94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Sustain. Food Syst., 18 March 2022

Sec. Nutrition and Sustainable Diets

Volume 6 - 2022 | https://doi.org/10.3389/fsufs.2022.856401

This article is part of the Research TopicSustaining Protein Nutrition through Plant-Based Foods: A Paradigm ShiftView all 14 articles

Oilseed cakes left after the oil extraction for different purposes are chiefly used as cattle feed, compost amendment, or plant conditioner. These oilseed cakes are rich in protein, nitrogenous compounds, and minerals. Beside its conventional usage, studies have been conducted to utilize these protein rich resources for human consumption. Considering the exponentially increasing human population and escalating food prices, these protein rich sources can be a novel food commodity and used to extract protein. The quality and functional properties of extracted oilseed cake proteins not only supplement the existing protein sources for the human consumption but also solve the problem of oilseed cakes disposal along with the additional income to the oilseed crop producers and processers. Production of proteins for human consumption from oil seed cakes may also reduce the carbon and water footprints while producing animal protein. The present review will focused on analyzing the oilseed cake as a protein source, characterization, extraction techniques, and utilization in food products.

In recent decades, a number of snowballing current issues e.g., over-exploitation and mismanagement of resources, the unsustainable consumption behaviors, the degradation of the environment and equilibrium of the ecosystems and climate change, were emerged. To mitigate these challenges, it is necessary to focus on new strategies and ways to make the best use of our natural resources and to eliminate the concept of wastes in supply chain. A new concept has been created where waste has been utilized by transforming into value-added products.

Edible oil industries processed raw seeds to extract oil and leftover solid by-products known as oilseed cakes. For the year 2017–2018, a total of ~580 million tons production of major oilseed crops was recorded, with the highest recorded for soybean followed by rapeseed, sunflower seed, and cotton seeds. According to FAO Statistics Division (2010), India produces over 25 million tons of oilseed cakes annually, being the world's largest oilseeds producers. Soybean seed cake followed by canola seed cake is the world's largest by-product in terms of quantities. In earlier times, oilseed cakes have been used as animal feed and soil compost, as it was an excellent and economical source to gain benefits. Oilseed cakes are rich source of protein, energy, carbohydrates, and mineral contents. It was found that the oilseed cake increased the weight of the young calves (Hessle et al., 2008). Hempseed cakes have some additional advantages as animal feed because they are rich in amino acids and proteins (Mustafa et al., 1998). Further, oilseed cakes are worthy of research as they have a potent role in human nutrition; however, they are bean underutilized due to lack of awareness and subsequent research. Evidences have been made on utilizing oilseed cake as dietary sources for human consumption.

Oilseed cakes have a great potential in obtaining various value added products having high nutrient value. To meet the increasing demand of food rich in protein, nutrients, and bioactive compounds, oilseed cake could be a potential candidate. Meyer (1971) reported protein extraction along with processing, functional and nutritional properties of soybean and other oilseed cakes. There is increasing demand for food supply which is rich in protein content. The recommended dietary allowance (RDA) for protein is 0.8 g protein per kilogram of the body weight, which indicates the minimum requirement of the protein for growth and development. Oil cakes/meals being a very rich source of proteins are also suitable alternative for human consumption (Teh and Bekhit, 2015). Plant proteins are versatile, non-toxic; easy to digest, low processing cost, and potent nutritional alternative for replacing animal protein (Sá et al., 2020; Langyan et al., 2022). However, flavor, color, and texture of foods are affected because plant protein lack sulfur amino acids. Although, there is no detailed review of protein from oilseed cakes which can be consumed by human. This paper provides a critical review of the existing literature on the quality and functional properties of extracted oilseed cake proteins to supplement the existing protein sources for the human consumption and also to present the problems associated with oilseed cakes disposal along with the additional income to the oilseed crop producers and processers.

The protein digestibility corrected amino acid score (PDCAAS) preferable method adopted by WHO/FAO to measure the value of protein in human nutrition. The principle of this method is comparing first limiting essential amino acid concentration with reference amino acid concentration pattern. In simple words, it is utilized for evaluation of food's protein quality and is generally used to calculate the %DV for showing on label in R&D Foods. This scoring pattern is taken from requirement of essential amino acids in small age group preschool children. The obtained chemical score by this is corrected for true fecal digestibility of the test protein. PDCAAS values more than 100% are not acceptable and hence it should be truncated to 100%. During adoption of the PDCAAS method, very few research have been done on requirement of amino acid, and therefore there is a need for validating the pattern of scoring, and this patter does not contain conditionally indispensable amino acids (Schaafsma, 2000).

Protein is isolated from oilseed cakes using an alkaline extraction which has been very well documented. Oilseed cakes are rich source of protein isolates having a wide range of applications in food industry as they differ in functional properties e.g., emulsification, creaming stability, water- and oil-holding capacities. The protein quality of soy protein isolates is very much comparable to those obtained from oilseed cakes such as hemp, canola, sunflower, and palm kernel (Tang et al., 2006; Wang et al., 2008; Tan et al., 2011; Chee and Ayob, 2013); therefore, these can be considered as an alternative to soy protein. Moure et al. (2006) studied in detail the modification process by which functional properties of protein isolates are changed in food products. Although oilseed protein with amino acid content has limited bioactive properties but their biological functions can be improved by chemical or enzymatic hydrolysis to produce protein hydrolysates (Vaštag et al., 2011; Girgih et al., 2013). The angiotensin-converting enzyme (ACE) inhibitory activity and antioxidant activity of oilseed cakes is reported higher as compared to the protein isolates (Marczak et al., 2003; Girgih et al., 2013).

With increasing world population and the demand for food supply and especially protein rich products are increasing. However, the raw material cost, energy consumption, competition for land use, environmental pollution, soil deterioration, and climate changes associated losses are increasing which all ultimately makes the food production process challenging and costlier. Also, the agro-waste generated during food harvesting to its processing create a lot of environmental problems beside problems associated with its proper disposal. Utilization these agro-wastes, including oilseed cakes is a sustainable methods for producing alternative food sources which can be used to meet the increasing protein consumption by the growing population.

There are many health benefits associated with diets high in plant protein e.g. lowering body weight, body cholesterol also with lower blood pressure levels. This is the main reason why these are preferred over animal protein (Wheeler et al., 2002; Craig, 2010; Langyan et al., 2022). Many reports have been documented that intake of diet rich in protein (about half from plants) cause lowering in blood pressure, reduction in cholesterol levels and reduce the risk of various health issues and severity related to heart functioning (Appel et al., 2005). Reduction in cholesterol levels and blood pressure by having a low-carb, high-plant protein diet also attract attention in comparison to a high-carb, low-fat diet (Jenkins et al., 2009). Serving of legumes (plant protein) in diet in place of red meat (animal protein) also reduce the risk of type 2 diabetes which occurs due to change dietary changes. One small study carried out on people with type 2 diabetes found that cholesterol and blood sugar were improved to a significant level when the patients were fed with legumes instead red meat (Hosseinpour-Niazi et al., 2015). Plant protein diets also prove very useful in case of obesity by helping in controlling body weight. Intake of plant proteins such as beans, chickpeas, lentils or peas per day in diet can prove very potent in weight management and weight loss (Li et al., 2014). Mozaffarian et al. (2011) studied 120,000 men and women over 20 years and found that eating more nuts causes a significant reduction in weight loss.

