- 1Department of Food Science and Technology, Faculty of Agriculture, Food and Consumer Sciences, University for Development Studies, Tamale, Ghana

- 2Department of Food Technology and Nutrition, School of Food Technology, Nutrition and Bio-Engineering, College of Agricultural and Environmental Sciences, Makerere University, Kampala, Uganda

- 3Council for Scientific and Industrial Research–Savanna Agricultural Research Institute, Tamale, Ghana

- 4Department of Biotechnology, Faculty of Biosciences, University for Development Studies, Tamale, Ghana

- 5Department of Horticulture and Crop Production, School of Agriculture and Technology, University of Energy and Natural Resources, Sunyani, Ghana

- 6Department of Food Science and Human Nutrition, University of Illinois at Urbana-Champaign, Urbana, IL, United States

- 7College of Agricultural, Consumer and Environmental Sciences, University of Illinois at Urbana-Champaign, Urbana, IL, United States

- 8Food Science and Human Nutrition Department, University of Florida, Gainesville, FL, United States

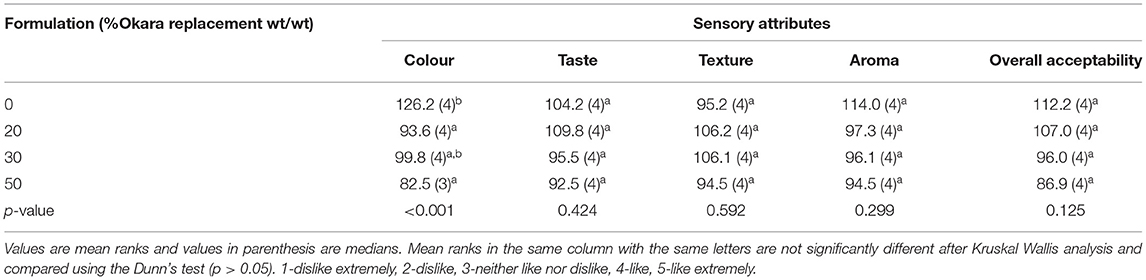

The study assessed the nutrient value and desirability of eight improved soybean varieties, for use in soymilk, tofu and as an ingredient to enhance staple foods. The soymilk, tofu, and soybean residue (okara) yields were determined across all varieties. The okara was subsequently used in composite with cassava, as a recipe refinement of gari, a popular cassava-based ready-to-eat food. Multiple composite ratios were compared against a control of 100% cassava gari; 80% cassava: 20% okara, 70% cassava: 30% okara, and 50% cassava: 50% okara. The soymilk and tofu from the various varieties and okara enriched-gari were also evaluated for proximate and sensory qualities (n = 50) using standard protocols. No differences (p > 0.05) existed among soybean varieties in terms of soymilk (p = 0.55; 13.0–14.1 L), tofu (p = 0.05; 0.12–0.15 kg/L) or okara (p = 0.08; 3.17–3.97 kg) yields. The proximate parameters evaluated for soymilk did not vary significantly (p > 0.05) among varieties. However, for total solids (3.33–7.93°Brix; p < 0.01) there were significant differences. Generally, there was an increasing trend in the crude protein, moisture, crude fat and total ash contents for the okara-enriched gari as the okara inclusion increased from 20 to 50%. Thus, the crude protein content of the 50% okara-enriched gari, the formulation with the highest okara incorporation was almost 11-times higher than the 100% cassava gari. The swelling capacity of the okara-enriched gari ranged from 3.29–5.47 and for water holding capacity 439.7–482.1%. The okara-enriched gari was equally preferred by consumers, except for colour which consumers were mostly indifferent towards. The 50%-okara enriched gari composite was compared equally with 100% cassava gari control. The sensory data showed that the “Favour” soybean variety was desirable for soymilk production while Salintuya 1 was desirable for tofu production. Recipe refinements using the desired varieties and compositing okara with cassava may help fill the protein gap among the vulnerable group in Ghana by improving the protein quality of ready-to-eat foods such as gari.

Introduction

Protein undernutrition and other micronutrient deficiencies are serious risk factors for infectious diseases that often coexist and exhibit complex interactions leading to a vicious cycle of malnutrition and infections (Bhaskaram, 2002) among people of all ages. Underprivileged populations living in low-income countries, particularly children, adolescents, and women are the most affected. In children and adolescents, undernutrition leads to poor academic achievements and additional vulnerability to disease (Lam and Lawlis, 2017). In pregnant women, undernourishment affects the mother and normal development and overall health of the foetus (Belkacemi et al., 2010).

Undernutrition continues to undermine development efforts in Sub-Saharan Africa. Although the aetiology of undernutrition is complex and involves many factors, its development may be attributed to low dietary intake of nutrient-rich foods, increased metabolic demands, or increased nutrient losses due to infection (Corish and Kennedy, 2000). Unfortunately, most of the staples consumed by the rural poor in low-income countries are characteristically starchy and limited in quality protein and some essential micronutrients. For instance, in rural Ghana, the overreliance on rapidly digestible carbohydrate staple foods has led to a greater prevalence in stunting, at 22.1% vs. the 14.8% experienced in urban settings (Ghana Statistical Service, 2015), where diets generally have greater diversity and include milk, eggs and meats.

Animal-sourced foods are nutrient-dense and very effective in ameliorating protein undernutrition and micronutrient deficiencies but they are very expensive and have limited affordability by resource-poor households. Additionally, most smallholder farmers in Ghana use their livestock as a source of emergency funds rather than consuming them to improve nutrition in their households (Nyantakyi-Frimpong et al., 2018). Therefore, there is, a need to fully exploit available, affordable, desirable, and sustainable plant-based protein sources such as soybean, to satisfy protein and other micronutrient gaps among the vulnerable population in sub-Saharan Africa. Soybean protein is one of the relatively cheaper sources of complete dietary protein because it contains most of the essential amino acids needed for human and animal nutrition (Hoffman and Falvo, 2004; Michelfelder, 2009) and could be a good alternative for animal-sourced protein (Sacks et al., 2006).

Soybean is a non-traditional staple crop in Sub-Saharan Africa and especially in Ghana (Martey and Goldsmith, 2020). In the recent past, initiatives to support the production of soybeans in Ghana have mainly been donor-driven (Avea et al., 2016), with a larger focus on increasing yields for oil and animal feed. The crop is increasingly attaining commercial attention as more producers and food processors are becoming aware of the opportunities to grow soybean for both its cash crop potential and its benefits to animal and human nutrition (Gage et al., 2012). Moreover, local promotion of soybean processing for human consumption, for instance, can stimulate the demand for nutrient-rich ingredients for food to food fortification and encourage domestic production. Therefore, both nutrient composition and yields are the focus of current efforts to stimulate the production of soybeans in Africa (Khojely et al., 2018). These efforts have led to the development and release of eight soybean varieties (i.e., Afayak, Salintuya 1, Salintuya 2, Songda, Suong-Pungun, Jenguma, Quarshie, and Favour) by the Savanna Agricultural Research Institute (SARI) of the Council for Scientific and Industrial Research (CSIR) in Ghana. Although some information on their nutritional profile exists, the desirability of the varieties for transformation into soymilk and tofu under the constraint of limited resources is scarce. More importantly, like any other industry, the creation of processed products results in the accumulation of food waste, which in the case of soymilk production is called okara. This material still contains a significant amount of protein, fibre and other micronutrients and represents an opportunity for food-to-food fortification if upcycled correctly.

Okara contains significant amount of protein (25.4–28.4%), oil (9.3–10.3%%), soluble fibre (12.6–14.6%) and insoluble fibre (40.2–43.6%) (van der Riet et al., 1989). Okara has minimal beany flavour (Golbitz and Jordan, 2006) often associated with soybean and lower polyunsaturated fatty acids (PUFAs) that could improve the shelf stability of its products compared with full-fat soy flour (FFSF). Earlier work indicates that for every 1 kg of dried soybeans used in the production of soymilk/tofu, an average of 1.1–1.2 kg of wet okara is produced accounting for a large volume of waste (Khare et al., 1995; Guimarães et al., 2018). In Ghana, most companies dispose of okara as animal feed or discarded. Okara has a huge potential of becoming a low-cost functional food ingredient. Nonetheless, drying of okara (i.e., from 80 to 90% moisture to ≤ 12% moisture) could be challenging (Redondo-Cuenca et al., 2008), especially in low-income countries where the power supply is not only expensive but erratic.

