- 1UR OPAALE, Irstea, Rennes, France

- 2Université Bretagne Loire, Rennes, France

Livestock manure management is the central issue for many environmental policies relating to water and air quality. However, there is little published data on the methods used in those countries affected by pollution from the livestock sector. This paper brings together the available data relating to manure management in France, specifically for pig, cattle and poultry production. An overview of livestock production and legislation is presented using data from the 2010 Agricultural Census, livestock farm surveys carried out in 2008 and other supporting documents relating to manure treatment (professional surveys, expert reports and technical publications). Cattle, pig, and poultry livestock produce around 120 million tons of manure per year not including those on pasture. This figure is made up from 60.6% solid manure, 38.8% livestock slurry (effluent) and a relatively small amount of poultry droppings. Solid manure is mainly stored in temporary field heaps. In the case of manure storage on the farm, the capacity varies from 45 days to 7.5 months depending on farm size and type of animals, time spent outside the buildings and the geographical location. Covered storage (whether rigid or natural crust) accounts for 17% of stored pig slurry, 45% of cattle slurry, and 39% of poultry slurry. Covered storage of solid manure is rarely used on pig or cattle farms whereas 27% of the solid poultry manure (including poultry droppings) is held in covered storage areas. Treatment applies to 13.6 million tons of the manure produced, mainly by methods based on composting or aerobic treatment. Nitrogen applied as slurry is mostly spread on the soil surface using splash plate tankers (83% in the case of cattle slurry, 63% for pig slurry, and 66% for poultry slurry). Incorporation within 24 h of the nitrogen spread on the soil concerns 28% of cattle, 44% of pig, and 56% of poultry manure. The most common method of manure management is storage (in building and pit) and spreading. The treatment of manure and the use of specific techniques to reduce gaseous emissions (such as frequent manure removal from buildings, storage covers, or injection) are not widely reported.

Introduction

Livestock activities have an environmental impact when manure is improperly handled due to the pollution from various nutrients and organic compounds (nitrogen, phosphorous, organic matter…), from the emission of ammonia (to water soil and air) and greenhouse gas emission (GG). The gases emitted (NH3, CH4, N2O) result from the breakdown of animal manure containing carbon and nitrogen and are released in the buildings, during subsequent storage and during land spreading (Chadwick et al., 2011; Webb et al., 2012). Water pollution by nitrates () or by phosphorous (P) in certain intensive livestock production areas arise from spreading manure rich in N and P beyond the capacity of the land. The surplus nitrogen and phosphorous is not used by the crop or soil and is washed out by surface run-off or seepage leading to eutrophication of water sources (Velthof et al., 2014; van Dijk et al., 2016). As a result, the livestock sector is considered as one of the principal sources of pollution leading to global warming (in the case of GG emission) water and soil contamination and the loss of biodiversity (Steinfeld et al., 2006). The scale of these impacts are thus closely linked to (amongst other factors) the management and composition of animal manure (Menzi et al., 2010; Chadwick et al., 2011; Petersen et al., 2013).

As a consequence, the management of livestock manure is a central issue in a series of international protocols, of European directives and national regulations. Effectively, the practical aspects of the methods chosen by farmers can influence the scale of diffuse emissions and the possibility to reduce these losses (Chadwick et al., 2011; Velthof et al., 2014). The European directive on emission ceilings (EC, 2001) resulting in the Gothenburg Protocol (The United Nations Convention on Long-range Transboundary Air Pollution or CLRTP) (UNECE, 1999) targets the control of ammonia emissions. Those emissions of CH4 and N2O are regulated by the Kyoto Protocol arising from the UN Framework Convention on climatic change (UN, 1997). Water pollution by nitrates and phosphorous is the subject of the EU Nitrates Directive (EEC, 1991) and the European Water Framework Directive (EC, 2000). The signatory countries of international conventions or those targeted by European Directives must measure the existing level of water pollution and make an inventory of current emissions of the listed gases. These measurements and inventories are thus the reference base for reduction objectives that imply the enactment of action programs.

Various published works relating to gas emission inventories or the movement of N and P, underline the need for detailed data due to the large variability of management methods in livestock production. In general terms, inventories and environmental analysis of livestock farms need data on animals, the operation of the farm, the level of manure production, the methods of handling of the manure (whether solid manure—FYM or slurry) and their composition (concentration of nitrogen, phosphorous, and organic matter). It is the acquisition of such data that is often considered the most demanding step in carrying out an inventory or an analysis of the farm. Furthermore, the quality of such data is central as this can improve the accuracy of the material balance and provide a reliable basis for subsequent actions (Milne et al., 2014; Velthof et al., 2015). Finally, the availability of data reflecting different manure management practices and its application in different countries remains limited or somewhat artificial or inconsistent thus rendering comparisons difficult between methods used in different countries affected by air and water pollution (Menzi et al., 2015b; Velthof et al., 2015).

France is one of the major livestock nations in Europe and the farming systems vary widely. In fact, the country makes the biggest contribution to the 1,400 million tons of animal manure estimated for the European Union (Foged et al., 2011). Thus, the purpose of this paper is to bring together, as far as possible, available data on the management of animal manure in France, especially information used in the different inventory tools or in the evaluation of technologies used for the reduction of water and air pollutants. This paper is not set out to provide new data but to assemble, standardize, and complete existing data sets.

Assessment of Policy, Guidelines Options, and Implications

Framework of French Regulations of Livestock

All livestock farms in France fall under French and European regulations that seek to protect both the environment and local inhabitants. Farmers are, depending on the size of the farm, subject either to the RSD or “Règlement Sanitaire Départemental” (Departmental health regulations), that is the “Code de la Santé Publique” (Public Health Code) or subject to legislation for those farms coming under the ICPE or “Installations Classées pour la Protection de l'Environnement” (Livestock farms listed for environmental protection: Environmental Code). Basic nationally prescribed measures set out in specific decrees (MEDDE, 2013a,b,c) that relate to the installation (and management) of farm buildings, effluent storage, and land spreading may be reinforced by local rules depending on the local climate and the vulnerability of the local environment. European rules, reworked into French texts are also applied to those livestock farms targeted by the specific directive relating to the integrated prevention and reduction of pollution (that is the IED Directive, previously known as IPPC) or regionally applied as in the case of the Nitrates Directive and/or the Water Framework Directive (MEDDTL, 2011; MEEM, 2017b). These obligatory reglementations can affect the management of farm manure both directly and indirectly.