Oilseed cakes rich in polyphenols such as canola and sunflower usually exert a dark color on the protein isolates and also affect their functional properties, e.g., emulsification, foaming, surface hydrophobicity, and water-holding properties, so their removal is recommended before protein extraction (Mansour et al., 1993; Xu and Diosady, 2002; Salgado et al., 2012). Extraction of protein from sunflower seed cake after removal of polyphenols had better functional characteristics such as lighter color, higher surface hydrophobicity, protein digestibility, and solubility as compared to the protein isolate containing polyphenols (Salgado et al., 2012). To determine the optimal use of protein extract, various studies have evaluated the functional properties of protein isolates from different oilseed cakes. For instance, protein isolates from hemp oilseed cakes have similar oil-holding capacity as from soy oilseed cake, but have lower emulsion stability index and water-holding capacity (Wang et al., 2008). Same characteristics also have been reported in gingerbread plum seed protein isolate which exhibited high emulsifying capacity and water-holding capacity, oil-binding capacity, and bulk density than the commercial soy protein isolate (Amza et al., 2011). Canola, flax, and whey proteins are very much comparable in their creaming stability (Karaca et al., 2011). The amino acid profiles of protein isolates from oilseed cakes are better or comparable to soy protein isolate in fulfilling the nutrition requirements of infants and elderly people. For instance, gingerbread plum seed protein isolate offers a better replacement in infant formula as they are rich in arginine, valine, tryptophan, glutamic acid, cysteine, serine and proline than the soy protein isolate (Amza et al., 2011). The gingerbread plum seed protein isolate acts as natural source of calcium supplementation for pregnant and lactating women, children and elderly people because of its high calcium content. As per Food and Agricultural Organization/World Health Organization (FAO/WHO) standards, palm kernel protein isolate have all essential amino acids at concentrations that met the suggested requirements except lysine for 2–5 years old infants. In addition to this, protein isolates from canola, hemp, and flax protein also meet all the requirements of essential amino acid profile when fortified with lysine for both adults and childrens (Tang et al., 2006; Tan et al., 2011; Teh et al., 2014). Methionine and cysteine concentration was found to be very high in protein extract after alkali extraction than soy protein extraction (Teh et al., 2014), which can be advantageous for use in infant formula. Canola seed protein isolates are rich in glutamic acid, aspartic acid, leucine, and proline and contains considerable amounts of phenylalanine, isoleucine, and tryptophan (Shahidi, 1990). The pumpkin seed protein isolate was shown to be nutritionally sounded in vivo. LDH, alanine transaminase, aspartate transaminase, and alkaline phosphatase levels are associated with protein malnutrition and can reduced to a considerable level after feeding pumpkin seed protein isolate to rats treated with carbon tetrachloride (CCl4) (Nkosi et al., 2005). Oilcake/ meal obtained after extraction of oil from the oilseeds are rich in protein. The highest content of protein (45–50%) was found in groundnut cake, followed by soybean, cottonseed, rapeseed, sesame, sunflower, palm oil, and olive oilcake. Protein hydrolysates (hydrolysed product of protein), protein isolates (>90% protein), and protein concentrates (30–80% protein) can be prepared by these protein rich oil cake. The preparation of protein isolates includes solubilizing the protein by alkali (0.1N NaOH) followed by isoelectric precipitation using acid (0.1N HCl), and subsequently washing and drying.

There are two categories of oilcakes, i.e., edible and non-edible. Oilcakes have high nutritional value and can be used for the consumption of human as well as animals. They are used as processed ingredients (hydrolysate, protein concentrate, isolate) or as substrate (in the production of amino acids, flavors, bioactive compounds, pigments, antibiotics, surfactants, enzymes, vitamins). The defatted edible cakes can be incorporated in multipurpose supplements, infant dairy products and bakery, and used in the diet of undernourished people. Oilseed cake /meal that consist of toxic compounds and are used as manure are called as non-edible oilseed cake/meal. It includes oilseed cakes obtained from linseed, karanja, castor, neem, and mauha (Gupta et al., 2018). According to the U.S. Department of Agriculture (USDA), the world production of oilseeds in 2018/2019 was 600.47 million metric tons, accounted for a large amount of press cakes and residues. Sustainable means to utilize oilseed cakes includes the use of these by-products and residues to develop new products rich in nutrients (Sarwar et al., 2013). Growing condition, extraction method and variety also determine the composition of oilcakes/meals.

The oilseed cakes have different physiochemical characteristics, depends on the initial raw materials, variety, growing condition, and extraction methods. For example, Walnut oilcakes are yellow to light brown, and sweetish. Pumpkin seeds oilcake color varies from brown to brownish green and has a sweetish, insipid taste. The color of sesame oilcake ranges from cream to light brown and contains an insipid, sweetish taste. Flaxseeds oilcakes show various shades of brown with an insipid, neutral taste (Bochkarev et al., 2016). The highest protein content was found in groundnut cake followed by soybean, almond, chia, rapeseed, sunflower, cottonseed, pumpkin, hemp, safflower, sesame, coconut, flaxseed, and olive oilcakes. The content of oil is 56% in peanut, more than in rapeseed (40%), sunflower (40%), and soybean and cotton (15–25%) (Savoire et al., 2012).

More than 200 species of oilseed plants are cultivated around the world. The most important in food production are soybeans, canola, sunflower, coconut, olive and peanut. Cakes and flours are the residues that remain after the removal of most of the oil from the oilseeds. Desserts and foods based on soybeans, peanuts, cottonseed, rapeseed, sunflower, coconut, palm kernel, linseed and sesame seeds are used. These oilseed cakes and flours are often used in dairy cattle concentrates. The amino acid profile in soybean cake (Table 1) and the flow chart of soybean protein extraction process (Figure 1) is presented below.

Soybean cake is a rich source of protein and energy with lower fiber content than most oil cakes (Table 1). They are widely used as feed ingredients for both animals and humans due to their high digestibility and palatability. Methionine was found to be the main limiting amino acid in soybean cake, while threonine, valine, and lysine were marginal in a chicken performance study (Smith, 1986).

Being a high production and price flour in the cake market, soybean cake is followed by rapeseed cake in production. Rapeseed oil expeller is comparable to soybean expeller in amino acid balance and is richer in sulfur amino acids such as methionine and cysteine. The carbohydrates in rapeseed cake are mainly pectins (14.5%), cellulose, seaweed, arabinan and arabinogalactan. Its use in poultry feed is limited by the presence of antinutrients such as glucosinates, sinapine, tannins, erucic acid and phytates. Rapeseed cultivars that are low in erucic acid and glucosinates that are widely grown in Canada are known as canola. Mustard is an oilseed crop and condiment that belongs to the same genus as canola. The chemical and amino acid composition of mustard oil cake is very similar to that of rapeseed cake, but it contains more glucosinates than canola, although of a different type (Achaya, 1990). Cottonseed oil cake comprises 45% of the seed and is high in protein. But its use as a food ingredient for non-ruminants is subject to severe limitations due to the presence of the toxic metabolite gossypol, high fiber content and low levels of lysine, cysteine and methionine. Genetically glandless cottonseed containing gossypol has been developed and the oil cake obtained from this strain is said to have immense potential as a protein diet. Peanut oil cake, a solid compound with high protein content, is high in arginine, but low in essential amino acids such as lysine. Aflatoxins, toxic fungal metabolites of the Aspergillus flavu group, are frequent contaminants in these cakes and their presence has serious implications on animal performance. Sunflower oil expeller has a composition similar to cottonseed expeller and is rich in sulfur amino acids, but remarkably low in lysine. The copra cake or coconut oil cake has a protein content of around 20% with low concentrations of essential amino acids, in particular tryptophan, lysine, methionine and histidine. Palm kernel cake is dry and granulated with high fiber content. This reduces its suitability for monogastric animals. Like sunflower cake, it is deficient in lysine and high in sulfur-containing amino acids. It has a better amino acid index than coconut oil cake. Pie digestibility is low for poultry and pigs due to high fiber content (Ravindran and Blair, 1992).

