94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

MINI REVIEW article

Front. Sustain. Food Syst. , 27 February 2024

Sec. Waste Management in Agroecosystems

Volume 8 - 2024 | https://doi.org/10.3389/fsufs.2024.1372148

This article is part of the Research Topic Agri-Food Waste Utilization for Sustainable Future: Challenges and Opportunities View all 10 articles

Soybeans are an important oil and protein supply crop, but the utilization of by-products from its processing products has never been effectively resolved, while a large number of nutritional resources have been wasted and environmental pollution is serious, restricting the sustainable development of the industry. The critical problem of soybean processing by-products includes excessive levels of microorganisms, residual proteins, metal ions, and other substances. Because the screw extrusion process has potentially advantageous processing characteristics, it appears that it’s just the right solution to the above problem of soybean processing by-products. We propose that this technology may be a potentially scalable technology for the immediate processing of soybean by-products. This paper reviews the theoretical foundations in existing research, briefly discusses the technological advantages, feasibility, and potential risks of this process, and hopes that researchers may pay attention to this technique and conduct feasibility studies.

With customers’ desire for healthier diets and the popularity of plant-based diets, soy has emerged as the primary source of plant-based lipids and protein for humans (Qin et al., 2022). Traditional soybean processing, like the processing of many primary agricultural products, generates a large number of by-products, most notably soybean dregs and soybean whey (Lyu et al., 2021; Yang et al., 2022), which are produced during the processing of traditional soy products (such as tofu) and new soy products (such as soybean protein isolate [SPI]), although the composition may differ (Chua and Liu, 2019). In traditional processing models, by-products are often used directly as waste or as animal feed. However, soybean by-products can no longer be used as waste and are not permitted to be used as such due to growing environmental consciousness and researchers’ usage of useful components.

Soybean dregs, also known as okara, are the main solid by-product of the preparation of traditional soy products and SPI. Its primary components are water and fiber; upon drying, insoluble dietary fiber predominates (Wang et al., 2021), meanwhile also contains some residual proteins and peptides (Fang et al., 2021). Rich in nutrients, soybean dregs are extremely prone to spoiling during storage, while the special structure of soybean fibers leads to their extreme water absorption (Lyu et al., 2021), making it difficult to dry and transport. As the traditional soybean product manufacturing businesses are often small and dispersed, the huge production of soybean dregs has become an intractable problem.

Soybean whey, also named yellow slurry water, soybean whey, or soy wastewater, plays a role similar to that of soybean dregs. Unlike this, however, the consequences of residual metal ions and excessive protein residues in the soybean whey are more serious (Wang and Serventi, 2019; Chen et al., 2024). Also, as a liquid by-product of soybean processing, it is more productive than the solids. The extremely high Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) of the soybean whey prevented it from being discharged properly (Chua and Liu, 2019), and the processors had to merge it into industrial sewer lines, thus facing high treatment costs. Furthermore, extra coagulants added during the soy product manufacturing process may result in excess metal ions in soybean whey. In summary, from the perspective of food safety risks, the main risks of soybean by-products come from three aspects: microbial contamination, metal ion contamination, and residual proteins.

To address the issue of soybean by-products, researchers have devised multiple pathways for high-value use, such as the use of soybean dregs to prepare dietary fiber (Wang et al., 2021) and the use of soybean whey to obtain isoflavones (Wang and Serventi, 2019). These methods have generally remained at the experimental level and have not been generalized to actual production due to various problems, such as high treatment costs. Finding a processing technology that applies to the production line, that can address all three food risks at the same time, and at a lower input cost, is imperative.

Screw extrusion technology for soybean food processing is mainly used for the production of soybean texturized protein (STP) (Zhang et al., 2023). The basic principle is to use the screw to generate high pressure and high shear at a high temperature so that the material in the molten state produces directional texturization of the structure (Dahl and Villota, 1991). This feature coincides with the food risk problem of soybean by-products we propose to address. Complementary single screw extrusion technology can be used to process coarse materials (Lyu et al., 2022a), which makes it possible to use screw extrusion equipment to mimic the STP production model to process by-products. Additionally, the screw extruder is a type of low-cost processing machinery.

