- The Pennsylvania State University (PSU), University Park, PA, United States

Given that over 95% of buildings are residential, there is an urgent need for carbon-storing materials and easy-to-construct methods to achieve energy-efficient and low-carbon homes, which can significantly impact CO2 reduction. Industrial hemp, used to produce hempcrete, is a promising construction material. Hempcrete, composed of hemp hurd and fibers mixed with lime and water, is currently used for thermal insulation and lightweight building blocks, intended for use in constructing non-load-bearing walls. With growing interest in hempcrete for home construction and a lack of comprehensive data on its performance, a case study assessed the thermal resistance of walls in a home retrofitted with hempcrete insulation in wood-framed walls. This paper focuses on practical in-situ instrumentation and determination of the thermal resistance of hempcrete walls in a retrofitted house. It also provides some basic background information on hemp and hempcrete. It discusses the practical application of the Heat Flow Meter Method for in-situ measurement of the thermal properties of hempcrete walls. The paper concludes with the developed thermal resistance of retrofitted hempcrete walls based on in-situ testing.

1 Introduction

Due to the extensive use of masonry, concrete, and steel in global building construction, buildings significantly contribute to energy consumption and CO2 emissions. The production of building materials is responsible for 10% of annual global CO2 generation, while the operation of buildings (heating, cooling, electricity, etc.) accounts for 27% of CO2 generation (Architecture 2030, 2022). This material production has contributed to about 1% annual increase in CO2 emission since 2010 due to increasing demand for buildings (Global Alliance for Buildings and Construction (GABC), 2019). Therefore, the need for new low-carbon or carbon-capturing construction materials and methods is not just a preference but a necessity for change.

With limited options available to replace traditional load-bearing structural systems like steel, concrete, masonry, and timber, the potential impact of this research is significant. Given that residential buildings constitute almost 95% of buildings, more specifically, 90% single-family and 4.5% multi-family (Potter, 2020), this research could inspire the development of new sustainable carbon-storing materials and easy-to-construct methods for home building, leading to a meaningful CO2 reduction on global scale.

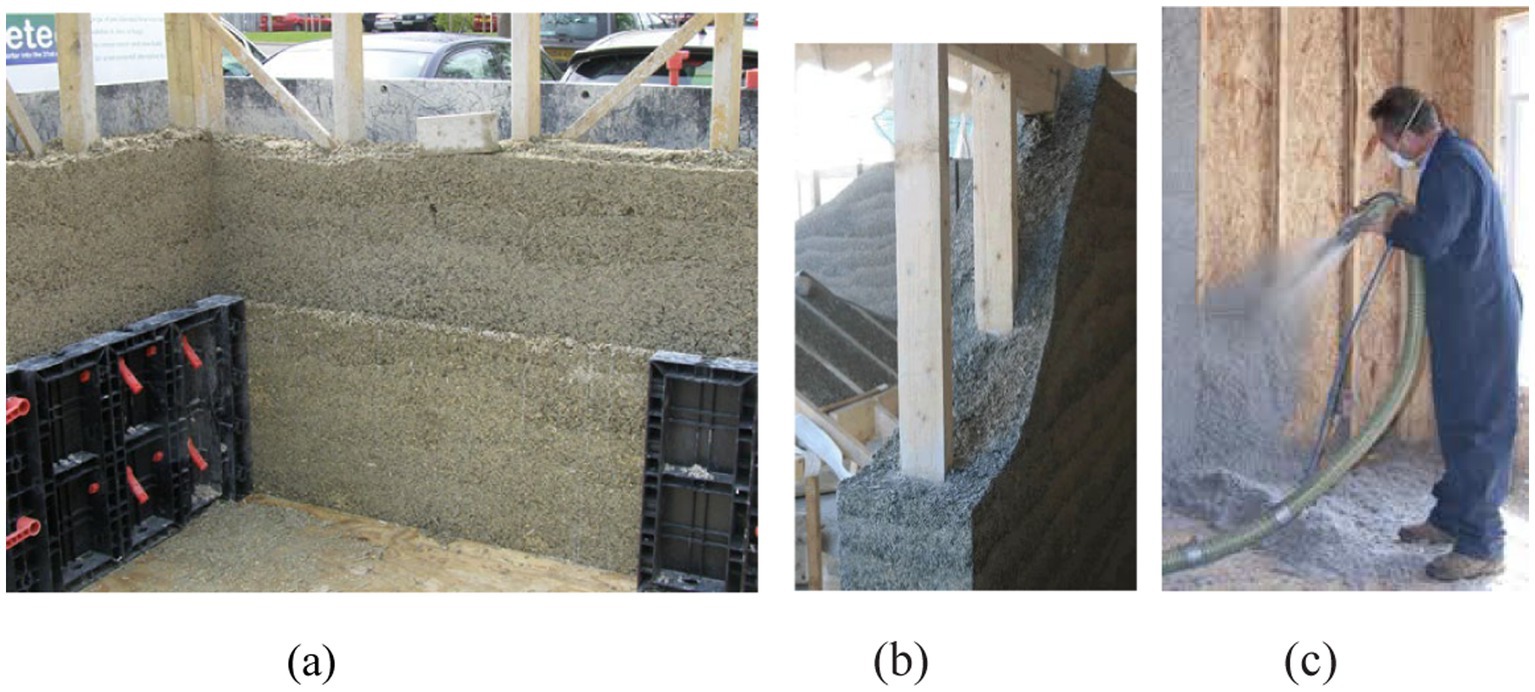

A mixture of hemp fiber, hemp hurd, lime, and water, hempcrete has been shown to have potential in residential construction applications to improve the thermal insulation properties of walls, reduce the consumption of carbon-intensive concrete, and reduce the weight of cement-based structures (Zuabi and Memari, 2021; Yi et al., 2020, 2022; Asghari and Memari, 2024). For wood-frame home building, hempcrete can be cast (Figures 1A,B), sprayed (Figure 1C), or used as prefabricated blocks (Figure 2). Given the recent reinstatement of industrial hemp cultivation in the US, hempcrete and similar construction materials now have the opportunity to be developed into market-ready products, considering the necessary supply chains, processes, and manufacturing facilities.

Figure 1. (A) and (B) Hempcrete cast wall with confining studs (Left, Courtesy of American Lime Technology, http://www.americanlimetechnology.com/tradical-hemcrete/; Right, Flahiff 2009, https://inhabitat.com/hemcrete-carbon-negative-hemp-walls-7x-stronger-than-concrete/); (C) Hempcrete spraying between studs (http://rjinsulation.com/nu-wool-premium-cellulose-insulation/).

Figure 2. Typical example of precast Hempcrete Block Building Construction (Left, Courtesy of Wikipedia, https://en.wikipedia.org/wiki/Hempcrete; Right, https://www.isohemp.com/en/hemp-blocks-buildings-hempro-system).

