95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. Food Syst. , 24 August 2023

Sec. Sustainable Food Processing

Volume 7 - 2023 | https://doi.org/10.3389/fsufs.2023.1253597

This article is part of the Research Topic Technological Advancements for Processing and Preservation of Fruits and Vegetables View all 15 articles

The processing of ‘Phulae’ pineapple fruit for juice generates a significant by-product called pineapple pomace (PAP) that has attracted interest from the functional snack industry. Pineapple pomace (PAP) is rich source of dietary fiber and antioxidants, which make it suitable for incorporating into mushroom products that are rich in high protein content. To investigate the impact of drum drying parameters on the physicochemical properties of PAP, response surface methodology (RSM) was employed for optimization of processing parameters such as steaming temperature (130 to 170°C) and rotation speed (1 to 3 rpm). The aim was to determine the optimal conditions for achieving the highest yield of diphenylpicrylhydrazyl (DPPH), ferric reducing antioxidant power (FRAP), and soluble dietary fiber (SDF), which are important indicators of antioxidant activity and dietary fiber content. These optimal conditions would be used in the production of crispy Pleurotus sajor-caju (PS-PAP) and Lentinus squarrosulus (LS-PAP) sheets both of which were supplemented with PAP. The response of PS-PAP and LS-PAP to the independent variables (steaming temperature and rotation speed) was adequately described by a second-order polynomial equation. The equations demonstrated a high degree of fit with respect to DPPH (R2 = 0.9693 for PS-PAP sheet and R2 = 0.9966 for LS-PAP sheet), FRAP (R2 = 0.9908 for PS-PAP sheet and R2 = 0.9877 for LS-PAP sheet), and SDF (R2 = 0.9689 for PS-PAP sheet and R2 = 0.9598 for LS-PAP sheet). Moreover, the experimental values of the dependent variables closely matched the predicted values, indicating the reliability of the generated models. It was evident that both steaming temperature and rotation speed significantly influenced DPPH, FRAP, and SDF contents and the optimized conditions could be employed for the production of functional crispy mushroom sheets. In conclusion, the study’s novelty lies in the optimization of PAP drum drying parameters for the production of functional crispy mushroom sheets. The research creates opportunities for sustainable and nutritious products, and future perspectives could include sensory evaluation, nutritional analysis, shelf-life studies, market potential and environmental impact assessment. Overall, this research contributes to the development of healthier and eco-friendly food options.

Over the past few years, more and more people have become aware of the links between health and diet, and there has been a trend toward healthier eating. The utilization agricultural waste byproducts such as straw, leaves, peel or pomace from fruits and vegetables has led to the development of new functional food products that cater to various consumer groups including those who consciously choose products with health-promoting properties. Nowadays there is growing awareness of the consequences for health that necessitates the consumption of plant-based protein from cereals, legumes, oil seeds, nuts, pseudocereals, tubers, fruits, vegetables, and mushrooms to reduce the consumption of animal meat (Langyan et al., 2021). Although legumes are a promising protein source, some consumers have pea protein allergies (Hertzler et al., 2020). As a result, there has been an increasing popularity in using mushrooms as the primary raw material for developing alternative protein products, catering to a broader range of consumers. Thailand, in particular, produces a wide variety of edible mushrooms, providing opportunities to diversify product options. It has been reported that oyster mushroom (Pleurotus sajor-caju) (PS) and white log (Lentinus squarrosulus Mont.) (LS) contains protein content of 50.29 ± 4.17% and 40.34 ± 3.23% by dry weight, respectively (Srikram and Supapvanich, 2016). These mushrooms can serve as essential ingredients in the production of high-protein health food products. Furthermore, their cost-effectiveness and widespread cultivation across the country ensure their year-round availability.

‘Phulae’ pineapple (Ananas comosus L. Merr.) holds significant geographical indications as an agricultural product of Chiang Rai Province, Thailand. It is highly nutritious, containing a wealth of vitamins, fibers, and minerals (Kongsuwan et al., 2009). One popular method of processing this variety is juice extraction, which yields valuable by-products such as peel, crown, core, and pomace that together constitute approximately 45–55% of the total pineapple weight (Banerjee et al., 2018). Among these by-products, pineapple pomace (PAP) stands out due to its immense potential for conversion into economically viable functional foods. PAP is a rich source of insoluble dietary fiber, compared to soluble dietary fiber (Jose et al., 2022). Insoluble dietary fiber (IDF) supports a healthy digestive tract, while soluble dietary fiber (SDF) aids in lowering LDL cholesterol and blood sugar levels (Liu et al., 2022). By incorporating PAP as an ingredient, the issue of low dietary fiber content in regular snacks can be addressed, thereby enhancing their functional properties and promoting a healthy digestive system. Moreover, dietary fiber possesses other beneficial properties such as water absorption capacity, oil holding capacity, and swelling capacity that are advantageous during the drum drying process (Zhang et al., 2020).

Twin drum drying is an alternative drying method that offers a fast dehydration rate, similar to refractance window and spray drying technologies, each of which has limitations and advantages (Caparino et al., 2012; Karthik et al., 2017). Twin drum drying is considered the easiest and most economical method of food processing in which a food slurry is spread onto a surface then rapidly heated by steaming between the drums to ensure crispy texture of food (Hidayat et al., 2021). The drums rotate to generate heat, aid in feeding the slurry, and discharge the dehydrated product using a scraper blade. The steaming temperature and holding time influence the degree of gelatinization, and drying rate (Taşkın and Savlak, 2022). Drum drying is commonly used for producing breakfast cereals, bakery foods, beverages, and dairy products, as the resulting dried product typically takes the form of flakes or powder (Wiriyawattana et al., 2018; Taşkın and Savlak, 2022). However, achieving a product with sheet-like characteristics through drum drying presented a significant challenge in this study. Previous research focused on developing a crispy ‘Phulae’ pineapple product from PAP using a drum dryer. The results of this preliminary study using a drying temperature of 150°C and a rotation rate of 2 rpm resulted in a product containing 11.1% dietary fiber and 4.2% protein. The product can be consumed as a functional snack with high dietary fiber content (not less than 6 g per 100 g of product, as listed in Attachment No. 4 of the Notification of the Ministry of Public Health No. 182, B.E. 2,541). However, the product did not consistently achieve a sheet-like texture, necessitating the addition of a binding or stabilizing agent, such as hydrocolloids (Li and Nie, 2016). The addition of flour and fortification with hydrocolloids tends to enhance thixotropic behavior of mushroom-based PAP sheets (Martínez et al., 2015).

This study aimed to develop a high-protein, crispy mushroom product enriched with healthy dietary fiber by utilizing the twin drum drying process that produces sheet-like characteristics. This product would serve as a plant-based protein rich functional product. The objective of this study was to investigate the influence of steaming temperature (130°C, 150°C, 170°C) and rotation rate (1, 2 and 3 rpm) on the functional properties of the mushroom sheets. The experimental runs were designed using the Box–Behnken design (BBD), which enables the creation of sequential designs, calculation of quadratic model parameters, and detection of the model’s lack of fit (Jafari et al., 2023). Subsequently, optimal drying conditions were determined through the use of response surface methodology (RSM) and were used to develop prototype products consisting of crispy mushroom sheets fortified with PAP. The products were evaluated for the proximate composition, physicochemical properties and dietary fiber content.

Pineapple pomace (PAP) from ‘Phulae’ pineapples was obtained from a pineapple juice factory in Chiang Rai. The PAP was washed three times with deionized water in a 1:3 ratio of pomace to water to reduce acidity and provide a less sour taste. After reducing the acidity, the water content was reduced using hydraulic press. The processed PAP was stored at −20°C until use to prevent fermentation by lactic acid bacteria. The oyster (Pleurotus sajor-caju) (PS) and white log (Lentinus squarrosulus Mont.) (LS) mushrooms were obtained from the Center of Excellence in Fungal Research, Mae Fah Luang University, Chiang Rai. Both PAP and mushroom samples were stored in a freezer at −20°C prior to the sample preparation and analysis.

