- 1School of Civil Engineering, Zhengzhou University, Zhengzhou, China

- 2Moscow Automobile and Road Construction State Technical University (MADI), Moscow, Russia

- 3Department of Civil Engineering, College of Engineering, Qassim University, Buraydah, Saudi Arabia

- 4School of Civil Engineering, National University of Science and Technology, Islamabad, Pakistan

- 5Department of Civil and Environmental Engineering, College of Engineering, Majmaah University, Majmaah, Saudi Arabia

The construction sector extensively utilizes natural resources and energy, contributing significantly to greenhouse gas emissions (GHG). Concrete production, in particular, contributes notably to environmental pollution. This study investigates the environmental and human health impact of concrete production, focusing on parameters such as Portland Cement, organic chemicals, diesel, medium voltage electricity, crushed gravel, natural gas heat, lubricating oil, sand and tap water. It also evaluates the impact of replacing cement with recycled concrete powder (RCP) using a life cycle assessment (LCA) approach through OpenLCA 2.1 software and the Ecoinvent database. Four concrete mixes were assessed with recycled concrete powder substitution ratios of 0, 5%, 10%, and 15%. Key indicators analyzed include climate change, human toxicity, ionising radiation, ozone depletion, photochemical oxidant formation, ecosystem quality, and resource depletion. Results show that cement is the most environmentally harmful ingredient, while RCP substitution reduces environmental impacts and resource depletion. Notably, the analysis indicates that higher RCP content leads to reduce environmental impacts. Specifically, the mix containing 15% RCP showed substantial improvements, lowering ozone depletion impacts from 100% to 90% and photochemical oxidant formation from 100% to 92%. These findings provide valuable insights for construction industry stakeholders and policymakers, supporting the advancement of more sustainable construction practices. Future research should focus on optimizing RCP content, long-term performance, and techno-economic feasibility to enhance sustainable construction practices.

1 Introduction

The construction industry is a major contributor to the generation of greenhouse gases (GHG), which substantially impacts the environment (Tangadagi et al., 2020; Shao et al., 2022). The construction industry is accountable for significant energy usage and negative environmental impacts, particularly in terms of raw material consumption (Zimmermann et al., 2005; Feiz et al., 2015). The activities involved in construction are primary contributors to the depletion of natural resources, responsible for 24% of the global extraction of natural resources, and they are also the major generators of waste (Zabalza Bribián et al., 2011). The construction industry continues to expand with time and these issues are compounded by an increase in atmospheric pollution and the acceleration of climate change. According to the Green Building Council of the United Kingdom, Carbon dioxide (CO2) levels have increased significantly (Colangelo et al., 2018). In addition, other environmental effects such as ecosystem degradation, landscape damage, damage to human health, and the contamination of water should also be considered (Blankendaal et al., 2014). Therefore, different researchers focusing on sustainability with the utilization of alternative materials (Fang et al., 2024; Liu et al., 2024).

Recently in China, the environmental impacts of ongoing construction projects have contributed significantly to challenges each year, potentially risking human health and ecosystems (Li et al., 2010). The European Union also indicates that the life cycle of a building including construction, operation and demolition accounts for up to 50% of total energy consumption, with nearly half the of total CO2 in the atmosphere (Dimoudi and Tompa, 2008). Despite this impact, the construction industry plays a key role in stimulating economic growth by creating job opportunities and income for a wide range of skilled and unskilled workers. However, a notable disparity exists between the ideal model of sustainable economic growth and the current construction practice, emphasizing the importance of aligning with sustainable development goals (Luo and Chen, 2020).

Sustainable development refers to the improvement of living standards, ensuring individuals reside in a healthy environment with better social, environmental and economic conditions (Ortiz et al., 2009). A critical challenge in sustainability for the coming decades is optimizing natural resource management to reduce the current environmental stress caused by human activities (Habert et al., 2010). According to the report (Borrion et al., 2012), it is estimated that 90% of the GHG emissions are caused by the extraction of raw materials for the preparation of concrete, the production of cement, mixing, placing and transportation of concrete and its constituent materials. Concrete is widely recognized as the most commonly used man-made material due to its low cost, mechanical properties and ease of molded into different shapes and sizes (Verma et al., 2020). In the assessment of the concrete production environmental impact, it is important to include the complete life cycle of the material, including factors that extend beyond individual projects. The entire production process is significant from a sustainability standpoint it encompasses the entire life cycle, from the extraction of raw materials to the final disposal of waste (Rebitzer et al., 2004). Methods for determining the main energy and related emissions in concrete products have been the subject of previous research (Zhang et al., 2020; Garces et al., 2022; Komkova and Habert, 2023; Basavaraj and Gettu, 2024). However, inconsistencies in the findings of these studies have arisen due to a lack of transparency, local inventory data unavailability, variation in scope, differing assumptions, and differences in system boundaries. As a result, it is difficult for decision-makers and design engineers to apply these techniques efficiently to evaluate the environmental effect (Caruso et al., 2023).

1.1 Research significance

Concrete is a widely used construction material globally, but its production significantly harms the environment and consumes natural resources. Several researchers focus on the utilization of different waste materials to improve concrete sustainability. However, these researchers mainly consider concrete strength properties and no detailed research is available on life cycle assessment. This leaves gaps in understanding the environmental impact of concrete ingredients, particularly in terms of harmful gas emissions and resource consumption. Furthermore, there is limited information on how waste materials can reduce environmental harm and preserve resources, making it challenging to identify eco-friendly options. No comprehensive research exists on various environmental impacts associated with concrete production such as climate change, human toxicity (carcinogenic and non-carcinogenic), ionising radiation, ozone depletion, photochemical oxidant formation, ecosystem quality (terrestrial acidification, freshwater ecotoxicity, marine ecotoxicity, terrestrial ecotoxicity, freshwater eutrophication, land use), and resource depletion (fossil, material resources, water) associated with the concrete production. Therefore, the fill the mentioned research gaps, this study evaluates the environmental impact of concrete using a comprehensive LCA approach, employing OpenLCA 2.1 software and the Ecoinvent database. This study’s findings highlight that cement is the most environmentally harmful concrete ingredient. However, the substitution of RCP reduces environmental impacts, demonstrating potential benefits in minimizing both environmental burdens and resource depletion in concrete production. This study’s results are valuable for the construction sector, including engineers, designers and the academic community, providing reliable LCA data for concrete. The findings offer insights into possible ecological improvements in current concrete products and allow for the monitoring of advancements in benchmark products over time.

2 Material and methodology

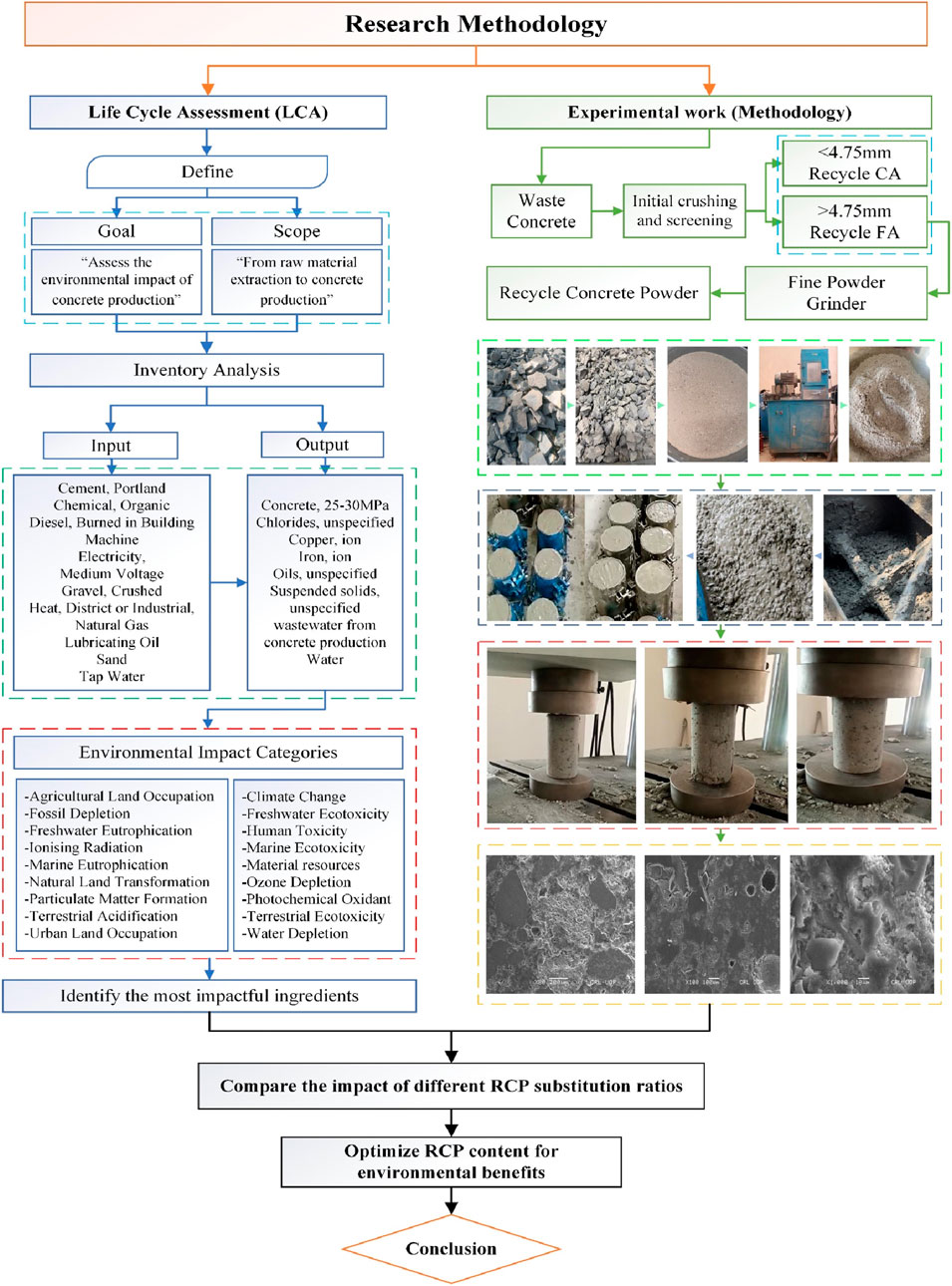

The study involves conducting a comprehensive life cycle assessment (LCA) to evaluate the environmental impacts and optimize the properties of concrete with partial replacement of cement by recycled concrete powder as shown in Figure 1.

2.1 Materials

The author assessed the environmental impacts of concrete with recycled concrete powder (RCP) at 0%–15% by weight of cement using a life cycle assessment (LCA). As part of this study has been published and can be consulted for detailed information in the article (Manan et al., 2024). The Ecoinvent database provided the binder data for the RCP process stage in the LCA model developed with OpenLCA software. A 53-grade Portland cement (OPC) was used as an input, with the OPC manufacturing process data sourced from Ecoinvent. Gravel and sand were used as filler and tap water was employed for mixing. Material quantification followed ASTM standards C39/39M (American Society for Testing and Materials, 2001), which specifics the procedure for determining the compressive strength of cylindrical concrete specimens. Concrete cylinders were cast with standard dimensions and cured under controlled conditions. Before testing, the specimens were measured to confirm compliance with dimensional requirements. Each specimen was placed centrally in a calibrated compression testing machine, ensuring proper alignment to avoid eccentric loading. A continuous and uniform load was applied at a specified rate until the specimen was then calculated using the formula, dividing the maximum load by the cross-sectional area of the specimen. Table 1 shows the mix proportions for the LCA model.

Table 1. Mix proportions of M30 grade concrete as per ASTM standard (American Society for Testing and Materials, 2001).

