94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. Food Syst. , 12 January 2023

Sec. Agro-Food Safety

Volume 6 - 2022 | https://doi.org/10.3389/fsufs.2022.1091209

This article is part of the Research Topic Food Safety in Low and Middle Income Countries View all 25 articles

Ayalew Assefa1,2*

Ayalew Assefa1,2* Michel Dione3

Michel Dione3 Guy Ilboudo4

Guy Ilboudo4 Valerie Lallogo4

Valerie Lallogo4 Biruk Alemu Gemeda2

Biruk Alemu Gemeda2 Delia Grace5,6

Delia Grace5,6 Theodore J. D. Knight-Jones2

Theodore J. D. Knight-Jones2Introduction: In low- and middle-income countries, chicken serves as a cheap source of protein and an income source for many households. It is particularly important in the capital, Ouagadougou, Burkina Faso, where chicken is regularly consumed. However, hygiene standards are very low, posing a significant public health risk.

Methods: To better understand the food safety situation, we conducted a cross-sectional survey of the hygienic practices of 155 randomly selected chicken slaughter outlets and carcass shops with a semi-structured questionnaire.

Results and discussion: Of the outlets visited, 59% are not licensed, and 63% are not regularly inspected, operating in the dominant, largely unregulated informal sector. More than 80% of the chickens are sourced from village production systems, but around 6% of the birds die during transport. The monetary loss due to chicken death during transportation is around four million USD annually. Market hygiene is poor; 86% of the holding pens have no hard floor and are not washed regularly. Almost all (92%) chickens are slaughtered on bare earth floors; bleeding, plucking, and evisceration are done on a wooden table that is rarely washed. On average, the same scalding water is used for 33 birds, seven scalded at a time. Most respondents (49%) thought that plucking and evisceration were the major cause of contamination of carcasses with foodborne pathogens. Most operators only washed their hands and knives with tap water at the beginning of the slaughtering process. Some shops use refrigerators and freezers to store carcasses before selling. However, they store carcasses with other foods like fish, beef and vegetables, facilitating further cross-contamination. There were rats (26%), cats (39%) and dogs (30%) present at outlets, roaming for food, especially roadside outlets. Training schemes on hygienic food handling practices were favoured by outlets as an approach to improve matters; however, improvements in food safety will be limited without significant upgrades in infrastructure and facilities. Slaughter slabs need a standard house with stable energy, adequate airflow, clean water, toilets, detergents and freezers. Also, they need equipment like knives, tables and dishes made of high-quality, easy-to-clean materials.

Foodborne diseases cause a huge global socioeconomic and health burden. Each year one in 10 people get ill from contaminated food, resulting in 600 million illnesses, 420,000 deaths and the loss of 33 million healthy years of life globally, a burden comparable to tuberculosis or malaria (WHO, 2015). In Africa, with the highest foodborne disease (FBD) burden, the 31 foodborne hazards caused 1,200–1,300 DALYs per 100,000 individuals in which nearly 70% of the burden is estimated to be due to non-typhoidal Salmonella and Enteropathogenic and Enterotoxigenic Escherichia coli (Mensah et al., 2012; Makinde et al., 2020).

The burden of Foodborne diseases in low and middle-income countries is increasing. Besides health impact, food safety has become a precondition for access to global food markets and increasingly for high-value domestic markets in lower-income countries (Hoffmann et al., 2019). In Sub-Saharan Africa, the dominant informal food sector standards are absent or poor, with little regulatory oversight. Although animal products are at higher risk in terms of foodborne diseases, they are vital components of the diets and livelihoods of the undernourished majority across Sub-Saharan Africa. An improved supply of safe foods is needed to improve food security, with processing and slaughter particularly important with a high risk of microbial contamination of meat with feces and dirt or microbes from hands, equipment and surfaces (Roesel and Grace, 2014).

In urban settings, food selection is determined by availability, affordability, nutrition, and convenience (Wong et al., 2017). Chicken meat is widely consumed in Burkina Faso, especially in Ouagadougou, where it is regularly eaten in chicken restaurants (“maquis”), or cooked chicken is taken home, ready-to-eat, at the end of the working day and during celebrations and festivals (Dione et al., 2021). As well as being sold in restaurants, consumers, restaurants and hotels often buy raw chicken carcasses slaughtered and prepared at the market and roadside outlets. However, studies report high levels of bacterial contamination in these settings, with 90% of carcasses contaminated with Campylobacter species and 100% of carcass washing solutions being contaminated with Salmonella species (Kagambèga et al., 2018).

Previous studies from the same ILRI “Pull-Push project”1 found consumer concerns about chicken safety (Dione et al., 2021). Disease-causing microorganisms can jump at any stage in the food chain of chicken processing. Among these stages, slaughtering is a key where microbes can be introduced from slaughterers, the environment, working equipment or washing water. Keeping the process hygiene clean at this stage is critical in ensuring chicken safety for consumers. These include clean hands, equipment like knives and containers, clean water, appropriate sanitiser and a clean working environment like a clean table and surfaces can play a paramount role in chicken safety. However, existing standards and practices are poorly described. This information is needed to understand what is required to improve the situation. In light of this, we conducted a quantitative knowledge, attitude and practices (KAP) survey amongst chicken slaughter points and retailers in Ouagadougou.

