- Department of Food Science and Technology, Faculty of Agriculture, Warmadewa Universitry, Denpasar, Indonesia

Siamese orange fruit is very popular today, driven by the increasing public demand or healthy food. Siamese oranges contain bioactive phenolic compounds, carotenoids, vitamins, minerals, and fiber which are good for health. The weakness of Siamese oranges is their quality declines quickly and their short shelf life. Postharvest handling with the application of coatings from natural ingredients to extend the shelf life of orange fruits is currently needed to reduce the use of synthetic materials. Natural ingredients that have the potential to be used as base materials for coatings are konjac tubers because they contain glucomannan polysaccharides and bioactive compounds that can form coatings. The purpose of this study was to determine the effect of nanocoating-konjacon the shelf life of Siamese oranges. The research began with the preparation of the nanocoating-konjac formula as the main ingredient of the nanocoating and the application of the nano coating-konjac on the surface of Siamese oranges. This study used a completely randomized two-factor design, namely nanocoating-konjac application (without coating, coating, and nanocoating) and storage time (0, 5, 10, and 15 days), three replications. Variables observed: Weight loss, number of damaged fruits, color, texture, acidity, total soluble solids, water content, vitamin C, and total plate count. The data obtained was tested for diversity with SPSS, if it shows differences the test is continued with Duncan's Multiple Range Test. The conclusion of this research is the application of nanocoating-konjac, coating-konjac and without coating on Siamese oranges to determine the effect of weight loss, number of damaged fruits, color, texture, acidity, total dissolved solids, water content, vitamin C, and total plate count during storage. This research recommends that the application of nanocoating-konjac as postharvest handling can extend the shelf life of Siamese oranges until the 10th days.

1. Introduction

Consumption of fruits is currently increasing. Public awareness of health indirectly increases the need for quality fruit. Fruits have a variety of specific shapes, sizes, tastes, and textures (Suriati et al., 2021). One of the fruits that are popular and have high economic value is the Siamese orange (Citrus nobilis var. microcarva L) (Silva-Espinoza et al., 2021). Siamese oranges taste good, they also contain bioactive phenolic compounds, carotenoids, vitamins, minerals, and fiber (Ferreira et al., 2021). The characteristic feature of the Siamese orange is its thin skin (about 2 mm), its surface is smooth, and shiny and sticks to the flesh. The base of the fruit is short-necked with a notched apex. The fruit stalk is short, about 3 cm long, and 2.6 mm in diameter. The flesh is soft with a sweet and fragrant taste. The fruit production is high with a weight per fruit of around 75.6 grams. It is usually harvested in May-August. According to Sulistyo et al. (2019), the bioactive components of phenolics, carotenoids, organic acids, vitamins, and fiber in Siamese oranges are beneficial for health. Besides being delicious to eat, Siamese oranges also function to facilitate digestion, overcome obesity, and increase immunity, as antioxidants, anticancer, and anti-inflammatory (Strano et al., 2021). Siamese orange production in Bali Indonesia was recorded at 4,862,385 tons in 2020, the price is only 5,000 rupiah per kilogram. The increase in Siamese orange production was also followed by an increase in postharvest losses due to improper handling during distribution and storage. A decrease in the quality of Siamese oranges due to mechanical damage of 15–20%, namely in the form of cracks on the skin and rot due to infection by microbial contaminants such as fungi, mold, and bacteria, thus reducing their shelf life (Khorram et al., 2017). The quality of orange fruit for marketing is influenced by variety uniformity, size uniformity (diameter and weight), maturity level, hardness level, total dissolved solids, total acid, and vitamin C content (Gao et al., 2018; Saberi et al., 2018). Siamese oranges spoil quickly, because after harvest they are only placed in bamboo baskets and taken directly to the market. Proper postharvest handling is needed to reduce the decline of Siamese oranges, and to extend their shelf life (Strano et al., 2021). Therefore, research is needed to maintain the quality of orange fruits during storage. The coating application method is needed so that the product reaches the consumer's hands and remains of fresh quality (Rasouli et al., 2019; Suriati et al., 2020b).

The use of coatings from natural ingredients to replace synthetic preservatives is urgently needed. One of the basic ingredients in the manufacture of nanocoatings from the polysaccharide group is glucomannan (Azeredo et al., 2022; Suriati, 2022). In recent years, glucomannan has attracted more and more attention than chitosan and gum, due to its harmless and non-toxic properties, good biocompatibility, biodegradability and hydrophilic ability (Behera and Ray, 2016). Konjac (Amorphophallus muelleri. Blume) is a potential source of glucomannan. Konjac tubers contain glucomannan or a source of water-soluble fiber which is quite high, namely 79.91% (Xiao et al., 2022). Glucomannan from konjac is biodegradable, has antioxidant power, low toxicity, is cheap, and is easy to apply (Devaraj et al., 2019; Wang et al., 2022). The function of glucomannan is as an emulsifier or emulsifier which is often applied in the food industry because glucomannan can form a gel that has a fairly high viscosity when it is in a liquid (Suriati et al., 2020a). Glucomannan from konjac also has elastic properties and can form crystals and form fine fiber structures thereby increasing coating properties (Zhou et al., 2018; Shi et al., 2019).

Coating ability is affected by particle size and chemical constituents (Suriati et al., 2022). Particles with a small size (nanocoating) cause a larger surface area resulting in an increase in solubility, release of active compounds, absorption, and attachment (Leena et al., 2020; Onyeaka et al., 2022). Nanocoating is a nano-sized thin layer that can be incorporated with active additives such as antioxidants, antisenescence, and antimicrobials (Gago et al., 2020; Correa-Pacheco et al., 2021). The application of nanocoating from natural materials is currently needed to improve the appearance and maintain quality (Suriati, 2022), so that it can support the green economy, namely increasing the welfare and social equality of the Siamese orange farming community, while significantly reducing the risk of environmental damage. The advantages of using nanocoating include antimicrobial capabilities, barrier, and mechanical properties, stability of the emulsion system, and adhesion (De León-Zapata et al., 2018; Sharif Hossain et al., 2018). Nanocoating can be applied to orange fruits, but there is no research yet.

