- 1Department of Food Technology, Faculty of Agricultural Technology, Sakon Nakhon Rajabhat University, Sakon Nakhon, Thailand

- 2Department of Food Technology and Nutrition, Faculty of Home Economics Technology, Rajamangala University of Technology Krungthep, Bangkok, Thailand

The objective of this study was to develop an expanded snack from Riceberry rice flour (RBF) and dried coconut meal (DCM), a by-product of coconut milk production, using a twin-screw extruder. A 3 x 3 factorial design was employed to investigate the effects of feed moisture contents (18, 21, and 24%) and DCM levels (0, 5, and 10%) on the physicochemical, functional, and sensory properties of the products. The results showed that increasing feed moisture content significantly reduced the cold peak viscosity but had no significant effect on the hot peak viscosity. DCM was the dominant factor affecting the hot peak viscosity. The substitution of DCM led to a decrease in the expansion of the extrudates while increasing the L* and b* values. The texture parameters were affected by both feed moisture and DCM, where increased feed moisture resulted in more rigid structures with higher density and hardness but lower crispiness. Antioxidant levels in the final product decreased by approximately 64 to 70% and 10 to 25%, as determined by DPPH and FRAP assays, respectively, compared to the initial RBF. However, the antioxidant levels remained high in the final product. Feed moisture content had no effect on the antioxidant activity as measured by the DPPH and FRAP assays. The total phenolic content (TPC) of the extrudates decreased as feed moisture and DCM content increased. Furthermore, the anthocyanin content (ATC) decreased when RBF was substituted with DCM. The sensory evaluation revealed that the product with 18% feed moisture content and 10% DCM had the highest overall liking score. These findings offer valuable insights into the potential use of a twin-screw extruder for developing expanded snacks from RBF and DCM and could be useful for further research in this area.

1. Introduction

Extrusion is one of the most widely used methods for producing snacks. The physicochemical and sensory properties of extruded products can vary significantly depending on operating conditions and raw material properties. Most snacks available on the market are made from cereals that are high in fat and low in nutrition. Today, consumers are increasingly interested in foods that not only taste good but also provide high levels of nutrients or other functional components. The healthy snack market is expanding, and new products must be developed to meet consumer demand. To provide more nutrition that partially or completely replaces flour, several nutritious ingredients such as protein (Philipp et al., 2017; Saldanha do Carmo et al., 2019; Zhong et al., 2021), fiber (Alam et al., 2016; Han et al., 2018; Zhong et al., 2021), and phytochemicals (Hirth et al., 2014; Neder-Suárez et al., 2021) have been added to the extruded snack.

Anthocyanins are polyphenol compounds that are found in red, purple, and blue plants such as blackberries, blueberries, bilberries, grapes, strawberries, and black rice. Riceberry rice (Oryza Sativa L.), a dark purple rice variety from Thailand, was developed through crossbreeding between Hom Nin rice, a non-glutinous purple rice, and Khao Dawk Mali 105. Riceberry rice has been found to contain high levels of antioxidants, including vitamin E (tocotrienols), anthocyanins (cyanidin-3-O-glucoside, peonidin-3-O-glucoside), and phytosterols (oryzanol, sitosterol, and triterpene alcohol) (Poosri et al., 2019). Therefore, Riceberry rice-based food products may be an excellent choice for gluten-free and health-conscious consumers.

Coconut (Cocos nucifera L.) is a significant economic crop that is mainly grown in tropical regions. Indonesia (16.82 million tons), India (14.70 million tons), and the Philippines (14.49 million tons) are the top three coconut-producing countries globally, with Thailand ranking ninth (0.8 million tons) (FAO, 2020). Coconuts are versatile and can be used in various applications, including food, beverages, wood, and handicrafts. Coconut meat or kernel can be consumed fresh, processed into other foods, or crushed to extract coconut milk, which is a common ingredient in many dishes. The production of coconut milk typically uses screw press or hydraulic extraction methods, which produce between 53 and 62% of coconut milk, resulting in 38 to 47% of coconut meal waste. Although commercial coconut milk manufacturing is growing in Thailand, generating 5,000 metric tons of coconut meal residue (Sangkharak et al., 2020), most of which is primarily used as a low-cost animal feed ingredient and fertilizer, only a small part is used in food products as a source of dietary fiber. Therefore, there is a need to utilize waste products to achieve sustainable development and reduce environmental pollution. Several by-products, such as pomace (Alam et al., 2016) and bagasse from fruits and vegetables (Navarro Cortez et al., 2016), bran, coat, and wasted grains from cereals (Fleischman et al., 2016; Unsaeng et al., 2019; Zhong et al., 2021), have been used in extruded snack applications. However, there have been only a few studies examining the use of coconut meal in extruded snacks (Khan et al., 2015; Dumchaiyapoom et al., 2019).

Thus, this research aimed to investigate the effects of different levels of feed moisture and dried coconut meal on the physicochemical properties (nutritional compositions, pasting properties, expansion index, bulk density, water absorption index, color, and texture), functional properties (DPPH, FRAP, total phenolic content, and anthocyanin content), and sensory evaluation of extrudates. The primary focus of this study was to examine the potential application of dried coconut meal and Riceberry rice flour in the production of healthy extruded snacks and to investigate the effect of the extrusion process on product properties. The findings of this study will provide valuable insights into the feasibility of utilizing these ingredients to create nutritious snacks while also contributing to the reduction of food waste and promoting sustainable development.

2. Materials and methods

2.1. Raw materials and dried coconut meal preparation

Riceberry rice flour (RBF) and dried coconut meal (DCM) were used to formulate the expanded snacks. Commercial RBF was purchased from a local market (Fancy Carp brand, Charoenworrakit Part., Ltd., Thailand). The mature coconuts were procured from a local market, the shells removed, and the white kernels mechanically scraped. Thick milk was extracted from the kernels using a hydraulic press, followed by thin milk extraction using water (1:1 w/v, 25°C) left for 15 min before pressing. Coconut meal, a by-product of coconut milk extraction, was dried at 70°C for 4 h in a hot-air tray dryer, milled, passed through a 60 mesh sieve, and packed into polyethylene bags. The RBF was substituted with DCM at three different levels (0, 5, and 10% w/w). The proximate compositions of RBF and DCM were determined using a standard method described by AOAC (2002) and are presented in Table 1.