Using locally available crops for food to food fortification is considered a sustainable and cost-effective approach in addressing malnutrition among poor populations. A successful food to food fortification program requires that the selected food should be widely consumed by the target population, and its production should be readily available all year round (Dary and Mora, 2002); the product(s) recipes should not extensively vary from existing ones. Gari is a fermented, partly gelatinised, creamy-white granular cassava (Manihot esculenta Crantz) product (Oduro et al., 2000; Sanni et al., 2009) widely consumed by individuals regardless of their economic status throughout West Africa sub-region. In Ghana, this economical, ready-to-eat household staple dish is largely consumed by adolescent students (15–25 years) and is a featured menu item in Ghana's school feeding programme (Agbozo et al., 2018). Gari consists of mostly starch and is almost devoid of other nutrients required for growth and development. Therefore, blending protein-rich okara with cassava could significantly bridge the protein and some micronutrient deficiency gaps among the vulnerable in Ghana. Due to gari's low nutritive value, there have been attempts to improve its nutrition using FFSF or okara (Sanni and Sobamiwa, 1994), defatted soybean flour (Twum et al., 2021), and orange-fleshed sweetpotato (Ojo and Akande, 2013; Abano et al., 2020; Atuna et al., 2021). However, the beany flavour associated with FFSF affects the consumer acceptability of products containing FFSF (Iwuoha and Umunnakwe, 1997). Also, the content of PUFAs in FFSF makes these products susceptible to oxidative rancidity thus producing off-flavours and consequently affecting the overall quality of the product (Park et al., 2018).

In this study, we characterised soymilk and tofu from several soybean varieties in Northern Ghana in terms of proximal composition and sensory acceptability. Then, we explored the proximal composition and desirability of okara originating from only “Afayak” variety and blended with cassava for gari.

Materials and Methods

The eight (8) varieties of soybean (i.e., Afayak, Favour, Jenguma, Quarshie, Salintuya 1, Salintuya 2, Songda, and Suong-Pungun) of soybean were obtained from the Council for Scientific and Industrial Research - Savanna Agricultural Research Institute (CSIR-SARI), Nyankpala, Northern Region, Ghana. The production of soymilk and tofu and subsequent determination of their yields was conducted at the Soyplus Facility and Training Centre, Nyankpala. The determination of the total soluble solids content of the soymilk was also assessed at the Spanish Laboratory Complex, University for Development Studies, (UDS) Nyankpala Campus.

Soymilk Extraction

The soybeans of the different varieties were sorted, removing foreign materials, rotten or cracked beans that may affect the taste and quality of the soymilk. Quality soybeans were washed and rinsed with potable water and used to produce the soymilk. About 1 kg from each soybean variety was separately weighed for either soymilk or tofu production. The soybeans were then soaked in 6 L of water for 6 h and then drained and rinsed. About 6 L of water was then added to the soybeans and milled with an electric grinder (F E 05 High-Speed grinding machine). The resulting slurry was cooked by adding another 6 litres of water using Soy-Cow Machine (comprising a boiler, the pressure cooker, the compressor, and a sieve) using steam at a temperature between 110°C and 115°C and pressure of 1 psi. The cooked slurry was then filtered through a filter bag by pressing for about 15 min and the extract (soymilk) was obtained.

Soymilk and Tofu Preparation

Soymilk

The extracted soymilk (5 L) and 150 g of sugar, 20 g of salt, and 15 ml of vanilla essence flavour were added and stirred to obtain a uniform mixture. The soymilk was then refrigerated for about 5 h for sensory analysis, and the samples were obtained for the total soluble solids analysis. Samples of the soymilk were also freeze-dried and milled into powder and packaged for proximate analysis and calcium content determination. All determinations were in triplicate.

Total Soluble Solids Determination

TSS was determined using a Labolan refractometer at room temperature as described by Raja and co-workers (Raja et al., 2014). In determining the TSS, a drop of distilled water was placed on the illumination plate and zeroed. After zeroing, the water was wiped off the illumination plate. A drop of soymilk was placed on the illumination plate. The percent Brix was then read by observing through the eyepiece of the refractometer on a scale of 0 to 32% Brix at 20°C. The process of zeroing was repeated preceding each sample reading.

Tofu

A coagulant solution of citric acid (15 g in 250 L of hot water; 70°C) was prepared and gently poured into 7 L of soymilk while stirring gently with a wooden spatula. The soymilk was allowed to settle for 15 min, and the curds were transferred to a cheesecloth-lined metal box (34 × 23 × 10 cm) and pressed using a compressor for 1 h. The weight was then taken and recorded as the yield of the tofu. The yield of tofu was determined by the procedure of Khatib and co-workers (Khatib et al., 2002).

Gari Recipe Refinement

Sample Collection

Cassava tubers were purchased locally from the Tamale Central market, Northern Region. Okara from Afayak variety was used for the recipe refinement of gari due to its availability.

Sample Preparation

Cassava tubers (5 kg) were sorted to remove bruised tubers, washed under running tap water, peeled with a kitchen knife, washed and grated into a mash using a locally fabricated grater. As reported elsewhere, the cassava mash was stored in a porous sack and pressed mechanically on an adjustable press to drain excess water while being allowed to ferment for three (3) days (Oluwamukomi and Adeyemi, 2013).

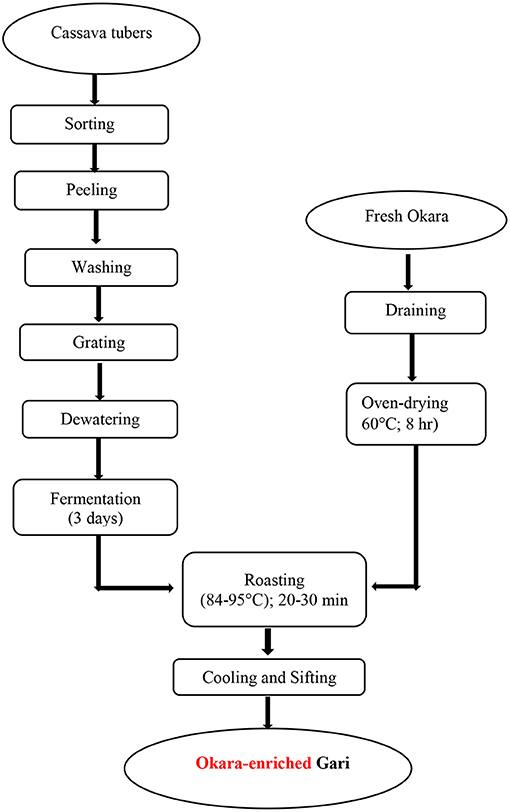

Processing of Okara-Enriched Gari

The existing 100% cassava gari prepared under the same conditions as the okara-enriched gari was used as the control (Figure 1). Fermented cassava and the oven-dried okara were mixed in ratios: 80:20, 70:30, and 50:50 on, as-is basis. The mixtures were then roasted separately at 84–95°C for 25–30 min. The samples were allowed to cool, sifted with a 355 μm sieve, and packaged in high-density polyethylene bags, and kept under refrigerated (4°C) storage until ready for further analysis.

