- Department of Food Science and Technology, National Center for Electron Beam Research, Texas A&M University, College Station, TX, United States

Introduction: This study evaluated the effects of specific electron beam (eBeam) doses between 1 kGy and 4 kGy on the quality attributes of fresh-cut romaine lettuce that focused on color, texture, moisture retention, and odor during a 14-day storage period at 7°C.

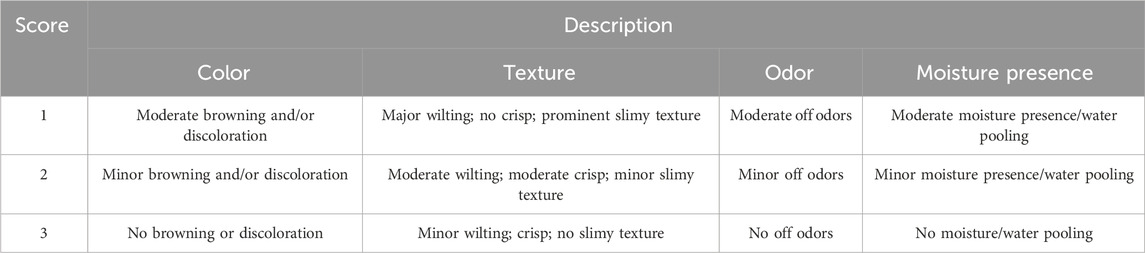

Materials and methods: Selected quality attributes were analyzed using instrumental color readings and a subjective appearance scoring rubric provided by a major U.S. supermarket chain to replicate their real-world evaluation process.

Results: Electron beam dose-mapping treatments confirmed uniform dose delivery, ensuring reliability in experimental outcomes. Colorimetric analyses showed that lower doses (1 kGy–2 kGy) preserved lightness (L*), yellowness (b*), and minimized green color loss (a*) while higher doses (3 kGy–4 kGy) resulted in significant darkening, yellowing, and degreening over time. Subjective evaluations revealed that 1 kGy and 2 kGy treatments maintained color stability, texture, and moisture, with minimal off odor development, outperforming both untreated and higher-dose samples. In contrast, lettuce samples exposed to higher doses (3 kGy and 4 kGy) exhibited pronounced browning, wilting, moisture losses, and off-odors by day 14, indicative of dose-related tissue damage and subsequent spoilage mechanisms.

Conclusions: These findings demonstrate the critical importance of dose optimization in preserving the quality of fresh-cut produce, with low-dose treatments effectively extending shelf life. The upper dose of 2 kGy can result in significant improvements in the microbiological safety of lettuce without compromising lettuce quality.

1 Introduction

Fresh produce are valuable commodities due to their essential role in human nutrition, contributing vitamins, minerals, and dietary fiber critical for health and wellbeing (Slavin and Lloyd, 2012). Globally, the fresh produce market continues to grow, with fruits and vegetables accounting for a significant portion of food purchases. In the United States alone, the fresh produce market was valued at roughly $63 billion in 2022 and is expected to reach $100 billion in 2031 at a compound annual growth rate (CAGR) of 5.2% (Skyquest, 2024). However, spoilage and microbiological safety remains a pressing issue, as high numbers of fresh produce is wasted along the global supply chain due to microbial spoilage, physical damage, and improper storage (Rezaei and Liu, 2017). Addressing this problem is vital not only to reduce economic losses for producers and retailers but also to combat food insecurity and the environmental impacts associated with food waste. Developing effective postharvest treatments offers a sustainable solution to prolong shelf life and maintain the quality of these highly perishable and valuable commodities.

In the initial phase involved in consumer purchasing habits, overall appearance is the main factor that influences choice (Lund and Snowdon, 2000). Of all the appearance attributes, color is a critical determinant of consumer acceptance and purchasing behavior for fresh produce, including cut and bagged lettuce. Research has demonstrated that vibrant, uniform coloration serves as a visual cue for food freshness and quality, heavily influencing consumer perceptions at the point of sale (Spence and Piqueras-Fiszman, 2016; Hurling and Shepard, 2003; Imram, 1999). In fact, fluctuations in expected color, such as browning or yellowing, are strongly associated with spoilage and reduced shelf appeal, often leading to product rejection. This preference for visually appealing products is rooted in the heuristic decision-making process, where consumers rely on appearance as a primary indicator of eating quality (Cohen and Babey, 2012).

Beyond color, other appearance attributes such as visual texture, the presence of water that is lost by produce in or on the product package or surface, and overall structural integrity are also critical to consumer perception (Péneau et al., 2006; Cantwell and Suslow, 2002). Crispness, which can be visually assessed by firmness and structural uniformity, is a key indicator of freshness in leafy greens and other vegetables (Fillion and Kilcast, 2002; Szczesniak, 1988; Szczesniak and Kahn, 1971). Softening or wilting often signals senescence or improper storage, leading consumers to perceive the product as lower quality (Mayta et al., 2019; Karakurt and Huber, 2003; Piagentini et al., 2002; Agar et al., 1999). Similarly, the presence of water that is lost from fresh produce plays a role in accelerating senescence and increasing susceptibility to chilling injury and membrane disintegration, which can lead to visual quality loss by initiating wilting and browning (Alegbeleye et al., 2022; Kays and Paull, 2004; Ben-Yehoshua and Rodov, 2002; Ben-Yehoshua, 1983). This water loss is often caused by inadequate pre- and post-harvest conditions, which must be optimized (Tyagi et al., 2017; Lobos et al., 2016; Laribi et al., 2013; Peña et al., 2013; Elshiekh and Abu-Goukh, 2008). Other indicators, such as slime formation, discoloration of cut edges, or unpleasant odors, also deter consumers and are viewed as signs of advanced deterioration (Barrett et al., 2010; Hodges and Toivonen, 2008). Together, these cues play a crucial role in consumer decision-making and emphasize the importance of postharvest treatments such as electron beam (eBeam) processing in maintaining quality, preventing spoilage, and extending shelf life to minimize waste in retail settings.

