- 1Département de Génie Rurale et Eaux et Forêt, Université Dan Diko Dan Koulodo, Maradi, Niger

- 2Institut National de la Recherche Agronomique du Niger, Niamey, Niger

- 3Department of International Environment and Development Studies, Faculty of Landscape and Social Sciences, Norwegian University of Life Sciences, Ås, Norway

The objective of this study was to characterize pearl millet production in Niger and to assess the potential impact of a low-cost production package on land- and labor productivity. The survey showed that 62% of the farmers used manure, while 22% used mineral fertilizer. Of those who used mineral fertilizer only 18% practiced microdosing. High labor demand was given as the reason why 89% of the farmers did not practice microdosing. In field experiments, we tested at three sites and over 2 years a control (no fertilizer and manual sowing) against two improved production packages consisting of mechanized sowing, seed priming, seed treatment with fungicide and NPK fertilizer in treatment 1 (T1), or phosphate coating in treatment 2 (T2). In the production package T1, seed and NPK fertilizer were mixed in a 1:1 ratio and this mixture was thereafter applied by a planter giving a fertilizer rate of 0.3 g NPK hill−1. In treatment T2, the seeds were coated with rock phosphate, and were thereafter sown by a planter giving a rate of 0.35 g rock phosphate hill−1. Compared to the control, the T1 and T2 treatments increased yield by 70.9 and 42.7%, respectively. The two improved production packages reduced time to maturity by 10 days. The net benefit increased for the T1 and T2 treatments compared to the control by 111.8 and 72.8%, respectively. This increase was particularly due to the higher grain and stover yield as well as lower weeding costs. These technologies will also render pearl millet production more resistant to climate change due to timelier sowing and weeding, a better crop establishment, and a shortened growing season.

Introduction

Niger is the second largest producer of pearl millet in Africa (after Nigeria) with a production of 3,489,400 tons. This production is limited more by a lack of plant nutrients than by the lack of available water (Payne, 1995). Therefore, it is of vital importance to improve soil fertility in order to increase pearl millet production (Bationo et al., 2003).

One option for the farmers is to use mineral fertilizer; however, the high cost of mineral fertilizer limits its use. Even the recommendation to use 20 kg NPK ha−1 (2 g diammonium phosphate hill−1 or 20 kg NPK ha−1) represents a cash outlay beyond the reach of many farmers. Lack of phosphorus is a problem in Sahelian agriculture and use of locally mined rock phosphate has been suggested as a solution to remediate this problem because of its low cost. Studies have shown that rock phosphate has the potential to increase cereal production in Niger (Bationo and Waswa, 2011) and can be applied directly to the crops (Bationo et al., 2003). However, applying rock phosphate is difficult as it is only available in powder form meaning it is easily dispersed by the wind. Farmers also dislike applying rock phosphate because it readily enters the eyes when being spread (Zapata and Roy, 2004). These problems render it necessary to identify other ways to apply rock phosphate. Mechanical application of rock phosphate may solve this problem by directly inserting the rock phosphate into the soil.

Mechanization was first introduced in Niger in the 1950s in relation to groundnut production in the regions of Maradi and Zinder (Salamatou, 1988). The equipment that was introduced at that time were the ox-drawn plow, the ripper, the Super-eco planter, and the weeder. This equipment was first imported from Senegal (SISCMA) and France (ARARA), but local production soon started. Units for production and maintenance of farm equipment were started in the Dosso, Tahuoa, and Zinder regions. The Atelier de Fabrication de Materiel Agricole (AFMA) was created in the 1970 and the Centre de Développement de l'Artisanat Rural et du Machinisme Agricole (c-DARMA) was created in Dosso in 1974 (C-DARMA). Likewise, in the Zinder region l'Unité de Construction de Matériel Agricole (UCOMA) was created in 1976, with the l'Atelier de Construction et de Réparation de Matériel Agricole (ACREMA) being created a year later in 1977 in Tahoua. These production units are still operating, but at a limited capacity.

These units were successful until the time of drought in the 1980s. These droughts reduced the demand for agricultural equipment causing agriculture to become more oriented toward subsistence production without using mechanization for sowing and weeding. Moreover, the demand for equipment was reduced when subsidies for agriculture were stopped in the 1980s and 1990s as a result of structural adjustment policies.

In 2010, the Niger government created the Centre d'Approvisionnement en Intrants et Materiéls Agricole (CAIMA) to ensure the supply of inputs and agricultural equipments at a reasonable price. However, the resources available to CAIMA are rather limited.

The objectives of this study were to describe farmers' current management of soil fertility in the regions of Maradi, Tahoua, and Tillabery. Furthermore, field experiments were conducted to compare farmers' traditional practices against two improved technology packages which included mechanized sowing, seed priming, seed treatment, and fertilizer application (mineral fertilizer or rock phosphate). This study assessed the effects of the treatments on labor demand, agronomic performance, and profitability.

Materials and Methods

The methods used in the study included a household survey to assess farmers' soil fertility management and field experiments. Both the survey and the field experiment were conducted in the regions of Maradi, Tahoua, and Tillabery. The field experiments were conducted in the national research centers located in these three regions.

Data on economic parameters was collected during the time of the focus group discussions.

Household Survey

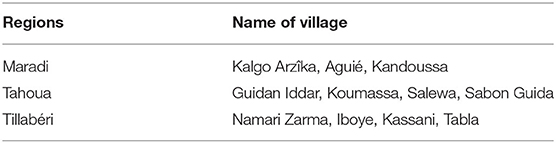

A household survey was undertaken in 11 villages in the regions of Maradi, Tahoua, and Tillaberi. Twenty farmers were randomly selected from each of these villages, thus providing a total of 220 farmers to participate in the survey. The objective of the survey was three-fold: to characterize farmers' soil fertility management practices, to understand the causes for adoption and non-adoption of these practices and to assess key socio-economic characteristics of the farmers.

In addition, focus group discussions were undertaken in each of the 11 villages included in the study (Table 1). In each village, a focus group was organized at the end of the survey at the village chief's house in order to collect information relating to the price of inputs and the cost of labor for the various farming operations.

