- Plant Industries, Department of Industry, Tourism and Trade, Northern Territory Government, Berrimah, NT, Australia

Global demand of vanilla, as a natural flavour, is consistently growing. Vanilla is an emerging crop with high potential for Australian growers due to its climatic suitability in some regions, and high domestic and global demand. In this paper, the priorities of Australian vanilla industry are recognised based on the current issues, challenges, and opportunities. We show the priorities and related activities as established through one-on-one interaction and group engagement with industry wide stakeholders to capture a varied range of views. Critical feedback from the industry included the need for structuring an industry association, arrangements that offer training for example on production, postharvest and product diversification, improvements to the linkages between stakeholders, and technical support from research and development agencies. The priorities were ranked by stakeholders according to their importance as follows: (a) capacity building, (b) harvest and postharvest protocols, (c) production procedures, and (d) selection of better clonal material. Addressing the industry’s needs and priorities will ensure its future development is sustainable and economically viable. Policymakers are encouraged to take into account these discerned priorities and the proposed strategies designed to confront the industry’s needs and challenges.

1. Introduction

The commercial species of vanilla, Vanilla planifolia G. Jacks., is an orchid that, according to genetic evidence, originated in Mexico, specifically the Papantla region (de Oliveira et al., 2022). In response to the expanding demand for vanilla beans in Europe, V. planifolia vines have been vegetatively propagated and cultivated on the eastern coast of Mexico since the mid-eighteenth century (Favre et al., 2022). It is one of the most important aromatic plants used in the global food industry (Salazar-Rojas et al., 2012). At roughly $8–55 per pod (~ 4 g), cured vanilla is one of the most expensive spices, especially when compared to $30–40/kg for synthetic vanillin (Anonymous, 2023b).

Vanilla extract is utilized in food, beverage, perfume, cosmetics, and pharmaceuticals, prized for its flavor, aroma, antimicrobial, and antioxidant attributes (Baqueiro-Peña and Guerrero-Beltrán, 2017; Anonymous, 2023a). It is also a powerful antioxidant biophenol and can serve as an alternate food-preserving agent capable of imparting extra nutraceutical characteristics due to its antimicrobial, anti-mound, anti-yeast, and antioxidant activities (Ciriminna et al., 2019). In addition, it is utilized as a fixer for more volatile notes in fragrances because of its distinctive aroma.

Hoffman et al. (2005) reviewed and reported presence of 200 volatiles in cured vanilla beans. Vanillin (C8H8O3) is the primary flavoring compound in vanilla. It is an organoleptic chemical derived from the pods of the natural vanilla. It is an aromatic aldehyde (3-methoxy-4-hydroxybenzaldehyde) belonging to the group of phenolic compounds. Vanillin is a white, solid substance that is soluble in water. It has a molecular weight of 152.15 g/mol, a melting point of 80°C–83°C, and a boiling temperature of 285°C (Chattopadhyay et al., 2018; Banerjee and Chattopadhyay, 2019). The unique aroma of vanillin, which can differ depending on the growing region, does not develop in the green vanilla beans. After processing (curing), the fragrant qualities of vanilla beans become remarkably perceptible (Gassenmeier et al., 2008; Baqueiro-Peña and Guerrero-Beltrán, 2017).

