- 1Kosmode Health Singapore Pte. Ltd., Singapore, Singapore

- 2Department of Food Science and Technology, National University of Singapore, Singapore, Singapore

- 3Department of Dietetics, National University Hospital, Singapore, Singapore

- 4Glycemic Index Research Unit, School of Applied Science, Temasek Polytechnic, Singapore, Singapore

Spent barley grains (SBG) were valorized into a spent barley protein and fibers (SBPF) ingredient. The ingredient was utilized to formulate SBPF-derived starchless noodles with a negligible glycemic response (GR) in healthy individuals, a significant reduction of 93.16% (SD = 8.07) postprandial GR after consumption when compared to conventional starch-based noodles. Their nutritional content, visual analog scale, textural property, and palatability were also evaluated. The SBPF-derived starchless noodles showed comparable hardness and springiness to the conventional starch-based noodles, but their cohesiveness and chewiness were improved. There was no significant difference in appetite and hunger ratings between the two types of foods. The overall palatability ratings for both foods were comparable. The SBPF-derived noodles were a source of nutrients (such as protein and fibers). This study has considerable potential for the development of functional food and food as medicine industries.

1. Introduction

The global barley production is 147.05 × 106 tons in the 2021/2022 crop year, reducing from around 160.53 × 106 tons in 2020/2021 (Shahbandeh, 2022). Meanwhile, the pandemic and geopolitical tensions seriously impact the safety of the food supply chains (Aday and Aday, 2020; Jagtap et al., 2022). Thus, there is an urgent need to ensure food sustainability and security. Pristine barley grains provide fermentable sugars to yeasts during beer brewing (Kok et al., 2019), and 20 kg SBG is generated per 100 L beer production (Mussatto et al., 2006). The global beer production was 1.91 × 1011 L in 2022 (Chee, 2022), which was equivalent to 38.2 × 106 tons SBG. The SBG contains water insoluble protein, husk residues, pericarp, and seed coat within the grains (Townsley, 1979). The barley grain has been approved as a functional food by the U.S. Food and Drug Administration since 2006, and regular barley consumption reduces blood cholesterol and controls cardiovascular diseases (Geng et al., 2022). The β-Glucan, arabinoxylans (AX), and phenolic compounds within the barley significantly improve human immunity, and provide reliefs for type 2 diabetes, stroke, hypertension, and cardiovascular diseases (Maheshwari et al., 2019; Tosh and Bordenave, 2020; Zannini et al., 2022).

The SBG is made of 70% fibers, 20% protein, and 10% fats (Reshamie et al., 2018). The SBG fibers include approximately 17% cellulose, 28% non-cellulosic polysaccharides, mainly AX, β-Glucan, and 28% lignin (a poly-phenolic macromolecule) (Mussatto et al., 2006). The SBG protein contains essential and non-essential amino acids including phenylalanine, lysine, tryptophan, histidine, methionine, alanine, glycine, proline, and serine (Mussatto et al., 2006). Cookies made of 20% SBG showed increments of protein, lysine, and fibers by 55, 90, and 220%, respectively (Özvural et al., 2009). The SBG lowers the sweetness and increases the shelf-life of sourdough and bread (Plessas et al., 2007; Stojceska and Ainsworth, 2008; Szwajgier et al., 2010; Waters et al., 2012). The phenolic extracts from the SBG used in fruit beverages show better ferric reducing antioxidant power (FRAP) activity (Celus et al., 2007). The SBG is nutritious and not a food waste. There is a possibility for SBG valorization to meet the nutritional needs of the aging population.