The mixture was created by separately mixing PS (85% dry weight basis, db) and LS (85% db) with PAP (12% db), tapioca flour (1% db), sugar (1% db), and xanthan gum (0.17% db) and blended with water in a ratio of 1:1 in preparation for the drum drying process. The slurry samples were then allowed to dry in a twin drum dryer. To obtain dried samples, the temperature was controlled at 130°C, 150°C, and 170°C, while the rotation speed was fixed at either 1, 2, and 3 rpm. Thin and crispy sheets of PAP, PS or LS fortified with PAP were obtained as the finished product after the twin drum drying process and were sealed in a container with silica oxide and nitrogen gas filling the headspace to remove any residual atmospheric air.

The Box–Behnken design (BBD) for response surface methodology was employed to optimize the levels of steaming temperature and rotation speed of drum drying and their impact on the antioxidant and dietary fiber responses. Two factors, steaming temperature (X1: 130°C to 150°C) and rotation speed (X2: 1 to 3 rpm), were coded into five levels (−1.414, −1, 0, 1, 1.414), representing the lowest to highest values, respectively (Table 1). A total of thirteen experiments were conducted based on the natural variable design. To validate the model generated by the software under the optimal conditions, an experiment was performed, and the experimental values were compared with the predicted values. The experiment was conducted in duplicate (n = 2), and the composition analysis was carried out in triplicate (n = 3). The response surface was analyzed to validate the regression coefficients, determine the statistical significance of the model, and fit the mathematical models to optimize the dependent variable. The following quadratic polynomial equation [1] was used to fit the experimental data and investigate the response function (Y):

In the equation, Y represents the dependent variable, β0 is a constant coefficient, and β1, β2, β11, β22, and β12, represent the linear, squared, and interaction coefficients, respectively. Non-significant coefficients were removed from the equation during the modeling process. A three-dimensional model graph was used to interpret the relevance of the factors and the responses. The variables of steaming temperature and rotation speed was established for numerical optimization. The superimposed contour graphs of significant (p < 0.05) response variables illustrated the optimal conditions and predicted response values.

Various physicochemical parameters of pineapple pomace were measured including water activity (aw), pH, titratable acidity (TA % citric acid), antioxidant potential (DPPH and FRAP assays) and insoluble (IDF) and soluble dietary fiber (SDF) (McCleary et al., 2013). The aw of the PAP sample was measured in triplicate at 25°C using a METER Aqualab 4TE Benchtop instrument. To prepare a PAP sample for pH measurement, the suspension was created by blending 10 g of PAP with 100 mL deionized water. The suspended sample was then centrifuged, and the supernatant collected for pH measurement using a pH meter (Model pH 700, Benchtop pH Meter). The 40 mL aliquot was titrated with 0.1 N NaOH to reach a pH of 6.5, and then the titratable acidity was expressed as grams of citric acid per 100 g of the sample.

The analysis of total dietary fiber was performed on dried PAP and mushroom sheets, both with and without PAP, were analyzed following the method of Bird et al. (2016) with some modifications. Briefly, 1 g of the samples in triplicate was subjected to sequential enzymatic digestion using heat-stable α-amylase, protease, and amyloglucosidase. The insoluble dietary fiber (IDF) was filtered, and then the residue was washed with warm distilled water. The filtrate and water washings were precipitated with 4 volumes of 95% ethanol for the determination of soluble dietary fiber (SDF). The precipitate was then filtered and dried. Both the SDF and IDF residues were adjusted for protein, ash, and blank values in order to calculate the final SDF and IDF contents. The SDF was precipitated with ethanol, and the residue was subsequently filtered, dried, and weighed. The total dietary fiber (TDF) content was adjusted for protein and ash content.

The DPPH method was used to determine radical scavenging activity in both dried PAP and mushroom sheets with and without PAP as described by Philip (2004). Briefly, the sample was extracted with deionized water at 50°C for 30 min in a sonication bath. The ratio of the sample to water was 1:5. The extract was then centrifuged at 10,000 rpm for 5 min. The supernatant was collected and filtered using a nylon filter membrane with a pore size of 0.45 μm. Then, 50 μL of the filtered sample was added to 1950 μL of methanolic DPPH (60 μM of 2,2′-diphenyl-1-picryl-hydrazyl in methanol) and vortexed for 30 s. The mixture was kept in a dark place at room temperature. After 30 min, the mixture was placed in a spectrophotometer to determine the absorbance at 517 nm against the blank. The DPPH scavenging activity was expressed as the percentage of scavenging using the following equation [2].

DPPH scavenging activity (%) = 1- Ac/Ad(2)

Where Ac is the absorbance of solution, Ad is the absorbance of DPPH solution.

The sample was extracted for ferric reducing antioxidant power (FRAP) analysis using the same method of sample preparation employed for DPPH scavenging activity. Ascorbic acid was used as a working standard to generate a calibration curve. Both the standard and sample were pipetted into test tubes, with 1 mL in each tube. The FRAP reagent was prepared by adding 2.5 mL of phosphate buffer (pH 6.6) and 2.5 mL of 1% potassium hexacyanoferrate and vortexed to mix well. The mixture was incubated in a thermostatic bath at 50°C for 30 min. Then, 2.5 mL of 10% trichloroacetic acid was added. The mixture was centrifuged at 10,000 rpm for 10 min. The supernatant was collected and 2.5 mL of deionized water and 0.5 mL of 0.1% ferric chloride were added. It was filtered through a 0.45 μm nylon membrane. The absorbance was measured at 700 nm against the blank. The FRAP was expressed as the reducing antioxidant power in the unit of μmol ascorbic acid/100 g wet basis (Zhong and Shahidi, 2015).

The determination of total plate counts (TPC), counts of yeasts and molds (YM), and counts of Clostridium perfringens followed the FDA BAM method (U.S. Food and Drug Administration, 2001) and was reported as CFU/g. Bacillus cereus counts were reported in the unit of CFU/g, while Escherichia coli counts were reported as MPN/g (U.S. Food and Drug Administration, 2020). Staphylococcus aureus was determined according to the FDA BAM (U.S. Food and Drug Administration, 2016) and reported in the unit of CFU/g. The determination of Salmonella spp. was carried out on a 25 g sample of the product, following the method of the International Organization for Standardization (2020). The report represented Salmonella spp. in 25 g of the product.

The data were statistically analyzed using Design-Expert Version 6.0.10 software. The completely randomized design was employed for the experimental design. The mean values of the three replicates of the response results were used for analysis. The R2 values were determined to assess the fitness of the developed model, and the significance of the model was examined using analysis of variance (ANOVA) at (p < 0.05).

Optimization of steaming temperature and rotation speed of a twin drum dryer on the antioxidant and dietary fiber content of pineapple pomace fortified in crispy mushroom sheets.

