- 1Key Laboratory of Biotechnology and Bioresources Utilization, College of Life Sciences, Ministry of Education, Dalian Minzu University, Dalian, China

- 2Chinese Academy of Inspection and Quarantine, Beijing, China

- 3Collaborative Innovation Center of Provincial and Ministerial Co-construction for Marine Food Deep Processing, Dalian Polytechnic University, Dalian, China

- 4Faculty of Arts, Science, and Technology, Wrexham Glyndwr University, Wrexham, United Kingdom

The effects of calcium sodium alginate on quality and starch digestion of pure buckwheat noodles were investigated. The incorporation of calcium ions into noodles containing sodium alginate was found to reduce water absorption by the noodles during cooking, together with an increase of the turbidity. Calcium addition improved the noodle texture, as shown by the measurement of hardness, elasticity, adhesion, and chewability. In vitro simulations of digestion showed that calcium ion cross-linking with sodium alginate reduced glucose formation by approximately 23.3 mg/g. X-ray diffraction and Fourier transform infrared spectroscopy showed alterations in the crystal zone of the noodles induced by an alginate gel network, although no new chemical substances were generated. Noodles prepared by this exogenous method may be useful as functional foods for patients with diabetes.

1. Introduction

Starch is an essential carbohydrate component of the human diet. Hydrolysis by amylase reduces the starch to glucose that can then be utilized by the body. However, starch, especially in the form of processed foods, tends to be rapidly digested, leading to potential health issues such as obesity and diabetes, and thus people are becoming more aware of the importance of consuming healthy food (1, 2).

Noodles are a staple food in many Asian countries and have become increasingly popular among consumers around the world (3). However, noodles have a high glycemic index (GI) indicating that they are easily hydrolyzed (4). It is thus important to attempt to reduce the GI of noodles. Buckwheat and its processed products contain a variety of bioactive substances, including specific polysaccharides, dietary fiber, and polyphenols, all of which are of great nutritional values (5). Therefore, buckwheat noodles have attracted increased consumer attention (6). It has been found that buckwheat noodles can slow down sugar release resulting from starch digestion in vitro and that the addition of 45% Tartary buckwheat to noodles can be beneficial to human health (7).

It is well-documented that adding functional components to starchy foods can slow the rate of digestion (8–10). Sodium alginate is a natural polysaccharide obtained from brown algae. It is a linear compound composed of (1→4)-linked β-D-mannuronic acid and α-L-guluronic acid pyranose residues (11). Sodium alginate, being highly hydrophilic, has good hygroscopic properties and dissolves readily in both hot and cold water where it rapidly forms a viscous colloidal solution with strong activity. It can also incorporate divalent metal ions (excluding mercury and magnesium) to form an alginate gel of high tensile strength within the food (12–14). Muhammad Lubowa et al. prepared rice noodles with pre-gelatinized high amylose corn starch combined with Ca2+ induced sodium alginate, which solidified alginate, improved the tensile strength of noodles, and made the noodles more dense (15). Similarly, Masahiro Yuasa et al. used a plastic syringe to add mentsuyu containing 1% (w/w) sodium alginate to 5% (w/w) calcium lactate solution in a drop by drop manner. The solution immediately gelled to form mentsuyu caviar, which gave mentsuyu and caviar an even more striking visual appearance (16).

However, the effect of Ca2+ induced sodium alginate gel on the quality and digestive characteristics of buckwheat noodles has not been systematically studied. In this study, two methods of Ca2+ incorporation into sodium alginate and its effects on the digestion of pure buckwheat noodles were investigated. The first method was exogenous, where Ca2+ permeated sodium alginate-containing noodles from the outside during cooking, resulting in the formation of a stable gel network. The second method was endogenous, where the Ca2+ was released from calcium carbonate after acid treatment and subsequent cross-linking with sodium alginate to form the gel network during the procedure of making the noodles. Here, the effects of these different methods of Ca2+ incorporation into the sodium alginate networks on the digestion of the noodles were studied, measuring parameters associated with cooking, texture, and in vitro digestion of the noodles. In addition, the effects of calcium and sodium alginate cross-linking on the crystal structure of the starch were assessed by X-ray diffraction (XRD) and Fourier transform infrared spectroscopy (FTIR). The results indicate the preferable methods for the manufacture of functional noodles.

2. Materials and methods

2.1. Materials

Pure buckwheat flour was provided by Dalian Hongrun Whole Grain Food Co., Ltd., (Dalian, China). Pepsin (≥ 3,800 U/g), trypsin (1:4000), and amyloglucosidase (15 U/mL) were purchased from Shanghai Yuanye Bio Biotechnology Co., Ltd., (Shanghai, China). Other reagents were obtained from Beijing Chemical Reagent Co., (Beijing, China). All reagents were of analytical grade.

2.2. Methods

2.2.1. Preparation of noodles

Preparation of pure noodles: the noodles were prepared by mixing 90 g of pure buckwheat flour with 50 g of deionized water. The optimal cooking time was 3 min 40 s. It’s as the control group.

Exogenous method: 90 g of pure buckwheat flour was mixed with 50 g of sodium alginate solution (0.1–0.5%) using a mixer (HMJ-A35M1, Guangdong, China) for 15 min. After allowing the dough to rest for 15 min, it was sheeted using a noodle machine (MR-08, Guangdong, China) and the sheets were cut into noodles 6.0 mm wide and 2.0 mm thick. Then use the prepared CaCl2 solution (0.3–0.5 M) to cook the noodles until the optimal cooking time: 3 min and 40 s.

Endogenous method: 90 g of pure buckwheat flour was mixed with CaCO3 powder (3–9% of the dough) and added to 50 g sodium alginate solution (0.1–0.5%) using a mixer for 15 min. After allowing the dough to rest for 15 min, it was sheeted using a noodle machine and the sheets were cut into noodles 6.0 mm wide and 2.0 mm thick. The noodles were cooked with the citric acid solution, pH 4.0, until the optimal cooking time: 3 min and 40 s.

2.2.2. Cooking characteristics of noodles

In a separate experiment, the characteristics of the noodles were evaluated according to the method of Gimenez et al. (17) with slight modifications.

Water absorption of noodles: Ten pieces of noodles were weighed on a balance and the weight was recorded as M1. The noodles were then boiled in 500 ml of deionized water at 160°C until cooked. The noodles were then immediately removed from the water, washed with cool water for 10 s, and placed on a screen mesh. After standing at room temperature for 5 min, the noodles were weighed, with the weight recorded as M2. The rate of water absorption was calculated using the equation below and the experiment was repeated three times.