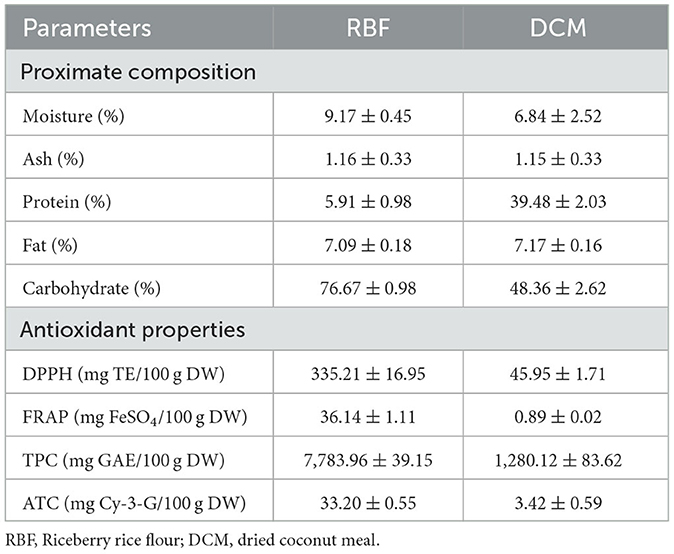

Table 1. Proximate composition and antioxidant activity of raw material used for expanded snack production.

2.2. Experiment design and extrusion process

The experiment was carried out using a 3 x 3 factorial arrangement in a completely randomized design (CRD) to investigate the two factors, including feed moisture content (18, 21, and 24% w/w) and DCM (0, 5, and 10% w/w) substituted for RBF.

Extrusion was performed using a pilot scale co-rotating intermeshing twin-screw extruder (CTE–D22L32 model, Chareun Tut Co., Ltd., Thailand). The screw had a diameter of 24.70 mm with a length-to-diameter ratio of 32:1. The barrel consisted of six jacketed zones. The temperature from the first zone to the sixth zone was maintained at 30, 45, 80, 125, 130, and 140°C, respectively, throughout the experiment. The extrudates were carried out in the twin-screw extruder using a 1.5-mm die diameter. The extruder was powered by a 3.7 kW motor with a screw speed of 400 rpm at a die temperature of 90°C. The raw material was fed into the extrusion barrel at 20 kg/h. The extrudates, in each experiment, were produced in duplicates. The extrudates were packed and stored at room temperature for further analysis.

2.3. Pasting properties

The pasting properties of the RBF and extrudate flour were measured using a Rapid Visco Analyzer (Newport Scientific PTY Ltd, Australia) combined with the Thermocline for Windows™ (TCW3) software. In the aluminum RVA canister, 4.5 g of sample was mixed with 25 mL of distilled water and corrected to a moisture basis of 14%. The mixture was rotated with a paddle until no lumps were observed. The canister and paddle were inserted into the RVA instrument, and the analysis was started. After 2 min of equilibration at 25°C, the suspension was heated to 95°C for 5 min and maintained for 3 min at the same temperature (95°C). Then, the temperature was reduced to 25°C for 5 min and held for 1 min.

2.4. Physical properties of extruded product

2.4.1. Expansion ratio

The diameter of extrudates from each treatment was measured using a digital caliper and divided by the die diameter (1.5 mm) of the extruder (Saeleaw et al., 2012).

2.4.2. Bulk density

Bulk density is a measure of weight per unit volume. The sesame seed displacement method was used to determine the volume of extrudates (Promsakha na Sakon Nakhon et al., 2018).

2.4.3. Water absorption index

The water absorption index (WAI) was determined using a modified method from Li et al. (2019). A 2.5 g sample of the ground product was sieved at 60 mesh, then suspended in 30 mL of water at 30°C in a 50 mL tarred centrifuge tube, stirred intermittently for 30 min, and then centrifuged at 3,000 x g for 10 min. The liquid from the supernatant was gently poured into an evaporating dish. The water absorption index was derived from the weight of the remaining solid.

2.4.4. Color measurement

The color parameters were assessed with a colorimeter (200 M model, Datacolor, NJ, USA) in the CIELAB parameters (L*, a*, and b* values), which are used to characterize color in three dimensions.

2.4.5. Texture analysis

The hardness and crispness of the extrudates were determined using the modified methodology of Nascimento et al. (2017). A texture analyzer (TA. XT Plus, Stable Micro Systems, Surrey, UK) was fitted with a 5 kg load cell and a 2 mm diameter stainless steel cylinder probe. A probe punctured the samples to a depth of 50% of the extrudate diameter of each specimen, and the test speed was 1 mm/s. Ten measurements were performed on each treatment. A force–time curve was recorded and analyzed to calculate the peak force and the number of force peaks.

2.5. Proximate composition

The proximate compositions of the RBF, DCM, and extrudates were determined according to AOAC (2002) methods. The carbohydrate content was calculated by difference.

2.6. Antioxidant activity, total polyphenolic content, and anthocyanin content

The antioxidant activity (DPPH and FRAP), total phenolic content (TPC), and anthocyanin content (ATC) of RBF, DCM, and extrudates were extracted according to the methods of Shao et al. (2021) with some modifications. Two g of each sample was mixed with 20 mL of 70% methanol (v/v) and then centrifuged at 3,000 x g for 10 min. The supernatant was filtered by a 0.45 μm nylon syringe filter (Minisart® SRP15, Sartorius AG, Germany), and the supernatant was transformed and stored at 4°C for further analysis. All extracts were used for antioxidant activity (DPPH and FRAP), TPC, and ATC.

The DPPH (2,2-diphenyl-1-picrylhydrazyl) radical capacity was determined using the methods suggested by Xu et al. (2015) with some modifications and using a freshly prepared solution of 0.1 mM solution of DPPH in 70% methanol with the absorbance of approximately 1.0 AU at 517 nm. The absorbance was then measured at a wavelength of 517 nm using a double-beam spectrometer (Libra S70, Biochrom, UK). Methanol was used as a blank control. The antioxidant capacity was expressed as milligram of Trolox equivalent (TE) per 100 g dry weight (DW) of the sample (mg TE/100 g DW).

FRAP assay was determined using the method described by Benzie and Strain (1996) with a slight modification. The extract (200 μL) was added to a 1,000 μL FRAP reagent and incubated for 1 h in darkness before measuring absorbance at 593 nm using a double-beam spectrometer. Fresh ferrous sulfate solutions (FeSO4) were used as the calibration curve and expressed as milligram of ferrous sulfate equivalent (FeSO4) per 100 g dry weight (DW) of the sample (mg FeSO4/100 g DW).

The TPC was measured using the Folin–Ciocalteu colorimetric method reported by Gong et al. (2017) with some modifications. The sample extracts or standard solutions were alkalinized with Na2CO3, mixed well, and then allowed to stand for 2 min, followed by being added to 100 μL of Folin–Ciocalteu reagent (Folin–Ciocalteu: Methanol, 1:1), vortexed, and then allowed to stand for 30 min at room temperature. The absorbance was then measured at 760 nm using a double-beam spectrometer. Gallic acid was used as the standard, and the TPC was expressed as milligram of gallic acid equivalent (GAE) per 100 g dry weight (DW) of the sample (mg GAE/100 g DW).

The ATC was determined using a spectrophotometric pH differential protocol described by Ti et al. (2015) with some modifications. Fifty μL of extracts were mixed thoroughly with 3 mL of 0.025 M potassium chloride (pH 1) buffer. The absorbance of the mixture was then measured at 520 and 700 nm against a distilled water blank. Similarly, the extracts were dissolved with sodium acetate buffer (pH 4.5), and the absorbance of these solutions was measured at the same wavelengths using a double-beam spectrometer. The ATC was calculated using the following equation and expressed as milligram of cyanidin-3-glucoside equivalent (Cy-3-G) per 100 g dry weight (DW) of the sample (mg Cy-3-G/100 g DW).