The Legal Status of Livestock Manure

Livestock manure (raw or treated) come under several legal categories (waste, by-product, product) depending on their use and each with different land spreading constraints (Houot et al., 2014). Raw livestock manure managed on the farm are considered as by-products from animal production and must respect the environmental rules set out by the RSD, ICPE, and IED with respect to collection, storage, and land spreading. The outputs from treatment (composting, anaerobic digestion, separation, drying,…) that are carried out on the farm or at an external site (composting center, joint AD facilities, and others), are still considered as farm manure and must be applied to the field following an approved scheme of land spreading. However, these same outputs (composts, digestates, solids from separators, dried material, etc.) may be considered as “organic fertilizers” (for free use of as a commercialized product) if they are standardized, homologated or in agreement with a specification approved by regulation. These fertilizer products are thus used according to the recommendations of the supplier without the need of a land spreading plan. Composts from the solids removed by separation and dried materials are generally put on the market (or made available) under the name “organic fertilizer” by simply following set standards (French Standard “Amendement organique) or “Organic soil improvers,” NFU 44-051 or the (French Standard “Engrais organiques” or organic fertilizers, NFU 42-001). Digestates from AD must be approved (a long and costly procedure limiting approvals to just 3 products in 2014) or more recently, they can be used by following a set of procedures detailed under a decree published in 2017 (MAA, 2017). A farmer is allowed to give away, sell, or exchange (for straw) raw or treated effluents (that are neither standardized nor authorized) under a specific contract where the recipient undertakes to spread these effluents on land in full compliance with the rules in place. In the case of exported composts and AD digestate, a sanitary certificate is required.

Principal Regulations That Govern the Management of Livestock Manure

Minimal Distances for Buildings, Storage Tanks, and Land Spreading Operations

Livestock buildings, storage tanks and the spreading of effluent must observe minimal distances from residences or aquatic resources which vary depending on the effluent being spread (compost, raw manure, digestates from AD units…), on the specific regulation (RSD, ICPE, water protection…) and the specific region (rules governing vulnerable areas). The minimal distance is set at 100 m for buildings and storage facilities for all effluents. On the other hand, the minimal distances for land spreading depend on the effluent type (slurry, FYM, treated effluent) and the method of land spreading: thus 10 m for composts, 15 m for injected livestock slurry or that incorporated immediately, but up to 100 m for other products. In vulnerable areas, the spreading of slurry and solid manures is forbidden closer than 35 m from the banks of rivers and streams unless there is a permanent vegetative zone (where the minimal distance is reduced to 10 m).

Storage of Farm Manure

Livestock farmers must have available adequate storage capacity (measured in cubic meters for slurries or square meters for FYM), sufficient to enable compliance with the minimal storage periods before land spreading. The minimal storage capacity is for 45 days (RSD), 4 months (ICPE) or varies from 4 to 7.5 months in vulnerable zones depending on the animal type, the length of time at pasture and the geographical location. Two software tools (called Pré-Dexel and DeXeL) are recognized by the state for sizing and checking storage capacity for livestock farm manure (MEEM and MAAF, 2016). Legal exceptions are possible if the existing capacity is enough to enable the good agronomic use of applied manure. Field storage is allowed in the case of stable FYM (i.e., without drainage) and poultry manure with over 65% dry matter for periods not exceeding 10 months (ICPE) or 9 months (in vulnerable zones) with the stipulation that there is no reuse of the same site for storage for at least 3 years. Within vulnerable zones, field storage is forbidden from the 15 November to the 15 January except for grasslands or if the heap is placed on a bed of absorbent material (around 10 cm thick and with C/N ratio of less than 25) or if the heap is covered.

Land Spreading of Manure

Land spreading is forbidden during certain periods or on certain land that would otherwise lead to environmental impact via run off or by leaching of the applied nitrogen and phosphorous (e.g., bare soil, sloping ground, saturated land, frozen ground, etc.). In vulnerable areas, spreading periods are determined with respect to the effluent type in terms of the level of mineralization of the organic nitrogen content, local climatic conditions, and technical limitations (soil firmness, access to the field, etc.). The implementation of a maximum 170 kg N/ha in vulnerable zones is a restriction that can lead the farmer to treat livestock manure to allow legal application on fields. Under the ICPE rules, incorporation after land spreading on bare soil is obligatory within 24 h for cattle FYM and solid pig manure (raw or treated) previous held for at least 2 months in storage (for stabilizing with respect to drainage liquids) and 12 h for all other effluents from the farm, whether raw or treated.

Manure Treatment

Livestock manure treatment is obligatory in France under the Nitrate Directive for those farms located in high risk zones (known as ZAR or “zones d'actions renforcées”) where the maximum applied nitrogen dose in the spread effluent, which can vary between departments and defined vulnerable zones, can be even more severe than the usual 170 kg N/ha. Effluent treatment is also obligatory under the Water Framework Directive in the Loire-Brittany catchment area with the purpose of ensuring an agronomic phosphorous balance. Treatment also becomes obligatory when using effluents or digestates in the case of AD as a soil improver or organic fertilizer defined by French standards (AFNOR, 2016).

Description of Livestock Production and Manure Management

Livestock Description

France is one of the main producers of meat in Europe being the largest in the case of cattle production, second for poultry and fourth for pig production (Eurostat, 2016). In 2010, the national agricultural census counted 490 000 farms of which 291 000 (59%) included a livestock activity (Agreste, 2011; Idele, 2013b). Cattle rearing covered 193 000 farm units and numbered in total 19.4 million animals; pig rearing covered 22 300 farms and numbered 13.8 million animals whereas poultry production was represented by 95 300 production farms with a total of 292 million birds. More recent data from 2013 indicates that livestock numbers are unchanged but spread across fewer farms (Agreste, 2013a): 176 500, 17 400, and 67 200 farms in the case of cattle, pig, and poultry respectively.

