95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Sustain. Food Syst. , 20 April 2021

Sec. Sustainable Food Processing

Volume 5 - 2021 | https://doi.org/10.3389/fsufs.2021.654313

This article is part of the Research Topic Retaining Quality when Drying Food: Challenges and Solutions View all 5 articles

Food waste is a worldwide concern as it represents a constant threat to the environment and a serious operational problem for the food industry. The by-products of fruits and vegetables being a valuable source of bioactive compounds have the potential to be reused and reintroduced in the agri-food chain. This circular approach contributes to a sustainable production system. In this context, a collaborative project with the primary sector for the integral valorization of the waste generated in the fresh-processing vegetable lines of an agricultural cooperative is currently being developed, particularly focused on cabbage, carrot, celery, and leek. The objective of this project is to transform vegetable wastes into functional powdered ingredients and be able to use them in food formulations in order to improve the nutritional profile of foods, contributing to the development of sustainable healthy diets. Through an exhaustive bibliographic review, this research studies the influence of pretreatments, drying and in vitro digestion on the bioactive compounds of vegetable residues, with the aim of identifying the appropriate production parameters to achieve an adequate functional and physicochemical profile of the final powders.

Food loss and food waste (FLW) impacts negatively on society, the environment and the economy. It represents a threat to the environment and a serious operational problem for the production plants (Goula and Lazarides, 2015). Environmental issues related to FLW are a matter of increasing concern since food production is resource-intensive and the growing population and incomes is expected to increase the demand of agricultural products of 50% by 2050 if there is no change in dietary habits and reduction of food waste (Food2030 Pathways for Action). FLW also participates from a societal paradoxin a world in which food insecurity and malnutrition continues to increase, while a substantial amount of food that could have been consumed is lost or ends up as residues. Therefore, reducing FLW in the next decade is a priority, which is expected to have an impact on all of the four Food 2030 priorities: nutrition, climate, circularity, and communities.

The Food and Agriculture Organization of the United Nations (FAO, 2019) has been working toward the harmonization of the concept of Food loss and Food waste, whereas EU legislation refers to food waste (FW) as the concept which covers all stages from farm to fork (except for the crops plowed in/not harvested) (Food2030 Pathways for Action). FW is generated throughout the whole supply chain (Mirabella et al., 2014). Primary production (25%) and processing (24%) accounts for about 50% of the total losses, fruit and vegetables being the products which participate most from this percentages (Food2030 Pathways for Action). In the first processing stages, these losses are mainly due to discards produced as a consequence of high commercial standards, as well as to edible parts which are eliminated by peeling or cutting in the fresh-processing lines (outer leaves, stems, damaged parts). Surpluses and spoilage may also contribute to these numbers. Although most of these wastes have the potential to be reused and possess high biological and nutritional value, they are usually underused and considered as low-value material. According to the Food and Agriculture Organization (FAO) of the United Nations, approximately a third of the edible parts of food produced for human consumption are lost or wasted globally. It has been estimated that the food currently wasted in Europe could feed 200 million people. In 2016 it was estimated that FWL in the EU was around 88 million tons representing an associated cost of 143 billion euros (Stenmarck et al., 2016). Furthermore, the respective consumption of resources and the emission of pollutants implies an increase in the environmental burden.

It is necessary to focus production systems in terms of minimizing wastes, and reintroducing them into the production chain. In this sense, concepts such as “circular economy,” “industrial ecology,” and “zero waste economy,” among others, have arisen to orient eco-innovation toward the use of waste as raw material for the development of new products and applications (Mirabella et al., 2014). The reduction of food waste (FW) has an enormous potential for lowering the resources used to produce it, saving money and decreasing the environmental impact (Stenmarck et al., 2016). This also represents an important contribution to the Circular Economy Action Plan adopted by the European Commission within the European Green Deal, which promotes sustainable initiatives along the entire life cycle of products. A circular approach benefits sustainable food production (European Commission, 2019).

As defined by the Food and Agriculture Organization of the United Nations (FAO, 2019), a sustainable food system must be able to ensure sustainable consumption and production patterns, as well as deliver safe, healthy, and nutritious diets. Accordingly, the food industry must incorporate processes and products which provide both a lower environmental impact and an increased positive impact on diets and health. Reformulation of processed foods provides a genuine opportunity to improve people's health by modifying the nutritional characteristics of commonly consumed processed foods (Bas-Bellver et al., 2020b), therefore addressing the FAO sustainable development goal “Ensure healthy lives and promote well-being for all at all ages.” This is in accordance with the definition of a sustainable healthy diet, which states that food consumption should be adequate in energy and nutrients for growth and development, meeting the needs of an active and healthy life. This concept states that dietary patterns should promote all dimensions of individuals' health and well-being, while having low environmental impact and reducing food loss (FAO and WHO, 2019).

Increased awareness of the association between improper diet and health disorders has led to the development of a healthier food industry. Recommendations based on scientific evidence include increasing the consumption of plant-based foods, basically fruits and vegetables, as they are excellent sources of fiber and other bioactive compounds (Rao and Rao, 2007). These are perishable commodities which deteriorate in a short period of time if not handled properly, for which dehydration is a suitable method to extend their shelf life. Dehydration and milling can be combined to obtain fruit and vegetable powders. The current food industry shows a growing interest in the application of dried fruits and vegetables in powder form (Karam et al., 2016). In 2006, Zhang et al. (2006) already mentioned the growing increase of this market. Applications of fruit and vegetable powders include their use as ingredients in the confectionery, bakery, sweet, and distilling industries to improve the nutritional value of foodstuff (Camire et al., 2007), and include other applications such as dressings, soups or ready-to-eat products. Applications of fruit and vegetable powders is not limited to the use of the whole food, but the waste generated in the transformation industry is also a valuable source of bioactive compounds such as fiber, antioxidants and other phytochemicals (Tseng and Zhao, 2013) that can be transformed into powdered ingredients. Fruit and vegetables waste powders can also be proposed as new food ingredients, used to fortify food products or improve their technological properties (Elleuch et al., 2011; Ferreira et al., 2015; Plazzota et al., 2018; Bas-Bellver et al., 2020b). In this way, FW can be considered a source of valuable components at a low cost.

In this context, an eco-innovation project in collaboration with an agricultural cooperative (producers and fresh-processing industry) is currently being developed (Bas-Bellver et al., 2020b). The project aims to recover and reuse the waste generated in the vegetables fresh-processing lines (cabbage, carrot, celery and leek wastes) to obtain powdered functional ingredients to be used in the food industry. The annual production of these vegetable residues as estimated by the cooperative is ~180 tons in the case of leeks (some of the white part and the green leaves on top), ~250 tons in the case of cabbage (outer leaves), and between 2,000 and 3,000 tons in the case of carrots and celery, since most of these residues comes from the ready-to-eat lines in which the discard percentages increase substantially. This project seeks to reach an integral use of the by-products by applying different dehydration technologies, and it is not focused on extracting the bioactive compounds, thus avoiding solvent extraction and the generation of other residues. Processing conditions, including pretreatments, determine the physicochemical and functional properties of the powders, and thus their applications, as well as the bioaccesibility of their bioactive compounds. Thus, the purpose of this review is to provide scientific evidence for the optimal integral recovery of vegetable residues by reviewing drying techniques and pretreatments and their impact on the product characteristics and compounds bioavailability, to contribute to food chain circularity and the development of sustainable food diets.

The present review has been divided into three categories which allows the objectives to be addressed effectively. First, the current context of obtaining functional powder ingredients from fruit and vegetable wastes is presented, with special attention to the vegetables involved in the project. Then, the effects of processing on the functional and physicochemical profile of fruit and vegetable powders are exposed to identify the drying methodologies and possible pretreatments or additional steps that could increase the biological or nutritional value and define appropriate production parameters. Finally, the response to in vitro digestion of the various bioactive compounds of interest and their effects on human health is detailed. Considering the above, bibliographic research will help define the process conditions for producing vegetable waste powders of high quality, with a physicochemical profile suitable for subsequent application in food formulations and with functional properties capable of exerting beneficial effects on consumer's health. Hence, food ingredients and products contributing to the principles of sustainable healthy diets could be developed.

Selected keywords were entered into the most important databases of scientific journals, such as Science Direct, Scopus, Emerald Insight, Springer Link, Taylor & Francis Group, and Wiley Online Library. Additionally, tools such as Google Scholar and technical dictionaries such as IATE (Terminology of the European Union) and CAB Thesaurus were used. The titles and abstracts of more than 120 publications were selected and examined. Subsequently, the most relevant documents were chosen based on the previously defined criteria. In short, a total of 98 documents and investigations were selected and are the basis of the present bibliographic review. These works come from a total of 18 scientific journals, classified in the fields of food research, biotechnology, chemistry, and waste management. No geographic or time restrictions were applied in the initial search process. Once selected, temporality of the selected studies was determined, resulting in 80% of the investigations to have been published in the last 10 years (2011–2020) and 45% belonging to the last 5 years (2016–2020). Therefore, recent and updated information related to the subject of study is presented.

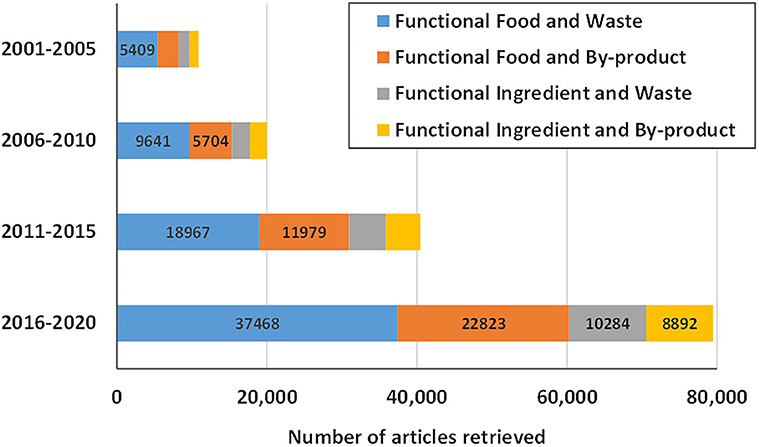

Figure 1 shows the evolution in the last 20 years of the number of published papers dealing with functional food development from food wastes (retrieved from ScienceDirect). For this search, the terms “functional food” or “functional ingredient” were combined with “food waste” or “by-product.” Other terms used in the literature to define food waste such as “residue” or “co-product” were not specific and retrieved a significant number of papers not dealing with the topic of interest, for which they were neglected for this analysis. According to the results plotted in Figure 1, the research interest in developing functional foods and obtaining functional ingredients from food waste has increased dramatically in the last years, the total number of published articles doubling every 5 years.