Nanocoating functions as a barrier to chemical, physical and biological changes (Hu et al., 2020; Ghosh et al., 2021). The application of nanocoating also improves the appearance of bright and shiny fruit, retains moisture, prevents weight loss, and acts as an antimicrobial (Correa-Pacheco et al., 2021). According to Basaglia et al. (2021), nanocoating helps maintain quality and extends the shelf life of fruits. In line with the opinions of Ghosh et al. (2021), nanocoating can maintain the physicochemical, physiological, and microbiological properties of food so that it can maintain quality, and safety and extend shelf life. Research comparing without coating application, coating application, and application with nanocoating to extend the shelf life of Siamese oranges have no information, further research is needed. The novelty of this research is the effectiveness of the application of konjac-based nanocoating on the shelf life of Siamese oranges. The research objective was to determine the effect of the application of nanocoating-konjac on the shelf life of Siamese oranges.

2. Materials and methods

2.1. Tools and materials

Research tools: refractometer (950.032 B-ATC, France), spectral colorimeter (CS-280, Zhejiang China), viscometer fluid meter (NDJ8S, UK), pH meter (Hanna HI 8424, Romania), oven (Memmert, Germany), sonicate (model Q125 mesonic USA), spectrometer UV Vis (Libra S60, USA), Scanning Electronic Microscope (SEM) (JSM-6510LA, Japan), homogenizer (VWR IKA VMS-C7 USA), texture analyzer (TA. XT plus C, UK). Research materials: konjac (Amorphophallus muelleri Blume) aged 6 months and Siamese orange (Citrus nobilis Tan) aged 8 months from flowering were obtained from Catur Village, Kintamani District, Bangli Regency, Bali Province. The criteria for the Siamese oranges used: the bottom of the fruit when squeezed feels soft, the color is uniformly yellow and the sugar content is at least 10%. Additives NaCl, Ca (OH)2, and glycerol was obtained at UD. Bharata Chemical Denpasar. This research was conducted at the Food Analysis Laboratory, Faculty of Agriculture, Warmadewa University, Denpasar.

2.2. Research implementation

Testing the quality of Siamese oranges was prepared as a whole and sorted based on the optimal level of ripeness and each research unit consisted of 30 fruits. The research design used was a factorial complete randomized design. The first factor is postharvest handling, i.e., without coating application, konjac-coating application (non-nano), and nanocoating-konjac application. The second factor is storage time (0, 5, 10, 15 days). Variables observed: Weight loss, number of damaged fruits, color, texture, acidity, total soluble solids, water content, vitamin C, and total plate count. The data obtained was tested for diversity with SPSS, if it shows differences the test is continued with Duncan's Multiple Range Test.

2.3. Preparation of konjac flour

The preparation of konjac flour as a basic ingredient for coating and nanocoating-konjac begins with the konjac sorting process, then stripping is carried out to remove the skin. Slicing is done after the washing process, with a thickness of 5 mm. Soaking in 15% (w/v) salt solution for 30 min, after which rinsing was carried out to remove the remaining salt solution. The next process is immersion in 15% (w/v) Ca(OH)2 solution for 20 min. Drying in an oven at 50°C for ±24 h was carried out after the konjac was drained. The dried konjac slices were ground and then sieved using a 50 mesh sieve to obtain konjac flour as the basic ingredient for nanocoating (Septiawan et al., 2021).

2.4. Formulation nanocoating-konjac

Coating-konjac is made by dissolving 1% konjac flour in water. Then, 1% glycerol emulsifier was added, and a homogenization process was carried out for 10 min using a heating process carried out at 70 ± 1°C for 5 min, then cooled and the konjac coating was ready to be applied. Nanocoating-konjac was prepared by dissolving 1% konjac flour in water, adding 1% glycerol, and then homogenizing for 10 min using a sonicate model Q125 to produce nano-sized particles, with a 59-time delay pulse of 30 s for 50 min. The size of nanocoating konjac was determined using the UV–vis spectrophotometer. The maximum absorbance indicated a particle size of 20–110 nm. The heating process was carried out at 70 ± 1°C for 5 min, then cooled and the konjac nanocoating was ready to be applied. The physicochemical properties of nanocoating-konjac are strongly influenced by air, light and heat. Nanocoating-konjac should be stored in dark glass containers to avoid light affecting sensitive bioactive agents and stored in (7 ± 1)°C.

2.5. Application of coating and nanocoating-konjac on Siamese oranges

Coating and nanocoating-konjac applications were carried out after sorting the Siamese oranges and preparing the experimental units. Each experimental unit was filled with 20 oranges weighing 150–200 g each. The dyeing process uses a nanocoating concentration of 50% and an immersion time of 2 min. After immersion, it is dried with a blower for 10 min, then stored at room temperature. Observations were made periodically on days 0, 5, 10, and 15 which included: Weight loss, number of damaged fruits, color, texture, acidity, total soluble solids, water content, vitamin C, and total plate count.

3. Results and discussions

3.1. Weight loss

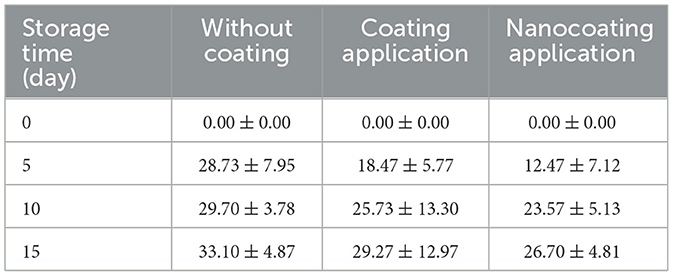

The results showed that the storage time showed a very significant effect on the weight loss of Siamese oranges, while application of the coating and the interactions between type of coating and storage time were not different. The highest weight loss value of 33.10% was obtained from the treatment without coating and on the 15th day of storage, as shown in Table 1. The weight loss of Siamese oranges with the application of nanocoating-konjac was also lower than the treatment with the application of konjac-coating. This shows that the nanocoating-konjac treatment was most effective in suppressing the weight loss of orange fruits. Opinion of Xiao et al. (2022), samples sealed with nanocoating-konjac showed a decrease in weight loss. This is due to the stronger water-retaining properties of the nanocoating-konjac (Xiao et al., 2021). Non-toxicity properties and high efficiency to preserve fruit, then nanocoating-konjac can be considered a good candidate for commercial coatings (Behera and Ray, 2016).