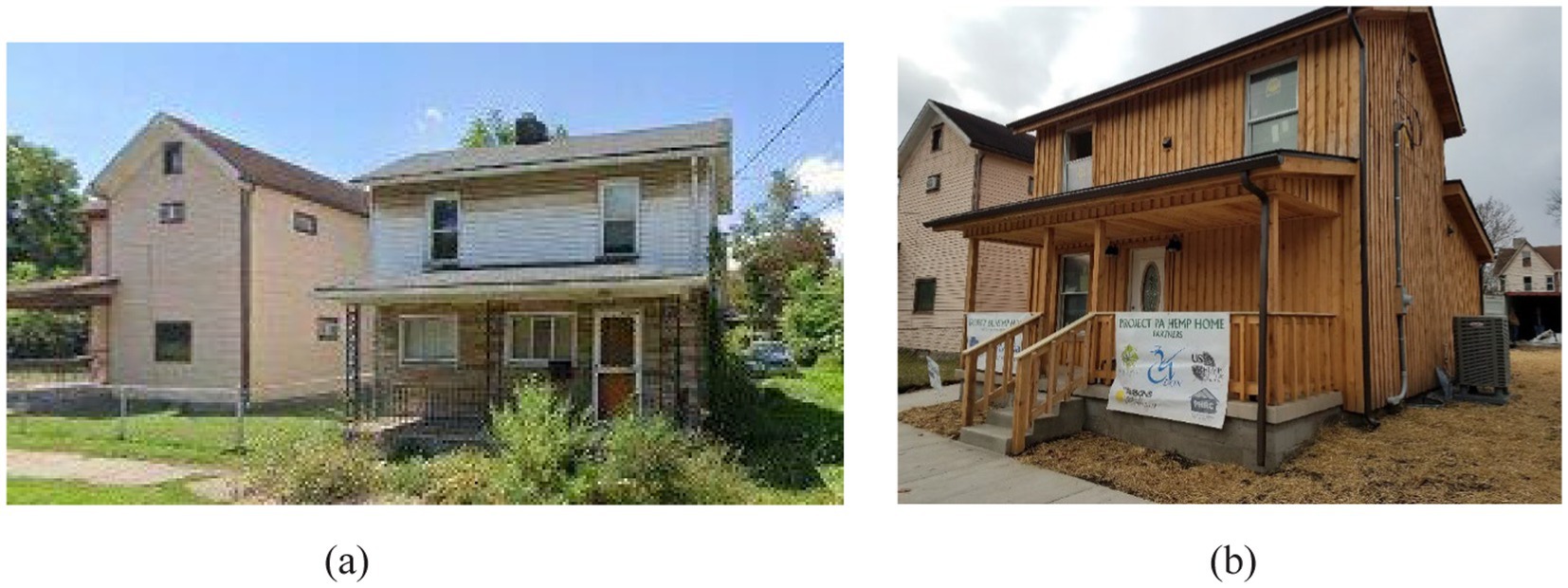

Pennsylvania is one of the leading states that can produce industrial hemp as an alternative building material. This paper reports the efforts of the Penn State research team in studying a renovated house in New Castle, PA. DON Enterprises, Inc.1 acquired the blighted property with assistance from another project team at Parsons School of Design. DON Enterprises Inc. developed the renovation design for the New Castle revitalization program. Figures 3A,B depict the house before and after the retrofit, respectively. Figure 4A showcases the hempcrete material used in the project, highlighting the hemp fiber and hurd, along with a cast block of hempcrete.

Figure 3. (A) House located at 506 Spruce Street, New Castle, PA before retrofit (https://www.zillow.com/homedetails/506-Spruce-St-New-Castle-PA-16101/86510118_zpid/); (B) House after retrofit.

Figure 4. (A) Examples of the materials used for retrofit: hemp hurd (left), fiber (center), and hempcrete block (right); (B) pictures of the hemp plant (left), hemp fiber (center), and vertical section of hemp stock. (Photos courtesy of Forest Concepts LLC.).

2 Objectives

The main objective of this paper is to document the measurement of hempcrete’s thermal insulative properties within the scope of a residential renovation. Accordingly, the study used the experimental Heat Flow Meter method (Lu and Memari, 2019, 2022) to determine the in-situ thermal resistance of the retrofitted walls of the subject house. More specifically, the thermal properties of hempcrete in the New Castle PA Hemp House walls were assessed using wall-mounted instruments to collect data, followed by the heat flow meter method to determine the in situ R-value. It should be noted that while other properties of hempcrete are also of great significance, and have been reported elsewhere (e.g., Zuabi and Memari, 2021; Asghari and Memari, 2024), the scope of the paper presented here is mainly on thermal resistance.

3 Literature review on hempcrete

Hemp is an industrial, non-load-bearing variant of cannabis primarily cultivated for its fiber, hurd, and seeds (Figure 4B). Due to a long-standing ban on growing and researching industrial hemp, it has not been considered a viable renewable resource for U.S. building products. However, these bans have recently been lifted due to the growing need and interest in renewable resources. In the United States, Senate Bill S.2667 by the 115th Congress makes hemp producers eligible for the Federal Crop Insurance Program and certain USDA research grants.2 Consequently, there is a significant need for research and development on its processing and utilization to support increased cultivation. However, according to Popescu (2018), out of 30 countries that now grow industrial hemp, only about 10,000 acres in the U.S. grow this crop, half of the acreage in Canada. Conversely, following the passage of the 2018 Farm Bill, it was anticipated that U.S. hemp acreage would expand significantly, which it did, tripling within a year. However, this rapid growth led to some disappointment due to oversupply (the demand lagged behind supply), price drops, and ineffective regulations (Zhang and Demko, 2020). The industry soon recognized the need for production to match demand and the importance of identifying uses for industrial hemp to broaden markets. One effective application of industrial hemp is in construction, and this study showcases the practical use of hemp fiber and hurd in homebuilding.

From an agricultural crop perspective, hemp’s yield is reported to be quite high (2.5–8.7 tons of dry straw per acre), which makes it hard for any other crop to provide this volume of biomass (Green Home Gnome (GHG), 2017). Also, the fast growth rate (about 4 months) makes hemp a highly profitable crop, especially with the potential for a reduced need for fertilizer and pesticides (Popescu, 2018).

As far as carbon sequestering is concerned, according to GreenSpec (2019), hempcrete sequesters 110 kg of CO2 per 1 m3 of hempcrete, considering the carbon emission due to producing the lime binder. According to another report (Green Home Gnome (GHG), 2017), on average, a 2,000 ft2 home would sequester about 5 tons of CO2 if built using hempcrete. This is substantially less than the emission of 1 ton of CO2 in the production of batt insulation for the same home.

Although builders and industry have suggested some hempcrete mixture proportions, research into basic material mixture design is necessary to fully understand various designs and select the most suitable one for the intended system. Generally, hempcrete is made by mixing hemp hurds, lime, sand, plaster, cement, additives, and water (Priesnitz, 2006). The proportions of each ingredient should be adjusted until the optimal properties for precast block and cast-in-place options are achieved. Currently, there is no standard mixture design. Different manufacturers have their mixture designs. For instance, the mixture design by Chanvra Core hurd, marketed as KanaBat and distributed in the U.S. by Americhanvre Cast Hemp (Figure 5A), involves mixing the hurds as aggregate with a lime binder, specifically LCG mortar (Figure 5B).

