94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. Food Syst., 04 April 2023

Sec. Sustainable Food Processing

Volume 7 - 2023 | https://doi.org/10.3389/fsufs.2023.1048450

Coconut (Cocos nucifera) is a raw material that has gained particular relevance for agribusiness in recent years. This has come about largely owing to the paradigm shift regarding its genuine nutritional benefits. It is especially due to innovation that has been incorporated into agro-industrial processing and the development of new products, and the fruits of such labor can be seen in the growing demand by consumers around the world. Integrally making full use of coconut, it turns out, is extremely important for agribusiness. Coconut indeed has become a benchmark, not only from the environmental dimension but also from the social and economic perspectives both of the communities that plant it and the agribusinesses that transform it. This study aims to identify technologies, new uses, trends, and innovations related to the coconut agro-industrial chain, as well as their prioritization, by means of a prospective study, using the Delphi method in two rounds. Two methods applied at the methodological level comprised a technological surveillance study by means of a literature review in a SCOPUS database, PatentsInspiration, complemented with commercial surveillance for the four major topics of plastic wood, coconut oil extraction, high salinity and moisture, and small-scale coconut by-products. Moreover, the Delphi method was used, in two rounds, with 178 topics, technologies, and innovations, classified into seven thematic groups. The Delphi was answered by 32 experts in the two rounds. Vantage Point text mining software was also applied for the analysis of the surveillance results. Within the seven thematic groups, the following 10 priority technologies are highlighted: functional phytochemicals, non-caloric sweeteners, coconut milk preservation technologies, water activity and shelf life, coconut sugar extraction methods, batch and continuous drying technologies, lyophilization, coconut fiber and shredded recycled PET, magnetic particle modification of activated carbon derived from coconut shell and biochar to effectively remove phenol from water, and biodegradable packaging for coconut derivatives. In addition, the following topics were prioritized in the sustainability grouper: sustainable agriculture, bioeconomy, family agriculture, and circular economy.

The coconut [Cocos nucifera (L.)] agroindustry is an important part of the world economy, with an annual production of 11.7 million tons of coconut (copra equivalent-CE) in 2020, representing an export value close to US$1.2 billion (International Coconut Community, 2022). The USA contributes approximately 7.5% of the world's coconut production (889 thousand CE tons in 2020), with Brazil and Mexico contributing the largest amounts (492 and 179 thousand CE tons, respectively, in 2020). Colombia's part in 2020 was close to 31 thousand CE tons, grown by small producers in the coastal areas of the three main producing departments: Nariño, Cauca, and Córdoba, which together account for 80% of the national total production. In the department of Cauca, production is concentrated in Afro-descendant communities in the municipalities of Timbiquí, Guapi, and López de Micay.

On the other hand, demand for coconut derivatives has increased by 500% in the last decade, and both the value and volume of the market are expected to grow by 11.3 and 79.9%, respectively, in the coming years (Rethinam, 2019; Alouw and Wulandari, 2020). This demand is principally due to the beneficial properties of coconut, elucidated by means of research conducted, in the main, by its biggest producers, including Indonesia, Philippines, India, and Brazil. While traditionally coconut meat and water have been consumed fresh, today some variety of products derived from coconut can be found, such as coconut water, coconut milk, grated coconut, coconut snacks, coconut cream, coconut fiber, coconut wood, coconut flour, coconut sugar, coconut powder, coconut chips, coconut oil, coconut plastic wood, coconut butter, and coconut shell charcoal, as well as copra, shell, or pulp. In that sense, while the marketing of conventional derivatives such as copra or oil exhibits some stability, high-value products such as coconut water, coconut milk, and dehydrated coconut have increased by 149, 33, and 29%, respectively (Chen et al., 2020). All of these products are produced via specialized techniques to process the coconut and extract all its derivatives, as well as special packaging techniques and materials for its storage since most of the primary coconut production areas correspond to places with high humidity, temperature, and salinity (Perlaza and Carrillo, 2020).

Although the coconut market is promising, the total planted area and production decreased slightly between 2015 and 2020 due to many reasons. The Colombian coconut value chain shares many of the world's difficulties, including scarce technical and statistical information on coconut, incipient strengthening initiatives by national and local government, serious phytosanitary problems due to the incidence of pests such as “picudo” (Rhynchophorus palmarum) and “anillo rojo” (Rhadinaphelenchus cocophilus), which have decimated a large number of plantations, low-tech and poorly managed cultivation systems, inadequate harvest and post-harvest processes, and low level of technological development, innovation, and diversification of high value-added products, since approximately 99% of production is marketed as fresh fruit. Nevertheless, in the national context, there is a favorable climate for the coconut derivatives industry as a result of the increase in domestic per capita consumption and the increase in imports of copra and higher value-added derivatives. Since Colombia belongs to the tropical region—an optimal zone for producing coconut—and yet is an underdeveloped coconut producer, it is imperative that it now seeks the conditions that allow the biggest advances in the coconut agro-industrial chain. For this reason, technological and institutional innovations are key strategies that will make it possible to solve many of the problems which can lead to an increase in the competitiveness, development, and improving the quality of life of small- and medium-sized producers, processors, and marketers in the coconut value chain in Colombia.

Given the lack of knowledge about new processing technologies for coconut, the need to generate innovations in products derived from coconut, and the opportunity to propose new business models for the stakeholders of the coconut chain, this study is presented, which seeks to answer two questions: “What are the issues and technologies related to plastic wood, oil extraction, high salinity, and small-scale agro-industrial use of coconut?” and “What are the priority innovations and technologies for the coconut chain for the year 2030?” In order to answer the questions, the study is divided into four phases or stages. In the first phase, a conceptual theoretical framework of the subject is presented, placing emphasis both on world areas of production and world production itself. In addition, production at the national level is also given, associated with both zones and quantity. In the second phase, the methodology is presented, emphasizing the search equations used in the SCOPUS and PatentsInspiration databases, and explaining the Delphi method. In the third phase, the results are explained in a series of time of publications, affiliation geographies, and topics. The last phase contains the analysis of the results both in surveillance and the prospective study, as well as a discussion focused on the products derived from coconut and the technologies that intervene in the same chain and on the results of the prospective study.