2.7. Sensory evaluation

The extrudate samples were coded with random three-digit numbers and served to consumers in a random order. Thirty panelists, who were regular snack consumers and aged between 20 and 40, assessed the samples using a 9-point hedonic scale (1-extremely dislike to 9-extremely like). The experiment was reviewed through the exemption review mode and approved for its adherence to the basic principles of international research ethics by the Human Research Ethics Committee of the Sakon Nakhon Rajabhat University (COA NO. 074/2565, IEC NO. 65-004). Informed consent was obtained from all participants for the experiments.

2.8. Statistical analysis

The physicochemical and functional properties of all treatments were analyzed using analysis of variance (ANOVA) at a significance level of 0.05. Duncan's multiple range test (DMRT) was used to compare the means of all treatments. A 3 x 3 factorial design was used to investigate the effect of two factors and evaluate the interaction of the factors on all response variables.

Sensory properties were subjected to variance analysis for statistical significance using a randomized completely block design (RCBD).

3. Result and discussion

3.1. Pasting properties

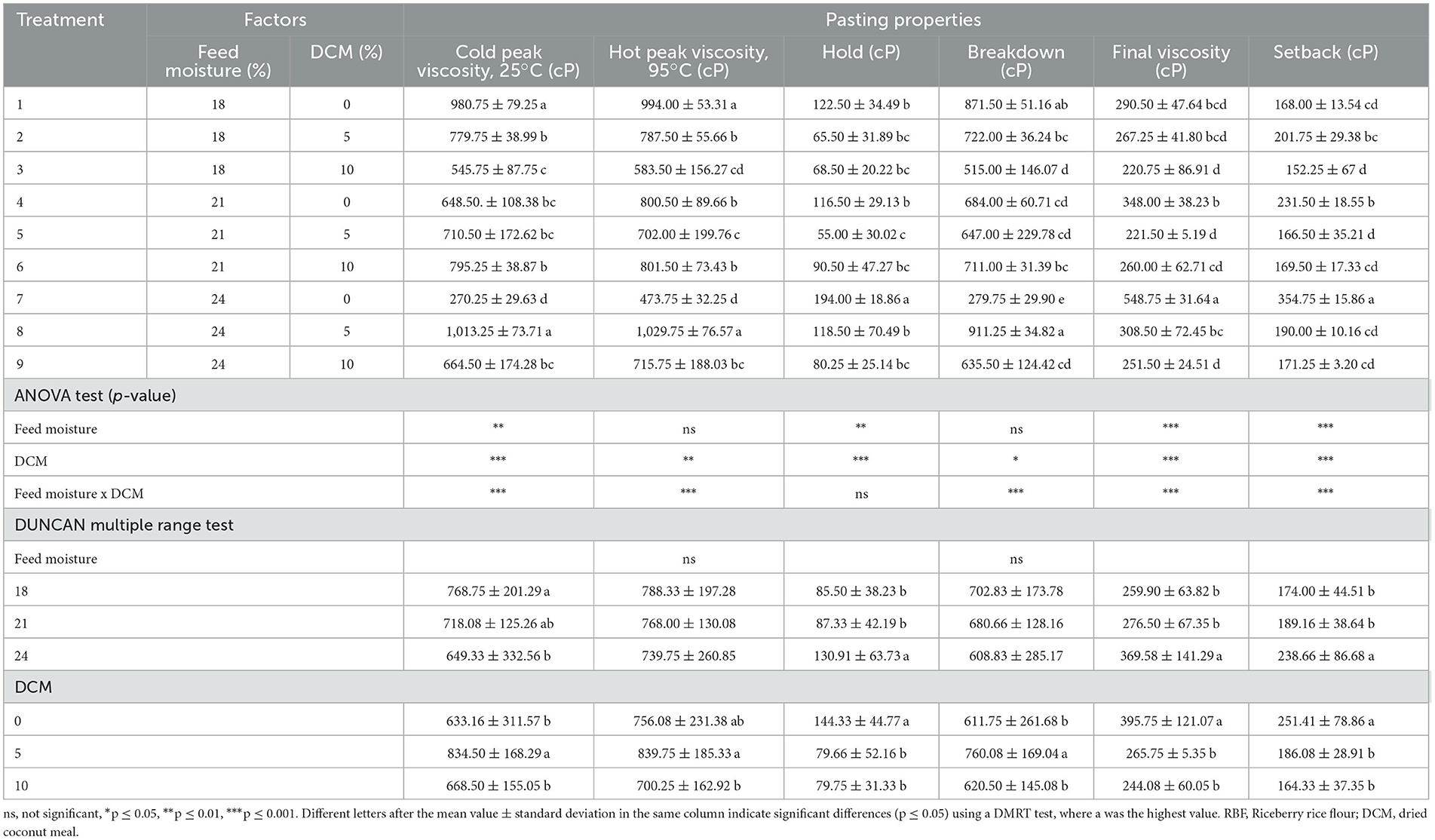

Table 2 presents the pasting properties of the extruded flours as measured using the Rapid Visco Analyzer (RVA). The initial degree of starch modification can be determined by re-cooking the processed food product in the RVA. The results indicated that the feed moisture content had a significant effect on pasting properties, including the cold peak viscosity, hold, final viscosity, and setback. Furthermore, the replacement of DCM affected several pasting properties, including the cold viscosity, hot peak viscosity, hold, breakdown, final viscosity, and setback.

Table 2. Pasting properties of extrudates made from RBF as affected by feed moisture and DCM content.

The measurement of cold peak viscosity (initial viscosity at 25°C) is important for the production of cereal breakfast, modified starch, and snack product. This property determines the ability of instant food to dissolve in cold water or absorb water at room temperature and transform into a paste, viscous substance, gel, or snack. The RBF (unprocessed flour, data not shown in the table) exhibited a very low initial or cold viscosity (10 cP), a high hot peak viscosity (3,077 cP) caused by the swelling of raw starch granules, and a higher setback viscosity (2,386 cP) than those of the extruded flours. The cold peak viscosity of all extrudate flour varied from 270.25 to 1,013.25 cP. The minimum cold viscosity value of 270.25 cP was observed for design treatment 7, which had 24% feed moisture content and 0% DCM. Factorial analysis indicated that the feed moisture content had a significant (p ≤ 0.01) effect on the cold peak viscosity, with increased feed moisture leading to a decrease in the cold peak viscosity (p ≤ 0.05).