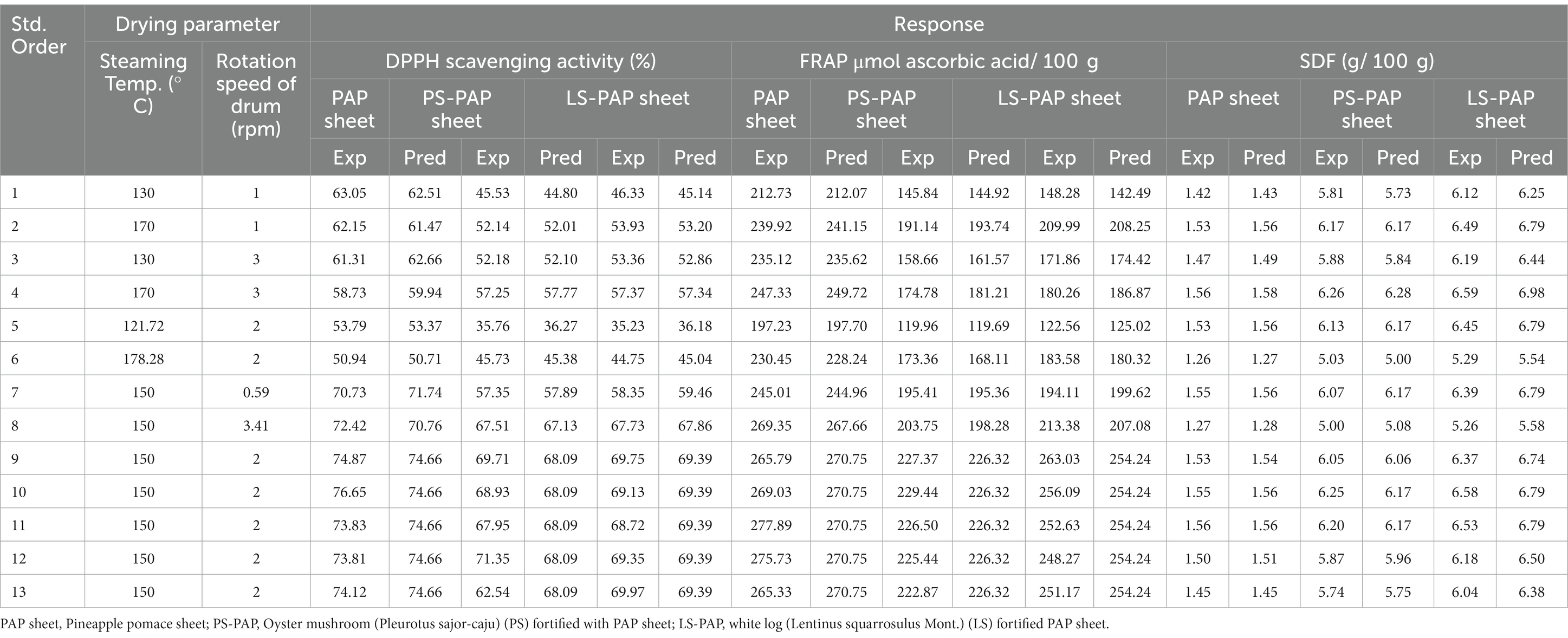

A Box–Behnken design (BBD) using two independent variables (viz steam temperature (X1) and rotation speed of the drum (X2)) was employed in the optimization of treatment conditions using response surface methodology (RSM). The coded values used for these variables were − 1.414, −1, 0, 1, and 1.414. The steam temperature (X1) varied between 121.72°C to 178.28°C, corresponding to the coded values of −1.414, −1, 0, 1, and 1.414, respectively. The rotation speeds of the drum (X2) ranged from 0.59 rpm to 3.41 rpm and the speeds were again assigned the coded values of −1.414, −1, 0, 1, and 1.414 (Table 1). The results of the optimization of twin drum drying of the PAP, PS-PAP and LS-PAP sheets using RSM-BBD are presented in Table 2. The table includes the experimental and predicted values for various response variables, such as DPPH scavenging activities, FRAP, and SDF contents at different combinations of steaming temperature and drum speeds. The DPPH scavenging activity ranged from 50.94 to 76.65% for the different experimental runs. The highest DPPH scavenging activity was observed at a steaming temperature of 150°C and a drum speed of 2 rpm and was predicted to be 74.66%. Similarly, the FRAP ranged from 230.45 μmol ascorbic acid/100 g to 277.89 μmol ascorbic acid/100 g. The highest FRAP was also observed at a steaming temperature of 150°C and a drum speed of 2 rpm and was predicted to be 270.75 μmol ascorbic acid/100 g. This suggests that the optimized drying conditions led to a high reducing power of the dried samples, which is indicative of its antioxidant capacity. The SDF content ranged from 1.26 g/100 g to 1.56 g/100 g. The highest SDF content was observed at a steaming temperature of 178.28°C and a drum speed of 2 rpm and was predicted to be 1.27 g/100 g.

Table 2. Optimization of twin drum drying: steaming temperature and rotation speed using response surface methodology.

The response surface methodology and the experimental data allowed for construction of a predictive model for the drying process. The predicted values obtained from the model were found to be in good agreement with the experimental values, indicating the reliability of the model in optimizing the drying process. The optimization results suggest that a steaming temperature of around 150°C and a drum rotation speed of 2 rpm are optimal for achieving high DPPH scavenging activity, FRAP, and SDF contents in the dried samples.

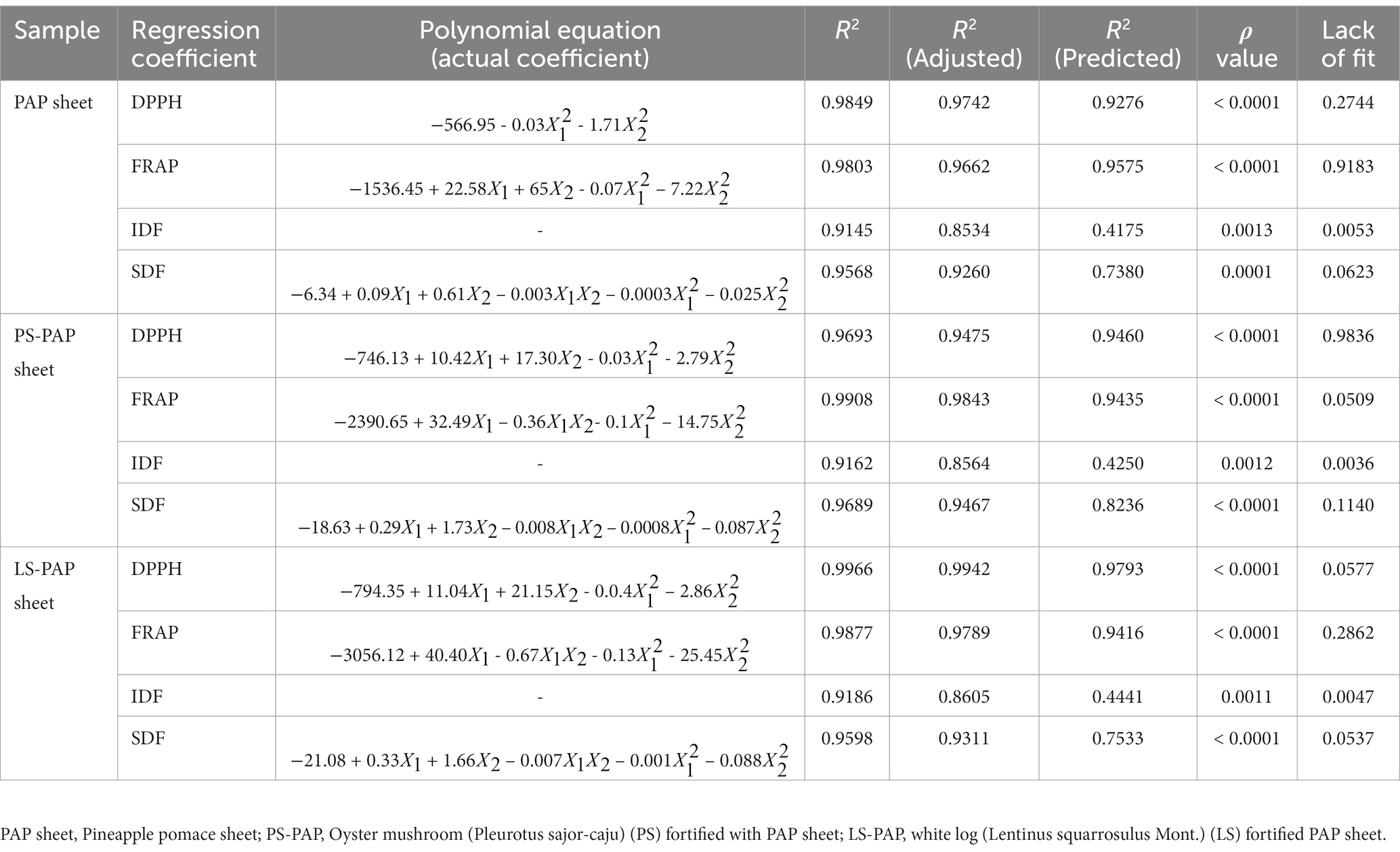

Table 3 presents the regression coefficients of the predicted second-order polynomial models for the antioxidant properties and dietary fiber content. The models were developed using the Box–Behnken design and the responses of the dependent variables to twin drum drying. For the antioxidant property, DPPH, the regression equation for the PAP sheet samples is given by:

Table 3. Regression coefficient of the predicted second-order polynomial models (BBD) for antioxidant properties and dietary fiber content.