3.2. Number of damaged fruits

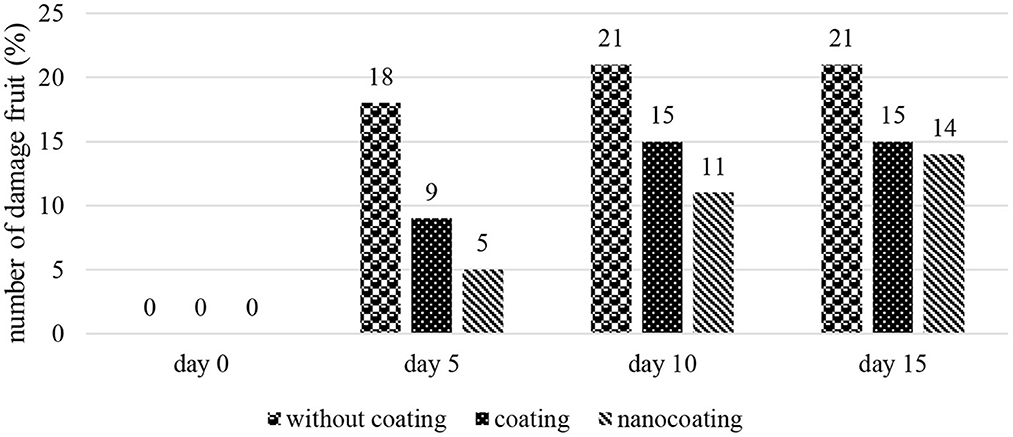

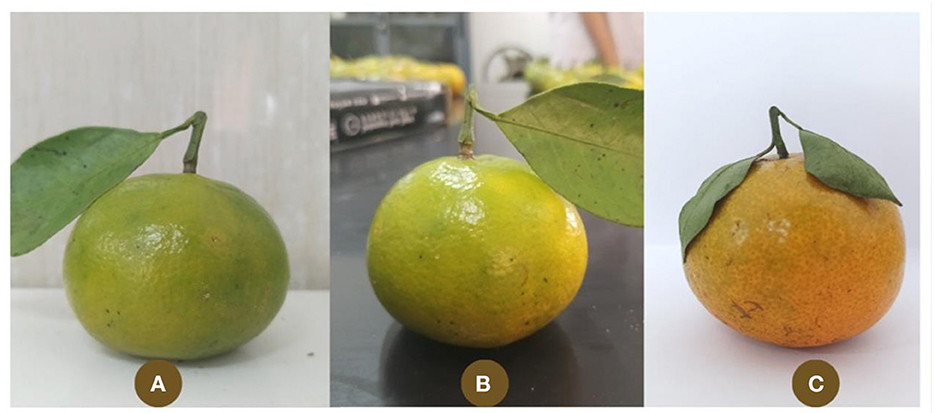

The results showed that the coating application, storage time, and interaction showed a very significant effect on the number of damaged fruits from Siamese oranges. The highest damaged fruit value of 21% was obtained from the non-coated treatment, starting on the 10th day of storage, on day 0 there was no fruit damage in all treatments (Figure 1). The quality of Siamese oranges decreases due to mechanical damage by 15–20%, namely in the form of cracks on the skin and rot due to infection by microbial contaminants such as fungi, mold and bacteria, thereby reducing their shelf life (Khorram et al., 2017). The number of damaged Siamese oranges with the application of nanocoating-konjac was the lowest compared to the treatment with the application of coating-konjac and without coating. This shows that the nanocoating-konjac treatment is the most effective in suppressing orange fruit damage. Opinion (Zhou et al., 2018) that konjac glucomannans coating could maintain the quality of fresh-cut lotus root by the phenolic, a polysaccharide found in glucomannan in konjac, is a polysaccharide that has great potential as a basic material for sustainable packaging, namely edible coatings (Zhao et al., 2021). Siamese orange color based on maturity level can be seen in Figure 2.

Figure 2. Siamese orange color based on the level of maturity. (A) Siamese orange maturity level I. (B) Siamese orange maturity level II. (C) Siamese orange maturity level III.

3.3. Color

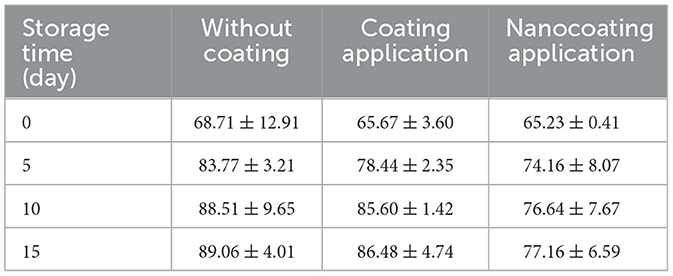

Color is a major key in preferences for food selection and acceptance and even influences taste threshold, sweetness perception, and preferences. The results showed that the coating application and storage time showed a very significant effect on the color of Siamese oranges, while the interaction was not different. The average color value of Siamese oranges ranged from 65.23 to 89.06, as shown in Table 2. Fruit color increased during 15 days of storage. This indicates that there is a color change from green to yellow due to the ripening process. The quality of Siamese oranges will quickly decline if the whole fruit is yellow. The nanocoating-konjac treatment produced the lowest color value compared to the konjac-coated and non-coated treatments. Nanocoating-konjac application can delay the deterioration of the quality of Siamese oranges, in other words, it can extend the shelf life. Konjac glucomannan properties can form crystals and form fine fiber structures (Zhou et al., 2018). In addition, glucomannan also has elastic properties and can improve the characteristics of the konjac coating (Zhang et al., 2020).

