- Department of Soil, Plant and Food Science, University of Bari Aldo Moro, Bari, Italy

While the paradigm of circular economy (CE) and the processes of socio-technical transition have been broadly investigated at the theoretical level, understanding how the transition toward circular models can be implemented in practice is still limited. This contribution aims to provide in-depth and evidence-based insights on an emerging pathway for the operability of CE into the olive oil supply chain. A case study from the Apulia region (the leading olive oil producing area in Italy) is presented to show how an existing business model can be transformed into a circular one, and to what extent it can be replicated. The study focuses on a vertically integrated firm, in which a new industrial process has been introduced to manage olive pomace, which is one of the most important by-products obtained from olive oil extraction. The empirical analysis is built on the Circular Business Model Canvas (CBMC), which is conceived as a suitable theoretical and methodological tool to speed up the transition process toward CE at a micro-economic level. This analytical framework allows us to identify the interplaying elements that the firm combines to capture, create, and deliver value, as well as the relationships with the broader economic system. Particular attention is paid to two distinctive components of CBMC: material loops and adoption factors. Also, internal and external factors affecting the adoption of the new circular business model have been discussed by separating drivers and barriers of the transition process.

Introduction

The paradigm of circular economy (CE) has gained a prominent role in addressing the transition toward more sustainable, clean, and regenerative agri-food systems. The CE emerges as a plausible and promising strategy to overcome the shortcomings and environmental impacts of the business-as-usual linear system (Esposito et al., 2020). Such strategy is based on the guiding principles of (i) designing out waste from production and consumption patterns; (ii) optimizing the resource-use efficiency; (iii) preserving and restoring the natural capital; and (iv) enhancing the whole system efficiency (Ellen MacArthur Foundation, 2013b). The Ellen MacArthur Foundation (EMF) offered the most recognized definition of the CE as “an industrial system that is restorative or regenerative by intention and design” (Ellen MacArthur Foundation, 2013a). However, many other definitions have been provided and critically analyzed in the academic literature (Kirchherr et al., 2017; Awan et al., 2020; Borrello et al., 2020; Jäger-Roschko and Petersen, 2022). The core idea of the EMF's CE vision is, on one side, maintaining the use within the technical cycle of finite, non-biodegradable materials, products, and components (together with the imbedded energy), as long as possible and at their highest value; on the other side, reincorporating into the biosphere, directly or in a cascade of consecutive uses, biodegradable materials that are renewable by nature, in order to recirculate them within the biological cycle (MacArthur et al., 2015). The ultimate objectives are to minimize the use of virgin resources, the amount of waste and systemic leakages, the harmful emissions, and negative externalities upstream and downstream, thus reducing the pressures on the planetary carrying capacity. In addition, economic prosperity is upheld by the opportunity of creating new value chains by reusing, recycling, and cascading end-of-life resources. While conceptualizations of CE are increasingly emerging, potentially weak points of the CE, as those highlighted in recent works (Niero et al., 2021; Morseletto, 2022), point to unintended side effects on environmental sustainability.

Moving to a CE has been increasingly mainstreamed at an institutional level and supported in the policy agenda of the European Union (EU), as a main cross-cutting strategy to realize ecological transition: in the first instance by means of the new Circular Economy Action Plan (European Commission, 2020a) and the Farm to Fork Strategy (European Commission, 2020b), both of which are main pillars of the European Green Deal (European Commission, 2019). CE is also included under the environmental and climate objectives of Next Generation EU (NGEU) (European Commission, 2020c). NGEU is a temporary policy instrument designed to boost the recovery of the European economy after the pandemic crisis. It is the largest stimulus package ever financed in the EU (€2.018 trillion in current prices) for a greener, more digital, and more resilient Europe.

Besides, ever-pressing constraints (i.e., raw materials accessibility and price volatility) and market drivers (i.e., growing demand for more sustainable products) are strongly impacting the managerial mindset and the ways businesses look at resource use and value creation. We are thus facing an unprecedented scenario to accelerate the transition toward CE.

However, progress toward a robust implementation of CE in the industry is still under scrutiny (De Angelis, 2022). Although the concept of CE has been broadly explored at a theoretical level (Geissdoerfer et al., 2017; Kirchherr et al., 2017; Korhonen et al., 2018; Reike et al., 2018), how to implement such a promising paradigm in practice, in different production systems and territorial contexts, has witnessed lesser efforts. Indeed, there is a literature gap in empirical studies regarding the adoption of new business models within the context of CE (Antikainen and Valkokari, 2016; Piispanen et al., 2020). Moreover, the CE framework has not yet been comprehensively adapted to specific fields such as that of agri-food systems (Batlles-delaFuente et al., 2022), although they represent the most important supply chains for the consumer good industry (Ellen MacArthur Foundation, 2013a).

This work contributes to building the empirically grounded, scientific knowledge needed to foster practical transition processes in the agri-food sector (Esposito et al., 2020; Batlles-delaFuente et al., 2022; De Angelis, 2022). It examines, in-depth, a promising pathway for applying CE into the olive oil supply chain, which is economically relevant in the Mediterranean region. The work focuses on a real case study, which is represented by a vertically integrated firm located in the Apulia region (the most important olive oil producing area in Italy).

The research aims to investigate a successful circular solution for tackling the manifold problems related to the disposal of a main olive oil by-product, namely, wet olive pomace. The case is a good example of innovation and adaptation at the firm level that leads to close material loops locally, making circular the whole company's business model. In this regard, the circular pathway undertaken allows to close the loop with soil for a truly regenerative practice as envisaged in Morseletto (2020).

The study shows how the considered business model works and discusses the conditions for its replicability. Also, the research contributes to validating the applicability of the circular business model canvas (CBMC) as a conceptual and analytical framework (Lewandowski, 2016). It contributes to filling the gap in the literature of few empirical cases adopting the CBMC, especially in the agri-food sector.

Background

Business model innovation for circular transition

The whole olive oil supply chain has a great potential for achieving a circular shift, given the huge amounts of residues and by-products that it generates. Previous studies estimated that the European olive oil producing system overall generates 21 million tons of biomass yearly, 9.6 million tons of which derive solely from the milling stage (Berbel and Posadillo, 2018). In Italy, 2.5–3 million tons of organic by-products result yearly from olive mills.

A range of interesting valorization options for such by-products have been already proposed, including: recovering bioactive compounds; producing biofuel or bioenergy; manufacturing sustainable building materials; fertilizing or irrigating soil; practicing regenerative agriculture; feeding livestock; producing polymeric biomaterials; providing sorbents for aqueous effluents; synthetizing bio-fertilizers or bio-stimulants (Stempfle et al., 2021; Chojnacka et al., 2022). However, material recirculation, which is at the foundation of CE models, is not always feasible because of several technical and/or economic reasons (Donner and Radić, 2021).

Recovering and valorizing olive oil by-products in a circular perspective require radical and systemic changes to overcome cultural, technological, market, and regulatory barriers (Kirchherr et al., 2017) at all stages of the olive oil supply chain. Therefore, firms are seen as crucial actors in pushing the transition toward CE at the micro-economic level (Vermunt et al., 2019; Donner et al., 2022), because they often must transform radically their operational patterns (Urbinati et al., 2017) by adopting and bringing eco-innovations to the market (De Jesus et al., 2018; Böckin et al., 2022). From a business-driven transition perspective, designing new business models plays a key role in implementing the paradigmatic shift into CE (Geissdoerfer et al., 2020).

A business model (BM) is a conceptual construct that was developed in management theory to describe how a firm captures, creates, and delivers value, through the utilization and conversion of resources (Hofmann, 2019). The BM helps to recognize the key bottleneck assets for doing business activities depending on the firm's position along the supply chain (Teece, 2010). Moreover, the BM contributes to identifying the links between a single firm and the larger production and consumption system in which it operates (Boons et al., 2013).

A wide body of literature refers to business model innovation as the development of a BM that is novel to the firm and perceived as such by customers, by changing one or more of its components (Frankenberger et al., 2013; Planing, 2018). In the realm of CE, business model innovation can be understood as the process of re-designing a BM with and within closed material loops (Mentink, 2014). In the last years, academic research has increasingly focused on Circular Business Models (CBMs), which emerged as a specific sub-category of sustainable business models (Bocken et al., 2014) incorporating CE principles. Although a commonly agreed definition has not been formulated, CBMs can be identified as eco-innovative BMs that apply strategies of closing, narrowing, slowing, or regenerating material loops (Bocken et al., 2016). More specifically, the conceptual logic for value creation in a CBM is based on utilizing the economic value retained in products after use in the production of new offerings (Linder and Williander, 2017).