The individual amino acid content (mg/100 g dry extract) in the extracts of pumpkin, hemp and linseed is shown in Table 3. Cystine and cysteine were not detected with this analysis method. A strong correlation (r = 0.833; p <0.05) was observed between the results obtained with the Kjeldahl and RP-HPLC methods. In general, the extraction of carbon dioxide into the atmosphere led to higher amino acid recoveries (p <0.05) of all the matrices analyzed. The sum of the total amino acids in the extracts of pumpkin, hemp and linseed was, respectively, 75.09; 409.51 and 65.23 mg/100 g of dry extracts. For extractions in a nitrogen atmosphere with pure water, lower contents (p <0.05) of total amino acids were found: 20.40 (pumpkin); 219.50 (hemp) and 18.84 (flax) mg/100 g of dry extract. The addition of hydrochloric acid in a nitrogen atmosphere enhanced the release of amino acids from the peptides / proteins. The amino acid recoveries (8.48–38.4% of the total protein content) obtained from different subcritical extraction conditions coincided with the values reported for other plant sources (5–53%) [32]. All oilseed extracts had high levels of essential amino acids (EAA: Thr, His, Lys, Val, Met, Trp, Phe, Ile and Leu). Pumpkin seed extracts had a significantly higher percentage of EAA (p <0.05) (51.49–58.58%) than flaxseed extracts (35.91–40.66%) and hemp (22, 60–27.28%). The highest content of essential amino acid Lys (12.37 ± 0.10 mg/100 g dry extract) was observed in extracts of pumpkin seeds obtained in a carbon dioxide atmosphere, while Thr (34.70 ± 0.12 mg/100 g dry extract) and Leu (5.31 ± 0.06 mg/100 g of dry extract) were found to be the most abundant in hemp and linseed extracts, respectively, applying the same extraction method. In general, these amino acids are also dominant in raw materials [33–35]. The high concentrations of EAA in the characterized oilseed extracts suggest their potential use as food ingredients with a beneficial amino acid profile. The hemp seed extracts showed a high content of aromatic amino acids (FAA) Asp, Glu and Ala, with respective average ranges for three extraction conditions of 49.17–72.67 (Asp); 41.98–77.86 (Glu) and 10.77–17.83 (Ala) mg/100 g of dry extract. On the contrary, Gly levels were significantly (p <0.05) higher in extracts of pumpkin seeds (4.82 ± 0.02 mg/100 g for example) and flax (6.08 ± 0.05). Mg /100 g e. Carbon dioxide atmosphere. The % FAA was as follows: 39.85–47.63% (hemp extracts) > 27.95–41.20% (flax extracts) > 16.56–24.88% (pumpkin extracts) high levels of FAA can contribute to the desirable sensory properties of all three oilseed cake extracts (Table 2).

For preparing protein isolates/concentrates from oilseed cakes, the most widely used method is the two-step process patented by Anson and Pader (1955). After alkaline solubilization of proteins, insoluble materials (mainly starch and fiber) are removed by centrifugation. By adding hydrochloric acid to the supernatant, the protein is isoelectrically precipitated (pH 4.0–5.0), separated by centrifugation and neutralized. The co-product contains the other soluble components, mainly sugars, soluble fiber, fat, and ash. There are other modified versions of this historic 2-step process (Extraction/Isolation) on an industrial scale. In one of the modified method, the extraction was carried out under acidic conditions (Alli et al., 1993), or in water (Klamczynska et al., 2001). In general, the acidic or alkaline extraction can lead to a high level of purity (> 90%). In other method, instead of precipitation with pHi (assisted or not with heat treatment), it is possible to use the ultrafiltration route to purify proteins. This process was developed at the Food Technology Laboratory (Lyngby, Denmark) by Olsen and Hinge Andersen (1978). The main difference between pHi and the filtration process is the solubility and functionality, generally higher in the case of ultrafiltration.

Alternatives to two-step processes (extraction/isolation) have also been proposed on a pilot scale. For instance, the Prairie Regional Laboratory (Canada) has developed a simpler wet process, derived from those described above, to process pea proteins. All the alkaline extract is atomized and the protein content can reach up to 60%. “Micelization,” proposed by Paredes-Lopez et al. (1991) is based on the phenomenon of salting in the salting of food proteins. As reviewed by Boye et al. (2010), after protein extraction using a saline solution suitable for the desired ionic strength, the solution is diluted, inducing the precipitation of proteins that can then be recovered by centrifugation or filtration, followed by drying. A purity of 88% has been achieved; however, due to the high consumption of water the scaleup of the process to the industrial scale is challenging.

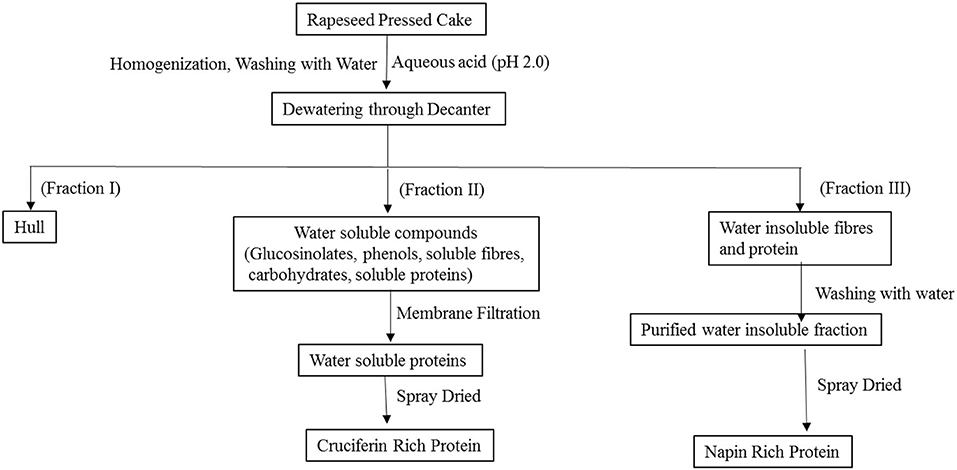

The Food and Agriculture Organization of the United Nations (FAO) mentioned that protein will be limiting macronutrient in near future, therefore, to sustain the current and future requirements; researchers are adapting different kinds of method and processes to extract protein from oilseed cakes (Arrutia et al., 2020). Researchers extract protein from oil seed cakes using solvent extraction, acid or alkaline aqueous extraction assisted by salt and enzymes. In general, oil cakes are rich in polyphenols and these polyphenols were removed by purification approaches such as isoelectric separation followed by membrane separation (Xu and Diosady, 2002; Ghodsvali et al., 2005), protein micellar formation (Murray et al., 1980), use of ion-exchange resin or/and adsorbate resins (Pickardt et al., 2015). Rehder et al. (2017) reported the extraction of cruciferin rich protein (41.9%) and napin rich protein (58.3%) from rapeseed mustard cake (Brassica napus L.) using aqueous acid extraction (pH 2.0) followed by membrane filtration and spray drying technique (Figure 2). Similarly, cruciferin and napin protein were extracted and purified by Moreno-González et al. (2021) using ion exchange chromatography through high throughput experimentation technique (HTE). The experimental procedure involves the use of cation exchange resins (CaptoS, POROS 50HS, CM Sheparose and MacroPrep50) and mixed mode resins (CaptoMMC, Nuvia cPrime, PPA HyperCel and Toyopearl MX-Trp-650 M) and standardized procedure under different pH and salt concentration. Among different resins, POROS 50HS showed a promising result with cruciferin (>98% purity and 99% yield) and napin (98% yield with >99% purity) extraction.

