- College of Food Science and Technology, Henan University of Technology, Zhengzhou, China

This study was designed to evaluate the effects of different rice nutrient compounds on steamed bread’s nutritional characteristics and sensory evaluation. The mixture design approach was used to research the interactions between different rice flours and wheat flours on the sensory evaluation of steamed bread. The arginine content of different rice flour (long-grained rice, polished round-grained rice, and black rice) was higher at 44.19, 21.74, and 34.78% than that of the common wheat, respectively. When the added amount of mixed rice flours exceeds 15%, the steamed bread gradually reduces its elasticity, and sensory score, and has a smaller specific volume. Rice is a widely consumed grain product, which provides energy and nutrients for more than half of humanity, especially in Asia. Different rice varieties have received increased attention from researchers for their high bioactive substances and other health benefits. The results of the current study provide a theoretical basis for the nutritional steamed bread and noodle industries to use different rice flour as an ingredient for enhancing or to improving the nutritional value of flour products.

Introduction

A significant number of researches have recently been carried out to develop gluten-free products by removal of gluten from wheat flour products, such as noodles, biscuits, cake, and steamed bread, which introduces some significant technological challenges (1–3). These challenges are indispensable for achieving desired farinograph properties, gas-holding ability, and texture characteristics of dough (4–11). Alternative compositions such as starch and protein from different flour sources have been recently used to acquire previously mentioned properties to satisfy its technological functions. However, the use of different flour sources is limited because manufacturers are still accustomed to using refined, enriched other flour sources (5, 12–14).

Rice is a widely consumed grain, which provides energy and nutrients for more than half of humans, especially with regard to Asians (15). Recently, different rice varieties have received increased attention from researchers for their high bioactive substances, resistant starch, and other health benefits (16). Rice flour is utilized in a wide variety of food products, so it can affect the final product quality (17, 18). Different rice flours have also become a popular raw material in many health food products because of consumers’ health concerns (19). It is deemed to be a more nutritious and healthier product than non-organic flours due to the wide use of heavy metal contamination, pesticide residue, herbicides, and chemical fertilizers (20). Variations in the properties of different rice flours have significant effects on the overall quality of the food products (21). Oil absorption capacities of different rice flours are associated with rancidity that naturally occurs in food products, which have a major predictor of shelf-life (12, 22, 23). The high-viscosity of different rice flours could be properly employed in high-viscosity products as a thickening agent (24).

Recently, more attention has been focused on color-grained rice varieties, which contain polyphenols in the aleurone and the pericarp, respectively, whereas common rice varieties contain small amounts of polyphenols (25–28). Polyphenols, such as phenolic acids, anthocyanins, and proanthocyanidins, have been reported as the primary antioxidants in different rice varieties (29–32). Generally, white rice contains mainly phenolic acids, and the presence of procyanidins characterizes red rice; however, black rice is characterized by the presence of anthocyanins (33–35).

However, little is known about the effect of different rice flours on steamed bread’s nutritional characteristics and performance (36–39). Therefore, it is necessary to illustrate how different color-grained rice flours contribute to steamed bread’s nutritional characteristics and performance (40). So, three different rice varieties (long-grained rice, polished Round-grained rice, and black rice) and the common wheat variety were milled into different flours with the mixture design approach to clarify the effect of proteins, fat, microelement, and total dietary fiber (TDF) on the quality of steamed bread. Thus, this research aimed to investigate the effect of different rice flours on the nutritional characteristics and sensory evaluation of steamed bread.

Materials and methods

Materials

The common wheat (Wenmai 2504, Kato, Prosky) and three different rice varieties were obtained from the 2021 harvest in Henan, Hubei, and Heilongjiang provinces. Long-grained rice (LGR) variety (Oryza sativa L. subsp. indica Kato) was provided by Jingshan Hongda grain and oil industry Co., Ltd. (Jingmen, Hubei, China). The polished round-grained rice (PRGR) variety (Oryza sativa L. subsp. japonica Kato) was provided by Yuanyang Kangjian Co., Ltd. (Xinxiang, Henan, China). Black rice (BR) variety (Oryza sativa L. cv. Khao Niaw Dam Peuak Dam) was provided by Wuchang Changxinxing Food Co., Ltd. (Heilongjiang, China), and Wenmai 2504 (W 2504) as the common wheat was purchased at farmers’ markets (Jiaozuo, Henan, China).

Sample preparation

The common wheat was manually cleaned and stored in a 4°C freezer. The incomplete wheat and other impurities were removed. The moisture content of wheat before milling was controlled at 15 ± 0.5% for 16 h. LFS-30 (Buhler, Wuxi, China) was used in milling of the common wheat, and assembling at 3B flour system. Whole wheat kernels were first used to remove the bran layer using a grain polisher (TYT200, Tianyang Machinery Co., Ltd., Shandong, China) before preparing the flour. The different rice flours were collected by the universal grinder. The mixed flour was prepared with LGR (A), polished round-grained rice (B), and black rice (C). According to the orthogonal test, the ratio of A: B: C was 1: 1: 1, 1: 2: 2, 1: 3: 3, 2: 1: 2, 2: 2: 3, 2: 3: 1, 3: 1: 3, 3: 2: 1, and 3: 3: 2, respectively. The dough was prepared using the method of Chen (41). After preparation, the dough was put in a 4°C refrigerator to cool. For each dough, samples were prepared in duplicate.

