- 1Fisheries Observer Agency, Walvis Bay, Namibia

- 2Department of Applied Educational Science, University of Namibia, Windhoek, Namibia

- 3Environmental Management Section, Municipality of Walvis Bay, Walvis Bay, Namibia

- 4Environmental Research Institute, University of the Highlands and Islands, Thurso, United Kingdom

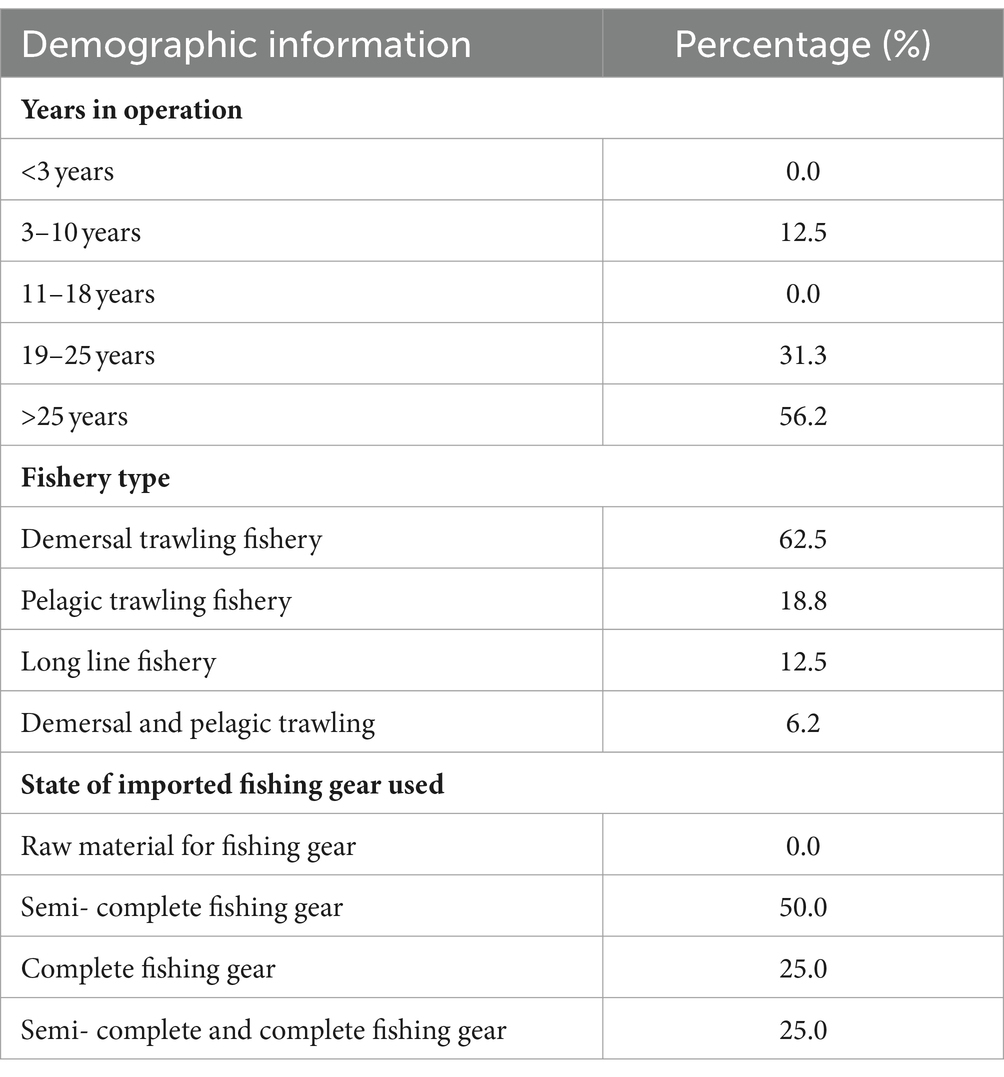

Using data collected through survey questionnaires with fleet managers of 16 (61.5%) Namibian fishing companies, we explored the current practices, challenges, and opportunities in promoting Circular Economy (CE) in the context of End-Of-Life (EOL) fishing gear. Most fishing companies (56.2%) have been in operation for more than 25 years. A majority of fishing companies (62.5%) are involved in demersal trawling, mostly targeting hake (Merluccius species). Survey findings reveal that the companies import fishing gear mostly in a semi – complete format (50.0%). The current durability of fishing nets and lines/ropes is about 3 and 2 years respectively, highlighting a continuous generation of fishing gear waste. We estimated (that) approximately 104 tons of EOL fishing gear, lines/twine and ropes (are) generated annually by the Namibian fishing industry, however about 10% of some parts of the EOL fishing gear are recovered and reused. None of the fishing companies recycle EOL fishing gear, which is mostly attributed to a lack of recycling facilities. Current standard practices of EOL fishing nets, lines and ropes management include selling to employees, donating to other institutions, or disposal at dumping sites. Although some of the EOL fishing nets, lines and ropes are sold at open markets, they are not converted into value-added products, thus they are not fully utilized to significantly contribute to the CE. We recommend the implementation of circular practices such as converting EOL fishing nets, lines and ropes into value-added products such as clothing, shoes, and accessories, i.e., sunglasses, thereby reducing environmental pollution, minimising energy usage, and promoting sustainable production and consumption.

Introduction

The world is placing immense pressure on natural resources to sustain human population expansion and economic growth. To keep up with this demand, novel ways need to be developed to promote sustainable production and consumption. One approach to achieve this goal is to transition from the traditional Linear Economy (LE) that involves ‘take, create, use and dispose’ (Wijkman and Skånberg, 2017; Ghosh, 2020) to a Circular Economy (CE) model. The CE paradigm has existed for decades but gained momentum in the 1970s. This study adopts the CE definition put forth by Valavanidis (2018) which broadly revolves around turning products at the end of their service life into resources for others, closing loops in industrial ecosystems and minimizing waste to promote sustainability. The CE model serves as a countermeasure to the wasteful and unsustainable practices of the conventional LE model (Furkan, 2017; Gill and Verma, 2021). The CE paradigm is versatile and can be applied in numerous industries including seafood waste (Erasmus et al., 2021; Cooney et al., 2023), wastewater (Morseletto et al., 2022) and car manufacturing (Despeisse et al., 2015). The CE model aims at minimizing industrial waste while using resources sustainably (Principato et al., 2018; Gill and Verma, 2021).

The consumption of natural material is on a rapid increase globally and predicted to double by 2050. Although the end products can be utilized through application of one of the three basic principles (3Rs): reduce, reuse, or recycle, thereby extending the life cycle of products or resources, the generation of waste follows an increasing trend (Kaza et al., 2018). The fishing industry is one of the sectors producing waste including in the form of seafood (Erasmus et al., 2021), wastewater (Cristóvão et al., 2015) and fishing gear (Wilcox et al., 2016; Eimontas et al., 2023). Information on quantities of EOL fishing gear is patchy, with robust regional values, such as the estimated 4,000 tons of EOL fishing gear per year in Norway (Deshpande et al., 2020b), being the exception. However, other estimates give an indication of the mass of material, with an estimated 1.8% of fishing gear is lost to the ocean annually across the globe, including approximately 2,963 km2 gillnets, 75,049 km2 purse seine nets, and 739,583 km longline mainlines (Richardson et al., 2022). When fishing gear such as nets, hooks, ropes, lines, pots, and traps become obsolete, lose usability, and are beyond repair, they are disposed of (Basurko et al., 2023). Whilst Erasmus et al. (2023) listed mariculture gear as sources of marine pollution, the long standing, substantial, and increasing presence of fishing gear debris in the marine environment has also been highlighted (Macfayden et al., 2009). Globally, fishing related gear has been assessed to be the most harmful type of anthropogenic debris to birds, mammals, and sea turtles (Wilcox et al., 2016). This impact is observed more locally in Namibia, for instance fishing nets, lines and ropes have been recorded to entangle Cape fur seals (Arctocephalus pusillus) since the 1970’s (Shaughnessy, 1980) and were more recently determined as the two debris types which cause the most incidents of entanglement. In total fishing nets, lines, and ropes represent at least 64% (221 out of 346) of all Cape fur seal entanglements reported in a 21-month period up to December 2019 (Curtis et al., 2021), and can cause severe injury or even death. However, comprehensive data on fishing debris is severely lacking in Namibia and around the seas of Africa, with Macfayden et al. (2009) recommending the development of monitoring programmes to address this fundamental knowledge gap.