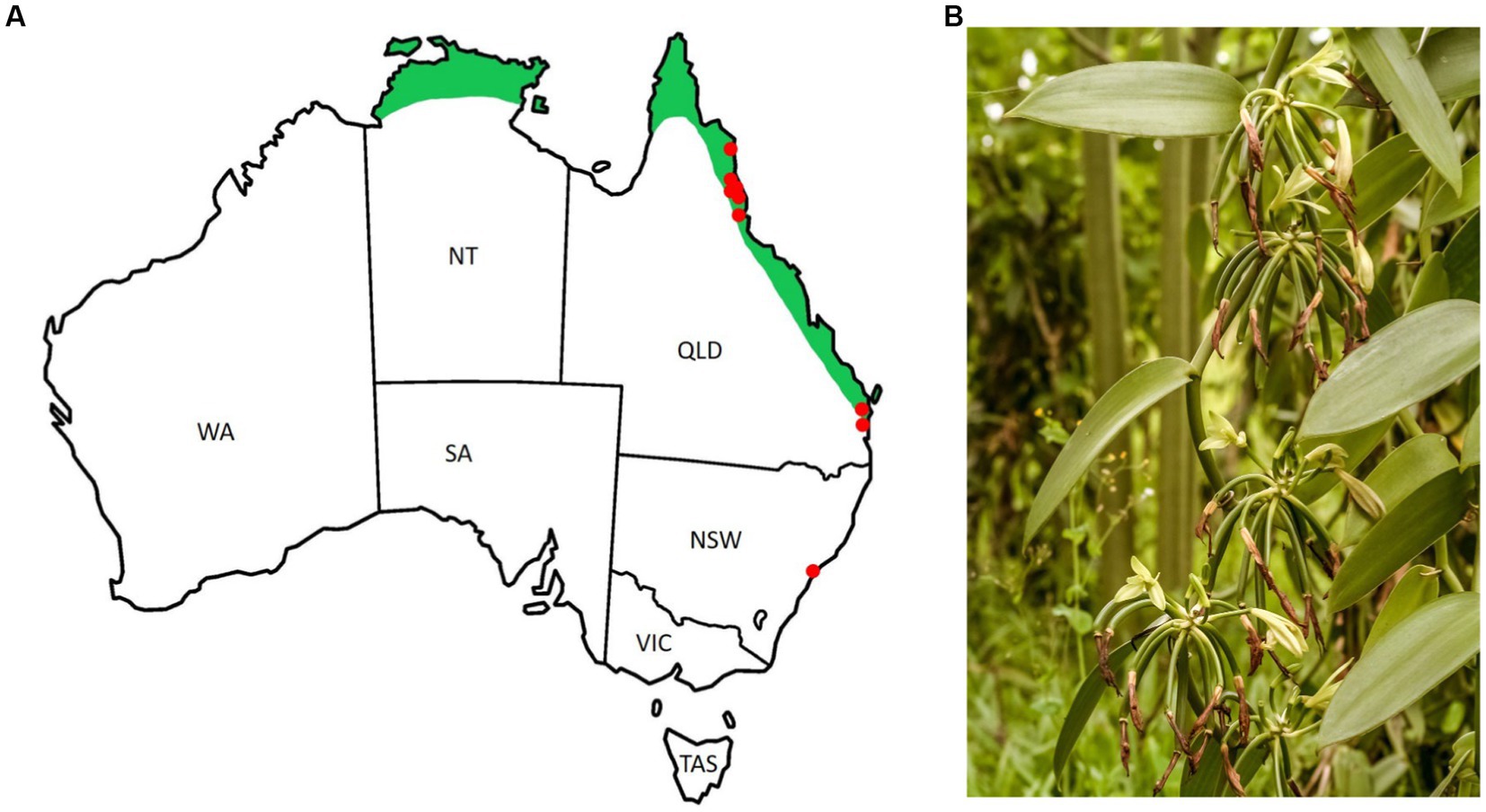

The global market for natural vanilla is expected to maintain its substantial growth trend due to the limitations of the synthetic alternatives and changing consumer awareness, along with rising demand for processed foods, driving new markets for natural vanilla. However, vanilla vines are grown on a commercial scale only in a certain climatic conditions offered in only a few countries, including Madagascar, Indonesia, Mexico, Papua New Guinea, China, Türkiye, Tonga, and Uganda (FAOSTAT, 2020). Vanilla grows well in tropical and subtropical forests primarily between the 27th North and South parallels, requiring hot and humid conditions to be productive (Andriamihaja et al., 2020). Vanilla cultivation requires temperatures ranging from 20°C to 30°C to achieve optimal growth and production conditions and can sustain slightly high temperatures of up to 32°C. Temperatures below 20°C restrict plant development and flowering intensity; temperatures above 32°C cause yellowing of vegetative parts and premature fruit drop. Vanilla requires an annual average precipitation range of 2000 to 3,000 mm. The optimal altitudes for vanilla cultivation are between sea level and 600 meters. Under 50% shade, vanilla grows most vigorously. During dry months with intense sunlight, 50%–70% shade should be used for optimal soil and air humidity conservation. The land that will be used for vanilla production should have good drainage, rich humus content, and a pH between 6 and 7 (Havkin-Frenkel and Belanger, 2018). Considering the geographical, climatic, and edaphic considerations, a wide tropical belt in northern Australia, as identified in Figure 1A, is suitable for future expansion of the Australian vanilla industry.

Figure 1. (A) The red dots indicate existing plantations in Australia, while the green area approximately shows the potential production areas in Australia. (B) Vanilla plants in Australia (photo credit: AgriFutures Australia).

In addition to these environmental considerations, duration of the crop cycle is the other major factor. Phenological stages of vanilla, as outlined by Havkin-Frenkel and Belanger (2018) include:

• Vines take up to three years to reach the maturity required for commercial scale bearing.

• Flowering happens once annually over a period of two to three months.

• Flowers are viable for hand pollination only for a few hours in the morning, and it requires experienced work force.

• The pollinated flowers take eight months to produce ready-to-harvest vanilla beans.

Curing the beans is also a laborious process but is obligatory required to produce desirable and flavorful final product (Havkin-Frenkel and Belanger, 2018).