Chemical analyses of the different rice flours

The lipid content of the different rice flours and wheat flour was determined using the method of Moreau with some modifications (42). Moisture was measured according to the National Standard of the People’s Republic of China GB 5009.3-2016. The protein content of the different flours was determined by the Kjeldahl method. In a 100 ml round bottom flask, 0.5 g of various rice and common wheat samples were mixed with 4 ml of concentrated sulfuric acid, and the mixture was heated to 440°C with a conventional convection-conduction heating system until boiling. However, the heating time should not exceed 3–5 min.

Analysis of amino acids

Amino acids analysis of the rice and common wheat samples was accomplished according to the method of Du (43). The rice and common wheat samples (100 mg) were hydrolyzed with 10 ml 5 M NaOH at 110°C for 20 h. The hydrolyzate was transferred and dissolved with deionized water in a 50 ml volumetric flask. The mixture was then filtered through a 0.45 μm of nylon syringe filter (Filtrex Technology, Singapore). The analysis of amino acids from different rice and common wheat samples was determined with an automatic amino acid analyzer (Biochrom 30+, Cambridge, UK). Amino acids were derivatized with ninhydrin reagent for postcolumn (0–50 ml/h) and determined at wavelengths of 570 nm (for the quantitation of α-amino acids) and 440 nm (for the imino acids). Amino acids of different samples and standard solution were analyzed under the same conditions, and all the above measurements were performed in triplicate.

Determination of total dietary fiber and microelement

The content of TDFs was determined according to the method of Prosky (44). Microelement determinations of the rice and common wheat samples were performed using an Agilent 240FS atomic absorption spectrometer (Agilent Technologies, Santa Clara, CA, USA) equipped with flame atomization [a mixture of acetylene (2.9 L/min) and air (13.5 L/min)] (45). The emission mode of K is set to 766.5 nm.

Preparation of rice dough and steamed bread

Different ratios of rice flours into wheat flours were made to steamed bread according to the sponge dough method of He with some modification (46). The recipe of steamed bread is as follows: The common wheat flour is the base flour, and the different rice flours are added by 5, 10, 15, 20, 25, and 30% with the total amount being 100 g. Dry yeast, 1 g (Anqi, Anqi Yeast Co., Ltd., Hubei, China) was added into water (30°C). A total of 100 g samples were mixed with yeast/water which Farinograph water absorption rate up to 85% in a dough maker (B10, Henglian Food Machinery Co., Ltd., Guangdong, China). After mixing at medium speed for 10 min with the appropriate amount of warm water (38°C), and using a rolling pin to press the sheet 20 times, the dough was divided into three parts, and shaped by hand into a round, long, and straight dough with a smooth surface. Then, the dough pieces were proofed for 2 h at 30°C with 80% RH, and remixed flour and dough by hand until the dough was sticky. After that, the proofed steamed bread was put in a steamer (ASD, Zhejiang, China), when the water boiled, and steamed for 20 min.

Sensory evaluation of steamed bread making

The numbers of panelists were 18 (10 men and 8 women). Panelists included 18 adults between the ages of 27 and 65. They were selected, screened, and recruited according to international standards (47). A total of 15 of them were university faculty, and 13 of them had received theoretical and practical training in sensory analysis and experience in tasting different flour products such as bread, steamed bread, or noodles. The other five had not participated in the panel discussion before. Assessors were not paid for participating in the panel.

Statistical analysis

Data were collected for analysis of variance to determine differences between different rice flours and to investigate the effect of mixture design approach on farinograph and extensometer performance. Significance analysis was performed using Statistica 7.0 software to study the relationship between rheological properties and mixture design approach. Data were reported as the mean (standard deviation SD) of triplicates.

Results and discussion

Physicochemical properties of different-grained rice flours

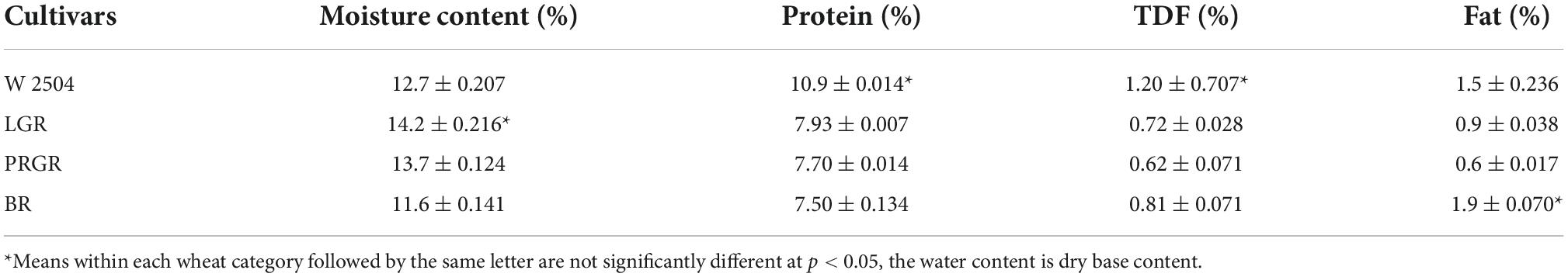

The chemical composition of the different rice flours and wheat flour was shown in Table 1. The protein content of different rice flours was 27.24–43.04% lower than that of the common wheat. Protein is the main food component of humans and other animals. However, there are still challenges in formulating gluten-free products with rice because rice flour does not function as wheat gluten, which is known as an essential structural protein (48). The fat and total TDF content were almost lower than the common wheat. The fat of wheat is mainly concentrated in the germ; however, the fat of rice flour is mainly concentrated in the bran (49). TDF was mainly concentrated in the pericarp and seed coat, while the content of endosperm was very few. The content of fat was abundant in black rice flour because the rice bran was reserved in the process.

