- 1Australian Centre For Robotics (ACFR), University of Sydney, Sydney, NSW, Australia

- 2Department of Marine Technology, Norwegian University of Science and Technology (NTNU), Trondheim, Norway

This paper presents methods for finding optimal configurations and actuator forces/torques to maximise contact wrenches in a desired direction for underwater vehicle manipulator systems (UVMS). The wrench maximisation problem is formulated as a bi-level optimisation problem, with upper-level variables in a low-dimensional parameterised redundancy space, and a linear lower-level problem. We additionally consider the cases of one or more manipulators with multiple contact forces, maximising the wrench capability while tracking a trajectory and generating large wrench impulses using dynamic motions. The specific cases of maximising force to lift a heavy load and maximising torque during a valve-turning operation are considered. Extensive experimental results are presented using a 6 degree of freedom (DOF) underwater robotic platform equipped with a 4DOF manipulator and show significant increases in the wrench capability compared to existing methods for mobile manipulators.

1 Introduction

High degree of freedom (DOF) vehicle manipulator systems have seen increased use in both industrial and field robotics settings due to the advantages provided by kinematic redundancy. Since these systems have a large number of DOFs responsible for end effector motion, kinematic positioning generally requires iterative techniques. Despite this, these kinematically redundant systems can make use of the continuous space of configurations, which solve a particular inverse kinematics problem to optimise additional secondary objectives (Klein and Huang, 1983). Secondary objectives may include obstacle avoidance, optimisation of dynamic manipulability, and avoidance of configurations limits (Cieslak et al., 2015; Antonelli, 2005). During interaction tasks with objects or the environment, end effector poses and contact wrenches are of importance (Khatib, 1987; Antonelli et al., 2001). External contact forces and torques between the end effector and the environment are transmitted through each DOF of the system responsible for end effector motion, in a way which is highly dependent on the configuration. Exploiting the continuous redundancy offered by high-DOF systems allows for configurations which simultaneously achieve a desired end effector pose and maximise the wrench capabilities (Busson and Béarée, 2018).

Interaction tasks in underwater environments for scientific exploration or industrial purposes have been traditionally conducted by medium-to-large underwater vehicle manipulator systems (UVMS), requiring specialised equipment and multiple operators for launch and recovery, as well as operation (Sivčev et al., 2018). In recent years, the emergence of smaller and lower cost commercial off-the-shelf underwater vehicles and manipulators has seen a transition to small vehicles for some interaction tasks (Bezanson et al., 2017; Carlucho et al., 2021). This reduces both operation costs and time and increases the accessibility of these systems since they can be launched, operated, and recovered by a small team without specialised equipment. This work improves the capability of these small systems, allowing them to perform a larger range of interaction tasks. Specifically, we consider maximising contact wrenches between the end effector and the environment. This work assumes the object to be manipulated has already been firmly grasped by the end effector of the UVMS, and the system can then transition to a configuration which allows for the maximum wrench to be applied at the end effector.

We compare a number of cases whose wrench capabilities should be maximised. The first is the static case, where the aim is to maximise the wrench at a single configuration, which we further extended to consider multiple contact points with the environment. The second case considers a trajectory where a given desired end effector path should be tracked while finding a set of configurations along the way which are dynamically feasible and maximise the lowest applicable wrench along the path. Finally, the case of generating large wrench impulses for a fixed end effector pose is considered. Extensive experimental validation of the proposed methods is provided, which shows significant increases in the wrench capability compared to previous methods for UVMS and other mobile manipulators.

This paper presents the following contributions:

The rest of this paper is structured as follows: Section 2 provides a recap of the mathematical background and current methods for wrench analysis and finding optimal configurations for wrench maximisation. Section 3 describes the methods proposed in this work for maximising the static wrench capability for UVMS, including consideration of multiple contact points. Section 4 extends the methods used for static analysis to consider dynamic trajectories, given an end effector path. Section 5 describes the proposed method for generating large wrench impulses using dynamic motions. Finally, Section 6 presents experimental results for each section, followed by concluding remarks and directions for future work in Section 7.

2 Background and related work

2.1 Kinematic and dynamic modelling

A vehicle manipulator system has system configuration

for which analytical solutions in the reverse direction, the inverse kinematics problem, are generally not available. Numerical solutions make use of the linear velocity relationship Equation 2

where

where

where

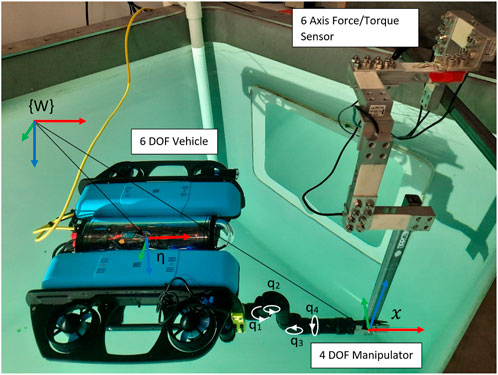

Figure 1. UVMS used in experiments with a 6DOF BlueROV vehicle and 4DOF Reach Robotics Alpha manipulator, showing vehicle pose

Now, we have the end effector wrench vector in Equation 5

consisting of end effector forces

where

where

2.2 Wrench ellipsoids

Analysis of wrench capability typically involves ellipsoids and polytopes. Velocity ellipsoids and their counterparts, wrench ellipsoids, were introduced by Yoshikawa (1985). These provide a mapping from a unit ball of joint torques to the end effector wrench, according to Equation 6. Care must be taken to avoid physical inconsistency due to the use of norms and inner products on wrench and axis force/torque spaces (Duffy, 1990). The use of appropriate scaling metrics (Doty et al., 1993; Doty et al., 1995) gives a modified version of Equation 6 expressed as Equation 9

where

Dropping the scaling metrics for brevity, the wrench ellipsoid is defined as Equation 10

Recent work proposed maximising the volume of the velocity ellipsoid by projecting the gradient onto the null space of the system, as shown in Equation 4, and by further solving the problem as a quadratic program (Zhang et al., 2016). A similar null space projection method was used by Bae et al. (2018) to maximise the dynamic manipulability ellipsoid during a value-turning operation for a UVMS.

2.3 Transmission ratios

The volume of the wrench ellipsoid accounts for the ability of the system to apply forces and torques in all directions in an isotropic manner. In this work, it is desired to maximise the wrench along a single force/torque direction; therefore, anisotropic capability measures are more appropriate. One such measure is the transmission ratio—which is defined as the distance to the wrench ellipsoid from the origin in a desired direction—which can been optimised by null space projection (Faroni et al., 2016).

