95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Nutr. , 09 September 2022

Sec. Food Chemistry

Volume 9 - 2022 | https://doi.org/10.3389/fnut.2022.983212

This article is part of the Research Topic Exploring Traditional Functional Fermented Foods and Beverages for Alleviating Malnutrition and Diabetes View all 5 articles

Consumption of high Glycemic Index (GI) foods is a risk factor for increasing prevalence of diabetes mellitus (DM). The extent of variation in starch digestibility and GI of Yam varieties and products is not yet fully understood. This study was therefore designed to evaluate in vitro and in vivo Glycemic Index properties of commonly consumed products prepared from varieties of White Yam. Four products (boiled, fried, pounded yam, and Amala) were prepared from 5 common varieties of Yam and evaluated for Digestible Starch (DS) and Resistant Starch (RS). Based on results, two products-pounded yam and Amala-were processed from three of the most popular varieties. Analysis of Rapidly Digestible Starch (RDS), Slowly Digestible Starch (SDS), and estimated in vitro GI (eGI) were then carried out in this stage. Glycemic Index (GI) of these products consumed by apparently healthy young adults were also determined. Variety Amula had highest DS in Amala (19.1/100 g) and pounded Yam (20.4/100 g) while variety Alumaco had highest RS in all the products (2.9–3.3/100 g). When compared with RS in its raw tuber, RS of Alumaco generally increased after processing. Variety Alumaco had lowest RDS in Amala (0.6/100 g) and pounded yam (0.3/100 g) while eGI was lowest in Alumaco made into Amala (53) and pounded yam (48). Assessment of GI resulted in high GI for all products across each variety. Irrespective of variety, processing Yam into Amala released RDS fraction faster when compared with pounded yam. Generally, even though the products are considered as having high GI, Amala raised eGI and GI faster than Pounded yam. Variety-Alumaco particularly showed favorable properties applicable to dietary management of diabetes. Exploring more processing methods and genetic diversity is recommended.

Global rates of prevalences of non-communicable diseases such as diabetes mellitus have been reported to be on the increase even in African countries where problems of undernutrition still persist (1, 2). One of the major risk factors related to this high prevalence is the consumption of high carbohydrate content foods especially when it forms the bulk of dietary source of energy (3). Among diabetic patients including individuals applying body weight control diet plans, there is usually a careful selection of carbohydrate rich foods. A long-standing in vivo metric for measuring and managing blood glucose control in diabetics and healthy individuals is the Glycemic Index (GI) which is derived by comparing blood glucose response caused by a food/meal against a similar estimation of a reference food item, which could be glucose or white bread (4, 5).

In recent times, several studies have shown a significant association between the time taken for starch to digest and the glucose released using various in-vitro methods that simulate the popular in vivo GI methodology (3, 6). This rests on the discoveries that Carbohydrates which were historically classified as simple and complex fractions can now be categorized based on their digestibility and physiological impact as food passes through the gastrointestinal tract. Accordingly, mono- and disaccharides and rapidly or slowly absorbed starches are now categorized to be glycemic carbohydrates (7). Thus, measurement of physiological effects by categorizing foods based on their glycemic effects are now providing useful guidelines for managing morbidity and preventing mortality in diabetic individuals (6).

The rate of starch digestibility still depends largely on the agronomic origin of the food which influences starch structure, starch gelatinization after processing quantity, type of resistant starch and dietary fiber (8, 9). Yam-a major food security crop for Sub-Saharan Africa-is the second most produced root and tuber crop after cassava (10, 11). Yam (Dioscorea spp.) has a large biological diversity with more than 600 species worldwide but only six are widely cultivated in Sub-Saharan Africa as follows: D. alata, D. bulbifera, D. dumetorum, D. esculenta, D. cayenensis, and D. rotundata (11). Of them all, the most popularly cultivated of all is White Yam (D. rotundata) of which about 73 million tons were produced in 2020 with about 70% coming from Nigeria (10).

