94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Sustain. Food Syst., 29 April 2021

Sec. Sustainable Food Processing

Volume 5 - 2021 | https://doi.org/10.3389/fsufs.2021.630393

This article is part of the Research TopicSustainability and Efficiency of Food Packaging: from Food Preservation to SaleView all 7 articles

Food packaging has a crucial function in the modern food industry. New food packaging technologies seek to meet consumers and industrial's demands. Changes related to food production, sale practices and consumers' lifestyles, along with environmental awareness and the advance in new areas of knowledge (such as nanotechnology or biotechnology), act as driving forces to develop smart packages that can extend food shelf-life, keeping and supervising their innocuousness and quality and also taking care of the environment. This review describes the main concepts and types of active and intelligent food packaging, focusing on recent progress and new trends using biodegradable and biobased polymers. Numerous studies show the great possibilities of these materials. Future research needs to focus on some important aspects such as possibilities to scale-up, costs, regulatory aspects, and consumers' acceptance, to make these systems commercially viable.

Food packaging has a crucial function in modern food industry, since it contributes to preserve food products quality and guarantee food safety during its shelf-life (Ghaani et al., 2016). Traditional food packaging has four basic functions: protection and preservation, containment, communication and marketing, and convenience (Biji et al., 2015). Packages are used to protect the product from spoilage and damage brought about by environmental factors, such as microbes, insects, light, heat, oxygen, water vapor, smells, dirt, dust, etc. (Fuertes et al., 2016a). They can take different shapes and sizes to hold food products, with the aim of improving logistical efficiency (Yam and Lee, 2012). They communicate with the consumer by means of written texts (the ingredients list, nutritional facts, preparation instructions, etc.) and the brand logo. They adapt to consumer's lifestyle, for example, saving time (suitable for ready-to-eat meals) or facilitating their handling (easy to open, reclosable or suitable for microwave) (Vanderroost et al., 2014). Figure 1 resumes these functions, that traditionally, these have been fulfilled minimizing the interaction between food and package (Lee et al., 2015).

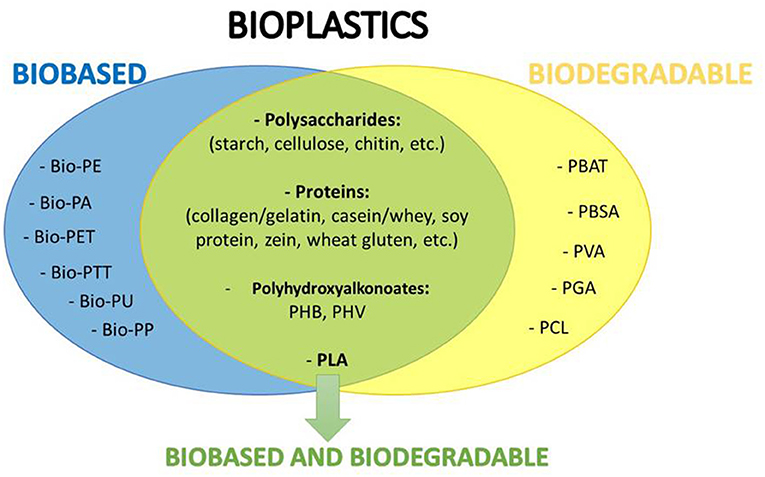

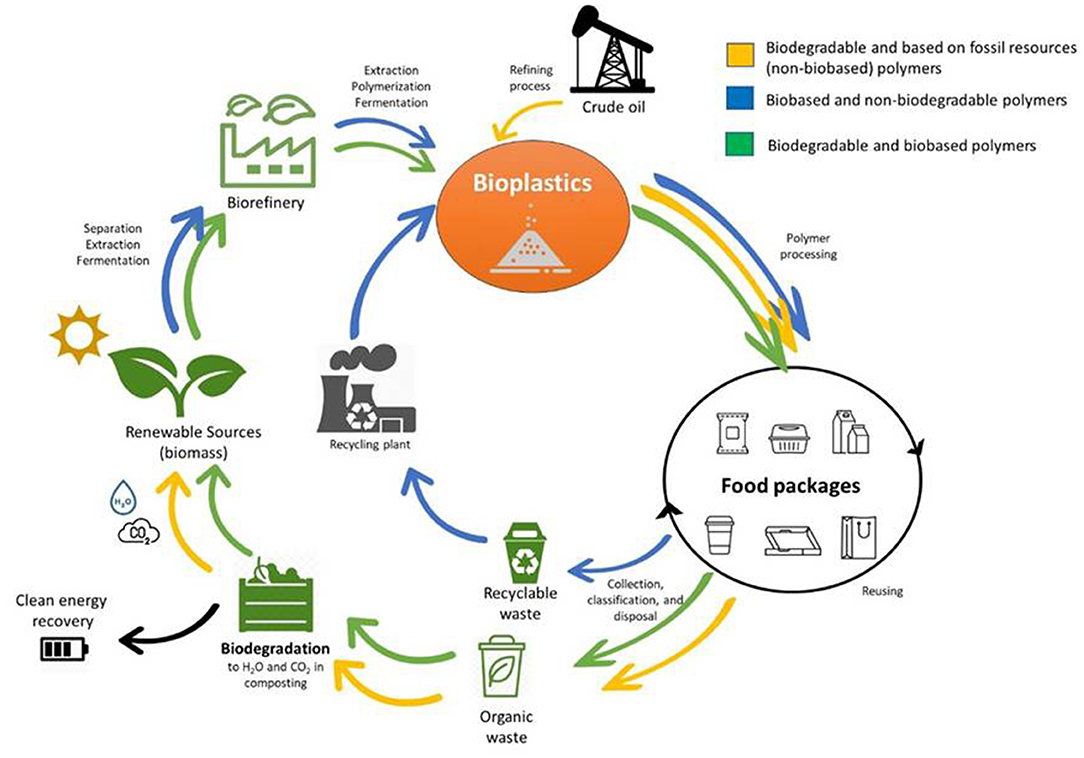

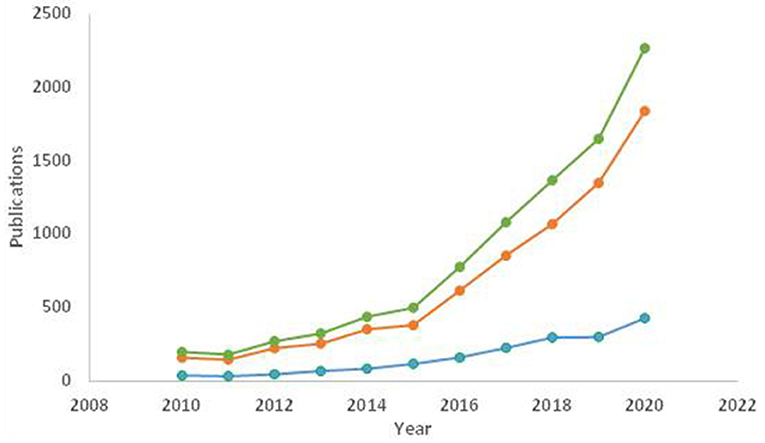

For about five decades, plastic packages have been widely used by the food industry due to their advantageous characteristics. They are economical, functional, light and very versatile, since they can be rigid (bottles, jars, boxes, cases), thermoformed (food trays) or flexible (woven mesh, multi-layer, films). Therefore, they have replaced other traditional materials such as glass, metals (aluminum, laminated, tinplate and steel), paper and cardboard, until representing recently 37% of food packaging materials (Food Packaging Forum, 2015). This massive use has caused serious environmental problems worldwide, because most of these materials derive from petroleum, are non-degradable and during their manufacturing and disposal they pollute the environment. The development of new eco-friendly packages along with innovative packaging concepts is changing the market. The use of biodegradable and renewable materials represents a great alternative to protect the environment and give economic value to underutilized products or industrial waste materials (Cazón et al., 2017). In this sense, bioplastics have begun to gain prominence. According to the European Bioplastics Organization, they are defined as plastic materials that are either biobased (partly or entirely) or biodegradable, or feature both properties. “Biobased” means that the material or product is derived from biomass and “biodegradable” means that it can be biological degraded down to base substances such as water, carbon dioxide, methane, basic elements, and biomass by living organisms that are available in the environment (Goswami and O'Haire, 2016). Thus, bioplastics can be classified into three main groups (Figure 2): (i) biobased but non-biodegradable plastics such as bio-polyethylene (Bio-PE), bio-polyamide (Bio-PA), bio-polyethylene terephthalate (Bio-PET), bio-polytrimethylene terephthalate (Bio-PTT), bio-polyurethanes (Bio-PU), biopolypropylene (Bio-PP); (ii) plastics that are biodegradable and based on fossil resources, such as poly(butylene adipate-co-terephthalate) (PBAT), poly(butylene succinate-co-butylene adipate) (PBSA), polyvinyl alcohol (PVA), polyglycolic acid (PGA), polycaprolactone (PCL); and (iii) plastics that are both biobased and biodegradable. This last group include: polymers directly extracted from biomass such as polysaccharides (e.g., starch, cellulose, chitin, etc.) and proteins (e.g., collagen, gelatin, casein, whey, soy protein, zein, wheat gluten, etc.); whose further modification can produce additional valuable biobased materials such as cellulose acetate, cellulose acetate butyrate, cellulose acetate propionate, cellulose nitrate, regenerated cellulose, carboxymethyl cellulose, lignocellulosic products, chitosan, etc.); polymers produced by chemical synthesis using renewable biobased monomers, such as polylactic acid (PLA), a bio-polyester polymerized from lactic acid monomers produced by fermentation of carbohydrate feedstock; and polymers produced by microorganisms or genetically modified bacteria such as polyhydroxyalkonoates (PHA) like polyhydroxybutyrate (PHB) and polyhydroxyvalerate (PHV) and bacterial cellulose (Petersen et al., 1999). Biobased and biodegradable plastics heads for a circular economy and sustainability (Bio-based News—www.news.bio-based.eu). Figure 3 shows the life cycle assessment (LCA) of the three types of bioplastics mentioned before. Biobased plastics, which are generally drop-in products for their petroleum-based counterparts, are adequate for material recycling and/or energy recovery, whereas biodegradable plastics are intended for organic recycling. These last ones are specially promising when plastic products withhold food, as in those cases material recycling would be unreasonably expensive. The proper handling, separation and collection of bio-waste could increase the yield of valuable compost that could be used later as fertilizer for those crops that are at the beginning of the cycle. In this way bioplastics reduce the environmental impact (European Bioplastics Organization). Figure 4 shows the evolution of the number of publications during the last 10 years concerning these materials as food packaging. The increment observed shows the interest in the area and the preference of biodegradable ones for this application, according to was noted above.