To address the issue of soybean processing by-products, an overview of the barriers to their integrated use is necessary and can be summarized in the following three sections:

Fresh soybean dregs can have a moisture content of between 80 and 85% (Chen et al., 2022), which affects the separation and purification of the dry matter in them directly. Based on the large amount of soybean dregs produced in practice, processors must dry the dregs as soon as possible to facilitate storage; otherwise, the high moisture content and unhygienic storage conditions would cause the dregs to quickly deteriorate. However, soybean dregs are different from ordinary food materials, their drying is extremely difficult, often accompanied by a large amount of energy consumption and long-time input (Lu et al., 2022). Even if the dregs are dried through higher processing costs, their rough palatability often makes them difficult for consumers to accept, which led to the frequent use of soybean dregs as animal feed (Jiang et al., 2019; Hu et al., 2023). To improve the processing performance of dreg as food, it is often modified using different methods, such as fermentation, chemical modification, etc., (Zhou et al., 2019; Wu et al., 2023), which undoubtedly diminishes the suitability of soybean dregs as a food ingredient for processing.

Soybean whey’s unsuitability for food processing can be shown in its inability to be utilized in food preparation. It is challenging to link this effluent to food processing because of its bitter flavor (Huang et al., 2022) and high concentrations of several constituents, such as trypsin inhibitors and lectins. The conventional way of processing soybean whey into food is to ferment it with probiotics to improve its potential functionality and processing characteristics (Tian et al., 2021; Yang et al., 2021), which gives some special potential functionality to the soybean whey but does not enhance its suitability for processing from a practical production point of view. Instead, it raises the cost of processing.

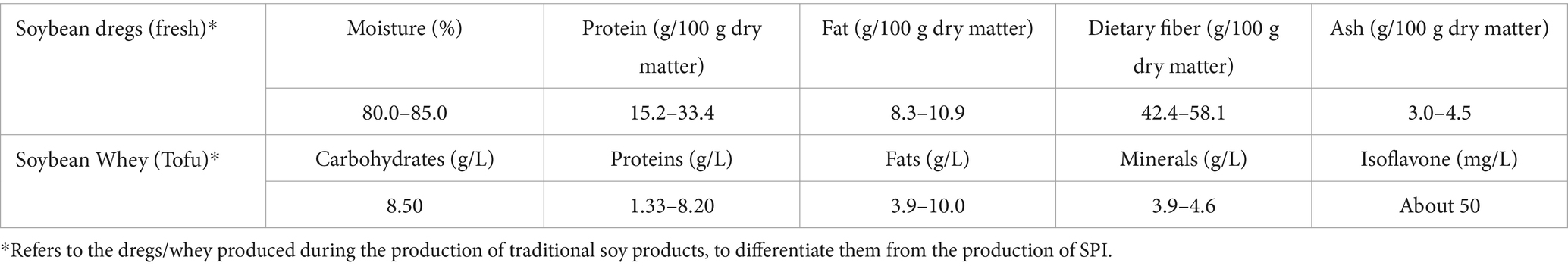

As shown in Table 1, soybean processing by-products do contain a large number of potential processing resources (Li et al., 2012; Chua and Liu, 2019). However, obtaining these processing resources comes at a significant expense due to processing.

Table 1. Main components and content of soybean by-products (Li et al., 2012; Chua and Liu, 2019).

The most worthwhile potential processing resources to be obtained from soybean dregs are soybean dietary fiber and functional peptides (Fang et al., 2021; Wang et al., 2021). Insoluble dietary fiber from soybean dregs, for example, has been shown to regulate the body’s glucose-lipid metabolism and intervene in the intestinal internal environment at high purity (Lyu et al., 2022b; Wang et al., 2023), which is considered a good resource for functional food. However, to obtain it, a combination of drying methods and the use of enzyme engineering techniques are required (Lyu et al., 2021), whose level of cost is unacceptable in industrial production.