Proximate Composition

The proximate composition and calcium content were determined at the Central Laboratory Facilities, College of Science, Kwame Nkrumah University of Science and Technology, Kumasi. The soymilk and okara-enriched gari were analysed in triplicates using standard methods of the Association of Official Analytical Chemists (AOAC, 1995) for moisture (AOAC 925.10) protein (AOAC 960.52), ash (923.03), crude fat (AOAC 922.06) and fibre (AOAC 962.09). Total carbohydrate content was determined by difference as shown in the equation below:

Carbohydrate (%) = 100 – (%Moisture + %Crude protein + %Crude fat + % Crude fibre + %Ash). The calcium content was determined following the oxalate precipitation method as described by Kirk and Sawyer (1991). The amount of calcium present in the samples was calculated using the following formula: Calcium (mg) = 1:2V/W.

where V=volume (mL) of standard KMnO4 solution required to titrate calcium oxalate; W=Weight (mg) of soymilk sample taken to prepare ash.

Determination of Functional Properties of Okara-Enriched Gari

Bulk Density Determination

Bulk density of the okara-enriched gari and the control (100% cassava gari) was determined using the gravimetric method described by Wang and Kinsella (1976) with a modification in the weight of the sample and volume of the graduated cylinder. A sample of 20 g was weighed into a 100 ml graduated cylinder. The cylinder was gently tapped on the benchtop 10 times from a height of 5 m from the ground until a constant volume was observed. The loose bulk density and tapped bulk density were then expressed as the weight per unit volume of the sample (g/ml) after tapping and before tapping, respectively as given in the equations below:

Water Absorption Capacity

The water absorption capacity (WAC) of the okara-enriched gari and the control (100% cassava gari) was determined by using the procedure of Sathe et al. (1982). The procedure was modified by using two (2) grammes of sample and 30 ml of water. Two grammes of the sample were mixed with 30 ml water and shaken for 1 min with a mechanical shaker. The mixture was left to stand undisturbed for 10 min. The mixture was then centrifuged (ROTOFIX 32 A model) at 3,500 rpm for 15 min and the volume of the supernatant was noted. The WAC was calculated using the equation below:

Swelling Capacity Determination

The swelling capacity of the okara-enriched gari and the control (100% cassava gari) was determined by a modification of Onwuka (2005) method. Two (2) grammes of the sample were weighed into a measuring cylinder, and the volume was recorded. Ten (10) millilitres of distilled water was then added to each sample and the solution was allowed to stand for 30 min at room temperature (25°C). The volume of each sample was retaken and recorded. The index of the swelling ability of the sample was calculated using the equation below

Water Activity

The water activity of the gari samples was determined using a water activity metre (model: HBD5-MS2100Wa). The gari sample was weighed to fill about two-thirds of the sample holder. The filled sample holder was placed in the device and was sealed with masking tape after which it was allowed to stand for 10 min before the device was turned on. The temperature and the water activity readings were displayed on the screen of the water activity metre 5 min after it was switched on.

pH

The pH of gari samples was determined as described by the method of AOAC (2005) using the pH metre (JENWAY model: 3510).

Sensory Evaluation

The soymilk, tofu, and okara-enriched gari were separately evaluated by selected undergraduate students of UDS, Nyankpala campus. There were 50-untrained panellists (19–32 years). The panellists were asked to evaluate the appearance, aroma, taste, sweetness, and overall acceptability for soymilk and the aroma, appearance, chewiness, and overall acceptability of tofu samples and the colour, taste, texture, aroma, and overall acceptability of the okara-enriched gari samples by using a 5-point hedonic scale (1-dislike extremely, 2-dislike, 3-neither like nor dislike, 4-like, 5-like extremely) that was employed for all evaluations. The soymilk (20 ml) and okara-enriched gari (10 g) samples were served in 3-digit coded disposable cups and evaluated. The fresh tofu from each variety was cut into cubes (2 g) and deep-fried separately in vegetable oil (frytol) for 10 min and then served on disposable plates for the sensory assessment. To minimise sensory fatigue, four (4) products of soymilk and tofu were separately evaluated in a day. However, for the okara-enriched gari, all the formulations including the existing 100% cassava gari were presented randomly at the same time. The panellist used water in between samples as a palate cleanser.

Statistical Analysis

Statistical analysis was carried out using Minitab statistical software v.16.2.4. (Minitab® Inc. USA). The effect of soybean variety on the yields of soymilk, tofu, and okara, the proximate composition of soymilk and okara-enriched gari, total soluble solids of the soymilk, and the functional properties of okara-enriched gari were analysed using One-way Analysis of Variance (ANOVA). The sensory data of soymilk, tofu and okara-enriched gari were analysed using Kruskal Wallis non-parametric data analysis procedure. The Fisher's Least Significant Difference (LSD) procedure was used to compare differences between means when the ANOVA result was significant (p < 0.05). For the sensory data, the Dunn test was used to compare differences among means when the ANOVA result was significant (p < 0.05).

Results and Discussion

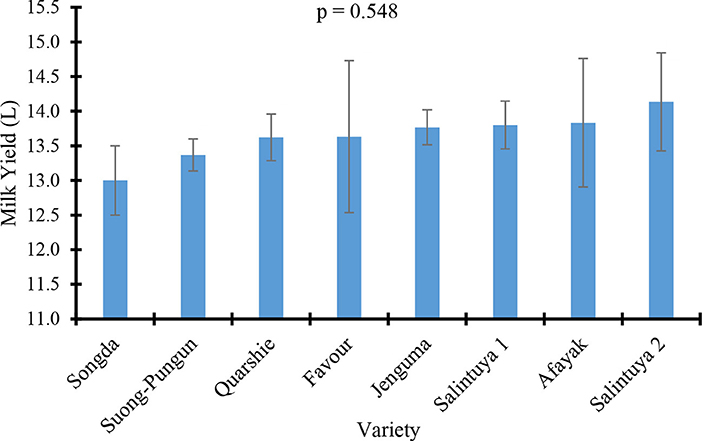

Effect of Variety on Soymilk Yield

From Figure 2, soymilk yield did not vary significantly (p = 0.548) among the eight (8) soybean varieties ranging between 13.00 and 14.13 L. This finding supports previous work by Bhardwaj et al. (1999) who observed that genotype had no significant effect on soymilk yield. Thus, all the varieties are equally suitable for milk extraction.

Figure 2. Effect of soybean variety on the yield of soymilk. Bars are means ± SD; n = 3. No statistical differences after ANOVA and means compared using LSD test (p > 0.05).

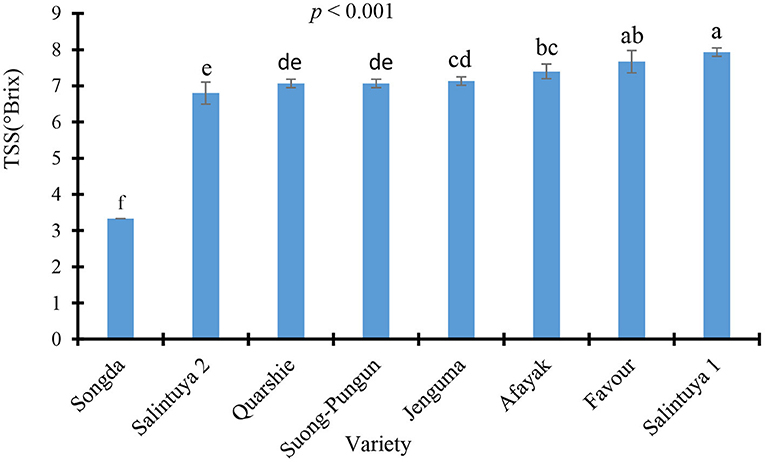

The total soluble solids (TSS) of the eight (8) soybean varieties showed marked (p < 0.001) differences with Songda recording the lowest TSS (3.33°Brix) (Figure 3). The low TSS recorded in Songda soymilk could be ascribed to the higher moisture content (Table 1) of the soymilk. The current findings deviate from earlier works by Khatib et al. (2002) who reported that soymilk produced from soybean varieties did not differ significantly in TSS.

Figure 3. Total soluble solids of soymilk as affected by soybean variety. Bars are means ± SD; n = 3. Different letters on top of bars represent statistical differences after ANOVA and means compared using LSD test (p < 0.05).