To determine the distance to the wrench ellipsoid in a given direction, consider a unit vector

and solving for

This analysis does not include the effect of gravity, buoyancy, and dynamical effects, which offsets the centre of the ellipsoid, yielding a dynamic wrench ellipsoid defined as dynamic wrench ellipsoid defined in Equation 13

For an ellipse with its centre not at the origin, we can solve for

for

The idea of wrench ellipsoids was extended by Ajoudani et al. (2017) by scaling the ellipsoid by a desired force/stiffness matrix and instead optimising the trace of the resultant ellipsoid (the sum of the square of the radii) to obtain a configuration-dependent measure. Bowling and Khatib (2005) explored combining velocity, acceleration, and wrench capabilities in the joint torque space for serial manipulators. This involves mapping maximal balls of velocity, acceleration, and wrench individually onto ellipsoids in the joint torque space and then combining to form a torque hypersurface, which has to satisfy actuator constraints. Since the method combines worst-case scenarios for velocities, accelerations, and wrenches, it provides a very conservative measure of the manipulator capability.

2.4 Wrench polytopes

It has been shown that wrench ellipsoids provide only an approximate measure of manipulator performance as it fails to capture the true constraints of the system, as compared to wrench polytopes, which provides a better description of the true capabilities of a system (Chiacchio et al., 1996). By finding the set of effector wrenches which satisfy joint constraints, the wrench polytope is define in Equation 15

where

2.5 Redundancy parameterisation

The idea of redundancy parameterisation has been proposed in several works to greatly reduce the number of dimensions over which a given performance objective needs to be optimised, as well as to remove the non-linear inverse kinematics constraint. These methods avoid the use of the Jacobian null space projection in Equation 4 and instead explicitly consider a minimal set of DOF, which describe the available self-motions while keeping a fixed end effector pose. Redundancy parameterisation has been used for choosing optimal stiffness configurations in serial manipulators with one degree of redundancy (Busson et al., 2017), as well as for exploring the force capabilities of a manipulator to apply forces normal to a surface (Nützi et al., 2013). This work was extended in Busson and Béarée (2018) to an exhaustive search over two redundant DOFs for a 7DOF manipulator, where the saturating wrench was used to find the weightlifting capability for each pose, while Boudreau and Nokleby (2012) examined a planar parallel manipulator with a 3DOF redundant space to minimise the sum of squared joint torques for a given wrench. Given an appropriate parameterisation of the redundant DOF written as

where

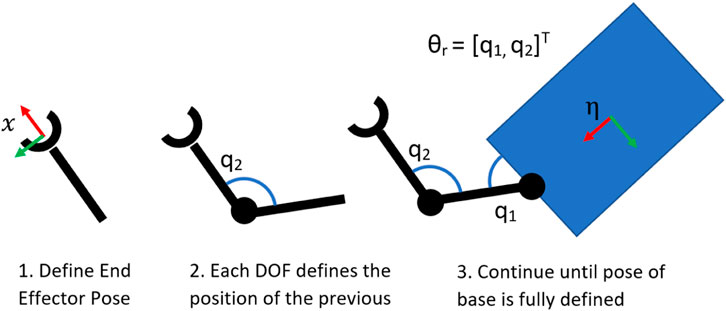

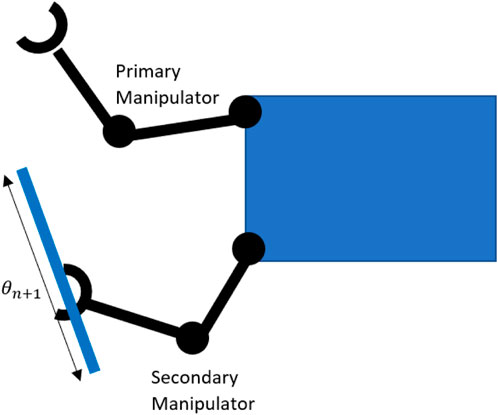

A redundancy parameterisation method for UVMS was introduced by Marais et al. (2021), which is illustrated in Figure 2. Given a desired end effector pose, each DOF in reverse order starting from the end effector is a redundant DOF until the pose of the base is fully defined, with invalid poses due to self-collision discarded. The redundant configuration

Figure 2. Sequence of images showing the proposed redundancy parameterisation method for UVMS, with redundancy parameters

2.6 Wrench capability over a trajectory

The previous analysis has considered wrench capabilities for a single end effector pose. In some cases, the wrench capability over an entire trajectory has to be considered. Local redundancy resolution methods have been used for continuous wrench maximisation over a trajectory (Bae et al., 2018), yet local methods may lead to numerical instability and sub-optimal trajectories (Kazerounian and Wang, 1988). Global redundancy resolution methods which consider entire paths have been proposed for trajectory planning in kinematically redundant systems (Suh and Hollerbach, 1987). Early works in global redundancy resolution (Papadopoulos and Gonthier, 1995a; Papadopoulos and Gonthier, 1995b) focused on planning paths, which avoid actuator saturation while experiencing a large fixed load. Further work used the intersection of the wrench polytope with an expected cone of disturbances for generating trajectories for kinematic manipulators which are robust to disturbances (Ferrolho et al., 2021; Lin and Chen, 2016) and used an evolutionary algorithm combined with multiple lower-level linear programming solutions to find the maximum wrench capability over a trajectory for a re-configurable parallel robot. An iterative linear programming method was proposed for trajectory optimisation to maximise the allowable load for mobile manipulators between two end effector set points (Korayem et al., 2004), yet the computational complexity restricted its application to a 2DOF manipulator.

Hamiltonian control approaches, which make use of Pontryagin’s minimum principle over an entire trajectory (Korayem et al., 2009; Korayem et al., 2012), have been used for finding the maximum load carrying capacity for mobile manipulators yet often result in control laws which require instantaneous switching of actuator forces or torques, which are not physically realisable for the systems considered in this work. Additionally, these methods require solving two-point boundary value problems and, therefore, are generally restricted to systems with low degrees of redundancy. Recent work has considered receding horizon style planning using model predictive control (MPC) to track desired wrenches (Wahrburg and Listmann, 2016), or for trajectory planning for a mobile manipulator actuating a large load (Sleiman et al., 2021). Other works Li and Nguyen (2023) have considered kinodynamic pose optimisation for whole body control of a humanoid robot manipulating an object, with real-time trajectory tracking formulated as a constrained MPC problem, yet few of these works have considered explicitly maximising the wrench capability using these methods.

To the best of the authors' knowledge, no effective methods exist for explicitly maximising the wrench capability of high DOF vehicle manipulator systems, which appropriately consider and exploit the full capabilities and constraints which are unique to these systems.

3 Maximising the static wrench capability

This section details how to find optimal configurations and actuator efforts to maximise the wrench capability in a desired direction, for a single end effector pose and system configuration. Dynamic effects due to velocity and acceleration are, therefore, ignored yet are considered in Section 4. Cases in which the maximising static wrench capabilities are relevant include lifting a heavy load or maximising instantaneous torque when turning a valve.