Field Experiments

The on-station field experiments were conducted in the Sudano-Sahelian and Sahelian regions of Niger at the research centers of INRAN. These sites are found between 12 and 14° latitude north. The sites are Lossa (E 13°54′58,5″et N 1°35′3,1″), Konni (N 13°49′10,53″and E 5°17′22,1″), and Magaria (N 12°58′27,2″and E 8°55′6,2″). The farming system in these regions can be characterized by mixed crop-livestock systems with pearl millet as the main crop. Farmers hardly use any commercial inputs and the level of mechanization is very low. Nevertheless, agriculture is the main economic activity in these regions.

Experimental Design and Treatments

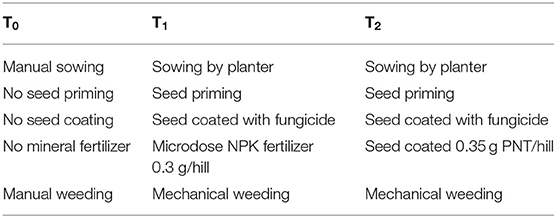

The experiment was a completely randomized Block Fischer experiment with 3 treatments and 12 replications. A high number of replications were used because the ability of the planter to uniformly deliver seeds was not known at the start of the experiment. The elementary plot measured 10 m × 5 m (50 m2) and each site had 36 plots. The distance between each plot was 1.5 m. The treatments are presented in Table 2. The pearl millet variety HKPAQ was used in the experiment because of its adaptability to the three regions (CNEV, 2012). It heads 50–55 days after sowing and reaches maturity 70–80 days after sowing. The normal plant height is 175–180 cm. The variety is resistant to the stem borer [Coniesta ignefusalis (Hampson, 1919)] and downy mildew [Sclerospora graminicola (Sacc.) J. Schröt].

Prior to sowing, the land was tilled, after which, thinning was undertaken 2–3 weeks after sowing to obtain two plants per hill. Thinning was only necessary in the manually sown treatment.

The seeds used for sowing were first cleaned by sieving followed by winnowing. Then, the seeds were soaked in water and any floating grain was removed (Treatments T1 and T2). The next step consisted of soaking the seeds in water of ambient temperature for 8 h. This was followed by drying the seeds on a canvas bag for 2 h. After this procedure, the seeds were coated by mixing the seeds with fungicide. In the next step, the coated seeds and mineral fertilizer were mixed in a 1:1 ratio in order to achieve an application rate of 3 kg NPK ha−1 corresponding to 0.3 g NPK per hill (treatment T1).

For the treatment with Tahoua rock phosphate (T2), the seeds were first soaked in water for 8 h and then dried on a canvas bag as previously described. This was followed by mixing the seeds and fungicide. In the next step, seed and water were mixed in a 5:1 volumetric ratio, after which fungicide was added to this mixture. This was followed by mixing equal volumes of the treated seeds and PNT. This mixture had to be thoroughly kneaded in order to gain granules containing one or two seeds. This is a double coating as the seeds will be coated with both the fungicide and the PNT. This corresponded to 0.35 g PNT ha−1 (3.5 kg PNT ha−1) when using a disc with perforations of 10 cm in diameter in the Super-eco planter.

Mechanical weeding was undertaken using the same planter, but only after mounting tines to the frame of the planter. The planter is used for interrow weeding, but manual weeding is used within rows.

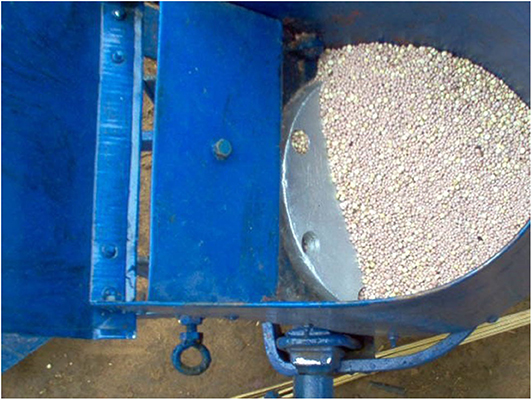

The planter used was the Super-eco planter imported from Mali (Figure 1). The essential part of this planter consists of the hopper, the rotating disc with holes/perforations (Figure 2), which measures the amount of seed and fertilizer to apply; the seed delivery tubes; the furrow opener; the tine that close the furrow; and finally, a wheel that compresses the soil to increase the contact between the soil and seeds. The disc used in this experiment has perforations with a diameter of 10 mm. The land was plowed prior to using the planter.

The On-Farms Experiments

The on-farm experiments were conducted in the regions of Maradi, Tahoua, and Tillabery during 2017 and 2018. These tests were conducted in the villages of Karosofoua, Danja, Kandoussa, Girataoua, and Aguié in the region of Maradi; the village of Konni in the Tahoua region; and the villages of Lossa and N'Dounga in the Tillabery region. In each village, the fields of three farmers were chosen to host the tests. In each field, each of the three elementary plots in the farmers' field were 250 m2 (5 m × 50 m). The three treatments were the same as in the on-station experiment, but fewer observations were taken.

Agronomic Observations

Data were collected on the speed of germination, plant height, time to 50% maturity, as well as the yield of grain and stover. The germination rate was obtained by counting the number of hills 2.5 days after sowing. In the on-farm experiments, we only measured the grain and stover yield.