In most cases, the discarded materials are useful as raw materials for other value-added products. Returning “waste” resources back into the economy slows down the exploitation of natural resources, reduces landscape and habitat disruption and minimises biodiversity loss (Korhonen et al., 2018; Rashid and Malik, 2023). Furthermore, the CE model supports the United Nations Sustainable Goals (SDGs), particularly SDG 12 which highlights sustainable consumption and production (UNDP, 2016). Similarly, the Committee on Fisheries (COFI) of the Food and Agriculture Organization of the United Nations (FAO) acknowledged the pressure of all types of pollution on aquatic systems in a Declaration for Sustainable Fisheries and Aquaculture which states that they “Support the implementation of integrated and coordinated multisectoral, evidence and ecosystem based management approaches” (FAO, 2021).

Globally, the subject of EOL fishing gear is receiving moderate attention (Boopendranath, 2012; Nogueira et al., 2022; Basurko et al., 2023; Eimontas et al., 2023), although in general, data on EOL fishing gear generation is still severely inadequate. Notwithstanding the work done globally, Charter (2023) opined that current best practice in recycling fishing gear is very constrained. In the Namibian context, although the country possesses some of the most prolific fishing grounds globally (FAO, 2024), there is a severe paucity of information on EOL fishing gear quantities and management. A study on waste generation in Walvis Bay, Namibia, placed the fishing industries among the main generators of solid waste, in addition to households, business facilities and industrial institutions (Haimbala and Ambi, 2020). However, in 2022, Namibia imported a total of 560 tons of fishing nets, lines and ropes (Data obtained from the Namibia Revenue Agency (NamRA)). The Namibian fishing sector is significant, ranked the third-highest contributor to the Gross Domestic Product (GDP) (NSA, 2021), and with a catch of approximately 411,000 tons from marine fisheries in 2021 (FAO, 2024), making it the 3rd largest fishery in Africa (NPD5, 2017). This implies that the Namibian fishing industry uses fishing gear in large volumes in order to sustain the fishing activities. However, there is a paucity of information on the quantities of fishing gear used annually and the EOL fishing gear generated. Furthermore, there is inadequate information with regards to the fate of fishing gear waste generated. The objectives of this study were three-fold; to (i) estimate the End-Of-Life fishing nets, lines, and ropes generated in the Namibian commercial fishing industry, (ii) investigate the current management and utilization of End-Of-Life fishing gear in Namibia, and (iii) present opportunities and challenges in promoting Circular Economy in the context of End-Of-Life fishing gear.

Materials and methods

Study area

This study was carried out in Walvis Bay, Namibia (Figure 1). Namibia is a maritime state in southwest Africa along the Atlantic Ocean. Namibia has a 1,572 km coastline, and approximately 564,700 km2 Exclusive Economic Zone (EZZ), with only two ports, Lüderitz, and Walvis Bay, of which the latter is Namibia’s largest port. The Namibian coastline is largely desert and thus sparsely inhabited.

Data collection and analysis

The study was divided into two phases. In the first phase, Namibian fishing companies were surveyed between July and November 2023 to collect data on the amount of EOL fishing gear generated. For the purpose of this work, we considered fishing companies as the fishing operators with land-based processing facilities (factories). There are many fishing gear types including nets, hooks, lines, pots, and traps, however, this study only focused on fishing nets, lines and ropes because they are the most common fishing gear used to harvest marine resources off Namibia. We use the term fishing lines to refer to the twine used for longline fishing. Fleet managers from fishing companies were surveyed using a questionnaire in the English language. Prior to the survey, the questionnaire was piloted with four respondents and thereafter modified to include questions on the use of biodegradable fishing gear. The questionnaire consisting of 16 open-ended and structured questions was emailed to 21 fishing companies. We received 16 responses representing 61.5% of all fishing companies in Namibia, with no response from the remaining five companies to the voluntary questionnaire. All survey participants consented to participate and were not incentivized to take part in this study. Questionnaires were coded such as ‘Company A, Company B etc’ to ensure anonymity.

This study delves into quantities of End-of-Life (EOL) fishing nets, lines and ropes generated in Namibia and discusses them in the context of the Circular Economy paradigm. However, as a limitation, the quantities of the EOL fishing gear stated in the questionnaire responses were not validated, thus they are only based on the self-reporting of the surveyed fishing companies. Currently, EOL fishing gear are not recorded separately at the municipality weighbridge, they are categorized as “waste from fishing factories” when they enter the landfill site. Although there are drawbacks, the self-reporting method is an established method used in various studies such as Deshpande et al. (2019) and Richardson et al. (2022) with the use of fishers’ knowledge being highly valuable, especially valuable in data-poor fields (Johannes et al., 2000; Deshpande et al., 2019). Deshpande et al. (2020b) noted that “Using fishers’ knowledge (FK) to estimate local patterns in fishing is common practice in natural resource management.”

To estimate the weight of EOL fishing nets, lines and ropes generated per year, we employed a soft measure technique (described in Hassan et al., 2018), by using a questionnaire and thereafter estimated quantities based on data collected from 16 fishing companies. The survey prompted the respondent on the waste generated in the last 12 months (January – December 2022), and therefore did not capture variation per year, including annual differences in what types of fishing nets, lines and ropes used. We extrapolated these data to all fishing companies in Namibia, under the assumption that the companies are producing approximately the similar quantities (weight) of EOL fishing nets, lines and ropes. Furthermore, we listed the current EOL fishing nets, lines and ropes management practices. Qualitative data were coded to allow for analysis.

In the second phase, the Kuisebmund open market in Walvis Bay was visited in September 2023, to observe and record the utilization of EOL fishing nets, lines and ropes. We recorded the state (original state or recycled state) in which EOL fishing nets, lines and ropes are sold in the open market.

Results

Demographic information

Most fishing companies (56.2%) surveyed have been in operation for more than 25 years. A large proportion of fishing companies (62.5%) engage in demersal trawling fisheries and use fishing nets. These companies mostly import fishing nets from Spain (27.7%), in a semi – complete state (50.0%) gear (Table 1). There are also companies (33.3%) that use locally sourced fishing nets, from two Namibia based fishing gear manufacturers.

Characteristics and life span of fishing nets, lines, and ropes

The fishing gear considered in this study were fishing nets, lines and ropes, which are mostly made out of plastic polymers and other less numerous components, such as rubber discs, wires and, stainless steel. The lifetime (longevity) of the fishing nets is approximately 3 years, while for lines is 2 years on average before the gear becomes worn out and not usable. All fishing companies (100%) do not use biodegradable fishing gear (BFG).