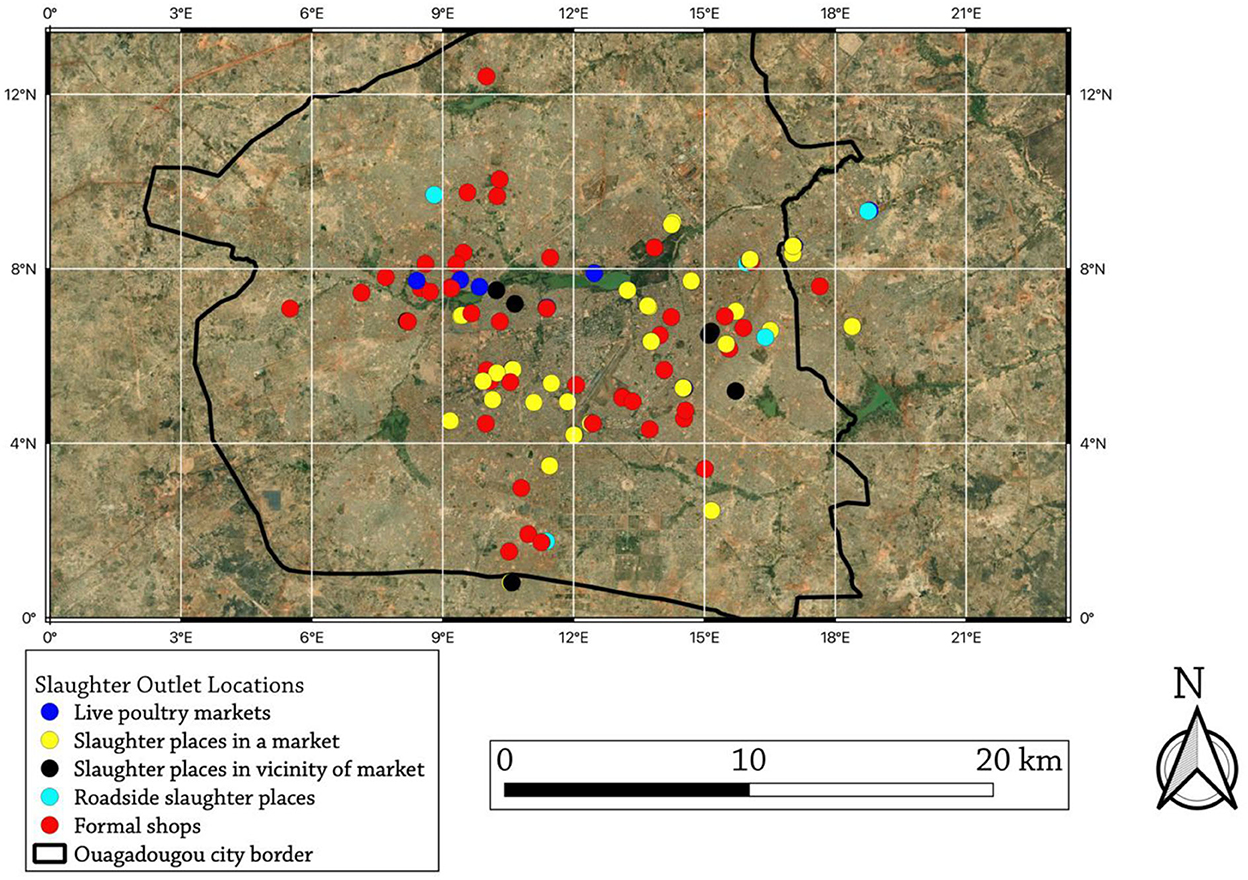

A cross-sectional survey with stratified sampling was carried out in Ouagadougou, the capital of Burkina Faso. First, chicken slaughter points in Ouagadougou were mapped to create a sampling frame in which the city's main roads were georeferenced, and a route was defined for trained enumerators. The enumerator then surveyed the route and recorded the location of each eligible outlet. At the end of the mapping, 81 live chicken markets and 273 chicken carcass outlets were recorded. The official list of markets in Ouagadougou was obtained from the municipal authorities to capture more outlets providing twenty-five (25) additional live chicken markets, each with many outlets, giving 106 live chicken markets. All markets with less than two sellers and without slaughtering sites were excluded, leaving 50 markets with 1,331 outlets (including those inside and outside markets). In a separate sampling stratum, there were 273 chicken carcass outlets (shops) with no chicken slaughtering. The inclusion criteria for the sampling frame were that an outlet has to slaughter chickens or at least have a slaughtering place or have to trade chicken carcasses. Based on that, a total of 155 outlets were included (Table 1). Of the 155 outlets included, 65 slaughter chickens themselves, 46 purchase carcasses from other outlets and re-sell them, while the rest 44 were involved in live poultry trading. However, these markets have slaughtering points so that chicken buyers can hire slaughterers and get their chickens slaughtered since there are many slaughter teams in a market. Some outlets have a slaughter team (young men) in which the outlet owner is often involved. Sampling points in the city are depicted in Figure 1.

Figure 1. Map with an expanded view of Ouagadougou showing locations of sampled chicken slaughter establishments.

A semi-structured questionnaire was delivered using tablets with Open Data Kit by trained enumerators. The survey consisted of three sections; (1) background information, including demographics, regulatory information and live bird source and trading, (2) process hygiene, including slaughtering, personal and processing practices; and (3) personal knowledge and perception of food safety.

A list of outlets was developed for each enumerator to visit over 21 days (conducted in June 2021). A list of extra outlets was selected and used to replace those who did not consent to the survey. Slaughter outlets were located using GPS information from the mapping exercise and visited. The questionnaire was administered to individuals working at the outlet knowledgeable about chicken slaughter and carcass handling practices.

The collected data with ODK-installed tablets were stored in a centralized hub and exported to MS Excel (Microsoft, 2021), cleaned and checked before analysis started. Then it was summarized with descriptive statistics using STATA 14 (STATA, 2016) and the summary of results was presented in tables and graphs.

Of the 155 participants, 128 (82.6%) were males, and most (104/155, 67%) were owners of the outlets. Only six (3.2%) participants had attended food safety related training (Table 2).

Only 57 (36.8%) participants held a license to trade chicken or an appropriate health certificate, while the rest were not authorized or licensed to work; also, only 41 (26.4%) reported that the authorities regularly inspected them. Outlets that slaughtered chickens kept live chickens for some time [1–5 days, average (mean) of 2 days] before slaughter. Besides, 80 (36.8%) kept other live animals at their slaughter slab or shop (Table 3), most commonly guinea fowl, turkey and ducks (Supplementary Table 1).

Outlet types were stratified by their involvement in chicken slaughter and trade. Based on this, most participants were from slaughter places in the market or adjacent to the market. Of the total outlets visited, 65 slaughtered chicken themselves, 46 purchase carcasses for retail, while the rest, 44, were involved only in live chicken marketing and hence not included in the slaughtering section (Table 4).

Sixty percent of the outlets transported chickens to the place of slaughter by motorbike, with tricycles and wooden cages used by 32 and 30% of outlets, respectively. The mean price of a live bird sold by an outlet is 2,328 XOF, equivalent to 3.5 USD (1 USD = 664.56 XOF as of September 2022 exchange rate); chicken sale prices varied between 1982 XOF to 3410 XOF (Table 5). The journey time from the bird's place of purchase to the outlet where it is slaughtered takes more than 12 h on average (mean) (7 h on the minimum and 22 h on the maximum) with a mean travel distance of 100 km. On average, 6% of the birds die during transport or within 12 h of arrival at their market and more than 3% of the birds become weak or sick after arrival (Table 5). Chickens typically stay at the outlet for 2 days before slaughter. From the 155 outlets, 65 (42%) slaughter chickens themselves, while 46 (30%) obtain carcasses from other slaughter slabs. The rest, 44 (28%), were involved only in live chicken trading but not slaughtering and carcass trading. On average, they slaughter 54 chickens per day (31–106). The majority (73.8%) (48/65) of outlets slaughter birds even if they are sick. They use various medicines to treat sick birds. Among the common medicines, antibiotics 30% and vitamin 10% are their favorites to treat sick birds (Table 6).

