- 1Department of Mechanical & Aerospace Engineering, Nazarbayev University, Astana, Kazakhstan

- 2Department of Intelligent Systems & Cybersecurity, Astana IT University, Astana, Kazakhstan

- 3Department of Biomedical Sciences, School of Medicine, Nazarbayev University, Astana, Kazakhstan

3D food printing (3DFP) is emerging as a vital innovation in the food industry’s pursuit of sustainability. 3DFP has evolved to significantly impact food production, offering the capability to create customized, nutritionally balanced foods. Central Asia has a higher than global average level of meat consumption per capita, which might be influenced by its historical and cultural background of nomadism. This dietary trend might potentially result in negative impacts on both the environment and human health outcomes, as it leads to increased greenhouse gas emissions and increased risk of chronic diseases. Reducing meat consumption holds the potential to address these sustainability and health issues. A possible strategy to reduce meat consumption and promote plant-based foods is 3D Food Printing (3DFP), which can rely on plant-protein sources from the region to create appealing and tasty alternatives for these populations. This review summarizes recent studies on plant protein-rich materials for 3DFP as a substitute to meet the growing global demand for meat as well as the 3DFP printing parameters associated with the different plant-based proteins currently used (e.g., lentils, soybeans, peas, and buckwheat). The findings revealed that buckwheat, a dietary staple in Central Asia, can be a promising choice for 3DFP technology due to its widespread consumption in the region, gluten-free nature, and highly nutritious profile.

1 Introduction

In recent times, there has been a noticeable increase in the consumption of meat, contributed by the burgeoning global population and increased affluence in various regions (1) Average meat consumption increased by almost 60 percent across the world, while consumption per capita increased by almost 25 percent. Meat consumption is expected to continue growing by 1.7 percent per year through 2022 (2). Besides potential health problems caused by excessive meat consumption, there has been concerns raised about the environmental impact of meat production, contributing to issues such as increased greenhouse gas emissions, water depletion, pollution, and loss of biodiversity (3). A possible strategy to address the issues involves adopting a more plant-based diet with reduced reliance on meat consumption. This approach holds significant relevance, particularly in Central Asia (CA) (4) which consists of five countries, namely Kazakhstan, Uzbekistan, Kyrgyzstan, Tajikistan, and Turkmenistan.

The CA region is composed of diverse cultures, many of which originated from nomadic lifestyle and practices that depend on livestock farming and meat consumption as a main source of nourishment (5). In these societies, meat is not just a simple dietary choice; it has been an integral component of their way of life for many generations. Beyond providing essential nutrients, it sustains communities in remote terrains with adverse and harsh climatic conditions, preserving cultural identities (6). As the region undergoes rapid urbanization and dietary transformations, adapting these traditional dietary practices related to meat production and consumption presents unique challenges. Encouraging the population to shift toward diets richer in plant-based proteins poses practical challenges, necessitating innovative approaches. One potential solution is the application of 3D food printing (3DFP) to create meat analogs based on plant-based proteins, which are both acceptable and familiar to the populations in this region, offering a novel and sustainable dietary option.