Quantities of fishing nets and lines waste generated

When the quantities of EOL fishing nets, lines and ropes for 16 fishing companies were combined, approximately 64 tons were generated in 2022. Given that there are 26 fishing companies in Namibia, and with an assumption that the companies generate similar quantities, then the total tentative annual estimate of EOL fishing nets, lines and ropes generated is 104 tons for the Namibian fishing industry.

81.2% of the surveyed fishing companies recover some parts (about 10%) of EOL fishing gear such as galvanized steel components, ropes, metal chains and cod-end of nets and reuse them on refurbished gear. None of the studied fishing companies recycle EOL fishing gear into new products.

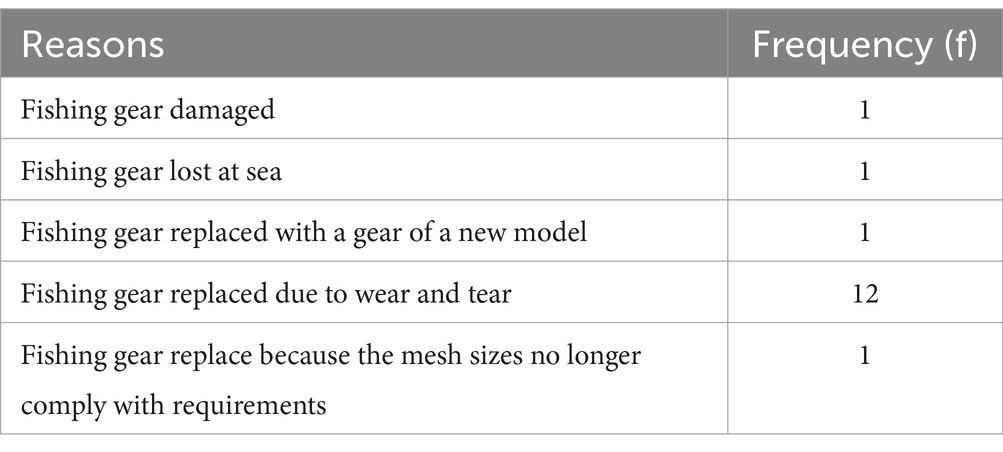

The results in Table 2 show that ‘replaced due to wear and tear’ was the most reason fishing companies changed the previous fishing nets, lines and ropes. Other reasons for replacing the previous fishing line, ropes, or net, were ‘fishing gear lost at sea’, ‘fishing gear damaged’ and ‘gear replaced with a gear of a new model’.

Table 2. Frequency table for the reasons for replacing fishing nets, lines and ropes in the Namibian fishing companies.

When fishing nets, lines and ropes reach their end of life, they are sold to fishing company employees, sent to scrap yards, discarded at a landfill site, or donated to the community. Fleet managers opined that it would be easier to manage waste generated from fishing nets, lines and ropes if there was a centralized place where this waste could be dropped off.

The management of EOL fishing gear

Three practices were observed among the Walvis Bay based fishing companies; selling the EOL fishing nets, lines and ropes (to their employees or to scrap dealers), donating to institutions like correctional service, and landfilling of EOL fishing gear. Unquantified amounts of EOL fishing gear are disposed of at the Walvis Bay Municipality (WBM) landfill site by the fishing companies (as the generators). They either transport it themselves to the site or through third-party waste management contractors. The WBM applies the polluter pays principle and also fines the polluter for polluting the environment. Furthermore, the polluter also pays costs of decontaminating the environment. At the landfill site, the EOL fishing gear is disposed of together with other general and domestic waste.

However, the community members mostly collect them to be sold. Thereafter, they are sold at open markets, to be repurposed, although this probably only represents a small percentage of the total quantity of EOL fishing nets, lines and ropes (Figure 2). The actual quantities of EOL fishing gear collected by community members are unknown, highlighting data gaps.

Figure 2. End-of-life fishing nets, lines and ropes at the Kuisebmund open market in Walvis Bay, Namibia prepared to be sold for various purposes.

Old ropes and lines are used as reinforcement in construction, and also used to stitch shoes by shoemakers while inland, farmers use them to herd, handle and restrain cattle, serve as harness for horse riding and also used to pull water buckets out of water wells. Some old fishing nets are used as door mats, sports nets (goalkeeper nets), ornaments, gardening tools, home décor and to make shades. Some fishing nets are used in the transportation to cover goods (Figure 3) and as floor coverings (Figure 4).

Figure 4. End-of-life fishing nets used to cover goods during transportation from Walvis Bay to various locations in Namibia.

Challenges with EOL fishing gear

When probed about the challenges the fishing companies face with regard to EOL fishing gear management and disposal, fleet managers listed the following seven challenges:

• Derelict fishing gear accumulation at fishing factories, because fishing nets, lines and ropes can be extremely large and heavy, thereby taking up space.

• Lack of waste recovery factory/facility to collect and process EOL fishing gear to create value-added products.

• Fear of additional costs in recycling (converting EOL fishing gear into new value-added products)

• Lack of expertise in recycling or repurposing fishing nets, ropes, and lines.

• Disposing of the EOL fishing gear to landfill sites due to added financial burden.

• A shorter lifespan for fishing gear in Namibia, makes it necessary for frequent replacing which leads to more fishing gear waste.

• Current fishing gear not designed for Circular Economy.

Discussion

In this study, we investigated the contribution of End-Of-Life (EOL) fishing nets and lines to a circular economy, focusing on current practices, challenges, and opportunities in the Namibian context. The fishing industry has become a focal point for the CE initiatives, due to its reliance on finite resources and potential environmental impact. This study confirms that the Namibian fishing industry indeed generates waste as initially listed by Haimbala and Ambi (2020), although the quantities were not provided in that study. When these materials are obsolete as fishing gear, lose usability and are beyond repair, they are disposed of, and such waste contributes to marine and terrestrial pollution, if not correctly managed. This study explored the possibility of full utilization of EOL fishing nets, lines and ropes to promote sustainable consumption and to achieve circularity within the fishing industry. The data from this survey are useful as they represent responses from 61.5% of fishing companies studied. Therefore, the study provides findings to support the need for novel approaches to manage EOL fishing gear.

Quantities of EOL fishing lines and nets

The Namibian fishing industry generates a significant amount of EOL fishing nets, lines and ropes (approximately 104 tons) annually. It remains a challenge to quantify EOL fishing gear, thus the figure presented is an estimate, based on self-reporting, which could introduce some bias as seen in other studies such as McCormick et al. (2013). This highlights a need for the Walvis Bay Municipality (and other municipalities) to record the EOL fishing gear waste separately rather than categorising it as ‘waste from fishing factories” which includes other waste such as boxes, straps, detergent containers, damaged waste bins and old pallets, this would help in validating quantities provided by the fishing companies.

If the fishing gear are of longer life span, the estimated quantities of waste generated would be lower. With an average lifetime of 3 years for fishing nets and 2 years for fishing lines, frequent use would ultimately lead to wear and tear, as revealed by the fleet managers, thus making replacement of EOL fishing gear necessary (Table 2). The lifespan of fishing nets is on par with estimates from Scotland (Large polyethylene demersal: 3 years, small polyethylene demersal: 5 years, nylon pelagic nets: 8 years, polyethylene beam travel nets: 0.5 years, nylon gill nets: 0.5 years; Chambers et al., 2021) and Norway (trawl: 2.8 years, purse seine: 10.2 years, Danish seine: 3.9 years, gillnets: 2.1 years; Deshpande et al., 2019). Replacing fishing gear lost at sea was also discussed in Nogueira et al. (2022). Our findings support the premise that fishing nets and lines should be designed and manufactured to be resilient and long-lasting in order to enhance resource efficiency and the ability to be reused and recycled. Many factors influence the lifespan of a fishing gear, for example if fishing nets are exposed to the sun rays for a prolonged period, they lose their strength as the sun breaks down polyester nets and twine. In Namibia two factors accelerate deterioration of fishing gear, firstly, the sun rays break down the nets and rope quicker than countries with less sunshine. Secondly, the iron parts of fishing gear is quicker to rust as Namibia is one of the worst countries in the world where rust is aggressive.