Figure 2. Classification of bioplastics into three main groups: () biobased but non-biodegradable polymers; () plastics that are biodegradable and based on fossil resources, and () polymers that are both biobased and biodegradable.

Figure 3. Life cycle assessment (LCA) of the three types of bioplastics: () biobased but non-biodegradable polymers; () plastics that are biodegradable and based on fossil resources, and () polymers that are both biobased and biodegradable.

Figure 4. Evolution of the number of publications during the last 10 years (2010–2020) with the terms “renewable + biobased + biodegradable food packaging” (), “renewable” (), “biobased” (), or “biodegradable” () as title and/or topic (Scholar Google, March 2021, http://scholar.google.com).

Currently novel food packaging technologies seek to meet new consumers' and industrial demands (Figure 5). Changes in production practices and food sale (for example, market globalization that gives a longer food distribution as a result), population increase, consumers' lifestyles, who reduce time devoted to buying fresh food and cooking but ask for safer and healthier foods and try to take care of environment, along with the advance in new areas of knowledge, such as nanotechnology and biotechnology, act as driving forces to develop new and better packages that can extend food shelf-life, keeping and supervising their innocuousness and quality. In this context, new concepts of smart packaging arise, including active and intelligent packaging, which besides interacting with food establish a communication with the consumer (Biji et al., 2015).

Figure 6 shows the evolution of publications on smart food packaging during the last 10 years, differentiating them between active and intelligent. The increased number of publications was significantly higher for active packaging, which became more marked since 2015, although those of intelligent packaging also grew steadily during the analyzed period. These trends reflect the interest in these new packaging technologies that focus on a safer and more efficient food supply chain, reducing food loss and waste and preventing unnecessary transport and logistics from an early stage. Among these publications, excellent reviews on active and intelligent food packaging systems have been reported during last years (Vanderroost et al., 2014; Bastarrachea et al., 2015; Biji et al., 2015; Brockgreitens and Abbas, 2016; Fuertes et al., 2016a; Ghaani et al., 2016; Mellinas et al., 2016; Ahmed et al., 2017; Fang et al., 2017; Haghighi-Manesh and Azizi, 2017; Gaikwad et al., 2018, 2019, 2020; Han et al., 2018a; Majid et al., 2018; Poyatos-Racionero et al., 2018; Schumann and Schmid, 2018; Vilela et al., 2018; Yildirim et al., 2018). As far as we know, only that recently published by Halonen et al. (2020) deals with describing the development of biobased antimicrobial films and sensors to be used as indirect indicators of food spoilage. In this context, the present review attempts to describe recent progress and new trends in the production of smart, active and intelligent food packaging, with focus on biodegradable and biobased polymers, which will be referred as biopolymers throughout this review.

Figure 6. Evolution of the number of publications during the last 10 years (2010–2020) with the terms “smart food packaging” (), “active” (), and “intelligent” (), as title and/or topic (Scholar Google, March 2021, http://scholar.google.com).

Smart packaging is a broad term that describes new packaging concepts, most of which can be classified in one of two main categories: active or intelligent packaging (Kerry, 2012). Considering the features described by diverse authors, we can define:

– An active package as the one that modifies the condition of packaged foods to extend shelf-life or improve its safety or sensorial properties, keeping its quality. Sometimes this is achieved by the intrinsic properties of the polymer and others adding some specific additives in the packaging material or in the headspace in order to attain a better package yield (Kuorwel et al., 2015; Fuertes et al., 2016a). In this sense, the European Community regulation defines active materials and components as those aimed at extending shelf-life or keeping or improving the condition of packaged foods, designed to deliberately incorporate components that release or absorb substances toward or from the packaged foods and the environment surrounding the foods (Framework Regulation on Food Contact Materials 1935/2004 and 450/2009, 2020). Although bioactive packaging can also be considered in this category, they have another purpose that is to provoke a direct and positive impact on consumers' health through the generation of healthier packaged foods (Lopez-Rubio, 2011).

– An intelligent package as the packaging system capable of carrying out intelligent functions, such as detecting, registering, locating, communicating and applying scientific logics, in order to ease decision-making, extend shelf-life, improve safety and quality, provide information and warn of possible problems (Yam and Lee, 2012). The European Community Framework Regulation (Framework Regulation on Food Contact Materials 1935/2004 and 450/2009, 2020) acknowledges them as those materials and objects that control the state of packaged foods or the environment surrounding them. These systems, which are attached as labels or incorporated or printed on the food packaging material, offer better possibilities to check product quality, track critical items and provide more detailed information during all the food supply chain (storage, transport, distribution and sale) (Lee et al., 2015). They can also inform about product history such as storage conditions, composition of headspace, microbial growth, etc. (Realini and Marcos, 2014).

Intelligent packages do not act directly to extend food shelf-life and do not aim at releasing their components onto the food, as active packaging does. Instead, intelligent packages have the aim to convey information related with food quality to manufacturers, retailers, and/or consumers.

These definitions imply product-package-environment interactions (Vanderroost et al., 2014; Biji et al., 2015; Fang et al., 2017). Thus, active packaging would be considered as an extension of the protection and preservation function of traditional food packaging, while intelligent ones can be considered as an extension of their communication and marketing function (Fuertes et al., 2016a). So, smart packaging gives a total packaging solution: on the one hand, it monitors changes in the product or the environment (intelligent packaging), and on the other hand, it acts upon these changes (active packaging) (Vanderroost et al., 2014; Janjarasskul and Suppakul, 2018). Figure 7 shows a schematic diagram of active and intelligent packaging concepts and Figure 8 presents the classification of smart packaging analyzed in this manuscript.

Active packaging is one of the most dynamic technologies used to preserve foods. Its activity is based on the intrinsic properties of the polymer or the specific properties of additives included into the packaging systems (Fuertes et al., 2016a; Mellinas et al., 2016).

Among biopolymers, chitosan have antibacterial and antifungal activity per se, which is attributed to changes in cellular permeability of microorganisms caused by electrostatic interactions between the chitosan amine groups and the electronegative charges on cellular surface (Lunkov et al., 2018). The introduction of an active monomer into the polymer chain could be an alternative route that conduct to polymers with new functionalities (Dainelli et al., 2008).

On the other hand, active agents can be incorporated into the packaging material, coated on its surface (Halonen et al., 2020), or also inside certain elements associated with the package, such as bags, labels, pads, bottle caps (Ortiz et al., 2013; Gómez-Estaca et al., 2014) instead of being applied directly on foods, in order to meet the desired objective with lower concentrations, thus limiting undesired flavors and smells to foods (Kapetanakou and Skandamis, 2016).

These active compounds are added to release or absorb substances to/from the packaged food or its surrounding environment, or to make changes in food composition or organoleptic features, as long as these changes adjust to current regulations (Ortiz et al., 2014). These active agents may migrate (partially or completely) through gradual diffusion into the food or headspace, or act only when the food is in direct contact with the packaging (Brockgreitens and Abbas, 2016; Halonen et al., 2020).

The nature of active agents can be diverse, including organic acids, enzymes, bacteriocins, fungicides, natural extracts, ions, ethanol, polyphenols, protein hydrolysates, etc. (Salgado et al., 2015). Currently there is a preference in the use of natural additives, instead of synthetic ones that sometimes are associated to certain health risks. Even some agro-industrial waste or byproducts, as those derived from fruit and vegetable processing, or from wine, beer, dairy and meat industries, provide practical and economical sources of potent active compounds (Sanches-Silva et al., 2014; Bhargava et al., 2020). Thermal resistance and action mechanism of these additives should be considered to avoid their damage or loss during material's processing and to ensure their activity in the package. The previous encapsulation of active compounds, could contribute to protect them during processing and to control their release, modulating their activity (Ezhilarasi et al., 2012; Salgado et al., 2019a). Different biopolymers have been studied to encapsulate bioactives such as whey protein isolate, soy protein isolate, zein protein, chitosan, maltodextrin, and modified starch by different techniques (Ezhilarasi et al., 2012; Ðordević et al., 2015; Brandelli et al., 2017; Di Giorgio et al., 2019).

Active package systems for the food industry, with different functionality, are described below with more detail.