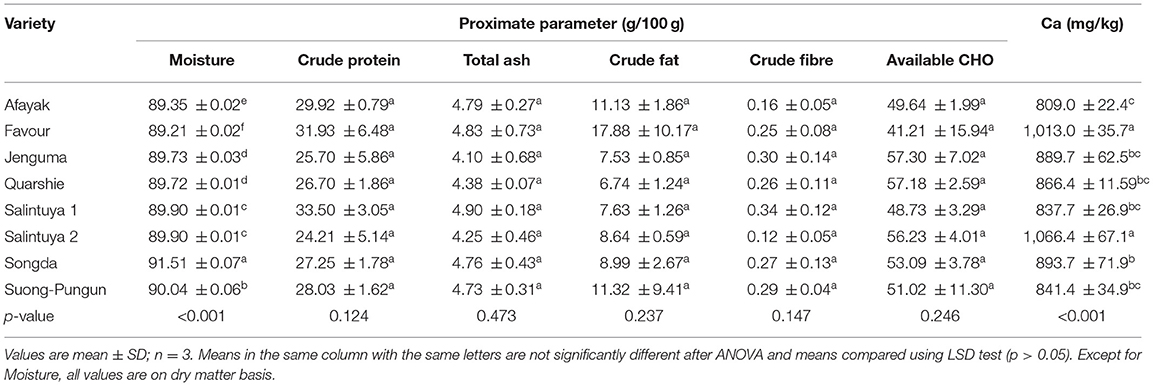

Effect of Soy Variety on Compositional Quality of Soymilk

Generally, soybean variety showed no significant (p > 0.05) effect on the proximate parameters evaluated except for the moisture (p < 0.001). The moisture content of the soymilk as presented in Table 1 ranged from 89.21 to 91.51%, similar to those reported in previous studies (Khatib et al., 2002; Ugochi et al., 2015; Abagoshu et al., 2017). Although the protein content did not statistically vary among varieties, it is noteworthy that soymilk produced from Salintuya 1 recorded the highest protein (33.50%) content while soymilk from Salintuya 2 also had the least protein content of 24.21%. The finding in this study contradicts those of Min and Martin who reported that the variety of soybean had a significant effect on the protein content of soymilk (Min et al., 2005a). The total ash content of the soymilk, which represents the total mineral content of soymilk samples in this study ranged from 4.1 to 4.9%. Salintuya 1 recorded the highest total ash content compared to the other varieties.

The crude fat content of the soymilk ranged from 6.74 to 17.88% and did not differ markedly among the soy varieties (Table 1). The highest crude fat content was recorded in soymilk produced from Favour. The crude fibre content of soymilk was relatively low varying from 0.12 to 0.34% and did not significantly (p = 0.147) vary among the varieties. The available carbohydrate content among the varieties did not vary significantly (p = 0.246) and ranged from 41.21 to 57.30%. The calcium content of the soymilk ranged from 809.0 to 1,066.4 mg/kg and varied significantly (p < 0.001) among varieties.

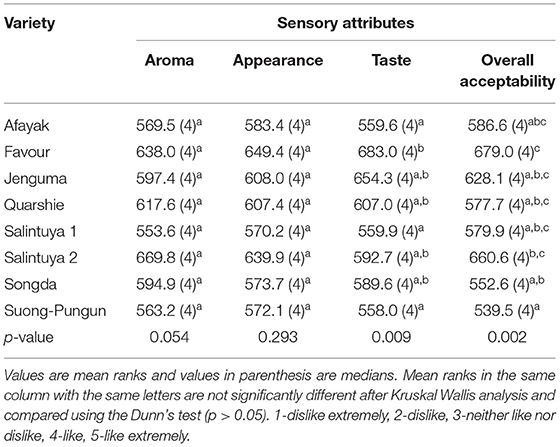

Consumer Acceptability of Soymilk

The consumer acceptability scores of soymilk made from the soy varieties evaluated in this study were all within the acceptable limit (sensory score = 4), indicating the soymilk-making potential of all the soybean varieties used in the current study (Table 2). Varieties did not differ markedly (p > 0.05) in terms of their aroma and appearance. However, Favour recorded a significantly higher score for taste (p = 0.009; mean rank = 683) and overall acceptability (p = 0.002; mean rank = 679). Based on these sensory scores, Favour could be promoted among varieties for soymilk production. The sensory quality of soymilk has been reported to be affected by genotype, processing method, and environmental conditions (Min et al., 2005b) among other factors.

Tofu

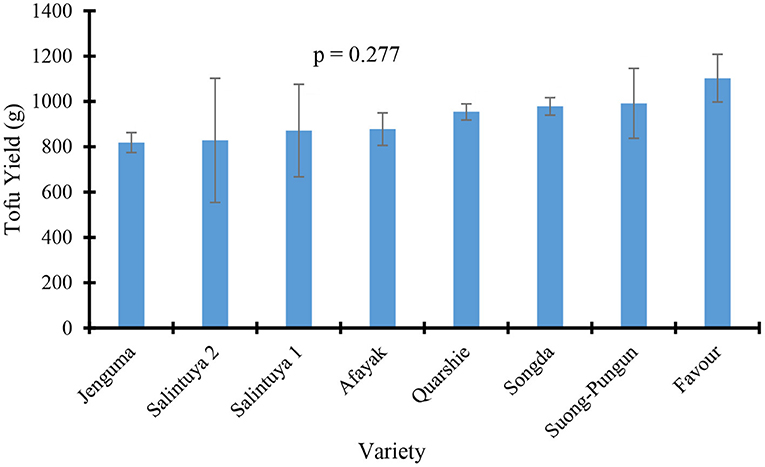

Effect of Soy Variety on Tofu Yield

The yield of fresh tofu did not vary significantly (p = 0.277) among varieties contrary to the findings of Wang et al. (1983) who reported significant varietal differences in fresh tofu. The discrepancies in the findings could be attributed to the differences in the water content of the fresh tofu. The yield of tofu ranged from 818.0 to 1102.5 g (Figure 4).

Figure 4. The yield of Tofu as affected by soy variety. Bars are means ± SD; n = 3. No statistical differences after ANOVA and means compared using LSD test (p > 0.05).

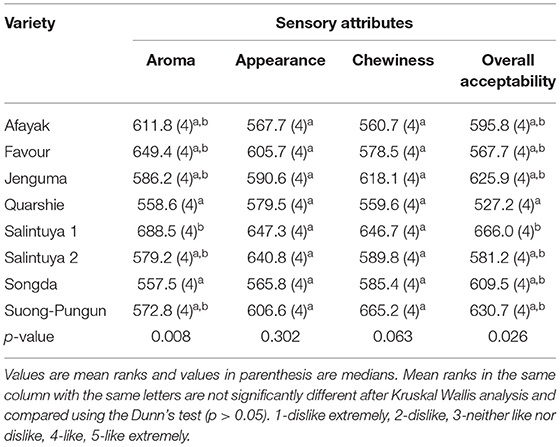

Consumer Acceptability of Tofu

The consumer acceptability of tofu processed from the eight (8) varieties of soybean is shown in Table 3. Generally, consumers liked tofu prepared from all the eight varieties considering that the median sensory score for all the attributes was 4. Salintuya 1, however, presented significantly higher mean ranks for aroma (p = 0.008; mean rank = 688.5) and overall acceptability (p = 0.026; mean rank = 666.0) than other varieties. This is an indication that the soybean varieties evaluated in this study are all desirable for tofu production.

