- 1Department of Molecular Biology and Biotechnology, University of Sheffield, Sheffield, United Kingdom

- 2Grantham Centre for Sustainable Futures, University of Sheffield, Sheffield, United Kingdom

- 3Management School, University of Sheffield, Sheffield, United Kingdom

- 4Department of Geography, University of Sheffield, Sheffield, United Kingdom

- 5Green Knight Sustainability Consulting Ltd., Bakewell, United Kingdom

Achieving global food security requires a new approach that integrates not only all aspects of the growing, harvesting and processing of food (necessary to ensure sufficient affordable and sustainable production to alleviate hunger) but also the complexities associated with food consumption including deterring unhealthy overconsumption. Inefficiencies occur at various points along the agri-food supply chain but at present they are inadequately conceptualized via separate accounts of food loss, food waste, supply chain management, and public health. Here we re-define food loss and waste through the concept of conversion efficiency applied to the entire system, an approach up to now only applied to the primary processes of crop productivity. Nine conversion efficiencies are defined: sunlight capture efficiency; photosynthesis use efficiency; biomass allocation efficiency; harvesting efficiency; storage and distribution efficiency; processing efficiency; retailing efficiency; consumption efficiency; and dietary efficiency. Using the production and consumption of bread in the UK as an example, we demonstrate how efficiencies may be estimated and thus where the main inefficiencies lie, so indicating where the most significant improvements could be made. We suggest that our approach, which introduces the term Food Chain Inefficiency (FCI) to re-define food loss and waste, provides a rational and effective way to devise the practical interventions and policies needed to deliver a sustainable agri-food system.

Introduction

Providing food security for the growing human population without widespread environmental degradation is one of the biggest challenges of the twenty-first century (Godfray et al., 2010), one which underpins many of the United Nations Sustainable Development Goals (Rockström and Sukhdev, 2016). The agri-food system is the largest single contributor of greenhouse gases, a significant source of pollution of land, water courses and oceans, and depletes non-renewable resources. It relies upon input of unsustainable amounts of agrochemicals, leading to a degradation of the soil upon which it depends (Horton, 2017). Its failures are the obesity epidemic from over consumption and the undernutrition of nearly 1 billion people. Food security is a complex or wicked problem, often considered intractable (DeFries and Nagendra, 2017). Progress will only be made if the many parts of the agri-food system are viewed as a whole (Horton et al., 2017), with integrated, joined up thinking across the issues of environment and biodiversity to all aspects of the growing, harvesting and processing of food, and the processes associated with food consumption including nutrition and health. Furthermore, scientific and technical knowledge has to be considered in a political, cultural, and economic context (Horton and Brown, 2018).

Reducing food loss and waste has been identified as an essential requirement in achieving global food security (Parfitt et al., 2010; Institution of Mechanical Engineers, 2013) and is also seen as a key objective of SDG 12, Responsible Consumption and Production (UNEP, 2015). Five key global drivers of food waste have been identified: lack of consumer awareness, poor infrastructure, inefficiency, lack of collaboration, and a poor policy environment (BCG, 2018). The issue of food waste has assumed great significance in many parts of the world, although the bulk of these actions have focused on re-distribution of waste, often re-characterized as “surplus,” rather than addressing these underlying drivers (WRAP, 2018a). For example, the French government introduced legislation requiring retailers to donate surplus food (Gore-Langton, 2017) and in Denmark, the Danmark Mod Madspild (Denmark Against Food Waste) cross-sector campaign was launched (Askew, 2018). In the UK, there are similar programmes led by a range of stakeholders, for example businesses donating surplus product to food banks (Cohen, 2016a). Major UK food retailers have also attempted to address the causes of food waste: re-branding sub-standard b-grade produce as “too good to waste” and retailing it directly; and removal of “best before dates” in an attempt to reduce losses through adherence to relatively arbitrary shelf-lives (Smithers, 2018). Similarly, local UK government and charities have worked together to encourage behavior change in the home (Restorick, 2018).

Defining Process Efficiencies in the Agri-food System

One problem with such initiatives is that they often operate in isolation, divorced from the wider issues that link food production and consumption, and human health, fragmenting both agri-food research and agri-food policy. Indeed, how we separately define food loss and waste is evidence of the lack of joined up thinking: loss and waste are expressed in different ways with different meanings, and discussed by different sectors, leading to confusion about their relative importance and what should be done to reduce them. Food loss is often seen as something that is unavoidable, such as the effect of weather on a crop yield, whereas food waste is frequently viewed as resulting from a poor human practice that should be (easily) avoided. Furthermore, only rarely is the ill-health that results from overconsumption of food described in a “food waste” context.

The UK waste charity WRAP has developed a “waste roadmap” attempting to cover the entire “field to fork” value chain and has enlisted major manufacturers and retailers to work on a common set of metrics (WRAP, 2018b). Similarly, the Global Champions 12.3 group is a coalition of executives from governments, businesses, international organizations, research institutions, farmer groups, and civil society dedicated to inspiring ambition, mobilizing action, and accelerating progress toward reducing food waste (Hanson and Mitchell, 2017). Nevertheless, these approaches still fall short of considering the entirety of the agri-food system.

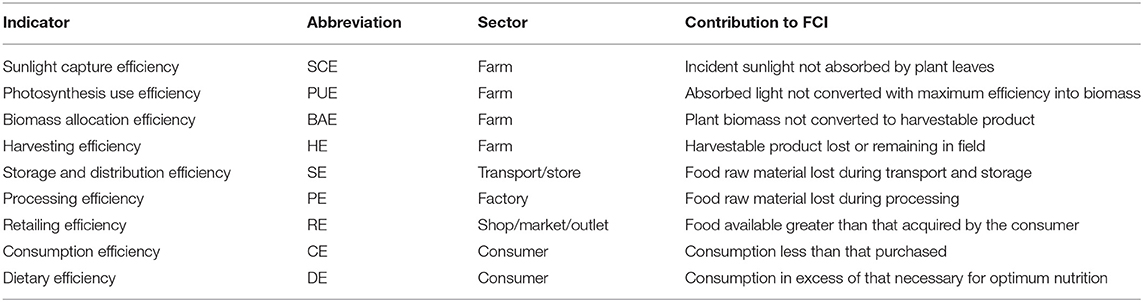

Food loss and waste are both indicators of the inefficiency of the process at which they occur, and therefore they should be viewed together in the wider context of all the factors that reduce the efficiency of the agri-food system; food loss and waste across an entire food supply chain could be defined as Food Chain Inefficiency (FCI). In agriculture, the productivity of crops has long been described in terms of radiation-use-efficiency (RUE), a term which relates the amount of biomass produced by a crop to the amount of intercepted solar radiation, and the Harvest Index (HI), which describes the proportion of biomass in the harvestable yield (Monteith, 1977; Mitchell et al., 1998; Mitchell and Sheehy, 2018). Linked to these terms are Yield Potential, the maximum productivity of a crop and the Yield Gap, which describes the difference between this and the actual recorded yield. These terms define the performance of a crop at the local and global level (Guilpart et al., 2017). Moreover, they define food loss in terms of conversion efficiencies. In this article, we propose an extension to this terminology to redefine food loss and waste in terms of FCI, which invokes a single accounting methodology to cover the entire food system, linking aspects of environment, plant physiology, agronomy, harvesting, processing, distribution, consumption, and nutrition. We define nine process conversion efficiencies (defined simply as output as a proportion of input) in the agri-food system, and we outline the range of factors which determine their value (Table 1). We then describe these process efficiencies in an illustrative FCI case study, the wheat-bread supply chain.