Figure 2. Extraction of cruciferin and napin rich protein from rapeseed mustard cake using acid extraction.

In another approach, Gerzhova et al. (2016) extracted canola protein (58%) from defatted canola meal. using 15% w/w defatted canola meal at pH 12, without salt medium. The increase concentration of salt (0.4–1 M NaCl) tends to decrease the protein concentration (58–43%) under 15% w/w defatted canola meal. The schematic procedure for extraction of canola protein is depicted in Figure 3. Similarly, black cumin protein concentrates were extracted by alkaline treatment followed by isoelectric precipitation method.

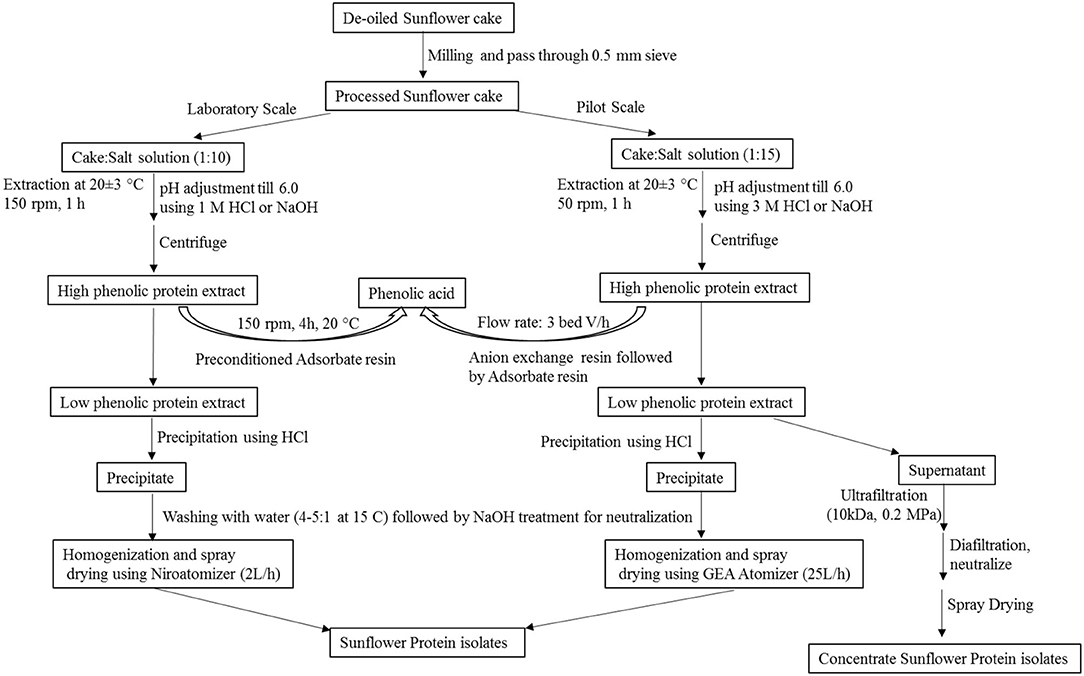

The application of resin is increasing widely due to rapid adaption of protein extraction approaches from de-oiled cake. Pickardt et al. (2015) standardized the process for extraction of protein isolates and concentrates at laboratory and pilot scale (Figure 4). In this approach, cold pressed sunflower cakes were milled and after homogenization, samples were processed into salt solution to remove protein and phenolic fractions. Phenolic fractions were removed through use of adsorbate resin (styrene-divinylbenzene resin Amberlite XAD 16HP), whereas, protein solution were processed through mild acidic extraction followed by isoelectric precipitation. At pilot scale, anion resins were separately used to remove phenolic compounds from the high phenolic protein solution. After spray drying, 94–98% protein isolates and 65–68% protein concentrates were obtained.

Figure 4. Schematic process for extraction of protein isolates and concentrates from de-oiled sunflower cake.

Extraction of protein from oilseed cake using novel and advanced extraction technologies and green solvents, have been searched from past decades. As such the innovative techniques, including ultrasonic, microwave, enzyme-assisted, natural deep eutectic solvents, pulsed electric field, and subcritical water extraction were considered for protein extraction from oilseed cake (Phan et al., 2009; Russin et al., 2011; Bardeau et al., 2015; Sicaire et al., 2015).

Ultrasonicaltion-assisted extraction of protein from sunflower meal was performed and tested for its effect on the physicochemical and functional properties of the protein. It was found that under optimal extraction condition of power density (220 W/L), temperature (45°C), extraction time (15 min), the protein yield of 54.26% was obtained. It was observed that under the optimal extraction condition, the protein content, particle size, bulk density, and water and oil holding capacity was 934.92 g/kg, 627.6 nm, 0.372 g/ml, 0.985 g water/ g protein, and 2.06 g oil/ g protein, respectively. The solubility, emulsifying capacity, and emulsion stability was also recorded highest as 74.59, 52.45, and 50.45%, respectively. It was found that the ultrasonication helps in extracting the protein content and providing functional properties and further the product could be used for salad dressing and for meat products (Dabbour et al., 2018). In another study, ultrasound assisted extraction of rapeseed was optimized with a power of 5.6 W/cm2 and temperature of 45°C which provide protein extraction yield of 4.24 g/100 g. It was found that UAE followed by two stage of conventional extraction provide the total protein yield of 9.81 g/100 g (Boukroufa et al., 2017).

In a study, high voltage electric discharge was applied on rapeseed and rapeseed press cake for the recovery of protein, antioxidants, and isothiocyanates. The high voltage electric discharge was applied at different energy (0–400 KJ/kg) and different rapeseed press cake water ratio (1:5 to 1:20 w/w). It was found that the optimal energy input for polyphenols was 80 KJ/kg and 240 KJ/g for rapeseed press cake and rapeseed, respectively. For protein the optimal extraction condition is 240 KJ/kg with ratio of 1:20, which provide a protein extraction yield of 9.41 g/100 g and 15.76 g/100 g for rapeseed and rapeseed press cake, respectively (Barba et al., 2015). A multistage counter current extraction process was applied to improve the protein recovery from Jatropha curcas seed press cake. The higher protein content was found as 82% under the extraction condition of four stage counter current extraction, 0.055M NaOH at sample to solvent ratio of 10 g/g. It was found that increasing the extraction cycle from one to four significantly increased the extraction yield of protein from 35 to 71% (Lestari et al., 2020). Phenolic compounds and proteins were extracted from sesame cake using pulsed electric fields and high voltage electrical discharges. These were applied as pre-treatment to diffusion. It was found that the polyphenol and protein content increased during extraction with 83 KJ/kg of energy inputs. The electrotechnology reduce the need of organic solvents and high temperature (Sarkis et al., 2015).