Soy Residue (Okara)

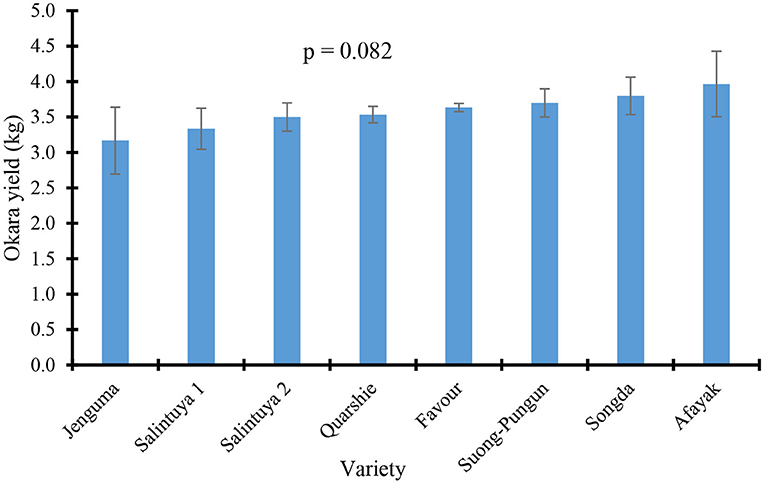

Effect of Soy Variety on Okara Yield

The okara yield of soybean varieties did not show marked (p = 0.082) differences ranging from 3.17 to 3.97 kg (Figure 5). The fresh okara yield obtained in the present study is slightly higher than the 1.1–1.2 kg of fresh okara per kilogramme of soybean processed for either soymilk or tofu reported in other studies (Khare et al., 1995; Guimarães et al., 2018). The amount of water in the fresh okara and the efficiency of pressing to remove the liquid fraction could explain the differences in fresh okara yield in this study relative to the earlier studies.

Figure 5. Soy residue (Okara) yield as influenced by soybean variety. Bars are means ± SD; n = 3. No statistical differences after ANOVA and means compared using LSD test (p > 0.05).

Recipe Refinement of Gari With Okara

Functional and Physicochemical Properties of Cassava-Okara Gari

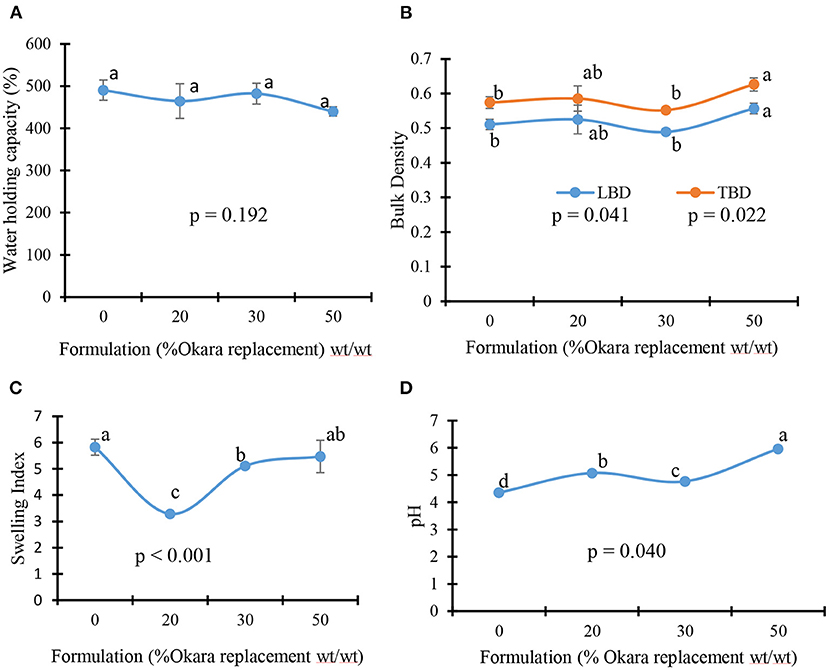

Partial substitution of cassava with okara at 20, 30, and 50% did not significantly (p = 0.192) affect the water absorption capacity of the cassava-okara composite gari relative to the 100% cassava gari (Figure 6A). The water absorption capacity measures the volume occupied by the starch after swelling in excess water, which maintains the integrity of starch in aqueous dispersion (Bajo et al., 2019). It is an important index for the development of ready-to-eat food products such as gari because a high absorption capacity may assure product cohesiveness (Houssou and Ayernor, 2002).

Figure 6. Water absorption capacity (A), Bulk density (B), Swelling capacity (C), and pH (D) of okara-enriched cassava grits. Values are means ± SD; n = 3. Data points with the same letters are not significantly different after ANOVA and means compared using LSD test (p > 0.05). Average pH of fresh okara = 6.3.

Bulk densities (tapped or loose) measure the heaviness of flour products and are largely influenced by the particle size and density of the product (Bajo et al., 2019). It is essential in determining packaging requirements and material handling (Huang et al., 2019). In the current study, both the loose and tapped bulk densities of the cassava-okara composite gari followed a similar trend with the 50% okara enrichment recording a significantly higher tapped (0.63 vs. 0.57 g/ml; p = 0.022) and loose (0.56 vs. 0.51; p = 0.041) bulk densities (Figure 6B). This finding lends credence to previous works by Ilelaboye and Ogunsina (2018), who reported increased bulk density with the addition of okara flour. The values obtained for the tapped and loose bulk densities are comparable to those reported elsewhere (Oluwamukomi and Adeyemi, 2013) for okara-melon seed enriched gari.

The swelling capacity measures the ability of particles to imbibe water and swell. It is an essential sensory and mechanical attribute that determines the quality of the product, including mouldability (Udofia et al., 2011). The swelling capacity in the present study (Figure 6C) shows that the blend with the highest level of okara incorporation (50% okara-enriched) had a similar swelling capacity (5.5 vs. 5.8) as the existing 100% cassava gari. The higher the swelling capacity, the greater its suitability for use in most West African dishes such as “eba” in which greater mouldability is preferred (Apea-Bah et al., 2009). The decline in the swelling capacity of the composited blends is expected because the swelling capacity of a product is a function of the starch content (ratio of amylose to amylopectin) (Ilelaboye and Ogunsina, 2018) and the extent of gelatinisation of starch (Huang et al., 2019). The low starch content of okara relative to cassava could account for the decline in swelling capacity since starch enhances swelling. The current findings agree with previous works that showed that swelling capacity decrease as the levels of soy flour increase in cassava-soy-melon composite gari (Oluwamukomi and Adeyemi, 2013).

The cassava-okara composite gari had a significantly higher pH (4.36 vs. 5.96; p = 0.040) than the existing 100% cassava gari (Figure 6D). The pH of the composited blends steadily increased with increasing incorporation levels of okara. The general increase in pH with okara incorporation could be because the fresh okara with a pH of 6.3 was first dried before compositing with the fermented cassava grits. Hence the okara did not undergo any fermentation. The pH of gari is a function of fermentation and an indicator of its storage life. The lower the pH, the better the storage life as it inhibits microbial activity. The blend with the highest okara incorporation with pH 5.96 is almost similar to those obtained in a previous work when cassava grits were supplanted with soy-melon flour (Oluwamukomi and Adeyemi, 2013).