In general, existing literature, points to a variation in digestibility of starch and GI due to processing method, structure, or origin of plant material. The GI of foods (and in some cases their starch digestibility) has been established as a tool for managing abnormal blood glucose levels, but the existence of biodiversity in commonly consumed starchy staples with the purpose of influencing differing post-prandial blood glucose levels is not yet fully explored. While published studies have established the possible intra-varietal differences in GI and starch digestibility (using in vitro methods) of some common products of Cassava (12), Sweet Potato (13), Yellow yam (14, 15), there is still little information on possible variation among common products of different varieties of White Yam commonly cultivated in Nigeria. This study therefore sought to evaluate in vitro and in vivo Glycemic Index properties of commonly consumed products prepared from some varieties of Yam.

The study combined laboratory experiments and a human feeding experiment carried out in three stages. The first stage involved food compositional analysis of products of selected yam varieties. In stage two, digestible and resistant starch fractions were evaluated. In the final stage, three varieties (and two products) were analyzed for rapidly and slowly digestible starch fractions, estimated glycemic index (eGI), and glycemic index (GI).

A literature and database search of yam varieties cultivated in Nigeria was carried out which was shortlisted to 5 most popular varieties in consultation with the Yam Breeding Unit of the International Institute of Tropical Agriculture (IITA) Ibadan, Nigeria (16). The varieties (Meccakusa, TDr02665, Alumaco, Oju Iyawo, Amula) were grown under rain-fed conditions with no fertilizer or herbicides added.

The peeled and washed samples were reduced into small sizes of about 12 cm diameter and boiled in water at 100°C for 20–30 min (17).

Washed yam slices were boiled in distilled water and pounded with a mortar and pestle until a constant dough was obtained (17).

Yam tubers were peeled and sliced. Washed yam slices were deep fried in vegetable oil at constant heat of 180°C for 5 min. Small quantity of water was added at intervals so the sample could uniformly cook and also to reduce the evaporation of the frying oil (17).

Tubers were peeled and washed with distilled water but not sliced further before being parboiled at 60°C for 12 min, and soaked in water for 18 h. The slices were then dried in the sun for 3–4 days. After which it was ground to flour (elubo), and cooked into a thick dough (17).

Moisture, protein, fat, dietary fiber and ash content were determined using the methods described previously (12, 18). Carbohydrate was determined by difference. The moisture content was determined through drying for 16 h at a constant temperature 103°C (18). The protein content was determined based on method described in literature (19) which involved spectrophotometric determination after the food matrix is subjected to digestion using concentrated acid solution. Fat content was determined using an Automated Soxhlet extractor (FOSS SoxtecTM 8000) which used hexane as the extracting solvent. Dietary fiber was determined gravimetrically after subtraction of digested fat and protein content as described in (12, 16, 20). Ash content was measured after the food sample was placed in pre-heated muffle furnace for 6 h at 550°C (18).

The evaluation of digestible and resistant starch fractions in raw tuber and products was done using methods described previously in literature (12, 20) which involved the initial process of hydrolysis and solubilization of starch in the yam product before the quantifications of the different fractions of starch. Hydrolysis was achieved by mixing an enzymatic solution with sample and incubating (with continuous shaking) for 16 h. Hydrolysis was stopped with addition of ethanol and the mixture was centrifuged. The supernatant was then separated from the mixture and evaluated for digestible (solubilized) starch while the remainder pellets were used to calculate non-solubilized (Resistant) starch. Mathematical calculations were done using the Megazyme Mega-CalcTM which was made available as a spreadsheet application via www.megazyme.com.