However, vanilla is not a difficult crop – it is only a different crop. For instance, vanilla is an orchid, with unusual root requirements, and in some latitudes, it does not flower every year. Nonetheless, farmers who are willing to understand the crop differences can build a successful and profitable business (Bianchessi, 2012) and it can be a beneficial crop diversification option (Komarek, 2010) from biodiversity and economic perspective.

This study aimed to identify the priority of activities towards establishing a sustainable vanilla industry in northern Australia. The research gaps and relevant priorities and activities were identified through engagement and consultation with a wide range of participants, including current and potential Australian vanilla industry stakeholders, to find a common understanding of the research, development, and extension (RD&E) needs of growing, processing, and marketing Australian vanilla. This paper offers related perspectives to guide existing and new vanilla industry stakeholders.

2. Current state of the Australian vanilla industry

The Australian vanilla industry is at an early stage of development, with the potential for increased production to service markets desiring a high-quality product (Figure 1B). Our recent feasibility study (Mazhar, 2022) has shown that acceptable-quality vanilla beans can be grown in northern Australia. Vanilla cultivation in northern Australia promotes the conservation of local biodiversity and ecosystems because it fosters the development of vanilla plants while sustaining native flora and fauna. However, despite the potential, there are only limited vanilla plantations in northern Australia. As such, Australian vanilla production is currently limited to a few plantations in Queensland. A small scale vanilla production unit has recently been established in New South Wales; and there is no commercial vanilla plantation in the Northern Territory (Mazhar, 2022). A Strengths, Weaknesses, Opportunities, and Threats (SWOT) analysis of the Australian vanilla industry is depicted in Table 1.

Table 1. SWOT for the Australian vanilla industry adapted from Mazhar and Taghadomi-Saberi (2022).

An economic analysis of vanilla production in Australia found that the most critical and time-consuming step in vanilla production is pollination, with a labor cost of around AUD 60 per hour, validating vanilla’s reputation for high labor costs in Australia. The same analysis found plantations need to be established at a scale big enough to be commercially feasible when utilizing new technology such as the Vanilla Dome for growing vanilla vines. The minimum threshold adequate for sustainable return was found to be around 1,000 vanilla vines per business. Large-scale production will add value to business sustainability in terms of farm profitability and return on investment. One critical issue affecting the viability of the vanilla industry is low genetic diversity. This has resulted from the widespread reliance on the successors of a small number of foundational clones in commercial implementation (Chambers et al., 2021).