In enzymatic extraction of protein from rapeseed press cake treated with pectinolytic, xylanolytic, and cellulolytic enzyme pre-treatments. It was found that these enzyme treatments cause 56 and 7% extraction of the total protein in the intact and dehulled press cake. It was recorded that the enzymatic treatment cause enhancement in the extraction process (Rommi et al., 2014). Enzymatic and non-enzymatic extraction of proteins from defatted rapeseed cold-pressing residue was tested under different pH. It was found that after enzymatic extraction the protein yield was 40–41% at pH 6, which is higher than the non-enzymatic alkaline extraction (pH 10). Also, water extraction provides protein stability, high zeta potential, and smaller particle size (Rommi et al., 2015). Similarly, the alkaline extraction method was compared with the enzyme-assisted method for the recovery of protein from Sacha inchi cake meal. Under alkaline extraction the optimal extraction condition was temperature of 54.2°C, solvent/meal ratio 42:1, NaCl concentration 1.65 M, pH 9.5 for 30 min and obtain 29.7% of protein yield, whereas under enzyme extraction a higher protein yield of 44.7% was obtained at an enzyme concentration of 5.6%, 40.4 min, 50:1 ratio, pH 9.0, and temperature of 50°C (Chirinos-Cuadros and Rosado-Samaniego, 2016).

Two different raw material, i.e., pre-pressed and cold-pressed rapeseed press cake were examined for protein extraction under different factors, i.e., solid to solvent ratio, extraction time, temperature, pH value, NaCl concentration, and number of extraction cycle. The protein yield was obtained as 52.3 and 36.7% for cold-pressed and pre-pressed rapeseed cake, respectively, under mild extraction condition. The protein yield under enzyme assisted extraction condition was 59.5 and 60.6% for cold-pressed and pre-pressed rapeseed cake, respectively, for one step process and 80.7 and 78.3% for three step process (Fetzer et al., 2020).

The use of deep eutectic solvents (DES) for protein extraction from flax cake, camelina cake, and sunflower cake was evaluated. In flax cake and camelina cake the protein yield was higher in DES as compared to n-hexane. Increasing temperature increased the protein extraction yield (Parodi et al., 2021). DES was used to extract protein from rapeseed cake and Evening primrose cake using glycerol-choline chloride deep eutectic solvent. It was found that the increasing temperature increase the extraction yield of 20 and 35% at 140°C from rapeseed cake and Evening primrose cake, respectively (Grudniewska et al., 2018). The valorization potential for extraction of protein from oilseed cakes of hemp, pumpkin and flax seed by subcritical water were carried out by Švarc-Gajić et al. (2020). In this approach, sample to solvent ratio were kept as 1:30 and subjected to increase of pressure with 10°C/min till 160°C and process was conducted till 1 h. The total protein content in pumpkin, hemp, and flax varied from 1.94–4.87, 4.83–6.83, and 1.30–2.84 g/100 g dry extract, respectively. Among Nitrogen (N2) and Carbon dioxide (CO2), CO2 provide better atmosphere for protein yield.

Oilcake/meal obtained after the extraction of oil from the oilseeds are an alternatively rich source of protein. The highest content of protein was found in groundnut cake (45–50%), followed by soyabean, cottonseed, rapeseed, sesame, sunflower, palm oil and olive oilcake. Protein hydrolysates (hydrolysed product of protein), protein isolates (>90% protein) and protein concentrates (30–80% protein) can be prepared by these protein rich oil cake. A variety of protein rich foods can be prepared using protein isolates. Protein isolates can be used as a functional ingredient in the development of protein beverages, shakes, energy bars, frozen desserts, sour cream, sour cream dips, meat analogs; cheese analogs extruded products, protein rich pasta, convenience beverage powders, and infant and weaning food. Protein hydrolysate can result from the hydrolysis of protein isolate and can be used in food industry. As a result of hydrolysis structural modification can occur in proteins, which improves the hydration and gelling properties, solubility, surface active properties, and the functionality of protein. The type of enzyme used, its specificity as well as degree of hydrolysis determines its functionality. A specific fragment of protein known as bioactive peptides, are known to have biological activity and positively influences the human health (Langyan et al., 2021). Health benefits of bioactive peptide comprises of immuno-modulatory activity, hypocholesterolemic activity, antioxidant activity, bile acid binding activity and antithrombotic activity. For instance, cleavage of soybean protein hydrolysate under controlled condition followed by hydrolysis with microbial protease results in peptide with good functionality (like enhanced iron chelating activity and improved surface active properties). Hydrolysis of sesame oilcake/meal with alcalse, pepsin, and protein forms a peptide with enhanced functionality comprising of antioxidant activity, enhanced digestibility and antihypertensive property (Chatterjee et al., 2015). Table 3 listed the benefits of protein from oilseed cake.

The present review provides a detailed overview on the protein content from oilseed cake, characterization, extraction techniques, and applications in food and health. It was found that a number of oilseed cake have been utilized as a protein rich substitute using both conventional and advanced extraction techniques. The most utilized oilseed cake for protein extraction includes rapeseed press cake and sunflower meal. A large number of aminoacids are present in oilseed cake. However, as plant based proteins have lower concentrations of essential amino acids, like methionine, tryptophan, lysine, and threonine, that limits their use as a complete protein source in human diet, hence research on combining different oilseed cake for meeting the protein requirement are urgently required. For instance, combining corn gluten meal with soybean meal provides a number of amino acids, as the former is a good source of methionins and cysteine but low in lysine and typtophan, and the latter has rich lysine and tryptophan content but deficient in cysteine and methionine. Moreover, research on extraction and purification of proteins from toxic substances by economically efficient method that saves the nutritional quality and/or improves digestibility require further efforts. The utilization of oilseed cake proteins in food and health products are now limited, which require further research on utilization of this enormously rich protein sources in diet.

RS: conceptualization, methodology, investigation, formal analysis, resources, writing—original draft, writing—review and editing, visualization, supervision, project administration, and funding acquisition. SL: investigation, writing—original draft, and writing—review and editing. SS, BR, and AK: writing—original draft, writing—review and editing. MS: conceptualization, methodology, resources, and writing—original draft. All authors contributed to the article and approved the submitted version.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Adeleke, B. S., and Babalola, O. O. (2020). Oilseed crop sunflower (Helianthus annuus) as a source of food: Nutritional and health benefits. Food Sci Nutr. 8, 4666–4684. doi: 10.1002/fsn3.1783

Alli, I., Gribbs, B. F., Okoniewska, M. K., Konishi, Y., and Dumas, F. (1993). Identification and characterization of phaseolin polypeptides in a crystalline protein isolated from white kidney beans (Phaseolus vulgaris). J. Agric. Food Chem. 41, 1830–1834. doi: 10.1021/jf00035a005

Amza, T., Amado, I., Zhu, K., and Zhou, H. (2011). Effect of extraction and isolation on physicochemical and functional properties of an underutilized seed protein: gingerbread plum (Neocarya macrophylla). Food Res Int. 44, 2843–2850. doi: 10.1016/j.foodres.2011.06.029

