94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. Food Syst., 29 November 2021

Sec. Urban Agriculture

Volume 5 - 2021 | https://doi.org/10.3389/fsufs.2021.787281

This article is part of the Research TopicBuilding Sustainable City Region Food Systems to Increase Resilience and Cope with CrisesView all 11 articles

To secure sustainable and resilient food systems, new approaches, innovations, techniques, and processes are needed. In recent years, urban farming firms have been developing and experimenting with innovative approaches to expand their offerings and connect with consumers in new ways. New business models are being developed to provide functions and services instead of traditional products to meet demands from consumers, retailers, and users. As such, modular growing systems are increasing in popularity to provide fresh produce, visual appeal, transparency, and other tailor-made functions and services in so-called “growing-service systems” (GSS). Using GSS approaches, firms are developing and providing modular and small-scale farms in restaurants, residential spaces, supermarkets, and other commercial spaces, often including a large degree of automation and optimization of digital solutions to remotely control their operation. Using qualitative methods, the aim of this study is to explore and analyze the development of these novel GSS systems, highlighting different strategies, business models, motivations, and challenges. The results illustrate the divergence in approaches to GSSs for vertical farming. This includes different scales of modular units and varying business models for capturing value from the combination of products and services. All of the systems include varying degrees of automation and digitalized solutions to ensure the services are monitored, which is done to improve growing conditions and improve the experience for the users. Business-to-business systems are being developed as both market expansion and awareness-building strategies, where modular units are provided as a rental or subscription model that includes a number of services. Business-to-consumer systems are being introduced as an alternative for consumers, particularly in urban areas, to have greater control and access over growing their own fresh produce. The modules are purchased by consumers, which includes a number of ongoing services from the GSS firms. By categorizing and exploring these systems, this article offers novel insights and a first endeavor to distinguish these new GSS systems in the growing segment of urban agriculture, controlled-environment agriculture, and product-service system literature.

In order to secure sustainable and resilient food systems, new approaches, innovations, techniques, and processes are needed for both food production and consumption. In recent years, agriculture has seen dramatic innovations and development to bring food production systems closer to consumers (Klerkx and Rose, 2020). There has been an increasing interest in urban agricultural systems and alternative food systems focusing on shorter supply chains (Eigenbrod and Gruda, 2015; Benke and Tomkins, 2017; Pulighe and Lupia, 2020). As such, urban farming has been identified as a promising solution to secure food supplies and reduce pressure on agricultural land; (see e.g., Despommier, 2009; O'Sullivan et al., 2020). There are many examples and methods for urban farming, although approaches such as vertical and hydroponic farming have been popular options worldwide in urban environments; (see e.g., Kozai, 2013; Kozai and Niu, 2016; Weidner et al., 2019). In particular, vertical farming1 has seen extensive expansion, technical innovations, prolific growth, and upscaling taking place worldwide (Specht et al., 2014; Armanda et al., 2019; Appolloni et al., 2020).

Beyond the many prevalent large-scale vertical farming systems available worldwide, also called “plant factories,” which have met critique in recent years (Banerjee and Adenaeuer, 2014; Cox, 2016; Pinstrup-Andersen, 2018; Bryce, 2019; McDougall et al., 2019), urban farming companies have been developing and experimenting with new approaches. These have spawned from the need to expand their offerings, business models, and connect with consumers in different ways. In recent years, small-scale modular, in-store growing systems are also increasing in popularity and number in connection to residential, commercial, and retail spaces; see also (Bustamante, 2020; Butturini and Marcelis, 2020). These new systems employ new business models for ensuring that customers are provided with fresh plants or tailor-made functions. Worldwide, several flagship systems have received extensive investments and expansion, (see e.g., Jürkenbeck et al., 2019; Butturini and Marcelis, 2020; InFarm, 2021; Renmark, 2021). Often these systems provide fresh plants, while the vertical farming company retains ownership and control of the infrastructure. Using these new business models, alternatives to traditional sales of products in conventional retail supply chains from centralized production locations, e.g., from plant factories, are increasingly being explored (Tukker, 2004; Mont et al., 2014; Geissdoerfer et al., 2018). As such, the operation and farming are provided as a service, i.e., “growing as a service.” In this study, we refer to these developing modular systems as growing-service systems (GSS), as they are inherently linked to the concept of product-service systems (PSS).

PSS refers to an approach where a company (or provider) sells a service, function, or a result, instead of a traditional product, placing value on designing for durability and remanufacturing (Tukker, 2004). There are different types of PSS offerings, depending on how the product is used, the business models employed, and what is to be the result of the contract. The literature categorizes different approaches to this to include product-oriented services, the most common being product, use, and result-oriented services; see a more thorough description in Tukker (2004). Integrating product and service offerings has been outlined to improve efficiency, which can lead to positive economic and environmental effects for industry and society (Mont and Tukker, 2006; Reim et al., 2015; Lingegård, 2020). Thus, PSS examples can be framed as sustainable business models which can help providers with approaches for a transition to the circular economy and provide differentiation from competitors (Amaya et al., 2014; Michelini et al., 2017). However, while such PSS systems and circular use of products are promoted as sustainable alternatives to conventional sales, their sustainability implications are rarely accounted for and are often confined to qualitative reviews of their potential (Lindahl et al., 2014; Salazar et al., 2015; Bocken et al., 2018). Furthermore, PSS research has tended to focus on the use of electronic equipment and manufacturing, with no studies related to food production systems, or services related to plant production. Despite the expansion of the field, insights on the implementation, adoption, and reasons for PSS business models are still very limited (Baines et al., 2007; Gaiardelli et al., 2014; Reim et al., 2015; Annarelli et al., 2016). Furthermore, as outlined by several authors, consumer-oriented products have received little attention, despite their potential (Skjelvik et al., 2017; Bocken et al., 2018; Martin et al., 2019a, 2021).

The aim of this study is to explore and analyze the development of these novel GSS systems in order to highlight their divergence in methods, business models, motivations, challenges, and of their implementation contexts. As such the article offers novel insights and the first of its kind to distinguish these new GSS systems in this growing segment to connect the urban agriculture, controlled-environment agriculture, sustainable business model, and product-service system literature for an emerging business-to-business (B2B) and business-to-consumer (B2C) service.

In the following sections, we outline the methodology employed to collect information on these systems (Section Methodology), highlight results from our qualitative review (Section Results), and provide a discussion on the results, including limitations and future research opportunities (Section Discussion). This is followed by a concluding discussion (Section Conclusions).

This study used an exploratory case study design to identify and characterize GSS firms2 and solutions. Due to the focus on how and why GSS solutions are being introduced along with the relative novelty of the phenomenon, case study methodology was deemed appropriate, which enables rich data collection despite a small number of cases (Eisenhardt, 1989; Voss et al., 2002). Multiple cases were selected in order to prevent researcher bias and increase the external validity of generalized findings (Voss et al., 2002). Qualitative research methods that enabled an in-depth investigation of the GSS systems were utilized (Denscombe, 2007).