Current EOL fishing gear management practices

Apart from selling the EOL fishing nets and lines to employees and donating to institutes, the study indicates that landfilling of EOL fishing gear is a primary route in Namibia, which is also common in other countries such as Sweden (Charter, 2023), Norway (Deshpande et al., 2020a) and Scotland (Cole et al., 2019). Landfilling, although a generally acceptable waste management method, presents environmental risks because landfills are potential causes of fires or explosions, and can contaminate soil and water, whilst they also cause other negative implications including reducing the value of the surrounding areas (Vaverkova, 2019). Thus, landfill should be a last option for EOL fishing gear, with recycling representing a more desirable end-of-life treatment than incineration and landfilling (Cole et al., 2019; Tippet, 2023; Karadurmus and Bilgli, 2024).

Generally fishing nets, lines and ropes are not single use, thus the element of reuse is invariably present. However, 81.2% of the fishing companies indicated that they recover some parts of the EOL fishing gear to reuse when the gear is in poor condition, without recycling them into new products. Reusing and recycling fishing gear was already proposed as a ‘Take-back scheme for fishing gear’ by Nogueira et al. (2022), and countries such as Iceland have already started recycling fishing gear (Bergmann et al., 2022). While the Namibian fishing industry might not fully conform to a CE in terms of fishing gear waste, we cannot conclude that EOL fishing nets, lines and ropes are not part of CE. It is commendable that while EOL fishing gear is dumped at dumpsites, individual vendors in coastal areas collect EOL fishing nets, lines and ropes which they repurpose for various activities such as gardening, transportation and at the carwash to serve as carpets/floor coverings. Here we advocate for the creation of artisanal value-added products from EOL fishing gear, however, this warrants a study opportunity to identify and map products that can potentially be made out of EOL fishing gear. Globally there are instances of EOL fishing gear recycled or repurposed into accessories, clothing, footwear, homeware, and recreational products (Charter, 2022).

Some fishing companies sell derelict fishing nets, lines and ropes to their employees. Old fishing nets and lines are also sold by vendors inland (away from the coast) catering to consumers who have limited access to the ocean and fishing companies (NBC, 2023). We observed that some EOL fishing nets are sold in pieces as bathing scrubbing nets, however the quantities are unknown, because they are not recorded. Although these EOL fishing nets are in demand as they have many uses, we observed that no value is added to these fishing gear waste as they are simply repurposed.

Opportunities to promote a circular economy

Transitioning from LE to CE presents many benefits including resource efficiency, waste reduction, creation of employment opportunities, reducing business production costs, economic opportunities, and business models. Thus, implementing a CE is a catalyst in accelerating economic growth (Naustdalslid, 2014; Darmandieu et al., 2021; Eimontas et al., 2023; Longfor et al., 2023), with numerus opportunities. Instead of disposing of resources in landfills as the final waste management alternative, the CE model emphasizes recycling and reusing materials, a practice beneficial to the environment and can lead to sustainability (Deshpande et al., 2020a). In addition, nets, lines and ropes are predominantly composed of plastic polymers made from petrochemicals (Merrington, 2017). Increasing the amount of fishing gear that is recycled, reused, or repurposed offsets the creation or use of virgin plastic materials. Therefore, encouraging and supporting solutions for EOL fishing gear can help support the move away from fossil fuels and increase resource sustainability. However, the price of virgin plastics is linked to the price of oil (Hopewell et al., 2009; Gu et al., 2020), and consequently recycled plastics are less economically viable when oil prices are lower (Merrington, 2017) which poses a challenge for developing a CE for fishing gear.

The CE presents an opportunity to convert ‘trash’ to ‘treasure’. For example, investing in waste-to-energy and conversion technologies can address the challenge of waste disposal while simultaneously contributing to renewable energy production and resource recovery (Suprapto, 2022). Meanwhile, new technologies may offer a pathway to the creation of products of added value. For instance, Wyss et al. (2023) demonstrated how plastic waste can be converted into clean H2 along with high purity graphene. This idea and technique could be applied to EOL fishing gear, as Eimontas et al. (2023) indicated its suitability as a feedstock for additional higher added value energy product generation. The practice of value addition is well highlighted in the concept of the Blue Economy, which most countries, including Namibia, are advocating for. The integration of CE principles in the blue economy can lead to sustainable growth, reduced environmental impact, and improved livelihoods for coastal communities, while preserving the health and integrity of marine ecosystems and resources.

As CE practices become more widespread, new business opportunities will emerge, particularly in the recycling, repair, and remanufacturing sectors. Sweden created a recycling centre focusing on fishing gear waste (Charter, 2023), that can serve as a model for other countries. Recycling fishing nets has the potential to generate income, create employment opportunities, and reduce environmental pollution. Recovered fishing nets, lines and ropes can promote CE, as they can be used as reinforcement materials in construction materials such as cementitious mortars and gypsum boards (Ottosen et al., 2018; Bertelsen and Ottosen, 2022) and can also be used to manufacture new fishing nets (European Commission, 2015). The model can help conserve virgin materials and by sourcing inputs locally, businesses can reduce the risks associated with supply chain disruptions, such as price fluctuations and shortages (Longfor et al., 2023), especially as a substantial number of companies source fishing gear from Spain (27.7%) and other countries. This can help local businesses maintain their operations during periods of economic uncertainty and contribute to the overall stability of the local economy.

Locally manufactured products can be good for the economy and stimulate development and growth, through employment creation (workers to operate machinery, manage inventory, and handle customer service), which in turn boosts the local economy. Former fishermen were reported to have created employment opportunities through selling old fishing nets to farmers (NBC, 19 September 2023). CE promotes sustainable and responsible business practices that benefit both the environment and the economy (Nilsen, 2020; Darmandieu et al., 2021). Local manufacturing firms can respond more quickly to changes in demand and supply and increase local competitiveness and market conditions adaptability. This can lead to greater innovation and creativity, and designs by means of repurposing, recycling, and reuse of fishing nets, lines and ropes. In addition, there can be a breakthrough in technology, new products, and new industries, and a win-win for both local firms and healthy trade for a resilient domestic economy (Aligod and Kaoud, 2023). The fishing gear ‘manufacturing’ companies in Namibia have been described as ‘net-loft’ that repair and maintain the fishing gear (Endjambi, 2017). Although the existing fishing gear manufacturing companies are not ‘true manufacturing companies’, because they import fishing gear parts and assemble them, their establishment in Namibia is a step in the right direction to stimulate the industry and grow the economy. In 2022 alone, Namibia imported 560 tons of fishing nets, lines and ropes (Data obtained from the Namibia Revenue Agency (NamRA)). The local manufacturing companies hold the potential to recycle the EOL fishing gear as an action geared toward transitioning from the LE model that centres around “take, make, use and dispose” (Furkan, 2017; Gill and Verma, 2021; Rashid and Malik, 2023). The EOL fishing gear studied are largely made out of plastics, which can be recycled, reused, and adopted as input materials by manufacturers such as Plastic Package which are already making plastics from recycled materials. Fishing nets are primarily made from the polymers polyethylene (PE), polypropylene (PP), and Nylon (polyamide/PA) (Andrady, 2011; Deshpande et al., 2020b). However, whilst nylon is of higher value and use for recycling as it maintains its structural and mechanical properties through several recycling cycles, this is not the case for other polymers (Deshpande et al., 2020a). For instance, recycling PE fishing gear has its limitations, with a degradation of mechanical properties requiring the addition of virgin plastics or consideration of other uses (Juan et al., 2021). Consequently, nylon as a recycled material tends to retain its economic value to a greater extent than PE and PP.