Ancut, P., and Sonia, A. (2020). Oil press-cakes and meals valorization through circular economy approaches: a review. Appl. Sci. 10, 1–30. doi: 10.3390/app10217432

Appel, L. J., Sacks, F. M., Carey, V. J., Obarzanek, E., Swain, J. F., Miller, E. R., et al. (2005). Effects of protein, monounsaturated fat, and carbohydrate intake on blood pressure and serum lipids: results of the OmniHeart randomized trial. JAMA. 294, 2455–2464. doi: 10.1001/jama.294.19.2455

Arrutia, F., Binner, E., Williams, P., and Waldron, K. W. (2020). Oilseeds beyond oil: press cakes and meals supplying global protein requirements. Trends Food Sci. Technol. 100, 88–102. doi: 10.1016/j.tifs.2020.03.044

Barba, F. J., Boussetta, N., and Vorobiev, E. (2015). Emerging technologies for the recovery of isothiocyanates, protein and phenolic compounds from rapeseed and rapeseed press-cake: effect of high voltage electrical discharges. Innov. Food Sci. Emerg. Technol. 31, 67–72. doi: 10.1016/j.ifset.2015.06.008

Bardeau, T., Savoire, R., Cansell, M., and Subra-Paternault, P. (2015). Recovery of oils from press cakes by CO2-based technology. OCL 22, D403. doi: 10.1051/ocl/2015004

Bochkarev, M. S., Egorova, E. Y., Reznichenko, I. Y., and Poznyakovskiy, V. M. (2016). Reasons for the ways of using oilcakes in food industry. Foods Raw Mater. 4, 4–12. doi: 10.21179/2308-4057-2016-1-4-12

Boukroufa, M., Sicaire, A. G., Fine, F., Larré, C., Goff, A. L., Jamault, V. S., et al. (2017). Green sonoextraction of protein from oleaginous press rapeseed cake. Molecules 22, 80. doi: 10.3390/molecules22010080

Boye, J., Zare, F., and Pletch, A. (2010). Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res. Int. 43, 414–431. doi: 10.1016/j.foodres.2009.09.003

Chatterjee, R., Dey, T. K., Ghosh, M., and Dhar, P. (2015). Enzymatic modification of sesame seed protein, sourced from waste resource for nutraceutical application. Food Bioprod. Process. 94, 70–81. doi: 10.1016/j.fbp.2015.01.007

Chee, K. L., and Ayob, M. K. (2013). Optimization of hexametaphosphate-assisted extraction and functional characterization of palm kernel cake protein. Food Sci. Tech. Int. 19, 109–122. doi: 10.1177/1082013212442185

Chen, C. C., Shih, Y. C., and Chiou, P. W. S. B. (2010). Evaluating nutritional quality of single stage- and two stage-fermented soybean meal. Asian-Aust. J. Anim. Sci. 23, 598–606. doi: 10.5713/ajas.2010.90341

Chirinos-Cuadros, C. R., and Rosado-Samaniego, J. F. (2016). Estrategia de diferenciación: el caso de las empresas industriales. Ingeniería Industrial 165–174.

Craig, W. J. (2010). Nutrition concerns and health effects of vegetarian diets. Nutr. Clin. Pract. 25, 613–620. doi: 10.1177/0884533610385707

Dabbour, M., He, R., Ma, H., and Musa, A. (2018). Optimization of ultrasound assisted extraction of protein from sunflower meal and its physicochemical and functional properties. J. Food Process Engg. 41:e12799. doi: 10.1111/jfpe.12799

FAO Statistics Division (2010). FAOSTAT-Agriculture. Available online at: http://faostat. fao.org/site/567/DesktopDefault.aspx?PageID=567ancor (accessed January 26, 2010).

Fetzer, A., Müller, K., Schmid, M., and Eisner, P. (2020). Rapeseed proteins for technical applications: processing, isolation, modification and functional properties-a review. Ind. Crops Prod. 158:112986. doi: 10.1016/j.indcrop.2020.112986

Gerzhova, A., Mondor, M., and Benali, M. M. (2016). Study of total dry matter and protein extraction from canola meal as affected by the pH, salt addition and use of zeta-potential/turbidimetry analysis to optimize the extraction conditions. Food Chem. 201, 243–252. doi: 10.1016/j.foodchem.2016.01.074

Ghodsvali, A., Khodaparast, M. H. H., Vosoughi, M., and Diosady, L. L. (2005). Preparation of canola protein materials using membrane technology and evaluation of meals functional properties. Food Res. Int. 38, 223–231. doi: 10.1016/j.foodres.2004.10.007

Girgih, A., Udenigwe, C., and Aluko, R. (2013). Reverse-phase HPLC separation of hemp seed (Cannabis sativa L.) protein hydrolysate produced peptide fractions with enhanced antioxidant capacity. Plant Foods Hum. Nutr. 68, 39–46. doi: 10.1007/s11130-013-0340-6

Grudniewska, A., de Melo, E. M., Chan, A., Gnilka, R., Boratynski, F., and Matharu, A. S. (2018). Enhanced protein extraction from oilseed cakes using glycerol-choline chloride deep eutectic solvents: a biorefinery approach. ACS Sustain. Chem. Eng. 6, 15791–15800. doi: 10.1021/acssuschemeng.8b04359

Gupta, A., Sharma, R., Sharma, S., and Singh, B. (2018). “Oilseed as potential functional food Ingredient,” in Trends and Prospects in Food Technology, Processing and Preservation, 1st Edition, eds. Prodyut Kumar, P., Mahawar, M. K., Abobatta, W., and Panja, P. (Today and Tomorrow's Printers and Publishers: New Delhi, India), 25–58.[]

Hessle, A., Eriksson, M., Nadeau, E., Turner, T., and Johansson, B. (2008). Cold-pressed hemp seedcake as a protein feed for growing cattle. Acta Agric. Scand. Sect. A Anim. Sci. 58, 136–145. doi: 10.1080/09064700802452192

Hicks, T. M., and Verbeek, C. J. R. (2016). “Protein-rich by-products: production statistics, legislative restrictions, and management options,” in Protein Byproducts. Amsterdam: Elsevier Inc.

Hosseinpour-Niazi, S., Mirmiran, P., Hedayati, M., and Azizi, F. (2015). Substitution of red meat with legumes in the therapeutic lifestyle change diet based on dietary advice improves cardiometabolic risk factors in overweight type 2 diabetes patients: a cross-over randomized clinical trial. Eur. J. Clin. Nutr. 69, 592–597. doi: 10.1038/ejcn.2014.228

Houmy, N., Melhaoui, R., Belhaj, K., Richel, A., Sindic, M., Hano, C., et al. (2020). “Chemical characterization of almond meal as a co-product of the mechanical extraction of almond oil,” in E3S Web of Conferences (EDP Sciences), 183.