DPPH = −566.95 - 0.03X₁2–1.71X₂2

The effects of steaming temperature and rotation speed on DPPH in the PAP sheets were found to be significant (p < 0.05) when fitted with a second-order quadratic linear effect (X₁2, X₂2) with no interaction occurring between the effects of steaming temperature and rotation speed. According to the equation, temperature has a greater impact on the response value compared to time. For PS-PAP sheets, a first-order quadratic linear effect (X₁) and a second-order quadratic linear effect (X₁2, X₂2) with no interaction term was found to be significant (p < 0.05). In the case of LS-PAP sheets, the effect of steaming temperature was more significant than rotation speed. Both steaming temperature and rotation speed were found to affect DPPH scavenging activity, with rotation speed having a greater impact than temperature. The regression coefficients (R2) for PS-PAP and LS-PAP sheets were 0.9693 and 0.9966, respectively, indicating a good fit. The predicted R2 and adjusted R2 values were in reasonably close agreement.

For the antioxidant property, FRAP, in the PAP sheets, the regression equation is:

FRAP = −1536.45 + 22.58X₁ + 65X₂ - 0.07X₁2–7.22X₂2

The R2 value for this model is 0.9803, indicating that 98.03% of the variability in FRAP can be explained by the independent variables. The adjusted R2 value is 0.9662, and the predicted R2 value is 0.9575, indicating a good fit and predictive capability of the model. The regression (value of p) value is less than 0.0001, suggesting a significant relationship. The lack of fit is 0.9183, indicating a satisfactory fit of the model. Steaming temperature and rotation speed significantly affected the FRAP with a first-order quadratic linear effect (X₁, X₂) and a second-order quadratic effect (X₁2, X₂2), with no interaction occurring between steaming temperature and rotation speed. The interaction p-values for PS-PAP and LS-PAP sheets were 0.0135 and 0.0048, respectively, indicating significance. The R2 values for PAP, PS-PAP, and LS-PAP sheets were 0.9803, 0.9908, and 0.9877, respectively, showing good predictability of the models.

Regarding dietary fiber, the regression equation for IDF was not included in the polynomial prediction due to a significant lack-of-fit (ρ > 0.05). Only SDF was fitted to the regression model. The SDF response of the PAP sheet showed a significant effect of steaming temperature and rotation speed. For PAP, PS-PAP, and LS-PAP sheets, all terms of the polynomial prediction equations were found to be significant for PAP, PS-PAP, and LS-PAP sheets. The significant polynomial terms include the first-order quadratic linear effects (X₁, X₂), second-order quadratic effects (X₁2, X₂2) and an interaction between steaming temperature and rotation speed (X₁X₂). The R2 values for PAP, PS-PAP, and LS-PAP sheets were 0.9568, 0.9689, and 0.9598, respectively, indicating good predictability. Dong et al. (2019) reported that thermal processing can affect the structural and functional properties of SDF whole grain oats, leading to an increase in molecular weight, particle size, and molecular aggregation.