Figure 2 illustrates the compressive strength of concrete mixes with carrying percentage of RCP at 7, 14 and 28 days. As the RCP percentage increases from 0% to 15%, the compressive strength improves across all curing periods. The highest compressive strength is observed at 28 days for all mixes, with RCP-15 exhibited the maximum value. This trend indicates that partial replacement of cement with RCP positively influences the long-term strength development of the concrete.

Figure 2. Compressive strength (Manan et al., 2024).

2.2 Methodology

2.2.1 Life cycle assessment (LCA)

The Life Cycle Assessment (LCA) was conducted using an open-source software OpenLCA (version 2.1), employing the Ecoinvent database (version 1.0–3.10) (MORENO-RUIZ et al., 2023). The LCA framework involves four key stages: definition of the goal and scope, inventory analysis, impact evaluation, and interpretation as shown in Figure 3. Goal and scope, where the purpose, objective, system boundaries and assumptions for the assessment are established. Inventory analysis, involves quantifying inputs like materials and energy, and output such as emissions across the life cycle. Impact assessment, where potential environmental impacts are assessed using the inventory data, categorizing effects on climate, resources, and health. Interpretation, where results are analyzed to draw conclusions and identify sustainable improvement. The LCA computation structure is based on matrix algebra, a mathematical method that organizes numbers into a rectangular grid for systematic calculation as shown in Equation 1 (Heijungs and Sun, 2002). It can be represented as follows:

Figure 3. LCA framework (ISO, 2004).

A represents the internal flows of the technology matrix or economic system, B indicates the environmental interventions (intervention matrix), each process scaling vector is denoted by s, f describes the final demand of the product system, and g pertains to the environmental impact under consideration.

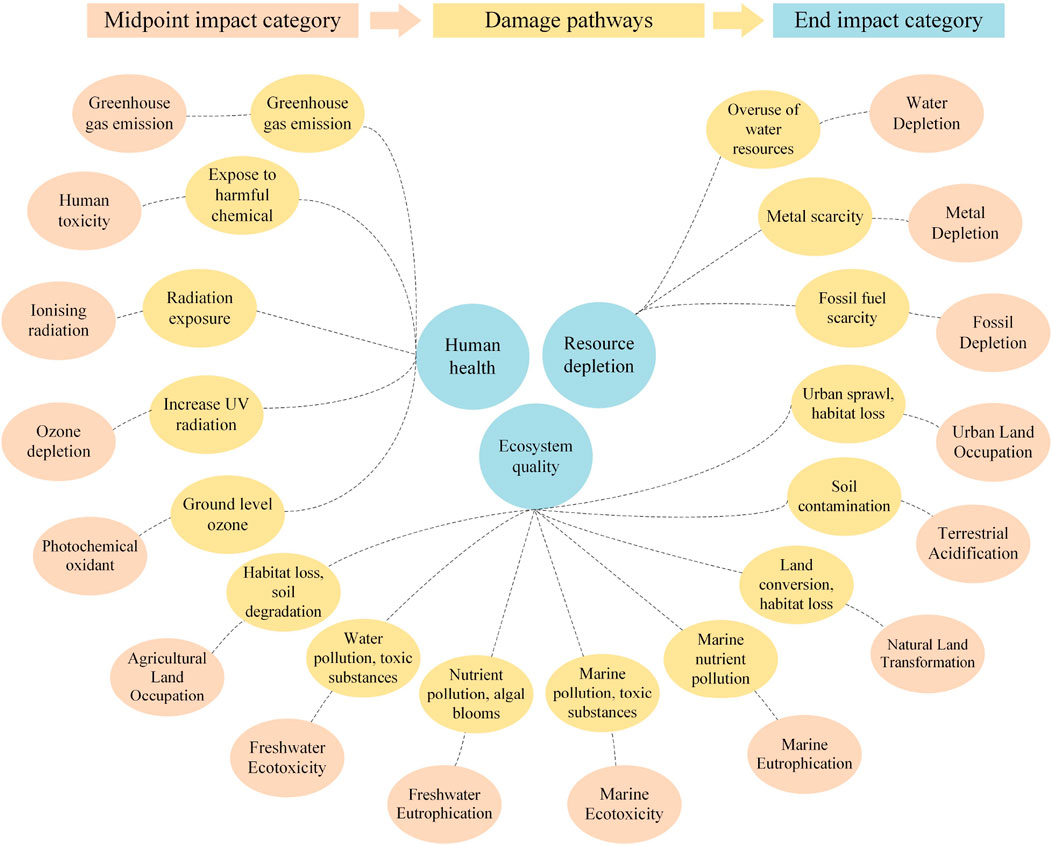

In the impact assessment phase, the ReCiPe 2016 (V1.03) midpoint (H) impact categories were employed (Huijbregts et al., 2017). ReCiPe2016 provides three perspectives: individualist, heiarchist, and egalitarian, each reflecting different cultural viewpoints and timeframes for impact assessment. The heiarachist perspective was chosen because it balances short-term and long-term emissions effect, which is crucial for understanding the broader implications of concrete production and the use of RCP. This perspective is particularly effective because it incorporates a wide array of environmental effects, allowing for a nuanced analysis that considers the interplay of different impact categories over varying timeframes. It considers 18 impact categories at the midpoint level. These impact categories are GWP, ALOP, FDP, FET, HTP, IRP, METP, MEP, material resources: metal/minerals, NLTP, ODP, PMFP, POFP, TAP, TETP, ULOP and WDP. Three damage categories human health, ecological quality, and resources are then created from the endpoint eighteen midpoint environmental effect categories. Figure 4 displays the midpoint, damage pathway, and endpoint environmental effect categories.

2.2.2 Life cycle inventory analysis (LCI)

The environmental data used in the calculations is sourced from thousands of products within the Ecoinvent database (Ecoinvent, 2022). It is important to recognize that the quality and validity of data are critical in any Life Cycle Assessment (LCA) (Pascual-González et al., 2016). In fact, different LCA data sources and tools may yield varying results for the same analysis. While recognizing the possibility of inconsistencies between databases, it is believed that these differences are unlikely to significantly impact the outcomes of this LCA analysis (Herrmann and Moltesen, 2015). The selection of Ecoinvent as the LCA comparison source is justified by its status as one of the most comprehensive international Life Cycle Inventory (LCI) databases available. Ecoinvent provides reliable, relevant, transparent and accessible information on thousands of LCI datasets (Frischknecht and Rebitzer, 2005). Covering 4087, processes related to human activities, the data is organized by region, economic sector and product type (Ecoinvent, 2007).

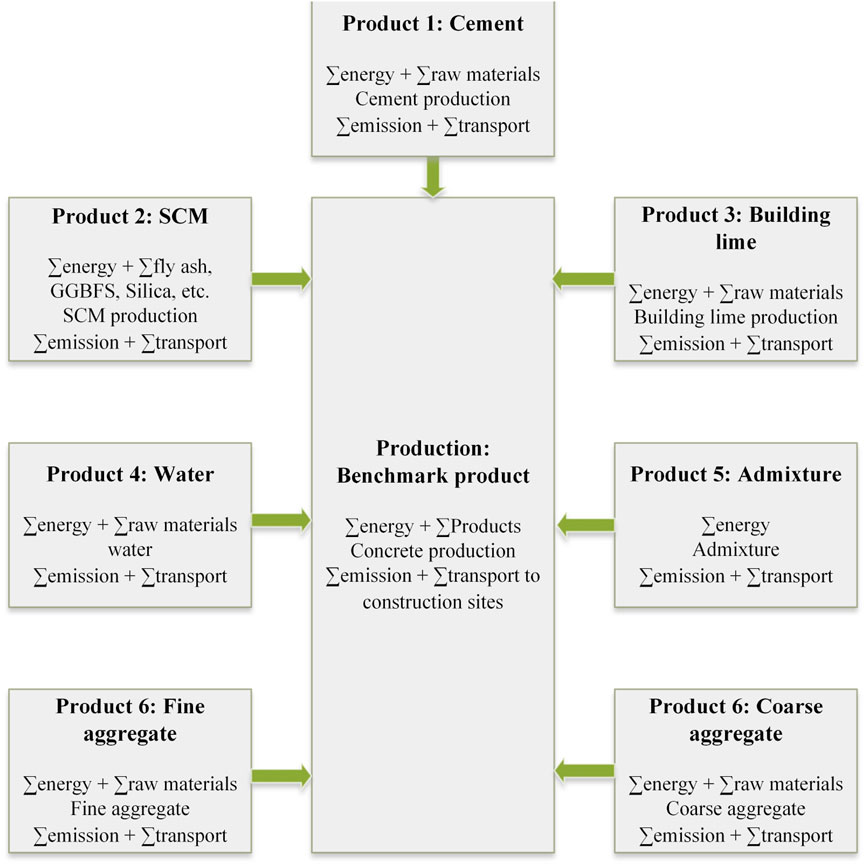

Life cycle inventory (LCI) analysis is an important aspect of the life cycle assessment (LCA) approach, which consists of four key phases (ISO, 2004) developed by the ISO. LCI is often regarded as the most data-intensive and time-consuming phase (Bicalho et al., 2017; Miah et al., 2018). This phase involves the thorough method of data collection, which is defined as “the process of gathering data for a specific purpose” (UNEP, 2011). Effective data collection is essential because it serves as the foundation of each LCA study and directly influences both the quality and the uncertainty of the results (Ciroth et al., 2021). Despite this, the methodological framework for LCI analysis, as described in ISO 14040/44, has been criticized in previous studies for lacking specific procedural guidance for systematic data collection (Zamagni and Buttol, 2008). Volumetric units are used for measuring, ordering, and supplying concrete. This is crucial for decision makers and design engineers to assess and compare the ecological consequences of construction materials. Inventory analysis systematically collects and computes data to measure the significant inputs and outputs of a benchmark product within a defined system boundary, as illustrated in Figure 5.