The hot peak viscosity, defined as the maximum viscosity during the heating step (95°C), was affected by the loss of starch granule structure during extrusion, which decreased its capacity for swelling and led to a low viscosity at 95°C. No significant (p > 0.05) differences were found in the hot peak viscosity among the different feed moisture levels, indicating that the starch had already been fully gelatinized during the extrusion process at a low feed moisture content. The DCM content was the dominant factor affecting the hot peak viscosity, with an increase from 5 to 10% DCM resulting in a significant (p ≤ 0.05) decrease from 839.75 to 700.25 cP. However, a statistically significant interaction was observed between the feed moisture content and DCM. This could be due to water absorption by fiber, which reduces the amount of available water molecules for starch granules, leading to the loss of starch to form a gel-like structure. Moreover, Table 2 shows that the viscosity of the cold peak was slightly different from that of the hot peak. It can be assumed that no hot peak viscosity was detected, indicating that these flours were completely gelatinized during extrusion (Huang et al., 2020). Conversely, a hot peak viscosity greater than the cold peak viscosity indicates the presence of intact starch granules or a partially maintained starchy structure.

When flour is combined with water and heated, the starch granules initially swell, leading to an increase in the viscosity of the paste. Hold viscosity is determined by continuously stirring and heating the paste during the heating cycle, causing the starch granules to break down, resulting in the lowest viscosity. The results of the study showed that the hold viscosities of all extrudates ranged from 55.00 to 194.00 cP. The factorial design revealed that extrudates containing 5% and 10% DCM had significantly lower hold viscosity than those containing 0% DCM. The breakdown is an index of starch stability to withstand heating and shear stress during cooking. The factorial results showed that the substitution of 5% DCM resulted in a higher breakdown compared to 0 and 10% DCM, while feed moisture content had no significant effect on breakdown.

The final viscosity of flour is an indicator of its ability to form a viscous paste after cooling. Setback is defined as the difference between the hold and final viscosity. Both feed moisture and DCM were significant parameters affecting final viscosities and setback values. Masatcioglu et al. (2014) reported that samples with higher levels of feed moisture content exhibited higher setback values. The substitution of DCM resulted in a decrease in both final viscosity and setback, indicating that DCM may limit the ability to form a paste after cooling. In a previous study, Muñoz-Pabon et al. (2022) reported that a high fiber content from adding quinoa flour results in a lower retrogradation value compared to the cereal extrudate without quinoa. Moreover, Khan et al. (2015) reported that increasing the amount of virgin coconut meal resulted in a significant decrease in breakdown, final viscosity, and setback. This may be due to the formation of a complex during extrusion that combines lipids, proteins, fiber, starch, and high molecular weight compounds. However, the observed changes in viscosity may vary depending on the type of material used and extrusion parameters.

3.2. Physical properties of extrudate product

3.2.1. Expansion ratio

Based on the ANOVA results of the full factorial experiment, Table 3 presents the results, including the expansion ratio, bulk density, WAI, color measurement (L*, a*, and b* values), and textural properties (hardness and crispiness). In the industrial production of extruded products, expansion is a critical factor as product containers are usually filled by weight rather than volume. Expanded products are expected to have a light, puffed structure (Nascimento et al., 2017).

Table 3. Physical properties of extrudates made from RBF as affected by feed moisture and DCM content.

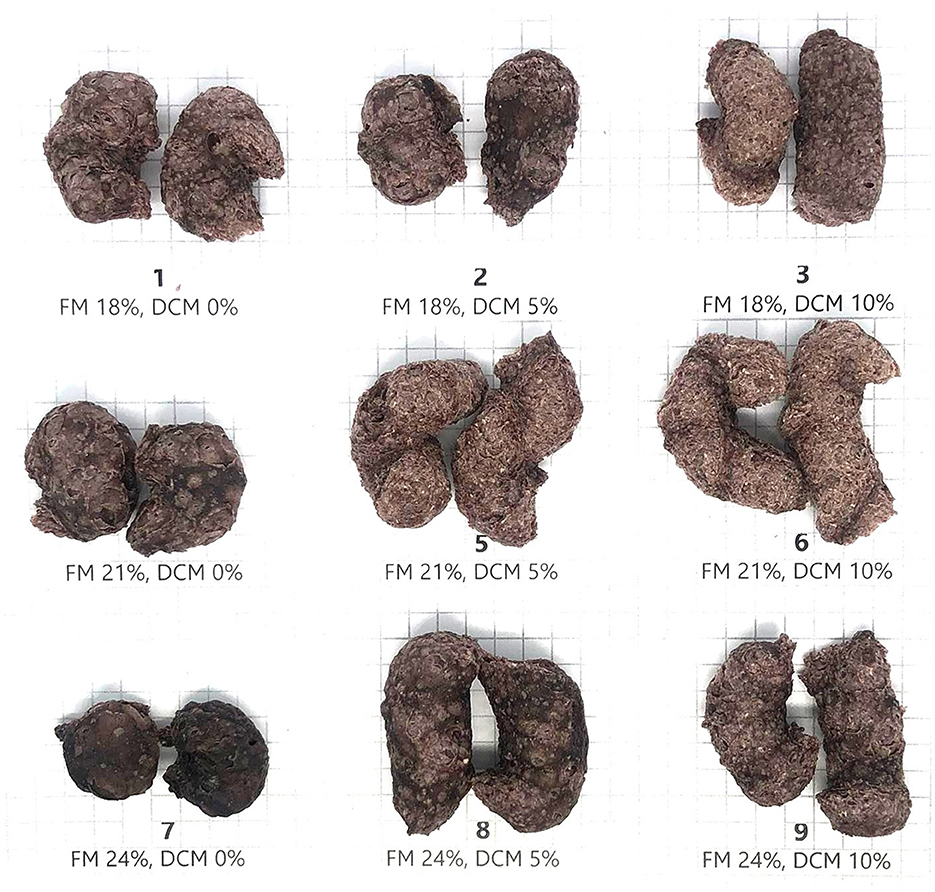

The results indicated that both feed moisture and DCM content significantly (p ≤ 0.001) affected the expansion of the extruded products. The extrudates produced with a feed moisture content of 24% showed a higher expansion than those with a feed moisture content of 18 and 21%. Additionally, the extrudates containing 5 and 10% DCM exhibited lower radial expansion ratios than the control (0%). It was also observed that the interaction between feed moisture and DCM content was statistically significant (p ≤ 0.001). Figure 1 illustrates examples of extrudates made from RBF under different extrusion process conditions.

As reported by Raghavendra et al. (2006), defatted coconut residue had 63.24% dietary fiber, including 4.53% soluble fiber and 58.71% insoluble fiber. The presence of fiber particles can reduce the elastic properties of starch, leading to lower radial expansion. Similar effects have been observed in other fiber sources such as tomato skin (Dehghan-Shoar et al., 2010) and wheat bran (Hernández-Díaz et al., 2007). However, some studies have found that product expansion increased with the addition of fibers such as barley and mushrooms (Brennan et al., 2012, 2013). On the other hand, other researchers have reported that the expansion ratio of products was not significantly affected by the inclusion of dietary fibers in the flour-based extruded snack (Brennan et al., 2008). Therefore, the effect of fiber content on expansion may also depend on other process conditions such as barrel temperature, screw speed, and residence time, which are considered the governing factors.