Distribution of amino acid, total amino acid, and essential amino acid content

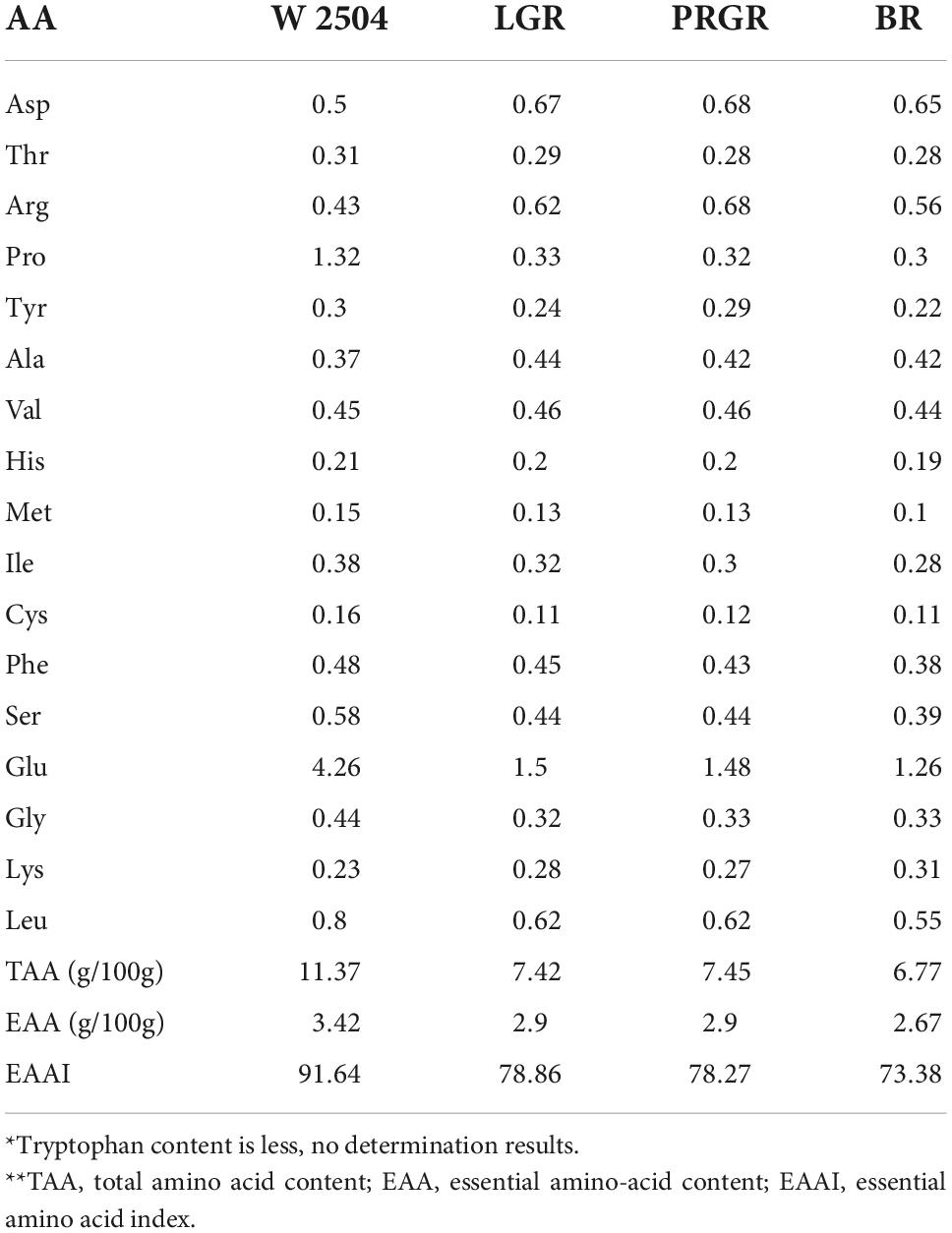

The amino acid contents for different rice flours and wheat flour were shown in Table 2. The nutritional characteristics of different rice flours mainly refer to the balance of protein content and amino acid composition, and the essential amino acid content is the key to determining the nutritional quality of different rice flours (50). TAA and EAA contents of different rice flours were lower than those of common wheat flour, and TAA content was 34.12–40.46% lower than that of common wheat flour. The essential amino acid content of different rice flours was 15.2–21.93% lower than that of common wheat. The results showed that the quantity and quality of protein and amino acids of common wheat flour were greater than those of different rice flours. Due to the amino acid composition characteristics of different rice flours, people can directly eat them to meet nutritional needs, and can also be used as breeding materials (51). The arginine content of different rice flours was higher than that of common wheat: Long-grain rice flour increased by 44.19%, polished round-grained rice by 21.74%, and black rice flour by 34.78%.

