood.2020.3.327

Suriati, L., Ni Made Ayu Suardani, S., and Bria, W. H. (2021b). Edible coating of aloe gel for maintain quality of strawberry fruit during storage. IOP Confere. Series Earth Environ. Sci. 709, 1. doi: 10.1088/1755-1315/709/1/012029

Suriati, L., and Singapurwa, N. M. A. S. (2020). Edible Coating Base on Aloe Gel with Additives on Strawberry Fruit. SEAS 04, 18–25. doi: 10.22225/seas.4.1.1685.18-25

Suriati, L., and Suardani, N. M. A. (2021). Application Ecogel Incorporation additive for maintain freshness of Strawberry fruit during storage. IOP Conferen. Series: Mater. Sci. Eng. 1098, 062055. doi: 10.1088/1757-899X/1098/6/062055

Suriati, L., and Utama, I. M. S. (2019). Characteristic filet of aloe vera gel as edible coating. J. Physic. Conferen. Series 1402, 6. doi: 10.1088/1742-6596/1402/6/066021

Suriati, L., Utama, I. M. S., Harjosuwono, B. A., and Gunam, I. B. W. (2020a). Stability aloe vera gel as edible coating. IOP Conferen. Seri. Earth Environ. Sci. 411, 1. doi: 10.1088/1755-1315/411/1/012053

Suriati, L., Utama, I. M. S., Harjosuwono, B. A., and Wayan Gunam, I. B. (2020b). Physicochemical characteristics of fresh-cut tropical fruit during storage. Int. J.Adv. Sci. Eng. Inform. Technol. 10, 1731–1736. doi: 10.18517/ijaseit.10.4.10857

Suriati, L., Utama, I. M. S., Harsojuwono, B. A., and Gunam, I. B. W. (2022). Effect of additives on surface tension, viscosity, transparency and morphology structure of aloe vera gel-based coating. Front. Sustain. Food Syst. 6, 1–9. doi: 10.3389/fsufs.2022.831671

Suriati, L., Utama, I. M. S., Harsojuwono, B. A., Gunam, I. B. W., Adnyana, I. M., and Fudholi, A. (2021a). Nano-ecogel to maintain the physicochemical characteristics of fresh-cut mangosteen. AIMS Agricult. Food 6, 988–999. doi: 10.3934/agrfood.2021059

Suriati, L., Utama, I. M. S. M. S., Harsojuwono, B. A. B. A., and Gunam, I. B. W. I. B. W. (2020d). Ecogel incorporated with nano-additives to increase shelf-life of fresh-cut mango. J. Appl. Horticult. 22, 189–195. doi: 10.37855/jah.2020.v22i03.34

Tabassum, N., and Khan, M. A. (2020). Modified atmosphere packaging of fresh-cut papaya using alginate based edible coating: quality evaluation and shelf life study. Scientia Horticulturae 259, 2019. doi: 10.1016/j.scienta.2019.108853

Tkaczewska, J. (2020). Peptides and protein hydrolysates as food preservatives and bioactive components of edible films and coatings—a review. Trends Food Sci. Technol. 106, 298–311. doi: 10.1016/j.tifs.2020.10.022

Umaraw, P., Munekata, P. E. S., Verma, A. K., Barba, F. J., Singh, V. P., Kumar, P., et al. (2020). Edible films/coating with tailored properties for active packaging of meat, fish and derived products. Trends Food Sci. Technol. 98, 10–24. doi: 10.1016/j.tifs.2020.01.032

Wang, Y., Cen, C., Chen, J., and Fu, L. (2020). MgO/carboxymethyl chitosan nanocomposite improves thermal stability, waterproof and antibacterial performance for food packaging. Carbohydrat. Polym. 20, 236. doi: 10.1016/j.carbpol.2020.116078

Wangprasertkul, J., Siriwattanapong, R., and Harnkarnsujarit, N. (2021). Antifungal packaging of sorbate and benzoate incorporated biodegradable films for fresh noodles. Food Control 123, 107763. doi: 10.1016/j.foodcont.2020.107763