Microbial growth increases food-borne diseases risk and accelerates smell, color and texture changes of foods, resulting in a shorter shelf-life. The development of antimicrobial packages presents a promising approach to inhibit, reduce or delay microorganism growth. They can be classified into two types: (i) those that contain antimicrobial agents that migrate to food surface and (ii) those that are effective against surface microbes without requiring the migration of the active agent to food (Han, 2014). Malhotra et al. (2015), Mousavi Khaneghah et al. (2018), Sofi et al. (2018), Huang et al. (2019), Said and Sarbon (2019), and Al-Tayyar et al. (2020) recently reviewed the advances on antimicrobial packaging. The growing trend is to apply natural antimicrobial compounds into the packaging (Kapetanakou and Skandamis, 2016). In this sense, the following substances have been recently incorporated into biopolymers food packaging to activate them with antimicrobial properties in food packages based on biopolymers:

– Organic acids and their salts. Sorbic, benzoic, acetic, propionic, ascorbic acids are strong antimicrobial agents as they can alter membrane transport and permeability, and reduce intracellular pH. Ascorbic, citric, lactic, tartaric, gallic, and vanillic acids have also been used as preservative agents (Coban, 2020). Sodium benzoate and potassium sorbate have a GRAS status and can inhibit the growth of bacterial and fungal cells, being the preservative effect of sorbic acid 5–10 times more resistant than that of benzoate while sodium citrate inhibits the growth of Listeria monocytogenes and Escherichia coli O157:H7 (Rawdkuen, 2018; Huang et al., 2019). They had been incorporated as antimicrobial agent in biopolymers and nanocomposite films such as chitosan (Remedio et al., 2019), pullulan and gelatin (Kowalczyk et al., 2020), and corn starch/chitosan/nanoclay (Na-MMT) (Jha, 2020).

– Plant extracts and essential oils. Aqueous or alcoholic extracts and essential oils from spices and vegetables such as cinnamon, allspice, clove, ginger, sage, eucalyptus, thyme, mustard, basil, rosemary, oregano, onion, garlic, lemon, horseradish, and others have been studied as antimicrobial agents (Çoban et al., 2016; Noshirvani et al., 2017; Ribeiro-Santos et al., 2017; Sirocchi et al., 2017; Mir et al., 2018; Bouarab Chibane et al., 2019), and were incorporated in chitosan-carboxymethyl cellulose, starch, gelatin, PLA, soy protein isolated, alginate, cellulose acetate films, and were proved to be effective as packaging of refrigerated beef meat, fresh rainbow, lard, chicken breast cuts, bologna and ham, etc.

– Bacteriocins. They are antimicrobial peptides produced by microorganisms that can inhibit other strictly related microorganisms. They are not toxic, thermostable, commercially available and used for specific applications in a wide range of foods (Johnson et al., 2018; Santos et al., 2018). Nisin, produced by a Lactococcus lactis, is the most effective bacteriocin against Gram positive bacteria. It acts especially in acid conditions by incorporating into the cytoplasmic membrane of the target cells. Nisin had been incorporated in PLA (Holcapkova et al., 2018), chitosan (Remedio et al., 2019), and carboxymethyl/chitosan films (Zimet et al., 2019). Natamycin and pediocin were also used as antimicrobial agents in pectin and sodium caseinate and corn starch films (Meira et al., 2017; Eghbal et al., 2019).

– Enzymes. Lysozyme can inhibit bacterial infections, especially those caused by Gram-positive bacteria. Its activity is attributed to its ability to hydrolyze peptidoglycans (the main cell wall component), causing the loss of intracellular materials and bacterial death (Syngai and Ahmed, 2019). Lyzozyme had been immobilized on calcium alginate (Wang et al., 2018a), pullulan (Silva et al., 2018), and Jackfruit starch (Bonomo et al., 2018) films. Lactoperoxidase, a glycoprotein enzyme found naturally in milk, saliva, and tear, is another antimicrobial agent with broad spectrum that was included in alginate, chitosan, gelatin (Ehsani et al., 2019), and whey protein films (Shokri and Ehsani, 2017; Farshidi et al., 2018); while lactoferrin had been proposed as antimicrobial agent in pullulan films (Zhao et al., 2019).

– Inorganic and metal oxide-based nanoparticles. The use of metal oxide-based nanoparticles, such as ZnO, MgO, CuO, and TiO2, had been explored as antimicrobial agents to be applied in food packaging because their high stability and potent antimicrobial activities (Garcia et al., 2018; Hoseinnejad et al., 2018; Dobrucka and Ankiel, 2019). Particularly, silver salts work by direct contact, but they slowly migrate and react preferably with organic products. Silver ions inhibit a wide range of enzymes and have a strong broad-spectrum antimicrobial activity; they particularly reduce the growth of pathogens transmitted by foods such as Salmonella, Escherichia coli and Campylobacter in fresh meat (Realini and Marcos, 2014). The addition of silver nanoparticles to different polymers allowed an effective inhibition of microorganism growth. For example, Singh and Sahareen (2017) developed cellulosic packets impregnated with silver nanoparticles that enhance the shelf-life of vegetables, showing antimicrobial activity against Aeromonas hydrophila; and Musso et al. (2017a) developed gelatin films with important antimicrobial properties against E. coli by incorporating silver nanoparticles. Also, Arfat et al. (2017) developed a nanocomposite film based on fish skin gelatin and bimetallic silver-copper nanoparticles with higher antibacterial activity against L. monocytogenes and S. enterica. Recently, Kraśniewska et al. (2020) reviewed the biopolymers-based materials containing silver nanoparticles as food active packaging.

– Macromolecules. Some polymers such as chitosan that have inherent antimicrobial properties, had been used as films and coatings (Lunkov et al., 2018) or had been added as an additive in whey protein films (Vanden Braber et al., 2021). Their action method has been mentioned above.

– Ethanol. Ethanol (C2H5OH) is used as an antimicrobial agent, particularly effective against fungi although it can also inhibit yeast and bacteria growth (Larson, 1991). Several reports have shown that spraying with ethanol 95% delays the appearance of fungi and extends the shelf-life of bread, cake, and pizza (Pereira de Abreu et al., 2012; Mane, 2016). However, a more practical and safer method currently consists of using ethanol-emitter bags because C2H5OH absorbed or embedded in a carrier material allows its vapor-controlled release (Hempel et al., 2013). Commercial devices are produced by the direct adsorption of C2H5OH and H2O on adsorbents, such as silica, packaged as sachets based on paper and laminated ethyl-vinyl-acetate or low-density polyethylene. When food is packed with these bags, H2O is absorbed by the food and C2H5OH vapor is released and spread in the headspace (Dobrucka and Cierpiszewski, 2014). Nevertheless, ethanol can be absorbed by the food product generating nasty smells, which could be reduced heating up the food before its consumption. Therefore, controlled release technologies should overcome the disadvantages of conventional ethanol emitters. Mu et al. (2017) developed a controlled release ethanol emitter based on an ethanol-gel prepared by ethanol and sodium stearate esterification added with diatomite as adsorbent capable to preserve the quality of fresh Chinese bayberry fruit during refrigerated storage; and anticipated that it could be applied for other perishable fruit because of the appropriate selection of sodium stearate content in agreement with the storage period to reach precise storage goals.

Lipid oxidation is the second cause of food spoilage, after microbial growth. Foods with high lipid content, and especially those with a high unsaturation degree, such as nuts, vegetable and fish oils, meat and fishing products, are susceptible to oxidation (Ganiari et al., 2017). Lipid oxidation in food products results in the development of rancid smells, making the product unacceptable for human consumption. Other negative effects are aldehyde formation and nutritional quality loss produced by the degradation of polyunsaturated fatty acids (Gómez-Estaca et al., 2014). There are two main action methods for antioxidant packages: (i) the addition of antioxidant compounds or (ii) the elimination of undesired compounds that can accelerate oxidation reactions, such as O2, singlet oxygen (1O2), UV light, or metallic ions from the headspace or foods (Islam et al., 2017).