Framing the problem of managing by-products at the mill stage

The olive oil by-products resulting from the milling stage are among the most troubling and challenging to manage, both on the organizational and environmental sides. Organizational issues are mainly due to their producing conditions, since they are seasonally generated in huge amounts and in a few months, and due to their logistic issues, since they are difficult to stock and transport. Environmental problems are related to their biochemical composition, which is characterized by a high content of polyphenols with polluting and phytotoxic properties, so potentially harmful for soil and groundwater if improperly discarded. Further constraints derive from legislation that requires short timeframes and a bureaucratic burden to manage such by-products safely.

Various kinds of by-products derived from the different olive oil extraction methods are employable. The continuous three-phase extraction process, most prevalent over the last decades, generates two distinct by-products: dry pomace with 50−55% humidity (about 400–550 kg per ton of processed olives) and wastewater (about 800–950 kg per ton of processed olives). Traditionally, such by-products found some consolidated destinations: the former is used by refineries for pomace oil extraction, while the latter is spread on farmland. Such destinations based on the recovery of residual value and reuse can be framed as examples of circular practices. However, the recirculation of organic matter into the biosphere is limited since exhausted pomace is usually burned in biomass plants to produce energy. Besides, the effect of wastewater on the soil and groundwater is not clearly assessed, also considering that huge amounts of such effluent are discarded in a short timeframe, not always according to correct agronomic practices.

In recent years, the continuous two-phase extraction method has become increasingly widespread, strongly encouraged by the machinery industry, and also welcomed by many olive millers, thanks to the improved product quality and process efficiency. Such technology allows considerable savings of process water and generates a unique by-product, namely, wet olive pomace, in the amount of about 80−85% of the processed olives' mass. Wet pomace is a slurry, dark-brown effluent consisting of a mixture of crushed olive pulp, skin, stones, and residual water, with a humidity rate of 60−65% (Tamborrino et al., 2021a). Thanks to the recently introduced pitting machinery, wet pomace can be easily destoned to extract up to 60−70% of the stone fragments of the olives (20 kg of stone/100 kg olives), which can be sold as a solid fuel for feeding stoves and boilers for both domestic and industrial use. The relatively high market value of such biomass ensures revenues that can fully cover the extraction cost. Therefore, the pitting operation is broadly carried out, decreasing the volume of wet pomace by about 15% (Leone et al., 2015).

However, dealing with the remaining huge quantity of effluent remains a big concern for olive millers. Olive pomace must be rapidly disposed of to avoid blocking the milling activities, but since it is highly fermentable, it cannot be easily stored for a long time. Differently from the triphasic dry pomace, the biphasic wet one is not accepted by pomace oil refineries due to its high humidity: it needs a drying pre-treating process which is highly energy-consuming.

Therefore, in compliance with the Italian law, olive mills should equip themselves with treatment plants that are able to separate reclaimed water, usable for irrigation purposes, from sewage sludges, that must be properly discarded. However, this option is usually not pursued because of the elevated costs.

Alternatively, wet pomace can be spread on farmlands as a soil conditioner and fertilizer, within the legal limits of 80 tons per hectare and the timespan of 1 month after production. However, the agronomic use of such by-products must also comply with rational spreading standards, according to the conditions of the sites intended to receive them (pedological, geomorphological, hydrologic, and agro-environmental features). In wintertime, when olive mill by-products are usually produced, further problems may arise because of weather conditions that can often be unfavorable to spreading practices. If so, olive mills without stocking capacity are even forced to halt production until disposal of the pomace is once again possible.

As established by the latest legislative measure (Ministerial Decree No. 264 of 13 October 2016), a third possible way to use wet pomace for energy production, as a matrix for feeding biomass power plants based on thermochemical conversion process (combustion), or biogas plants based on biochemical conversion process (anaerobic digestion). Anaerobic digestion appears more and more as a valid alternative for reusing agri-food waste (Catalano et al., 2021), also in light of a more recent Italian law (Law no. 51 of 20 May 2022), which promotes and regulates the use of digestate (the by-product obtained from anaerobic digestion) for agricultural purposes in the replacement of chemical fertilizers.

Research methodology

Aiming at providing theoretically and empirically grounded insights about a meaningful pathway for implementing CE into the olive oil supply chain, the research methodology is based on a case study approach. This research method is particularly relevant for understanding “how” and “why” complex social phenomena work, by exploring real-life events extensively and in-depth (Yin, 2003).

Among other research areas, the case study approach is commonly employed in business studies to analyze organizational and managerial processes and to a lesser extent in the economic field to analyze the structure of a given entity (Yin, 2003).

In this study, the empirical analysis focuses on a circular business model in the realm of the olive oil supply chain and explores its technological and economic aspects, as well as the main factors affecting the innovation development. The research was carried out following four steps: (i) case study selection; (ii) data collection; (iii) data analysis; and (iv) reporting.

Case study selection

Case study selection was guided by two criteria: geographical location and typology of the circular pathway enacted. The selected firm is in the Apulia region, which is the most important olive oil producing area in Italy, accounting for about 25% of olive-growing farms, 33% of olive groves, and 50% of olive oil production at the national level (data from the Agricultural Census ISTAT, 2011; ISMEA, 2021). Energetic valorization was elected as the circular pathway to focus on, since it is thematically dominant in scientific literature inquiring about the implementation of CE into the olive oil supply chain (Stempfle et al., 2021). Besides, energy crisis and independence from fossil fuels have become more and more relevant topics as also demonstrated by the recent geopolitical events (Russia-Ukraine crisis) that have highlighted the great vulnerability of the global energy supply chain due to the propagation of trade-related risks and price volatility, and the need to maintain this supply chain resilient using long-term approaches such as the recycling and circular strategy (Sun, 2022).

The case study is represented by a leading firm in olive oil production, with a portfolio of diversified activities. Recently, the firm installed an anaerobic digestion plant for biogas production only fueled with olive pomace. In Apulia, along with a smaller biogas plant 100% powered with multi-phasic olive pulp (Tamborrino et al., 2021b), it is the only industrial-scale facility that anaerobically digests olive oil by-products. Moreover, it is the only European case of a biogas plant exclusively fed with biphasic wet pomace.

Therefore, the case study was considered particularly suitable for the research topic, specifically for the opportunity of investigating how an existing BM can be transformed into a circular one.

Data collection

The data informing the case study were collected by means of interviews, site visits, as well as gray and scholarly literature examination. Interviews were held between December 2021 and May 2022 with a representative of the firm and one of its head technicians.

First, two qualitative open interviews took place, accompanied by site visits. The interviews were completely unstructured, and progressed in a conversational style, with few non-prefixed open-questions to bring up the case-related narrative and the most important aspects from the practitioners' internal viewpoint. The aim was to obtain the richest and broadest information possible, including subjective interpretations and meanings about apparently peripheral topics without leading the witness, to address a deep understanding of the BM.

Then, a desk research based on the scrutiny of newspaper articles, documents, websites, and scientific literature was also performed to acquire further information.

Finally, two additional interviews were conducted: a qualitative, semi-structured one, guided by a checklist of open-ended questions intended to cover all the topics relevant to the study; a structured one for gaining quantitative and technical information specifically related to the olive mill and the biogas plant.

Analysis

Innovations at the micro-economic level can be effectively analyzed when building on the concepts of BM and BM innovation. Specific analytical tools have been created to identify the interplaying elements that a firm mobilizes to create value on an economic, ecological, and social level. The best-known and proven one is the business model canvas (BMC) (Osterwalder and Pigneur, 2010), which is organized in nine building blocks to characterize each mobilized element, as well as to understand how they relate to each other, to the larger operational environment, and to the technological development trajectories (Teece, 2010).