Determination of the microelement in different rice flours

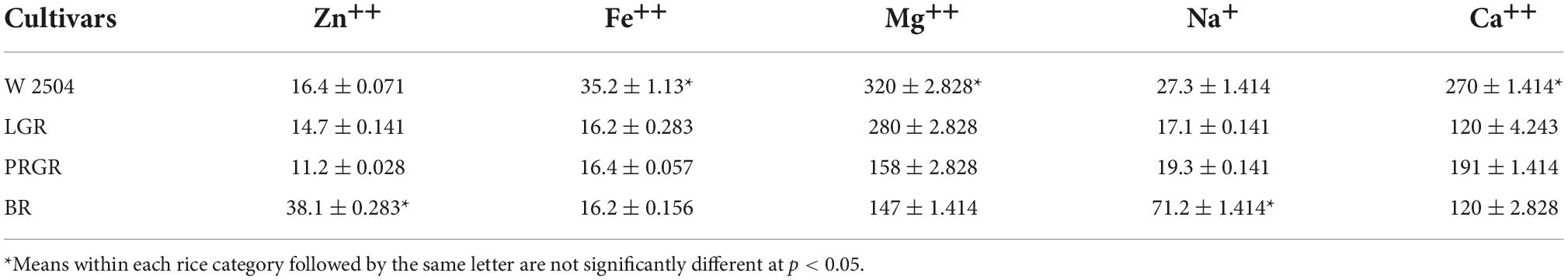

The microelement contents for different rice flours and wheat flour were shown in Table 3, and the content of zinc in black rice flour was 132.32% higher than that of W 2504. Zinc has a role in helping intellectual growth and development (52). The content of sodium in black rice flour was 160.81% higher than that of W 2504. Sodium is an essential trace element for the human body, an important part of water balance, and a complex component of pancreatic juice, bile, sweat, and tears. Therefore, sodium can promote physical development and increase the body’s ability to resist disease. At the same time, sodium can also regulate tissue respiration and prevents fatigue (53). However, the content of other microelements in different rice flours was lower than that of W 2504. Therefore, the mixture design approach can improve their nutritional value.

Effect of mixture design approach on nutritional characteristics

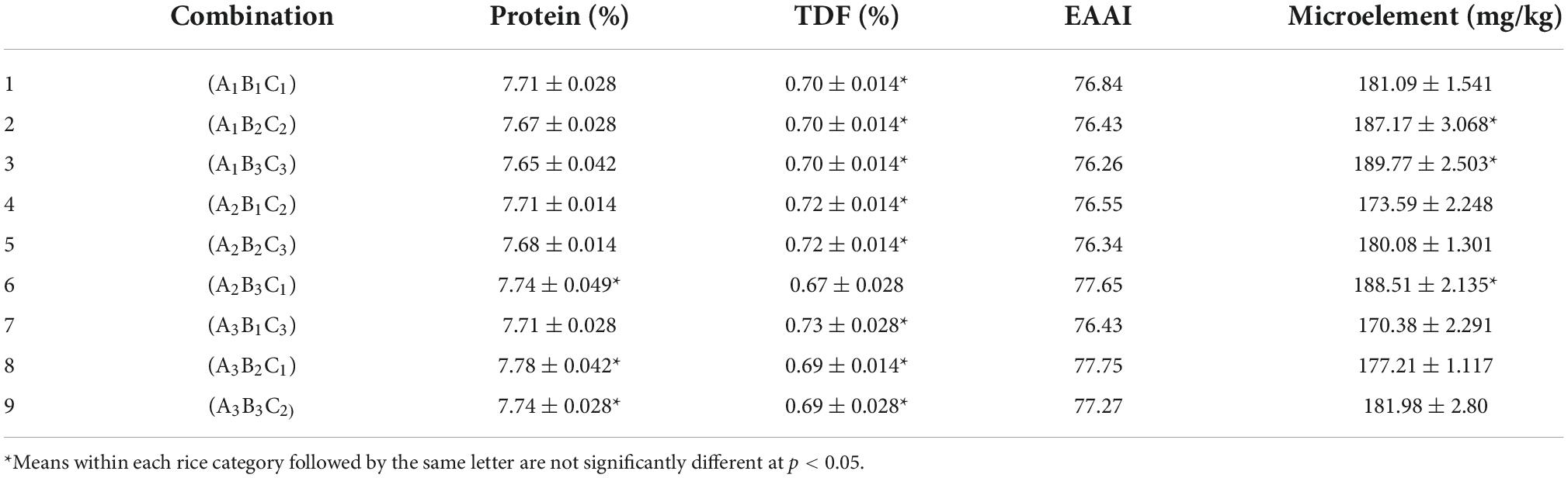

Flour products are a major part of the Chinese daily diet, with wheat as the main source, but are mainly made from the seeds of common wheat. However, different rice flours contain most of the valuable protein, micronutrients, and phytochemicals found in grains, and if included in flour or used as food ingredients, they would go to a long way toward improving the nutritional quality of human food (54). Nutritional characteristics of mixed flours from different rice flours and wheat flour were shown in Table 4. The results showed that the highest protein content was no. 8 (A2B3C1), 6 (A2B3C1), and 9 (A3B3C2). However, the highest value of EAAI was no. 8 (A3B2C1) and 6 (A2B3C1). The microelement content highest is the no. 3 (A1B3C3) and 6 (A2B3C1). Therefore, when paired with these factors, we choose no. 6 (A2B3C1) as a nutritional content more rich.