3 LCIA trends in concrete production

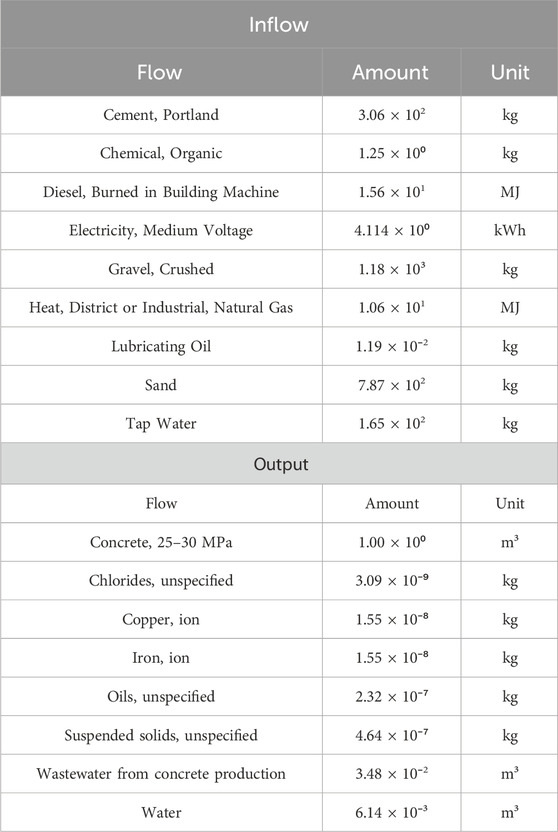

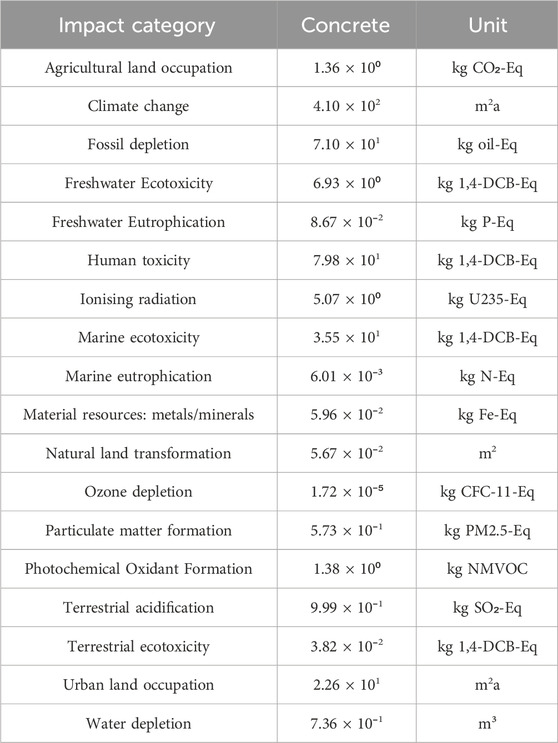

The Life Cycle Inventory (LCI) analysis for 1 m3 of concrete with a compressive strength of 25–30 MPa offers a detailed assessment of the material and energy inputs required and the environmental outputs generated. Table 2 shows the inventory captures the inflows and outflows during the production process, and Table 3 reflects the effects of producing concrete on the environment. These indicators include kilograms of CO2 equivalent (kg CO2-Eq) for climate change, which consolidates greenhouse gas emissions in terms of CO2 impact, and square m year (m2a), which measures the ecological effects of land use over time. Kilograms of 1,4-Dichlorobeneze equivalent (kg 1,4-DCB-Eq) quantify human and ecological toxicity, assessing the effects of harmful chemicals, while kilograms of CFC-11 equivalent (kg CFC-11-Eq) evaluate the potential for ozone layer depletion. Resource depletion is measured in kilograms of oil equivalent (kg oil-Eq) for fossil energy use, and kilograms of sulfur dioxide equivalent (kg SO2-Eq) address acidification potential from emissions that contribute to acid rain. Lastly, kilograms of particular matter 2.5 equivalent (kg PM2.5-Eq) assess air quality impacts due to fine particles harmful to respiratory health.

The inflow in concrete production includes a combination of raw materials like Portland cement, gravel, sand, and energy inputs such as diesel, electricity, and natural gas. These inputs are critical for producing concrete with the desired strength and properties. Outflows primarily consist of the final concrete products, with minor outputs of pollutants and wastewater, highlighting the necessity for effective waste and water management practices to minimize the environmental impact of the production process as shown in Table 2. Table 3, shows the production of 1 m3 concrete environmental impacts.

Climate change is the primary concern, with 320 kg of CO2-equivalents emitted, contributing to global warming. Fossil depletion is significant at 71 kg oil-eq, indicating reliance on non-renewable resources. Human toxicity and freshwater ecotoxicity are notable at 16.2 kg and 1.56 kg 1,4 DCB-equivalent, respectively, indicating harmful effects on human health and aquatic life. Marine and terrestrial ecotoxicity affect ocean and land ecosystems. The process occupies 1.4 m2a of agricultural land, reflects the impact on land used, and depletes water resources by 0.736 m3. Ozone depletion potential is 1.72E-05 kg CFC-11 eq, indicating a minor impact on the ozone layer. The production also leads to particulate matter formation and photochemical oxidant formation, affecting air quality. Ionising radiation (0.886 kg U235-eq) indicates exposure to harmful radioactive substances, and marine and freshwater eutrophication results in nutrient runoff and ecosystem imbalance.

4 LCI trends in concrete production

4.1 Climate change

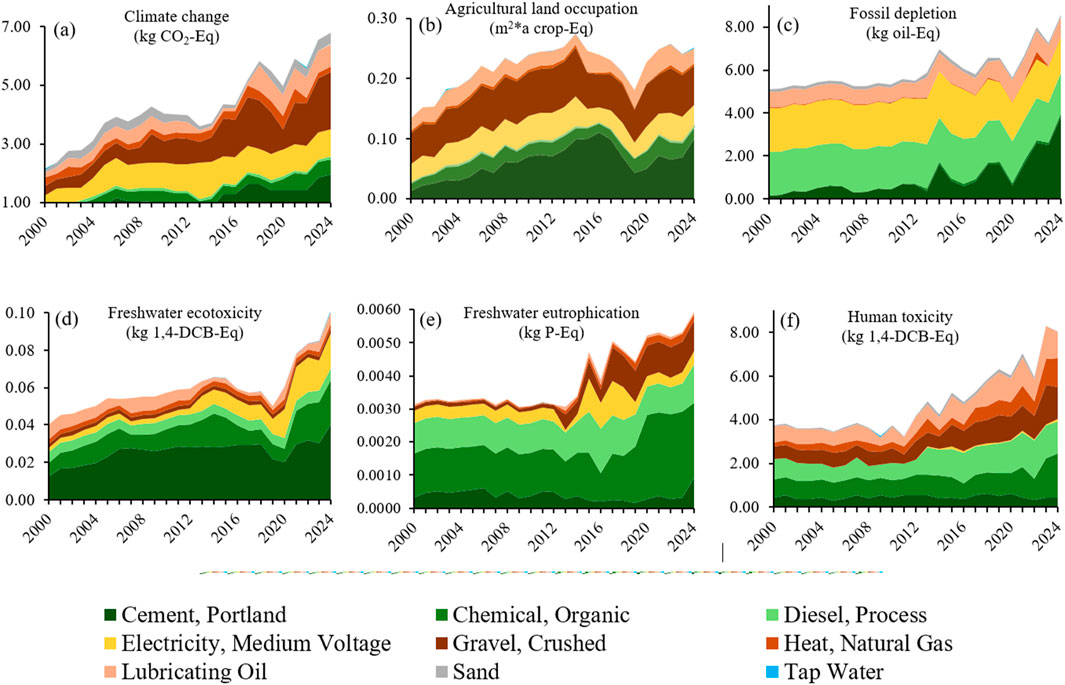

The midpoint characterization factors for climate change, represented by global warming potential (GWP) in kg CO2-equivalent, measure the cumulative increase in infrared forcing by greenhouse gases (GHGs) (Stocker et al., 2013; Joos et al., 2013; Zhang et al., 2019). Cement, Portland, shows a rise in GWP from 3.10 × 101 kg CO2-eq in 2000 to 1.95 kg CO2-eq in 2024 due to increased global demand and energy-intensive clinker production and transportation. Similarly, chemical and organic materials increased from 2.0 × 10−1 kg CO2-eq in 2000 to 5.22 × 10−1 kg CO2-eq, driven by industrial chemical production and energy use, as shown in Figures 6A, 7A. Diesel, process exhibits fluctuations but maintains a consistent contribution, while gravel, crushed and heat, and natural gas, indicate substantial emission from energy-intensive processes in aggregate extraction and concrete production.

Figure 6. Environmental impact of concrete ingredient production (A) Climate change, (B) Agriculture land occupation, (C) Fossil depletion, (D) Freshwater ecotoxicity, (E) Freshwater eutrophication, (F) Human toxicity.

Figure 7. Cumulative percentage contribution of concrete ingredient production to various environmental impact categories from 2000 to 2024. (A) climate change, (B) agricultural land occupation, (C) fossil depletion, (D) freshwater ecotoxicity, (E) freshwater eutrophication, and (F) human toxicity.

4.2 Agricultural land occupation

Midpoint characterization factors in m2 indicate the relative loss of species due to land use like forestry, urbanization, pastures, and various agricultural activities, measured in annual crop equivalents. This loss is based on field data comparing species richness across natural and anthropogenic land covers (Mollayosefi et al., 2019). For land conversion, passive recovery towards a semi-natural habitat is assumed, considering average recovery times (Curran et al., 2014). Figures 6D, 7D show that from 2000 to 2024, Portland cement had the highest Agricultural Land Occupation Potential (ALOP), peaking at 0.11 m2a crop-eq in 2016, followed by gravel, lubricating oil production and electricity generation.

4.3 Fossil depletion

Fossil Depletion Potential (FDP in kg oil-eq) is calculated by comparing the higher heating value of fossil resources to the energy content of crude oil (Althaus et al., 2010). Diesel, Process and Electricity exhibit the highest FDP values, reaching 2.04 and 2.01 kg oil-eq, respectively, due to high fossil fuel consumption in energy production and transportation, as shown in Figures 6C, 7C. Cement, Portland also significantly impacts fossil depletion, raising to a maximum of 3.85 kg oil-eq in 2024, attributed to the intensive energy requirements in cement manufacturing. Lubricating oil and heat, natural gas exhibits moderate contributions reflecting the fossil fuel dependency in their production processes.

4.4 Freshwater ecotoxicity

Freshwater ecotoxicity assesses the impact of chemical emissions on the freshwater ecosystem, measured in kg 1, 4-dichlorobenzene-equivalents (1,4DCB-eq) at the midpoint level. This metric evaluates how chemicals affect the concentration and fate in freshwater environments, using the global multimedia fate, exposure and effects model USES-LCA 2.0 (Van Zelm et al., 2009). From 2000 to 2024 as shown in Figures 6D, 7D, the impact of various materials on freshwater ecotoxicity potential. Cement, Portland consistently presents the highest contribution, reaching a peak of 0.04 kg 1,4-DCB-Eq in 2024, attributed to its intensive use of raw material and emissions in the manufacturing process. Electricity chemicals and organic also contribute significantly with maximum values of 0.0189 kg 1,4-DCB-Eq and 0.024 kg 1,4-DCB-Eq, respectively in 2024.

4.5 Freshwater eutrophication

The freshwater eutrophication potential (FEP), measured in kg P-equivalents, reflects the impact of phosphorus emissions on freshwater ecosystems (Helmes et al., 2012). Approximately 10% of these emission from agricultural soils reach surface waterways (Bouwman et al., 2009). From 2000 to 2024, FEP has significantly increased across various sectors, notable in chemical, organic, and diesel processes, due to heightened industrial activities and chemical use as shown in Figures 6E, 7E cement production has shown fluctuations, with a recent increase linked to diesel emissions, while electricity contribution to FEP has grown, especially after 2010, driven by rising energy demands. These trends highlight the need for stronger emission controls and sustainable practices to mitigate freshwater eutrophication.

4.6 Human toxicity

Human toxicity at the midpoint level was evaluated using characterization factors, with chemical emissions measured in kg 1,4-dichlorobenzene equivalents (1,4 DCB-eq). The toxicological effect factors for humans were separately calculated for both carcinogenic and non-carcinogenic impacts, representing the variation in lifetime disease incidence due to changes in substance intake (Rosenbaum et al., 2008; 2015). Cement, Portland shows a general increase from 4.55 × 10−1 kg 1,4-DCB-eq in 2000 to 4.35 × 10−1 kg 1,4-DCB-eq in 2024, with slight intermediate variations. This increase is attributed to emissions associated with cement manufacturing, including particulate matter and other pollutants. These emissions contribute to both carcinogenic and non-carcinogenic impacts, potentially leading to respiratory and other chronic diseases over time (Schuhmacher et al., 2004), as shown in Figures 6F, 7F. Chemical, organic significantly rises from 8.18 × 10−1 to 2.00 × 100 kg 1,4-DCB-eq, reflecting increasing chemical emissions. This increase reflects growing emission of hazardous chemicals in concrete production. These high levels of organic chemical emissions contribute substantially to carcinogenic effects, posing long-term risks to human health, particularly through exposure to volatile organic compounds (VOCs) which may affect respiratory, neurological, and immune systems (Xiu et al., 2020; Huang et al., 2022). The diesel, process escalates notably from 9.10 × 10−1 to 1.5 × 10-1 kg 1,4-DCB-eq, indicating a rise in diesel-related toxicity. Diesel combustion contributes significantly to human health impacts, particularly through emissions of nitrogen oxides and particular matter. These emissions are linked to respiratory conditions, cardiovascular diseases, and carcinogenic risks, emphasizing the impact of fossil fuel use in concrete production (Reşitoʇlu et al., 2015; Nakhjiri and Kakroodi, 2024). Electricity remains relatively stable but slightly increases overall. Gravel and heat, natural gas show consistent rises, with heat, natural gas reaching 1.03 × 10−1 kg 1,4-DCB-eq by 2024. Emission from natural gas combustion contribute to respiratory and cardiovascular health risks due to pollutants like nitrogen oxides and other combustion byproducts. Although cleaner than diesel, the sustained rise in natural gas use still poses health risks through chronic exposure to these emissions (Larki et al., 2023).