To identify cases, we made use of an exploratory approach to identify firms implementing GSS solutions. An initial set of firms were identified from previous research conducted by the researchers. This list was expanded through information found in vertical farming newsletters and other industry news sources. Furthermore, we conducted online searches using keywords such as “growing-as-a-service,” “farming-as-a-service,” with a combination of terms such as modular, in-store, and vertical farming. To be included in the study, the firms needed to have a business model that went beyond the sale of plants to include a service component, typically realized through the combination of hardware and software systems. In addition, an effort was made to include firms with a business-to-business focus and ones with a business-to-consumer focus in order to capture the full spectrum of GSS solutions on the market.

The data was collected between February and September 2021. Questionnaires and interviews with firms made up the primary data sources. Due to the start-up environments of the firms, the researchers decided to give a choice between completing open-ended questions via an online survey tool or a video-based interview format so that firms could respond in the manner they deemed best because of often busy schedules. The questionnaire and interviews were developed and focused on seven key areas: (1) Company background and motivations, (2) Overview of how the modular unit/system work, (3) General business model (product and services), (4) Customer experience/training, (5) Benefits of the modular systems, (6) Barriers for modular systems, and (7) Sustainability aspects of the systems. The open-ended questions in the survey and structured interview questions were aligned to enable analysis of the qualitative information whether gathered in written or spoken form. The questionnaire and interview guide employed for the data collection are provided in the Supplementary Material for further information.

Questionnaires and interview requests were sent to 16 firms through the online questionnaire system Typeform. Survey responses were received from seven firms. Two of these were determined to be invalid for the study due to insufficient information or outside the case study criteria. Two firms elected to conduct a structured qualitative interview instead of participating in the survey. Primary data provided by the questionnaires and interviews were supplemented with secondary data sources, including online media articles, videos, and podcasts in order to enhance the reliability of the study through triangulation of data (Yin, 2014). This resulted in seven cases built on primary and secondary data. In addition, despite not having answered questionnaires or being interviewed, further cases were added through the sole use of secondary materials due to the richness of online sources (Yin, 2014; Salmons, 2015). Some of the largest firms providing GSS solutions had ample information in online interviews, podcasts, and their respective websites that enabled the researchers to answer questions in the questionnaire and interview protocol outlined above. Thus, a total of 11 firms from six countries in North America, Europe, and the Middle East were included in the study. See Table 1 for a summary of the data collection and firms analyzed for the study.

As the first step in data analysis, the results of the questionnaires and interviews were compiled and reviewed as individual cases. The two interviews were recorded and transcribed to enable the compilation of data and analysis. During this initial phase of analysis, research memos were written to capture emerging themes (Saldaña, 2013). The researchers were also inspired by themes from the PSS literature (e.g., based on business models and value creation), thus an iterative process between data and literature began, which resulted in the construction of a data matrix encompassing these themes: system characteristics, general business model, benefits/drivers, barriers, and sustainability. The data collection and analysis process is illustrated in Figure 1. The matrix was used to plot information from both primary and secondary sources for all cases and enabled a systematic cross-case analysis and comparison during the second phase of analysis. The goal during this phase was to identify similarities and differences across cases (Miles and Huberman, 1994) as well as convergent or divergent views about the benefits and future needs of GSS solutions. The data matrix is not provided in the Supplementary Materials due to proprietary information and requests from the firms involved. However, anonymized information and data can be provided upon request to the corresponding authors.

In this section, we present the findings of the analysis of the firms employing GSS systems. Five key areas were observed when analyzing the data, including (1) drivers and perceived benefits, (2) key characteristics of the systems, (3) business models, (4) sustainability, and (5) barriers and challenges.

All firms employ principles of controlled environment agriculture in their modular farms, including closed environment, sensors, LED lighting, and circulating water systems. While most firms boast a simple “plug-and-play” system, behind the hardware of the modules are complex software components, with remote monitoring of the systems for both business-to-business and consumer options. This happens through a wifi connection and is often accompanied by an App for the customer to also track and monitor the status of the plant growth and environment. Analytics technology is typically applied from the data gathered in order to improve conditions within the modules and promote “self-learning farms.” This enables optimization of the plant environment, with little knowledge or action needed from the user of the module.

Automation is a priority for the providers of the systems in order to minimize manual labor and ensure the systems are easy to use. Most firms include automation of key aspects, including lighting, climate controls, and pumps. Aspects that require human intervention, such as harvesting and cleaning, are handled through push notifications in accompanying Apps in order to minimize planning and time spent on the module. All systems require the initial placement of seedlings or seed pods in the system, and some also separate a “nursery chamber” for young plants that requires movement to a different shelf in the system until the plants are ready for harvest. The systems themselves range from small cube-like structures to shipping containers, with many likened to a large refrigerator unit found either in a home or retail location. The main products grown in the modular systems to date include leafy greens, herbs, and microgreens, with a few offering tomatoes and one focused exclusively on mushrooms.

The results highlight that many of the firms point to undesirable aspects of the current food system, e.g., long transport needs, unpredictability, and pesticide use as drivers to develop new ways to produce and distribute food. These drivers also translate into the perceived benefits of the systems. The ability for hyper-local production is believed to reduce transportation but also give more people the opportunity to be growers, whether that means in a retail location, restaurant, office, or at home. Some firms point to the desire to expose more people to the health benefits of a green environment, especially in cities, despite the fact that the systems themselves are not limited to use in urban areas. Contributing to food resiliency and helping to increase the local food supply are also mentioned by multiple firms as motivations for developing such modular systems.