3.4. Texture

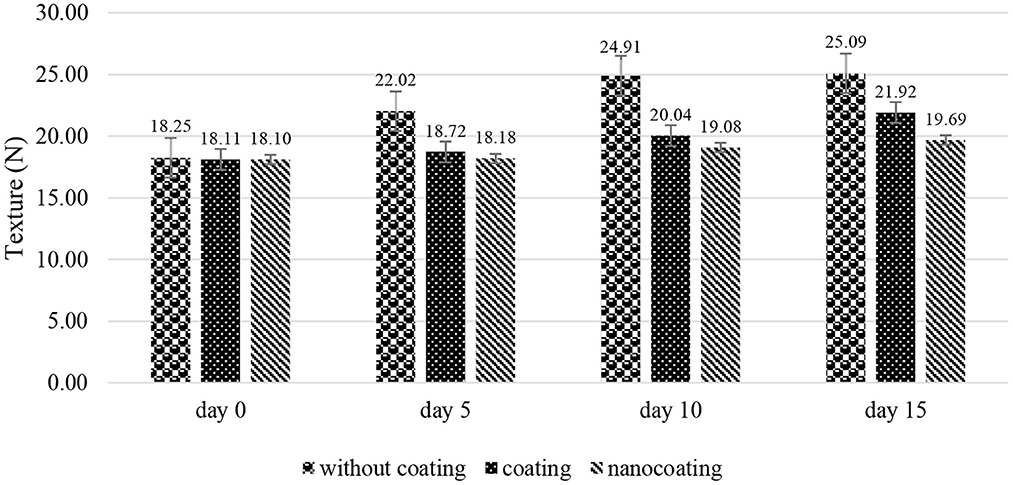

The results showed that the coating application, storage time, and interaction showed a very significant effect on the texture of Siamese oranges. The texture was measured with a texture analyzer using a speed of 5 mm/s and a distance of 20 mm. The texture value of the non-coated treatment continued to increase from 18.25 to 25.09 N, while the orange fruit with the Konjac-coated and nano-coated Konjac treatments was lower. This means that the surface of the uncoated orange peel dries faster and is harder when punctured with a texture analyzer tool to produce a larger value (Figure 3). The nanocoating-konjac application produces a relatively stable texture value up to 15 days of storage, which ranges from 18.10 to 19.69 N. Nanocoating-konjac can maintain the texture of Siamese oranges during storage. Polysaccharide-based edible coatings have been explored as safe and environmentally friendly food packaging materials (Zhao et al., 2021; Xiao et al., 2022). These results indicate that coatings can be used to inhibit oxidation (Díaz-Montes and Castro-Muñoz, 2021). The water barrier property is due to the increased diffusion of water vapor molecules across the coating. Thus, the coating has a high potential for use in fruit packaging (Xiao et al., 2022).

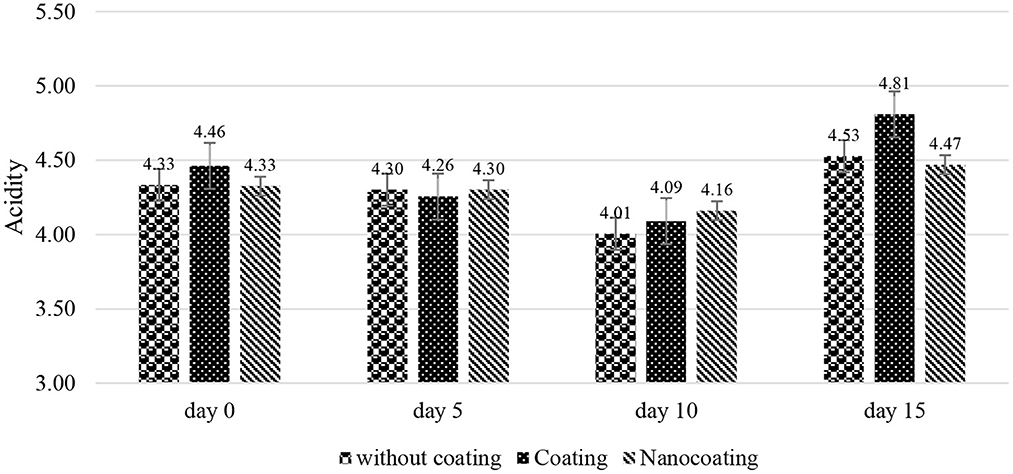

3.5. Acidity

The degree of acidity is one of the important variables that determine the quality of Siamese oranges. The results showed that the coating application, storage time, and interaction showed a very significant effect on the acidity of Siamese oranges. The acidity value of Siamese oranges tended to decrease until the 10th day but increased again on the 15th day of storage, namely between 4.47 and 4.81, as shown in Figure 4. This occurs due to organic acids being used as substrates for the respiration process. The respiration process still occurs even though the orange has been applied with nanocoating, but the rate is lower. Siamese oranges taste good and contain bioactive compounds such as phenolics, carotenoids, vitamins, minerals, and fiber (Ferreira et al., 2021). Orange fruit quality is influenced by acidity, variety uniformity, size, ripeness, level of hardness, total dissolved solids, and vitamin C content (Saberi et al., 2018). Fruit quality parameters such as titratable acidity, total dissolved solids, fruit hardness, ascorbic acid, and skin color can be maintained by coating treatment (Shah and Hashmi, 2020).