Figure 1. Evolution in the number of published articles (retrieved from Science Direct) using the combination of keywords “Functional Food” and “Waste,” “Functional Food” and “By-Product,” “Functional Ingredients” and “Waste,” “Functional Ingredient” and “By-product.”

At the beginning of the 21st century food industry and researchers were already aware of the need for developing valorization processes which reduced the environmental impact of the food industry and contributed to food industry sustainability. Nevertheless, it is the recent definition of the FAO sustainable goals for development that have boosted this research trend which contributes to the idea of sustainable food systems from a social, economic, and environmental point of view. The definition of this concept states that a sustainable food system must ensure sustainable consumption and production patterns, as well as deliver safe, healthy and nutritious diets Food and Agriculture Organization of the United Nations (FAO, 2019). Concerns related to FW have been presented in the scientific community since the 90s (Mirabella et al., 2014), such is the case of the research carried out by Kroyer (1995), who studied the impact of food processing on the environment highlighting the importance of waste treatment efficiently, reusing those by-products that are unavoidable to produce and turning them into new edible foods, thus rescuing biomass and valuable nutrients while reducing environmental burdens caused by inadequate management of waste.

In parallel, health benefits associated to dietary fibers (DF) has led to the development of a large and potential market for fiber-rich products and ingredients, thus boosting the search for new sources of DF. This is one of the reasons why the by-products of fruits and vegetables that have been traditionally devalued are today considered a valuable source of this compound of interest (Rodríguez et al., 2006). This increasing attention to DF thanks to its beneficial physiological effects on human beings and its contribution to several functional and technological properties when incorporated into various food products, has led to the development of functional powdered ingredients obtained from pomaces or bagasse generated in the beverage and juice industries. In fact, studies dealing with this topic were found to be related to the levels of beverages consumption, as well as to DF content. Therefore, fruits like orange, apple, or grape (Figuerola et al., 2005; Aguedo et al., 2012; Tseng and Zhao, 2013), and vegetables such as carrot and cabbage retrieved more papers (Stoll et al., 2003; Chantaro et al., 2008; Nilnakara et al., 2009; Baljeet et al., 2014; Nouri et al., 2017), while other fruits or vegetables such as raspberry, mango or leek have been studied to a lesser extent (Ajila et al., 2010; Górecka et al., 2010; Wang et al., 2020).

The scientific literature contains many reports on DF additions obtained from by-products of fruits and vegetables, in various food products such as baked goods, beverages, confectionery, dairy, frozen dairy, meat, pasta and soups (Elleuch et al., 2011). Figuerola et al. (2005) used apple and citrus residues to obtain fiber concentrates with functional properties and use them in food fortification. Physicochemical characteristics of the powder, and particularly particle size, provided these powders high water retention and fat adsorption capacity. The powders also had a high DF content and a relatively low caloric value. Regarding the effectiveness of its incorporation in the development of foods reduced in calories and rich in dietary fiber, it was found to depend not only on the characteristics of each concentrate, but also on the way of adding them to the food matrix (particle size, temperature, ionic strength). Authors also stated that the characteristics of each concentrate determine the volume replacement and their thickening or texturizing effect.

Other authors (Tseng and Zhao, 2013) used grape pomace from the wine industry to produce antioxidant DF. Results showed that the content of phenolic compounds was affected by many factors such as grape variety, growth climate and location, harvest time, processing and storage conditions or extraction procedure. Wine grape pomace was reported to contain 61% of DF which, together with its content of antioxidant compounds, remained stable after 16 weeks of storage, as a prove of the stability of these kind of products. The application of this powder as a food ingredient to increase the nutritional value and improve the storage capacity of a yogurt and a salad dressing were investigated. Results showed that the addition of wine grape pomace powder resulted in a 35–65% reduction in peroxide values in all samples and that the products had a DF content of 0.94–3.6% (w/w).

Lulo fruit is a tropical species rich in antioxidant compounds, minerals, and fiber. In a previous study (Hinestroza-Córdoba et al., 2020) lulo fruit bagasse, a by-product generated during lulo fruit juice manufacturing, was proposed to obtain a functional powdered ingredient. The obtained lulo bagasse powder was rich in fiber, phenols, and flavonoids with antioxidant capacity, which makes it an interest functional ingredient to enrich different types of food matrices. Blueberry bagasse and persimmon wastes have also been proposed for similar purposes (Bas-Bellver et al., 2020a) due to their fiber content and bioactive compounds: anthocyanins in the case of blueberry and carotenoids for persimmon. Overproduction and growing industrialization of the latter generates huge amounts of discards and residues, for which its valorization is gaining importance in recent years (Conesa et al., 2020). Ajila et al. (2010) obtained powders from mango peels and applied it to improve the antioxidant properties of macaroni preparations.

Regarding vegetables, Plazzota et al. (2018) obtained flours from fresh-cut salad waste to be used as food ingredients rich in antioxidants and with high solvent loading capacity. Their study concluded that drying is a feasible strategy to give value to these discards and obtain products with tailored physicochemical properties, as a function of the drying methods being used and mechanisms involved. Ferreira et al. (2015) proposed the integral exploitation of several fruits and vegetables (orange, passion fruit, watermelon, lettuce, courgette, carrot, spinach, mint, taro, cucumber, and rocket) by obtaining an isotonic beverage and a functional flour from the generated wastes. The residues flours showed good water holding capacity, associated to their fiber content, and were used to formulate biscuits and cereal bars rich in fiber and minerals.

Focusing on the vegetables of interest for the project being developed (cabbage, carrot, leek, celery), the literature evidenced more interest in obtaining powders or flours from cabbage and carrot residues as compared to celery and leek, possibly due to their production and consumption levels. Cabbage is rich in sulforaphane, a product of hydrolysis of glucosinolates that is known to be a potent food-derived anticancer substance (Tanongkankit et al., 2011). Carrots are one of the most important root crops and a rich source of α- and β-carotene (Hiranvarachat et al., 2011; Chen et al., 2016), which are important precursors of vitamin A in the human metabolism (Barzee et al., 2019). It is also characterized by being rich in dietary fiber (Chau et al., 2004). Celery stands out for its high apigenin content, a known flavone which has been claimed to exert remarkable health benefits (Yusni et al., 2018). Finally, leek is an important source of sulfides (Luo et al., 2014).

Nilnakara et al. (2009) evaluated the production of antioxidant DF powder from the outer leaves and kernel of cabbage. This specific by-product represents the 40% of the total weight and it is often used as fertilizer or animal feed. The researchers studied the effects of blanching in hot water and hot air drying at different temperatures on the quality of the final product. As for carrot, a large proportion of this root is consumed as juice (Chau et al., 2004), which generates thousands of tons of carrot pomace which are generally disposed of as animal feed. It has been reported that ~80% of the carotenes remain in this by-product (Baljeet et al., 2014). Based in the previous, Nouri et al. (2017) sought to reuse it and develop a functional powder ingredient to be used in the formulation of a fried pastry product with the aim of improving its nutritional profile by producing low-fat donuts with high fiber content.

In contrast, publications related to celery and leek were very limited. Specific research dealing with the recovery of by-products of these respective vegetables and their reuse for the development of functional foods was scarce. Researchers, Wang et al. (2020) studied the effects of wheat flour replacement by celery powder (CP) at different levels (1, 2, 3, and 5/100 g of flour) on bread quality. Results showed that the higher CP content, the greater the water absorption of the dough; however, the protein network, the maximum viscosity and the crystallinity of the starch decreased with an increase on the CP content. On the other hand, a higher level of CP increased the hardness and chewiness of the bread. It is important to highlight that the addition of CP significantly increased the total phenol content of the bread and, therefore, caused a significant improvement of its antioxidant properties. Regarding leek, Ozgur et al. (2011) studied the changes in some physicochemical properties and the variations in the antioxidant compounds of leek caused by the drying process. Leek drying resulted in a loss of ascorbic acid and phenolic compounds, so that the antioxidant capacity was reduced by more than 50% after drying.

This section has evidenced that FW can be transformed into functional food ingredients which, in fact, have been proved to increase the nutritional profile of several formulated foods contributing to the concept of sustainable diets and participating of circularity and food systems sustainability.

Processing is one of the main factors affecting bioactive compounds, by increasing or decreasing their content, and having an impact on their bioaccessibility (Cilla et al., 2018). Focusing on vegetables and fruit waste powders, it is crucial to study the impact of different available technologies on the functional properties of the obtained powders, given that functional foods are those that, in addition to providing nutrients, are capable of positively affect specific biological functions and thus improving the general state of people's health (Rodríguez et al., 2006). Food processing techniques are increasingly sophisticated and diverse in response to the growing demand for quality food with functional properties, for which emerging technologies are proposed for the development of functional foods (Galanakis, 2021). In addition to processing stages, characteristics of the food powders also depend on the composition and physicochemical properties of the raw materials, which in turn need to be considered when choosing the appropriate processing parameters. Therefore, to maximize the value of the waste, processing and pre-processing stages must be well-defined.