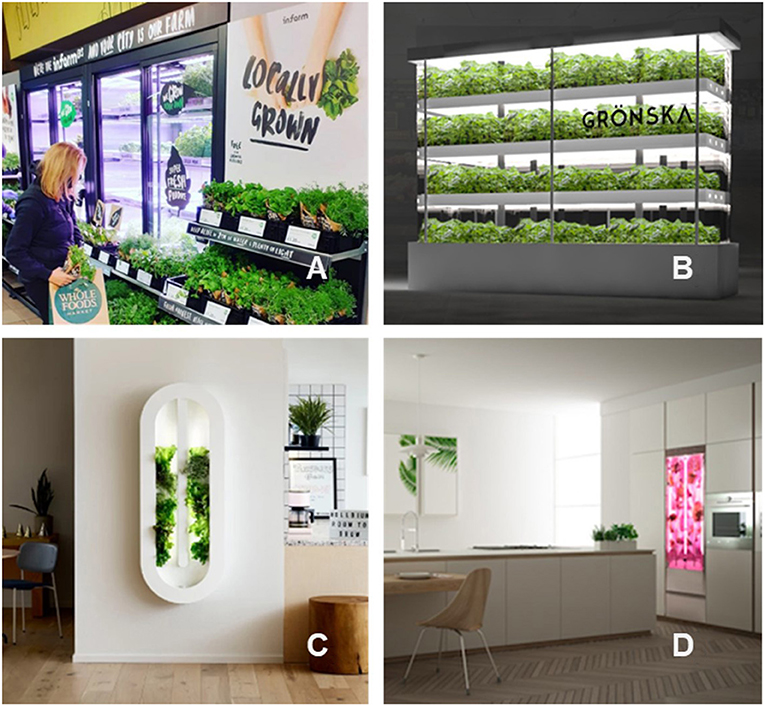

Beyond these systematic ambitions are also business-specific drivers and benefits. As identified by several firms, the size of the systems opens up possibilities, both for location and revenue diversification. The size of the module systems also enables firms to distribute growing across locations and avoid the strict zoning and building needs of larger farming systems. But aside from these benefits, the systems also play an important role in marketing the firms and their technology. From a firm level, several firms identified that the systems bring visibility to the farms and the use of hydroponics and technology in food production. For business-to-business clients, the firms providing the GSS systems believe there are benefits to the visual appeal of the systems in stores and restaurants. In fact, one of the firms in the study initially envisioned the systems being placed in the back of the house in restaurants. However, the restaurant owners themselves began to demand well-designed systems that could be used in the front of the restaurant as a kind of art installation. This is also apparent in consumer models, where design is a key element of the systems to ensure its integration into the home where space is limited. See Figure 2 for a depiction of different types of GSS modular farms.

Figure 2. Depiction of different types of GSS systems analyzed in the study, with (A) showing an in-store farm by InFarm (2021), (B) showing an in-store/in-restaurant farm by Grönska (2021), (C) depicting a growing unit in an office environment by Hollbium (2021), and (D) showing a B2C example by Natufia (2021).

Seven of the firms in this study focus exclusively on the business-to-business (B2B) market, though the users of the systems vary from food retailers, restaurants, offices, and public institutions such as elderly care homes. Two of the firms focus exclusively on the consumer market, i.e., business-to-consumer (B2C), while the remaining two have deployed both B2B and B2C models. One of these firms had plans to launch a B2C module and accelerated those plans when the Covid-19 pandemic hit. The remaining firm remains focused chiefly on B2B customers but launched a B2C solution during the pandemic as a pivot when many restaurants in its area were shut down due to restrictions.

The input from firms suggests that the value created by the systems is largely connected to the idea that consumers want better access to fresh, local food products. The characteristics of the systems outlined above provide a compelling experience to provide hyper-local production. From a B2C perspective, this value is expressed as the ability to grow your own fresh produce and increased access to nutrition-dense leafy greens and herbs. Some system providers are able to show a cost comparison between the long-term use of their systems vs. buying (and in many cases wasting) produce at the store. This is translated into clear value from a consumer perspective. The end-consumer is compelled to purchase a system due to a desire to grow their own produce at home in an easy, low-maintenance manner.

The value creation from a B2B perspective includes the proposition of fresh, local produce but is also driven by intangible assets such as technology, innovation, intellectual property, customer relations, and branding (both for the firms and users). These aspects are harder to quantify in economic terms, especially in a retail environment where space for modules is limited and often expensive. So while there is value being created, the economic value, specifically the profitability of the systems for the firms (providers) and the revenues generated for the users of the GSSs, is unclear at this stage, pointing to the general novelty of the systems.

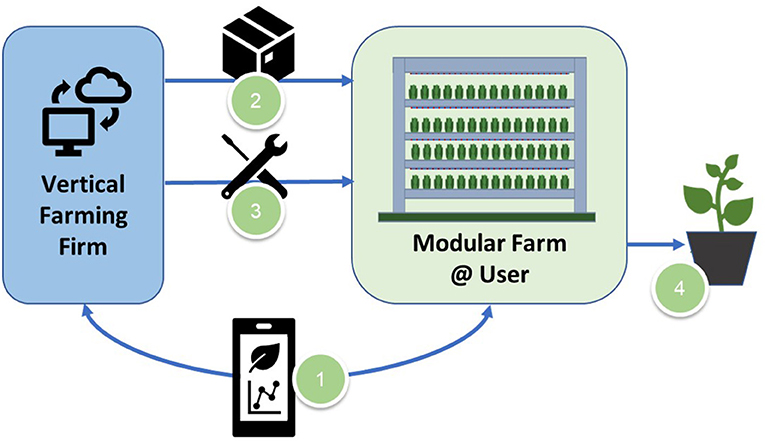

While the specific technology and services offered by the firms, as well as the locations of the farms can vary, all firms were found to use an operational model built on the integration of hardware and software to deliver value. This is typically realized through a type of platform for digital interaction between providers and users of the system. This requires a combination of people, processes, and technology in order to deliver value. Figure 3 depicts a generalized system and value delivery model for GSS systems.

Figure 3. Generalized system and value delivery model for GSS systems. The farm and vertical farming firm are connected through (1) cloud-based application to monitor and provide feedback for (2) consumables and other inputs, (3) possible maintenance and optimization, and finally (4) information about the cultivation and final harvesting periods.

From a people perspective, there is a combination of resources inside the system providers and people in the customer organization needed in order to maximize the value. Though, as pointed out in the section on characteristics of the systems, the firms look to minimize the need for human intervention from the customer, thus hoping to reduce the demand for new skill sets or a reorganization of job responsibilities. The process is largely automatic and continues to be optimized through business intelligence tools such as machine learning and artificial intelligence analytics. Off-site monitoring and proprietary software applications also help streamline the process for the end-user. The technology includes the hardware of the modules and needed input materials. There is a mix of proprietary hardware solutions and the use of third-party inputs. To deliver consumables and other materials, a number of suppliers and partners are needed, including seed providers, substrate materials, and delivery, which usually occurs through regular mail.

From a B2B perspective, scalability remains a challenge of the modular system, particularly in the retail sector. While some firms focus solely on modular solutions, others are combining the approach of both modules and their larger-scale centralized vertical farms, also called “mega farms,” in order to deliver desired volumes of local, fresh produce. Many times these are different technical set-ups, however, in one of the cases, the firm is building mega farm solutions built on its modular technology, which can easily be scaled up or down based on customer needs. Others are taking the principles of the “growing-as-a-service” model, but integrating it into partnerships in mega farm facilities, where retailers or real estate owners invest in a modular farm, and the firm takes care of the growing for them.

While surveys, interviews, and secondary sources provide some insights into the revenue models of these systems, there is a mix of strategies at this stage and it is unclear if the modular systems offer a sustainable profit model over time. This also points to a relatively young phenomenon. Though specifics vary, the customers of these systems are paying for the bundling of both products and services. The majority of the B2B module systems are either leased or rented, with some firms requiring longer-term contracts.

Using a subscription-based model, many firms offer a service package that includes a number of features such as access to remote monitoring and a software application and certain services, including maintenance, training, system servicing, etc. Inputs such as nutrient solutions and seeds/plugs are sometimes included in a monthly subscription fee, while others require users to purchase them on demand. Other services that may require a separate fee or are included in package pricing include installation and a customized product mix plan for the units. Some of the firms do require the B2B customers to purchase the systems, which include the hardware and software components. Customers must then pay either monthly or on-demand costs for needed supplies and inputs.