The method and principles earlier reported (12, 16) were applied in this study. First a preparation of enzyme solution of Pancreatic α-amylase (0.45 g) and amyloglucosidase (AMG) was done. Secondly, the sample and a buffer solution of sodium acetate (pH 5.2) were incubated in a shaking water bath (37°C, 120 rpm). At the designated time intervals, aliquots were taken from the incubating mixture for glucose determination using a Glucose reagent kit (supplied by Megazyme, Ireland, UK). The rate of starch digestion was expressed as the percentage of total starch hydrolyzed at different times (0, 10, 20, 30, 60, 90, 120, and 180 min). The total starch hydrolysis (%) which was a fraction of glucose (converted to starch) released per time was calculated and classified as follows:

1. Rapidly digestible starch (RDS, digested within 20 min).

2. Slowly digestible starch (SDS, digested between 20 and 120 min).

The method described (21) was applied to extrapolate the first order kinetic equation: C = C (1 - e-kt), where C represented the percentage of starch hydrolyzed at time t (min), C is the equilibrium percentage of starch hydrolyzed after 180 min, and k is the kinetic constant. The parameters, C and k, were estimated for each product based on the data obtained from the in vitro starch digestion. The hydrolysis index (HI) was then derived by dividing the Area Under Curve (AUC) of each starch hydrolysis by the AUC of the reference food (white bread). The HI represented the rate of starch digestion and the eGI indicated the digestibility of the starch in relation to the digestibility of starch in the reference material. The pGI was then calculated using the equation presented and applied by previous studies (16, 21); eGI = 39.71 + 0.54HI.

The methods described in literature (5) were applied in determining GI of the food products. Apparently healthy participants (n = 33) were recruited and screened before being admitted to the procedure. The portion used for testing was 50 g of available carbohydrate both of the reference food item (glucose) and the food products. The experimental portions served were deduced from the values of digestible carbohydrates. Glycemic responses of each participant were obtained from capillary blood and used in calculating the incremental area under the glucose response curve (IAUC) after which GI was obtained by calculating the percentage area under the curve of the reference material (glucose) in comparison with the test food. The GI categorization of foods was based on low (<55), medium (56–69), high (>70).

Data obtained from the study was entered into spreadsheets before descriptive and inferential statistical procedures were applied to present the study's results with p-value set at α0.05. Mean, standard deviation, coefficient of variation and analysis of variance tests (one-way and two-way repeated measures) were applied on the study's results. Duncan's test was applied to separate mean of values. For all inferential statistics, significance was set at p < 0.05. Ethical guidelines including informed consent before blood collection were followed as prescribed by the University College Hospital/University of Ibadan ethical review committee where the study's ethical clearance was registered with approval number UI/EC/17/0407 (approved 28/11/2017).

The nutrient composition of Boiled, fried, pounded yam and Amala are presented in Table 1. In boiled yam, the mean moisture content was 70.25 ± 3.58/100 g, while the total dietary fiber ranged from 2.34 to 5.21/100 g in varieties Meccakusa, and Amula, respectively. The coefficient of variation was highest in the ash contents of the products at 69.43% and lowest in moisture contents (5.09%). The average moisture content of pounded yam was 72.15/100 g while the carbohydrate content ranged from 19.41/100 g in Oju-iyawo to 24.12/100 g in TDr/02665. The total dietary fiber ranged from 2.53/100 g in Meccakusa to 4.46 g in Alumaco and the coefficient of variation was lowest in moisture content (2.62%). The mean moisture content of fried yam was 41.89 ± 7.32/100 g and the coefficient of variation was highest in the ash content of the products at 63.72%. The lowest ash content was found in Amula which had 0.88/100 g while TDr/02665 had 4.84/100 g which was the highest of all. Amala from selected Yam varieties had the highest mean moisture content of 77.12 ± 2.02/100 g when compared with other products. The carbohydrate contents ranged from 14.77 g in Oju-iyawo to 21.58/100 g in TDr/02665 while the total dietary fiber was from 2.69/100 g in Alumaco to 4.05/100 g in Amula.