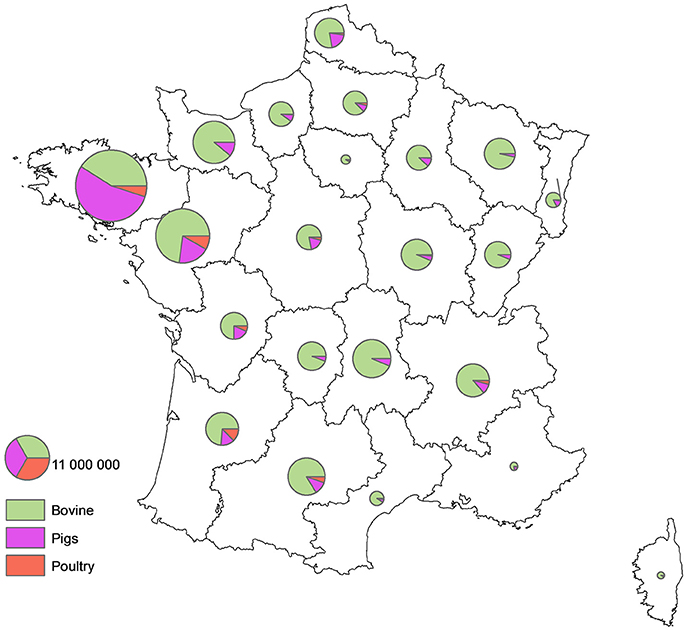

Geographic Distribution of Livestock Farms

Livestock numbers are not evenly spread across the country. More than half (55.3%) of cattle, pig, and poultry is found in two regions in the west of France (Brittany and the Pays de la Loire). These two regions contain around 70% of pigs and 60% of poultry numbers. Cattle is more evenly spread accross the French countryside but with nonetheless different regional concentrations of dairy cows (found predominantly in the north of the country) and beef animals (found mostly in the center of the country).

Utilized Agricultural Area (UAA) Associated With Livestock Farms

Agricultural land dedicated to the three livestock sectors, pig, cattle, and poultry, amounts to 15.2, 0.9, and 1.2 million hectares, respectively (Agreste, 2008a,b,c). For pig production, barely 10% of farms (representing 15% of pig numbers) have no adjoining farmland and a mean size much above the average (1,800 pigs or 310 sows) (Agreste, 2013b). Other farms have more than 50 ha of farmland (averaging 83 ha) of which 55% is in cereal production and oilseed/protein crops. In the case of poultry production, the mean area of farmland was in 2010: 63 ha per broiler farms, 56 ha for egg laying farms and 46 ha for pullets (Itavi, 2013a). Those poultry farms lacking any farmland account for 10% of broiler farms and 13% of egg laying farms (Itavi, 2013a). The average area of farmland of dairy farms was (in 2010) 91 ha of which 36% was given over to forage production, 37% was permanent pasture and 50% was used for cereal production and oilseed/protein crops (Agreste Centre, 2013a). In the case of beef farms, the average farmland area was slightly less at 83 ha of which 26% was used for cereal production and oilseed/protein crops and 71% was as permanent pasture (Agreste Centre, 2013b). More generally, these averages hide large regional differences. For example, in the Brittany region, many poultry farms have little agricultural land (over 30% of farms have less than 10 ha) whereas the 51 % of poultry farms in the Champagne region have more than 100 ha of farmland available.

Livestock Production and Farm Size

Livestock farms fall under either “standard” production or “quality” production the latter being such as “Plein air” (free range), “Lable Rouge” (Red label), “Biologique” (Organic), or “Appellation d'Origine Contrôlée” (AOC). Those “quality” farms have to follow certain official conditions laid out by the Ministry of Agriculture which includes rearing times, food regime, and so on. The conditions have an impact on the quantity and composition of the animal manure produced. 63% of broiler farms, 14% of turkey farms, and 67% of guinea fowl is currently subject to special regulations governing quality (Itavi, 2010). The organic production concerns mostly broiler and egg production, representing 1.0 and 7.6% of numbers respectively in 2014 (Agence Bio, 2016). In 2014, the pig sector covered by the regulations of Red Label code accounted for less than 3.3% of the total French pig production (Badouard, 2016) and sows managed under organic rules accounted for just 0.9% (Agence Bio, 2016). In the cattle sector, around 3% of beef animals fall under special quality regulations whereas the organic codes cover 4.2% of all french dairy cows (FranceAgrimer, 2016). The number of livestock farms covered by one or other quality codes is projected to increase for all types and especially for dairy and beef cattle farms (FranceAgrimer, 2016).

Cattle farm size

On average, the typical cattle farm had 101 animals in 2010 rising to 110 in 2015 (Agreste, 2016b), but the variation of the mean size from region to region was much greater ranging from 58 to 144 animals in 2010 (Agreste, 2014b). Considering the different herds of cattle, the average size is 45 heads of dairy cows, 34 heads of suckler cows while other animals (divided into <1 year, 1–2 years, and >2 years) are rearing in farms with less than 19 heads (Agreste, 2013a). In the case of milk production, 60% of farms keep only dairy animals whereas 40% have beef animals as well and/or veal calf production (Idele, 2013a). Dairy farms with more than 20 cows are predominantly for breeding (73.2% of farms) or for breeding and fattening including young beef and veal calf (20.8% of farms).

Pig farm size

In 2010, 48% of pig farms had fewer than 20 sows (or fewer than 100 pigs where the pig numbers were less than 1% of all farm animals) and the mean for this sector with very small herds was just 9 pigs (Agreste, 2013b). The bulk of pig numbers are thus held in livestock farms with more than 100 pigs (or 20 sows) and the mean size for this sector is 1,200 pigs, but with large regional differences ranging from a mean of 1,860 pigs per farm in Champagne-Ardenne, down to 150 pigs per farm in Corsica. Depending on their principal activity, pig farms can be divided between breeder/fattening (50% of the total), fattening farms (43% and generally without weaners), and pig breeding farms (6% including those with or without weaning).

Poultry farm size

The size of farms varies widely depending on the type of production and the methods used (whether standard practice or following specific codes relating to quality). In the case of both standard broiler production and egg laying systems (in cages), the farms are especially large scale (Agreste, 2013c). More than 60% of meat and egg poultry production is carried out in farms larger than 20 000 and 50 000 birds respectively. Those poultry farms governed by specific codes relating to quality are generally smaller (Itavi, 2010). As an example, the average size of a poultry house following standard practice is 870 m2 whereas the average for a farm applying a quality code is 220 m2.