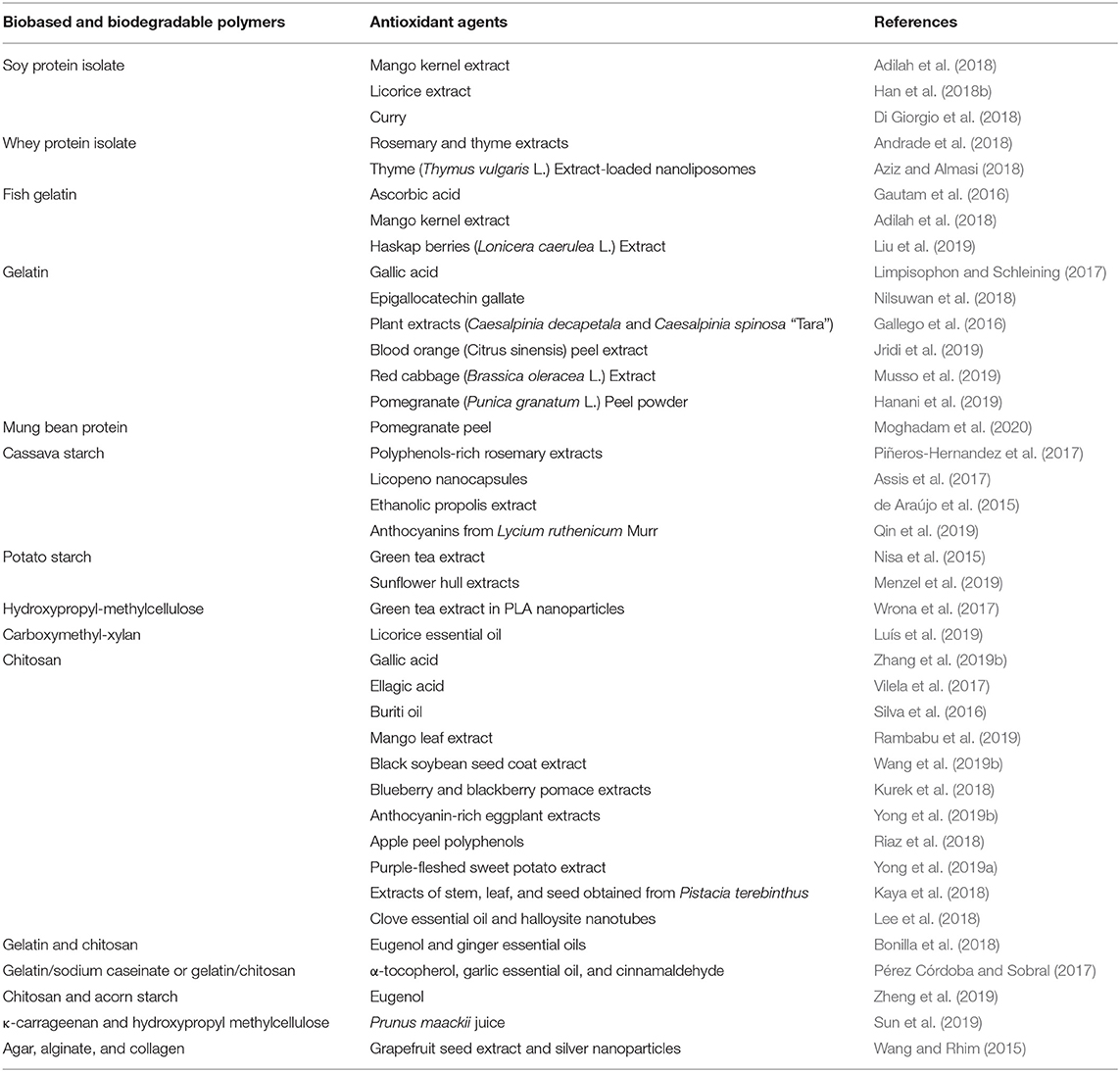

The direct addition of antioxidants to food surface can face the limitation that, once the active compounds are consumed in the reaction, protection ceases, and food quality degrades at a higher speed. Besides, it can change food quality parameters, such as color or taste, and currently consumers prefer the exclusion of additives in food. Thus, the addition of antioxidant agents to packaging formulation became a good alternative (Vilela et al., 2018). In this regard, synthetic antioxidants, such as butylated hydroxytoluene (BHT) or butylated hydroxyanisole (BHA), have been added to PLA (Jamshidian et al., 2012), gelatin (Sai-Ut et al., 2015), carrageenan (Wan Yahaya et al., 2019), gum cordia and carboxymethyl cellulose (Haq et al., 2015) films proving to effectively reduce lipid oxidation in several foods. However, the use of natural antioxidants like pure compounds (e.g., tocopherols, caffeic acid, chlorogenic acid, ferulic acid, rosmarinic acid, salvianolic acid, carnosic acid and ascorbic acid carvacrol, thymol, carnosol, quercetin, luteolin, apigenin, eriodictyol, catechin, rutin), plant and fruit extracts (e.g., rosemary, grape seed, green tea, oregano, murta, mint, marjoram, savory, and pomegranate peel), and essential oils or oleoresins from herbs and spices (e.g., cinnamon, lemongrass, clove, thyme, ginger, sage, oregano, pimento and bergamot) (Amorati et al., 2013; Sanches-Silva et al., 2014; Valdés et al., 2015; Ganiari et al., 2017; Tsimogiannis et al., 2017) is currently preferred. Likewise, it is important to mention the potential use of extracts obtained from plant by-products like barley husks, pomegranate peel, olive leaves, as sources of antioxidant agents (Pereira de Abreu et al., 2012; Barbosa-Pereira et al., 2013; Marcos et al., 2014; Qin et al., 2015; Yuan et al., 2015; de Moraes Crizel et al., 2016). The antioxidant properties of peptides obtained from diverse food proteins were also studied (Salgado et al., 2011; Blanco-Pascual et al., 2014; Rostami et al., 2017; da Rocha et al., 2018; Lima et al., 2018; de Oliveira Filho et al., 2019; Montero et al., 2019). Over the last years, several studies have been published dealing on addition of different antioxidant compounds to biodegradable and biobased polymers and their assessment in diverse food systems (Eça et al., 2014; Sanches-Silva et al., 2014; Ganiari et al., 2017; Lourenço et al., 2019; Sahraee et al., 2019; Jacob et al., 2020).

Acting as antioxidants, free-radical scavengers can donate hydrogen to reactive free radicals and convert them into (fairly) stable products unable to participate in initiation or propagation reactions (Vilela et al., 2018). Table 1 summarized some newly published research on this topic. In addition to primary antioxidants, other additives like chelating agents, ultraviolet absorbers, singlet oxygen quenchers, and oxygen scavengers are also used to reduce the oxidation rate in active packaging (Vilela et al., 2018). Metal pro-oxidants (e.g., iron or copper derivatives) could be converting into stable products using metal chelators such as ethylenediaminetetraacetic acid (EDTA), poly (acrylic acid), citric acid, and lactoferrin (Rawdkuen, 2018). Some examples of UV absorbers are lignin (Aadil et al., 2016; Yang et al., 2016a), naringin, boric acid, bixin, α-tocopherol, ellagic acid, natural extracts rich in phenolic compounds (Vilela et al., 2018), and pigments like phtalocyanine and TiO2 (Tian et al., 2013). On the other hand, carotenoids, tocopherols and polyphenols have been described as singlet oxygen (1O2) quenchers (Vilela et al., 2018). Finally, oxygen scavengers are described latter as affect more than one activity.

Table 1. Recent examples of antioxidant agents incorporated into biobased and biodegradable polymer matrices.

The adequate selection of the antioxidant compound to be incorporated in the polymeric matrix is very important and should be considered for each application. The antioxidant compound and polymer matrix should be compatible to achieve a homogeneous distribution, and the antioxidant partition coefficients in the different phases must that favor their release toward the food or headspace. Once released, the antioxidant solubility features could determine its efficacy, so in turn the antioxidant must be selected depending on food type.

These devices try to control water activity inside the package in order to reduce microbial growth; eliminate defrosting water from frozen products and blood or fluids from flesh food products such as meat and poultry; avoid excessive condensation or dehydration of fresh products such as fruit, vegetables and meat products; keep the properties of dry foods to prevent seizure in powder products such as instant milk or coffee, softening of crunchy products such as biscuits, and dampening of hygroscopic products as candy and sweets; and avoid lipid oxidation in products such as cheese and nuts (Janjarasskul and Suppakul, 2018; Gaikwad et al., 2019).

Moisture absorbents can be classified into: relative humidity (RH) regulators that absorb moisture and control humidity in the headspace of the package, and liquid removers that absorb and hold exuded liquids from food products (Yildirim et al., 2018). Moisture absorbers are hygroscopic substances that absorb and retain water from the surrounding environment through physical adsorption, while moisture absorbers absorb water through a chemical reaction between two functional materials. Common desiccants such as silica gel, CaO, CaSO4, CaCl2, KCl, K2CO3, natural clays (montmorillonite, zeolite, and bentonite), fructose, xylitol, and sorbitol, or superabsorbent polymers like carboxymethyl cellulose and starch can be located between two layers of a microporous polymer (such as sachets, sheets or pads) and are typically placed below fresh products in different packaging concepts (Dobrucka and Cierpiszewski, 2014; Pinming et al., 2016; Yildirim et al., 2018).

These devices could be used together with adequate water-barrier materials without interfering with the external structure of packaging. Furthermore absorbers could be incorporated inside the bulk packaging material or as a coating for commercial food product applications such as fresh fruits, vegetables, fish, and meat (Yildirim et al., 2018). Using biopolymers, Rhim and Wang (2013) proposed agar, carrageenan, and konjac glucomannan films as potential food packaging moisture absorbents because of their safety and large water vapor absorption capacity. Guo et al. (2018) studied the hygroscopic behavior of cellulose nanofiber-based films, Chand and Kumar (2018) analyzed the application of hydroxypropylmethyl cellulose and carboxymethyl cellulose edible coatings on Jaggery cubes. Sängerlaub et al. (2018) developed PLA films with dispersed CaCl2 (2-4 wt%) by extrusion that could absorb up to 15 wt% water vapor at 75% RH at 23°C. The functionality of these devices could be broadened by adding other types of active components such as O2-scavengers, CO2-generators, and antimicrobials (Janjarasskul and Suppakul, 2018). Future research focused in this area is expected.

MAP technology involves the alteration of the gas atmosphere inside a food package to preserve the food quality and extend its shelf-life (Sängerlaub et al., 2018). So, it can consider as an active packaging. This method can extend the conditions of fresh food products and has been applied to perishable food products. High O2 concentrations favor oxidative processes, which can modify food quality, whereas its reduction delays breathing speed, ethylene production, enzymatic browning, and metabolic activity of fruit. Breathing implies the oxidation of starch, sugar, and organic acids to produce simpler molecules such as CO2 and H2O and heat. CO2 in packages prevents microorganism and bacteria growth associated with meat products spoilage. For these reasons, MAP can prolong shelf-life, reduce microbial growth and smells development or delay ripening (Lee et al., 2015). The most utilized gases in MAP are O2, N2, and CO2. These gases are used individually or combined to keep the characteristics and quality of foods on the shelf (Zhang et al., 2015). Other gases such as helium, nitrous oxide, ozone, neon, argon, ethylene oxide, sulfur dioxide, and chlorine have also been used (Lee et al., 2015). Numerous studies have shown the successful application of MAP in products such as fresh vegetables, fruit, meat, and fish (Oliveira et al., 2015; Belay et al., 2016; Saini et al., 2017). Han (2014), for example, describes various bioplastics and MAP combinations to extend shelf-life of lettuce, green pepper, broccoli, mushroom, and blueberries, among other vegetables. Leceta et al. (2015) reported that packaged carrots exhibited better properties when MAP and chitosan coating were combined. Priyadarshi et al. (2020) discussed the applications of various polysaccharides in MAP systems, such as alginate, cellulose, and chitosan, gellan gum, pectin, carrageenan, and xanthan. Finally, it is worth highlighting that the potential uses of MAP increase when it is used in conjunction with natural or chemical additives and biopolymers, and other technologies such as nanotechnology, irradiation, high pressure, and other active and intelligent devices (Tajeddin et al., 2018). For example, the O2 that permeates through the package film from the external environment cannot be eliminated by MAP systems. In these cases, the use of materials with low O2 permeability, such as those based on proteins and PLA (Ebnesajjad, 2012) or the addition of O2 scavengers to the packaging system can be suggested. Also, when a mixture of CO2 and O2 are applied in MAP, CO2 generators presence could be helpful and required for maintaining the desired CO2 concentration in the package to ensure MAP system efficacy, as its concentration dynamically diminish in the package due to its dissolution in food and/or permeation to the external environment through the packaging material (being CO2 permeability 3–5 times higher than that of O2 in most synthetic polymers) (Han et al., 2018a).