Table 1. The nine indicators of process conversion efficiency that contribute to Food Chain Inefficiency.

Sunlight Capture Efficiency (SCE)

Firstly we consider the efficiency with which sunlight falling on cultivated land areas is used. Sunlight Capture Efficiency (SCE) has the following components.

The Proportion of Sunlight Incident on Leaf Surface

This is determined by a range of agronomic and physiological factors: the density of planting, the rate at which the plant canopy develops, and how long it stays “green” as the product develops. A frequently used term is “canopy closure” to describe the point at which all sunlight is incident upon leaf surfaces (Duncan, 1971). Other factors include the three dimensional architecture, how many leaves are produced, the dynamics of the plant canopy, and the direction of sunlight. Canopies of rice for example have erect leaves which preferentially absorb sunlight at the beginning and end of the day (Murchie et al., 1999), whereas other crop species adjust leaf angle to either track or avoid direct sunlight (Denison et al., 2010).

The Proportion of Incident Photons That Are Absorbed

Light can be reflected from the leaf surface, although this is not significant in most crops. In all crop species, chlorophylls a and b (and some carotenoid) absorb the sunlight capturing only a portion of the solar spectrum, Photosynthetically Active Radiation (PAR). PAR is ~50% of sunlight (Mitchell et al., 1998) and the extinction coefficient is determined by leaf structure and composition including the pigment content per chloroplast membrane area, the membrane area per chloroplast, the chloroplast number per leaf cell and the number of cells. All of these are determined genetically and acclimate to the environment. There are ambitions to manipulate the type and concentration of chlorophyll in the chloroplast to increase the efficiency of absorption or even extend PAR (Chen and Blankenship, 2011; Ort et al., 2011).

Photosynthesis Use Efficiency (PUE)

If all absorbed photons are used with maximum efficiency, the maximum amount of carbon fixed in photosynthesis is determined by the quantum yield. Although in theory it is possible to extract more photosynthesis per photon absorbed, in practice, quantum yield is best regarded as a constant, being highly conserved through evolution and unlikely to see improvement by plant breeding or genetic modification. Thus, we propose a move away from using RUE, a term that includes quantum yield and instead introduce the term PUE to describe the factors that cause the conversion of absorbed sunlight into biomass to be less that that theoretically expected from the quantum yield. These factors include responses to the external environment and internal physiological processes, both of which vary between species. A key benefit of using PUE is that it introduces those factors which could be manipulated in order to increase efficiency (Zhu et al., 2008; Murchie et al., 2009). These are numerous and include the following.

Photorespiration

Photorespiration, resulting from the binding of oxygen rather than CO2 to the carbon fixation enzyme ribulose bisphosphate carboxylase oxygenase (Rubisco) is acknowledged to be a principal source of lost potential photosynthesis. International programmes of research are aimed at suppressing photorespiration (Zhu et al., 2008; Murchie et al., 2009), through alteration of the properties of Rubisco, modification of the photorespiratory pathway or by introducing CO2 concentrating pathways.

Respiration

Not all photosynthetic product is converted to biomass, some being lost as respiration (Mitchell et al., 1998). Energy from respiration is needed to maintain plants during periods of darkness and to fuel growth, making plant structures, accumulate nutrients by roots and so on. Some pathways of wasteful respiration are a source of lost potential yield.

Rate of Photosynthesis

Photosynthesis has a finite capacity limited by the rates of the enzyme catalyzed reactions of carbon metabolism, and therefore the intensity of sunlight can be high enough to lead to light saturation, and consequent reduction in PUE (Horton and Murchie, 2000). This capacity is highly variable between species and is affected by the light intensity and spectral quality experienced during growth. The availability of nutrients from the soil is also a factor. The rate of photosynthesis at any time is also determined by ambient environmental conditions: drought and extremes of temperature may limit photosynthetic rate and cause yield loss. Specific enzymes have been identified as targets through which capacity could be increased (Driever et al., 2017). The light environment is rarely constant in nature (due to clouds, movement of leaves etc.), and therefore the efficiency with which light is used in photosynthesis is in part determined by the rate at which various internal regulatory mechanisms adjust to the change in light intensity and spectral quality (Kromdijk et al., 2016).

Biotic Factors

In addition to the effect of environmental conditions, plant pests and pathogens may considerably reduce the amount of crop biomass. Animals, insects, viruses, bacteria, and fungi either consume plant material directly, reducing the leaf area supporting photosynthetic activity, or siphon away metabolites to promote their growth at the expense of plant growth (e.g., Berger et al., 2007). Parasitic plants also take metabolites from their crop plant hosts, reducing that available for crop biomass accumulation (Frost et al., 1997).

Biomass Allocation Efficiency (BAE)

BAE measures the proportion of total plant biomass allocated to harvestable product. The development of the product usually involves complex physiological and developmental changes including remobilisation of resources from vegetative tissues. BAE also incorporates consideration of “secondary” food sources, such as the conversion of primary plant biomass into animal biomass. As with PUE, there is a maximum attainable value for allocation for each crop species, and so BAE is estimated as the extent to which that limit is reached. Factors affecting BAE include the following.

Plant Morphology and Physiology

Intrinsic properties of plants determine how much biomass can be trapped in the harvestable product. Breeding for increased product was important in crop redesign during the Green Revolution and is already maximal for most cereal crops, though probably not so for many others (Shearman et al., 2005). In a cereal such as rice, grain filling coincides with leaf senescence which allows nitrogen from protein degradation to be deposited in the grain, but flag-leaf photosynthesis is essential to provide carbohydrate for grain filling; thus, optimisation of these two potentially conflicting demands is required for maximizing BAE (Horton and Murchie, 2000).

Environmental Conditions

BAE can fall below the potential set by plant morphology because environmental conditions affect all stages of product development (Shearman et al., 2005; Murchie et al., 2009). For example, a restriction of photosynthetic rate during the period of flower initiation can reduce the number of flowers formed, whilst high temperature can lead to loss of flowers or developing fruits. Crop management can also affect BAE: high planting density, whilst important for high SCE, can reduce BAE through competition between plants and over-investment in stem and leaf growth (Deng et al., 2012); and fertilizer application can stimulate excess vegetative growth and reduce that allocated to the fruit or grain (Unkovich et al., 2010).

Biotic Factors

Pests and diseases can severely inhibit the formation and development of harvestable products, which are rich in nutrients and hence major targets for such pests. The list of pests that destroy potential food products is huge. Loss of biomass to biotic factors is a major cause of the yield gap—leading to an “arms race” to develop effective and sustainable chemical control and huge research efforts to breed varieties that are resistant or have increased tolerance (Oerke, 2006).

Structure of the Food Chain

Biomass from grasses and other plants is used for animal grazing, either directly or after harvesting and storage. This is a very efficient use of above-ground plant biomass. However, the production of meat from the animals is much less efficient (McMichael et al., 2007) because the consumed plant biomass is used for the growth and maintenance of the animal during its lifetime and because not all of the animal biomass is suitable for food.

Harvesting Efficiency (HE)

Not all harvestable product is collected. Inevitably, even with modern technology, the harvesting process cannot be 100% efficient. Factors determining HE include the following.