Electron beam (eBeam) processing is a promising technology for the postharvest treatment of fresh produce due to its ability to inactivate microbial species responsible for both safety and quality deterioration, while also preserving key quality attributes. The primary mechanism of action involves the generation of high-energy electrons that disrupt the bonds in microbial DNA, effectively inactivating pathogens without the need of chemical additives or heat treatment (Pillai and Shayanfar, 2015). This nonthermal approach is particularly advantageous for fresh produce like lettuce, as it minimizes the risk of heat-related damage for delicate tissues. Current research highlights that eBeam treatment can significantly reduce bacterial and fungal populations, thereby extending shelf life and reducing spoilage rates in a variety of fresh produce items (Omac et al., 2021; Smith et al., 2020; Madureira et al., 2019; Smith et al., 2017; Shayanfar et al., 2017; Morata et al., 2015; Palekar et al., 2015; Kong et al., 2014; Trinetta et al., 2011). Despite these benefits, high eBeam doses, particularly those exceeding 3 kGy–4 kGy, may lead to undesirable changes in texture, such as increased softness or wilting, and can cause slight discoloration and weight loss (Gomes et al., 2008; Han et al., 2004). Additionally, the efficacy of this treatment is influenced by factors such as produce geometry, water content, and packaging material, which can affect dose uniformity (Mehta and O’Hara, 2013). However, when applied at optimal doses, eBeam processing is highly effective in maintaining the visual and structural integrity of fresh produce. The growing body of evidence suggests that eBeam technology offers a sustainable, chemical-free alternative to conventional postharvest treatments, making it an attractive solution for the fresh produce industry to meet consumer demands for safe, high-quality products with extended shelf life. In 2008, the United States Food and Drug Administration approved the use of eBeam and other ionizing technologies, such as gamma and X-ray technologies, for iceberg lettuce using doses up to 4 kGy.

This dependance on specific eBeam doses on quality highlight the need for precise dose optimization to balance microbial inactivation efficacy with the preservation of quality attributes when applying eBeam technology to fresh produce. Given the sensitivity of lettuce to postharvest treatments, determining an optimal dose range–one that effectively achieves safety while enhancing long-term quality–is critical for maximizing the commercial viability of the technology. Additionally, understanding the interactions between dose, product geometry, and packaging can further refine its application and ensure consistent results. By addressing these gaps, this study provides valuable insights to the fresh produce industry to help them make informed decisions about the eBeam doses that would meet their benchmarks for product quality, microbiological safety and product shelf life.

2 Materials and methods

2.1 Experimental design development

The experimental design employed during this study was based on guidelines provided by the quality team of a major U.S. supermarket chain. All quality metrics, analysis procedures, sampling timepoints, sample sizes, and number of independent trials were determined according to their specifications to replicate their real-world evaluation process. The authors acknowledge that these protocols may differ from standard academic research methodologies.

2.2 Sample preparation

Bagged, cut romaine lettuce samples were purchased at a local supermarket in College Station, TX and transported to the National Center for Electron Beam Research (NCEBR) at the Texas A&M University, College Station campus for overnight storage under refrigerated conditions (7°C) prior to eBeam treatment.

2.3 eBeam treatment

2.3.1 Dose mapping

Dose-mapping is a critical step in the use of using ionizing technologies in the food industry. eBeam technology, unlike gamma and X-ray technologies, has certain limitations in dose penetration depending on the energy of the eBeam treatment equipment utilized. In these studies, a 10 MeV commercial scale linear accelerator was used, which is typically employed in commercial applications. Prior to eBeam treatment, the bagged produce was first dose-mapped to determine the dose distribution, the minimum (Dmin) and maximum (Dmax) absorbed doses, and the Dose Uniformity Ratio (DUR) within the system. Three replicate samples were used for dose-mapping to validate the processing protocol. The absorbed eBeam doses within the bags were measured using alanine dosimeters, placed on the top interior and exterior of the package as well as the bottom interior of the package. For delivering doses for the experimental samples, opening the bags to place the dosimeters was avoided. Therefore, the dosimeters were placed only on the exterior top and bottom of the bagged lettuce samples. The samples were placed in a single layer on trays that were placed on the conveyor system. The samples were then treated to specific target doses (1 kGy, 2 kGy, 3 kGy and 4 kGy) by adjusting the conveyor speed. All attempts were made to achieve measured doses as close as to the target doses as possible. The actual measured doses were determined.

During the experimental treatment, the lettuce samples were subjected to four target eBeam dose levels (1, 2, 3, and 4 kGy) using a 10 MeV, 15 kW linear accelerator at the NCEBR at the Texas A&M University, College Station campus. Un-treated (0 kGy) samples served as the experimental control samples.

2.4 Sample storage

The eBeam treated samples, along with the untreated control samples, were stored in a walk-in cooler at 7°C for up to 14 days. Experimental samples were taken periodically during storage (days 0, 7, and 14) for analysis. Sampling day 7 represented the “best by” date indicated on the product package, and day 14 represented 1-week post-“best by” date to examine the degree of shelf-life extension. Only one independent experimental trial was performed.

2.5 Instrumental color analysis

At each sampling timepoint, three replicate samples were utilized for color analysis and overall appearance. Color was measured using a Minolta Colorimeter CR-410 Chroma Meter (Konica Minolta Sensing Americas, Inc., NJ, United States), with three readings taken from each sample. To account for the uneven surface of cut romaine lettuce and the resulting variability in color measurements, readings were taken exclusively from the leaf region to minimize inconsistencies. A white calibration plate was used to prepare the instrument prior to measurement. The color parameters obtained include L* (lightness), a* (red/green), and b* (yellow/blue), and were used to calculate the total color difference (ΔE) using the following formula:

where ΔL*, Δa*, and Δb* represent the differences between the non-eBeam treated control on each storage timepoint (ΔEdose) or the day 0 samples for each dose level (ΔEtime) versus the other samples. Changes in color during storage were evaluated using hue angle (h°), that was calculated using the formula:

since the b ∗ and a* values are expected to be >0 and <0, respectively, for green vegetables. Three samples were analyzed for each dose and storage timepoint.

2.6 Subjective appearance

Overall appearance was scored following the rubric provided by the quality team of a major U.S. supermarket chain (Table 1). Digital images were obtained for each sample throughout the duration of storage. The use of a commercially relevant quality metric modeled the decision-making process at the commercial scale, where a buyer evaluates and either accepts or rejects a received batch of bagged lettuce. To replicate the supermarket’s standard quality evaluation process, three untrained assessors conducted these observations, as recommended by the quality team. Samples were deemed unacceptable when overall appearance score fell below 2.0.