Figure 5. (A) Hemp hurd (Hemp: https://chanvra.org/pages/hemp-construction-materials-hempcrete; A bulk sample of Kanabat Building Grade Hemp Hurd that can be used as an alternative aggregate of hempcrete); (B) Lime used for making hempcrete (Lime: https://www.lcgfrance.com/mortiers-et-enduits-isolants/; https://chanvra.org/pages/hemp-construction-materials-hempcrete).

3.1 Hemp and hemp hurd

The fibers on the exterior surface of hemp stalks are believed to have a tensile strength comparable to steel, making them the most valuable part of the stalk. The woody core, or hurd, can be chopped into shiv and used as a construction aggregate material, creating a wall system with excellent thermal insulation and thermal mass properties.

Hemp can grow up to 4.5 m tall and 25 mm in diameter while it absorbs a substantial amount of CO2, approximately 716 lbs. (325 kg) of CO2 per tonne (1,000 kg) of dried hemp (Green Home Gnome (GHG), 2017). Hempcrete’s greenhouse gas storage capabilities are remarkable, with 1 m3 of hempcrete able to store 110–180 kg of CO2. Constructing a 300 mm thick hempcrete wall can result in a net negative 40 kg of CO2 per square meter of the wall, considering the emissions from hydrated lime production and its re-absorption over time.

From a life-cycle perspective, hemp hurd is essentially a by-product of hemp fiber production, as the valuable fibers are stripped from the hemp stalk, leaving the hurd without any added value. However, using hemp hurd in hempcrete for thermal insulation offers a significant advantage over conventional construction materials. Additional benefits include its renewability, carbon storage capability, and availability as a by-product from the waste stream.

In addition to its insulative properties, hemp hurd has a significant capacity to absorb moisture on the internal surfaces of the plant fibers and within the voids of its cellular structure. This characteristic is highly desirable for construction materials, as it allows the hurd to store vapor driven by interior-exterior vapor pressure differences and release it when conditions change. This vapor storage capacity is particularly important in high-humidity areas, as it helps maintain wall performance and durability without adverse effects.

3.2 Lime

Natural hydraulic lime can be considered an alternative to Portland cement, particularly when longer curing times are acceptable and reducing CO2 emissions is a primary goal. An example of lime being used to make concrete is when it is used as a binder with lightweight aggregates, which results in “breathable” concrete, i.e., allowing vapor to pass through (Abbott, 2014; Pullen, 2017). However, increasing the lime content enhances strength but decreases breathability, which is a consideration for slab-on-grade floors.

Hydrated lime (calcium carbonate) is the binder that holds hurd (shiv) aggregates together in modern hempcrete. Over time, the carbonation process continues: as water evaporates from the lime mixture, CO2 from the air is absorbed, solidifying the lime and gradually turning it back into calcium carbonate. This process depends on air humidity, absorbed by the hemp hurd and utilized by the lime to sustain carbonation. Commercial limes, such as the LCG mortar used in this project, include natural volcanic mineral additives to reduce the initial setting and curing time.

3.3 Making hempcrete

Bio-fiber hemp hurd is used as an aggregate, replacing gravel to create hempcrete. Hydrated lime is a mineral binder that adheres the mulch-like hemp hurd pieces together. Figures 6, 7 illustrate the mixing process of hemp hurd, lime, and water. Similar to how limecrete uses lime as a binder with lightweight aggregates to form lightweight concrete, hempcrete uses lime as the binder and hemp hurd (shiv) as the aggregate, with the lime coating the hemp shiv. During mixing, the reaction between lime and water creates a binding property that holds the hurd particles together. Additionally, lime can include additives to control setting time, durability, and strength.

Figure 6. Mixing hemp hurd, lime, and water to make hempcrete for cast-in-place demonstration by Americhanvre Inc.

Curing of the lime takes longer than Portland cement, but unlike Portland cement, it absorbs CO2 as it sets and dries. A volumetric mixer can measure the proportions of lime, aggregate, and water to make concrete using lime, and then an auger is used to mix the ingredients and prepare the concrete (Abbott, 2014). Regarding CO2 generation and absorption, it is important to note that CO2 is produced and released during the creation of hydraulic lime. While CO2 is emitted during the calcination of limestone to produce quick lime, once water is added to create hydrated lime, it reabsorbs 20–75% of the original CO2 from the atmosphere as the concrete cures, a process known as the “lime cycle.”

Taking these factors into account, hempcrete is net carbon negative. For example, constructing a 300 mm thick hempcrete wall can result in a net reduction of 40 kg of CO2 per m2 of the wall, considering the CO2 absorbed during hemp growth, emissions from hydrated lime production, and the reabsorption of CO2 by lime over time. In contrast, a masonry wall emits 100 kg of CO2 per m2 of wall (Lime Technology, 2024).

3.4 Hempcrete properties

One difference between hempcrete and conventional concrete is that the voids between shiv aggregates are not necessarily filled with a lime binder, thus providing enhanced thermal insulation properties (Green Home Gnome (GHG), 2017). In addition, because of hempcrete’s porous structure, the breathability property of concrete made with lime is consistent with timber construction (Abbott, 2014). Therefore, hempcrete walls allow vapor to pass through and limit the moisture accumulation that can cause many issues in walls, including mold growth.

Usually, the presence of stored moisture in construction material is detrimental to its durability. In the case of hempcrete, lime with high pH coats each hemp hurd aggregate and enhances its antimicrobial and antifungal properties. As a result, lime protects the hemp hurd from mold development under humidity and temperature conditions that can adversely affect other insulation materials. Therefore, its high thermal insulation properties and high moisture storage capacity make it suitable for home construction in cold and hot climates (Green Home Gnome (GHG), 2017). For this study, the material properties of hemp and lime, i.e., density, strength, and moisture content, were determined using the information from the product manufacturers.

4 Methodology

The Heat Flow Meter Method (HFM) (Lu and Memari, 2019, 2022) is a standardized method for in-situ measurement of building envelope assemblies. It incorporates on-site installation of temperature sensors and heat flux transducers (heat flux sensors) on existing building walls whose thickness is much smaller than the other dimensions. Therefore, the lateral in-plane heat flow can be ignored. The most commonly used calculation method for HFM is the same as that shown in Equation 1, which is generally referred to as the “Average Model,” as stated in Atsonios et al. (2017) and Deconinck and Roels (2016). However, environmental conditions can vary significantly and never reach a quasi-steady-state for in-situ measurement. Therefore, the Anderlind’s Multiple Regression Model (Equation 2) was used for in-situ measurement.