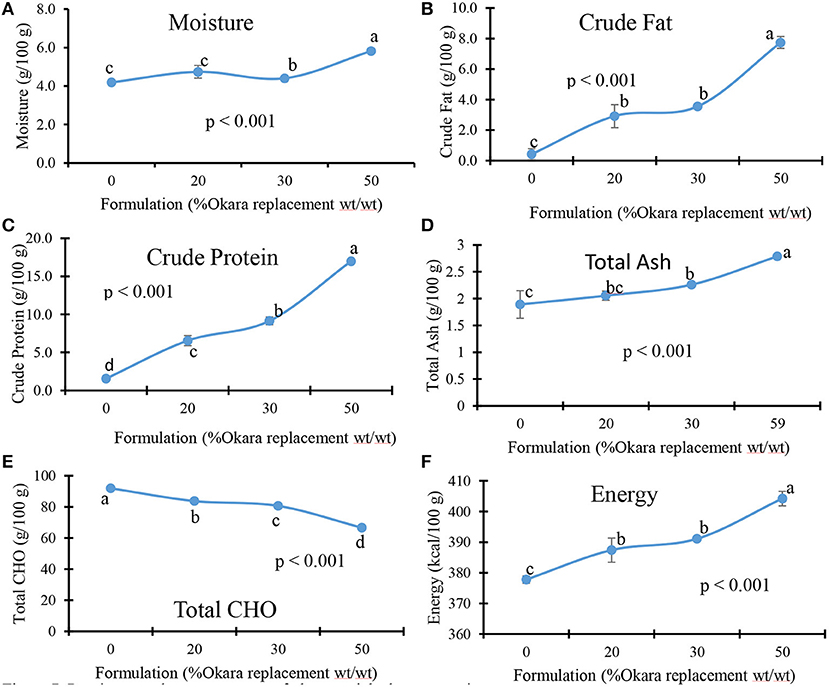

Proximate Composition and Energy Content

From Figures 7A–E, all proximate parameters steadily increased as the level of okara increased in the cassava-okara blends except for total carbohydrates content. The moisture content of the blends ranged from 4.2 to 5.8% (Figure 7A) and was all below the 12% threshold per Codex standards for gari (FAO/WHO, 1995). The significantly higher moisture content (p < 0.001) of the blend with the highest okara inclusion could be due to the relatively high insoluble fibre and protein contents of okara. Due to the hygroscopic nature of protein and fibre, the blends retained more moisture (Nilufer-Erdil et al., 2012) relative to the existing 100% cassava gari.

Figure 7. Proximate and energy content of okara-enriched cassava grits. Except for moisture, all determinations are on dry matter basis. Values are means ± SD; n = 3. Data points with the same letters are not significantly different after ANOVA and means compared using LSD test (p > 0.05). Proximate [Moisture (A), Crude fat (B), Crude Protein (C), Total Ash (D), Total CHO (E)] and energy (F) content of okara-enriched cassava grits.

The crude fat content of the 50% okara-enriched blend was significantly (p < 0.001; 7.7/100 g vs. 0.4/100 g) higher than the existing 100% cassava grits (Figure 7B). The blend with the highest okara incorporation (50% okara enrichment) was almost 19-times higher than the cassava-only gari. This was expected because okara contains a considerable amount of fat and could account for the increased fat content of the blends (Grizotto et al., 2010). Similar trends were reported for sorghum-okara composited flours for local staples in an earlier study (Uzo-Peters and Ola, 2020).

The crude protein content increased significantly (p < 0.001) with okara substitution (Figure 7C) almost 11-fold in the 50% okara-enriched gari compared with the cassava-only gari (Figure 7C). The crude protein of the composite blends ranged from 6.5 to 17.0/100 g. The increase in the crude protein content of the composite blends is expected because okara contains protein since it is a by-product of soybean regarded as a powerhouse of quality protein (Grizotto et al., 2010). This increase in crude protein content with okara substitution will complement the protein profile of cassava which is limited in most essential amino acids. Therefore, the okara-enriched gari may be inferred as capable of supporting the growth of school-age children who often consume “gari” as convenience food. For example, to meet the Recommended Daily Allowance of 34 g/day for protein for a school child (11–14 years) (Oluwamukomi and Adeyemi, 2013), he/she would need to consume about 2.13 kg of regular gari per day, but with the 50% okara-enriched gari he/she will need to consume only 0.2 kg.

The total ash content of the blends also steadily increased with okara substitution as presented in Figure 7D. Comparatively, the 50% okara-enriched composite blend had a significantly (2.79/100 g vs. 1.89/100 g; p < 0.001) higher total ash content, nearly 1.5 times compared with the existing 100% cassava gari (Figure 7D). The high total ash content of composite blend with okara substitution indicates that the mineral content of the okara-enriched samples would be enhanced since total ash may represent the mineral content of a food product. The current finding corroborates previous works (Ostermann Porcel et al., 2017) that also observed an increased total ash content of okara-enriched bread.

On the contrary, the total carbohydrates followed a downward trend with the increased substitution of okara. The existing 100% cassava gari was significantly (91.9/100 g vs. 66.7/100 g; p < 0.001) higher (Figure 7E). The low carbohydrate content of okara (O'Toole, 1999) could account for the decrease in total carbohydrates with increased okara substitution. A similar decrease in carbohydrate was reported in okara-enriched bread (Ostermann Porcel et al., 2017), gari enriched with okara and melon seeds (Oluwamukomi and Adeyemi, 2013), and sorghum-okara composite blend (Uzo-Peters and Ola, 2020).

The energy value of the composite blends increased markedly (p < 0.001) with the increased inclusion level of okara (Figure 7F). The energy content in the 50% okara-enriched blend increased almost 26.5 kcal/100 g more than the existing 100% cassava gari. This observation is consistent with earlier works that showed increased caloric value in gari enriched with full-fat soy (Oluwamukomi and Adeyemi, 2013). This increase in caloric value with the increased substitution of okara could be attributed to the relatively high-fat content in soybeans and its derivatives such as okara since fat is a high energy-yielding nutrient compared with carbohydrates and protein (Ikya et al., 2013). Higher calorie-dense foods may pose an economic advantage as smaller amounts would have to be consumed to meet the caloric needs of the body compared to lower calorie-dense foods.

Consumer Acceptability

Generally, the okara-enriched blends were all acceptable (sensory score = 4) by consumers for all the sensory attributes assessed (Table 4). All the sensory attributes did not significantly differ (p > 0.05) except for colour that showed marked significant (p < 0.001) difference among the formulations (Table 4). The findings in this study suggest that substituting okara up to 50% with cassava is likely to be accepted by Ghanaian consumers in terms of taste, texture, aroma, and overall acceptability. Thus, there is a great potential of improving the nutritional quality of the existing 100% cassava gari using low-cost okara with a minimal effect on most of the sensorial properties. Generally, the colour of gari is creamy-white (Alamu et al., 2019) because it is traditionally processed from white cassava and this has influenced most Ghanaian consumers to perceive that gari must be white to be acceptable. Therefore, compositing okara flour beyond 30% (w/w) with white cassava darkened the product, hence consumers' indifferent posture. The brownish colour of gari could be directly related to the increase in fibre content (Kassahun and Gebremicheal, 2019) as well as caramelisation and Maillard reactions, as the protein contributed by okara may have reacted with sugar during the roasting process. Similar findings have been reported on declined colour scores with increased okara enrichment in bread (Kassahun and Gebremicheal, 2019), cassava-orange fleshed sweetpotato gari, “eba” (Atuna et al., 2021), and okara-enriched biscuits (Grizotto et al., 2010).

The anti-nutritional factors such as trypsin inhibitors and phytate in soymilk and tofu as well as cyanogenic glucosides, in the cassava-based gari, were not considered in the current study and have been acknowledged as the limitation.

Conclusion and Recommendation

The eight (8) soybean varieties evaluated were generally desirable for soymilk and tofu production based on yield. The sensory data showed that, though consumers generally rated soymilk and tofu from all soybean varieties high (score = 4) for all sensory attributes, Favour and Salintuya 1 were more desirable for soymilk and tofu production, respectively. For every 1 kg of soybean used to produce either soymilk or tofu, almost 3.17–3.97 kg of fresh okara was produced. Recipe refinement of gari with dried okara up to 50% (w/w) inclusion showed increased nutritional composition in the okara-enriched gari. However, beyond 30% (w/w) okara inclusion, the sensory properties of the okara-enriched gari are less preferred by consumers. Thus, recipe refinements using the desired varieties and compositing okara with cassava may help fill the protein gap among the vulnerable group in Ghana and the West African Sub-region by improving the protein quality of ready-to-eat foods such as gari.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

RA, FCA, FKA, and ND conceived and designed experiments. RA, VA, SF, EB, and GK performed the research, analysed, and visualised the data. RA, EG, and MT wrote the manuscript. FCA, AD, FKA, and JL critically revised the draft manuscript. All authors contributed to the article and approved the submitted version.