Jenkins, D. J., Wong, J. M., Kendall, C. W., Esfahani, A., Ng, V. W., Leong, T. C., et al. (2009). The effect of a plant-based low-carbohydrate (“Eco-Atkins”) diet on body weight and blood lipid concentrations in hyperlipidemic subjects. Arch. Intern. Med. 169, 1046–1054. doi: 10.1001/archinternmed.2009.115

Karaca, A. C., Low, N., and Nickerson, M. (2011). Emulsifying properties of canola and flaxseed protein isolates produced by isoelectric precipitation and salt extraction. Food Res. Int. 44, 2991–2998. doi: 10.1016/j.foodres.2011.07.009

Klamczynska, B., Czuchajowska, Z., and Baik, B. K. (2001). Composition, soaking, cooking properties and thermal characteristics of starch of chickpeas, wrinkled peas and smooth peas. Int. J. Food Sci. Technol. 36, 563–572. doi: 10.1046/j.1365-2621.2001.00486.x

Langyan, S., Yadava, P., Khan, F. N., Dar, Z. A., Singh, R., and Kumar, A. (2022). Sustaining protein nutrition through plant-based foods. Front. Nutr. 8, 772573. doi: 10.3389/fnut.2021.772573

Langyan., S, Khan, F. N., Yadava, P., Alhazmi, A., Mahmoud, S. F., Saleh, D. I., et al. (2021). In silico proteolysis and analysis of bioactive peptides from sequences of fatty acid desaturase 3 (FAD3) of flaxseed protein. Saudi J. Biol. Sci. 28, 5480–5489. doi: 10.1016/j.sjbs.2021.08.027

Lestari, S. D., Leon, F. M., Widyastuti, S., Brabo, N. A., and Putra, A. H. P. K. (2020). Antecedents and consequences of innovation and business strategy on performance and competitive advantage of SMEs. J. Asian Finance Econ. Bus. 7, 365–378.

Li, S. S., Kendall, C. W., de Souza, R. J., Jayalath, V. H., Cozma, A. I., Ha, S., et al. (2014). Dietary pulses, satiety and food intake: a systematic review and meta-analysis of acute feeding trials. Obesity 22, 1773–1780. doi: 10.1002/oby.20782

Mansour, E. H., Dworschk, E., Lugasi, A., Ga?l, O., Barna, E., and Gergely, A. (1993). Effect of processing on the antinutritive factors and nutritive value of rapeseed products. Food Chem. 47, 247–252. doi: 10.1016/0308-8146(93)90156-A

Marczak, E. D., Usui, H., Fujita, H., Yang, Y., Yokoo, M., Lipkowski, A. W., et al. (2003). New antihypertensive peptides isolated from rapeseed. Peptides 24, 791–798. doi: 10.1016/S0196-9781(03)00174-8

Moreno-González, M., Chuekitkumchorn, P., Silva, M., and Groenewoud, R. M. (2021). High throughput process development for the purification of rapeseed proteins napin and cruciferin by ion exchange chromatography. Food Bioprod. Process. 125, 228–241. doi: 10.1016/j.fbp.2020.11.011

Moure, A., Sineiro, J., Dom?nguez, H., and Paraj,?, J. C. (2006). Functionality of oilseed protein products: a review. Food Res. Int. 39, 945–963. doi: 10.1016/j.foodres.2006.07.002

Mozaffarian, D., Hao, T., Rimm, E. B., Willett, W. C., and Hu, F. B. (2011). Changes in diet and lifestyle and long-term weight gain in women and men. New Engl. J. Med. 364, 2392–2404. doi: 10.1056/NEJMoa1014296

Murray, D. E., Terrence, M. J., Barker, L. D., and Myers, C. D. (1980). Process for Isolation of Proteins Using Food Grade Salt Solutions at Specified pH and Ionic Strength. US4208323A, USA Patent 1980.

Mustafa, A. F., Christensen, D. A., and McKinnon, J. J. (1998). Effects of moist heat treatment on crude protein composition and degradability of field peas. Can. J Anim. Sci. 78, 453–456. doi: 10.4141/A97-093

Nega, T., and Woldes, Y. (2018). Review on nutritional limitations and opportunities of using rapeseed meal and other rape seed by-products in animal feeding. J. Nutr. Health Food Eng. 8, 43–48. doi: 10.15406/jnhfe.2018.08.00254

Nkosi, C. Z., Opoku, A. R., and Terblanche, S. E. (2005). Effect of pumpkin seed (Cucurbita pepo) protein isolate on the activity levels of certain plasma enzymes in CCl4-induced liver injury in low-protein fed rats. Phytother. Res. 19, 341–345. doi: 10.1002/ptr.1685

Nourmohammadi, E., Mahoonak, A. S., Alami, M., and Ghorbani, M. (2017). Amino acid composition and antioxidative properties of hydrolysed pumpkin (Cucurbita pepo L.) oil cake protein. Int. J. Food Prop. 20, 3244–3255. doi: 10.1080/10942912.2017.1283516

Olsen, S. H., and Hinge Andersen, J. (1978). The estimation of vicine and convicine in fababeans (Vicia faba L.) and isolated fababean proteins. J. Sci. Food Agri. 29, 323–331.

Paredes-Lopez, O., Ordorica-Falomir, C., and Olivares-Vazque, M. R. (1991). Chickpea protein isolates: physicochemical, functional and nutritional characterization. J. Food Sci. 56, 726–729. doi: 10.1111/j.1365-2621.1991.tb05367.x

Parodi, E., La Nasa, J., Ribechini, E., Petri, A., and Piccolo, O. (2021). Extraction of proteins and residual oil from flax (Linum usitatissimum), camelina (Camelina sativa), and sunflower (Helianthus annuus) oilseed press cakes. Biomass Conv. Bioref. 1–12. doi: 10.1007/s13399-021-01379-z

Phan, L., Brown, H., White, J., Hodgson, A., and Jessop, P. G. (2009). Soybean oil extraction and separation using switchable or expanded solvents. Green Chem. 11, 53–59. doi: 10.1039/B810423A

Pickardt, C., Eisner, P., Kammerer, D. R., and Carle, R. (2015). Pilot plant preparation of light-coloured protein isolates from de-oiled sunflower (Helianthus annuus L.) press cake by mild-acidic protein extraction and polyphenol adsorption. Food Hydrocolloids. 44, 208–219. doi: 10.1016/j.foodhyd.2014.09.020

Purohit, C., and Rajyalakshmi, P. (2011). Quality of products containing defatted groundnut cake flour. J. Food Sci. Technol. 48, 26–35. doi: 10.1007/s13197-010-0125-y

Ravindran, V., and Blair, R. (1992). Feed resources for poultry production in Asia and the Pacific. II. Plantprotein sources. World Poultry Sci. J. 48, 205–231. doi: 10.1079/WPS19920017

Rehder, A., Sulewska, A. M., Markedal, K. E., Sørensen, S., and Sørensen, J. C. (2017). Solubility of a cruciferin-rich protein product purified from rapeseed pressed cake (Brassica napus L.) by an aqueous processing method. Int. J. Food Sci. Technol. 52, 1653–1659. doi: 10.1111/ijfs.13446

Rommi, K., Hakala, T. K., Holopainen, U., Nordlund, E., Poutanen, K., and Lantto, R. (2014). Effect of enzyme-aided cell wall disintegration on protein extractability from intact and dehulled rapeseed (Brassica rapa L. and Brassica napus L.) press cakes. J. Agri. Food Chem. 62, 7989–7997. doi: 10.1021/jf501802e

Rommi, K., Holopainen, U., Pohjola, S., Hakala, T. K., Lantto, R., Poutanen, K., and Nordlund, E. (2015). Impact of particle size reduction and carbohydrate-hydrolyzing enzyme treatment on protein recovery from rapeseed (Brassica rapa L.) press cake. Food Biopress. Technol. 8, 2392–2399. doi: 10.1007/s11947-015-1587-8

