- 1College of Agriculture, Ningxia University, Yinchuan, China

- 2College of Food and Wine, Ningxia University, Yinchuan, China

The key aroma compounds and water distribution of the beef at different roasting times (0, 3, 6, 9, 12, 15, and 18 min) were identified and analyzed. The results showed that the L* value increased considerably before peaking and then decreased. On average, a* values decreased significantly first and then kept stable, while b* values increased first and then decreased. A total of 47 odorants were identified in all samples, including 14 alcohols, 18 aldehydes, 6 ketones, 1 ester, 3 acids, 4 heterocyclic compounds, and 1 other compound. Among them, 11 key aroma compounds were selected and aldehydes and alcohols predominantly contributed to the key aroma compounds. The fluidity of the water in the beef during the roasting process was decreased, and the water with a high degree of freedom migrated to the water with a low degree of freedom. The correlation analysis showed that water content and L* were negatively correlated with key aroma compounds of the samples, while M21 was positively correlated with key aroma compounds.

Introduction

Beef is widely consumed and has gained favor among many consumers worldwide because of its high-quality protein and vital elements such as essential amino acids, unsaturated fatty acids, minerals and vitamins (1). In 2019, China produced 6.67 million tons of beef, while imports were 1.6595 million tons and exports totaled just 0.02 million tons (2). Qinchuan cattle are the dominant breed in the Shaanxi-Gansu-Ningxia region. In the past 5 years, there have been about 3 million cattle in stock, with an average annual output of ~1 million cattle.

Aroma is a significant indication for evaluating food quality as well as a factor that influences consumer purchase behavior. Aroma compounds contribute to the aroma profile of meat and remarkably influence flavor perception (3). Raw meat has almost no aroma, and the majority of aroma compounds in meat were formed during the heating process. The primary reaction involved in the formation of aroma compounds in meat during heat processing includes lipid oxidation, Maillard reaction and Steckler degradation reaction, the interaction of lipids, Maillard reaction and thiamine degradation (4). Due to intramuscular lipid, many aroma compounds were identified at high concentrations even in lean muscle (5). Some linear aldehydes, alcohols, ketones and acid compounds were regarded as the byproducts of lipid oxidation (6). The Maillard process was principally responsible for the production of heterocyclic compounds such as pyrazines and furans. Multiple reactions arising from thermal degradation and lipid oxidation result in the formation of aroma compounds from non-volatile water-soluble precursors and lipids (5). Recently, a study evaluated 332 odorants found in thermally cooked meat by GC-O in the last 40 years by a search of relevant literature (7). A pleasant flavor is crucial for the appreciation of roasted beef. However, numerous compounds that are harmful to human health, such as heterocyclic amines (8), polycyclic aromatic hydrocarbons (9) and various kinds of aldehydes (10), were produced during the roasting process. Thus, understanding the production and key control points of aroma compounds during the roasting process of beef would help producers improve the aroma of beef or minimize the formation of unwanted odors (11).

Low field-nuclear magnetic resonance (LF-NMR) technology has been widely used in the analysis of the status, content and movement of water in samples as a standard instrument analysis method (12). It is most commonly employed in the food and agriculture fields since it is accurate, rapid and non-destructive (13–17). LF-NMR technology was also used to study the drying rate and textural features of meat products during drying (18). In addition, dynamic investigations have also been performed on meat undergoing processing including curing (19), cooking (20) and freezer storage (16). Meat contains considerable amounts of water (~70–75%), and the properties of the water are crucial for meat quality. The molecular mobility of water, protein and fat may affect the quality of the meat product during the heating process. The degree and nature of specific interactions (chemical or non-chemical, such as hydrogen bonding) between tiny solutes such as water molecules and ions and big food molecules may affect the meat's texture and flavor (21). In addition, water loss also means a reduction in production yield and thereby economic loss. Thus, the water in meat is important for both consumers and the meat industry.

The study aimed to (i) analyze and identify the aroma compounds of roasted beef during the electric roasting process through gas chromatography-mass spectrometry (GC-MS) combined with chemometric analysis; (ii) determine the key aroma compounds in roasted beef during the electric roasting process based on odor activity values (OAVs); (iii) analyze the water distribution and migration in the roasted beef for different periods by LF-NMR; (iv) determine the correlation between the moisture and color value and the formation of key aroma compounds in roasted beef The study may provide useful information and guidance for proper selection of roasting processes in the production of industrial beef.

Materials and methods

Materials

Beef from the hind legs of the Qinchuan cow was purchased from Yichuan's Xinbai market (Ningxia, China). The following chemicals were purchased from Sigma-Aldrich (Shanghai, China):1,2-dichlorobenzene (internal standard) and n-alkanes (C7-C40, ≥ 97%), hexanal (95%), heptanal (97%), 1-heptanol (97%), octanal (99%), (E)-2-octenal (97%), non-anal (99.5%), (E)-2-non-enal (97%), benzaldehyde (99.5%), (E, E)-2,4-decadienal (94%), 2-pentylfuran (98%), 2,5-dimethyl pyrazine (98%) and 1-octen-3-ol (98%). (E)-2-undecenal (l (94%), 2-pentylfuran (98%), 2,5-dime. (E, E)-2,4-non-adienal (95.8%) was from TCI Development Co., Ltd. (Shanghai, China). (E)-2-hexenal (97%) and (E)-2-heptenal (97%) were purchased from TCI (Shanghai, China). Methanol (analytical grade) was purchased from Thermo Fisher Scientific Co., Ltd (Shanghai, China).

Sample preparation

The lean meat of the Qinchuan cow was separated and cut into 3.0 × 3.0 × 2.0 cm slices after the fascia was removed. The beef was then placed in an HQ-405 electric oven (Qingdao Hanshang Electric Company, Ltd., Shandong, China) for roasting with both top and bottom burners set to 250°C. The samples were roasted for a total of 0, 3, 6, 9, 12, 15, and 18 min and three replicates were performed for each sample.

Instrumental color analysis

The color (CIE-L, a, b) of samples was determined using a TES-135A Chroma Meter (TES Co., Ltd., Taiwan, China). After roasting, the samples were placed in the room for 20 min to allow the roasted beef at the same temperature as room temperature (25 ± 1°C). Prior to measurement, the instrument was calibrated using a standard white plate covered with white paper (22). Meat samples were placed on a white paper and the color of the meat's surface was measured. L* represents the lightness component, with a value ranging from 0 to 100 (from black to white). a* denotes a red-green chromatic component with a value ranging from −60 to +60 (from green to red). b* is a yellow-blue chromatic component with a range from −60 to +60 (from blue to yellow). Total color difference (ΔE) was calculated according to Eq. (1).

where ΔE is the color difference between raw beef and roasted samples; , , and L*, a*, b* are the color parameters of the raw and roasted beef, respectively.