The statistical measures of coefficient of variation and means separation as applied in this study establishes that there are differences in the selected varieties. This was similarly found by Kouassi and et al. (15) who evaluated different varieties of yellow yam (Dioscorea cayenensis). Worthy of note in line with the study's objective to probe carbohydrate properties is the differences found with dietary fiber composition which is scarce. There is sufficient evidence that dietary fiber has potentials to provide short and long-term functionality to the gastrointestinal tract (22). Even though the variations in the total dietary fiber among varieties were not substantial, this study found an effect of processing on this nutrient. However, the impact on dietary intake and nutrient adequacy may be marginal especially when compared with values obtainable from local and regional food databases (23, 24). Albeit, this study still successfully highlights the different variations in composition that could be exploited for breeding purposes or food science applications.

Figures 1, 2 depicts the digestible and resistant starch fractions in the raw tuber and four products processed from five varieties of yam as considered in this study. The variety with the highest digestible starch when processed into boiled yam was Alumaco (15.42/100 g) while the lowest was found in Oju-iyawo (11.38/100 g). A comparison between digestible starch in raw tubers and processed boiled yam shows that the highest percentage increase in digestibility is shown in Meccakusa (95.50%) while the lowest was in TDr 02665 which showed a 90.10% increase compared with the raw tubers. The variety with the highest content of digestible starch and digestibility when processed into pounded yam was Amula (20.42/100 g) with digestibility of 96.28% while the lowest was found in Alumaco (13.89/100 g) at 92.15%. When the raw tubers were processed into fried yam, digestible starch was highest in TDr 02665 (18.17 g) and was lowest in Oju-iyawo (11.33/100 g). The highest percentage increase in digestibility results for Amala was shown in Amula (96.02%) and Oju-iyawo (96.02%) while the lowest was in TDr 02665 which showed a 91.34% increase compared with raw tubers. In boiled yam, the variety with the highest content of resistant starch per 100 g after processing was Meccakusa (3.24/100 g) while the lowest was 2.19/100 g in Alumaco and TDr 02665 which contained 2.03/100 g.

The highest depletion in resistant starch in pounded yam occurred in TDr 02665 (24.60%) while the highest increase was in Alumaco which showed a 25.46% increase compared to the resistant starch in their respective raw tubers. The variety with the highest content of resistant starch per 100 g after processing into pounded yam was Alumaco (2.96 g) while the lowest was 2.36/100 g in TDr 02665. After processing into fried yam, the highest depletion in resistant starch was in TDr 02665 (30.03%) while the highest increase was in Alumaco which showed a 29.13% increase compared to the resistant starch content in its raw tubers. As for depletions or increment in resistant starch content after processing into Amala, Meccakusa (10.83%) was depleted the most while the highest increase was in Alumaco which showed a 27.95% increase compared to the resistant starch in raw tubers.

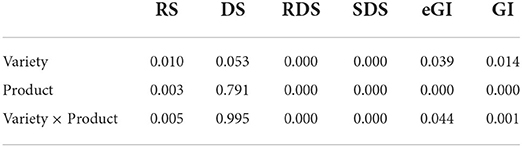

The similar proportion of increased digestible starch across the four products considered in this study confirms the known fact that disrupting the food matrix from its raw state into consumable forms will increase digestibility. Ahmed and Urooj (25) presented results supporting this fact in a trial of cooking Dioscorea alata tubers using different methods. A test of between-subjects effect of DS as influenced by yam variety and product (Table 3) also revealed no statistical difference while there was an observed significance for RS. The importance of the resulting fractions (digestible and resistant) to the rate of carbohydrate digestion has been reviewed (7, 26) but more emphasis has been placed on RS fractions due to their physiological and nutritional relevance during carbohydrate metabolism (20, 22). In general, foods with significant amount of resistant starch have been proven to contribute not only to controlling the release of glucose post-prandially but also to colonic health since they constitute soluble dietary fiber that is beneficial in the large intestine. A distinct varietal attribute was observed in the resistance of starch in the yam products considered in this study. This distinction (asides from the general depletion of RS after processing) was an increase in resistant starch content of some of the products made from variety Alumaco which had an increase in RS contents with processing. This attribute places this variety in a class of its own against the expected depletion of resistant starch with processing and can be further explored for application in the control of blood glucose among diabetic individuals. The product that resulted in a substantial decrease in resistant starch after processing was fried yam which implies it will result in faster glucose release post-prandially. A similar impact of frying on food matrix was reported in a study that evaluated different Yam species and cooking methods whereby frying resulted in highest glycemic response (GI) compared to boiling or roasting (14). This attribute seems to be peculiar to fried products which undergo high heat preparation, since a similar observation in French fries (from potatoes) has been reported (13, 27).