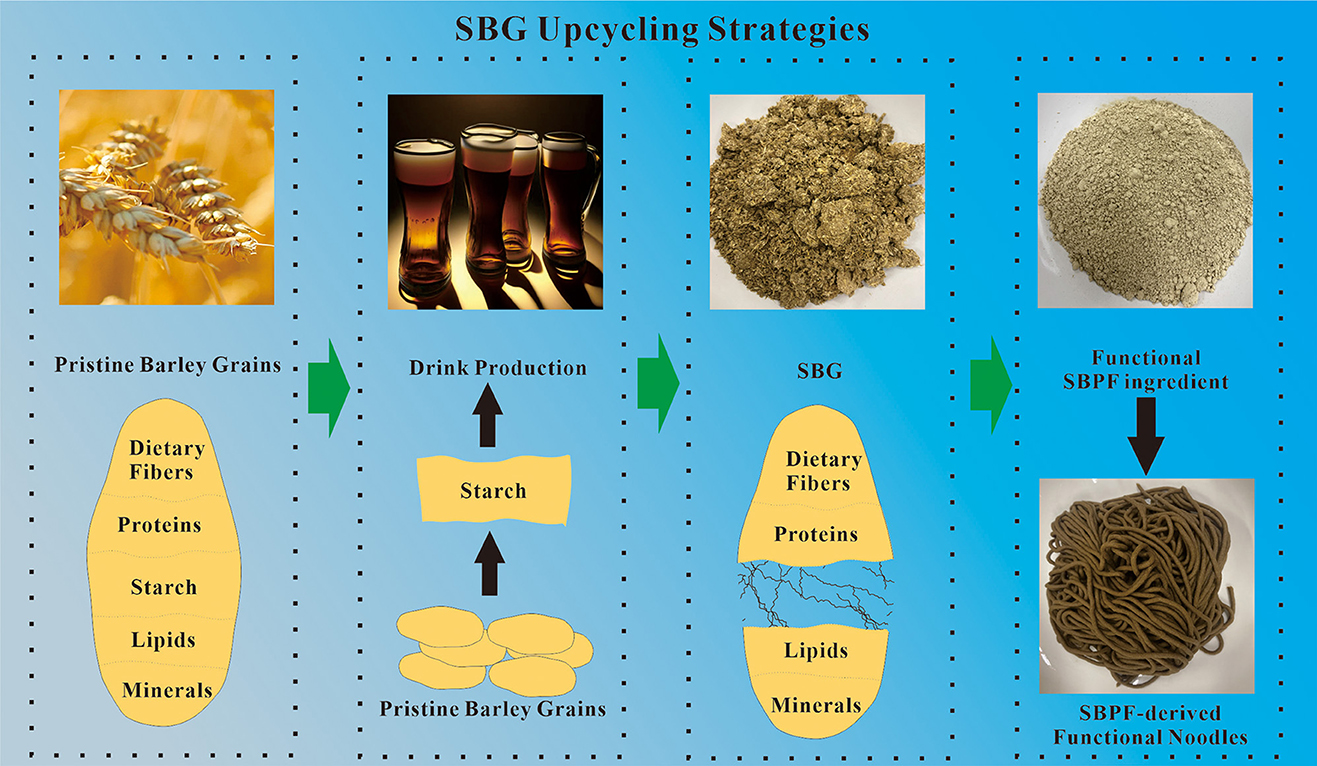

A practical method to produce the SBPF ingredient is developed and reported in this article (Figure 1). The SBPF ingredient is exploited to create a brand new representative functional food in noodle form (SBPF-derived noodles). The appearance, texture, and GR of the SBPF-derived noodles are investigated and compared with the property of conventional starch-based noodles. The SBPF-derived noodles have the potential to replace conventional starch-based noodles as a protein and fibers rich Asian staple food with negligible GR. The SBPF-derived noodles address the perennial challenge faced by diabetics. The starchless noodles can be palatably and tastily prepared without blood glucose elevation.

Figure 1. Flowchart of the collection of SBG, extraction and purification of SBPF ingredient and the representative SBPF-derived noodle production.

2. Materials and methods

2.1. SBG valorization, SBPF ingredient, and SBPF-derived noodles preparation

The dry SBG was obtained from a local malt production site, and placed in an electric superfine powder machine (Horus Industry, China) and ground continuously into powder with a stainless-steel blade at 6,000 rpm. The SBPF ingredient was obtained in powder form within 3 h. Subsequently, the SBPF ingredient was mixed with vital wheat gluten, konjac powder, premium quality fine salt, sodium carbonate, and water to form a paste. The paste was directly extruded by a stainless-steel manual noodle maker (Sailnovo, Malaysia) into water to form the SBPF-derived noodles. The noodles were pasteurized and vacuum packed and could be served directly without cooking. All the abovementioned items were food-grade and purchased from Phoon Huat Pte Ltd, Singapore. The control of this study was starch-based noodles (ready to eat) procured from a local vendor (Hokkien noodle round, FORTUNE brand, Singapore). The frozen vegetables were purchased from Watties, New Zealand. Sesame oil was from Pagoda, Singapore, and the light soy sauce was acquired from Tai Hua, Singapore.

2.2. Nutritional content analysis and physical tests

2.2.1. Nutritional content analysis

The SBPF ingredient and SBPF-derived noodles were sent to the Setsco lab (Setsco Services Pte Ltd) for nutritional content analysis. Nutritive values including energy, protein, dietary fibers, carbohydrates, fat, moisture, and ash of the samples were determined according to BCTD/FC/IHM068/2018 Rev(2), BCTD/FC/IHM123/2013 Rev(1), AOAC official method No. 985.29 (2005), BCTD/FC/IHM068/2018 Rev(2), AOAC official method No. 996.06 (2008), AOAC official method No. 950.46 (2008) and AOAC official method No. 920.153 (2005), 930.30 (2005), and 923.03 (2005), respectively. The nutritional information for starch-based noodles, vegetables, sesame oil, and soy sauce was acquired from their respective product nutritional information panels.

2.2.2. Characterization of SBPF-derived noodles and starch-based noodles

A texture analyzer (TA/TX-plus, Stable Micro System, Surrey, UK) with a 5 kg load cell was employed to perform the texture measurements. Hardness (g), springiness (mm), cohesiveness, and chewiness (g × mm) were analyzed respectively. Texture profile analysis was performed and a P35 cylinder probe was used (with pre-test, test, and post-test speeds at 2, 1, and 2 mm/s, respectively). The target mode was set at 70% strain, the trigger type was auto, and the trigger force was 5 g. The measurements were conducted fifteen times.