Not all firms surveyed have developed their own technology behind the systems. All but one use a mix of proprietary and purchased components in order to package the products and services into a unique offering. One of the firms is using a more standard white label strategy, where it resells the hardware/software bundle developed by another farm in a different market under its own brand in its region.

Unlike the majority of B2B offerings, the B2C modules are purchased by the end-consumer. Prices of the consumer GSS systems place them in a luxury category, with the current in-home units offered by the firms in our study ranging from US$4,000–US$8,000. The purchase price typically includes a starter kit of seeds and nutrient solutions, as well as access to a software application and remote monitoring support. From there, some firms offer a monthly subscription option to cover supplies, while others use an on-demand purchase model.

The majority of the firms suggested that their GSSs are, or are becoming, more sustainable. This is often related to environmental sustainability, where many of the firms suggest that the modular farms offer resource-efficiency advantages, primarily through reduced water and fertilizer consumption in the horticultural production methods employed.

As mentioned previously, location was identified as a key benefit of these systems. The production of hyper-local foods is often recognized by the different firms as a sustainable advantage, providing reduced transportation through shorter distances in their supply chain, and bringing the crops closer to the consumer. Connected to this are the many suggestions of increased freshness and shelf-life, which in turn are suggested to add to the quality of the product. Furthermore, this proximity to the end-users is suggested to reduce waste along the supply chain by a number of firms.

Sustainability was also suggested by many firms to be a priority in their work. Some firms are looking into reducing supply chain sustainability impacts by reducing shipping distances for consumables needed in the modular farms. Several firms also addressed the sustainability of their packaging materials, suggesting they are moving away from conventional plastics, and have been using, or experimenting with new materials. Furthermore, circularity was also discussed, as several firms are taking steps to include more circular approaches in their production. This includes reusing materials, developing new fertilizers, and improving the integration with urban environments and their building hosts. Nearly all firms were aware of the impacts of energy use, mentioning electricity and its negative environmental impacts. As such many of the studied cases highlight their purchasing of renewable energy or optimization developments to reduce energy consumption; see also discussions above on key characteristics.

The barriers and challenges outlined by the firms can be categorized into broader industry barriers and firm-specific challenges. From an industry perspective, the cost of technology is considered a current barrier, though many admit the costs are decreasing. The variety of products grown in the systems is also seen as a challenge for long-term growth and demand generation. Overall, the efficiency and sustainability factors of the systems are noted as an area that needs to be improved. In addition, one firm also identified the need for better business models in order to achieve economic sustainability of the modular offering. This includes aspects of the contracts and ensuring the long-term use of the systems so they are not seen as just marketing or display tools that are frequently changed out for other product displays, as floor space is often limited and/or expensive. Due to the novelty of the systems and hydroponic growing in general, supply and demand management is also difficult for most firms at this stage.

From a firm-specific perspective, the cases seem to be at different stages of development or concentrating on different concerns. In general, most of the firms are focused on bringing greater efficiency to the hardware/software interaction in order to further decrease the work required by the customer. As noted by one B2B-focused firm, the customers do not want to be farmers, so improving automation and services are seen as vital. Others are focused on increasing the variety of plants that can be grown in the systems and/or the mix within one unit. For B2C-focused firms, the initial costs of the units are seen as a barrier, as they may be considered luxury products in the current market. In addition, space is a concern, especially for city apartments. One firm mentioned the development of smaller units and units with less technology included to bring different price options to the consumer segment.

This section further elaborates on themes that emerged from the analysis and also presents avenues for future research.

While there has been an extensive expansion of larger-scale centralized production systems for vertical farming (Butturini and Marcelis, 2020; Kotsier, 2020), our results highlight an expanding smaller-scale modular system for vertical farming. It was found that the novel approach to food provisioning in urban areas is being conducted worldwide, and encompasses a number of different products and systems. As highlighted in previous studies, there is a growing market for such solutions (Jürkenbeck et al., 2019; Butturini and Marcelis, 2020; Renmark, 2021). Our findings imply that these systems are being offered as novel, or niche, approaches, and in B2B environments, as an expansion of the vertical farming firms' own business portfolio. It was found that several firms are combining modular farms with conventional larger scale vertical farms; either starting directly with modular units or starting from larger farms and exploring the use of modular units. Once again, this approach has been highlighted as a way to differentiate from competitors in the market; aligning with previous studies on vertical farm market development, (e.g., Bustamante, 2020). As such, these tailored systems can create customized products to increase competitiveness and a unique profile in the retail market; (see e.g., Pine and Gilmore, 2014; Charters et al., 2017; Jürkenbeck et al., 2019; Sjölander-Lindqvist et al., 2020). A few of the firms in the study highlighted the ability to increase the types of products grown in the systems as an important area for expansion, which would address previous criticism of vertical farming in general (Cox, 2016; Pinstrup-Andersen, 2018); though others argue this limitation is more about economics than system ability (Banerjee and Adenaeuer, 2014).

Jurkenbeck et al. (2020) also found that the transparency provided by such modular solutions, which are directly visible to consumers, greatly improves their acceptance of such systems. Nonetheless, research has shown that consumers may be reluctant to consume foods from these more “technical” or less “natural” solutions (Siegrist, 2008; Coyle and Ellison, 2017; Grebitus et al., 2020), due in part to the lack of knowledge of these systems (Coyle and Ellison, 2017; Jürkenbeck et al., 2019; Yano et al., 2021). As such, by providing a visual element, the GSS providing firms are attempting to break down barriers by providing further transparency to how food is produced in vertical farming environments and engage with consumers. The firms in our study also pointed to this important aspect of the distributed model, which enables consumers to understand hydroponic growing. Placed in the retailers, the module systems provide a unique experience and educational opportunity. Located in homes, consumers are given the power over the product decisions, harvesting and availability. Such effects expand previous PSS research which have highlighted how consumer awareness of PSS systems challenges conventional product ownership, especially in urban areas, with systems for rental, sharing, and services (Acquier et al., 2017; Zamani et al., 2017; Hollingsworth et al., 2019; Martin et al., 2019b, 2021). In addition, few previous studies have outlined B2C examples of PSS systems, where the module is included at home. While such examples are available for B2C applications in the home, e.g., printing (McIntyre, 2018), robotic vacuums (Electrolux, 2019), no systems have outlined food production systems.

While the study provides some general insights into the business models of GSS solutions, it was difficult to obtain a detailed view of any one firm's business model. This could be due to a number of factors including the relative recent entrance of GSS solutions in the market, a desire for secrecy about this aspect of the farms and also the limitation of using open-ended surveys, where firms may have felt less inclined to write detailed commentary on this aspect. This was especially difficult in the B2B-focused firms. However, the analyzed information did uncover a number of interesting points.