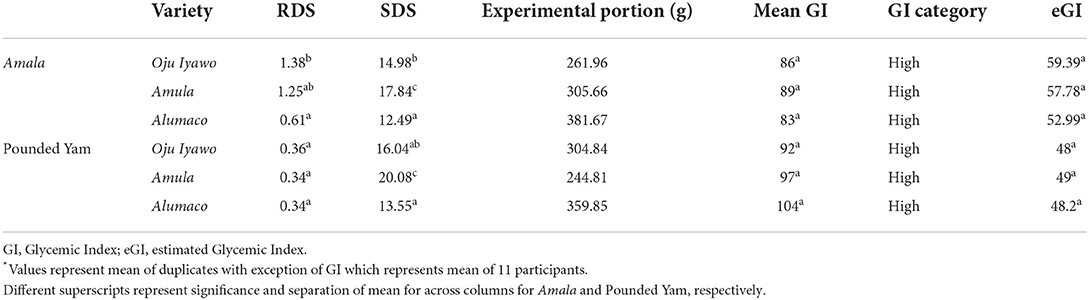

Starch digestibility results from in vitro analysis using the parameters- rapidly and slowly digestible starch and eGI are presented in Table 2 with in vivo GI results. Results for Pounded Yam showed that Amula had the highest SDS fraction (20.08/100 g). Oju-iyawo had a slightly higher RDS (0.36/100 g) in comparison with the other two varieties considered. The values of both RDS and SDS fractions were similarly lowest in Alumaco at 0.34/100 g and 13.55/100 g, respectively. In Amala, Amula had the highest slowly digestible starch fraction (17.84/100 g). Oju-iyawo had the highest rapidly digestible starch (1.38/100 g) in comparison with the other two varieties. Despite the similarities in rapid and slowly digestible starches of pounded yam and Amala, when the Yam was processed into Amala, it released RDS fraction faster when compared to pounded yam. This is explainable due to the impact of processing which is obvious by the steps required to obtain Amala in which boiling, drying, blending to flour and then cooking to dough will disrupt starch structure more when compared with preparing pounded yam. The method of processing pounded yam which involves a pounding effort that increases cohesiveness in the texture of the final product could also be responsible for its resistance to starch hydrolysis. In a study of Chinese yam (Dioscorea opposita), a similar inhibitory character was attributed to starch-protein interaction in the food matrix (28) while another study reported enzymatic inhibition (29).

Table 2. *Rapidly Digestible Starch (RDS), Slowly Digestible Starch (SDS) and GI values in Amala and Pounded Yam made from Yam (g/100 g).