Method of Harvesting

Depending upon the geographical area and the type of crop, there are varying extents of mechanization of harvesting. Generally, mechanization increases the efficiency of harvesting (McGuire et al., 2011). Various kinds of work practices are also important: e.g., payment by the amount harvested encourages more complete harvesting. The combine harvester and its many derivatives dominate industrial agriculture, with purpose-built machines for many types of crops. Crops are bred for hardy products—those less susceptible to damage by machinery. However, mechanization can also reduce flexibility within the harvesting process: e.g., the configuration of equipment may be such that under- or over-sized product is rejected in the field.

Conditions During Harvest

Adverse conditions may damage a crop, making harvesting impossible, for instance through lodging, or by preventing operation of machinery. The suitability (and therefore economic value) of the crop product for subsequent processing may also be lowered: e.g., the effect of rainfall on the wetness of cereal crops or the visual appearance of a fruit or vegetable.

Markets

Because of the costs involved, it may not be profitable for a crop to be harvested if the market value for the product is lower than expected. Related to this is the extent to which all parts of the crop are harvested. Historically, in subsistence farming every part of an animal or a crop plant would be used. Today, there is a renewed emphasis on similarly making use of biomass not directly suitable for human consumption, according to the new principles of the circular economy, which can make the harvest more profitable and hence increase HE.

Availability of Labor

Despite extensive mechanization, harvesting relies upon the availability of labor. Often this involves low skill, low wage and physically demanding tasks that are largely taken by migrant labor in developed countries such as the USA and UK. Such labor enables profitability of the harvesting of many crops and thereby serves to increase HE (Murali and Balakrishnan, 2012). However, the hostile immigration environment developing in the UK is resulting in a reduction in seasonal migrant labor movement and threatens agricultural efficiency. In the future, increased use of robotic harvesting could reduce the requirement for labor (Dong et al., 2011).

Storage and Distribution Efficiency (SE)

Very rarely does a crop product immediately become a food that is consumed on site: harvested product has to be collected, transported and stored, and then made available for processing or consumption. Factors affecting SE include the following.

Storage Conditions

Many food products, such as wheat grain, are stored in large volumes for long periods of time. Risks of infestation by fungi, insects and small mammals are high unless optimally managed conditions are adhered to. Large storage facilities where grain is collected and stored are commonplace in developed countries, usually found near transport hubs and sea ports. In less developed countries, the absence of such storage infrastructure is a significant source of loss. For some products, such as vegetables or sea fish, harvested product is quick-frozen on site, preventing natural deterioration post-harvest.

Transport Infrastructure

Effective transport is particularly important in the transfer of agricultural produce from the farm to the storage or processing facility (Gustavsson et al., 2011). In developed countries, the quality of transport infrastructure is high, for example with dedicated rail links and fine-tuned collection and delivery road transport operations. This is not always the case in less developed countries (Hodges et al., 2011). Serious issues can arise even in well-developed economies when sectors seek to reduce costs. For example, in the UK, a change in distributer to save costs resulted in severe disruption in chicken supply to food outlets (Wood, 2018).

Supply Chain Logistics

Deterioration of harvested product due to poor supply chain logistics can be a significant cause of food waste (Kader, 2004). The integrity of food being distributed depends upon a mix of skills and technologies, such as temperature controlled vehicles and specialist warehousing, which need to be optimized for maximum efficiency. For example, bananas are transported in temperature controlled containers (at 13.5°C) to their ripening centers where the conditions are altered to secure ripening at a time when the retailer requires stock (Wilson, 1996). Many food processors and manufacturers are examining how the adoption of blockchain technology (Kim and Laskowski, 2018) could help with quality control and transparency, for example across borders to ensure that fiscal and regulatory requirements are met with minimal additional cost and delay. Other accounting tools, such as Open Book and Vendor Managed Inventory, are starting to play a significant part in improving efficiency (Martinez Ramos, 2004).

Packaging

Packaging, mostly with single-use plastic, is used in part to protect food from damage and decay, hence extending shelf life and reducing waste. Unnecessary over-packaging is an issue that is being addressed by the industry, but as with many such issues, there are many dilemmas e.g., the shelf life of cucumber is enhanced considerably by being wrapped in plastic. Consumer resistance to packaging reduction can also be an issue; a pizza manufacturer lost sales through dispensing with cardboard box packaging because consumers prefer to stack items on top of the pizza boxes in the refrigerator.

Processing Efficiency (PE)

The food processing industry is highly competitive, sophisticated and complex, resulting in maximization of the amount of raw material converted to food product. There are potential conflicts with food standards, with supply chain transparency and factory processes sometimes falling short of expectations: for example, horse meat used as a beef substitute (Van der Meulen et al., 2015) and the relabelling of poultry at processing plants to extend saleable shelf life, are both recent examples of food fraud. Factors affecting PE include the following.

Factory Logistics

Modern food processing plants in developed countries, such as millers or bakers have increasingly sought to minimize waste and resource use, driven by the need to reduce costs and maximize profit. The principles of recycling, finding economic uses for materials previously regarded as waste, and the ideas of the circular economy have become increasingly dominant. Increased automation, use of robotics in all stages from initial food produce selection (and rejection) to final processing to the end product are now commonplace.

Economics of Food Processing

Cost per saleable unit is a key metric that does not always lend itself to optimisation of material yield. Low-cost, low-quality raw material may deliver a cheaper product, even at the cost of reduced yield. For instance, abrasive peeling of lower cost irregularly shaped and variable size potatoes removes flesh as well as skin and generates a lower PE.

Product Quality Control

Food production has strict requirements on the quality of raw materials to ensure particular aspects of food quality, texture, taste, and suitability for effective processing. All of these can lead to reductions in PE. An important step forward would be the capability to predict the quality of a crop product pre-harvest, and ideally to be able to manipulate conditions in the field to enhance quality. Bakers and millers regard this as a crucial area for further research. Many quality controls relate to secondary features of food such as size, shape and weight to meet the uniformity requirements for packaging, resulting in rejection of potentially edible product. To increase profit, rejected materials are used for other purposes, but this may actually encourage food waste; for example, rejected bread crusts and end slices from sandwich producers are used as an ingredient in beer making (Melikoglu and Webb, 2013). Very significant of course is maintenance of food safety—the presence of toxins, contaminants or microbial infection or infestation render food products unsafe. Production facilities are audited and inspected and there are a series of legal frameworks imposed on suppliers by retailers covering environmental, safety, and ethical issues.

Consumer Preferences

Visual appearance is a crucially important feature of food, which has perverse consequences: so-called “wonky” products (such as carrots and potatoes) are suitable to eat but are rejected because of aesthetic appearance (Topolansky Barbe et al., 2017). What is acceptable as a food in a particular culture is also an important factor. For example, Western consumers generally prefer white over dark poultry meat with some parts of the bird being viewed as totally unacceptable. Cultural factors similarly determine willingness to consume some parts of livestock, such as offal. However, cultural norms can change, exemplified by the growing interest in Western societies in novel food sources, such as insects (House, 2016), and current trends such as “nose to tail” eating.

Retailing Efficiency (RE)

Manufactured food is distributed to various retailers and food outlets. But not all of it is sold to the consumer. Retailing efficiency is a well-documented source of waste. In some countries, surplus food is increasingly redistributed to food banks where it is also available to be consumed (Galli et al., 2019). This alternative route to consumption hence contributes to reducing waste and increasing RE. Three inter-related factors dominate the value of RE.