3. Growth opportunities for the Australian vanilla industry

Individual and group consultations with a range of stakeholders in the Australian vanilla industry were conducted to determine an industry-wide perspective on growth opportunities for the Australian vanilla industry. The industry ranked capacity building as the highest priority across all facets of supply chain management, followed by harvest and postharvest protocols, the development of standards for production procedures, and the selection of better clones. Priorities are explained and discussed in detail in the following sections:

3.1. Priority 1: capacity building

Australian vanilla industry needs to focus on long-term growth, robust involvement with all domestic and international stakeholders, and sustainable development. Support in all areas, including economic, social, and governance data collection, technology, extension, and consulting, is required if Australian vanilla is to be recognized as a premium quality brand internationally.

An institutional intermediary, such as an industry association, can provide these support functions and lead industry development. It can work as an avenue for increasing the innovativeness and sustainable development of the vanilla industry in Australia. By facilitating collaboration, communication, and execution, such an intermediary can aid in the growth of the vanilla industry (Goswami et al., 2017). For example, by providing training opportunities, access to grants, research and development support, and conducting a workshop where it is needed and possible, they would be able to make a considerable impact.

Additionally, they can aid in establishing connections among supply chain stakeholders (Yaoa et al., 2022). With the development of vanilla industry, supply chain coordination, whether horizontal coordination among farmers or vertical coordination in contracts between farmers and buyers, can lead to more transparency and efficiency in food supply chains (Watteyn et al., 2022). New growers can benefit from paid consulting that can be offered by more experienced growers. The involvement of smallholder farmers in the supply chains of vanilla as a highly priced product has the potential to lead to rural income mobility (Watteyn et al., 2022). Playing a central role in efficiently implementing RD&E activities, this intermediary body should keep reviewing and updating the industry’s short-, medium-, and long-term development needs.

First Nations communities in tropical Australia may find vanilla farming a healthy income generation activity, aligned with their interests of forest farming, to maintain carbon sequestration in plant biomass and soil and claim carbon credit through avoiding deforestation (Soazafy et al., 2021).

In addition to the advantages of active engagement of different stakeholders, Australian producers can profit from the Australian “clean green image” worldview and can distinguish their products as genuine, distinct, and potent (Wilkinson et al., 2021). A high-integrity supply chain, which is traceable and transparent, will set Australian vanilla apart in export markets and place it in the premium category of the market for food, drink, and pharmaceutical items with health and well-being features.

3.2. Priority 2: harvest and postharvest protocols

In Australia, the market for vanilla is huge, and the supply is largely underdeveloped due to the limited tropical area, high labor cost, and difficulties involved in producing the green beans and subsequently processing them into marketable cured vanilla beans.

Dry matter is highly correlated with glucovanillin (its hydrolysis creates vanillin) content, and the best time to harvest is when dry matter accumulation in the middle of beans slows. Near-infrared spectrometry as a non-invasive method has been shown to have the capability for in-field monitoring of maturity (Van Dyka et al., 2014). Other parameters such as weeks after pollination should be taken into account to develop a more precise indicator.

Curing is the first step after harvest and its procedure varies in the various production regions and is not fully understood. The secret to high-quality, premium vanilla beans is to cure the beans at a high temperature, which is akin to fermentation. A study found that in order to create cured beans with a great look and appealing aroma, a light hot water blanching procedure, followed by sweating at 35–45°C and rapid drying, is necessary (Van Dyk et al., 2010).

Although it is not proven scientifically; anecdotally, the presence of a crust of tiny white crystals on cured vanilla beans is an indicator of high vanillin content (Weiss, 2002). Vanillin’s biosynthesis has been studied from biotechnological perspectives in several studies (Ma et al., 2022; Liu et al., 2023), but scientific evidence on improving its quality, guaranteed reproducibility, and increased effectiveness of the curing process are limited (Korthou and Verpoorte, 2007). It is necessary to conduct additional research on the biochemistry of the formation of vanillin and other distinctive flavor molecules in plants. In addition to vanillin, visual qualities, including size, flexibility, and an unblemished appearance, are said to be closely related to the aroma/flavor quality (Sisifa et al., 2019).