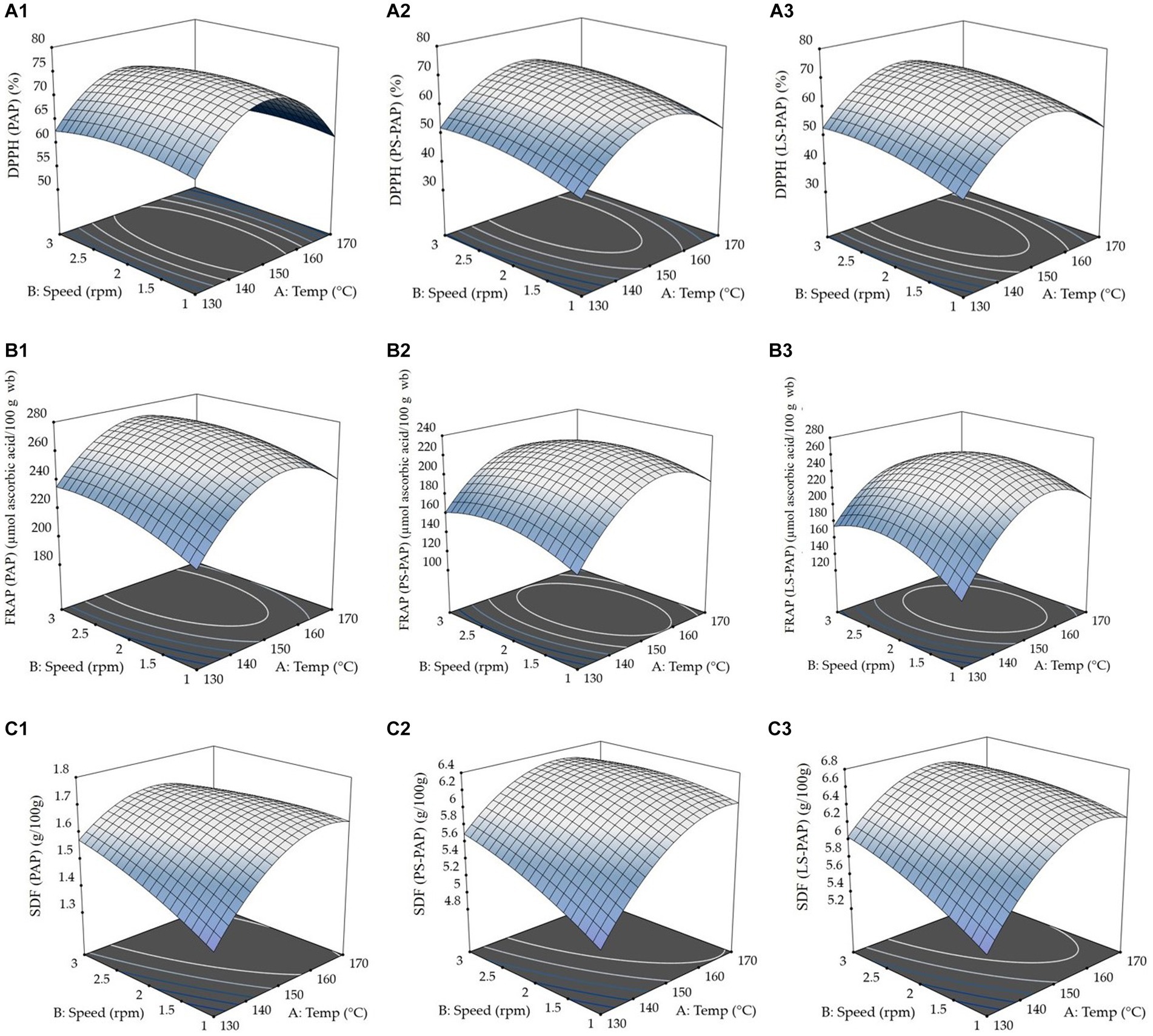

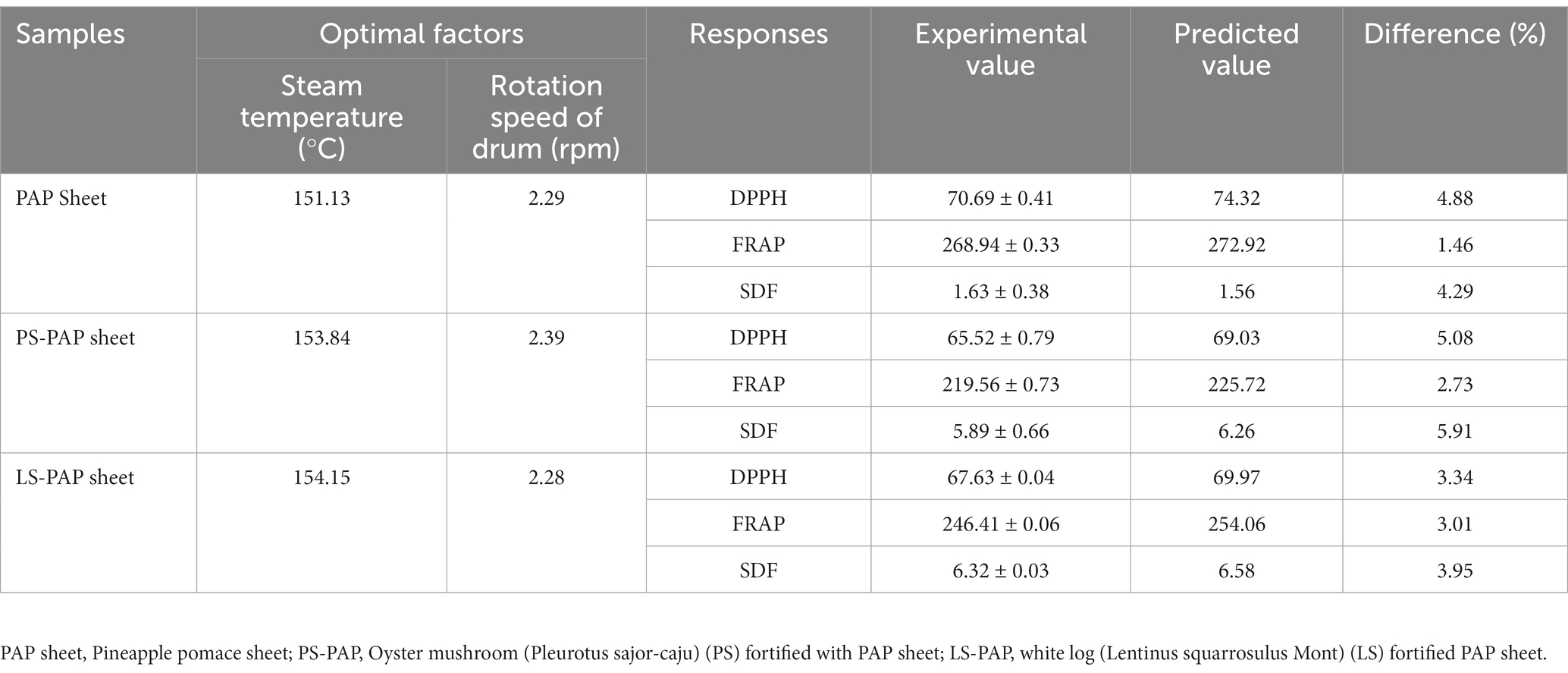

Figure 1 shows the surface response with contours of the quadratic effects of steaming temperature and drum speed. The three-dimensional response surfaces for DPPH, FRAP, and SDF are presented individually for PAP, PS-PAP, and LS-PAP sheets. The contours’ internal center helps visualize the impact of steaming temperature and rotation speed on the optimal conditions that yield the maximum response in the dependent variables. A second-order polynomial model was used to predict the response of the dependent variables, as shown in Table 3. The experimental values were then compared to the predicted values, revealing a close agreement between the two. This indicates that the model is reasonable for prediction. The twin drum drying process using a combination of moderate steaming temperature and rotation speed yields the highest responses in all dependent variables (DPPH, FRAP, and SDF). When applying a steaming temperature of 150°C and a drum rotation speed of 2 rpm, the predicted maximum DPPH scavenging activities for PAP, PS-PAP, and LS-PAP sheets were 74.32, 69.03, and 69.97%, respectively and the experimental values were 70.69 ± 0.41%, 65.52 ± 0.79%, and 67.63 ± 0.04%, respectively. Additionally, for FRAP, the predicted maximum values for PAP, PS-PAP, and LS-PAP sheets were 272.92, 225.72, and 254.06 μmol ascorbic acid/100 g, while the experimental values were 268.94 ± 0.33, 219.56 ± 0.73, and 246.41 ± 0.06 μmol ascorbic acid/100 g, respectively. For SDF of PAP, PS-PAP, and LS-PAP sheets, the predicted values were 1.56, 6.26, and 6.58 g/100 g, and the experimental values were 1.63 ± 0.38, 5.89 ± 0.66, and 6.32 ± 0.03 g/100 g.

Figure 1. Response surface plot of steaming temperature and rotation speed on; DPPH (% scavenging activity) of PAP sheet (A1), PS-PAP sheet (A2), and LS-PAP sheet (A3); FRAP (μmol ascorbic acid/ 100 g) of PAP sheet (B1), PS-PAP sheet (B2), and LS-PAP sheet (B3); and SDF (g/100 g) of PAP sheet (C1), PS-PAP sheet (C2), and LS-PAP sheet (C3).