2.3. In vivo GR studies

The study aimed to compare the GR of each participant after consuming the SBPF-derived and conventional starch-based noodles, respectively. The in vivo studies followed previous publications regarding GR tests (Jang et al., 2017; Crummett and Grosso, 2022) and were performed using the Singapore Accreditation Council's (SAC) FFT-2010-0001A Functional Food Testing Scheme, based on ISO/IEC 17025:2017 and Technical Note FFT 01. Ethical approval for GR testing was sought from an independent ethics committee before conducting the GR tests. The ethical approval reference number for this study was TP-IRB Ref: IRB170102. The details of the GR testing protocol were explained to the subjects and informed consent was obtained. Fifteen (15) healthy volunteers (19–60 years old) were recruited into the study based on the following inclusion and exclusion criteria in Supplementary Table 1. The two types of test foods were assessed separately in each subject on separate days (with a washout period of at least 2 days).

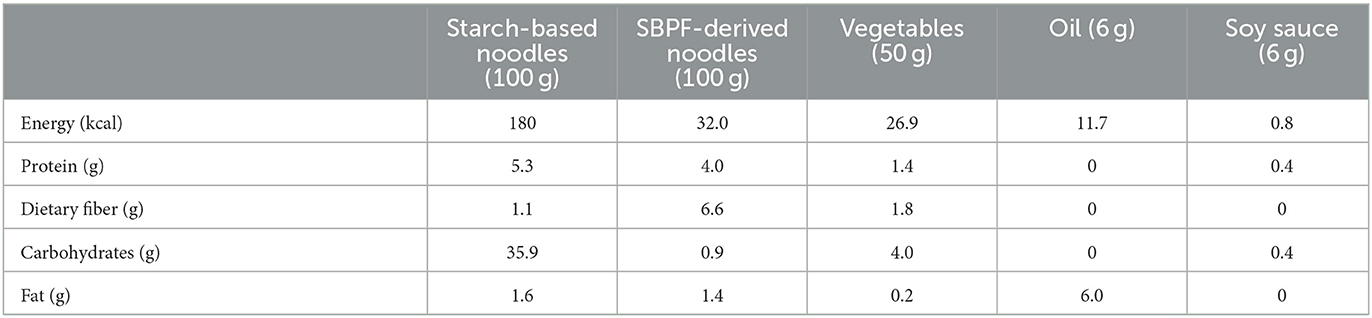

The 100 g SBPF-derived and starch-based noodles were prepared in the same manner. Briefly, both were warmed up in 500 ml of hot water (approximately 90°C) in < 1 min. Then, they were mixed with 50 g cooked vegetables, 6 g sesame oil, and 6 g light soy sauce for GR tests (Table 1). The food was served with 250 ml water to the test subjects. The subject's capillary fasting samples were obtained by a finger prick after ensuring an overnight fast of 10–14 h. They consumed the test food within 12 min and remained seated. Their blood samples were obtained at 15, 30, 45, 60, 90, and 120 min after food consumption. The participants' capillary blood samples were analyzed by calibrated YSI 2300 Stat Plus Glucose and Lactate analyzer. Analysis of test data was conducted by evaluating incremental areas under the curve (AUC) for the two samples and plotted in a graph. The equation used to determine the GR difference between starch-based and SBPF-derived noodles is:

Table 1. Nutritive values of SBPF ingredient and SBPF-derived noodles, results are expressed as mean.

2.4. Overall palatability rating

The overall palatability ratings of the starch-based and SBPF-derived noodles were analyzed using the 7-point hedonic scale (Supplementary Figure 1).