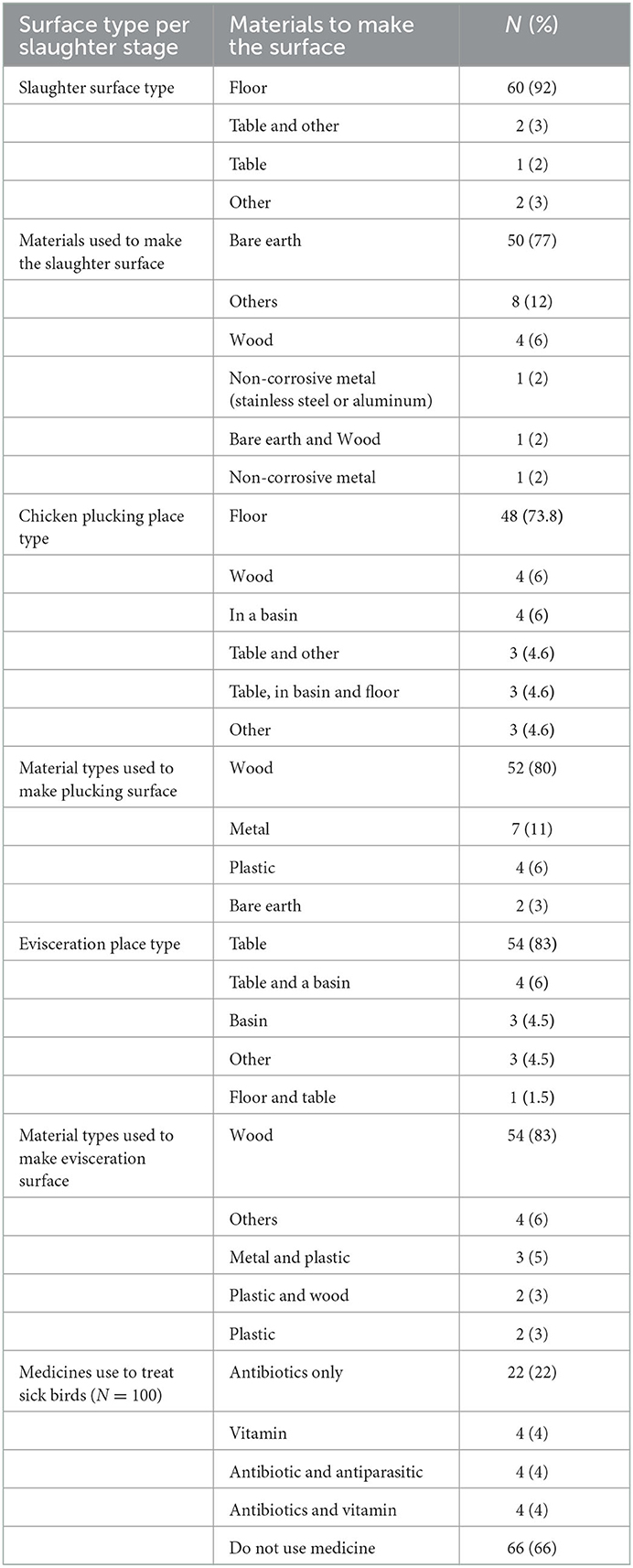

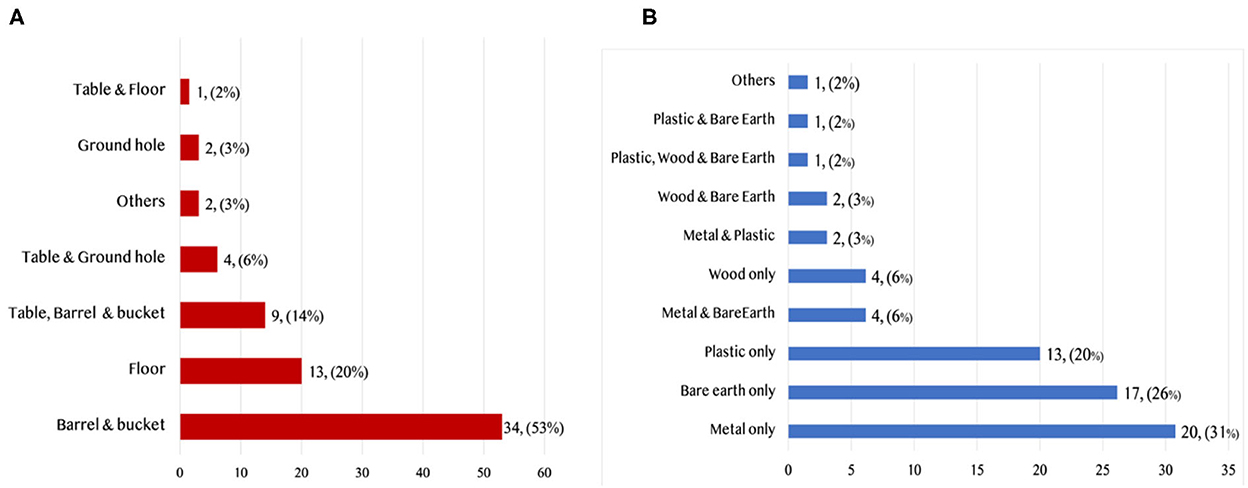

Table 6. Slaughtering, plucking and surface type and materials used to construct the surface (N = 65).

Sixty/sixty-five (92%) of the participants slaughter chickens on a bare earth floor (Table 6). Most slaughter slabs bled birds on the floor or in barrel containers (Figure 2A). The bleeding surfaces were mainly made of metal, plastic, or bare earth (Figure 2B). Most respondents said they dispose of blood and blood washings on-site or throw them away on the floor without proper disposal.

Figure 2. (A) Chicken bleeding surface types (N = 65), (B) materials used to make the bleeding surface (N = 65).

On average, 33 birds use the same scalding water, while seven birds are scalded at once in the scalding tank. The scalding water is changed once a day at most outlets. Outlets estimated that 25 L of water is used in the scalding tank; on average, nearly 20 outlets share the slaughtering site. Most of the respondents use a table as a plucking surface 48 (73.8%), which is made of wood 53 (70.7%) (Table 6). After removing the feathers (plucking), most slaughters (23%) dispose of them in a bin or dump them, e.g., on the street or in the market (20%) or a combination of the two (17%) (Supplementary Table 3).

After plucking, the next stage in carcass processing is evisceration. Most respondents (49%) do pluck and eviscerate in the same place; scalding and plucking were done at the same location in 12.3% of outlets. Among the concerning practices reported in this study was that 50% said that they just drop solid slaughter and processing waste on the ground, followed by outside the market and down the drain (Table 7).

Table 7. Cross-contamination possibilities through multiple steps performed at the same point, equipment washes and waste disposal methods (N = 65).

Most 22/65 (33.8%) of the respondents wash knives at the beginning of slaughter and the end of the day, while some 6/65 (9%) wash after each batch of chickens. A quarter of slaughterers wash their hands at the end of slaughtering, with fewer washing at the start (16%) (Supplementary Table 3). Most respondents (31%) use tap water to wash knives, followed by carcass rinse water (15.4%) and then store wash water (17%). Most respondents (52%) said they throw solid slaughter waste outside the market (not in a specified waste disposal site). Only seven (11%) prepare the waste material to be taken by waste collection services (Table 7).