3.1 Problem formulation

The static wrench maximisation problem can be expressed as Equation 17

with constraints

where as before,

This formulation has a linear objective with combined linear and non-linear constraints and is intractable to solve in a reasonable timescale using available non-linear solvers for the system considered in this work. In particular, satisfying the inverse kinematics equality constraint in Equation 18 is difficult due to the absence of analytical solutions for kinematically redundant systems. This work proposes two methods to make solving the above problem tractable: redundancy parameterisation and separation into a bi-level optimisation problem. Bi-level optimisation has been used in several works on kinematically redundant manipulators to make optimisation problems tractable (Nusbaum et al., 2020; Menasri et al., 2013; Menasri et al., 2015). Typically, the problem is partitioned between two sets of decision variables and solved in a nested framework (Dempe, 2002). This work uses the proposed redundancy parameterisation method in Marais et al. (2021), allowing the inverse kinematics constraint in Equation 18 to be explicitly satisfied and, therefore, removed from the list of constraints and replacing

with constraints in Equations 25, 26

where

with constraints given in Equations 21–23.

It must be noted that for certain sets of upper-level variables, the lower-level problem may not have a feasible solution. Physically, this corresponds to configurations where the system is unable to hold a static configuration due to external forces such as gravity and buoyancy acting on the system. Although not an issue for the system considered in this work, programmatically, these configurations are penalised with a large negative cost. This is further discussed for the case of dynamic trajectories in Section 4.

3.2 Analysis using ellipsoids and polytopes

First, the previous definitions of wrench ellipsoids and polytopes have to be extended to include the overactuated mapping given in Equation 7. We can invert the mapping in Equation 8 to obtain Equation 28

giving a new definition for the wrench ellipsoid Equation 29

where the actuator weighting matrix (Xing et al., 2020) is given by

for a given desired wrench along the direction

although

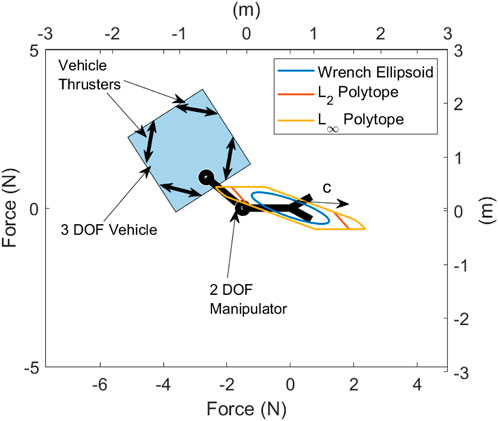

which gives a true measure of the actuator capabilities. A simple 2-dimensional (2D) test case is considered to compare each capability measures shown in Figure 3. This shows an underwater vehicle with diagonally mounted thrusters on each corner which can apply 1 N thrust. The arm has two joints, of which each can apply a torque of 1 Nm. The wrench ellipsoid

Figure 3. Wrench ellipsoid and polytopes measured in Newton (N) for a 2D UVMS with dimensions in metres (m), showing the force capability in the given configuration and the desired direction

3.3 Optimising for the maximum wrench capability

Now, consider finding the configuration and combination of thruster forces and joint torques which maximises the wrench capability of the system shown in Figure 3 in the direction

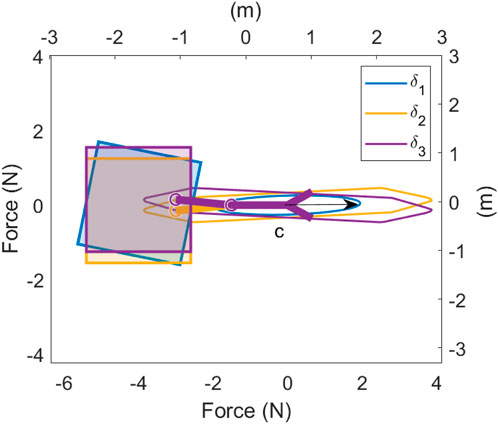

For the system considered in Figure 3, there are three vehicle DOFs, two manipulator DOFs, four vehicle thrusters, two joint torques, and three wrench DOFs for a total of 14 variables to solve while simultaneously needing to satisfy the inverse kinematics constraint. Now, consider solving the optimisation problem using the bi-level approach proposed above, separating the problem into a linear programming problem with nine variables (four vehicle thrusters, two joint torques, and three wrench DOFs), and an upper-level problem with two variables (two manipulator DOFs). In this case, redundancy parameterisation has resulted in a bi-level optimisation problem with three fewer total variables to solve. Due to the low dimensionality of the upper-level problem, a simple grid search is used to search the configuration space for the globally optimal configuration. The lower linear programming problem is solved using the dual-simplex method in MATLAB’s linprog function. The optimal solution is shown in Figure 4 labelled

Figure 4. Optimal configurations for a wrench in the

3.4 Removing the orthogonal wrench constraint

The orthogonal wrench equality constraint in Equation 23 can be removed in some scenarios. One example is during a valve-turning operation, where reaction forces orthogonal to

3.5 Comparison with the transmission ratio

Typical methods for maximising the wrench capability seek to maximise the transmission ratio (Faroni et al., 2016; Nemec, 1997). Considering that the proposed bi-level programming approach determines how to optimally configure the

with constraints in Equations 34, 35

where

In this case,

Figure 4 shows the results of bi-level optimisation using each of these objectives

3.6 Multiple contact points

The case of multiple contact points is common when using two or more manipulators. The reaction forces of the end effector of a second manipulator on some nearby grasp point can help increase the wrench applied by the first manipulator. This creates a closed kinematic chain between the UVMS system and the environment, requiring more careful analysis.

For multiple contact points’ case, we define

where the terms

The redundancy parameterisation for the dual manipulator case is similar to the single-arm case, with the primary arm again defining all degrees of redundancy until the pose of the base is fully defined. The inverse kinematics solution to reach the grasp point for the second arm can then be analytically solved. In the case of multiple inverse kinematics solutions for the second arm, the solution which maximises the lower-level objective is taken. In case of no solution, the configuration is considered invalid. The resultant bi-level optimisation problem is written as Equation 38

with constraints in Equations 39–42

where

subject to constraints in Equations 44, 45

Again, the decision variables for the upper-level problem are the redundancy parameters

The above bi-level optimisation problem again separates the wrench maximisation problem into a linear lower-level optimisation and a low-dimensional higher-level problem. Again, the lower-level problem is solved using the dual-simplex method in MATLAB’s linprog function, and the upper-level problem uses simulated annealing, followed by the interior-point method to effectively search the highly non-linear space for an approximate global optimum.