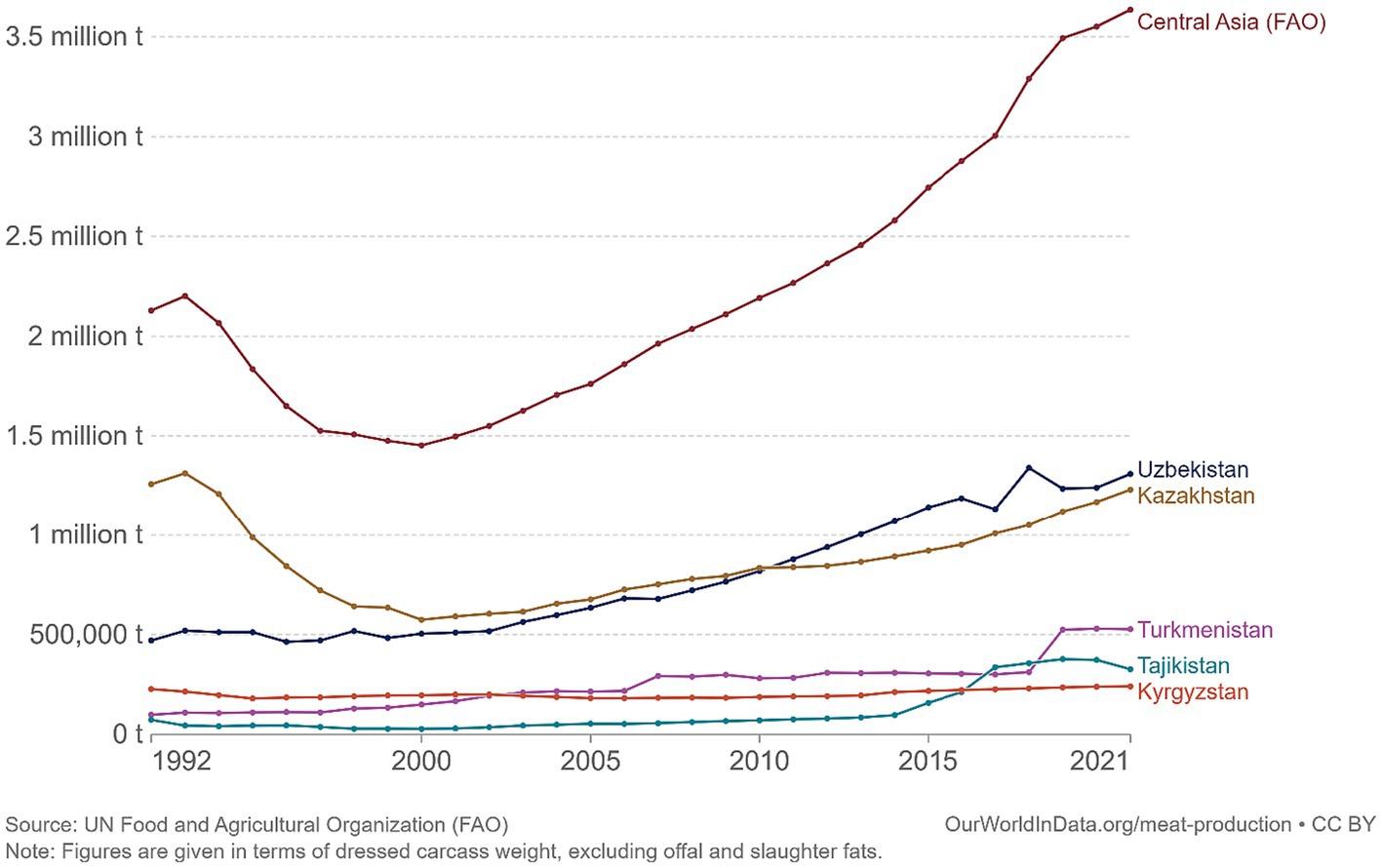

According to the United Nation’s Food and Agricultural Organization (FAO), in CA meat production has been increasing dramatically since 2000s up to 2021 (Figure 1) (7). This trend of rapidly growing meat production and consumption could potentially yield negative consequences, including environmental degradation and adverse public health impact. Particularly, the possible adverse effects include the strain on global resources caused by the extensive water and land usage in livestock farming (5), as well as the health risks associated with excessive consumption of processed meats (8–13).

Figure 1. Meat production in Central Asia in the last decades (7).

Consequently, promoting alternatives to meat protein consumption is a critical issue for both food security and public health.

The average meat consumption in CA ranges from 50 kg to 70 kg per capita per year. The average daily intake (124.76 g/day) for CA is reported to be one of the highest (14). According to World Population Review, Kazakhstan has the highest per capita consumption of sheep meat in the world, with an average of 8.5 kilograms per person annually. It has been recently shown that replacing a diet high in animal-based protein foods to one higher in plant-based protein foods can be beneficial for reducing risks factors associated with cardiovascular diseases and all-cause mortality (15, 16). Alternative plant-based diets are advantageous since not only are they rich in vital nutrients such as vitamins, minerals, and fiber, but they also have a lower environmental impact compared to meat-based diets. This potentially results in a substantial decrease in greenhouse gas emissions and the preservation of essential water and land resources, ultimately fostering an eco-friendlier food system (17). The structure of this paper is organized in such a way that it first discusses various strategies involving 3DFP for reducing meat consumption in CA. It then explores the utilization of plant-based proteins like soybean, pea, lentil, and buckwheat for 3DFP. Additionally, the review assesses how different printing parameters, such as print speed, layer height, and nozzle size, impact the quality of the printed food items and the properties of the plant-based materials used. Furthermore, the unique properties of buckwheat in the context of 3DFP are considered, and challenges in 3DFP’s use within the food industry are outlined. Finally, the challenges in 3DFP’s use within the food industry are outlined with respect to use.

2 The need for sustainable food solutions

To reduce the CO2 emissions of food production, it is important to move from a meat-based diet to a fruits and vegetables diet. This will help achieve sustainability in food production.

2.1 Reducing meat consumption in CA

In regions similar to CA, where a long-standing tradition of high meat consumption prevails, promoting plant-based diets requires innovative strategies that should be informed by both scientific principles and cultural considerations (18). To be effective, these strategies must take into account various factors, including taste preferences, cultural norms, preferences for familiar sensory experiences, and the prevailing symbolism of having meat in the diet (6). The challenges of shifting dietary patterns in the CA region are amplified by the strong meat-eating culture, deeply rooted in nomadic traditions. Throughout history, meat has served as a fundamental source of sustenance, intimately intertwined with the way of life in the region. This profound cultural attachment to meat consumption continues to pose a significant barrier to the widespread acceptance of alternative dietary choices (15). Therefore, any efforts to promote plant-based diets in this context must be thoughtfully developed, considering both the scientific and cultural dynamics at play.

2.2 Environmental and health benefits of plant-based diets

To enhance the promotion of plant-based diets, an alternative strategy involves increasing the awareness of their health benefits (19). Extensive research demonstrates that adopting plant-based diets can significantly lower the risk of chronic diseases such as heart diseases, diabetes, colorectal, pancreatic and prostate cancer (20–22).

Emphasizing the environmental advantages of plant-based diets is another effective approach. By reducing meat consumption, individuals can actively participate in mitigating the significant impact of livestock farming on greenhouse gas emissions and deforestation, ultimately promoting a more sustainable future. (23–25).

Additionally, it may be helpful to introduce plant-based alternatives that are similar in taste and texture to traditional meat dishes (26). Educational campaigns can help raise awareness about the benefits of plant-based diets and provide information on the preparation of healthy and delicious plant-based meals (27).

Emerging technologies such as 3DFP can provide exciting opportunities to influence dietary preferences and promote plant-based diets in CA by offering healthy, individualized substitutes for traditional meat consumption (28–30). Figure 2 provides a visual representation of the shift from a meat-based diet to a plant-based diet that is still rich in protein, a transition that is facilitated by the innovative use of 3DFP.

3 Potential of 3D printing in plant-based food production offering customization and innovation

3D printing technology has been gaining attention as an innovative approach to reducing meat consumption. The technology involves producing meat substitutes using plant-based ingredients that are 3D printed into the desired shape and texture (31). This approach has several potential benefits, including alleviating the environmental impact of meat production and improving animal welfare by reducing the need for livestock (10).

One of the most significant applications of 3D printing technology is the production of cell-based meat (32), which involves using animal cells to create meat products without the need for raising and slaughtering animals. The process involves the collection of a small sample of animal cells, which are consequently grown in a laboratory to produce muscle tissue. The resulting meat products are identical to traditional meat in terms of taste and texture offering customization to a greater extent and a substantially lower environmental impact (33).

While 3DFP technology is still in its early stages, it has the potential to revolutionize the food industry by providing a more sustainable and ethical alternative to traditional meat production. As research in this field progresses, an increase in innovative applications of 3D printing technology in the food industry can be expected.

4 Plant-based materials for 3D food printing

This section will discuss the different plant-based protein currently available and their applications in 3DFP.