Sixteen percent of outlets sell frozen chicken. For shops that purchase, freeze and resell carcasses, the mean transport time from place of purchase to their shop was 30 min. On average, they sell 77 chicken carcasses per week. They keep frozen chicken carcasses for about 35 days before selling them (Table 8).

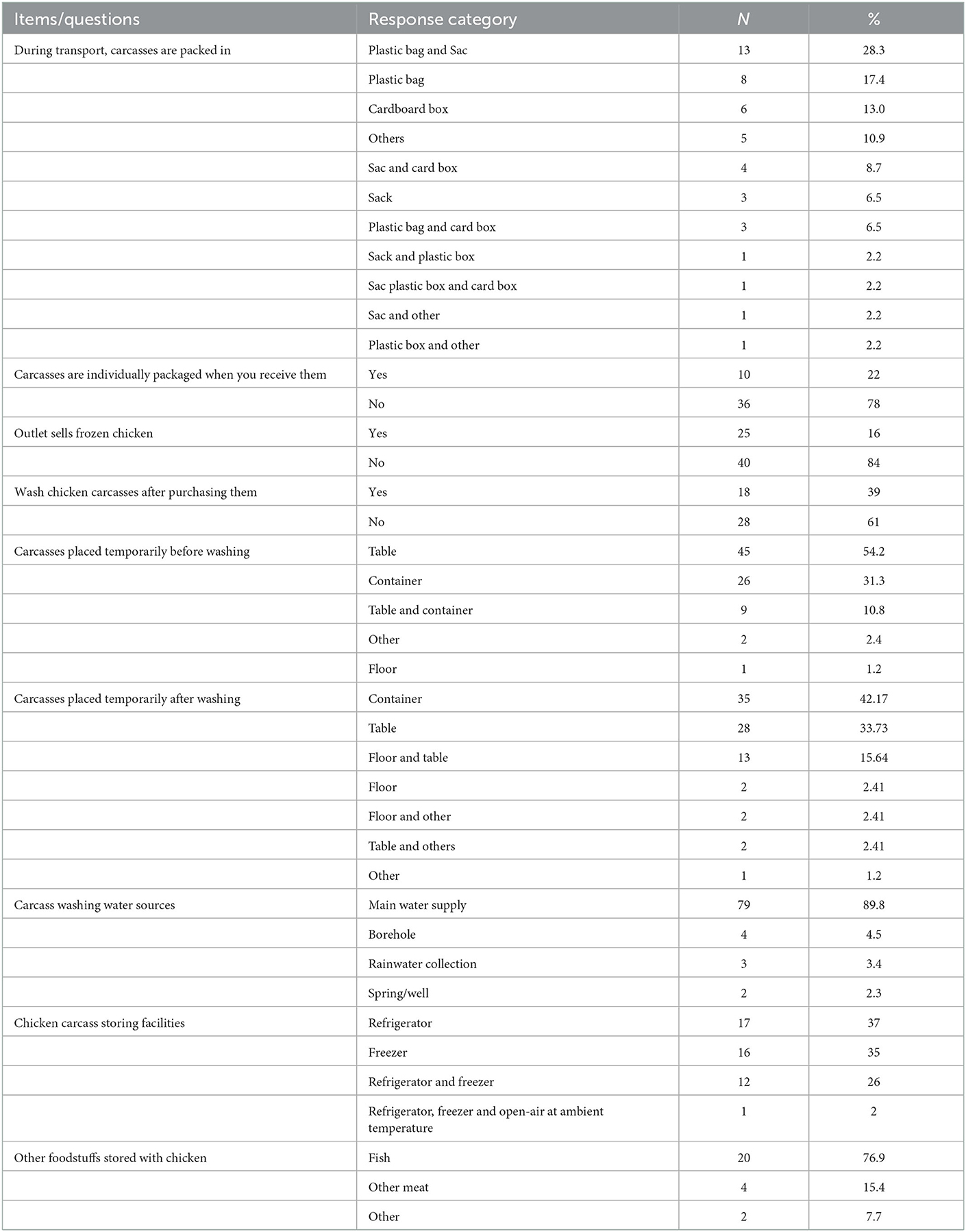

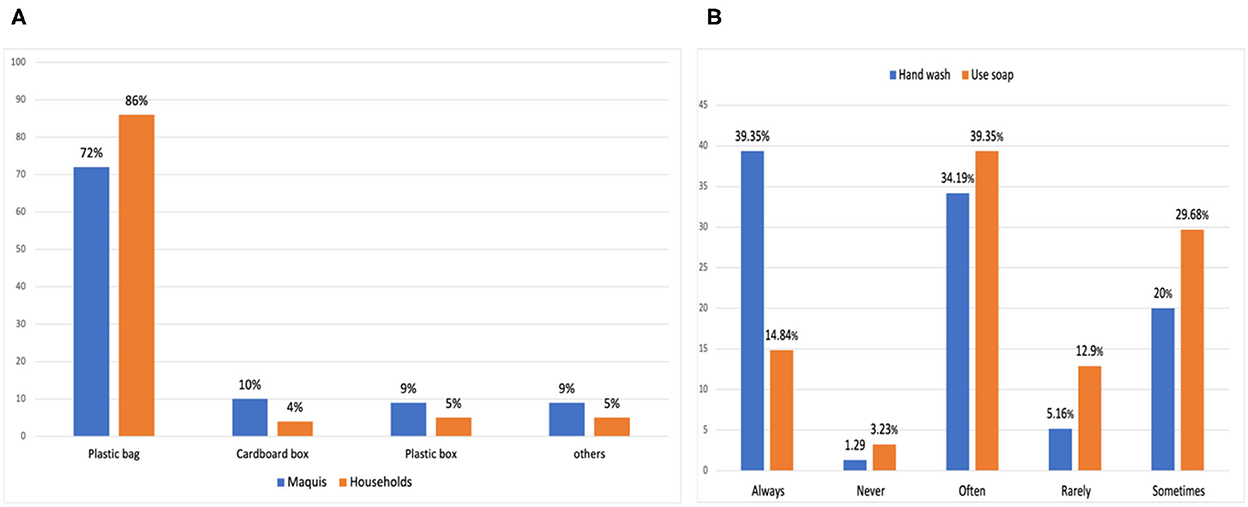

Only 22% said carcasses are individually packed when receiving them (Table 9). They use plastic bags followed by sacks and cardboard boxes to transport carcasses to households and street restaurants (“maquis”) (Figure 3A).

Table 9. Carcass storage, packaging, transport means and storage surfaces before and after washing and storage facilities.

Figure 3. (A) Percentage of carcass carrying materials during transport to deliver to households and restaurants/maquis (n = 65). (B) How often do respondents wash their hands (blue) and use soap (orange) during the working day (N = 155).