3.7 Regrasping

The above case considered grasping a fixed point with a second arm. Generally, multiple grasping points will be available. We consider cases where these regrasp points can be parameterised to provide extra dimensions over which to optimise. Figure 5 shows a simple 2D example, where a one-dimensional set of parameterised re-grasping points result in an additional kinematic DOF, which can be optimised over. This leads to an additional DOF in the parameterised redundancy space

Figure 5. Parametrised regrasp points for second manipulator adding an additional kinematic variable

4 Wrench maximisation over a trajectory

In this section, a predefined end effector trajectory is considered, with corresponding desired wrench directions which should be maximised along the path. Only a UVMS with a single manipulator is considered, yet the analysis can be easily extended to multiple manipulators. Use cases for this method may be during a valve-turning operation, which requires maximising torque along the same direction throughout, or a waterjet blasting operation around a pipe, which requires resisting large forces normal to the pipe surface along the path. Dynamical effects due to velocities and accelerations cannot be ignored in this case. It is assumed that there is a given fully defined end effector pose trajectory parameterised in time and that the velocities at the start and end are zero. To maximise the capability of the system along this path, the objective is to maximise the minimum wrench capability along this trajectory.

4.1 Problem formulation

In order to make the problem tractable, the trajectory of the end effector is discretised into a set of

where

with Equation 49

where

where

At each timestep, the wrench is given by

The trajectory optimisation problem can be written as the following bi-level optimisation problem

where

where

where

subject to Equation 56

where

where

where

As before, this constraint can be relaxed under certain conditions. Finally, there is a constraint on large changes to actuator efforts throughout the trajectory given by

where

This is again a bi-level optimisation problem, with the linear program in Equation 55 as the lower-level optimisation. Changes to

where

Given a dynamically infeasible trajectory due to large dynamics terms, the lower-level LP cannot find a feasible solution, which satisfies the constraints in Equation 57. In this case, the lower-level problem is set to return a max–min wrench of

4.2 Tracking dynamic trajectories

The above method finds a trajectory with smoothly varying actuator efforts, which maximises the minimum wrench in a given desired direction along the entire trajectory. The actual reaction forces and torques between the end effector and the environment during this trajectory will not be the same as those in the LP solution. Since the actuator constraints form a convex set, any value for

where

which is simply the actuator model. Using the method of Lagrange multipliers, this has solution in Equation 64

where

This result does not incorporate the inequality constraints on the actuators. These are in Equation 66

which account for actuator effort limits and Equation 67

which account for actuator effort rate change limits. This is a quadratic programming problem, which can be solved efficiently in real time for control.

5 Maximum wrench impulse

This section looks at generating a maximum momentary wrench for a fixed end effector pose, using dynamic vehicle manipulator motions while keeping the end effector fixed. A use case for this method may be for shifting a very heavy weight or a stuck valve. Humans naturally perform these motions for similar tasks, where the momentum of the person is used to momentarily generate large forces.

5.1 Problem formulation

For a given fixed end effector pose and set of redundant configurations which define a dynamic trajectory, the maximum wrench problem is given by Equation 68

which is a linear

All constraints from the dynamic wrench maximisation in Equations 57–60 also apply. This is a linear program which again is the lower-level problem for the bi-level trajectory optimisation with upper level given by Equation 52, with the solution and gradients found in the same way as before.

6 Results

We present the wrench maximisation results for the 4DOF manipulator and 6DOF vehicle shown in Figure 1. This system has a degree of redundancy of 4. Two wrench objectives are compared, torque along the z direction simulating turning a valve, and force in the z direction, which tests lifting a heavy load. The torque limit on each joint is

6.1 Static wrench capability

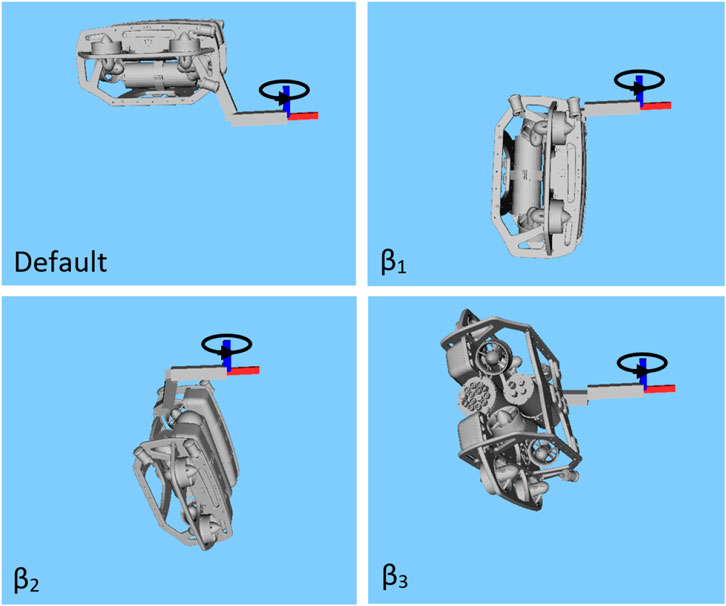

For the case of static torque maximisation in the z direction, four configurations are compared, shown in Figure 6. First is the default configuration, which is simply the manipulator in a neutral position with the vehicle upright. The three other cases are the optimised configurations for

Figure 6. Optimal static configuration for torque in the z-direction (blue axis), comparing the default upright case, to the solutions which optimise

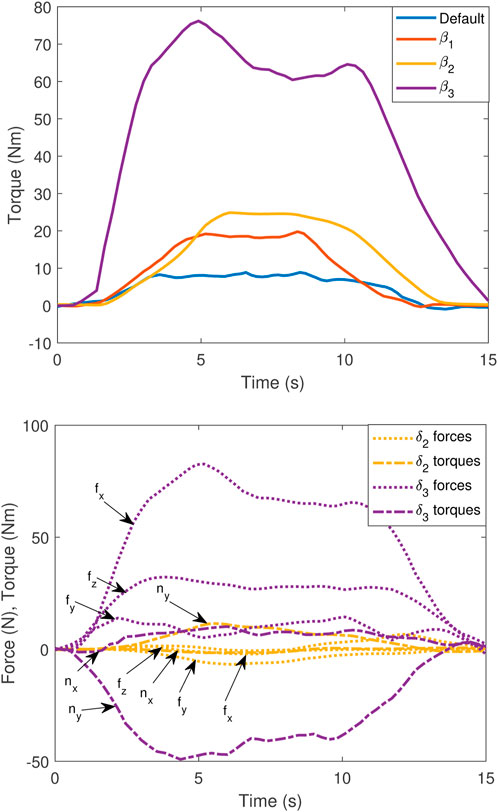

Figure 7 (top) shows the torque along the z direction, as measured by the sensor setup during the experiments for each of the four configurations. Each experiment consists of a 5-s ramp-up and ramp-down and a 5-s maximum wrench.