4.1 Plant-based proteins

Plant-based materials, specifically proteins, are an excellent source of nutrition and a great alternative to meat proteins. Some popular plant-based protein sources include pea, buckwheat, soybean and lentil.

• Pea protein is a high-quality protein that is rich in essential amino acids, particularly lysine and threonine, (34). This protein is also easily digestible and has been shown to help reduce blood pressure (35) and improve kidney function (36).

• Buckwheat, on the other hand, is a gluten-free grain that is high in protein and fiber. It is also rich in antioxidants and has been shown to help lower cholesterol levels (37).

• Lentils, which are high in protein and fiber, may be ground into flour to make textured, protein-rich foods with customizable taste (38).

• Soybeans, also known for their high protein content, are employed in plant-based alternatives, giving sustainable possibilities for meat and dairy substitutes in 3D printing applications (39).

Incorporating these plant-based proteins into one’s diet can be a great way to improve health and reduce environmental impact. These plants can be used to prepare a variety of dishes, including soups, stews, salads, and smoothies, and to supplement a daily diet in the form of protein powder as well.

4.2 Applications of protein-rich plants to 3DFP

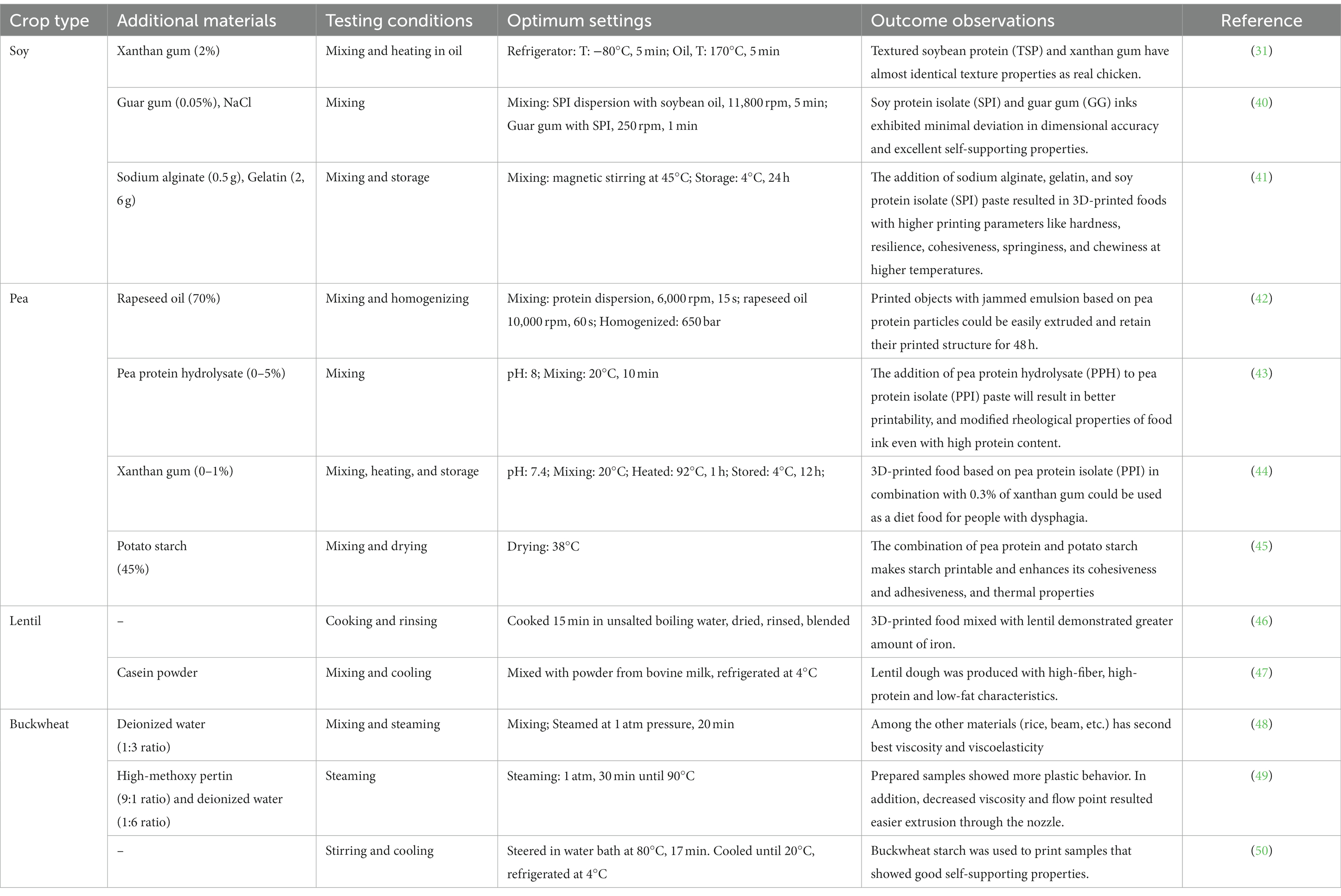

The use of 3D printing technology in food production has opened new possibilities for creating personalized nutrition and sustainable food system. Various plant-based food sources, such as soybean, pea, lentil, and buckwheat, offer diverse nutritional profiles that can be utilized for 3DFP. However, it is important to note that these protein-rich plants are most effective when combined with other ingredients and under optimized experimental conditions, as outlined in Table 1. By taking these factors into account, the potential for sustainable and nutrient-rich3D-printed food production can be fully realized.

Soybeans have long been a staple in foods made from plants due to their high protein content. Soy-based components such as soy protein isolates or soybean flours can be used in 3DFP to produce meat and dairy replacements as well as other plant-based goods (31). It is now possible to create textured and esthetically pleasing soy-based meals that imitate the qualities of conventional animal-based goods by printing complex structures with exact control over component ratios (51). For example, textured soybean protein (TSP) in combination with xanthan gum (2%) closely replicates the texture of real chicken (31). Additionally, excellent dimensional accuracy and great self-supporting properties can be achieved by soy protein isolate (SPI) and guar gum (0.05%) (40) by incorporating sodium alginate, gelatin, and SPI paste, 3D-printed soy-based foods can exhibit enhanced characteristics such as hardness, resilience, cohesiveness, springiness, and chewiness at higher temperatures (41). Furthermore, soybeans also have the additional advantage of being a sustainable source of protein, which fits with the expanding need for environmentally friendly food manufacturing techniques in the 3DFP sector (52).