2.7 Statistical analysis

GraphPad Prism 10.3.1 (GraphPad Software Inc., New York, United States) was used to conduct a two-way analysis of variance (ANOVA) for a five (eBeam dose) by three (storage time) factorial arrangement of a completely randomized design followed by Tukey’s post hoc multiple comparisons test between groups for the analyses of all main effects and their interaction. Results are reported as LSMeans (least squares means) of the interaction effect. Different letters indicate significant (P < 0.05) differences between groups.

3 Results

3.1 Dose-mapping

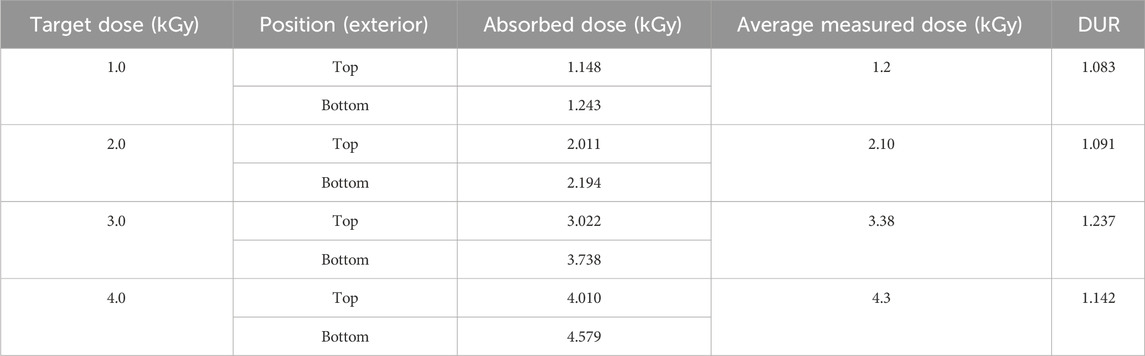

The results from the dose-mapping studies are shown in Tables 2, 3. The dose uniformity ratio in the commercial bagged lettuce samples was 1.34 (Table 2). The actual measured doses are shown in Table 3. The average of absorbed dose measured in the top and bottom alanine dosimeters is indicated as the measured dose.

3.1.1 Colorimeter measurements

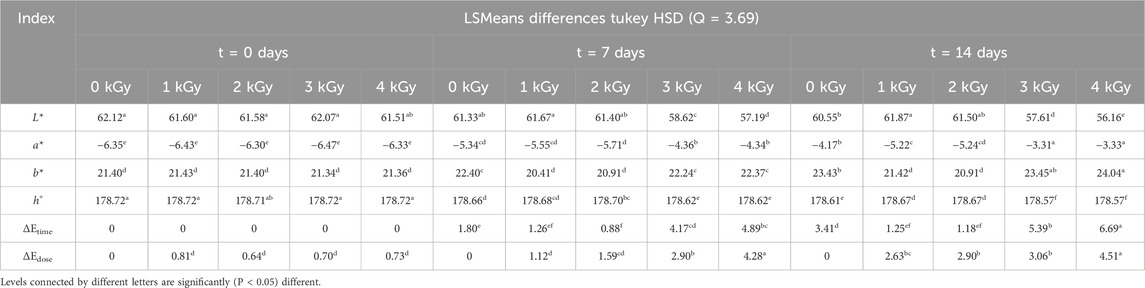

The color analysis for the bagged lettuce samples (L*, a*, b*, h°, and ΔE values) followed by a two-way ANOVA showed that there was a statistically significant difference in mean color index value between at least two groups for all values, where dose, storage time, and their interaction were all statistically significant effects (Supplementary Table S1). Tukey’s HSD Test for multiple comparisons confirmed these effects (Table 4).

Table 4. Color index (L*, a*, b*, and ΔE) values for bagged lettuce following eBeam treatment throughout storage.

Directly following eBeam treatment, no significant differences in L*, a*, b*, or h° values were observed among the treatment groups. Over time, L* value declined in untreated samples and those exposed to higher doses (3 kGy and 4 kGy), with changes becoming noticeable on day 7 for the two treated groups and intensifying by day 14 in all three. In contrast, samples treated with lower doses (1–2 kGy) maintained stable L* values throughout the storage period. On day 7, untreated and lower-dose samples exhibited comparable L* values, whereas higher-dose samples had significantly lower values. By day 14, samples treated with 1 kGy displayed the highest L* value, followed by 2 kGy and untreated samples, and the higher doses exhibited the lowest values. A similar trend was observed in b* values, with untreated and higher-dose samples showing increasing values during storage and the 1 kGy and 2 kGy samples remaining stable. On day 7, lower-dose samples exhibited the lowest b* values, whereas untreated and higher-dose samples showed more significant increases. By day 14, the greatest b* value was observed in the 4 kGy group, followed by 3 kGy, untreated, and finally the 1 kGy and 2 kGy samples. Regarding a* values, all samples exhibited decreasing values by day 7. This reduction persisted in untreated and higher-dose samples through day 14, but not in the lower-dose treatments. On day 7, untreated and lower-dose samples retained comparable a* values, while higher-dose samples had significantly higher values. By the end of the storage period, the 1 kGy and 2 kGy samples preserved their a* values better than the untreated or higher-dose groups. While all groups experienced decreased h° values over time, the 1 and 2 kGy samples did not experience these changes until day 7 and day 14 of storage, respectively. On day 7 and day 14, the lower-dose samples had higher h° values than the untreated samples and the upper-dose samples had the lowest values.

The overall changes in color in the samples, both as a function of time (ΔEtime) and dose (ΔEdose) aligned with the instrumental color values. Changes in untreated and higher-dose samples were more pronounced over time compared to their initial state, while lower-dose samples exhibited greater color stability. On day 7, untreated and lower-dose samples demonstrated less overall color change than the higher-dose groups. By day 14, untreated samples and those treated with higher doses showed more significant color alterations, with dose-dependent effects evident across the treated samples. While lower-dose samples did not exhibit noticeable changes until day 14, higher-dose groups began showing color shifts as early as day 7. Notably, changes in the 3 kGy samples did not advance further by the end of storage. Among all groups, the 4 kGy samples experienced the most substantial color shifts by day 14, followed by 3 kGy, 2 kGy, and 1 kGy, confirming a dose-dependent trend in color changes.