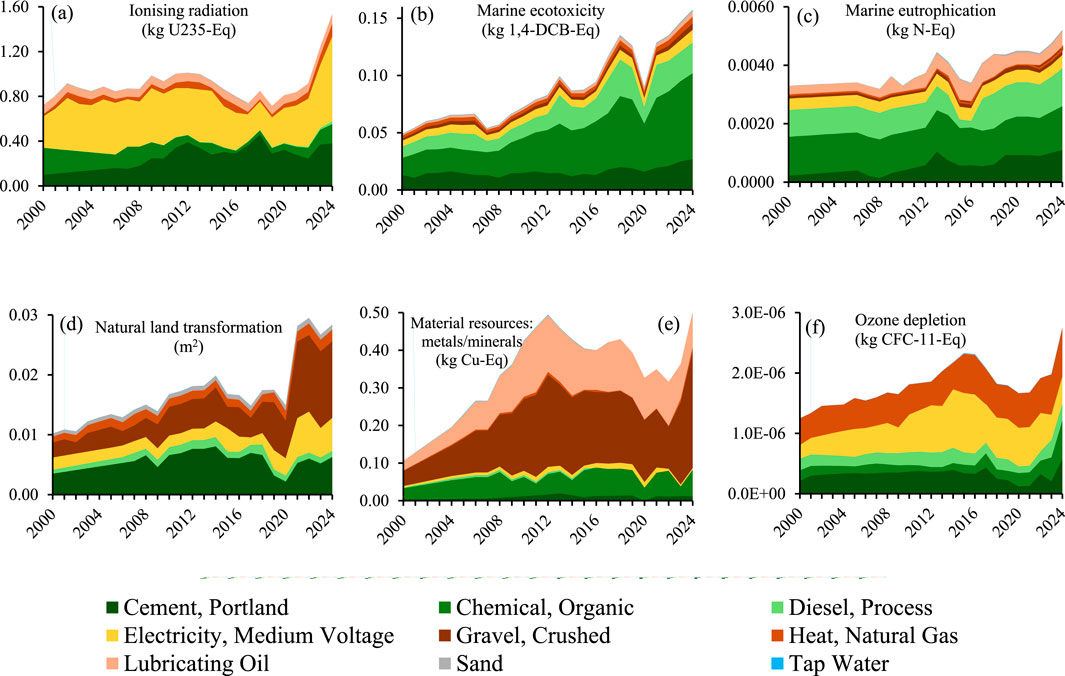

4.7 Ionising radiation

Radionuclide emissions are assessed at the midpoint level using ionizing radiation potential (IRP), measured in Cobalt-60 and U235 equivalents. From 2000 to 2024, Portland cement shows an increase from 1.00 × 10−1 to 3.80 × 10−1 kg U235-eq, driven by manufacturing advancements. Chemical, organic materials rise from 2.40 × 10−1 to 1.72 × 10−1 kg U235-eq, likely due to energy-intensive production methods involving radioactive materials (Figures 8A, 9A). Electricity jumps from 2.80E-01 to 7.58E-01 U235-eq, reflecting the growing reliance on nuclear power for electricity generation, leading to higher radioactive waste. The impact of this reliance on nuclear power includes potential environmental and health risks associated with the management of radioactive waste, as well as the long-term sustainability of energy production methods. The increase in U235-eq indicated a need for careful monitoring and assessment of nuclear power’s contribution to overall energy production and its associated ricks (Sadiq et al., 2022). For Gravel, crushed and heat, and natural gas the increase is more modest but significant, indicating more widespread use and extraction processes that might be indirectly influenced by nuclear energy production.

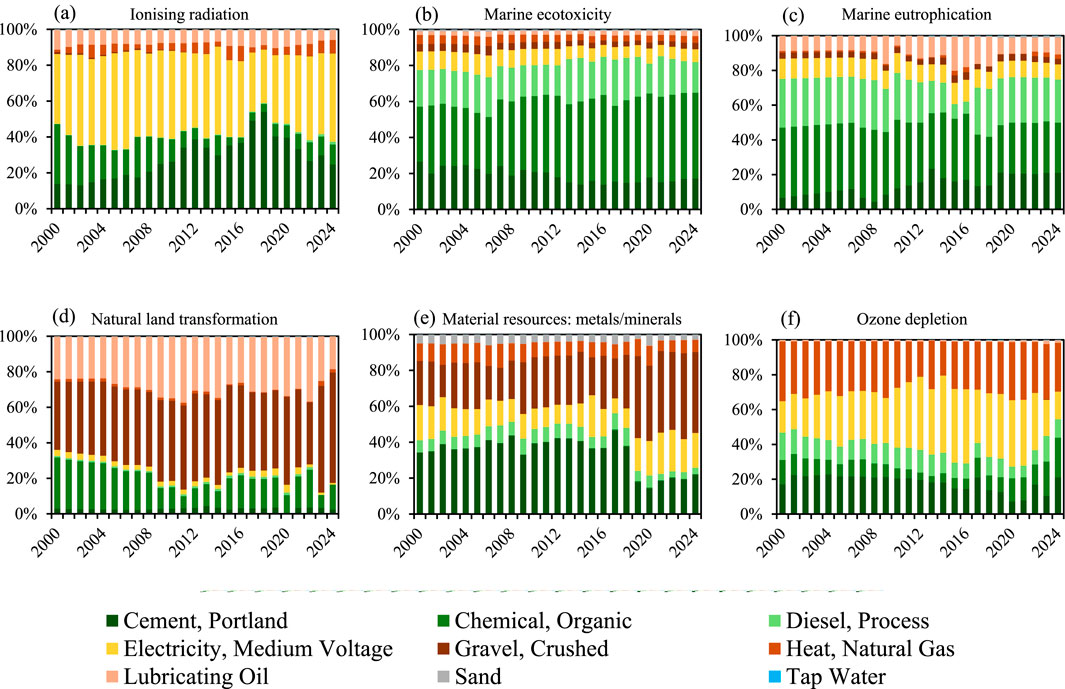

Figure 8. Environmental impact of concrete ingredient production (A) Ionising radiation, (B) Marine ecotoxicity, (C) Marine eutrophication, (D) Natural land transformation, (E) Material resources: metals/minerals, (F) Ozone depletion.

Figure 9. Cumulative percentage contribution of concrete ingredient production to various environmental impact categories from 2000 to 2024. (A) Ionising radiation, (B) Marine ecotoxicity, (C) Marine eutrophication, (D) Natural land transformation, (E) Material resources: metals/minerals, (F) Ozone depletion.

4.8 Marine ecotoxicity

Marine ecotoxicity assesses the potential negative effects of chemical emissions on marine ecosystems, measured in kg 1,4-dichlorobenzene-equivalents (1,4DCB-eq) at the midpoint level (van Zelm et al., 2013). Between 2000 and 2024, there was a notable increase in marine ecotoxicity related to concrete production materials like Portland cement, chemicals, and diesel, as shown in Figures 8B, 9B. For cement, Portland the value rises from 1.30E-02 kg 1,4DCB-eq in 2000 to 2.70E-02 kg 1,4DCB-eq in 2024, reflecting the industry’s reliance on raw materials that contribute to marine pollution. Organic chemicals see a dramatic increase from 1.50E-02 kg 1,4 DCB-eq to 7.50E-02 kg 1,4 DCB-eq in 2024, highlighting the growing use of hazardous substances in concrete additives and admixtures.

4.9 Marine eutrophication

Marine eutrophication potential (MEP) assesses nutrient enrichment in marine ecosystems, measured in kg nitrogen-equivalents (kg-N-Eq). It evaluates the impact of nutrient inputs like nitrogen and phosphorus on marine species, considering their role in algal blooms and oxygen depletion (van Zelm et al., 2013). Portland, cement increased from 2.20 × 10−4 kg N-eq in 2000 to 1.10 × 10−3 kg N-eq in 2024 as shown in Figures 8C, 9C. This rise can be attributed to higher nitrogen emissions linked to the production processes, including more intensive use of raw materials and energy sources that contribute to eutrophication. Chemical additives used in concrete maintain high MEP values around 1.30 × 10−3 to 1.50 × 10−3 kg N-eq, as they can cause runoff and leaching into aquatic systems. Diesel emissions increased from 9.24 × 10−4 kg-N-Eq in 2000 to 1.30 × 10−3 kg-N-Eq in 2024 due to diesel fuel use in concrete transport and mixing. Gravel and natural gas show minimal MEP increases, indicating improved production and usage efficiency.

4.10 Material resources: metals/minerals

Assessing material resources involves evaluating the depletion and consumption of metallic and mineral resources, measured in kilograms of copper-equivalents (kg Cu-Eq). Extracting primary mineral resources reduces global ore grade, necessitating more ore to extract each kilogram of the mineral. The stockpiling opportunity perspective (SOP) quantifies future additional ore production required due to current extraction (Vieira et al., 2017). Figures 8D, 9D, show the material resources utilization from 2000 to 2024 particularly impacting concrete production. Cement, Portland sees a gradual increase from 3.00 × 10−3 kg Cu-eq in 2000 to 1.19 × 10−2 Cu-eq in 2024, influenced by the rising demand for construction materials driven by urbanization and infrastructure projects. The chemical, and organic categories show fluctuations but remain relatively stable, reflecting consistent use in concrete additives. Electricity and medium voltage exhibit a steady rise, indicating increased energy consumption in concrete processes, including mining, manufacturing, and construction operations.

4.11 Natural land transformation

Natural land transformation (NLTP) involves quantifying the conversion of natural land cover into anthropogenic land uses, typically measured in square meters (m2) (Jun et al., 2020). Cement, Portland consumption has steadily increased from 3.50 × 10−3 m2 in 2000 to 6.21 × 10−3 m2 in 2024 as shown in Figures 8E, 9E. The rise in chemical, and organic materials from negligible levels to 9.29 × 10−5 m2 suggests increased land use for chemical production facilities supporting cement manufacturing processes. Diesel, process and electricity, medium voltage show fluctuations but generally trend upwards, indicating the reliance on transport and energy-intensive production processes that contribute to land use change through infrastructure and power generation expansions.

4.12 Ozone depletion

The potential for ozone depletion (ODP), measured in kilograms of CFC-11 equivalents, serves as an indicator at the midway level. ODPs represent the cumulative reduction of ozone content in the stratosphere over an endless period of time frame (World Organization, 2011). As shown in Figures 8F, 9F, cement production contributes substantially due to its energy-intensive processes and emissions ranging from 1.21 × 10−7 to 5.82 × 10−7 kg-CFC-11-eq. This sector not only releases CO2 but also emits pollutants that indirectly impact ozone depletion through environmental interactions. Electricity consumption, particularly from medium voltage sources, also plays a pivot role, emitting between 6.20 × 10−7 to 9.82 × 10−7 kg-CFC-11-eq annually. Additionally, Organic chemicals used in various stages of concrete production also contribute to ozone depletion, releasing between 7.29 × 10−8 to 6.32 × 10−7 kg CFC-11 eq annually. The heat, natural gas combustion for heat in concrete production emits CO2 and other pollutants, with emissions ranging from 3.73 × 10−7 to 7.68 × 10−7 kg CFC-11-eq. These emissions contribute to the greenhouse effect, indirectly influencing ozone depletion.