4.1 Instruments for thermal resistance measurement study

Instruments that were employed in the hemp house thermal resistance study are as follows:

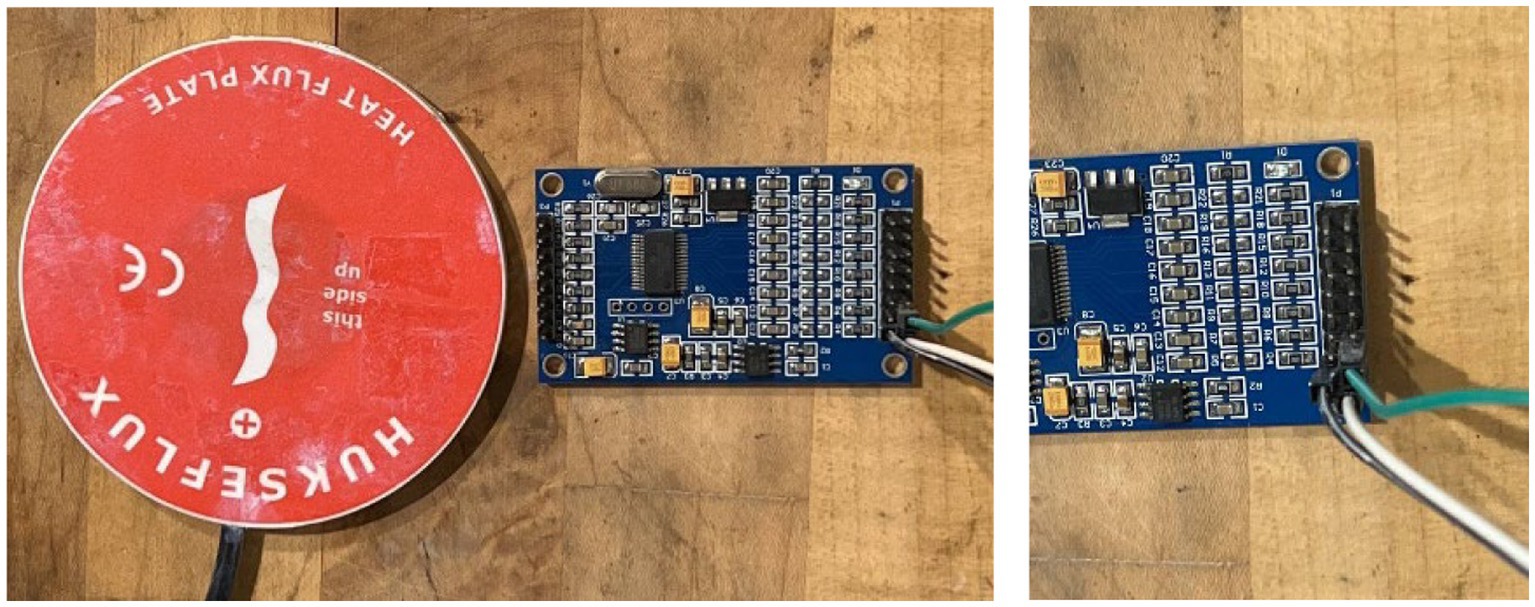

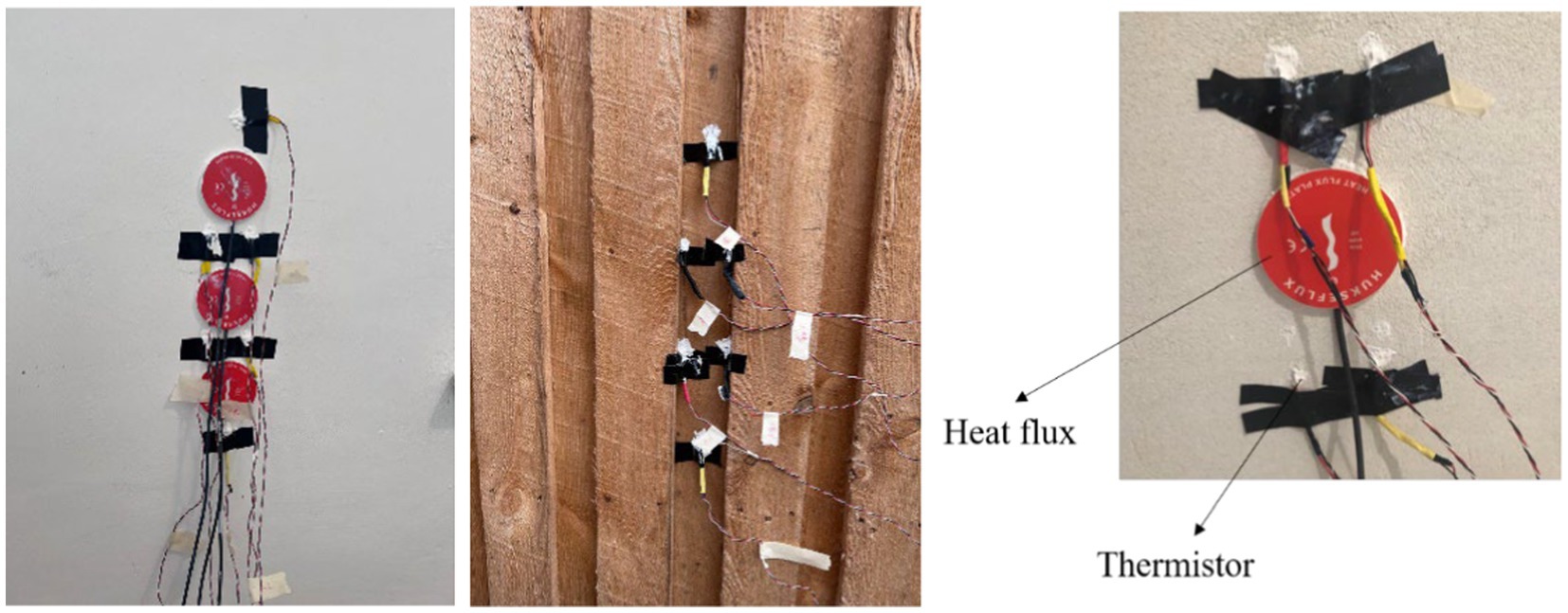

A. Six heat flux sensors (HFP01) (Figure 8): Heat-flow density, or heat flow rate intensity, measure the energy flow per unit area per unit of time. The HFP01 is a widely used heat flux sensor suitable for measuring heat flow through soil, walls, and building envelopes. It features a ceramics-plastic composite body, which results in low total thermal resistance, making it a robust and stable sensor. It is designed for easy, long-term use and can be deployed in multiple locations. The uncertainty of model HFP01 is approximately ±3% (Hukseflux, 2022).

B. 24 MF52-103/3435, 10 k Ohm thermistors (Figure 9): Negative Temperature Coefficient (NTC) thermistors are compact and lightweight temperature measurement devices encased in ethoxyline resin, with a resistance of 10 K Ohm. They are versatile and suitable for various applications. The resistance of NTC thermistors decreases as the temperature rises. These thermistors are widely used for air-conditioning equipment, heating apparatus, and electric thermometers (Amazon, 2022).

C. Three Arduino Mega 2560 boards (Figure 10): The Arduino Mega 2560 is a microcontroller board featuring 54 digital input/output pins, 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button. It can be easily connected to a computer via a USB cable, an AC-to-DC adapter, or a battery. Most shields designed for Uno, Duemilanove, and Diecimila are compatible with the Mega 2560 board (Arduino Mega, 2022).