Figure 7. (Top) Torque along the z direction during static wrench maximisation, comparing the default,

The default case is limited to a torque of 9 Nm since the z-axis is aligned with the base joint of the manipulator in this case. The standard approach of optimising for the transmission ratio

The default,

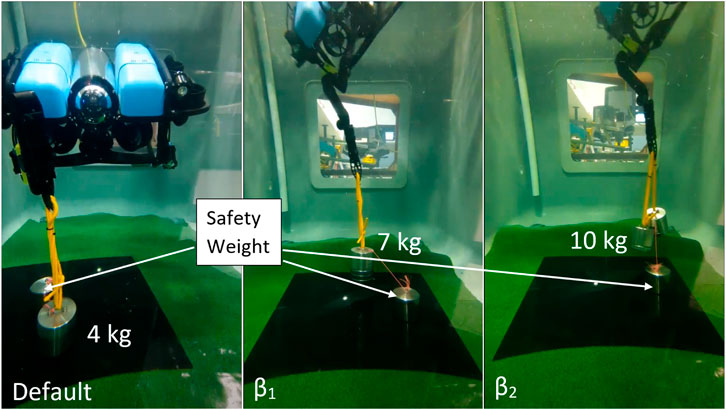

For the case of static force maximisation in the z direction, three configurations are compared, shown in Figure 8. Again, the first is the default configuration, followed by optimal configurations for

Figure 8. Experiments comparing the default,

The results for both the torque maximisation and force maximisation experiments show significant increases of approximately 30% and 40%, respectively, in wrench capability when comparing optimisation using the transmission ratio

6.2 Multiple contact points

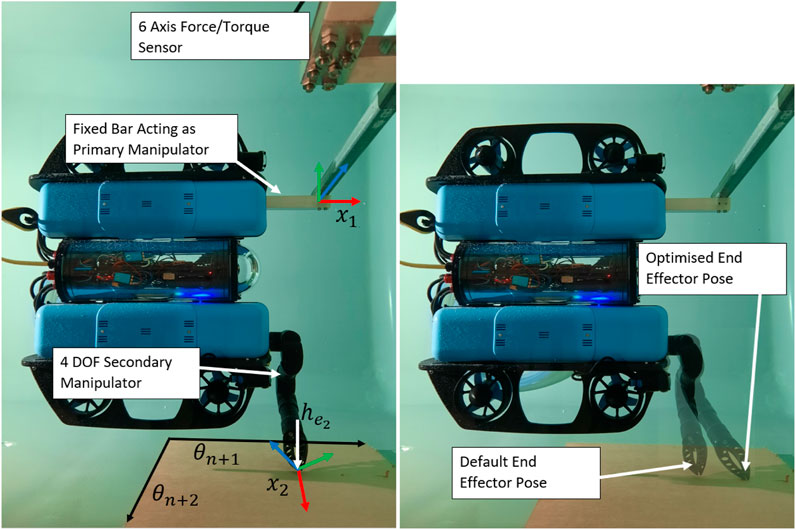

The experimental setup for multiple contact point is shown in Figure 9 (left). A fixed bar is used as the primary manipulator with end effector

Figure 9. (Left) Experimental setup for multiple contacts points. A fixed bar is used as the primary manipulator, with the end effector pose

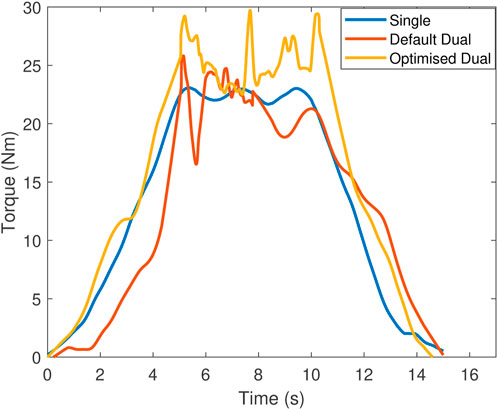

Figure 9 shows the set of possible regrasping points which provide two additional DOFs over which to optimise. Figure 10 shows the results for torque maximisation along the z direction, comparing the single and dual manipulator cases. For the dual manipulator case, both the default end effector pose and the optimised end effector pose are tested, shown in Figure 9 (right). The single manipulator torque reaches a maximum of 23 Nm, the default dual case reaches 26 Nm, and the optimised dual case reaches 30 Nm, an increase of 13% and 30%, respectively. The data for this experiment contain more noise since the vehicle is very close to the edge of the tank by necessity, causing large effects from swirling water in the tank. These effects may be significant near solid structures in the underwater environment, requiring additional modelling which is left as future work.

Figure 10. Torque along the z direction during static wrench maximisation comparing single manipulator, dual manipulators in the default end effector pose, and dual manipulators in the optimised end effector pose.

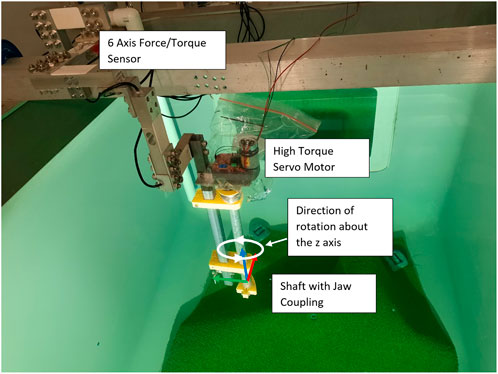

6.3 Wrench maximisation over a trajectory

The experimental setup for testing wrenches over a rotating end effector trajectory along the global z-axis is shown in Figure 11. This simulates turning a valve along this direction of rotation. A high-torque servo motor above the water line is used to generate the controlled rotation and is attached to a shaft, which reaches into the tank. By controlling the rotation of the simulated valve, the maximum wrench capability throughout the trajectory can be accurately determined. The end effector of the UVMS attaches to a jaw coupling on the end of the shaft, and the whole setup is mounted to the end of the 6-axis force–torque sensor.

Figure 11. Setup for testing dynamics wrenches over a trajectory, using a servo motor and attached shaft to simulate a turning valve.