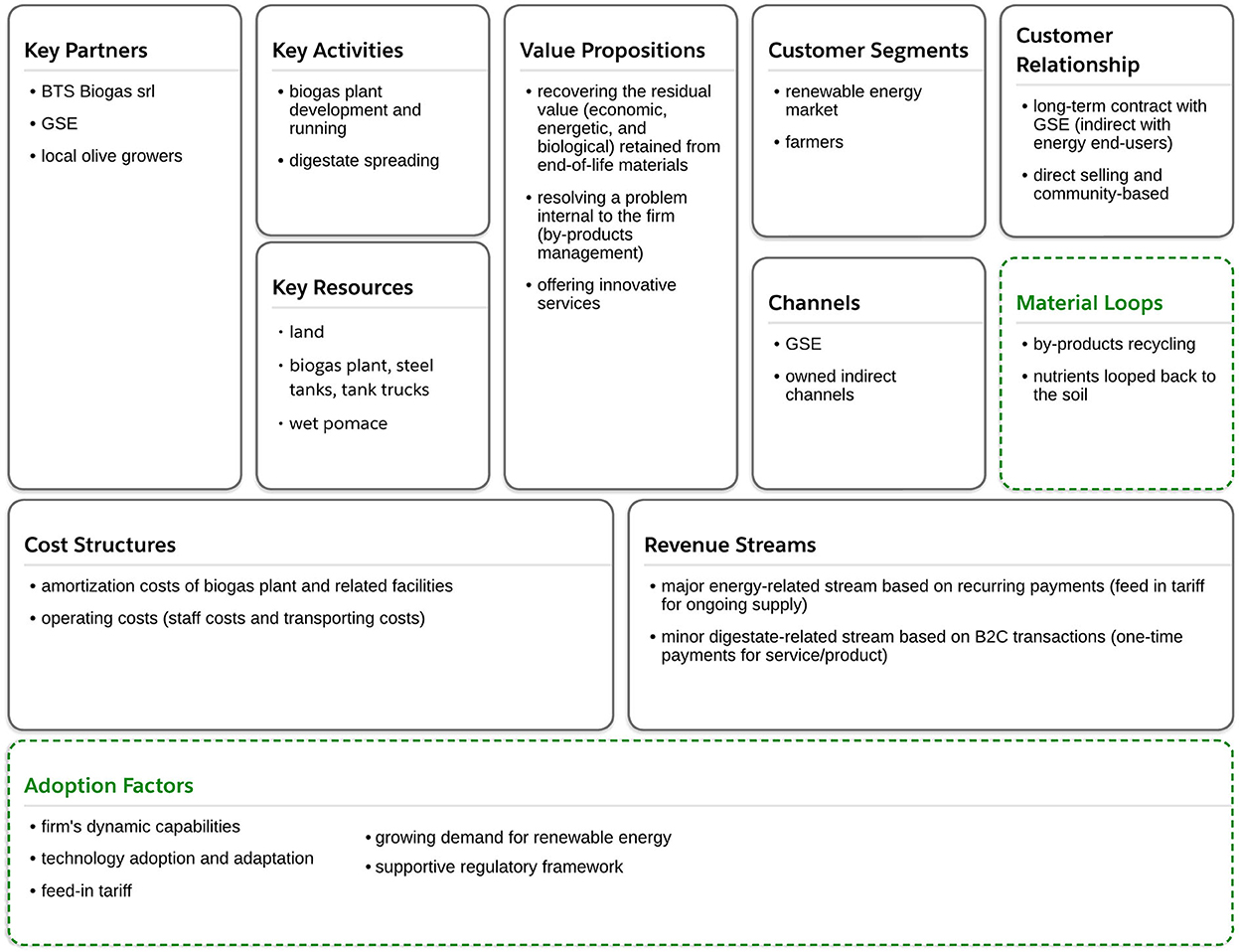

In the present work, the case study was analyzed through the Circular Business Model Canvas (CBMC), which is a comprehensive framework proposed by Lewandowski (2016) to design or examine circular business models, and thus accelerate the transition toward circularity at a micro-economic level. The CBMC was developed starting from the formerly devised BMC, whose original components were partially revised to incorporate explicitly CE principles, and integrated with two distinctive and supplementary elements: one focusing on the take-back systems arranged to close material loops (the core idea of the CE), and another one focusing on internal and external factors supporting the adoption of a circular business model (Lewandowski, 2016). Thus, the CBMC overall includes eleven building blocks.

The CBMC analytical framework was chosen according to the descriptive and explanatory purpose of the investigation: it allows to describe the architecture and the functioning of the business activity under review, as well as to explain its enabling conditions (or causal mechanisms), especially thanks to the location of adoption factors. The CBMC was applied to the firm as a unit of analysis, mainly from an internal view (organization-centric).

Reporting

First, the case study is introduced descriptively by presenting the firm and the milestones that led to innovate its BM by establishing a new business activity in the frame of CE. Then, an overview of the technical process underpinning the CBM is provided, mainly building on the quantitative and technical data collected. Besides the configuration and functioning of the biogas plant, a clarification is provided for the technological innovation developed. Finally, the qualitative data gathered have been organized according to the CBMC's building blocks, to unfold the CBM's architecture and logic, and to pinpoint the conditions under which it works. The focus is on the business division managing the biogas plant. Some considerations are extended to the value network (value exchange between the focal organization and other external stakeholders of the organizational environment).

Results

Case study description

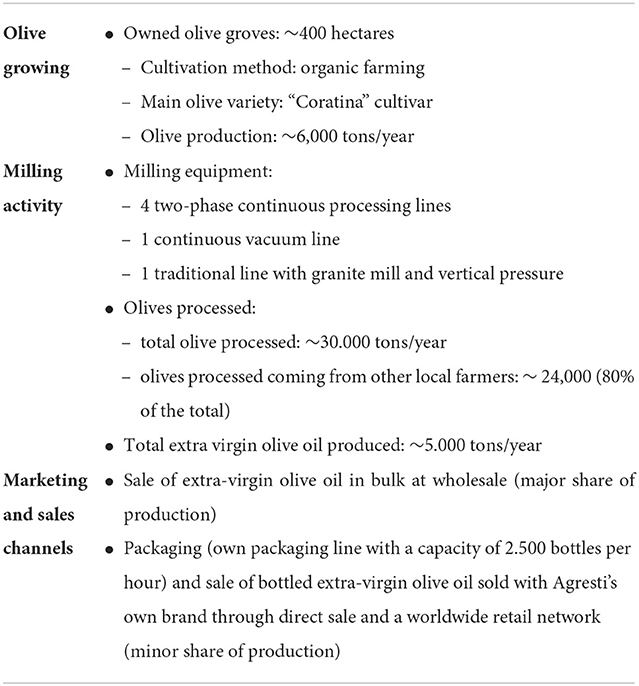

The firm selected as a case study is in the core area of Apulian olive oil production, the municipality of Andria. Founded in the 1930s, the firm has been run by the Agresti family for three generations, with a long history of extra virgin olive oil production, marked by a continuous effort to improve the quality of the product. The firm owns a milling plant with a huge production capacity. Only a minor part of the processed olives is cultivated directly, while most of the incoming olives for oil production are bought from other farmers nearby or processed for third parties. A packaging process closes the cycle of a controlled production chain, from harvesting up to bottling. More information about the firm's features and equipment is detailed in Table 1.

The main milling equipment was renewed about 10 years ago, moving from the three-phase extraction technology to the two-phase one, with the twofold aim of enhancing the olive oil quality, and saving processing water. Such a change raised the problem of dealing with the resulting by-product, namely, wet olive pomace, different from the dry one to which the firm was familiar, and more challenging to discard for the reasons outlined in section “Framing the problem of managing by-products at the mill stage.” Installing a biogas plant at the olive mill was envisioned as an advantageous solution to manage the new by-product. However, this required finetuning of an existing technology that had never been applied before to such an oleaginous matrix: so far, no experience of biogas plants only fed with wet pomace was available as a benchmark. After a period of experimentation, engineering, and application for authorization procedures, the realization of a biogas plant of 500 KWel installed power was completed in 2019 (fully operational from 2020).

The biogas obtained through anaerobic digestions of previously de-pitted wet pomace is used for co-generating electric and thermal energy: while the former is fed into the national grid, the latter is used for self-consumption. The residual organic material deriving from anaerobic digestion (digestate) is reutilized for agronomic purposes.