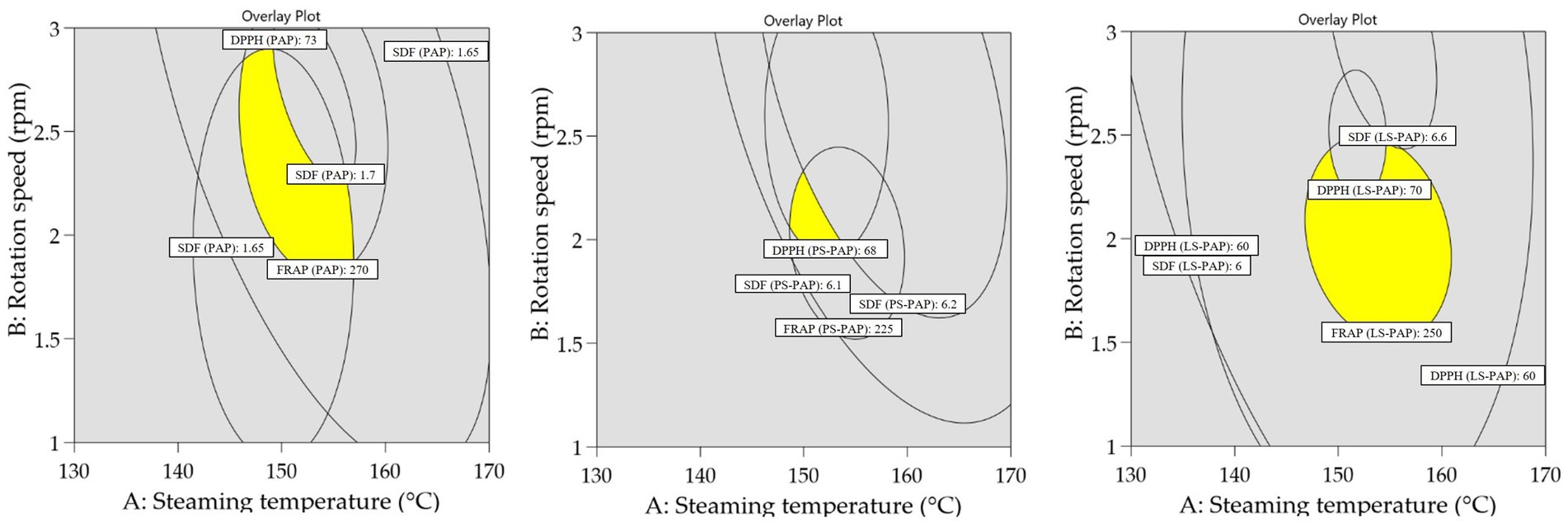

The experimental values for DPPH (Y1), FRAP (Y2), IDF (Y3), and SDF (Y4) were subjected to multiple regression analysis using response surface analysis to fit a quadratic polynomial equation. The experimental values closely matched the predicted values, indicating an adequate model. The R2 values, adjusted R2 values, probability values, and lack-of-fit values of the dependent variables are presented in Table 3. The lack-of-fit test showed that the response model accurately predicted the dependent variables. Graphical optimization was performed to determine the optimal conditions of the drum drying process. The desirability value represents the desirable value that maximizes DPPH, FRAP, and SDF. Figure 2 displays the overlaying contour plots that indicate the optimal steaming temperature and rotation speed. Numerical optimization revealed the optimum conditions for the PAP, PS-PAP, and LS-PAP sheets to be 151.88°C at 2.40 rpm, 154.41°C at 2.36 rpm, and 154.16°C at 2.28 rpm, respectively. The desirability plot area represents the range of independent variables within which the desirable values of the dependent variables are achieved. This area accounts for variations or fluctuations in steaming temperature and rotation time. Table 4 presents the predicted response values for DPPH, FRAP, and SDF. The predicted DPPH values for PAP, PS-PAP, and LS-PAP sheets were 74.04, 68.93, and 69.97%, respectively. The experimental DPPH values were 70.69 ± 0.41%, 65.52 ± 0.79%, and 67.63 ± 0.04%, indicating differences of 4.53, 4.95, and 3.34%, respectively. Similarly, for FRAP, the predicted values for PAP, PS-PAP, and LS-PAP sheets were 273.43, 225.93, and 254.04 μmol ascorbic acid/100 g. Comparing these values to the experimental values of 268.94 ± 0.33, 219.56 ± 0.73, and 246.41 ± 0.06 μmol ascorbic acid/100 g, the differences were 1.64, 2.82, and 3.00%, respectively. Regarding SDF, the predicted values for PAP, PS-PAP, and LS-PAP sheets were 1.70, 6.26, and 6.58, while the experimental values were 1.63 ± 0.38, 5.89 ± 0.66, and 6.32 ± 0.03, indicating differences of 4.06, 5.91, and 3.94%, respectively.

Figure 2. Superimpose of the desirable area with the effect of steaming temperature and rotation speed of PAP, PS-PAP and LS-PAP sheets.

Table 4. Comparison of optimized drum drying factors for verifying predicted and experimental values of antioxidant properties and fiber content.

Table 4 presents a comparison of the optimized drum drying factors used for verifying the predicted and experimental values for the antioxidant properties and fiber contents of the different samples. The optimized factors include steam temperature and rotation speed of the drum. For the PAP sheets, the optimal factors were determined to be a steam temperature of 151.13°C and a rotation speed of 2.29 rpm. The experimental values for the antioxidant properties and fiber content were compared to the predicted values. The differences between the experimental and predicted values ranged from 1.46 to 4.88%. These differences indicate a reasonably good agreement between the predicted and experimental values, suggesting that the optimization process was effective in achieving the desired properties. Similarly, for the PS-PAP sheets, the optimal factors were a steam temperature of 153.84°C and a rotation speed of 2.39 rpm. The differences between the experimental and predicted values ranged from 2.73 to 5.08%. While there is some variability between the predicted and experimental values, the overall agreement suggests that the optimized factors had a positive impact on the antioxidant properties and fiber content of the sample. For the LS-PAP sheets, the optimal factors were a steam temperature of 154.15°C and a rotation speed of 2.28 rpm. The differences between the experimental and predicted values ranged from 3.01 to 3.95%. These results indicate a relatively good agreement between the predicted and experimental values, demonstrating the effectiveness of the optimized drum drying factors and suggests that the optimization process was successful in achieving the desired antioxidant properties and fiber content for all three samples. The close agreement between the predicted and experimental values indicates the potential of drum drying as a viable method for producing antioxidant-rich and fiber-rich food products.

The desirability of the optimized formulations using different variables was analyzed based on the response surface methodology (RSM) and the predicted values obtained from the regression models. The desirability function is a tool that combines multiple response variables and provides a single value that represents the overall desirability of a set of conditions. In this study, the response variables include DPPH scavenging activity, FRAP, and SDF content. The goal was to find the optimal combination of steaming temperature and drum rotation speed that maximizes these response variables simultaneously. The desirability function ranges from 0 to 1, where 0 indicates the least desirable conditions, and 1 indicates the most desirable conditions. A desirability value of 1 means that all response variables are at their highest values, representing the best combination of variables. To determine the optimal conditions for the different samples (PAP, PS-PAP, and LS-PAP sheets), the desirability function was used to find the combination of steaming temperature and drum rotation speed that yields the highest desirability value (Table 1). The optimal conditions for the PAP sheets were a steaming temperature of 151.13°C and a drum rotation speed of 2.29 rpm. At these conditions, the predicted values for DPPH scavenging activity, FRAP, and SDF content were 74.04%, 273.43 μmol ascorbic acid/100 g, and 1.70 g/100 g, respectively. The desirability value for these conditions would be calculated based on how close these predicted values are to the ideal values of 100% for DPPH scavenging activity, the highest possible value for FRAP, and the highest possible value for SDF content. A higher desirability value indicates a more optimal combination of variables. The same process was employed for the PS-PAP and LS-PAP sheets, with different optimal conditions and desirability values for each sample. Overall, the desirability function was used to identify the best combination of steaming temperature and drum rotation speed that maximizes the antioxidant and dietary fiber content of the pineapple pomace fortified in crispy mushroom sheets. The reported results suggest that the optimized drying conditions led to high antioxidant properties and dietary fiber content in the dried samples.

The physicochemical properties of ‘Phulae’ pineapple pomace powder subjected to drum drying processing are presented in Table 5. The physicochemical characterization of drum dried PAP powder revealed its potential as a valuable byproduct. The PAP powder was moderately acidic pH of 4.53 ± 0.17 and had considerable titratable acidity (1.85 ± 0.25% citric acid), indicating its potential use as an ingredient in acidic food formulations. Moreover, PAP demonstrated significant antioxidant activity, with a DPPH scavenging activity of 70.13 ± 1.12% and a high FRAP of 161.85 ± 3.18 μmol ascorbic acid/100 g, suggesting its potential as a natural antioxidant source. Additionally, PAP contained substantial amounts of insoluble dietary fiber (30.44 ± 0.14 g/100 g) and smaller amounts of soluble dietary fiber (0.63 ± 0.03 g/100 g), indicating its potential as a dietary fiber source. The results of physicochemical properties especially TDF were compared with the reports of Selani et al. (2014) that indicated that pineapple pomace powder contains 99.2% insoluble dietary fiber and 0.8% soluble dietary fiber. pH and titratable acidity values showed variation with the values reported for PAP powder possibly due to differences in species, environmental factors such as microbial load, enzymatic activity, or biochemistry of fruit (Meena et al., 2022).