Turbidity: the cooking water was then cooled and transferred to a 500 ml volume bottle, which was reached volume with deionized water, shaken and left for 2 h, and the absorbance at 460 nm measured by ultraviolet spectrophotometer is turbidity. Measurements were obtained in triplicate.

2.2.3. Texture profile analysis

The texture profile analysis (TPA) of the noodles was conducted with a texture analyzer (TA-XTC, Boson Tech Co., Ltd., China) (18). The parameters used for the analysis were as follows: P/5 probe, pre-test speed = 2.0 mm/s; test speed = 0.8 mm/s; post-test speed = 0.8 mm/s; compression degree = 50%. Samples were analyzed in octuplicate.

2.2.4. Starch digestion in vitro

The digestibility of the noodles was analyzed in vitro as described by Englyst et al. with minor modifications (19). The cooked fresh noodles were ground and the sample (3 g) was mixed with 30 mL of distilled water in a beaker and stirred using a magnetic stirrer at 37°C for 10 min. Pepsin (1.0 mL) was then added and stirred for 30 min to simulate gastric digestion (pH = 2). Once completed, an aliquot (1.0 mL) was withdrawn (time 0) and added to 4 mL absolute alcohol to stop any further enzyme reaction. Amyloglucosidase (0.1 mL) was then added to the beaker to prevent inhibition of the end products of pancreatic α-amylase. Then 1 ml 5% trypsin was added to represent ileal digestion. Aliquots (1.0 mL) were removed at different times (20, 30, 60, 90, 120, and 180 min), which were inactivated by the addition of absolute ethanol (4.0 mL). Subsequently, the glucose content was determined by the 3,5-dinitrosalicylic acid (DNS) method (20). Absorbances at 540 nm were measured using a UV-3600 spectrophotometer (Shimadzu, Kyoto, Japan) and the amount of hydrolyzed sugar was calculated as follows:

where,

CHO: amount of hydrolyzed sugar generated in the whole system during digestion in vitro (mg)

C: standard amount of glucose detected from the standard operating curve (mg)

D: dilution ratio of dialysis solution

V: total volume of the solution for digestion of the whole system in vitro (mL)

S: volume of solution taken from the system each time (mL).

2.2.5. X-ray diffraction analysis

The cooked noodles were immediately frozen in a −80°C freezer. The noodle samples were lyophilized, ground to powder (SCIENTZ 18N, Zhejiang Side Equipment Co., Ltd., Zhejiang, China) and passed through a 60-mesh sieve before X-ray diffraction analysis. X-ray diffraction analysis of the noodles was conducted using an XRD-6000 diffractometer (Shimadzu) with an operating voltage of 40 kV and a current of 30 mA. The diffraction scan angle (2θ) ranged from 5 to 50° with a scanning speed of 2°/min.

2.2.6. FTIR analysis

The sample preparation was in a similar manner to the X-ray diffraction analysis. Samples were ground to a fine powder and were mixed with dry potassium bromide (1:100, w/w) and tableted at 10 000 PSI. Spectra were recorded in an IR-Affinity-1 spectrophotometer (Shimadzu) between 399 and 4,000 cm–1 at a resolution of 2 cm–1.

2.2.7. Statistical analysis

All experiments were performed with three replicates. Data were expressed as mean ± standard deviation and analyzed using Origin 2021 (Origin-Lab, Inc., USA) and GraphPad Prism 8.4.0 (GraphPad Software, LLC, USA) for Windows. Differences between means were assessed by one-way analysis of variance (ANOVA) followed by Duncan’s test.