Coconut is a fruit that gives rise to a number of products as derivatives that can be found around the world. It has great nutritional value and is, thus, in demand on the market for use in multiple gastronomic preparations, as well as meat and water, extracts such as oil can be used for gastronomy or in the production of cosmetic and health products, being highly beneficial to hair and skin, among other uses (Perlaza and Carrillo, 2020). Worldwide, in 2020, 61,938,690 tons of coconut were harvested, with the coastal areas of the Pacific Ocean being the main region of production. Indonesia topped the list with 16,824,848 tons, followed by India with 14,695,000 tons, the Philippines with 14,490,923 tons, and Brazil with 2,458,839 tons, Colombia currently ranks 23rd in production with 153,832 tons (FAO, 2021). Coconut is the sixth most cultivated fruit in the world. It is found in 93 countries. Production covers an area of 12.3 million hectares, of which more than 70% is concentrated in just three countries—the Philippines with 29%, Indonesia with 25%, and India with 17%. The market is worth approximately 6,500 million dollars annually. At a commercial level, coconut can be found mainly in the form of dried coconut, copra, coconut oil, and coconut water, thus becoming a very important crop in the tropical and subtropical zones—the zones of highest production—due to its great contribution to local economies from the creation of employment and income generation (Sacchi, 2020).

Colombia contributes approximately 0.16% of the world production of coconut, and at the national level, it enjoys the participation of 10 producing departments, namely, Nariño, Cauca, Córdoba, Magdalena, Antioquia, Sucre, La Guajira, Valle del Cauca, Bolívar, and Chocó. Leading the list as the largest producer is the department of Nariño with 73,430 (t) for the year 2018, followed by Cauca and Córdoba with 27,042 (t) and 16,042 (t), respectively (Minagricultura, 2019). At the national level, the coconut chain is basically made up of communities that are victims of the armed conflict, Afro-descendants, and peasants. This chain is made up of producers, harvesters, processing industries, distributors, and consumers, as well as universities, research centers, and regional institutions. Production is destined for industry and commerce in food markets, supermarkets, and industries in cities such as Bogotá, Cali, and Medellín (Minagricultura, 2019). This chain suffers from several problems that restrict its proper functioning. These range from seed handling, optimal soil conditions, phytosanitary problems, insufficient technological infrastructure, and external factors such as armed conflict and many other situations that can lead to delaying the optimum development of the sector (Flórez, 2020). Commercialization of coconut has traditionally been performed with meat and water, either for fresh consumption or as an ingredient in different gastronomic preparations. Currently, coconut can be commercialized in more ways, both derived from its traditional forms and the use of by-products such as tow and shell, as well as from the innovations that have enabled new products to emerge. Starting with the traditional forms, the products would ideally have a longer shelf life. As such, research has been put forward for the commercialization of dried coconut chips (Ranasinghe, 2000) and powdered coconut milk and water (Boonnumma et al., 2014), where these products preserve the main components and particularities of the fresh product. As in all industries and chains, the coconut industry also has by-products and waste that often ends up in water sources, vacant lots, or, in the best of cases, as compost, all of which can cause pollution. Today, however, many of these waste materials are used to obtain different products such as coconut fiberboards (Ngadiman et al., 2018), pallets with agglomerate fiber from coconut shells (Cocopallet, 2021) and, thus, provide a second use to the two or the shell, which was traditionally simply waste, and not only the fruit itself can be used to generate income but also the palm or its heart has been used to make sugar (Sari et al., 2021).

Technologies and equipment also play an important role in the processing and commercialization of the coconut. One of the most widely used pieces of equipment is oil extractors since these are employed in obtaining this key derivative of coconut, useful not only in gastronomy but also as a component in preparing a variety of cosmetic products, such as soaps and body and facial creams (Perlaza and Carrillo, 2020). This extractor can be simple with only the application of mechanical force and with operations carried out by the operators (Machinery, 2021) or more modern with complete equipment to carry out almost the entire process of cutting and oil extraction (Gbasouzor and Nwanekezie, 2018). In Colombia, given the increase in coconut production in recent years and expansion of product supply, the future of coconut might be well considered as having great potential, but multiple uncertainties arise due to various crossroads that have made difficult any advancement or development of the sector such as the low supply of coconut at the national level, which leads to increased prices and hinders agro-industrial transformation operations, and consequently the dependence on imports of fresh and processed coconut to achieve compliance with commercial sales quotas (Minagricultura, 2019), thus affecting the national coconut chain.