3.2.2. Bulk density

The texture of the final product of extruded starch-based snacks is directly related to its density. The bulk density of all extrudates, which ranged from 0.38 to 0.60 g/cm3, was significantly influenced by feed moisture content (p ≤ 0.001) but showed no significant effect from DCM. Increasing feed moisture content tends to increase bulk density. Furthermore, the interaction between feed moisture content and DCM exhibited a significant effect (p ≤ 0.05). In starch-based extruded snacks, water acts as a plasticizer, which reduces the viscosity of the dough and gelatinization in the extruder, thereby increasing product density (Pardhi et al., 2019). This result is in agreement with those of Khan et al. (2015), who observed that an increase in the amount of virgin coconut meal in snack products led to a decrease in the expansion ratio while bulk density increased.

3.2.3. Water absorption index

The results of this study demonstrated that the WAI of extruded flour was slightly increased with increased feed moisture content. Similar findings have been reported by Sahu et al. (2022) for maize-based extruded snacks. Additionally, the results also show that the addition of DCM decreased the WAI. This finding is in agreement with those of Wang et al. (2017), who explained that adding cherry pomace significantly decreased the WAI of snacks due to competition for water absorption between the pomace and starch. Earlier, Dumchaiyapoom et al. (2019) found that WAI decreased with increased coconut meal in mixed rice and glutinous rice-based extrudates. Furthermore, it can be observed that the interaction had a significant (p ≤ 0.001) effect on the WAI.

3.2.4. Color

Increasing the feed moisture content resulted in a significant decrease in L* and b* values, as shown in Table 4. The color of the final product can be influenced by various reactions that occur during the extrusion process, such as pigment degradation, the Maillard reaction, caramelization, and hydrolysis. The substitution of DCM increased both the L* and b* values. This could be explained by the fact that the anthocyanin in RBF is responsible for the purple color of the extrudates. Furthermore, the a* value indicated that the substitution of DCM did not significantly (p > 0.05) affect the red color.

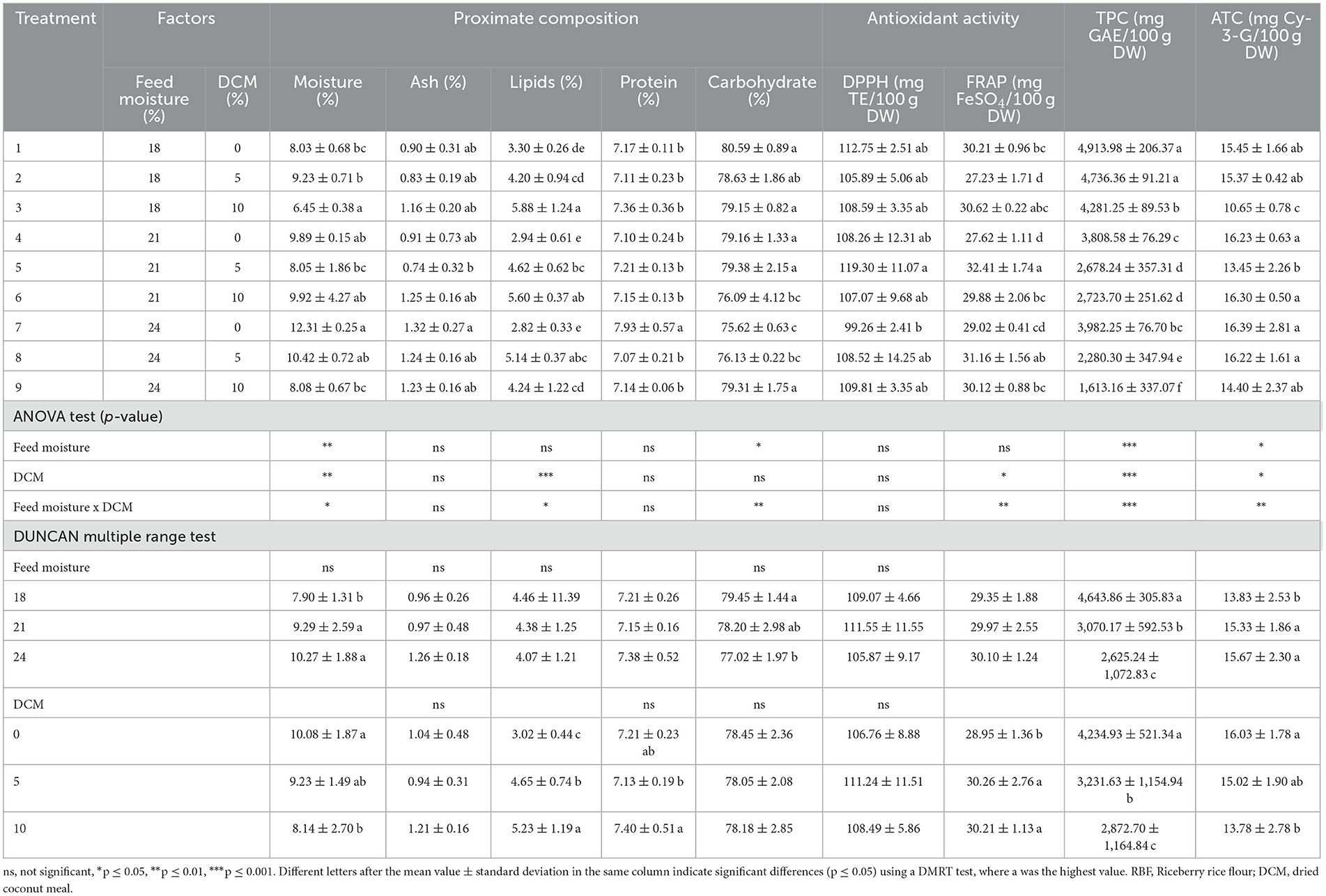

Table 4. Proximate composition and antioxidant activity of extrudates made from RBF as affected by feed moisture and DCM content.

3.2.5. Texture analysis

The hardness and crispness were measured by puncture force, which represents cell wall rupture resistance and structural development during extrusion. The force and time plot for each treatment during the fracturing exhibits as many peaks as the cell wall ruptures, which is correlated with the crispiness (Saeleaw et al., 2012). The values of maximum force (hardness) and the number of force peaks (crispiness) were within the range of 2.29 to 4.26 kg and 17.55 to 75.00 peaks, respectively.

The hardness and crispiness of extrudates were affected by both feed moisture and DCM content. An increase in feed moisture content results in more rigid structures with higher density and hardness but lower crispiness. The extrudates had the hardest texture when RBF was substituted with DCM at 10%. The previous study by Khan et al. (2015) also showed that increasing the amount of virgin coconut meal increased the amount of protein and fiber, resulting in an increase in hardness. A significant interaction (p ≤ 0.001) occurred between feed moisture and DCM on the texture parameters. At moisture contents of 24%, crispiness increased with increasing amounts of DCM.