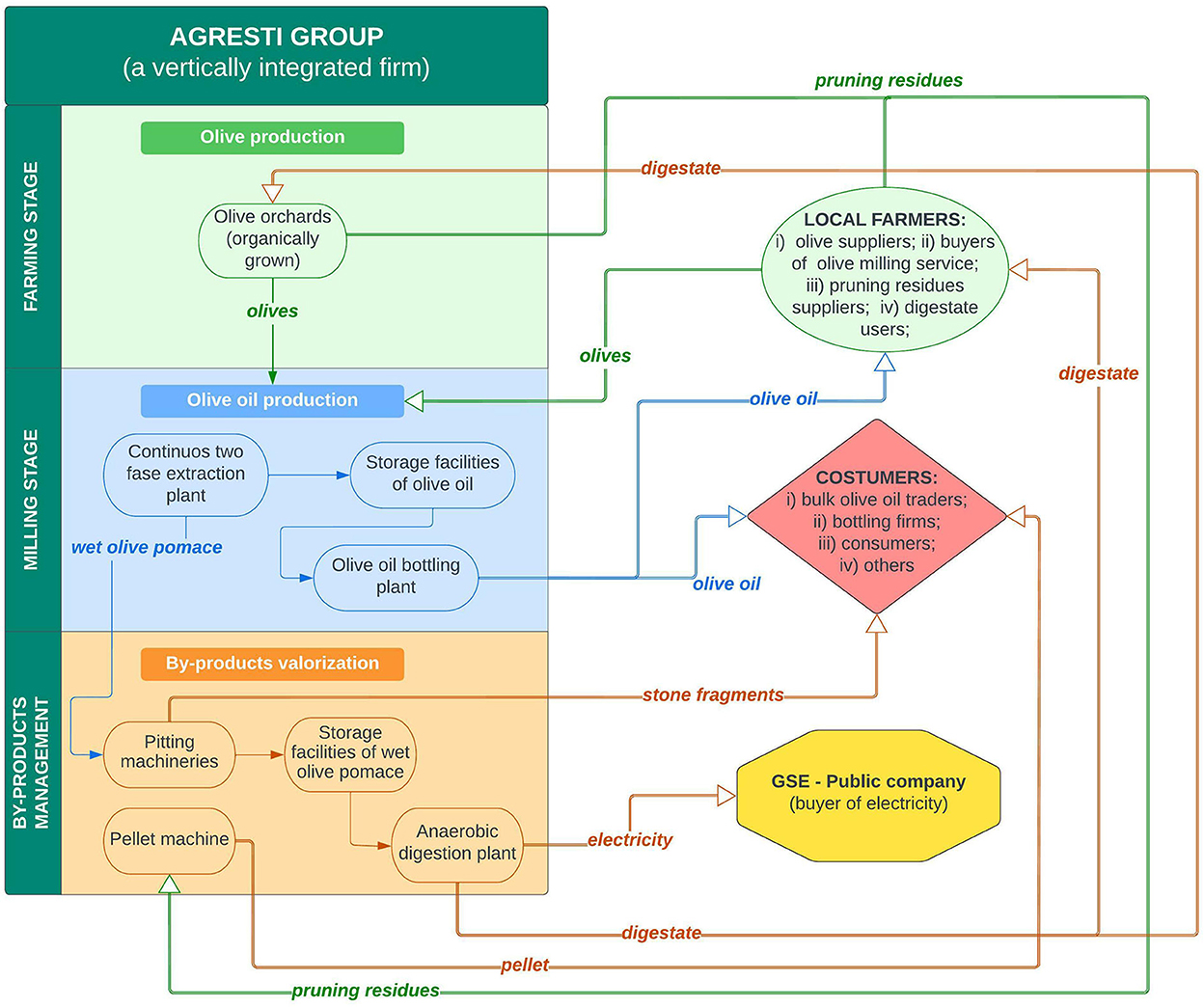

The biogas plant is run by a dedicated company, Agroenergy s.r.l. Società Agricola (henceforth shortened to Agroenergy), which is integrated into a wider group of business units with self-standing legal forms, all controlled and managed by the Agresti family. Besides the cultivation, milling, and energetic valorization activities, the Agresti group provides services of technical assistance and selling of phytosanitary and fertilizing products to local farmers, as well as the service of collecting pruning residues to produce pellets. Therefore, the entrepreneurial group includes a large body of vertically integrated divisions with distinctive but interrelated activities, covering all the stages of the olive oil supply chain (Figure 1), and engaging multiple relations with the wider economic system.

Technological and technical description of the biogas plant

Anaerobic digestion is a process by which bacteria break down organic matter in the absence of oxygen (Jiang et al., 2022). Anaerobic digestion for biogas production takes place in a sealed reactor. In the reactor, complex microbial communities break down (or digest) the waste (organic matter) and produce biogas and resultant digestate (the solid and liquid material end-products of the anaerobic digestion process), which is discharged from the digester (Franca and Bassin, 2020). Usually, multiple organic materials are combined in one digester to increase biogas production (co-digestion). Co-digested materials include animal manure, food waste, crop residues, and many other sources (Karki et al., 2022).

Agroenergy carries out the anaerobic digestion using only the two-phase pomace, without the addition of other organic matrices, using complex microbial communities combined with a liquid solution of specific nutrients to favor their development, if necessary, based on process monitoring. The plant is also integrated with a trigeneration system (CCHP - Combined Cooling, Heating, and Power) in which the biogas obtained from anaerobic digestion is used by a co-generator to produce electricity and heat, making it possible to subsequently use the thermal energy recovered from the thermodynamic transformation to produce cooling energy. Figure 2 shows the trigeneration plant.

Figure 2. Scheme of the biogas plant. (1) Wet pomace tanks, (2) pomace stator pump, (3) hydrolysis tank, (4) mixed pomace stator pump, (5) anaerobic digester, (6) digestate stator pump, (7) condensate pit, (8) biogas torch, (9) endothermic engine, (10) electric generator, (11) electricity grid, (12) absorption refrigerator, (13) cooling cell, (14) solid-liquid separator, (15) liquid digestate tanks.

After the olive oil extraction, the two-phase pomace is de-pitted. In this phase, about 50%−70% of the pit fragments are separated. The remaining product (partially pitted two-phase pomace) is stored in vertical steel silos awaiting anaerobic digestion.

Based on the daily demand for organic matter entering the digester, ~40 tons of pomace per day are pumped from the storage silos to the hydrolysis tank by means of rotor/stator pumps. The hydrolysis tank has a vertical vessel with a circular section, equipped with a mechanical and hydraulic mixing system and a heating system in the walls. In this tank, the pomace is stirred and heated to about 30°C and plied with micro-nutrients. The homogeneous organic matter is then pumped at pre-set time intervals from the bottom into the anaerobic digester. The digester is a vertical vessel with a circular section equipped, like for the hydrolysis tank, with three mechanical mixing systems and a thermal conditioning system placed on the walls. On top, the digester is covered with a double tarpaulin inflated using compressed air.

As the anaerobic digestion process takes place, the biogas produced accumulates in the headspace of the reactor and is retained by the double tarpaulin, then by means of an ad hoc pumping station, it is sent to the co-generator after the condensate is eliminated. The biogas obtained has a methane percentage of about 50%. The co-generator is a thermic engine connected to an electric generator. In this phase, the energy contained in the biogas is transformed into mechanical energy and heat by the engine, and then the mechanical energy is transformed into electricity by the electric generator. When the internal system is fully operational, the engine is always switched on, and electricity and heat are generated on a continuous basis. If for any reason the accumulation of biogas in the reactor falls below a minimum value, the engine switches off automatically, while if the biogas produced is greater than the capacity of the engine, the co-generator switches off, a blower channels the excess biogas, and a torch burns it. The biogas torch is an elevated burner equipped with a high-energy ignition pilot and a thermocouple flame detection system. The ignition system is automatic, activated by the electric panel installed on the underside of the torch. The system initially switches on the pilot and then opens the main biogas valve.

As shown in Figure 2, the heat produced by the engine is partly used to heat the hydrolysis tank and the digester, while the remaining part is used by an absorption refrigerator to generate cooling energy.

As the digester is fed with pomace and the biogas is withdrawn, a pre-set quantity of biomass, that has now exhausted its methane-generating capability, is removed from the bottom of the digestion tank and sent to the separator by the third pumping station. The separator is a horizontal-axis industrial centrifuge that separates the solid (solid digestate) from the liquid fraction (liquid digestate). The solid digestate is stored in an accumulation tank on a waterproofed floor. The liquid digestate is finally deposited in two storage tanks, waiting to be used for agricultural purposes.

Under normal operating conditions, the Agroenergy plant produces gross daily electricity of about 12.2 MWh and gross daily thermal energy of about 12.5 MWh.

Circular business model description

Agroenergy's CBM is briefly shown in the canvas represented in Figure 3. According to the original BCM (Osterwalder and Pigneur, 2010), on the left side of the value proposition, which is the heart of the business architecture, stands the components pertaining to efficiency (key activities, key resources, key partners, and cost structure), while on the right side, there are the components related to value (customer segments, costumer relations, channels, and revenue streams). In the upgraded version of Lewandowski's CBMC, the additional component related to take-back systems is embedded as an integral part of the value, while the extra-block concerning adoption factors is cross-sectional. Since the firm selected as a case study does not comply with take-back management through reverse logistics (aimed at collecting products or wastes from consumers) but recycles its internal by-products, this specific component has been reformulated as “material loops,” which is the ultimate goal of take-back systems in Lewandowski's vision. Each component of CBMC is described more in detail hereafter.

Value proposition

Agroenergy creates economic, energetic, and biological value from end-of-life materials, using the wet pomace generated from Agresti's core agro-industrial activity to feed the biogas plant, and then cycling the by-products resulting from anaerobic digestion for agronomic purposes. The liquid digestate is utilized internally as a soil conditioner and fertilizer on the owned farmland and is also offered to other local farmers by including a service of mechanized spreading. The ways of valorizing the minor solid fraction are under trial, such as experimenting with its usage as an alternative substrate for plant growing in nurseries. In the next future, it will be also bagged and sold.

Since the problem of managing by-products and wastes of a production cycle is usually disregarded by actors' upstream and downstream, in this case respectively olive growers and olive oil consumers, the CBM has been designed to address the challenge of dealing with a new kind of by-product after the switch to a new olive oil extraction technology. Again, the use of digestate as a value-added agronomic input to be employed in the olive tree cultivation cycle creates value for the firm.