A CE can significantly increase efforts aimed at reducing marine pollution of plastic waste from EOL fishing gear, which is a major threat to marine life and ecosystems, including in the form of microplastics which known to be shed from Abandoned, Lost, or otherwise Discarded Fishing Gear (ALDFG) (Syversen et al., 2022). None of the fishing companies have reported deliberate dumping of fishing nets, most likely due to their high financial cost, with fishing nets estimated at approximately N$450000 (USD 30200). However, 30% have indicated a loss of fishing nets without retrieval in the last 12 months. In addition to the costs, the International Convention for the Prevention of Pollution from Ships (MARPOL, 1973) mandates fishing vessels to retrieve all lost fishing gear and minimize pollution. It is easy now to retrieve fishing gear as modern equipment, for example net sensor, makes easier to search and locate gear. The CE aims to minimize waste generation by keeping the products circulating in the economy (Rashid and Malik, 2023). Furthermore, since none of the surveyed companies use biodegradable fishing gear (BFG) at the moment, the fishing industry could transition to BFG that is potentially less harmful to the environment and biota when lost at sea, especially in terms of reduced “ghost fishing” (Drakeford et al., 2023). However, this calls for regulation to enforce the use of BFG to compel the fishing industry to adopt its use. Since there are fishing gear manufacturing companies, it might be ideal to restrict fishing companies to use a certain percentage (e.g., 60%) of the gear manufactured locally, where regulation could be passed to ensure that the fishing gear manufactured is biodegradable. Namibia only has two ports, as opposed to other countries like South Africa with multiple ports, which should make it easy to address the issue of EOL fishing gear. However, reluctance to switch to BFG could be attributed to the fact that currently it appears to be technically inferior to conventional fishing gear, giving a lower performance and leading to relatively lower catches (Grimaldo et al., 2019; Kim et al., 2019), however this warrants further investigation. CE also presents opportunities for value addition if the waste is repurposed into valuable goods, there by presenting hidden opportunities for economic growth.

Challenges to circular economy

The fishing industry has recognized key challenges associated with EOL fishing gear, highlighting an urgent need to address them. Key to the success of adopting the CE model is a need for the establishment of regulatory tools specific to the adoption of the CE model which would compel both consumers and producers to transition from LE to CE with an aim to design products with longer lifespans to be able to be recycled and reused (Nogueira et al., 2022; Rashid and Malik, 2023). For example, the European Commission has approached the challenge of EOL fishing gear and ALDFG by incorporating CE (Basurko et al., 2023). Similarly, the United Nations with Global Ghost Gear Initiative and other developed countries including India have already adopted the CE model (Gill and Verma, 2021). However, the concept is still novice in Africa (Mhlanga et al., 2022). Kenya (Muriithi and Ngare, 2023), South Africa (Republic of South Africa, 2020) and Nigeria (Olukanni et al., 2018) are among the few countries in Africa reported having policies and practices that align with CE.

The Namibian Marine Resources Regulations of 2001 (Government Notice 241 of 2001) prohibits fishing gear to be left in the sea or on the seashore on the termination of harvesting. Furthermore, any costs incurred in connection with the removal of any fishing gear, or any other non-biodegradable object may be recovered from the person by whom the gear or object was left on or in the sea or on the seashore, which costs constitute a debt owing to the State. Although this regulation places Namibia among the few countries committed to protect the environment, there are still gaps regarding how fishing gear waste should be managed. For effective waste management, countries should formulate waste management laws and policies (Suprapto, 2022). Although the CE model in Namibia is embedded in the National Solid Waste Management Strategy (GRN, 2017), not much is achieved to this effect. To accelerate the transition to CE, municipal waste regulations such as the WBM Solid and Hazardous Waste Management Regulations: Local Authorities Act 1992 (GRN, 2011) can be amended to consider the use of waste to promote CE. At a local level, the WBM promotes CE through their Integrated Environmental Policy (Municipality of Walvis Bay, 2023). The WBM is guided by the National Waste Management Strategy for the Ministry of Environment Forestry and Tourism (GRN, 2017), the Environmental Management Act (EMA) of 2007 (EMA, 2007) and other international best practices. Addressing challenges associated with the incorporation of EOL fishing gear into CE requires a multi-faceted approach involving collaboration between governments, fishing industry stakeholders, environmental organizations, and local communities to develop sustainable solutions for recycling EOL fishing gear. However, care should be taken to recycle into products that are non-toxic.

The lack of recycling expertise and waste recovery facilities to collect and convert EOL fishing gear to value-added products further limits the practice of CE in Namibia. This challenge is not unique to Namibia, for example Deshpande et al. (2020a) recognized the large quantities of EOL fishing gear generation in Norway, however, they opined that the lack of recycling capacity and inadequate infrastructure has resulted in exporting most of the recyclable fraction out of Norway for further processing. Another report based on work done in 2019 in Scotland indicated that there are currently no recycling facilities for waste nets in Scotland and typically the only viable waste destination is landfill (Cole et al., 2019). This challenge can be addressed by for example introducing a port reception facility, which can facilitate more efficient collection of gear (Tippet, 2023). Establishment of recycling facilities coupled with CE expertise make a good receipt for promotion of CE. A long-term goal could be the establishment of an innovation hub, including a port reception facility, near one of the two ports, that brings together and engages key stakeholders, and adds to the value chain of EOL fishing nets, lines, and ropes.

The strategies to promote CE should involve key stakeholders to promote engagement and collaboration, especially in the blue economy. Key stakeholders include national government, local governments, businesses, local communities, and NGOs working together to develop and implement sustainable practices. Stakeholders need to have a solid understanding of the possible economic gains, waste reduction, reduced environmental load, and material reuse for the CE concept to be implemented successfully (Despeisse et al., 2015; Nogueira et al., 2022). Central to the strategies is a need to prioritize awareness-raising efforts to help consumers understand the benefits of the CE. Marketing campaigns that highlight the environmental benefits of sustainable products to educational programs that rise awareness to consumers to recycle and reuse products effectively. By implementing these strategies, businesses can successfully adopt the CE model and make a positive impact on the environment while also improving business profits.

Key challenges toward developing a CE for fishing nets, lines and ropes included a lack of recycling facilities and infrastructure, and paucity of data on the amount and types of material reaching EOL. However, despite these challenges, Namibia has the potential to be a lodestar for fishing nets, lines, and ropes CE within the wider African region. The low number of ports (two), in combination with the presence of smalls-scale reuse and recycling practices are favorable to the establishment and scaling-up of fishing gear management and recycling efforts. In addition, the Namibian Government has aligned with key goals striving toward sustainable development and fisheries (FAO, 2015; UNDP, 2016; FAO, 2022), and has named environmental sustainability as one of the four integrated pillars of sustainable development in the 5th National Development Plan (NDP5, 2017).