Effect of mixed flours on sensory analysis of steamed bread

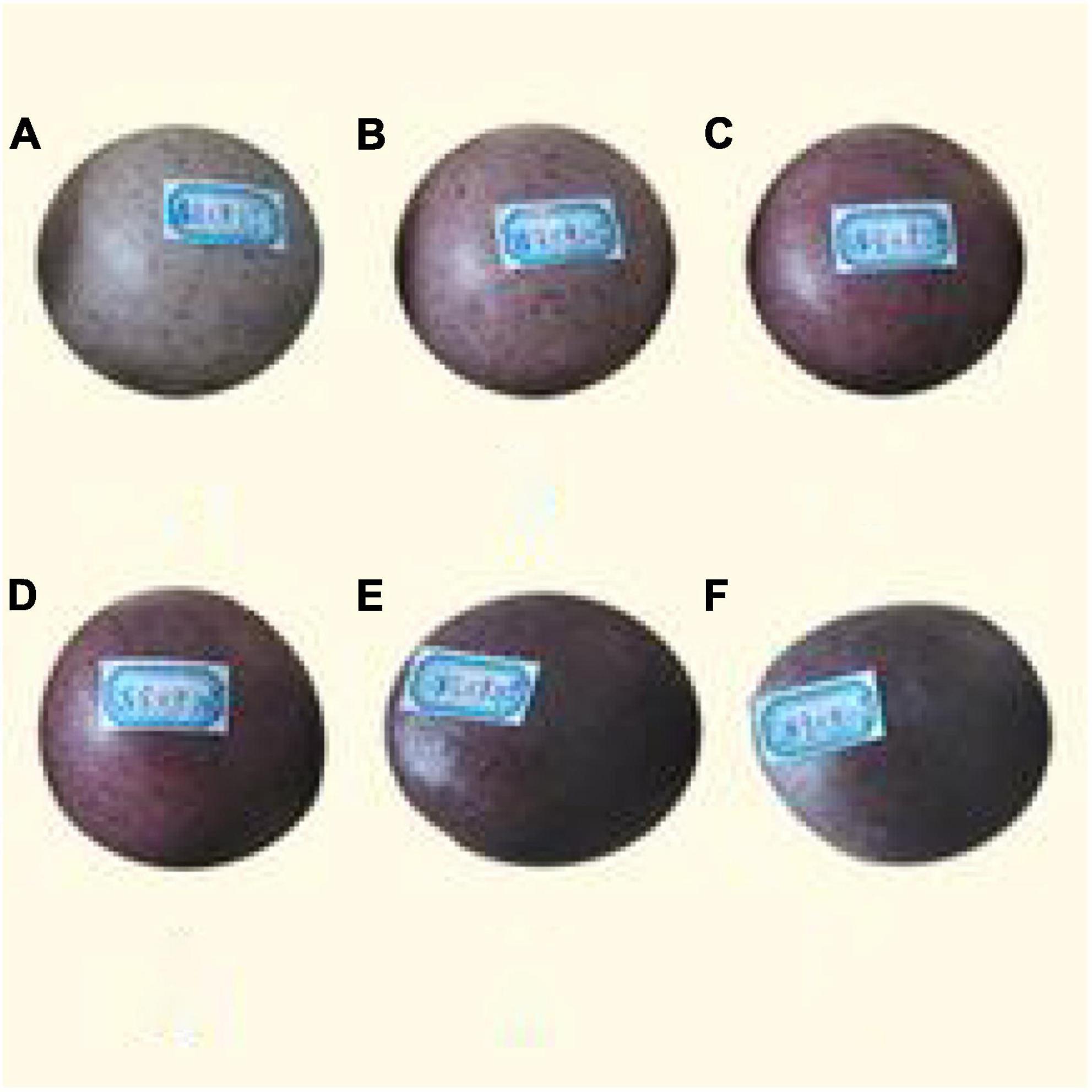

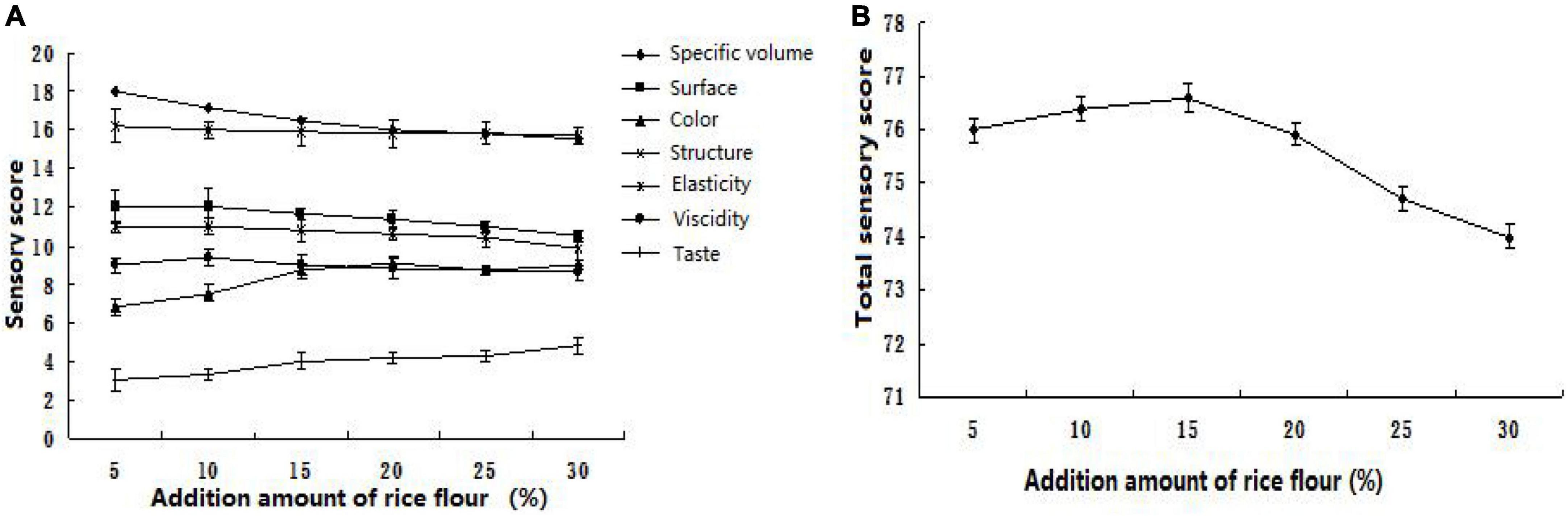

As shown in Figures 1, 2, with the increase in the amount of different rice flours, the specific volume of steamed bread is getting smaller and smaller. Because different rice flours do not contain gluten, the steamed flours cannot form a gluten network structure. The results have shown that the different rice flours have some effects on weakened gluten network structure. The amount of different rice flours exceeded the ultimate value, so small size, low specific volume, bouncy toughness and bite, and poor shape would appear in the steamed bread. When the added amount of different rice flours exceeds 15%, the steamed bread gradually reduces elasticity and has a smaller specific volume.