Wide Choice and Full Shelves

Retailers, particularly large supermarkets strive to have full shelves of food with ever-increasing variety to give wide consumer choice. Because of the complexity of the supply chains that make this possible and the finite shelf life of most foods, waste is inevitable (Parfitt et al., 2010; Eriksson et al., 2016). However, in the highly competitive retail market, the cost of such waste is absorbed and part of the business model. In the UK, the recent move away from a single weekly shop to more frequent, smaller basket shops has seen a reduction in waste as stock turnover is faster, with less waste through out-of-date produce.

Freshness and Safety

Deterioration of food quality and the imperative to prevent customer illness results in disposal of food. Retailers, manufacturers and processors have been working together to reach new levels of extended shelf-life for perishable foods. Technological innovations include a longer shelf-like milk through the use of ceramic filtration of milk post-pasteurization, which removes bacteria that otherwise act to render the milk sour and unusable (Martinez-Ferez et al., 2006). The resultant shelf-life increase is very significant, therefore increasing RE.

Information and Labeling

Misunderstanding of date labels, including confusion between “best-before” and “use-by” labels, can also lead to unintended waste based on a conflation of guidance about food quality and safety standards (WRAP, 2017). In fact, consumer behavior is a root cause of much food waste and difficult to change (Reynolds et al., 2019). For example, a UK supermarket invested £10 m in a 5-year “waste less, save more” initiative project intended to establish how information, tools and community events could help reduce food waste, but the results fell short of target with householders telling the retailer that the issue was not a priority (Weinbren, 2017).

Consumption Efficiency (CE)

Not all food that is purchased is consumed, and the food that is consumed may not be eaten with peak nutritive value. CE therefore is estimated not only from the mass of food consumed but the potential nutritive value acquired from that consumption. The following are the two principal factors influencing CE.

Food Purchase

The supermarket environment encourages over-purchase, through “special offers” and attractive displays, backed up by extensive advertising. The reduced unit cost in larger pack sizes and the unavailability of small packs are also important factors. Over-purchased food is often not eaten due to it passing beyond what is culturally and medically safe to eat. Moreover, the nutritive value of food changes over time (i.e., as fruit ripens the nutritional composition changes), and therefore misjudgement about when to consume foods means that the optimal nutrition may not be gained. In addition, if food is over-purchased, the food may have to be consumed over a longer time period (from under to over ripe), with some of the foods eaten at a non-optimal nutrition level. The edible nature of a product can be extended through food preservation methods such as canning, drying, salting, and freezing, though these may also reduce the nutritive value of the product.

Food Handling

Methods used to prepare foods (i.e., cooking style and gastronomic traditions) alter how much of the food is available for final eating and the nutritive value of the edible food. For example, different methods of preparing and cooking potatoes (i.e., steamed whole, baked in skin, fried as chips) result in different amounts of edible potato and different nutritive value. In fruits and vegetables in general there is significant variation in the nutritional content through the skin and flesh, so that peeling can similarly reduce nutritive value. There is also a tendency to prepare more food than is needed, “better to serve too much than too little.”

Dietary Efficiency (DE)

Over-consumption of food should be regarded as a waste, and this can be calculated by estimating what proportion of consumption is in excess of that needed to provide the level of nutrition required to maintain good health. Methodologies exist for making these estimates (e.g., Hall et al., 2011). Measurement of food intake at the population level (from estimates of gross food consumption) and from survey of individual consumption (and purchase) behavior can be used to measure the level of overconsumption, although the consumption of certain foods is often incorrectly reported (Stubbs et al., 2014). For example, surveys indicate a consumption of <2,000 kcal per person in the UK, inconsistent with over 60% of the population being obese or overweight. Moreover, not all foods have the same nutritional benefit or health penalty, so DE, like CE cannot simply be estimated in terms of food mass. Thus, consumption (and production) of “unhealthy” food should also be considered a symptom of an inefficient system. Factors affecting DE therefore include the following.

Calories and Nutrients

There are two distinct issues here, one of which is the total calorie intake—the other is per person nutrient intake. Over-consumption of calories and nutrients can both result from over-consumption of food. However, over-consumption of calories is by far the larger health risk, the root cause of the obesity and the non-communicable disease (NCD) epidemic occurring in all countries. Different foods contribute differentially to NCDs and there is debate over the relative harm from high fat and high carbohydrate food (Dehghan et al., 2017).

Physiology and Genetics

The optimum consumption of energy is related to human physiology and genetics (Van Zant, 1992). The process by which nutrients are extracted by the human body from eaten foods also varies and there are many factors that affect the rate at which food is digested in the alimentary tract and absorbed into the bloodstream. One issue of contemporary concern is gut health—or the efficiency of a person's gut microbial community. The gut microbiome changes according to what is eaten, and this in turn influences the efficiency of nutrient metabolism (Kau et al., 2011). An efficient and healthy gut microbiome requires a balanced and varied diet.

Culture and Behavior

There are a myriad of reasons, many not understood, for the over-consumption of food. Some relate to over-purchase (CE) and the increased availability of food, others to particular culturally-embedded social practice or individual behaviors. In a range of countries, survey data show that the major driver of the obesity epidemic is the increased food energy supply (Vandevijvere et al., 2015). Ultraprocessed foods are increasingly available globally and viewed as contributing significantly to obesity (Monteiro et al., 2018). The extent to which a given amount of food consumption leads to obesity is determined by a number of factors including the level of physical exercise and basal metabolic rate, both of which depend on body weight (Hall et al., 2009). The challenge therefore is to discover ways to bring about change in behavior and practice, for example through incentives, taxation, product reformulation and education.

Implications for Agricultural Land Use

All of the above processes which govern the efficiency of the agri-food system in effect determine the number of humans that can be properly fed per unit of agricultural land area. Creation of agricultural land has involved deforestation and destruction of other natural habitats such as savannahs and grasslands. This has implications not only for biodiversity (Tilman et al., 2017), but also for the provision of other ecosystem services and the emission of greenhouse gases that follows land use change (Tubiello et al., 2015). There is competition for land not only between urban development and agriculture but also for non-food cropping such as biofuel production, maize for anaerobic digesters, intensive solar panel infrastructure and land “set aside” to enable restoration to a more natural state to increase biodiversity. With a world population growing toward 10 billion, it is only by decreasing the FCI within the agri-food system that agricultural land use can be stabilized and even reduced. As an example, it has been estimated that 540 Mha could be saved by 2050 through the global adoption of a (more efficient) vegetarian diet compared to the (inefficient) meat-rich diet associated with increasing prosperity (Tilman and Clark, 2014).

It is important to consider not only the process efficiencies in the agri-food system but also the geographical distribution of the factors that govern these efficiencies: temperature, rainfall, soil quality and the intensity and duration of solar radiation govern SCE, PUE, BAE, and HE. Of equal importance are the logistic considerations (proximity to transport links, markets etc), availability of labor, and the socio-economic and political environment, which determine SE, PE, RE, CE, and DE. Moreover, we need to consider the amount of land used for a particular crop or livestock; each one has a geographical distribution based mainly on environmental adaptation, but local and global demand for products is a key determinant of how much of the potential land area is used. This is not fixed: genetic improvement extends the dynamic range of a species, societal change alters demand, and climate change shifts environmental boundaries. Thus, it is not just about how much land area is used for agriculture, but about which land areas promote the highest agri-food system efficiency.