4.13 Terrestrial acidification

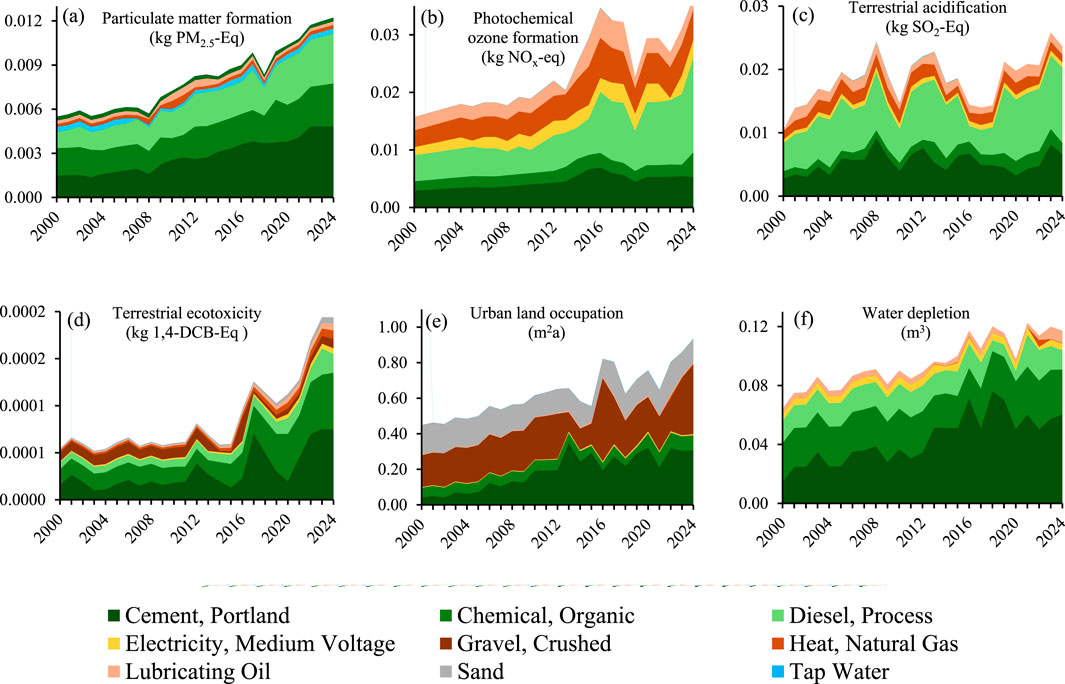

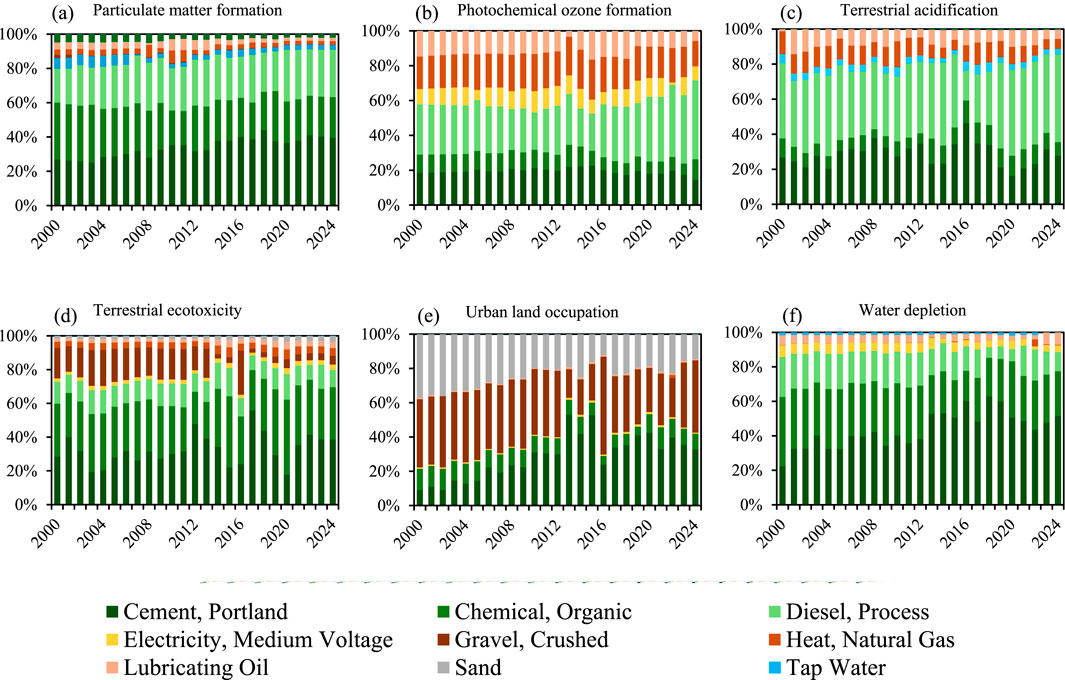

The study utilized characterization factors from (Roy et al., 2014) to assess the fate of pollutants like NOx, NH3, and SO2, expressed as acidification potentials (AP) in kg SO2-equivalents. Variations in acid deposition from altered air emissions were modeled using the GEOS-Chem model (Roy et al., 2012b), and the impact on soil acidity was analyzed with the PROFILE geochemical model (Roy et al., 2012a). Diesel is a major contributor to terrestrial acidification with its impact increasing from 4.46 × 10−3 kg SO2-eq in 2000 to 1.19 × 10−2 kg SO2-eq in 2024. Diesel fuels machinery such as trucks and construction equipment. Cement production also contributes significantly, peaking at 9.20 × 10−3 kg SO2-eq in 2008, due to SO2 and NOx emissions from calcination and fuel combustion as shown in Figures 10C, 11C. Lubricating oil used in machinery maintenance adds to acidification, with a contribution of 1.40 × 10−2 kg SO2-eq in 2023 due to hydrocarbons and sulfur compounds released during the use and disposal.

Figure 10. Environmental impact of concrete ingredient production (A) Particulate matter formation, (B) Photochemical ozone formation, (C) Terrestrial acidification, (D) Terrestrial ecotoxicity, (E) Urban land occuption, (F) Water depletion.

Figure 11. Cumulative percentage contribution of concrete ingredient production to various environmental impact categories from 2000 to 2024. (A) Particulate matter formation, (B) Photochemical ozone formation, (C) Terrestrial acidification, (D) Terrestrial ecotoxicity, (E) Urban land occuption, (F) Water depletion.

4.14 Terrestrial ecotoxicity

Terrestrial ecotoxicity potential (TET) assesses the density of chemical emissions impacting terrestrial ecosystems, measured in kilograms of 1,4-dichlorobenzene equivalents (1,4DCB-eq) (Rosenbaum et al., 2015). For concrete production from 2000 to 2024, key contributors include Portland cement, organic chemicals, and diesel processes. Portland cement TET fluctuates but remains significant, starting at 1.55E-05 kg 1,4DCB-eq in 2000, and peaking at 7.00 × 10−5 kg in 2017 and 2022, indicating a rising trend. This reflects the substantial environmental impact of cement production, with intensive energy use and emissions contributing to soil toxicity. Organic chemicals show a similar trend, starting at 1.70 × 10−5 kg 1,4DCB-eq in 2000 and increasing to 6.00 × 10−5 kg 1,4DCB-eq in 2024 (Figures 10D, 11D). Diesel processes also contribute significantly, beginning at 7.10 × 10−6 kg 1,4DCB-eq in 2000, rising to 2.80 × 10−5 kg in 2023, due to its role in machinery and transportation in concrete production.

4.15 Urban land occupation

Urban land occupation (ULOP) quantifies land used by urban activities, measured in square meters per year (m2/a) (Mattila et al., 2011). In concrete production, ULOP is significantly impacted by gravel and sand as shown in Figures 10E, 11E. Gravel shows the highest ULOP values, reflecting the extensive land required for its extraction and processing, ranging from 1.79 × 10−1 m2/a in 2000 to 3.93 × 10−1 m2/a in 2024, peaking at 4.69 × 10−1 m2a in 2016. Sand also has notable ULOP values, from 1.67 × 10−1 m2/a in 2000 to 1.36 × 10−1 m2/a in 2024. Cement production contributes significantly with values from 4.09 × 10−2 m2a in 2000 to 3.07 × 10−1 m2a in 2024, peaking at 3.49 × 10−1 m2/a in 2013, due to land used for mining, infrastructure, and storage. Electricity has moderate ULOP values. Chemical substances and lubricating oil have minimal impact.

4.16 Water depletion

Water usage impacts human health through DALYs related to malnutrition in less developed countries. Its effect on terrestrial ecosystems, derived from (Pfister et al., 2009), is measured using net primary productivity (NPP), while the impact on freshwater ecosystems, sourced from (Hanafiah et al., 2011), is quantified by fish species loss due to reduced water discharge. In concrete production, water depletion is linked to the use of various raw materials and processes. Data from 2000 to 2024, shown in Figures 10F, 11F, indicate significant variation in water depletion.

5 Results and discussion

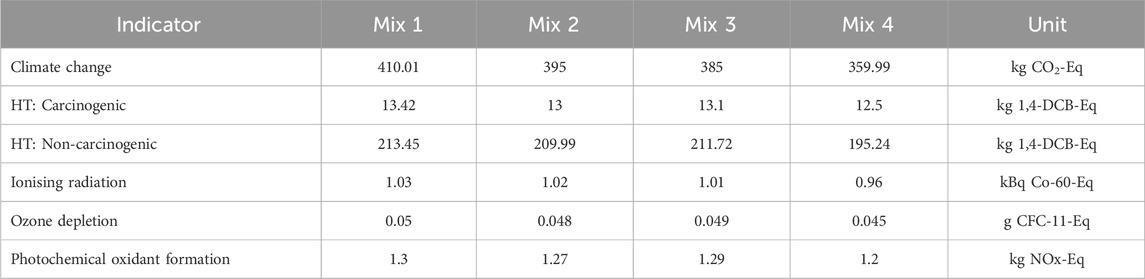

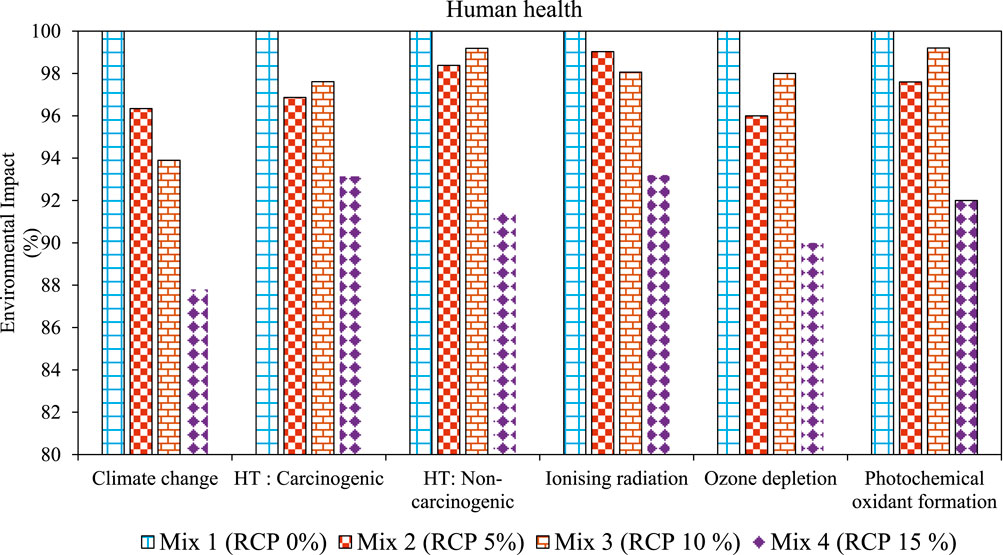

5.1 Human health

In this research, a comparative analysis assessed the human health impacts of concrete mixes with varying RCP proportion, examining indicators such as climate change, human toxicity (carcinogenic and non-carcinogenic), ozone depletion, photochemical oxidant production, and ionising radiation. The primary reason that higher RCP content reduces environmental impacts across these indicators is the significant decrease in Portland cement demand. Cement production is energy-intensive and is one the largest sources of CO2 emission due to the calcination process and high-temperature requirement (Barbhuiya et al., 2024). By replacing a portion of cement with RCP, the environmental burden associated with cement manufacturing decreases, thereby lowering the overall climate change impact. As shown in Table 4, with increased RCP content, there are consistent reductions across multiple indicators. For example, climate change impact decreased from 410.01 kg CO2-Eq (100%) in Mix 1%–87.8% 359.9 kg CO2-Eq (87.8%) in Mix 4. Similarly, carcinogenic human toxicity dropped from 13.42 kg 1,4-DCB-Eq (100%) to 12.5 kg 1,4-DCB-Eq (93.14%) with human toxicity being a known cancer cause (Lvel et al., 2020).