Although the value proposition represents a unique solution for a problem faced by the firm itself, it also creates value for customers, in the form of products (energy) and services (distribution of digestate on the soil) from whose delivery the firm captures value. While producing bioenergy is a well-established activity, although starting from a biomass never used alone before, the service of digestate spreading is an innovative idea that makes unique the related value proposition component: the servitization of the offering, shifting from a simple product sale to a service provisioning. Besides allowing the firm to move upward in the value chain, this allows it to attract customers willing to use such soil conditioner/fertilizer, but without technical equipment dedicated, thus eliminating a possible adoption barrier.

Lastly, Agroenergy's value proposition is also strongly conveyed on the communication channels, becoming an integral part of the core product value: extra-virgin olive oil produced according to sustainable and circular practices.

Customer segments

Agroenergy creates a differentiated value for two distinct customer segments with different needs. The first one is represented by the national authority that acquires, manages, and distributes electricity, namely, Gestore Servizi Energetici (GSE). The case firm contributes to providing the amount of renewable energy that GSE should place on the market, given the minimum mandatory quota required by law for public and private buildings (Legislative Decree No 28/2011 and subsequent), as well as the growing demand of clean energy from utilizers who are concerned about environmental issues. They are usually interested in reducing their ecological footprint as individuals, firms, or organizations, and thus they are willing to pay a premium price for greener energy alternatives.

The second customer segment is represented by local olive growers interested in receiving the service of digestate spreading. Reflecting the prevailing farming specialization of the area and the composition of Agresti's portfolio of customer relationships, this group of customers is based on similarities, such as physical proximity, economic activities, and behaviors. In addition, such olive growers should be willing to adopt alternatives to the conventional soil conditioners and fertilizers, due to cost savings or a sustainability-oriented vision. In the next future, when the solid digestate will be bagged, it can be destinated to a typologically similar, but nationally widespread customer segment of farmers, since the product can be easily moved, and sold as it is, disjointed from the distribution service.

Customer relationships

Two main types of relationships, distinguished for customer segments, are involved in Agroenergy's business model. The relation with GSE is based on a specific contract that is regulated by dedicated national rules. In fact, GSE acts as a unique national contractor that purchases electricity from producers and resale it to the end-users through the national grid.

The connections with the second group of customers are closer and much more meaningful, building both on direct selling and community-based types. The beneficiaries of the digestate spreading service are reached thanks to the network relationships already established and continuously maintained in the local socio-economic fabric. They are mainly due to the trading, milling, and technical supporting activity carried out by the firm. Network relationships allow connecting directly with the customers, also targeting the solutions provided to better serve their needs. A consolidated trust and the direct knowledge of the producing subject and process, are crucial to enable the acceptance of an unconventional soil conditioner/fertilizer, such as digestate. As for the case of many innovative practices introduced in agriculture, emulation also plays an important role, since the Agresti family itself experimented and started the soil application of digestate on their own farmland. Demonstrative organic gardens are also a testimony to the effects of digestate use on vegetables and fruit trees.

Channels

Distribution and communication channels are also diversified according to the specific component of value which is delivered to each customer segment. Energy supply is provided through the external channels of GSE. Therefore, like most renewable energy producers, Agroenergy does not strive to connect with the end-users to deliver electricity.

Conversely, indirectly owned channels are the touchpoints to reach out to the second group of customers: the case firm leverages its diversified business activities as avenues to connect with local farmers to sell the service of digestate spreading. Since the owned channels are already in place, the marginal costs of utilizing them to deliver an additional value proposition are very low. Informal communication and commercial ties play a key role in raising awareness among local olive growers, helping them to evaluate the value proposition, and allowing the purchase and delivery of the newly offered service. Since technical assistance is a mission of the Agresti group, post-purchase support can also be provided, so that all channel phases are covered.

Key activities

The key activities performed to fulfill the first part of the circular value proposition fall under the category of production: in the first place, producing and delivering biogas from the anaerobic digestion of wet pomace. Once the biogas plant has been installed, the required main activity is running and managing the facility itself, which is facilitated by a digitalized intelligent calculation software providing real-time information on the digestion process and helping the operators to optimally supply the biogas plant. A joint essential activity is transporting wet pomace from the stocking tanks placed at the olive oil mill to the biogas plant, located at a distance of about 500 m.

The main activities to accomplish the second part of the value proposition relate to the specific management of the digestate destined for agronomic applications. Besides the internal use on the own farmland, a fundamental element of the CBM is organizing and delivering the service of digestate spreading offered to external subjects, who are represented by local olive growers.

Key resources

Several types of essential resources are needed to carry out the key activities. The main physical ones include: the land surface to install the biogas plant, the biogas plant itself with its equipment and buildings, the steel cylindric tanks for stocking wet pomace, the tank trucks to transport wet pomace from stocking tanks of the mill to the biogas plant. Special tank trucks to operate on farmland, already part of the firm's assets, are also needed to spread the digestate. Another crucial resource is wet pomace, used as the main input of the anaerobic digestion process. Being an internal by-product, it is available in-house, without having to obtain it from third parties. This represents a crucial aspect of the firm, when compared with other biogas plants that must externally acquire the organic matrixes to be digested.

Further workforce was also needed to run the plant. Most of the processes are automated and computerized, making plant management capital-intensive. However, five additional job positions were created.

The set of financial resources required to sustain the CBM comprises of: a credit line, represented by a bank loan to cover the huge initial investment required to install the facility; and incentives for renewable energy production, that Agroenergy receives in the form of a feed-in tariff paid by GSE.

Key partners

Partnerships with external subjects were established for both acquiring key-resources and reducing risks. Once envisioned the business idea, the Agresti group met experienced developers from the renewable energy and anaerobic digestion industry, in order to acquire the external know-how to adjust an available technology, not yet mature to work only with wet pomace. The group BTS Biogas Srl was involved as a crucial partner: after performing experimental trials to finetune the anaerobic digestion process, the partner upscaled the innovation at the industrial level and realized the plant in collaboration with AB Holding S.p.a., skilled in solutions for co-generating electric and thermic energy from renewable sources, such as biogas. BTS Biogas Srl remains a strategic partner for plant management, as it is in charge of ordinary and extra-ordinary maintenance.

Another crucial, contract-based partnership to carry out Agroenergy's key activities is with GSE, which oversees the planning and sale of energy from renewable-source plants on the Italian electricity market, as well as the auctioning of carbon dioxide emissions quotas on the European carbon market.

Besides this, strategic albeit informal partnerships with local olive growers, building on consolidated relationships, are activated regarding the service of digestate spreading on soil.

Material loops

The case firm closes material loops based on recycling and cycling by-products as end-of-use strategies (Geissdoerfer et al., 2020). Such strategies allow to create new profitable value chains and recirculate biomass in the biosphere, recovering both its economical and biological residual value. While wet pomace is primarily recycled to produce biogas to be converted into electric and thermal energy, the digestate remaining from anaerobic digestion is looped back to the soil as organic conditioner and fertilizer. Nutrient cycling substantially contributes to regenerating and restoring natural capital, which is one of the main principles of CE (Ellen MacArthur Foundation, 2013b), particularly relevant when dealing with biological metabolism. Besides its restorative function within the nutrient cycles, digestate, being rich in organic matter, can contribute to maintaining and likely enhancing soil fertility. The latter goes in the direction of the regenerative function of CE (Morseletto, 2020; Velasco-Muñoz et al., 2021; Batlles-delaFuente et al., 2022). At the same time, the heat produced during the anaerobic treatment entails a sanitation process, dramatically decreasing the pathogenic bacteria load and making the product safe to be used for agronomic applications (Weiland, 2010; Möller and Müller, 2012; Nkoa, 2014; Albuquerque et al., 2019).

In the presented case study, the digestate is spread on the groves on which the olives destined to be processed are cultivated, returning to the soil the nutrients caught by olive trees and thus establishing a very closed loop. Besides, this practice allows substituting chemical fertilizers with greener bio-based and locally sourced equivalents, resulting in a reduction of imported agro-chemical inputs.

Since wet pomace is produced and recycled by the same firm, the arrangement of take-back systems or material exchanges was not needed: just the logistics of transporting the biomass from the mill to the nearby biogas plant. Regarding the digestate spreading service offered to olive growers nearby, a forward logistic system is activated to recirculate the bioresource outside the firm gate.

Structure cost

The structure cost is made up of all the sources of expenditure that Agroenergy sustains to implement its activities. The most relevant cost item is the facility itself, whose realization amounted to an overall of 4.5 million euro (including engineering, installation, commissioning, and administrative costs). The highly specific investment in the biogas plant entailed massive fixed costs for the entrepreneurial subject, mainly represented by mortgage payments and maintenance costs. The variable costs represent a minor quota, and they include labor cost (employed personnel), fuel for moving wet pomace, minor production inputs (i.e., fishmeal used to rebalance the biodigester floral bacteria), and taxes. Being a by-product of a previous production cycle available in-house, the main input represented by wet pomace is available for free. Moreover, its internal recycling allows for avoiding disposal costs.