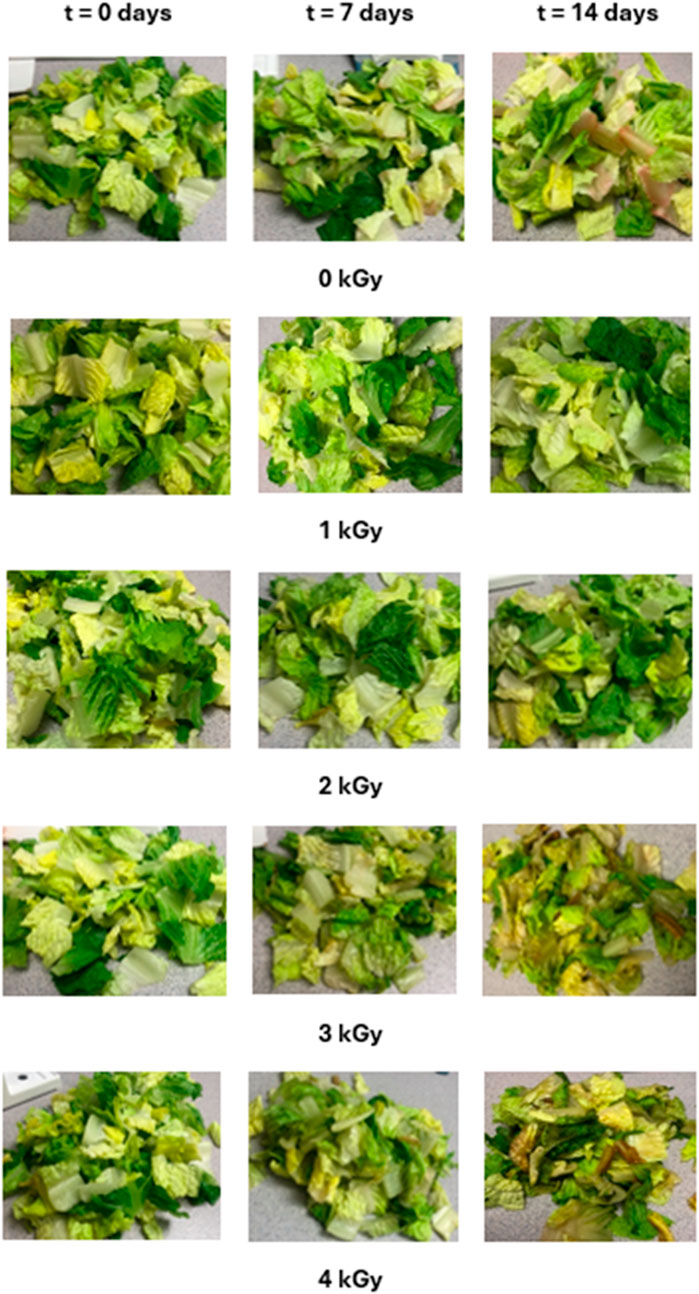

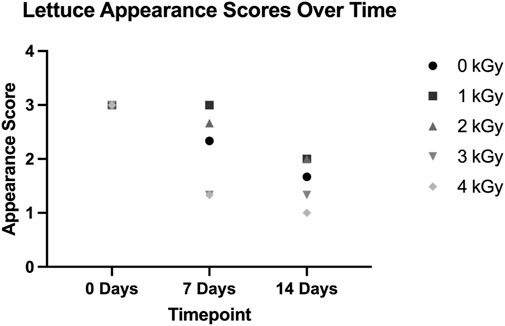

3.2 Subjective appearance evaluation

Changes in subjective visual appearance were observed as a result of both eBeam dose and storage time (Figures 1, 2; Supplementary Table S2). The two-way ANOVA showed that there was a statistically significant difference in mean appearance score between at least two groups, with dose, storage time, and their interaction being statistically significant effects (Supplementary Table S3).

Figure 2. Overall appearance scores for bagged lettuce following eBeam treatment during storage (n = 3).

While untreated samples experienced discoloration as early as day 7 of storage, all treatment groups showed varying degrees of discoloration by day 14, with higher doses exhibiting more pronounced changes. Untreated samples developed slight browning by day 7 and, by the end of storage, significant pink-rib discoloration–an effect not observed in any of the treated samples. The samples subjected to higher eBeam doses displayed browning similar to the untreated samples on day 7, which progressed significantly by day 14, accompanied by pronounced yellowing that was absent in the untreated group. Overall, samples treated with 1 kGy and 2 kGy demonstrated the greatest color stability, showing only mild yellowing by the end of storage. These lower-dose treatments also retained better texture and moisture, with minimal wilting and noticeable moisture retention throughout storage. While untreated samples appeared less crisp by day 14 and developed a slimy texture absent in the lower-dose groups, higher-doses (3 kGy and 4 kGy) resulted in severe wilting, water-soaked surfaces, and marked moisture loss, indicated by pooling water in the package. These high-dose samples also developed a slimy texture similar to the untreated samples by day 7 of storage. Additionally, off-odors emerged in higher-dose samples as early as day 7 and intensified by day 14. By the end of the storage period, untreated and lower-dose samples began to develop subtle off-odors, resembling those detected in the high-dose samples earlier in the storage timeline.

4 Discussion

4.1 eBeam dose delivery

During eBeam treatment, it is critically important to ensure that the doses are accurately delivered in a uniform manner, as the penetration ability of accelerated electrons is inherently dependent on the food matrix and packaging configuration (Mehta and O’Hara, 2013). Therefore, understanding the dose pattern within the food product is necessary to ensure that the dose absorbed by all areas of the product is comparable to the target dose, thereby limiting the risk of under- or over-dosing. This is achieved through robust dose-mapping treatments, which effectively characterize the absorbed dose variation and distribution within the sample bags (Lucas et al., 2023). Additionally, this data aids in establishing a process for delivering eBeam doses reproducibly for both experimental studies and commercial processing. As was expected the DUR of the packaged lettuce sample was not 1.0 but rather 1.34 (Table 2). The measured doses (based on the average of the top and bottom dosimeters) were as anticipated different from the target doses. These results suggest that it is extremely important a clear understanding of the dose distribution within commercial packages of packaged lettuce be understood during both experimental studies as well as during commercial processing. Overlooking the dose distribution during commercial processing could lead to fluctuations from the expected quality and sensory metrics.