3. Results and discussion

3.1. Cooking characteristics of noodles

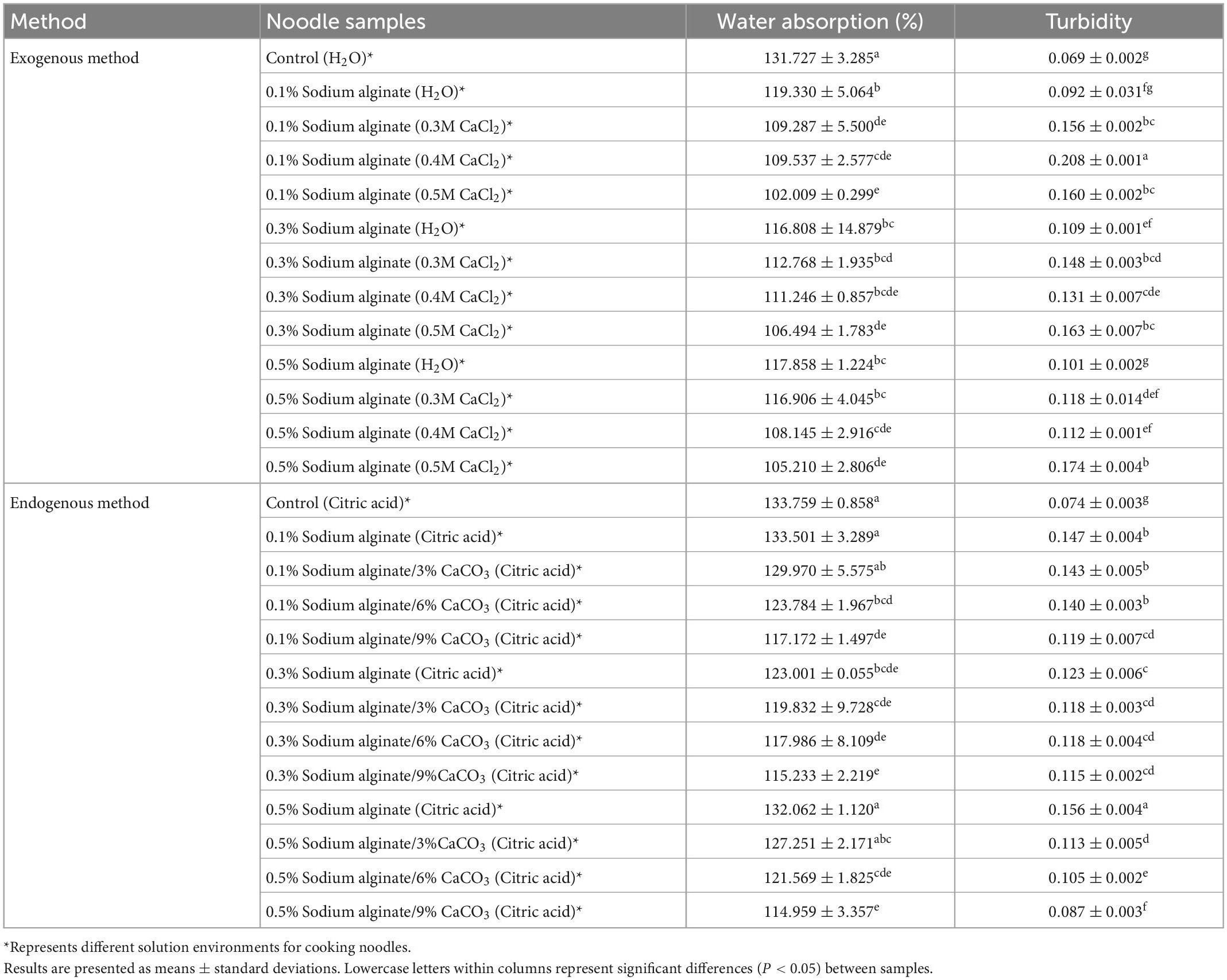

The results of the water absorption and turbidity of noodles prepared by the exogenous method are shown in Table 1. Water absorption is defined as the ability of the noodles to retain water, and is controlled mainly by the strength of the network formed by starch, fiber, or protein (21). Compared with the control groups in both exogenous and endogenous methods, the water absorption of noodles supplemented with sodium alginate colloid was significantly reduced, and further decreases were seen in the noodles in which calcium ions had been incorporated with the sodium alginate (p < 0.05). This may be because the capacity for water absorption is related to the integrity of the structural network, and a highly cross-linked network structure limits water absorption (22). The noodles cooked by the exogenous method are more turbid than the noodle soup of the control group. The possible reason is that during the cooking process, part of calcium chloride entered the noodles and combined with sodium alginate to form a network structure, while the other part of calcium chloride remained in the noodle soup, increasing the turbidity degree of the noodle soup. However, different from the exogenous method, the turbidity of noodles prepared by the endogenous method decreased with the increase of the concentrations of sodium alginate and calcium carbonate, which may be caused by the increase of the concentration of both, which further promoted the formation of gel network structure.

3.2. Textural properties of noodles

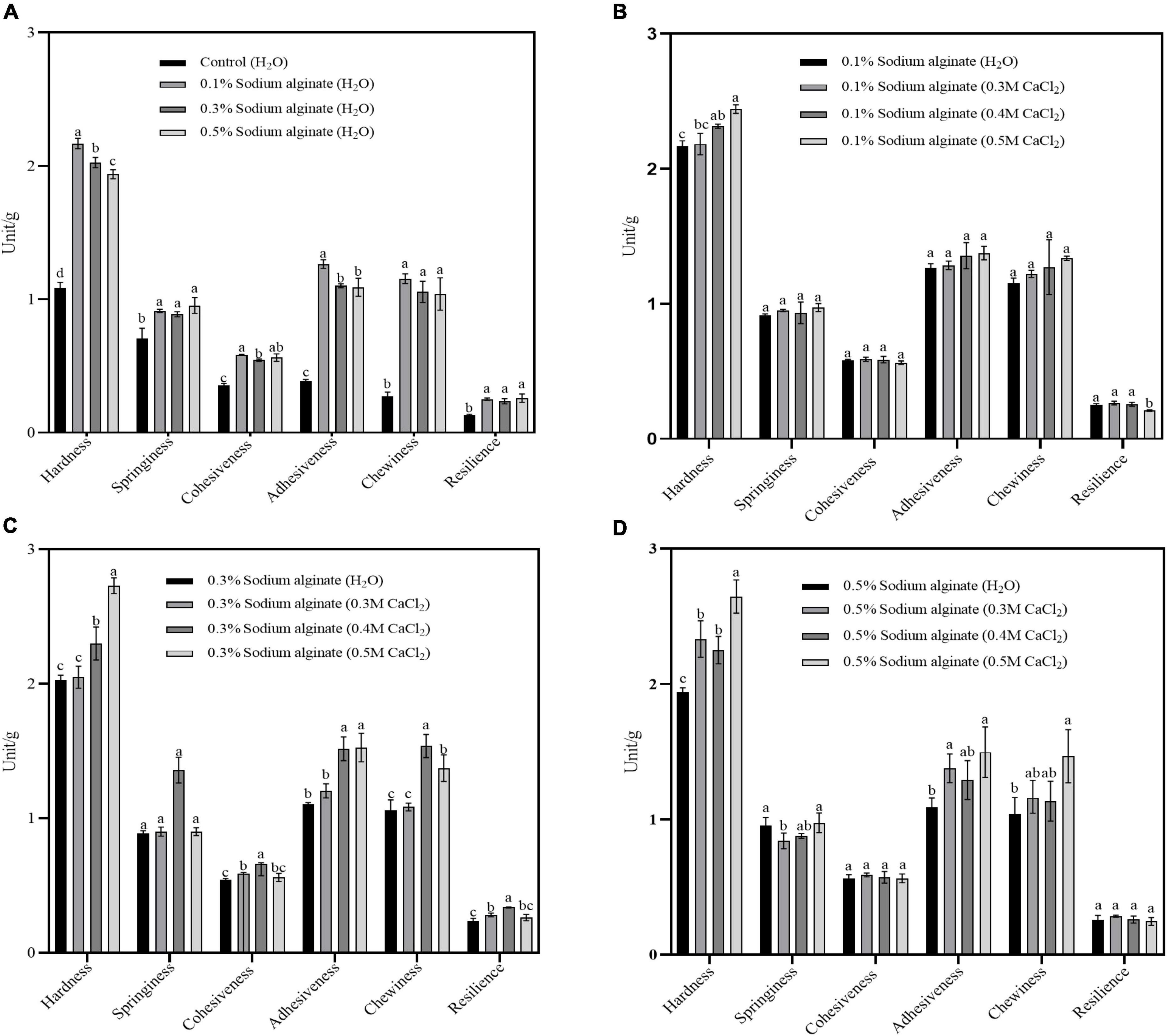

Figure 1 illustrates the textural properties of the noodles. It was found that, compared with the control noodles, the hardness, springiness, cohesiveness, adhesiveness, chewiness, and other textural properties were enhanced by the addition of sodium alginate at different concentrations (Figure 1A). The hardness, adhesiveness, and chewiness of noodles with Ca2+ incorporated into the sodium alginate by the exogenous method were significantly higher than those in the sodium alginate only groups (Figures 1B–D). The increase in these properties may be due to the effective cross-linking of Ca2+ with sodium alginate, resulting in the strengthening of the three-dimensional structures. However, compared with the exogenous method, there were no significant differences in the textural characteristics between the noodles prepared by the endogenous method with Ca2+ and the sodium alginate only groups (Figures 2A–D), which may be due to the fact that citric acid is a weak electrolyte with weak ionizing ability, and the reaction with calcium carbonate releases less calcium ions, resulting in a poor ability to bind sodium alginate and not form a more stable strong gel. These results confirm that the gel network structure of Ca2+ and sodium alginate formed by the exogenous method could improve the texture of noodles.