When starch hydrolysis was compared using the reference food material (white bread) as a basis, the Amala prepared from Oju-iyawo had the highest starch hydrolysis rate after 30 min compared to the other two varieties (Figure 3). Beyond 30 min Amula had a slightly higher rate of hydrolysis compared with the other varieties while Alumaco had the lowest rate of hydrolysis over the total time of hydrolysis. These hydrolysis rates resulted in eGI of 59, 57, and 53 for Oju Iyawo, Amula, and Alumaco, respectively. Compared to Amala, the rate of hydrolysis in pounded yam (Figure 4) was not pictorially distinct across each variety but was similar to that of Amala whereby variety Amula marginally had highest hydrolysis rates across 180 min while Alumaco had the lowest rate. These rates resulted in eGI of 48, 49, and 48 for Oju Iyawo, Amula, and Alumaco, respectively. The low gradient curves in comparison to white bread (more pronounced in pounded Yam) seems to be an attribute of yam species due to an increased degree of α-amylase and α-glucosidase inhibition action when its flours are processed into dough (29). All the products made from the yam varieties were in the high category of GI with Amula having highest GI of 89 in Amala and Alumaco (104) in pounded Yam. The results of the in-vivo assessments presented in this study were similar to a compilation of GI literature values which confirms Yam in most of its different food forms and varieties will result in high GI after consumption (14, 15, 30). Despite all products falling in the high GI category (>70), the numerical differences found with each product show that variety and cooking method can impact GI in Yam (14, 15). In comparison with literature values these differences may be attributed to variations in human responses and method or tools used to estimate the glycemic response (4).

Overall, despite the similarities in quantitative values, there was a statistical difference across the RDS, SDS, GI and eGI values across both varieties and products, respectively (Table 3). This distinction in each variety and product were more pronounced when the products were subjected to in vitro analysis than results gotten from the in vivo test. The main varietal distinction was observed in Alumaco which resulted in the lowest rapidly digestible starch across the two products. Real life applications of these findings will include dietary management of diabetic patients and also an advantage over the use of GI which can hardly be used to distinguish between varieties in this manner. Another observable trend in the results is that the higher/lower the content of rapidly digestible material in the food, the more glucose is released into the blood which translated into a higher/lower eGI. This suggests that there are stronger associations between the glycemic parameters (such as rapidly/slowly digestible starch, dietary fiber and resistant starch) with eGI and GI compared to proximate parameters such as fat, ash and protein. This assertion was also suggested by Arvidsson-Lenner et al. (22) and Afandi et al., (31) who reported that variation in digestibility properties is more reliant on resistant starch composition and the granular structure of the starch.

Table 3. Test of between-subjects effect of in vitro and in vivo parameters as influenced by yam variety and product.

This study evaluated the differences in nutrient compositions, starch digestibility properties and GI of common staples made from Yam varieties across three stages of experiments. Overall, there were differences based on processing and variety across each stage of the experiments. Even though each product was different in composition, varietal differences were marginal in the first stages of food compositional analysis. A further evaluation of the digestible and resistant fractions of starch in stage two revealed further differences in varieties after processing. Particularly, variety Alumaco which distinctly showed an increase in resistant starch across most of the processing method and fried yam losing most resistant starch during processing. In the third stage of evaluation, processing substantially reflected on the rate of starch hydrolysis when pounded yam and Amala was compared. Also, varietal differences were more detectable using the estimated Glycemic Index (eGI) compared with the glycemic index (GI). In summary, this study provides evidence about factors such as variety and most importantly the effect of processing on starch fractions which are main determinants that affect GI and in-vitro starch digestibility properties of products from White Yam. Considering the diversity of varieties that exists and other products of white yam that are commonly consumed (and were not considered in this study), exploring more genetic diversity and processing methods is recommended for further studies.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

The studies involving human participants were reviewed and approved by University College Hospital University of Ibadan Ethical Review Committee. The patients/participants provided their written informed consent to participate in this study.

Study design and conceptualization and writing—original draft paper: TE, RS, and BM-D. Methodology: TE and BM-D. Data analysis: TE. All authors contributed to the article and approved the submitted version.