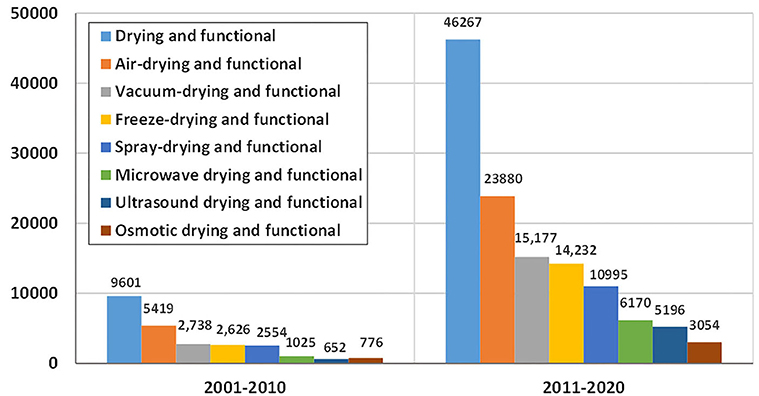

Dehydration or drying is a fundamental stage for the production of powdered ingredients. It involves the transient transfer of heat and mass accompanied by physical, chemical and phase change transformations. These transformations have a significant impact on heat and mass transfer mechanisms during drying, but they also impact the product quality and determine its technological properties, such as water and oil interaction properties. Dehydration is a widely studied operation of great application in the food industry. Figure 2 summarizes the evolution in the number of papers which have studied the application of different dehydration techniques to obtain functional foods or ingredients, and their impact on the bioactive compounds present in the food material. Results evidence that dehydration is a common technique applied to obtain functional food ingredients. Research interest on the impact of drying on the development of ingredients and functional foods, and its effects on their bioactive compounds is patent in the last decade.

Figure 2. Dehydration techniques applied in the process of functional food or functional ingredients obtention. Average number of articles retrieved when using each technique combined with the terms “functional food powder,” “functional ingredient,” or “bioactive compound.”

In order to select the most suitable dehydration technique to obtain functional powders it is necessary to detail the different drying methods available and analyze their advantages, disadvantages and limitations. It is also relevant to compare different studies and analyze the impact of each dehydration technique on the bioactive compounds present in different fruit and vegetable matrices and the technological properties of the ingredients.

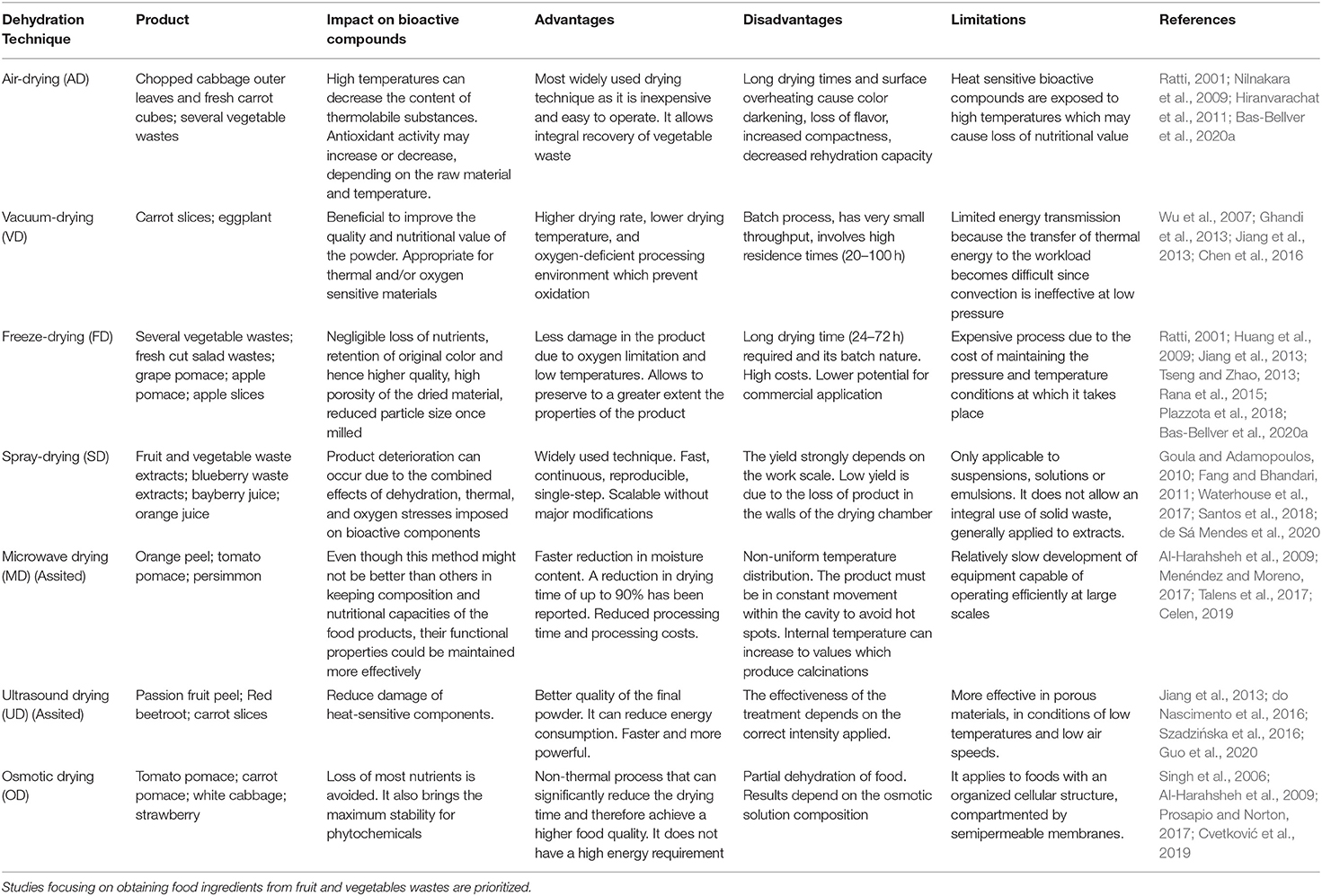

Table 1 gathers the main dehydration techniques applied to develop functional ingredients and foods from vegetables and fruit wastes and summarizes some advantages and disadvantages of their use. Air-drying (AD), vacuum-drying (VD), freeze-drying (FD), and spray-drying (SD) are all dehydration technologies commonly applied to obtain powdered ingredients, alone or in combination with others (Zhang et al., 2006; Sagar and Suresh Kumar, 2010). On the one hand, hot air drying (HAD) is commonly applied in the food industry due to its lower processing and investment costs. From an industrial point of view, it is a suitable technology for the valorization of solid wastes from the fruit and vegetable sectors since it allows the integral recovery of the biowastes. VD is a technique similar to air-drying, with the advantage of increasing mass transfer rates due to the low pressure generated in the drying chamber, while reducing the damage since the food is not exposed to a high temperature and in the absence of air oxidation reaction does not occur (Maisnam et al., 2017). Indeed, Wu et al. (2007) reported higher effective moisture diffusivity values of vacuum-dried vegetables as compared to hot-air dried samples. On the other hand, freeze-drying (FD) could also be used for an integral valorization approach, and it provides high-quality products and powders which strongly preserve their functional properties; however, this technology has limited industrial applications due to its high operating costs, which are 4–8 times higher compared to air-drying (Ratti, 2001). Other drying techniques such as spray-drying (SD) have gained importance for the development of functional foods or preservation of bioactive constituents since it consists of generating small droplets from which water is evaporated nearly instantaneously, in an almost adiabatic process (Patel et al., 2009). The thermal energy carried by the air is mostly used to evaporate water from the droplets while the sample remains at a moderate temperature, close to the wet bulb temperature of the air, thus helping preserve bioactivity. However, SD is suitable for liquids, emulsions and suspensions, for which it cannot be considered a viable option for the integral valorization of fruit and vegetables wastes. In order to obtain powders from biowastes by SD, it would be necessary to perform a previous solid-liquid extraction and a further drying of the extracts, thus not allowing the integral valorization of the wastes.

Table 1. Main dehydration techniques available for the development of functional ingredients and foods.

As for the other techniques being presented in Table 1, such as osmotic dehydration (OD) and microwave (MD) or ultrasound (UD) assisted drying, this consist of combinations of this technique with one of the previous, as a previous stage or as assisted drying in order to reduce energy consumption and/or heat damage (Sagar and Suresh Kumar, 2010). OD has the advantage of being a non-thermal process that requires little energy, but its effectiveness in reducing the water content of foods depend on many variables, such as the osmotic agent and concentration, temperature, sample to solution ratio, agitation, sample size and shape, other pre-treatments applied, etc. As an example, Prosapio and Norton (2017) reported a significant reduction in the processing time (8–2 h) in strawberry cubes which had been previously subjected to OD. Singh et al. (2006) applied OD combined with HAD to produce a value-added ingredient from carrot pomace to be used in the formulation of a dairy-based product, obtaining good acceptability results. Partial dehydration by osmosis has also been proposed prior to microwave drying in order to reduce processing time, limit energy consumption and improving the product quality (Al-Harahsheh et al., 2009). Drying with microwave energy (MW) differs significantly from conventional drying methods since the electromagnetic field implies a volumetric heating and causes the water molecules in the material to vibrate millions of times every second, thus allowing the moisture in the material to evaporate fast. When applied to drying, MW are usually coupled with drying in order to increase the dehydration rates. Talens et al. (2017) produced an orange peel fiber powder by combining MW and HAD in a process which allowed reducing time and energy consumption. Their results revealed that coupling both technologies allowed to positively modify de physicochemical properties of the fiber powder so that swelling capacity of orange fiber was improved. Regarding ultrasounds (US) application to drying, it has been proved to be an effective aid for fruit and vegetable preservation. Indeed, the mechanical and cavitation effects of ultrasound are responsible for the reduction of both internal and external diffusion resistances of materials in mass transfer during drying, and as a result, drying rate could be improved (Guo et al., 2020). do Nascimento et al. (2016) used an ultrasonic assisted drying to study the effect of temperature and ultrasound application on drying kinetics and antioxidant potential of passion fruit peel. According to their results, US reduced both, the internal and external mass transfer resistance. Antioxidant potential of passion fruit peels were found to be affected by drying conditions, best results being obtained in samples dried at 40°C when US were applied.

HAD has been proved to be a suitable technique for the integral valorization of the vegetable wastes generated in the cooperative. In the following paragraphs, information on air drying applied to the vegetables of interest (cabbage, carrot, leek, and celery), and how processing variables impact the bioactive compounds and determines the product quality is addressed.