In postharvest management of cured vanilla beans, the high standards of handling and holding the beans, as set during production and curing, are maintained. Moisture content, temperature, humidity, gas composition, and packing type are the primary determinants of bean quality in storage. These conditions would determine the effect of microorganisms on quality (Havkin-Frenkel and Frenkél, 2006). Pathogenic studies on vanilla beans have reinforced the importance of vanilla bean blanching as an important quality control measure. Researchers recognized the sweating, drying, and conditioning of green vanilla beans as the next three crucial control points (Mageme Kulwa, 2020).

The results of a recent meta-analysis (Arte and Larimo, 2022) showed that performance in the postharvest processing of products is higher when there is a diversity of related products. Higher performance of the processing unit is also expected for companies with higher research and development and advertising tendency. Therefore, it is worth developing value-added products, identifying new markets, and supporting domestic and international marketing campaigns to promote Australian-grown vanilla for its quality and provenance.

All in all, to satisfy domestic and international demand and offer desirable value-add, the post-harvest supply chain needs to be examined and developed to maintain premium quality. To achieve this, specific training on production, postharvest and product diversification is necessary for the vanilla sector to transit to the next phase of industry establishment. Intelligent agriculture is a promising approach to providing consistent quality, quantity, and cost for vanilla beans. For example, a computer-assisted curing procedure can be used to control interior environmental conditions such as temperature and humidity to enhance the flavor and aroma of any given batch of vanilla beans.

There is a need to re-evaluate current concepts and practices, particularly in the curing and post-curing handling of vanilla beans, which is brought on by the need for high and consistent quality of cured beans in the Australian and international market.

3.3. Priority 3: production procedures

The major agronomic problems need to be addressed to create a profitable and sustainable Australian vanilla industry. For example, standardized agronomic procedures in response to local seasonal variables should be developed to guarantee a continuously high yield. The agronomic challenges are likely to be eased through the accessibility of technology resources for growing and processing vanilla in Australia. The issue of vanilla’s labor-intensive pollination, for example, has been suggested to be tackled by some technology solutions, such as a vision feedback robotic docking crane system (Shaneyfelt et al., 2013).

Vanilla production is severely hampered by the incidence of various diseases (Talubnak and Soytong, 2010). High humidity and temperatures, which are ideal for growing vanilla, also favor the growth of pathogens, primarily fungi (Havkin-Frenkel and Belanger, 2018). Therefore, continuous and frequent monitoring and control of pests of concern and integrated pest management is crucial to scrutinize present pests and illnesses and potential exotic ones, as well as their biology, ecology, management, and mitigation strategies. The creation of a database of such information would clarify the RD&E gaps in this area.

The results of all research into agronomic aspects can be compiled into a manual of best management practices and disseminated to existing and new vanilla farmers for the secure, long-term conservation of accessions, guidelines, and standard procedures. This document can incorporate a cost-and-benefit analysis of vanilla production under various farming systems to provide potential investors with reliable and transparent information.

3.4. Priority 4: selection of better clonal material

The selection of better and uniform clonal material was ranked as the fourth priority by stakeholders in the Australian vanilla industry.

It is necessary to find varieties that are appropriate for Australian conditions and are desirable in domestic and foreign markets. For example, self-pollination, disease resistance, larger fruit, decreased fruit photosensitivity, and an improved fragrance profile are among the traits that can be investigated through hybridization and breeding (Divakaran et al., 2006). Growers require varieties that enable them to handle expensive labor, a changeable and unpredictable climate, and various farming methods. Additionally, high-yielding, premium-quality beans must be produced by these varieties. Biotechnological techniques have the capacity to make modifications in vanilla flavor production. Some attempts have been made to produce high-quality vanilla flavor products. For example, the bioconversion of cheap substrates using plant or microbial cells as biocatalysts has been studied to develop flavors of high value (Ramachandra Rao and Ravishankar, 2000).