2.5. Visual analog scale

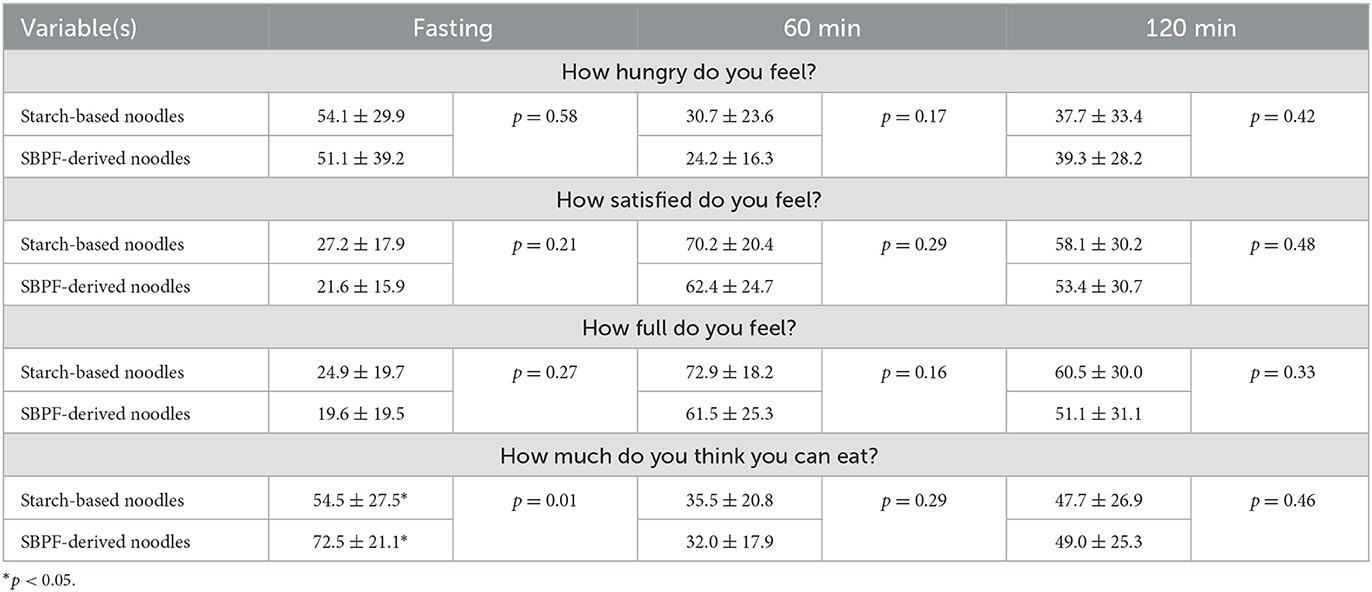

A visual analog scale (VAS) questionnaire was provided to the participants. Appetite and other sensations were assessed using 100 mm VAS (Supplementary Figure 2). Eight variables were questioned. On each 100 mm line, an appetite (hunger, satisfaction, fullness, and desire to eat) sensation was paired with the opposing sensation, (for example, “hungry” and “not hungry” or “full” and “not full”). To determine “prospective consumption,” the participants were asked questions including “How much do you think you can eat?” and the analog scales were administered at each time point when blood samples were obtained, namely fasting, 15, 30, 45, 60, 90, and 120 min after the consumption of the test foods. The individual response was measured (in mm) and then the average value ± SD was reported.

2.6. Statistical analysis

The statistical significance between data sets was calculated using Student's t-test, and p < 0.05 is considered statistically significant. All the tests were conducted at least in triplicate.

3. Results

3.1. Nutritive value of SBPF ingredient and SBPF-derived noodles

Spent barley protein and fibers ingredient yielded energy at 280 kcal per 100 g, and contained 29.1 g protein, 45.9 g fibers, 6.6 g carbohydrates, and 15.3 g total fats (8.2% of the total fats were polyunsaturated fats). Meanwhile, 100 g SBPF-derived noodles provided 32 kcal energy, 4 g protein, 6.6 g fibers, 0.85 g carbohydrates, and 1.42 g fats. The 100 g conventional starch-based noodles provided 180 kcal energy, 5.3 g protein, 1.1 g fibers, 1.6 g fat, and 35.9 g carbohydrates (Table 1). The nutritive values of 50 g vegetables, 6 g sesame oil, and 6 g soy sauce were included in the table. The amounts of energy and macronutrients contained in the test meals can be calculated.

3.2. Textural parameters of starch-based and SBPF-derived noodles

The textural properties of starch-based and SBPF-derived noodles could be seen in Table 2. There was no significant difference in hardness (p = 0.824) and springiness (p = 0.065) of the two representative foods. Interestingly, significant differences were observed in cohesiveness (p = 0.0024) and chewiness (p = 0.026) measurements.

Table 2. Textural analysis of starch-based and SBPF-derived noodles: hardness (g), springiness (mm), cohesiveness, chewiness (g × mm), and average palatability ratings; results are expressed as mean ± standard deviation.