Technological surveillance can be defined as an organized, selective, and permanent process by which to capture information, whether external or internal, mainly on science and technology, in order to select that information, analyze it, disseminate it, and communicate it so that it can be converted into knowledge that might serve to make decisions that involve less risk and be able to anticipate changes (Padilla et al., 2018). The UNE 166006 standard of 2018 speaks of surveillance and intelligence as a system for capturing and analyzing information focusing on sources and with the information recommending actions or generating alerts that allow rapid and effective communication. The process is transversal to the organization and involves different responsibilities and tasks to a group of the organization or even to its area of influence, but this implies a sustained process over time (Sánchez-Torres, 2002). “Technological prospective studies have a great influence on innovation policies of countries, since they offer the possibility of identifying and taking advantage of future opportunities in which a certain sector must bet on science, technology, industry and society through a process participation of scientists, industrialists and government” (Suarez et al., 2021). A prospective study, thus, serves to give a focus to future research or trade since it offers the opportunity to be aware of “What is changing?,” “What might change?,” “What should change?,” “Who can make these changes?,” and “What are the implications of those changes?” Knowing this, it is easier to be able to identify which topic provides the highest possible profitability or which topic is of greatest interest to the public (Suarez et al., 2021). The prospective study relates to the art or science of studying and providing the future, generating a reflection that allows clarifying the action of the present under possible futures, thus generating a tool that allows organizing and structuring actions for the future transparently and effectively (Ramírez et al., 2016). The Delphi method is a systematic and interactive method for which a panel of independent experts is required, and with the use of a series of expert opinions in anonymous communication and feedback, it allows the creation of a flexible tool for enriching consensus in which judgments are summarized and sent again in order to refine the problem (Palacio et al., 2016). “Such as the innovation strategy and the innovation management model in organizations. The study of these three components, their possible forms of alignment, and the conceptual model base can give rise to the generation of a new method and technique for its application in the field of innovation that contributes to the development of organizations in the productive sector.” The method has undergone some changes in its methodology but is characterized by anonymity, the presentation of alternatives to consensus, and fewer rounds (Zartha et al., 2019). The method is applied in two or more rounds, which allows an iteration and statistical response, which differentiates it from other group techniques, which is achieved by presenting the same questionnaire several times, and due to methodological elements, each expert can review their approaches based on the results of the previous phase and gradually modify their opinion in such a way that the responses of the other participants force them to reflect on the complexity of the topic in question, which allows systematically integrating the opinions of the group, with a high degree of consensus (Ramírez et al., 2016).

The project was carried out by means of the alignment of two methodological components, the first one was technological surveillance in which information was sought through the SCOPUS database, FreePatentOnline, and as a complement, Google scholar to process the information in the software of Vantage point text mining. The methodology had been previously applied and validated in studies on other agro-industrial chains or processes (Padilla et al., 2018; Zartha et al., 2018, 2020; Solarte et al., 2021; Foronda et al., 2022), where good results were obtained using the methodology.

The second methodological component was based on the application of a prospective study for which the Delphi method was used in two rounds. It has been used in previous studies in agro-industrial sectors of plantain (Suarez et al., 2020), blackberry (Suarez et al., 2021), cocoa (Meza et al., 2020), and biodegradable packaging (Zartha et al., 2015).

The Delphi method used in this study took into account the application of statistical techniques such as mode, modal frequency, consensus percentages, decisions on the prioritization of topics, technologies, and innovations, and the methodology and techniques used in this study were applied and tested in studies previous ones in agro-industrial sectors such as cocoa (Meza et al., 2020), blackberry (Suarez et al., 2021), banana (Suarez et al., 2020), and biodegradable packaging (Zartha et al., 2015), among others.

Stage 1: The coconut agro-industrial chain was analyzed, and the search turned up the subtopic of plastic wood, which, in turn, was divided into recycled plastic wood, in general, coconut and reinforced plastic, and recycled wood or plastics, and coconut, oil extraction, and high salinity and small-scale coconut by-products. The subdivision was carried out based on the approaches established by the executing team of the project in CAUCA. The analysis and definition of the interest groups or stakeholders for the subsequent application of the surveys were also carried out, and in this case, national and international experts were taken into account on issues related to the coconut production chain on the Pacific coast of Cauca.

Stage 2: Different keywords were defined, according to the sub-themes, for the information search. In the same way, different search equations were created in order to obtain the best and most specific results, the SCOPUS database was used, and in some cases, Google scholar. The questionnaire was formulated to apply to the experts. For this, it was taken into account that it covered the entire coconut production chain, obtaining the following groups: SOCIO-BUSINESS, PRIMARY PRODUCTION, HARVEST AND POST-HARVEST, TRANSFORMATION, LOGISTICS AND DISTRIBUTION, CONVERGENT TECHNOLOGIES, and SUSTAINABILITY OF COCONUT.

Stage 3: After obtaining the necessary bibliography for the study, the relevant information was extracted and consolidated to be graphed using the Vantage point software. With this software, it is possible to graphically identify the results of the information consulted. The invitation with the survey was also sent to more than 100 selected experts, managing to collect responses from 32 of them.

Stage 4: Finally, an analysis of both the bibliographic results and the responses to the survey was carried out, in order to build a report that compiled the most important information from technological surveillance and the prospective study, in order to provide elements for the future of coconut production in Colombia and other countries. All stages can be seen in Figure 1.

The surveillance study was a lengthy process that covered four major topics. These four topics summarize and cover the main characteristics of the central topic. Similarly, the most relevant results are presented along with what further information they might provide the study.

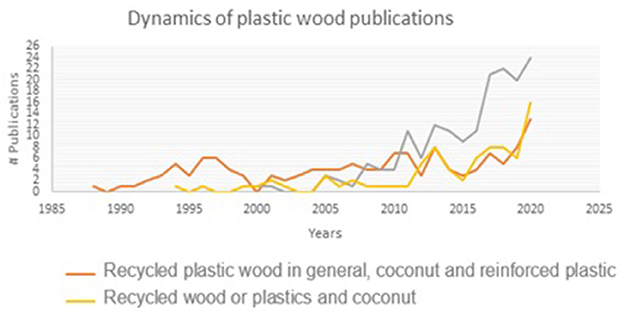

Table 1 is presented below, detailing the Search strategy employed for plastic wood. Three different search equations were formulated in the SCOPUS database. The first dealt with the subject of recycled plastic wood in general, in which the following search words were used: wood, board, lumber, deck, cover, timber, plastic, polymer, recycle, convert, recover, salvage, and reprocess. For the date consulted, 15 March 2021, 137 articles were published on the subject. The second equation dealt with the subject of coconut and reinforced plastic, using the following search words: coconut, plastic, polymer, reinforced plastics, and reinforcement, finding 177 articles on the subject. The third search equation dealt with the topic of recycled wood or plastic and coconut using the search words: wood, board, lumber, deck, cover, timber, plastic, polymer, recycle, convert, recover, salvage, reprocess, and coconut, with which 81 articles were found.