4. Conclusion

Australia can benefit from natural tropical agro-climatic zones for producing high quality vanilla extract to meet the growing needs of domestic and international markets. Implementation of effective strategies and an enabling environment, guided by industry-led RD&E and government support, can fast-track the achievement of a highly profitable, economically viable, and sustainable Australian vanilla industry. Capacity building efforts require specific attention to transfer the existing findings to growers and coordinate supply chains for a more transparent and efficient industry. Increased engagement among stakeholders including growers, processors, researchers and user companies will facilitate local access to key information in vanilla production. Innovation and technology have potential for improvement in the production through to postharvest procedures of Australian vanilla, specifically the processing and pollination bottlenecks. Once the vanilla industry is well established in Australia, genomic improvement research is expected to continue to further advance the production of premium-quality vanilla lines. Policy makers could use the findings of this paper to drive and guide the sustainable development of Australian vanilla industry. For instance, policymakers might explore suitable funding frameworks, particularly in domains necessitating research and developmental endeavors.

Data availability statement

Publicly available datasets were analyzed in this study. This data can be found at: https://agrifutures.com.au/wp-content/uploads/2022/11/22-120.pdf.

Author contributions

ST-S, DY, and MM conceptualized and wrote the paper. MM conceived and designed the analysis. MM and ST-S conducted consultations with Australian vanilla industry stakeholders. All authors contributed to the article and approved the submitted version.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This output has been developed as follow on from AgriFutures Australia funded project “Feasibility study and development of RD&E Plan for the Australian vanilla industry, PRJ-013003”.

Acknowledgments

The authors would like to acknowledge the contribution of the Australian vanilla industry stakeholders for providing transparent and open information compiled in this paper.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Andriamihaja, C. F., Ramarosandratana, A. V., Grisoni, M., Jeannoda, V., and Besse, P. (2020). The leafless Vanilla species-complex from the south-West Indian Ocean region: a taxonomic puzzle and a model for orchid evolution and conservation research. Diversity 12:443. doi: 10.3390/d12120443

Anonymous (2023a). Vanilla – uses, side effects, and more [online]. WebMD: Available at: https://www.webmd.com/vitamins/ai/ingredientmono-206/vanilla#:~:text=In%20foods%20and%20beverages%2C%20vanilla,as%20a%20fragrance%20in%20perfumes (Accessed July 31, 2023).

Anonymous (2023b). vanilla price [Online]. David Vanille. Available at: https://www.davidvanille.com/en/search?s=vanilla (Accessed July 31, 2023).

Arte, P., and Larimo, J. (2022). Moderating influence of product diversification on the international diversification-performance relationship: a meta-analysis. J. Bus. Res. 139, 1408–1423. doi: 10.1016/j.jbusres.2021.10.037

Banerjee, G., and Chattopadhyay, P. (2019). Vanillin biotechnology: the perspectives and future. J. Sci. Food Agric. 99, 499–506. doi: 10.1002/jsfa.9303

Baqueiro-Peña, I., and Guerrero-Beltrán, J. Á. (2017). Vanilla (Vanilla planifolia Andr.), its residues and other industrial by-products for recovering high value flavor molecules: a review. J. Appl. Res. Med. Arom. Plants 6, 1–9. doi: 10.1016/j.jarmap.2016.10.003

Bianchessi, P. (2012). Vanilla handbook. [Online]. Available at: https://hdl.handle.net/10568/76745 (Accessed 17/05/2023).