Pea-based materials for 3D printing are a remarkable addition to the repertoire of sustainable and eco-conscious filament options. These filaments offer strong layer adhesion, ensuring that each print layer sticks well to the previous one, resulting in a structurally sound and reliable final product (42). Experiments have shown that pea protein particles mixed with 70% rapeseed oil can be easily extruded and maintain their structure for up to 48 h (42). It was reported that pea protein hydrolysate (PPH) with inclusion of pea protein isolate (PPI) paste reveals enhanced printability and modified rheological properties of food ink with a high protein content (43). Adding 0.3% xanthan gum to 3D-printed PPI-based food allows it to meet the dietary needs of individuals with dysphagia (44). Potato starch (45%) combined with pea protein makes the mixed starch printable and improves its cohesiveness, adhesiveness, and thermal properties (53). Moreover, the renewability of peas not only addresses concerns of resource depletion but also contributes to the economic viability and accessibility of pea-based materials (54).

Lentils are a great source of protein and fiber and can be turned into lentil flour, which makes them an excellent choice for 3D printing textured and protein-rich food items (45). Lentils can be used in 3D-printed food to enhance iron content by cooking for 15 min in unsalted boiling water (46). Additionally, mixing lentil flour with casein powder, exhibits lentil dough with high-fiber, high-protein, and low-fat characteristics, expanding the potential applications of lentils in 3D printing (47).

Buckwheat is a unique material in the realm of 3D printing due to its distinct characteristics. When used as a filament, it offers a range of properties that make it suitable for specific applications. Firstly, buckwheat, a gluten-free pseudo-cereal, possesses a rich nutritional profile. It is abundant in fiber, vitamin B6, magnesium, zinc, and other minerals (55). Moreover, buckwheat-based filaments can produce prints with a unique, slightly grainy texture. This can be desirable for certain applications where a natural, organic appearance is preferred. Due to its highly suitable rheological properties for 3D printing buckwheat performs as the best option as an alternative material among cereal grains (48). Particularly, mixing and steaming with buckwheat with deionized water at 1 atm for 20 min resulted in the samples with second-best viscosity and viscoelasticity. Additionally, increased plastic behavior was reported when buckwheat starch is utilized with high-methoxyl pectin and deionized water (in a 9:1 ratio) (49). This also decreased viscosity and flow point by making easier extrusion through the nozzle. Furthermore, 3D-printed samples displayed good self-supporting properties like in soybean achieved by stirring and cooling buckwheat-based materials (50). In section 4, application of buckwheat in 3D printing will be discussed.

Table 1 summarizes various plant-based materials utilized in 3DFP. Further research is warranted to optimize processing techniques and explore potential synergies with other food materials.

5 Buckwheat as a focus in 3DFP

Buckwheat is very popular in CA and has a relatively high content of protein. Therefore, it can be seen as an ideal candidate to produce eco-friendly 3D-printed food, as it is produced locally.

5.1 Buckwheat’s historical significance and applications in 3D printing

Buckwheat is cultivated in nearly every country that farms grains for local consumption. The significance of buckwheat as a crop is worth mentioning, especially in less fertile areas particularly, in colder and high-altitude regions of Asia. The origins of buckwheat cultivation can be traced back to inland Southeast Asia, approximately around 6,000 BCE. Afterward, this crop gradually spread to CA and Tibet, eventually reaching the Middle East and Europe by the 15th century 52. Fagopyrum esculentum (common buckwheat) and F. tataricum (Tartary buckwheat) are the main cultivated species of buckwheat which are believed to have originated in upland southwestern China, which were separate from the primary hubs of agricultural regions linked to the cultivation of rice and millet (56).

The incorporation of buckwheat in 3DFP offers several advantages. First, the nutritional composition of this crop can contribute to the development of customized and nutritious 3D-printed food products. Its gluten-free nature and unique flavor add distinctive taste profiles to the printed food (56). A study by S. Ji et al. investigated the rheological behavior of buckwheat-based pastes for extrusion-based 3D printing (50). The study found that varying the buckwheat content influenced the flow behavior and printability of the dough. Owing to its aromatic components, buckwheat has a unique flavor and scent. Jie Shi et al., utilized a sensory-directed flavor analysis approach to study the key odorants of tartary buckwheat for the first time (57). 49 aroma-active constituents with flavor dilution (FD) factors ranging from 1 to 2,187 were achieved through solvent-assisted flavor evaporation (SAFE) followed by an extraction of the volatile compounds of tartary buckwheat. Moreover, Malgorzata et al. provide an overview of the most recent developments concerning the sensory attributes, consumer choices, and the analysis of volatile compounds in both buckwheat and products made from buckwheat (58).

5.2 Buckwheat: an eco-friendly ingredient for sustainable food printing

Due to its many advantages, buckwheat emerges as a viable material for 3DFP, especially in regions where buckwheat is common such as CA (59–61). Small-scale farmers have social prospects owing to the production of buckwheat, particularly in areas with a shortage of arable land (62–64). It supports regional economies by providing a sustainable crop with minimal input needs (65). Buckwheat production is advantageous from an environmental standpoint as well (66, 67). The reduced chance of soil erosion and chemical discharge is due to fewer synthetic inputs needed (68). The quick growth cycle of buckwheat and its capacity to flourish in a range of environments combine with sustainable farming techniques, promoting soil health and biodiversity preservation (69).

While the integration of eco-friendly ingredients as in the case of buckwheat in 3DFP showcases the potential for sustainable food production, it also brings us to the forefront of technical challenges in 3DFP. Next, the critical aspects of 3D printing technology that directly affect the production of food will be examined.