Some of these active devices, such as oxygen and ethylene scavengers and carbon dioxide (CO2) generators and scavengers are outlined below.

Oxygen accelerates and eases the oxidative spoilage of foods, the growth of aerobic microorganisms, the development of nasty smells and unwanted color changes and the loss of aroma, flavors and nutritional value of food products, reducing their general stability and shelf-life (Hogan and Kerry, 2008). Consequently, it is important to control oxygen levels into the packages to limit different spoilage reactions rate in foods (Janjarasskul and Suppakul, 2018).

Oxygen scavengers are designed to quickly oxidize to eliminate or decrease the level of free O2 in hermetically packaged food system or to reduce O2 permeation rates through container walls (Janjarasskul and Suppakul, 2018). Most oxygen scavengers currently available are based on bags containing Fe with different catalysts. It reacts with the water provided by food producing a hydrated metal reducing agent that absorbs oxygen and converts it into a stable oxide inside the container (Day, 2008). But packaging industry has become progressively interested in the development and application of novel non-metallic scavenging agents such as reducing organic compounds like ascorbic acid, α-tocopherol, 2-methyl hydroquinone, catechol, sorbose, lignin, gallic acid, polyunsaturated fatty acids, sulfite, thiosulfate, some enzymes (glucose oxidase/catalase in presence of glucose, oxalate oxidase/catalase, ethanol oxidase, and laccase), and some microorganisms and yeasts (Bacillus amyloliquefaciens, Kocuria varians, and Pichia subpelliculosa), among others (Gaikwad et al., 2018; Dey and Neogi, 2019). Besides, there are photosensitive colorants that activate oxygen elimination when they are irradiated with UV light (Lopez-Rubio et al., 2004). Most of these systems are beneficial for food with high water content but need to be triggered by Fe2+, Cu+, and/or UV radiation. In particular, those based on enzymes and microorganisms are highly susceptible to temperature, pH and water activity changes; and polyunsaturated fatty acids based systems, are an excellent option for dry foods, but the formation of by-products like aldehydes, ketones or organic acids may affect the sensory quality of food (Dey and Neogi, 2019). These systems are more expensive, that is why they are not widely used (Dobrucka and Cierpiszewski, 2014).

These systems can be incorporated as part of multilayer films, sandwiched between inert layers, or physical absorbed or coated onto the packaging material surface or also onto food surface. Thus, potential O2 scavenger systems based on biopolymers were developed, such as whey protein edible films added with ascorbic acid (Janjarasskul et al., 2011, 2013), ascorbyl palmitate-β-cyclodextrin inclusion complexes (Byun and Whiteside, 2012), cast extruded PLA films added with α-tocopherol microparticles (Di Maio et al., 2014; Scarfato et al., 2017), carboxymethyl cellulose films incorporated with α-tocopherol nanoparticles (Noronha et al., 2014), fish gelatin films added with α-tocopherol nanoparticles and FeCl2 (Byun et al., 2012), cationic nanofibrillated cellulose and polygalacturonic acid coatings (Mølgaard et al., 2014), starch-based films incorporated with laccase and lignosulfonates (Johansson et al., 2012), and extruded thermoplastic starch films containing ascorbic acid, iron powder and CuCl2 (Mahieu et al., 2015). These systems have better consumers acceptance than sachets or labels traditionally used inside the package (Gaikwad et al., 2018).

CO2 can be added inside the packages to inhibit a wide range of aerobic bacteria and fungi by reducing O2 relative levels in certain products such as fresh meat, poultry, fish, cheese and baked products; reduce breathing rate of fresh products and avoid partial emptying of flexible packaging caused by oxygen scavengers or by CO2 concentration decrease due to its dissolution in food and/or permeation to the external environment through polymeric packaging (Han et al., 2018a; Yildirim et al., 2018). On the contrary, high levels of CO2 can cause adverse effects in food products quality and on package integrity. In those cases, including CO2 scavengers in food packages would be recommended (Dobrucka and Cierpiszewski, 2014). Some CO2 generators and scavengers can be used as bags or labels placed in the package. Dripping losses, in meat for example, can be absorbed in pillows and react with citric acid and sodium bicarbonate present in the pillow, generating carbon dioxide as a result (Kerry et al., 2006). This kind of active package is habitually associated with MAP to balance CO2 losses, due to dissolution in meat and permeation through the package material (Coma, 2008). A device enclosing NaHCO3 and citric acid dry powder could act as both liquid absorber and CO2 generator pad (Biji et al., 2015). Also, dual-function O2-scavenging and CO2-generating sachets and labels based on either FeCO3 or a mixture of NaHCO3 and ascorbic acid were reported (Vilela et al., 2018). However, only some studies have described the development of synthetic films that can produce CO2, scavenge O2, or perform both functions, but none using biodegradable and biobased polymers, as this concept is yet in its early stage of research (Han et al., 2018a). Meanwhile CO2 excess can be eliminated using highly permeable plastics and/or chemical [CaO, MgO, NaOH, KOH, Ca(OH)2, Mg(OH)2, Na2CO3, NaHCO3 and silica gel] and physical (activated carbon and zeolites) absorbers. It should be noted that physical CO2 sorption on the adsorbent can be modified by moisture content (Marx et al., 2013). Although the absorbents are usually enclosed in sachets or pads prepared with synthetic polymers and placed in the food package, other formats have been recently proposed. Agar-based films containing Na2CO3 and/or sodium glycinate were developed by Wang et al. (2015a) for fresh product packaging. This device could modulate CO2 and H2O absorption and be used for MAP of shiitake mushrooms as an insert label, generating the desired internal atmosphere and showing the best quality preservation in terms of color, firmness, flavor, and bacterial growth.

Until now, CO2 scavengers have been applied using a trial-and-error approach rather than a systematic design process. Thus, their optimization should be achieved by characterizing the dynamics of the interactions among the food, the packaging material, the absorber device and the environment in terms of CO2 production, dissolution, absorption and permeation (Lee, 2016).

Ethylene (C2H4) is a phytohormone which accelerates fruit and vegetable breathing and promotes its ripening, softening and senescence, even in a low concentration. Eliminating C2H4 from a package helps to delay the ripening rate of climacteric fruit, a crucial issue for fresh fruit exportation (East et al., 2015). The C2H4 can be controlled in three ways: (i) reduction of the C2H4 concentration through MAP by the exchange of the different gases; (ii) use of micro-perforated packaging materials; and iii) removal of ethylene through the use of C2H4 scavengers or absorbers (Vilela et al., 2018; Gaikwad et al., 2020).

The most common C2H4 scavenger agent is KMnO4 which oxidizes C2H4 –in presence of water– to CO2 and H2O (Gaikwad et al., 2020). Potassium permanganate immobilized on inert matrices (e.g., silica gel or alumina) is available in the form of sachets for packages and in blankets for storage rooms (Janjarasskul and Suppakul, 2018), prepared with C2H4 highly permeable materials (Yildirim et al., 2018). Recently, Warsiki (2018) developed chitosan films activated with KMnO4 to wrap tomatoes that managed to prolong their shelf-life. Nevertheless, KMnO4 cannot be utilized in direct contact with foods due to its high toxicity and has a limited long-term efficacy in high-moisture environments (Yildirim et al., 2018).

The use of 1-methylcyclopropane (1-MCP) is another option to diminish the effect of C2H4. Its action mechanism implies its irreversible union to the C2H4 receptor in fruit, thus blocking C2H4 effects by competitive inhibition. It is encapsulated in cyclodextrins in commercial products and released when the formulation is mixed with water (Ortiz et al., 2013). Ortiz et al. (2013) showed that pillows prepared with soybean proteins could use the RH inside the package to release 1-MCP and delay tomatoes softening and suggested that it could be useful for postharvest treatments in the own package.

Ethylene can also be eliminated by physical adsorption on active surfaces such activated carbon, carbon impregnated with metal catalysts or activated clays (zeolite, vermiculite, and montmorillonite) contained into ethylene-permeable sachets (Álvarez-Hernández et al., 2018) or incorporated into the packaging film (Gaikwad et al., 2020). Biodegradable and biobased polymers have been reinforced by nanoclays addition (Belibi et al., 2013; Echeverría et al., 2014; Azevedo et al., 2018; Souza et al., 2018). Bessa et al. (2015) developed starch-zeolite films able to maintain the natural characteristics of guava fruit during refrigerated storage, and García et al. (2014) showed that chitosan-zeolite coating could delay tomatoes ripening during refrigerated storage, although did not constitute an effective barrier against their weight losses. However, the clay properties as C2H4 capturers were not studied in these studies. Recently, Kaewklin et al. (2018) developed chitosan films containing nanosized TiO2 that exhibited C2H4 photodegradation into CO2 and H2O which might contribute to delay the ripening process and extend the storage life of cherry tomatoes stored at 25 °C and 50% RH. But it should be noted that the C2H4 removal capacity of the chosen material must be considered in conjunction with the proposed application and expected shelf-life when designing a packaging system for ethylene sensitive foods.