Only 40% of the participants said they washed carcasses before selling. Most respondents put the carcass on a wooden table before and after washing. They use the main water supply to wash the carcass. Carcasses are typically stored in refrigerators or freezers if kept for a prolonged period (37 and 35%, respectively). However, they keep fish and other meat together with the chicken carcass in the same refrigerator/freezer, and power cuts are frequent (Table 9).

Households are the leading customers of fresh chicken carcasses. Local breeds are the most commonly sold frozen chicken type, followed by imported broilers and locally reared improved breeds. Furthermore, households are the leading buyers of frozen chicken, followed by restaurants. Most (70%) of outlets said there is no refrigerated transportation mechanism for carcasses; 54% of the respondents said that carcasses come in contact with other carcasses during transportation (Table 9).

Out of the 46 carcass retailers, 17 (37%) wash carcasses immediately after receiving them, washing on-average 20 carcasses at a time. The majority (61/155, 39.5%) of the respondents frequently wash their hands with soap. However, 3% of participants admitted they never or rarely wash their hands (Figure 3B).

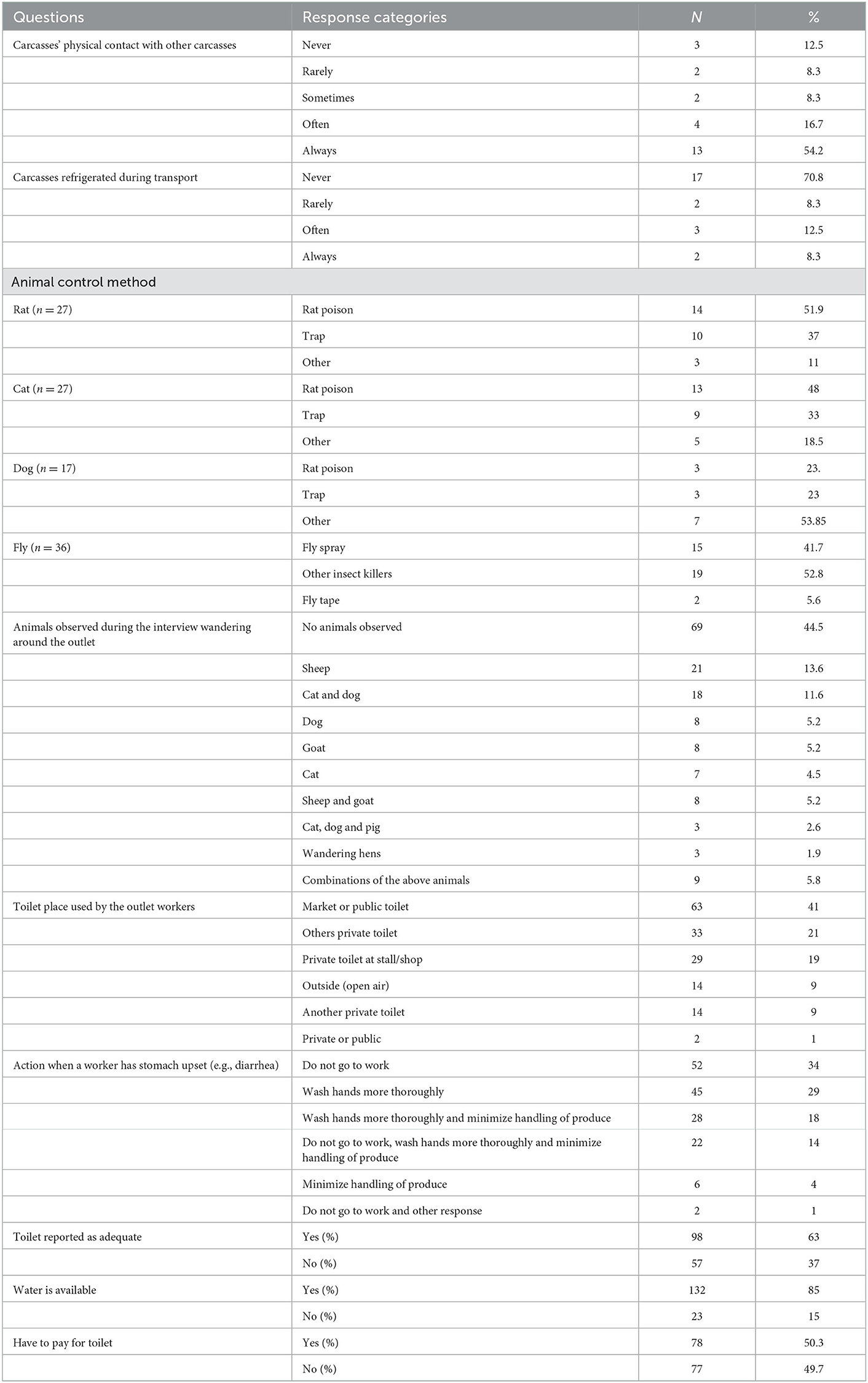

There were rats, cats and dogs roaming around certain outlets searching for food; from roadside outlets, 40/155 (26%) reported rats, 61/155 (39%) reported cats, and 47/155 (30%) reported that most of the time dogs will come close to food preparation surfaces. However, only 17, 17, and 10% have control measures for these pests, respectively. Poisons are the most common control method, followed by traps and other approaches like covering the carcasses tightly to prevent access. Also, they use fly sprays and other insect killers (Table 10). However, slaughter places in the market were free from rats, cats and dog visits, with zero reports of these animals from the informants (Supplementary Table 4).

Table 10. Carcass contact, frequency of using refrigerator, animal control methods, and animals observed during the interview.

Interviewers observed several animals during their visits. Among the animal species observed, sheep, cats, dogs, and goats were most often seen wandering around the outlets. Most informants had access to toilets and water, often in the market or a public toilet; 63% reported the toilet was adequate and 85% reported they had access to water at the toilet (Table 10).

Ninety percent of interviewees stated that they had not heard of food poisoning incidents from chicken consumption and knew that temperature is important for the safety of carcass storage. Furthermore, 98% know water hygiene is important for food safety (Figure 4).