4.2 Effect of eBeam treatment on lettuce color

In retail settings, color changes in bagged, fresh-cut produce are typically the first visual signs of quality loss perceived by the consumer. The findings of this study reveal dose- and time-dependent effects on color stability, highlighting the importance of dose optimization to maintain lettuce quality during storage. The treatment doses did not result in immediate changes in lettuce color in terms of lightness, green coloration, or yellowing. However, differences emerged and continued throughout the storage duration, namely, for the samples treated with doses of 3 kGy and above, suggesting potential dose-related effects.

The darkening of the lettuce samples, evidenced by decreases in L* value, over time is indicative of browning development (Rico et al., 2007). It has been established that tissue disruption following abiotic stressors like high eBeam doses can lead to the stimulation of oxidative processes directly responsible for the browning of leafy green vegetables (Barrett et al., 2010; Hodges and Toivonen, 2008). Phenolic compounds are of particular importance, as their oxidation via polyphenol oxidase (PPO) and peroxidase (POD) enzymes during prolonged storage leads to the formation of quinones capable of polymerizing into brown pigments that can be observed on the surface of lettuce (Degl’Innocenti et al., 2005). Additionally, wound-induced increases in phenylalanine ammonia lyase (PAL) activity has been demonstrated, leading to the production of phenolic compounds that can participate in this browning development process (Degl’Innocenti et al., 2005). The generation of reactive oxygen species (ROS), which stimulate oxidative stress in produce and can participate in the oxidation of food components like phenolic compounds, following treatment with ionizing doses is well known (Miller, 2005). Therefore, the darkening of the lettuce samples during storage is most likely attributed to tissue browning as a result of spoilage- and dose-related effects involving enzymatic browning and ROS activity.

Differences in a* values, with lower values representing greener color, were also observed between the higher dose treatments and untreated samples versus the lower dose treatments, with the latter appearing greener than the former throughout storage. This can be attributed to a higher rate of chlorophyll retention, as low-dose ionizing treatments have been reported to delay chlorophyll degradation by suppressing chlorophyll degrading enzyme activity and decreasing ethylene production in a variety of fresh produce (Nguyen et al., 2021; Hussain et al., 2019; Kumar et al., 2014; Hussain et al., 2013; Wani et al., 2008). Additionally, the lower-dose samples becoming less green on day 7, with the color remaining consistent until the end of storage, indicates a stabilization of the initial discoloration seen in these samples. Previous studies have found that eBeam-generated ROS can oxidize the chlorophyll phytyl chain and lead to its degradation during the early stages of storage (Rontani and Galeron, 2016; Rontani, Cuny and Grossi, 1996). Since the concentration of these generated ROS decline over time, the initial loss of green color and subsequent stabilization can be attributed to a lower rate of chlorophyll degradation due to the loss of these degrading species during the storage duration (Nguyen et al., 2021). While this is also the case regarding higher-dose treatments, the continued loss of green color in these samples is indicative of over-dosing, as extreme treatments have been shown to induce stress responses that result in enhanced ethylene production and a subsequent acceleration of chlorophyll loss (Saltveit, 1999). Similar effects were seen in the treatment groups when considering b* value, with higher values indicating yellower color, where the high dose treatments experienced significant yellowing by day 14. This is also historically attributed to chlorophyll degradation, and the yellowing seen in the upper-dose samples can assumed to be the result of ROS-induced chlorophyll losses (Barrett et al., 2010; Hodges and Toivonen, 2008). Notably, the 1 and 2 kGy samples demonstrated the most consistent b* values during storage, reflecting greater color stability and suggesting that yellowing intensified with dose over time, aligning with the sub-lethal nature of lower dose eBeam treatment. For green vegetables, increases in a* and b* values, along with a simultaneous decrease in h° value, are indicative of yellowing (Luo et al., 2020). Therefore, overall hue angle values support the observation of eBeam-induced yellowing when doses exceed the upper limit of 2 kGy. These results highlight the need for the careful selection of eBeam treatment doses when applied to fragile products like fresh produce.

Analysis of the overall color changes in the samples, both as a function of time as well as dose, further supported the trends observed in individual color parameters. The overall change in color as a function of time (ΔEtime) was lowest for the 1 kGy and 2 kGy samples, indicating their ability to maintain color stability during storage. Additionally, changes in these samples appeared only on day 14 of storage, indicating that low-dose eBeam treatment played a role in delaying color deterioration. Notably, changes in the 3 kGy samples did not advance further by the end of storage, indicating that while there were differences in individual color parameters, they were not significant enough to impart meaningful instrumental differences between day 7 and day 14. Conversely, the overall change in color as a function of dose (ΔEdose) highlighted an increasing rate of color change with increasing eBeam doses, particularly at or above 3 kGy, demonstrating the trade-offs associated with higher treatment intensities discussed previously.

4.3 Changes in subjective appearance of lettuce

During subjective sensory analysis, marked differences between the lower (1 kGy and 2 kGy) and upper-doses (3 kGy and 4 kGy) were observed, namely, in terms of browning and yellowing, wilting and moisture retention, and off-odor development. Doses up to 2 kGy maintained these quality attributes the longest during storage, with those at or above 3 kGy showing high rates of spoilage along with the untreated samples. These findings align with the instrumental color measurements, except when considering changes in the 3 kGy samples between storage day 7 and day 14. While the instrumental analysis did not reveal differences between the ΔEtime values for these two storage days, perceptible differences were observed. This highlights the importance of employing methods involving human subjects when exploring possible sensory effects, as they provide a more immediate and reliable measure of the complex mechanisms involved in human perception (Ross, 2009). Therefore, combining these methods with instrumental analysis is critical to develop valid measurements of food sensory attributes.

