94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Sustain. Food Syst., 21 April 2021

Sec. Nutrition and Sustainable Diets

Volume 5 - 2021 | https://doi.org/10.3389/fsufs.2021.634038

This article is part of the Research TopicNutrition at the Crossroads: Food at the Intersection Of Health, Environmental, Economic, And Social Sustainability – Volume 2View all 5 articles

Packaging play a key role on food quality preservation and shelf-life increase. Even if the link between shelf life and food loss has not yet clearly been formalized, it is generally observed that a well-designed packaging contributes to reduce food loss and waste and thus the corresponding useless negative impact that producing and distributing uneaten or inedible food has on our environment and economy. In order to anticipate the usage benefit of a given packaging, decision making tools are needed to be developed. While some authors' separately showed the importance of shelf life model, food loss and waste prediction model and Life Cycle Analysis, so far no connection was really made between them. In this context, this paper aims to analyze the different mathematical modeling approaches proposed in the available scientific literature, from the prediction of food shelf life gain thanks to well-designed packaging to the environmental benefice due to the decrease of food loss and waste. The article presents a review of 29 models developed on this thematic during the last two decades. The analyzed models were split in three categories: (1) the food shelf life models, (2) the models linking shelf life to food loss and waste, and (3) the Life Cycle Analysis including direct (production, processing and end of life) and indirect (food loss and waste) packaging environmental impacts. In one hand, the review showed that if many predicting approaches were conducted to assess food shelf life, only few of them were enough mechanistic (by coupling mass transfer to food deterioration) to be used in other conditions than the ones initially studied. Moreover, the consumers' practices and believes being strongly influent on the quantity of food waste at household, it should be more systematically integrated in the food loss and waste estimation for a fairer evaluation. On the other hand, this review highlighted that even if indirect environmental benefit of packaging, e.g., through food loss and waste decrease, is more and more integrated in life cycle analyses of the food packaging system, most of studies were only based on rough estimation and not on real quantification of the food loss and waste reduction obtained thanks to the well-designed packaging. Therefore, further research is needed to facilitate the representation/quantification of the links between shelf life increase for packed food, resulting food loss and waste reduction and environmental benefit to support the packaging sectors to choose and validate the best packaging solution to decrease the environmental impact of food/packaging system.

Nowadays, despite of a high primary food production, the food security is not reached for the still growing worldwide population (Tscharntke et al., 2012). Indeed, the planet is struggling in supplying sufficient resources for human beings (Kummu et al., 2012) and 795 millions of people are undernourished in the world (McGuire et al., 2015). With an expected increase of 25% of the population by 2050 (United Nations, 2013), the food security is and will be one of the priority for the coming years. Meanwhile FAO identified high food loss and waste, from 20 to 40% depending on the type of foodstuff products, corresponding to 100 million tons of foods in the European Union (EU), which is expected to double by 2050 (Gustavsson et al., 2011). Avoiding this food loss and waste, is a major issue not only for global food security, but also for its environmental impact and its economic cost (Scialabba, 2013).

The terms “food loss” and “food waste” have many and various definitions depending on actors of food chain (Vilariño et al., 2017). That's the reason why FAO developed a benchmark definition and declared that “food loss and waste” (FLW) is considered as a decrease in quantity or quality of food along the supply chain (Food Agriculture Organization of the United Nations, 2019). Decrease in quantity refers to food that exits the food supply chain while decrease in quality refers to the decrease in food attributes that reduces its value in terms of intended use. Both qualitative and quantitative FLW occur all long the supply chain but inevitably become concentrated at their maximal level at the end of chain, e.g., at household. Following FAO, food losses are considered as occurring along the food supply chain from harvest (or slaughter) up to, but not including, retail level while food waste occurs at the retail and consumer stages (Food Agriculture Organization of the United Nations, 2019; Cattaneo et al., 2020). This review is only focused on FLW due to decrease in quantity and quality of food at processing, distribution and consumption steps caused by a lack of processing and preservation technologies, and/or poor grasp of these technologies by the stakeholders of the food chain, and consumers in particular. Therefore, this refers to losses that could be, in general, predicted and anticipated using food engineering approaches (study of food degradation reactions).

The key element to avoid food loss and waste is to use a well-adapted packaging to protect products from degradation (Verghese et al., 2015). Indeed, the packaging allow to maintain the optimal conditions around the products as long as possible during the storage (Coussy et al., 2013). Unfortunately, this essential role of packaging is often forgotten, and even worse, packaging is solely considered as additional economic and environmental cost, and its reduction is promoted, quite often at the expense of food preservation and environment itself (Wikström and Williams, 2010). Indeed, food production is responsible of 30–35% of the global climate impact, 70% of the global water use and largely contribute to species extinction (Foley et al., 2011). Therefore, food production being one of the major element pushing environment beyond its planetary boundary, it seems essential to do our best to avoid food loss and waste and by the same the unnecessary food production (Rockström et al., 2009). One efficient solution is to refocus packaging on its food protection role.

Indeed, even if the relation between FLW and shelf-life is not straightforward, there is a high potential to reduce FLW through packaging functions well designed and optimized to food requirements in terms of preservation (Coussy et al., 2013; Verghese et al., 2015). Among them, modified atmosphere packaging (MAP) technology is specially designed to extend the shelf life for a lot of products as fruits and vegetables, fish, meat, cheese, etc. by modification of the gas composition surrounding the product (Floros and Matsos, 1991; Dalgaard, 1995; Guillaume et al., 2010; Guillard et al., 2016; Matar et al., 2018a). The development of high-functionalized packaging was widely treated in literature through experiments. However, for a better optimization of the packaging system, authors often needed to develop and use mathematical modeling tools. These latest integrated the mass transfer between food and external atmosphere through packaging and degradation reactions of food products (physical-chemical, microbial and/or physiological reactions). They are used, for example, to identify the suitable gas pack permeabilities for respiring fresh fruits and vegetable (Cagnon et al., 2013) or to select the suitable atmosphere composition to limit microbial growth (Guillard et al., 2017). These models could be easily used to predict a shelf life providing that they are linked to a shelf life model but it is rarely the case. Therefore, until now, benefit of packaging on shelf life gain was only scarcely quantified and formalized, although this knowledge is essential to really quantify the environmental and economic benefit of technical solutions, such as MAP, implemented to reduce FLW.

In addition, stakeholders' practices were proved to influence a lot the benefit of these technical solutions, especially packaging (Plumb et al., 2013; Verghese et al., 2015; Porat et al., 2018). For instance, if packaging is open by the consumer before storing the product (as is often the case for fresh fruits and vegetable) that means that modified atmosphere, if any, will be broken and benefit of MAP lost (Plumb et al., 2013; Verghese et al., 2015). Although scarcely realized, it is thus very important to take into account stakeholders' and in particular consumers' behavior in the shelf life predicting tools to correctly estimate the FLW.