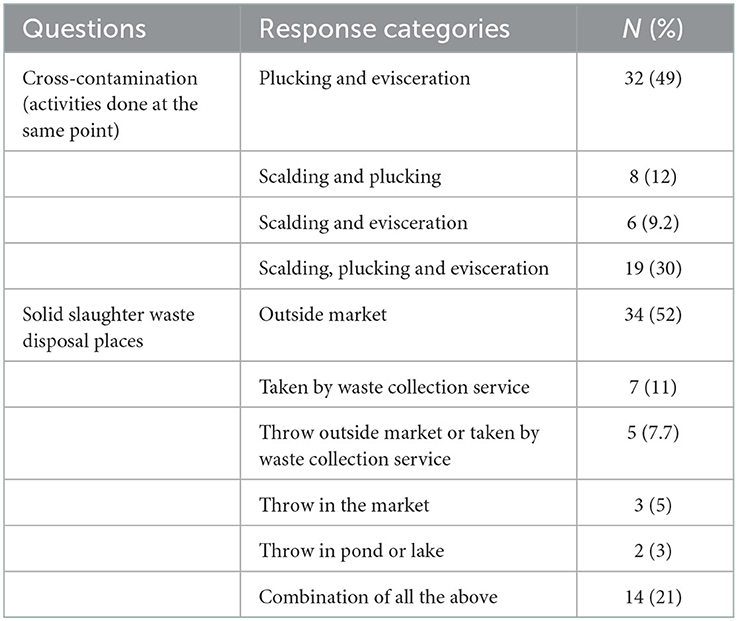

Chicken is a highly consumed animal source of food in Ouagadougou, Burkina Faso. However, the hygienic practice in slaughtering outlets and carcass shops is very poor (Figure 5). Among the risky sanitary practices and perceptions observed in this study, most participants were not licensed to work and were not regularly inspected by authorities; almost all workers have no training on food safety and related topics. Most outlets keep live chickens and other birds like guinea fowl, turkey, and ducks in and around outlets. Also, rodents and other mammals, such as cats, dogs and goats, many stressed and in poor health, are near food preparation areas creating a favorable environment for disease transmission. The house where birds stay before slaughtering is rarely washed or sanitized, exacerbating risks of transmission of zoonotic disease pathogens like avian influenza that could affect people and birds. The unhygienic handling practices in live markets before slaughtering can be a hotspot for the possible emergence of new pathogens that can cause local or global pandemics unless there is improvement in housing, marketing and transportation of birds in the city.

Figure 5. Typical carcass processing work environment. (As it can be observed from the picture, the working area has substandard hygiene levels; worker is not properly dressed (at least no gloves, shoes and mask), and the table is unclean and messed with different equipment and garbage. The washing water is not changed with an imminent probability of contaminating the carcasses. The ground is polluted and contaminated with visible dirt).

Various studies in chicken slaughtering, processing, and consumption in sub-Saharan African countries indicated below-standard chicken handling practices, in line with this study. Ovai et al. (2022) reported in Gahanna that consumers transport chicken meat with other items, store it in the same refrigerator, and have low hand and equipment washing habits. Birgen et al. (2020) have also discussed that chicken consumers in Kenya had a medium hygienic practice level. Also, many similar unhygienic practices were reported in street-vended chicken, and loads of bacterial contamination of chicken carcasses were found to be high due to poor handling practices. Also, the presence of pests and flies, contaminated vending places, lack of appropriate clothing and the use of unclean water to wash carcasses are the main malpractices that are causing cross-contamination in chicken slaughtering, vending and consumption chains (Hessel et al., 2019; Mpundu et al., 2019; Musawa et al., 2020).

Most slaughter outlets get chickens from local markets. On average, chickens travel more than 12 h to reach the city's market. During transportation, a large number of birds die due to stress-associated diseases. The mode of transport of the chickens to the slaughter point with birds hung together from motorbikes or other vehicles not only stresses the birds but also contributes to increased pathogen shedding and animal suffering; the close contact between the birds increases cross-contamination with fecal microbes such as Campylobacter species (Neri et al., 2019). Also, long-distance transportation is associated with an increased mortality rate of birds (Caffrey et al., 2017; Dos Santos et al., 2017, 2020). Around 6% of the birds die during transport or within 24 h of arrival. To have an intuitive of the loss due to death, we used a simple calculation to estimate the amount of the monetary loss in the city alone. According to Somda et al. (2018), 50,000 chickens are consumed daily in Ouagadougou. Eight per cent loss of this amount is around 3,000 chickens with an average estimate of chicken price of 2,328 XOF per bird; the daily loss in the city is XOF 7 million per day, equivalent to more than four million USD per year that instead have to contribute to the national economy. Not all of this loss is preventable—but it can easily be reduced with better transport, which will also reduce cross-contamination of birds with FBD pathogens like non-typhoidal Salmonella and Campylobacter, reduce stress which precipitates pathogen shedding and improve animal welfare.

If a bird is diseased during transport, they administer medications like antimicrobials, vitamins and antiparasitic drugs at the site. Inappropriate antimicrobial use without considering the withdrawal period poses a significant public health risk in terms of drug residue. Studies indicated that tetracyclines, aminoglycosides and fluoroquinolones are commonly used antimicrobial classes to treat various diseases in poultry in sub-Sahara Africa (Azabo et al., 2022). Various organisms that have veterinary and public health importance have been reported to develop antimicrobial resistance to these drugs mainly due to irresponsible use (Economou and Gousia, 2015). There were numerous diabolical practices with little to no concept of hygiene. Many outlets slaughter and sell sick chickens, a practice that poses significant risks to consumers. Food preparation surfaces were not food-grade; if they were cleaned, mostly they were not, they would still harbor high microbial loads. When there is cleaning, they rarely use detergents. Tap water alone will not eliminate microbes at an acceptable level. Strong detergents that have low residual risk to public health, like Lactic Acid, Acetic Acid, and Trisodium Phosphate sprays, must be used to effectively kill most pathogens from the surface, utensils and meat (Sallam et al., 2020; Nkosi et al., 2021).

Almost all of the tables used to slaughter, bleed, scald, and eviscerate chickens were made of either bare earth or wood. Many stages of slaughter and dressing, such as plucking and evisceration, were conducted in the same place or by the same person, with no cleaning of surfaces, equipment or hands. Slaughtering and dressing are the main sources of contamination (Althaus et al., 2017; Emanowicz et al., 2021). Plucking, which is removing the feather, can contaminate the worker's hand and, when done together with evisceration, can contaminate the carcass. Scalding and other activities should be segregated from evisceration to reduce cross-contamination because most contamination with pathogens like Salmonella spp., E. coli and Campylobacter species are introduced at the evisceration stage (Mpundu et al., 2019; Zeng et al., 2021). On average, twenty outlets share the same scalding water. Mixing different chickens will promote cross-contamination between birds, and the non-standardized approach to heating the scalding water would not ensure a consistently high temperature that would inactivate microbes. Certain disease causing agents are known to spread in scalding tanks unless additives are used to sterilize the water (Projahn et al., 2018; Mpundu et al., 2019). Scald additives like sodium hydroxide significantly reduce the bacterial load by creating an unsuitable alkaline environment in the tank, which must be practiced in slaughtering outlets visited and elsewhere (McKee et al., 2008). Most workers wash their hands and knives at the beginning of the day with only tap water, contributing to massive cross-contamination. Given the tenacity of some microbes, tap water alone cannot eliminate all pathogens unless standardized detergents are used. There was also an issue of environmental contamination with blood and feathers dumped near the site or in the market, exposing the public and animals to diseases and attracting vermin. Humans and free-rooming urban livestock can get infected from the inappropriately disposed waste and keep the disease transmission cycle alive (Cook et al., 2017).