6 Challenges and future directions

To guarantee the successful integration of 3D printing in food manufacturing, critical printing parameters must be adequately understood and controlled. Key parameters such as layer height, print speed, and nozzle size offer valuable insights into how they influence the final printed food (70, 71). A layer height, specifically, refers to the thickness of each individual layer that constitutes the final object and is a fundamental parameter that directly affects the resolution and surface finish of a printed part. The smaller layer heights result in finer details and smoother surfaces, but they also increase printing time (72). A print speed determines how quickly the printer’s nozzle moves while extruding material. It affects the overall printing time and can impact printed food’s quality. Higher print speeds may lead to reduced print quality due to less time for each layer to cool, potentially causing issues such as stringing or warping (73). A nozzle size also plays a critical role; smaller nozzles yield higher-resolution prints with detailed features, while larger nozzles enable faster printing but at a lower resolution (74). Understanding and effectively adjusting these key parameters in 3D printing processes is crucial for achieving high-quality, accurate, and reliable prints.

Beyond the technical aspects of printing, procurement of high-quality plant-based materials, ensuring taste and texture consistency, associated cost-effectiveness and scalability of 3DFP poses additional challenges for broad adoption (29). Consumer acceptance and awareness of 3D-printed foods could pose challenges due to individuals’ reluctance to include the 3D printing technology in their dietary habits (30). There is a need for strategic marketing and educational campaigns to build trust and familiarity with 3D-printed foods (3). The market trends indicate a potential shift toward innovative food technologies that align with sustainability and health trends (75), but this shift will require continuous engagement with consumers to understand their preferences and address their concerns. Therefore, overcoming the technical, economic, and consumer-related challenges might be a key to unlocking the full potential of 3D printing in reduced meat consumption.

7 Conclusion

CA’s escalated meat consumption poses significant threats to the environment and public health. Particularly, environmental degradation, freshwater pollution, and increased greenhouse gas emissions are the potential consequences of meat production. Thus, there is an urgent need for the promotion of sustainable diets that advocate for the reduction of meat consumption. This challenge can be addressed by utilizing plant-based alternatives which are essentially enriched with vitamins and ingredients that can lower environmental impact and provide a healthy lifestyle.

The convergence of 3D printing technology with the food industry holds significant promise for mitigating global meat consumption. Plant-based substitutes without relying on traditional livestock can be enabled by 3DFP In places such as CA where meat consumption is firmly ingrained in culture, 3DFP can play a critical role in manufacturing plant-based alternatives that mimic the flavor and feel of traditional meat, helping the transition to more sustainable eating patterns. Nevertheless, currently, the list of 3D food printable food types is still limited. Furthermore, the technology’s cost for professional use, coupled with the need to address consumer acceptance, should be taken into account, as adoption will require time.

Author contributions

UA: Data curation, Investigation, Project administration, Writing – original draft, Writing – review & editing. AA: Data curation, Investigation, Writing – original draft, Writing – review & editing. TS: Data curation, Investigation, Writing – original draft, Writing – review & editing. DD: Data curation, Formal analysis, Investigation, Validation, Writing – review & editing. DT: Conceptualization, Supervision, Writing – review & editing. M-YC: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Supervision, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This research study was funded by Nazarbayev University, under the Faculty Development Competitive Research Grant Program 2024-2026, project “3D-FOODPRINT: Characterizing Applications of Functional Protein-Based 3D Food Inks for Sustainable Resourcing in Agri-Food Systems with a Focus on Buckwheat Proteins” (grant No. 201223FD8807).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Food and Agricultural Organization. How to Feed the World in 2050, High-Level Expert Forum, Rome. (2009). 2–10. Available at: https://www.fao.org/fileadmin/templates/wsfs/docs/expert_paper/How_to_Feed_the_World_in_2050.pdf (Accessed December 04, 2023).

2. Meat Consumption by Country. (2023). Available at: https://worldpopulationreview.com/country-rankings/meat-consumption-by-country (Accessed November 15, 2023).

3. Michel, F, Hartmann, C, and Siegrist, M. Consumers’ associations, perceptions and acceptance of meat and plant-based meat alternatives. Food Qual Prefer. (2021) 87:104063. doi: 10.1016/J.FOODQUAL.2020.104063

4. Chen, T, Tang, G, Yuan, Y, Guo, H, Xu, Z, Jiang, G, et al. Unraveling the relative impacts of climate change and human activities on grassland productivity in Central Asia over last three decades. Sci Total Environ. (2020) 743:140649. doi: 10.1016/j.scitotenv.2020.140649

5. Qin, J, Duan, W, Chen, Y, Dukhovny, VA, Sorokin, D, Li, Y, et al. Comprehensive evaluation and sustainable development of water–energy–food–ecology systems in Central Asia. Renew Sustain Energy Rev. (2022) 157:112061. doi: 10.1016/j.rser.2021.112061

6. Hurmethan, M . Nomadic civilization of Central Asia: (origin, development, decline and globalization). J Int Stud. (2008) 1:117–26. doi: 10.5564/jis.v1i1.2077

7. FAOSTAT. (2023). Available at: https://www.fao.org/faostat/en/#data/QCL (Accessed September 17, 2023).

8. Kwasny, T, Dobernig, K, and Riefler, P. Towards reduced meat consumption: a systematic literature review of intervention effectiveness, 2001–2019. Appetite. (2022) 168:105739. doi: 10.1016/j.appet.2021.105739

9. Stoll-Kleemann, S, and Schmidt, UJ. Reducing meat consumption in developed and transition countries to counter climate change and biodiversity loss: a review of influence factors. Reg Environ Chang. (2017) 17:1261–77. doi: 10.1007/S10113-016-1057-5/METRICS

10. Sanchez-Sabate, R, and Sabaté, J. Consumer attitudes towards environmental concerns of meat consumption: a systematic review. Int J Environ Res Public Health. (2019) 16:1220. doi: 10.3390/IJERPH16071220

11. Mekonnen, MM, and Hoekstra, AY. A global assessment of the water footprint of farm animal products. Ecosystems. (2012) 15:401–15. doi: 10.1007/S10021-011-9517-8/TABLES/4

12. Espinosa-Marrón, A, Adams, K, Sinno, L, Cantu-Aldana, A, Tamez, M, Marrero, A, et al. Environmental impact of animal-based food production and the feasibility of a shift toward sustainable plant-based diets in the United States. Front Sustain. (2022) 3:841106. doi: 10.3389/FRSUS.2022.841106/BIBTEX

13. Mateo-Sagasta, J, Marjani Zadeh, S, and Burke, J. Water pollution from agriculture: a global review-executive summary. Food Agricul Organiz United Nations. (2017):5–29.