Chambers, A., Cibrián-Jaramillo, A., Karremans, A. P., Moreno Martinez, D., Hernandez-Hernandez, J., Brym, M., et al. (2021). Genotyping-by-sequencing diversity analysis of international Vanilla collections uncovers hidden diversity and enables plant improvement. Plant Sci. 311:111019. doi: 10.1016/j.plantsci.2021.111019

Chattopadhyay, P., Banerjee, G., and Sen, S. K. (2018). Cleaner production of vanillin through biotransformation of ferulic acid esters from agroresidue by Streptomyces sannanensis. J. Clean. Prod. 182, 272–279. doi: 10.1016/j.jclepro.2018.02.043

Ciriminna, R., Fidalgo, A., Meneguzzo, F., Parrino, F., Ilharco, L. M., and Pagliaro, M. (2019). Vanillin: the case for greener production driven by sustainability megatrend. ChemistryOpen 8, 660–667. doi: 10.1002/open.201900083

de Oliveira, R. T., da Silva Oliveira, J. P., and Macedo, A. F. (2022). Vanilla beyond Vanilla planifolia and Vanilla × tahitensis: taxonomy and historical notes, reproductive biology, and metabolites. Plan. Theory 11:3311. doi: 10.3390/plants11233311

Divakaran, M., Babu, K. N., and Peter, K. V. (2006). Conservation of Vanilla species, in vitro. Sci. Hortic. 110, 175–180.

FAOSTAT (2020). FAOSTAT statistical database [online]. Food and agriculture Organization of the United Nations. Available at: https://www.fao.org/faostat/en/#rankings/countries_by_commodity (Accessed May 27, 2022).

Favre, F., Jourda, C., Grisoni, M., Piet, Q., Rivallan, R., Dijoux, J.-B., et al. (2022). A genome-wide assessment of the genetic diversity, evolution and relationships with allied species of the clonally propagated crop Vanilla planifolia jacks. Ex Andrews. Genet. Resour. Crop. Evol. 69, 2125–2139. doi: 10.1007/s10722-022-01362-1

Gassenmeier, K., Riesen, B., and Magyar, B. (2008). Commercial quality and analytical parameters of cured vanilla beans (Vanilla planifolia) from different origins from the 2006–2007 crop. Flavour Fragr. J. 23, 194–201. doi: 10.1002/ffj.1874

Goswami, K., Mitchell, J. R., and Bhagavatula, S. (2017). Accelerator expertise: understanding the intermediary role of accelerators in the development of the Bangalore entrepreneurial ecosystem. Strateg. Entrep. J. 12, 117–150. doi: 10.1002/sej.1281

Havkin-Frenkel, D., and Belanger, F. C. (2018). Handbook of vanilla science and technology. Hoboken, NJ, USA: Wiley-Blackwell.

Havkin-Frenkel, D., and Frenkél, C. (2006). Postharvest handling and storage of cured vanilla beans. Stewart Postharvest Review. 2, 1–9. doi: 10.2212/spr.2006.4.6

Hoffman, P., Harmon, A., Ford, P., Zapf, M., Weber, A., King, S., et al. (2005). “Analytical approaches to vanilla quality and authentication,” in Vanilla: The first international congress (Würzburg, Germany and Carol stream: Allured).

Komarek, A. M. (2010). Crop diversification decisions: the case of vanilla in Uganda. Q. J. Int. Agric. 49, 227–242.

Korthou, H., and Verpoorte, R. (2007). Vanilla. In: Flavours and Fragrances. Eds. R. G. Berger , (Berlin, Heidelberg: Springer).

Liu, Y., Sun, L., Huo, Y.-X., and Guo, S. (2023). Strategies for improving the production of bio-based vanillin. Microb. Cell Factories 22:147. doi: 10.1186/s12934-023-02144-9

Ma, Q., Liu, L., Zhao, S., Huang, Z., Li, C., Jiang, S., et al. (2022). Biosynthesis of vanillin by different microorganisms: a review. World J. Microbiol. Biotechnol. 38:40. doi: 10.1007/s11274-022-03228-1

Mageme Kulwa, K. (2020). “Spoilage moulds in cured vanilla beans in Tanzania: a case study of Kilimanjaro region” Master thesis (Morogoro, Tanzania: Sokoine university of agriculture).