From chicken carcass shops visited, a limited number of the outlets receive individual-packed carcasses, while most receive carcasses mingled. After receiving, less than half of the outlets wash before selling, contributing to cross-contamination between carcasses from single or multiple sources. They keep the cold chain by storing the carcass in refrigerators and freezers but with other foodstuffs, which can cause cross-contamination among foods. Even though cooking may kill most organisms, cross-contamination will happen without proper storage protocol. Rodents and pests could access food storage and preparation areas. Unhygienic and unmanaged places are likely to be visited by animals and insects carrying nasty zoonotic pathogens. The first line measure must manage the outlet by making it neat and hygienic, which is unfavoured by rodents and flies. However, they prefer to use unsafe approaches like poisons and insecticides, increasing the public health risk with active poisoning and long-term residual effects.

Although many described toilets as adequate, they are, in fact, little more than holes in the ground that are not cleaned, and given that most have to pay to use these toilets, open excretion is likely. Clean water with detergents is definitely among the easiest yet most effective measures to reduce foodborne diseases, but water is not available in most toilets, contributing to the poor hygiene of the working environment of the outlets. 34% do not go to work when workers feel sick, which is good practice. However, a significant number (29%) continue to work, posing risks to consumers through contamination with pathogens the sick worker may be shedding, which is exacerbated by the shortage of clean water in most outlets.

Even though most food safety practices were exceptionally poor, participants had some knowledge of basic food safety and hygiene requirements. They understood the importance of the cold chain, although carcasses were often kept at ambient temperatures. Chicken eaten in restaurants is typically thoroughly cooked, killing foodborne microbes. Given the poor upstream hygiene, this microbial kill-step before consumption is critical. However, massive microbial loads will be introduced into the food preparation area on the carcass, contaminating other foods stored or prepared with the chicken, such as salads commonly eaten with chicken. Cooked carcasses may also become re-contaminated through unwashed hands, utensils and surfaces. This is a problem in homes, where preparation practices will be highly variable, and children, the most vulnerable to foodborne disease, routinely eat at restaurants, where food poisoning can impact many customers.

Low income and lack of resources could account for the poor standards. However, some improvements could be made with little to no investment, such as processing in sequential, linear steps with separation of clean and dirty areas and wiping clean surfaces. However, the impact of such measures on food safety may be limited, given the lack of food-safety prerequisites, such as clean water, pest control, and clean and cleanable environments. Given that preventing cross-contamination of cooked and ready-to-eat food prepared at home and in restaurants and adequate cooking of meat are the main control points that will limit the impact of poor hygiene upstream, it is advisable to promote awareness of measures to ensure appropriate practices at these control points. The focus on reducing this risk is not on what the average person does but on reducing the percentage that does not apply appropriate measures or utilize particularly hazardous approaches.

Massive and preventable loss of birds was observed, through poor handling and transport, resulting in undue economic loss for the outlet and supply chain, and appalling animal welfare, in turn exacerbating zoonotic disease risks, including foodborne. Concerning food safety, standards are so poor and infrastructure so limited that major improvements would require massive investment to improve facilities and train slaughterers and other value chain actors, combined with an appropriate level of regulation. There are, in fact, many stages that intervention can be done to safeguard consumers from foodborne illnesses. The easiest and possibly cheapest measure can be awareness creation for workers because most faulty practices can be reverted with simple educational campaigns. Importantly there needs to be much greater consumer awareness of the dangers of eating unhygienically prepared food. This may create consumer demand for safer food, with market forces beginning to drive improvements and sustaining investments in improved food safety and infrastructure.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethical review and approval was not required for the study on human participants in accordance with the local legislation and institutional requirements. Written informed consent from the participants was not required to participate in this study in accordance with the national legislation and the institutional requirements.

AA: cleaned the data, performed analysis, and wrote the manuscript's draft. MD: developed survey tools and supervised the surveys. GI: trained enumerators and supervised and conducted the surveys. VL: trained enumerators and conducted the surveys. BG: participated in data analysis and commented on the first draft of the manuscript. DG: conceptualized the project. TK-J: conceptualized and supervised the overall project. All authors contributed to the article and approved the submitted version.

This study was funded by the Bill and Melinda Gates Foundation, UK Government Foreign, Commonwealth and Development Office (FCDO)—UK Aid from the United Kingdom government (INV-008430–OPP1195588) and the CGIAR Research Program on Agriculture for Nutrition and Health. The funder played no role in the design or conclusion of the study.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2022.1091209/full#supplementary-material

1. ^Urban food markets in Africa: Incentivising food safety using a Pull-Push approach www.ilri.org/research/projects/urban-food-markets-africa-incentivizing-food-safety-using-pull-push-approach.

Althaus, D., Zweifel, C., and Stephan, R. (2017). Analysis of a poultry slaughter process: influence of process stages on the microbiological contamination of broiler carcasses. Ital. J. Food Saf. 6, 190–194. doi: 10.4081/ijfs.2017.7097

Azabo, R., Dulle, F., Mshana, S. E., Matee, M., and Kimera, S. (2022). Antimicrobial use in cattle and poultry production on occurrence of multidrug resistant E. coli. A systematic review with focus on sub-Saharan Africa. Front. Vet. Sci. 9, 1625. doi: 10.3389/fvets.2022.1000457

Birgen, B. J., Njue, L. G., Kaindi, D. M., Ogutu, F. O., and Owade, J. O. (2020). Determinants of microbial contamination of street-vended chicken products sold in Nairobi County, Kenya. Int. J. Food Sci. 2020, 2746492. doi: 10.1155/2020/2746492

Caffrey, N. P., Dohoo, I. R., and Cockram, M. S. (2017). Factors affecting mortality risk during transportation of broiler chickens for slaughter in Atlantic Canada. Prevent. Vet. Med. 147, 199–208. doi: 10.1016/j.prevetmed.2017.09.011

Cook, E. A. J., de Glanville, W. A., Thomas, L. F., Kariuki, S., Bronsvoort, B. M. D. C., and Fèvre, E. M. (2017). Working conditions and public health risks in slaughterhouses in western Kenya. BMC Public Health 17, 1–12. doi: 10.1186/s12889-016-3923-y

Dione, M. M., Diarra, S., Ilboudo, G., Konkobo-Yameogo, C., Lallogo, V. R., Roesel, K., et al (2021). Value chain assessment of animal-source foods and vegetables in Ouagadougou, Burkina Faso–Considering food safety, quality and hygiene perceptions and practices. ILRI Research Report 87. Nirobi: ILRI. Available online at: https://cgspace.cgiar.org/handle/10568/117352

Dos Santos, V. M., Dallago, B. S., Racanicci, A. M., Santana, Â. P., Cue, R. I., and Bernal, F. E. (2020). Effect of transportation distances, seasons and crate microclimate on broiler chicken production losses. PLoS ONE 15, e0232004. doi: 10.1371/journal.pone.0232004

Dos Santos, V. M., Dallago, B. S. L., Racanicci, A. M. C., Santana, Â. P., and Bernal, F. E. M. (2017). Effects of season and distance during transport on broiler chicken meat. Poult. Sci. 96, 4270–4279. doi: 10.3382/ps/pex282