Representative potential processing ingredients in soybean whey are oligosaccharides and isoflavones (Hu et al., 2024). As of today, the most efficient method recognized for separating these two components from soybean whey is membrane separation technology (Liu et al., 2015a,b). Complemented by larger yields than soybean dregs, it is more costly to achieve efficient separation of oligosaccharides and isoflavones from soybean whey in practical production. Again, no producers are doing this.

The process of extracting potential processing ingredients from soybean by-products is characterized by the fact that it is generally easy to succeed in the laboratory but difficult to scale up and apply in actual production. High processing expenses should be held primarily responsible for this.

Contamination and food safety risks of soybean by-products can be summarized in three categories: microorganisms, residual proteins, and metal ions.

Microorganism overload is a common problem in the treatment of soybean dregs and soybean whey. Among plant-based food wastes, microbiologically contaminated soybean dregs have the highest acidity (Wahab et al., 2022). Although fewer microbial species spoil soybean dregs in the natural environment, food microbial contamination is high in acidophilic microorganisms (Rawat, 2015), which are highly susceptible to risks such as Pseudomonas putida (Cunha et al., 2022). The microbial spoilage pattern of soybean whey is similar to that of soybean dregs, which will spoil within a day under conventional storage conditions (Chua and Liu, 2019). Conventional processing methods make it difficult to process soybean whey in 1 day. In addition, the odor of soybean whey is hard to receive after rotting and remains even after sterilization (Hao et al., 2023), which makes it no longer suitable for food processing.

Residual proteins in by-products are closely related to microbial contamination. Insoluble dietary fiber and soluble sugars provide a rich source of carbon for microbial reproduction, while, residual proteins provide an amount of nitrogen. Residual protein in soybean dregs comes from proteins that are not fully soluble in water, and conversely, the residual protein in the soybean whey stems from incomplete cross-linking or reactions during the production of soy protein products. More seriously, the removal of certain residual proteins is not achieved by changes in processing methods, such as certain acid-soluble proteins found in soybean whey (Liu et al., 2016). In short, residual protein increases the risk of microbial contamination of by-products.

Contamination by metal ions, on the other hand, occurs mainly in soybean whey, which mainly comes from excessive coagulants added during the processing of tofu. Common tofu coagulants include gypsum (main ingredient: CaSO4), salt brine (main ingredient: MgCl2, etc.), and glucono-δ-lactone (Li et al., 2022), the first two of which cause metal ion contamination. The root cause of metal ion residues is the excessive use of coagulants to ensure the yield of tofu, and the salt ions that are not bound to proteins in this process are present in the soybean whey. Again, this problem cannot be solved at this stage by adjusting the production process.

Technologies commonly used include single-screw extrusion and twin-screw extrusion. Either technology provides a high-temperature, high-pressure, high-shear process that is just right for solving the problem of utilizing soybean by-products.

As mentioned above, the food safety risks of by-products include microorganisms, residual proteins, and metal ions, which can be avoided in the raw material processing environment provided by screw extrusion technology.

Any type of screw extruder can easily provide a processing environment above 120°C, especially during the production of STP using screw extrusion, where temperatures often exceed 200°C (Lyu et al., 2022a). This environment, coupled with the minutes-long processing time, is such that no microorganisms can survive, at least not at the moment the material leaves the extruder. The risk of microbial contamination is also non-existent.

Residual proteins are no longer considered by-products in the screw extrusion process but as raw materials. The central idea presented in this paper is to use by-products to replace some of the key raw materials in the STP production process, e.g., using soybean dregs to replace a portion of water and soybean meal, meanwhile using soybean whey to completely replace pure water. According to estimates, soybean dregs can replace at least 20% of the total amount of raw materials, and more for soybean whey. Therefore, in this substitution process, the residual protein is involved in the texturization process of the raw protein, which, together with the absence of microbiological risks, does not pose additional food safety risks.