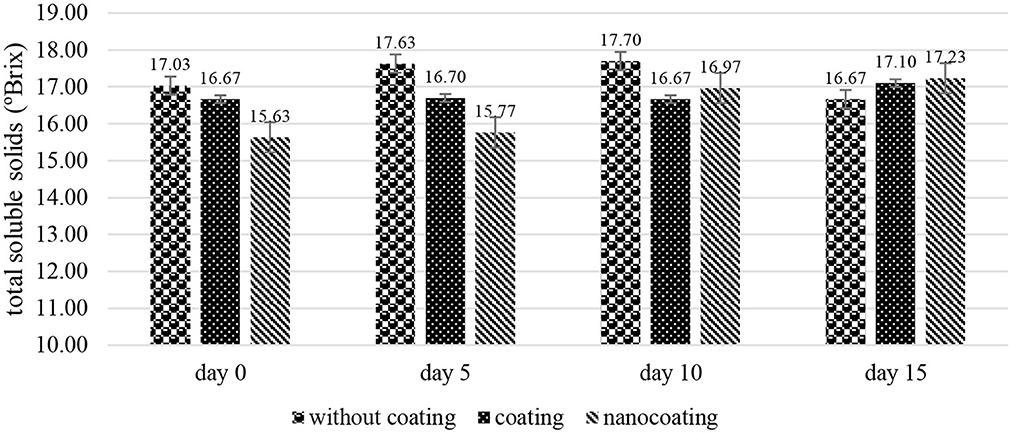

3.6. Total soluble solids

The results showed that the coating application, storage time, and interaction showed a very significant effect on the total soluble solids of Siamese oranges. The total soluble solids value of Siamese oranges without coating increased until the 10th day and decreased again on the 15th day. Meanwhile, the total soluble solids of Siamese oranges with the nanocoating-konjac treatment continued to increase slowly until the 15th day, namely 17.23°Brix (Figure 5). This shows that the nanocoating-konjac treatment can restrain the rate of respiration so that the breakdown of starch into simple sugars can be suppressed. Thus, ripening and decreasing the quality of Siamese oranges can be prevented. Opinions (Shah and Hashmi, 2020) say that coating treatment can maintain total dissolved solids, suppress disease and maintain the natural properties of fruit during postharvest storage. Supported by the opinion Suriati et al. (2020c) that coating can extend the shelf life of fresh fruit.

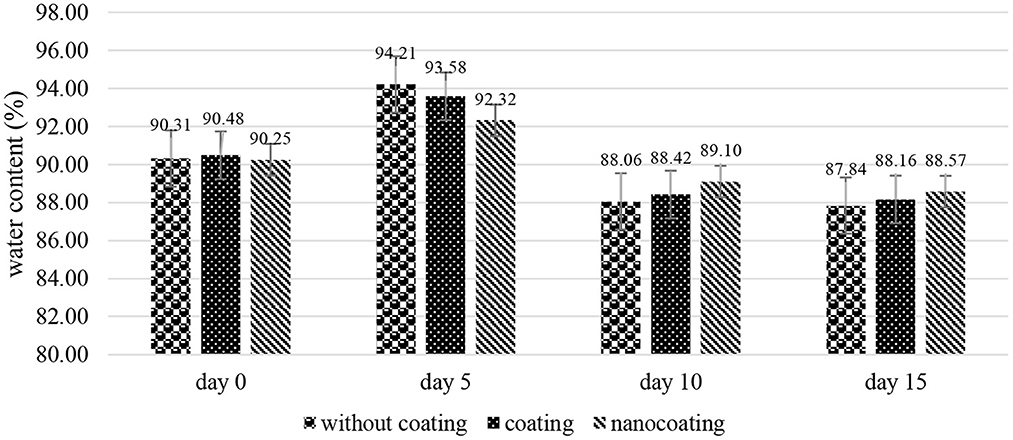

3.7. Water content

Water content is an important factor affecting the quality of Siamese oranges. The results showed that the coating application, storage time, and interaction showed a very significant effect on the water content of Siamese oranges. The average water content of Siamese oranges increased at 5 days of storage, then decreased until the 15th day of storage (Figure 6). This shows that there is an increase in the amount of Siamese orange juice due to the breakdown of starch into simpler components and also water. Moisture content affects the freshness and resistance of ingredients to attack by microorganisms during postharvest handling (Mangkua et al., 2022). According to Shi et al. (2019), konjac coatings have the potential to be used in fruit packaging. Konjac glucomannan is a widely used polysaccharide for the preparation of edible coatings with the superior film-forming ability (Xiao et al., 2021). On the other hand, firmness is also closely related to moisture content, as it facilitates the preservation of tissue cell integrity. Shi et al. (2019) suggested that konjac glucomannan could maintain the quality of fresh-cut fruit.