3.3. Proximate composition

Table 4 presents the chemical composition of the products. Moisture content ranged from 8.03 to 12.31%, ash content ranged from 0.74 to 1.32%, lipid content ranged from 2.82 to 5.88%, protein content ranged from 7.07 to 7.93%, and carbohydrate content ranged from 75.62 to 80.59%. Interestingly, the feed moisture content had no impact on the ash, lipid, or protein content. However, the substitution of DCM for RBF resulted in a slightly higher fat content.

3.4. Antioxidant activity, total polyphenolic content, and anthocyanin content

The results presented in Table 4 indicate that extrusion significantly decreased the antioxidant activity, TPC, and TAC of all extrudates compared to the unextruded RBF samples (as shown in Table 1). The DPPH and FRAP assays were used to measure antioxidant activity, and their values ranged from 99.26 to 119.30 mg TE/100 g DW and 27.23 to 32.41 mg FeSO4/100 g DW, respectively. The antioxidant levels decreased by nearly 64.41 to 70.39% using the DPPH assay and by 10.32 to 24.65% using the FRAP when compared to the initial RBF flour, but the levels were still high in the final product. Feed moisture changes had no impact on antioxidant activity (p > 0.05). By DPPH assay, there was no significant interaction (p > 0.05) between feed moisture and DCM content on the antioxidant activity of extrudate products. However, the FRAP assay revealed that the amount of DCM had a small effect on the antioxidant activity, with FRAP values of 28.95, 30.26, and 30.21 mg FeSO4/100 g DW at DCM levels of 0, 5, and 10%, respectively, as shown in Table 3. These findings are similar to those of previous studies on colored rice-based extrudates by Sompong et al. (2011), which showed that the different feed moisture levels (12 and 16%) had no statistically significant effect on the FRAP and DPPH values. Due to the complexity of the extrusion process, which involves numerous variables that can influence the antioxidant properties of extruded snacks, it is possible that other factors such as temperature and residence time may play a significant role in the final antioxidant properties of the snacks.

The TPC in the extrudates ranged from 1,613.16 to 4,913.98 mg GAE/100 g DW, which reduced in the range of 36.87 to 79.28% compared to the initial RBF (7,783.96 mg GAE/100 g DW). The factorial design was evaluated, and both the feed moisture content and DCM variables had a significant (p ≤ 0.001) effect on the TPC. As the feed moisture and DCM increased, the TPC of extrudates decreased. This observation is in agreement with the previous study by Sompong et al. (2011), which reported that the TPC of red rice extrudates decreased as the moisture content increased from 12 to 16%.

The ATC of extrudates varied from 10.65 to 16.39 mg Cy-3-G/100 g DW. The losses in ATC caused by extrusion were 50.63 to 67.92% when compared with raw RBF (33.20 mg Cy-3-G/100 g DW). The higher feed moisture content may have prevented anthocyanin loss. Khanal et al. (2009) found that the extrusion process reduced anthocyanin by 33 to 42% in blueberry pomace-sorghum flour-based extruded snacks, whereas increasing feed moisture reduced loss. In addition, the ATC decreased when DCM was substituted.

3.5. Sensory evaluation

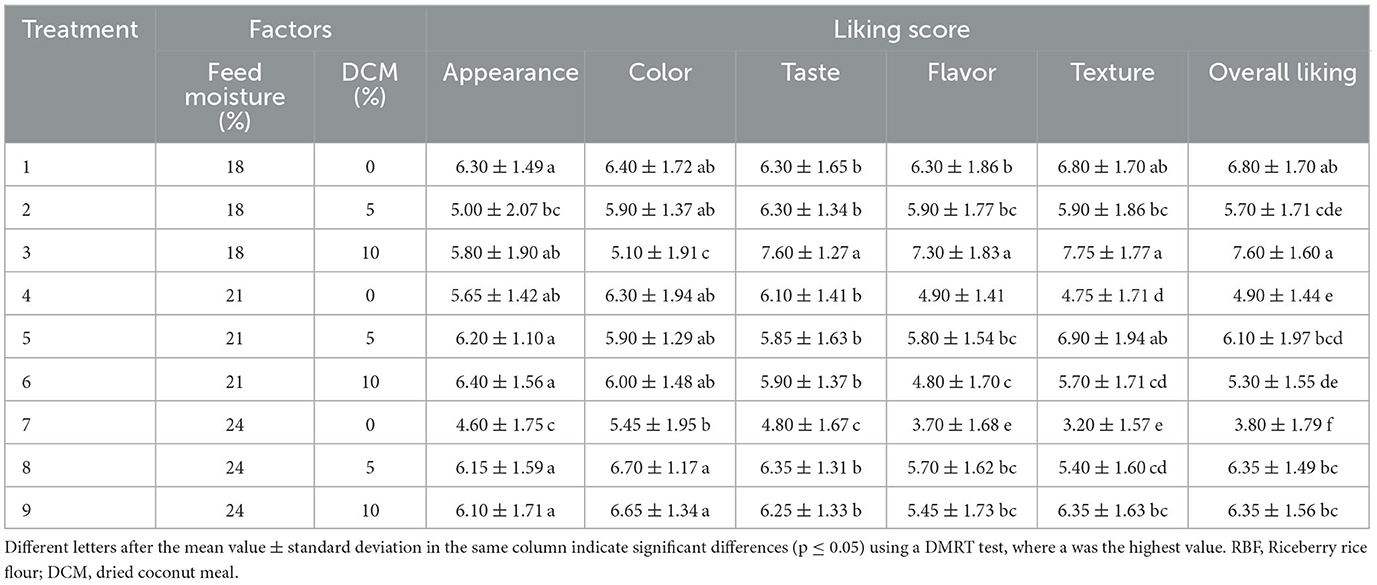

The results of the hedonic scores showed significant differences (p ≤ 0.05) among the sensory characteristics, as presented in Table 5. The appearance and color attributes of all extrudates received low scores because some panelists did not enjoy the dark purple hue of the product, possibly due to the prevalence of yellow snacks in the market. The extrudates with 18% feed moisture content and 10% DCM had the highest score for overall liking (7.60), indicating that the panelists moderately to very much preferred this sample. The authors suggest that incorporating flavoring powder as a coating for snacks could potentially enhance their sensory acceptance scores in terms of taste and flavor. Conversely, the samples with 24% feed moisture content and 0% DCM had the lowest scores. This could be explained by the fact that the density, hardness, and crispiness may have related to the sensory score.

Table 5. Sensory liking scores of extrudates made from RBF as affected by feed moisture and DCM content.