Funding

This research was funded by Agency for International Development (USAID) Feed the Future Innovation Lab for Soybean Value Chain Research, grant number AID-OAA-L-140000-1; and USAID/Ghana – Council for Scientific and Industrial Research-Savanna Agricultural Research Institute Technical and Financial Support Project. Implementation No. 641-A18-FY14-IL#03. This work was also supported by the ADM Institute for the Prevention of Postharvest Loss at the University of Illinois, through the sponsorship of ADM Cares, the corporate social responsibility office of ADM Corporation and the Office of International Programs at the College of Agricultural Consumer and Environmental Sciences at the University of Illinois at Urbana Champaign.

Author Disclaimer

The contents are the responsibility of the authors and do not necessarily reflect the views of USAID or the United States government.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

This paper was made possible by the benevolent support of the American people through USAID.

References

Abagoshu, N. A., Ibrahim, A. M., Teka, T. A., and Mekonnen, T. B. (2017). Effect of soybean varieties and processing methods on nutritional and sensory properties of soymilk. J. Food Process. Preserv. 41:e13014. doi: 10.1111/jfpp.13014

Abano, E. E., Quayson, E. T., Bosompem, M., and Quarm, M. (2020). β-Carotene-fortified gari: processing variables effect on nutritional and sensory qualities. J. Food Process Eng. 43, 1–10. doi: 10.1111/jfpe.13322

Agbozo, F., Atitto, P., Jahn, A., and Abubakari, A. (2018). Nutrient composition and dietary diversity of on-site lunch meals, and anthropometry of beneficiary children in private and public primary schools in Ghana. Nutr. Health 24, 241–249. doi: 10.1177/0260106018793048

Alamu, E. O., Ntawuruhunga, P., Chibwe, T., Mukuka, I., and Chiona, M. (2019). Evaluation of cassava processing and utilization at household level in Zambia. Food Sec. 11, 141–150. doi: 10.1007/s12571-018-0875-3

AOAC (1995). Official methods of analysis of AOAC International. 18th Edn. Gaithersburg, MD; Washington, DC: AOAC International.

AOAC (2005). Cereal Foods (AOAC International. Official Method AOAC 925.10 for Moisture in Flour) Official Methods of Analysis of the Association of Official Analytical Chemists, 17th Edn. Gaithersburg, MD.

Apea-Bah, F. B., Oduro, I., Ellis, W. O., and Safo-Kantanka, O. (2009). Principal components analysis and age at harvest effect on quality of gari from four elite cassava varieties in Ghana. Afr. J. Biotechnol. 8, 1943–1949.

Atuna, R. A., Achaglinkame, M. A., Accorley, T. A. S., and Amagloh, F. K. (2021). Cassava orange-fleshed sweetpotato composite gari: a potential source of dietary vitamin, A. Front. Nutr. 8:230. doi: 10.3389/fnut.2021.646051

Avea, A. D., Zhu, J., Tian, X., BaleŽentis, T., Li, T., Rickaille, M., et al. (2016). Do NGOs and development agencies contribute to the sustainability of smallholder soybean farmers in Northern Ghana—a stochastic production frontier approach. Sustainability 8:465. doi: 10.3390/su8050465

Bajo, W., Gudisa, A., and Nigusu, Y. (2019). Optimization of common bean and finger millet blends for porridge. Food Sci. Nutr. Comp. Res. 23, 23–34.

Belkacemi, L., Nelson, D. M., Desai, M., and Ross, M. G. (2010). Maternal undernutrition influences placental-fetal development. Biol. Reprod. 83, 325–331. doi: 10.1095/biolreprod.110.084517

Bhardwaj, H., Bhagsari, A., Joshi, J., Rangappa, M., Sapra, V., and Rao, M. (1999). Yield and quality of soymilk and tofu made from soybean genotypes grown at four locations. Crop Sci. 39, 401–405. doi: 10.2135/cropsci1999.0011183X0039000200017x

Bhaskaram, P. (2002). Micronutrient malnutrition, infection, and immunity: an overview. Nutr. Rev. 60 (suppl_5):S40–5. doi: 10.1301/00296640260130722

Corish, C. A., and Kennedy, N. P. (2000). Protein-energy undernutrition in hospital in-patients. Br. J. Nutr. 83, 575–591. doi: 10.1017/S000711450000074X

Dary, O., and Mora, J. O. (2002). Food fortification to reduce vitamin A deficiency: International Vitamin A Consultative Group recommendations. J. Nutr. 132, 2927S–2933S. doi: 10.1093/jn/132.9.2927S

FAO/WHO (1995). Report of a Joint FAO/WHO Food Standards Programme, Codex Alimentarius Commission, Standard for Gari CXS 151–1989. FAO: Rome. P. 76.

Gage, D., Bangnikon, J., Abeka-Afari, H., Hanif, C., Addaquay, J., Antwi, V., et al. (2012). The Market for Maize, Rice, Soy, and Warehousing in Northern Ghana. Accra: USAID, The Enabling Agricultural Trade (EAT) project.

Ghana Statistical Service, Ghana Health Service, and ICF International (2015). Demographic and Health Survey 2014. Rockville, ML: GSS, GHS, and ICF International. Available online at: https://dhsprogram.com/pubs/pdf/FR307/FR307.pdf (accessed September 10, 2021).

Golbitz, P., and Jordan, J. (2006). “Soyfoods: market and products,” in Soy Applications in Food, ed N. M. Riaz (London; New York, NY: Francis and Taylor). p. 1–21.

Grizotto, R. K., Rufi, C. R. G., Yamada, E. A., and Vicente, E. (2010). Evaluation of the quality of a molded sweet biscuit enriched with okara flour. Food Sci. Technol. 30, 270–275. doi: 10.1590/S0101-20612010000500041

Guimarães, R. M., Silva, T. E., Lemes, A. C., Boldrin, M. C. F., da Silva, M. A. P., Silva, F. G., et al. (2018). Okara: a soybean by-product as an alternative to enrich vegetable paste. LWT 92, 593–599. doi: 10.1016/j.lwt.2018.02.058

Houssou, P., and Ayernor, G. (2002). Appropriate processing and food functional properties of maize flour. Afr. J. Sci. Technol. 3, 126–131. doi: 10.4314/ajst.v3i1.15297

Huang, S., Martinez, M. M., and Bohrer, B. M. (2019). The compositional and functional attributes of commercial flours from tropical fruits (breadfruit and banana). Foods 8:586. doi: 10.3390/foods8110586

Ikya, J., Gernah, D., and Sengev, I. (2013). Proximate composition, nutritive and sensory properties of fermented maize, and full fat soy flour blends for agidi production. Afr. J. Food Sci. 7, 446–450. doi: 10.5897/AJFS09.224

Ilelaboye, N., and Ogunsina, T. (2018). Proximate composition, functional properties and sensory evaluation of stiff dough (Amala). Prepared from Okara fortified plantain-sorghum flours. Asian Food Sci. J. 5, 1–10. doi: 10.9734/AFSJ/2018/44093

Iwuoha, C. I., and Umunnakwe, K. E. (1997). Chemical, physical and sensory characteristics of soymilk as affected by processing method, temperature and duration of storage. Food Chem. 59, 373–379 doi: 10.1016/S0308-8146(96)00250-6

Kassahun, C., and Gebremicheal, H. (2019). Nutritional and sensory quality of breads from bread wheat and soybean flour blends. Food Sci. Nutr. Comp. Res. 45, 45–51.

Khare, S., Jha, K., and Gandhi, A. (1995). Citric acid production from okara (soy-residue) by solid-state fermentation. Bioresour. Technol. 54, 323–325. doi: 10.1016/0960-8524(95)00155-7

Khatib, K., Aramouni, F., Herald, T., and Boyer, J. (2002). Physicochemical characteristics of soft tofu formulated from selected soybean varieties. J. Food Qual. 25, 289–303. doi: 10.1111/j.1745-4557.2002.tb01026.x

Khojely, D. M., Ibrahim, S. E., Sapey, E., and Han, T. (2018). History, current status, and prospects of soybean production and research in sub-Saharan Africa. Crop J. 6, 226–235. doi: 10.1016/j.cj.2018.03.006

Kirk, S., and Sawyer, R. (1991). Pearson's Composition and Analysis of Foods, Vol. 9. Harlow: Longman Group Ltd.