Additionally, non-carcinogenic human toxicity, ionising radiation, ozone depletion, and photochemical oxidant formation also decreased with higher RCP content. Notably, Mix four improved ozone depletion from 0.05 g CFC-11-Eq (100%) to 0.045 g CFC-11-Eq (90%) The ozone depletion potential is reduced with the inclusion of RCP. RCP, as a partial replacement for cement, reduced the need for energy-intensive cement production, thereby decreasing emissions related to high-temperature combustion processes. This substitution lessens the release of ozone depletion compounds, resulting in an overall decrease in ODP values. The use of RCP reduces demand on medium-voltage electricity and natural gas for heating generation, both which contribute substantial ODP emissions.

Furthermore, photochemical oxidants contribute to smog and respiratory health issue. Cement production release significant quantities of NMVOCs and nitrogen oxides (NOx), which are precursors to photochemical smog, primarily due to high combustion temperature and chemical reactions during clinker production (Inglezakis and Poulopoulos, 2006). By replacing a portion of cement with RCP, there is a notable reduction. As RCP content increases, there is a notable decrease in photochemical oxidant formation from 1.3 kg NOx-Eq (100%) to 1.2 kg NOx-Eq (92%) as shown in Figure 12. This reduction in photochemical oxidants further emphasizes the environmental benefits of using RCP in concrete production. These findings indicate that incorporating RCP not only diverts waste from landfills but also significantly reduces the environmental and human health impact associated with concrete production.

5.2 Ecosystem quality

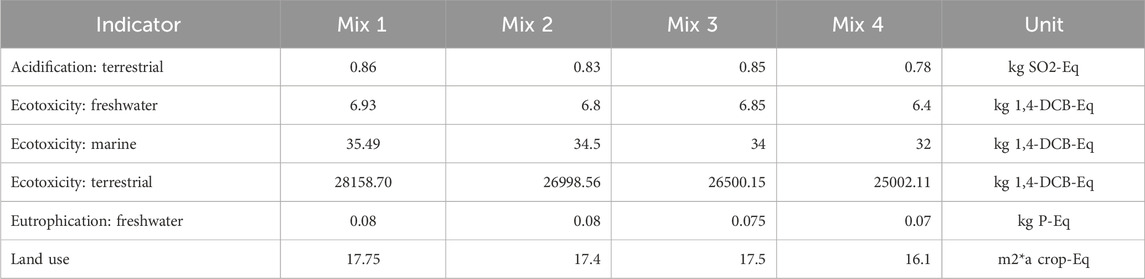

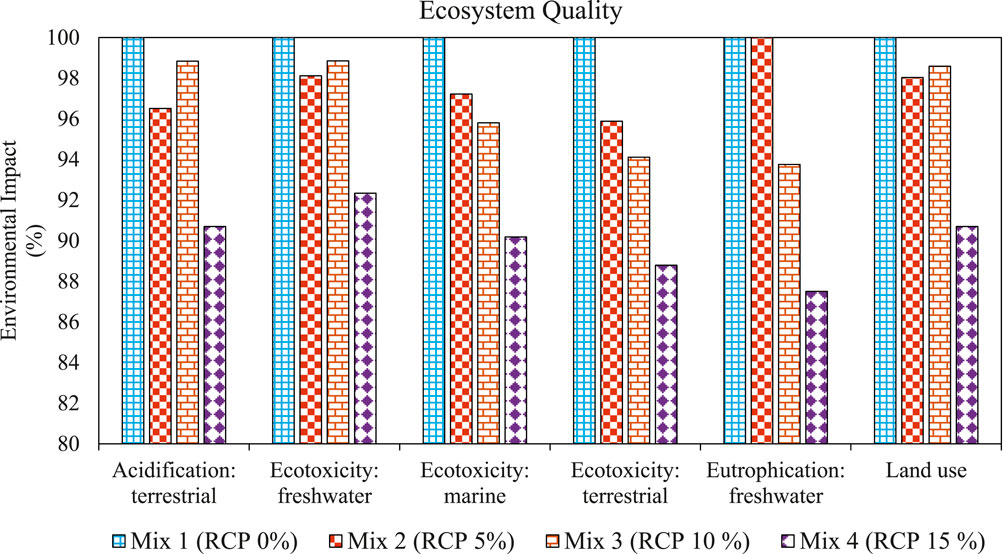

New insights into ecosystem quality impacts were explored through a comparative analysis of concrete mixes containing varying proportions of RCP. This analysis assessed various environmental indicators, including terrestrial acidification, freshwater ecotoxicity, marine ecotoxicity, terrestrial ecotoxicity, freshwater eutrophication, and land use. Increasing the proportion of RCP consistently showed reductions across these indicators, suggesting notable environmental benefits. Table 5 provides a compressive view of ecosystem quality impact indicators for different RCP mixtures. For instance, terrestrial acidification, driven primarily by sulfur and nitrogen oxides, decreased significantly from 0.86 kg SO2-Eq (100%) in Mix 1 to 0.78 kg SO2-Eq (90.7%) in Mix 4. This reduction is largely attributed to the lower emissions associated with cement replacement, as RCP reduces the reliance on high-temperature process.

Similarly, freshwater ecotoxicity, which reflects the potential for chemical emissions to affect freshwater organisms, decreased from 6.93 kg 1,4-DCB-Eq (100%) in Mix 1–6.4 kg 1,4-DCB-Eq (92.34%) in Mix 4. Freshwater eutrophication, often linked to phosphorus emissions that lead to algal blooms, also improved, with values dropping from 0.08 kg P-Eq (100%) in Mix 1 to 0.07 kg P-Eq (87.5%) in Mix 4, as shown in Figure 13. These reductions indicates that RCP can meaningfully mitigate the ecological footprint of concrete production. The incorporation of RCP reduces that need for virgin cement and associated emissions, thereby enhancing ecosystem quality by lowering contributions to acidification, eutrophication, and toxicity across multiple environmental compartments. Overall, these findings highlight the potential environmental benefits of integrating recycled materials like RCP into the concrete production process.

5.3 Resource depletion

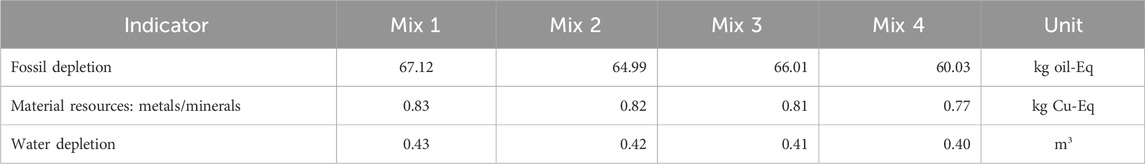

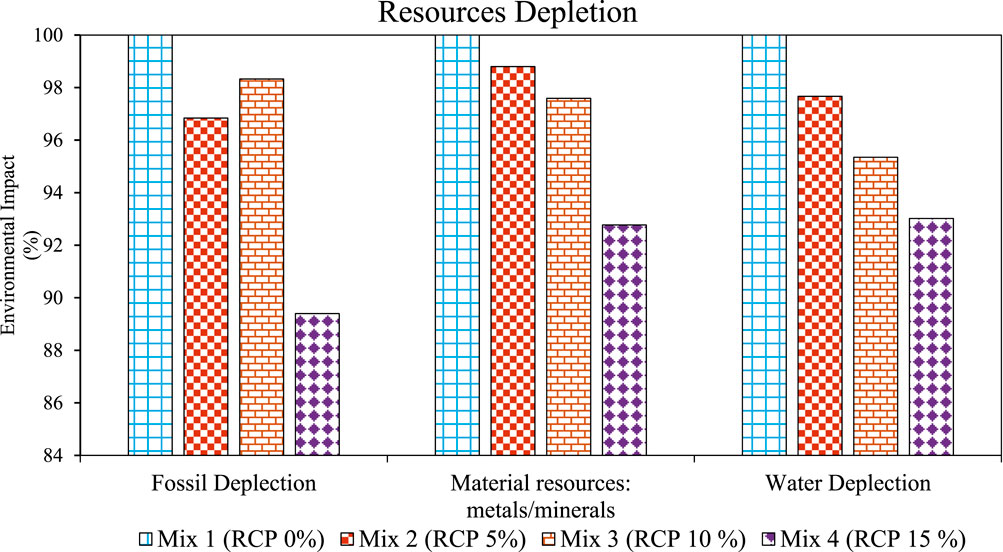

Resource depletion results reveal a clear trend of decreasing impacts with an increase in RCP proportion, which positively affects various categories such as fossil depletion, material resources (metals/minerals), and water depletion. The replacement of traditional cement with RCP in concrete reduces reliance on resource intensive cement production, significantly lessening the environmental burden of raw material extraction and energy use.

Table 6 shows resource depletion impact indicators for various RCP mixtures for fossil depletion, Mix four demonstrated the lowest impact at 60.03 kg oil-Eq (89.4%), a significant decrease compared to Mix 1 at 67.12 kg oil-Eq (100%). Intermediate mixes with lower RCP content, mix 2 and Mix 3, exhibited reduction to 64.99 kg oil-Eq (96.84%) and 66.01 kg oil-Eq (98.33%), respectively, indicating a gradual decline on fossil fuel dependence as RCP content increases.

Similarly, for material resource depletion, Mix four again achieved the greatest reduction in metal and mineral depletion, measured in copper equivalents. Mix 1, the standard concrete mix, had a depletion impact of 0.83 kg Cu-Eq (100%), while Mix four reduced this impact to 0.77 kg Cu-Eq (92.77%). Mixes with moderate RCP level, such as Mix 2 and Mix 3, showed decreases to 0.82 kg Cu-Eq (98.8%) and 0.81 kg Cu-Eq (97.5%), respectively, as shown in Figure 14.

These reduction across fossil and material resource depletion categories can be attributed to the lower extraction, processing, and transportation demands of cement alternatives, such as RCP, which require less energy intensive inputs. Additionally, for future concrete production, these results indicate that adopting RCP on a larger scale could be an effectively strategy to address resource scarcity while supporting environmentally responsible practices. RCP can contribute to circular economy practices by repurposing construction waste, further diminishing the depletion of primary resources.