Manure Management

Manure storage

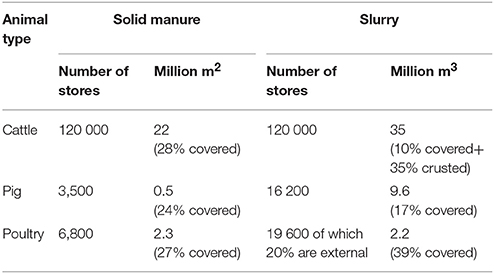

Livestock farms for cattle, pig, and poultry had together in 2008 (Agreste, 2008a,b,c) around 155 000 slurry stores (mostly away from the animal house in the case of cattle and pig farms) and with a combined storage volume of 47 million m3 (Table 1). Seventeen percentage of the storage pits were covered (in 2008) in the case of pig farms and 10% on cattle farms. Thirty-nine percentage of poultry farms had covers on their external stores. It should be noted in this last case, that for 80% of poultry houses, manure storage is within the building which may be considered as covered. The storage of solid manure was in 2008 carried out at 130 000 stores representing a combined area of 25 million m2 (2500 ha). Covers for such stores were in place for 21% of cattle FYM stores, 16% of solid pig manure stores but only 21.5% of those stores for poultry manure. A large part of the solid manure (55 million tons), mostly from the cattle sector (52 million tons), was stored in field heaps.

Table 1. Storage capacities of French livestock according to the 2008 survey (Agreste, 2008a,b,c).

Manure Treatment

In 2008, 12% of pig farms, 11% of poultry farms, and 7.5% of cattle farms used some sort of treatment for their manure. Manure treatment for the three main farm animal types accounted for 13.6 million tons (Loyon, 2017), that is, 11.3% of the 120 million tons of manure produced annually. The main processes, predominantly used at the farm, were composting (8.5 million tons), aerobic treatment (2.9 million tons of pig slurry), and anaerobic digestion or AD (1 million tons). Other treatments of solid manure including physical-chemical methods, were less common (0.4 million tons). In addition, a large part of poultry droppings is dried in or out of the rearing house.

Land Spreading of Livestock Manure

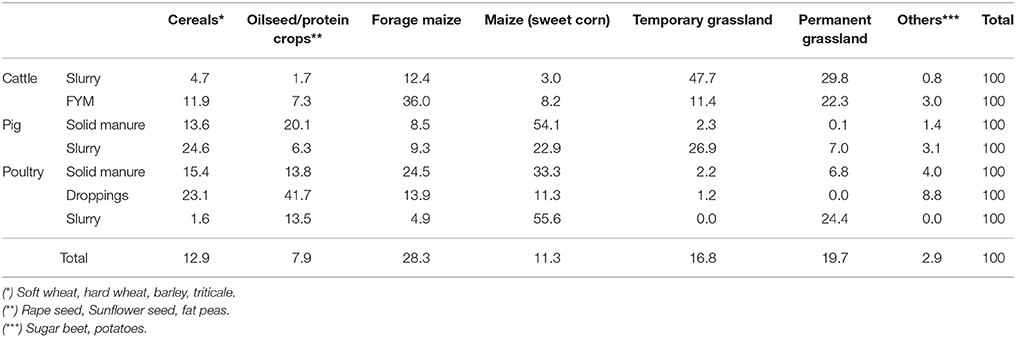

The application of livestock manure (whether raw or treated) is mainly done on farmer's land or other land generally close to the farm (Quideau, 2010). Fields available for taking the applications of manure are linked to the crop rotation in practice at the farm (Ramonet et al., 2014). Based on the data given in Table 2, of the total nitrogen in the manure from livestock farms destined for land spreading [estimated as around 540 kt N: (Citepa, 2017), and personal communication] 36.5% is spread on grassland, 39.6% on maize ground, and 12.9% on cereal land. Nitrogen from cattle manure is more often spread on grassland than that from piggery manure because of differences in the crop cycle between the farm types whereas nitrogen from poultry manure is mostly spread on cereal land. In certain regions (Brittany, Pays de la Loire, Limousin), livestock manure make up the main source of nitrogen and are spread essentially on maize ground, of which the area included in crop rotation is greater than elsewhere (Agreste, 2014a).

Table 2. Types of crop that receive the nitrogen contained in land-spread cattle, pig, and poultry manure (given as % of N applied) (Agreste, 2014a).

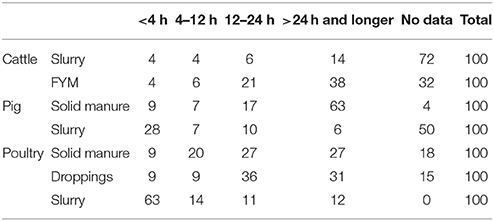

According to the crop survey 2011 (Agreste, 2014a), nitrogen in the form of solid manure is more than 90% surface land spread but up to 67% is not incorporated within 24 h (Table 3). Nitrogen applied as slurry is mostly spread on the soil surface using splash plate tankers (83% of the nitrogen tonnage in the case of cattle slurry, 63% for pig slurry, and 66% for poultry slurry) (Table 4). Incorporation of the nitrogen content in the following 24 h occurs to 88% of the nitrogen tonnage of applied poultry slurry and to 45% of pig slurry whereas 73% of cattle slurry seems not incorporated. Incorporation within 24 h of nitrogen from solid manure concerns 31% of the nitrogen tonnage for cattle, 33% for pig and 56% for poultry manure. This difference between the animal types is explained by the large proportion of the slurry form produced by pig farms and the related obligation to reduce the odor nuisance (with respect to nearby people) by using the method of incorporation. The applied dose of organic nitrogen varies from 87 kg/ha on rapeseed crops to 154 kg/ha on forage maize.

Table 3. Time for incorporation of applied nitrogen (as a % of total nitrogen applied) (Agreste, 2014a).

Table 4. Application method of nitrogen as livestock slurry (as % of total slurry nitrogen applied) (Agreste, 2014a).

Estimation of the Amount of Manure Produced

Manure type (slurry, FYM, or dropping) and the quantities produced at a farm depend on the housing type (slatted floor or bedding) and the stage of animal rearing. Manure management in the building (drying belt, scrapping, flushing, storage pit, etc.) also affect the quantities of manure to be handled. Generally, solid manure (FYM) is stored in field heaps or in manure stores and slurries stored in pits.