There is also a track record for implementing innovative solutions in the fisheries sector within the region to alleviate negative impacts on wildlife. For instance, changes to Namibian hake (Merluccius spp) fisheries to include bird-scaring lines, following regulations passed by the Ministry of Fisheries and Marine Resources, resulted in 98.4% reduction in seabirds killed (Da Rocha et al., 2021). Additionally, it is important that environmental sustainability is embedded within the fisheries development as the sector is important in terms of employment and the economy in Namibia (NPD5, 2017; NSA, 2021; FAO, 2024), and because fisheries themselves are likely to suffer reduced efficiency and productivity due to marine plastics including fishing gear (Beaumont et al., 2019). Therefore, there exists the potential to combine innovation, industry, businesses, and policy together with community engagement and entrepreneurs to drive initiatives that enhance the movement toward a circular economy fishing nets, lines, and ropes in Namibia.

Conclusion and recommendations

Our results highlight an urgent need for the adoption of a CE model focusing on EOL fishing gear generated in the Namibian fishing industry, thereby contributing to effective waste management, and promoting sustainable consumption of resources. Although our study makes an important contribution to the CE paradigm, in relation to EOL fishing gear, it was limited to only fishing nets, lines and ropes, while other fishing gear such as fishing traps were not considered. Future studies, therefore, can include other EOL fishing gears to allow for more generalized conclusions. Furthermore, there is a need for the Walvis Bay Municipality (and other municipalities) to record the EOL fishing gear waste separately. This study highlights a paucity of data as far as EOL fishing gear is concerned. To better inform recyclers and understand the potential for new products it is vital that the amount of the material available is established. The fishing industry, who bears the costs and time associated with the management and disposal of EOL fishing gear is best placed to take a comprehensive inventory of the types and amount of waste produced annual. We also recommend the Government of Namibia to strictly enforce the Polluter pays principle stipulated in the Namibia’s National Marine Pollution Contingency Plan (NMPCP) (NPC, 2017), whereby the costs of pollution are borne by those causing it, rather than on those who are affected by its consequences. In addition, although supporting sustainable practices is a key underlying principle of the SSF guidelines adopted as part of Namibia’s National Plan of Action for Small-Scale Fisheries (FAO, 2022), there is no specific reference, recommendations, or guidelines concerning waste or end-of-life fishing gear, nor its disposal or recycling. We recommend the inclusion of sustainable fishing gear management in the next iteration of Namibia’s National Development Plan to support sustainable fishing practices and enhance resource management and efficiency, and to encourage the movement toward a more circular economy. There is an opportunity to extend the life of materials used in fishing gear by ensuring that they remain in circulation and not disposed when they reach their end-of-life. We recognize the community recycling of fishing gear on a small scale and on a more informal practice; however, this concept can be extended to various commercial fields to maximize the economic and environmental gains. It is undeniable that realizing the transition from LE to CE requires considerable legislation changes that can compel both users and producers to embrace the CE model and at the same time hold fishing companies accountable for their fishing gear waste. Furthermore, it is important to involve key stakeholders in the business sector when driving the CE, as consultations with key stakeholders can provide valuable insight on how to effectively implement CE. Reducing waste and promoting circularity of resources holds promises to advance a more sustainable and prosperous planet and global market economy.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

Written informed consent was not obtained from the individual(s) for the publication of any potentially identifiable images or data included in this article because this is a picture of a car at a carwash and there is a human that is not identifiable.

Author contributions

VE: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Visualization, Writing – original draft, Writing – review & editing, Supervision. FJ: Visualization, Writing – original draft, Writing – review & editing. NA: Writing – review & editing. NJ: Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

The authors are grateful to fleet managers of various fishing companies for participating in the survey used to collect data used in this study.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aligod, L., and Kaoud, H. (2023). A framework to facilitate the transition to a circular economy in smart cities. J. Namibian Stud. 34, 521–535,

Andrady, A. L. (2011). Microplastics in the marine environment. Mar. Pollut. Bull. 62, 1596–1605. doi: 10.1016/j.marpolbul.2011.05.030

Basurko, O. C., Markalain, G., Mateo, M., Peña-Rodriguez, C., Mondragon, G., Larruskain, A., et al. (2023). End-of-life fishing gear in Spain: quantity and recyclability. Environ. Pollut. 316:120545. doi: 10.1016/j.envpol.2022.120545

Beaumont, N. J., Aanesen, M., Austen, M. C., Börger, T., Clark, J. R., Cole, M., et al. (2019). Global ecological, social and economic impacts of marine plastic. Mar. Pollut. Bull. 142, 189–195. doi: 10.1016/j.marpolbul.2019.03.022

Bergmann, M., Collard, F., Fabres, J., Gabrielsen, G. W., Provencher, J. F., Rochman, C. M., et al. (2022). Plastic pollution in the Arctic. Nat. Rev. Earth Environ. 3, 323–337. doi: 10.1038/s43017-022-00279-8

Bertelsen, I. M. G., and Ottosen, L. M. (2022). Recycling of waste polyethylene fishing nets as fibre reinforcement in gypsum-based materials. Fibers Polymers 23, 164–174. doi: 10.1007/s12221-021-9760-3

Chambers, K., Jarvis, F., and Powell, K. (2021). Policy options for fishing and aquaculture gear, phase 1: gear inventory. Department for Environment food & Rural Affairs (DEFRA) ME5240. Available at: https://randd.defra.gov.uk/ProjectDetails?ProjectID=20655

Charter, M., and Whitehead, P. (2023). Sotenäs marine recycling Centre in Sweden: a case study related to waste fishing gear. In Gamstad, S. V., Ottosen, L. M., and James, N. A. (eds) (2023). Marine Plastics: Innovative Solutions to Tackling Waste. Springer.

Charter, M. (2022). Products from waste fishing nets: accessories, clothing, footwear, home ware and recreation. Blue Circular Economy. Available at: https://cfsd.org.uk/wp-content/uploads/2022/04/Products-from-waste-fishing-gear-March-2022.pdf

Cole, G., Thomas, B., Jones, B., Hargreaves, S., Chambers, K., Powell, K., et al. (2019). Mapping economic, Behavioural and social factors within the plastic value chain that lead to marine litter in Scotland : Resource Future Ltd. Prepared for the Scottish Government. Available at: https://www.gov.scot/binaries/content/documents/govscot/publications/research-and-analysis/2020/02/mapping-economic-behavioural-social-factors-within-marine-plastic-value-chain-scotland/documents/summary-report/summary-report/govscot%3Adocument/summary-report.pdf

Cooney, R., de Sousa, D. B., Fernández-Ríos, A., Mellett, S., Rowan, N., Morse, A. P., et al. (2023). A circular economy framework for seafood waste valorisation to meet challenges and opportunities for intensive production and sustainability. J. Clean. Prod. 392:136283. doi: 10.1016/j.jclepro.2023.136283

Cristóvão, R. O., Botelho, C. M., Martins, R. J. E., and Loureiro, J. M. (2015). Fish canning industry wastewater treatment for water reuse – a case study. J. Clean. Prod. 87, 603–612. doi: 10.1016/j.jclepro.2014.10.076

Curtis, S., Elwen, S. H., Dreyer, N., and Gridley, T. (2021). Entanglement of cape fur seals (Arctocephalus pusillus pusillus) at colonies in Central Namibia. Mar. Pollut. Bull. 171:112759. doi: 10.1016/j.marpolbul.2021.112759

da Rocha, N., Oppel, S., Prince, S., Matjila, S., Shaanika, T. M., Naomab, C., et al. (2021). Reduction in seabird mortality in Namibian fisheries following the introduction of bycatch regulation. Biol. Conserv. 253:108915. doi: 10.1016/j.biocon.2020.108915

Darmandieu, A., Garcés-Ayerbe, C., Renucci, A., and Rivera-Torres, P. (2021). How does it pay to be circular in production processes? Eco-innovativeness and green jobs as moderators of a cost-efficiency advantage in European small and medium enterprises. Bus. Strateg. Environ. 31, 1184–1203,