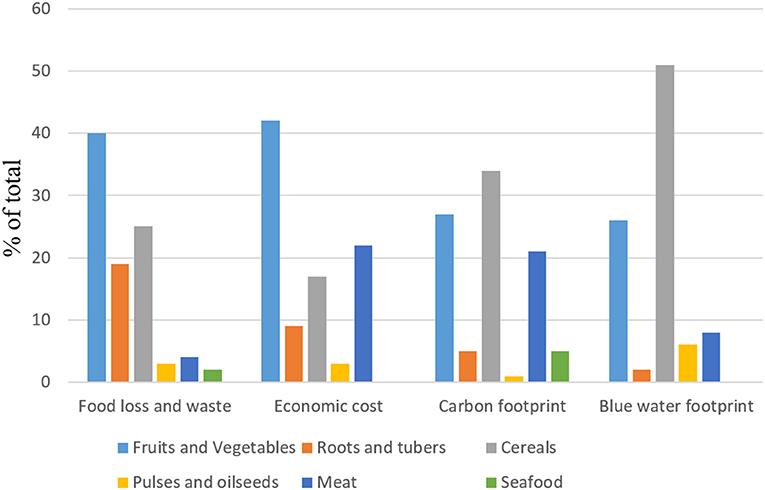

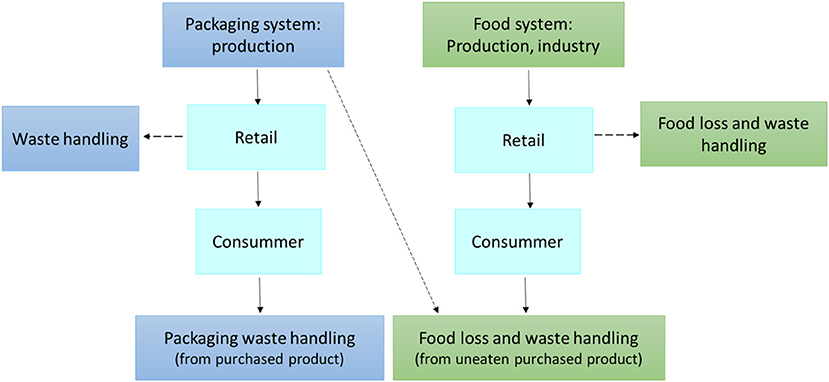

When food is lost or wasted, both discarded food and discarded packaging will contribute to increase the economic costs and the environmental burden, such as high carbon footprint, blue water footprint, vain land use, etc. (Scialabba, 2013) (Figure 1). The direct contributions of packaging raw material to environment such as production step, processing and end-of-life treatment were widely included in life cycle assessment (Licciardello, 2017; Molina-besch, 2019), while indirect contributions such as usage benefit and FLW reduction were insufficiently considered (Wikström et al., 2019). However, these indirect effects were proved to compensate in some cases part of the direct ones and permit to decrease the overall environmental burden that adding a packaging could have on the environmental impact assessment of the product as a whole (Wikström et al., 2014, 2016; Manfredi et al., 2015; Licciardello, 2017; Molina-besch, 2019; Zhang et al., 2019). Despite its potential, packaging's usage benefit is still too sparsely explored in literature on sustainability and rarely integrated into life cycle analysis (Wikström and Williams, 2010; Lindh et al., 2016; Wohner et al., 2019). Indeed, in web of sciences, with the keywords “food shelf life,” “food shelf life AND food loss and waste,” “food shelf life AND food loss and waste AND environmental impact,” we obtain 10,509, 111, and 17 articles, respectively (October 2020). However, these former articles were principally based on hypothesis concerning the potential of FLW reduction. Indeed, in the few studies that have tried to consider the impact of the packaging on loss and waste reduction and on the overall environmental impact of system (Wikström and Williams, 2010; Williams and Wikström, 2011; Conte et al., 2015; Gutierrez et al., 2017), it remains unclear to what extent the authors consider the interrelationship between food chain and packaging chain and the usage benefit of packaging for the reduction of FLW (Molina-besch, 2019). Therefore, it is urgent to solve the environmental issues of the food/packaging system as a whole and in a more realistic scheme to better evaluate the benefice/risk balance. A key action is to minimize, as much as possible, the loss and waste of edible food all long the food value chain and to mitigate both burden of edible FLW and packaging waste on our environment.

Figure 1. Impact of food loss and waste on economic cost, carbon, and blue water footprint of several food commodities expressed in % of total volume for food waste, % of total price for economic cost and % of green gases emission per kg of product for carbon footprint and blue water footprint [data came from (Scialabba, 2013)].

Several authors already proposed a review on the modeling of food quality (Shimoni and Labuza, 2000; Van Boekel, 2008; Chaix et al., 2015a; Putnik et al., 2017a; Salehi, 2020), food loss and waste (Minner and Transchel, 2010), or direct and indirect environmental of packed food (Vignali, 2016; Molina-besch, 2019; Omolayo et al., 2020). However, to the best of our knowledge, no one proposed an integrative approach combining these three kinds of models. Yet, this connection is essential to be as close as possible to a realistic scheme and easily identify a packaging with low environmental impact. To fill this gap, 29 mathematical modeling of shelf life, food loss and waste and LCA analysis from literature were analyzed and discussed. In this context, through the use of mathematical models for a clearer estimation, this paper aims to decipher the role of the shelf life gain obtained thanks to packaging on the decrease of FLW at the supplier and consumer stage and the corresponding potential environmental benefit of developing packaging that reduce FLW. This paper proposes some recommendations to elaborate a complete and strong modeling tools allowing to easily identified the most appropriate packaging for a given product with an environmental impact as low as possible for the food/packaging system. In a first part, the existing shelf life model of packed food will be presented, by focusing on those models that consider both gas transfers between food and external atmosphere and its effect on the food preservation (through a degradation reaction model). In a second part, the connection between these shelf life models and the prediction of FLW will be addressed. Then in a third part, the connection between the FLW and the environmental impact assessment will be highlighted. Lastly, in the fourth part, some recommendations for an accurate evaluation of the benefit/risk balance of food packaging for our environment will be proposed.

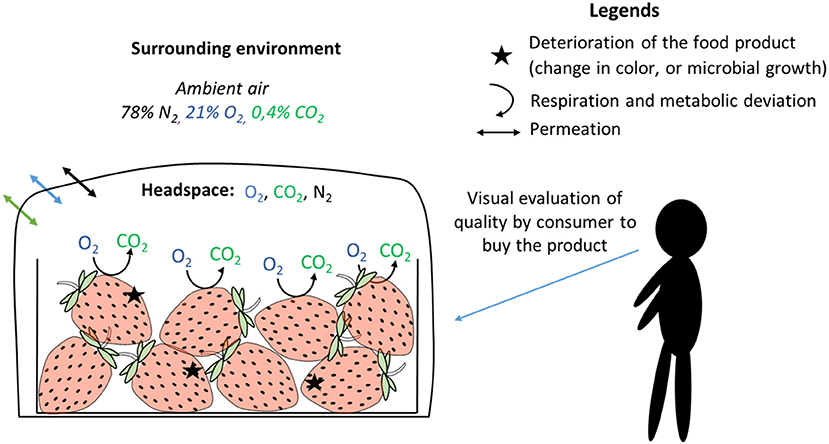

“Shelf life is defined as the time during which the food product will: (i) remain safe, (ii) be certain to retain desired sensory, chemical, physical and microbiological characteristics and (iii) comply with any label declaration of nutritional data when stored under the recommended conditions” (Institute of Food Science and Technology, 1993). Therefore, the shelf life of a product directly depends on the food quality and safety and is correlated to the degradation reactions occurring during each steps of the postharvest chain. These degradations reactions rely on the intrinsic properties of the product (pH, water activity, antimicrobial or antioxidant constituents, etc.) (Valero et al., 2012) and so differ from a product to another (Van Boekel, 2008) and on extrinsic parameters (temperature, light, gas composition) (Figure 2). For instance, one of the most important challenge is minimizing the microbiological spoilage for meat or fish quality (Ghaly et al., 2010; Zhou et al., 2010), minimizing oxidation for high unsaturated lipids concentrated products (Elez-Martinez et al., 2005; Kanavouras et al., 2006; Ghaly et al., 2010), and minimizing respiration and desiccation for fresh fruits and vegetables (Matar et al., 2018a). Microorganism growth, oxidation rate, respiration rate, … and thus shelf life as a whole are strongly influenced by temperature, humidity, or gases composition. In such system, the primary role of packaging is to preserve food quality and safety by providing the optimal gas & RH conditions in the headspace and around the product as long as possible in order to limit degradation reactions.

This role of packaging is even reinforced in case of Modified Atmosphere Packaging (MAP) where the targeted gas composition in headspace is obtained and maintained during storage only if the functional packaging properties, and more specifically its mass transfer properties (gases, water etc.) are correctly chosen (Mangaraj et al., 2009; Belay et al., 2016). For example, in the case of products affected by oxidation or aerobic microorganism development, a flushing allowing to obtain an internal atmosphere free of oxygen have sense only if the packaging barrier properties are high enough to limit the oxygen entrance during storage (Siracusa, 2012; Chaix et al., 2015a). On the contrary, to avoid anaerobiose fermentation while decreasing respiration of vegetables, passive MAP with an equilibrium at a low but non-null O2 and high CO2 contents is possible only if packaging barrier properties match with the respiration rate of the product (Caleb et al., 2012). Usually, identification of such barrier properties needed for a targeted application is not trivial and mathematical models could be a help. Establishing such model requires to identify the main limiting degradation reaction in the food and to use an equation that represents evolution of this degradation considering the main intrinsic and extrinsic parameters (e.g., second order reaction kinetic to model an oxidation of vitamin that will depend on O2 content and temperature or predictive microbiology model that considers among others impact of CO2 and O2 on microorganism growth). Face to the difficulty of developing mechanistic models, most authors often just used empirical models to fit on experimental observations.

To build a shelf life model, the transfer-reaction model need to be connected to an acceptability limit. Indeed, the shelf life of a product depends on the food quality and perception of the consumer may have of this quality that should satisfy his expectations (Cardello, 1995; Valero et al., 2012). The frequently cited definition of food quality is “The combination of attributes or characteristics of a product that have significance in determining the degree of acceptability of a product to a user” (Gould, 1977). Attributes and characteristics of the product include the perception of food's safety, convenience, cost value and its sensory attributes (Reeves and Robertson, 2010). In all the definitions, when the user decides of the acceptability of a product, the quality is compared to a threshold value, the acceptance limit. The product is only accepted if the quality exceeds the acceptance limit. Thus, acceptability of a product depends on product quality and on the level of the acceptance limit (Steele, 2004).

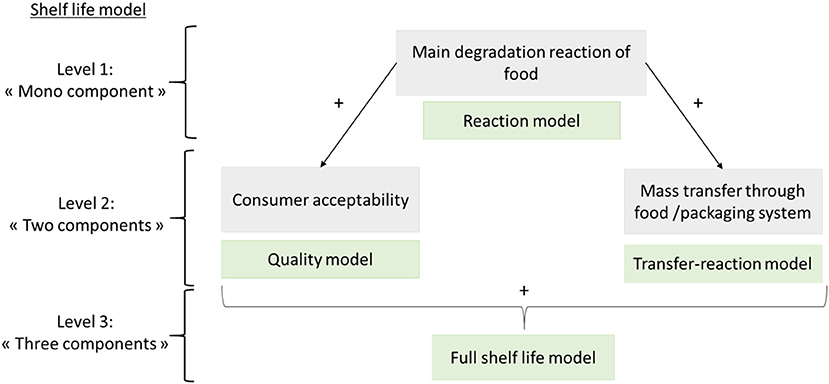

Therefore, a shelf life model should integrate all these interactions: product deterioration, mass transfer through food/packaging system and consumers acceptability, in a simplified model but still well-representative of the system (Figure 3).