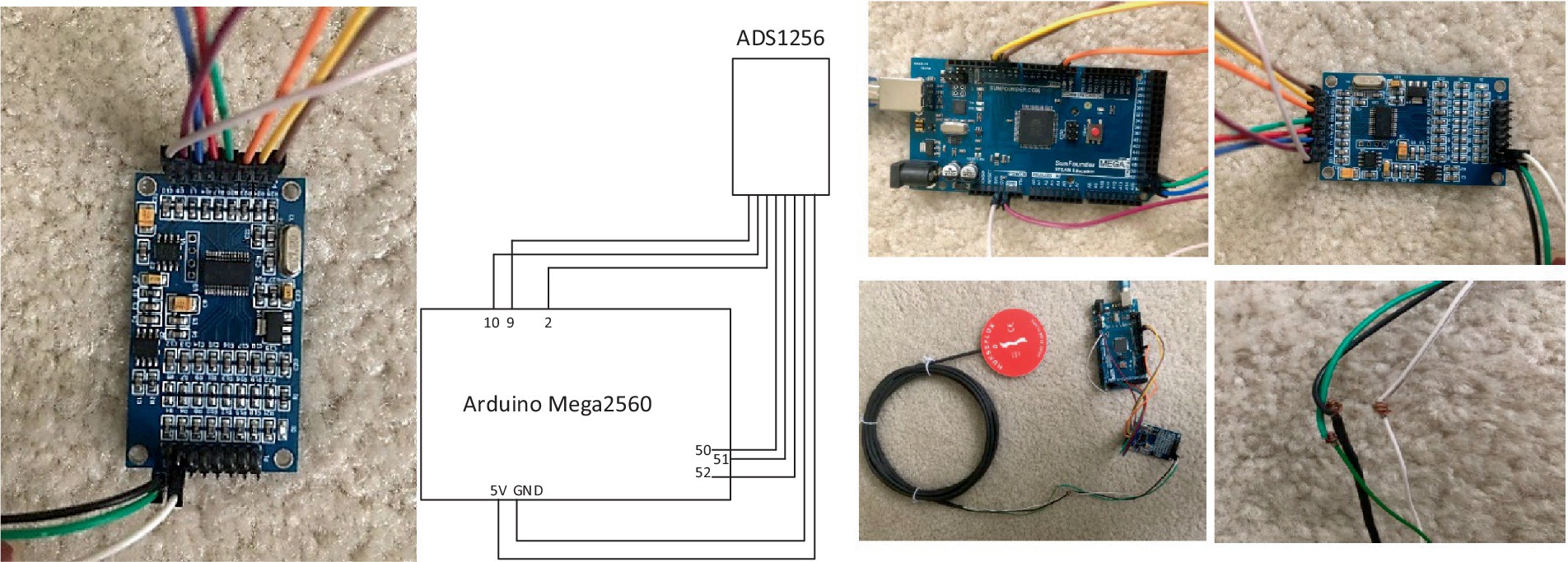

D. Two Analog-to-Digital Converters (ADC) (ADS1256) (Figure 11): The ADS1256 is a 24-bit analog-to-digital converter known for its very low noise (e.g., 23-bit noise-free), making it suitable for high-resolution measurement solutions. The converter includes a delta-sigma (ΔΣ) modulator (4th-order) followed by a programmable digital filter (Texas Instruments, 2022).

E. Several Breadboards (Figure 12): A breadboard is utilized to develop electronic circuits and wiring for microcontroller boards such as Arduino. No soldering is needed to use this breadboard (Seed Studio, 2022).

F. Some resistors (Figure 13): A resistor is a circuit element that provides electrical resistance through two terminals. It serves a wide variety of purposes in circuits, including reducing current flow and adjusting signal levels, dividing voltages, biasing active elements, and terminating transmission lines (Wikipedia, 2022).

G. Silicon heat transfer compounds (Figure 14): Silicon Heat Transfer Paste is a versatile synthetic base enhanced with metal oxides and designed to have a paste-like consistency. It offers high thermal conductive properties, is highly resistant to heat, and is extremely stable at high temperatures (Walmart, 2022).

H. Some jumper wires and long wires (Awg22) (Figure 15): Awg20 = 0.81 mm Diameter, Awg22 = 0.65 mm, Awg24 = 0.51 mm (Adafruit, 2022).

Figure 8. Heat flux sensor HFP01 (Hukseflux, 2022).

Figure 9. MF52-103/3435, 10 k Ohm thermistors (Amazon, 2022).

Figure 10. Arduino Mega2560 (Arduino Mega, 2022).

Figure 11. Analog-to-digital converter (ADC) (ADS1256) (Texas Instruments, 2022).

Figure 12. Breadboard (Seed Studio, 2022).

Figure 13. Electrical resistors (Wikipedia, 2022).

Figure 14. Silicon heat transfer compound (Walmart, 2022).

Figure 15. Jumper wires and long wires (Awg22) (Adafruit, 2022).

4.2 Heat flow meter methodology

At stationary conditions, the thermal resistance for the tested layer can be calculated using Equation 1:

where

• q = density of the heat flow, W/m2

• Tf = temperature at the hot surface (heat flow meter), °C

• Tc = temperature at the cold surface, °C

• R = thermal resistance (R-value), m2 °C/W

It is acceptable to use the method only if (1) R is roughly constant, (2) the heat flow direction does not change, (3) there is relatively little energy stored during the period, and (4) the duration of the test to be long enough (Anderlind, 1992). Given that the simultaneous occurrence of such conditions is impractical, alternative methods have been explored.

Accordingly, Anderlind’s Multiple Regression Method was used as follows to consider the dynamic thermal performance of building envelopes on site:

where qi is the heat flux at that time (with measurement), Tsurf, int is the interior surface temperature, Tsurf, ext is the exterior surface temperature, and p is the number of historical data points. The constants A1, …, A5, B1,…, and B5 can be obtained using the regression technique over the experimental data, and R represents the thermal resistance (Lu and Memari, 2018). According to Anderlind’s suggestion, to get acceptable and accurate R-value results, it would be enough to measure the data for about 3 days (i.e., 2-day periods) (Anderlind, 1992). This paper follows the procedures in Lu and Memari (2018) for the practical application of Anderlind’s Multiple Regression Method.