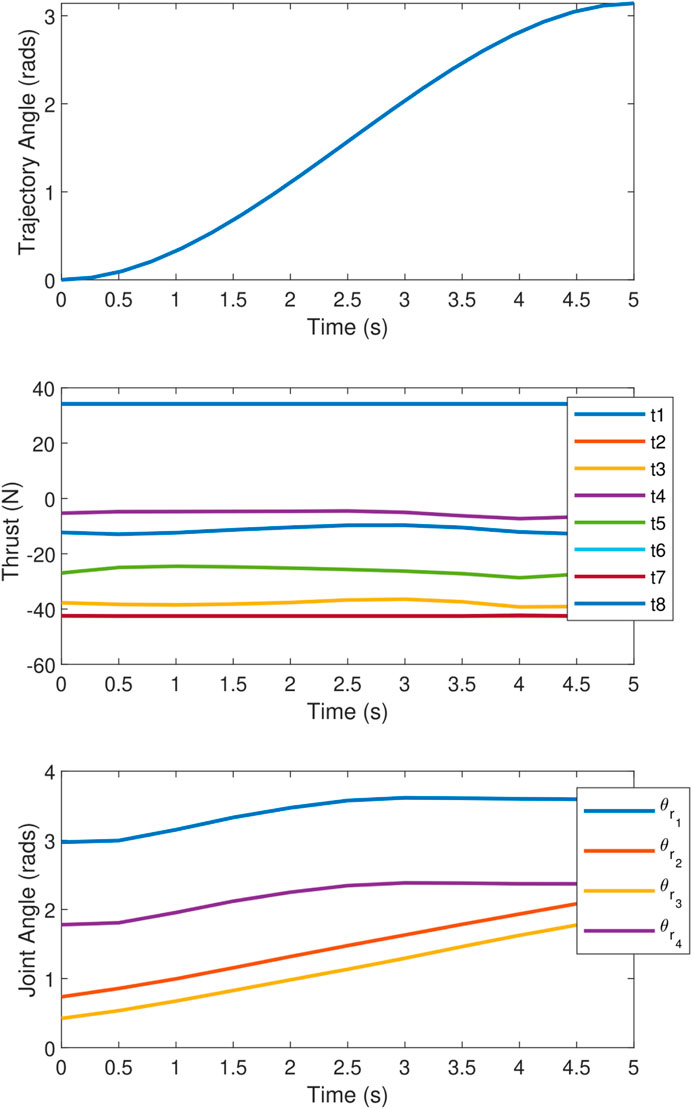

The objective which is tested is maximising the torque along the z-axis with no orthogonal wrench components, while the end effector tracks a

Figure 12. Plots during the rotating end effector trajectory showing (top) the end effector angle, (middle) vehicle thrust forces, and (bottom) redundant joint angles.

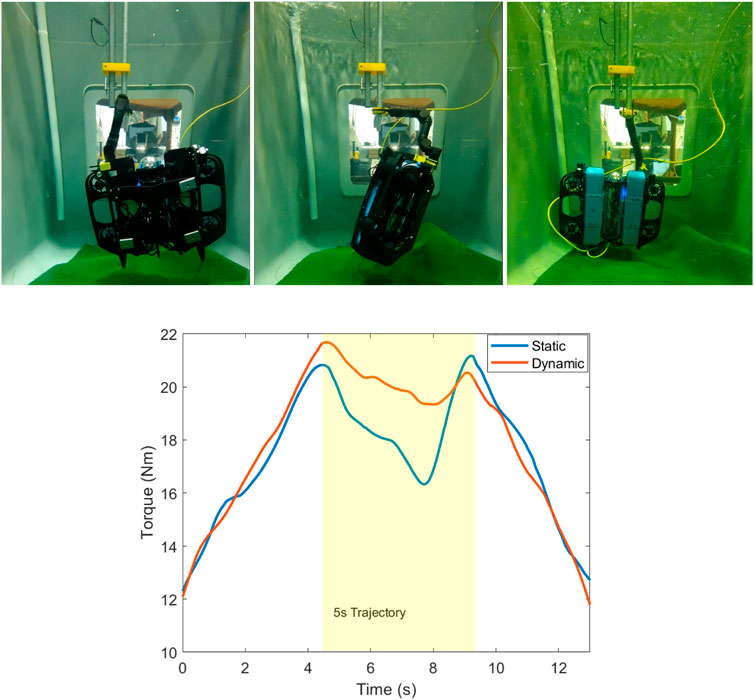

Figure 13 (top) shows a sequence of images of the UVMS during the experiment at

Figure 13. (Top) Sequence of images during the 5-s

Figure 13 (bottom) shows the results of the torque along the z-axis, comparing the dynamic case which tracks the optimised trajectory, and the static case which maintains a fixed redundant configuration throughout. The static redundant configuration which is chosen is the configuration which maximises the static torque capability using

Since this rotation is about the vertical axis, the effects of changing gravity and buoyancy vectors in the UVMS frame due to the end effector rotation are not present. Therefore, the improved performance of the dynamic case, as compared to the static case, is purely due to consideration of dynamical effects from velocity and acceleration. The difference in performance between the dynamic trajectory optimised case and the static case is likely to be much more significant with end effector trajectories which include rotations about a non-vertical axis.

6.4 Maximum wrench impulse

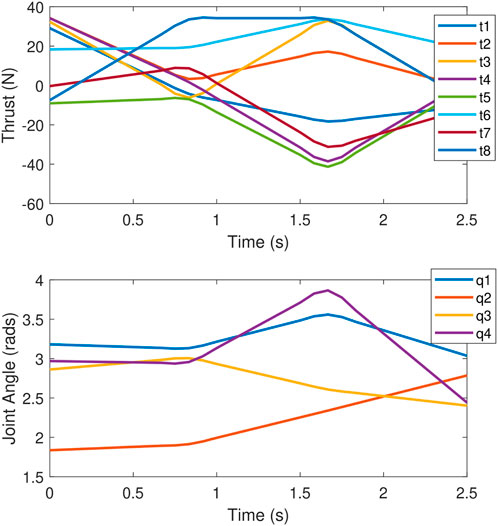

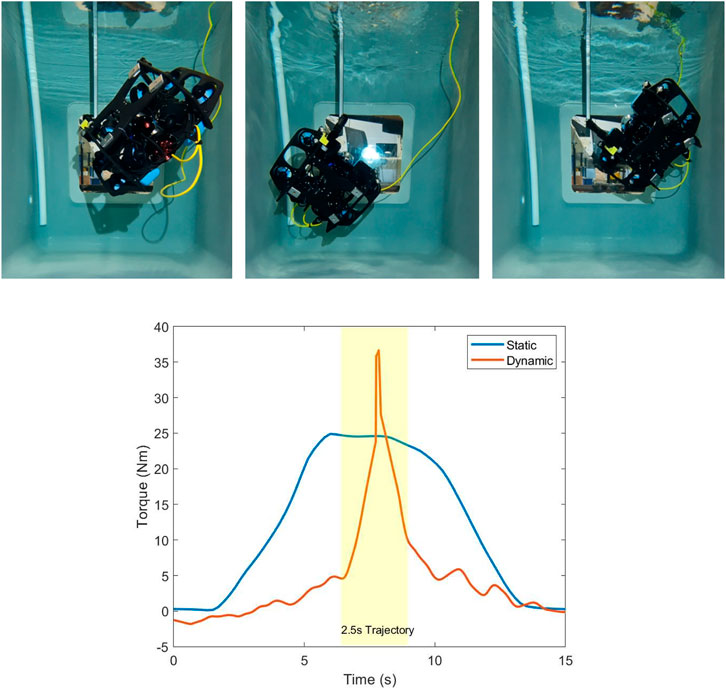

The experimental setup for maximum wrench impulse trajectories is the same as the static wrench maximisation setup shown in Figure 1. Again, the objective is to maximise the torque along the z direction with no orthogonal wrench components, in this case by using dynamic motions to generate a large torque impulse momentarily, while keeping the end effector fixed. A trajectory of 2.5 s with four intermediate configurations was chosen; therefore,

Figure 14. Plots during the maximum wrench impulse trajectory showing (top) the vehicle thrust forces and (bottom) redundant joint angles.