Figure 3. A shelf life approach combining the evolution of food quality, the transfer through packaging, and the acceptance limits of consumers.

The food shelf life estimation and solutions to increase shelf life were extensively studied during the last decade. In web of sciences, with the keywords “packed food shelf life” and “packed food shelf life AND modeling,” we obtain 745 and 123 articles, respectively. In majority of studies, the authors showed the importance of a well-dimensioned packaging to preserve food and increase shelf life. The strategies proposed were (i) to correctly chose packaging regarding gas and water permeabilities to limit for example the oxidation (Rovira et al., 2019; Witik et al., 2019), or the water intake of dried products (Seth et al., 2018), (ii) use an optimal modified atmosphere to limit for example microbial spoilage (Chaix et al., 2015b; Guillard et al., 2016), quality loss of vegetables (Tsironi et al., 2017) or texture modification (Wyrwisz et al., 2017), and (iii) use an active packaging (ie packaging in which components were deliberately added to be liberated in food or headspace or to absorb a substance to increase the food shelf-life), as antimicrobial compounds (Ag, potassium sorbate etc.) to protect products from microbial growth (Marcuzzo et al., 2013; Apjok et al., 2019). Due to the high interest of MAP in preservation of the majority of food products, the studies examining the impact of MAP on food shelf life, sometimes in combination with packaging properties (gas and water permeabilities), is rapidly increasing nowadays and are dominating in the available scientific literature (Opara et al., 2019). That is the reason why a focus will be made on the predictive shelf life models in MAP.

More than 15 different predictive shelf life models in MAP more or less complete were described in literature (Table 1). For the sake of clarity, they all have been allocated to one of the three following categories that represent increasing complexity level (Figure 3): (i) level 1: shelf life model based on the main degradation reaction(s) occurring in food (reaction model) with none other coupling with other type of model (transfer, etc.), (ii) level 2: shelf life model coupling the reaction model with consumer's behavior analysis to determine the consumers acceptability limit, (quality model) or with mass transfer through food/packaging system (transfer-reaction model), (iii) level 3: model based on the coupling of transfer-reaction model and the quality model. These three levels of model showed an increasing complexity and consequently were more and more descriptive and mechanistic.

This category of models predicts product shelf life in MAP using an equation representing only one experimental quality parameters (Guynot et al., 2003; Koutsoumanis et al., 2008; Lee et al., 2008) or a pool of up to 5 parameters at the same time at a maximum (Limbo et al., 2010; Putnik et al., 2017b) (Table 1). They are mostly empirical, based on experimental assessment /observations, but some more elaborated semi mechanistic model have been nevertheless proposed.

One example of an empirical “mono-component” shelf life model is the one of Putnik et al. (2017b) that integrated different physicochemical parameters (pH, sensory evaluation, color measurements, soluble solids) in one linear regression model to determine the impact of anti-browning treatment (ultrasound, ascorbate and citric acid) on the shelf life of two apple cultivars (Putnik et al., 2017b). Aiello et al. (2012) also used a linear regression model (zero order reaction) to determine the peach degradation at each post-harvest step (Aiello et al., 2012). This model was then used to quantify the FLW along the supply chain (see section Without the Stakeholders' Behavior). However, these two shelf life models were simple and consequently less realistic than semi mechanistic shelf life model.

Among the most advanced “mono-component” shelf life model are the one based on predictive microbiology. For example, Lee et al. (2008) used the model of Baranyi and Roberts (1994) to study the aerobic microbial growth on fish-based ready-to-eat food (Lee et al., 2008), this growth being the main critical quality criteria for such type of product (Table 1). The shelf life was defined as the time to reach a bacterial count of 105 CFU/g and was quantified at different temperature and in different internal atmosphere conditions (Lee et al., 2008). Koutsoumanis et al. (2008) used the same model to predict shelf life of minced pork in two different atmosphere conditions controlled by (i) a low and (ii) a high gas (O2, CO2) permeability (Koutsoumanis et al., 2008). Although Koutsoumanis et al. (2008) highlighted the importance of gases transfer through packaging on food shelf life, there was no information about internal gas composition that made their results difficult to explain (the authors observed the best shelf life extension in the pack with the highest film permeability and illogically attributed this effect to the microorganisms' respiration that consumed O2 and thus limit growth of aerobes) (Koutsoumanis et al., 2008). In the previous study of Lee et al. (2008) and Putnik et al. (2017b), if we knew the initial gas concentrations, the evolution of gases in headspace with time was not mastered and measured. Therefore, in all the works described in Table 1, the proposed shelf life model remained difficult to extrapolate to other atmosphere, or film permeabilities conditions and the consumer acceptability was not included.

a. Quality Models

In this case, the reaction model was combined with consumers' behavioral analysis to determine the quality threshold value for the product as perceived by the consumer. Estimation of consumer acceptability is used for a fairer determination of product's shelf life (Figure 3; Table 1) (Lareo et al., 2009; Adobati et al., 2015; Manzocco et al., 2017; Skjerdal et al., 2017). The consumer acceptability is based on a combination of various criteria (visual aspect, color change, cost, convenience of the pack of the food …). In majority of studies including this consumer acceptability as input in their shelf life model, only one criterion among the aforementioned list is used. The apparent quality through visual inspection is the most studied, probably because the simplest to assess and the closest to the reality mimicking the consumer decision-making process during purchase act. This assessment was widely applied in the case of fruits and vegetables, which are also products for which such shelf life models were usually developed. This apparent quality assessment by the consumer was established only during one stage of the post-harvest chain (retail or consumer stage) and thus represent different aspects of consumers' acceptability. At the retail stage this assessment has permitted to evaluate a kind of threshold limit for purchase while at consumer stage this correspond to a threshold value for consumption, the product being (partially) or entirely discarded above the later.

A first example of integration of threshold limit for purchase at retail stage in a shelf life model is the study of Lareo et al. (2009). In their work, the authors described shelf life estimation by non-linear regression for each sensory attribute including wilting appearance, presence of brown and necrotic strains, browning on the midribs and off odors of lettuce (Lareo et al., 2009). This has been done by a trained panel which could be questionable because it does not reflect the feeling of untrained consumer as regard overall lettuce quality: their threshold limit for purchase may be misestimated. That's the reason why, in parallel, for different storage conditions, consumers (untrained panel, thus different of the panel used for sensory estimation) had to evaluate product appearance and respond “yes” or “no” to the question “Imagine you are in a supermarket, you want to buy a minimally processed lettuce, and you find a packaging of lettuce with leaves like this, would you normally buy it?” The threshold limit for purchase (= limit of acceptability in their model) was set up by the shelf life achieved by the product before 25% of the consumers rejected the product. Same approach was considered by Manzocco et al. (2017) for fresh-cut Iceberg salad packed under MAP (Manzocco et al., 2017). They built a rejection function at household based on consumer consumption habits about salad (probability to consume) and by answering to the question “if this salad was in your refrigerator would you consume it, or would you throw it away?” (probability to reject). However, if Lareo et al. (2009) focused only on retail stage, Manzocco et al. (2017) focused only on consumer stage. In both cases the probability of rejection at retail stage and consumer stage clearly did not reflect the shelf life of the product on the entire post-harvest chain. A combination of both must be used: the threshold limit at retail for purchase and at home for consumption may differ. The quality assessment by the consumer changes according to the place, context of evaluation and because the consumer may be reluctant to discard a product that he bought, his tolerance at home about quality degradation may be thus higher than at supermarket (Porat et al., 2018).

The most elaborate study that set up a two-components shelf life model depending on consumers acceptability at retail stage including also cost acceptability is the one of Skjerdal et al. (2017). They developed a decision support tool (STARTEC) for food companies to assure food safety in conformation with the HACCP system (Skjerdal et al., 2017). This was as far as we know the most achieved multicriteria quality tool for helping the user to define his product shelf life. The integrated criteria were food safety, nutrition, costs and quality criteria provided by legislation, costumers or by companies. For example, in case of pasta salads (Skjerdal et al., 2017), the shelf life was modeled using microbial growth models (L. monocytogenes) (food safety), an ascorbic acid (vitamin C) degradation model (nutrition) depending on external (temperature) and internal factors (pH), a quadratic sensory-based model (quality criteria), built from panelist's evaluation for color, odor, texture and freshness. Moreover, the production cost was evaluated (calculation based on ingredients, energy, salary, packaging and distribution) and compared to an acceptability limits depending on the amount of money that consumers are willing to pay for an alternative product compared to the standard one (consumers survey). The used models and parameters could be customized and consequently the interface tool was adapted to different and complex ready-to-eat food products, as long as the process conditions and products information were known. Indeed, if this model finally predicted quality and shelf life using exhaustive multicriteria approach, as all model described in this section, they are not easily extrapolated to other packaging conditions because mass transfer occurring in the food/packaging system and thus, gases composition surrounding the product, are not considered in the approach. Thus, if the packaging conditions change, their effect on food quality could not be anticipated limiting the interest of these models.

b. Transfer-Reaction Models

More mechanistic approach have been proposed to tackle the aforementioned issues of lack of generalization and extrapolation of shelf life models to other packaging and storage conditions. These models were based on the coupling of reaction models with gas transfer models in the food/packaging system (Fabiano et al., 2000; Coutelieris and Kanavouras, 2006; Simpson et al., 2007; Bacigalupi et al., 2013; Chaix et al., 2015b; Guillard et al., 2016; Putnik et al., 2017c; Joshi et al., 2019) (Figure 3; Table 1). Several examples of such coupling could be found in the literature to predict for instance the degradation of vitamin C in orange juice (Bacigalupi et al., 2013), the oxidation of fatty acids in oil (Coutelieris and Kanavouras, 2006), the evolution of microorganisms growth in cheese, meat or fish (Chaix et al., 2015b; Guillard et al., 2016), or the evolution of respiration of fruits and vegetables (Joshi et al., 2019), that were all depended on O2 and sometimes CO2 (microorganism growth and respiration) concentration in the product or in the headspace. This evolution of O2 and CO2 concentration was due to the gases exchange through the packaging that is generally modeled by Ficks' law and coupled with reaction models (e.g., first order, second order reactions) though a set of coupled ordinary differential equations. These models are thus more complex than the simple reaction or quality models described above but are more representative of the different mechanisms prevailing in the food/packaging system and essential for predicting food quality evolution. This approach was therefore already developed for a large panel of the product and degradation reactions.