As the by-products undergo the texturization process with the protein, the risk of metal ion residues is not present. Studies have shown that although some coagulants are toxic, they are rendered harmless when they bind or react with proteins (Ali et al., 2021). The violent reaction environment of the screw extrusion process causes the metal ions to fully cross-link with the proteins, and with a high content of proteins and a low content of metal ions, this reaction should be regarded as complete for the metal ions.

In addition to the feasibility of the basic principles, the most limiting factor for the high-value utilization of by-products is the high cost of treatment. As a technology that has long been used in food processing and soybean product processing (Shelar and Gaikwad, 2019), screw extruders are not high-end processing equipment and have very low acquisition and operating costs. Especially single-screw extruders, which are more suitable for processing rough materials, such as soybean dregs (Lyu et al., 2022a), whose running cost is lower than others. This means that manufacturers can upgrade their inherent production lines at a very low cost and realize the utilization of by-products without affecting the production of the original products.

As mentioned previously, screw extrusion technology is mainly used in soybean processing for the production of STP. Compared to SPI, STP is a high-value product in its own right. As long as the by-product can be successfully turned into one of the feedstocks for STP production, its economic value is already very high because there are no more by-product treatment costs. On this basis, the inclusion of by-products will increase the content of dietary fiber, oligosaccharides, and isoflavones in STP, which will result in a significant increase in the value of the end product. This will help to realize the upgrading of ordinary food ingredients into potentially functional foods and get more market attention. The hidden value is very significant.

From the perspective of sustainable food processing, the use of screw extrusion technology to treat soybean by-products has longer-term significance.

For the soybean industry, this will be an attempt to utilize soybeans for laddering and whole-seed processing. This will achieve high-value utilization of more than 20% of the dry matter in soybeans, an amount that cannot be ignored in countries and regions where there is a scarcity of high-quality plant-based food resources, which will also further reduce pressure on the planting side regarding increased soybean production.

As far as the environment is concerned, in addition to the basic advantages mentioned above, zero-emission processing technology represented by screw extrusion has long-term significance for soybean processing and even for the food processing industry. Due to emissions and pollution issues, in most countries and regions, food processing companies must be located in suburban areas and cannot produce in urban or densely populated areas, which undoubtedly increases the cost of food production, especially transportation and storage. With the promotion of zero-emission processing technology, the urbanization of food processing will be promoted, which will bring many advantages, such as reduction of production costs, alleviation of labor problems, application of new technology, improvement of consumer acceptance, and so on.

In summary, the use of soybean processing by-products to replace some of the traditional raw materials in the screw extrusion process is a feasible way to utilize the by-products in a high-value way. However, there may be some constraints on the realization of this process.

Primary soybean processing is a traditional and stereotypical industry, but screw extrusion technology is currently only used in soy protein producers. Getting traditional primary soy producers to recognize and embrace screw extrusion technology is a long process, especially since the industry is highly fragmented. At the same time, compared to other new processing technologies, screw extrusion technology has a smaller overall investment. However, it is not easy to get producers to voluntarily bear the added costs in the actual production process. In addition to economic costs, there is an increase in hidden inputs to producers, such as labor and policy inputs.

While the use of screw extrusion to process by-products has proven theoretically feasible (Wang et al., 2020, 2024), there is an imbalance in raw material and product throughput capacity for soybean processors. On the one hand, there is an imbalance between the amount of by-product output and the processing capacity of the screw extruder. The current capacity of large screw extruders is only a few tons per day (in STP or SPI), but conventional soybean producers produce much more than that as by-products. This means that producers need to introduce several screw extruders to solve the by-product handling problem, which undoubtedly raises production costs. On the other hand, the by-products are only co-materials of the STP production process. To realize the treatment of by-products, producers also need to purchase or produce SPI, gluten (wheat protein), soybean meal, pea protein, etc. as the main raw materials, which are exactly what the traditional soybean processing enterprises do not have. The above process again raises the cost of running it.