Brassica vegetables such as cabbage are known to be rich in glucosinolates and isothiocyanates, which have been proved to act as antimicrobial, antioxidant and anticarcinogenic agents (Deng et al., 2015). Glucosinolates are degraded into isothiocyanates, specially to mention sulphoraphane, by means of the enzyme myrosinase upon tissue disruption (Mawlong et al., 2017). Therefore, the impact of the drying variables on myrosinase activity is of great importance when designing the drying stage. In addition, cabbage contains other interesting compounds from the nutritional point of view such as fiber or antioxidants (Nilnakara et al., 2009). Myrosinase thermal stability depends on the enzyme source. According to Ghawi et al. (2012), thermal stability of cabbages myrosinase ranges between 40 and 60°C. Tanongkankit et al. (2012) studied the effect of HAD on cabbage and its glucosinolates content and found that a temperature range between 60 and 69°C produced a significant reduction on their content. It was also reported that the formation of sulforaphane occurred when the temperature of the vegetable was in the range of 25–53.5°C, and that thermal degradation occurred when this temperature was exceeded (Tanongkankit et al., 2011). Lekcharoenkul et al. (2014) proposed a multi-stage drying process in which drying temperature is modified in order to achieve a greater retention of sulphoraphane in fiber-rich powders produced from the outer leaves of cabbage. Hence, in the early drying period the heating rate should be high to rapidly increase the temperature of the material to a value above 40°C and, after on, the temperature of the material must be controlled so that it does not exceed 50°C. According to Gamet-Payrastre et al. (2000), to ensure the functional properties of the powder it should contain a minimum sulforaphane content of ~2.7 mg/L.

In the case of carrot, air drying has been used alone or combined with other technologies to obtain value added products, focusing on dietary fiber content and carotenoids content. Carrot peels have been used as a raw material to produce antioxidant dietary fiber powder by means of air drying (Chantaro et al., 2008). The authors studied the impact of air drying (60–80°C), alone or in combination with blanching (90°C), on the physicochemical properties of the powders. Fiber content and related properties such as water retention and swelling capacities, were significantly affected by blanching; in contrast, drying did not significantly influence hydration properties. Thermal degradation of bioactive compounds such as β-carotene and phenolic compounds occurred both during air drying and blanching. This study demonstrated the feasibility of obtaining powders from carrot wastes to be used as functional ingredients, and demonstrated that the processing stages had a significant impact on the powder properties. In addition, particle size was found to be closely related to the physicochemical and hydration properties of the fiber powders, and their subsequent application. In fact, particle size has been demonstrated to be a critical parameter when developing powders and both pre-drying and post-drying milling stages determine powder properties (Bas-Bellver et al., 2020b). Milling will be discussed at the end of the present section as an additional stage of the powder manufacturing process. Nevertheless, it is worth mentioning at this point that not only milling but drying itself has a great impact on particle size and, hence, on powder physicochemical and hydration properties. The different structure generated during drying implies a different behavior during milling. Thus, air-drying usually generates harder materials which are more difficult to grind, leading to powders which usually show poorer hydration properties as compared to freeze-dried. On the contrary, freeze-drying leads to smaller particle sizes due to the increased porosity and brittleness of the dried material (Martínez-Las Heras et al., 2017; Plazzota et al., 2018; Bas-Bellver et al., 2020a).

As for thermal degradation of carotenoids, Mayer-Miebach et al. (2005) reported a 20% of β-carotene breaks down at 90°C. Hiranvarachat et al. (2011) tested air-drying at 70, 80, and 90°C during 5, 4, and 3 h, respectively, and concluded that β-carotene was better preserved at the lower temperature assayed. The most stable individual carotenoid of this vegetable is lutein, because its content is reduced by only 15.1% at 80°C. In contrast, under the same conditions β-carotene is heavily degraded. On the other hand, combining ultrasound and vacuum processes to dehydrate carrot slices can decrease the drying time in 41–53%. This novel technique called ultrasonic vacuum drying can also improve the rehydration potential, nutritional value, color, and texture properties of the samples (Chen et al., 2016).

As indicated previously, less research effort has been focused on leek and celery. Regarding leek, Ozgur et al. (2011) investigated changes in some physicochemical properties and antioxidant compounds caused by HAD at 63 ± 2°C for 3 h with an air velocity of 2.5 m/s. They observed that the antioxidant capacity decreased by more than 50%, there was a loss of ascorbic acid and the dehydrated samples showed a significant color difference mainly due to the effect of temperature on heat sensitive compounds. However, the α and β chlorophyll content was higher in dried leeks than in fresh ones. Regarding celery, no detailed studies were found on the impact of HAD on their properties. Priecina et al. (2018) investigated the effect of convective and microwave-vacuum drying on the bioactive compounds of celery roots and found that carotenoids and ascorbic acid were sensitive to thermal processing, while phenolic compounds increased with drying process.

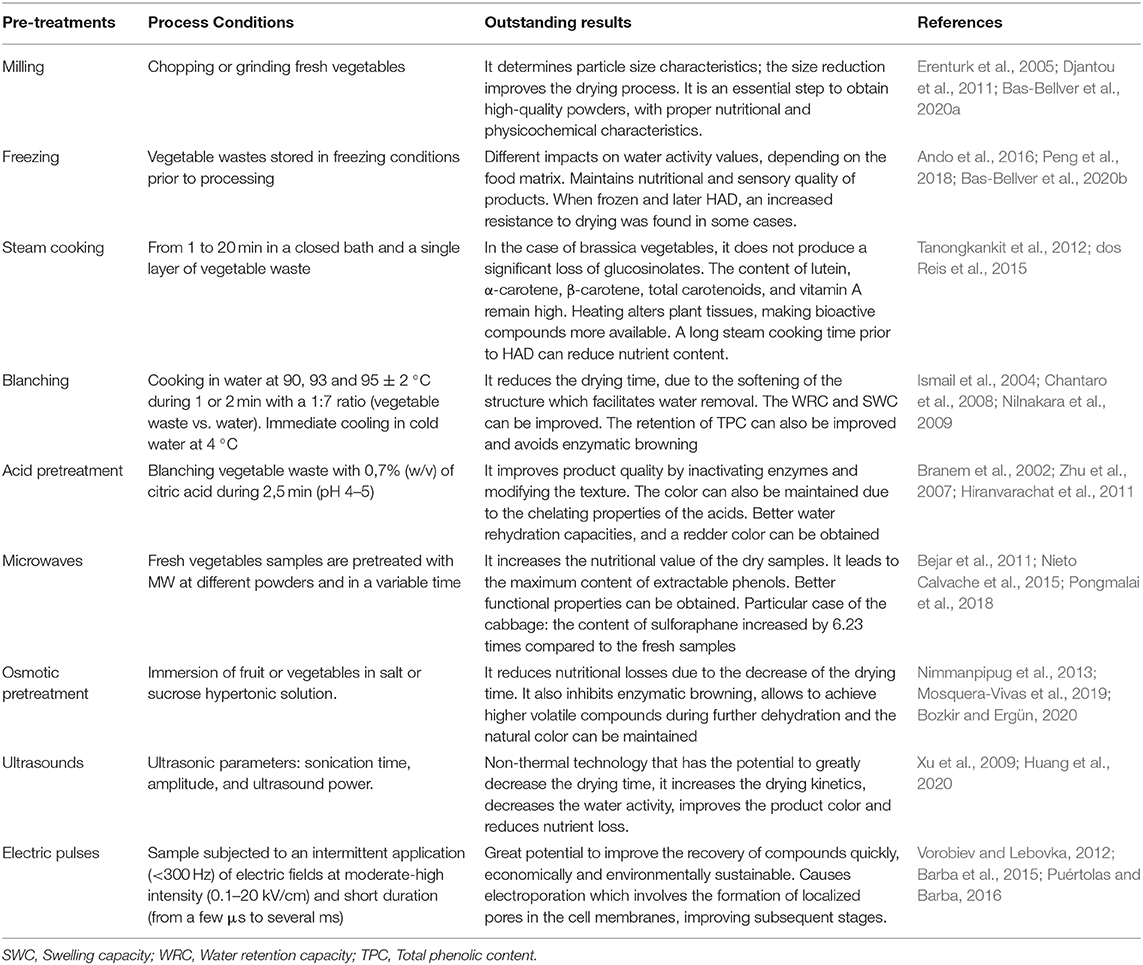

One way to alleviate the adverse effect of HAD is to pretreat a product, either physically or chemically, before drying (Górnicki and Kaleta, 2007). The main purpose of pretreating the sample prior to drying is generally to inactivate enzymes such as polyphenoloxidase, peroxidase, and phenolase, as well as to inhibit some undesirable chemical reactions, which may cause adverse changes in a product. In addition, pretreatments modify structures, soften the tissue, and release bioactive constituents, promoting changes which determine the response to the drying process and the quality of the dried product. Table 2 summarizes some of the pretreatments applied to obtain functional powders, according to the literature reviewed. In this table, information on process conditions and the potential impact on the fruit or vegetable matrix, as well as on the bioactive compounds is given. Milling, freezing or (steam) blanching are common pre-treatments which can easily be scaled up. Many pretreatment techniques have been used in the food industry, including blanching and the use of weak acids (Prakash et al., 2004; Górnicki and Kaleta, 2007). Novel technologies such as electric pulses or ultrasounds may be an interesting option thanks to their positive effects, but their industrial application is more limited.

Table 2. Pretreatments discussed in the literature and potential impact on fruit and vegetable tissue and its bioactive compounds.