These systems absorb unwanted gas molecules such as volatile ingredients of the package, food chemical metabolites, microbial and deterioration reactions products, breathing products or unwanted smells coming from raw foods (Rooney, 2005). Some examples could be sulfides and amines produced from protein degradation, and aldehydes and ketones produced from lipid oxidation or anaerobic glycolysis. These volatile compounds could be selectively eliminated to prevent food product rejecting by the consumer when opening the package (Mane, 2016). These systems use a mass transfer mechanism and in general are films, sachets, tapes, labels, or trays that are placed inside the containers or combined with other permeable materials.

Porous materials such as zeolites, clays, activated charcoal, maltodextrin and cyclodextrin have been used as smell capturers; for example, charcoal and nickel were proposed to absorb fruit smells (Morris, 1999). Volatile amines, such as trimethylamine, from fish flesh could be eliminated by adding citric or ascorbic acid into polymeric material (Hoshino and Osanai, 1986). Polar materials can be used to prevent the absorption of smells with non-polar features in foods (Sajilata et al., 2007). In some products, especially fat-rich or vacuum-packaged foods, nasty smells are absorbed during storage or distribution. These smell-proof packages have been mainly developed based on synthetic polymers such as polyethylene terephthalate, polyethylene, polyvinylidene chloride, and polypropylene (Biji et al., 2015). Nasty smells can also be avoided by improving the barrier properties of films combining different package materials or adding nanoparticles to prepare nanocomposites (Mihindukulasuriya and Lim, 2014). However, it is worth noting that even though eliminating stinking components is recommended to improve packaged foods quality, these technologies should not be used to mask smells produced by dangerous microorganisms that could jeopardize consumers. As far as we know, there is no literature related to the development of smell capturers using biodegradable polymers.

These packages do not have the aim of extending the shelf-life of the packaged food, but they are oriented to generate comfort situations such as ready-to-eat food. A self-heating package can heat the food content without external heat sources or energy. They use calcium or magnesium dioxide and water to produce an exothermic reaction in a device that takes a significant amount of package volume (almost half of it). They have been used for coffee packets, military portions, etc. (Lee et al., 2014). Some self-cooling packages involve endothermic chemical reactions and heat pump technology using water vapor as the heat transfer fluid. They have been used to cold single-serve beverage packaging. Active packages for microwaves are designed to improve food heating by means of shielding, field modification and the use of susceptors. Shielding can be applied to attain a more uniform, differential, and controlled heating to different portions of food. Modifiers for microwave heating consist of a series of structures that alter the way microwaves reach food, resulting in a uniform and crunchy heating. Microwaves susceptors consist of aluminum or stainless steel deposited on substrates, such as polyester or cardboard films, that serve to dry, leaving a crunchy texture in food products (Realini and Marcos, 2014; Biji et al., 2015). As these technologies are new, there is no literature related to the development of these materials using biodegradable and biobased polymers.

Intelligent packaging can sense, monitor, record, trace, and provide information about the quality of food (Han et al., 2018a; Schaefer and Cheung, 2018). It can be used with decisions making concerning shelf-life, safety, and quality (Dobrucka and Przekop, 2019). They can disclose the conditions of the packaged product, but cannot interact with the food (Biji et al., 2015).

Intelligent packaging systems can be classified into three main categories: indicators, sensors and data carriers (Ghaani et al., 2016; Müller and Schmid, 2019):

(i) Indicators. They supply immediate information (visual, qualitative, or semi-quantitative) about food through a color (or color intensity) change or by dye diffusion (Kerry et al., 2006). They report a change in the product or its environment (for example, temperature, pH) through visual changes, such as time-temperature indicators (TTI), oxygen indicators, comfort indicators and freshness indicators (Hogan and Kerry, 2008; Lee et al., 2015; Ghaani et al., 2016).

(ii) Sensors. They are devices used to detect, locate, or quantify energy or matter, sending a detection signal or measurement of a physical or chemical property captured by the device. They can detect small molecules of pollutants, pathogens, allergens, or adulterants in food matrixes (Ramos et al., 2015). Sensors are more complex than indicators since they are formed by a receptor that transform the chemical or physical signal into energy, and a transducer that turns that energy into an analytic signal (Ghaani et al., 2016). Commonly, they are gas sensors (for example, for nut respiration products, microorganism metabolites, gases in the headspace of the container) or bio-sensors (used for example in the detection of pesticides in fruits and vegetables) (Biji et al., 2015; Lee et al., 2015).

(iii) Data carriers. They are new devices that provide information or control the flow of products, particularly appropriate for big productions such as supply chains. Compared with indicators and sensors, they do not provide quantitative or qualitative information. They are used for identification, automation, traceability, anti-theft prevention or forgery protection. The most important devices in the packaging industry are radiofrequency identification (RFID) labels, bar codes and QR code (Quick Response) (Robertson, 2012; Ghaani et al., 2016; Kalpana et al., 2019).

Some examples of useful intelligent packages in the food industry are described below.

They provide information on food product quality from biochemical changes or contaminating microorganisms growth (Kuswandi et al., 2013; Realini and Marcos, 2014). Certain metabolites such as glucose, CO2, organic acids, volatile nitrogen compounds, biogenic amines, ethanol, ATP degradation products, and sulfuric compounds, among others, are considered “quality indicators” (Fang et al., 2017). Changes in their concentrations are monitored through indicators and are generally observed as a change in color response that can be sensed and correlated with the freshness of the food product (Fuertes et al., 2016a; Wang et al., 2018b). The reaction between these metabolites and indicators within the packaging system presents visual information about the microbiological quality of the products.

Most indicators are based on pH change due to the production of certain specific metabolites such as n-butyrate, L-lactic acid, D-lactate, acetic acid and volatile amines (Kerry et al., 2006; Yoshida et al., 2014). Eagland and Crowther (2007) developed pH indicators incorporating a mixture of universal indicators in synthetic or polyvinyl alcohol matrixes. Gorski and Booher (2011) included different acid-base indicators such as xylenol blue, bromocresol purple, bromocresol green, cresol red, phenolphthalein, bromothymol blue, neutral red, p-naphtholbenzein and their combinations in polyethylene films, that were used to pack chicken. Chicken, pork and beef spoilage sensors have recently been developed by incorporating pH sensitive material into packaging (Ghaani et al., 2016; Chen et al., 2019a). These reports are basing the measurement on the simple chemical or pH change that can indirectly indicate food spoilage.

Musso et al. (2016) formulated gelatin films with different synthetic acid-base indicators: methyl orange, neutral red and bromocresol green, that could change their color with microbial growth in fish (Musso et al., 2017a). Chen et al. (2018) developed a fresh cut green bell pepper freshness label based on methyl red and bromothymol blue mixtures that changed from yellow-green to orange when pepper decay.

But nowadays the use of natural dyes within biopolymers is prefer considering consumer expectations for food safety (Saliu and Della Pergola, 2018). De La Puerta et al. (2014) developed a solid partially polar adsorbent support (based on paper, cardboard, and polypropylene) impregnated in a vanillin solution, capable of going from colorless to violet when detecting pH changes in food. Anthocyanins, flavonoids responsible for the bright and attractive orange, red, purple, and blue colors of most fruits, vegetables, flowers, and some cereal grains are suitable candidates to be used in pH-sensing labels that can be added inside packages to give simple signals related to food preservation (Singh et al., 2018b; Zhang et al., 2019c; Chen et al., 2020; Sun et al., 2020). Liang et al. (2019) prepare an intelligent Artemisia sphaerocephala Krasch gum-based film capable of anchoring the natural dye extracted from red cabbage that exhibited a color change from pink to green along with pH variations ranging from 3 to 10. Halász and Csóka (2018) immobilized dyes from black chokeberry (Aronia Melanocarpa) pomace extract in chitosan films, that responded well to the pH change and showed a high color difference from pH 1 to pH 10. Medina-Jaramillo et al. (2017) and Yoshida et al. (2014) developed colorimetric pH indicators which consisted of chitosan or starch films formulated with anthocyanin or green tea and basil extracts, respectively. Musso et al. (2017b, 2019) obtained gelatin films added with anthocyanins extracted from red cabbage and curcumin capable of responding to pH changes in the environment. But it should be noted that most of these materials also presented antioxidant activity, due to the presence of active compounds in their formulation. Zhang et al. (2019a) developed an starch/PVA/roselle anthocyanins film that changes its color from red to green when was used to monitor the freshness of pork stored at 25°C, before the TVBN value of the pork gradually increased to the rejection limit (15 mg/100 g) at 36 h.

Betalains are other interesting natural compounds to use as indicators of pH change. They are water-soluble nitrogen containing pigments that can be divided into red and yellow colored ones. Kanatt (2020) developed PVA and gelatin films incorporated with Amaranthus leaf extract to monitor freshness of fish and chicken meat. The film showed a visible color change from red to yellow on spoilage that could be corroborated with the increase in pH, TVBN and microbial counts of the spoiled samples. And Moreira et al. (2018) developed PLA/PEO ultrafine fibers containing phycocyanin (pigment of intense blue color, constituting the biomass of microalga) to be used as pH indicators membranes for food packaging.