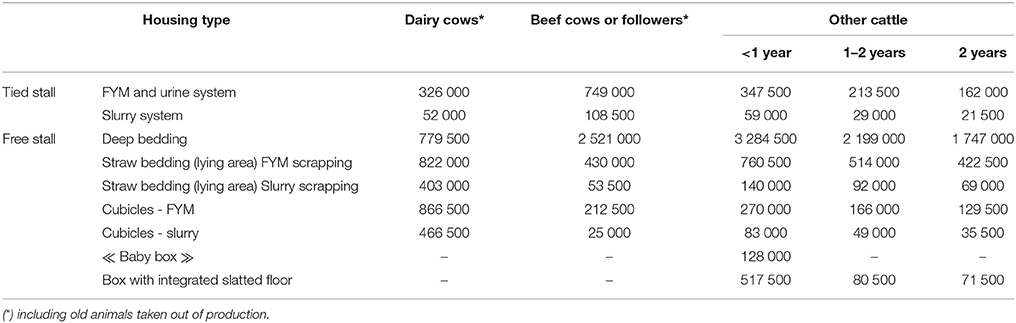

Cattle production

Eleven building types have been defined (MAPE and MAP, 2001) in order to estimate the storage capacity according to foor type (bedding or slatted floor), housing method (tied or free, “straw flow”—sloping floor with bedding, straw bedding, cubicle), possible inclusion of a yard for animal exercise—covered or exposed, and the amount of straw bedding in the different area accessible by the cattle. The most common system for all animal types is an open house design with FYM production (from deep litter, straw bedding areas or from cubicles) covering 80% of all animals (Table 5). Deep litter barns without an exercise yard is predominant in the case of cows with followers and other cattle but less so for dairy cows where straw bedding or cubicles are also common. Slurry-based systems are rarely used except for veal calf production and for dairy cows kept in cubicles with slatted floors. These different housing types produce slurry and/or solid manure more or less of high concentration in terms of the dry matter content (DM) (Degueurce et al., 2016). Only high solid FYM (defined as those with a dry matter between 18 and 25%) and very high solid FYM (over 25% dry matter) may be kept in field heaps. Wet FYM (below 18% dry matter) must be kept in FYM bunkers for at least 2 months before possible storage in the field. (MAPE and MAP, 2001; Idele, 2005).

Table 5. Distribution of cattle numbers on the basis of housing type in 2010 (Agreste, 2010).

Poultry production

Slurry is produced principally from farms rearing duck for the table or those force fed (for “foie gras”): otherwise, the slurry system is now virtually inexistent for egg producing hens (Itavi, 2013a). Solid manure arises from broiler production on litter, from pullets and from birds retained for future chick production (Itavi, 2010). Poultry houses operating alternative (non-cage based systems) for egg production (30% of layers) also produce solid manure (Itavi, 2013b). Laying birds that are kept in cages produce droppings that are collected and removed relatively frequently by conveyor belt (with or without drying) directing the manure to storage barns or a drying tunnel or drying building. Otherwise, the system is a building with a basement to collect and store the droppings produced being emptied at the end of a production cycle (one year) or removed more frequently using a scraping system.

Pig production

Buildings are mostly fitted with slatted floors (complete or partial) for all animal types, this system accounting for 91.5% of pig places (Ifip, 2010). Straw-based systems represent less than 8% of animal production. Slurry is held in pit located under the floor of the building for the whole production cycle or emptied more frequently to an external slurry pit. An alternative to this standard approach is the frequent removal of manure (gravity emptying every 15 days, automatic scraping several times each day…) but this remains unusual (estimated as representing less than 1% animal numbers in each case (Martin and Mathias, 2013). In the case of bedding systems, the solid manure is managed by accumulation (during a cycle) or removed by scraping 1 or 2 times a week.

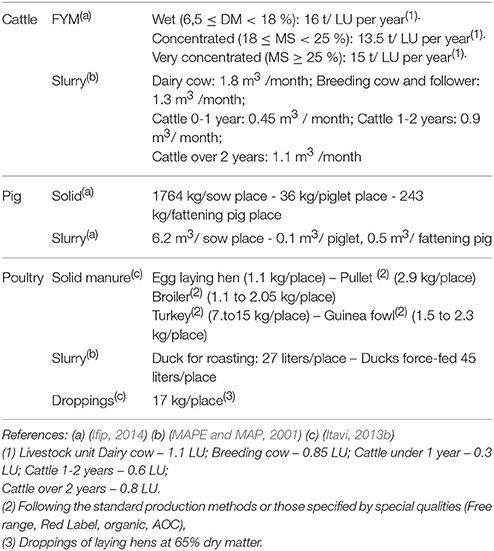

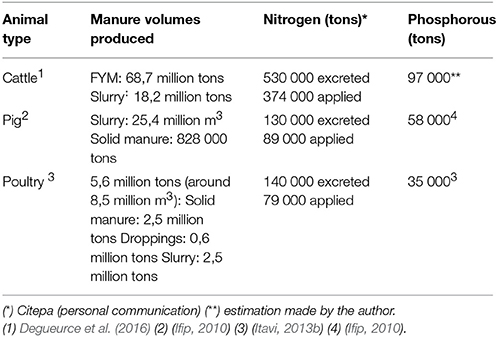

The specific quantity of livestock manure produced (per animal) depends on many factors linked to the animal (feed regime, stage of process, type of production system, and so on) and the housing method used. Default values have been proposed by specialist and these are used by the administration to allow the farmers to estimate the storage capacity required by the regulations (Table 6). Based on numbers of animals (different from the number of places) in 2010 given as 19.5 million cattle, 13.9 million pigs, and 221.6 million birds, and applying standard data on amounts of manure per animal, recent estimates (Ifip, 2010; Itavi, 2013b; Degueurce et al., 2016) place the total quantity of manure produced annually as around 120 million tons (Table 7) of which 60.6% is as solid manure, 38.8% as slurry, and the remaining 0.6% as poultry droppings. This value is less than the 263 million tons estimated by Foged et al. (2011) due to different quantity of manure produced by animal or place and the distribution of place between slurry and solid manure. Linked to the regional distribution of livestock farms, the largest amount of slurry and solid manure is produced in the “Grand Ouest” of France (Brittany, Pays de la Loire and Lower Normandy, Figure 1).

Table 6. Reference values of the specific quantities of livestock manure produced by the main animal types.

Table 7. Estimation of the total manure quantities (as raw manure) and corresponding nitrogen and P amounts produced by cattle, pig, and poultry farms (given as tons of raw manure and excluding manure deposited in pasture).

Figure 1. Regional distribution of manure produced by cattle, pig, and poultry livestock in France (in tons).

Environmental Impact

In France, total ammonia emissions amounting for 679 kt in 2015 (Citepa, 2017) arise principally from the handling of livestock manure (64%). The contribution from manure to emissions of methane and nitrous oxide in 2017 amounted to 2300 and 137 kt respectively which represent 11 and 4.5% of the national emission of each gas (Citepa, 2017). Manure production from intensive livestock farming in certain areas lead to a surplus of nitrogen (both organic and mineral) estimated nationally in 2013 as 902 kt (MEDDE, 2013d) which equates to an average of 32 kg N/ha of farmland. There is a large variation around this mean between areas of extensive farming (around 15 kg N/ha) and intensive regions (e.g., 69 kg N/ha in Brittany). In 2014 the surplus of phosphorous on average was 1 kg P/ha but 20 kg P/ha in Brittany (Agreste, 2016a).