Analysis of aroma compounds

GC-MS

Aroma compounds were analyzed by a GC-MS system (GC-MS 2010 plus, SHIMADZU) equipped with a DB-WAX capillary column (30 m × 0.25 mm × 0.25 μm, Agilent Technologies, Santa Clara, CA). The SPME fiber of 50/30 m DVB / CAR / PDMS should be aged before extracting the aroma compounds. 2 ± 0.01 g of minced samples were placed into a 15 mL headspace bottle. 1,2-dichlorobenzene (4 μL, 6.42 μg/mL) was added as an internal standard to each sample. The headspace container was sealed with a PTFE diaphragm after being mixed with a vortex. The headspace container was put into a water bath at 55°C for 20 min. The SPME fiber was inserted into a sealed extraction bottle and left on top of the sample for adsorption. The samples were extracted for 30 min and immediately transferred to the GC inlet for 5 min of desorption at 250 °C. The GC conditions were as follows: helium was used as the carrier gas at a flow rate of 1.8 mL/min. The front inlet temperature was 250°C, with a solvent delay of 3 min. The oven temperature was maintained at 40°C for 3 min, ramped to 90°C at a rate of 5 °C/min, then ramped to 230°C at a rate of 8°C/min, and held at 230°C for 10 min. The volatile components from the capillary column were separated into the mass spectrometer (MS) at a ratio of 1:1 (v/v). The MS source was set at 230°C. MS fragmentation was observed in electron-impact (EI) mode (ionization energy of 70 eV) with a full-scan collection range of 20–350 m/z. Compounds were identified based on the NIST 14 database, retention indices (RI) with reference values and authentic volatile standards. The linear retention index values (LRIs) were calculated with a formula by Liu et al. (23).

Quantitation and OAVs analysis of aroma compounds

The content of aroma compounds was determined using a 5-point external standard curve. Prior to quantitation analysis, the deodorized matrix was prepared to eliminate the influence of the matrix effect according to a previous method (24), with several modifications. Briefly, diethyl ether and n-pentane were added into the beef (diethylether-n-pentane-beef puree ratio of 2:1:1, m/m/m). After shaking for 12 h, the organic solvent was extracted 5 times. The samples were then frozen in an FD-1A-50 freeze-dryer using liquid nitrogen (Shanghai Zheng-Qiao Science Instrument Plant, Ltd., Beijing, China) at−50°C for 24 h. The concentration of each aroma compound was divided by the reported odor threshold to get the OAVs (25). The contribution rate was the OAVs ratio of each odorant to all odorants.

Water analysis

The content of moisture in beef samples was determined by DHG-9213A Electric Blast Drying Oven (Jinghong Test Equipment Co., Ltd., Shanghai, China). The sample was dried at 105°C to a constant weight and the mass difference before and after drying was calculated to obtain the moisture content. The moisture distribution of the roasted beef was characterized by an NMI20-NMR analyzer (Niumag Co., Ltd., Shanghai, China) based on the method described by Li et al. (26). Typical pulse parameters were similar to those described by Li et al. (26). The spin-spin relaxation time (T2) was measured using the Carr–Purcell–Meiboom–Gill sequence with the following parameters: SF = 18 MHz; O1 = 3 82.241 65 Hz; TW = 3000 ms; RFD = 0.2 ms; RG1 = 20 db; P2 = 33 μs; TE = 0.251; NECH = 5000; SW = 100; DRG1 = 3; NS = 8. Three relaxation times (T21, T22 and T23) and their corresponding relaxation signal components (M21, M22 and M23) were recorded (27).

Sensory evaluation

The sensory evaluation was performed according to previous reports (28, 29). A total of 10 sensory panelists were screened and chosen based on GB/T 16291.1-2012. ISO 4121:2003 and GB/T 29604-2013 guidelines were used to train all panelists. Sensory analysis was performed in an odor-free room at 25 ± 1°C. Sample blocks were put into a 20-mL glass bottle and heated in a water bath at 70 °C until the core temperature reached 35°C. Six aroma attributes, including meaty, fatty, roasty, grassy, sweet and total odors were selected to evaluate the aroma quality of roasted beef. The sensory evaluation panel evaluated the sensory properties of roasted beef on a ten-point scale (8–10: very strong, 6–8: strong, 4–6: medium, 2–4: weak, 0–2: very weak). To avoid odor interaction between samples, panelists were required to take 30 s break.

Statistical analysis

Results were expressed as the means ± standard deviation. Data were analyzed by ANOVA, followed by Duncan's multiple range test (P < 0.05) using SPSS 19.0 software (IBMCorporation, USA). The graphs were made by Origin 18C software, and R software and MetaboAnalyst 4.0 were used to plot and combine figures.

Results and analysis

Sensory evaluation

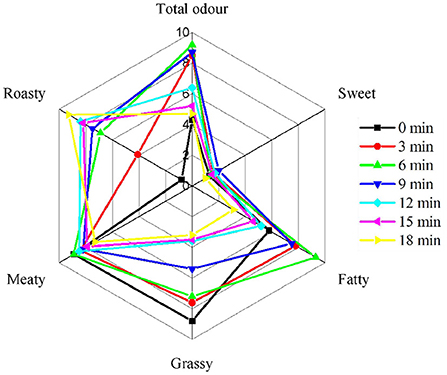

The purpose of sensory evaluation was to characterize the different flavor profiles of samples. As shown in Figure 1, the beef roasted for 6 min showed significantly high scores for total aroma (P < 0.05), indicating that a lot of aroma compounds were generated in the beef. It was worth noting that the sweet aroma of roasted beef showed low scores in all stages, while the meaty aroma exhibited high scores in all stages. In addition, the beef roasted for 18 min gained high scores of roasty aroma, while the raw meat gained high scores of grassy aroma. Moreover, high scores of fatty aroma were observed in the beef roasted for 6 min. However, what aroma compounds were produced by the beef at different roasting times needs further analysis.

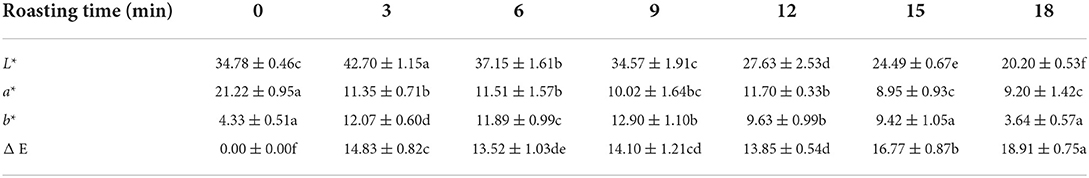

Changes in the color value of beef

The color of the cooked meat provides important information about the quality, flavor and safety of the meat products (30, 31). During the roasting process, the L* values of the beef significantly increased and subsequently decreased after 3 min of roasting (Table 1). Similar results were also reported for the infrared heating (grilling) of fish (32, 33), convective roasting of chicken breast meat (34) or microwave cooking of beef meat (35). Meanwhile, the a* values decreased significantly in the samples roasted for 0–3 min and then kept stable, and the b* values increased in the samples roasted for 0–9 min and then decreased at the end stage of roasting. The ΔE values of the beef were significantly increased (0–14.83) in the samples roasted for 0–3 min, then became stable (13.52–14.83) in the samples roasted for 3–12 min, and finally significantly increased (13.85–18.91) in the samples roasted for 12–18 min.