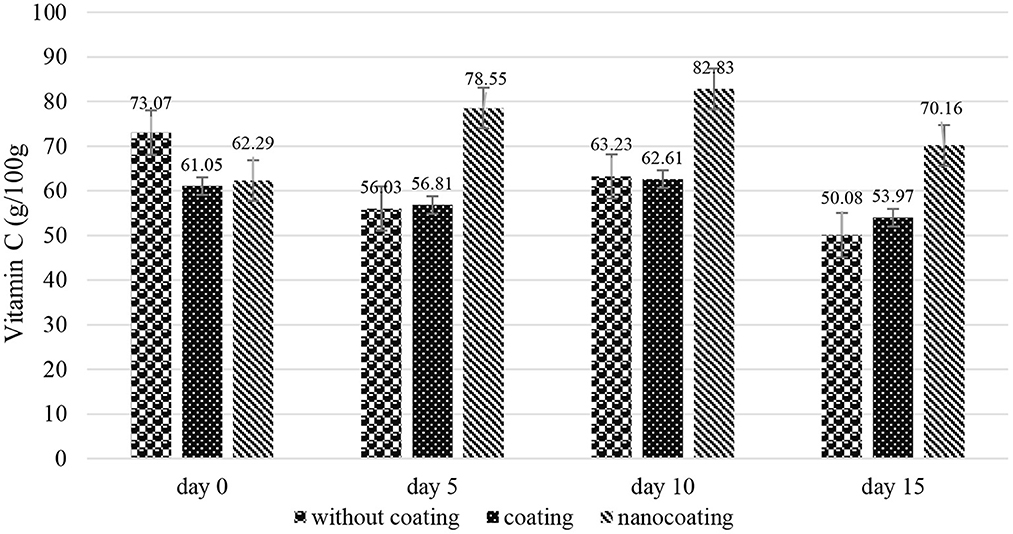

3.8. Vitamin C

The results showed that the storage time treatment had a very significant effect on vitamin C from Siamese oranges, while the nanocoating application and its interaction had no significant effect. The highest vitamin C value of Siamese oranges was obtained in the nanocoating-konjac treatment, namely 73.46 mg/100 g, as shown in Figure 7. This means that the konjac nanocoating treatment was able to maintain vitamin C levels of Siamese oranges during 15 days of storage. This shows that the application of the konjac coating can maintain the vitamin C content of Siamese oranges (Díaz-Montes and Castro-Muñoz, 2021), edible coatings/films based on konjac glucomannan have received more consideration as a promising method to increase the shelf life of fresh kiwifruit. Fruit quality parameters such as titratable acidity, ascorbic acid, and skin color can be maintained by coating treatment (Shah and Hashmi, 2020).

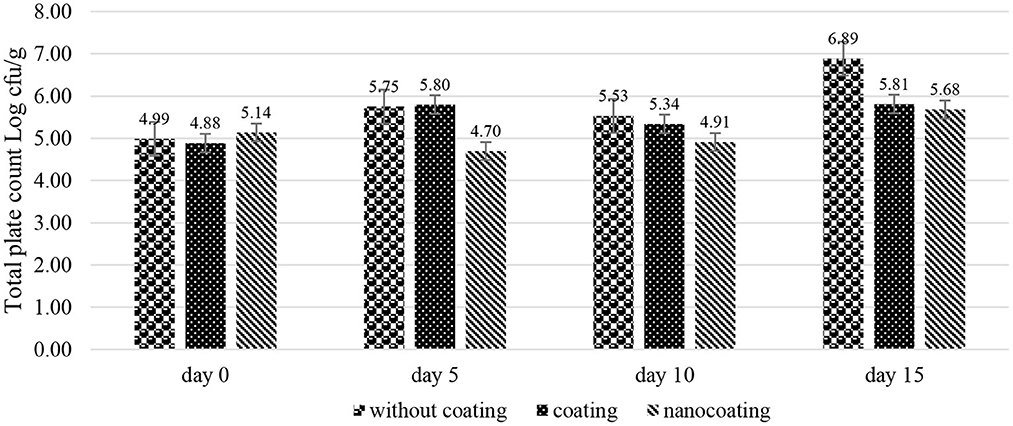

3.9. Total plate count

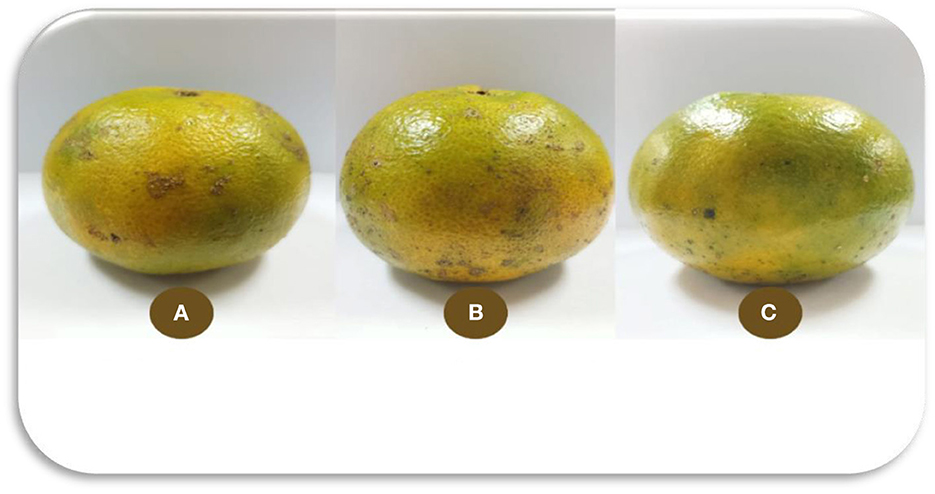

The results showed that the coating application, storage time, and interaction had a very significant effect on the total plate count of Siamese oranges. The highest total plate count value of Siamese oranges was obtained in the non-coated treatment at 15 days of storage, namely 6.89 log cfu/gram, and the lowest in the nanocoating-konjac treatment of 5.68 log cfu/gram, as shown in Figure 8. The increase in total microbes that occurred in week 5 was due to the development of microbes that already exist in orange fruits. Li et al. (2021) also stated that konjac-based coatings showed a more significant and positive effect on ginger quality during storage. Therefore, konjac coatings hold promise in preservation (Xiao et al., 2022). In line with the opinion Li et al. (2021), these results indicate that polysaccharide-based coatings are very helpful in maintaining the quality of Siamese orange fruit. Performance of Siamese orange after nanocoating application show in Figure 9.

Figure 9. Siamese orange. (A) Siamese oranges without coating. (B) Siamese oranges with coating application. (C) Siamese oranges with nanocoating application.

4. Conclusion

The conclusion of this research is the application of nanocoating-konjac, coating- konjac and without coating on Siamese oranges to determine the effect of weight loss, number of damaged fruits, color, texture, acidity, total dissolved solids, water content, vitamin C, and total plate count during storage. This research recommends that the application of nanocoating-konjac as postharvest handling can extend the shelf life of Siamese oranges until the 10th days.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

The author asserts to be the sole contributor of this work.