14. The Dietary Culture of Asia. Asia Society (2008). Available at: https://asiasociety.org/blog/asia/dietary-culture-asia (Accessed November 4, 2023).

15. Papier, K, Fensom, GK, Knuppel, A, Appleby, PN, Tong, TYN, Schmidt, JA, et al. Meat consumption and risk of 25 common conditions: outcome-wide analyses in 475,000 men and women in the UK biobank study. BMC Med. (2021) 19. doi: 10.1186/s12916-021-01922-9

16. Neuenschwander, M, Stadelmaier, J, Eble, J, Grummich, K, Szczerba, E, Kiesswetter, E, et al. Substitution of animal-based with plant-based foods on cardiometabolic health and all-cause mortality: a systematic review and meta-analysis of prospective studies. BMC Med. (2023) 21:404. doi: 10.1186/s12916-023-03093-1

17. MacDiarmid, JI . The food system and climate change: are plant-based diets becoming unhealthy and less environmentally sustainable? Proc Nutr Soc. (2022) 81:162–7. doi: 10.1017/S0029665121003712

18. Otunchieva, A, Borbodoev, J, and Ploeger, A. The transformation of food culture on the case of Kyrgyz nomads—a historical overview. Sustainability (Switzerland). (2021) 13:8371. doi: 10.3390/SU13158371/S1

19. Johns Hopkins Center for Livable Future. Meatless Monday throughout the years an analysis of the campaign’s reach and impact background (2023). Available at: https://www.mondaycampaigns.org/wp-content/uploads/2023/08/Meatless-Monday-throughout-the-years.pdf (Accessed December 12, 2023).

20. Mcevoy, C, Temple, N, Woodside, J, Pan, A, Sun, Q, and Bernstein, A. “Meat reducers”: meat reduction strategies and attitudes towards meat alternatives in an emerging group. Proc Nutr Soc. (2015) 74:E313. doi: 10.1017/S0029665115003602

21. Giromini, C, and Givens, DI. Benefits and risks associated with meat consumption during Key life processes and in relation to the risk of chronic diseases. Foods. (2022) 11. doi: 10.3390/foods11142063

22. Cancer. Carcinogenicity of the consumption of red meat and processed meat (2015). Available at: https://www.who.int/news-room/questions-and-answers/item/cancer-carcinogenicity-of-the-consumption-of-red-meat-and-processed-meat (Accessed November 4, 2023).

23. Graham, MW, Butterbach-Bahl, K, du Toit, CJL, Korir, D, Leitner, S, Merbold, L, et al. Research Progress on greenhouse gas emissions from livestock in sub-Saharan Africa falls short of National Inventory Ambitions. Front Soil Sci. (2022) 2:927452. doi: 10.3389/fsoil.2022.927452

24. Meier, EA, Thorburn, PJ, Bell, LW, Harrison, MT, and Biggs, JS. Greenhouse gas emissions from cropping and grazed pastures are similar: a simulation analysis in Australia. Front Sustain Food Syst. (2020) 3:491303. doi: 10.3389/FSUFS.2019.00121/BIBTEX

25. Schiermeier, Q . Eat less meat: UN climate-change report calls for change to human diet. Nature. (2019) 572:291–2. doi: 10.1038/D41586-019-02409-7

26. Albuquerque, G, Lança de Morais, I, Gelormini, M, Sousa, S, Casal, S, Pinho, O, et al. Availability and nutritional composition of street food in urban Central Asia: findings from Almaty, Kazakhstan. Int J Public Health. (2022) 67. doi: 10.3389/ijph.2022.1604558

27. Havermans, RC, Rutten, G, and Bartelet, D. Adolescent’s willingness to adopt a more plant-based diet: a theory-based interview study. Front Nutr. (2021) 8:688131. doi: 10.3389/FNUT.2021.688131/BIBTEX

28. Portanguen, S, Tournayre, P, Sicard, J, Astruc, T, and Mirade, PS. 3D food printing: genesis, trends and prospects. Future Foods: Global Trends, Opportun Sustain Challenges. (2021):627–44. doi: 10.1016/B978-0-323-91001-9.00008-6

29. Burke-Shyne, S, Gallegos, D, and Williams, T. 3D food printing: nutrition opportunities and challenges. Br Food J. (2021) 123:649–63. doi: 10.1108/BFJ-05-2020-0441

30. Jayaprakash, S, Paasi, J, Pennanen, K, Ituarte, IF, Lille, M, Partanen, J, et al. Techno-economic prospects and desirability of 3d food printing: perspectives of industrial experts, researchers and consumers. Foods. (2020) 9. doi: 10.3390/foods9121725

31. Chen, Y, Zhang, M, Bhandari, B, Marini, F, and Biancolillo, A. 3D printing of steak-like foods based on textured soybean protein. Foods. (2021) 10:2011. doi: 10.3390/FOODS10092011

32. Jones, N . Lab-grown meat: the science of turning cells into steaks and nuggets. Nature. (2023) 619:22–4. doi: 10.1038/D41586-023-02095-6

33. Ramachandraiah, K . Potential development of sustainable 3D-printed meat analogues: a review. Sustainability. (2021) 13:938. doi: 10.3390/SU13020938

34. Shanthakumar, P, Klepacka, J, Bains, A, Chawla, P, Dhull, SB, and Najda, A. The current situation of pea protein and its application in the food industry. Molecules. (2022) 27:5354. doi: 10.3390/MOLECULES27165354

35. Li, H, Prairie, N, Udenigwe, CC, Adebiyi, AP, Tappia, PS, Aukema, HM, et al. Blood pressure lowering effect of a pea protein hydrolysate in hypertensive rats and humans. J Agric Food Chem. (2011) 59:9854–60. doi: 10.1021/JF201911P