Some of these indicators had been used to detect changes in CO2 levels in packages, product of microbial development. Morris et al. (2004) worked with agar and silicone films containing a mixture of bromothymol blue and methyl orange, which turns from green to orange when the pH decreases due to the presence of CO2. Other indicators of CO2 were developed based on aqueous solutions of chitosan or whey protein isolate whose transparence changes depending on pH due to the appearance of CO2 (Puligundla et al., 2012; Lee and Ko, 2014). Perez de Vargas-Sansalvador et al. (2017) developed a CO2 sensor by including anionic liquid (1-ethyl-3-methyl-imidazolium chloride) in a hydroxyethylcellulose matrix that was effective to indicate microbial spoilage in pork. Saliu and Della Pergola (2018) investigated the performance of a food grade mixture constituted of L-Lysine, ε-poly-l-lysine, and anthocyanins as CO2 sensing. Choi and Han (2018) developed a CO2 indicator based on reactions of sodium caseinate and pectin that was applied to kimchi packaging.

Other authors focused on detecting volatile amines, resulting from the degradation of trimethylamine N-oxide, through total volatile basic nitrogen (TVBN) determination as indicators of freshness in fish, poultry, and meat (Kuswandi et al., 2012); as theses amines are responsible for fish odor and taste. Boscher et al. (2014) described the detection of trimethylamine, triethylamine, and dimethylamine using PET films coated with metalloporphyirin. Pacquit et al. (2006, 2007) developed a colorimetric indicator capable of detecting an increase in volatile amines concentration as an indicator of fish spoilage that managed to correlate the response with the total viable count and the growth of pseudomonas. Kuswandi et al. (2012, 2014) also developed indicators of volatile amines based on polyaniline films, cellulose and bacterial cellulose membranes added with methyl red or curcumin, capable of indicating spoilage in fish.

Hydrogen sulfide, which is released by meat during aging because of cysteine decomposition, correlates with the color of myoglobin and is considered a quality attribute for meat products. Smolander et al. (2002) and Smolander (2008) developed a freshness indicator containing myoglobin immobilized in agarose for poultry meat with a modified atmosphere.

In the case of fruit, labels that change their color indicating different maturity stages have been developed. They work through the reaction of the aromas released by the fruit as it ripens (Fuertes et al., 2016a). The aforementioned indicators detect a single compound or parameter, and may have certain limitations, such as lack of specificity giving erroneous results, since false positives or negatives may be generated (Kerry et al., 2006; Nopwinyuwong et al., 2010; Kuswandi et al., 2011).

In addition to colorimetric tests to detect volatile amines, electrochemical sensors have also been used. Bhadra et al. (2015), for example, created a hydrogel-coated pH- electrode passive sensor that reports basic volatile concentration.

As humidity is one of the most important factors to take into account in the shelf life of food, numerous studies have been done on humidity sensors used in real time for packaged foods in order to prevent spoilage (Amin et al., 2013; Feng and Lee, 2016). Vilela et al. (2019) developed an antibacterial conductive nanocomposite films composed of poly(sulfobetaine methacrylate) and bacterial nanocellulose that could shield the food from the effects of UV-radiation, inhibit the growth of pathogenic microorganisms responsible for food spoilage and foodborne illness, absorb moisture and water, and act as conductimetric humidity sensors to control humidity levels in foodstuff.

Package integrity is an essential requirement to maintain the quality and safety of food products along the whole production and distribution chain (Vanderroost et al., 2014). Gas indicators are the most commonly used integrity indicators for packaging applications. They are found in packaging film or can also be found in the form of packaging labels. These labels react in response to changes in the internal atmosphere of the packages (metabolism of microorganisms, permeation phenomena and enzymatic or chemical reactions in food) (Yam et al., 2005). Variation in composition of gases induce color changes that might be attributed to the incorrect package sealing, leaking, and/or has been tempered with (Fuertes et al., 2016a).

Gas indicators for O2, CO2, water vapor, hydrogen sulfide, ethanol, and other gases have been reported (Meng et al., 2014). The leakage in a container with modified atmosphere implies a considerable increase in the O2 concentration and a decrease in CO2 concentration, which could produce a faster deterioration of the packaged food. Therefore, there are leakage indicators for MAP based on the detection of O2 and CO2 (Fuertes et al., 2016a; Matindoust et al., 2016).

Most of the O2 indicators used are colorimetric indicators based on a redox reaction, for example methylene blue in the presence of a reducing agent such as glucose in an alkaline medium (Mills, 2005; Silva-Pereira et al., 2015). Consequently, the dye oxidizes with O2, which causes the color change. However, these dyes have certain limitations, for example, the color change becomes less visible as the O2 level decreases (reversible phenomenon), which can be an inconvenience to detect subsequent microbial growth (Saarinen et al., 2017). To avoid this problem, O2 indicators and oxygen scavengers can be placed together in the packaging (Mitsubishi Gas Chemical, 2014; Realini and Marcos, 2014). Commercially reversible O2 indicators such as Ageless Eye tablets (Mitsubishi Gas Chemical Company Inc) are used in conjunction with AGELESS oxygen absorbers. The tablets change color (from pink to blue) and depends on the temperature. Tell-Tab O2 Indicator Tablets (IMPAK) work the same way (Sorbent Systems, 2014). Likewise, OxySense is a commercial luminescence oxygen indicator label to indicate any leaks in modified atmosphere packaging, and Emco Packaging developed a non-reversible O2 indicator labels for the same purpose.

Lawrie et al. (2013) and Lee et al. (2008) developed UV-activated oxygen indicators. They consist of an ink, composed of a semiconductor such as TiO2, a redox dye such as methylene blue, an electron donor as triethanolamine and an encapsulating polymer like hydroxyethyl cellulose, which can be used as a coating or printed afterwards on a variety of substrates to produce a blue film indicating oxygen concentration that, when is activated by UV light becomes colorless (Ghaani et al., 2016).

Recently, Saarinen et al. (2017) developed a large-scale oxygen indicator, which is based on a colorimetric change and is activated by ultraviolet light. Provides an inexpensive MAP leak indicator that is printed on the packaging material or the label is affixed to the inside of the package lid.

Similarly, Vu and Won (2013) developed an O2 indicator that is activated on exposure to UV-light and can recover its original color in the existence of oxygen. These authors had also developed a way to prevent the dye from seeping out of the O2 indicator labels using alginate. To solve this problem, Jang and Won (2014) also proposed a pressure activated O2 indicator in such a way as to physically separate the components of the O2 indicator. Another type of oxygen sensors are those that are based on phosphorescence. Generally an O2 sensitive probe is encapsulated in an O2 permeable polymer, which allows the dye to access O2 (Banerjee et al., 2016). Optical sensors based on luminescent dyes have also been used to monitor CO2 in food packaging (Wang et al., 2017a). The limitation of these luminescent dyes is that they require the use of sophisticated instrumentation (that can generate excitation and detection) (Wang et al., 2017a; Saliu and Della Pergola, 2018).

Finally, there are also O2 detection systems based on oxidative enzymes (Mattila et al., 1990; Gardiol et al., 1996) which can be formulated in pills (Ageless Eye, Mitsubishi Gas Chemical company), as a printed layer (Emco Packaging), or laminated in a polymeric film (Smolander et al., 1997; Fuertes et al., 2016a).

The time-temperature indicators record the temperature history, either totally or partially, and thus indicate the shelf life of perishable products (Lee and Rahman, 2014; Wang et al., 2015b; Biegańska, 2017). In this way they can indicate and alert consumers to potential microbial growth or possible protein denaturation (Wang et al., 2015b; Zabala et al., 2015).

TTIs are based on irreversible color changes, so consumers can quickly tell if the product is safe (Ahmed et al., 2018).

Three categories of TTI are described: (i) critical temperature indicators, which sense whether the products are at a temperature above or below their corresponding temperature; (ii) indicators of partial history, which indicate if a product has been subjected to temperature at any time, which will cause a change in the quality of the product; (iii) complete history indicator that records temperature throughout the entire food supply chain (O'Grady and Kerry, 2008; Müller and Schmid, 2019).

TTIs are based on sensing time- and temperature-dependent changes in a food product. These changes can be chemical (acid-base reactions or polymerization), electrochemical, mechanical, enzymatic, or microbiological (Pavelková, 2013). The measured values are usually expressed as a visible response, like color changes or mechanical deformations (Dobrucka and Przekop, 2019).

Chun et al. (2013) developed enzymatic TTI to indicate ground pork patty quality based on color changes from green to red due to the cumulative effect of time period and temperature of the enzymatic reactions. Meng et al. (2018) developed an enzymatic TTI consisting of an agar coating and a coating containing microcapsules of sodium alginate, iodine, amylose and glucoamylase, and it was used to control the quality of fresh chilled pork. The thermal history of refrigerated fresh pork could be reflected by the color change of the TTI.

Xu et al. (2017) established a tyrosinase-based TTI for determining the turbot sashimi quality using total plate counts. Park et al. (2013a) employed a prototype of LAB-based TTI to identify the quality changes of vacuum packaged chicken breast during storage. Wang et al. (2017b) developed a plasmonic thermal history indicator taking advantage of the localized surface plasmon resonance of gold nanoparticles (AuNPs) synthesized in situ in alginate. TTI color became more intense with increased storage temperature and time and change from gray to red with time of exposure at high temperature (40°C).

Singh et al. (2018a) developed temperature-sensitive packaging using a eutectic mixture of soybean oil and tetradecane as a thermo-regulating material. This temperature-sensitive packaging is useful to control the temperature of fresh beef from the store to preparation and consumption.