4. Conclusion

The results of this study revealed that increasing feed moisture content significantly decreased the cold peak but had no significant effect on the hot peak and breakdown. DCM was the dominant factor affecting the hot peak. In addition, extrudates containing DCM had significantly lower hold, final viscosity, and setback than those without DCM. The substitution of DCM for RBF also led to an increase in L* and b* values. Increasing feed moisture content resulted in harder structures with decreased crispiness. Feed moisture content had no effect on antioxidant activity. TPC decreased as feed moisture and DCM levels increased. The product with 18% feed moisture content and 10% DCM had the highest overall liking score and contained DPPH, FRAP, TPC, and ATC at 108.59 mg TE/100 g DW, 30.62 mg FeSO4/100 g DW, 4,281.25 mg GAE/100 g DW, and 10.65 mg Cy-3-G/100 g DW, respectively. Overall, this study successfully developed a new product using RBF and DCM as raw materials with the potential for commercialization and the ability to reduce waste from the coconut milk industry. However, this study is limited as it only investigated the effects of two variables, namely feed moisture and DCM content. Therefore, future research could use response surface methodology (RSM) to optimize and examine the combined effects of DCM with other extrusion parameters, such as barrel temperature, feed rate, and screw speed. A comprehensive understanding of the reactions that occur during extrusion is essential for achieving the desired snack quality and advancing the development of novel snack products.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

The studies involving human participants were reviewed and approved by Human Research Ethics Committee of the Sakon Nakhon Rajbhat University (COA NO. 074/2565, IEC NO. 65-004). The patients/participants provided their written informed consent to participate in this study.

Author contributions

All authors listed have significantly contributed to the development and writing of this article and approved the submitted version.

Funding

This study was funded by the Research and Development Institute (RDI, 10/2565), Sakon Nakhon Rajabhat University, and Rajamangala University of Technology Krungthep.

Acknowledgments

The authors thank the Department of Food Technology Laboratory, Sakon Nakhon Rajabhat University, and the Department of Food Product Development, Rajamangala University of Technology Krungthep for the use of their facility and equipment for the preparation of samples and experiments.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alam, M. S., Pathania, S., and Sharma, A. (2016). Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. LWT Food Sci. Technol. 74, 135–144. doi: 10.1016/j.lwt.2016.07.031

AOAC (2002). Official Methods of Analysis, Association of Official Analytical Chemists, Vo. 2, 17th edition. AOAC International Gaithersburg, Md.

Benzie, I. F. F., and Strain, J. J. (1996). The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal. Biochem. 239, 70–76. doi: 10.1006/abio.1996.0292

Brennan, M. A., Derbyshire, E., Tiwari, B. K., and Brennan, C. S. (2012). Enrichment of extruded snack products with coproducts from chestnut mushroom (Agrocybe aegerita) production: interactions between dietary fiber, physicochemical characteristics, and glycemic load. J. Agric. Food Chem. 60, 4396–4401. doi: 10.1021/jf3008635

Brennan, M. A., Derbyshire, E., Tiwari, B. K., and Brennan, C. S. (2013). Integration of β-glucan fibre rich fractions from barley and mushrooms to form healthy extruded snacks. Plant Foods Hum. Nutr. 68, 78–82. doi: 10.1007/s11130-012-0330-0

Brennan, M. A., Monro, J. A., and Brennan, C. S. (2008). Effect of inclusion of soluble and insoluble fibres into extruded breakfast cereal products made with reverse screw configuration. Int. J. Food Sci. Technol. 43, 2278–2288. doi: 10.1111/j.1365-2621.2008.01867.x

Dehghan-Shoar, Z., Hardacre, A. K., and Brennan, C. S. (2010). The physico-chemical characteristics of extruded snacks enriched with tomato lycopene. Food Chem. 123, 1117–1122. doi: 10.1016/j.foodchem.2010.05.071

Dumchaiyapoom, K., Hannanta-anan, P., and Phongpipatpong, M. (2019). “Effect of extrusion conditions on the physical properties of coconut rice-based extrudates,” in IOP Conference Series: Earth and Environmental Science. (IOP Publishing), 301. doi: 10.1088/1755-1315/301/1/012056

FAO (2020). Coconut Production Worldwide in 2020, by Leading Country. Available online at: https://www.fao.org/faostat/en/#data/QC/visualize (accessed September 22, 2022).

Fleischman, E. F., Kowalski, R. J., Morris, C. F., Nguyen, T., Li, C., Ganjyal, G., et al. (2016). Physical, textural, and antioxidant properties of extruded waxy wheat flour snack supplemented with several varieties of bran. J. Food Sci. 81, E2726–E2733. doi: 10.1111/1750-3841.13511

Gong, E. S., Luo, S., Li, T., Liu, C., Zhang, G., Chen, J., et al. (2017). Phytochemical profiles and antioxidant activity of processed brown rice products. Food Chem. 232, 67–78. doi: 10.1016/j.foodchem.2017.03.148

Han, Y. J., Tra Tran, T. T., and Man Le, V. V. (2018). Corn snack with high fiber content: effects of different fiber types on the product quality. LWT Food Sci. Technol. 96, 1–6. doi: 10.1016/j.lwt.2018.05.014

Hernández-Díaz, J. R., Quintero-Ramos, A., Barnard, J., and Balandrán-Quintana, R. R. (2007). Functional properties of extrudates prepared with blends of wheat flour/pinto bean meal with added wheat bran. Food Sci. Technol. Int. 13, 301–308. doi: 10.1177/1082013207082463

Hirth, M., Leiter, A., Beck, S. M., and Schuchmann, H. P. (2014). Effect of extrusion cooking process parameters on the retention of bilberry anthocyanins in starch based food. J. Food Eng. 125, 139–146. doi: 10.1016/j.jfoodeng.2013.10.034

Huang, S., Roman, L., Martinez, M. M., and Bohrer, B. M. (2020). Modification of physicochemical properties of breadfruit flour using different twin-screw extrusion conditions and its application in soy protein gels. Foods 9:1071. doi: 10.3390/foods9081071

Khan, M. A., Mahesh, C., Semwal, A. D., and Sharma, G. K. (2015). Effect of virgin coconut meal (VCM) on the development of rice-based extruded snacks. Int. J. Adv. Res. 3, 717–725.