Actionable Recommendations and Conclusions

The management of livestock manure (120 million tons per year nationally) depends greatly on the animal type, the region and the form of the manure (solid or slurry). The largest source of animal manure is from cattle farms that produce either solid manure (69 million tons per year) or slurry (18.2 million tons per year) across the country. Pig farms mostly produce slurry (25.4 million tons per year) which is principally concentrated in two regions of France (Brittany and the Pays de la Loire). Poultry production concentrated in the west of the country produces manure as solid manure, slurry, or droppings. In the case of cattle farms, 75% of the FYM produced is stored in the field (Loyon, 2015).

Slurry is most often stored in pits before land spreading on farmland. Poultry droppings are often dried and transported to other regions. The management of livestock manure is typically without the intentional use of methods to reduce ammonia emissions. In reality, the use of covers for external stores is not widespread and likewise the use of advanced spreading equipment (trailing hose, injection). The treatment of manure is above all used as a means to reduce the nitrogen surplus in those regions with a high livestock density, motivated by the demands of regulations linked to the Nitrates Directive. Treatment by composting is often used to enable a reduction in the obligatory minimal distances during landspreading. The use of methanisation (anaerobic digestion) to treat manure is restricted mostly due to financial reasons but also because of legal constraints. Until recently, the agricultural use of digestate required the registration or product standardization to reclassify it as a soil improver or organic fertilizer (Loyon, 2017). However, this constraint was due to be relaxed with the emergence in 2017 of a set of procedures enabling the marketing and use of agricultural digestates as fertilizing products (MAA, 2017). The movement of raw (untreated) animal manure between farms and the application of joint land-spreading plans is rare in France. This approach runs up against logistical issues about collection and a negative reaction from local people (Paillat et al., 2009). However, analysis of the best means of gaining value from livestock manure underline the importance to reformulate the manure as standard product to enable both the transport and satisfactory use on other farms bringing in (if possible) a commercial return as well (MEDDE and MAAF, 2013; Ademe, 2014). Nevertheless, for this strategy to succeed requires modified techniques that are economically viable for all livestock farms, and not just large farms are required (Quideau, 2010). This survey arising from 2010 is leading to the development of the release of new national action plans supported with financial packages that seek the reduction of ammonia emission (MEEM, 2017a) and of factors leading to climate change (MTES, 2017). The new BREF document for livestock farming (EC, 2017) arising from the Industrial Emissions Directive (EC, 2010) seeks to impose on around 3,300 pig and poultry farms in France practices determined as Best Available Technology (BAT) between the present time and 2021. New surveys of 2016 will enable an updating of the situation with manure management at livestock farms in France.

The current state of livestock manure management in France reveals that manure handling varies depending on the farm and the region. The main strategy is storage then local land spreading. In regions with a high animal density, policies of restoring water quality and the reduction of manure nuisance (especially with respect to offensive odor) have limited the agronomic use of animal manure. Newly emerging factors (depletion of mineral sources, energy costs, and economic guidelines) should increase the use of treatment technologies as well as new strategies for joint management of livestock manure.

Failing more recent data (2015 survey being in press), the compilation presented here is an important starting point to understand the French livestock production and the remaining efforts to be made to reduce its environmental impact. However, this paper is based on the analysis of a large number of official and non-official documents. One of the difficulties has been to cross-check the data most often formulated in different formats and based on unreported assumptions. As pointed out in recent publications (Kupper et al., 2015; Menzi et al., 2015a; Velthof et al., 2015; Smith and Williams, 2016; European Commission, 2017) the methodologies and data used by EU member states are often not well described. Thus, and whatever the environmental issue, there is a need for a common and harmonized methodology and procedure for collecting the data from reliable sources for the estimation of manure production and the nutrient balance.

Author Contributions

The author confirms being the sole contributor of this work and approved it for publication.

Conflict of Interest Statement

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Ademe (2014). Analyse d'une Stratégie d'Actions Visant la Réduction de la Dépendance Énergétique des Exploitations Agricoles par la Maîtrise de la Fertilisation Azotée, 132.

AFNOR (2016). NF U42-001 - ≪ Engrais - Dénominations et Spécifications ≫ 44-051. Available online at: https://www.boutique.afnor.org/norme/nf-u42-001/engrais-denominations-et-specifications/article/743864/fa032284

Agence Bio (2016). “La bio en France des producteurs au consommateurs,” in Les Carnets de l'Agence Bio (Montreuil), 38.

Agreste (2008a). Bâtiments d'Élevage Bovin. Available online at: http://agreste.agriculture.gouv.fr/enquetes/pratiques-d-elevage/batiments-d-elevage-bovin/

Agreste (2008b). Bâtiments d'Élevage Porcin. Available online at: http://agreste.agriculture.gouv.fr/enquetes/pratiques-d-elevage/batiments-d-elevage-porcin/

Agreste (2008c). Enquête Aviculture 2008. Available online at: http://agreste.agriculture.gouv.fr/enquetes/pratiques-d-elevage/enquete-aviculture-2008/.

Agreste (2010). Available online at: http://agreste.agriculture.gouv.fr/recensement-agricole-2010/resultats-donnees-chiffrees/.

Agreste (2011). Recensement Agricole 2010. Structure des Exploitations Agricoles. Les Productions se Concentrent dans les Exploitations Spécialisées. Agreste Primeur n° 272, 4.

Agreste (2013a). Enquête sur la Structure des Exploitations Agricoles 2013 et Recensement Agricole 2010. Nombre d'Exploitations, Superficie Agricole Utilisée, Volume de Travail en UTA et Production Brute Standard Par Région en 2013 (xls - 698,5 ko).

Agreste (2013b). Les Élevages de Porcs en France Métropolitaine en 2010. 11500 Élevages Porcins Détiennent la Quasi-Totalité du Cheptel National. Agreste Primeur Numéro 300, 8.

Agreste Centre (2013a). L'élevage Bovin Laitier: Des Exploitations Moins Nombreuses Mais Plus Grandes. Agreste n°total French pig production 2013AR10, 5.

Agreste Centre (2013b). L'élevage Bovin Viande: Moins d'Exploitations Mais un Effectif de Vaches Stable. Agreste n° 2013 AR 38, 5.