Even if several examples could be found in the literature, recent and most achieved studies in that field are the works of Chaix et al. (2015b) and Guillard et al. (2016) that developed a shelf life model for non-respiring food as processed cheese, fresh salmon and poultry meat stored in MAP (Chaix et al., 2015b; Guillard et al., 2016). The product quality was described by a predictive microbiological model for Listeria monocytogenes and/or Pseudomonas fluorescens depending on environmental factors as temperature, pH, Aw, O2 and CO2 concentration in headspace. The shelf life model included gas transfer in the food/ packaging system by considering the mass flow through the packaging, the dissolution and diffusion of gases in the food. The variation of O2 and CO2 concentration was also dependent on the microorganisms' respiration. The used acceptability limit was a microbiological count corresponding to the maximal load tolerated at the use-by-date. These integrations of gases transfer-reaction model are important because the microbiological growth is dependent on the O2 and CO2 concentration in food and headspace. Indeed, the authors demonstrated that their model was indispensable to adequately design the MAP system for various meat, fish and dairy products and, to avoid over-packaging (e.g., use of costly high barrier packaging while such high barrier performance is not required) (Guillard et al., 2017). The same approach was applied on respiring products, as described by Joshi et al. (2019), who developed a transfer-reaction shelf life model on strawberries stored in MAP. The authors described the product quality through microbiological and weight loss models that were dependent on the gases and water transfer through the packaging, themselves coupled to respiration and transpiration models (Joshi et al., 2019).

However, if degradation reactions could be well-anticipated using such mechanistic models, these predictive approaches could be used for shelf life evaluation only if the consumer's acceptability limit (at retail and consumer stage) for this quality criteria (maximal microorganism count, minimal vitamin loss or fatty acid concentration…) is clearly stated which is rarely the case. Indeed, consumer's quality evaluation is clearly not based on microorganism count or vitamin loss evaluation but on visual inspection of the product (Van Boxstael et al., 2014) that may not reflect the microbial state or quality parameter evolution considered in the model used for predicting food shelf life. It is thus difficult to integrate consumer's acceptability limit in such mechanistic models.

A complete shelf life evaluation model for a packed product should ideally integrate, one global quality parameter evolution, impact of headspace gases composition on this global quality evolution and consumer acceptability (threshold value for purchase at retail stage and for consumption at consumer stage) (Matar et al., 2018b) (Figure 3). Such full shelf life models integrating the three aforementioned components are almost inexistent in the literature due to the complexity of their implementation. Indeed, the “component” related to the mechanistic model coupling gas transfer and quality evolution in the whole system is usually the limiting point due to the need of input parameters and knowledge, time consuming to determine.

One of the must achieved “three components” shelf life model for MAP of fresh produce was the one developed by Matar et al. (2018a), who predicted through a logistic function, the deterioration of fresh strawberries as a function of time, temperature and CO2 concentration in headspace. This last one was itself predicted using Fick's law and mass balance in the food/packaging system between gas transfer and fruit's respiration represented by Matar et al. (2018a) (Figure 4; Table 1). Global deterioration was assessed by using a visual evaluation of the strawberries deterioration, encompassing color change, texture softening, and microorganism development (Matar et al., 2018b). Consumer acceptability was identified after asking to untrained consumers just by looking at the strawberries whether they will buy or not the product, the limit of acceptability being the time when 50% of the product are rejected. This limit was reached for 13% of strawberries deterioration. This threshold value determined the limit of purchase in supermarket but did not determine the shelf life at home. At household, it was assumed that the waste were directly proportional to fruit's degradation. The consumer would throw away only spoilt fruits and consume the good fruits let to not waste too much.

Figure 4. Estimation of strawberries' shelf life by integrating the deterioration of the product, the gas evolution depending on transfer through packaging and strawberries' respiration and the acceptability of consumers, from Matar et al. (2018a).

Due to increased product shelf life thanks to well-dimensioned packaging system, a decrease of FLW is expected. The challenge is now to be able to quantify from shelf life gains evaluated using one of the more or less complete shelf life models presented above, the decrease of FLW obtained at the different steps of the supply chain. If the benefit of packaging, and more specifically MAP to reduce FLW is generally well-recognized (Muriana, 2017; Porat et al., 2018), only few studies pushed the approach further measuring and quantifying the amount of FLW reduction. Quantification means formalization (e.g., modeling) of the link between shelf life and loss and waste reduction, which is not straightforward. Beyond shelf life extension, many other factors may impact loss and waste in the post-harvest chain, one but not least factor being the consumer's behavior which is tricky to anticipate.

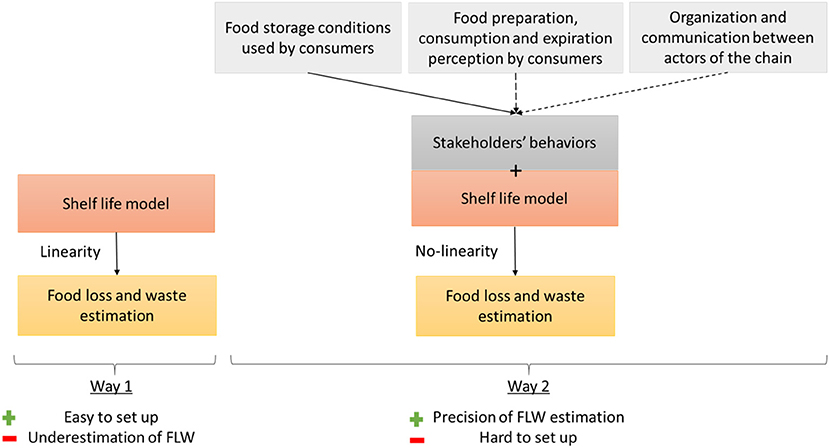

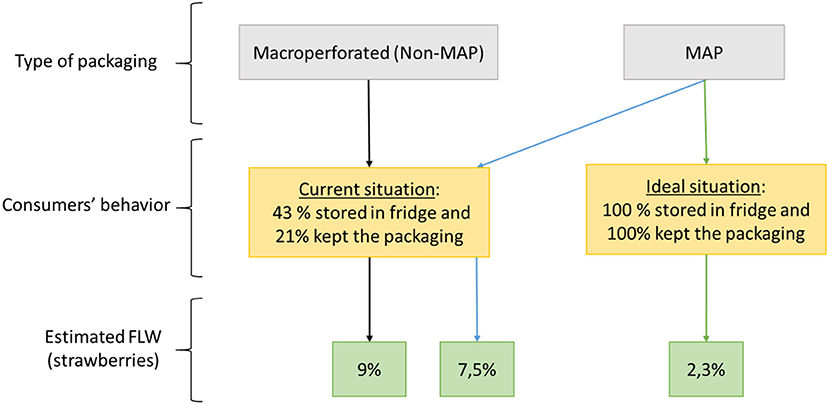

To better quantify the impact of an increase of shelf life on FLW reduction, it seems essential to consider the stakeholders and more specifically the consumers' behavior. A lot of articles showed that consumers behavior is complex and depends on a lot of factors, as habits, emotions, social rules and norms, personal capabilities, knowledge and experiences, etc. (Williams et al., 2012; Quested et al., 2013; Farr-Wharton et al., 2014; De Hooge et al., 2017; Hebrok and Boks, 2017; Russell et al., 2017; Porat et al., 2018; Schanes et al., 2018; Pellegrini et al., 2019). One major issue is the lack of knowledge about the optimal storage conditions and the technologies used to increase shelf life of products. Indeed, different authors showed, that some fresh products were rapidly expired because they were not stored in the fridge (Farr-Wharton et al., 2014; Porat et al., 2018; Matar et al., 2020) or the packaging was removed or pierced (Plumb et al., 2013; Verghese et al., 2015; Matar et al., 2020) while it should not be to preserve optimal atmosphere for the product. This loss of optimal storage conditions was strongly dependent on the product and was particularly observed for fruits and vegetables. For example, a French survey on strawberries consumer's practice showed that 79% of consumers removed the packaging just after purchase and 57% of them still kept the product at ambient temperature even if recommendation of producers is to store it in the fridge. When the cold chain or the MAP is broken, the expected shelf life extension will be consequently partly or integrally lost. Therefore, it seems essential to integrate the consumers' behavior in the FLW quantification to confirm the interest to develop modified atmosphere packaging (Figure 5).