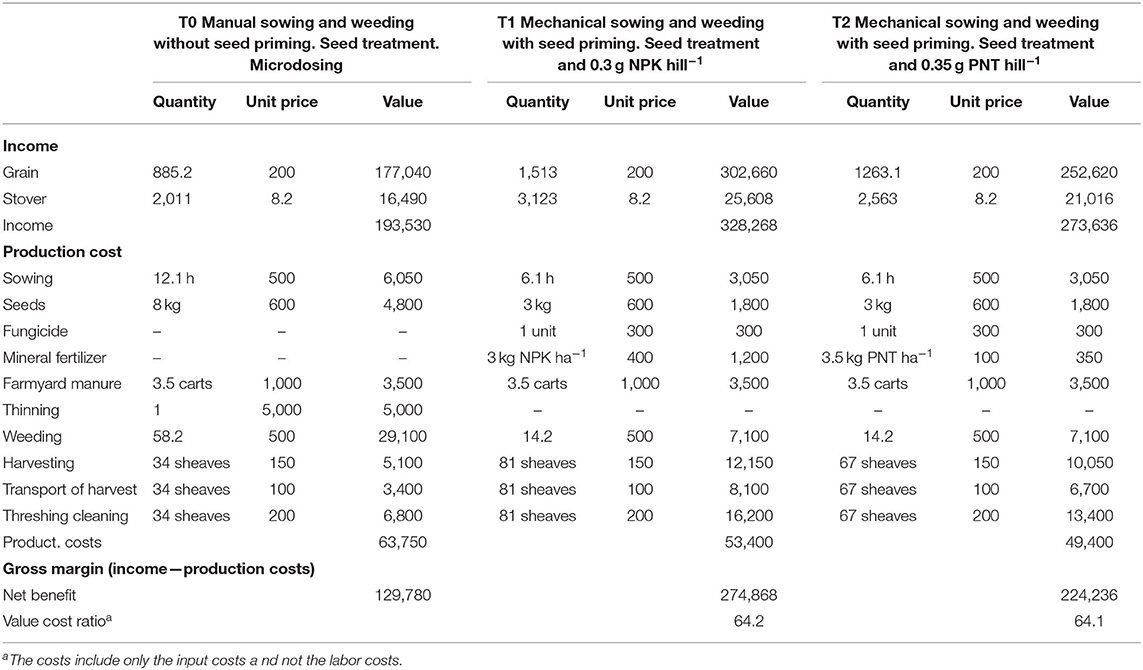

Financial Analysis

The input cost in CFA per ha−1 were 3,000 for seeds, 1,200 for NPK fertilizer (400 CFA kg−1), 525 CFA rock phosphate (PNT 150 CFA kg−1) and 300 for fungicide treatment of seeds. The farmers used on average 3.5 donkey carts of manure, which was estimated at a cost of 1,000 CFA per cart. The labor cost of thinning of the millet was assessed at 5,000 CFA for the treatment with manual tillage; however, there was no need to thin after mechanized sowing because the seed rate per hill was lower. The cost of harvesting was assessed at 150 F per sheaf, transport 100 per sheaf, and threshing 200 per sheaf. The value of the straw was assessed at 8.2 CFA kg−1, the farm price of the grains at 200 FCFA kg−1. These production costs are the average results obtained from the focus groups' discussions. The net benefit of each treatment was calculated by first calculating the value of the grain and stover and thereafter subtracting the input and labor costs. The Value Cost Ratios (VCR) for treatment T1 and T2 were calculated by diving the value of the increased production compared to the control (T0) by the increased input costs (labor cost not included).

Statistical Analysis

The statistical analyses of the survey data were carried out using Sphinx2 version 4.5 and Excel 2016. The field experiments were analyzed with GenStat version 9.2 and Excel 2016. The treatments were considered significant at a threshold of 5% and highly significant at p < 0.01.

Results

Farm Characteristics

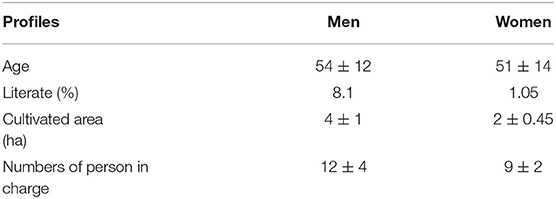

The farmers included in the survey were poor as evidenced by their high illiteracy rate, low use of agriculture inputs, and very low possession of livestock and farm equipment (Table 3).

The survey showed that female- and male-headed households differed in socio-economic characteristics. The female-headed households were widows in 88% of the cases. The female-headed households cultivated on average 2 ha, while the male-headed households cultivated 4 ha. The average number of persons in the household was 9 for female-headed households and 12 for male-headed ones. The level of literacy was 8.1% for men and 1% for females.