Badouard, B. (2016). La production de porcs Label Rouge, une perspective dans le contexte 2015? Tech. Porc. 29, 9–11.

Chadwick, D., Sommer, S., Thorman, R., Fangueiro, D., Cardenas, L., Amon, B., et al. (2011). Manure management: implications for greenhouse gas emissions. Animal Feed Sci.Technol. 166–167, 514–531. doi: 10.1016/j.anifeedsci.2011.04.036

Citepa (2017). Organisation et Méthodes des Inventaires Nationaux des Émissions Atmosphériques en France OMINEA - 14ème édition Mai 2017. Available online at: www.citepa.org, 838.

Degueurce, A., Capdeville, J., Perrot, C., Bioteau, T., Martinez, J., and Peu, P. (2016). Fumiers de Bovins, une Ressource à Fort Potentiel Pour la Filière de Méthanisation en France. Sciences Eaux &Territoires Hors-série numéro 24, 9.

EC (2000). Directive 2000/60/EC of the European parliament and of the council of 23 October 2000 establishing a framework for the community action in the field of water policy. Off . J. Eur. Comm. L327, 1–72.

EC (2001). Directive 2001/81/EC of the European Parliament and of the Council of 23 October 2001 on national emission ceilings for certain atmospheric pollutants. off. J. Eur. Comm. L309, 22–30.

EC (2010). Directive 2010/75/EU of the European Parliament and the Council of 24 November on industrial emissions. Off. J. Eur. Union 2010 L334, 17–118.

EC (2017). Commission implementing decision (EU) 2017/302 of 15 February 2017 establishing best available techniques (BAT) conclusions, under Directive 2010/75/EU of the European Parliament and of the Council, for the intensive rearing of poultry or pigs. Off. J. Eur. Union 2017, L43, 231–279.

EEC (1991). Directive 91/676/EEC of 12 December 1991 concerning the protection of waters against pollution caused by nitrates from agricultural sources. Off. J. Eur. Comm. L375, 1–8.

European Commission (2017). Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs. JRC science for policy report, European Commission, 898.

Eurostat (2016). Agricultural Production – Animals. Data extracted in October 2016. Available online at: http://ec.europa.eu/eurostat/statistics-explained/index.php/Agricultural_production_-_animals

Foged, H. L., Flotats, X., Bonmati, A., Palatsi, B. J., Magri, A., and Schelde, K. M. (2011). Inventory of Manure Processing Activities in Europe. Technical Report No. I concerning “Manure Processing Activities in Europe” to the European Commission, Directorate-General Environment. 138 pp.

Houot, S., Pons, M., Pradel, M., and Tibi, A. (2014). Valorisation des Matières Fertilisantes d'Origine Résiduaire Sur les Sols à Usage Agricole ou Forestier, Impacts Agronomiques, Environnementaux, Socio-économiques. Expertise Scientifique Collective, rapport, INRA-CNRS-Irstea (France), 930.

Idele (2005). Etat des Lieux des Bâtiments, des Capacités de Stockage des Déjections, des Types d'Effluents Produits et des Pratiques d'Épandage dans les Exploitations Bovines Francaises. Dépouillement de l'enquête Scees.

Idele (2013a). L'élevage d'Herbivores au Recensement Agricole 2010. Cheptels, Exploitations, Productions. Le dossier Economie de l'Elevage, 100p.

Idele (2013b). L'élevage d'Herbivores au Recensement Agricole 2010: Cheptels, Exploitations, Productions. Dossiers Économie de l'Élevage Novembre-Décembre 2013; n° 440–441, 100.

Ifip (2010). Bâtiments d'Élevage Porcin et Environnement. Analyse de l'enquête de novembre 2008 réalisée par le SCEES. 272p.

Ifip Idele, and Itavi. (2014). Composim, Calculateur de la Quantité et Composition des Effluents d'Élevage. Notice d'emploi et Guide Méthodologique, 35.

Itavi (2010). Caracterisation des Exploitations Avicoles Françaises a Partir de l'Enquête Aviculture 2008, 213.

Itavi (2013a). Caractérisation des Élevages Avicoles et Cunicoles en France à Partir du Recensement Agricole 2010. Typologie des exploitations avicoles et cunicoles françaises. 77.

Itavi (2013b). Estimation des Rejets d'Azote, Phosphore, Potassium, Calcium, Cuivre et Zinc par les Élevages Avicoles. Mise à jour des références CORPEN-Volailles de 2006. 63p.

Kupper, T., Bonjour, C., and Menzi, H. (2015). Evolution of farm and manure management and their influence on ammonia emissions from agriculture in Switzerland between 1990 and 2010. Atmos. Environ. 103, 215–221. doi: 10.1016/j.atmosenv.2014.12.024

Loyon, L. (2015). “A French inventory of solid manure (cattle, pig, poultry) stored in temporary field heaps,” in Proceedings of RAMIRAN 2015 – 16th International Conference Rural-Urban Symbiosis. Abstract book 8th – 10th September 2015 Hamburg University of Technology (Hamburg), 4.

Loyon, L. (2017). Overview of manure treatment in France. Waste Manage. 61, 516–520. doi: 10.1016/j.wasman.2016.11.040

MAA (2017). Arrêté du 13 Juin 2017 Approuvant un Cahier des Charges Pour la Mise Sur le Marché et l'Utilisation de Digestats de Méthanisation Agricoles en tant Que Matières Fertilisantes. JORF n°0142 du 18 juin 2017, texte n° 13

MAPE, and MAP (2001). Circulaire DEPSE/SDEA n° 2001-7047 du 20 décembre 2001 Relative à la Capacité de Stockage des Effluents d'Élevage et à l'Application de la Réglementation des Installations Classées Relatives aux élevages, 80.

Martin, E., and Mathias, E. (2013). Analyse du Potentiel de 10 Actions de Réduction des Émissions d'Ammoniac des Élevages Français Aux Horizons 2020 et 2030. Rapport. Ed ADEME, Angers, 242.

MEDDE (2013a). Arrêté du 27/12/13 Relatif aux Prescriptions Générales Applicables Aux Installations Classées Pour la Protection de l'Environnement Soumises à Déclaration Sous les Rubriques n° 2101-1, 2101-2, 2101-3, 2102 et 2111. JORF n°0304, texte n° 63.

MEDDE (2013b). Arrêté du 27/12/13 Relatif Aux Prescriptions Générales Applicables Aux Installations Relevant du Régime de l'Autorisation Au Titre des Rubriques n° 2101, 2102, 2111 et 3660 de la Nomenclature des Installations Classées Pour la Protection de l'Environnement. JORF n°0304, texte n° 61.