Aroma compounds

HS-SPME-GC-MS analysis

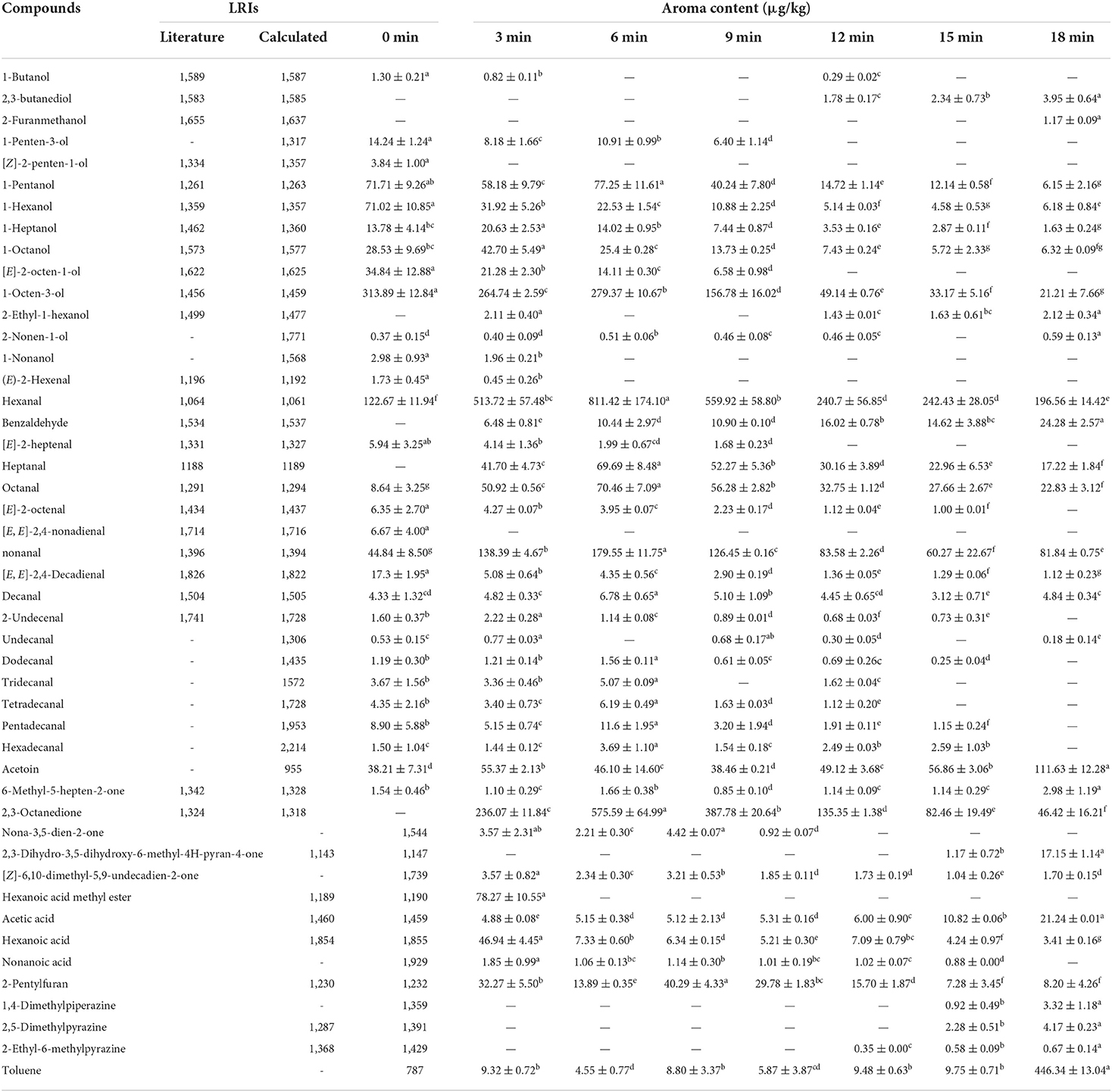

Aroma compounds of the beef were extracted by SPME from different roasting times. As shown in Table 2 and Figure 2, a total of 47 odorants were identified and these compounds were classified into seven chemical classes: 14 alcohols, 18 aldehydes, 6 ketones, 1 esters, 3 acids, 4 heterocyclic compounds and 1 other compound. A total of 37, 38, 33, 33, 34, 32, and 28 volatile compounds were identified in the beef at 0, 3, 6, 9, 12, 15, and 18 min, respectively. In the raw meat, methyl ester hexanoic acid, [Z]-2-penten-1-ol and [E, E]-2,4-non-adienal were identified, whereas they disappeared after roasting for 3 min. The concentrations of 1-penten-3-ol, 1-hexanol, [E]-2-octen-1-ol, 1-octen-3-ol, 1-nonanol, [E]-2-octenal, [E, E]-2,4-decadienal, [Z]-6,10-dimethyl-5,9-undecadien-2-one, non-anoic acid and hexanoic acid in the raw meat were significantly higher (P < 0.05) than those in the other beef samples roasted for 3–18 min. In contrast, benzaldehyde, heptanal and 2,3-octanedione were observed in the beef roasted for 3 min. The beef roasted for 6 min had the highest concentrations of 1-pentanol, hexanal, heptanal, octanal, non-anal, decanal, dodecanal, tridecanal, tradecanal, pentadecanal, hexadecanal, 2,3-octanedione, nona-3,5-dien-2-one and 2-pentyl-furan. However, the beef roasted for 18 min had the highest concentrations of 2,3-butanediol, 2-furanmethanol, 2-ethyl-1-hexanol, benzaldehyde, acetoin, 6-methyl-5-hepten-2-one and toluene. Interestingly, all pyrazines and piperazines appeared in the samples roasted for 12–18 min, such as 1,4-dimethylpiperazine, 2,5-dimethylpyrazine and 2-ethyl-6-methylpyrazine.

In all stages, aldehydes and alcohols had the highest concentrations in either raw or roasted beef. Hexanal, heptanal, octanal and nonanal were the major aldehydes, with hexanal having the highest value. 1-pentanol, 1-hexanol, 1-heptanol, 1-octanol and 1-octen-3-ol were the main alcohols in the roasted beef. Compared to the raw meat, the concentrations of alcohols in the roasted meat decreased with the increase of roasting times. While the levels of aldehydes, ketones and heterocyclic compounds significantly increased in the roasted beef after roasting for 3–6 min (P < 0.05) and subsequently decreased after roasting for 9 min. In particular, 1-pentanol (77.25 μg/kg), hexanal (811.42 μg/kg), heptanal (69.69 μg/kg), octanal (70.46 μg/kg), nonanal (179.55 μg/kg), 2,3-octanedione (575.59 μg/kg) and 2-pentylfuran (40.29 μg/kg) predominantly contributed to the aroma in the beef roasted for 6 min.