Used as a pretreatment, milling is a key step to achieve the desired results and improve the drying process. Food matrix breakage has an impact on drying rates and on the release of bioactive compounds. When producing powders, a final milling stage is needed to obtain the desired particle size; nevertheless, particle size is also determined by the grinding applied prior to drying since it conditions the response of the food matrix to the drying step and, therefore, the structure of the dried material, which determines the grinding results. Therefore, milling as a pretreatment is an essential step to obtain high-quality powders, with proper nutritional and physicochemical characteristics (Erenturk et al., 2005; Djantou et al., 2011; Bas-Bellver et al., 2020b). As for freezing, Ando et al. (2016) investigated the impact of the freeze-thaw process on the drying rates of carrot roots, obtaining that the frozen-thawed samples damaged by ice crystals had the highest drying rate. However, Bas-Bellver et al. (2020b) reported an increased resistance to drying due to a more compacted bed during drying, making it more difficult to reach low moisture content and water activity values in frozen samples vs. fresh ones. In brassica vegetables, such as cabbage, pretreatments contributing to cell disruption such as milling or freeze-thawing are expected to promote sulforaphane formation and its bioaccessilibility (Pongmalai et al., 2018).

Blanching is another pretreatment generally applied prior to drying to preserve the quality of the obtained product (Chantaro et al., 2008; Nilnakara et al., 2009). The main purpose of blanching is the inactivation of enzymes that cause quality losses such as browning and nutrient loss, but it has also been proved to be effective for increasing the drying rate of vegetables by softening the tissue and modifying its structure (Ando et al., 2016). Blanching is generally performed by submerging samples in hot water, although it is also possible to apply steam (Priecina et al., 2018). Nilnakara et al. (2009) applied blanching in hot water as a pretreatment to HAD to obtain fiber powders from cabbage residues. Their study revealed no significant differences with regard to antioxidant properties of samples; however, blanching provided a better appearance in terms of color due to the inhibition of enzymes responsible for enzymatic browning reactions. Chantaro et al. (2008) combined blanching and air drying to obtain powders rich in fiber from carrot peels. Their findings were that blanching had a significant effect on the fiber contents and compositions, as well as on water retention and swelling capacities of the fiber powder. Although some antioxidants degraded during blanching and drying, there were no significant differences in terms of the total phenols, β-carotene and antioxidant activity of blanched and unblanched carrot peel powders. As for total DF, blanching improved its yield as well as the insoluble to soluble fiber ratio. Water retention and swelling capacities, which are relevant for food formulations, were favored by the blanching pretreatment. Ando et al. (2016) also assayed blanching as a pretreatment to air drying and compared it to the freeze-thawing process. In their study, drying rates of blanched carrots were significantly slower than those of freeze-thawed and non-pretreated ones. Priecina et al. (2018) combined steam-blanching with convective air drying and microwave-vacuum drying of celery, and reported that both drying and steam-blanching processes may help improve the bioactive constituents, but their amount can decrease or increase differently depending on processing or drying time and the applied temperature.

With regard to post-treatments applied to obtain powdered ingredients, it is worth mentioning the importance of milling and its role in determining particle size, which has a relevant impact on physicochemical and technological properties and subsequent applications of the powder as a food ingredient. Researchers such as Chantaro et al. (2008) and Tanongkankit et al. (2012), ground the dehydrated carrot and cabbage, respectively, to obtain a specific particle size for particular applications. As introduced previously, particle size is the result of both pre- and post-drying milling, as well as the drying technology and conditions being used, and it has been proved to be related to several quality parameters of powders (Djantou et al., 2011; Plazzota et al., 2018; Bas-Bellver et al., 2020a,b). Sieving is an additional post-treatment which has served to obtain a specific desired particle size. At this point, rehydration is an additional parameter to be considered as an indicator of quality (Hiranvarachat et al., 2011; Ozgur et al., 2011; Chen et al., 2016).

Thus, it is deduced that a proper selection of processing parameters which include conditions of pretreatments and drying stages, are critical to preserve the quality of the obtained powders and optimize their functional and technological properties.

The goals of nutrition are to provide nutrients in such quantity and quality as are necessary to meet body requirements. Optimal nutrition should include bioactive compounds such as fiber, antioxidants, phytochemicals, among others, since these have the capacity to improve health, generate well-being and are useful to prevent the risk of suffering diseases (Cilla et al., 2018). The potential of these physiologically active components which are present in foods to exert beneficial effects depends on several factors, which include their release from the matrix, changes during digestion, absorption, metabolism and biodistribution. In order for these compounds to exert their bioactivity, they must be bioavailable. Other factors such as dose and host must also be considered (Bohn et al., 2015).

The term bioavailability has various working conditions and there is no universally accepted definition. From a nutritional point of view, it is defined as the fraction of ingested component that is available for use in normal physiological functions (Wood, 2005). This concept includes two additional terms, which are bioaccessibility and bioactivity. Bioaccessibility is defined as the fraction of a compound that is released from its food matrix in the gastrointestinal tract and, therefore, is available for intestinal absorption. Bioactivity includes events related to the way in which the bioactive compound reaches the systemic circulation and are transported to the target tissue; it also refers to the interaction with the metabolism of biomolecules in these tissues and the entire cascade of physiological effects it generates.

Designing a process to obtain functional ingredients must aim to preserve and, if possible, improve the functional properties of the processed material, but it must also ensure the functionality of the bioactive compounds contained in the food ingredients by testing the impact of the digestion process on these constituents and, therefore, on their bioaccessibility. Potential health benefits of any functional ingredient require analyzing if the digestion process affects the stability and function of its bioactive compounds (Carbonell-Capella et al., 2014; Galanakis 2020). In the case of powdered ingredients, it has been previously mentioned that processing determines the available bioactive compounds as well as the powder structure, which in turn determines the bioactive compounds bioaccessibility (Gouw et al., 2017; Lucas-González et al., 2018; Bas-Bellver et al., 2020a). In vitro methods can evaluate the bioaccessibility of the compounds of interest by simulating gastrointestinal digestion (Cilla et al., 2018), and in this way helping design functional foods which health promoting effects can be claimed.

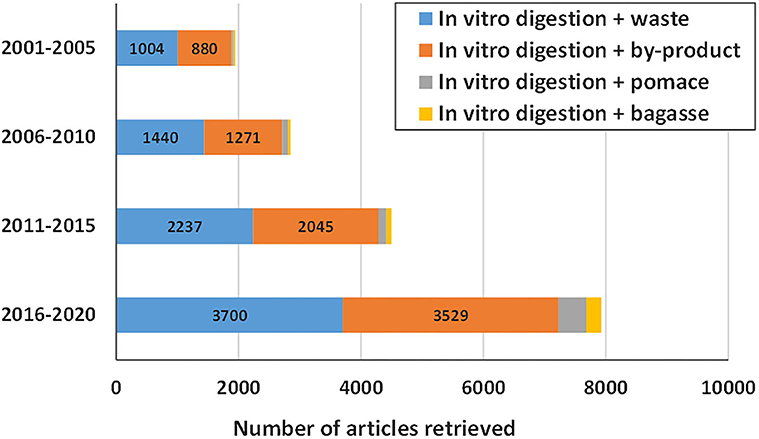

As shown in Figure 3, the interest in understanding the response of the bioactive compounds present in products or ingredients obtained from fruit or vegetable wastes has increased considerably in the last years. Main terms used by researchers are, again, “waste” and “by-product,” whereas the use of other keywords such as “pomace” or “bagasse” is marginal.

Figure 3. Evolution in the number of published articles (retrieved by Science Direct) which combine the keywords “in vitro digestion” and “waste,” “by-product,” “pomace,” or “bagasse,” in the last 20 years.

Regarding the development of functional food or ingredients from fruit and vegetables wastes (particularly cabbage, carrot, celery, and leek) research on the digestion of the powder ingredient, alone or as part of a formulated food, becomes essential. A method commonly applied for the study of the gastrointestinal digestion of food powders obtained from fruit and vegetable residues, is the practical static in vitro digestion methodology. It consists of mouth mastication, stomach digestion, and intestinal digestion of the food or ingredient in the presence of simulated gastrointestinal fluids and under controlled conditions. To this aim, Minekus et al. (2014) proposed a standardized method which is generally accepted and applied. In the revised literature, fruit, and vegetable powders are digested directly in the simulated intestinal fluids (Gouw et al., 2017; Bas-Bellver et al., 2020a), diluted in water or lipid (Gullon et al., 2015; Zhang et al., 2018), or as part of a (model) formulated food (Sarvan et al., 2017).

Gouw et al. (2017) used this method to study the impact of the digestion process on the bioactive compounds present in different dried fruit pomaces (apple, blueberry, raspberry, and cranberry). Results evidenced that bound polyphenols from food powders are liberated in the simulated gastrointestinal digestion and that phenolics can be released from the food matrix by direct solubilization in the intestinal fluids and through the action of digestive enzymes. Low molecular weight polyphenols are partially absorbed in the small intestine, while high molecular weight can be fermented in the colon by the microbiota and partially absorbed to gut epithelial cells, acting as the counteract of prooxidants. Gullon et al. (2015) evaluated the in vitro gastrointestinal digestion of date seed meal and apple bagasse by diluting the powders in water, and studied further colonic fermentation. The powders were characterized by being rich in dietary fiber and exhibited high bioaccessibility values of phenolic compounds. Fermentation by colonic bacteria generated short chain fatty acids such as formate, succinate, acetate, propionate, and butyrate. Results of the in vitro simulated process confirmed that these by-products could be used to obtain functional food ingredients.

Zhang et al. (2018) applied an in vitro digestion model through which they evaluated the impact of digestion on carotenoids, in fresh and air-dried samples rich in these bioactive compounds such as carrots. Results obtained showed that the cell wall acts as the main natural structural physical barrier that governs the release of carotenoids. Pectin composition and the presence of other polysaccharides in the cell wall influence the bioacessibility of carotenoids by interacting differently with target compounds. Comparison of digested fresh and hot air-dried samples revealed that HAD promoted cell wall disruption and induced an anticipated release of carotenoids leading to higher bioaccessibility values. Addition of lipid to dried samples during digestion had a marked positive effect on the bioaccessibility of individual carotenoid. In this sense, Hornero-Méndez and Mínguez-Mosquera (2007) evaluated the effect of both processing and lipid content (cooking oil) in the bioaccessibility of carrot carotenoids. Although the heat treatment during cooking showed to have a negative impact on the carotenoid content, a positive effect was found on the micellarization of the carotenes and therefore on their bioaccessibility. Carotenoids bioaccessibility in fruit waste powders were also evaluated by Bas-Bellver et al. (2020a). In this study, blueberry and persimmon wastes were processed to obtain functional powders rich in anthocyanins and carotenoids, respectively. The study revealed that the release of antioxidant constituents along the digestion process depended on several factors such as type of residue, drying process and fiber content and type. It was evidenced that the anthocyanin content after digestion was particularly affected by the dehydration technique being used, since despite providing a powder with a higher anthocyanin content, freeze-dried samples were more significantly affected by digestion. In vitro colonic fermentation was also carried out in this study, evidencing that the carotenoids and anthocyanins remaining in the digested samples after the intestinal phase can reach the colon to be fermented by gut microbiota and promote a benefit for human health.