The increased intensity of browning and yellowing in the upper-dose samples can be attributed to dose-related tissue damage and subsequent spoilage mechanisms responsible for losses in visual appearance (Nguyen et al., 2021; Hussain et al., 2019; Rontani and Galeron, 2016; Kumar et al., 2014; Hussain et al., 2013; Barrett et al., 2010; Hodges and Toivonen, 2008; Wani et al., 2008; Degl’Innocenti et al., 2005; Rontani, Cuny and Grossi, 1996). Additionally, the observed water pooling in the untreated and upper-dose samples reinforces this mechanism, as tissue damage in green vegetables has been shown to induce respiration and subsequent moisture losses (Agüero et al., 2011; Ke and Saltveit, 1989). Off-odor development can also be seen as a result of these pathways and has been reported to be a limiting factor in the quality and marketability of fresh-cut lettuce (Cameron, 2003). In iceberg lettuce, several aroma compounds have been tied to off-odor generation as a result of tissue injury, including alcohols, aldehydes, terpenes, esters, and acids (Tudela et al., 2013). Further research efforts should be geared towards exploring the generation of off-odors as a result of the stimulation of volatile aromatic compounds in romaine lettuce, as research has shown genetic differences between cultivars (Kader, 2002). Overall, these findings further support the use of low-dose eBeam treatment, at an upper-dose limit of 2 kGy, for the extension of cut, bagged romaine lettuce shelf life.

5 Conclusions

This study highlights the significance of understanding the eBeam dose thresholds which could compromise lettuce quality. The results illustrate the eBeam dose- and time-dependent effects on key quality attributes such as color, texture, moisture retention, and odor. Low eBeam dose treatments (1 kGy and 2 kGy) appear as the most effective in maintaining color stability and retaining textural integrity during storage, with minimal development of off-odors. In contrast, higher doses (3 kGy and 4 kGy) led to accelerated quality deterioration. These findings, coupled with the already existing intellectual foundation established by previous research surrounding the use of eBeam processing for microbial reduction even at low doses, demonstrate the delicate balance required to achieve the dual objectives of food safety and quality preservation when applying this technology to fragile products like fresh-cut produce. An upper-dose limit of 2 kGy for the eBeam treatment of bagged, fresh-cut romaine lettuce is suggested.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

KH: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Writing–original draft. SP: Conceptualization, Funding acquisition, Investigation, Methodology, Project administration, Supervision, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frfst.2025.1556103/full#supplementary-material

References

Agar, I. T., Massantini, R., Hess-Pierce, B., and Kader, A. A. (1999). Postharvest CO2 and ethylene production and quality maintenance of fresh-cut kiwifruit slices. J. Food Sci. 64, 433–440. doi:10.1111/j.1365-2621.1999.tb15058.x

Agüero, M. V., Ponce, A. G., Moreira, M. R., and Roura, S. I. (2011). Lettuce quality loss under conditions that favor the wilting phenomenon. Postharvest Biol. Technol. 59 (2), 124–131. doi:10.1016/j.postharvbio.2010.08.018

Alegbeleye, O., Odeyemi, O. A., Strateva, M., and Stratev, D. (2022). Microbial spoilage of vegetables, fruits and cereals. Appl. Food Res. 2 (1), 100122. doi:10.1016/j.afres.2022.100122

Barrett, D. M., Beaulieu, J. C., and Shewfelt, R. (2010). Color, flavor, texture, and nutritional quality of fresh-cut fruits and vegetables: desirable levels, instrumental and sensory measurement, and the effects of processing. Crit. Rev. Food Sci. Nutr. 50, 369–389. doi:10.1080/10408391003626322

Ben-Yehoshua, S. (1983). Extending the life of fruit by individual seal-packaging in plastics fil; status and prospects. Plasticulture 58, 45–57.

Ben-Yehoshua, S., and Rodov, V. (2002). “Transpiration and water stress,” in Postharvest physiology and pathology of vegetables. Boca Raton, FL: CRC Press, 111–159.

Cameron, A. C. (2003). Modified-atmosphere packaging of perishable horticultural commodities can be risky business. Acta Hortic. 600, 305–310. doi:10.17660/ActaHortic.2003.600.42

Cantwell, M. A., and Suslow, T. V. (2002). “Postharvest handling systems: fresh-cut fruits and vegetables,” in Postharvest technology of horticultural crops. University of California, Agriculture and Nature Resources, 445–464.

Cohen, D. A., and Babey, S. H. (2012). Contextual influences on eating behaviours: heuristic processing and dietary choices. Obes. Rev. 13 (9), 766–779. doi:10.1111/j.1467-789X.2012.01001.x

Degl’Innocenti, E., Guidi, L., Pardossi, A., and Tongoni, F. (2005). Biochemical study of leaf browning in minimally processed leaves of lettuce (Lactuca sativa L. var. Acephala). J. Agric. Food Chem. 53, 9980–9984. doi:10.1021/jf050927o

Elshiekh, F., and Abu-Goukh, A. A. (2008). Effect of harvesting method, waxing and fungicide treatment on quality and storability of grapefruits. Uni. Khartoum J. Agric. Sci. 16 (1), 1–14.

Fillion, L., and Kilcast, D. (2002). Consumer perception of crispness and crunchiness in fruits and vegetables. Food Qual. Prefer. 13 (1), 23–29. doi:10.1016/S0950-3293(01)00053-2

Gomes, C. L., Silva, P. F., Chimbombi, E., Kim, J., Castell-Perez, E., and Moreira, R. G. (2008). Electron-beam irradiation of fresh broccoli heads (Brassica oleracea L. italica). LWT - Food Sci. Technol. 41, 1828–1833. doi:10.1016/j.lwt.2008.02.014

Han, J., Gomes-Feitosa, C. L., Castell-Perez, E., Moreira, R. G., and Silva, P. F. (2004). Quality of packaged romaine lettuce hearts exposed to low-dose electron beam irradiation. LWT – Food Sci. Technol. 37 (7), 705–715. doi:10.1016/j.lwt.2004.02.007

Hodges, D. M., and Toivonen, P. M. A. (2008). Quality of fresh-cut fruits and vegetables as affected by exposure to abiotic stress. Postharvest Biol. Technol. 48, 155–162. doi:10.1016/j.postharvbio.2007.10.016

Hurling, R., and Shepard, R. (2003). Eating with your eyes: effect of appearance on expectations of liking. Appetite 41 (2), 167–174. doi:10.1016/S0195-6663(03)00058-8

Hussain, P. R., Dar, M. A., and Wani, A. M. (2013). Impact of radiation processing on quality during storage and post-refrigeration decay on plum (Prunus domestica L.) cv. Santaroza. Radiat. Phys. Chem. 85, 234–242. doi:10.1016/j.radphyschem.2013.01.020

Hussain, P. R., Rather, S. A., Suradkar, P. P., and Ayob, O. (2019). Gamma irradiation treatment of quince fruit (Cydonia oblonga Mill): effect on post-harvest retention of storage quality and inhibition of fungal decay. J. Radiat. Res. Appl. Sci. 12 (1), 118–131. doi:10.1080/16878507.2019.1618588

Imram, N. (1999). The role of visual cues in consumer perception and acceptance of a food product. Nutr. Food Sci. 99 (5), 224–230. doi:10.1108/00346659910277650

Kader, A. A. (2002). “Postharvest technology of horticultural crops,” in Postharvest biology and technology: an overview. University of California, Division of Agricultural and Natural Resources Publication, 39–48.