The authors appreciate the contributions of staff working in the Yam breeding Unit and the Food and Nutrition Sciences Laboratory of International Institute of Tropical Agriculture, Ibadan, Nigeria. TE also appreciates the research fellowship that covered the research costs of the study.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1. Popkin BM, Adair LS, Ng SW. Global nutrition transition and the pandemic of obesity in developing countries. Nutr Rev. (2012) 70:3–21. doi: 10.1111/j.1753-4887.2011.00456.x

2. Mutyambizi C, Pavlova M, Chola L, Hongoro C, Groot W. Cost of diabetes mellitus in Africa: a systematic review of existing literature. Global Health. (2018) 14:1–3. doi: 10.1186/s12992-017-0318-5

3. Livesey G, Taylor R, Hulshof T, Howlett J. Glycemic response and health—a systematic review and meta-analysis: relations between dietary glycemic properties and health outcomes. Am J Clin Nutr. (2008) 87:258S−68S. doi: 10.1093/ajcn/87.1.258S

4. Jenkins DJ, Wolever TM, Taylor RH, Barker H, Fielden H, Baldwin JM, et al. Glycemic index of foods: a physiological basis for carbohydrate exchange. Am J Clin Nutr. (1981) 34:362–6. doi: 10.1093/ajcn/34.3.362

5. Carbohydrates in Human Nutrition: Report of a Joint FAO/WHO Expert Consultation, Rome 14–18 April 1997. In: Rome, 1998.

6. Magaletta RL, DiCataldo SN, Liu D, Li HL, Borwankar RP, Martini MC. In vitro method for predicting glycemic index of foods using simulated digestion and an artificial neural network. Cereal Chem. (2010) 87:363–9. doi: 10.1094/CCHEM-87-4-0363

7. Englyst KN, Englyst HN. Carbohydrate bioavailability. Br J Nutr. (2005) 94:1–1. doi: 10.1079/BJN20051457

8. Cleary L, Brennan C. The influence of a (1 → 3) (1 → 4)-β-d-glucan rich fraction from barley on the physico-chemical properties and in vitro reducing sugars release of durum wheat pasta. Int J Food Sci Technol. (2006) 41:910–8. doi: 10.1111/j.1365-2621.2005.01141.x

9. Björck I, Granfeldt Y, Liljeberg H, Tovar J, Asp NG. Food properties affecting the digestion and absorption of carbohydrates. Am J Clin Nutr. (1994) 59:699S−705S. doi: 10.1093/ajcn/59.3.699S

10. FAOSTAT. Yam production in 2020. (2022). Available online at: https://www.fao.org/faostat/en/#compare (accessed May, 2022).

11. Asiedu R, Ng SY, Vuylsteke D, Terauchi R, Hahn SK. Analysis of the need for biotechnology research on cassava, yam and plantain. Biotechnol Enhanc Res Trop Crops Afr. (1992) 1:70–4.

12. Eyinla TE, Sanusi RA, Maziya-Dixon B. Effect of processing and variety on starch digestibility and glycemic index of popular foods made from cassava (Manihot esculenta). Food Chem. (2021) 356:129664. doi: 10.1016/j.foodchem.2021.129664

13. Odenigbo A, Rahimi J, Ngadi M, Amer S, Mustafa A. Starch digestibility and predicted glycemic index of fried sweet potato cultivars. Funct Foods Health Dis. (2012) 2:280–9. doi: 10.31989/ffhd.v2i7.83

14. Ampofo D, Agbenorhevi JK, Firempong CK, Adu-Kwarteng E. Glycemic index of different varieties of yam as influenced by boiling, frying and roasting. Food Sci Nutr. (2021) 9:1106–11. doi: 10.1002/fsn3.2087

15. Kouassi NK, Tiahou GG, Abodo JR, Camara-Cisse M, Amani GN. Influence of the variety and cooking method on glycemic index of Yam. Pakistan J Nutr. (2009) 8:993–9. doi: 10.3923/pjn.2009.993.999

16. Eyinla TE. Evaluation of Starch Digestibility and Glycemic Index of Commonly Consumed Staple Foods From Selected Varieties of Cassava (Manihot Esculenta) and Yam (Dioscorea rotundata). (PhD Thesis). Ibadan: University of Ibadan (2019).