Figure 1. (A–D) Show the effects of varying Ca2+ concentrations on the textural properties of buckwheat noodles prepared by the exogenous method. Control group panel (A) was steamed with deionized water. The experimental group in panels (B–D) were steamed with calcium chloride solution of different concentrations.

Figure 2. (A–D) Show the effects of Ca2+ concentrations of the textural properties of noodles prepared by the endogenous method. The solution environment for cooking noodles in panels (A–D) is 0.1 g/L citric acid solution (pH = 4).

3.3. Digestibility of noodles in vitro

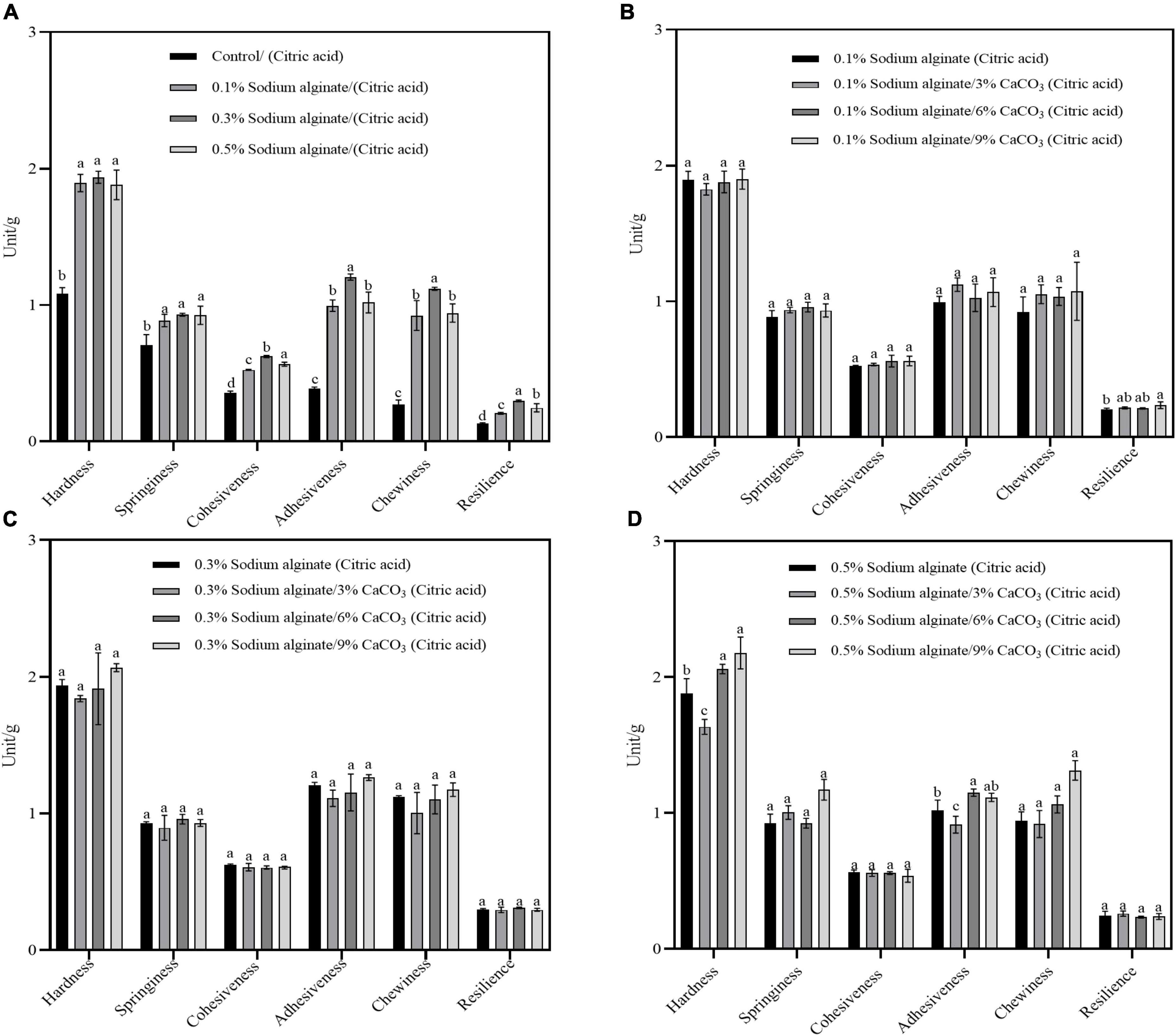

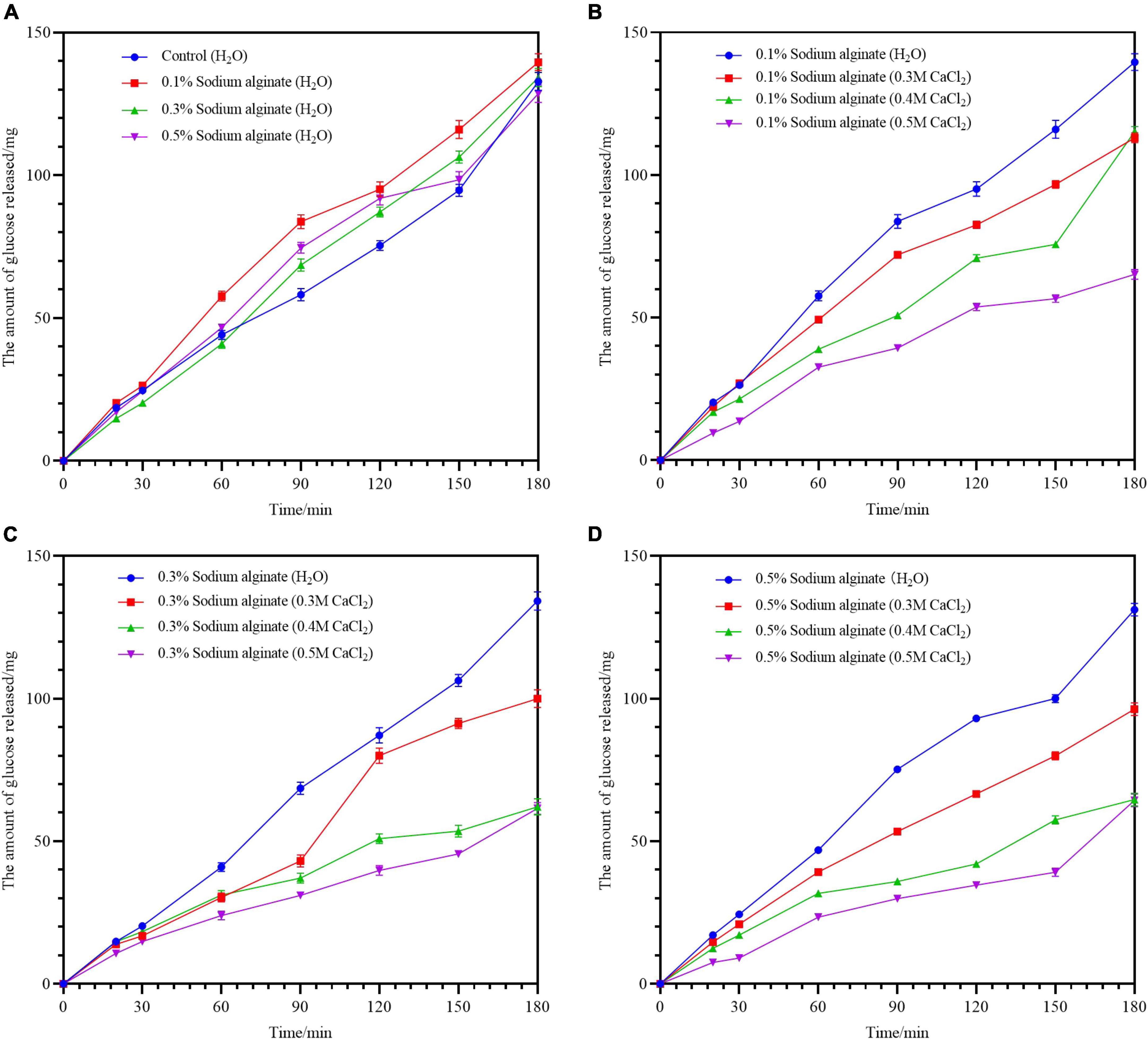

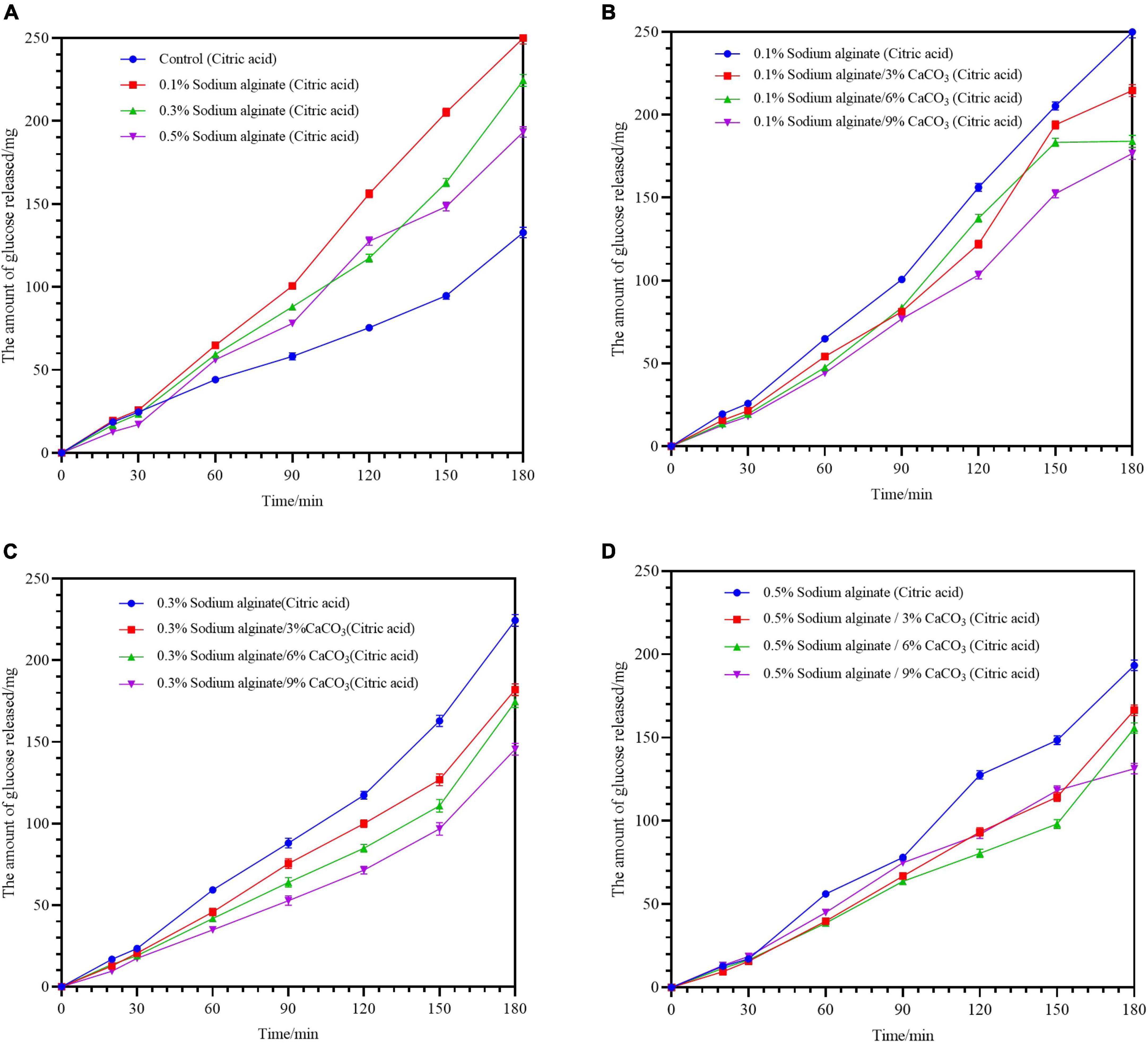

Figure 2 shows the amounts of reduced sugars released over 180 min of in vitro digestion for all the noodle samples. The same trend of starch hydrolysis was seen in all samples, with the amount of glucose released increasing gradually over time. Compared with the control noodles, the addition of different concentrations of sodium alginate (0.1–0.5%) did not reduce the glucose release (Figure 3A). However, the incorporation of Ca2+ into the sodium alginate-containing noodles using the exogenous method resulted in reductions in glucose release, with noodles containing higher concentrations of Ca2+ showing lower glucose release; the maximum reduction in glucose release was approximately 23.3 mg/g (Figures 3B–D). This is likely the consequence of the denser network formed by the calcium and sodium alginate, preventing the leaching of internal molecules. These findings indicate that the network composed of sodium alginate and calcium ions can protect the starch from amylase hydrolysis. The concomitant use of higher concentrations of Ca2+ results in a denser gel network that provides a better barrier to enzymatic hydrolysis. These results are consistent with previous findings where Ca2+ was used for cross-linking with sodium alginate to form a core-shell structured macrocapsule calcium alginate (23).