Deshpande, P. C., Brattebø, H., and Fet, A. M. (2019). A method to extract fishers’ knowledge (FK) to generate evidence for sustainable management of fishing gears. MethodsX. 6, 1044–1053. doi: 10.1016/j.mex.2019.05.008

Deshpande, P. C., Philis, G., Brattebø, H., and Fet, A. M. (2020b). Using material flow analysis (MFA) to generate the evidence on plastic waste management from commercial fishing gears in Norway. Resources, Conservation & Recycling: X 5:100024. doi: 10.1016/j.rcrx.2019.100024

Deshpande, P. C., Skaar, C., Brattebo, H., and Fet, A. M. (2020a). Multi-criteria decision analysis (MCDA) method for assessing the sustainability of end-of-life alternatives for waste plastics: a case study of Norway. Sci. Total Environ. 719:137353. doi: 10.1016/j.scitotenv.2020.137353

Despeisse, M., Kishita, Y., Nakano, M., and Barwood, M. (2015). Towards a circular economy for end-of-life vehicles: a comparative study UK -Japan. Procedia CIRP 29, 668–673. doi: 10.1016/j.procir.2015.02.122

Drakeford, B., Forse, A., and Failler, P. (2023). The economic impacts of introducing biodegradable fishing gear as a ghost fishing mitigation in the English Channel static gear fishery. Mar. Pollut. Bull. 192:114918. doi: 10.1016/j.marpolbul.2023.114918

Eimontas, J., Striugas, N., Zakarauskas, K., and Kiminaite, I. (2023). Catalytical thermal conversion of waste fishing nets for a higher added value energy products generation and caprolactam recovery. Fuel 334:126735. doi: 10.1016/j.fuel.2022.126735

EMA (2007). Available at: https://www.laws.parliament.na/cms_documents/environmental-management-act-98a722d979.pdf (Accessed December 07, 2023).

Endjambi, T. (2017). Biomass survey manual: A proposed standard guide for conducting annual biomass survey for the monkfish fishery in Namibia. Reykjavik: United Nations University -Fisheries Training Programme, 48.

Erasmus, V. N., Hamutenya, S. S., Numwa, O., and Petrus, E. (2023). “The Namibian Mariculture: productivity, challenges and opportunities” in Emerging sustainable aquaculture innovations in Africa. eds. N. N. Gabriel, E. Omoregie, and K. P. Abasubong. 1st ed. (Singapore: Springer Nature Singapore). 441–458.

Erasmus, V. N., Kadhila, T., Gabriel, N. N., Thyberg, K. L., Ilungu, S., and Machado, T. (2021). Assessment and quantification of Namibian seafood waste production. Ocean Coast. Manag. 199:105402. doi: 10.1016/j.ocecoaman.2020.105402

European Commission (2015). Communication from the commission to the European Parliament, the council, the European economic and social committee and the Committee of the Regions. Closing the loop – An EU action plan for the circular economy. Brussels. COM (2015) 614 final. Available at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614

FAO (2015). Voluntary guidelines for securing sustainable small-scale fisheries in the context of food security and poverty eradication. Rome.

FAO (2022). National Plan of Action for Small-Scale Fisheries 2022–2026. Available at: https://namibia.un.org/en/207292-national-plan-action-small-scale-fisheries-2022-2026-npoa-ssf

FAO (2024). Fishery and Aquaculture Country Profiles. Namibia, 2024. Country Profile Fact Sheets. Fisheries and Aquaculture Division [online]. Rome. Available at: https://www.fao.org/fishery/en/facp/nam?lang=en (Accessed December 7, 2023).

Furkan, S. (2017). Linear economy versus circular economy: a comparative and analyzer study for optimization of economy for sustainability. Visegrad J. Bioecon. Sust. Dev. 6, 31–34. doi: 10.1515/vjbsd-2017-0005

Gill, K., and Verma, I. (2021). Circular economy: a review of global practices and initiatives with special reference to India. J. Press Ind. 8, 187–205. doi: 10.17492/jpi.focus.v8i1.812109

Grimaldo, E., Herrmann, B., Su, B., Føre, H. M., Vollstad, J., Olsen, L., et al. (2019). Comparison of fishing efficiency between biodegradable gillnets and conventional nylon gillnets. Fish. Res. 213, 67–74. doi: 10.1016/j.fishres.2019.01.003

GRN (2011). Solid and hazardous waste management regulations: Local authorities act, 1992. Government gazette no. 151. Windhoek: Government Printer.

GRN (2017). Ministry of Environment and Tourism (MET) 2017. National Solid Waste Management Strategy. Windhoek. Republic of Namibia. Available at: https://faolex.fao.org/docs/pdf/nam193634.pdf (Accessed July 30, 2023).

Gu, F., Wang, J., Guo, J., and Fan, Y. (2020). Dynamic linkages between international oil price, plastic stock index and recycle plastic markets in China. Int. Rev. Econ. Fin. 68, 167–179. doi: 10.1016/j.iref.2020.03.015

Haimbala, T., and Ambi, H. E. A. (2020). A comparison of waste Management Systems in the Towns of Walvis Bay and Limbe: experience from Vienna, Austria. Int. J. Sci. Res. Publ. 10, 385–394. doi: 10.29322/IJSRP.10.07.2020.p10345

Hassan, S. H., Aziz, H. A., Daud, N. M., Keria, R., Noor, S. M., Johari, I., et al. (2018). The methods of waste quantification in the construction sites (a review). Adv. Civil Eng. Sci. Technol.,

Hopewell, J., Dvorak, R., and Kosior, E. (2009). Plastics recycling: challenges and opportunities. Phil. Trans. Royal Soci. B Biol. Sci. 364, 2115–2126. doi: 10.1098/rstb.2008.0311

Johannes, R. E., Freeman, M. M. R., and Hamilton, R. J. (2000). Ignore fishers’ knowledge and miss the boat. Fish Fish. 1, 257–271. doi: 10.1111/j.1467-2979.2000.00019.x

Juan, R., Domínguez, C., Robledo, N., Paredes, B., Galera, S., and García-Muñoz, R. A. (2021). Challenges and opportunities for recycled polyethylene fishing nets: towards a circular economy. Polymers 13:3155. doi: 10.3390/polym13183155

Karadurmus, U., and Bilgli, L. (2024). Environmental impacts of synthetic fishing nets from manufacturing to disposal: a case study of Türkiye in life cycle perspective. Mar. Pollut. Bull. 198:115889. doi: 10.1016/j.marpolbul.2023.115889

Kaza, S., Yao, L. C., Bhada-Tata, P., and Van Woerden, F. (2018). What a waste 2.0: A global snapshot of solid waste management to 2050 : World Bank.

Kim, S., Kim, P., Lim, J., An, H., and Suuronen, P. (2019). Use of biodegradable driftnets to prevent ghost fishing: physical properties and fishing performance for yellow croaker. Anim. Conserv. 19, 309–319. doi: 10.1111/acv.12256

Korhonen, J., Honkasalo, A., and Seppälä, J. (2018). Circular economy: the concept and its limitations. 143 ecological economics 37; Heidi Rapp Nilsen, “the hierarchy of resource use for a sustainable circular economy”. Int. J. Soc. Econ. 143, 37–46. doi: 10.1016/j.ecolecon.2017.06.041

Longfor, N. R., Dong, L., Wang, J., and Qian, X. (2023). A techno-economic assessment on biomass waste-to-energy potential in Cameroon. Environ. Res. Letter 18:104031. doi: 10.1088/1748-9326/acfbed

Macfayden, G., Huntington, T., and Cappell, R. (2009). Abandoned, lost or otherwise discarded fishing gear. Rome: Food and Agriculture Organization of the United Nations (FAO).