Figure 2 shows the dynamics of publications on plastic wood, within which is found recycled plastic wood (in general), coconut and reinforced plastic, and recycled wood or plastic, and coconut. In the graph, it can be seen that the publications in this area begin in the mid-1980s and show a more or less constant behavior until the year 2010 when they have a notable rise in the number of publications. It can be noted how coconut and reinforced plastic is the area of research that has increased the most in the last decade, going from four publications in 2010 to 24 in 2020. Meanwhile, recycled wood or plastic and coconut showed an increase of 167% in the number of publications in the last year. Table 2 shows main geographies of affiliation of the authors.

Figure 2. Dynamics of plastic wood publications. Own compilation, based on the results of the Vantage Point Software.

Among the countries, with the highest number of publications in terms of plastic wood are the United States with 38.13% and China with 13.67%. Regarding the themes of coconut and reinforced plastic and recycled wood and plastic and coconut, India is found with 29% and 10.5% of publications, respectively, for each sub-theme, and Brazil with 18% and 8.4% of publications, respectively. Malaysia was also found to be one of the leading researchers in the area of recycled wood and plastic and coconut with 17.9% of publications.

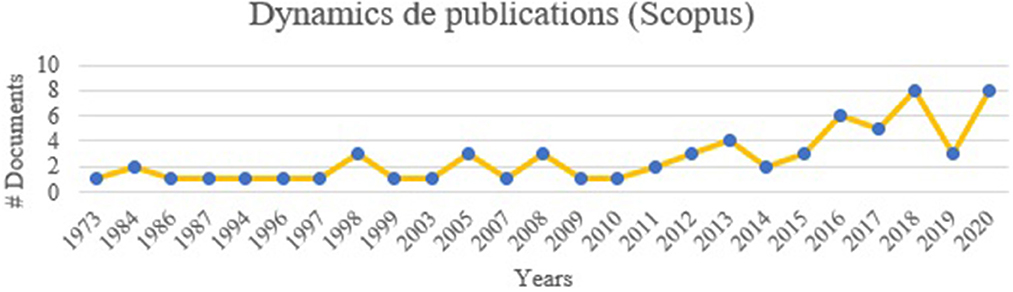

Below is the Table 3 related to the search strategy for the extraction of coconut oil. For the case of coconut oil extraction, a search equation was formulated in the SCOPUS database on 26 April 2021. For the equation, the following search words were used: oil extraction and coconut, finding 71 published articles that referred to the topic.

Figure 3 presents the Dynamics of oil extraction publications. According to the data provided by SCOPUS, it can be seen that, over time, the dynamics of publication on coconut oil extraction has increased substantially from the year 2013, presenting an average of 4.9 scientific publications per year from that moment. The years 2018 and 2020 stand out since eight documents were published per year in the consulted database. Below is presented the Table 4 with main geographies of affiliation of the authors.

Figure 3. Dynamics of oil extraction publications. Own compilation, based on the results of the Vantage Point Software.

India with 19% of the total publications leads the list of geographies of affiliation of the authors, that is, 13 documents, followed by Brazil and Thailand with 10.3%, respectively, which corresponds to seven scientific publications each. Malaysia and Indonesia also have a considerable representation in the total publications, contributing 8.8 and 7.4%, respectively.

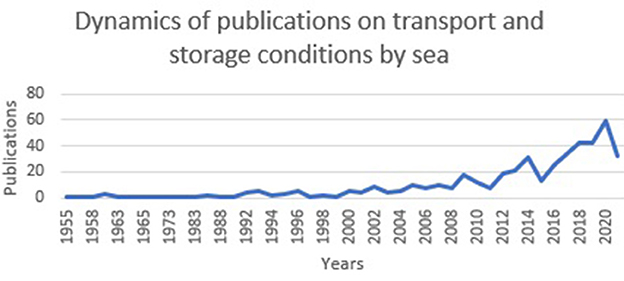

Table 5 strategy used for high salinity and humidity. The topic of high salinity and humidity addresses two sub-topics which are the salinity of the sea and the logistics and storage conditions. This aspect is relevant to the study of the coconut chain because these conditions are common in the places where coconut is planted. In this case, a single search equation was created on 21 June 2021, with the search words: high humidity, humidity, high temperature, salinity, corroding, packing, product conservation, logistic, preserve, fresh, storage, storage condition, coconut product, and coconut, finding 457 articles that addressed the subject. Figure 4 related to the dynamics of publications on transport and storage conditions by sea.

Figure 4. Dynamics of publications on transport and storage conditions by sea. Own compilation, based on the results of the Vantage Point Software.

According to the graphs obtained from SCOPUS in the area of transport and storage conditions by sea, it can be seen that the number of publications has been increasing in the last decade, reaching a peak of up to 59 publications in the year 2020 and with increases since 2016. Table 6 main geographies of affiliation of the authors.

In this case, the geography of affiliation of the authors is led by Brazil with 12.2%, followed by India with 11.4% of publications, and then Indonesia with 10.3% of publications on the subject.

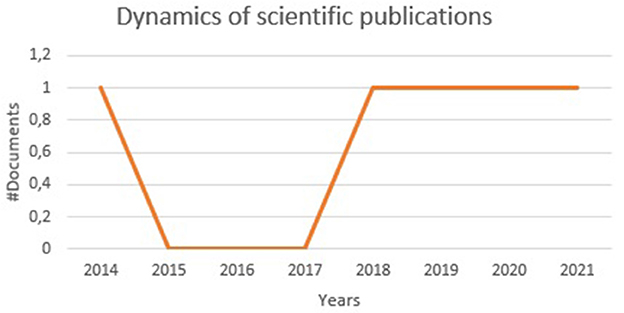

Table 7 search strategies used for small-scale by-products of coconut. For the analysis of small-scale by-products of coconut, different search equations were used, but according to the results, only five articles deal with by-products of coconut, small-scale applicable technologies and techniques were obtained, and this search was carried out on 24 July 2021 in the SCOPUS database.