Regarding glucosinolates and isothyocianates, Sarvan et al. (2017) studied the form of conversion of glucoraphanin and the bioaccessibility of the decomposition products released, evaluating the effect of steam cooking, as well as the composition of food (addition of proteins or lipids) through an in vitro digestion model. They were able to determine that the main formation of sulforaphane and sulforaphane nitrile occurred during in vitro chewing. The addition of proteins or lipids had no influence on the formation and bioaccessility of sulphoraphane, concluding that the main factor for the formation of sulphoraphane in vitro upper digestive tract is the presence of active myrosinase in the plant.

The development of functional food ingredients from vegetables and fruit wastes requires scalable processes which allow to preserve or enhance functional properties and bioactive compounds, as well as products that meet the standards of high quality, safety, and organoleptic characteristics demanded by consumers. Many studies have evidenced that agricultural fruits and vegetables residues are promising sources of dietary fibers and other functional compounds. The way of processing these wastes determines the characteristics and functionality of the final products, for which research must focus on the development of particularized processes.

Dehydration as a food preservation technology is a useful technique for the transformation of plant-based food residues into functional powdered ingredients. An integral recovery is important to avoid other residues and rescue the main bioactive compounds. Hot air drying remains to be the dehydration technique most used in the food industry, mainly due to its lower processing and investment costs. Applied to vegetable wastes processing, it provides stable ingredients and allows the integral valorization of the biowastes, without the need for extraction and concentration stages. Nevertheless, drying technologies reported in the literature are increasingly sophisticated and diverse. Vacuum-drying and freeze-drying can be exploited by the food industry to integrally valorize these residues and produce functional powdered ingredients; microwaves or ultrasounds assisted procedures can be applied to optimize drying rates and improve the powder characteristics. However, these technologies imply higher costs and the need for specialized staff, for which their implementation is more limited, especially in the first stages of transformation. Alternatively, pretreatments can also be applied to improve drying rates and product properties. Available pretreatments include emerging technologies such as microwaves or ultrasounds, but also conventional ones such as blanching or milling. The recent literature reveals that well-established pretreatments such as blanching or milling may increase drying rates and reduce the adverse effects of dehydration, improve the efficiency of the process and enhance technological and functional properties of the powders produced. The selection of these widely known and scalable technologies is of particular relevance in early transformation processes.

The literature review has also evidenced that process conditions have an impact on the beneficial effect derived from consumption of vegetable powders. Selection of processing conditions must focus on the preservation of bioactive compounds but also on product structure, since it conditions their bioaccessibility throughout the digestion process, including their potential impact on gut microbiota.

As key indicators of the final quality of the vegetable powders, the physicochemical composition, the functional properties, and the potential physiological effects on human health through in vitro digestion must be evaluated, in order to guarantee the quality of the powders and their effective application in food formulations. A comprehensive approach should include particularized processes for specific applications and preservation trials to ensure sustainable industrial production of functional powdered ingredients from vegetable wastes.

CB and LS participated in the conceptualization of the paper. BR-P, CB-B, CB, and LS performed the literature review. BR-P, CB, CB-B, and LS participated in the original draft preparation. LS, CB, and NB participated in the writing, reviewing, and editing process. LS was responsible for supervision and project administration. All authors have read and agreed to the published version of the manuscript.

This research and APC were funded by Generalitat Valenciana under the Rural Development Program 2014–2020 (Ayudas para la cooperación en el marco del Programa de Desarrollo rural de la Comunitat Valenciana 2014–2020. Experiencias de transformación agroalimentaria innovadoras, especialmente vinculadas a figuras de calidad diferenciada y producción ecológica) and the Spanish Ministry of Agriculture, fisheries and food, under the European Agricultural Fund for Rural Development. Grant number AGCOOP_D/2018/025.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

We would like to thank Generalitat Valenciana, Spanish Ministry of Agriculture, fisheries and food, and European Agricultural Fund for Rural Development for financial support.

Aguedo, M., Kohnen, S., Rabetafika, N., Vanden Bossche, S., Sterckx, J., Blecker, C., et al. (2012). Composition of by-products from cooked fruit processing and potential use in food products. J. Food Comp. Anal. 27, 61–69. doi: 10.1016/j.jfca.2012.04.005

Ajila, C. M., Aalami, M., Leelavathi, K., and Rao, U. J. S. P. (2010). Mango peel powder: A potential source of antioxidant and dietary fiber in macaroni preparations. Innovat. Food Sci. Emerg. Technol. 11, 219–224. doi: 10.1016/j.ifset.2009.10.004

Al-Harahsheh, M., Al-Muhtaseb, A. H., and Magee, T. R. A. (2009). Microwave drying kinetics of tomato pomace: effect of osmotic dehydration. Chem. Eng. Process. Process Intensif. 48, 524–531 doi: 10.1016/j.cep.2008.06.010

Ando, Y., Maeda, Y., Mizutani, K., Wakatsuki, N., Hagiwara, S., and Nabetani, H. (2016). Impact of blanching and freeze-thaw pretreatment on drying rate of carrot roots in relation to changes in cell membrane function and cell wall structure. LWT - Food Sci. Technol. 71, 40–46. doi: 10.1016/j.lwt.2016.03.019

Baljeet, S. Y., Ritika, B. Y., and Reena, K. (2014). Effect of incorporation of carrot pomace powder and germinated chickpea flour on the quality characteristics of biscuits. Int. Food Res. J. 21, 217–222. Available online at: http://www.ifrj.upm.edu.my/21%20%2801%29%202014/31%20IFRJ%2021%20%2801%29%202014%20Balijit%20258.pdf

Barba, F. J., Brianceau, S., Turk, M., Boussetta, N., and Vorobiev, E. (2015). Effect of alternative physical treatments (ultrasounds, pulsed electric fields, and high-voltage electrical discharges) on selective recovery of bio-compounds from fermented grape pomace. Food Bioprocess Technol. 8, 1139–1148. doi: 10.1007/s11947-015-1482-3

Barzee, T. J., El- Mashad, H. M., Zhang, R., and Pan, Z. (2019). “Carrots,” in Integrated Processing Technologies for Food and Agricultural By-Products, eds Z. Pan, R. Zhang, and S. Zicari (Oxford: Academic Press; Elsevier Ltd.), 297–330. doi: 10.1016/B978-0-12-814138-0.00012-5

Bas-Bellver, C., Andrés, C., Seguí, L., Barrera, C., Jiménez-Hernández, N., Artacho, A., et al. (2020a). Valorization of persimmon and blueberry byproducts to obtain functional powders: in vitro digestion and fermentation by gut microbiota. J. Agricult. Food Chem. 68, 8080–8090. doi: 10.1021/acs.jafc.0c02088

Bas-Bellver, C., Barrera, C., Betoret, N., and Segu,í, L. (2020b). Turning agri-food cooperative vegetable residues into functional powdered ingredients for the food industry. Sustainability (Switzerland). 12, 1–15. doi: 10.3390/su12041284

Bejar, A. K., Kechaou, N., and Mihoubi, N. B. (2011). Effect of microwave treatment on physical and functional properties of orange (Citrus sinensis) peel and leaves. J. Food Process. Technol. 2:109. doi: 10.4172/2157-7110.1000109

Bohn, T., Mcdougall, G. J., Alegría, A., Alminger, M., Arrigoni, E., Aura, A. M., et al. (2015). Mind the gap-deficits in our knowledge of aspects impacting the bioavailability of phytochemicals and their metabolites-a position paper focusing on carotenoids and polyphenols. Mol. Nutr. Food Res. 59, 1307–1323. doi: 10.1002/mnfr.201400745

Bozkir, H., and Ergün, A. R. (2020). Effect of sonication and osmotic dehydration applications on the hot air drying kinetics and quality of persimmon. Lwt 131:109704. doi: 10.1016/j.lwt.2020.109704

Branem, A. L., Davidson, P. M., Salminen, S., and Thorngate, J. I. T. III. (2002). Food Additives (2nd edition). New York, NY: Marcel Dekker. doi: 10.1201/9780367800505

Camire, M. E., Dougherty, M. P., and Briggs, J. L. (2007). Functionality of fruit powders in extruded corn breakfast cereals. Food Chem. 101, 765–770. doi: 10.1016/j.foodchem.2006.02.031

Carbonell-Capella, J. M., Buniowska, M., Barba, F. J., Esteve, M. J., and Frigola, A. (2014). Analytical methods for determining bioavailability and bioaccessibility of bioactive compounds from fruits and vegetables. A review. Compr. Rev. Food Sci. Food Saf. 13:155–71. doi: 10.1111/1541-4337.12049

Celen, S. (2019). Effect of microwave drying on the drying characteristics, color, microstructure, and thermal properties of Trabzon persimmon. Foods 8, 7–9. doi: 10.3390/foods8020084

Chantaro, P., Devahastin, S., and Chiewchan, N. (2008). Production of antioxidant high dietary fiber powder from carrot peels. LWT Food Sci. Technol. 41, 1987–1994. doi: 10.1016/j.lwt.2007.11.013

Chau, C. F., Chen, C. H., and Lee, M. H. (2004). Comparison of the characteristics, functional properties, and in vitro hypoglycemic effects of various carrot insoluble fiber-rich fractions. LWT Food Sci. Technol. 37, 155–160. doi: 10.1016/j.lwt.2003.08.001