Acknowledgments

The author would like to thanks the Ministry of Education and Culture Research and Higher Education Technology of the Republic of Indonesia for funding assistance. The author also thanks the Chancellor of Warmadewa University and all colleagues for their support in this research.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Azeredo, H. M. C., Otoni, C. G., and Mattoso, L. H. C. (2022). Edible films and coatings – Not just packaging materials. Curr. Res. Food Sci. 5, 1590–1595. doi: 10.1016/j.crfs.2022.09.008

Basaglia, R. R., Pizato, S., Santiago, N. G., Maciel de Almeida, M. M., Pinedo, R. A., and Cortez-Vega, W. R. (2021). Effect of edible chitosan and cinnamon essential oil coatings on the shelf life of minimally processed pineapple (Smooth cayenne). Food Biosci. 41, 100966. doi: 10.1016/j.fbio.2021.100966

Behera, S. S., and Ray, R. C. (2016). Konjac glucomannan, a promising polysaccharide of Amorphophallus konjac K. Koch in health care. Int. J. Biol. Macromol. 92, 942–956. doi: 10.1016/j.ijbiomac.2016.07.098

Correa-Pacheco, Z. N., Corona-Rangel, M. L., Bautista-Baños, S., and Ventura-Aguilar, R. I. (2021). Application of natural-based nanocoatings for extending the shelf life of green bell pepper fruit. J. Food Sci. 86, 95–102. doi: 10.1111/1750-3841.15542

De León-Zapata, M. A., Ventura-Sobrevilla, J. M., Salinas-Jasso, T. A., Flores-Gallegos, A. C., Rodríguez-Herrera, R., Pastrana-Castro, L., et al. (2018). Changes of the shelf life of candelilla wax/tarbush bioactive based-nanocoated apples at industrial level conditions. Sci. Hortic. 231, 43–48. doi: 10.1016/j.scienta.2017.12.005

Devaraj, R. D., Reddy, C. K., and Xu, B. (2019). Health-promoting effects of konjac glucomannan and its practical applications: a critical review. Int. J. Biol. Macromol. 126, 273–281. doi: 10.1016/j.ijbiomac.2018.12.203

Díaz-Montes, E., and Castro-Muñoz, R. (2021). Edible films and coatings as food-quality preservers: An overview. Foods 10, 249. doi: 10.3390/foods10020249

Ferreira, T. H. B., Rodrigues Basaglia, R., Marques Paes da Cunha, T., and Faria Freitas, M. L. (2021). Production and physical, chemical, microbiological, and sensory characterization of extra fruit jam. J. Culin. Sci. Technol. 20, 453–462. doi: 10.1080/15428052.2020.1862009

Gago, C., Antão, R., Dores, C., Guerreiro, A., Miguel, M. G., Faleiro, M. L., et al. (2020). The effect of nanocoatings enriched with essential oils on “Rocha” pear long storage. Foods 9, 1–15. doi: 10.3390/foods9020240

Gao, Y., Kan, C., Wan, C., Chen, C., Chen, M., and Chen, J. (2018). Quality and biochemical changes of navel orange fruits during storage as affected by cinnamaldehyde -chitosan coating. Sci. Hortic. 239, 80–86. doi: 10.1016/j.scienta.2018.05.012

Ghosh, A., Saha, I., Debnath, S. C., Hasanuzzaman, M., and Adak, M. K. (2021). Chitosan and putrescine modulate reactive oxygen species metabolism and physiological responses during chili fruit ripening. Plant Physiol. Biochem. 163, 55–67. doi: 10.1016/j.plaphy.2021.03.026

Hu, X., Saravanakumar, K., Sathiyaseelan, A., and Wang, M. H. (2020). Chitosan nanoparticles as edible surface coating agent to preserve the fresh-cut bell pepper (Capsicum annuum L. var. grossum (L.) Sendt). Int. J. Biol. Macromol. 165, 948–957. doi: 10.1016/j.ijbiomac.2020.09.176

Khorram, F., Ramezanian, A., and Hosseini, S. M. H. (2017). Shellac, gelatin and Persian gum as alternative coating for orange fruit. Sci. Hortic. 225, 22–28. doi: 10.1016/j.scienta.2017.06.045

Leena, M., Yoha, K. S., Moses, J. A., and Anandharamakrishnan, C. (2020). Edible coating with resveratrol loaded electrospun zein nanofibers with enhanced bioaccessibility. Food Biosci. 36, 100669. doi: 10.1016/j.fbio.2020.100669

Li, L., Yi, P., Li, C., Xin, M., Sun, J., He, X., et al. (2021). Influence of polysaccharide-based edible coatings on enzymatic browning and oxidative senescence of fresh-cut lettuce. Food Sci. Nutr. 9, 888–899. doi: 10.1002/fsn3.2052

Mangkua, I. G. P., Suriatia, L., Ardanab, D. G. Y., and Putrab, W. W. (2022). The effects of processing methods on the quality of Arabica Kintamani green beans. Int. J. Food Stud. 11, 374–385. doi: 10.7455/ijfs/11.2.2022.a9

Onyeaka, H., Passaretti, P., Miri, T., and Al-Sharify, Z. T. (2022). The safety of nanomaterials in food production and packaging. Curr. Res. Food Sci. 5, 763–774. doi: 10.1016/j.crfs.2022.04.005

Rasouli, M., Koushesh Saba, M., and Ramezanian, A. (2019). Inhibitory effect of salicylic acid and Aloe vera gel edible coating on microbial load and chilling injury of orange fruit. Sci. Hortic. 247, 27–34. doi: 10.1016/j.scienta.2018.12.004

Saberi, B., Golding, J. B., Marques, J. R., Pristijono, P., Chockchaisawasdee, S., Scarlett, C. J., et al. (2018). Application of biocomposite edible coatings based on pea starch and guar gum on quality, storability and shelf life of ‘Valencia’ oranges. Postharvest Biol. Technol. 137, 9–20. doi: 10.1016/j.postharvbio.2017.11.003

Septiawan, A. R., Cahya, G., Darma, E., and Aryani, R. (2021). Pembuatan dan Karakterisasi Glukomanan dari Umbi Porang (Amorphophallus muelleri Blum.) sebagai Bahan Pengikat Tablet. Prosiding Farmasi 7, 508–515. doi: 10.29313/.v0i0.29642