Figure 5 shows small-scale by-products of coconut. Based on the data obtained from SCOPUS, it can be seen that research in this area is scarce, but in recent years, there has been a slight increase, presenting one research per year since 2018. It should also be noted that before this date, there was only one piece of research in the area in 2014.

Figure 5. Small-scale by-products of coconut. Own compilation, based on the results of the Vantage Point Software.

Table 8 is presented above, detailing the Geographies of affiliation of the authors. Although there are very few publications, the geographies of affiliation of the authors are divided into five different countries. Indonesia and Thailand participate, each with 28.57% of publications, followed by Austria, Japan, and Vietnam with 14.29% each. Figure 6 present Level of experience of the respondents.

The form of the Delphi method for the prospective study was answered by 32 national and international experts in the first round. It should be noted that one of the important and complementary aspects, at the methodological level, is the calculation of the coefficient of expert competence K, which includes the knowledge coefficient Kc and the argumentation coefficient Ka. The Kc, in summary, is presented in the following Figures 7–9.

The argumentation coefficient Ka is shown in the previous Figure 7, and this coefficient is used to measure the level of influence of the expert on the subject and how well he knows the subject.

The academic level of the experts who responded to the survey is also an important factor of which to be aware. The questionnaire was filled out by experts from Colombia (30) and Ecuador (2), where 20 of them have Master or Doctoral degrees.

An important aspect to highlight is that 21 of the participants have authored or co-authored research articles, research books or chapters, patents, and software registrations, among others.

Definition of priority groups: Using the average percentage of consensus per group, it was established that an issue would be considered a priority in the first round if it presented a percentage of consensus higher than the average of the group, and a modal value greater than or equal to 4 or 5 in the rating. The modal value is the rating that is repeated the most within the number of responses. Topics with a modal value in the rating of less than or equal to 2, with a percentage greater than the group average, were classified as non-priority in the first Delphi round. The other topics that did not meet the above conditions were considered topics under discussion. The classification gave rise to five groups of topics as follows: priority topics (PT), 76 were found; topics under discussion (TD) 102 were found; non-priority topics (NP) and don't know/no answer, none were encountered; and new topics (NT), 16 were found. Apart from the resulting topics, each of the seven groupers presented several comments by the experts as follows: business partner: 18, primary production: 10, harvest and post-harvest: 11, transformation: 12, logistics and distribution: 10, converging technologies: 7, and coconut sustainability: 8, for a total of 76 comments. Apart from the comments, it was found that each topic had a different number of sub-topics, and these topics, in turn, were divided mainly into priority topics and topics under discussion. The topics with the highest percentage of participation and the average percentage of consensus were also found.

The main axis of this study seeks to find the principal technologies and innovations related to the four major issues and the main innovations on which to bet in the coming years in the coconut chain. Tables 9, 10 were, therefore, constructed in order to visualize these findings more easily; the main coconut-based products and the main technologies involved in this chain are presented along with a very broad analysis of the topics of the prospective study. The table of products covers a large number of products made not only with meat or water from the coconut but also from coconut waste or with the coconut palm itself.

Within the technological surveillance process, it was possible to identify different products obtained from the coconut or the coconut palm, such as for the manufacture of boards or wood-type boards, for the construction of furniture, or finishes in construction. Although the fiber or coconut shell by itself is not strong enough for this purpose, some studies or companies such as Ngadiman et al. (2018) and (Cocopallet, 2021) have obtained shell-based boards of coconut by mixing them with recycled PET bottles and combining them with a binder. These boards presented better results than conventional panel boards, allowing the board to swell less, have lower water absorption, and allow a high rupture modulus and low elastic modulus. As a result, this material is used for the construction of pallets, presenting good durability and easy handling due to its low weight. Organic products and foods for consumption that are marketed with a minimum of industrial processing present a major challenge—the expiration time or period suitable for use. Ways have, thus, been sought to extend their useful life. Drying of products is a great ally and allows obtaining a product with a long useful life able to preserve its main organoleptic characteristics. This is the case with coconut chips—after extracting the water, they are subjected to a process of baking to shell them and obtain the slices with a peeler (Ranasinghe, 2000). In the case of powdered coconut water, the coconut water is subjected to a freeze-drying process to obtain the coconut concentrate (Boonnumma et al., 2014). With these processes, both the coconut water and the meat were able to increase their shelf life and at the same time preserve their organoleptic characteristics. The products mentioned earlier are the best-known or traditional derivatives of coconut, but there are other products that also come from coconut or rather from the coconut palm and that are very useful in daily life, such as sugar and molasses—both from the sap of the coconut palm. For the production of sugar, the sap is collected between 6 and 9 a.m. and 3 and 6 p.m. every day, and after a filtering and evaporation process, the concentrate or sugar is obtained (Ranasinghe, 2000). The process is not very different from molasses, it is only necessary not to let the sap concentrate until it crystallizes, and thus obtain a viscous but liquid product (Jayasundera and Kulatunga, 2014). The sweet product, be it sugar or molasses, can be obtained due to the fact that the spathe or heart of the coconut palm contains a very sweet sap and through the appropriate agro-industrial processing, the solids present in it are obtained.

In all agro-industrial processes, technology is used to help increase the efficiency and profitability of the plant or company. The coconut, for its part, also uses the technologies that are presented in the following. With these technologies that are not only equipment but also the use of more traditional coconut parts and waste is promoted.