4.3 Test setup for the heat flow meter method

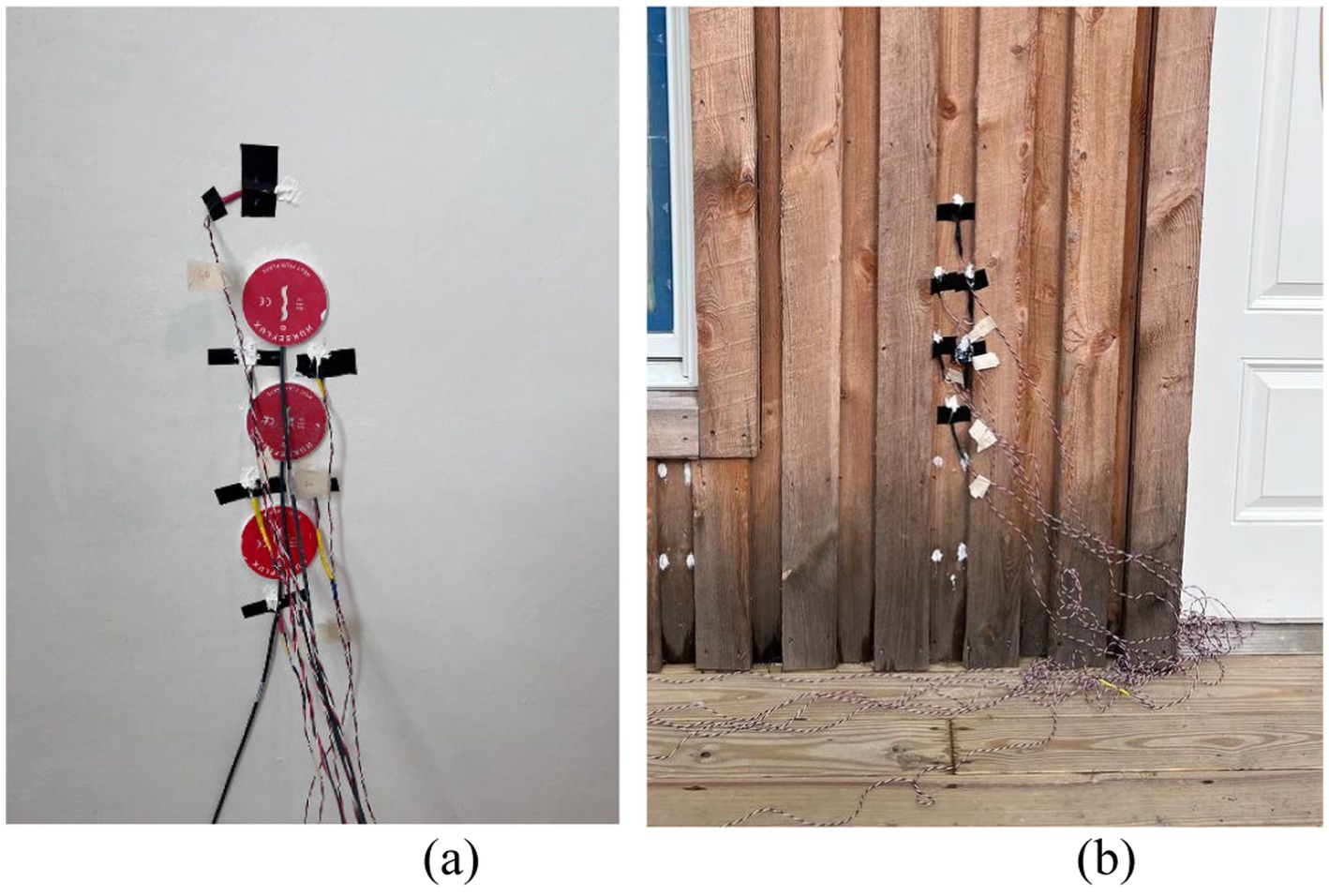

Two experimental tests were conducted on the walls of a single-family house retrofitted with hempcrete. This house, built in 1900 in New Castle, PA, is depicted in Figure 3 before the retrofit and in Figure 16 with four photos of the exterior after the retrofit. A modified Heat Flow Meter Method test was used to measure the R-value of the hempcrete in the walls. The back wall and sidewall of the house were selected for testing after the retrofit. Figure 17 shows the interior walls with the attached instruments.

The Arduino should be connected to the heat flux sensor using an analog-to-digital converter (ADC) to prepare the heat flux sensors. Although the Arduino Mega 2560 has an internal ADC, it is relatively weak, so a separate ADC is recommended for more accurate results. Figure 18 illustrates how to connect the ADS1256 to the Arduino Mega 2560. Since each Arduino has two ground (GND) pins and one 5 V pin, a breadboard is very useful for extending these pins. In a breadboard, the pins in each row share the same properties. To increase the number of GND and 5 V pins, connections should be made between these pins on the Arduino and the breadboard. Figure 18 also demonstrates extending 5 V and GND pins using a breadboard. For this study, an Arduino code was prepared. According to the code developed, the connection between the heat flux sensor and the Arduino is shown in Figure 19.

It is important to note that heat flux data should be positive. If heat is transferred from the environment to the room, the direction of heat transfer reverses, resulting in negative data. The raw data from the heat flux sensor is not in voltage form, so it must be converted to voltage. The calculation involves the following steps:

a. Define the ADC’s reference voltage, resolution, and gain amplifier.

b. Define the full scale of the ADC by dividing the reference voltage over the gain amplifier.

c. Define the voltage at each binary step by dividing the voltage at each binary step over the resolution.

d. Calculate the measured voltage by multiplying the raw data from the ADC to step c.

e. Define q by dividing the measured voltage over the sensitivity of the heat flux obtained from the datasheet.

Three heat flux sensors were mounted on the hot side (room) wall for the experimental test. It is preferred to mount more than one heat flux sensor to compare the results, and also, by calculating the mean value of the three heat flux sensors, the results would be more reliable. Moreover, six thermistors were mounted around the heat flux sensors fully in contact with the wall’s surface to allow temperature measurement of the wall’s surface. Using a heat transfer compound, the heat flux sensors and thermistors were attached to the wall surface. On the other hand, six thermistors were mounted on the cold side wall (environment/outside) opposite the hot side. Figures 20–22 show the experiments from the overall and closeup views.

5 Thermal resistance results

In this section, we present the thermal resistance results obtained from the study, which focused on the thermal performance of hempcrete walls constructed/retrofitted, and then compare the thermal resistance of the constructed wall with the existing wall systems (assumed to have no insulation between studs) as well as a hypothetical case of using fiberglass batt insulation between studs. For the actual retrofitted case, the raw data obtained from the heat flux sensors should be converted to a voltage per instructions published by the manufacturer. The heat flow density is determined by dividing the measured voltage by the sensitivity of the heat flux as specified in the datasheet. Additionally, the thermistor data provide the surface temperatures on the hot and cold sides. Using these values in Anderlind’s formulation, the R-value of the hempcrete wall is calculated.

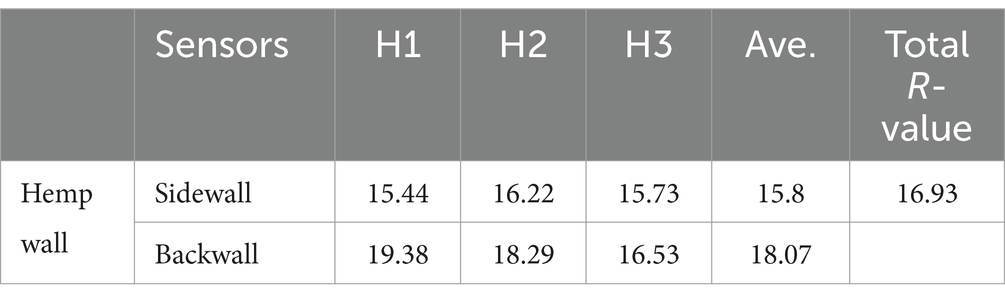

Table 1 lists the results of the Heat Flow Meter Method used in the study. In Table 1, H1, H2, and H3 represent the R-values obtained from each heat flux sensor. The column labeled ‘Ave.’ shows the average R-value from the three heat flux sensors on each wall, i.e., sidewall and backwall, as shown in Figure 20. The ‘Total R-value’ refers to the average R-value of the two walls. The variation in R-values between the sets is due to the proximity of the air conditioning vent to the back wall, as depicted in Figure 20. Therefore, the average R-value of the two sets (sidewall and backwall) provides a more accurate value. As shown in Table 1, the average R-value for the wall is 16.93, or approximately R-17.