Key aroma compounds in roasted beef

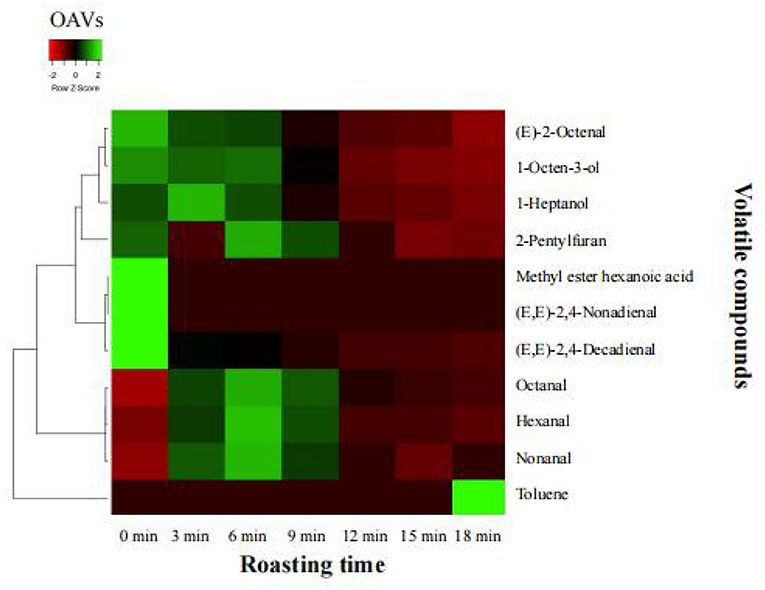

Aroma compounds (OAVs >1) played a vital role in the aroma expression of the samples. To better understand the importance of each aroma compound, the OAVs and contribution rates were calculated. As shown in Figure 3, a total of 11 aroma compounds were found to be the key odorants in the roasted beef, including 1-heptanol, 1-octen-3-ol, hexanal, octanal, (E)-2-octenal, (E, E)-2,4-nonadienal, nonanal, (E, E)-2,4-decadienal, methyl ester hexanoic acid, 2-pentylfuran and toluene. Ten out of 11 odorants played vital roles in aroma expression in the raw meat with OAVs >1, including 1-heptanol, 1-octen-3-ol, hexanal, octanal, (E)-2-octenal, (E, E)-2,4-nonadienal, nonanal, (E, E)-2,4-decadienal, methyl ester hexanoic acid and 2-pentylfuran. Eight out of 11 odorants were initially considered the key odorants in the beef roasted for 6 min with OAVs >1, including 1-heptanol, 1-octen-3-ol, hexanal, octanal, (E)-2-octenal, nonanal, (E, E)-2,4-decadienal, and 2-pentylfuran. The concentrations and OAVs of 1-octen-3-ol, (E)-2-octenal and (E, E)-2,4-decadienal decreased significantly (P < 0.05) from 0 to 18 min. However, the levels of hexanal, octanal and nonanal increased significantly (P < 0.05) from 0 to 6 min, and then their values decreased significantly (P < 0.05) from 9 to 18 min. In comparison with the raw meat, 4 key odorants were all detected and were maintained at high levels in the samples roasted for 6 min, among which hexanal (16.23), octanal (100.66), nonanal (179.55), and 2-pentylfuran (6.72) had the highest OAVs. Particularly, 1-octen-3-ol had the highest concentration and OAV (P < 0.05) in the raw meat, followed by the samples at 6 min, and the lowest concentration was found in the beef roasted for 18 min. The contribution rate was further used to exhibit the importance of each odorant. 1-octen-3-ol (41.35%), nonanal (26.58%), octanal (14.90%), (E, E)-2,4-decadienal (12.88%), hexanal (2.40%) and 2-pentylfuran (0.99%) predominantly contributed to the aroma in the beef roasted for 6 min. Furthermore, raw meat, roasted beef, and the beef that exceeded the roasting time could be discriminated by the concentrations of 1-octen-3-ol, octanal and nonanal.

The changes of water in the process of beef roasting

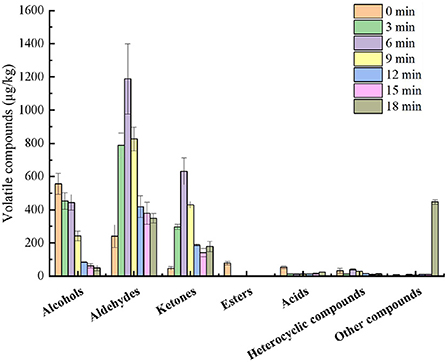

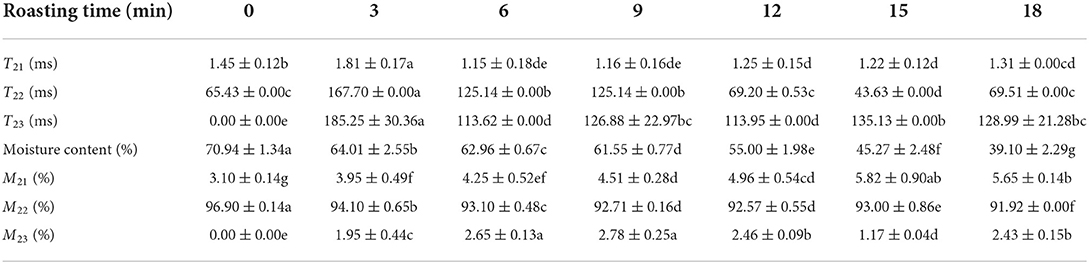

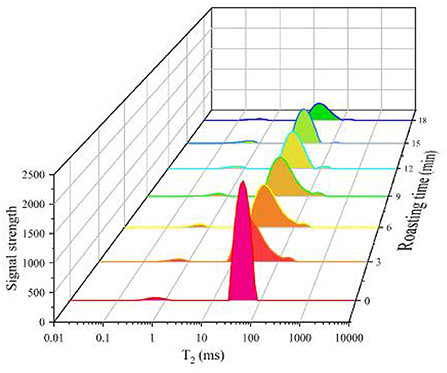

NMR spectroscopy, a well-established method for characterizing the state, mobility, and distribution of water in polymer systems, has been widely used (36). In the study, the proton transverse relaxation time (T2) was used to evaluate the water distribution and properties in myofibrillar proteins of the beef samples during roasting. There are three distinct types of water, T21, T22 and T23. The relaxation signal components of T21, T22, and T23 are represented by M21, M22 and M23, respectively. The water populations reflected the mobility of water fractions from the most tightly bound to the least tightly bound, which were described as bound water (T21), immobilized water (T22) and free water (T23), respectively (37). T21 (0.01 to 10 ms) is tightly connected with hydrophilic groups in macromolecules (38); T22 (10–100 ms) is the major water component among the three varieties of water in the muscle and is entrapped in the myofibrillar network or between the thin and thick filaments (39); T23 (100–1,000 ms) resides between fiber bundles and is easy to lose (40).

As shown in Table 3 and Figure 4, the total peak area decreased gradually with increasing roasting time, indicating that the moisture content of the samples decreased. The peak positions of T22 and T23 shifted to the left, indicating that the fluidity of the water in the samples was decreased and the water with a high degree of freedom migrated to the water with a low degree of freedom.

Figure 4. T2 relaxation time distribution curve of the roasted beef at the different roasting times.

Discussion

Sensory evaluation

The aroma is one of the most predominant qualities that affect the product's sensory characteristics. The total concentration of the compounds identified by GC-MS was the highest in the beef roasted for 6 min, especially alcohols and aldehydes. This may be the reason for the high total odor score of the beef roasted for 6 min. In addition, a high score of roasted aroma was observed in the beef roasted for 18 min, which may be related to the heterocyclic compounds generated from the Maillard reaction, like 2,5-dimethylpyrazine and 2-ethyl-6-methylpyrazine (41). Pyrazines, particularly alkylpyrazines, are extensively distributed and are responsible for the nutty, musty, or cocoa aroma odor in the roasted foods (41). The fatty aroma may be related to the linear aldehydes formed by lipid oxidation like hexanal, nonanal (E, E)-2,4-nonadienal and octanal. Numerous studies have shown that these compounds have a fatty aroma (7, 24, 42). Alcohols generally have lower thresholds with a green aroma, and large amounts of alcohol were observed in the raw meat.