MEDDE (2013c). Arrêté du 27/12/13 Relatif Aux Prescriptions Générales Applicables Aux Installations Relevant du Régime de l'Enregistrement Au Titre des Rubriques n° ≪ 2101 ≫, 2102 et 2111 de la Nomenclature des Installations Classées Pour la Protection de l'Environnement. JORF n°0304, texte n° 62.

MEDDE (2013d). Les Suplus d'Azote et les Gaz À Effet de Serre de l'Activité Agricole en France Métropolitaine en 2010. Commissariat Général au Développement Durable. Chiffres et statistiques 448, 11.

MEDDE and, MAAF. (2013). Plan d'Action Relatif à la Meilleure Utilisation de l'Azote en Agriculture. CGAAER N°13019, 101p.

MEDDTL, and MAAPRAT. (2011). Arrêté du 19 décembre 2011 Relatif au Programme D'actions National à Mettre en Œuvre dans les Zones Vulnérables afin de Réduire la Pollution des eaux par les Nitrates d'origine Agricole. JORF n°0295, texte n° 12.

MEEM (2017a). Arrêté du 10 mai 2017 Établissant le Plan National de Réduction des Émissions de Polluants Atmosphériques. JORF n°0110; texte n° 37.

MEEM (2017b). Arrêté du 23/03/17 Portant Modification des Prescriptions Générales Applicables Aux Installations Relevant du Régime de l'Autorisation Au Titre des Rubriques nos 2101, 2102, 2111 et 3660 de la Nomenclature des Installations Classées Pour la Protection de l'Environnement. JORF n°0077, texte n° 14.

MEEM and MAAF. (2016). Arrêté du 11 octobre 2016 Modifiant l'Arrêté du 19 décembre 2011 Relatif au Programme d'Actions National à Mettre en Œuvre Dans les Zones Vulnérables afin de Réduire la Pollution des Eaux par les Nitrates d'origine Agricole. jorf n°0239 du 13 octobre 2016, texte n° 4.

Menzi, H., Kupper, T., and Spiess, E. (2015b). “Example of a country manure management profile – Switzerland,” in Proceedings of RAMIRAN 2015 – 16th International Conference Rural-Urban Symbiosis. Abstract book 8th – 10th September 2015 Hamburg University of Technology (Hamburg), 4.

Menzi, H., Oenema, O., Burton, C., Shipin, O., Gerber, P., Robinson, T., et al. (2010). Impacts of intensive livestock production and manure management on the environment. Livestock Changing Landsc. 1, 139–163.

Milne, A. E., Glendining, M. J., Bellamy, P., Misselbrook, T., Gilhespy, S., Rivas Casado, M., et al. (2014). Analysis of uncertainties in the estimates of nitrous oxide and methane emissions in the UK's greenhouse gas inventory for agriculture. Atmos. Environ. 82, 94–105. doi: 10.1016/j.atmosenv.2013.10.012

MTES (2017). Plan Climate. Available online at: https://www.ecologique-solidaire.gouv.fr/sites/default/files/2017.07.06%20-%20Plan%20Climat_0.pdf

Paillat, J. M., Lopez-Ridaura, S., Guerrin, F., Van der Werf, H., Morvan, T., and Leterme, P. (2009). Simulation de la faisabilité d'un plan d'épandage de lisier de porc et conséquences sur les émissions gazeuses au stockage et à l'épandage. J. Rec. Porcine 41, 271–276.

Petersen, S. O., Blanchard, M., Chadwick, D., Del Prado, A., Edouard, N., Mosquera, J., et al. (2013). Manure management for greenhouse gas mitigation. Animal 7, 266–282. doi: 10.1017/S1751731113000736

Quideau, P. (2010). “Les effluents d'élevage, les coproduits de traitement et leurs incidences environnementales,” in Elevages et Environnement. Editions Quae. (Versailles), 260.

Ramonet, Y., Giteau, J. L., Tersiguel, E., and Martel, G. (2014). Le choix des cultures dans les exploitations porcines en Bretagne. Innovat. Agron. 39, 43–53.

Smith, K. A., and Williams, A. G. (2016). Production and management of cattle manure in the UK and implications for land application practice. Soil Use Manage. 32, 73–82. doi: 10.1111/sum.12247

Steinfeld, H., Gerber, P., Wassenaar, T., Castel, V., Rosales, M., and de Haan, C. (2006). Livestock's Long Shadow – Environmental Issues and Options. Rome: FAO.

UN (1997). Kyoto Protocol to the United Nations Framework Convention on Climate Change. New York NY.

UNECE (1999). Protocol to the 1979 Convention on Long-range Transboundary Air Pollution to Abate Acidification, Eutrophication and Ground-level Ozone (Gothenburg Protocol).

van Dijk, K. C., Lesschen, J. P., and Oenema, O. (2016). Phosphorus flows and balances of the European Union Member States. Sci. Tot. Environ. 542 (Pt B), 1078–1093. doi: 10.1016/j.scitotenv.2015.08.048

Velthof, G. L., Hou, Y., and Oenema, O. (2015). Nitrogen excretion factors of livestock in the European Union: a review. J. Sci. Food Agric. 95, 3004–3014. doi: 10.1002/jsfa.7248

Velthof, G. L., Lesschen, J. P., Webb, J., Pietrzak, S., Miatkowski, Z., Pinto, M., et al. (2014). The impact of the Nitrates Directive on nitrogen emissions from agriculture in the EU-27 during 2000–2008. Sci. Tot. Environ. 468–469, 1225–1233. doi: 10.1016/j.scitotenv.2013.04.058

Keywords: overview, manure management, livestock, poultry, cattle, pig, France

Citation: Loyon L (2018) Overview of Animal Manure Management for Beef, Pig, and Poultry Farms in France. Front. Sustain. Food Syst. 2:36. doi: 10.3389/fsufs.2018.00036

Received: 18 January 2018; Accepted: 19 June 2018;

Published: 10 July 2018.

Edited by:

Claudia Wagner-Riddle, University of Guelph, CanadaReviewed by:

Harald Menzi, Federal Office for the Environment, SwitzerlandDavid Fangueiro, Instituto Superior de Agronomia (ISA), Portugal

Copyright © 2018 Loyon. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Laurence Loyon, bGF1cmVuY2UubG95b25AaXJzdGVhLmZy

Laurence Loyon

Laurence Loyon