Chen, Z. G., Guo, X. Y., and Wu, T. (2016). A novel dehydration technique for carrot slices implementing ultrasound and vacuum drying methods. Ultrasonics Sonochem. 30, 28–34. doi: 10.1016/j.ultsonch.2015.11.026

Cilla, A., Bosch, L., Barberá, R., and Alegría, A. (2018). Effect of processing on the bioaccessibility of bioactive compounds – A review focusing on carotenoids, minerals, ascorbic acid, tocopherols and polyphenols. J. Food Compos. Analysis. 68, 3–15. doi: 10.1016/j.jfca.2017.01.009

Conesa, C., Laguarda-Miró, N., Fito, P., and Seguí, L. (2020). Evaluation of persimmon (Diospyros kaki thunb. cv. rojo brillante) industrial residue as a source for value added products. Waste Biomass Valor. 11, 3749–3760. doi: 10.1007/s12649-019-00621-0

Cvetković, B. R., Pezo, L. L., Mišan, A., Mastilović, J., Kevrešan, Ž., Ilić, N., et al. (2019). The effects of osmotic dehydration of white cabbage on polyphenols and mineral content. LWT 110, 332–337. doi: 10.1016/j.lwt.2019.05.001

de Sá Mendes, N., Favre, L., Rolandelli, G., dos Santos Ferreira, C., Édira.C. B. de, A., and Gonçalves, wBuera, M. P. (2020). Flour from “fruits and vegetables” waste with addition of a South-American pepper (Capsicum baccatum) proposed as food ingredient. Int. J. Food Sci. Technol. 55, 1230–1237. doi: 10.1111/ijfs.14358

Deng, Q., Zinoviadou, K. G., Galanakis, C. M., Orlien, V., Grimi, N., Vorobiev, E., et al. (2015). The effects of conventional and non-conventional processing on glucosinolates and its derived forms, isothiocyanates: extraction, degradation, and applications food and energy reviews. Food Eng. Rev. 7, 357–381. doi: 10.1007/s12393-015-9122-2

Djantou, E. B., Mbofung, C. M. F., Scher, J., Phamba, N., and Morael, J. D. (2011). Alternation drying and grinding (ADG) technique, a novel approach for producing ripe mango powder. Food Sci. Technol. 4, 1585–1590. doi: 10.1016/j.lwt.2011.01.022

do Nascimento, E. M. G. C., Multe, A., Ramírez, J. L., de Carvalho, C. W. P., and Cárcel, J. A. (2016). Effects of high-intensity ultrasound on drying kinetics and antioxidant properties of passion fruit peel. J. Food Eng. 170, 108–118. doi: 10.1016/j.jfoodeng.2015.09.015

dos Reis, L. C. R., de Oliveira, V. R., Hagen, M. E. K., Jablonski, A., FlÔres, S. H., and de Oliveira Rios, A. (2015). Carotenoids, flavonoids, chlorophylls, phenolic compounds and antioxidant activity in fresh and cooked broccoli (Brassica oleracea var. Avenger) and cauliflower (Brassica oleracea var. Alphina F1). LWT Food Sci. Technol. 63, 177–183. doi: 10.1016/j.lwt.2015.03.089

Elleuch, M., Bedigian, D., Roiseux, O., Besbes, S., Blecker, C., and Attia, H. (2011). Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem. 124, 411–421. doi: 10.1016/j.foodchem.2010.06.077

Erenturk, S., Gulaboglu, M. S., and Gultekin, S. (2005). The effects of cutting and drying medium on the vitamin C content of rosehip during drying. J. Food Eng. 68, 513–518. doi: 10.1016/j.jfoodeng.2004.07.012

European Commission (2019). Sustainable Products in a Circular Economy - Towards an EU Product Policy Framework contributing to the Circular Economy. Available online in: https://ec.europa.eu/environment/circular-economy/pdf/sustainable_products_circular_economy.pdf

Fang, Z. X., and Bhandari, B. (2011). Effect of spray-drying and storage on the stability of bayberry polyphenols. Food Chem. 129, 1139–1147. doi: 10.1016/j.foodchem.2011.05.093

FAO (2019). The State of Food and Agriculture. Food and Agriculture Organization of the United Nations.

FAO and WHO. (2019). Sustainable Healthy Diets – Guiding Principles. Rome: Food and Agriculture Organization of the United Nations and World Health Organization. doi: 10.4060/CA6640EN

Ferreira, M. S. L., Santos, M. C. P., Moro, T. M. A., Basto, G. J., Andrade, R. M. S., and Gonçalves, E. C. B. A. (2015). Formulation and characterization of functional foods based on fruit and vegetable residue flour. J. Food Sci. Technol. 52, 822–830. doi: 10.1007/s13197-013-1061-4

Figuerola, F., Hurtado, M. L., Estévez, A. M., Chiffelle, I., and Asenjo, F. (2005). Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 91, 395–401. doi: 10.1016/j.foodchem.2004.04.036

Galanakis, C. M. (2021). Functionality of food components and emerging technologies. Foods 10:128. doi: 10.3390/foods10010128

Gamet-Payrastre, L., Li, P., Lumeau, S., Cassar, G., Dupont, M. A., Chevolleau, S., et al. (2000). Sulforaphane, a naturally occurring isothiocyanate, induces cell cycle arrest and apoptosis in HT29 human colon cancer cells. Cancer Res. 60, 1426–1433.

Ghandi, A., Adhikari, B., and Powell, I. B. (2013). “Powders containing microorganisms and enzymes,” in Handbook of Food Powders: Processes and Properties, eds B. Bhandari, N. Bansal, M. Zhang, and P. Schuck (Oxford: Woodhead Publishing; Elsevier Ltd), 593–624. doi: 10.1533/9780857098672.3.593

Ghawi, S. M., Methven, L., Rastall, R. A., and Niranjan, K. (2012). Thermal and high hydrostatic pressure inactivation of myrosinase from green cabbage: a kinetic study. Food Chem. 131, 1240–1247. doi: 10.1016/j.foodchem.2011.09.111

Górecka, D., Pachołek, B., and Dziedzic, K. (2010). Raspberry pomace as a potential fiber source for cookies enrichment. Acta Sci. Pol. Technol. Aliment. 9, 451–462. Available online at: https://www.food.actapol.net/pub/5_4_2010.pdf

Górnicki, K., and Kaleta, A. (2007). Drying curve modelling of blanched carrot cubes under natural convection condition. J. Food Eng. 82, 160–170. doi: 10.1016/j.jfoodeng.2007.02.002

Goula, A. M., and Adamopoulos, K. G. (2010). A new technique for spray-drying orange juice concentrate. Innov. Food Sci. Emerg. Technol. 11, 342–351. doi: 10.1016/j.ifset.2009.12.001

Goula, A. M., and Lazarides, H. N. (2015). Integrated processes can turn industrial food waste into valuable food by-products and/or ingredients: the cases of olive mill and pomegranate wastes. J. Food Eng. 167, 45–50. doi: 10.1016/j.jfoodeng.2015.01.003

Gouw, V. P., Jung, J., and Zhao, Y. (2017). Functional properties, bioactive compounds, and in vitro gastrointestinal digestion study of dried fruit pomace powders as functional food ingredients. LWT Food Sci. Technol. 80, 136–144. doi: 10.1016/j.lwt.2017.02.015

Gullon, B., Pintado, M. E., Barber, X., Fernández-López, J., Pérez-Álvarez, J. A., and Viuda-Martos, M. (2015). Bioaccessibility, changes in the antioxidant potential and colonic fermentation of date pits and apple bagasse flours obtained from co-products during simulated in vitro gastrointestinal digestion. Food Res. Int. 78, 169–176. doi: 10.1016/j.foodres.2015.10.021

Guo, Y., Wu, B., Guo, X., Ding, F., Pan, Z., and Ma, H. (2020). Effects of power ultrasound enhancement on infrared drying of carrot slices: Moisture migration and quality characterizations. Lwt 126:109312. doi: 10.1016/j.lwt.2020.109312

Hinestroza-Córdoba, L. I., Duarte Serna, S., Segu,í, L., Barrera, C., and Betoret, N. (2020). Characterization of powdered lulo (Solanum quitoense) bagasse as a functional food ingredient. Foods 9:723. doi: 10.3390/foods9060723

Hiranvarachat, B., Devahastin, S., and Chiewchan, N. (2011). Effects of acid pretreatments on some physicochemical properties of carrot undergoing hot air drying. Food Bioprod. Proc. 89, 116–127. doi: 10.1016/j.fbp.2010.03.010

Hornero-Méndez, D., and Mínguez-Mosquera, M. I. (2007). Bioaccessibility of carotenes from carrots: effect of cooking and addition of oil. Innov. Food Sci. Emerg. Technol. 8, 407–412. doi: 10.1016/j.ifset.2007.03.014

Huang, D., Men, K., Li, D., Wen, T., Gong, Z., Sunden, B., et al. (2020). Application of ultrasound technology in the drying of food products. Ultras. Sonochem. 63:104950. doi: 10.1016/j.ultsonch.2019.104950

Huang, L. L., Zhang, M., Mujumdar, A. S., Sun, D. F., Tan, G. W., and Shameel, T. (2009). Studies on decreasing energy consumption for a freeze-drying process of apple slices. Dry Technol. 27, 938–946. doi: 10.1080/07373930902901844

Ismail, A., Marjan, Z. M., and Foong, C. W. (2004). Total antioxidant activity and phenolic content in selected vegetables. Food Chem. 87, 581–586. doi: 10.1016/j.foodchem.2004.01.010

Jiang, H., Zhang, M., and Adhikari, B. (2013). “Fruit and vegetable powders,” in Handbook of Food Powders: Processes and Properties, eds B. Bhandari, N. Bansal, M. Zhang, and P. Schuck (Woodhead Publishing Limited), 532–552. doi: 10.1533/9780857098672.3.532