An Illustrative Case Study

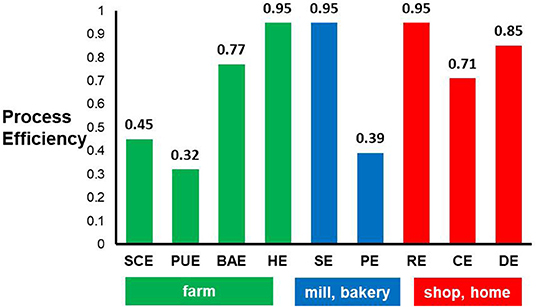

In this section we illustrate how our FCI approach can lead to an integrated view of the performance of a food supply chain. The wheat-bread agri-food system has been analyzed and the environmental impact determined for each of the process stages, from wheat growth on the farm through to production of a loaf of bread by the food manufacturer (Goucher et al., 2017). We have used the same system, extended to include bread consumption to illustrate the application of the above nine process conversion efficiencies (Figure 1). We stress that this case study is an illustrative one only. In the real world, as reported by Goucher et al. (2017), primary data with a high degree of granularity is needed, data from an identified supply chain—farmer to processor to retailer to consumer—in which specific inefficiency values can be measured and appropriate local remedies for improvement suggested.

Figure 1. Illustrative case study: estimated processes efficiencies during the production and consumption of bread in the UK. Processes on the farm, mill & bakery, and shop & home are defined and estimated as described in the text.

Sunlight Capture Efficiency (SCE). The important determinant for the wheat crop is the rate of development of leaf area, and also the senescence of leaves during grain maturation. It is estimated that ~47% of incoming sunlight is incident on leaves over the growing season (AHDB, 2015) with ~95% absorbed.

Photosynthesis Use Efficiency (PUE). Wheat is a C3 crop and hence significant losses occur through photorespiration and “canopy factors,” the difference between photosynthesis of individual leaves and the photosynthesis of the canopy (Mitchell and Sheehy, 2018).

Biomass Allocation Efficiency (BAE). A typical value for the allocation of photosynthate to roots relative to above ground growth is 0.85. Approximately 48% is an average value for the proportion found in the mature grain (Shearman et al., 2005) and this value is close to what might be considered the theoretical maximum value of 0.62 (Reynolds et al., 2009).

Harvesting Efficiency (HE). For UK wheat, there has been investment to maximize harvesting, through mechanization and other aspects of logistics such as field size and shape.

Storage and Distribution Efficiency (SE). Modern grain storage facilities in UK have refined control over environmental conditions (temperature and humidity) and great attention to biocontrol. Barring rare cases of infestation, losses are hence very low.

Processing Efficiency (PE). The quality of wheat grain determines its suitability for bread making, a function of the Hagberg Falling Number (indicator α-amylase activity), protein and water content. These vary considerably from year to year, dependent upon weather conditions. In the 2017 UK wheat harvest, as a result of adverse environmental conditions, only 53% of the group 1 and 2 harvest was of the high and medium bread making quality, with a mean value of 60% for the years 2015–2017 (NABIM, 2017). Losses through milling of whole grain are relatively low (3%) and loss during baking (10%) is also low in modern commercial establishments, and arise primarily from rejections based on flour quality (Goucher et al., 2017). In the UK over 80% of bread is baked with refined white flour, which results in further ~25% loss of wheat grain mass. A typical value for PE would therefore be about 0.39.

Retailing Efficiency (RE). RE was estimated (Cohen, 2016b) using 2016 supermarket self-reported food waste data (213,000 tons), and multiplied by an estimate of bread product waste (i.e., 41%) as a percentage of its total food waste stream (WRAP, 2015). Applied to the retail industry we estimate that 87,000 tons of supermarket food waste in 2016 were bread and bakery products out of a total 1,848,000 tons of bread purchased in 2015, ~4.5%.

Consumption Efficiency (CE). The “household food and drink waste: a product focus” report states that 460,000 tons of bread was thrown away from UK homes in 2012 [estimated to be ~29% of that purchased—see Gov.UK (2018)] most of which was avoidable and due to not being used in time, cooking or serving too much and accidents (Quested and Murphy, 2014).

Dietary Efficiency (DE). DE was estimated using the National Diet and Nutrition Survey (NDNS), which provides high quality data on dietary intake and nutritional status in a representative sample of the UK population. Twenty-three percent of the sampled population were found to have a bread consumption that was either partly or totally overconsumption (Public Health England Food Standards Agency, 2016). The average amount of bread partly or totally over-consumed per day was 17 g. Scaled up to the total UK population, this would mean that 96,000 tons of bread are partly or totally over-consumed in the UK every year out of an estimated total bread consumption of 1,126,000 tons.

The FCI in the wheat-bread supply chain is illustrated in Figure 1. Four processes stand out. The inefficiencies in wheat growth are almost entirely intrinsic features of wheat physiology and morphology. There is scope to improve PUE by manipulation of photosynthesis and to raise SCE by increasing the rate of canopy development and extending the period of light capture by delaying leaf senescence as grains fill. Wheat PE is also particularly low, mostly because of the stringent grain composition requirements for the bread making process, imposed in turn by the high demand for uniform, high quality white bread by the retailers and consumers. Inefficient consumption (CE), due to over-purchase and product deterioration is also the source of significant waste.

Conclusions

The comprehensive rationalization of the wastes and losses in the agri-food system into a series of process conversion efficiencies allows analysis to determine how best to bring about improvements. Different food supply chains in different countries will show different FCI, with different values for the efficiency of the nine process steps we describe. This points to the need for granularity in our food datasets. It is important to map each food chain, including the origins of primary food stuffs, such as grains, where and how processing occurs, how it is distributed and so on. As discussed previously, this requires an unprecedented level of co-operation of the actors across the food chain (Horton et al., 2016; Horton, 2017). But only with such data will it be possible to know on a case by case basis where the inefficiencies lie and therefore to direct attention to where there is maximum potential gain. All too often attention is focussed on making further gains on processes already highly efficient rather than focussing of the most inefficient steps.

Having a methodology that allows all of these issues to be analyzed and assessed together is a significant advance. Crop physiology and agricultural productivity can then be considered alongside the food businesses involved in processing and retailing, together with the issues of diet, nutrition and health. We can discuss all of these in terms of a baseline of agri-food efficiency and not become distracted by unnecessary fragmentation, which leads to bias in decision-making as to where to focus attention for intervention. Similarly, an integrated account also helps avoid the attribution of unwarranted blame on different food system actors, instead focussing on a more rational distribution of responsibilities (Evans, 2011). It also provides a mechanism to include assessment of the various trade-offs between different parts of system. For example, the drive to increase the efficiency of production at the farm level (defined in terms of product mass or number) may increase waste further down the chain, and contribute to over-consumption as well as under-nutrition (Horton, 2017).