The coconut transformation process, like other raw materials, requires different equipment and specific processes to achieve an optimal final product; one of the derivatives of coconut is oil, an essential product in gastronomy, which requires appropriate equipment to obtain good performance. This equipment is essentially extractors and simple ones can be found that have a system to apply mechanical pressure by feeding previously grated or crushed coconut over bumps. These are the most widely used for small operations and can process 4–5 kg/h (Machinery, 2021). Other more advanced systems or equipment have the necessary tools to cut or grate the coconut within the same pressing equipment and have five integral parts: the frame, the power transmission shaft or piston, the compression chamber, the compression plate (ram press), electrical heating devices, and the grater (Odunlami, 2017), and others have a motorized system to carry out these same grating and pressing tasks (Gbasouzor and Nwanekezie, 2018). With these modern pieces of equipment, it was possible to increase the performance of the process and at the same time the income to the companies.

Coconut is a coarse product and can be very difficult to work with or to carry out some preliminary operations such as peeling or husking and chopping the meat, which can lead to more expenses in terms of time and personnel. Therefore, there are different machines in charge of carrying out these operations. The equipment, in general, is made up of a frame, feed hopper, peeling cutter assembly, and transmission, among others. To carry out the operation, people lift the copra and it sticks to the peeling knife. The copra is, then, quickly turned to remove its outer skin (Alibaba, 2021). Not only do the equipment and machines lead to an agro-industrial operation or process being carried out faster, more efficiently, or to improve some quality of the product but also the techniques used have a significant influence on the final result where it is always sought to obtain an added value to it. In the products obtained from coconut, we also find techniques such as osmotic dehydration—a technique that allows the removal of water through the application of a hypertonic solution, generally water with salt, thereby extending the life and improving some characteristics of the product (Matusek and Merész, 2002); vacuum drying—this technique is used to produce dried palm sugar, but it must be taken into account that if the temperature and time are increased, the physicochemical properties of the powder that are vacuum dried can also be affected. With these techniques, it is possible to obtain products with longer useful life and which, in turn, preserve the initial qualities of the fresh product.

The prospective study allows an overall vision of the possible path to take for a product, chain, or service, and in the case of the coconut chain, there are also several topics distributed by different groups, which are presented as follows. Table 11 is presented below, detailing the priority themes by thematic group.

One of the main needs of coconut producers is the incursion into the industrial or transformation stage of the same since it is known according to Minagricultura (2019) that on many occasions, the coconut processors of the country import the raw material from other parts; due to the low supply of the product at the national level, it is important to look for ways to incorporate small producers into the transformation stage, and according to the prospective study, the experts put this grouper, transformation, as one of the most important to improve for future and also as the one that shows the most priority topics, with topics very focused on obtaining products derived from coconut, such as coconut flour, coconut water and its characteristics, natural fibers, and plastic wood, among others, and that would generate a lot of added value to the economy of the producers, to achieve a correct articulation of the producers to the transformation, the implementation can be made by the creation of small factories with machinery appropriate to the space and production (Machinery, 2021), and in this way, the national production of coconut can be encouraged.

Transformation technologies cover a wide number of topics to be taken into account, reviewed, and implemented in the future since they are part of the stage of greatest added value in production; within this stage of transformation are conservation technologies such as super-freezing, microfiltration, freeze-drying, and controlled atmosphere, among others. Technologies identified as priorities and of high relevance for the transformation and conservation of food (Zartha et al., 2019); technologies or topics also identified as priorities within this study, which can be part of the group of technologies for the preservation of coconut milk, freeze-drying, itself, and others related to the useful life and activity of the water. This point in common suggests that these conservation technologies are of great importance for the future since they become an input for the different actors involved in the coconut agro-industrial chain (Zartha et al., 2019).

Apart from the topics proposed by the responders to the survey, the 32 experts proposed 16 new topics as follows: three topics on sociobusiness grouping—analysis of return on investment in both social, environmental, and financial aspects, circular economy (green elements of the productive chain), and agricultural extension; four topics on primary production—transport and storage, agronomic management practices, integrated control of insect pests (IPM), precautionary principle, and in vitro seed production for coconut cultivation; two topics on harvest and post-harvest—manufacture of dry products (chips, copra), pasteurized milk, or oils and dehydration by frying under vacuum; two topics on transformation—nutraceuticals and nutracosmetics and panels biofabricated 100% with coconut fibers, one topic on logistics and distribution—bag-type containers (bag-in-box); one topic on converging technologies—process simulation; and three topics on coconut sustainability—biorefineries, regenerative agriculture–precision agriculture, and digital twins. These proposed topics can serve as a focus for future research since they express the interest of a group of people who are experts and are part of this agro-industrial chain. Primary production—transport and storage.

Comparing the 16 new topics with the results of the prospective study in agroindustrial engineering to 2,035, it is observed that 5 of the 16 priority topics or technologies, including agricultural extension, integrated control of insect pests (IPM), dry products, sustainability, and agriculture of precision, were winning themes in the study of agroindustrial engineering to 2,035, the theme of circular economy was also common in both studies but with the difference that in the study to 2,035, it was not a priority in Delphi but in the structural analysis as input for the scenario methodology.

The countries with the largest coconut production in the world are also the largest producers of research related to the coconut chain, which shows their great interest in continuing to innovate and continuing as powers in the production, transformation, and marketing of coconut.

Coconut is used not only in fresh consumption but also in many other ways of consuming it, which preserves the product and its characteristics due to the range of equipment and transformation methods developed in the different research studies. Studies that work not only with coconut but also with waste—or what was considered waste, the product of the industrialization of coconut—thus generating greater use and income for producers and processors.

The prospective study allows a future vision of what is expected of the coconut chain and within this study, transformation is the topic that addresses the greatest sub-topics. Ten of the main transformation technologies are functional phytochemicals, non-caloric sweeteners, coconut milk preservation technologies, water activity and shelf life, coconut sugar extraction methods, batch and continuous drying technologies, lyophilization, coconut fiber and shredded recycled PET, magnetic particle modification of activated carbon derived from coconut shell and biochar to effectively remove phenol from water, and biodegradable packaging for coconut derivatives.