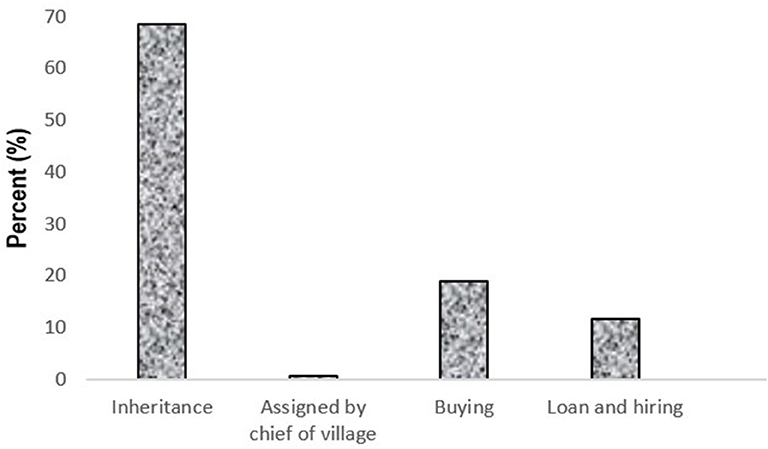

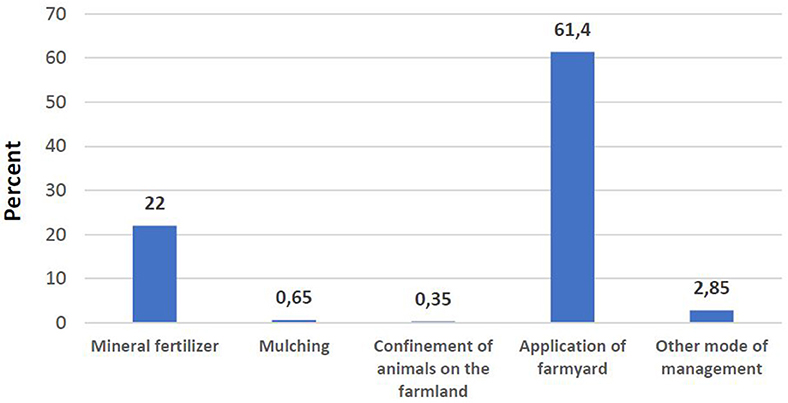

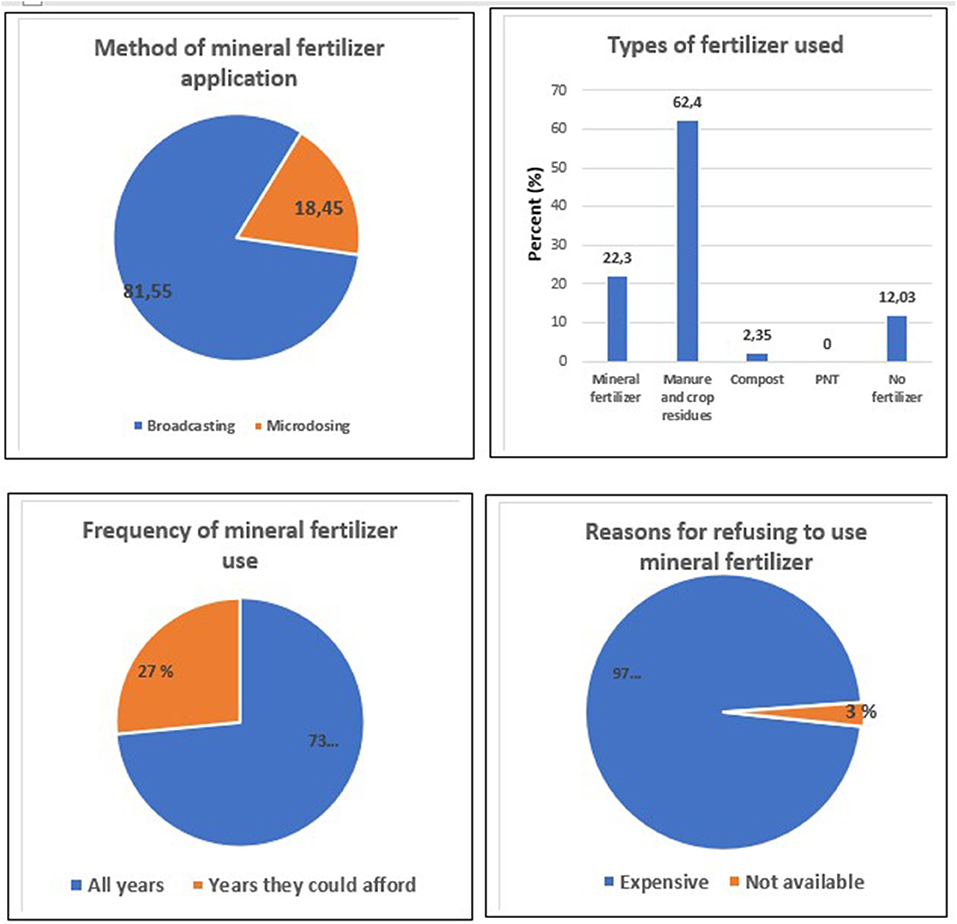

Land acquisition was mainly by heritage as 68.8% of the households obtained access to land through heritage in comparison to 18.9% who had purchased the land, and 11.7% who had rented theirs (Figure 3).

Applying farmyard manure is the main form of soil fertility management with 62.4% of the farmers following this method (Figure 4). Mineral fertilizer is used by 22.3% of the farmers, and compost by 2.4%. No application of any type of fertilizer is practiced by 12% of the farmers. Mulching was only practiced by 0.65% of the households, whereas only 0.35% used confinement of animals on the farmland. Microdosing, which is the application of small amounts of fertilizer (organic or mineral) next to the planting hill, is practiced by 18.5% of the farmers, in contrast to 81.6% practicing broadcasting of mineral fertilizer (Figure 5). Of those applying mineral fertilizer, 72% practiced annual application, while the rest applied fertilizer during the years they could afford it. Ninety-seven percentage of the farmers stated that the high cost was the reason for not using mineral fertilizer. According to 89% of the farmers, the reason for the low use of microdosing was due to the high labor demand of the method (Figure 5). Moreover, a small percent of farmers (11%) thought that microdosing is harmful to the plants. A majority of the farmers (84.3%) were not aware of PNT, whereas only 15.7% were aware of it.

Figure 5. Method of mineral fertilizer application, types of fertilizer use, frequency of mineral fertilizer use, and reasons for refusing to use mineral fertilizer.

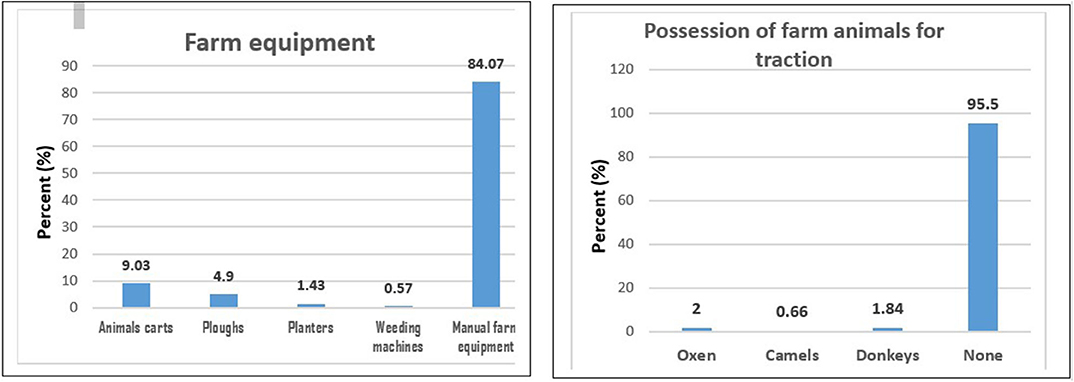

The survey found that possession of traction animals is very low, as much as 95.5% of the households did not possess any animals (Figure 6). Oxen were owned by 2.0% of the households while 1.8% of the households possessed donkeys. Manual farm equipment was possessed by 84% of the farmers in comparison to 16% of the farmers who owned animal traction equipment. Planters were owned by 1.4%, plows by 4.9%, and donkey carts by 9%.