It is to be emphasized that an analysis in terms of FCI alone is inadequate. The analysis should be extended in various ways to include: metrics of economic efficiency, a potentially vital trade-off in interventions to reduce food loss and waste; parallel analyses of the efficiency of use of various inputs such as water, fertilizers and packaging materials; and extent of environmental impact, such as greenhouse gas emission (Goucher et al., 2017). Thus, an intervention to reduce FCI may lead to greater environmental impact, for example by increased use of fertilizer and water on the farm, increased energy use from refrigeration and transport or increased pollution from plastic waste in packaging designed to increase product shelf-life and reduce damage. Furthermore, a highly efficient, high throughput food supply chain with consequent low levels of waste (i.e., implying lower excess capacity) may have reduced resilience in the face of global shocks and the effects of climate change (Horton, 2017).

Of course many challenges remain. It first needs to be demonstrated that these conversion parameters can be successfully applied across a range of food chains, many of which are much more complicated than in our illustrative example. We need to deliberate carefully on the impact of measures used to reduce inefficiency, such as recycling of waste and redistribution of surpluses, and how these affect estimates of conversions efficiencies. These wastes often have economic and social benefits (Galli et al., 2019), and hence the concept of “unavoidable waste” is useful—it is impossible and indeed not desirable (given the trade-offs discussed above), to have a 100% efficient food chain, and then the challenge is how best to deal with any waste that is produced. Thus, broader issues also need to be addressed: who is in charge of the reduction in FCI; who collects, collates and analyses the data; and who directs the interventions required. Various social, ethical and political issues arise: what incentives/penalties are needed to drive change; what is the role of national governments; and how is international co-operation developed.

Ultimately, providing sustainable food security to humankind, depends absolutely upon increasing the efficiency of the agri-food system, whilst at the same time making sure it is resilient and keeping resource use and environmental impact within sustainability limits. This can only be achieved if we first establish a uniform approach to analyse each step in the system, as begun here.

Author Contributions

PH conceived the idea, planned the paper, provided expertise on plant biology and agriculture, and wrote the first draft. CR contributed knowledge of food waste, food consumption, and nutrition. RB provided expertise on food business and the food supply chain. GM made contributions to the areas of agriculture, food waste and food retail business. All authors helped in manuscript preparation, and editing.

Funding

PH and RB acknowledge the generous support from the Grantham Foundation for the Protection of the Environment. CR was supported by the HEFCE Catalyst-funded N8 AgriFood Resilience Programme and matched funding from the University of Sheffield. CR has additional funding from NERC (NE/R007160/1) to support an Innovation Placement at the Waste & Resources Action Programme (WRAP).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

We thank Prof. Peter Jackson (Sheffield) for his help in preparation of the manuscript.

References

AHDB (2015). The Wheat Growth Guide (Third Edition). Available online at: https://cereals.ahdb.org.uk/media/185687/g66-wheat-growth-guide.pdf

Askew, K. (2018). ‘Its Going to Require Openness and Courage': Nestlé, Unilever, Arla, Salling Join Danish Push to Halve Food Waste. Available online at: https://www.foodnavigator.com/Article/2018/08/16/Danish-push-to-halve-food-waste.

BCG (2018). Tackling the 1.6-Billion-Ton Food Loss and Waste Crisis. Available online at: https://www.bcg.com/en-gb/publications/2018/tackling-1.6-billion-ton-food-loss-and-waste-crisis.aspx

Berger, S., Sinha, A. K., and Roitsch, T. (2007). Plant physiology meets phytopathology: plant primary metabolism and plant–pathogen interactions. J. Exp. Bot. 58, 4019–4026. doi: 10.1093/jxb/erm298

Chen, M., and Blankenship, R. E. (2011). Expanding the solar spectrum used by photosynthesis. Trends Plant Sci. 16, 427–431. doi: 10.1016/j.tplants.2011.03.011

Cohen, D. (2016a). Food for London: Supermarkets Donate 2% of Surplus to Southeast London Charity. Available online at: https://www.standard.co.uk/news/foodforlondon/food-for-london-supermarkets-donate-2-per-cent-of-surplus-to-southeast-london-charity-a3362991.html

Cohen, D. (2016b). Food for London: Revealed, the Full Scale of Supermarket Waste. Available online at: https://www.standard.co.uk/news/foodforlondon/revealed-the-full-scale-of-supermarket-waste-a3348381.html

DeFries, R., and Nagendra, H. (2017). Ecosystem management as a wicked problem. Science 356, 265–270. doi: 10.1126/science.aal1950

Dehghan, M., Mente, A., Zhang, X., Swaminathan, S., Li, W., Mohan, V., et al. (2017). Associations of fats and carbohydrate intake with cardiovascular disease and mortality in 18 countries from five continents (PURE): a prospective cohort study. Lancet 390, 2050–2062. doi: 10.1016/S0140-6736(17)32252-3

Deng, J., Ran, J., Wang, Z., Fan, Z., Wang, G., Ji, M., et al. (2012). Models and tests of optimal density and maximal yield for crop plants. Proc. Nat. Acad. Sci. U.S.A. 109, 15823–15828. doi: 10.1073/pnas.1210955109

Denison, R. E., Fedders, J. M., and Harter, B. L. (2010). Individual fitness versus whole-crop photosynthesis: solar tracking tradeoffs in alfalfa. Evol. Appl. 3, 466–472. doi: 10.1111/j.1752-4571.2010.00148.x

Dong, F., Heinemann, W., and Kasper, R. (2011). Development of a row guidance system for an autonomous robot for white asparagus harvesting. Comp. Elect. Agri. 79, 216–225. doi: 10.1016/j.compag.2011.10.002

Driever, S. M., Simkin, A. J., Alotaibi, S., Fisk, S. J., Madgwick, P. J., Sparks, C. A., et al. (2017). Increased SBPase activity improves photosynthesis and grain yield in wheat grown in glasshouse conditions. Phil. Trans. R. Soc. B. 372:20160384. doi: 10.1098/rstb.2016.0384

Duncan, W. G. (1971). Leaf angles, leaf area, and canopy photosynthesis. Crop Sci. 11, 482–485. doi: 10.2135/cropsci1971.0011183X001100040006x

Eriksson, M., Strid, I., and Hansson, P. A. (2016). Food waste reduction in supermarkets–Net costs and benefits of reduced storage temperature. Resour. Conserv. Recycl. 107, 73–81. doi: 10.1016/j.resconrec.2015.11.022

Evans, D. (2011). Blaming the consumer – once again: the social and material contexts of everyday food waste practices in some English households. J. Crit. Public Health 21, 429–440. doi: 10.1080/09581596.2011.608797

Frost, D. L., Gurney, A. L., Press, M. C., and Scholes, J. D. (1997). Striga hermonthica reduces photosynthesis in sorghum: the importance of stomatal limitations and a potential role for ABA. Plant Cell Environ. 20, 483–492. doi: 10.1046/j.1365-3040.1997.d01-87.x

Galli, F., Cavicchi, A., and Brunori, G. (2019). Food waste reduction and food poverty alleviation: a system dynamics conceptual model. Agric. Hum. Values 36, 289–300. doi: 10.1007/s10460-019-09919-0

Godfray, H. C., Beddington, J. R., Crute, I. R., Haddad, L., Lawrence, D., Muir, J. F., et al. (2010). Food security: the challenge of feeding 9 billion people. Science 327, 812–818. doi: 10.1126/science.1185383

Gore-Langton, L. (2017). France's Food Waste Ban: One Year On. Available online at: https://www.foodnavigator.com/Article/2017/03/24/France-s-food-waste-ban-One-year-on.