First, although the long-term sustainability of the business model is unknown, almost all of the firms acknowledged the benefits of the systems in helping to grow awareness of hydroponics and build market acceptance. For the B2B focused firms, the modular-based systems also provided an opportunity to further develop relationships with retailers and restaurants by providing a unique experience for their end customers. Thus, by introducing the modular systems, even as the business model may be in flux, the GSS providers are able to explore the market and grow a network; which has been acknowledged as instrumental for technology entrepreneurs and a key function of business models (Doganova and Eyquem-Renault, 2009). This ability to extend the current offering beyond the delivery of plants and build relationships with their customers also aligns with key factors for the success of PSS offerings (Annarelli et al., 2016).

Second, while specifics vary, the customers of these systems are paying for a bundling of both products and services. B2C models require the purchase of the system, which also includes access to a number of software applications. The majority of the B2B systems are either leased or rented, and contracts include a number of services, which may or may not include performance indicators around the number of plants harvested and sold. From our results, it was difficult to suggest which conventional PSS model was employed and there does not seem to be one dominant model at this stage (i.e., product-oriented, use-oriented and results-oriented per Tukker, 2004). The B2C models align with a product-oriented model, as the main offering is still the product, which in this case could be considered both the plants and the physical module. B2B solutions, however, are harder to categorize. Some systems seem to align best with the use-oriented model, especially those found in restaurants or offices, as the systems are rented and largely run by the customer. However, retailer-focused solutions are harder to categorize. Some seem to be use-oriented, but others are also based on the number of plants harvested, aligning more with a results-oriented model. This difficulty in categorization points to the difference in our study vs. past PSS studies, which have generally focused on the manufacturing sector. Many times, in those cases, services were added to a long-term use product, where in GSS systems, a plant is the original product. Thus, the GSS system is introducing both a new product (the module) and services to a product that is consumed and used in a relatively short period of time, making it more difficult to fit into the established categories of PSS models. As highlighted, more information is needed for GSS firms to improve upon their business models in order to achieve economic viability of the offering. As such, further design developments and business model iterations may be necessary. Similar assertions are also highlighted in Kambanou and Lindahl (2016) and Bocken et al. (2018).

Last, our study uncovered some insights into business model innovation in the food industry. Vertical farming systems are constantly improving and expanding. As suggested in Klerkx and Rose (2020), vertical farming innovations are potentially game-changing, affecting the way in which food is produced, processed, traded, and consumed. The visibility and benefits of hydroponic growing enables customers to make decisions based on new characteristics of food, such as environmental effects, or by taking into account intangible benefits such as eating a product closer to harvest. The ability to differentiate products based on intangible and tangible benefits, along with “turning ordinary products into extraordinary experiences” have been identified as key PSS benefits (Annarelli et al., 2016). These developments are also in line with consumer demand for more locally produced food, especially in wake of the Covid-19 pandemics (Toler et al., 2009; Granvik et al., 2017; Pulighe and Lupia, 2020). In particular, the B2C modules are challenging the dominant business model in the food industry, where typically an individual buying a product from a store supports the business model of the food retailer (Kaplan, 2012). B2C modules enable the GSS firms to capture the value directly from the end-consumer. Some firms argue that giving the consumers the control over production is an intangible value consumers are willing to pay for. As all of the firms in the study point to a desirability to improve the environmental performance of the current food system, the experimentation of business models that support sustainable innovation is an important and ongoing endeavor, as it is difficult to simply transplant business models from one economy to another if sustainable development is a goal (Boons and Lüdeke-Freund, 2013).

The results suggest that most firms highlight a number of benefits of modular systems. Owing to their proximity to consumers, the location was highlighted as a beneficial aspect of these systems, where the freshness and nutritional aspects of the products were suggested to be superior in these systems. This is especially important for leafy greens, which can begin to lose nutritional value as soon as they are harvested. Indeed, previous studies have suggested that vertical farms can control the genetics, quality, and sensory experience of different croups through optimized conditions during growth and pre-harvest, (see e.g., Selma et al., 2012; Nicole et al., 2019; Sharathkumar et al., 2020). Furthermore, many firms also suggest location is important for sustainability, e.g., by reducing transportation along the supply chain. However, previous studies have shown that the transportation of foods has a relatively minor impact on the overall impact (Edwards-Jones et al., 2008; Coley et al., 2009), and specifically for urban-vertical farms (Martin and Molin, 2019). Nonetheless, an important benefit also highlighted for vertical farms in close proximity to consumers is also related to variety of crops which can be produced, which can be chosen for flavor and taste, thus providing differentiation, which is not always possible in conventional varieties found in retail which may be optimized for transportation resistance (Bogomolova et al., 2018; Harada and Whitlow, 2020; Renmark, 2021).

Beyond transportation, many of the firms outline the advantages the GSS systems provide for environmental sustainability, primarily relating to resource efficiency improvements and reduced toxicity from the lack of pesticides employed. Such motivations are common amongst urban agricultural systems, see e.g., assertions in Specht et al. (2014), and have been found to be a major driver in consumer acceptance of such systems for different vertical farming systems (Coyle and Ellison, 2017; Jürkenbeck et al., 2019). However, no firms highlighted other sustainability pillars, e.g., social or economic sustainability. There are a limited number of studies reviewing sustainability or specific case studies of urban farms in different scales beyond plant factories and rooftop farms (Kulak et al., 2013; Romeo et al., 2018; Martin et al., 2019b) and thus more research could focus on the implication of GSS systems in comparison to their larger counterparts. Furthermore, while such PSS systems are promoted as sustainable alternatives, their economic, social, and environmental implications are rarely accounted for and are often confined to qualitative reviews of the potential of these systems (Lindahl et al., 2014; Salazar et al., 2015; Kambanou and Lindahl, 2016; Bocken et al., 2018). It is important that further developments, case studies, and assessments are explored and tested to ensure they achieve the desired intentions and provide value to both provider and users of the systems (Kambanou and Lindahl, 2016; Bocken et al., 2018; Martin et al., 2021).

A further benefit outlined by most firms is the potential to control the systems to allow for learning and ease of use by the consumers. This is often included in PSS offerings, allowing for the provider to control the system and maintenance and reduce risks for the user (Tukker and Tischner, 2006; Lingegård, 2020), although its influence on the sustainability of the systems are not well-known (Martin et al., 2021).

Our analysis of GSS could be improved in a number of ways. First, the study sought to understand the nature of the activities and technical functions surrounding GSS solutions but did not evaluate their effectiveness in any one area, e.g., market development, sustainability, innovation management. Future studies of GSS systems could include further information and questions relating to the business models employed. As many of the firms suggested that they are designing the systems with the users and consumers in mind, in the future, research could focus on user and consumer perception and perspectives of these systems. Furthermore, while the questionnaire and interviews did not address the lifetime of the modular units, the lifetime, and design for durability are important for the PSS systems. Our study also highlighted a limited geographical selection of such cases, which has examples worldwide, but has a more European focus. Further work can be done to develop knowledge from a broader set of GSS solutions worldwide, especially as they are becoming increasingly apparent. Finally, as the study is focused on a novel method for vertical farming, a more longitudinal approach could be employed to study the change in these systems over time to study their development. Further studies could also focus on the complexity of business ecosystems for GSS solutions.