In addition to traditional coconut derivatives such as meat and fresh water, the experts considered priority products such as coconut boards and fibers obtained from coconut shells, in general, as well as others such as chips, flour, and medicinal compounds.

The main technologies developed in the coconut agro-industrial chain revolve around the transformation stage, and this became apparent not only in the technological surveillance but could also be evidenced in the prospective study, where the grouper with the largest number of topics was that of transformation. This makes sense because it is the stage in which the highest added value and income are obtained from coconut.

It was sought via the prospective study to prioritize topics, technologies, innovations, and new business models for the coconut agro-industrial chain, for which the greatest efforts ought to be made to achieve optimal development. With this, it was possible to see that this sector, as well as many others, can rely on the transformation of products within a framework of sustainability and venturing into topics such as nanotechnology, social investment, the use of waste, and the development of environmentally friendly systems.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Ethical review and approval was not required for the study on human participants in accordance with the local legislation and institutional requirements. Written informed consent from the participants was not required to participate in this study in accordance with the national legislation and the institutional requirements.

JG: review and analysis of papers in Scopus and patents, theoretical framework, and results. RM: search equation, patent analysis, results, and conclusions. JZ: application of the Delphi method, analysis of papers, methodology, discussion, and conclusions. All authors contributed to the article and approved the submitted version.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Alibaba (2021). Obtenido de Máquinas Cortadoras de chips de coco. Available online at: https://www.alibaba.com/product-detail/Commercial-Vegetable-Fruit-Coconut-GingerChips_1600158001763.html?spm=a2700.7724857.normal_offer.d_title.3c2f4d3aX9ECSO (accessed on August 2, 2021).

Alouw, J. C., and Wulandari, S. (2020). “Present status and outlook of coconut development in indonesia,” in IOP Conference Series: Earth and Environmental Science, Institute of Physics Publishing, 12035. Available online at: https://iopscience-iop-org.ezproxy.unal.edu.co/article/10.1088/1755-1315/418/1/012035 (accessed on April 16, 2021).

Boonnumma, S., Chaisawadi, S., and Suwanyuen, S. (2014). Freeze-dried coconut water powder processing for natural health drink. Acta Hortic 2014, 91–94. doi: 10.17660/ActaHortic.2014.1023.12

Chen, H., Wang, Y., Sun, X., Peng, Y., and Xiao, L. (2020). Mixing effect of polylactic acid microplastic and straw residue on soil property and ecological function. Chemosphere 243, 125271. doi: 10.1016/j.chemosphere.2019.125271

Cocopallet (2021). Cocopallet. Available online at: https://www.cocopallet.com/ (accessed January 2021).

FAO (2021). Organizacion de las Naciones Unidas para la Alimentacion y la Agricultura. Available online at: https://www.fao.org/faostat/es/#data/QCL (accessed January 2021).

Flórez, L. (2020). Estrategias de Fortalecimiento en la Cadena de valor de los Productores agrícolas de coco en Tumaco. Bogota: Ciencia unisalle.

Foronda, K., Gafaro, D., Restrepo, L., Mendoza, Y., Ricardo, J., Orozco, G., et al. (2022). Electrohydrodynamic drying in agribusiness: literature review. Front. Sustain. Food Syst. 5, 761297. doi: 10.3389/fsufs.2021.761297

Gbasouzor, A., and Nwanekezie, M. (2018). development of Improved Motorized Nmanu Akuoyibo (coconut oil) Extractor Designed for Employment Generation in Nigeria. Iaeng Transactions on Engineering Sciences. Available online at: https://www.worldscien (accessed January 2021).

Hai, L. V. (2020). An Integrated pollution prevention ecosystem for small-scale production of raw coco-nut jelly in craft villages —a case study from Mekong Delta, Vietnam. J. Environ. Account. Manag. 2020, 293–310. doi: 10.5890/JEAM.2020.09.007

Hainan Kunlun New Material Science Technology Co Ltd. (2021). KUNLUNSEA. Obtenido de Hainan Kunlun New Material Science Technology Co Ltd. Available online at: http://www.klmusu.com/eg/

International Coconut Community (2022). Coconut Statistical Yearbook 2020, 37th Edn. Jakarta: International Coconut Community.

Jayasundera, J., and Kulatunga, A. (2014). Spray-drying of coconut treacle into an amorphous powder. Coll. Food Agric. 26, 672–678. doi: 10.9755/ejfa.v26i8.17581

Machinery (2021). Small Scale Coconut Oil Extraction Machine. Available online at: http://www.bestoilpressmachines.com/quick-links/small-coconut-oil-extraction-machine.html (accessed on July 19, 2021).

Matusek, A., and Merész, P. (2002). Modelling of sugar transfer during osmotic dehydration of carrots. Period. Polytech. Chem. Eng. 46, 83–92.

Meza, D., Quintero, J., Zartha, J., and Hernandez, R. (2020). Estudio de prospectiva del sector cacao al año 2032 como base de programas de capacitación universitaria en el sector agroindustrial. Aplicación del método Delphi. Información tecnológica 31, 219–230. doi: 10.4067/S0718-07642020000300219

Minagricultura (2019). Cadena de coco, Dirección de Cadenas Agrícolas y Forestales. Bogota: Ministerio de agricultura.