Economou, V., and Gousia, P. (2015). Agriculture and food animals as a source of antimicrobial-resistant bacteria. Infect. Drug Resist. 8, 49. doi: 10.2147/IDR.S55778

Emanowicz, M., Meade, J., Bolton, D., Golden, O., Gutierrez, M., Byrne, W., et al. (2021). The impact of key processing stages and flock variables on the prevalence and levels of Campylobacter on broiler carcasses. Food Microbiol. 95, 103688. doi: 10.1016/j.fm.2020.103688

Hessel, C. T., de Oliveira Elias, S., Pessoa, J. P., Zanin, L. M., Stedefeldt, E., and Tondo, E. C. (2019). Food safety behavior and handling practices during purchase, preparation, storage and consumption of chicken meat and eggs. Food Res. Int. 125, 108631. doi: 10.1016/j.foodres.2019.108631

Hoffmann, V., Moser, C., and Saak, A. (2019). Food safety in low and middle-income countries: the evidence through an economic lens. World Dev. 123, 104611. doi: 10.1016/j.worlddev.2019.104611

Kagambèga, A., Thibodeau, A., Trinetta, V., Soro, D. K., Sama, F. N., Bako, É., et al. (2018). Salmonella spp. and Campylobacter spp. in poultry feces and carcasses in Ouagadougou, Burkina Faso. Food Sci. Nutr. 6, 1601–1606. doi: 10.1002/fsn3.725

Makinde, O. M., Ayeni, K. I., Sulyok, M., Krska, R., Adeleke, R. A., and Ezekiel, C. N. (2020). Microbiological safety of ready-to-eat foods in low- and middle-income countries: a comprehensive 10-year (2009–2018) review. Compreh. Rev. Food Sci. Food Saf. 19, 703–732. doi: 10.1111/1541-4337.12533

McKee, S. R., Townsend, J. C., and Bilgili, S. F. (2008). Use of a scald additive to reduce levels of salmonella typhimurium during poultry processing. Poult. Sci. 87, 1672–1677. doi: 10.3382/ps.2008-00061

Mensah, P., Mwamakamba, L., Kariuki, S., Fonkoua, M. C., and Aidara-Kane, A. (2012). Strengthening foodborne diseases surveillance in the who African region: an essential need for disease. Afr. J. Food Agric. Nutr. Dev. 12, 6336–6353. doi: 10.18697/ajfand.52.WHO-7

Mpundu, P., Mbewe, A. R., Muma, J. B., Zgambo, J., and Munyeme, M. (2019). Evaluation of bacterial contamination in dressed chickens in Lusaka abattoirs. Front. Public Health 7, 19. doi: 10.3389/fpubh.2019.00019

Musawa, I. A., Yakubu, Y., Garba, B., Ballah, F. M., Jibril, H. A., Bello, A. S., et al. (2020). Dressed chicken as potential vehicle for spread of methicillin-resistant Staphylococcus aureus in Sokoto, Nigeria. Fut. Sci. OA 6, FSO619. doi: 10.2144/fsoa-2020-0066

Neri, D., Di Giannatale, E., Di Serafino, G., Persiani, T., Romantini, R., Santarelli, G. A., et al. (2019). Study on the effects of transport stress on fecal shedding and poultry meat contamination from Campylobacter spp. Int. J. Infect. Dis. 79, 76. doi: 10.1016/j.ijid.2018.11.192

Nkosi, D. V., Bekker, J. L., and Hoffman, L. C. (2021). The use of organic acids (lactic and acetic) as a microbial decontaminant during the slaughter of meat animal species: a review. Foods 10, 2293. doi: 10.3390/foods10102293

Ovai, B., Kunadu, A. P. H., Gake, N., Doku, C., and Otwey, R. Y. (2022). Food safety risk factors associated with chicken consumption and chicken handling practices in Accra, Ghana. Sci. Afr. 16, e01263. doi: 10.1016/j.sciaf.2022.e01263

Projahn, M., Pacholewicz, E., Becker, E., Correia-Carreira, G., Bandick, N., and Kaesbohrer, A. (2018). Reviewing interventions against enterobacteriaceae in broiler processing: using old techniques for meeting the new challenges of ESBL E. coli. BioMed. Res. Int. 2018, 9346. doi: 10.1155/2018/7309346

Roesel, K., and Grace, D. (2014). Food Safety and Informal Markets, Food Safety and Informal Markets. London: Routledge. doi: 10.4324/9781315745046

Sallam, K. I., Abd-Elghany, S. M., Hussein, M. A., Imre, K., Morar, A., Morshdy, A. E., et al. (2020). Microbial decontamination of beef carcass surfaces by lactic acid, acetic acid, and trisodium phosphate sprays. BioMed. Res. Int. 2020, 2324358. doi: 10.1155/2020/2324358

Somda, N. S., Bonkoungou, O. J., Zongo, C., Kagambèga, A., Bassol,é, I. H., Traor,é, Y., et al. (2018). Safety of ready-to-eat chicken in Burkina Faso: microbiological quality, antibiotic resistance, and virulence genes in Escherichia coli isolated from chicken samples of Ouagadougou. Food Sci. Nutr. 6, 1077–1084. doi: 10.1002/fsn3.650

WHO (2015). WHO Estimates of the Global Burden of Foodborne Diseases: Foodborne Disease Burden Epidemiology Reference Group 2007–2015. Geneva: WHO. Available online at: https://apps.who.int/iris/bitstream/handle/10665/199350/?sequence=1 (accessed February 9, 2022).

Wong, J. T., de Bruyn, J., Bagnol, B., Grieve, H., Li, M., Pym, R., et al. (2017). Small-scale poultry and food security in resource-poor settings: a review. Glob. Food Sec. 15, 43–52. doi: 10.1016/j.gfs.2017.04.003

Keywords: chickens, food safety, KAP, Ouagadougou (Burkina Faso), slaughter outlets

Citation: Assefa A, Dione M, Ilboudo G, Lallogo V, Gemeda BA, Grace D and Knight-Jones TJD (2023) Quantitative analysis of knowledge, attitude and practice of workers in chicken slaughter slabs toward food safety and hygiene in Ouagadougou, Burkina Faso. Front. Sustain. Food Syst. 6:1091209. doi: 10.3389/fsufs.2022.1091209

Received: 06 November 2022; Accepted: 29 December 2022;

Published: 12 January 2023.

Edited by:

Karl Matthews, Rutgers, The State University of New Jersey, United StatesReviewed by:

Agnes Kilonzo-Nthenge, Tennessee State University, United StatesCopyright © 2023 Assefa, Dione, Ilboudo, Lallogo, Gemeda, Grace and Knight-Jones. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ayalew Assefa,  QXlhbGV3LkFzc2VmYUBjZ2lhci5vcmc=

QXlhbGV3LkFzc2VmYUBjZ2lhci5vcmc=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.