3.3. GR studies

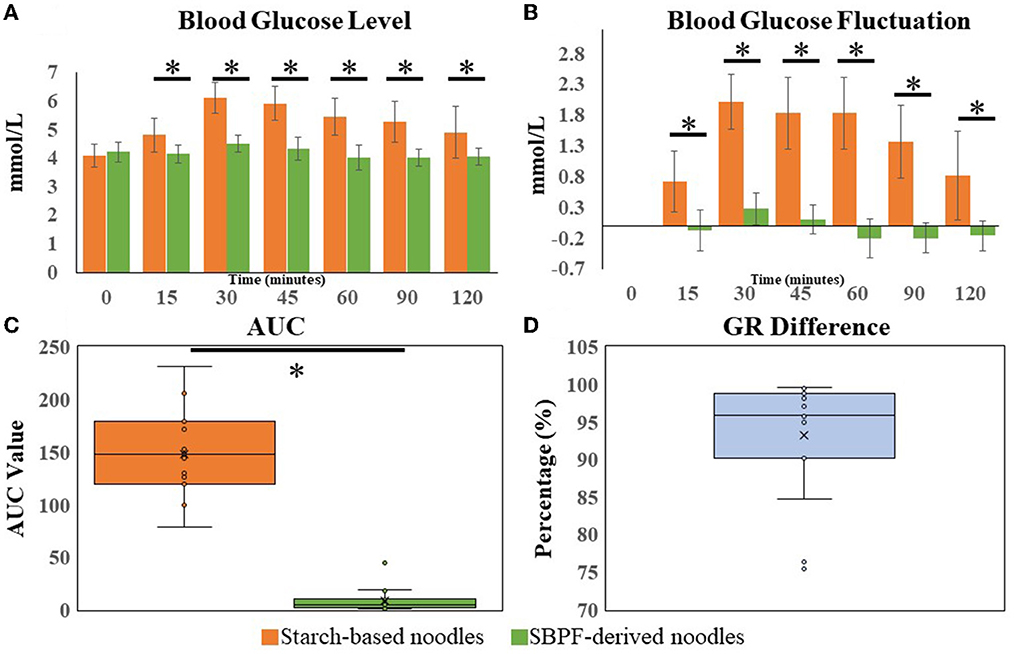

The average age of the 15 healthy participants (9 women and 6 men) was 40 years old (SD = 13.74). Their average BMI was 21.1 kg/m2 (SD = 2.17). The average 120 min GR responses of the participants for equal volumes of the two test foods were shown in Figure 2A. The fasting blood glucose concentration of each participant before food testing was evaluated as a control. The consumption of the starch-based noodles increased the mean blood glucose concentration from 4.09 mM (SD = 0.42, baseline level) to 6.11 ± 0.54 mM (48.8% higher than the baseline value) within the first 30 min. In addition, 2 h later, the blood glucose concentration gradually declined to 4.91 mM (SD = 0.91, 20% higher than the fasting baseline value). On the contrary, intake of SBPF-derived noodles did not increase blood glucose level significantly, the value was constant for 4.15 mM (SD = 0.32) for the first 30 min, and then at 4.06 mM (SD = 0.29) after 2 h. Moreover, the starch-based noodles consumption brought significant blood glucose fluctuations of the test subjects at 15, 30, 45, 60, 90, and 120 min after food consumption, when compared with the values at the same time after SBPF-derived noodles consumption (Figure 2B). It worth mentioning that the intake of SBPF-derived foods did not cause a significant increase in blood glucose values within 120 min. The p values are 0.18, 4.6 × 10−4, 5.06 × 10−11, 7.2 × 10−10, 4.74 × 10−8, 4.4 × 10−7, and 9.7 × 10−4 for blood glucose levels at 0, 15, 30, 45, 60, 90, and 120 min, respectively, after the test subjects consumed starch-based and SBPF-derived noodles. Meanwhile, the p values of blood glucose fluctuations are 1.06 × 10−5, 9.89 × 10−14, 1.37 × 10−11, 1.16 × 10−12, 1.34 × 10−10, and 1.29 × 10−5 at 15, 30, 45, 60, 90, and 120 min, respectively.

Figure 2. The average blood glucose concentrations (A) and fluctuations of blood glucose concentrations (B) before and after consuming the starch-based (orange) and SBPF-derived (green) noodles; Box and Whisker plots of the participants' AUC values after consuming starch-based noodles (orange) in contrast to the values of SBPF-derived noodles (green) within 2 h (C); and GR difference within the participants after consumption of starch-based and SBPF-derived noodles in 2 h (D), *P < 0.05.

The AUC calculation of individual participants was shown in Figure 2C box plot, the AUC spread in the participants consuming SBPF-derived noodles was narrower than that of the starch-based noodles (p = 3.46 × 10−9), and one unusual case (outlier) could be found in the participants consuming SBPF-derived noodles. The AUC values between consumptions of starch-based noodles and SBPF-derived noodles showed no intersection. Furthermore, the individual GR difference was plotted in the Box and Whisker graph in Figure 2D, the average GR difference was 93.16% (SD = 8.06). In addition, the upper extreme, upper quartile, median, lower quartile and lower extreme were 99.61, 98.82, 95.81, 90.15, and 84.64%, respectively. It was noticeable that two participants were having unusual GR differences (two outliers). There were 12 out of 15 (80%) participants in the interquartile range (IQR) of the GR difference Box and Whisker plot.

3.4. Overall palatability rating and visual analog scales

The overall palatability ratings for both foods were comparable (Table 2), and the average palatability ratings were 5.54 (SD = 0.85) and 4.95 (SD = 1.49) for starch-based noodles and SBPF-derived noodles (p = 0.347) individually. The average fasting, 60- and 120-min VAS ratings for four appetite variables of the starch-based, and SBPF-derived noodles were shown in Table 3. The participants preferred to eat more SBPF-derived noodles immediately after fasting. There was no significant difference in appetite and hunger ratings between the two types of foods at 60 and 120 min after consumption in all subjects.

Table 3. Average VAS ratings (in mm) at fasting, 60 min, and 120 min in 15 participants; results are expressed as mean ± standard deviation.