Costs should also include the opportunity costs of the resources involved in the production activity. In this case, we should consider the alternative uses of wet pomace and of the land occupied by the biogas plant. The business model is more value-driven than cost-driven, since it focuses on obtaining the maximum value from the by-products, rather than minimizing costs.

Revenue streams

Revenues pertain to the residual value of end-of-waste resources retrieved from material looping (Lewandowski, 2016). The biogas plant enables the generation of different revenue streams, accounting overall for about 20% of the whole business of the Agresti group.

The main revenue stream is related to the conversion of biogas into energy. The electricity channeled into the national grid, excluding a share of about 11% used in self-consumption, is paid based on a feed-in tariff, providing a revenue that ensures a pay-back period of the initial investment of about 6 years. This first stream belongs to a recurring revenue model, made from ongoing payments for the continuous energy supply, and is warranted by a 20-year contract stipulated with GSE. Furthermore, the cogenerated thermic energy covers the needs of the facility itself, hence cost savings derived from the business's energetic autonomy can be acknowledged as a further source of revenue.

A minor part of the revenue stream relates to the residues downstream of the wet pomace anaerobic digestion. Currently, the farmers benefitting from digestate distribution on soil compensate for the service in the form of a cost refund. As a result, a tiny revenue stream due to service integration (Grönroos and Ravald, 2011) is developed, based on a transaction-based model (one-time payments made by individual customers). A revenue source with greater potential could derive from bagging and selling the solid fraction of digestate, already in the firm's plans. Besides, the agronomic use of digestate by the firm itself, in (full or partial) replacement of chemical counterparts on the market, reduces farming management costs (Salerno et al., 2017).

Adoption factors

Both internal and external factors enabled the adoption of Agreoenergy's BM.

Internal factors are due to organizational capability (Lewandowski, 2016). The firm's dynamic capabilities (Teece, 2007) were fundamental to envisaging spaces for a technical breakthrough, establishing collaborations with key partners, devoting time to experimentation, taking advantage of the economic and regulatory framework, and diversifying the revenue streams. A crucial aspect is related to the problem-solving, open-minded, and resourceful managerial attitude shown by the entrepreneurs in overcoming the technical and financial barriers that could have hindered the new business activity setting-up. The Agresti family was able to establish fruitful partnerships to experiment on field and upscaling technical solutions to achieve the circular solution envisioned. The firm was also proficient in intercepting the economic opportunity offered by incentives, and in using them to acquire the financial resources needed to install the biogas plant. All those efforts entailed transaction costs.

External factors are related to technological, political, economic, and socio-cultural issues. Agroenergy made large investments in adopting a consolidated bio-chemical conversion technology, which had never been applied to wet pomace before. The main problem to solve was represented by the presence of hardy degradable compounds, such as polyphenols and lipids that typically inhibit the activity of methanogenic bacteria. In addition, the presence of pits fragments causes further problems in the management of the digestion process, by creating a deposit on the bottom of the tanks. Finally, how to store huge amounts of such fermentable biomass, pending to be entered into the plant, represented another crucial issue. The main innovation was transferring and adapting the anaerobic digestion process and related machinery to work with a particular kind of organic matrix represented solely by wet pomace.

Political and economic factors are closely related: a policy supportive framework providing economic incentives was fundamental for the economic sustainability of the investment. Biogas plants powered by biomass benefit from an incentive mechanism introduced in 2016 (Ministerial Decree 23 June 2016) consisting of a feed-in tariff, whose value is determined by the sum of a base incentive rate, the remuneration of the energy supplied, and any additional premium to which the plant is entitled. The feed-in tariff is disbursed by GSE based on a 20-year contract. Since such a contract also ensured a revenue for the average life cycle of the plant and stood as a guarantee to obtain the bank loan, it also represented a crucial economic enabling factor.

Still, on the policy-regulatory level, the agronomic use of digestate is allowed by the Italian Inter-ministerial Decree 5046/2016 (“Nitrates Regulation”) and has further progressed very recently by Decree Law 21/2022, which establishes the equalization of digestate with chemical fertilizers as a measure of promoting circular economy in agriculture.

Socio-cultural factors are related on one side to the expected growing demand for renewable energy; on the other side to the increasing favorable public opinion on sustainable and circular practices.

Discussion

The case study represents an example of how innovation can be advanced by adapting and bringing together existing solutions. The innovation lies in the fact that: (i) the firm realized the first biogas plant exclusively powered with wet olive pomace, and this required to adopt and adapt an existing technology that was not considered suitable to work only with such kind of matrix; (ii) beyond electricity production, even the thermal energy is fully recovered (this often does not happen) and converted into water and cold air; (iii) the biogas plant is installed at the mill and directly managed by the miller himself, so the by-products of the agro-industrial activity are recycled within the firm's gate, and their treatment is not externalized; and (iv) the by-products are not considered as a problem to be gotten rid of, but rather as a valuable resource to create, capture, and deliver value for the firm itself and for a larger community of local farmers.

Agreoenergy's BM generates value from a bundle of integrated products and services related to the olive oil sector. As a core activity, the firm provides high-quality extra virgin olive oil, in part certified as organic, bottled with its own brand. The entire range of olive oil by-products is valorized and kept in play in a market-oriented perspective. According to the Agresti brothers, the recently installed biogas plant “was the missing piece for closing the sustainable production cycle, based on circular economy.” CE permeated the firm's culture as a conceptual and operational driver and was explicitly integrated into the business strategy and vision. Pursuing circularity follows in line and further advances the cornerstones already implemented at the heart of the business mission: “the enhancement of the natural environment, together with the continuous search for the quality of our products.”

The firm innovated its global BM with a circular shift, by setting-up a new business activity aimed at creating value that previously could not be captured. According to the taxonomy of CBM innovation formulated by literature (Geissdoerfer et al., 2020), Agresti's innovation strategy is based on diversification, since an additional business model is integrated within the existing company, introducing a circular solution without transforming its core business's functioning. The development of Agroenergy's CBM builds on a recycling and cycling strategy (Bocken et al., 2016; Geissdoerfer et al., 2020), that allows for internalizing the outputs management, by closing material loops within the firm's gates, avoiding waste generation, and reducing the use of external inputs. At the same time, the economic potential of the available end-of-life materials is unlocked, further broadening the firm's income sources. Besides, the firm leverages its sustainable and circular behavior to increase the perceived value of the traditional product sold, namely, olive oil. As a result, the firm enhanced its resource use efficiency and profitability. Since data about the bio-chemical composition of the digestate and about the effects of its application on soil properties and fertility are not yet available, the restorative or regenerative potential of the implemented circular solution cannot be assessed so far. Thus, the real eco-efficacy of the CBM remains undetermined.

The main elements that enabled the implementation of the new CBM were: (i) a process adaptation put into effect at the industrial scale to overcome a hindering technological barrier; (ii) the capacity of benefitting from the available incentives to get through the economic barrier due to the huge initial investment, as well as to ensure its profitability in the medium-long term; and (iii) the absence of coordination challenges.

Technology innovation was not simply acquired from available industrial research, but proactively driven by the firm that expressed a specific demand for a targeted process adaptation (Dries et al., 2014). However, technological advancement can be understood as an open innovation (Chesbrough et al., 2006) rather than an internal process, since it was generated and accelerated by collaborating with a leading enterprise with a long experience in piloting, engineering, and managing cutting-edge plants. The joint venture occurred at the front end of innovation, nurturing the first experimentation at the laboratory scale, and enabling the implementation at full-scale.

Since all the activities aimed at closing the wet pomace material flow are mostly accomplished within a single corporation body managed by a unique entrepreneurial subject, the case study does not present remarkable aspects of cooperation between interplaying actors, usually needed to develop collaborative schemes in CBMs (Antikainen and Valkokari, 2016). Some elements of coordination stem from the organization of the digestate spreading service offered to the local olive growers; however, they involve mainly one-to-one interactions, and are facilitated by an already established relational capital. Thus, one crucial reason behind the case study's success is due to the absence of substantial coordination issues, often pinpointed as major barriers to circular transition in the literature (González-Sánchez et al., 2020; Fang et al., 2021; Li et al., 2021; Tseng et al., 2022).