Russin, T. A., Boye, J. I., Arcand, Y., and Rajamohamed, S. H. (2011). Alternative techniques for defatting soy: a practical review. Food Bioprocess Technol. 4, 200–223. doi: 10.1007/s.11947-010-0367-8

Sá, A. G. A., Moreno, Y. M. F., and Carciofi, B. A. M. (2020). Plant proteins as high-quality nutritional source for human diet. Trends Food Sci. Technol. 97, 170–184. doi: 10.1016/j.tifs.2020.01.011

Salgado, P. R., Drago, S. R., Molina Ortiz, S. E., Petruccelli, S., Andrich, O., Gonz?lez, R. J., et al. (2012). Production and characterization of sunflower (Helianthus annuus L.) protein-enriched products obtained at pilot plant scale. LWT–Food Sci. Technol. 45, 65–72. doi: 10.1016/j.lwt.2011.07.021

Sarker, A. K., Saha, D., Begum, H., Zaman, A., and Rahman, M. M. (2015). Comparison of cake compositions, pepsin digestibility and amino acids concentration of proteins isolated from black mustard and yellow mustard cakes. AMB Express 5, 1–6. doi: 10.1186/s13568-015-0110-y

Sarkis, J. R., Boussetta, N., Blouet, C., Tessaro, I. C., Marczak, L. D. F., and Vorobiev, E. (2015). Effect of pulsed electric fields and high voltage electrical discharges on polyphenol and protein extraction from sesame cake. Innov. Food Sci. Emerg. Technol. 29, 170–177. doi: 10.1016/j.ifset.2015.02.011

Sarwar, M. F., Sarwar, M. H., Sarwar, M., Qadri, N. A., and Moghal, S. (2013). The role of oilseeds nutrition in human health: A critical review. J. Cereals Oilseeds 4, 97–100. doi: 10.5897/JCO12.024

Savoire, R., Lanoisellé, J. L., and Vorobiev, E. (2012). Mechanical continuous oil expression from oilseeds: a review. Food Bioprocess Technol. 6, 1–16. doi: 10.1007/s11947-012-0947-x

Schaafsma, G. (2000). The protein digestibility–corrected amino acid score. J. Nutr. 130, 1865S−1867S. doi: 10.1093/jn/130.7.1865S

Shahidi, F. (1990). Canola and Rapeseed: Production, Chemistry, Nutrition, and Processing Technology. New York: Van Nostrand Reinhold.

Sicaire, A. G., Abert Vian, M., Fine, F., Carré, P., Tostain, S., and Chemat, F. (2015). Experimental approach versus COSMO-RS assisted solvent screening for predicting the solubility of rapeseed oil. OCL 22, D404. doi: 10.1051/ocl/2015010

Smith, K. (1986). “Advances in feeding soybean products,” in World Conference on Emerging Technologies in the Fats and Oils Industry, ed Baldwin, A. R. (IL: AOCS Press)

Srivastava, D., and Mathur, A. N. (2018). Use of de-oiled groundnut cake flour as an alternate source of nutrition. Int. J. Agric. Eng. 11, 150–152. doi: 10.15740/HAS/IJAE/11.1/150-152

Sunil, L., Appaiah, P., Prasanth Kumar, P. K., and Gopala Krishna, A. G. (2015). Preparation of food supplements from oilseed cakes. J. Food Sci.Technol. 52, 2998–3005. doi: 10.1007/s13197-014-1386-7

Sunil, L., Prakruthi, A., Prasanth Kumar, P. K., and Gopala Krishna, A. G. (2016). Development of health foods from oilseed cakes. J. Food Process Technol. 7, 1–6. doi: 10.4172/2157-7110.1000631

Švarc-Gajić, J., Morais, S., Delerue-Matos, C., Vieira, E. F., and Spigno, G. (2020). Valorization potential of oilseed cakes by subcritical water extraction. Appl. Sci.10, 8815. doi: 10.3390/app10248815

Tan, S. H., Mailer, R. J., Blanchard, C. L., and Agboola, S. O. (2011). Canola proteins for human consumption: extraction, profile, and functional properties. J. Food Sci. 76, R16–R28. doi: 10.1111/j.1750-3841.2010.01930.x

Tang, C. H., Ten, Z., Wang, X. S., and Yang, X. Q. (2006). Physicochemical and functional properties of hemp (Cannabis sativa L.) protein isolate. J. Agric. Food Chem. 54, 8945–8950. doi: 10.1021/jf0619176

Teh, S. S., Bekhit, A. E. D., Carne, A., and Birch, J. (2014). Effect of the defatting process, acid and alkali extraction on the physicochemical and functional properties of hemp, flax and canola seed cake protein isolates. J. Food Meas. Char. 8, 92–104. doi: 10.1007/s11694-013-9168-x

Teh, S. S., and Bekhit, A. E. D. A. (2015). “Utilization of oilseed cakes for human nutrition and health benefits,” in Agricultural Biomass Based Potential Materials (Cham: Springer), 191–229.

Vaštag, Z., Popović, L., Popovic, S., Krimer, V., and Pericin, D. (2011). Production of enzymatic hydrolysates with antioxidant and angiotensin-I converting enzyme inhibitory activity from pumpkin oil cake protein isolate. Food Chem. 124, 1316–1321. doi: 10.1016/j.foodchem.2010.07.062

Vasudha, C., and Sarla, L. (2021). Nutritional quality analysis of sunflower seed cake (SSC). Pharma Innov. J. 10, 720–728. doi: 10.22271/tpi.2021.v10.i4e.5957

Wang, X. S., Tang, C. H., Yang, X. Q., and Gao, W. R. (2008). Characterization, amino acid composition and in vitro digestibility of hemp (Cannabis sativa L.) proteins. Food Chem. 107, 11–18. doi: 10.1016/j.foodchem.2007.06.064

Wheeler, M. L., Fineberg, S. E., Fineberg, N. S., Gibson, R. G., and Hackward, L. L. (2002). Animal versus plant protein meals in individuals with type 2 diabetes and microalbuminuria: effects on renal, glycemic, and lipid parameters. Diab. Care 25, 1277–1282. doi: 10.2337/diacare.25.8.1277

Xu, L., and Diosady, L. L. (2002). Removal of phenolic compounds in the production of high-quality cano- la protein isolates. Food Res. Int. 35, 23–30. doi: 10.1016/S0963-9969(00)00159-9

Yang, M., and Zhu, W. H. C. (2021). Biorefinery methods for extraction of oil and protein from rubber seed. Bioresour. Bioprocess. 8:11. doi: 10.1186/s40643-021-00386-2

Keywords: oil seed cakes, by-products, protein, carbon, water foot print

Citation: Singh R, Langyan S, Sangwan S, Rohtagi B, Khandelwal A and Shrivastava M (2022) Protein for Human Consumption From Oilseed Cakes: A Review. Front. Sustain. Food Syst. 6:856401. doi: 10.3389/fsufs.2022.856401

Received: 17 January 2022; Accepted: 24 February 2022;

Published: 18 March 2022.

Edited by:

Ashish Rawson, Indian Institute of Food Processing Technology, IndiaReviewed by:

Jino Chacko, General Mills, United StatesCopyright © 2022 Singh, Langyan, Sangwan, Rohtagi, Khandelwal and Shrivastava. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Renu Singh, cmVudV9pY2FyQHlhaG9vLmNvbQ==; Sapna Langyan, c2luZ2guc2FwbmEwNkBnbWFpbC5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.