4. Discussion

The SBPF ingredient inherits the functional components from the pristine barley grain except for the starch (as illustrated in Figure 1 and Table 1). The addition of the SBPF ingredient not only increases the food's protein and dietary fiber content but also lowers the overall content of carbohydrates vs. starch-based foods (Townsley, 1979; Mussatto et al., 2006; Stojceska and Ainsworth, 2008). Our team utilized the SBPF ingredient to form the SBPF-derived noodles and evaluated its nutritional content, textural parameters, GR, VAS, and overall palatability rating. The palatability, texture, and taste aspects especially make it an attractive alternative staple for diabetics due to the significant GR reduction (93.16% less GR, SD = 8.06). Meanwhile, AX, β-glucan, and lignin are three major functional dietary fibers within SBG and the SBPF ingredient. The AX enters the large intestine and is fermented by colonic microflora to show prebiotic activity (Lu et al., 2000), and it increases bulk viscosity, slows gastric emptying and gastrointestinal motility, the blood glucose and insulin responses are subsequently delayed (Lu et al., 2000). The β-glucan reduces cholesterol and sugar levels in the blood upon consumption (Geng et al., 2022). The lignin prolongs the survival of bifidobacterial versus glucose as a substrate (Niemi et al., 2013). Moreover, the SBPF ingredient provides a rich combination of protein and minerals including hordeins, glutelins, globulins, albumins, phosphorus, calcium, and magnesium (Celus et al., 2006; Waters et al., 2012).

The textural analysis has been performed to evaluate the samples (Table 2), and the tensile test is used to elongate the sample and test the force required to break the sample. The texture profile analysis employs a double compression test to mimic the chewing of food. There is no significant difference between the data on hardness and springiness. Hardness describes the necessary forces to achieve a given deformation, the participants use a comparable force to break and crush the noodles during eating. The springiness measurements indicate the two representative noodles have comparable rates to return to their respective undeformed condition after force removal. The SBPF-derived noodles show better cohesiveness and chewiness, which is probably caused by the addition of dietary fibers, vital wheat gluten, and konjac powder (Lin and Huang, 2008; Barak et al., 2014; Liu et al., 2021).

In vivo GR study was conducted using starch-based noodles as control food (not any other control food like glucose or white bread). It is practical to compare the GR of SBPF-derived functional noodles with the starch-based noodles, and it will be helpful to ascertain that the SBPF-derived functional noodles have lower GR and will be an ideal choice for health-conscious consumers who wish to consume noodles without any blood glucose spike. In Figure 2A, the blood glucose level spikes from 4.09 mM (SD = 0.42, fasting baseline) to 6.11 mM (SD = 0.54) within 30 min upon intake of the starch-based food, then gradually reduces to 4.91 mM (SD = 0.91) within 120 min. The consumption of SBPF-derived noodles flattens the blood glucose curve without any spike. Furthermore, the fluctuations in blood glucose levels are illustrated in Figure 2B. Consumption of the starch-based noodles boosts the blood glucose level by 2 mM from its basal level within 30 min and the value remains peaked for another 30 min. However, the blood glucose fluctuations upon intake of SBPF-derived noodles are inconspicuous, and negligible when compared with the blood sugar levels after starch-based noodle consumption. The data from AUC and GR difference in Figures 2C, D is in line with the blood glucose analysis. The average AUC is 150.96 (SD = 38.81) for participants after consuming starch-based food, but 5.48 (SD = 4.98) for the same participants consuming SBPF-derived noodles. The participants show negligible GR after consumption of SBPF-derived noodles (narrow range of AUC Box and Whisker plot), while intake of starch-based noodles cause significant GR variations (long range of AUC Box and Whisker plot). Moreover, the GR difference value indicates 93.16% (SD = 8.06) GR reduction upon SBPF-derived noodles consumption and 12 out of 15 (80%) participants in the IQR of the GR difference Box and Whisker plot. The data concentrates on the IQR area indicating less variability and high repeatability of negligible GR for the participants after consuming SBPF-derived noodles. There are two outliers in the GR difference box plot, they might come from the personal physical variations, as we can exclude the data entry, measurement errors, sampling problems, and other unusual conditions. The SBPF-derived and the conventional starch-based noodles have comparable palatability (Table 2), and they have comparable VAS (Table 3). Interestingly, the participants consider eating more SBPF-derived noodles when they are fasting, and the starchless noodles provide less energy and carbohydrates with a larger volume of dietary fibers. Moreover, the participants indicate comparable fullness upon finishing both types of noodles in 60 and 120 min, respectively. Considering the two test foods show comparable values of sensory evaluations, and texture properties, the SBPF-derived noodles can be a green and functional replacement for conventional starch-based noodles. All the data endorses the effects of SBPF-derived noodles on controlling blood glucose (negligible GR). The SBPF-derived noodles provide nutrients and have enormous potential in empowering blood sugar control for people with diabetes, metabolic and body weight concerns, without the need for overbearing constraints in food intake. The inclusion of SBPF ingredient at high levels (>20%) is bound to have a greater positive impact on the nutritional levels of the end products but comes with costs, such as impacting the final product's texture, volume, color, and thus, sensorial characteristics and ultimate consumer acceptance (Lynch et al., 2016). The SBPF functional ingredient is herein utilized to produce functional noodles with negligible GR, and it is an ideal candidate for functional food preparation and health promotion. There is still technical progress that can be achieved to ensure and even improve the quality of the products. For example, the productivity of the SBPF functional ingredient can be improved with new milling methods and the consistency of nutritional content from various SBG batches must be ensured. Our team is constantly working on quality of the SBPF ingredient related foods, and major improvements could be reported in the future.