The layers from the interior to the exterior making up the hempcrete walls tested in this study consist of a ¾ in. hemp-rich plaster, 10-in. thick hempcrete, ½ in. air space, and ½ in. thick rough sawn hemlock board siding. So, for a total thickness of 11.75 in. and an average R-value of 16.93, we have approximately a wall with R-1.45/inch.

To compare this R-value (for the retrofitted wall) with some other cases of interest, first, we compare this with the case of a regular concrete wall. It is clear that the determined thermal resistance of the hempcrete wall is much superior to that of a regular concrete wall, which has an approximate R value of R-0.1/inch. Therefore, with the same thickness, the hempcrete wall can lead to at least 10 times better thermal resistance than regular concrete walls.

The next comparison is with the case of the building before retrofit. The original walls had conventional wood studs but without any insulation. Assuming the wall makeup consisted of 3/8 in. gypsum board (R = 0.5), 2 in. × 4 in. studs (R = 5) at 16 in. on center, 5/8 in. OSB sheathing (R = 0.75) and conventional vinyl siding (R = 0.6), we get the following R-values for the section through the stud, through the cavity, and an average based on the parallel path method, as shown below.

The air space between studs typically has an R-value of 1. Using the parallel path method, path 1 (through the air space) has an R-value of 0.5 + 1 + 0.75 + 0.6 = 2.85, and path 2 (through the stud) has an R-value of 0.5 + 5 + 0.75 + 0.6 = 6.85, so the overall equivalent R-value of the original wall can be calculated ( = 3 (total for the wall thickness)) using Equation 3 below, where A1, and A2 are the corresponding path areas, is the total equivalent R-value.

Then the last case to consider is when the cavity was filled with conventional batt insulation (R = 3.2/inch). In that case, the R-value through the stud, through the batt insulation, and the total equivalent R-value can also be calculated using Equation 3, with the result giving .

We can see that the retrofitted case, with an R-value of 16.93, is 5.6 times the R-value of the original wall and 1.3 times the R-value of the case if it were retrofitted using conventional batt insulation. It should be noted that building energy usage is influenced by multiple aspects in addition to the R-value of the material, including the quality of framing, fluctuations in outdoor temperatures, ventilation, humidity control, and so on. Therefore, while hempcrete is shown to have high R-value, careful consideration on these aspects are equally important in achieving energy efficiency.

On the other hand, because hemp shive in hempcrete sequester the carbon for an extended period of time, the use of hempcrete is expected to have a cumulative contribution to reduce greenhouse gas emission, making it a relevant choice for sustainable building. For example, cement brick and clay brick walls emit 11.3 and 57.6 kg of CO2 per m2 of wall (Kim et al., 2015), and common wall emits higher than 100 kg of CO2 per m2 of wall (Di Capua et al., 2021) whereas a hempcrete wall can produce as low as 15.22 kg of CO2 per m2 of wall (Di Capua et al., 2021) or even sequester 16–82.7 kg CO2 per m2 of wall (Arehart et al., 2020; Asghari and Memari, 2024).

The high R-value can be attributed to higher porosity of the hempcrete as well as the hemp shive. While this study demonstrates a superior thermal resistance of the hempcrete, a further study on pore structure, pore distribution, and overall porosity of hempcrete is necessary to understand the origin of insulative performance of the hempcrete.

6 Summary and conclusions

This study details the practical in-situ measurement of the thermal properties of hempcrete walls in a retrofitted home in New Castle, PA. The primary objectives were to determine the hempcrete walls’ thermal resistance and implement the Heat Flow Meter Method in situ. The measured R-value for the hempcrete walls was approximately R-17, which is more than 10 times better than a regular concrete wall of the same thickness. Consequently, incorporating hempcrete walls in buildings is expected to enhance thermal performance and significantly reduce energy consumption. However, considering that there are many other insulation products that can match or exceed hempcrete’s thermal resistance properties, one needs to consider other aspects that will make hempcrete stand out. For example, one can consider the following aspects/properties to see the advantage hempcrete brings to energy efficiency and sustainability: natural material that has sequestered carbon in its production, low embodied carbon, lack of use of synthetic material, thermal mass that a thick hempcrete wall brings about, and air-tightness of the whole house because of the nature of how hempcrete walls are constructied. Because there is limited research in this field, more future studies are needed on hempcrete walls regarding their life cycle performance and ease of manufacturing.

Data availability statement

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found in the article/supplementary material.

Author contributions

AM: Conceptualization, Funding acquisition, Supervision, Writing – original draft, Writing – review & editing. NM: Data curation, Investigation, Methodology, Writing – original draft. MH: Formal analysis, Software, Writing – original draft. XL: Formal analysis, Methodology, Software, Supervision, Writing – review & editing. CG-G: Conceptualization, Data curation, Investigation, Methodology, Writing – original draft. HY: Conceptualization, Writing – review & editing. SL: Software, Supervision, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This study was partially supported by DON Enterprize, Inc., a non-profit entity.

Acknowledgments

We also acknowledge the help and support of Ms. Lori Daytner (who was with DON Enerprize, Inc. at the time of the study) and Cameron MCIntosh (President and Principal Owner, Americhanvre LLC) toward planning for the field study. All view and conclusions are those of the authors, and do not necessarily reflect those of the sponsor. It is also acknowledged that parts of the paper have been published in the research report that resulted form the study. The report is cited in the reference list with the title of “Thermal, Energy, and Indoor Environmental Quality Performance of the PA Hemp House,” Memari et al. (2022).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

References

Abbott, T. (2014). “Limecrete FAQ,” the Limecrete company LTD sustainable construction. Available at: http://limecrete.co.uk/limecrete-faq/

Adafruit. (2022). Premium female/male ‘extension’ jumper wires. Available at: https://www.adafruit.com/product/1953?gclid=CjwKCAjwtKmaBhBMEiwAyINuwA-ole0WcEsP9EPTehY9VSjxbcNmG-o5dhIYbyAmvl79r02WIZaJBxoCgBsQAvD_BwE (Accessed May 19, 2022).

Amazon. (2022). Available at: https://www.amazon.com/uxcell-Thermistors-Resistor-MF52-103-Temperature/dp/B07L113D (Accessed May 19, 2022).

Anderlind, G. (1992). Multiple regression analysis of thermal measurements—study of an attic insulated with 800 mm loose. J. Build. Phys. 16, 81–104. doi: 10.1177/109719639201600109

Architecture 2030. (2022). “Why the built environment?” Available at: https://architecture2030.org/why-the-building-sector/#:~:text=The%20built%20environment%20generates%20nearly,for%20an%20additional%202025%20annually (Accessed September 9, 2022).