Figure 5. Ways used to estimate FLW from shelf life model. The way 2 include the post-harvest actors' behaviors that could be modeled (solid line) and the ones being non-predictive (dotted line). The main advantage (green +) and inconvenient (red –) were given for each way.

The first modeling attempt of the link between shelf life and FLW was made from experimental shelf life and without integrating the consumers' behavior (Table 2). Example of such approach is the work of Spada et al. (2018), that correlated the FLW evaluated through the expired product returned from the market and the use by date (corresponding to shelf life in this study) (Spada et al., 2018). This approach was empirical and unsatisfactory, the model working only for products with shelf life exceeded 30 days. In a same trend, Conte et al. (2015) empirically correlated ripened cheese shelf life assessment established in a previous study (Costa et al., 2016) based on microbial and sensory quality assessment to FLW probability. They supposed that FLW were maximal, i.e., equal to 1 [1] when shelf life was null and minimal, i.e., equal to 0 [0] when shelf life was infinite (Conte et al., 2015). The resulting predicted FLW strongly depends on the equation used for the correlation (kinetic, sigmoid or straight laws) and consequently, varied a lot for a same storage condition. This lack of precision was probably due to the arbitrary use of empirical equations, instead of mechanistic equations. A more mechanistic approach is the one of Gutierrez et al. (2017), that established a correlation between the FLW (cheesecake), determined as the unsold products, and the experimental shelf life of the product, determined through chemico-physical, microbiological and sensory quality assessment (Table 2) (Gutierrez et al., 2017). This study highlighted that FLW is more related to consumers' behavior and to their perception of product freshness than to product decay observed and measured. Nevertheless, in the previously cited studies, the shelf life was not well-formalized and modeled that could explained the lack of reliability of the empirical relations set up to link shelf life and FLW.

a. Without the Stakeholders‘ Behavior

A model of FLW quantification based on shelf life model instead of experimental assessment, is the one described by Aiello et al. (2012) on peaches (Table 2). The authors used a shelf life model integrating one reaction model (see Section “Mono-Component” Shelf Life Models: Reaction Models) depending on temperature and evaluated the fraction of the total shelf life consumed at each phase of the post-harvest chain: harvesting, warehousing, transportation and retailing (Aiello et al., 2012). If the total shelf life was reached before the purchase act (retail stage), the product was considered as a waste. In the same trend, Manzocco et al. (2017) modeled the fresh-cut Iceberg salad waste packed under MAP from quality model (see Section Quality Models). Nevertheless, if consumers' behavior was included to estimate the shelf life of salad, the stakeholders' behavior like used storage conditions was not included in the FLW estimation (way 1, Figure 5) (Manzocco et al., 2017). Yet, the authors showed that if the storage temperature at consumer's stage went from 8 to 12°C within 7 days, the FLW increased from 1 to 13%, proving that considering this consumers' habit, e.g., proportion of consumer who keeps the salad in the fridge or at ambient temperature, is of primary importance to precisely predict salad waste at consumer's stage.

b. Including the Stakeholder's Behavior

The most accomplished study about the link between shelf life and FLW quantification including modeling of the consumer's behavior is the one of Matar et al. (2020). The authors considered the diversity of consumers' practices in storage conditions of fresh packed strawberries in complement to overall fruits' degradation and mass transfer modeling in the MAP system (see section “Three-Components” Full Shelf Life Models) (Matar et al., 2018a, 2020) (way 2, Figure 5; Table 2). Thanks to distributors and consumers' surveys and interviews with wholesalers, the authors explored 132 scenarios that included various storage conditions of strawberries (temperature and duration) during the post-harvest chain and the consumer practice (kept or removed packaging, store in the fridge or at ambient temperature). The predictive loss and waste model integrated the shelf life model and the probability of occurrence of each scenarios. The results showed a limited reduction of 17% (from 9 to 7.5%) of loss and waste if the strawberries were packed in MAP conditions instead of macro-perforated packaging (Figure 6). This low reduction is principally due to the fact that 79% of consumers removed the packaging just after the purchase, disrupting the benefit of MAP during storage. Indeed, in the best storage conditions, i.e., if 100% of consumers keep the packaging and stored in the fridge, a 74% (from 9 to 2.3%) reduction of loss and waste would be expected (Figure 6).

Figure 6. Evaluation of percentage of strawberries waste depending on the type of packaging and the consumer's behavior, from Matar et al. (2020).

This work well-highlights that a good prediction of FLW reduction is hard to achieve without considering the consumers' consumption habits. Beyond that it seems also of primary importance to communicate about preservation technologies to change the habits and behavior of consumers who generally are not aware of the role they have on the FLW they generate (Figure 5) (Quested et al., 2011, 2013; Hebrok and Boks, 2017; Schanes et al., 2018). Indeed, it was showed that consumers were willing to follow the best conditions to preserve the products if they were specified on the packaging (Plumb et al., 2013). For example, in UK, it was proved that increase the awareness of FLW and provide some advices and the interests to reduce these loss and waste induced a decrease of 13.3 % of the FLW between 2007 and 2010 (Quested et al., 2011, 2013).

If modeling the FLW from shelf life model by including the consumers' behaviors seems the best approach to apply, its difficult implementation in practice due to the numerous input data needed (input on product, on packaging, on consumers' habits, on supply chain characteristics, etc.) explains why only few models of FLW were proposed in the literature. Beyond this difficulty of practical implementation, the prediction of loss and waste is generally hampered by several unpredictable elements that distort the prediction and may even conduct to false conclusions on the usage benefit of new technologies employed to reduce FLW. Indeed, for example, Yokokawa et al. (2018) showed that replacing the current standard pack of ham by a more barrier packaging would be not necessary in case of regular consumption while it would strongly decreased FLW in case of irregular consumption (Yokokawa et al., 2018). Among unpredictable elements, the major one is the unforeseen part of stakeholders' behavior which caused food waste and could not be integrated in any modeling approach (Figure 5). These unpredictable behaviors concern mostly consumer and are for example the contrasted way they manage the food preparation (removal more or less largely the non-edible part) and the leftovers (kept or discarded) or the food consumption habits and frequencies (regular or irregular) that generate more or less food waste (Van Boxstael et al., 2014; Jaeger et al., 2018; Porat et al., 2018). Unpredictable behaviors could also come from producers and retailers, as the way they manage the flow of products and communicate between them (Kaipia et al., 2013; Muriana, 2017; Spada et al., 2018). Indeed, it was proved that in production and retail warehouses, the personnel prioritized the control and manipulations of products with short shelf life (Spada et al., 2018). Therefore, when the shelf life of products is increased, their flow from producer to retailers is slow down inducing a partial loss of the increase shelf life benefice for the consumer.

Every technology with proven efficacy to reduce FLW have inevitably a beneficial impact on the environmental assessment of the overall food chain which remains to be determined (Silvenius et al., 2014; Dilkes-Hoffman et al., 2018; Mattsson et al., 2018). Given the high environmental cost of primary production, every FLW reduction means automatically high net savings on the environmental balance (Williams and Wikström, 2011; Eberle and Fels, 2016; Heller et al., 2019). This benefice must be put into balance with the environmental impact of the technology itself. It means to consider both, direct impacts due to packaging material and gas injection if any, and indirect positive impact due to FLW reduction. However, Life Cycle Analysis (LCA) classically focus on only one aspect and in majority on packaging direct environmental impact linked to materials production and end of life treatment. If the indirect environmental impact whose FLW reduction is more and more included in LCA, it remains insufficient in regard of the numerous cases where the FLW reduction largely compensate and even overcome the negative ones (Vignali, 2016; Meherishi et al., 2019; Molina-besch, 2019; Wikström et al., 2019). It is thus necessary to integrate both packaging direct and indirect impacts in LCA studies for a fair evaluation of the true impact of a packaging technology and make reasoned decision in the choice of materials and technologies.

One of the precursor LCA study including FLW in its evaluation is the one done by Wikström and Williams (2010) who developed a mathematical model that calculates the environmental impact of the food packaging system as a function of FLW generated by the use of a specific packaging (Wikström and Williams, 2010). The authors made a balance where the environmental impact of the eaten food was a sum of the environmental direct impacts of the purchased packed food (from primary production to end of life treatment of both food and packaging) plus the environmental indirect impact of the wasted food at consumer's stage (Table 3). In this balance, decrease of food waste at consumer stage permits to decrease the overall environmental impact if the sum of direct impacts being unchanged or may completely compensated the increase of direct impacts, if any, due to the use of a more efficient packaging.

The model of Wikström and Williams (2010) was thereafter reused by different authors to quantify the environmental benefice of developed packaging to reduce FLW (Wikström and Williams, 2010; Williams and Wikström, 2011; Wikström et al., 2014, 2016). For instance, Williams and Wikström (2011) used the model in their study (Williams and Wikström, 2011) to compare the overall environmental impact of two different packaging. For that, the authors made an assumption about (i) the initial FLW occurred with a first packaging and (ii) the decreased of FLW obtained thanks to a more elaborate packaging. Knowing the indirect environmental impact of the two packaging, they estimated thereafter the increase direct environmental impact that new packaging could reach to have a similar global environmental impact (direct + indirect) than the first packaging. Conversely, the authors also estimated the decrease indirect environmental impact that new packaging should reach to have a similar global environmental impact (direct + indirect) than the first packaging, by making this time an assumption about the increase direct environmental impact of the new packaging. The measurement was done for different environmental category (energy use, global warming, eutrophication, and acidification) (Williams and Wikström, 2011).