While the addition of soybean dregs and soybean whey to the STP production process certainly enhances the content of functional substances in the product, this process brings up many unresolved scientific questions, for example: reactions of proteins and functional substances in extrusion processes, the change of functional components in the extrusion process, conversion of dietary fiber from insoluble to soluble, conversion of isoflavones from aggregated to free state, evaluation of processing and flavor characteristics of end products, etc. Precise analysis of these issues is the key to scaling up the technology, which in turn provides a potential research direction for researchers.

The advantages, limitations, and further scopes of screw extrusion technology in soybean by-product processing are summarized in Table 2.

Table 2. The advantages, limitations, and further scopes of screw extrusion technology in soybean by-product processing.

YS: Conceptualization, Data curation, Writing – original draft. XH: Resources, Writing – original draft. YN: Investigation, Resources, Writing – original draft. HY: Funding acquisition, Supervision, Writing – original draft. BL: Funding acquisition, Supervision, Writing – original draft.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This work was supported by the China Agriculture Research System of MOF and MARA (no. CARS-04), the Science and Technology Project in Jilin Province Department of Education (no. JJKH20240432KJ).

The authors declared that they have no conflicts of interest and no commercial or associative interest that could be a conflict of interest with the work submitted.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Ali, F., Tian, K., and Wang, Z.-X. (2021). Modern techniques efficacy on tofu processing: a review. Trends Food Sci. Technol. 116, 766–785. doi: 10.1016/j.tifs.2021.07.023

Chen, J., Cai, L., Huang, X., Fu, H., Sun, L., Yuan, C., et al. (2024). Mathematical modeling of optimal coagulant dosage for tofu preparation using MgCl2. Food Chem X 21:101137. doi: 10.1016/j.fochx.2024.101137

Chen, T., Zhang, W., Liu, Y., Song, Y., Wu, L., Liu, C., et al. (2022). Effects of wet fermented soybean dregs on physical and mechanical properties of pellets of corn Stover. Animals 12:2632. doi: 10.3390/ani12192632

Chua, J.-Y., and Liu, S.-Q. (2019). Soy whey: more than just wastewater from tofu and soy protein isolate industry. Trends Food Sci. Technol. 91, 24–32. doi: 10.1016/j.tifs.2019.06.016

Cunha, J. T., Romaní, A., and Domingues, L. (2022). Whole cell biocatalysis of 5-hydroxymethylfurfural for sustainable biorefineries. Catalysts 12:202. doi: 10.3390/catal12020202

Dahl, S., and Villota, R. (1991). Effect of thermal denaturation on the texturization of soybean protein via twin-screw extrusion. Can Inst Food Sci Technol J 24, 143–150. doi: 10.1016/S0315-5463(91)70037-0

Fang, J., Lu, J., Zhang, Y., Wang, J., Wang, S., Fan, H., et al. (2021). Structural properties, antioxidant and immune activities of low molecular weight peptides from soybean dregs (Okara). Food Chem X 12:100175. doi: 10.1016/j.fochx.2021.100175

Hao, Z., Zhang, X., Peng, X., Shi, X., Wang, R., and Guo, S. (2023). Identification of the key off-flavor odorants for undesirable spoiled odor in thermally sterilized fermented soymilk. Food Res. Int. 164:112407. doi: 10.1016/j.foodres.2022.112407

Hu, M., Gao, Y., Wen, W., Zhang, P., Zhang, F., Fan, B., et al. (2024). The aggregation behavior between soybean whey protein and polysaccharides of diverse structures and their implications in soybean isoflavone delivery. Food Chem. 439:138061. doi: 10.1016/j.foodchem.2023.138061

Hu, H., Wu, C., Ge, F., Ren, Y., Li, W., and Li, J. (2023). Poly-γ-glutamic acid-producing Bacillus velezensis fermentation can improve the feed properties of soybean meal. Food Biosci. 53:102503. doi: 10.1016/j.fbio.2023.102503