Goucher, L., Bruce, R., Cameron, D., Koh, S. C. L., and Horton, P. (2017). Environmental impact of fertiliser embodied in a wheat-to-bread supply chain. Nature Plants 3:17012. doi: 10.1038/nplants.2017.12

Gov.UK (2018). Family Food Statistics. Annual Statistics About Food and Drink Purchase in the UK. Available online at: https://www.gov.uk/government/collections/family-food-statistics

Guilpart, N., Grassini, P., Sadras, V. O., Timsina, J., and Cassman, K. G. (2017). Estimating yield gaps at the cropping system level. Field Crops Res. 206, 21–32. doi: 10.1016/j.fcr.2017.02.008

Gustavsson, J., Cederberg, C., Sonesson, U., Van Otterdijk, R., and Meybeck, A. (2011). Global Food Losses and Food Waste (Rome: FAO), 1–38.

Hall, K. D., Guo, J., Dore, M., and Chow, C. C. (2009). The progressive impact of food waste in America and its environmental impact. PLoS ONE 4:e7940. doi: 10.1371/journal.pone.0007940

Hall, K. D., Sacks, G., Chandramohan, D., Chow, C. C., Gortmaker, S. L., and Swinburn, B. A. (2011). Quantification of the effect of energy imbalance on bodyweight. Lancet 378, 826–837. doi: 10.1016/S0140-6736(11)60812-X

Hanson, C., and Mitchell, P. (2017). The Business Case for Reducing Food Loss and Waste. Available online at: https://champions123.org/wp-content/uploads/2017/03/report_-business-case-for-reducing-food-loss-and-waste.pdf

Hodges, R. J., Buzby, J. C., and Bennett, B. (2011). Postharvest losses and waste in developed and less developed countries: opportunities to improve resource use. J. Agri. Sci. 149, 37–45. doi: 10.1017/S0021859610000936

Horton, P. (2017). We need radical change in how we produce and consume food. Food Security 9, 1323–1327. doi: 10.1007/s12571-017-0740-9

Horton, P., Banwart, S. A, Brockington, D., Brown, G.W., Bruce, R., Cameron, D., et al. (2017). An agenda for integrated system-wide interdisciplinary agri-food research. Food Security 9, 195–210. doi: 10.1007/s12571-017-0648-4

Horton, P., and Brown, G. W. (2018). Integrating evidence, politics and society: a methodology for the science–policy interface. Palgrave Commun. 4:42. doi: 10.1057/s41599-018-0099-3

Horton, P., Koh, S. C. L., and Shi Guang, V. (2016). An integrated theoretical framework to enhance resource efficiency, sustainability and human health in agri-food systems. J. Clean. Prod. 120, 164–169. doi: 10.1016/j.jclepro.2015.08.092

Horton, P., and Murchie, E. H. (2000). “C4 photosynthesis in rice: some lessons from studies of C3 photosynthesis in field grown rice,” in Redesigning Rice Photosynthesis to Increase Yield, eds J. E. Sheehy, P. L. Mitchell, and B. Hardy (Los Banos; Amsterdam: International Rice Research Institute; Elsevier Science BV), 127–146.

House, J. (2016). Consumer acceptance of insect-based foods in the Netherlands: academic and commercial implications. Appetite 107, 47–58. doi: 10.1016/j.appet.2016.07.023

Institution of Mechanical Engineers (2013). Global Food Waste Not, Want Not. Available online at: https://www.imeche.org/docs/default-source/default-document-library/global-food---waste-not-want-not.pdf?sfvrsn=0

Kader, A. A. (2004). Increasing food availability by reducing postharvest losses of fresh produce. Int. Postharvest Symp. 682, 2169–2176. doi: 10.17660/ActaHortic.2005.682.296

Kau, A. L., Ahern, P. P., Griffin, N. W., Goodman, A. L., and Gordon, J. I. (2011). Human nutrition, the gut microbiome and the immune system. Nature 474, 327–336. doi: 10.1038/nature10213

Kim, H. M., and Laskowski, M. (2018). Toward an ontology-driven blockchain design for supply-chain provenance. Intelligent Systems in Accounting, Finance and Management 25, 18–27. doi: 10.1002/isaf.1424

Kromdijk, J., Głowacka, K., Leonelli, L., Gabilly, S. T., Iwai, M., Niyogi, K. K., et al. (2016). Improving photosynthesis and crop productivity by accelerating recovery from photoprotection. Science 354, 857–861. doi: 10.1126/science.aai8878

Martinez Ramos, M. (2004). Interaction between management accounting and supply chain management. Supply Chain Manage. 9, 134–138. doi: 10.1108/13598540410527033

Martinez-Ferez, A., Guadix, A., and Guadix, E. M. (2006). Recovery of caprine milk oligosaccharides with ceramic membranes. J. Memb. Sci. 276, 23–30. doi: 10.1016/j.memsci.2005.09.027

McGuire, P., Rich, B., Inderbitzin, M., and Kent, G. (2011). The effect of whole crop harvesting on crop yield. Proc. Aust. Soc. Sugar Cane Technol. 33, 1–12.

McMichael, A. J., Powles, J. W., Butler, C. D., and Uauy, R. (2007). Food, livestock production, energy, climate change, and health. Lancet 370, 1253–1263. doi: 10.1016/S0140-6736(07)61256-2

Melikoglu, M., and Webb, C. (2013). “Use of waste bread to produce fermentation products,” in Food Industry Wastes: Assessment and Recuperation of Commodities, eds M. Kosseva and C. Webb (San Diego, CA: Elsevier Academic Press, 63–76.

Mitchell, P., Sheehy, J. E., and Woodward, F. (1998). Potential yields and the efficiency of radiation use in rice. IRRI Discussion Paper Series No. 32 (Manila: International Rice Research Institute).

Mitchell, P. L., and Sheehy, J. E. (2018). Potential yield of wheat in the United Kingdom: how to reach 20 t ha−1. Field Crops Res. 224, 115–125. doi: 10.1016/j.fcr.2018.05.008

Monteiro, C. A., Moubarac, J. C., Levy, R. B., Canella, D. S., Louzada, M. L. C., and Cannon, G. (2018). Household availability of ultra-processed foods and obesity in nineteen European countries. Public Health Nutr. 21, 18–26. doi: 10.1017/S1368980017001379

Monteith, J. L. (1977). Climate and the efficiency of crop production in Britain. Phil. Trans. R. Soc. B 281, 277–294. doi: 10.1098/rstb.1977.0140

Murali, P., and Balakrishnan, R. (2012). Labour scarcity and selective mechanisation of sugarcane agriculture in Tamil Nadu, India. Sugar Tech. 14, 223–228. doi: 10.1007/s12355-012-0153-1

Murchie, E. H., Chen, Y-Z., Hubbart, S., Peng, S., and Horton, P. (1999). Interactions between senescence and leaf orientation determine in situ patterns of photosynthesis and photoinhibition in field grown rice. Plant Physiol. 119, 553–564. doi: 10.1104/pp.119.2.553

Murchie, E. H., Pinto, M., and Horton, P. (2009). Agriculture and the new challenges for photosynthesis research. New Phytol. 181, 532–552. doi: 10.1111/j.1469-8137.2008.02705.x

NABIM (2017). UK Wheat Harvest Briefing. Available online at: http://www.nabim.org.uk/download/document/64b46c4b114799ffb762b6fb5c0e8b47