5. Conclusion

The SBG protein and fibers are valorized into SBPF functional ingredient, which can be applied to the preparation of functional noodles/foods with negligible GR. The SBPF-derived functional noodles show optimistic consumer acceptance and provide fiber and protein rich nutrition. The SBPF ingredient and SBPF-derived noodles and foods are especially suitable for consumers with blood sugar and body weight concerns, and potentially attractive alternative staple foods for people with diabetes. Our food waste upcycling strategies may resolve food sustainability and security concerns, and provide a source of nutrients to address nutritional needs without further planetary damage.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding authors.

Ethics statement

The studies involving human participants were reviewed and approved by Singapore Accreditation Council's (SAC) FFT-2010-0001A Functional Food Testing Scheme, based on ISO/IEC 17025:2017 and Technical Note FFT 01. The patients/participants provided their written informed consent to participate in this study.

Author contributions

PS: conceptualization, methodology, validation, formal analysis, writing—original draft, writing—review and editing, and visualization. RN: sample preparation, investigation, and writing—original draft. PV: characterization of SBPF-derived noodles and starch-based noodles. SL: writing—review and editing. KB: conceptualization, methodology, validation, formal analysis, and writing—review and editing. All authors contributed to the article and approved the submitted version.

Acknowledgments

Kosmode Health Singapore Pte. Ltd. supplied SBG, SBPF, and SBPF-derived noodles for this research. We would like to express our thanks to our Co-PIs Ms. Saihah Mohd Salleh and Ms. Sharifah Fattah from the Glycemic Index Research Unit, Temasek Polytechnic for their invaluable contributions in conducting the in vivo glycemic response study, and in analyzing the results.

Conflict of interest

PS and RN were employed by Kosmode Health Singapore Pte. Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2023.1146614/full#supplementary-material

References

Aday, S., and Aday, M. S. (2020). Impact of COVID-19 on the food supply chain. Food Qual. Safety 4, 167–180. doi: 10.1093/fqsafe/fyaa024

Barak, S., Mudgil, D., and Khatkar, B. S. (2014). Effect of compositional variation of gluten proteins and rheological characteristics of wheat flour on the textural quality of white salted noodles. Int. J. Food Propert. 17, 731–740. doi: 10.1080/10942912.2012.675611

Celus, I., Brijs, K., and Delcour, J. A. (2006). The effects of malting and mashing on barley protein extractability. J. Cereal Sci. 44, 203–211. doi: 10.1016/j.jcs.2006.06.003

Celus, I., Brijs, K., and Delcour, J. A. (2007). Enzymatic hydrolysis of brewers' spent grain proteins and technofunctional properties of the resulting hydrolysates. J. Agric. Food Chem. 55, 8703–8710. doi: 10.1021/jf071793c

Chee, C. (2022). Beer Industry Statistics and Facts For 2022. Available online at: https://trulyexperiences.com/blog/beer-industry-statistics (accessed January 15, 2023).

Crummett, L. T., and Grosso, R. J. (2022). Postprandial glycemic response to whole fruit versus blended fruit in healthy, young adults. Nutrients 14, 4565. doi: 10.3390/nu14214565

Geng, L., Li, M., Zhang, G., and Ye, L. (2022). Barley: a potential cereal for producing healthy and functional foods. Food Quality Safety, 6, fyac012. doi: 10.1093/fqsafe/fyac012

Jagtap, S., Trollman, H., Trollman, F., Garcia-Garcia, G., Parra-López, C., Duong, L., et al. (2022). The Russia-Ukraine conflict: its implications for the global food supply chains. Foods 11, 2098. doi: 10.3390/foods11142098

Jang, E., Lee, J., Lee, S., and Kim, M.-H. (2017). Short-term effect of convenience meal intake on glycemic response and satiety among healthy college students in South Korea. Clin. Nutr. Res. 6, 215–220. doi: 10.7762/cnr.2017.6.3.215

Kok, Y. J., Ye, L., Muller, J., Ow, D. S.-W., and Bi, X. (2019). Brewing with malted barley or raw barley: what makes the difference in the processes? Appl. Microbiol. Biotechnol. 103, 1059–1067. doi: 10.1007/s00253-018-9537-9

Lin, K. W., and Huang, C. Y. (2008). Physicochemical and textural properties of ultrasound-degraded konjac flour and their influences on the quality of low-fat Chinese-style sausage. Meat. Sci. 79, 615–622. doi: 10.1016/j.meatsci.2007.10.026

Liu, Y., Chen, Q., Fang, F., Liu, J., Wang, Z., Chen, H., et al. (2021). The influence of konjac glucomannan on the physicochemical and rheological properties and microstructure of canna starch. Foods 10, 422. doi: 10.3390/foods10020422