Despite the promising reduction in resource depletion achieved through RCP usage, certain limitations and challenges persist. First, the quality and performance consistency of RCP can vary depending on the source and processing methods, which can affect the material properties and durability of the final concrete product. Additionally, as the RCP content increases, potential decrease in compressive strength and durability arises (Rocha and Toledo Filho, 2023), which might limit its application in high-strength or specialized concrete applications.

6 Conclusion

This research provides a detailed evaluation of the environmental and human health impacts associated with traditional concrete and concrete incorporating recycled concrete powder (RCP). It comprehensive investigates a wide array of environmental indicators, assessing how varying proportions of RCP influence these impacts. By analyzing the performance of concrete mixes with different RCP content, the study highlights the potential environmental benefits and sustainability implications of replacing conventional cement with RCP in concrete production. The conclusions are:

• Cement is the most dangerous concrete ingredients which significantly contribute to harmful gases in the atmosphere and also consume significant natural resources. Therefore, special attention should be given to using alternative materials instead of cement.

• The higher RCP content (15%) leads to reduced environmental impacts, including climate change, human toxicity, ionising radiation, ozone depletion and photochemical oxidant formation.

• The analysis indicates that the mix containing 15% RCP, showed particularly significant improvements, such as lowering ozone depletion impacts from 100% to 90% and photochemical oxidant formation from 100% to 92%. However, slight variation was observed in some indicators.

• The analysis of ecosystem quality impacts highlighted decreases in terrestrial acidification from 100% to 92.7%, freshwater ecotoxicity from 100% to 92.34%, and freshwater eutrophication from 100% to 87.5% with 15% RCP content, emphasizing the environmental benefits of RCP utilization in concrete production.

Moreover, the findings on resource depletion indicated that mixes with higher RCP content (15%) generally resulted in lower impacts on fossil depletion, material resources and water depletion. These outcomes highlight the potential of RCP as a sustainable alternative in concrete production, offering significant reductions in both environmental burdens and resource depletion, thereby contributing to more sustainable construction practices.

7 Recommendations for future research

For future research, it is recommended to conduct long-term performance assessments of concrete mixes with recycled concrete powder (RCP) to evaluate durability under various conditions. Optimizing RCP content and conducting sensitivity analyses in life cycle assessment (LCA) studies can refine environmental impact assessment. These efforts will support informed decision-making and enhance sustainable construction practices.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

AM: Conceptualization, Formal Analysis, Investigation, Methodology, Writing–original draft. ZP: Methodology, Supervision, Writing–review and editing. MS: Funding acquisition, Investigation, Methodology, Project administration, Writing–review and editing. WA: Formal Analysis, Project administration, Writing–review and editing. JA: Formal Analysis, Methodology, Software, Visualization, Writing–review and editing. AA: Conceptualization, Project administration, Validation, Investigation, Formal Analaysis, Writing-review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research was partially funded by Ministry of Science and Higher Education of Russian Federation (funding No FSFM-2024-0025).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Althaus, H.-J., Bauer, C., Doka, G., Dones, R., Frischknecht, R., Hellweg, S., et al. (2010). Implementation of life cycle impact assessment methods (ecoinvent report No. 3). Ecoinvent Cent.

American Society for Testing and Materials (2001). Astm C39/C39M. Stand. Test. Method Compressive Strength cylind. Concr. Specimens. Available at: https://cdn.standards.iteh.ai/samples/108483/0318d1c8cafb4b4cac903d64727feb4d/ASTM-C39-C39M-21.pdf

Barbhuiya, S., Kanavaris, F., Das, B. B., and Idrees, M. (2024). Decarbonising cement and concrete production: strategies, challenges and pathways for sustainable development. J. Build. Eng. 86, 108861. doi:10.1016/j.jobe.2024.108861

Basavaraj, A. S., and Gettu, R. (2024). Primary life cycle inventory data for cement production, with relevance to sustainability assessment–Indian cases. Data Br. 54, 110258. doi:10.1016/j.dib.2024.110258

Bicalho, T., Sauer, I., Rambaud, A., and Altukhova, Y. (2017). LCA data quality: a management science perspective. J. Clean. Prod. 156, 888–898. doi:10.1016/j.jclepro.2017.03.229

Blankendaal, T., Schuur, P., and Voordijk, H. (2014). Reducing the environmental impact of concrete and asphalt: a scenario approach. J. Clean. Prod. 66, 27–36. doi:10.1016/j.jclepro.2013.10.012

Borrion, A. L., Khraisheh, M., and Benyahia, F. (2012). “Environmental life cycle impact assessment of Gas-to-Liquid processes,” in Proceedings of the 3rd gas processing symposium. doi:10.1016/b978-0-444-59496-9.50011-4

Bouwman, A. F., Beusen, A. H. W., and Billen, G. (2009). Human alteration of the global nitrogen and phosphorus soil balances for the period 1970-2050. Glob. Biogeochem. Cycles 23. doi:10.1029/2009GB003576

Caruso, M., Couto, R., Pinho, R., and Monteiro, R. (2023). Decision-making approaches for optimal seismic/energy integrated retrofitting of existing buildings. Front. Built Environ. 9. doi:10.3389/fbuil.2023.1176515

Ciroth, A., Recanati, F., and Arvidsson, R. (2021). Principles of life cycle inventory modeling: the basic model, extensions, and conventions. Extensions, Conventions, 15–51. doi:10.1007/978-3-030-62270-1_2

Colangelo, F., Petrillo, A., Cioffi, R., Borrelli, C., and Forcina, A. (2018). Life cycle assessment of recycled concretes: a case study in southern Italy. Sci. Total Environ. 615, 1506–1517. doi:10.1016/j.scitotenv.2017.09.107

Curran, M., Hellweg, S., and Beck, J. (2014). Is there any empirical support for biodiversity offset policy? Ecol. Appl. 24, 617–632. doi:10.1890/13-0243.1

Dimoudi, A., and Tompa, C. (2008). Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 53, 86–95. doi:10.1016/j.resconrec.2008.09.008

Ecoinvent (2022). Ecoinvent database v3. EcoInvent v3.9. Available at: http://www.ncbi.nlm.nih.gov/pubmed/10523

Fang, B., Qian, Z., Song, Y., Diao, X., Shi, T., Cai, X., et al. (2024). Evaluation of early crack resistance performance of concrete mixed with ternary minerals using temperature stress testing machine (TSTM). J. Clean. Prod. 465, 142780. doi:10.1016/j.jclepro.2024.142780

Feiz, R., Ammenberg, J., Baas, L., Eklund, M., Helgstrand, A., and Marshall, R. (2015). Improving the CO2 performance of cement, part II: framework for assessing CO2 improvement measures in the cement industry. J. Clean. Prod. 98, 282–291. doi:10.1016/j.jclepro.2014.01.103

Frischknecht, R., and Rebitzer, G. (2005). The ecoinvent database system: a comprehensive web-based LCA database. J. Clean. Prod. 13, 1337–1343. doi:10.1016/j.jclepro.2005.05.002

Garces, J. I. T., Beltran, A. B., Tan, R. R., Ongpeng, J. M. C., and Promentilla, M. A. B. (2022). Carbon footprint of self-healing geopolymer concrete with variable mix model. Clean. Chem. Eng. 2, 100027. doi:10.1016/j.clce.2022.100027

Habert, G., Bouzidi, Y., Chen, C., and Jullien, A. (2010). Development of a depletion indicator for natural resources used in concrete. Resour. Conserv. Recycl. 54, 364–376. doi:10.1016/j.resconrec.2009.09.002

Hanafiah, M. M., Xenopoulos, M. A., Pfister, S., Leuven, R. S. E. W., and Huijbregts, M. A. J. (2011). Characterization factors for water consumption and greenhouse gas emissions based on freshwater fish species extinction. Environ. Sci. Technol. 45, 5272–5278. doi:10.1021/es1039634

Heijungs, R., and Sun, S. (2002). The computational structure of life cycle assessment. Int. J. Life Cycle Assess. 7, 314. doi:10.1007/bf02978899

Helmes, R. J. K., Huijbregts, M. A. J., Henderson, A. D., and Jolliet, O. (2012). Spatially explicit fate factors of phosphorous emissions to freshwater at the global scale. Int. J. Life Cycle Assess. 17, 646–654. doi:10.1007/s11367-012-0382-2

Herrmann, I. T., and Moltesen, A. (2015). Does it matter which Life Cycle Assessment (LCA) tool you choose? - a comparative assessment of SimaPro and GaBi. J. Clean. Prod. 86, 163–169. doi:10.1016/j.jclepro.2014.08.004

Huang, L., Fantke, P., Ritscher, A., and Jolliet, O. (2022). Chemicals of concern in building materials: a high-throughput screening. J. Hazard. Mater. 424, 127574. doi:10.1016/j.jhazmat.2021.127574

Huijbregts, M. A. J., Steinmann, Z. J. N., Elshout, P. M. F., Stam, G., Verones, F., Vieira, M., et al. (2017). ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 22, 138–147. doi:10.1007/s11367-016-1246-y

Inglezakis, V. J., and Poulopoulos, S. G. (2006). Adsorption, ion exchange and catalysis: design of operations and environmental applications. doi:10.1016/B978-0-444-52783-7.X5000-9

ISO (2004). Environmental management - life cycle assessment - principles and framework (ISO 14040:2006). Br. Stand. 3, 32.

Joos, F., Roth, R., Fuglestvedt, J. S., Peters, G. P., Enting, I. G., Von Bloh, W., et al. (2013). Carbon dioxide and climate impulse response functions for the computation of greenhouse gas metrics: a multi-model analysis. Atmos. Chem. Phys. 13, 2793–2825. doi:10.5194/acp-13-2793-2013

Jun, W., Ling-xiao, Y., and Li-na, Z. (2020). Thinking for the transformation of land consolidation and ecological restoration in the new era. J. Nat. Resour. 35, 26. doi:10.31497/zrzyxb.20200104

Komkova, A., and Habert, G. (2023). Environmental impact assessment of alkali-activated materials: examining impacts of variability in constituent production processes and transportation. Constr. Build. Mater. 363, 129032. doi:10.1016/j.conbuildmat.2022.129032

Larki, I., Zahedi, A., Asadi, M., Forootan, M. M., Farajollahi, M., Ahmadi, R., et al. (2023). Mitigation approaches and techniques for combustion power plants flue gas emissions: a comprehensive review. Sci. Total Environ. 903, 166108. doi:10.1016/j.scitotenv.2023.166108

Li, X., Zhu, Y., and Zhang, Z. (2010). An LCA-based environmental impact assessment model for construction processes. Build. Environ. 45, 766–775. doi:10.1016/j.buildenv.2009.08.010

Liu, Y., Wang, B., Qian, Z., Yu, J., Shi, T., Fan, Y., et al. (2024). State-of-the art on preparation, performance, and ecological applications of planting concrete. Case Stud. Constr. Mater. 20, e03131. doi:10.1016/j.cscm.2024.e03131

Luo, L., and Chen, Y. (2020). Carbon emission energy management analysis of LCA-Based fabricated building construction. Sustain. Comput. Inf. Syst. 27, 100405. doi:10.1016/j.suscom.2020.100405

Lvel, J., Watson, R., Abbassi, B., and Abu-Hamatteh, Z. S. (2020). Life cycle analysis of concrete and asphalt used in road pavements. Environ. Eng. Res. doi:10.4491/eer.2018.399

Manan, A., Zhang, P., Alattyih, W., Alanazi, H., Elagan, S. K., and Ahmad, J. (2024). Mechanical and microstructural characterization of sustainable concrete containing recycled concrete and waste rubber tire fiber. Mater. Res. Express 11, 085701. doi:10.1088/2053-1591/ad7014

Mattila, T., Helin, T., Antikainen, R., Soimakallio, S., Pingoud, K., and Wessman, H. (2011). Land use in life cycle assessment Finnish Environment Institute.