The proximate composition of the mushroom sheets with and without PAP after drum drying are presented in Table 6. The sheets exhibited varying levels of dry matter prior to drum drying. After drum drying, the dry matter content increased significantly in all samples, with the PS-PAP and LS-PAP showing the highest contents at 95.17 ± 0.21% and 95.29 ± 0.17%, respectively. The fat contents of both the PS and LS sheets were low (~0.13%) before drum drying; the PAP sheets a slightly higher fat content (0.28 ± 0.01%). After drum drying, the fat content increased in all samples, with the PS-PAP sheets having the highest fat content (1.32 ± 0.03%) followed by the LS-PAP sheets (1.37 ± 0.02%). Protein contents were relatively similar among the samples before drum drying; however, the PS and LS sheets had higher protein contents compared to the PAP sheets. After drum drying, the protein content increased significantly in both PS-PAP (12.44 ± 0.05%) and LS-PAP sheets (13.36 ± 0.08%). Ash contents represent the inorganic mineral compositions. The PS and LS sheets had similar ash percentages before drum drying; however, the PAP sheets had a higher ash content (2.15 ± 0.01%). After drum drying, the ash contents increased in both the PS-PAP (5.77 ± 0.01%) and LS-PAP sheets (5.71 ± 0.01%). Total dietary fiber (TDF) provides an indication of the fiber content in the samples. The PS and LS sheets had comparable TDF percentages before drum drying; however, the PAP sheets had the highest TDF content (35.67 ± 0.18%). After drum drying (Table 6), the TDF content decreased in both PS-PAP (25.38 ± 0.05%) and LS-PAP sheets (27.03 ± 0.12%), possibly due to the effects of the drying process. Carbohydrate contents represent the remaining portions of the samples after accounting for the other proximate components. The PS and LS sheets had similar carbohydrate percentages before drum drying but the PAP sheets had the highest carbohydrate contents (20.62 ± 0.22%). After drum drying, the carbohydrate content increased significantly in both PS-PAP (50.26 ± 0.90%) and LS-PAP sheets (47.82 ± 0.81%) and were the highest of all of the sheets.

The drum drying processing had a significant impact on the proximate composition of the mushroom samples. The process led to a considerable increase in the dry matter content of all samples, indicating the removal of moisture during drying. This increase in dry matter is desirable for enhancing the shelf life and stability of the mushrooms. The fat content of the samples increased after drum drying and can also be attributed to a concentration effect caused by moisture removal. The higher fat content in the PS-PAP and LS-PAP sheets may be attributed to the addition of PAP, which likely contributed to the increase in fat content. The protein content significantly increased in both PS-PAP and LS-PAP sheets after drum drying. This increase may be attributed to a concentration effect resulting from the removal of water during drying. The addition of PAP also contributed to the higher protein content in these samples. The ash content, representing the inorganic mineral content, increased in both PS-PAP and LS-PAP sheets after drum drying. The higher ash content in the PAP and the incorporation of PAP in the PS and LS samples likely contributed to this increase. The decrease in TDF content after drum drying in PS-PAP and LS-PAP sheets is intriguing. The drying process might have caused some structural changes in the fiber components, leading to a reduction in TDF. Further analysis is required to understand the specific effects of drum drying on the fiber composition of mushrooms. Carbohydrate contents increased significantly in both PS-PAP and LS-PAP sheet samples after drum drying. This increase is likely due to the concentration effect caused by moisture removal during drying and the higher carbohydrate content in the PAP sheet itself. The proximate composition of the pineapple pomace fortification in mushroom sheets showed higher total dietary fiber. This was in agreement with the proximate composition results of functional pasta extruded by blending pineapple pomace and soy protein floor (Devi et al., 2023). The study evaluated the protein, fat, fiber, carbohydrate, and mineral contents of wheat flour biscuits developed with a functional additive of 5% pomace powder, aiming to create biscuits with health-promoting properties (Thivani et al., 2016). Another study showed apple pomace powder contains high levels of fiber (51%) and carbohydrate (31.24%), but low levels of fat (2.16%) and protein (4.88%) and that the pomace derived from apples can be effectively utilized as a fiber-enhancing ingredient in low-fiber foods, such as yogurt (Meena et al., 2022).

Table 7 presents the microbiological analysis results of the crispy sheet mushroom sheets supplemented with pineapple pomace. The total plate count provides an estimation of the total viable microbial population present in the samples. The PS-PAP sheets had a TPC of 8.0 × 10 CFU/g, while the LS-PAP sheets had a slightly higher TPC of 7.0 × 102 CFU/g. These counts indicate a relatively low microbial load in both samples. Yeast and mold counts were also determined in the samples. The PS-PAP sheet had a yeast and mold count of 4.7 × 10 CFU/g, while the LS-PAP sheet had a higher count of 7.5 × 102 CFU/g. These counts indicate the presence of yeasts and molds in both samples, although the LS-PAP sheet had a slightly higher count. The presence of specific pathogenic bacteria, such as Bacillus cereus, Clostridium perfringens, Escherichia coli, and Staphylococcus aureus, in the sheets was also determined. The counts for these pathogens were below the detectable limit (< 10 CFU/g) in both the PS-PAP and LS-PAP sheets, indicating the absence or presence at very low levels of these organisms. E. coli is a commonly-tested indicator of fecal contamination, and the Most Probable Number method was used to estimate the E. coli levels in the samples. Both the PS-PAP and LS-PAP sheets had E. coli levels below 3.0 MPN/g, indicating the absence or very low levels of this pathogen. The presence of Salmonella spp., a pathogenic bacterium associated with foodborne illness, was also investigated, and the PS-PAP and LS-PAP sheets tested negative for this pathogen. Staphylococcus aureus is another pathogenic bacterium commonly found in food, and counts for this pathogen were below the detectable limit (< 10 CFU/g) in both sheets. A study by Selani et al. (2014) was conducted on the development of an extruded snack product made from pineapple pomace and the authors found that fiber enhancement reduced microbial loads. The microbial counts determined in our study suggest that mushroom sheets supplemented with PAP have low microbiological hazards risk. This low risk was attributed to the minimal moisture content, which likely prevents microbial proliferation (Alp and Bulantekin, 2021). A study by Babaoğlu et al. (2022) found that the inclusion of water extracts from black chokeberry, blackberry, blueberry, and red currant pomace resulted in improved quality characteristics of beef patties. Specifically, the extracts inhibited the growth of mesophilic and psychotropic aerobic bacteria, lactic acid bacteria, and coliforms, thereby enhancing the overall microbial quality of the patties.

The pomace produced from the processing of ‘Phulae’ pineapples has great potential for the production of new functional snacks due to its physicochemical properties. The use of the Box–Behnken design allowed the determination of optimum parameters for the processing of PAP, PS-PAP, and LS-PAP sheets to achieve maximum DPPH, FRAP, and SDF contents. For the PAP sheet, the optimum parameters were a steaming temperature of 151.13°C and a rotation speed of 2.29 rpm. Similarly, for the PS-PAP sheets, the optimum parameters were 153.84°C and 2.39 rpm, and for the LS-PAP sheets, the optimum parameters were 154.15°C and 2.28 rpm. Furthermore, increasing the temperature and time showed the potential to transform a partial fraction of IDF into SDF. Moreover, the crispy sheet mushroom products were found to be safe, as there was no proliferation of pathogenic bacteria. In conclusion, these crispy sheet mushroom products can be considered functional food, as they provide an alternative protein snack fortified with dietary fiber and could be scaled up for production.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

PS: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Project administration, Writing – original draft. MN: Supervision, Writing – review & editing. SS: Conceptualization, Resources, Supervision, Writing – review & editing.

Reinventing University has received funding support from The Office of the Permanent Secretary of the Ministry of Higher Education, Science, Research and Innovation.