Color

In general, the levels of undenatured myoglobin (including oxymyoglobin) and globin haemochromogen influenced the color of the cooked meat (43). However, the roasting process was the primary reason for the changes in the meat color during a high temperature and long time roasting. In this study, the increase of the L* values and ΔE values in the beef roasted for 0–3 min may attribute to the changes in the levels of undenatured myoglobin and globin haemochromogen. The changes in the L*value of the beef samples roasted for 3–18 min may affect water content, which was quickly decreased due to evaporation during sustained high-temperature heating (44). The decrease of water content may result in a faster heating rate in the samples given the same heat per unit time, and may also accelerate some reactions, like the Maillard reaction. In the final stage of the Maillard reaction, condensation of carbonyls and amines produces brown-colored high molecular weight compounds, known as melanoidins (browning), resulting in the decrease of the L*value (45). This appearance was obvious and could be directly observed by the naked eyes (46). Meanwhile, a decrease in the water content may lead to reduced reflection of light, also decreasing the L*value (47). The ΔE values of the beef were significantly increased (P < 0.05) in the samples roasted for 12–18 min. This may be explained by a finding showing that the heat-induced unfolding of proteins may play an important role in the process of the Maillard reaction (48). The a* value, the most sensitive parameter of color measurement, reflects red color and color stability (49). The color of the roasted beef changed from light red to pale, with a decrease of a* value. Roasting also significantly increased the b* value of the roasted beef (P < 0.05). However, long time heat treatment at high temperatures may result in an unattractive color.

Aldehydes and alcohols predominantly contributed to the key aroma compounds in the roasted beef

Aldehydes and alcohols, which resulted from lipid oxidation as well as Maillard reactions and Strecker degradation of carbohydrates and amino acids, were the primary aroma compounds in meat products, such as 1-octen-3-ol nonanal, octanal and hexanal (50). The unsaturated fatty acids, like linoleic acid and α-linolenic acid, predominantly contributed to the formation of fatty aldehydes and alcohols such as 1-pentanol, pentanal, 1-hexanol, 1-heptanol, 1-octanol, hexanal, heptanal, decanal, octanal, nonanal, benzaldehyde (E)-2-octenal, 1-nonanol, 1-octen-3-ol and (E)-2-octen-1-ol (42, 50). In this study, a total of 47 aroma compounds were identified, including 14 alcohols and 18 aldehydes. A total of 11 aroma compounds were selected through OVAs as the key odorants of the roasted beef. However, 8 aldehydes and alcohols out of 11 key odorants were observed, with a high contribution (97.36–99.61%) to the aroma in the roasted beef. Its was also reported that aldehydes were the predominant class of compounds found in the roasted beef, followed by alcohols (51). In the beef roasted for 6 min, 1-octen-3-ol had the highest OAVs (313.89) and contribution rate (41.35%), followed by nonanal, octanal, (E, E)-2,4-decadienal and hexanal. Different roasting methods could change the concentrations of the aldehydes and alcohols, but these odors were still the most critical aroma compounds in the roasted beef (52). Furthermore, the concentrations of hexanal, octanal, and 1-octen-3-ol were higher than other compounds in the roasted meat at different aging stages, with the highest OAVs (25). 2-pentylfuran (OAVs >1) was observed in the roasted beef, and may also be a key aroma compound. In addition, harmful compound toluene was observed with OAVs >1 in the beef roasted for 18 min. Different from other key compounds, methyl ester hexanoic acid was only found in the raw meat.

Aroma contribution of key aroma compounds in roasted beef

The typical meaty, fatty, roasty, grassy and sweet aromas in the roasted beef were mostly produced by the 11 key aroma compounds with OAVs >1. 1-octen-3-ol, a key aroma compound in the roasted beef with mushroom aromas, was enzymatically produced by hydrolyzation and oxidation of the n-3, n-6 polyunsaturated fatty acids during the heating process (24). Octanal (fatty and green aromas), 1-heptanol (floral and green aromas) and nonanal (rose, citrus, and strong fat flavor) were derived from oleic acid oxidation (24, 53–55). (E, E)-2,4-decadienal (fruity/sweet orange, sweet melon and fatty/toasted/scallion biscuit aromas) formed by oxidation of n-3 unsaturated fatty acids when heated at 85 and 100 °C (55). (E, E)-2,4-nonadienal (toasted and fatty aromas) and (E)-2-octenal (grilled meat and peanut cake aromas) were generated from the degradation of linoleic acid at high temperatures (55). Hexanal was a product of linoleic acid oxidation and contributed mainly to fatty and grassy aroma (56). In addition, the ratio of hexanal to nonanal was proposed as an indicator of mutton freshness and overall quality (57). 2-pentyl-furan was responsible for the aromas of earthy and green notes and may be generated by autoxidation and oxidation of n-6 unsaturated fatty acids, such as linoleic acid (56). Toluenes may have no contribution to or negatively affect the aroma characteristics of the roasted beef if too many of these components were present (58). The concentrations of 11 key aroma compounds in the beef decreased during the roasting process, while the levels of aldehydes and 2-pentylfuran were increased in the beef roasted for 0–6 min and produced fatty and meat aroma. The whole aroma of the roasted beef gradually decreased during roasting for 6–18 min. The concentrations of each key aroma compound increased or decreased during the roasting process. The aroma of the roasted beef was dominated by the synergy of key aroma compounds (59).

Moisture migration of beef during the roasting process

Longer transverse relaxation time is related to higher degrees of freedom, while shorter transverse relaxation time is associated with lower degrees of freedom (60). As shown in Table 3, the value of T21 in the roasted beef decreased with increasing roasting time (P < 0.05). This result suggested that the water in the beef with a high degree of freedom migrated to the water with a low degree of freedom and the water was gradually restricted by the proteins during the roasting procedure (14). The changes of T22 in the roasted beef were similar to T21. The decrease in T22 indicated that the water located in the myofibrillar network of the roasted beef with increasing roasting time may flow into the extra-myofibrillar network space owing to myofibrils contraction (61). The changes in T23 in beef during the roasting process were not significant (P > 0.05).

The percentages of peak areas (M21, M22, and M23) corresponded to T2 relaxation time. The M21 and M22 in the roasted beef with the increase of roasting time were significantly increased and decreased, respectively (P < 0.05). No significant (P > 0.05) differences in M23 of the roasted beef samples were observed. The decrease in M22 indicated that the immobilized water entrapped in the myofibrillar network was transformed into free water located in the intercellular space during the roasting process. This result was similar to a previous report showing that the water amounts corresponding to the T22 domain were redistributed into the intercellular space, resulting in a decrease in the water-holding capacity of samples (62).