The business model analyzed, given the huge financial and biomass capacity needed, could only be replicated by a single organization with the size and features like those of the case firm. However, most of the businesses in the Apulian olive oil supply chain are smaller and non-vertically integrated. Therefore, olive oil by-products management should be reframed within collective initiatives, such as centralized biogas plants designed for homogeneous areas, to which olive millers can deliver wet pomace, and from which olive growers can withdraw digestate. When a multiplicity of stakeholders from different stages of the supply chain and different sectors must stably take part in a collaborative scheme, several problems may arise. A crucial problem is related to the correct sizing of the biogas plant, which should be superior to the minimum efficient scale and also proportionate to the available quantity of wet pomace. In the case of Agresti's firm, this problem has been overcome by sizing the biogas plant by solely considering the internal production capacity of wet pomace, which was sufficient to feed a plant with a superior size minimum efficient scale. Conversely, when several providers of wet pomace (small and medium mills) are involved, a correct sizing of a collective biogas plant should be made by considering their number and their production capacity. This may appear to be relatively easy, but it is actually very difficult to involve several actors in the same initiative because each of them must modify their previous business-as-usual and face a new activity that is characterized by a certain level of uncertainty and risk. They must undertake to ensure a continuous supply of wet pomace to the biogas plant and comply with the standards required by the biogas plant of the composition of organic matrixes (humidity, acidity, etc.), probably derived from different milling processes. Therefore, the coordination of several providers of wet pomace also implies that contracts or other forms of agreement are needed to ensure an ongoing and compliant supply of olive pomace; this can lead to conflicts between the different actors in defining what could be a balanced and fair distribution of benefits. Another non-negligible problem to be faced when several suppliers of olive pomace are involved is related to the need to design, implement and manage a more complex and flexible logistic system that should be able to serve a larger sourcing area, with differentiated frequency and load demand. In the case of Agresti's firm, since wet pomace is produced and recycled within a plant located at a very short distance, a simple system of transportation of the biomass from the mill was activated. Conversely, transporting olive pomace from several mills located at medium-long distances needs a more complex logistic system that could imply higher economic costs, as well as higher environmental impacts due to energy consumption and air gas emissions. It is not possible to exclude that also social concern or aversion against truck traffic and related polluting emissions may arise.

Comparing our results with previous literature, this study confirms that those by-products and residues from the olive oil supply chain, generated in high volumes, can offer various value propositions for CBMs: being bio-degradable resources, they are suitable to be fully reused in cascades for closing material loops within the biological cycle (e.g. Donner et al., 2022). Also, this study confirms and further investigates that the recovery of wet pomace is a service type of value proposition fitting into a CE approach, and that bio-energy production at a local scale can be a profitable valorization option, compared to other not always economically advantageous alternatives. The research sheds light on the regenerative potential of the explored circular pathway: the agronomic application of the digestate allows the recirculation of resources into the biosphere, both minimizing the leakages of nutrients and organic matter from the system and contributing to preserving and improving soil quality. The implementation of CE models into the agri-food sector should be thoroughly framed according to sustainable management schemes of the agri-environment, due to the close relationships with the natural ecosystems (Velasco-Muñoz et al., 2021; Morseletto, 2022). The case study analysis reveals that resolving problems related to resource management is the main stimulus in business model innovation, beyond other drivers already indicated by literature, such as environmental concerns, traditional olive mills' activities diversification, business opportunity, and circular thinking (Donner and Radić, 2021).

Conclusion

The paper can contribute to the extant research on the business models and the circular economy in the agri-food sector. While recent studies provided a brief overview of circular business models for the olive oil sector by applying the classic BMC (Donner and Radić, 2021; Donner et al., 2022), the adoption of the CBMC analytical tool allows to deepen more specifically the distinctive aspects of the CE. In literature, articles analyzing empirical cases and adopting the CBMC are sparse and only a few of these are related to the agri-food sector. The study explores a unique case in the panorama of the European olive oil industry. Furthermore, the circular pathway undertaken by the firm can be seen as truly regenerative practice (Morseletto, 2020).

Key lessons learned

Many elements were mobilized by the case firm to develop a new CBM. While some of them can be relatively easy to copy, it could be harder to reproduce more peculiar systems, processes, and assets to replicate the whole business model (Teece, 2010). The pivotal elements for the business model replicability are related to the firm's structural features (size, vertical integration, and diversification) and to its dynamic capabilities among the internal adoption factors. On the other hand, a supportive regulative framework and economic incentives play a crucial role among the external adoption factors.

Implications

The case study also shows that technology development makes it more than ever possible and accessible to overcome many existing technological barriers to convert waste materials into value-added products. A more challenging obstacle to replicating the promising circular solution with a multi-stakeholder approach, putting together different smaller producers from a spatial and economic cluster, is related to coordination issues, which the case firm did not have to go through. Therefore, coordination barriers may prevent a systemic transition toward a circular model, explaining the fact that, currently, innovative processes are occurring more inside the firm's gate, rather than among different actors of the supply chain. Nevertheless, designing regenerative value chains grounded on multi-actor communities remains the main challenge to address, also to boost the social dimension of CE.

Limitations and future research

This study was intended to generate explanations about how a BM can be innovated, and to identify the main adoption factors, in order to answer the “how,” rather than the “how much” questions. However, the lack of environmental performance and cost-effectiveness assessments represents the main limitation of the work. Moving toward circularity is expected to have positive environmental and economic impacts, but this is not guaranteed to do so. For example, Hanes et al. (2021) demonstrated that a specific recycling solution is an economically feasible option, but it requires high energy consumption which results in a 7.1% increase in global warming. Therefore, future research should analyze the environmental impacts of the circular pathway based on the energetic valorization of wet pomace through anaerobic digestion.

Another limitation of the work is related to the analytical tool applied, namely the CBMC framework. Although very useful to identify the constitutive elements of a business model and their interrelations, the canvas scheme provides a static picture instead of a dynamic perspective on business model innovation processes. At the moment, the model is focused on how to implement the latest technology, but it overlooks the fact that further new technologies may be available in the future considering, specifically, the rapid digital transformations, such as those at the heart of Industry 4.0, that may contribute in solving many problems related to the implementation of circular pathways (Awan et al., 2022).

Further research is required to comprehensively evaluate the presented CBM. The extent of circularity, as well as the achieved degree of resource efficiency and eco-efficacy, should be assessed, and comparatively evaluated with respect to alternative or competing uses of the considered by-product. For instance, the practice of spreading wet pomace on the farmland is often economically specious for olive millers, due to the bureaucratic and organizational duty entailed, and risks being improperly managed on the environmental side, especially when the by-product amount is as high as in a heavy production region like Apulia. Another crucial aspect to evaluate more in-depth regards the fertilizing properties of digestate, and the modalities to apply it, in order to ensure low emissivity and high nutrient recycling efficiency.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

Conceptualization and methodology: SS, LR, AL, and BDG. Validation: LR, DC, and BDG. Formal analysis and writing the original draft preparation: SS, LR, and AL. Data curation: SS. Writing, reviewing, editing, and visualization: SS, LR, DC, AL, BDG, and GG. Project administration and funding acquisition: GG. All authors have read and agreed to the published version of the manuscript.

Funding

This research received a grant from the Project PRIN DRASTIC Driving the Italian Agri-Food System Into A Circular Economy Model (cod. 2017JYRZFF), PRIN-MIUR—Call 2017, funded by the Italian Ministry of Education, University and Research (MIUR), Italy.

Acknowledgments

The authors express their warm gratitude to Savino Agresti and Antonio Cassanelli who have generated precious information for the case study analysis.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Albuquerque, J. N., Ratusznei, S. M., and Rodrigues, J. A. D. (2019). Biomethane production by thermophilic co-digestion of sugarcane vinasse and whey in an AnSBBR: effects of composition, organic load, feed strategy and temperature. J. Environ. Manag. 251, 109606. doi: 10.1016/j.jenvman.2019.109606

Antikainen, M., and Valkokari, K. (2016). A framework for sustainable circular business model innovation. J. Technol. Manag. Innov. 6, 5–12. doi: 10.22215/timreview/1000

Awan, U., Kanwal, N., and Bhutta, M. K. S. (2020). “A literature analysis of definitions for a circular economy,” in Logistics Operations and Management for Recycling and Reuse, ed P. Golinska-Dawson (Berlin, Germany: Springer), 19–34. doi: 10.1007/978-3-642-33857-1_2

Awan, U., Sroufe, R., and Bozan, K. (2022). Designing value chains for industry 4.0 and a circular economy: a review of the literature. Sustainability 14, 7084. doi: 10.3390/su14127084

Batlles-delaFuente, A., Abad-Segura, E., González-Zamar, M. D., and Cortés-García, F. J. (2022). An evolutionary approach on the framework of circular economy applied to agriculture. Agronomy 12, 620. doi: 10.3390/agronomy12030620

Berbel, J., and Posadillo, A. (2018). Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 10, 237. doi: 10.3390/su10010237

Bocken, N. M., De Pauw, I., Bakker, C., and Van Der Grinten, B. (2016). Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 33, 308–320. doi: 10.1080/21681015.2016.1172124

Bocken, N. M., Short, S. W., Rana, P., and Evans, S. (2014). A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 65, 42–56. doi: 10.1016/j.jclepro.2013.11.039

Böckin, D., Goffetti, G., Baumann, H., Tillman, A. M., and Zobel, T. (2022). Business model life cycle assessment: a method for analysing the environmental performance of business. Sustain. Prod. Consum. 32, 112–124. doi: 10.1016/j.spc.2022.04.014

Boons, F., Montalvo, C., Quist, J., and Wagner, M. (2013). Sustainable innovation, business models and economic performance: an overview. J. Clean. Prod. 45, 1–8. doi: 10.1016/j.jclepro.2012.08.013

Borrello, M., Pascucci, S., and Cembalo, L. (2020). Three propositions to unify circular economy research: a review. Sustainability 12, 4069. doi: 10.3390/su12104069

Catalano, F., Bianchi, B., Berardi, A., Leone, A., and Tamborrino, A. (2021). Experimental trials and dynamical simulation of the potential biogas production in a frozen food industry. Chem. Eng. Trans. 87, 295–300. doi: 10.3303/CET2187050

Chesbrough, H., Vanhaverbeke, W., and West, J. eds (2006). Open Innovation: Researching a New Paradigm. Oxford: Oxford University Press on Demand.