Wen, B., Li, D., Tang, D., Huang, Z., Kedbanglai, P., Ge, Z., et al. (2020). Effects of simultaneous ultrasonic and cysteine treatment on antibrowning and physicochemical quality of fresh-cut lotus roots during cold storage. Postharv. Biol. Technol. 168, 111294. doi: 10.1016/j.postharvbio.2020.111294

Xu, C. C., Liu, D. K., Guo, C. X., Wu, Y., and qing. (2020). Effect of cooling rate and super-chilling temperature on ice crystal characteristic, cell structure, and physicochemical quality of super-chilled fresh-cut celery. Int. J. Refrigerat. 113, 249–255. doi: 10.1016/j.ijrefrig.2020.01.024

Xu, L., Wang, L., Xu, Z., Zhang, X., Zhang, Z., and Qian, Y. (2021). Physicochemical quality and metabolomics comparison of the green food apple and conventional apple in China. Food Res.Int. 139, 109804. doi: 10.1016/j.foodres.2020.109804

Xu, Y., Guan, X., Lin, B., Li, R., and Wang, S. (2021). Oregano oil, epsilon-polylysine and citric acid assisted inactivation of Salmonella in two kinds of tahini during thermal treatment and storage. Foods. 10:1272. doi: 10.3390/foods10061272

Yang, F., Cao, Y., Yu, H., Guo, Y., Cheng, Y., Qian, H., et al. (2021). Transformation and degradation of barbaloin in aqueous solutions and aloe powder under different processing conditions. Food Biosci. 43, 101279. doi: 10.1016/j.fbio.2021.101279

Yousuf, B., and Qadri, O. S. (2020). Preservation of fresh-cut fruits and vegetables by edible coatings. Fresh-Cut Fruit. Vegetab. Technol. Mechan. Safety Control 20, 225–242. doi: 10.1016/B978-0-12-816184-5.00011-2

Yousuf, B., Wu, S., and Siddiqui, M. W. (2021). Incorporating essential oils or compounds derived thereof into edible coatings: effect on quality and shelf life of fresh/fresh-cut produce. Trends Food Sci. Technol. 108, 245–257. doi: 10.1016/j.tifs.2021.01.016

Yu, Y., Zheng, J., Li, J., Lu, L., Yan, J., Zhang, L., et al. (2021). Applications of two-dimensional materials in food packaging. Trends Food Sci. Technol. 110, 443–457. doi: 10.1016/j.tifs.2021.02.021

Zhang, W., Jiang, H., Cao, J., and Jiang, W. (2021). Advances in biochemical mechanisms and control technologies to treat chilling injury in postharvest fruits and vegetables. Trends Food Sci. Technol. 113, 355–365. doi: 10.1016/j.tifs.2021.05.009

Zhang, X., Liu, J. J., Yong, H., Qin, Y., Liu, J. J., and Jin, C. (2020). Development of antioxidant and antimicrobial packaging films based on chitosan and mangosteen (Garcinia mangostana L.) rind powder. Int. J. Biol. Macromol. 145, 1129–1139. doi: 10.1016/j.ijbiomac.2019.10.038

Keywords: aloe-gel, fresh-cut, fruit, nano-coating, shelf-life

Citation: Suriati L (2022) Nano Coating of Aloe-Gel Incorporation Additives to Maintain the Quality of Freshly Cut Fruits. Front. Sustain. Food Syst. 6:914254. doi: 10.3389/fsufs.2022.914254

Received: 06 April 2022; Accepted: 13 May 2022;

Published: 27 June 2022.

Edited by:

Syed Amir Ashraf, University of Hail, Saudi ArabiaReviewed by:

M. Leonor Faleiro, University of Algarve, PortugalCopyright © 2022 Suriati. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luh Suriati, c3VyeWF0aWx1aDFAZ21haWwuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.