Karam, M. C., Petit, J., Zimmer, D., Baudelaire Djantou, E., and Scher, J. (2016). Effects of drying and grinding in production of fruit and vegetable powders: a review. J. Food Engin. 188, 32–49. doi: 10.1016/j.jfoodeng.2016.05.001

Kroyer, G. T. (1995). Impact of food processing on the environment-an overview. LWT 28, 547–552. doi: 10.1016/0023-6438(95)90000-4

Lekcharoenkul, P., Tanongkankit, Y., Chiewchan, N., and Devahastin, S. (2014). Enhancement of sulforaphane content in cabbage outer leaves using hybrid drying technique and stepwise change of drying temperature. J. Food Eng. 122, 56–61. doi: 10.1016/j.jfoodeng.2013.08.037

Lucas-González, R., Viuda-Martos, M., Pérez-Álvarez, J., and Fernández-Lópiez, J. (2018). Changes in bioaccessibility, polyphenol profile and antioxidant potential of flours obtained from persimmon fruit (Diospyros kaki) co-products during in vitro gastrointestinal digestion. Food Chem. 256, 252–258. doi: 10.1016/j.foodchem.2018.02.128

Luo, Y., Xie, W., Hao, Z., Jin, X., and Wang, Q. (2014). Use of shallot (Allium ascalonicum) and leek (Allium tuberosum) to improve the in vitro available iron and zinc from cereals and legumes. CYTA J. Food 12, 195–198. doi: 10.1080/19476337.2013.814168

Maisnam, D., Rasane, P., Dey, A., Kaur, S., and Sarma, C. (2017). Recent advances in conventional drying of foods. Journal of Food Technology and Preservation. 1, 25–34.

Martínez-Las Heras, R., Landines, E. F., Heredia, A., Castelló, M. L., and Andrés, A. (2017). Influence of drying process and particle size of persimmon fibre on its physicochemical, antioxidant, hydration and emulsifying properties. J. Food Sci. Technol. 54, 2902–2912. doi: 10.1007/s13197-017-2728-z

Mawlong, I., Kumar, M. S. S., Gurung, B., Singh, K. H., and Singh, D. (2017). A simple spectrophotometric method for estimating total glucosinolates in mustard de-oiled cake. Int. J. Food Proper. 20, 3274–3281. doi: 10.1080/10942912.2017.1286353

Mayer-Miebach, E., Behsnilian, D., Regier, M., and Schuchmann, H. P. (2005). Thermal processing of carrots: lycopene stability and isomerisation with regard to antioxidant potential. Food Res. Int. 38, 1103–1108. doi: 10.1016/j.foodres.2005.03.018

Menéndez, J. A., and Moreno, A. H. (Eds.). (2017). Industrial Applications of Microwave Energy Heating. Latacunga, Ecuador: Editorial Universidad Técnica de Cotopaxi, First Edition, 315.

Minekus, M., Alminger, M., Alvito, P., Ballance, S., Bohn, T., Bourlieu, C., et al. (2014). A standardised static in vitro digestion method suitable for food – an international consensus. Food Funct. 5, 1113–1124. doi: 10.1039/C3FO60702J

Mirabella, N., Castellani, V., and Sala, S. (2014). Current options for the valorization of food manufacturing waste: a review. J. Cleaner Product. 65, 28–41. doi: 10.1016/j.jclepro.2013.10.051

Mosquera-Vivas, E. S., Ayala-Aponte, A. A., and Serna-Cock, L. (2019). Ultrasonido y deshidratación osmótica como pretratamientos a la liofilización de melón (Cucumis melo L.). Inform. Tecnol. 30, 179–188. doi: 10.4067/S0718-07642019000300179

Nieto Calvache, J. E., Fissore, E. N., Latorre, M. E., Soria, M., De Escalada Pla, M. F., and Gerschenson, L. N. (2015). Obtention of dietary fibre enriched fractions from peach bagasse using ethanol pre-treatment and microwave drying. LWT Food Sci. Technol. 62, 1169–1176 doi: 10.1016/j.lwt.2015.01.045

Nilnakara, S., Chiewchan, N., and Devahastin, S. (2009). Production of antioxidant dietary fibre powder from cabbage outer leaves. Food Bioprod. Proc. 87, 301–307. doi: 10.1016/j.fbp.2008.12.004

Nimmanpipug, N., Therdthai, N., and Dhamvithee, P. (2013). Characterisation of osmotically dehydrated papaya with further hot air drying and microwave vacuum drying. Int. J. Food Sci. Technol. 48, 1193–1200. doi: 10.1111/ijfs.12075

Nouri, M., Nasehi, B., Samavati, V., and Mehdizadeh, S. A. (2017). Optimizing the effects of Persian gum and carrot pomace powder for development of low-fat donut with high fibre content. Bioact. Carbohydr. Dietary Fibre. 9, 39–45. doi: 10.1016/j.bcdf.2017.01.001

Ozgur, M., Akpinar-Bayizit, A., Ozcan, T., and Yilmaz-Ersan, L. (2011). Effect of dehydration on several physico-chemical properties and the antioxidant activity of leeks (Allium porrum L.). Notulae Botanicae Horti Agrobotanici Cluj-Napoca. 39, 144–151. doi: 10.15835/nbha3915861

Patel, R. P., Patel, M. P., and Suthar, A. M. (2009). Spray drying technology: an overview. Indian J. Sci. Tech, 2, 44–47. doi: 10.17485/ijst/2009/v2i10.3

Peng, J., Yi, J., Bi, J., Chen, Q., Wu, X., Zhou, M., et al. (2018). Freezing as pretreatment in instant controlled pressure drop (DIC) texturing of dried carrot chips: Impact of freezing temperature. LWT. 89, 365–373. doi: 10.1016/j.lwt.2017.11.009

Plazzota, S., Calligaris, A., and Manzocco, L. (2018). Application of different drying techniques to fresh-cut salad waste to obtain food ingredients rich in antioxidants and with high solvent loading capacity. LWT 89, 276–283. doi: 10.1016/j.lwt.2017.10.056

Pongmalai, P., Fu, N., Soponronnarit, S., Chiewchan, N., Devahastin, S., and Chen, X. D. (2018). Microwave pretreatment enhances the formation of cabbage sulforaphane and its bioaccessibility as shown by a novel dynamic soft rat stomach model. J. Funct. Foods 43, 186–195. doi: 10.1016/j.jff.2018.02.009

Prakash, S., Jha, S. K., and Datta, N. (2004). Performance evaluation of blanched carrots dried by three different driers. J. Food Eng. 62, 305–313. doi: 10.1016/S0260-8774(03)00244-9

Priecina, L., Karklina, D., and Kince, T. (2018). The impact of steam-blanching and dehydration on phenolic, organic acid composition, and total carotenoids in celery roots. Innovat. Food Sci. Emerg. Technol. 49, 192–201. doi: 10.1016/j.ifset.2018.01.008

Prosapio, V., and Norton, I. (2017). Influence of osmotic dehydration pre-treatment on oven drying and freeze drying performance. LWT 80, 401–408. doi: 10.1016/j.lwt.2017.03.012

Puértolas, E., and Barba, F. J. (2016). Electrotechnologies applied to valorization of by-products from food industry: main findings, energy and economic cost of their industrialization. Food Bioprod. Proc. 100, 172–184. doi: 10.1016/j.fbp.2016.06.020

Rana, S., Gupta, S., Rana, A., and Bhushan, S. (2015). Functional properties, phenolic constituents and antioxidant potential of industrial apple pomace for utilization as active food ingredient. Food Sci. Hum. Wellness 4, 180–187. doi: 10.1016/j.fshw.2015.10.001

Rao, A. V., and Rao, L. G. (2007). Carotenoids and human health. Pharmacol. Res. 55, 207–216. doi: 10.1016/j.phrs.2007.01.012

Ratti, C. (2001). Hot air and freeze-drying of high-value foods: a review. J. Food Eng. 49, 311–319. doi: 10.1016/S0260-8774(00)00228-4

Rodríguez, R., Jiménez, A., Fernández-Bolaños, J., Guillén, R., and Heredia, A. (2006). Dietary fibre from vegetable products as source of functional ingredients. Trends Food Sci. Technol. 17, 3–15. doi: 10.1016/j.tifs.2005.10.002

Sagar, V. R., and Suresh Kumar, P. (2010). Recent advances in drying and dehydration of fruits and vegetables: a review. J. Food Sci. Technol. 47, 15–26. doi: 10.1007/s13197-010-0010-8

Santos, D., Maurício, A., Sencadas, V., Santos, J., Fernandes, M., and Gomes, P. (2018). Spray Drying: An Overview. Intech Open. doi: 10.5772/intechopen.72247

Sarvan, I., Kramer, E., Bouwmeester, H., Dekker, M., and Verkerk, R. (2017). Sulforaphane formation and bioaccessibility are more affected by steaming time than meal composition during in vitro digestion of broccoli. Food Chem. 214, 580–586. doi: 10.1016/j.foodchem.2016.07.111

Singh, B., Panesar, P. S., and Nanda, V. (2006). Utilization of carrot pomace for the preparation of a value added product. World J. Dairy Food Sci. 1, 22–27. Available online at: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.533.7770&rep=rep1&type=pdf

Stenmarck, Å., Jensen, C., Quested, T., Moates, G., Cseh, B., Juul, S., et al. (2016). FUSIONS - Estimates of European food waste levels. In Fusions. Available online at: https://www.eu-fusions.org/phocadownload/Publications/Estimates of European food waste https://phys.org/news/2016-12-quarter-million-tonnes-food-logistics.html#nRlv

Stoll, T., Schweiggert, U., Schieber, A., and Carle, R. (2003). Process for the recovery of a carotene-rich functional food ingredient from carrot pomace by enzymatic liquefaction. 4, 415–423. doi: 10.1016/S1466-8564(03)00060-2

Szadzińska, J., Kowalski, S., and Stasiak, M. (2016). Microwave and ultrasound enhancement of convective drying of strawberries: experimental and modeling efficiency. Int. J. Heat Mass Transf. 103, 1065–1074 doi: 10.1016/j.ijheatmasstransfer.2016.08.001