Karakurt, Y., and Huber, D. J. (2003). Activities of several mebrane and cell-wall hydrolases, ethylene biosynthetic enzymes, and cell wall polyuronide degradation during low-temperature storage of intact and fresh-cut papaya (Carica papaya) fruit. Postharvest Biol. Technol. 28 (2), 219–229. doi:10.1016/S0925-5214(02)00177-1

Kays, S. J., and Paull, R. E. (2004). “Stress in harvested products,” in Postharvest Biology. Exon Press, 355–414.

Ke, D., and Saltveit, M. (1989). Wound-induced ethylene production, phenolic metabolism and susceptibility to russet spotting in iceberg lettuce. Physiol. Plant. 76 (30), 412–418. doi:10.1111/j.1399-3054.1989.tb06212.x

Kong, Q., Wu, A., Qi, W., Qi, R., Carter, J. M., Rasooly, R., et al. (2014). Effects of electron-beam irradiation on blueberries inoculated with Escherichia coli and their nutritional quality and shelf life. Postharvest Biol. Technol. 95, 28–35. doi:10.1016/j.postharvbio.2014.04.004

Kumar, M., Ahuja, S., Dahuja, A., Kumar, R., and Singh, B. (2014). Gamma radiation protects fruit quality in tomato by inhibiting the production of reactive oxygen species (ROS) and ethylene. J. Radioanalytical Nucl. Chem. 301 (3), 871–880. doi:10.1007/s10967-014-3234-7

Laribi, A. I., Palou, L., Intrigliolo, D. S., Nortes, P. A., Rojas-Argudo, C., Taberner, V., et al. (2013). Effect of sustained and regulated deficit irrigation on fruit quality of pomegranate cv. “Mollar de Elche” at harvest and during cold storage. Agric. Water Manag. 125, 61–70. doi:10.1016/j.agwat.2013.04.009

Lobos, T. E., Retamales, J. B., Ortega-Farías, S., Hanson, E. J., López-Olivari, R., and Mora, M. L. (2016). Pre-harvest regulated deficit irrigation management effects on post-harvest quality and condition of V. corymbosum fruits cv. Brigitta. Sci. Hortic. 207, 152–159. doi:10.1016/j.scienta.2016.05.022

Lucas, J. R., Cárcel, J. A., Velasco, R., Benedito, J., and Cabeza, M. C. (2023). Modelling of the electron range for use of E-beam treatment for boned dry-cured hams sanitation. Innovative Food Sci. Emerg. Technol. 84, 103296. doi:10.1016/j.ifset.2023.103296

Lund, B. M., and Snowdon, A. L. (2000). “Fresh and processed fruits,” in The Microbiological Safety and Quality of Food. Aspen Publishing 1, 738–758.

Luo, F., Fang, H., Wei, B., Cheng, S., Zhou, Q., Zhou, X., et al. (2020). Advance in yellowing mechanism and the regulation technology of post-harvested broccoli. Food Qual. Saf. 4, 107–113. doi:10.1093/fqsafe/fyaa020

Madureira, J., Severino, A., Cojocaru, M., Garofalide, S., Santos, P. M. P., Carolino, M. M., et al. (2019). E-beam treatment to guarantee the safety and quality of cherry tomatoes. Innovative Food Sci. and Emerg. Technol. 55, 57–65. doi:10.1016/j.ifset.2019.05.013

Mayta, M. L., Hajirezaei, M.-R., Carrillo, N., and Lodeyro, A. F. (2019). Leaf senescence: the chloroplast connection comes of age. Plants 8 (11), 495. doi:10.3390/plants8110495

Mehta, K., and O’Hara, K. (2013). “Dosimetry for food processing and research applications,” in Food irradiation: research and technology. Malden, MA: Blackwell Publishing. doi:10.1016/C2014-0-03761-6

Miller, R. B. (2005). Introduction to food irradiation. Electronic Irradiation of foods: an Introduction to the technology. Springer.

Morata, A., Bañuelos, M. A., Tesfaye, W., Loira, I., Palomero, F., Benito, S., et al. (2015). Electron beam irradiation of wine grapes: effect on microbial populations, phenol extraction and wine quality. Food Bioprocess Technol. 8 (9), 1845–1853. doi:10.1007/s11947-015-1540-x

Nguyen, T. T., Uthairatanakij, A., Srilaong, V., Laohakunjit, N., Kato, M., and Jitareerat, P. (2021). Impact of electron beam irradiation on the chlorophyll degradation and antioxidant capacity of mango fruit. Appl. Biol. Chem. 64 (19), 19. doi:10.1186/s13765-021-00592-8

Omac, B., Moreira, R. G., and Castell-Perez, E. M. (2021). Integrated electron beam irradiation treatment with hydrogen peroxide aqueous solution to inactivate Salmonella on grape tomatoes. J. Food Process Eng. 45 (8), e14063. doi:10.1111/jfpe.14063

Palekar, M. P., Taylor, T. M., Maxim, J. E., and Castillo, A. (2015). Reduction of Salmonella enterica serotype Poona and background microbiota on fresh-cut cantaloupe by electron beam irradiation. Int. J. Food Microbiol. 202, 66–72. doi:10.1016/j.ijfoodmicro.2015.02.001