Miah, J. H., Griffiths, A., McNeill, R., Halvorson, S., Schenker, U., Espinoza-Orias, N., et al. (2018). A framework for increasing the availability of life cycle inventory data based on the role of multinational companies. Int. J. Life Cycle Assess. 23, 1744–1760. doi:10.1007/s11367-017-1391-y

Mollayosefi, M. M., Hayati, B., Pishbahar, E., and Nematian, J. (2019). Selecting weighting methodologies for evaluating agricultural sustainability in Iran. Proc. Inst. Civ. Eng. Eng. Sustain. 172, 207–217. doi:10.1680/jensu.18.00004

Moreno-Ruiz, E., Valsasina, L., Vadenbo, C., and Symeonidis, A. (2023). Ecoinvent – an introduction to the LCI database and the organization behind it. J. Life Cycle Assess. Jpn. 19, 215–226. doi:10.3370/lca.19.215

Nakhjiri, A., and Kakroodi, A. A. (2024). Air pollution in industrial clusters: a comprehensive analysis and prediction using multi-source data. Ecol. Inf. 80, 102504. doi:10.1016/j.ecoinf.2024.102504

Ortiz, O., Bonnet, C., Bruno, J. C., and Castells, F. (2009). Sustainability based on LCM of residential dwellings: a case study in Catalonia, Spain. Build. Environ. 44, 584–594. doi:10.1016/j.buildenv.2008.05.004

Pascual-González, J., Guillén-Gosálbez, G., Mateo-Sanz, J. M., and Jiménez-Esteller, L. (2016). Statistical analysis of the ecoinvent database to uncover relationships between life cycle impact assessment metrics. J. Clean. Prod. 112, 359–368. doi:10.1016/j.jclepro.2015.05.129

Pfister, S., Koehler, A., and Hellweg, S. (2009). Assessing the environmental impacts of freshwater consumption in LCA. Environ. Sci. Technol. 43, 4098–4104. doi:10.1021/es802423e

Rebitzer, G., Ekvall, T., Frischknecht, R., Hunkeler, D., Norris, G., Rydberg, T., et al. (2004). Life cycle assessment Part 1: framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 30, 701–720. doi:10.1016/j.envint.2003.11.005

Reşitoʇlu, I. A., Altinişik, K., and Keskin, A. (2015). The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean. Technol. Environ. Policy. doi:10.1007/s10098-014-0793-9

Rocha, J. H. A., and Toledo Filho, R. D. (2023). The utilization of recycled concrete powder as supplementary cementitious material in cement-based materials: a systematic literature review. J. Build. Eng. 76, 107319. doi:10.1016/j.jobe.2023.107319

Rosenbaum, R. K., Bachmann, T. M., Gold, L. S., Huijbregts, M. A. J., Jolliet, O., Juraske, R., et al. (2008). USEtox - the UNEP-SETAC toxicity model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 13, 532–546. doi:10.1007/s11367-008-0038-4

Rosenbaum, R. K., Meijer, A., Demou, E., Hellweg, S., Jolliet, O., Lam, N. L., et al. (2015). Indoor air pollutant exposure for life cycle assessment: regional health impact factors for households. Environ. Sci. Technol. 49, 12823–12831. doi:10.1021/acs.est.5b00890

Roy, P. O., Azevedo, L. B., Margni, M., van Zelm, R., Deschênes, L., and Huijbregts, M. A. J. (2014). Characterization factors for terrestrial acidification at the global scale: a systematic analysis of spatial variability and uncertainty. Sci. Total Environ. 500-501, 270–276. doi:10.1016/j.scitotenv.2014.08.099

Roy, P. O., Deschênes, L., and Margni, M. (2012a). Life cycle impact assessment of terrestrial acidification: modeling spatially explicit soil sensitivity at the global scale. Environ. Sci. Technol. 46, 8270–8278. doi:10.1021/es3013563

Roy, P. O., Huijbregts, M., Deschênes, L., and Margni, M. (2012b). Spatially-differentiated atmospheric source-receptor relationships for nitrogen oxides, sulfur oxides and ammonia emissions at the global scale for life cycle impact assessment. Atmos. Environ. 62, 74–81. doi:10.1016/j.atmosenv.2012.07.069

Sadiq, M., Wen, F., and Dagestani, A. A. (2022). Environmental footprint impacts of nuclear energy consumption: the role of environmental technology and globalization in ten largest ecological footprint countries. Nucl. Eng. Technol. 54, 3672–3681. doi:10.1016/j.net.2022.05.016

Schuhmacher, M., Domingo, J. L., and Garreta, J. (2004). Pollutants emitted by a cement plant: health risks for the population living in the neighborhood. Environ. Res. 95, 198–206. doi:10.1016/j.envres.2003.08.011

Shao, Z., Li, M., and Yu, D. (2022). Bibliometric analysis of construction and demolition waste recycling: review and prospects. Proc. Inst. Civ. Eng. Eng. Sustain. 175, 283–292. doi:10.1680/jensu.21.00089

Stocker, T. F., Qin, D., Plattner, G.-K., Tignor, M., Allen, S. K., Boschung, J., et al. (2013). IPCC, 2013: climate change 2013: the physical science basis. Contribution of working group I to the fifth assessment report of the intergovernmental panel on climate change. IPCC—Intergovernmental Panel on Climate Change.

Tangadagi, R. B., Manjunatha, M., Bharath, A., and Preethi, S. (2020). Utilization of steel slag as an eco-friendly material in concrete for construction. J. Green Eng. 10, 2408–2419.

UNEP (2011). Global Guidance principles for life cycle assessment databases. Shonan Guid. Princ. Available at: https://www.lifecycleinitiative.org/wp-content/uploads/2012/12/2011%20-%20Global%20Guidance%20Principles.pdf

Van Zelm, R., Huijbregts, M. A. J., and Van De Meent, D. (2009). USES-LCA 2.0-a global nested multi-media fate, exposure, and effects model. Int. J. Life Cycle Assess. 14, 282–284. doi:10.1007/s11367-009-0066-8

van Zelm, R., Stam, G., Huijbregts, M. A. J., and van de Meent, D. (2013). Making fate and exposure models for freshwater ecotoxicity in life cycle assessment suitable for organic acids and bases. Chemosphere 90, 312–317. doi:10.1016/j.chemosphere.2012.07.014

Verma, S. K., Singla, C. S., Nadda, G., and Kumar, R. (2020). “Development of sustainable concrete using silica fume and stone dust,” in Materials today: proceedings. doi:10.1016/j.matpr.2020.04.364

Vieira, M. D. M., Ponsioen, T. C., Goedkoop, M. J., and Huijbregts, M. A. J. (2017). Surplus ore potential as a scarcity indicator for resource extraction. J. Ind. Ecol. 21, 381–390. doi:10.1111/jiec.12444

World Organization (2011). Scientific assessment of ozone depletion: 2010. Glob. Ozone Res. Monit. Proj. Rep. No. 52. Available at: https://csl.noaa.gov/assessments/ozone/2010/

Xiu, M., Wang, X., Morawska, L., Pass, D., Beecroft, A., Mueller, J. F., et al. (2020). Emissions of particulate matters, volatile organic compounds and polycyclic aromatic hydrocarbons from warm and hot asphalt mixes. J. Clean. Prod. 275, 123094. doi:10.1016/j.jclepro.2020.123094

Zabalza Bribián, I., Valero Capilla, A., and Aranda Usón, A. (2011). Life cycle assessment of building materials: comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 46, 1133–1140. doi:10.1016/j.buildenv.2010.12.002

Zamagni, A., and Buttol, P. P. L. P. R. B. (2008). Critical review of the current research needs and limitations related to ISO-LCA practice. Deliv. D7 Work Packag. 5 CALCAS Proj. Available at: https://publications.jrc.ec.europa.eu/repository/handle/JRC48134

Zhang, J., Li, H., Pu, S., Skitmore, M., Philbin, S. P., and Ballesteros-Pérez, P. (2020). Environmental regulation and green productivity of the construction industry in China. Proc. Inst. Civ. Eng. Eng. Sustain. 174, 58–68. doi:10.1680/jensu.20.00013

Zhang, Y., Zhang, J., Lü, M., Wang, J., and Gao, Y. (2019). Considering uncertainty in life-cycle carbon dioxide emissions of fly ash concrete. Proc. Inst. Civ. Eng. Eng. Sustain. 172, 198–206. doi:10.1680/jensu.17.00058

Zimmermann, M., Althaus, H. J., and Haas, A. (2005). Benchmarks for sustainable construction: a contribution to develop a standard. Energy Build. 37, 1147–1157. doi:10.1016/j.enbuild.2005.06.017

Nomenclature

GHG Greenhouse gases

CO2 Carbon dioxide

FA Fine aggregate

LCA Life cycle assessment

LCI Life cycle inventory

GWP Climate change potential

ALOP Agricultural land occupation

MEPT Marine Ecotoxicity

NLTP Natural land transformation

PMFP Particular matter formation

TAP Terrestrial ecotoxicity

NLTP Natural land transformation potential

ULOP Urban land occupation potential

FASST Fast scenario screening tool

ft3 Cubic feet

m3 Cubic meter

∑ Summation sign

NOX Nitrogen oxide

ISO International organization for standardization

USES-LCA Unified synthesis and evaluation system

ppb Parts per billion

DALYs Disability adjusted life years

ppm Parts per million

NPP Net primary productivity

Kg Kilogram

N-Eq Nitrogen equivalent

MJ Megajoule

CA Coarse aggregate

kWh Kilowatt-hour

CO2-Eq Carbon dioxide-equivalents

DCB-Eq Dichlorobenzene-equivalents

IRP Ionising radiation

MEP Marine Eutrophication

ODP Ozone depletion

POFP Photochemical oxidant formation

ULO Urban land occupation

HTP Human toxicity potential

TETP Terrestrial ecotoxicity potential

WDP Water depletion potential

m2a Square meter year

Oil-Eq Oil equivalent

P-Eq Phosphate equivalent

U235-Eq Uranium-235 equivalent

NMVOC Non-methane volatile organic compounds

Fe-Eq Iron equivalent

m2 Square meter

CFC-11 Eq Trichloroflurormethane-11 equivalent

SO2Eq Sulfur equivalent

EOFP ecosystem ozone formation potential

Keywords: life cycle assessment, sustainability, human health impact, recycle concrete powder, concrete

Citation: Manan A, Pu Z, Sabri MM, Alattyih W, Ahmad J and Alzlfawi A (2025) Environmental and human health impact of recycle concrete powder: an emergy-based LCA approach. Front. Environ. Sci. 12:1505312. doi: 10.3389/fenvs.2024.1505312

Received: 03 October 2024; Accepted: 19 December 2024;

Published: 10 January 2025.

Edited by:

Peng Wang, Shenzhen University, ChinaReviewed by:

Tianyu Wang, Hong Kong University of Science and Technology, Hong Kong SAR, ChinaWalid Mansour, Kafrelsheikh University, Egypt

Copyright © 2025 Manan, Pu, Sabri, Alattyih, Ahmad and Alzlfawi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhang Pu, emhwdUB6enUuZWR1LmNu

Aneel Manan

Aneel Manan Zhang Pu1*

Zhang Pu1* Mohanad Muayad Sabri

Mohanad Muayad Sabri Jawad Ahmad

Jawad Ahmad