Figure 15. (Top) Sequence of images during the 2.5-s maximum impulse trajectory. Resultant trajectory is highly dynamic, allowing a large wrench impulse to be generated. (Bottom) Torque along the z direction during a heaving motion, compared to the static

7 Conclusion

This work focuses on maximising the maximum wrench capability of UVMS. A bi-level optimisation method is proposed for maximising static wrenches, and experimental results show a significant improvement over optimising the transmission ratio. Further results show that relaxing constraints on orthogonal wrenches lead to significant increases in the wrench capability in relevant use cases. The case of multiple contact points, as well as re-grasping of secondary points, is also considered, with experimental results again showing an increased wrench capability. A similar bi-level optimisation approach is introduced for max–min wrench optimisation over a trajectory, with experimental results confirming the validity of the method. Finally, a method is proposed for finding dynamic trajectories which generate large wrench impulses, with supporting experimental results. Further work is required for dealing with the effects of self-generated currents by the vehicle thrusters when operating near underwater structures. Additional work would look at automatic recognition of viable secondary contact points. Further experimental results are required to test the trajectory optimisation method for end effector trajectories which contain rotation about a non-vertical axis. Finally, further work is required to implement the proposed methods in a truly real-time implementation (rather than just pre-solving the optimisation several seconds before). This would allow for online configuration adjustments during application of an end effector wrench, for example, to reduce end effector tracking errors.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

WM: conceptualization, data curation, formal analysis, investigation, methodology, project administration, resources, software, validation, visualization, writing–original draft, and writing–review and editing. OP: conceptualization, project administration, supervision, visualization, and writing–review and editing. SW: conceptualization, project administration, supervision, visualization, and writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

This work has been enabled by the use of a Reach Alpha manipulator from Reach Robotics (https://reachrobotics.com/).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ajoudani, A., Tsagarakis, N. G., and Bicchi, A. (2017). Choosing poses for force and stiffness control. IEEE Trans. Robotics 33, 1483–1490. doi:10.1109/TRO.2017.2708087

Antonelli, G., Chiaverini, S., and Sarkar, N. (2001). External force control for underwater vehicle-manipulator systems. IEEE Trans. Robotics Automation 17, 931–938. doi:10.1109/70.976027

Bae, J., Bak, J., Jin, S., Seo, T., and Kim, J. (2018). Optimal configuration and parametric design of an underwater vehicle manipulator system for a valve task. Mech. Mach. Theory 123, 76–88. doi:10.1016/j.mechmachtheory.2018.01.014

Bezanson, L., Reed, S., Martin, E. M., Vasquez, J., and Barbalata, C. (2017). “Coupled control of a lightweight rov and manipulator arm for intervention tasks,” in OCEANS 2017 - Anchorage, Anchorage, AK, USA, 18-21 September 2017, 1–6.

Boudreau, R., and Nokleby, S. (2012). Force optimization of kinematically-redundant planar parallel manipulators following a desired trajectory. Mech. Mach. Theory 56, 138–155. doi:10.1016/j.mechmachtheory.2012.06.001

Boudreau, R., Nokleby, S., and Gallant, M. (2021). Wrench capabilities of a kinematically redundant planar parallel manipulator. Robotics 39, 1601–1616. doi:10.1017/S0263574720001381

Bowling, A., and Khatib, O. (2005). The dynamic capability equations: a new tool for analyzing robotic manipulator performance. IEEE Trans. Robotics 21, 115–123. doi:10.1109/TRO.2004.837243

Busson, D., and Béarée, R. (2018). A pragmatic approach to exploiting full force capacity for serial redundant manipulators. IEEE Robotics. Auto. Lett. 3, 888–894. doi:10.1109/LRA.2018.2792541

Busson, D., Bearee, R., and Olabi, A. (2017). Task-oriented rigidity optimization for 7 dof redundant manipulators. IFAC-PapersOnLine 50, 14588–14593. 20th IFAC World Congress. doi:10.1016/j.ifacol.2017.08.2108

Buttolo, P., and Hannaford, B. (1995). “Advantages of actuation redundancy for the design of haptic displays.” In Proceedings ASME, Fourth Annual Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, San Francisco, CA, United States.

Carlucho, I., Stephens, D. W., and Barbalata, C. (2021). An adaptive data-driven controller for underwater manipulators with variable payload. Appl. Ocean Res. 113, 102726. doi:10.1016/j.apor.2021.102726

Chiacchio, P., Bouffard-Vercelli, Y., and Pierrot, F. (1996). “Evaluation of force capabilities for redundant manipulators,” in Proceedings of IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 1996, 3520–3525. doi:10.1109/ROBOT.1996.509249

Cieslak, P., Ridao, P., and Giergiel, M. (2015). “Autonomous underwater panel operation by girona500 uvms: a practical approach to autonomous underwater manipulation,” in 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26-30 May 2015, 529–536. doi:10.1109/ICRA.2015.7139230

Doty, K. L., Melchiorri, C., and Bonivento, C. (1993). A theory of generalized inverses applied to robotics. Int. J. Robotics. Res. 12, 1–19. doi:10.1177/027836499301200101

Doty, K. L., Melchiorri, C., Schwartz, E. M., and Bonivento, C. (1995). Robot manipulability. IEEE Trans. Robotics. Auto. 11, 462–468. doi:10.1109/70.388791

Duffy, J. (1990). The fallacy of modern hybrid control theory that is based on “orthogonal complements” of twist and wrench spaces. J. Robotics. Syst. 7, 139–144. doi:10.1002/rob.4620070202

Faroni, M., Beschi, M., Visioli, A., and Molinari Tosatti, L. (2016). “A global approach to manipulability optimisation for a dual-arm manipulator,” in 2016 IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 06-09 September 2016, 1–6. doi:10.1109/ETFA.2016.7733725

Ferrolho, H., Merkt, W., Tiseo, C., and Vijayakumar, S. (2021). Residual force polytope: admissible task-space forces of dynamic trajectories. Robotics. Aut. Syst. 142, 103814. doi:10.1016/j.robot.2021.103814