Figure 3. (A–D) Show the effects of varying Ca2+ concentrations of the digestibility of buckwheat noodles prepared by the exogenous method. Control group panel (A) was steamed with deionized water. The experimental groups panels (B–D) were steamed with calcium chloride solution of different concentrations.

The glucose release of noodles prepared by the endogenous method of calcium ion combined with sodium alginate is shown in Figures 4A–D. The glucose release was lower than that in the sodium alginate group but was not decreased in comparison with the control group. Although increased Ca2+ concentrations were beneficial to glucose release compared with the sodium alginate only groups, the incorporation of calcium did not significantly reduce the glucose release compared with the control group. The likely explanation for this phenomenon may be as below. On the one hand, the relatively low concentrations of calcium ions were released by the reaction of calcium carbonate with acid, resulting in the formation of a weaker gel structure. On the other hand, the carbon dioxide formed during the reaction may affect the structure of the dough, creating greater looseness, which may also account for the poorer textural properties.

Figure 4. (A–D) Show the effects of varying Ca2+ concentrations on the digestibility of buckwheat noodles prepared by the endogenous method. The solution environment for cooking noodles in panels (A–D) is 0.2 g/L citric acid solution (pH = 4).

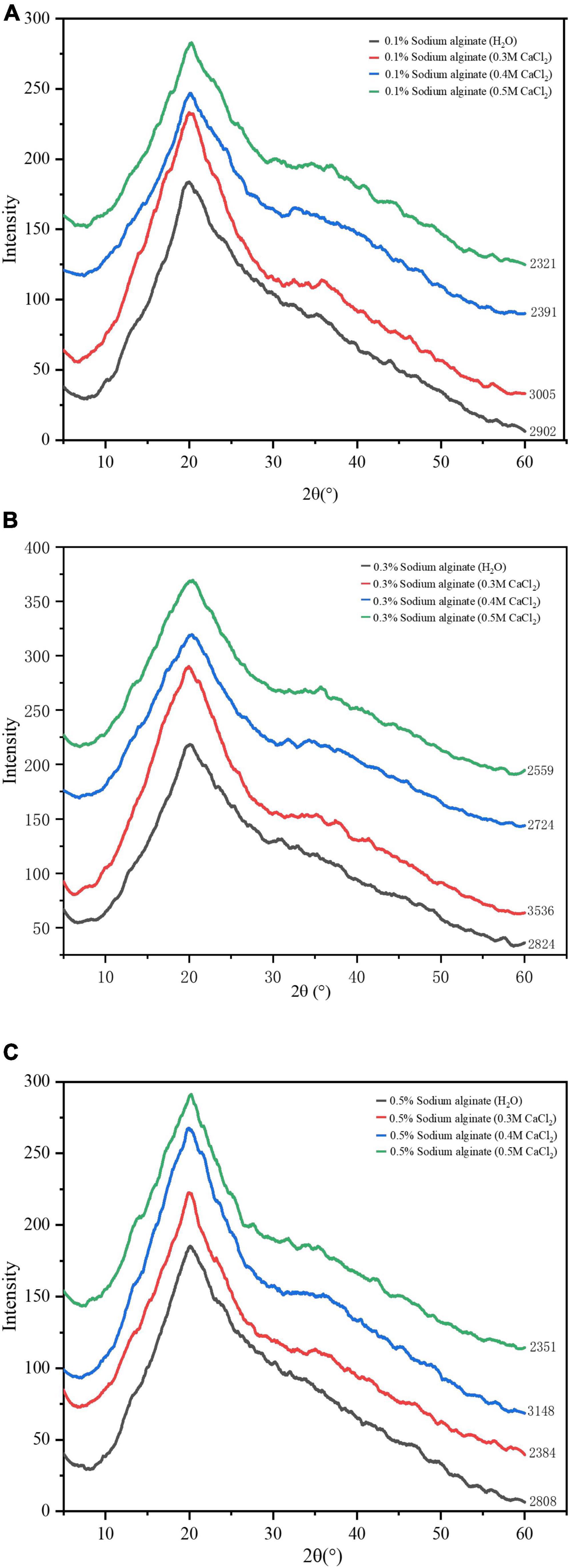

3.4. XRD patterns of starches

X-ray diffraction (XRD) was used to investigate changes in the crystallinity of noodles prepared by the exogenous method. The XRD patterns of all the samples are summarized in Figure 5. The crystallinity of foods is a significant determinator of their physical properties, and affects digestibility (24). Starch is composed of four types of crystal structures, namely, A, B, C, and V (25). As seen in the XRD patterns in the figure, clear peaks are visible at 2θ of 20°, which indicate the possible presence of an amylose-lipid complex (V-type) in the starch particles and endows the starch with properties such as resistance to digestion and improved food texture (26). The XRD patterns of the noodles with sodium alginate and calcium were similar to those of the sodium alginate only noodles; however, the area of the peak was altered by the addition of calcium ions. The X-ray diffraction pattern results of the endogenous method ara similar to those of the exogenous method, which only changed the crystal area of the noodles, which are not mentioned here. This indicates that the crystal structure of the starch was not changed by the cross-linking of calcium ions with sodium alginate, with the addition of calcium altering only the crystal area of the noodles, possibly affecting the quality of the noodles (27).

Figure 5. (A–C) Show the X-ray diffraction patterns of sodium alginate with the addition of varying Ca2+ concentrations by the exogenous method.