Mazhar, M. S., and Taghadomi-Saberi, S. (2022). “Australian Vanilla RD&E Plan (2023-2028)” in Emerging Industries (Wagga Wagga, NSW, Australia: AgriFutures Australia).

Ramachandra Rao, S., and Ravishankar, G. A. (2000). Vanilla flavour: production by conventional and biotechnological routes. J. Sci. Food Agric. 80, 289–304.

Salazar-Rojas, V. M., Herrera-Cabrera, B. E., Delgado-Alvarado, A., Soto-Hernández, M., Castillo-González, F., and Cobos-Peralta, M. (2012). Chemotypical variation in Vanilla planifolia Jack. (Orchidaceae) from the Puebla-Veracruz Totonacapan region. Genet. Resour. Crop. Evol. 59, 875–887. doi: 10.1007/s10722-011-9729-y

Shaneyfelt, T., Jamshidi, M. M., and Agaian, S. (2013). A vision feedback robotic docking crane system with application to vanilla pollination. Int. J. Autom. Control. 7:62. doi: 10.1504/IJAAC.2013.055096

Sisifa, S., Ofe Grant, B., and Stringer, C. (2019). Opportunities to improve vanilla value chains for small Pacific Island countries. Auckland, New Zealand: New Zealand Institute for Pacific Research.

Soazafy, M. R., Osen, K., Wurz, A., Raveloaritiana, E., Martin, D. A., Ranarijaona, H. L. T., et al. (2021). Aboveground carbon stocks in Madagascar’s vanilla production landscape – exploring rehabilitation through agroforestry in the light of land-use history. Global Ecology and Conservation 31:e01853. doi: 10.1016/j.gecco.2021.e01853

Talubnak, C., and Soytong, K. (2010). Biological control of vanilla anthracnose using Emericella nidulans. J. Agric. Technol. 6, 47–55.

Van Dyk, S., McGlasson, W. B., Williams, M., and Gair, C. (2010). Influence of curing procedures on sensory quality of vanilla beans. Fruits 65, 387–399. doi: 10.1051/fruits/2010033

Van Dyka, S., Holforda, P., Subedi, P., Walshb, K., Williams, M., and McGlasson, W. B. (2014). Determining the harvest maturity of vanilla beans. Sci. Hortic. 168, 249–257. doi: 10.1016/j.scienta.2014.02.002

Watteyn, C., Dejonghe, O., Van Hoyweghen, K., Azofeifa Bolaños, J. B., Karremans, A. P., Vranken, L., et al. (2022). Exploring farmer preferences towards innovations in the vanilla supply chain. J. Clean. Prod. 330:129831. doi: 10.1016/j.jclepro.2021.129831

Wilkinson, V., Morris, T., and Hughes, D. (2021). "The next wave of emerging industry opportunities " Emerging Industries (Wagga Wagga, NSW, Australia: AgriFutures Australia).

Keywords: vanilla, industry’s priority, Australia, capacity building, research, development, extension

Citation: Taghadomi-Saberi S, Yadav D and Mazhar MS (2023) An integrated strategic framework for priority setting in the Australian vanilla industry. Front. Sustain. Food Syst. 7:1240410. doi: 10.3389/fsufs.2023.1240410

Edited by:

Jianxu Liu, Shandong University of Finance and Economics, ChinaReviewed by:

Noé Aguilar-Rivera, Universidad Veracruzana, MexicoCopyright © 2023 Taghadomi-Saberi, Yadav and Mazhar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Saeedeh Taghadomi-Saberi, U2FlZWRlaC5UYWdoYWRvbWktU2FiZXJpQG50Lmdvdi5hdQ==

Saeedeh Taghadomi-Saberi

Saeedeh Taghadomi-Saberi Dakshina Yadav

Dakshina Yadav Muhammad Sohail Mazhar

Muhammad Sohail Mazhar