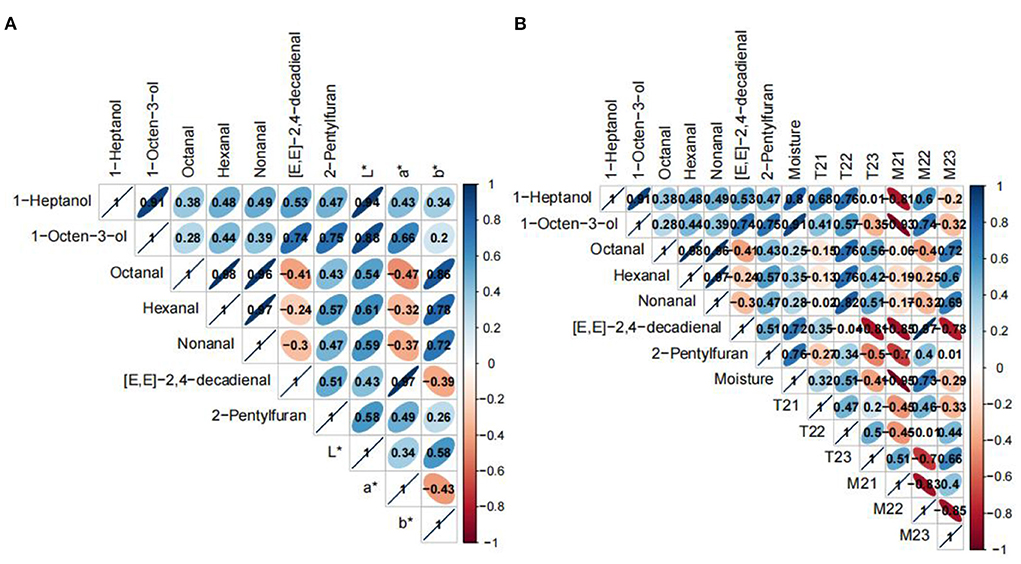

Correlation between color, moisture and key aroma compounds

Based on OAVs analysis, 7 key aroma compounds present in all samples were selected to correlate with color and water (Figure 5). The water content was negatively correlated with all the key aroma compounds, while M21 was positively correlated with all the key aroma compounds. It was reported that the moisture was easily lost by evaporation during heating at high temperatures for a prolonged time (63). The heat that causes water loss in the samples may also accelerate the generation of aroma compounds (64). M21 represents bound water, and it's not easy to lose during the roasting process because the water is tightly associated with hydrophilic groups in macromolecules. T21 was negatively correlated with 1-heptanol, 1-octen-3-ol and [E, E]-2,4-decadienal. T22 was negatively correlated with all the key aroma compounds, except [E, E]-2,4-decadienal. T23 was positively correlated with [E, E]-2,4-decadienal and 1-octen-3-ol. A study showed that water-holding capacity had a clear link with T22 and T23 populations (28). M22 was negatively correlated with [E, E]-2,4-decadienal, 1-octen-3-ol, 1-heptanol and 2-pentylfuran. M23 was negatively correlated with nonanal, hexanal and octanal. L* was negatively correlated with all the key aroma compounds. a* was negatively correlated with [E, E]-2,4-decadienal, 1-octen-3-ol and 1-heptanol. b* was negatively correlated with nonanal, hexanal and octanal. The difference in the L*value among the samples may be attributed to different moisture contents in the roasted beef samples. The samples with a lower water content possessed lower L* values.

Conclusions

The present work revealed the law of water distribution and the changes in aroma compounds in the roasted beef under the electric roasting process. A total of 47 volatile compounds were identified and 11 key aroma compounds were selected. In all stages, aldehydes and alcohols were the key aroma compounds. The fluidity of the water in the beef during the roasting process decreased, and the water with a high degree of freedom migrated to the water with a low degree of freedom. The moisture content and L* value were negatively correlated with the key aroma compounds, while M21 was positively correlated with the key aroma compounds. The color and water content are important parameters to evaluate the quality of the roasted beef. Thus, we hope that a predictive model between indicators, such as color and moisture content and the degree of roasting can be established in the future. This predictive model may be used to control the color and water level of the beef during the process of electric roasting, and at the same time ensure the safety of the final product. Furthermore, the roasting process can be optimized through this predictive model to make the production processes intelligent and to obtain the product with the highest quality for the consumers.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author/s.

Author contributions

Y-RW: resources, software, investigation, methodology, writing—original draft, and writing—review and editing. S-LW: conceptualization and supervision. R-ML and Y-RW: validation and visualization. All authors contributed to the article and approved the submitted version.

Funding

The State Key Research and Development Plan (2018YFD0400101), the Natural Science Foundation of China (31660484), and the Key Research and Development Plan of Ningxia Hui Autonomous Region (2019BEH03002) provided financial assistance for this work.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

GC-MS, Gas chromatography-mass spectrometry; LF-NMR, Low field-nuclear magnetic resonance; LRIs, linear retention index values; OAVs, Odor activity values.

References

1. Cabrera MC, Saadoun A. An overview of the nutritional value of beef and lamb meat from South America. Meat Sci. (2014) 98:435–44. doi: 10.1016/j.meatsci.2014.06.033

2. The people's Republic of China National Bureau of Statistics. Chinese Statistical Yearbook[M]. Beijing: China Statistics Press (2020).

3. Legako JF, Brooks JC, Quinn TGO, Hagan TD, Polkinghorne R, Farmer LJ, et al. Consumer palatability scores and volatile beef flavor compounds of five USDA quality grades and four muscles. Meat Sci. (2015) 100:291–300. doi: 10.1016/j.meatsci.2014.10.026

4. Zamora R, Hidalgo FJ. The Maillard reaction and lipid oxidation. Lipid Tech. (2011) 23:59–62. doi: 10.1002/lite.201100094

5. Gardner K, Legako JF. Volatile flavor compounds vary by beef product type and degree of doneness. J Anim Sci. (2018) 96:4238–50. doi: 10.1093/jas/sky287

6. Homsten L, Cowe P. Meat flavor chemistry, flavour studies an beef and pork. J Agr Food Chem. (1960) 8:194–498. doi: 10.1021/jf60112a022

7. Sohail A, Al-Dalali S, Wang JN, Xie JC, Shakoor A, Asimi S, et al. Aroma compounds identified in cooked meat: A review. Food Res Int. (2022) 157:111385. doi: 10.1016/j.foodres.2022.111385

8. Cao J, Ding R, Wang Y, Chen DJ, Guo DM, Liang CM, et al. Toxic effect of cooking oil fumes in primary fetal pulmonary type II-like epithelial cells. Environ Toxicol Phar. (2013) 36:320–31. doi: 10.1016/j.etap.2013.04.011

9. Lee T, Gany F. Cooking oil fumes lung cancer: A review of the literature in the context of the U.S. population. J Immigr Minor Healt. (2013) 15:646–52. doi: 10.1007/s10903-012-9651-1

10. Hu Y, Zhao G, Yin F, Liu Z, Wang J, Qin L, et al. Effects of roasting temperature and time on aldehyde formation derived from lipid oxidation in scallop (Patinopecten yessoensis) and the deterrent effect by antioxidants of bamboo leaves. Food Chem. (2021) 369:130936. doi: 10.1016/j.foodchem.2021.130936

11. Liu H, Huang J, Hu Q, Chen Y, Lai K, Xu J, et al. Dual-fiber solid-phase microextraction coupled with gas chromatography-mass spectrometry for the analysis of volatile compounds in traditional Chinese dry-cured ham. J Chromatogr B. (2020) 1140:121994. doi: 10.1016/j.jchromb.2020.121994

12. Xiao Q, Lim LT, Zhou YJ. Drying process of pullulan edible films forming solutions studied by low-field NMR. Food Chem. (2017) 230:611–7. doi: 10.1016/j.foodchem.2017.03.097

13. Yang HJ, Zhang WG, Li T, Zheng HB, Khan MA, Xu XL, et al. Effect of protein structure on water and fat distribution during meat gelling. Food Chem. (2016) 204:239–45. doi: 10.1016/j.foodchem.2016.01.053