Using a product-service system approach, the results of this study highlighted examples and characteristics in the development of technology and software systems in vertical farming, referred to as growing-service systems (GSS) in this paper. It was found that this novel method is employed by a number of firms as a new business model. This was used to extend and improve their markets, either as an additional approach to their larger centralized farms, or as their exclusive approach. The value created by these systems rests largely on intangibles such as fresher products, local production, and automated control over growing aspects. In order to deliver this value, all firms are developing a combination of hardware and software applications that provide a number of automated services to achieve the desired output. We found that the value capture strategies for the systems varies between the B2C and B2B contexts. While the modular units are often provided with a subscription service for B2B contexts, they are generally purchased in B2C contexts; though both concepts included a number of services to complement the hardware system.

The key motivations for these systems were the ease of use and the perceived benefits of hyper-local production, including improved product quality and building more resiliency in local food systems. Many of the firms also found the modular systems to be beneficial in their marketing by increasing transparency and awareness for vertical farming methods and products. Nearly all firms motivated the development and use of these systems to contribute to more sustainable food provisioning. Location was found to be a key aspect in both the sustainability and quality of the products, e.g., linked to the proximity to users and “freshness” of the product. However, the study also highlights some barriers to their development. These include improving the business models to allow for more economic viability, reducing costs, improving the efficiency of the systems, and technology for increased automation in limited space.

The results and knowledge produced contribute to the emerging literature on sustainable business models, urban-vertical farming, and PSS through empirical evidence from a novel segment of PSS in the food industry; once again referred to in this study as GSS. The results of this study can be useful for GSS firms, in addition to retailers and direct users, to further develop and improve the GSS offerings and modular vertical farming systems for different contexts. Future research should also be placed on understanding the implications of these modular systems in comparison to their larger-centralized counterparts, in addition to studying the role of technology and user perception/acceptance of these systems to add to the understanding of the opportunities and challenges of deploying sustainable business models.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

MM and MB equally contributed to the concept of the study, its data collection, analysis, and writing of the manuscript. All authors contributed to the article and approved the submitted version.

The research has been funded through a grant from the Swedish Innovation Agency (Vinnova) in the project Urban farming for resilient and sustainable food production in urban areas, Grant 2019-03178.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

We would like to thank the vertical farming firms which provided information on their modular farming systems to learn more about this exciting development. We would also like to thank our colleagues in the project for support and guidance and the reviewers for feedback leading toward the development of this article.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fsufs.2021.787281/full#supplementary-material

1. ^In this study we define vertical farming as the vertical production of edible plants and vegetables through controlled-environment agriculture (CEA) techniques.

2. ^Hereafter, we refer to farming companies as simply “firms,” while reference to specific sites as “farms.”

Acquier, A., Daudigeos, T., and Pinkse, J. (2017). Promises and paradoxes of the sharing economy: an organizing framework. Technol. Forecast. Soc. Change 125, 1–10. doi: 10.1016/j.techfore.2017.07.006

Amaya, J., Lelah, A., and Zwolinski, P. (2014). Design for intensified use in product–service systems using life-cycle analysis. J. Eng. Des. 25, 280–302. doi: 10.1080/09544828.2014.974523

Annarelli, A., Battistella, C., and Nonino, F. (2016). Product service system: a conceptual framework from a systematic review. J. Clean. Prod. 139, 1011–1032. doi: 10.1016/j.jclepro.2016.08.061

Appolloni, E., Orsini, F., Michelon, N., Pistillo, A., Paucek, I., Pennisi, G., et al. (2020). From microgarden technologies to vertical farms: innovative growing solutions for multifunctional urban agriculture. Acta Hortic. 1298, 59–70. doi: 10.17660/ActaHortic.2020.1298.10

Armanda, D. T., Guinée, J. B., and Tukker, A. (2019). The second green revolution: innovative urban agriculture's contribution to food security and sustainability—a review. Glob. Food Secur. 22, 13–24. doi: 10.1016/j.gfs.2019.08.002

Baines, T. S., Lightfoot, H. W., Evans, S., Neely, A., Greenough, R., Peppard, J., et al. (2007). State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 221, 1543–1552. doi: 10.1243/09544054JEM858

Banerjee, C., and Adenaeuer, L. (2014). Up, up and away! The economics of vertical farming. J. Agri. Stud. 2, 40–60. doi: 10.5296/jas.v2i1.4526

Benke, K., and Tomkins, B. (2017). Future food-production systems: vertical farming and controlled-environment agriculture. Sustain.: Sci. Pract. Policy 13, 13–26. doi: 10.1080/15487733.2017.1394054

Bocken, N. M. P., Mugge, R., Bom, C. A., and Lemstra, H.-J. (2018). Pay-per-use business models as a driver for sustainable consumption: evidence from the case of HOMIE. J. Clean. Prod. 198, 498–510. doi: 10.1016/j.jclepro.2018.07.043

Bogomolova, S., Loch, A., Lockshin, L., and Buckley, J. (2018). Consumer factors associated with purchasing local vs. global value chain foods. Renew. Agric. Food Syst. 33, 33–46. doi: 10.1017/S1742170516000375

Boons, F., and Lüdeke-Freund, F. (2013). Business models for sustainable innovation: state-of-the-art and steps toward a research agenda. J. Clean. Prod. 45, 9–19. doi: 10.1016/j.jclepro.2012.07.007

Bryce, E. (2019). The Trouble with the Urban Farming “Revolution.” Anthroprocene. Available online at: https://www.anthropocenemagazine.org/2019/04/the-trouble-with-the-urban-farming-revolution/ (accessed November 9, 2020).

Bustamante, M. J. (2020). Using sustainability-oriented process innovation to shape product markets. Int. J. Innov. Manag. 24:20400010. doi: 10.1142/S1363919620400010

Butturini, M., and Marcelis, L. F. M. (2020). “Chapter 4—vertical farming in Europe: present status and outlook,” in Plant Factory, 2nd Edn, eds T. Kozai, G. Niu, and M. Takagaki (Amsterdam: Academic Press), 77-91. doi: 10.1016/B978-0-12-816691-8.00004-2

Charters, S., Spielmann, N., and Babin, B. J. (2017). The nature and value of terroir products. Eur. J. Mark. 51, 748–771. doi: 10.1108/EJM-06-2015-0330

Coley, D., Howard, M., and Winter, M. (2009). Local food, food miles and carbon emissions: a comparison of farm shop and mass distribution approaches. Food Policy 34, 150–155. doi: 10.1016/j.foodpol.2008.11.001

Cox, S. (2016). Enough with the Vertical Farming Fantasies: There are Still Too Many Unanswered Questions About the Trendy Practice. Available: http://www.salon.com/2016/02/17/enough_with_the_vertical_farming_partner (accessed September 29, 2021).

Coyle, B. D., and Ellison, B. (2017). Will consumers find vertically farmed produce “out of reach?” Choices. 32, 1–8. doi: 10.22004/ag.econ.253382

Denscombe, M. (2007). The Good Research Guide For Small-Scale Social Research Projects, 3rd Edn. Birkshire: Open University Press.