On-Station Field Experiments

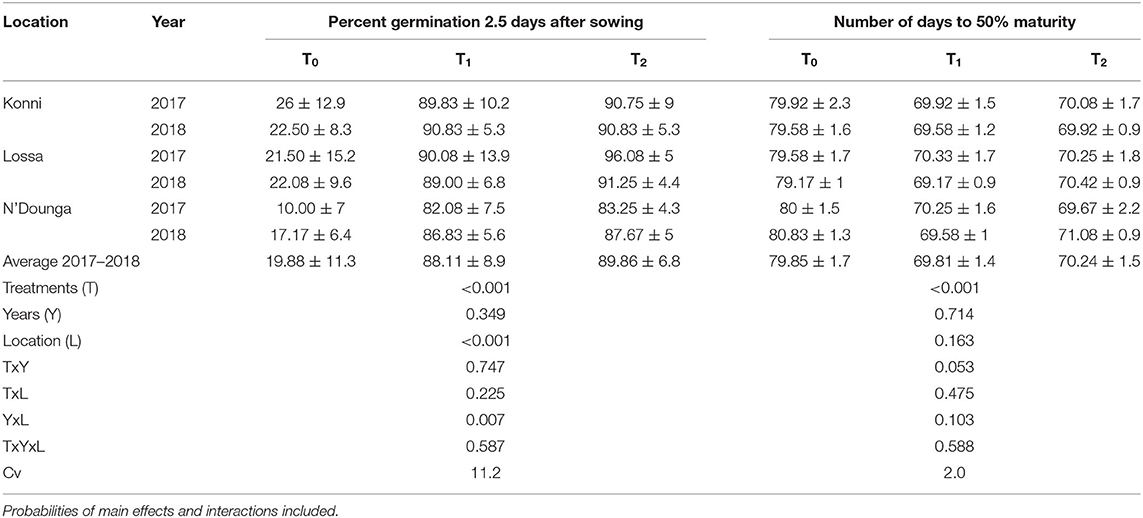

Effect of the Treatments on Percent Germination and Time to 50% Maturity

There was a clear effect of the treatments on percent germination 2.5 days after sowing for the three sites (Table 4). The improved treatments greatly improved the speed of germination. At 2.5 days after planting, the average germination rate was 19.9% for the control treatment (T0), while it was 88.1 and 89.9%, respectively, for the T1 and T2 treatments. In 2017 and 2018, the results were similar. Percent germination did not vary much between the sites.

Table 4. Effects of treatment on percent germination 2.5 days after sowing and number of days to 50% maturity including standard errors in parenthesis.

A clear effect of the treatments on time to 50% maturity was observed for all the sites (Table 4). The effect of the treatments on number of days to 50% maturity was consistent across the 2 years and the three sites. There was little variability within this variable. The pearl millet in the T1 and T2 treatments arrived at 50% maturity 10 and 9 days earlier than the control (T0).