Huang, Z., Liu, H., Zhao, L., He, W., Zhou, X., Chen, H., et al. (2022). Evaluating the effect of different processing methods on fermented soybean whey-based tofu quality, nutrition, and flavour. LWT 158:113139. doi: 10.1016/j.lwt.2022.113139

Jiang, K., Tang, B., Wang, Q., Xu, Z., Sun, L., Ma, J., et al. (2019). The bio-processing of soybean dregs by solid state fermentation using a poly γ-glutamic acid producing strain and its effect as feed additive. Bioresour. Technol. 291:121841. doi: 10.1016/j.biortech.2019.121841

Li, Q., Hua, Y., Li, X., Kong, X., Zhang, C., and Chen, Y. (2022). Effects of heat treatments on the properties of soymilks and glucono-δ–lactone induced tofu gels. Food Res. Int. 161:111912. doi: 10.1016/j.foodres.2022.111912

Li, B., Qiao, M., and Lu, F. (2012). Composition, nutrition, and utilization of okara (soybean residue). Food Rev. Intl. 28, 231–252. doi: 10.1080/87559129.2011.595023

Liu, Q.-R., Qi, J.-R., Yin, S.-W., Wang, J.-M., Guo, J., Feng, J.-L., et al. (2016). The influence of heat treatment on acid-tolerant emulsions prepared from acid soluble soy protein and soy soluble polysaccharide complexes. Food Res. Int. 89, 211–218. doi: 10.1016/j.foodres.2016.07.001

Liu, W., Wu, Z., Wang, Y., Li, R., and Huang, D. (2015a). Isolation of soy whey proteins from isoflavones in the concentrated solution using foam fractionation. Sep. Purif. Technol. 149, 31–37. doi: 10.1016/j.seppur.2015.05.010

Liu, W., Wu, Z. L., Wang, Y. J., Li, R., Yin, N. N., and Jiang, J. X. (2015b). Separation of isoflavone aglycones using chitosan microspheres from soy whey wastewater after foam fractionation and acidic hydrolysis. J. Ind. Eng. Chem. 25, 138–144. doi: 10.1016/j.jiec.2014.10.024

Lu, W., Zhang, Y., Xiao, C., Chen, D., Ye, Q., Zhang, C., et al. (2022). The comprehensive utilization of bean dregs in high-fiber tofu. Food Secur. 11:1475. doi: 10.3390/foods11101475

Lyu, B., Li, J., Meng, X., Fu, H., Wang, W., Ji, L., et al. (2022a). The protein composition changed the quality characteristics of plant-based meat analogues produced by a single-screw extruder: four Main soybean varieties in China as representatives. Food Secur. 11:1112. doi: 10.3390/foods11081112

Lyu, B., Wang, Y., Fu, H., Li, J., Yang, X., Shen, Y., et al. (2022b). Intake of high-purity insoluble dietary fiber from Okara for the amelioration of colonic environment disturbance caused by acute ulcerative colitis. Food Funct. 13, 213–226. doi: 10.1039/D1FO02264D

Lyu, B., Wang, H., Swallah, M. S., Fu, H., Shen, Y., Guo, Z., et al. (2021). Structure, properties and potential bioactivities of high-purity insoluble fibre from soybean dregs (Okara). Food Chem. 364:130402. doi: 10.1016/j.foodchem.2021.130402

Qin, P., Wang, T., and Luo, Y. (2022). A review on plant-based proteins from soybean: health benefits and soy product development. J Agric Food Res 7:100265. doi: 10.1016/j.jafr.2021.100265

Rawat, S. (2015). Food spoilage: microorganisms and their prevention. Asian J Plant Sci Res 5, 47–56.

Shelar, G. A., and Gaikwad, S. T. (2019). Extrusion in food processing: an overview. Pharm Innov J 8, 562–568.