Arduino Mega. (2022). Available at: https://store-usa.arduino.cc/products/arduino-mega-2560-rev3 (Accessed May, 19, 2022).

Arehart, J. H., Nelson, W. S., and Srubar, W. V. (2020). On the theoretical carbon storage and carbon sequestration potential of hempcrete. J. Clean. Prod. 266:121846. doi: 10.1016/j.jclepro.2020.121846

Asghari, N., and Memari, A. M. (2024). State of the art review of attributes and mechanical properties of hempcrete. Biomass 4, 65–91. doi: 10.3390/biomass4010004

Atsonios, I. A., Mandilaras, I. D., Kontogeorgos, D. A., and Founti, M. A. (2017). A comparative assessment of the standardized methods for the in–situ measurement of the thermal resistance of building walls. Energy Build. 154, 198–206. doi: 10.1016/j.enbuild.2017.08.064

Deconinck, A. H., and Roels, S. (2016). Comparison of characterisation methods determining the thermal resistance of building components from onsite measurements. Energy Build. 130, 309–320. doi: 10.1016/j.enbuild.2016.08.061

Di Capua, S. E., Paolotti, L., Moretti, E., Rocchi, L., and Boggia, A. (2021). Evaluation of the environmental sustainability of hemp as a building material, through life cycle assessment. Environ. Climate Technol. 25, 1215–1228. doi: 10.2478/rtuect-2021-0092

Global Alliance for Buildings and Construction (GABC) (2019). 2019 global status report for buildings and construction – towards a zero-emissions, efficient and resilient buildings and construction sector : U.N. Environment Programs, International Energy Agency.

Green Home Gnome (GHG). (2017). 6 advantages of building with hempcrete. Available at: https://www.greenhomegnome.com/advantages-building-hempcrete/ (Accessed May 2022).

GreenSpec. (2019). Tradical hempcrete -- bio-composite building material. Available at: http://www.greenspec.co.uk/green-products/in-situ-composites/details/tradical-hemcrete/ (Accessed May 2022).

Hukseflux. (2022). Available at: https://www.hukseflux.com/products/heat-flux-sensors/heat-flux-meters/hfp01-heat-flux-sensor (Accessed May 19, 2022).

Kim, S., Whang, S.-W., Kim, G.-H., and Shin, Y. (2015). Comparative study on the construction cost including carbon emission cost for masonry walls. Energ. Buildings 96, 187–192. doi: 10.1016/j.enbuild.2015.03.025

Lime Technology. (2024). Lime technology – sustainable building innovation. Available at: https://hml-prod.imgix.net/americanlimetechnology.com_wp-content_uploads_2011_11_Tradical_Hemcrete_Embodied_CO2.pdf (Accessed December 18, 2024).

Lu, X., and Memari, A. M. (2018). Comparative study of hot box test method using laboratory evaluation of thermal properties of a given building envelope system type. Energ. Buildings 178, 130–139. doi: 10.1016/j.enbuild.2018.08.044

Lu, X., and Memari, A. M. (2019). Determination of exterior convective heat transfer coefficient for low-rise residential buildings. J. Adv. Build. Energy Res. 15, 583–602. doi: 10.1080/17512549.2019.1612468

Lu, X., and Memari, A. M. (2022). Comparison of the experimental measurement methods for building envelope thermal transmittance. MDPI Buildings 12, 3–15p. doi: 10.3390/buildings12030282

Memari, A., Griffin, C., Yi, H., Lowe, S., Mirzai, N., and Hashemi, M. (2022). Thermal, energy, and indoor environmental quality performance of the PA hemp house, Report Submitted to DON Services, Inc.: The Pennsylvania Housing Research Center, Penn State University, 65.

Popescu, A. (2018). There is no place like home, especially if it is made of hemp. The New York Times, 2018, sec. Science. Available at: https://www.nytimes.com/2018/01/29/science/hemp-homes-cannabis.html (Accessed 08 December, 2023).

Potter, B. (2020). Every building in America – an analysis of the U.S. building stock. Constr. Phys. 30:2023.

Priesnitz, R. (2006). Hemp for houses. Natural Life Magazine. Available at: https://www.life.ca/naturallife/0604/hemphouse.htm (Accessed 08 December, 2023).

Pullen, T. (2017). What is Limecrete? Homebuilding & Remodeling, March 8. Available at: https://www.homebuilding.co.uk/what-is-limecrete/ (Accessed 08 December, 2023).

Seed Studio. (2022). Available at: https://www.seeedstudio.com/blog/2020/01/06/how-to-use-a-breadboard-wiring-circuit-and-arduino-interfacing/ (Accessed May, 19, 2022).

Texas Instruments. (2022). SBAS288K. (2003) − “Analog to digital converter (ADC).” Available at: https://www.ti.com (Accessed May 19, 2022).

Walmart. (2022). Available at: https://www.walmart.com/ip/MG-Chemicals-860-60G-Silicone-Heat-Transfer-Compound-60g-Jar-Special-synthetic-base-fortified-metal-oxides-compounded-a-By-Brand/503050765?wmlspartner=wlpa&selectedSellerId=14995 (Acessed May 19, 2022).

Wikipedia. (2022). Available at: https://en.wikipedia.org/wiki/Resistor#:~:text=A%20resistor%20is%20a%20passive,%20transmission%20lines%2C%20among%20other%20uses (Accessed May 19, 2022).

Yi, H., Griffin, C., and Memari, A. M. (2022). “Critical review of the characterization of environmental and mechanical properties of hemp hurd and hempcrete” in Proceedings of the 6th residential building design and construction conference (University Park, PA: Penn State University), 208–216.

Yi, H., Griffin, C., Memari, A., Lanning, D., and Dooley, J. H. (2020). “Hempcrete for as residential construction material: state-of-the-art and challenges” in Proceedings of the 5th residential building design and construction conference (University Park, PA: Penn State University), 10.

Zhang, M., and Demko, P. (2020). Hemp was a supposed to boost farmers. It’s turned out to be a flop. Available at: https://www.politico.com/news/2020/05/25/hemp-farmers-275046 (Accessed May 29, 2023).

Keywords: hempcrete, house construction, thermal resistance, heat flow meter method, energy efficiency

Citation: Memari AM, Mirzai N, Hashemi M, Lu X, Gracie-Griffin C, Yi H and Lowe SK (2025) In-situ measurement of residential buildings with hempcrete walls: a case study. Front. Sustain. 5:1508940. doi: 10.3389/frsus.2024.1508940

Edited by:

Runxiao Zhang, University of Toronto, CanadaReviewed by:

Ivan Ruziak, Technical University of Zvolen, SlovakiaShayan Aboodi, University of Toronto, Canada

Copyright © 2025 Memari, Mirzai, Hashemi, Lu, Gracie-Griffin, Yi and Lowe. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ali M. Memari, YW1tN0Bwc3UuZWR1

Ali M. Memari

Ali M. Memari Nadia Mirzai

Nadia Mirzai Xinrui Lu

Xinrui Lu Corey Gracie-Griffin

Corey Gracie-Griffin Hojae Yi

Hojae Yi