14. Shao JH, Deng YM, Jia N, Li RR, Cao JX, Liu DY, et al. Low-field NMR determination of water distribution in meat batters with NaCl and polyphosphate addition. Food Chem. (2016) 204:308–14. doi: 10.1016/j.foodchem.2016.01.013

15. Han G, Chen Q, Xia XF, Liu Q, Kong BH, Wang H. High hydrostatic pressure combined with moisture regulators improves the tenderness and quality of beef jerky. Meat Sci. (2021) 181:1–9. doi: 10.1016/j.meatsci.2021.108617

16. Cheng SS, Wang XH, Li RR, Yang HM, Wang HH, Wang HT, Tan MQ. Influence of multiple freeze-thaw cycles on quality characteristics of beef semimembranous muscle: With emphasis on water status and distribution by LF-NMR and MRI. Meat Sci. (2019) 147:44–52. doi: 10.1016/j.meatsci.2018.08.020

17. Xu DD, Wang YB, Jiao N, Qiu K, Zhang X, Wang LQ, et al. The coordination of dietary valine and isoleucine on water holding capacity, pH value and protein solubility of fresh meat in finishing pigs. Meat Sci. (2020) 163:1–9. doi: 10.1016/j.meatsci.2020.108074

18. García ABG, Rodríguez MIC, de Ávila Hidalgo MDR, Bertram HC. Water mobility and distribution during dry-fermented sausages “Spanish type” manufacturing and its relationship with physicochemical and textural properties: a low-field NMR study. Eur Food Res Technol. (2016) 243:455–66. doi: 10.1007/s00217-016-2759-0

19. Kang DC, Gao XQ, Ge QF, Zhou GH, Zhang WG. Effects of ultrasound on the beef structure and water distribution during curing through protein degradation and modification. Ultrason Sonochem. (2017) 38:317–25. doi: 10.1016/j.ultsonch.2017.03.026

20. Wang B, Li HJ, Huang ZB, Kong BH, Liu Q, Wang H, et al. Dynamic changes in the qualities and heterocyclic aromatic amines of roasted pork induced by frying temperature and time. Meat Sci. (2021) 176:108457. doi: 10.1016/j.meatsci.2021.108457

21. Wang Y, Wang Z, Handa C L, Xu J. Effects of ultrasound pre-treatment on the structure of beta-conglycinin and glycinin and the antioxidant activity of their hydrolysates. Food Chem. (2017) 218:165–72. doi: 10.1016/j.foodchem.2016.09.069

22. Sun S, Guo B, Wei Y, Fan M. Multi-element analysis for determining the geographical origin of mutton from different regions of China. Food Chem. (2011) 124:1151–6. doi: 10.1016/j.foodchem.2010.07.027

23. Liu H, Wang ZY, Zhang DQ, Shen QW, Hui T, Ma JR. Generation of key aroma compounds in Beijing roasted duck induced via Maillard reaction and lipid pyrolysis reaction. Food Res Int. (2020) 136:109328. doi: 10.1016/j.foodres.2020.109328

24. Liu H, Wang ZY, Zhang DQ, Shen QW, Pan T, Hui T, et al. Characterization of key aroma compounds in Beijing roasted duck by gas chromatography-olfactometry-mass spectrometry, odor-activity values, and aroma-recombination experiments. J Agr Food Chem. (2019) 67:5847–56. doi: 10.1021/acs.jafc.9b01564

25. Xiao X, Hou C, Zhang D, Li X, Ren C, Ijaz M, et al. Effect of pre- and post-rigor on texture, flavor, heterocyclic aromatic amines and sensory evaluation of roasted lamb. Meat Sci. (2020) 169:108220. doi: 10.1016/j.meatsci.2020.108220

26. Li X, Ma LZ, Tao Y, Kong B H, Li PJ. Low Field-NMR in measuring water mobility and distribution in beef granules during drying process. Adv Mater Res. (2012) 550–553:3406–10. doi: 10.4028/www.scientific.net/AMR.550-553.3406

27. Li S, Luo Z, Guan X, Huang K, Li Q, Zhu F, et al. Effect of ultrasonic treatment on the hydration and physicochemical properties of brewing rice. J Cereal Sci. (2019) 87:78–84. doi: 10.1016/j.jcs.2019.03.002

28. Biffin TE, Smith MA, Bush RD, Collins D, Hopkins DL. The effect of electrical stimulation and tenderstretching on colour and oxidation traits of alpaca (Vicunga pacos) meat. Meat Sci. (2019) 156:125–30. doi: 10.1016/j.meatsci.2019.05.026

29. Schmidberger PC, Schieberle P. Changes in the key aroma compounds of raw shiitake mushrooms (Lentinula edodes) induced by pan-frying as well as by rehydration of dry mushrooms. J Agr Food Chem. (2020) 68:4493–506. doi: 10.1021/acs.jafc.0c01101

30. Grunert KG, Bredahl L, Brunsø K. Consumer perception of meat quality andimplications for product development in the meat sector-a review. Meat Sci. (2004) 66:259–72. doi: 10.1016/S0309-1740(03)00130-X

31. Pedreschi F, León J, Mery D, Moyano P. Development of a computer vision system to measure the color of potato chips. Food Res Int. (2006) 39:1092–8. doi: 10.1016/j.foodres.2006.03.009

32. Matsuda H, Llave Y, Fukuoka M, Sakai N. Color changes in fish during grilling-influences of heat transfer and heating medium on browning color. J Food Eng. (2013) 116:130–7. doi: 10.1016/j.jfoodeng.2012.11.027

33. Nakamura M, Mao W, Fukuoka M, Sakai N. Analysis of the color change in fish during the grilling process. Food Sci Technol Res. (2011) 17:471–8. doi: 10.3136/fstr.17.471

34. Rabeler F, Skytte JL, Feyissa AH. Prediction of thermal induced color changes of chicken breast meat during convective roasting: A combined mechanistic and kinetic modelling approach. Food Control. (2019) 104:42–9. doi: 10.1016/j.foodcont.2019.04.018

35. Kondjoyan A, Kohler A, Realini CE, Portanguen S, Kowalski R, Clerjon S, et al. Towards models for the prediction of beef meat quality during cooking. Meat Sci. (2014) 97:323–31. doi: 10.1016/j.meatsci.2013.07.032

36. Guo ZW, Teng F, Huang ZX, Lv B, Lv XQ, Olga B, et al. Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocolloid. (2020) 105:105752. doi: 10.1016/j.foodhyd.2020.105752

37. Li K, Liu JY, Fu L, Zhao YY, Zhu H, Zhang YY, et al. Effect of bamboo shoot dietary fiber on gel properties, microstructure and water distribution of pork meat batters. Asian-Austr J Anim Sci. (2020) 33:1180–90. doi: 10.5713/ajas.19.0215

38. Li FF, Zhong Q, Kong BH, Wang B, Pan N, Xia XF. Deterioration in quality of quick-frozen pork patties induced by changes in protein structure and lipid and protein oxidation during frozen storage. Food Res Int. (2020) 133:109142. doi: 10.1016/j.foodres.2020.109142

39. Li FF, Wang B, Kong BH, Shi S, Xia XF. Decreased gelling properties of protein in mirror carp (cyprinus carpio) are due to protein aggregation and structure deterioration when subjected to freeze-thaw cycles. Food Hydrocolloid. (2019) 97:105223. doi: 10.1016/j.foodhyd.2019.105223