Firmani, F., Zibil, A., Nokleby, S. B., and Podhorodeski, R. P. (2008). Wrench capabilities of planar parallel manipulators. Part I: wrench polytopes and performance indices. Robotica 26, 791–802. doi:10.1017/s0263574708004384

Kazerounian, K., and Wang, Z. (1988). Global versus local optimization in redundancy resolution of robotic manipulators. Int. J. Robotics Res. 7, 3–12. doi:10.1177/027836498800700501

Khatib, O. (1987). A unified approach for motion and force control of robot manipulators: the operational space formulation. IEEE J. Robotics Automation 3, 43–53. doi:10.1109/JRA.1987.1087068

Klein, C. A., and Huang, C. (1983). Review of pseudoinverse control for use with kinematically redundant manipulators. IEEE Trans. Syst. Man, Cybern. SMC-13, 245–250. doi:10.1109/TSMC.1983.6313123

Korayem, M., Ghariblu, H., and Basu, A. (2004). Maximum allowable load of mobile manipulators for two given end points of end effector. Int. J. Adv. Manuf. Technol. 24, 743–751. doi:10.1007/s00170-003-1748-1

Korayem, M. H., Azimirad, V., Vatanjou, H., and Korayem, A. H. (2012). Maximum load determination of nonholonomic mobile manipulator using hierarchical optimal control. Robotica 30, 53–65. doi:10.1017/S0263574711000336

Korayem, M. H., Nikoobin, A., and Azimirad, V. (2009). Maximum load carrying capacity of mobile manipulators: optimal control approach. Robotica 27, 147–159. doi:10.1017/S0263574708004578

Li, J., and Nguyen, Q. (2023). “Kinodynamic pose optimization for humanoid loco-manipulation,” in 2023 IEEE-RAS 22nd International Conference on Humanoid Robots (Humanoids), Austin, TX, USA, 12-14 December 2023, 1–8. doi:10.1109/Humanoids57100.2023.10375151

Lin, C.-J., and Chen, C.-T. (2016). Reconfiguration for the maximum dynamic wrench capability of a parallel robot. Appl. Sci. 6, 80. doi:10.3390/app6030080

Marais, W. J., Williams, S. B., and Pizarro, O. (2021). Anisotropic disturbance rejection for kinematically redundant systems with applications on an UVMS. IEEE Robotics Automation Lett. 6, 7017–7024. doi:10.1109/LRA.2021.3097067

Menasri, R., Nakib, A., Daachi, B., Oulhadj, H., and Siarry, P. (2015). A trajectory planning of redundant manipulators based on bilevel optimization. Appl. Math. Comput. 250, 934–947. doi:10.1016/j.amc.2014.10.101

Menasri, R., Nakib, A., Oulhadj, H., Daachi, B., Siarry, P., and Hains, G. (2013). “Path planning for redundant manipulators using metaheuristic for bilevel optimization and maximum of manipulability,” in 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12-14 December 2013, 145–150. doi:10.1109/ROBIO.2013.6739450

Nemec, B. (1997). Force control of redundant robots. IFAC Proc. Vol. 30, 209–214. 5th IFAC Symposium on Robot Control 1997 (SYROCO ’97), Nantes, France, 3-5 September. doi:10.1016/S1474-6670(17)44266-2

Nusbaum, U., Weiss Cohen, M., and Halevi, Y. (2020). Path planning and control of redundant manipulators using bilevel optimization. J. Dyn. Syst. Meas. Control 142, 041008. doi:10.1115/1.4045976

Nützi, G., Feng, X., Siegwart, R., and Kock, S. (2013). Optimal contact force prediction of redundant single and dual-arm manipulators. J. Chin. Soc. Mech. Eng. 43, 251–258. doi:10.29979/JCSME

Papadopoulos, E., and Gonthier, Y. (1995a). Large force-task planning for mobile and redundant robots. Proc. 1995 IEEE/RSJ Int. Conf. Intelligent Robots Syst. Hum. Robot Interact. Coop. Robots 2, 144–149. doi:10.1109/IROS.1995.526152

Papadopoulos, E., and Gonthier, Y. (1995b). On manipulator posture planning for large force tasks. Proc. 1995 IEEE Int. Conf. Robotics Automation 1, 126–131. doi:10.1109/ROBOT.1995.525274

Sivčev, S., Coleman, J., Omerdić, E., Dooly, G., and Toal, D. (2018). Underwater manipulators: a review. Ocean. Eng. 163, 431–450. doi:10.1016/j.oceaneng.2018.06.018

Sleiman, J.-P., Farshidian, F., Minniti, M. V., and Hutter, M. (2021). A unified MPC framework for whole-body dynamic locomotion and manipulation. IEEE Robotics Automation Lett. 6, 4688–4695. doi:10.1109/LRA.2021.3068908

Suh, K., and Hollerbach, J. (1987). “Local versus global torque optimization of redundant manipulators," in Proceedings. 1987 IEEE International Conference on Robotics and Automation, Raleigh, NC, USA, 1987, 619–624. doi:10.1109/ROBOT.1987.1087955

Wahrburg, A., and Listmann, K. (2016). “MPC-based admittance control for robotic manipulators,” in 2016 IEEE 55th Conference on Decision and Control (CDC), Las Vegas, NV, United States, pp. 7548–7554. doi:10.1109/CDC.2016.7799435

Xing, H., Torabi, A., Ding, L., Gao, H., Deng, Z., and Tavakoli, M. (2020). Enhancement of force exertion capability of a mobile manipulator by kinematic reconfiguration. IEEE Robotics Automation Lett. 5, 5842–5849. doi:10.1109/LRA.2020.3010218

Yoshikawa, T. (1985). Manipulability of robotic mechanisms. Int. J. Robotics Res. 4, 3–9. doi:10.1177/027836498500400201

Keywords: underwater manipulation, kinematic redundancy, bi-level optimisation, redundancy parameterisation, wrench maximisation, trajectory optimisation

Citation: Marais WJ, Pizarro O and Williams SB (2025) Maximising the wrench capability of mobile manipulators with experiments on a UVMS. Front. Robot. AI 11:1442813. doi: 10.3389/frobt.2024.1442813

Received: 03 June 2024; Accepted: 16 December 2024;

Published: 30 January 2025.

Edited by:

Holger Voos, University of Luxembourg, LuxembourgReviewed by:

Fausto Ferreira, University of Zagreb, CroatiaAlessandro Ridolfi, University of Florence, Italy

Copyright © 2025 Marais, Pizarro and Williams. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wilhelm J. Marais, d21hcjU2MjdAdW5pLnN5ZG5leS5lZHUuYXU=, Oscar Pizarro, b3NjYXIucGl6YXJyb0BudG51Lm5v

Wilhelm J. Marais

Wilhelm J. Marais Oscar Pizarro

Oscar Pizarro Stefan B. Williams

Stefan B. Williams