Despommier, D. (2009). The rise of vertical farms. Sci. Am. 301, 80–87 doi: 10.1038/scientificamerican1109-80

Doganova, L., and Eyquem-Renault, M. (2009). What do business models do?: innovation devices in technology entrepreneurship. Res. Policy 38, 1559–1570. doi: 10.1016/j.respol.2009.08.002

Edwards-Jones, G., Milà I Canals, L., Hounsome, N., Truninger, M., Koerber, G., Hounsome, B., et al. (2008). Testing the assertion that “local food is best”: the challenges of an evidence-based approach. Trends Food Sci. Technol. 19, 265–274. doi: 10.1016/j.tifs.2008.01.008

Eigenbrod, C., and Gruda, N. (2015). Urban vegetable for food security in cities. A review. Agron. Sustain. Dev. 35, 483–498. doi: 10.1007/s13593-014-0273-y

Eisenhardt, M. (1989). Building theories from case. Acad. Manag. 14, 532–550. doi: 10.5465/amr.1989.4308385

Electrolux (2019). Vacuum-as-a-Service: Electrolux Trials New Subscription-Based Business Models. Available online at: https://www.electroluxgroup.com/en/vacuum-as-a-service-electrolux-trials-new-subscription-based-business-models-29880/ (accessed November 10, 2020).

Gaiardelli, P., Resta, B., Martinez, V., Pinto, R., and Albores, P. (2014). A classification model for product-service offerings. J. Clean. Prod. 66, 507–519. doi: 10.1016/j.jclepro.2013.11.032

Geissdoerfer, M., Vladimirova, D., and Evans, S. (2018). Sustainable business model innovation: a review. J. Clean. Prod. 198, 401–416. doi: 10.1016/j.jclepro.2018.06.240

Granvik, M., Joosse, S., Hunt, A., and Hallberg, I. (2017). Confusion and misunderstanding—interpretations and definitions of local food. Sustain. 9:1981. doi: 10.3390/su9111981

Grebitus, C., Chenarides, L., Muenich, R., and Mahalov, A. (2020). Consumers' perception of urban farming—an exploratory study. Front. Sustain. Food Syst. 4:79. doi: 10.3389/fsufs.2020.00079

Grönska (2021). Grönska Stadsodling 365 Homepage. Available online at: www.gronska.org (accessed August 12, 2021).

Harada, Y., and Whitlow, T. H. (2020). Urban rooftop agriculture: challenges to science and practice. Front. Sustain. Food Syst. 4:76. doi: 10.3389/fsufs.2020.00076

Hollbium (2021). Holbium Homepage. Available online at: www.hollbium.com (accessed August 10, 2021).

Hollingsworth, J., Copeland, B., and Johnson, J. (2019). Are e-scooters polluters? The environmental impacts of shared dockless electric scooters. Environ. Res. Lett. 14:084031. doi: 10.1088/1748-9326/ab2da8

InFarm (2021). InFarm Homepage. Available online at: www.infarm.com (accessed August 10, 2021).

Jürkenbeck, K., Heumann, A., and Spiller, A. (2019). Sustainability matters: consumer acceptance of different vertical farming systems. Sustainability 11:4052. doi: 10.3390/su11154052

Kambanou, M. L., and Lindahl, M. (2016). A literature review of life cycle costing in the product-service system context. Procedia CIRP 47, 186–191. doi: 10.1016/j.procir.2016.03.054

Kaplan, S. (2012). “Business models 101: creating, delivering, and capturing value,” in The Business Model Innovation Factory, ed S. Kaplan (New York, NY: Wiley), 17–33.

Klerkx, L., and Rose, D. (2020). Dealing with the game-changing technologies of agriculture 4.0: how do we manage diversity and responsibility in food system transition pathways? Glob. Food Secur. 24:100347. doi: 10.1016/j.gfs.2019.100347

Kotsier, J. (2020). This 2-Acre Vertical Farm Out-Produces 720 Acre “Flat Farms.” Available online at: https://www.forbes.com/sites/johnkoetsier/2020/11/20/this-2-acre-vertical-farm-out-produces-750-acre-flat-farms/?sh=6a8f4a567a57 (accessed June 21, 2021).

Kozai, T. (2013). Resource use efficiency of closed plant production system with artificial light: concept, estimation and application to plant factory. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 89, 447–461. doi: 10.2183/pjab.89.447

Kozai, T., and Niu, G. (2016). “Chapter 1—introduction,” in Plant Factory, eds T. Kozai, G. Niu and M. Takagaki (San Diego: Academic Press), 3-5. doi: 10.1016/B978-0-12-801775-3.00001-9

Kulak, M., Graves, A., and Chatterton, J. (2013). Reducing greenhouse gas emissions with urban agriculture: a life cycle assessment perspective. Land Urban Plan. 111, 68–78. doi: 10.1016/j.landurbplan.2012.11.007

Lindahl, M., Sundin, E., and Sakao, T. (2014). Environmental and economic benefits of integrated product service offerings quantified with real business cases. J. Clean. Prod. 64, 288–296. doi: 10.1016/j.jclepro.2013.07.047

Lingegård, S. (2020). “Product service systems: business models toward a circular economy,” in Handbook of the Circular Economy, eds M. Brandao, D. Lazarevic, and G. Finnveden (Cheltenham: Edward Elgar Publishing), 61-73. doi: 10.4337/9781788972727.00013

Martin, M., Heiska, M., and Björklund, A. (2021). Environmental assessment of a product-service system for renting electric-powered tools. J. Clean. Prod. 281:125245. doi: 10.1016/j.jclepro.2020.125245

Martin, M., Lazarevic, D., and Gullström, C. (2019a). Assessing the environmental potential of collaborative consumption: peer-to-peer product sharing in Hammarby Sjöstad, Sweden. Sustainability 11:190. doi: 10.3390/su11010190

Martin, M., and Molin, E. (2019). Environmental assessment of an urban vertical hydroponic farming system in Sweden. Sustainability 11:4124. doi: 10.3390/su11154124

Martin, M., Poulikidou, S., and Molin, E. (2019b). Exploring the environmental performance of urban symbiosis for vertical hydroponic farming. Sustainability 11:6724. doi: 10.3390/su11236724

McDougall, R., Kristiansen, P., and Rader, R. (2019). Small-scale urban agriculture results in high yields but requires judicious management of inputs to achieve sustainability. PNAS-Proc. Nat. Acad. Sci. 116, 129–134. doi: 10.1073/pnas.1809707115

McIntyre, K. (2018). “Accelerating the circular economy @ HP,” in Designing for the Circular Economy, 1st Edn, ed M. Charter (London: Routledge), 1–11. doi: 10.4324/9781315113067-27

Michelini, G., Moraes, R. N., Cunha, R. N., Costa, J. M. H., and Ometto, A. R. (2017). From linear to circular economy: PSS conducting the transition. Proc. CIRP 64, 2–6. doi: 10.1016/j.procir.2017.03.012

Miles, M. B., and Huberman, A. M. (1994). Qualitative Data Analysis: An Expanded Sourcebook. Thousand Oaks, CA: Sage.