Khanal, R. C., Howard, L. R., Brownmiller, C. R., and Prior, R. L. (2009). Influence of extrusion processing on procyanidin composition and total anthocyanin contents of blueberry pomace. J. Food Sci. 74, H52–H58. doi: 10.1111/j.1750-3841.2009.01063.x

Li, X., Masatcioglu, T. M., and Koksel, F. (2019). Physical and functional properties of wheat flour extrudates produced by nitrogen injection assisted extrusion cooking. J. Cereal Sci. 89:102811. doi: 10.1016/j.jcs.2019.102811

Masatcioglu, M. T., Yalcin, E., Hwan, P. J., Ryu, G. H., Celik, S., and Koksel, H. (2014). Hull-less barley flour supplemented corn extrudates produced by conventional extrusion and CO2 injection process. Innov. Food Sci. Emerg. Technol. 26, 302–309. doi: 10.1016/j.ifset.2014.06.003

Muñoz-Pabon, K. S., Parra-Polanco, A. S., Roa-Acosta, D. F., Hoyos-Concha, J. L., and Bravo-Gomez, J. E. (2022). Physical and paste properties comparison of four snacks produced by high protein quinoa flour extrusion cooking. Front. Sustain. Food Syst. 6:852224. doi: 10.3389/fsufs.2022.852224

Nascimento, T. A., Calado, V., and Carvalho, C. W. P. (2017). Effect of Brewer's spent grain and temperature on physical properties of expanded extrudates from rice. LWT Food Sci. Technol. 79, 145–151. doi: 10.1016/j.lwt.2017.01.035

Navarro Cortez, R. O., Gómez-Aldapa, C. A., Aguilar-Palazuelos, E., Delgado-Licon, E., Castro Rosas, J., Hernández-Ávila, J., et al. (2016). Blue corn (Zea mays L.) with added orange (Citrus sinensis) fruit bagasse: novel ingredients for extruded snacks. CyTA J. Food 14, 349–358. doi: 10.1080/19476337.2015.1114026

Neder-Suárez, D., Quintero-Ramos, A., Meléndez-Pizarro, C. O., de Jesús Zazueta-Morales, J., Paraguay-Delgado, F., and Ruiz-Gutiérrez, M. G. (2021). Evaluation of the physicochemical properties of third-generation snacks made from blue corn, black beans, and sweet chard produced by extrusion. LWT Food Sci. Technol. 146:111414. doi: 10.1016/j.lwt.2021.111414

Pardhi, S. D., Singh, B., Nayik, G. A., and Dar, B. N. (2019). Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J. Saudi Soc. Agric. Sci. 18, 7–16. doi: 10.1016/j.jssas.2016.11.006

Philipp, C., Buckow, R., Silcock, P., and Oey, I. (2017). Instrumental and sensory properties of pea protein-fortified extruded rice snacks. Food Res. Int. 102, 658–665. doi: 10.1016/j.foodres.2017.09.048

Poosri, S., Thilavech, T., Pasukamonset, P., Suparpprom, C., and Adisakwattana, S. (2019). Studies on riceberry rice (Oryza sativa L.) extract on the key steps related to carbohydrate and lipid digestion and absorption: a new source of natural bioactive substances. NFS J. 17, 17–23. doi: 10.1016/j.nfs.2019.10.002

Promsakha na Sakon Nakhon, P., Jangchud, K., Jangchud, A., and Charunuch, C. (2018). Optimization of pumpkin and feed moisture content to produce healthy pumpkin-germinated brown rice extruded snacks. Agric. Nat. Resour. 52, 550–556. doi: 10.1016/j.anres.2018.11.018

Raghavendra, S. N., Ramachandra Swamy, S. R., Rastogi, N. K., Raghavarao, K. S. M. S., Kumar, S., and Tharanathan, R. N. (2006). Grinding characteristics and hydration properties of coconut residue: a source of dietary fiber. J. Food Eng. 72, 281–286. doi: 10.1016/j.jfoodeng.2004.12.008

Saeleaw, M., Dürrschmid, K., and Schleining, G. (2012). The effect of extrusion conditions on mechanical-sound and sensory evaluation of rye expanded snack. J. Food Eng. 110, 532–540. doi: 10.1016/j.jfoodeng.2012.01.002

Sahu, C., Patel, S., and Tripathi, A. K. (2022). Effect of extrusion parameters on physical and functional quality of soy protein enriched maize based extruded snack. App. Food Res. 2:100072. doi: 10.1016/j.afres.2022.100072

Saldanha do Carmo, C., Varela, P., Poudroux, C., Dessev, T., Myhrer, K., Rieder, A., et al. (2019). The impact of extrusion parameters on physicochemical, nutritional and sensorial properties of expanded snacks from pea and oat fractions. LWT Food Sci. Technol. 112:108252. doi: 10.1016/j.lwt.2019.108252

Sangkharak, K., Chookhun, K., Numreung, J., and Prasertsan, P. (2020). Utilization of coconut meal, a waste product of milk processing, as a novel substrate for biodiesel and bioethanol production. Biomass Convers. Biorefin. 10, 651–662. doi: 10.1007/s13399-019-00456-8

Shao, Z., Han, J., Wang, J., Sun, Y., Li, X., and Liang, J. (2021). Process optimization, digestibility and antioxidant activity of extruded rice with Agaricus bisporus. LWT Food Sci. Technol. 152:112350. doi: 10.1016/j.lwt.2021.112350

Sompong, R., Siebenhandl-Ehn, S., Berghofer, E., and Schoenlechner, R. (2011). Extrusion cooking properties of white and coloured rice varieties with different amylose content. Starch 63, 55–63. doi: 10.1002/star.201000086

Ti, H., Zhang, R., Zhang, M., Wei, Z., Chi, J., Deng, Y., et al. (2015). Effect of extrusion on phytochemical profiles in milled fractions of black rice. Food Chem. 178, 186–194. doi: 10.1016/j.foodchem.2015.01.087

Unsaeng, K., Hannanta-anan, P., and Phongpipatpong, M. (2019). Effects of extrusion variables on extrudate characteristics from corn-based enriched with soybean residue. IOP Conf. Ser. Earth Environ. Sci. 301:012057. doi: 10.1088/1755-1315/301/1/012057

Wang, S., Kowalski, R. J., Kang, Y., Kiszonas, A. M., Zhu, M.-J., and Ganjyal, G. M. (2017). Impacts of the particle sizes and levels of inclusions of cherry pomace on the physical and structural properties of direct expanded corn starch. Food Bioproc. Technol. 10, 394–406. doi: 10.1007/s11947-016-1824-9

Xu, E., Wu, Z., Long, J., Wang, F., Xu, X., Jin, Z., et al. (2015). Improved bioaccessibility of phenolics and antioxidant activity of glutinous rice and its fermented Chinese rice wine by simultaneous extrusion and enzymatic hydrolysis. J. Funct. Foods 17, 214–226. doi: 10.1016/j.jff.2015.05.032

Keywords: extrusion, coconut meal, Riceberry rice, anthocyanin, pasting properties, functional properties, gluten-free, snack

Citation: Piayura S and Itthivadhanapong P (2023) The effects of feed moisture and dried coconut meal content on the physicochemical, functional, and sensory properties of gluten-free Riceberry rice flour-based extruded snacks. Front. Sustain. Food Syst. 7:1194594. doi: 10.3389/fsufs.2023.1194594

Received: 27 March 2023; Accepted: 12 June 2023;

Published: 04 July 2023.

Edited by:

Zhipeng Li, Jimei University, ChinaReviewed by:

Sunil C. K., Indian Institute of Food Processing Technology, IndiaMingjing Zheng, Jimei University, China

Copyright © 2023 Piayura and Itthivadhanapong. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Pimchada Itthivadhanapong, cGltY2hhZGEuaUBtYWlsLnJtdXRrLmFjLnRo

Sumeth Piayura

Sumeth Piayura Pimchada Itthivadhanapong

Pimchada Itthivadhanapong