MARPOL (1973). International Convention for the Prevention of Pollution from Ships (MARPOL). Available at: https://www.imo.org/en/about/Conventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx

McCormick, J. L., Quist, M. C., and Schill, D. J. (2013). Self-reporting Bias in Chinook SalmonSport fisheries in Idaho: implications for roving creel surveys. N. Am. J. Fish Manag. 33, 723–731. doi: 10.1080/02755947.2013.808293

Merrington, A. (2017). “9 - recycling of plastics” in Applied plastics engineering handbook. ed. M. Kutz. 2nd ed (William Andrew Publishing, Plastics Design Library).

Mhlanga, J., Haupt, T. C., and Loggia, C. (2022). Shaping circular economy in the built environment in Africa. A bibliometric analysis. J. Eng. Design Technol.,

Morseletto, P., Mooren, C. E., and Munaretto, S. (2022). Circular economy of water: definition, strategies and challenges. CircEconSust 2, 1463–1477. doi: 10.1007/s43615-022-00165-x

Municipality of Walvis Bay (2023). Integrated Environmental Policy- 2022 -2023. Namibia: Walvis Bay.

Muriithi, J. K., and Ngare, I. O. (2023). Transitioning circular economy from policy to practice in Kenya. Front. Sustain. 4:1190470. doi: 10.3389/frsus.2023.1190470

Naustdalslid, J. (2014). Circular economy in China–the environmental dimension of the harmonious society. Int. J. Sustain. Dev. World Ecol. 21, 303–313. doi: 10.1080/13504509.2014.914599

NBC (2023). Available at: https://www.nbcnews.na/node/102667

Nilsen, H. R. (2020). The hierarchy of resource use for a sustainable circular economy. Int. J. Soc. Econ. 47, 27–40. doi: 10.1108/IJSE-02-2019-0103

Nogueira, L. A., Kringelum, L. B., Olsen, J., Jørgensen, F. A., and Vangelsten, B. V. (2022). What would it take to establish a take-back scheme for fishing gear? Insights from a comparative analysis of fishing gear and beverage containers. J. Ind. Ecol. 26, 2020–2032. doi: 10.1111/jiec.13296

NPC (2017). National Marine Pollution Contingency Plan. Available at https://www.giwacaf.net/site/assets/files/1612/plan_na_en.pdf (Accessed December 10, 2023).

NPD5 (2017). 5th National Development Plan. Namibia. National Planning Commission. Available at: https://www.npc.gov.na/national-plans/national-plans-ndp-5/

NSA (2021). Namibia Trade Statistics Bulletin. Available at: https://https://www.nsa.org.na/page/publications/

Olukanni, D. O., Aipoh, A. O., and Kalabo, I. H. (2018). Recycling and reuse technology: waste to wealth initiative in a private tertiary institution, Nigeria. Recycling 3:44. doi: 10.3390/recycling3030044

Ottosen, L., Svensson, S., and Bertelsen, I. (2018). “Discarded nylon fishing nets as fibre reinforcement in cement mortar” in Waste management and the environment IX (Ashurst, Southampton, UK: WIT Press), 245–256.

Principato, L., Pratesi, C. A., and Secondi, L. (2018). Towards zero waste: An exploratory study on restaurant managers. Int. J. Hosp. Manag. 74, 130–137. doi: 10.1016/j.ijhm.2018.02.022

Rashid, S., and Malik, S. H. (2023). “Transition from a linear to a circular economy” in Renewable energy in circular economy, circular economy and sustainability. eds. S. A. Bandh, F. A. Malla, and A. T. Hoang vol. 2023.

Regulations relating to the Exploitation of Marine Resources (Government Notice 241 of 2001), Available at https://mfmr.gov.na/documents/411764/417987/Marine+Regulations+Relating+to+the+Exploitation+of+Marine+Resources.pdf/73eb8b75-312a-5ad8-bec5-293c99a47a8c (Accessed October 30, 2023).

Republic of South Africa (2020). South Africa’s National Waste Management Strategy. Available at: https://www.dffe.gov.za/sites/default/files/docs/2020nationalwaste_managementstrategy1.pdf (Accessed July 27, 2023).

Richardson, K., Hardesty, B. D., Vince, J., and Wilcox, C. (2022). Global estimates of fishing gear lost to the ocean each year. Science. Advances 8. doi: 10.1126/sciadv.abq0135

Shaughnessy, P. D. (1980). Entanglement of cape fur seals with man-made objects. Mar. Pollut. Bull. 11, 332–336. doi: 10.1016/0025-326X(80)90052-1

Suprapto, S. (2022). Waste management Laws and Policies in Indonesia: challenges and opportunities. J. Appl. Phys. Sci. 8, 1–8,

Syversen, T., Lilleng, G., Vollstad, J., Hannsen, B. J., and Sønvisen, S. A. (2022). Oceanic plastic pollution caused by Danish seine fishing in Norway. Mar. Pollut. Bull. 179:113711. doi: 10.1016/j.marpolbul.2022.113711

Tippet, A. W. (2023). “Life cycle assessment of fishing and aquaculture rope recycling” in Marine plastics: Innovative solutions to tackling waste. eds. S. V. Gamstad, L. M. Ottosen, and N. A. James, vol. 2023 (Cham, Switzerland: Springer).

UNDP (2016). United Nations development programme, sustainable development goals. Available at: www.undp.org/content/undp/en/home/sustainabledevelopment-goals.

Valavanidis, A. (2018). Concept and practice of the circular economy. Turning goods at the end of their service life into resources, closing loops in industrial ecosystems and minimizing waste. Available at: https://www.researchgate.net/publication/326625684_Concept_and_Practice_of_the_Circular_Economy

Vaverkova, M. D. (2019). Landfill impacts on the environment—review. Geosciences 9:431. doi: 10.3390/geosciences9100431

Wijkman, A., and Skånberg, K. (2017). The circular economy and benefits for society : Jobs and Climate Clear Winners in an Economy Based on Renewable Energy and ResourceEfficiency. Club of Rome Winterthur. Available at: https://www.clubofrome.org/wp-content/uploads/2020/03/The-Circular-Economy-and-Benefits-for-Society.pdf.

Wilcox, C., Mallos, N. J., Leonard, G. H., Rodriguez, A., and Hardesty, B. D. (2016). Using expert elicitation to estimate the impacts of plastic pollution on marine wildlife. Mar. Policy 65, 107–114. doi: 10.1016/j.marpol.2015.10.014

Keywords: circular economy, waste management, EOL fishing gear, sustainability, transition

Citation: Erasmus VN, Johannes FN, Amutenya N and James NA (2024) The potential contribution of end-of-life fishing nets, lines and ropes to a circular economy: the Namibian perspective. Front. Sustain. 5:1356265. doi: 10.3389/frsus.2024.1356265

Edited by:

Claudio Sassanelli, Politecnico di Bari, ItalyReviewed by:

Luka Traven, University of Rijeka, CroatiaAnupam Khajuria, United Nations University, Japan

Copyright © 2024 Erasmus, Johannes, Amutenya and James. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Victoria Ndinelago Erasmus, ZXJhc211cy52aWN0b3JpYUB5YWhvby5jb20=

Victoria Ndinelago Erasmus

Victoria Ndinelago Erasmus Fillemon Nadhipite Johannes2

Fillemon Nadhipite Johannes2 Neil A. James

Neil A. James