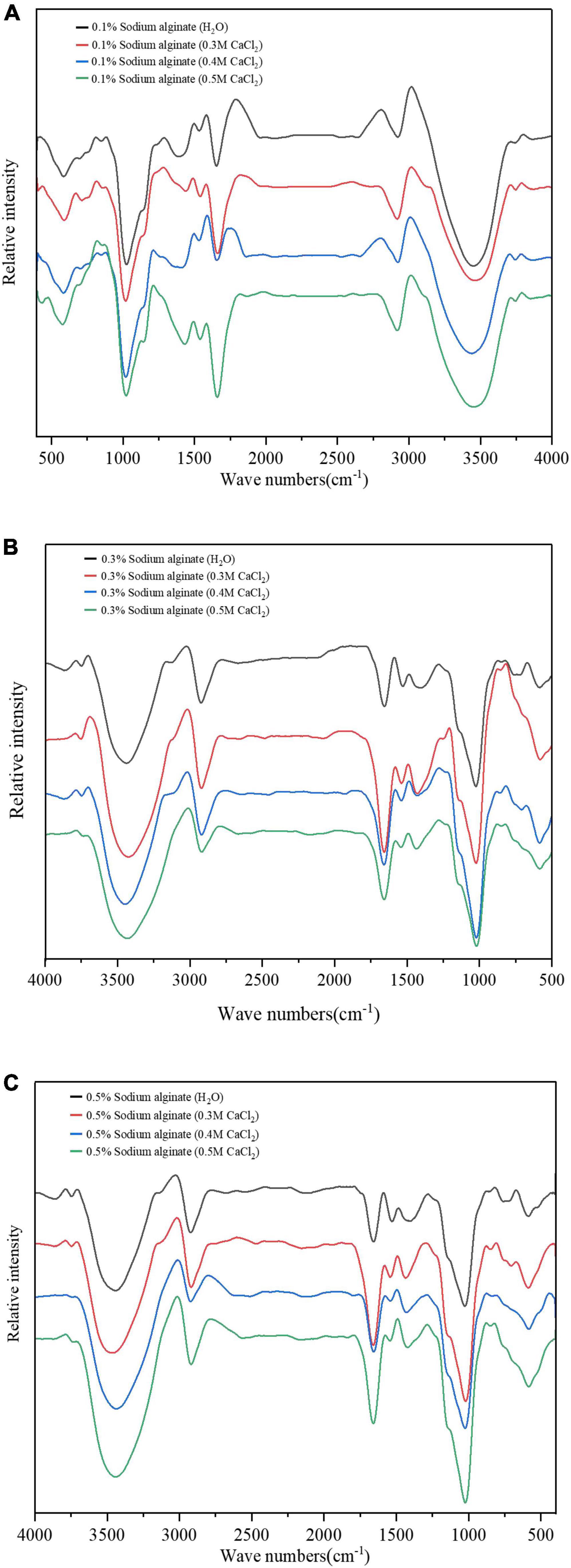

3.5. FTIR spectroscopy of starches

The FTIR spectra in the wavenumber range of 399–4,000 cm–1 of starches with exogenously incorporated Ca2+ and sodium alginate are shown in Figure 6. As seen in the figure, the spectra of the different samples are similar. The absorption peak at 1,652 cm–1 results from the stretching vibration of C = O, also seen in α-helical structures of proteins (28). The absorption peak at 2,927 cm–1 results from the asymmetric stretching vibration of CH2 (29). Major absorption peaks are visible in the hydroxyl region (centered at 3,394-3,423 cm–1), likely the result of hydrogen bonds between the starch particles, alginate, and gel polysaccharide molecules (30). Compared with the sodium alginate only samples, the addition of calcium ions did not result in a new absorption peak, indicating that no chemical bonds were formed between sodium alginate and calcium in the noodles. The Fourier infrared spectrogram results of the endogenous method are similar to those of the exogenous method, with no significant changes, which are not mentioned here.

Figure 6. (A–C) Show the Fourier transform infrared spectra of sodium alginate with the addition of varying Ca2+ concentrations by the exogenous method.

4. Conclusion

We prepared novel types of functional noodles by two simple methods and studied their properties in relation to cooking, texture, and digestion, as well as analyzing the structure of the starch. It was found that the stable cross-linking system formed by Ca2+ and sodium alginate could reduce the rate of water absorption by the noodles, and improve the textural properties of the noodles, such as hardness, springiness, cohesiveness, adhesiveness, and chewiness. In addition, the formation of the alginate network structure altered the area of the crystal zone of the noodles, although no new chemical bonds or substances were generated. Most importantly, the cross-linking of Ca2+ and sodium alginate significantly reduced the amount of glucose released from the noodles. In conclusion, the noodles prepared by the exogenous method were superior to those prepared using the endogenous method in terms of both noodle quality and lower glucose release, which will contribute to the development of functional foods. However, these results were obtained using simulated digestion in vitro, and further in vivo investigations are needed for verification.

Data availability statement

The original contributions presented in this study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

BH, JY, and JC contributed to the conception of the study. HW performed the experiment, data analyses, and wrote the manuscript. JZ and LH contributed significantly to analysis and manuscript preparation. YZ helped perform the analysis with constructive discussions. All authors contributed to the article and approved the submitted version.

Funding

This article was funded by the National Key Research and Development Project (2021YFF0601900), Liaoning Provincial Science and Technology Innovation Leading Talents Project (XLYC2002106), Natural Science Foundation of Liaoning Province (2021-MS-147), Dalian High-Level Talent Innovation, Scientific and Technological Talent Entrepreneurship and Innovation Team Support Projects in Key Fields (2020RQ122), Liaoning Province Livelihood Science and Technology Project (2021JH2/10200019), Department of Education of Liaoning Province (LJKZ0037), and Dalian Key Science and Technology Project (2021JB12SN038).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

2. Liu D, Song S, Tao L, Yu L, Wang J. Effects of common buckwheat bran on wheat dough properties and noodle quality compared with common buckwheat hull. LWT. (2022) 155:112971. doi: 10.1016/j.lwt.2021.112971

3. Gan CY, Ong WH, Wong LM, Easa AM. Effects of ribose, microbial transglutaminase and soy protein isolate on physical properties and in-vitro starch digestibility of yellow noodles. LWT - Food Sci Technol. (2009) 42:174–9. doi: 10.1016/j.lwt.2008.05.004

4. Atkinson FS, Foster-Powell K, Brand-Miller JC. International tables of glycemic index and glycemic load values: 2008. Diabetes Care. (2008) 31:2281–3. doi: 10.2337/dc08-1239

5. Zhu F. Chemical composition and health effects of Tartary buckwheat. Food Chem. (2016) 203:231–45. doi: 10.1016/j.foodchem.2016.02.050

6. Schoenlechner R, Drausinger J, Ottenschlaeger V, Jurackova K, Berghofer E. Functional properties of gluten-free pasta produced from amaranth, quinoa and buckwheat. Plant Foods Hum Nutr. (2010) 65:339–49. doi: 10.1007/s11130-010-0194-0

7. Jia B, Yao Y, Liu J, Guan W, Brennan CS, Brennan MA. Physical properties and in vitro starch digestibility of noodles substituted with tartary buckwheat flour. Starch Stärke. (2019) 71:1800314. doi: 10.1002/star.201800314

8. Lucas-Gonzalez R, Angel Perez-Alvarez J, Moscaritolo S, Fernandez-Lopez J, Sacchetti G, Viuda-Martos M. Evaluation of polyphenol bioaccessibility and kinetic of starch digestion of spaghetti with persimmon (Dyospyros kaki) flours coproducts during in vitro gastrointestinal digestion. Food Chem. (2021) 338:128142. doi: 10.1016/j.foodchem.2020.128142

9. Wang C, Li W, Chen Z, Gao X, Yuan G, Pan Y, et al. Effects of simulated gastrointestinal digestion in vitro on the chemical properties, antioxidant activity, alpha-amylase and alpha-glucosidase inhibitory activity of polysaccharides from Inonotus obliquus. Food Res Int. (2018) 103:280–8. doi: 10.1016/j.foodres.2017.10.058