Lu, Z. X., Walker, K. Z., Muir, J. G., Mascara, T., and O'Dea, K. (2000). Arabinoxylan fiber, a byproduct of wheat flour processing, reduces the postprandial glucose response in normoglycemic subjects. Am. J. Clin. Nutr. 71, 1123–1128. doi: 10.1093/ajcn/71.5.1123

Lynch, K. M., Steffen, E. J., and Arendt, E. K. (2016). Brewers' spent grain: a review with an emphasis on food and health. J. Inst. Brew. 122, 553–568. doi: 10.1002/jib.363

Maheshwari, G., Sowrirajan, S., and Joseph, B. (2019). β-Glucan, a dietary fiber in effective prevention of lifestyle diseases – An insight. Bioact. Carbohydr. Dietary Fibre 19, 100187. doi: 10.1016/j.bcdf.2019.100187

Mussatto, S. I., Dragone, G., and Roberto, I. C. (2006). Brewers' spent grain: generation, characteristics and potential applications. J. Cereal Sci. 43, 1–14. doi: 10.1016/j.jcs.2005.06.001

Niemi, P., Aura, A. M., Maukonen, J., Smeds, A. I., Mattila, I., Niemelä, K., et al. (2013). Interactions of a lignin-rich fraction from brewer's spent grain with gut microbiota in vitro. J. Agric. Food Chem. 61, 6754–6762. doi: 10.1021/jf401738x

Özvural, E. B., Vural, H., Gökbulut, I., and Özboy-Özbaş, Ö. (2009). Utilization of brewer's spent grain in the production of Frankfurters. Int. J. Food Sci. Technol. 44, 1093–1099. doi: 10.1111/j.1365-2621.2009.01921.x

Plessas, S., Trantallidi, M., Bekatorou, A., Kanellaki, M., Nigam, P., and Koutinas, A. A. (2007). Immobilization of kefir and Lactobacillus casei on brewery spent grains for use in sourdough wheat bread making. Food Chem. 105, 187–194. doi: 10.1016/j.foodchem.2007.03.065

Reshamie, C., Morrissey, H., Waidyaratne, E., Ball, P., and Manilka, S. (2018). The impact of individual health education on health literacy: evaluation of the translated version (Sinhala) of health education impact questionnaire in type 2 diabetes. Int. J. Diab. Clin. Res. 5, 87. doi: 10.23937/2377-3634/1410087

Shahbandeh, M. (2022). World barley production from 2008/2009 to 2021/2022. from Available online at: https://www.statista.com/

Stojceska, V., and Ainsworth, P. (2008). The effect of different enzymes on the quality of high-fibre enriched brewer's spent grain breads. Food Chem. 110, 865–872. doi: 10.1016/j.foodchem.2008.02.074

Szwajgier, D., Waśko, A., Targoński, Z., Niedzwiadek, M., and Bancarzewska, M. (2010). The Use of a Novel Ferulic Acid Esterase from Lactobacillus acidophilus K1 for the Release of Phenolic Acids from Brewer's Spent Grain. J. Inst. Brew. 116, 293–303. doi: 10.1002/j.2050-0416.2010.tb00434.x

Tosh, S. M., and Bordenave, N. (2020). Emerging science on benefits of whole grain oat and barley and their soluble dietary fibers for heart health, glycemic response, and gut microbiota. Nutr. Rev. 78, 13–20. doi: 10.1093/nutrit/nuz085

Townsley, P. M. (1979). Preparation of commercial products from brewer's waste grain and trub [Protein flours]. Master Brewers Association of the Americas, 16. Available online at: https://www.mbaa.com/publications/tq/tqPastIssues/1979/Abstracts/tq79ab28.htm (accessed January 15, 2023).

Waters, D. M., Jacob, F., Titze, J., Arendt, E. K., and Zannini, E. (2012). Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer's spent grain enrichment. Eur. Food Res. Technol. 235, 767–778. doi: 10.1007/s00217-012-1805-9

Keywords: spent barley protein and fibers (SBPF), valorization, functional foods, food as medicine, circular economy

Citation: Shi P, Ng RNYK, Vijayan P, Lim SL and Bhaskaran K (2023) Valorization of spent barley grains: isolation of protein and fibers for starch-free noodles and its effect on glycemic response in healthy individuals. Front. Sustain. Food Syst. 7:1146614. doi: 10.3389/fsufs.2023.1146614

Received: 17 January 2023; Accepted: 27 April 2023;

Published: 18 May 2023.

Edited by:

Rui Poínhos, University of Porto, PortugalReviewed by:

K. S. Yoha, Entrepreneurship and Management-Thanjavur, IndiaThomas Wolever, University of Toronto, Canada

Copyright © 2023 Shi, Ng, Vijayan, Lim and Bhaskaran. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Kalpana Bhaskaran, a2FscGFuYV9iaGFza2FyYW5AdHAuZWR1LnNn; Pujiang Shi, c2hpcHVqaWFuZ0Brb3Ntb2RlaGVhbHRoLmNvbQ==

†These authors have contributed equally to this work

Pujiang Shi

Pujiang Shi Rachel Ng Yuen Kai1†

Rachel Ng Yuen Kai1†