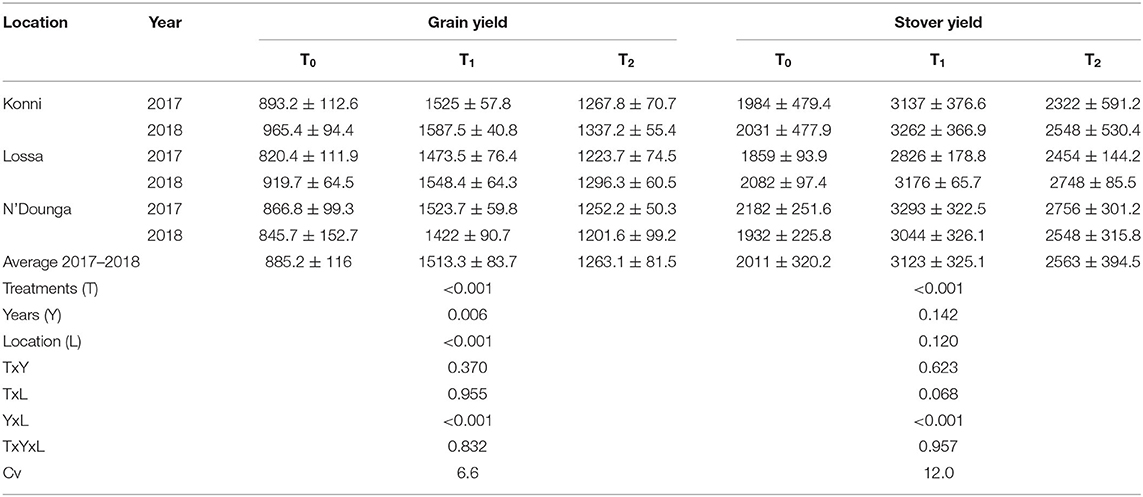

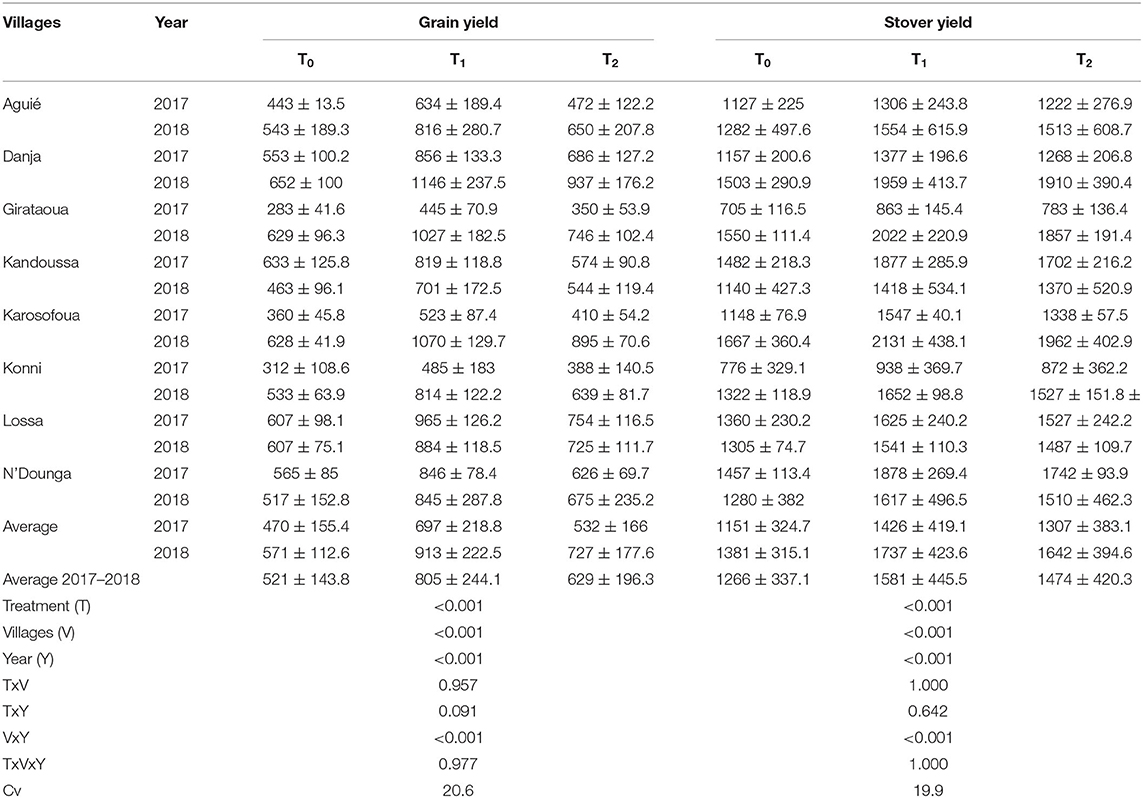

Effect of Treatments on Grain and Stover Yield

The effect of the treatments was generally the same across the years and between the sites (Table 5). The average grain yield in T1 was 647 kg ha−1 higher than in T0, whereas the corresponding increase for T2 compared to T0 was 388 kg ha−1.

The variability between the sites was also low regarding the stover yield. The treatment T1 increased the stover yield by 1,146 kg ha−1 compared to T0, thus representing a yield increase of 55.3%. The corresponding yield increase for the T2 compared to T0 was 640 kg ha−1 equivalent to a yield increase of 31.6% (Table 6).

Table 6. Effect of the treatments on grain and stover yield (kg ha−1) in farm experiments during two calendar years (standard error in parenthesis).

On-Farm Field Experiments

In addition to the on-station field experiments, eight sites were also included for on-farm field experiments.

The T1 and T2 treatments increased grain yield compared to the control (T0) in all the villages and during both years (Table 6). In the first year, the average grain yield for the control T0, T1, and T2 was 470 kg, 697 kg, and 532 kg ha−1, respectively. This represented an increase in grain yield compared to the control of 48.3 and 11.7% for T1 and T2, respectively. In the second year, the increase in grain yield was 59.9 and 27.3% for T1 and T2, respectively. Over the 2 years, the average grain yield of the control (T0) was 521 kg ha−1, whereas it was 805 kg and 629 kg ha−1 for T1 and T2, respectively. This represented an increase in grain yield over the control by 54.5 and 20.7% for T1 and T2, respectively. The interactions of treatment × year and treatment × village were not significant.

The average straw yield for the 2 years was 1,266, 1,581, and 1,474 kg ha−1 for the T0, T1, and T2, respectively. There was a significant difference between the treatments for all the villages and for both years.

Economic Analysis

Based on the average results from the on-station field experiments, the economic analysis showed that the net benefit for T0, T1, and T2 were 129,780, 274,868, and 224,236 FCFA ha−1, respectively (Table 7). This represented an increase in the net benefit compared to the control by 111.8 and 72.8% for the T1 and T2 treatments, respectively. The reason for the better performance of the T1 and T2 treatments was related to the higher income from grain and stover production as well as the lower production cost. The control (T0) did not incur any cost related to fertilizer and fungicide, while the costs for T1 and T2 were 1,500 and 740 FCFA ha−1, respectively. The labor cost related to sowing, thinning, and weeding was 40,150 FCFA ha−1 for the T0 treatment in contrast to 10,150 FCFA ha−1 for the T1 and T2 treatments. The T0 treatment had lower labor costs related to harvesting, transport of harvest, and threshing, because of the lower yield of these treatments compared to the two other treatments.

The VCR for the T1 and T2 treatments were 64.2 and 64.1, respectively.

Discussion

The survey showed that Niger farmers in the pearl millet producing areas are practicing subsistence agriculture with a very limited use of input and without any form of mechanization. The application of organic fertilizer is the main form of soil fertility management. The farmers are well aware of the importance of using organic fertilizer, but some farmers do not have access to manure, either because they do not possess animals or because they are not able to transport the manure to the fields due to the lack of traction animals and/or carts to transport it to the fields. Hardly any farmer practiced mulching of crop residue even though it has been shown that the recycling of straw is important for maintaining the long-term productivity of the soils (Buerkert et al., 2002). Mineral fertilizer is only used by 23.3% of all farmers, despite them unanimously agreeing that using mineral fertilizer is important for achieving a good yield. The high cost of fertilizer is stated as the main reason for the non-use of fertilizer, while only 3% claimed that the availability of mineral fertilizer is a problem. Using rock phosphate can be an alternative to mineral fertilizer because of its lower cost, but only 15.7% of the farmers were aware of it. Tahoua rock phosphate (containing 12.2% P) is mined in Niger and can be used for direct application (Bationo and Mokwunye, 1991). However, the production level is low due to limited demand and production problems in the industry.

The application of mineral fertilizer as microdosing has been recommended for more than 20 years in Niger by ICRISAT and Institut National de Recherche Agronomique au Niger (INRAN). Despite this, the survey showed that only 18.5% of the farmers practiced microdosing of mineral fertilizer, while the rest (81.5%) applied fertilizer by broadcasting. According to 89% of the farmers, high labor demand is the major constraint for practicing microdosing. This clearly shows the need for mechanizing the application of mineral fertilizer. However, the farmers are poorly equipped with farm machinery and only 1.4% of the farmers possess planters. An additional problem is that 95% of the farmers do not have access to traction animals, such as donkeys or oxen. There has been no promotion of animal traction in Niger in recent decades. Only 1.8% of the farmers in the survey own donkeys.