Figure 1. Images of steamed bread made by different rice flours [the added amount of panels (A–F): 5, 10, 15, 20, 25, and 30%].

Figure 2. Sensory analysis of different rice flour with different proportions (A: Sensory score; B: Total sensory score).

As shown in Figure 2A, the specific volume of steamed bread is becoming smaller and smaller with the increase of colored rice composite powder. This is because rice does not contain gluten, which cannot form a gluten network structure. The research shows that the medium gluten flour is more suitable for making steamed bread, while the coarse grain flour has a certain role in weakening the gluten strength. Excessive addition will lead to low gluten strength, making steamed bread small in volume, low in specific volume, poor in elasticity and bite strength, poor in shape, and large and uneven in pulp structure (1, 3). So the appearance, structure, elasticity, and toughness are slightly reduced. The evaluation value of color and smell has been rising due to the special color and aroma of rice. As shown in Figure 2B, with the increase of colored rice composite powder, the total sensory evaluation score of steamed bread increased first and then decreased. When the added amount exceeds 15%, the elasticity of steamed bread gradually decreases, the taste becomes worse, and the specific volume becomes smaller. When the addition amount was 15%, the total score of colored rice steamed bread was the highest. As mentioned in the color section above, the reduced whiteness of the crust and crumbs can easily be attributed to the color in the rice flour. Color change of cereals may appeal to consumers (40).

Conclusion

The effects of additions of different rice flours with different proportions on the nutritional characteristics and quality of steamed bread were investigated. Based on the analysis of protein, TDF, fat, amino acid composition, microelement, physicochemical index, nutritional characteristics, and quality of steamed bread, this study demonstrated that additions of different rice flours with different proportions primarily affected physicochemical index, nutritional characteristics, and quality of steamed bread. When the addition amount was 15%, the total score of colored rice steamed bread was the highest. The results of the current study offer opportunities for the steamed bread and noodle industry to use different rice flours as an ingredient for enhancing the nutrient-value amount of dough. The acceptability of dough with different proportions of different rice flours needs further study. The different rice flours have the potential to be utilized as nutrient-value foods.

Data availability statement

The original contributions presented in this study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

ST: data curation (equal), formal analysis (equal), investigation (equal), writing—original draft and review (equal), and editing (equal). YW: conceptualization (equal) and writing—review and editing (equal). ZC: formal analysis (equal), methodology (equal), writing—original draft (supporting), funding acquisition (equal), and writing—review and editing (equal). All authors contributed to the article and approved the submitted version.

Acknowledgments

We would like to acknowledge NSFC for financial assistance under NSFC Research Contract no. 31701636, Cultivation Program for Young Backbone Teachers in Henan Province (2021GGJS059), and Natural Science Innovation Fund Support Program from Henan University of Technology (2021ZKCJ12).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Delcour JA, Rouau X, Courtin CM, Poutanen K, Ranieri R. Technologies for enhanced exploitation of the health-promoting potential of cereals. Trends Food Sci Technol. (2012) 25:78–86. doi: 10.1016/j.tifs.2012.01.007

2. Liu W, Brennan MA, Serventi L, Brennan CS. Effect of cellulase, xylanase and α-amylase combinations on the rheological properties of Chinese steamed bread dough enriched in wheat bran. Food Chem. (2017) 234:93–102. doi: 10.1016/j.foodchem.2017.04.160

3. Ortolan F, Urbano K, Netto FM, Steel CJ. Chemical and structural characteristics of proteins of non-vital and vital wheat glutens. Food Hydrocoll. (2022) 125:107383. doi: 10.1016/j.foodhyd.2021.107383

4. Yilmaz MT, Yildiz Ö, Yurt B, Toker OS, Karaman S, Baştürk A. A mixture design study to determine interaction effects of wheat, buckwheat, and rice flours in an aqueous model system. LWT Food Sci Technol. (2015) 61:583–9. doi: 10.1016/j.lwt.2014.11.045

5. Gallagher E. Formulation and nutritional aspects of gluten-free cereal products and infant foods. In: Arendt EK, Dal Bello F editors. Gluten-Free Cereal Products and Beverages. Amsterdam: Elsevier (2008). p. 321–46. doi: 10.1016/B978-012373739-7.50016-2

6. Bock JE, Connelly RK, Damodaran S. Impact of bran addition on water properties and gluten secondary structure in wheat flour doughs studied by attenuated total reflectance Fourier transform infrared spectroscopy. Cereal Chem. (2013) 90:377–86. doi: 10.1094/CCHEM-01-13-0008-FI

7. Sivam AS, Sun-Waterhouse D, Quek SY, Perera CO. Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: a review. J Food Sci. (2010) 75:R163–74. doi: 10.1111/j.1750-3841.2010.01815.x

8. Liu W, Brennan MA, Serventi L, Brennan CS. Effect of wheat bran on dough rheology and final quality of Chinese steamed bread. Cereal Chem. (2017) 94:581–7. doi: 10.1094/CCHEM-09-16-0234-R

9. Gao Q, Liu C, Zheng X. Effect of heat treatment of rye flour on rye-wheat steamed bread quality. Int J Food Sci Technol. (2018) 53:1109–19. doi: 10.1111/ijfs.13662