Chojnacka, K., Moustakas, K., and Mikulewicz, M. (2022). Valorisation of agri-food waste to fertilisers is a challenge in implementing the circular economy concept in practice. Environ. Pollut. 312, 119906. doi: 10.1016/j.envpol.2022.119906

De Angelis, R. (2022). Circular economy business models as resilient complex adaptive systems. Bus. Strategy Environ. 31, 2245–2255. doi: 10.1002/bse.3019

De Jesus, A., Antunes, P., Santos, R., and Mendonça, S. (2018). Eco-innovation in the transition to a circular economy: an analytical literature review. J. Clean. Prod. 172, 2999–3018. doi: 10.1016/j.jclepro.2017.11.111

Donner, M., and Radić, I. (2021). Innovative circular business models in the olive oil sector for sustainable mediterranean agrifood systems. Sustainability 13, 2588. doi: 10.3390/su13052588

Donner, M., Radić, I., Erraach, T., and El Hadad-Gautier, F. (2022). Implementation of circular business models for olive oil waste and by-product valorization. Resources 11, 68. doi: 10.3390/resources11070068

Dries, L., Pascucci, S., Török, Á., and Tóth, J. (2014). Keeping your secrets public? Open versus closed innovation processes in the Hungarian wine sector. Int. Food Agribus. Manag. Rev. 17, 147–162. Available online at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84895155388&partnerID=40&md5=69dce178338bb96037992ddf8d4cf433

Ellen MacArthur Foundation (2013a). Towards the Circular Economy: Opportunities for the Consumer Goods Sector. Vol. 2. Cowes: Ellen MacArthur Found.

Ellen MacArthur Foundation (2013b). Towards the Circular Economy, Economic and Business Rationale for an Accelerated Transition. Cowes: Ellen MacArthur Found, 21–34.

Esposito, B., Sessa, M. R., Sica, D., and Malandrino, O. (2020). Towards circular economy in the agri-food sector. a systematic literature review. Sustainability 12, 7401. doi: 10.3390/su12187401

European Commission (2019). The European Green Deal COM/2019/640 Final, communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Brussels. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52019DC0640andfrom=IT (accessed June 06, 2022).

European Commission (2020a). A new Circular Economy Action Plan. For a cleaner and more competitive Europe COM (2020) 98 final, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Brussels. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0098&from=EN (accessed June 06, 2022).

European Commission (2020b). A Farm to Fork Strategy for a fair, healthy and environmentally-friendly food system COM/2020/381 final, communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Brussels. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0381andfrom=EN (accessed June 06, 2022).

European Commission (2020c). Europe's moment: Repair and Prepare for the Next Generation COM (2020) 456 final, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Brussels. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0456&from=IT (accessed June 06, 2022).

Fang, C., Ma, X., and Zhang, J. (2021). Personality information sharing in supply chain systems for innovative products in the circular economy era. Inter. J. Prod. Res. 59, 5992–6001. doi: 10.1080/00207543.2020.1798032

Franca, L. S., and Bassin, J. P. (2020). The role of dry anaerobic digestion in the treatment of the organic fraction of municipal solid waste: a systematic review. Biomass Bioenergy 143, 105866. doi: 10.1016/j.biombioe.2020.105866

Frankenberger, K., Weiblen, T., Csik, M., and Gassmann, O. (2013). The 4I-framework of business model innovation: a structured view on process phases and challenges. Int. J. Prod. Dev. 18, 249–273. doi: 10.1504/IJPD.2013.055012

Geissdoerfer, M., Pieroni, M. P., Pigosso, D. C., and Soufani, K. (2020). Circular business models: a review. J. Clean. Prod. 277, 123741. doi: 10.1016/j.jclepro.2020.123741

Geissdoerfer, M., Savaget, P., Bocken, N. M. P., and Hultink, E. J. (2017). The circular economy a new sustainability paradigm? J. Clean. Prod. 143, 757–768. doi: 10.1016/j.jclepro.2016.12.048

González-Sánchez, R., Settembre-Blundo, D., Ferrari, A. M., and García-Muiña, F. E. (2020). Main dimensions in the building of the circular supply chain: a literature review. Sustainability 12, 2459. doi: 10.3390/su12062459

Grönroos, C., and Ravald, A. (2011). Service as business logic: implications for value creation and marketing. J. Serv. Manag. 22, 5–22. doi: 10.1108/09564231111106893

Hanes, R., Ghosh, T., Key, A., and Eberle, A. (2021). The circular economy lifecycle assessment and visualization framework: a case study of wind blade circularity in Texas. Front. Sustain. 2, 671979. doi: 10.3389/frsus.2021.671979

Hofmann, F. (2019). Circular business models: business approach as driver or obstructer of sustainability transitions? J. Clean. Prod. 224, 361–374. doi: 10.1016/j.jclepro.2019.03.115

ISMEA (2021). Scheda di settore: olio di oliva, Rome: ISMEA. Available online at: https://www.ismeamercati.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/3523 (accessed June 06, 2022).

ISTAT (2011). VI Censimento generale dell'agricoltura (Italian Census of Agriculture). Rome: ISTAT. Available online at: http://dati-censimentoagricoltura.istat.it/Index.aspx (accessed June, 2022).

Jäger-Roschko, M., and Petersen, M. (2022). Advancing the circular economy through information sharing: a systematic literature review. J. Clean. Prod. 133210. doi: 10.1016/j.jclepro.2022.133210

Jiang, X., Xie, Y., Liu, M., Bin, S., Liu, Y., Huan, C., et al. (2022). Study on anaerobic co-digestion of municipal sewage sludge and fruit and vegetable wastes: methane production, microbial community and three-dimension fluorescence excitation emission matrix analysis. Bioresour. Technol. 347, 126748. doi: 10.1016/j.biortech.2022.126748

Karki, R., Chuenchart, W., Surendra, K. C., Sung, S., Raskin, L., Khanal, S. K., et al. (2022). Anaerobic co-digestion of various organic wastes: kinetic modeling and synergistic impact evaluation. Bioresour. Technol. 343, 12606. doi: 10.1016/j.biortech.2021.126063

Kirchherr, J., Reike, D., and Hekkert, M. (2017). Conceptualizing the circular economy: an analysis of 114 definitions. Resour. Conserv. Recycl. 127, 221–232. doi: 10.1016/j.resconrec.2017.09.005

Korhonen, J., Honkasalo, A., and Seppala, J. (2018). Circular economy: the concept and its limitations. Ecol. Econ. 143, 37–46. doi: 10.1016/j.ecolecon.2017.06.041

Leone, A., Romaniello, R., Peri, G., and Tamborrino, A. (2015). Development of a new model of olives de-stoner machine: evaluation of electric consumption and kernel characterization Biomass Bioenergy 81, 108–116. doi: 10.1016/j.biombioe.2015.06.016

Lewandowski, M. (2016). Designing the business models for circular economy—towards the conceptual framework. Sustainability 8, 43. doi: 10.3390/su8010043

Li, G., Wu, H., Sethi, S. P., and Zhang, X. (2021). Contracting green product supply chains considering marketing efforts in the circular economy era. Int. J. Prod. Econ. 234, 108041. doi: 10.1016/j.ijpe.2021.108041

Linder, M., and Williander, M. (2017). Circular business model innovation: inherent uncertainties. Bus. Strategy Environ. 26, 182–196. doi: 10.1002/bse.1906

MacArthur, E., Zumwinkel, K., and Stuchtey, M. R. (2015). Growth Within: A Circular Economy Vision for a Competitive Europe. New York, NY: Ellen MacArthur Foundation.

Mentink, B. A. S. (2014). Circular Business Model Innovation: A Process Framework and a Tool for Business Model Innovation in a Circular Economy [Master Theis]. Delft University of Technology and Leiden University, Delft.

Möller, K., and Müller, T. (2012). Effects of anaerobic digestion on digestate nutrient availability and crop growth: a review. Eng. Life Sci. 12, 242–257. doi: 10.1002/elsc.201100085

Morseletto, P. (2020). Restorative and regenerative: exploring the concepts in the circular economy. J. Ind. Ecol. 24, 763–773. doi: 10.1111/jiec.12987