36. Hidayat, M, Prahastuti, S, Yusuf, M, and Hasan, K. Nutrition profile and potency of RGD motif in protein hydrolysate of green peas as an antifibrosis in chronic kidney disease. Iran J Basic Med Sci. (2021) 24:734–43. doi: 10.22038/IJBMS.2021.50291.11459

37. Li, L, Lietz, G, and Seal, C. Buckwheat and CVD risk markers: a systematic review and Meta-analysis. Nutrients. (2018) 10. doi: 10.3390/NU10050619

38. Alrosan, M, Tan, TC, Mat Easa, A, Gammoh, S, and Alu’datt, MH. Recent updates on lentil and quinoa protein-based dairy protein alternatives: nutrition, technologies, and challenges. Food Chem. (2022) 383:132386. doi: 10.1016/j.foodchem.2022.132386

39. Messina, M, Sievenpiper, JL, Williamson, P, Kiel, J, and Erdman, JW. Perspective: soy-based meat and dairy alternatives, despite classification as ultra-processed foods, deliver high-quality nutrition on par with unprocessed or minimally processed animal-based counterparts. Adv Nutr. (2022) 13:726–38. doi: 10.1093/ADVANCES/NMAC026

40. Yu, J, Wang, X, Li, D, Wang, LJ, and Wang, Y. Development of soy protein isolate emulsion gels as extrusion-based 3D food printing inks: effect of polysaccharides incorporation. Food Hydrocoll. (2022) 131:107824. doi: 10.1016/J.FOODHYD.2022.107824

41. Chen, J, Sun, H, Mu, T, Blecker, C, Richel, A, Richard, G, et al. Effect of temperature on rheological, structural, and textural properties of soy protein isolate pastes for 3D food printing. J Food Eng. (2022) 323:110917. doi: 10.1016/J.JFOODENG.2021.110917

42. Sridharan, S, Meinders, J, Sagis, LM, Bitter, JH, and Nikiforidis, CV. Jammed emulsions with adhesive pea protein particles for elastoplastic edible 3D printed materials. Adv Funct Mater. (2021) 31:2101749. doi: 10.1002/ADFM.202101749

43. Lim, WS, Kim, HW, Lee, MH, and Park, HJ. Improved printability of pea protein hydrolysates for protein-enriched 3D printed foods. J Food Eng. (2023) 350:111502. doi: 10.1016/J.JFOODENG.2023.111502

44. Liu, Z, Chen, X, Dai, Q, Xu, D, Hu, L, Li, H, et al. Pea protein-xanthan gum interaction driving the development of 3D printed dysphagia diet. Food Hydrocoll. (2023) 139:108497. doi: 10.1016/J.FOODHYD.2023.108497

45. Wen, LH, and Dejian, H. Characterisation of red lentil (Lens Culinaris) protein and its applications in 3d bioprinting. Republic of Singapore (2019). 127. Available at: https://www.proquest.com/dissertations-theses/characterisation-red-lentil-lens-culinaris/docview/2724234567/se-2?accountid=134066

46. Schiell, C, Portanguen, S, Scislowski, V, Astruc, T, and Mirade, PS. Investigation into the physicochemical and textural properties of an Iron-rich 3D-printed hybrid food. Foods. (2023) 12. doi: 10.3390/foods12071375

47. McCaw, JCS, Fleck, TJ, Tejada-Ortigoza, V, Patel, B, Son, SF, Gunduz, IE, et al. Vibration-assisted printing of highly viscous food. Addit Manuf. (2022) 56:102851. doi: 10.1016/J.ADDMA.2022.102851

48. Guo, C, Zhang, M, and Devahastin, S. 3D extrusion-based printability evaluation of selected cereal grains by computational fluid dynamic simulation. J Food Eng. (2020) 286:110113. doi: 10.1016/j.jfoodeng.2020.110113

49. Guo, C, Zhang, M, and Devahastin, S. Improvement of 3D printability of buckwheat starch-pectin system via synergistic Ca2+−microwave pretreatment. Food Hydrocoll. (2021) 113:106483. doi: 10.1016/J.FOODHYD.2020.106483

50. Ji, S, Xu, T, Li, Y, Li, H, Zhong, Y, and Lu, B. Effect of starch molecular structure on precision and texture properties of 3D printed products. Food Hydrocoll. (2022) 125:107387. doi: 10.1016/J.FOODHYD.2021.107387

51. Phuhongsung, P, Zhang, M, and Devahastin, S. Investigation on 3D printing ability of soybean protein isolate gels and correlations with their rheological and textural properties via LF-NMR spectroscopic characteristics. LWT. (2020) 122:109019. doi: 10.1016/J.LWT.2020.109019

52. Islam, MS, Muhyidiyn, I, Islam, MR, Hasan, MK, Hafeez, AG, Hosen, MM, et al. Soybean and sustainable agriculture for food security. Soybean - Recent Advan Res App. (2022). doi: 10.5772/INTECHOPEN.104129

53. Chuanxing, F, Qi, W, Hui, L, Quancheng, Z, and Wang, M. Effects of pea protein on the properties of potato starch-based 3D printing materials. Int J Food Eng. (2018) 14. doi: 10.1515/IJFE-2017-0297/MACHINEREADABLECITATION/RIS

54. Powers, SE, and Thavarajah, D. Checking Agriculture’s pulse: field pea (Pisum Sativum L.), sustainability, and phosphorus use efficiency. Front Plant Sci. (2019) 10:482549. doi: 10.3389/FPLS.2019.01489/BIBTEX

55. Huda, MN, Lu, S, Jahan, T, Ding, M, Jha, R, Zhang, K, et al. Treasure from garden: bioactive compounds of buckwheat. Food Chem. (2021) 335:127653. doi: 10.1016/j.foodchem.2020.127653

56. Lin, LY, Hsieh, YJ, Liu, HM, Lee, CC, and Mau, JL. Flavor components in buckwheat bread. J Food Process Preserv. (2009) 33:814–26. doi: 10.1111/J.1745-4549.2008.00313.X