A second method of LCA analysis of the food/packaging system is the one depicted by Yokokawa et al. (2018). The authors measured the overall environmental impact as the sum of environmental impact product per unit of consumption (FLW being considered as null) and the environmental impact of the treatment of FLW, depending on the FLW rate (Table 3). The environmental impact of conventional packaging was then compared to highly functionalized packaging. Differently to Wikström and Williams (2010) that identified a maximum accepted FLW rate for an alternative packaging, Yokokawa et al. (2018) considered a break-even rate of FLW. This latest was defined as the required reduction of FLW rate to sufficiently decrease the environmental impact of the food/packaging system (Yokokawa et al., 2018).

For the two described methods, the authors made the same conclusion: a new packaging with higher environmental impact is capable to reduce the overall FLW and consequently the overall environmental impact of food/packaging system. However, all the cited LCA only integrated the environmental benefice of the FLW and packaging waste reduction generated at consumer's stage, without integrating the waste reduction at retail stage (Figure 7, dotted line). This means that the benefice of a FLW reduction on the overall environmental impact was probably higher than the one measured in these studies. Moreover, even though these authors made a connection between FLW and environmental impact of the food/packaging system, this was only based on hypothesis and none of them validated this hypothetical positive usage benefit of new or optimized packaging. For example, Wikström and Williams (2010) and Williams and Wikström (2011) made the assumption that replace the old packaging by a new one will reduce the FLW from 20 to 15%. But was this FLW rate realistic? Would the conclusion be the same if the FLW reduction was lower?

Figure 7. Stages taken into account in the environmental assessment of packed food system (Wikström and Williams, 2010; Williams and Wikström, 2011; Wikström et al., 2014, 2016; Yokokawa et al., 2018). Dotted lines and full lines represents, respectively, the missing and established link taken in account while assessing the environmental impact assessment of the packed food for different authors.

One example of LCA including experimental assessment of the usage benefit of reducing FLW is the one performed by Conte et al. (2015). After formalizing the link between shelf life and FLW (first order kinetic, or sigmoid, or straight line, see section Empirical Link Between Shelf Life and Food Loss and Waste Quantification), the authors modeled the link between FLW and environmental impact by calculating an eco-indicator depending on the direct environmental impacts of the package, the direct environmental impact of the food itself and the food waste probability at retail stage (Table 3) (Conte et al., 2015). Gutierrez et al. (2017) also made an LCA on cheesecake to compare the impact of two different packaging (multilayer gas barrier tray and film in N2/CO2: 70/30 MAP conditions vs. PET tray and film in ambient atmosphere) (Gutierrez et al., 2017). In this study the authors used an economic model to define the impact of shelf life on FLW by measuring the minimum amount of product that should be sold, considering the consumers buying habits (see section Empirical Link Between Shelf Life and Food Loss and Waste Quantification). The environmental impact of these estimated FLW (indirect impact) and environmental impact of packaging (direct impact) was included in a LCA based on several indicators that was split in three categories: damage to human health; damage to ecosystem and damage to resource availability. The results were similar for these two studies described above: the MAP packaging, even if it increased the direct environmental impact of the package (gas injection, difficulty to recycle multilayer, high barrier film needed in MAP etc.), was the best way to drastically reduce the FLW (from 36 to 9% for cheesecake) and the environmental impact of the food/packaging system (between 17 and 62% depending on the considered categories for cheesecake), because the cheese production was responsible of the majority of environmental impact.

Similar approach was also used and same conclusion was made for active or nano-packaging. Indeed, Manfredi et al. (2015) implemented the shelf life (experimental estimation from another study; Muriel-Galet et al., 2012) of conventional milk packaging and antimicrobial coating packaging (lauramide arginine ethyl ester) in a model (discrete event simulation; Quested, 2013) to estimate the FLW reduction at consumer stage. The normalized LCA method (International Organization for Standardization, 2006) was then used to estimate the average impact reduction on environment (14%) (Manfredi et al., 2015). Zhang et al. (2019) also used the estimated increase of shelf life due to nano-packaging measured in others studies (Emamifar et al., 2010; Gokkurt et al., 2012; Lloret et al., 2016; Huang et al., 2017) to evaluate FLW and global warming reduction (equation in Table 3). Therefore, the positive usage benefit of packaging in all these studies was evaluated thanks to experimental assessments, meaning that only a few packaging and few conditions were tested. No extrapolation could be done based on other type of material or storage conditions; while a mathematical model aiming at predicting FLW reduction obtained from shelf life model would have permitted to do such extrapolation (see section Empirical Link Between Shelf Life and Food Loss and Waste Quantification). In absence of such shelf life model, new experiments should therefore be performed to conduct an LCA for other packaging.

The only one LCA that integrated assessment of the usage benefit of reducing FLW by using a complete “three components” model is the one described by Matar (2018) (Table 3). Indeed, the author developed a full shelf life model on packed strawberries (see section “Three-Components” Full Shelf Life Models), that was coupled to a study of consumers behaviors (43% of consumers stored the product in the fridge and 21% kept packaging closed until consumption) to quantify the FLW reduction due to the new MAP packaging (17%) (see Section Including the Stakeholders' Behavior). All this information was then injected in life cycle analysis to quantify the environmental impact of a 1 day storage (61% of consumers) and a 3 days storage (14.5% of consumers) of packed strawberries at ambient temperature for two different packaging (macroperforated packaging vs. MAP). The results showed that replacing the macroperforated packaging by an optimized MAP is a valuable alternative to microperforated packaging for both low and ambient temperatures for short storage duration. For long storage duration (3 days), optimized MAP at ambient temperature could not substitute for macroperforated packaging at refrigeration temperature. Globally, MAP is a valuable option compared to standard packaging strategies providing that consumers are informed of the necessity to maintain MAP benefit until consumption (e.g., keep the packaging sealed).

Nowadays, it was pointed out that most of studies lacked of consensus and transparency about the used methodology and about the uncertainty of scenario and models used in LCA (Omolayo et al., 2020). These disparity and uncertainty lead to misleading and contrasted results between LCA analyses, making them incomparable (Corrado et al., 2017).

In addition, LCA does not include the current policy concerning food and packaging waste prevention, management and valorization (Omolayo et al., 2020). This potential of handling waste is dependent of facilities of each region and thus the packaging development should differ in function of this potential. Therefore, due to local handling waste facilities and seasonality of some products, the LCA should be spatially and temporally dependent to develop effective management of FLW, which is generally missing in LCA today (Omolayo et al., 2020). Indeed, using modeling approach of end of life currently available in LCA, Wikström and co-authors found that if the FLW was converted in energy and the packaging was well recycled, the potential to find new packaging solution with lower total environmental impact was reduced (Wikström and Williams, 2010). For example, the GHG emission per kg of minced meat consumed was divided by two if the material was totally recyclable (Wikström et al., 2016). This result may be completely different if in the targeted country for this application, focus is made on organic recycling through biodegradation. Recyclable packaging would be in that case, much less efficient than compostable one, even if same FLW reduction is achieved.

So far researchers were interested independently in the estimation of product shelf life, FLW estimation and ways to reduce its environmental impact along the post-harvest chain. Even if it is already known that there is a relation between these three main topics, the link between them was not yet clearly identified. This study highlighted the need to strengthen the knowledge and representation of these links to better quantify the benefit of product packed in high-functionalized packaging, or to propose a less environmental impact of a food/packaging system. A particular attention should be put on the following point:

1- A complete shelf life model should include a reaction model (microbiological, oxidation, sensory etc.), a mass transfer model in food packaging system (gas, water etc.) and a consumer acceptability (at which degradation point the product will be reject by consumers) (Link 1, Figure 8).

2- The best way to clearly quantify and map the FLW is to couple this complete shelf life model to the stakeholder's behavior (Link 2, Figure 8). For example, the FLW quantification should integrate the habits of consumers: Do the consumers store the product at fridge or ambient temperature? Do they store the product in its initial packaging?

3- To quantify the benefice of a FLW reduction on environmental impact (link 3, Figure 8), direct and indirect packaging impact should be coupled in one consensual LCA method and integrate all the steps from production until consumption for the packaging and the FLW handling. This latest depends on facilities and policy applied in the country or region, the LCA should consequently be spatially and temporally dependent.

4- To propose a more adapted packaging, realistic scenarios including the usage benefit of packaging should be tested thanks to the modeled link between shelf life, FLW and environmental impact (Figure 8, link 1, 2, and 3).