The authors would like to thank Mae Fah Luang University, Chiang Rai, Thailand, for providing research facilities, and Paul Holford from Western Sydney University, Australia, for proofreading and editing this manuscript.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Alp, D., and Bulantekin, Ö. (2021). The microbiological quality of various foods dried by applying different drying methods: a review. Eur. Food Res. Technol. 247, 1333–1343. doi: 10.1007/s00217-021-03731-z

Babaoğlu, A. S., Unal, K., Dilek, N. M., Poçan, H. B., and Karakaya, M. (2022). Antioxidant and antimicrobial effects of blackberry, black chokeberry, blueberry, and red currant pomace extracts on beef patties subject to refrigerated storage. Meat Sci. 187:108765. doi: 10.1016/j.meatsci.2022.108765

Banerjee, S., Ranganathan, V., Patti, A., and Arora, A. (2018). Valorisation of pineapple wastes for food and therapeutic applications. Trends Food Sci. Technol. 82, 60–70. doi: 10.1016/j.tifs.2018.09.024

Bird, P., Flannery, J., Crowley, E., Agin, J., Goins, D., and Jechorek, R. (2016). Evaluation of the 3M™ Petrifilm™ rapid aerobic count plate for the enumeration of aerobic bacteria: collaborative study, first action 2015.13. J. AOAC Int. 99, 664–675. doi: 10.5740/jaoacint.15-0260

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., and Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. J. Food Eng. 111, 135–148. doi: 10.1016/j.jfoodeng.2012.01.010

Devi, Y. B., Dhar, P., Kumari, T., and Deka, S. C. (2023). Development of functional pasta from pineapple pomace with soyflour protein. Food Chemistry Adv 2:100198. doi: 10.1016/j.focha.2023.100198

Dong, J. L., Yang, M., Shen, R. L., Zhai, Y. F., Yu, X., and Wang, Z. (2019). Effects of thermal processing on the structural and functional properties of soluble dietary fiber from whole grain oats. Food Sci. Technol. Int. 25, 282–294. doi: 10.1177/1082013218817705

Hertzler, S. R., Lieblein-Boff, J. C., Weiler, M., and Allgeier, C. (2020). Plant proteins: assessing their nutritional quality and effects on health and physical function. Nutrients 12:3704. doi: 10.3390/nu12123704

Hidayat, D., Sagita, D., Darmajana, D., Indriati, A., Rahayuningtyas, A., Sudaryanto, A., et al. (2021). Development and thermal evaluation of double drum dryer for ready-to-eat food products to support stunting prevention. INMATEH Agricultural Engineering 64, 43–53. doi: 10.35633/inmateh-64-04

Jafari, S., Karami, Z., Shiekh, K. A., Kijpatanasilp, I., Worobo, R. W., and Assatarakul, K. (2023). Ultrasound-assisted extraction of bioactive compounds from cocoa Shell and their encapsulation in gum Arabic and maltodextrin: a technology to produce functional food ingredients. Foods 12:412. doi: 10.3390/foods12020412

Jose, M., Himashree, P., Sengar, A. S., and Sunil, C. K. (2022). Valorization of food industry by-product (pineapple pomace): a study to evaluate its effect on physicochemical and textural properties of developed cookies. Measurement: Food 6:100031. doi: 10.1016/j.meafoo.2022.100031

Karthik, P., Chhanwal, N., and Chinnaswamy, A. (2017). “Drum drying” in Encyclopaedia of Agricultural, Food, and Biological Engineering. eds. D. R. Heldman and C. I. Moraru (New York: Marcel Dekker, Inc), 211–214.

Kongsuwan, A., Suthiluk, P., Theppakorn, T., Srilaong, V., and Setha, S. (2009). Bioactive compounds and antioxidant capacities of ‘Phulae’ and ‘Nanglae’ pineapple. As. J. Food Ag-Ind 2, S44–S50.

Langyan, S., Yadava, P., Khan, F. N., Dar, Z. A., Singh, R., and Kumar, A. (2021). Sustaining protein nutrition through plant-based foods. Frontiers Nutr 8:772573. doi: 10.3389/fnut.2021.772573

Li, J.-M., and Nie, S.-P. (2016). The functional and nutritional aspects of hydrocolloids in foods. Food Hydrocoll. 53, 46–61. doi: 10.1016/j.foodhyd.2015.01.035

Liu, H., Liang, J., Liang, C., Liang, G., Lai, J., Zhang, R., et al. (2022). Physicochemical properties of dietary fiber of bergamot and its effect on diabetic mice. Front. Nutr. 9:1040825. doi: 10.3389/fnut.2022.1040825

Martínez, M. M., Macias, A. K., Belorio, M. L., and Gómez, M. (2015). Influence of marine hydrocolloids on extruded and native wheat flour pastes and gels. Food Hydrocoll. 43, 172–179. doi: 10.1016/j.foodhyd.2014.05.012

McCleary, B., Sloane, N., Draga, A., and Lazewska, I. (2013). Measurement of Total dietary Fiber using AOAC method 2009.01 (AACC International approved method 32-45.01): evaluation and updates. Cereal Chem. 90, 396–414. doi: 10.1094/CCHEM-10-12-0135-FI

Meena, L., Neog, R., Yashini, M., and Sunil, C. K. (2022). Pineapple pomace powder (freeze-dried): effect on the texture and rheological properties of set-type yogurt. Food Chemistry Adv. 1:100101. doi: 10.1016/j.focha.2022.100101

Philip, M. (2004). The use of the stable free radical diphenylpicrylhydrazyl (DPPH) for estimating antioxidant. Songklanakarin. J. Sci. Technol. 26, 211–219.

Selani, M. M., Brazaca, S. G., Dos Santos Dias, C. T., Ratnayake, W. S., Flores, R. A., and Bianchini, A. (2014). Characterisation and potential application of pineapple pomace in an extruded product for fibre enhancement. Food Chem. 163, 23–30. doi: 10.1016/j.foodchem.2014.04.076

Srikram, A., and Supapvanich, S. (2016). Proximate compositions and bioactive compounds of edible wild and cultivated mushrooms from Northeast Thailand. Agricu. Nat. Res. 50, 432–436. doi: 10.1016/j.anres.2016.08.001

Taşkın, B., and Savlak, N. (2022). Functional, chemical, and sensorial properties of gluten-free fermented instant soup powders developed by use of mung bean and drum drying process. Food Biosci. 47:101677. doi: 10.1016/j.fbio.2022.101677

Thivani, M., Mahendran, T., and Kanimoly, M. (2016). Study on the physico-chemical properties, sensory attributes and shelf life of pineapple powder incorporated biscuits. Ruhuna J. Sci. 7:32. doi: 10.4038/rjs.v7i2.17

Wiriyawattana, P., Suwonsichon, S., and Suwonsichon, T. (2018). Effects of drum drying on physical and antioxidant properties of riceberry flour. Agricu. Nat. Res. 52, 445–450. doi: 10.1016/j.anres.2018.11.008

Zhang, Y., Liao, J., and Qi, J. (2020). Functional and structural properties of dietary fiber from citrus peel affected by the alkali combined with high-speed homogenization treatment. LWT 128:109397. doi: 10.1016/j.lwt.2020.109397

Zhong, Y., and Shahidi, F. (2015). “12 - methods for the assessment of antioxidant activity in foods11This chapter is reproduced to a large extent from an article in press by the authors in the journal of functional foods” in Handbook of antioxidants for food preservation. ed. F. Shahidi (Delhi: Woodhead Publishing), 287–333.

Keywords: pineapple pomace, mushroom, drum drying, response surface optimization, bioactive properties, functional snacks

Citation: Suthiluk P, Naradisorn M and Setha S (2023) Assessing the impact of drum drying on the nutritional properties of pineapple pomace-fortified crispy mushroom sheets. Front. Sustain. Food Syst. 7:1253597. doi: 10.3389/fsufs.2023.1253597

Received: 05 July 2023; Accepted: 10 August 2023;

Published: 24 August 2023.

Edited by:

Muhammad Faisal Manzoor, Foshan University, ChinaReviewed by:

Jyoti Singh, Lovely Professional University, IndiaCopyright © 2023 Suthiluk, Naradisorn and Setha. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Phunsiri Suthiluk, cGh1bnNpcmkuc0BtZnUuYWMudGg=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.