57. Shi, J, Tong, G, Yang, Q, Huang, M, Ye, H, Liu, Y, et al. Characterization of Key aroma compounds in Tartary buckwheat (Fagopyrum tataricum Gaertn) by means of sensory-directed flavor analysis. J Agric Food Chem. (2021) 69:11361–71. doi: 10.1021/ACS.JAFC.1C03708

58. Starowicz, M, Koutsidis, G, and Zieliński, H. Sensory analysis and aroma compounds of buckwheat containing products-a review. Crit Rev Food Sci Nutr. (2018) 58:1767–79. doi: 10.1080/10408398.2017.1284742

59. Waghmare, R, Suryawanshi, D, and Karadbhajne, S. Designing 3D printable food based on fruit and vegetable products—opportunities and challenges. J Food Sci Technol. (2023) 60:1447–60. doi: 10.1007/s13197-022-05386-4

60. Varvara, RA, Szabo, K, and Vodnar, DC. 3D food printing: principles of obtaining digitally-designed nourishment. Nutrients. (2021) 13. doi: 10.3390/nu13103617

61. Sofi, SA, Ahmed, N, Farooq, A, Rafiq, S, Zargar, SM, Kamran, F, et al. Nutritional and bioactive characteristics of buckwheat, and its potential for developing gluten-free products: an updated overview. Food Sci Nutr. (2023) 11:2256–76. doi: 10.1002/FSN3.3166

62. Muraoka, R, Chien, H, and Zhao, M. Production and market participation of buckwheat farmers: Micro-evidence from Shaanxi Province, China. Sustainability. (2023) 15:4822. doi: 10.3390/su15064822

63. Joshi, DC, Chaudhari, GV, Sood, S, Kant, L, Pattanayak, A, Zhang, K, et al. Revisiting the versatile buckwheat: reinvigorating genetic gains through integrated breeding and genomics approach. Planta. (2019) 250:783–801. doi: 10.1007/s00425-018-03080-4

64. Popović, V, Sikora, V, Berenji, J, Filipović, V, Dolijanović, Ž, Ikanović, J, et al. Analysis of buckwheat production in the world and Serbia economics of agriculture analysis of buckwheat production in the world and Serbia. Economics of Agriculture. Економика пољопривреде. (2014) 61:1–53.

65. Myers, R . “Growing Buckwheat for Grain or Cover Crop Use | MU Extension.” [Online]. Available at: https://extension.missouri.edu/publications/g4163 (Accessed December 12, 2023).

66. Krzyzanska, M, Hunt, HV, Crema, ER, and Jones, MK. Modelling the potential ecological niche of domesticated buckwheat in China: archaeological evidence, environmental constraints and climate change. Veg Hist Archaeobotany. (2022) 31:331–45. doi: 10.1007/s00334-021-00856-9

67. Singh, M, Malhotra, N, and Sharma, K. Buckwheat (Fagopyrum sp.) genetic resources: what can they contribute towards nutritional security of changing world? Genet Resour Crop Evol. (2020) 67:1639–58. doi: 10.1007/s10722-020-00961-0

68. Germ, M, and Gaberšick, A. The effect of environmental factors on buckwheat. Molecular Breed Nutritional Aspects of Buckwheat. Academic Press (2016):273–8.

69. Pinski, A, Zhou, M, and Betekhtin, A. Editorial: advances in buckwheat research. Front Plant Sci. (2023) 14. doi: 10.3389/fpls.2023.1190090

70. Chen, X, Zhang, M, Teng, X, and Mujumdar, AS. Recent Progress in modeling 3D/4D printing of foods. Food Eng Rev. (2022) 14:120–33. doi: 10.1007/s12393-021-09297-6

71. Sun, J, Zhou, W, Huang, D, Fuh, JYH, and Hong, GS. An overview of 3D printing Technologies for Food Fabrication. Food Bioproc Tech. (2015) 8:1605–15. doi: 10.1007/s11947-015-1528-6

72. Hussain, S, Malakar, S, and Arora, VK. Extrusion-based 3D food printing: technological approaches, material characteristics, printing stability, and post-processing. Food Eng Rev. (2022) 14:100–19. doi: 10.1007/S12393-021-09293-W/TABLES/4

73. Nachal, N, Moses, JA, Karthik, P, and Anandharamakrishnan, C. Applications of 3D printing in food processing. Food Eng Rev. (2019) 11:123–41. doi: 10.1007/S12393-019-09199-8/FIGURES/4

74. Yang, F, Zhang, M, Fang, Z, and Liu, Y. Impact of processing parameters and post-treatment on the shape accuracy of 3D-printed baking dough. Int J Food Sci Technol. (2019) 54:68–74. doi: 10.1111/IJFS.13904

75. Food 3D Printing Market Size & Share Analysis. Industry Research Report - Growth Trends. Available at: https://www.mordorintelligence.com/industry-reports/global-food-3d-printing-market (Accessed November 18, 2023).

Keywords: meat consumption, Central Asia, 3D food printing, plant-based diets, protein-rich plants

Citation: Auyeskhan U, Azhbagambetov A, Sadykov T, Dairabayeva D, Talamona D and Chan M-Y (2024) Reducing meat consumption in Central Asia through 3D printing of plant-based protein—enhanced alternatives—a mini review. Front. Nutr. 10:1308836. doi: 10.3389/fnut.2023.1308836

Edited by:

Parinya Punpongsanon, Saitama University, JapanReviewed by:

Ishtiaq Ahmad, Huazhong Agricultural University, ChinaCopyright © 2024 Auyeskhan, Azhbagambetov, Sadykov, Dairabayeva, Talamona and Chan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mei-Yen Chan, eWVuLmNoYW5AbnUuZWR1Lmt6

Ulanbek Auyeskhan

Ulanbek Auyeskhan Arman Azhbagambetov

Arman Azhbagambetov Temirlan Sadykov1

Temirlan Sadykov1 Didier Talamona

Didier Talamona Mei-Yen Chan

Mei-Yen Chan