Ngadiman, N., Kaamin, M., Abs, A., Sahat, S., Zaini, A., Raihana, S., et al. (2018). “Panel board from coconut fibre and pet bottle,” in E3S Web of Conferences, CENVIRON, 0–34. Available online at: https://www.e3s-conferences.org/articles/e3sconf/abs/2018/09/e3sconf_cenviron2018_01014/e3sconf_cenviron2018_01014.html

Odunlami, S. A. (2017). Design and fabrication of an extracting machine for small-scale production of local pomade from coconut. Imperial J. Interdisc. Res. 3, 737–740. Available online at: https://www.researchgate.net/profile/Olayinka-Ramonu/publication/320015044_Design_and_Fabrication_of_an_Extracting_Machine_for_Small-Scale_Production_of_Local_Pomade_from_Coconut/links/59c8a64aa6fdccc719267ba8/Design-and-Fabrication-of-an-Extracting-Machine-for-Small-Scale-Production-of-Local-Pomade-from-Coconut.pdf

Padilla, J., Zartha, J., Alvarez, V., and Orozco, G. (2018). Technological Surveillance for the Identification of Innovations in Leather tanning byproducts. Inf. Tecnol. 29, 127–142. doi: 10.4067/S0718-07642018000400127

Palacio, J., Hernández, R., Ríos, A., and Zartha, J. (2016). Estudio de prospectiva: aplicación del método delphi en cafés especiales en colombia al 2025. Revista Espacios 37, 14. Available online at: https://www.revistaespacios.com/a16v37n14/16371407.html

Perlaza, D., and Carrillo, F. (2020). Estudio de factibilidad para el procesamiento de aceite y leche de coco, en la parroquia borbón- esmeraldas. riobamba: universidad nacional de chimborazo.

Ramírez, C., Zartha, J., Arango, B., and Orozco, G. (2016). “Prospectiva 2025 de la Carrera de Ingeniería Química en algunos Países pertenecientes a la Organización de Estados Americanos (OEA),” in Formacion Universitaria, 127–138. Available online at: https://www.scielo.cl/pdf/formuniv/v9n6/art12.pdf

Ranasinghe, T. K. (2000). Potential value-added products and uses. Obtenido de UNIDO Consultant and Managing Director. Techno Consult (PVT) Ltd. Available online at: https://www.bioversityinternational.org/fileadmin/bioversity/publications/Web_version/198/ch04.htm (accessed January 2021).

Rethinam, P. (2019). “International scenario of coconut sector.” in The Coconut Palm (Cocos Nucifera L.)-Research and Development Perspectives (Singapore: Springer), 21–56.

Sacchi, G. (2020). Sector del coco: análisis de mercado y aspectos socioeconómicos, Marco general sobre el sector del coco en Jamaica. Ghana: Tropicsafe.

Sánchez-Torres, J. (2002). Herramientas de software para la práctica en la empresa de la vigilancia tecnológica e inteligencia competitiva: evaluación comparativa/J. M. Sánchez Torres; pref. de Eduardo Ríos Pita; presen. de Fernando Palop Marro.

Sari, E., Djoko, A., and Cahyo, A. (2021). Risk assessment on supply chain of the geographical indication granulated coconut sugar in kulon progo regency, special region of yogyakarta, indonesia. Int. J. Adv. Sci. Eng. Inf. Technol. 11, 236–243. doi: 10.18517/ijaseit.11.1.7923

Solarte, J., Zartha, J., and Osorio, O. (2021). Innovación Abierta en el Sector Agroalimentario: perspectivas desde una Revisión Sistemática de la Literatura y una Encuesta Estructurada en MIPYMES. Revista de Mercado de Tecnología de Innovación Abierta y Complejidad 7, 161. Available online at: https://doi.org/10.3390/joitmc7020161

Suarez, L., Agudelo, A., Zartha, J., and Orozco, G. (2021). La cadena productiva de mora en el Departamento Risaralda en el marco de un estudio de prospectiva a 2032. Ciencia y Tecnica 26, 83. doi: 10.22517/23447214.23921

Suarez, L., Escobar, N., and Zartha, J. (2020). Estudio de prospectiva al 2032 de la cadena de plátano, un enfoque hacia los programas académicos del sector agroindustrial. Inf. Tecnol. 31, 95–104. doi: 10.4067/S0718-07642020000600095

Zartha, J., Álvarez, J., and Orozco, G. (2018). Barriers to sustainability for small and medium enterprises in the framework of sustainable development—Literature review. Bus. Strategy Environ. 28, 512–524. doi: 10.1002/bse.2261

Zartha, J., Halal, W., and Hernandez, R. (2019). Delphi method: analysis of rounds, stakeholder and statistical indicators. Foresight 21, 525–544. doi: 10.1108/FS-11-2018-0095

Zartha, J., Solleiro, J., Montes, J., and Hernández, R. (2020). Innovation Management Models - A Literatura Review.

Zartha, J., Villada, S., Avalos, A., Arango, B., Fernandez, A., Orozco, G., et al. (2015). Application of Technological Intelligence Tools and S-Curves in a Foresigth Evaluation Regarding Biodegradables Packaging and Environmentally Friendly Up to 2032. Caracas: Magazine Espacios. Available online at: https://www.researchgate.net/publication/281832059_Application_of_Technological_Intelligence_Tools_and_S-Curves_in_a_Foresigth_Evaluation_Regarding_Biodegradables_Packaging_and_Environmentally_Friendly_Up_to_2032

Keywords: coconut, agroindustry, foresight, technological surveillance, innovation

Citation: Grass Ramírez JF, Muñoz RC and Zartha Sossa JW (2023) Innovations and trends in the coconut agroindustry supply chain: A technological surveillance and foresight analysis. Front. Sustain. Food Syst. 7:1048450. doi: 10.3389/fsufs.2023.1048450

Received: 19 September 2022; Accepted: 27 February 2023;

Published: 04 April 2023.

Edited by:

B. N. Dar, Islamic University of Science and Technology, IndiaReviewed by:

Pablo Pérez-Akaki, Monterrey Institute of Technology and Higher Education (ITESM), MexicoCopyright © 2023 Grass Ramírez, Muñoz and Zartha Sossa. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ricardo Camacho Muñoz, cmNtdW5vekB1bmljYXVjYS5lZHUuY28=; Jhon Wilder Zartha Sossa, amhvbnphcnRoYXNvc3NhQGdtYWlsLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.