Tian, J., Mao, Q., Dong, M., Wang, X., Rui, X., Zhang, Q., et al. (2021). Structural characterization and antioxidant activity of exopolysaccharide from soybean whey fermented by Lacticaseibacillus plantarum 70810. Food Secur. 10:2780. doi: 10.3390/foods10112780

Wahab, N., Hassan, H. H. M., Yusuf, W. N. S. W., Jahwi, R. A., Kasim, M. M. M., and Rashid, M. R. A. (2022). Physicochemical and Microbial Analysis of Plant-Based Food Waste for Potential Used as an Animal Feed. In AIP Conference Proceedings. AIP Publishing. 2610.

Wang, Y., and Serventi, L. (2019). Sustainability of dairy and soy processing: a review on wastewater recycling. J. Clean. Prod. 237:117821. doi: 10.1016/j.jclepro.2019.117821

Wang, F., Sukmanov, V., Zeng, J., and Jiang, J. (2020). Improving the quality of soybean by-products by physical methods during its use in bakery technology. Review. Ukrainian Food J 9, 513–544. doi: 10.24263/2304-974X-2020-9-3-4

Wang, S., Sun, W., Swallah, M. S., Amin, K., Lyu, B., Fan, H., et al. (2021). Preparation and characterization of soybean insoluble dietary fiber and its prebiotic effect on dyslipidemia and hepatic steatosis in high fat-fed C57BL/6J mice. Food Funct. 12, 8760–8773. doi: 10.1039/D1FO01050F

Wang, H., Wang, M., Zeng, J., Gao, H., and Zhang, K. (2024). Effect of physical treatments on the functional and structural features of soluble dietary fiber from soybean dregs. J. Sci. Food Agric. 104, 1777–1783. doi: 10.1002/jsfa.13083

Wang, S., Wang, J., Zhang, J., Liu, W., Jing, W., Lyu, B., et al. (2023). Insoluble dietary fiber from okara combined with intermittent fasting treatment synergistically confers antiobesity effects by regulating gut microbiota and its metabolites. J. Agric. Food Chem. 71, 13346–13362. doi: 10.1021/acs.jafc.3c03948

Wu, L., Tang, C., Chen, L., and Zhao, J. (2023). Modified dietary fiber from soybean dregs by fermentation alleviated constipation in mice. Food Chem X 19:100810. doi: 10.1016/j.fochx.2023.100810

Yang, Z., Hu, Y., Wu, J., Liu, J., Zhang, F., Ao, H., et al. (2022). High-efficiency production of Auricularia polytricha polysaccharides through yellow slurry water fermentation and its structure and antioxidant properties. Front. Microbiol. 13:811275. doi: 10.3389/fmicb.2022.811275

Yang, Y., Wang, B., Fu, Y., Chen, F. L., Guan, H. N., Liu, L. L., et al. (2021). HS-GC-IMS with PCA to analyze volatile flavor compounds across different production stages of fermented soybean whey tofu. Food Chem. 346:128880. doi: 10.1016/j.foodchem.2020.128880

Zhang, T., Yu, S., Pan, Y., Li, H., Liu, X., and Cao, J. (2023). Properties of texturized protein and performance of different protein sources in the extrusion process: a review. Food Res. Int. 174:113588. doi: 10.1016/j.foodres.2023.113588

Keywords: soybean processing, soybean dregs, soybean whey, processing technology, texturized protein

Citation: Shen Y, Huang X, Nan Y, Yu H and Lyu B (2024) Possibility of immediate treatment to soybean processing by-products using screw extrusion: a mini review. Front. Sustain. Food Syst. 8:1372148. doi: 10.3389/fsufs.2024.1372148

Received: 17 January 2024; Accepted: 19 February 2024;

Published: 27 February 2024.

Edited by:

Shalini Gaur Rudra, Indian Agricultural Research Institute, IndiaReviewed by:

Digambar Kavitake, National Institute of Nutrition (ICMR), IndiaCopyright © 2024 Shen, Huang, Nan, Yu and Lyu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hansong Yu, eXVoYW5zb25nQDE2My5jb20=; Bo Lyu, bWljaGFlbF9sdmJvQDE2My5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.