It is worth noting that there are some commercial TTI, small, light, fast, clear, accurate, efficient, easy to interpret, and cost effective for food packaging (Bizerba SE & Co.; DeltaTrak; Thermographic Measurements Ltd; Timestrip UK Ind).

A thermochromic ink is a specialized dynamic ink that changes its color when exposed to different temperatures. They are used to indicate thermal abuse and comfort conditions. Their activation temperatures go from low temperatures of refrigeration, happening through the temperature of the human body until high temperatures that surpass the threshold of pain. They can be activated by cold, by touch or by hot temperatures. Those activated by touch become transparent when are rubbed or touched to reveal an image or other color printed below. Some of them are based on the use of liquid crystals that change their color within the visible spectrum (Vanderroost et al., 2014).

Their color change can be irreversible or reversible. Irreversible ones are colorless until they are exposed to a certain temperature at which an intense color develops and remains constant or changes leaving a permanent mark that indicates the temperature change (Roya and Elham, 2016). They are used as indicators of thermal abuse to show that the storage temperature of a product exceeded a recommended value, for example that the cold chain was broken in a refrigerated product. Therefore, they can be considered as a TTI of partial thermal history. On the other hand, reversible thermochromic inks change their color when they heat up and return to their original color when temperature decreases or vice versa. They are used to indicate comfort situations, for example, to ensure consumers that a drink in a container is perfectly refrigerated or to warn consumers that a package in the microwave has reached the desired temperature or is too hot (Vanderroost et al., 2014). In this sense, Musso et al. (2017a) developed comfort indicators based on gelatin films and different thermochromic inks, whose coloration changes reversibly at different temperatures (15 and 33°C) according to the inks nature.

Recently, Liu and Watts (2019) patented articles and methods for detecting heating patterns within model food compositions containing irreversible thermochromic ink. The irreversible thermochromic inks can exhibit a variable change in at least one-color parameter in response to temperature change across a selected temperature range.

They are used to detect, register and transmit information regarding biological reactions (Yam et al., 2005). In food packaging they can control the freshness of the products, reducing food waste and food-borne illnesses risks (Park et al., 2015).

Biosensors contain bio-receptors (biological or organic materials) that recognizes the desired analyte and transducers (optical, calorimetric, electrochemical, or piezoelectric devices) that turn the biochemical signals into a quantifiable electronic reply (Ahmed et al., 2018). For example, Food Sentinel System (SIRA Technologies Inc.) is a commercial biosensor developed to detect food pathogens with a specific antibody joined to a membrane that is part of a bar code. In the presence of pathogens, a band of dark coloration is formed which prevents the bar code from being read (Yam et al., 2005). ToxinGuard® (Toxin Alert, Canada) is a commercial visual diagnostic that displays antibodies imprinted on a polyethylene-based material that detects specific pathogenic microorganisms such as such as Salmonella spp., Campylobacter spp., E coli., Listeria spp. (Poyatos-Racionero et al., 2018).

Nanotechnology arrival has revolutionized this field of action, and new and more effective nanobiosensors are being developed in order to detect pathogens, chemical polluters, spoilage, product handling, and follow-up of ingredients or products through processing (Srivastava et al., 2018).

For non-destructive evaluation of the aroma of various foods, colorimetric sensors are used. Volatile components react with chemical colorants causing color change and subsequent detection of chemical vapors (Ahmed et al., 2018).

Chen et al. (2017a) reused the food barcode and turned it into a colorimetric sensor integrated with a camera, to sense the state of packaged products and indicate the end of their useful life. This colorimetric sensor is composed of vapor sensitive colorants encapsulated in resin microbeads. With this device it was possible to monitor the deterioration of chicken meat in different temperature ranges.

Hypoxanthine (produced by the metabolic degradation of ATP) and trimethylamine oxide (that degrades to trimethylamine increasing the fishy odor) are ones of the main freshness indicators in fish products (Ashie et al., 1996; Park et al., 2013b; Mustafa and Andreescu, 2018). To detect the amount of hypoxanthine and xanthine, several enzymatic biosensors based on a colorimetric or electrochemical reaction using the enzyme xanthine oxidase have been investigated (Lawal and Adeloju, 2012; Chen et al., 2017b) immobilized on silver, graphite, and platinum electrodes (Devi et al., 2013; Dervisevic et al., 2016). Yan et al. (2017) reported a colorimetric sensor for xanthine detection using a copper nanocluster with peroxidase-like activity, while Chen et al. (2017b) developed a multicolor sensor for hypoxanthine detection by using gold nanorods.

Schaude et al. (2017) developed a colorimetric system for the detection of trimethylamine oxide based on pH indicator dyes immobilized on cellulose microparticles embedded into food-grade silicone and were safely integrated into food packaging, that change color from green to red when the food is spoiled.

Gluten is another interesting component that can be detected, since some people are intolerant of this ingredient, which can cause serious disorders of the digestive system (Malvano et al., 2017). It is usually detected by the conventional enzyme-linked immunosorbent assay (Nassef et al., 2008). White et al. (2018) developed an electronic sensor based on antibodies that were used as selective receptors to bind wheat and barley gluten.

Biosensors are a good choice for the detection of pathogenic microorganisms due to their portability and potential for in situ detection. Most of these biosensors are based on immunological or DNA recognition, but they have the disadvantage that the preparation procedures are time consuming and require labeling and specialized facilities (Palumbo et al., 2003; Cai et al., 2014; Mustafa and Andreescu, 2018). A variant that has been proposed to avoid the aforementioned drawbacks is to use synthetic antimicrobial peptides as recognition agents, which ensure the detection and quantification of pathogens such as Staphylococcus aureus, Escherichia coli, Pseudomonas aeruginosa, and Staphylococcus epidermidis (Liu et al., 2016). Synthetic antimicrobial peptides are inexpensive, can be produced on a large scale and have high stability and furthermore, they could also be used to inactivate pathogens. The development of colorimetric biosensor strips based on immobilized peptides that were used for the detection of Listeria monocytogenes in milk and meat samples has been reported (Alhogail et al., 2016). Recently, a fluorescent DNAzyme probe that specifically binds E. coli was developed and printed on a cyclo-olefin polymer transparent package with meat and apple-juice samples (Yousefi et al., 2018a).

Over the past few years, researchers have attempted to create bacteria-detecting devices easy to read that required minimal user intervention; however, most of them are destructive and require to open the food package for analysis. Some authors developed lateral-flow strip assays (Yang et al., 2016b; Ramos et al., 2017; Tominaga, 2017, 2018) based on antibodies labeled to colloidal gold or palladium nanoparticles (PdNPs) applied to a test strip. This process takes approximately 15 min and does not require special equipment and has been used to detect Listeria monocytogenes and bacteria in the Klebsiella group (Tominaga, 2017, 2018).

Portable microfluidic devices were also developed for bacterial detection. Thus, Tokel et al. (2015) created a device that has antibodies capable of responding to antigens found on the surface of Escherichia coli.

Bright-field imaging allowed to visualize bacteria accumulation. Thus, Altintas et al. (2018) used a mechanism similar to that described above, but also incorporated sensor chips that allow electrochemical detection in real time. Other devices included E. coli sensors on graphene based flexible acetate sheets, that used electrodes as the main method of detection (Basu et al., 2014).

DuVall et al. (2015) created a phone application to calculate bacteria's presence based on paramagnetic silica beads aggregation. Cells were first lysed, the target DNA strand was then amplified through loop-mediated isothermal amplification, subsequently causing beads aggregation.

Techniques such as surface functionalization, microcontact printing and automated printers have been extensively used to target cells detection (Didar et al., 2015; Shakeri et al., 2017; Yousefi et al., 2018a). Recently, Yousefi et al. (2018b) created a simple E. coli-detecting device based on the use of DNAzymes capable of performing a specific reaction, that could be incorporated into food packaging.

Gas detection within the package has acted as a driving force in the development of many biosensors (Meng et al., 2014; Banerjee et al., 2016). Luminescence-based optical fiber O2 sensor had been fabricated via layer-by-layer nanoassembly technique. The resulting sensor was enhanced by tuning the spacing between fluorophore layers by the introduction of poly(acrylic acid) (de Acha et al., 2017). Mao et al. (2017) developed a new optical O2 sensor using microstructured pillar detection layer arrays, which improves sensitivity (detection in the nanometric range). Likewise, Lee and Park (2017) also observed highly improved sensitivity using luminescent O2 sensors based on porous sensing films with augmented photoluminescence and O2 accessibility. Antropov et al. (2018) proposed a new material associating the O2 permeability of fluorinated polymers with an even dissemination of the photostable dye on the surface. The mesoporous structures allowed the determination of O2 at a very low level as well as avoided dye leaching and microbiological fouling.

CO2 sensors are being of great interest in detecting spoilage in food. There are optochemical detection techniques involving a colorimetric pH indicator and a phosphorescent dye (Neethirajan et al., 2009; Puligundla et al., 2012; Lochman et al., 2017). There are several devices on the market that detect both dissolved and gaseous CO2, such as Severinghaus-type sensors and non-distributive infrared (NDIR). Their disadvantage is that they are large, expensive, and susceptible to contamination and water vapor, which is why cheaper and more compact sensors are preferred (Ahmed et al., 2018). Sun et al. (2016) developed a highly sensitive squaraine-based system for colorimetrically and fluorescently sense CO2 gas in dimethyl sulfoxide (DMSO). Xia et al. (2015) synthesized an unsymmetrical squaraine-based chemosensor for sensing CO2 gas by proton nuclear magnetic resonance and UV-visible spectroscopies in DMSO. Similarly, Sun et al. (2017) developed a CO2 squaraine-based cationic chemosensor that allows the change to be seen with the naked eye and is highly sensitive.