Mont, O., Neuvonen, A., and Lähteenoja, S. (2014). Sustainable lifestyles 2050: stakeholder visions, emerging practices and future research. J. Clean. Prod. 63, 24–32. doi: 10.1016/j.jclepro.2013.09.007

Mont, O., and Tukker, A. (2006). Product-service systems: reviewing achievements and refining the research agenda. J. Clean. Prod. 14, 1451–1454. doi: 10.1016/j.jclepro.2006.01.017

Natufia (2021). Natufia Resources Page. Available online at: https://natufia.com/gallery/ (accessed September 28, 2021).

Nicole, C. C. S., Mooren, J., Pereira Terra, A. T., Larsen, D. H., Woltering, E. J., Marcelis, L. F. M., et al. (2019). Effects of LED lighting recipes on postharvest quality of leafy vegetables grown in a vertical farm. Acta Hortic. 1256, 481–488 doi: 10.17660/ActaHortic.2019.1256.68

O'Sullivan, C. A., McIntyre, C. L., Dry, I. B., Hani, S. M., Hochman, Z., and Bonnett, G. D. (2020). Vertical farms bear fruit. Nat. Biotechnol. 38, 160–162. doi: 10.1038/s41587-019-0400-z

Pine, J., and Gilmore, J. (2014). A leader's guide to innovation in the experience economy. Strat. Lead. 42, 24–29. doi: 10.1108/SL-09-2013-0073

Pinstrup-Andersen, P. (2018). Is it time to take vertical indoor farming seriously? Glob. Food Secur. 17, 233–235. doi: 10.1016/j.gfs.2017.09.002

Pulighe, G., and Lupia, F. (2020). Food first: COVID-19 outbreak and cities lockdown a booster for a wider vision on urban agriculture. Sustainability 12:5012. doi: 10.3390/su12125012

Reim, W., Parida, V., and Örtqvist, D. (2015). Product–Service Systems (PSS) business models and tactics–a systematic literature review. J. Clean. Prod. 97, 61–75. doi: 10.1016/j.jclepro.2014.07.003

Renmark, A. (2021). Hajpad trend växer–men är den hållbar? Dagligvarunytt 5. Available online at: https://www.dagligvarunytt.se/marknadsnytt/innovation/hajpad-odlingstrend-vaxer-i-butiken-som-bake-off-for-kryddgront/ (accessed July 10, 2021).

Romeo, D., Vea, E. B., and Thomsen, M. (2018). Environmental impacts of urban hydroponics in Europe: a case study in Lyon. Proc. CIRP 69, 540–545. doi: 10.1016/j.procir.2017.11.048

Salazar, C., Lelah, A., and Brissaud, D. (2015). Eco-designing product service systems by degrading functions while maintaining user satisfaction. J. Clean. Prod. 87, 452–462. doi: 10.1016/j.jclepro.2014.10.031

Saldaña, J. (2013). The Coding Manual For Qualitative Researchers, 2nd Edn. Thousand Oaks, CA: Sage.

Salmons, J. E. (2015). Doing Qualitative Research Online. Thousand Oaks, CA: Sage. doi: 10.4135/9781473921955

Selma, M. V., Luna, M. C., Martínez-Sánchez, A., Tudela, J. A., Beltrán, D., Baixauli, C., et al. (2012). Sensory quality, bioactive constituents and microbiological quality of green and red fresh-cut lettuces (Lactuca sativa L.) are influenced by soil and soilless agricultural production systems. Postharv. Bio. Technol. 63, 16–24. doi: 10.1016/j.postharvbio.2011.08.002

Sharathkumar, M., Heuvelink, E., and Marcelis, L. F. M. (2020). Vertical farming: moving from genetic to environmental modification. Trends Plant Sci. 25, 724-727. doi: 10.1016/j.tplants.2020.05.012

Siegrist, M. (2008). Factors influencing public acceptance of innovative food technologies and products. Trend. Food Sci. Technol. 19, 603–608. doi: 10.1016/j.tifs.2008.01.017

Sjölander-Lindqvist, A., Skoglund, W., and Laven, D. (2020). Craft beer–building social terroir through connecting people, place and business. J. Place Manag. Dev. 13, 149–162. doi: 10.1108/JPMD-01-2019-0001

Skjelvik, J. M., Erlandsen, A. M., and Haarvardsholm, O. (2017). Environmental Impacts and Potential of the Sharing Economy. Paris: OECD. doi: 10.6027/TN2017-554

Specht, K., Siebert, R., Opitz, I., Freisinger, U., Sawicka, M., Werner, A., et al. (2014). Urban agriculture of the future: an overview of sustainability aspects of food production in and on buildings. Agric. Hum. Values 31, 33–51. doi: 10.1007/s10460-013-9448-4

Toler, S., Briggeman, B. C., Lusk, J. L., and Adams, D. C. (2009). Fairness, farmers markets, and local production. Am. J. Agric. Econ. 91, 1272–1278. doi: 10.1111/j.1467-8276.2009.01296.x

Tukker, A. (2004). Eight types of product–service system: eight ways to sustainability? Experiences from SusProNet. Bus. Strat. Environ. 13, 246–260. doi: 10.1002/bse.414

Tukker, A., and Tischner, U. (2006). Product-services as a research field: past, present and future. Reflections from a decade of research. J. Clean. Prod. 14, 1552–1556. doi: 10.1016/j.jclepro.2006.01.022

Voss, C., Tsikriktsis, N., and Frohlich, M. (2002). Case research in operations management. Int. J. Oper. Prod. Manag. 22, 195–219. doi: 10.1108/01443570210414329

Weidner, T., Yang, A., and Hamm, M. W. (2019). Consolidating the current knowledge on urban agriculture in productive urban food systems: learnings, gaps and outlook. J. Clean. Prod. 209, 1637–1655. doi: 10.1016/j.jclepro.2018.11.004

Yano, Y., Nakamura, T., Ishitsuka, S., and Maruyama, A. (2021). Consumer attitudes toward vertically farmed produce in Russia: a study using ordered logit and co-occurrence network analysis. Foods 10:638. doi: 10.3390/foods10030638

Keywords: vertical farming (VF), product-service system (PSS), business model, in-store, urban agriculture, modular farming, hydroponic agriculture

Citation: Martin M and Bustamante MJ (2021) Growing-Service Systems: New Business Models for Modular Urban-Vertical Farming. Front. Sustain. Food Syst. 5:787281. doi: 10.3389/fsufs.2021.787281

Received: 30 September 2021; Accepted: 25 October 2021;

Published: 29 November 2021.

Edited by:

Francesco Orsini, University of Bologna, ItalyReviewed by:

Bernd Pölling, South Westphalia University of Applied Sciences, GermanyCopyright © 2021 Martin and Bustamante. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Michael Martin, bWljaGFlbC5tYXJ0aW5AaXZsLnNl

†These authors have contributed equally to this work and share first authorship

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.