The low profitability of microdosing may also explain the low use of microdosing as a study by Bielders and Gerard (2015) showed, in which 36% of the farmers lost money by practicing this method.

The on-station field experiments clearly showed that the T1 and T2 treatments performed better than the T0 (control) treatment for all agronomic parameters. TI and T2 reduced germination time, stimulated plant vigor, shortened time to maturity, increased grain, and stover yield as well as improved gross margin.

Percent germination 2.5 days after sowing was nearly 90% in the T1 and T2 treatments, while it was only 20% for the control. Plant vigor assessed on a scale from 0 to 4 was 3.8 for the T1 and T2 treatments, in contrast to 1.4 for the control. This faster crop establishment and the high vigor at crop establishment is a combined effect of mechanized sowing, seed priming, microdosing, and seed treatment. Mechanization facilitates crop establishment as a result of placing the seeds at a correct depth and seed rate (Aune et al., 2019), while seed priming has been shown to be an important factor in promoting crop establishment under dry and hot conditions (Harris, 2006; Aune and Ousman, 2011; Aune et al., 2012; Coulibaly et al., 2019). The phosphorus applied through microdosing stimulates crop establishment microdosing by promoting early tillering and lateral root development (Ibrahim et al., 2016). Sahelian soils are particularly low in phosphorous. The coating of the seeds with PNT did not negatively affect germination. The acidity of mineral fertilizer may negatively affect germination, but the solubility of rock phosphate is low.

T1 and T2 treatments also shortened time to maturity by 10 days. This is an effect of more vigorous growth from crop establishment to maturity. This will likely reduce the effect of early season drought as well as drought occurring late in the growing period.

The average grain yield across the three sites and 2 years increased from 885 kg ha−1 in the control to 1,513 and 1,263 kg ha−1 for the T1 and T2 treatments, respectively. This represents an increase in grain yield compared to the control by 70.9 and 42.6% for T1 and T2, respectively. The stover yield increased from 2,011 kg ha−1 in the control to 3,123 kg and 2,563 kg ha−1 for the T1 and T2 treatments, respectively, thus representing an increase compared to the control of 55.2 and 27.4%. The increase in stover yield of more than 1,100 kg ha−1 for the T1 treatment compared to the T0 treatment will be of great value for the farmers as fodder. In the on-farm experiments, the yield level was generally lower; in the sites, the T1 and T2 treatments increased the grain yield compared to the control by 54.5 and 20.7%, respectively. The increase in grain and stover yield in these experiments is likely a combined effect of mechanized sowing, seed priming, seed treatment, and microdosing. It is not likely that only one of these factors can fully explain the increase in grain yield. Mechanized sowing played a minor role in this yield increase as it has been found in Mali that use of a planter increased the yield on average by 14% (Aune et al., 2019). In addition, seed priming typically increased yield between 20 and 30% (Aune et al., 2017), while microdosing has been found to increase yield by more than 50% (Aune et al., 2017). Therefore, it seems reasonable to assume that microdosing is the factor that contributes the most to an increase in yields. The only difference between the T1 and the T2 treatments is the type of fertilizer used. In the T1 treatment, 0.3 NPK hill−1 is applied, in contrast to T2 in which 0.35 g PNT hill was used. The results clearly showed that the NPK 15-15-15 is more efficient in increasing grain and stover yield than Tahoua rock phosphate. However, no difference was observed between the T1 and T2 regarding speed of germination, plant vigor, and time to 50% maturity. The lower effect of Tahoua rock phosphate as compared to NPK fertilizer has also been found in other studies in Niger (Buerkert et al., 2002). However, there are contrasting results on the efficiency of Tahoua rock phosphate as Bationo and Mokwunye (1991) report that Tahoua rock phosphate has an efficiency of 76% compared to Single Super Phosphate (SSP).

The net benefit increased compared to the control by 117.7 and 72.8% for T1 and T2, respectively. This shows the potential of these two low-cost technologies to increase farmers' revenues. This increase was due to more income resulting from higher yields and lower weeding costs. The price of the planter used in the experiment is 70,000 FCFA, while the increase in gross margin per ha was 145,088 FCFA. This shows this low-cost mechanization is highly profitable, particularly since each farmer cultivates on average 4 ha. It is important to emphasis that mechanization alone is not profitable unless it is combined with yield-enhancing technologies. This study also shows that using seed coating with Tahoua rock phosphate can be an alternative to NPK fertilizer for cases in which NPK is not available. The VCR of the T1 and T2 treatments were 64.2 and 64.1, respectively which shows that investing in seed treatment and microdosing and/or seed coating is a very financially attractive technology.

The two improved production packages presented in this study potentially represent the first step in sustainable intensification because of the low cost of the packages, their ability to increase yield, and generate an economic surplus. Furthermore, the packages will be considered as an appropriate adaption to climate change because of timelier sowing, better crop establishment, and earlier maturity.

Conclusion

The survey revealed that farmers practice subsistence pearl millet production with limited use of input and with only traditional farm equipment. The application of farmyard manure is the main form of soil fertility management. Only 18% of the farmers use mineral fertilizer, and of those who are using mineral fertilizer only 18.5% practice microdosing. The high labor demand is the main reason for limited use of this practice. Indeed, microdosing has been recommended for more than 20 years; therefore, this study underscores the importance of mechanizing the application of microdosing. However, farmers lack both planters and traction animals; both of these constraints need to be addressed through policy interventions such as access to credit if this type of intensification is to succeed. The use of motorized planters might be an option.