10. Başar Ş, Karaoğlu MM. The effects of Cephalaria syriaca flour on physical, rheological and textural properties of sunn pest (Eurygaster integriceps) damaged wheat dough and bread. J Cereal Sci. (2021) 99:103215. doi: 10.1016/j.jcs.2021.103215

11. Wardy W, Jack AR, Chonpracha P, Alonso JR, King JM, Prinyawiwatkul W. Gluten-free muffins: effects of sugar reduction and health benefit information on consumer liking, emotion, and purchase intent. Int J Food Sci Technol. (2018) 53:262–9. doi: 10.1111/ijfs.13582

12. Fitzgerald MA, Martin M, Ward RM, Park WD, Shead HJ. Viscosity of rice flour e a rheological and biological study. J Agric Food Chem. (2003) 51:2295–9. doi: 10.1021/jf020574i

13. Kaushal P, Kumar V, Sharma HK. Comparative study of physicochemical, functional, antinutritional and pasting properties of taro (Colocasia esculenta), rice (Oryza sativa) flour, pigeonpea (Cajanus cajan) flour and their blends. LWT Food Sci Technol. (2012) 48:59–68. doi: 10.1016/j.lwt.2012.02.028

14. Isela CP, Mu T, Zhang M. Effect of high hydrostatic pressure to sweet potato flour on dough properties and characteristics of sweet potato-wheat bread. Int J Food Sci Technol. (2018) 53:1087–94. doi: 10.1177/1082013217719006

15. Zhang MW, Zhang RF, Zhang FX, Liu RH. Phenolic profiles and antioxidant activity of black rice bran of different commercially available varieties. J Agric Food Chem. (2010) 58:7580–7. doi: 10.1021/jf1007665

16. Chen M-H, Choi SH, Kozukue N, Kim H-J, Friedman M. Growthinhibitory effects of pigmented rice bran extracts and three red bran fractions against human cancer cells: relationships with composition and antioxidative activities. J Agric Food Chem. (2012) 60:9151–61. doi: 10.1021/jf3025453

17. Yalcin S, Basman A. Effects of gelatinisation level, gum and transglutaminase on the quality characteristics of rice noodle. Int J Food Sci Technol. (2008) 43:1637–44.

18. Srikanlaya C, Therdthai N, Ritthiruangdej P, Zhou W. Effect of hydroxypropyl methylcellulose, whey protein concentrate and soy protein isolate enrichment on characteristics of gluten-free rice dough and bread. Int J Food Sci Technol. (2018) 53:1760–70.

19. Jin L, Xiao P, Lu Y, Shao Y, Shen Y, Bao J. Quantitative trait loci for brown rice color, phenolics, flavonoid contents, and antioxidant capacity in rice grain. Cereal Chem. (2009) 86:609–15.

20. Keawpeng I, Meenune M. Physicochemical properties of organic and inorganic Phatthalung Sungyod rice. Int Food Res J. (2012) 19:857–61.

21. Shafi S, Wani IA, Gani A, Sharma P, Wani HM, Masoodi FA, et al. Effect of water and ether extraction on functional and antioxidant properties of Indian horse chestnut (Aesculus indica Colebr) flour. Food Meas. (2016) 10:387–95.

22. Tharise N, Julianti E, Nurminah M. Evaluation of physico-chemical and functional properties of composite flour from cassava, rice, potato, soybean and xanthan gum as alternative of wheat flour. Int Food Res J. (2014) 21:1641–9.

23. Chung HJ, Liu Q, Lee L, Wei D. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents. Food Hydrocoll. (2011) 25:968–75. doi: 10.1111/jpn.13512

24. Ye L, Wang C, Wang S, Zhou S, Liu X. Thermal and rheological properties of brown flour from Indica rice. J Cereal Sci. (2016) 70:270–4.

25. Shao Y, Xu F, Sun X, Bao J, Beta T. Identification and quantification of phenolic acids and anthocyanins as antioxidants in bran, embryo and endosperm of white, red and black rice kernels (Oryza sativa L.). J Cereal Sci. (2014) 59:211–8.

26. Shao Y, Xu F, Chen Y, Huang Y, Beta T, Bao J. Genotype, environment, and their interaction effects on the phytochemicals and antioxidant capacities of red rice (Oryza sativa L.). Cereal Chem. (2015) 92:204–10.

27. Abdel-Aal ESM, Young JC, Rabalski I. Anthocyanin composition in black, blue, pink, purple and red cereal grains. J Agric Food Chem. (2006) 54:4696–704.

28. Shao Y, Zhang G, Bao J. Total phenolic content and antioxidant capacity of rice grains with extremely small size. Afr J Agric Res. (2011) 6:2289–93.

29. Shao Y, Bao J. Polyphenols in whole rice grain: genetic diversity and health benefits. Food Chem. (2015) 180:86–97. doi: 10.1016/j.foodchem.2015.02.027

30. Min B, McClung AM, Chen M-H. Phytochemicals and antioxidant capacities in rice brans of different color. J Food Sci. (2011) 76:C117–26.

31. Min B, Gu L, McClung AM, Bergman CJ, Chen M-H. Free and bound total phenolic concentrations, antioxidant capacities and profiles of proanthocyanidins and anthocyanins in whole grain rice (Oryza sativa L.) of different bran colours. Food Chem. (2012) 133:715–22.

32. Serpen A, Gökmen V, Pellegrini N, Fogliano V. Direct measurement of the total antioxidant capacity of cereal products. J Cereal Sci. (2008) 48:816–20.

33. Finocchiaro F, Ferrari B, Gianinetti A. A study of biodiversity of flavonoid content in the rice caryopsis evidencing simultaneous accumulation of anthocyanins and proanthocyanidins in a black-grained genotype. J Cereal Sci. (2010) 51:28–34.