Shah, S., and Hashmi, M. S. (2020). Chitosan–aloe vera gel coating delays postharvest decay of mango fruit. Hortic. Environ. Biotechnol. 61, 279–289. doi: 10.1007/s13580-019-00224-7

Sharif Hossain, A. B. M., Uddin, M. M., Veettil, V. N., and Fawzi, M. (2018). Nano-cellulose based nano-coating biomaterial dataset using corn leaf biomass: an innovative biodegradable plant biomaterial. Data Brief 17, 162–168. doi: 10.1016/j.dib.2017.12.046

Shi, X. D., Yin, J. Y., Zhang, L. J., Huang, X. J., and Nie, S. P. (2019). Studies on O-acetyl-glucomannans from Amorphophallus species: comparison of physicochemical properties and primary structures. Food Hydrocoll. 89, 503–511. doi: 10.1016/j.foodhyd.2018.11.013

Silva-Espinoza, M. A., García-Martínez, E., and Martínez-Navarrete, N. (2021). Protective capacity of gum Arabic, maltodextrin, different starches, and fibers on the bioactive compounds and antioxidant activity of an orange puree (Citrus sinensis (L.) Osbeck) against freeze-drying and in vitro digestion. Food Chem. 357, 129724. doi: 10.1016/j.foodchem.2021.129724

Strano, M. C., Restuccia, C., De Leo, R., Mangiameli, S., Bedin, E., Allegra, M., et al. (2021). Efficacy of an antifungal edible coating for the quality maintenance of Tarocco orange fruit during cold storage. Crop Prot. 148, 105719. doi: 10.1016/j.cropro.2021.105719

Sulistyo, S. B., Margiwiyatno, A., Wijaya, K., Arsil, P., Furqon, S. A., and Kuncoro, P. H. (2019). “Color-based analysis for non-destructive quality evaluation of siamese orange (citrus nobilis) during storage in room and cold temperature,” in IOP Conference Series: Earth and Environmental Science (IOP Publishing), 406. doi: 10.1088/1755-1315/406/1/012004

Suriati, L. (2022). Nano coating of aloe-gel incorporation additives to maintain the quality of freshly cut fruits. Front. Sustain. Food Syst. 6, 914254. doi: 10.3389/fsufs.2022.914254

Suriati, L., Made Supartha Utama, I., Admadi Harsojuwono, B., and Bagus Wayan Gunam, I. (2020a). Incorporating additives for stability of Aloe gel potentially as an edible coating. AIMS Agric. Food 5, 327–336. doi: 10.3934/agrfood.2020.3.327

Suriati, L., Utama, I. M. S., Harjosuwono, B. A., and Gunam, I. B. W. (2020c). “Stability aloe vera gel as edible coating,” in IOP Conference Series: Earth and Environmental Science (IOP Publishing), 411. doi: 10.1088/1755-1315/411/1/012053

Suriati, L., Utama, I. M. S., Harsojuwono, B. A., and Gunam, I. B. W. (2020b). Ecogel incorporated with nano-additives to increase shelf-life of fresh-cut mango. J. Appl. Hortic. 22, 189–195. doi: 10.37855/jah.2020.v22i03.34

Suriati, L., Utama, I. M. S., Harsojuwono, B. A., and Gunam, I. B. W. (2022). Effect of additives on surface tension, viscosity, transparency and morphology structure of aloe vera gel-based coating. Front. Sustain. Food Syst. 6, 831671. doi: 10.3389/fsufs.2022.831671

Suriati, L., Utama, I. M. S., Harsojuwono, B. A., Gunam, I. B. W., Adnyana, I. M., and Fudholi, A. (2021). Nano-ecogel to maintain the physicochemical characteristics of fresh-cut mangosteen. AIMS Agric. Food 6, 988–999. doi: 10.3934/agrfood.2021059

Wang, P., Zheng, Y., Li, Y., Shen, J., Dan, M., and Wang, D. (2022). Recent advances in biotransformation, extraction and green production of D-mannose. Curr. Res. Food Sci. 5, 49–56. doi: 10.1016/j.crfs.2021.12.002

Xiao, M., Luo, L., Tang, B., Qin, J., Wu, K., and Jiang, F. (2022). Physical, structural, and water barrier properties of emulsified blend film based on konjac glucomannan/agar/gum Arabic incorporating virgin coconut oil. LWT 154, 112683. doi: 10.1016/j.lwt.2021.112683

Xiao, N., Huang, X., He, W., Yao, Y., Wu, N., Xu, M., et al. (2021). A review on recent advances of egg byproducts: preparation, functional properties, biological activities and food applications. Food Res. Int. 147, 110563. doi: 10.1016/j.foodres.2021.110563

Zhang, K., Yang, W., Ge, F., Xu, B., Chen, Y., Yin, X., et al. (2020). A self-curing konjac glucomannan/CaCO3 coating for corrosion protection of AA5052 aluminum alloy in NaCl solution. Int. J. Biol. Macromol. 151, 691–701. doi: 10.1016/j.ijbiomac.2020.02.223

Zhao, Y., Li, B., Li, C., Xu, Y., Luo, Y., Liang, D., et al. (2021). Comprehensive review of polysaccharide-based materials in edible packaging: a sustainable approach. Foods 10, 1845. doi: 10.3390/foods10081845

Keywords: konjac glucomannan, nanocoating, quality, shelf life, orange

Citation: Suriati L (2023) Nanocoating-konjac application as postharvest handling to extend the shelf life of Siamese oranges. Front. Sustain. Food Syst. 7:1104498. doi: 10.3389/fsufs.2023.1104498

Received: 21 November 2022; Accepted: 15 February 2023;

Published: 27 March 2023.

Edited by:

Chen Li, Nanjing Tech University, ChinaReviewed by:

Feng Xue, Nanjing University of Chinese Medicine, ChinaYufan Sun, Northeast Agricultural University, China

Mingming Zhong, Northeast Agricultural University, China

Copyright © 2023 Suriati. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luh Suriati, c3VyaWF0aV9sdWhAeWFob28uY29t

Luh Suriati

Luh Suriati