Peña, M. E., Artés-Hernández, F., Aguayo, E., Martínes-Hernández, G. B., Galindo, A., Artés, F., et al. (2013). Effect of sustained deficit irrigation on physicochemical properties, bioactive compounds and postharvest life of pomegranate fruit (cv. ‘Mollar de Elche’). Poastharvest Biol. Technol. 86, 171–180. doi:10.1016/j.postharvbio.2013.06.034

Péneau, S., Hoehn, E., Roth, H.-R., Escher, F., and Nuessli, J. (2006). Importance and consumer perception of freshness of apples. Food Qual. Prefer. 17 (1-2), 9–19. doi:10.1016/j.foodqual.2005.05.002

Piagentini, A. M., Guemes, D. R., and Pirovani, M. E. (2002). Sensory characteristics of fresh-cut spinach preserved by combined factors methodology. J. Food Sci. 67, 1544–1549. doi:10.1111/j.1365-2621.2002.tb10319.x

Pillai, S. D., and Shayanfar, S. (2015). Electron beam pasteurization and complimentary food processing technologies. Sawston, Cambridge, United Kingdom: Woodhead Publishing.

Rezaei, M., and Liu, B. (2017). “Food loss and waste in the food supply chain,” in Nutfruit. Retrieved on November 20th, 2024, from Food loss and waste in the food supply chain.

Rico, D., Martín-Diana, A. B., Barat, J. M., and Barry-Ryan, C. (2007). Extending and measuring the quality of fresh-cut fruit and vegetables: a review. Trends Food Sci. and Technol. 18, 373–386. doi:10.1016/j.tifs.2007.03.011

Rontani, J. F., Cuny, P., and Grossi, V. (1996). Photodegradation of chlorophyll phytyl chain in senescent leaves of higher plants. Phytochemistry 42 (2), 347–351. doi:10.1016/0031-9422(95)00872-1

Rontani, J. F., and Galeron, M. (2016). Autoxidation of chlorophyll phytyl side chain in senescent phototrophic organisms: a potential source of isophytol in the environment. Org. Geochem. 97, 35–40. doi:10.1016/j.orggeochem.2016.03.008

Ross, C. F. (2009). Sensory science at the human-machine interface. Trends Food Sci. and Technol. 20 (2), 63–72. doi:10.1016/j.tifs.2008.11.004

Saltveit, M. E. (1999). Effect of ethylene on quality of fresh fruits and vegetables. Postharvest Biol. Technol. 15, 279–292. doi:10.1016/s0925-5214(98)00091-x

Shayanfar, S., Mena, K. D., and Pillai, S. D. (2017). Quantifying the reduction in potential infection risks from non-O157 Shiga toxin producing Escherichia coli in strawberries by low dose electron beam processing. Food control. 72, 324–327. doi:10.1016/j.foodcont.2016.04.057

Skyquest (2024). US fruit and vegetable market industry forecast 2024-2031. Retrieved on november 21st, 2024, from U.S. Fruit and vegetable market size. Trends and Forecast | 2031. Available at: https://www.skyquestt.com/report/us-fruit-and-vegetables-market.

Slavin, J. L., and Lloyd, B. (2012). Health benefits of fruits and vegetables. Adv. Nutr. 3 (4), 506–516. doi:10.3945/an.112.002154

Smith, B., Ortega, A., Shayanfar, S., and Pillai, S. D. (2017). Preserving quality of fresh cut watermelon cubes for vending distribution by low-dose electron beam processing. Food control. 72, 367–371. doi:10.1016/j.foodcont.2016.02.017

Smith, B., Shayanfar, S., Walzem, R., Alvarado, C. Z., and Pillai, S. D. (2020). Preserving fresh fruit quality by low-dose electron beam processing for vending distribution channels. Radiat. Phys. Chem. 168, 108540. doi:10.1016/j.radphyschem.2019.108540

Spence, C., and Piqueras-Fiszman, B. (2016). “Food color and its impact on taste/flavor perception,” in Multisensory flavor perception. Duxford, United Kingdom: Woodhead Publishing, 107–132. doi:10.1016/B978-0-08-100350-3.00018-3

Szczesniak, A. S. (1988). The meaning of textural characteristics – crispness. J. Texture Stud. 19 (1), 51–59. doi:10.1111/j.1745-4603.1988.tb00924.x

Szczesniak, A. S., and Kahn, E. L. (1971). Consumer awareness of and attitudes to food texture: I: adults. J. Texture Stud. 2 (3), 280–295. doi:10.1111/j.1745-4603.1971.tb01005.x

Trinetta, V., Vaidya, N., Linton, R., and Morgan, M. (2011). A comparative study on the effectiveness of chlorine dioxide gas, ozone gas and e-beam irradiation treatments for inactivation of pathogens inoculated onto tomato, cantaloupe and lettuce seeds. Int. J. Food Microbiol. 146 (2), 203–206. doi:10.1016/j.ijfoodmicro.2011.02.014

Tudela, J. A., Marín, A., Martínez-Sánchez, A., Luna, M. C., and Gil, M. I. (2013). Preharvest and postharvest factors related to off-odours of fresh-cut iceberg lettuce. Postharvest Biol. Technol. 86, 463–471. doi:10.1016/j.postharvbio.2013.07.028

Tyagi, S., Sahay, S., Imran, M., Rashmi, K., and Mahesh, S. S. (2017). Pre-harvest factors influencing the postharvest quality of fruits: a review. Curr. J. Appl. Sci. Technol. 23 (4), 1–12. doi:10.9734/CJAST/2017/32909

Keywords: quality, lettuce, electron beam, dose, color and, color

Citation: Howie KA and Pillai SD (2025) Quality attributes of fresh-cut, bagged romaine lettuce exposed to specific electron beam doses. Front. Food. Sci. Technol. 5:1556103. doi: 10.3389/frfst.2025.1556103

Received: 06 January 2025; Accepted: 14 February 2025;

Published: 05 March 2025.

Edited by:

Nikolaos D. Andritsos, University of Patras, GreeceReviewed by:

Spiros Paramithiotis, University of Ioannina, GreeceIoannis Karabagias, University of Patras, Greece

Copyright © 2025 Howie and Pillai. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Suresh D. Pillai, c3VyZXNoLnBpbGxhaUBhZy50YW11LmVkdQ==

Kendall A. Howie

Kendall A. Howie Suresh D. Pillai

Suresh D. Pillai