Despite the high interest of developing mathematical modeling linking LCA to food loss and waste and food shelf life prediction, in depth analyze of literature revealed that this link is lacking, the authors generally studying these three items separately. Yet, these links are necessary to develop efficient, packaging well-dimensioned at its strict minimum while optimizing food shelf life and food waste and loss reduction. This review showed that despite the high development of shelf life model, majority of them did not integrate the evolution of internal packaging headspace conditions (such as O2 and CO2) during storage. In consequence, these kinds of models cannot be generalized and used for other type of conditions than the ones tested, what would however be essential to rapidly screen different conditions and packaging solutions. From food shelf life, an estimation of food loss and waste were made by several authors. Nevertheless, this estimation was generally distorted due to the missing integration of consumer and retailer behavior. Unfortunately, this lack may conduct to false conclusions on the usage benefit of a given packaging solution. Research on packaging's LCA more and more includes the indirect environmental impact of packaging, as food loss and waste reduction, besides the direct ones linked to the material itself. All the articles showed that investment in packaging technology would decrease the environmental impact of the food/packaging system, thanks to the food loss and waste reduction highlighting the positive role of this packaging on food preservation. However, fair and realistic estimation of the packaging usage benefit was generally missing in LCA studies; these ones were mostly based on hypothetic scenarios. Finally, the review proposed some recommendations to develop modeling tools including a LCA linked to food loss and waste estimation, itself connected to a complete shelf life model, and to stakeholders' behaviors.

These recommendations highlight that further research should be conducted at the interface of different disciplines: food sciences, social sciences, environmental sciences, mathematics in order to consider the multiple faces of food loss and waste reduction (mathematical prediction, consumers behavior, impact on environment). Indeed, to develop a sustainable and eco-friendly packaging, this latest has to fulfill its primary function: protect the product from degradation thanks to the use of the just necessary quantity of packaging. If the development of new packaging to protect food from deterioration was largely conducted, the knowledge needs to be formalized in an easy and complete way and transmitted to all post-harvest steps. This means that researchers firstly need to assure that new developed technology (as MAP for example) is accepted by all actors and that consumers is ready to change its habits if necessary. However, each product being different, there is as much packaging solution as food product. Therefore, to be sure to develop the best packaging for a given product, the researchers need to develop some making support tools that could be easily used by the actors of the food packaging sectors.

FC, CM, and VG contributed to conceptualization. FC, CM, SGa, NG, SGu, and VG participated to the redaction. All authors contributed to the article and approved the submitted version.

This project was conducted in the context of GLOPACK project funded by the European Union's Horizon 2020 research and innovation program under grant agreement No 773375; and the Pack4Fresh project funded by the INRA-CIRAD Metaprogram Glofoods and of the FP7-ERA-NET 618107 EcoBerries.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Adobati, A., Uboldi, E., Franzetti, L., and Limbo, S. (2015). Shelf life extension of raspberry: passive and active modified atmosphere inside master bag solutions. Chem. Eng. Trans. 44, 337–342. doi: 10.3303/CET1544057

Aiello, G., La Scalia, G., and Micale, R. (2012). Simulation analysis of cold chain performance based on time–temperature data. Product. Planning Control. 23, 468–476. doi: 10.1080/09537287.2011.564219

Apjok, R., Cozmuta, A. M., Peter, A., Cozmuta, L. M., Nicula, C., Baia, M., et al. (2019). Active packaging based on cellulose-chitosan-Ag/TiO 2 nanocomposite for storage of clarified butter. Cellulose 26, 1923–1946. doi: 10.1007/s10570-018-02226-7

Bacigalupi, C., Lemaistre, M. H., Boutroy, N., Bunel, C., Peyron, S., Guillard, V., et al. (2013). Changes in nutritional and sensory properties of orange juice packed in PET bottles: An experimental and modelling approach. Food Chem. 141, 3827–3836. doi: 10.1016/j.foodchem.2013.06.076

Baranyi, J., and Roberts, T. A. (1994). A dynamic approach to predicting bacterial growth in food. Int. J. Food Microbiol. 23, 277–294. doi: 10.1016/0168-1605(94)90157-0

Belay, Z. A., Caleb, O. J., and Opara, U. L. (2016). Modelling approaches for designing and evaluating the performance of modified atmosphere packaging (MAP) systems for fresh produce: a review. Food Pack. Shelf Life. 10, 1–15. doi: 10.1016/j.fpsl.2016.08.001

Cagnon, T., Méry, A., Chalier, P., Guillaume, C., and Gontard, N. (2013). Fresh food packaging design: a requirement driven approach applied to strawberries and agro-based materials. Innovat. Food Sci. Emerg. Technol. 20, 288–298. doi: 10.1016/j.ifset.2013.05.009

Caleb, O. J., Opara, U. L., and Witthuhn, C. R. (2012). Modified atmosphere packaging of pomegranate fruit and arils: a review. Food Bioproc. Technol. 5, 15–30. doi: 10.1007/s11947-011-0525-7

Cardello, A. V. (1995). Food quality: relativity, context and consumer expectations. Food Qual. Prefer. 6, 163–170. doi: 10.1016/0950-329300039-X

Cattaneo, A., Sánchez, M. V., Torero, M., and Vos, R. (2020). Reducing food loss and waste: Five challenges for policy and research. Food Policy 98:101974. doi: 10.1016/j.foodpol.2020.101974

Chaix, E., Broyart, B., Couvert, O., Guillaume, C., Gontard, N., and Guillard, V. (2015b). Mechanistic model coupling gas exchange dynamics and Listeria monocytogenes growth in modified atmosphere packaging of non respiring food. Food Microbiol. 51, 192–205. doi: 10.1016/j.fm.2015.05.017

Chaix, E., Couvert, O., Guillaume, C., Gontard, N., and Guillard, V. (2015a). Predictive microbiology coupled with gas (O2/CO2) transfer in food/packaging systems: how to develop an efficient decision support tool for food packaging dimensioning. Compreh. Rev. Food Sci. Food Safe. 14, 1–21. doi: 10.1111/1541-4337.12117

Conte, A., Cappelletti, G. M., Nicoletti, G. M., Russo, C., and Nobile, M. A.. (2015). Environmental implications of food loss probability in packaging design. Food Res. Int. 78, 11–17. doi: 10.1016/j.foodres.2015.11.015

Corrado, S., Ardente, F., Sala, S., and Saouter, E. (2017). Modelling of food loss within life cycle assessment: from current practice towards a systematisation. J. Clean. Prod. 140, 847–859. doi: 10.1016/j.jclepro.2016.06.050

Costa, C., Lucera, A., Lacivita, V., Saccotelli, M. A., Conte, A., and Del Nobile, M. A. (2016). Packaging optimisation for portioned Canestrato di Moliterno cheese. Int. J. Dairy Technol. 69, 401–409. doi: 10.1111/1471-0307.12275

Coussy, H., Guillard, V., Guillaume, C., and Gontard, N. (2013). Role of packaging in the smorgasbord of action for sustainable food consumption. Agro-food-Industry Hi Tech. 24, 15–19.

Coutelieris, F. A., and Kanavouras, A. (2006). Experimental and theoretical investigation of packaged olive oil: development of a quality indicator based on mathematical predictions. J. Food Eng. 73, 85–92. doi: 10.1016/j.jfoodeng.2005.01.008

Dalgaard, P. (1995). Modelling of microbial activity and prediction of shelf life for packed fresh fish. Int. J. Food Microbiol. 26, 305–317. doi: 10.1016/0168-1605(94)00136-T

De Hooge, I. E., Oostindjer, M., Aschemann-Witzel, J., Normann, A., Loose, S. M., and Almli, V. L. (2017). This apple is too ugly for me!: Consumer preferences for suboptimal food products in the supermarket and at home. Food Qual. Prefer. 56, 80–92. doi: 10.1016/j.foodqual.2016.09.012

Dilkes-Hoffman, L. S., Lane, J. L., Grant, T., Pratt, S., Lant, P. A., and Laycock, B. (2018). Environmental impact of biodegradable food packaging when considering food waste. J. Clean. Prod. 180, 325–334. doi: 10.1016/j.jclepro.2018.01.169

Eberle, U., and Fels, J. (2016). Environmental impacts of German food consumption and food losses. Int. J. Life Cycle Assess. 21, 759–772. doi: 10.1007/s11367-015-0983-7

Elez-Martinez, P., Soliva-Fortuny, R. C., Gorinstein, S., and Martin-Belloso, O. (2005). Natural antioxidants preserve the lipid oxidative stability of minimally processed avocado purée. J. Food Sci. 70, S325–S329. doi: 10.1111/j.1365-2621.2005.tb09986.x

Emamifar, A., Kadivar, M., Shahedi, M., and Soleimanian-Zad, S. (2010). Evaluation of nanocomposite packaging containing Ag and ZnO on shelf life of fresh orange juice. Innovat. Food Sci. Emerg. Technol. 11, 742–748. doi: 10.1016/j.ifset.2010.06.003

Fabiano, B., Perego, P., Pastorino, R., and Del Borghi, M. (2000). The extension of the shelf-life of ‘pesto'sauce by a combination of modified atmosphere packaging and refrigeration. Int. J. Food Sci. Technol. 35, 293–303. doi: 10.1046/j.1365-2621.2000.00336.x

Farr-Wharton, G., Foth, M., and Choi, J. H.-J. (2014). Identifying factors that promote consumer behaviours causing expired domestic food waste. J. Consumer Behav. 13, 393–402. doi: 10.1002/cb.1488

Floros, J. D., and Matsos, K. I. (1991). Introduction to modified atmosphere packaging. Innovat. Food Pack. 159–172. doi: 10.1016/B978-012311632-1/50042-5

Foley, J. A., Ramankutty, N., Brauman, K. A., Cassidy, E. S., Gerber, J. S., Johnston, M., et al. (2011). Solutions for a cultivated planet. Nature 478, 337–342. doi: 10.1038/nature10452

Food and Agriculture Organization of the United Nations (2019). The State of Food and Agriculture- Moving Forward on Food Loss and Waste Reduction. Rome: FAO.