The field experiments showed that the two improved treatments with the use of an animal-drawn planter, seed priming, and microdosing-facilitated crop establishment reduced the time to maturity, increased the grain and stover yield as well as improved the net benefit. Grain yield increased compared with the control by 70.9 and 42.7% for the T1 (mechanization + seed priming + seed treatment +NPK microdosing) and T2 (mechanization + seed priming + rock phosphate seed coating), respectively. For the net benefit, the increase compared to the control was 117.7 and 72.8% for T1 and T2, respectively. The mechanization particularly reduced the weeding costs. The price of the planter used in the experiment is 70,000 FCFA with the increase in gross margin per ha being 145,088 FCFA. This shows this low-cost mechanization is highly profitable especially since each farmer cultivates on average 4 ha. It is important to emphasis that mechanization alone is not profitable unless it is combined with yield-enhancing technologies. Thus, the package can be recommended for widescale upscaling in the Sahelian zone of Niger.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

AN participating in the planning of the study, implementation of the study, analyzing the result, and writing the first draft of paper. AS participated in the planning of the study, implementation of study, participated in writing, and supervising the work. JA took part in the planning of the study, supervising the study and in editing of the final version of the paper. All authors contributed to the article and approved the submitted version.

Funding

This work was supported by Norwegian Ministry of Foreign Affairs.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

The authors would like to talk the Norwegian Ministry of Foreign Affairs for funding this study. We also thank CARE and their partners for facilitate the work. Finally, a word of thanks to the farmers that so willingly participated in this study.

References

Aune, J. B., Coulibaly, A., and Giller, K. E. (2017). Precision farming for increased land and labour productivity n semi-arid West Africa. A review. Agron. Sustain. Dev. 37:16. doi: 10.1007/s13593-017-0424-z

Aune, J. B., Coulibaly, A., and Woumou, K. (2019). Intensification of dryland farming in Mali through mechanization of sowing, fertilizer application and weeding. Arch. Agron. Soil Sci. 65, 400–410. doi: 10.1080/03650340.2018.1505042

Aune, J. B., and Ousman, A. (2011). Effect of seed priming and micro-dosing of fertilizers on sorghum and pearl millet in Western Sudan. Exp. Agr. 47, 419–435. doi: 10.1017/S0014479711000056

Aune, J. B., Traoré, C. O., and Mamadou, S. (2012). Low-cost technologies for improved productivity of dryland farming in Mali. Outlook Agr. 41, 103–108. doi: 10.5367/oa.2012.0084

Bationo, A., and Mokwunye, A. U. (1991). Alleviating soil fertility constraints to increased crop production in West Africa: the experience of the Sahel. Fertil. Res. 29, 95–115. doi: 10.1007/BF01048992

Bationo, A., Mokwunye, U., Vlek, P. L. G., Koala, S., and Shapiro, B. (2003). “Soil fertility management for sustainable land se in the west African Sudano-Sahelian Zone,” in Soil Fertility Management in Africa: A Regional Perspective, eds M. P. Gichuru, A. Bationo, M. A. Bekunda, C. H. Goma, P. L. Mafongaonya, D. N. Mugendi, H. M. Murwira, et al. (Nairobi: Academy Science Publishers; TSBF- CIAT), 253–292.

Bationo, A., and Waswa, B. S. (2011). “New challenges and opportunities for integrated soil fertility management ISFM in Africa,” in Innovations as Key to the Green Revolution in Africa – Vol. 1, eds A. Bationo, B. Waswa, J. M. Okeyo, F. Maina, and J. Kihara (New York, NY; London: Springer), 3–17. doi: 10.1007/978-90-481-2543-2_1

Bielders, C. L., and Gerard, B. (2015). Millet response to microdose fertilization in south-western Niger: effect of antecedent fertility management and environmental factors. Field Crop. Res. 171, 165–175. doi: 10.1016/j.fcr.2014.10.008

Buerkert, A., Piepho, H.-P., and Bationo, A. (2002). Multi-site time-trend analysis of soil fertility management effects on crop production in Sub-Saharan West Africa. Exp. Agric. 38, 163–183. doi: 10.1017/S0014479702000236

Coulibaly, A., Woumou, K., and Aune, J. B. (2019). Sustainable intensification of sorghum and pearl millet production by seed priming. Seed treatment and fertilizer microdosing under different rainfall regimes in Mali. Agronomy 9, 1–14. doi: 10.3390/agronomy9100664

Harris, D. (2006). Development and testing of “on-farm” seed priming. Adv. Agron. 90, 129–178. doi: 10.1016/S0065-2113(06)90004-2

Ibrahim, A., Abaidoo, R. C., Fatondji, D., and Opoku, A. (2016). Determinants of fertilizer microdosing-induced yield increment of pearl millet on an acid sandy soil. Exp. Agric. 52, 562–578. doi: 10.1017/S0014479715000241

Payne, W. (1995). Managing yield and water use of pearl millet in the Sahel. Agron. J. 89, 481–490. doi: 10.2134/agronj1997.00021962008900030019x

Salamatou, A. (1988). Mesure d'effort de la traction des animaux de trait et comparaison culture attelée-travail manuel. Mémoire de fin d'étude. École Supérieur d'Agronomie Tropicale de Montpellier 177.

Keywords: sustainability, gross margin, planter, microdosing, seed priming, mechanizatition, farmers constraints

Citation: Nourou AIM, Saidou AK and Aune JB (2020) Farmers' Soil Fertility Management in Niger and Opportunities for Improvements Through Mechanization, Microdosing, and Seed Coating. Front. Sustain. Food Syst. 4:570561. doi: 10.3389/fsufs.2020.570561

Received: 08 June 2020; Accepted: 02 November 2020;

Published: 26 November 2020.

Edited by:

Luuk Fleskens, Wageningen University and Research, NetherlandsReviewed by:

Alpha Kamara, International Institute of Tropical Agriculture (IITA), NigeriaSawadogo Hamado, Institut de l'environnement et de la Recherche Agricole (INERA), Burkina Faso

Shamie Zingore, African Plant Nutrition Institute (APNI), Morocco

Copyright © 2020 Nourou, Saidou and Aune. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jens B. Aune, amVucy5hdW5lQG5tYnUubm8=

Abdourahamane Issa M. Nourou

Abdourahamane Issa M. Nourou Addam Kiari Saidou

Addam Kiari Saidou Jens B. Aune

Jens B. Aune