40. Pan N, Dong CH, Du X, Kong BH, Sun JY, Xia XF. Effect of freezethaw cycles on the quality of quick-frozen pork patty with different fat content by consumer assessment and instrument-based detection. Meat Sci. (2021) 172:108313. doi: 10.1016/j.meatsci.2020.108313

41. Wei CQ, Liu WY, Xi WP, Cao D, Zhang HJ, Ding M, et al. Comparison of volatile compounds of hot-pressed, cold-pressed and solvent-extracted flaxseed oils analyzed by SPME-GC/MS combined with electronic nose: Major volatiles can be used as markers to distinguish differently processed oils. Eur J Lipid Sci Technol. (2014) 116:1–11. doi: 10.1002/ejlt.201400244

42. Zhang C, Zhang H, Liu M, Zhao XG, Luo HL. Effect of breed on the volatile compound precursors and odor profile attributes of lamb meat. Foods. (2020) 9:1178. doi: 10.3390/foods9091178

43. Varnan AH, Sutherland JP. Meat and meat products: Technology, chemistry and microbiology. Meat Sci. (1995) 43:7879. doi: 10.1016/0309-1740(96)86989-0

44. Zhang L, Du HZ, Zhang P, Kong BH, Liu Q. Heterocyclic aromatic amine concentrations and quality characteristics of traditional smoked and roasted poultry products on the northern Chinese market. Food Chem Toxicol. (2020) 135:110931. doi: 10.1016/j.fct.2019.110931

45. Starowicz M, Zieliński H. How maillard reaction influences sensorial properties (color, flavor and texture) of food products? Food Rev Int. (2019) 35:707–25. doi: 10.1080/87559129.2019.1600538

46. Zhang Y, Zhu GF, Xie YK, Liu YH. Effects of radio frequency on physicochemical properties of powdered infant formula milk as compared with conventional thermal treatment. LWT-Food Sci Technol. (2020) 134:110194. doi: 10.1016/j.lwt.2020.110194

47. Hong GP, Park SH, Kim JY, Min SG. The effects of high pressure and various binders on the physico-chemical properties of restructured pork meat. Asian-Austr J Anim Sci. (2006) 19:1484–9. doi: 10.5713/ajas.2006.1484

48. Wang H, Tu Z, Liu G, Liu C, Huang X, & Xiao H. Comparison of glycation in conventionally and microwave-heated ovalbumin by high resolution mass spectrometry. Food Chem. (2013) 141:985–91. doi: 10.1016/j.foodchem.2013.04.045

49. García-Esteban M, Ansorena D, Gimeno O, & Astiasara'n I. Optimization of instrumental color analysis in dry-cured ham. Meat Sci. (2003) 63:287–92. doi: 10.1016/S0309-1740(02)00084-0

50. Zhang J, Pan D, Zhou G, Wang Y, Dang Y, He J, et al. The changes of the volatile compounds derived from lipid oxidation of boneless dry-cured hams during processing. Eur J Lipid Sci Technol. (2019) 121:1900135. doi: 10.1002/ejlt.201900135

51. Al-Dalali S, Li C, Xu BC. Insight into the effect of frozen storage on the changes in volatile aldehydes and alcohols of marinated roasted beef meat: Potential mechanisms of their formation. Food Chem. (2022) 385:132629. doi: 10.1016/j.foodchem.2022.132629

52. Liu H, Ma J, Pan T, Suleman R, Wang Z, Zhang D. Effects of roasting by charcoal, electric, microwave and superheated steam methods on (non)volatile compounds in oyster cuts of roasted lamb. Meat Sci. (2021) 172:108324. doi: 10.1016/j.meatsci.2020.108324

53. Wang HY, Yang YY, Li HQ, Zhang QD, Xu F, Li ZJ. Characterization of aroma-active compounds in steamed breads fermentedwith Chinese traditional sourdough. LWT-Food Sci Technol. (2021) 152:112347. doi: 10.1016/j.lwt.2021.112347

54. Xi JP, Zhan P, Tian HL, Wang P. Effect of spices on the formation of VOCs in roasted mutton based on GC-MS and principal component analysis. J Food Quality. (2019) 15:1–11. doi: 10.1155/2019/8568920

55. Qi SS, Wang P, Zhan P, Tian HL. Characterization of key aroma compounds in stewed mutton (goat meat) added with thyme (Thymus vulgaris L.) based on the combination of instrumental analysis and sensory verification. Food Chem. (2022) 371:131111. doi: 10.1016/j.foodchem.2021.131111

56. Du W, Zhao M, Zhen D, Tan J, Wang T, Xie J. Key aroma compounds in Chinese fried food of youtiao. Flavour Frag J. (2020) 35:88–98. doi: 10.1002/ffj.3539

57. Ioannis KK. Volatile profile of raw lamb meat stored at 4 ± 1°C: The potential of specific aldehyde ratios as indicators of lamb meat quality. Foods. (2018) 7:1–11. doi: 10.3390/foods7030040

58. Wei CQ, Zhou Q, Han B, Chen Z, Liu WY. Changes occurring in the volatile constituents of flaxseed oils (FSOs) prepared with diverse roasting conditions. Eur J Lipid Sci Technol. (2019) 121:1800068. doi: 10.1002/ejlt.201800068

59. Zhu J, Chen F, Wang L, Niu Y, Xiao Z. Evaluation of the synergism among volatile compounds in oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem. (2017) 221:1484–90. doi: 10.1016/j.foodchem.2016.11.002

60. Fan DM, Ma SY, Wang LY, Zhao HF, Zhao JX, Zhang H, et al. 1H NMR studies of starch-water interactions during microwave heating. Carbohydrate Polym. (2013) 97:406–12. doi: 10.1016/j.carbpol.2013.05.021

61. Li CL, Peng A, He LC, Ma SM, Wu WM, Yang HY. Emulsifying properties development of pork myofibrillar and sacroplasmic protein irradiated at different dose: A combined FT-IR spectroscopy and low-field NMR study. Food Chem. (2018) 252:108–14. doi: 10.1016/j.foodchem.2018.01.104

62. Han MY, Wang P, Xu X, Zhou GH. Low-field NMR study of heat-induced gelation of pork myofibrillar proteins and its relationship with microstructural characteristics. Food Res Int. (2014) 62:1175–82. doi: 10.1016/j.foodres.2014.05.062

63. Li L, Wang P, Xu X, Zhou G. Influence of various cooking methods on the concentrations of volatile N-nitrosamines and biogenic amines in dry-cured sausages. J Food Sci. (2012) 77:560–5. doi: 10.1111/j.1750-3841.2012.02667.x

Keywords: water distribution, key aroma compounds, beef, roasting, correlation analysis

Citation: Wang YR, Luo RM and Wang SL (2022) Water distribution and key aroma compounds in the process of beef roasting. Front. Nutr. 9:978622. doi: 10.3389/fnut.2022.978622

Received: 26 June 2022; Accepted: 16 August 2022;

Published: 13 September 2022.

Edited by:

Maomao Zeng, Jiangnan University, ChinaReviewed by:

Jin Wang, Nankai University, ChinaYongzhu Zhang, Jiangsu Academy of Agricultural Sciences (JAAS), China

Copyright © 2022 Wang, Luo and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Song-Lei Wang, d2FuZ3NvbmdsZWkxNjNAMTI2LmNvbQ==

Yong-Rui Wang

Yong-Rui Wang Rui-Ming Luo2

Rui-Ming Luo2