17. Oladejo T. Effects of processing methods on nutrient retention and contribution of white yam (Dioscorea rotundata) products to nutritional intake of Nigerians. Afr J Food Sci. (2012) 6:163–7. doi: 10.5897/AJFS11.192

18. AOAC International Arlington. Official methods of analysis (21st ed.). (2019). AOAC International. Available online at: https://www.aoac.org/official-methods-of-analysis21st-edition-2019/ (accessed August 9, 2022).

19. Hach Procedures Manual. Systems for Food, Feed and Beverage Analysis. Loveland, CO., Hach Company (1990). p. 224.

20. McCleary BV, McNally M, Rossiter P. Measurement of resistant starch by enzymatic digestion in starch and selected plant materials: collaborative study. J AOAC Int. (2002) 85:1103–11. doi: 10.1093/jaoac/85.3.665

21. Goñi I, Garcia-Alonso A, Saura-Calixto F, A starch hydrolysis procedure to estimate glycemic index. Nutr Res. (1997) 17:427–37. doi: 10.1016/S0271-5317(97)00010-9

22. Arvidsson-Lenner R, Nils-Georg A, Axelsen M, Bryngelsson S, Haapa E, Jarvi A, et al. Glyceamic index: relevance for health, dietary recommendations and food labelling. Scand J Nutr. (2004) 48:84–94. doi: 10.1080/11026480410033999

23. West African Food Composition Table. Available online at: http://www.fao.org/documents/card/en/c/ca7779b (accessed April 9, 2019).

24. USDA. FoodData Central. Available online at: https://fdc.nal.usda.gov (accessed April 9, 2019).

25. Ahmed F, Urooj A. In vitro starch digestibility characteristics of Dioscorea alata tuber. World J Dairy Food Sci. (2008) 3:29–33.

26. Muir JG, Birkett A, Brown I, Jones G, O'Dea K. Food processing and maize variety affects amounts of starch escaping digestion in the small intestine. Am J Clin Nutr. (1995) 61:82–9. doi: 10.1093/ajcn/61.1.82

27. Nayak B, Berrios JJ, Tang J. 2014 Impact of food processing on the glycemic index (GI) of potato products. Food Res Int. (2014) 56:35–46. doi: 10.1016/j.foodres.2013.12.020

28. Yu B, Li J, Tao H, Zhao H, Liu P, Cui B. Physicochemical properties and in vitro digestibility of hydrothermal treated Chinese yam (Dioscorea opposita Thunb) starch and flour. Int J Biol Macromol. (2021) 176:177–85. doi: 10.1016/j.ijbiomac.2021.02.064

29. Adedayo BC, Oboh G, Akindahunsi AA. Estimated glycemic indices and inhibitory action of some yam (Dioscorea Spp.) products on key enzymes linked with type−2 diabetes. Futa J Res Sci. (2015) 11:25–35.

30. Foster-Powell K, Holt SH, Brand-Miller JC. International table of glycemic index and glycemic load values: 2002. Am J Clin Nutr. (2002) 76:5–6. doi: 10.1093/ajcn/76.1.5

Keywords: yam, glycemic carbohydrates, starch, diabetes, starch digestibility

Citation: Eyinla TE, Sanusi RA and Maziya-Dixon B (2022) Evaluation of in vitro and in vivo Glycemic Index of common staples made from varieties of White Yam (Dioscorea rotundata). Front. Nutr. 9:983212. doi: 10.3389/fnut.2022.983212

Received: 30 June 2022; Accepted: 16 August 2022;

Published: 09 September 2022.

Edited by:

Gloria A. Otunola, University of Fort Hare, South AfricaReviewed by:

Ana Maria Calderon De La Barca, Consejo Nacional de Ciencia y Tecnología (CONACYT), MexicoCopyright © 2022 Eyinla, Sanusi and Maziya-Dixon. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Busie Maziya-Dixon, Yi5tYXppeWEtZGl4b25AY2dpYXIub3Jn

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.