Ort, D. R., Zhu, X-G., and Melis, A. (2011). Optimizing antenna size to maximize photosynthetic efficiency. Plant Physiol. 155, 79–85. doi: 10.1104/pp.110.165886

Parfitt, J., Barthel, M., and Macnaughton, S. (2010). Food waste within food supply chains: quantification and potential for change to 2050. Phil. Trans. R. Soc. B 365, 3065–3081. doi: 10.1098/rstb.2010.0126

Public Health England Food Standards Agency (2016). National Diet and Nutrition Survey: Results From Years 5 and 6 (Combined) of the Rolling Programme (2012/2013 – 2013/2014). Available online at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/551352/NDNS_Y5_6_UK_Main_Text.pdf

Quested, T., and Murphy, L. (2014). Household Food and Drink Waste: A Product Focus. Available online at: http://www.wrap.org.uk/content/household-food-drink-waste-%E2%80%93-product-focus

Restorick, T. (2018). Getting Food Savvy in East Anglia. Available online at: https://www.hubbub.org.uk/blog/food-savvy-campaign

Reynolds, C., Goucher, L., Quested, T., Bromley, S., Gillick, S., Wells, V. K, et al. (2019). Consumption-stage food waste reduction interventions–what works and how to design better interventions. Food Policy 83, 7–27. doi: 10.1016/j.foodpol.2019.01.009

Reynolds, M., Foulkes, M. J., Slafer, G. A., Berry, P., Parry, M. A., Snape, J. W., et al. (2009). Raising yield potential in wheat. J. Exp. Bot. 60, 1899–1918. doi: 10.1093/jxb/erp016

Rockström, J., and Sukhdev, P. (2016). How Food Connects All the SDGs. Available online at: https://www.stockholmresilience.org/research/research-news/2016-06-14-how-food-connects-all-the-sdgs.html

Shearman, V.J, Sylvester-Bradley, R., Scott, R. K., and Foulkes, M. J. (2005). Crop physiology and metabolism. Physiological processes associated with wheat yield progress in the UK. Crop Sci. 45, 175–185.

Smithers, R. (2018). Tesco to Axe 'Confusing' Best Before Dates on Its Fruit and Vegetables. Available online at: https://www.theguardian.com/business/2018/may/21/tesco-best-before-dates-fruit-avegetables-food-waste

Stubbs, R. J., O'Reilly, L. M., Whybrow, S., Fuller, Z., Johnstone, A. M., Livingstone, M. B., et al. (2014). Measuring the difference between actual and reported food intakes in the context of energy balance under laboratory conditions. Br. J. Nutr. 111, 2032–2043. doi: 10.1017/S0007114514000154

Tilman, D., and Clark, M. (2014). Global diets link environmental sustainability and human health. Nature 515, 518–522. doi: 10.1038/nature13959

Tilman, D., Clark, M., Williams, D. R., Kimmel, K., Polasky, S., and Packer, C. (2017). Future threats to biodiversity and pathways to their prevention. Nature 546, 73–81. doi: 10.1038/nature22900

Topolansky Barbe, F., Von Dewitz, P., and Gonzalez Triay, M. (2017). Understanding consumer behaviour to develop competitive advantage: a case study exploring the attitudes of German consumers towards fruits with cosmetic flaws. Int. J. Acad. Res. Busin. Soc. Sci. 7, 554–580. doi: 10.6007/IJARBSS/v7-i6/3013

Tubiello, F. N., Salvatore, M., Ferrara, A. F., House, J., Federici, S., Rossi, S., et al. (2015). The contribution of agriculture, forestry and other land use activities to global warming, 1990-2012. Global Change Biol. 21, 2655–2660. doi: 10.1111/gcb.12865

UNEP (2015). Sustainable Consumption and Production Indicators for the Future SDGs. Available online at: https://www.unenvironment.org/resources/report/sustainable-consumption-and-production-indicators-future-sdgs-unep-discussion

Unkovich, M. J., Baldock, J. A., and Forbes, M. (2010). Variability in Harvest Index of grain crops and potential significance for carbon accounting. Adv. Agronomy 105, 173–219. doi: 10.1016/S0065-2113(10)05005-4

Van der Meulen, S., Boin, G., Bousoula, I., Conte-Salinas, N., Paganizza, V., Montanari, F., et al. (2015). Fighting food fraud: horsemeat scandal; use of recalls in enforcement throughout the EU. Eur. Food Feed Law Rev. 10, 2–13.

Van Zant, R. S. (1992). Influence of diet and exercise on energy expenditure—a review. Int. J Sport Nut. 2, 1–19. doi: 10.1123/ijsn.2.1.1

Vandevijvere, S., Chow, C. C., Hall, K. D., Umali, E., and Swinburn, B. A. (2015). Increased food energy supply as a major driver of the obesity epidemic: a global analysis. Bull. World Health Organ. 93, 446–456. doi: 10.2471/BLT.14.150565

Weinbren, E. (2017). Sainsbury's Falls Short of Swadlincote Food Waste Reduction Target. Available online at: https://www.thegrocer.co.uk/home/topics/waste-not-want-not/sainsburys-falls-short-of-swadlincote-food-waste-reduction-target/553150.article

Wilson, N. (1996). Supply chain management: a case study of a dedicated supply chain for bananas in the UK grocery market. Supply Chain Manage. 1, 28–35. doi: 10.1108/13598549610155279

Wood, Z. (2018). KFC Returns to Original Supplier After Chicken Shortage Fiasco. Available online at: https://www.theguardian.com/business/2018/mar/08/kfc-returns-to-original-supplier-after-chicken-shortage-fiasco

WRAP (2015). Reducing Food Waste by Extending Product Life. Available online at: http://www.wrap.org.uk/sites/files/wrap/Product%20Life%20Report%20Final_0.pdf

WRAP (2017). Food Date Labelling and Storage Advice. Available online at: http://www.wrap.org.uk/food-date-labelling?utm_source=PR&utm_medium=media-wrap&utm_campaign=date-labelling

WRAP (2018a). UK Food Redistribution on the Increase. Available online at: http://www.wrap.org.uk/content/uk-food-redistribution-increase.

WRAP (2018b). The Food Waste Reduction Roadmap. Available online at: http://www.wrap.org.uk/sites/files/wrap/food-waste-reduction-roadmap-toolkit_0.pdf

Keywords: food supply chain, food security, food loss and waste, food consumption, agrifood systems, agriculture

Citation: Horton P, Bruce R, Reynolds C and Milligan G (2019) Food Chain Inefficiency (FCI): Accounting Conversion Efficiencies Across Entire Food Supply Chains to Re-define Food Loss and Waste. Front. Sustain. Food Syst. 3:79. doi: 10.3389/fsufs.2019.00079

Received: 28 March 2019; Accepted: 06 September 2019;

Published: 20 September 2019.

Edited by:

Kathleen L. Hefferon, Cornell University, United StatesReviewed by:

Boyd Swinburn, The University of Auckland, New ZealandFrancesca Galli, University of Pisa, Italy

Copyright © 2019 Horton, Bruce, Reynolds and Milligan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Peter Horton, cC5ob3J0b25Ac2hlZmZpZWxkLmFjLnVr

Peter Horton

Peter Horton Richard Bruce

Richard Bruce Christian Reynolds

Christian Reynolds Gavin Milligan

Gavin Milligan