34. Zaupa M, Calani L, Del Rio D, Brighenti F, Pellegrini N. Characterization of total antioxidant capacity and (poly) phenolic compounds of differently pigmented rice varieties and their changes during domestic cooking. Food Chem. (2015) 187:338–47. doi: 10.1016/j.foodchem.2015.04.055

35. Zhang H, Shao Y, Bao J, Beta T. Phenolic compounds and antioxidant properties of breeding lines between the white and black rice. Food Chem. (2015) 172:630–9. doi: 10.1016/j.foodchem.2014.09.118

36. Song X, Zhu W, Pei Y, Ai Z, Chen J. Effects of wheat bran with different colors on the qualities of dry noodles. J Cereal Sci. (2013) 58:400–7.

37. Oko AO, Ugwu SI. The proximate and mineral compositions of five major rice varieties in Abakaliki, South-Eastern Nigeria. Int J Plant Physiol Biochem. (2011) 3:25–7.

38. Ronda F, Villanueva M, Collar C. Influence of acidification on dough viscoelasticity of gluten-free rice starch-based dough matrices enriched with exogenous protein. LWT Food Sci Technol. (2014) 59:12–20.

39. Tudorica CM, Kuri V, Brennan CS. Nutritional and physicochemical characteristics of dietary fiber enriched pasta. J Agric Food Chem. (2002) 50:347–56. doi: 10.1021/jf0106953

40. Zhu F, Sakulnak R, Wang S. Effect of black tea on antioxidant, textural, and sensory properties of Chinese steamed bread. Food Chem. (2016) 194:1217–23. doi: 10.1016/j.foodchem.2015.08.110

41. Chen WZ, Hoseney RC. Development of an objective method for dough stickiness. LWT Food Sci Technol. (1995) 28:467–73.

42. Moreau RA, Powell MJ, Singh V. Pressurized liquid extraction of polar and nonpolar lipids in corn and oats with hexane, methylene chloride, isopropanol, and ethanol. Journal of the American Oil Chemists’. Society. (2003) 80:1063–7.

43. Du P, Wang X, Xu C, Gao Y. PseAAC-Builder: a cross-platform stand-alone program for generating various special Chou’s pseudo-amino acid compositions. Anal Biochem. (2012) 425:117–9. doi: 10.1016/j.ab.2012.03.015

44. Prosky L, Asp NG, Schweizer T, De Vries JW, Furda I. Determination of insoluble and soluble dietary fiber in food and food products: collaborative study. J AOAC Int. (1992) 75:360–7.

45. AACC International. Approved Methods Of Analysis. 11th ed. St. Paul, MN: AACC International (2000).

46. He S, Liu C, Zhuo J. Study on the technics of one-time-fermentation method steamed-bread making procession. Grain Process. (2004) 4:47–51.

47. ISO 8586-1. Sensory Analysis. General Guidance for the Selection, Training and Monitoring of Assessors. Part 1: Selected Assessors. Geneva: International Organization for Standardization (2012).

48. Detchewa P, Prasajak P, Phungamngoen C, Sriwichai W, Naivikul O, Moongngarm A. Substitution of rice flour with rice protein improved quality of gluten-free rice spaghetti processed using single screw extrusion. LWT. (2022) 153:112512.

49. Lee JH, Cho A, Hong JY, Park D, Lim S. Physical properties of wheat flour composites dry-coated with microparticulated soybean hulls and rice flour and their use for low-fat doughnut preparation. J Cereal Sci. (2012) 56:636–43.

50. Pal P, Kaur P, Singh N, Kaur A, Misra NN, Tiwari BK, et al. Effect of nonthermal plasma on physico-chemical, amino acid composition, pasting and protein characteristics of short and long grain rice flour. Food Res Int. (2016) 81:50–7.

51. Longvah T, Boiroju NK, Prasad VSS, Kumar KO, Mangthya K, Sharma P, et al. Nutrient diversity in 251 Indian rice germplasms and dietary nutrient supply through rice in rice based diets. LWT. (2021) 148:111721.

52. Jafari F, Mohammadi H, Amani R. The effect of zinc supplementation on brain derived neurotrophic factor: a meta-analysis. J Trace Elem Med Biol. (2021) 66:126753.

53. Feng Q, Yang Z, May M, Tsoi KK, Ingle S, Lee EK, et al. The role of body mass index in the association between dietary sodium intake and blood pressure: a mediation analysis with NHANES. Nutr Metab Cardiovasc Dis. (2021) 31:3335–44. doi: 10.1016/j.numecd.2021.08.051

Keywords: mixture design approach, steamed bread, flour, rice flour, nutritional characteristics

Citation: Tian S, Wei Y and Chen Z (2022) Effect of mixture design approach on nutritional characteristics and sensory evaluation of steamed bread added rice flour. Front. Nutr. 9:989090. doi: 10.3389/fnut.2022.989090

Received: 08 July 2022; Accepted: 24 October 2022;

Published: 11 November 2022.

Edited by:

Pilar Gómez Cortés, Spanish National Research Council (CSIC), SpainReviewed by:

Yuzhu Zhang, Western Regional Research Center, Agricultural Research Service (USDA), United StatesMichael Tilley, Center for Grain and Animal Health, Agricultural Research Service (USDA), United States

Copyright © 2022 Tian, Wei and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shuangqi Tian, dGlhbnNodWFuZ3FpQGhhdXQuZWR1LmNu

Shuangqi Tian

Shuangqi Tian Yichun Wei

Yichun Wei Zhicheng Chen

Zhicheng Chen