Lam, L. F., and Lawlis, T. R. (2017). Feeding the brain–The effects of micronutrient interventions on cognitive performance among school-aged children: a systematic review of randomized controlled trials. Clin. Nutr. 36, 1007–1014. doi: 10.1016/j.clnu.2016.06.013

Martey, E., and Goldsmith, P. (2020). Heterogeneous demand for soybean quality. Afr. J. Agric. Resour. Econ. 15, 27–50. doi: 10.53936/afjare.2020.15(1).03

Min, S., Yu, Y., and Martin, S. S. (2005a). Effect of soybean varieties and growing locations on the physical and chemical properties of soymilk and tofu. J. Food Sci. 70, C8–C21. doi: 10.1111/j.1365-2621.2005.tb09026.x

Min, S., Yu, Y., Yoo, S., and Martin, S. S. (2005b). Effect of soybean varieties and growing locations on the flavor of soymilk. J. Food Sci. 70, C1–C11. doi: 10.1111/j.1365-2621.2005.tb09009.x

Nilufer-Erdil, D., Serventi, L., Boyacioglu, D., and Vodovotz, Y. (2012). Effect of soy milk powder addition on staling of soy bread. Food Chem. 131, 1132–1139. doi: 10.1016/j.foodchem.2011.09.078

Nyantakyi-Frimpong, H., Colecraft, E. K., Awuah, R. B., Adjorlolo, L. K., Wilson, M. L., and Jones, A. D. (2018). Leveraging smallholder livestock production to reduce anemia: a qualitative study of three agroecological zones in Ghana. Soc. Sci. Med. 212, 191–202. doi: 10.1016/j.socscimed.2018.07.028

Oduro, I., Ellis, W., Dziedzoave, N., and Nimako-Yeboah. (2000). Quality of gari from selected processing zones in Ghana. Food Control 11, 297–303. doi: 10.1016/S0956-7135(99)00106-1

Ojo, A., and Akande, E. (2013). Quality evaluation of ‘gari produced from cassava and sweet potato tuber mixes. Afr. J. Biotechnol. 12, 4920–4924. doi: 10.5897/AJB12.2504

Oluwamukomi, M., and Adeyemi, I. (2013). Physicochemical characteristics of “Gari” semolina enriched with different types of Soy-melon supplements. Eur. J. Nutr. Food Saf. 3, 50–62.

Onwuka, G. (2005). Food Analysis and Instrumentation: Theory and Practice. Lagos: Napthali Print, 133–137.

Ostermann Porcel, M. V., Campderrós, M. E., and Rinaldoni, A. N. (2017). Effect of okara flour addition on the physical and sensory quality of wheat bread. MOJ Food Process. Technol. 4, 1–7. doi: 10.15406/mojfpt.2017.04.00111

O'Toole, D. K. (1999). Characteristics and use of okara, the soybean residue from soy milk production a review. J. Agric. Food Chem. 47, 363–371. doi: 10.1021/jf980754l

Park, S.-K., Prabakaran, M., An, Y., Kwon, C., Kim, S., Yang, Y., et al. (2018). Impact of storage stability on soybean (Glycine max L.) flour stored in different conditions and package materials. Korean J. Crop Sci. 63, 338–359. doi: 10.7740/kjcs.2018.63.4.338

Raja, J., Punoo, H. A., and Masoodi, F. A. (2014). Comparative study of soy paneer prepared from soymilk, blends of soymilk and skimmed milk. J. Food Process. Technol. 5:2. doi: 10.4172/2157-7110.1000301

Redondo-Cuenca, A., Villanueva-Suárez, M. J., and Mateos-Aparicio, I. (2008). Soybean seeds and its by-product okara as sources of dietary fibre. Measurement by AOAC and Englyst methods. Food Chem. 108, 1099–1105. doi: 10.1016/j.foodchem.2007.11.061

Sacks, F. M., Lichtenstein, A., Van Horn, L., Harris, W., Kris-Etherton, P., and Winston, M. (2006). Soy protein, isoflavones, and cardiovascular health: an American Heart Association Science Advisory for professionals from the Nutrition Committee. Circulation 113, 1034–1044. doi: 10.1161/CIRCULATIONAHA.106.171052

Sanni, L., Adebowale, A., Awoyale, W., and Fetuga, G. (2009). Quality of gari (roasted cassava mash) in Lagos State, Nigeria. Nigerian Food J. 26, 125–134. doi: 10.4314/nifoj.v26i2.47446

Sanni, M. O., and Sobamiwa, A. O. (1994). Processing and characteristics of soybean-fortified gari. World J. Microbiol. Biotechnol. 10, 268–270. doi: 10.1007/BF00414860

Sathe, S., Deshpande, S., and Salunkhe, D. (1982). Functional properties of winged bean [Psophocarpus tetragonolobus (L.) DC] proteins. J. Food Sci. 47, 503–509. doi: 10.1111/j.1365-2621.1982.tb10112.x

Twum, L. A., Ocloo, F. C., Duah-Bisiw, D., and Odai, B. T. (2021). Determining the effect of heat treatment on iron fortified soybean gari blend and its bioavailability. Sci. Afr. 12:e00763. doi: 10.1016/j.sciaf.2021.e00763

Udofia, P., Uduodo, P., Eyen, N., and Udoekong, N. (2011). Optimizing gari quality attributes for different groups of consumers with response surface methodology. J. Agric. Biotechnol. Sustain. Dev. 3, 28–34

Ugochi, N. F., Chukwuma, U. M., Nwanneoma, O. J., Ndako, K. J., and Nwabugo, M. A. (2015). Nutrient and sensory quality of soymilk produced from different improved varieties of soybean. Pak. J. Nutr. 14, 898–906 doi: 10.3923/pjn.2015.898.906

Uzo-Peters, P., and Ola, S. (2020). Proximate composition and functional properties of composite sorghum-okara flour and sensory evaluation of local snack product (sosa). Agrosearch 20, 158–167. doi: 10.4314/agrosh.v20i1.14S

van der Riet, W. B., Wight, A. W., Cilliers, J. J. L., and Datel, J. M. (1989). Food chemical investigation of tofu and its byproduct okara. Food Chem. 34, 193–202. doi: 10.1016/0308-8146(89)90140-4

Wang, H., Swain, E., Kwolek, W., and Fehr, W. (1983). Effect of soybean varieties on the yield and quality of tofu. Cereal Chem. 60, 245–248.

Keywords: gari, Ghana, okara, protein deficiency, soybean, soymilk and tofu

Citation: Atuna RA, Amagloh FC, Denwar NN, Asase VR, Faisal S, Baako E, Koomson G, Gulkirpik E, Toc M, Donnelly A, Amagloh FK and Andrade Laborde JE (2022) Filling the Protein Gap in Ghana: The Role of Soy. Front. Sustain. Food Syst. 5:781571. doi: 10.3389/fsufs.2021.781571

Received: 22 September 2021; Accepted: 22 December 2021;

Published: 08 February 2022.

Edited by:

Pranjal Yadava, Indian Agricultural Research Institute (ICAR), IndiaReviewed by:

Folake Samuel, University of Ibadan, NigeriaLucretia Barber, Rivers State University, Nigeria

Copyright © 2022 Atuna, Amagloh, Denwar, Asase, Faisal, Baako, Koomson, Gulkirpik, Toc, Donnelly, Amagloh and Andrade Laborde. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Francis Kweku Amagloh, ZmthbWFnbG9oQHVkcy5lZHUuZ2g=

Richard Atinpoore Atuna

Richard Atinpoore Atuna Flora Christine Amagloh2,3

Flora Christine Amagloh2,3 Ece Gulkirpik

Ece Gulkirpik Francis Kweku Amagloh

Francis Kweku Amagloh Juan E. Andrade Laborde

Juan E. Andrade Laborde