Ghaly, A. E., Dave, D., Budge, S., and Brooks, M. S. (2010). Fish spoilage mechanisms and preservation techniques. Am. J. Appl. Sci. 7:859. doi: 10.3844/ajassp.2010.859.877

Gokkurt, T., Findik, F., Unal, H., and Mimaroglu, A. (2012). Extension in shelf life of fresh food using nanomaterials food packages. Polym. Plast. Technol. Eng. 51, 701–706. doi: 10.1080/03602559.2012.661899

Guillard, V., Couvert, O., Stahl, V., Buche, P., Hanin, A., Denis, C., et al. (2017). MAP-OPT: A software for supporting decision-making in the field of modified atmosphere packaging of fresh non respiring foods. Packag. Res. 2, 28–47. doi: 10.1515/pacres-2017-0004

Guillard, V., Couvert, O., Stahl, V., Hanin, A., Denis, C., Huchet, V., et al. (2016). Validation of a predictive model coupling gas transfer and microbial growth in fresh food packed under modified atmosphere. Food Microbiol. 58, 43–55. doi: 10.1016/j.fm.2016.03.011

Guillaume, C., Guillard, V., and Gontard, N. (2010). Modified Atmosphere Packaging of Fruits and Vegetables: Modeling Approach. Advances in Fresh-Cut Fruits and Vegetables Processing (New York, NY: CRC Press), 257–286.

Gustavsson, J., Cederberg, C., Sonesson, U., Van Otterdijk, R., and Meybeck, A. (2011). Global food losses and food waste. FAO Rome.

Gutierrez, M. M., Meleddu, M., and Piga, A. (2017). Food losses, shelf life extension and environmental impact of a packaged cheesecake: a life cycle assessment. Food Res. Int. 91, 124–132. doi: 10.1016/j.foodres.2016.11.031

Guynot, M. E., Marin, S., Sanchis, V., and Ramos, A. J. (2003). Modified atmosphere packaging for prevention of mold spoilage of bakery products with different pH and water activity levels. J. Food Prot. 66, 1864–1872. doi: 10.4315/0362-028X-66.10.1864

Hebrok, M., and Boks, C. (2017). Household food waste: drivers and potential intervention points for design–An extensive review. J. Clean. Prod. 151, 380–392. doi: 10.1016/j.jclepro.2017.03.069

Heller, M. C., Selke, S. E., and Keoleian, G. A. (2019). Mapping the influence of food waste in food packaging environmental performance assessments. J. Industr. Ecolo. 23, 480–495. doi: 10.1111/jiec.12743

Huang, J.-Y., Limqueco, J., Chieng, Y. Y., Li, X., and Zhou, W. (2017). Performance evaluation of a novel food packaging material based on clay/polyvinyl alcohol nanocomposite. Innovat. Food Sci. Emerg. Technol. 43, 216–222. doi: 10.1016/j.ifset.2017.08.012

Institute of Food Science and Technology (1993). Shelf Life of Foods : Guidelines for its Determination and Prediction. London : Institute of Food ScienceandTechnology (UK).

International Organization for Standardization (2006). Environmental Management: Life Cycle Assessment; Requirements and Guidelines. Geneva: ISO Geneva.

Jaeger, S. R., Machín, L., Aschemann-Witzel, J., Antúnez, L., Harker, F. R., and Ares, G. (2018). Buy, eat or discard? A case study with apples to explore fruit quality perception and food waste. Food Qual. Prefer. 69, 10–20. doi: 10.1016/j.foodqual.2018.05.004

Joshi, K., Tiwari, B., Cullen, P. J., and Frias, J. M. (2019). Predicting quality attributes of strawberry packed under modified atmosphere throughout the cold chain. Food Pack. Shelf Life. 21:100354. doi: 10.1016/j.fpsl.2019.100354

Kaipia, R., Dukovska-Popovska, I., and Loikkanen, L. (2013). Creating sustainable fresh food supply chains through waste reduction. Int. J. Phys. Distribut. Log. Manag. 43, 262–276. doi: 10.1108/IJPDLM-11-2011-0200

Kanavouras, A., Hernandez-Munoz, P., and Coutelieris, F. A. (2006). Packaging of olive oil: quality issues and shelf life predictions. Food Rev. Int. 22, 381–404. doi: 10.1080/87559120600865149

Koutsoumanis, K. P., Stamatiou, A. P., Drosinos, E. H., and Nychas, G.-J. (2008). Control of spoilage microorganisms in minced pork by a self-developed modified atmosphere induced by the respiratory activity of meat microflora. Food Microbiol. 25, 915–921. doi: 10.1016/j.fm.2008.05.006

Kummu, M., De Moel, H., Porkka, M., Siebert, S., Varis, O., and Ward, P. J. (2012). Lost food, wasted resources: global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Sci. total Environ. 438, 477–489. doi: 10.1016/j.scitotenv.2012.08.092

Lareo, C., Ares, G., Ferrando, L., Lema, P., Gambaro, A., and Soubes, M. (2009). Influence of temperature on shelf life of butterhead lettuce leaves under passive modified atmosphere packaging. J. Food Qual. 32, 240–261. doi: 10.1111/j.1745-4557.2009.00248.x

Lee, K.-E., Kim, H. J., An, D. S., Lyu, E. S., and Lee, D. S. (2008). Effectiveness of modified atmosphere packaging in preserving a prepared ready-to-eat food. Pack. Techn. Sci. Int. J. 21, 417–423. doi: 10.1002/pts.821

Licciardello, F. (2017). Packaging, blessing in disguise. Review on its diverse contribution to food sustainability. Trends Food Sci. Technol. 65, 32–39. doi: 10.1016/j.tifs.2017.05.003

Limbo, S., Torri, L., Sinelli, N., Franzetti, L., and Casiraghi, E. (2010). Evaluation and predictive modeling of shelf life of minced beef stored in high-oxygen modified atmosphere packaging at different temperatures. Meat Sci. 84, 129–136. doi: 10.1016/j.meatsci.2009.08.035

Lindh, H., Williams, H., Olsson, A., and Wikström, F. (2016). Elucidating the indirect contributions of packaging to sustainable development : a terminology of packaging functions and features. Pack. Technol. Sci. 29, 225–246. doi: 10.1002/pts.2197

Lloret, E., Picouet, P. A., Trbojevich, R., and Fernández, A. (2016). Colour stability of cooked ham packed under modified atmospheres in polyamide nanocomposite blends. LWT-Food Sci. Technol. 66, 582–589. doi: 10.1016/j.lwt.2015.11.012

Manfredi, M., Fantin, V., Vignali, G., and Gavara, R. (2015). Environmental assessment of antimicrobial coatings for packaged fresh milk. J. Clean. Prod. 95, 291–300. doi: 10.1016/j.jclepro.2015.02.048

Mangaraj, S., Goswami, T. K., and Mahajan, P. V. (2009). Applications of plastic films for modified atmosphere packaging of fruits and vegetables: a review. Food Eng. Rev. 1:133. doi: 10.1007/s12393-009-9007-3

Manzocco, L., Alongi, M., Lagazio, C., Sillani, S., and Nicoli, M. C. (2017). Effect of temperature in domestic refrigerators on fresh-cut Iceberg salad quality and waste. Food Res. Int. 102, 129–135. doi: 10.1016/j.foodres.2017.09.091

Marcuzzo, E., Peressini, D., and Sensidoni, A. (2013). Shelf life of short ripened soft cheese stored under various packaging conditions. J. Food Process. Preserv. 37, 1094–1102. doi: 10.1111/j.1745-4549.2012.00810.x

Matar, C. (2018). Eco-Design of Modified Atmsophere Packaging Coupled With Chilled Chain System for Minimizing the Environmental Impact of Post-Harvest Chain of Fresh Fruit and Vegetables (Ph.D. thesis). Montpellier.

Matar, C., Gaucel, S., Gontard, N., Guilbert, S., and Guillard, V. (2018a). Predicting shelf life gain of fresh strawberries ‘Charlotte cv' in modified atmosphere packaging. Postharvest Biol. Technol. 142, 28–38. doi: 10.1016/j.postharvbio.2018.03.002

Matar, C., Gaucel, S., Gontard, N., Guilbert, S., and Guillard, V. (2018b). A global visual method for measuring the deterioration of strawberries in MAP. MethodsX. 5, 944–949. doi: 10.1016/j.mex.2018.07.012

Matar, C., Guillard, V., Gauche, K., Costa, S., Gontard, N., Guilbert, S., et al. (2020). Consumer behaviour in the prediction of postharvest losses reduction for fresh strawberries packed in modified atmosphere packaging. Postharvest Biol. Technol. 163:111119. doi: 10.1016/j.postharvbio.2020.111119

Mattsson, L., Williams, H., and Berghel, J. (2018). Waste of fresh fruit and vegetables at retailers in Sweden–Measuring and calculation of mass, economic cost and climate impact. Resour. Conserv. Recycling. 130, 118–126. doi: 10.1016/j.resconrec.2017.10.037