10. Foschia M, Peressini D, Sensidoni A, Brennan MA, Brennan CS. Synergistic effect of different dietary fibres in pasta on in vitro starch digestion? Food Chem. (2015) 172:245–50. doi: 10.1016/j.foodchem.2014.09.062

11. Lubowa M, Yeoh SY, Varastegan B, Easa AM. Effect of pre-gelatinised high-amylose maize starch combined with Ca2+ induced setting of alginate on the physicochemical and sensory properties of rice flour noodles. Int J Food Sci Technol. (2020) 56:1021–9. doi: 10.1111/ijfs.14754

12. Hong T, Zhang Y, Xu D, Wu F, Xu X. Effect of sodium alginate on the quality of highland barley fortified wheat noodles. LWT. (2021) 140:110719. doi: 10.1016/j.lwt.2020.110719

13. Kakita H, Kamishima H. Some properties of alginate gels derived from algal sodium alginate. J Appl Phycol. (2008) 20:543–9. doi: 10.1007/s10811-008-9317-5

14. Koh LW, Kasapis S, Lim KM, Foo CW. Structural enhancement leading to retardation of in vitro digestion of rice dough in the presence of alginate. Food Hydrocoll. (2009) 23:1458–64. doi: 10.1016/j.foodhyd.2008.07.020

15. Muhammad L, Yeoh S, Varastegan B, Easa AM. Effect of pre-gelatinized high amylose maize starch combined with Ca2+ -induced setting of alginate on the physicochemical and sensory properties of rice flour noodles. Int J Food Sci Technol. (2021) 56:1021–9.

16. Yuasa M, Tagawa Y, Tominaga M. The texture and preference of “mentsuyu (Japanese noodle soup base) caviar” prepared from sodium alginate and calcium lactate. Int J Gastron Food Sci. (2019) 18:100178. doi: 10.1016/j.ijgfs.2019.100178

17. Gimenez MA, Gonzalez RJ, Wagner J, Torres R, Lobo MO, Samman NC. Effect of extrusion conditions on physicochemical and sensorial properties of corn-broad beans (Vicia faba) spaghetti type pasta. Food Chem. (2013) 136:538–45. doi: 10.1016/j.foodchem.2012.08.068

18. Deng Y, Wu Y, Li Y. Physiological responses and quality attributes of ‘Kyoho’grapes to controlled atmosphere storage. LWT- Food Sci Technol. (2006) 39:584–90. doi: 10.1016/j.lwt.2005.05.001

19. Englyst HN, Kingman SM, Cummings J. Classification and measurement of nutritionally important starch fractions. Eur J Clin Nutr. (1992) 46:S33–50.

20. Brennan MA, Derbyshire E, Tiwari BK, Brennan CS. Ready-to-eat snack products: the role of extrusion technology in developing consumer acceptable and nutritious snacks. Int J Food Sci Technol. (2013) 48:893–902. doi: 10.1111/ijfs.12055

21. Gupta A, Sharma S, Reddy Surasani VK. Quinoa protein isolate supplemented pasta: Nutritional, physical, textural and morphological characterization. LWT. (2020) 135:110045. doi: 10.1016/j.lwt.2020.110045

22. Sandhu KS, Kaur M, Mukesh. Studies on noodle quality of potato and rice starches and their blends in relation to their physicochemical, pasting and gel textural properties. LWT - Food Sci Technol. (2010) 43:1289–93. doi: 10.1016/j.lwt.2010.03.003

23. Cui C, Li M, Ji N, Qin Y, Shi R, Qiao Y, et al. Calcium alginate/curdlan/corn starch@calcium alginate macrocapsules for slowly digestible and resistant starch. Carbohydr Polym. (2022) 285:119259. doi: 10.1016/j.carbpol.2022.119259

24. Dona AC, Pages G, Gilbert RG, Kuchel PW. Digestion of starch: In vivo and in vitro kinetic models used to characterise oligosaccharide or glucose release. Carbohydr Polym. (2010) 80:599–617. doi: 10.1016/j.carbpol.2010.01.002

25. Liu Y, Xu Y, Yan Y, Hu D, Yang L, Shen R. Application of raman spectroscopy in structure analysis and crystallinity calculation of corn starch. Starch Stärke. (2015) 67:612–9. doi: 10.1002/star.201400246

26. Hung PV, Vien NL, Lan Phi NT. Resistant starch improvement of rice starches under a combination of acid and heat-moisture treatments. Food Chem. (2016) 191:67–73. doi: 10.1016/j.foodchem.2015.02.002

27. Jia M, Yu Q, Chen J, He Z, Chen Y, Xie J, et al. Physical quality and in vitro starch digestibility of biscuits as affected by addition of soluble dietary fiber from defatted rice bran. Food Hydrocoll. (2020) 99:10. doi: 10.1016/j.foodhyd.2019.105349

28. Jeong S, Kim HW, Lee S. Rheological and secondary structural characterization of rice flour-zein composites for noodles slit from gluten-free sheeted dough. Food Chem. (2017) 221:1539–45. doi: 10.1016/j.foodchem.2016.10.139

29. Flores-Morales A, Jimenez-Estrada M, Mora-Escobedo R. Determination of the structural changes by FT-IR, Raman, and CP/MAS (13)C NMR spectroscopy on retrograded starch of maize tortillas. Carbohydr Polym. (2012) 87:61–8. doi: 10.1016/j.carbpol.2011.07.011

Keywords: buckwheat noodles, sodium alginate, calcium ions, in vitro simulated digestion, release of glucose

Citation: Wang H, Zhang J, Han L, Cao J, Yang J, Zhang Y and Hu B (2023) Calcium ion regulation of sodium alginate in pure buckwheat noodles shown by in vitro simulated digestion. Front. Nutr. 9:1105878. doi: 10.3389/fnut.2022.1105878

Received: 23 November 2022; Accepted: 29 December 2022;

Published: 12 January 2023.

Edited by:

Shuzhen Cheng, Dalian Polytechnic University, ChinaReviewed by:

Zhang Yayuan, Guangxi Academy of Agricultural Sciences, ChinaWeimin Zhang, Hainan University, China

Copyright © 2023 Wang, Zhang, Han, Cao, Yang, Zhang and Hu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bing Hu,  aHViaW5nQGRsbnUuZWR1LmNu; Jijuan Cao,

aHViaW5nQGRsbnUuZWR1LmNu; Jijuan Cao,  Y2FvamlqdWFuQGRsbnUuZWR1LmNu

Y2FvamlqdWFuQGRsbnUuZWR1LmNu

Hongyan Wang1

Hongyan Wang1 Lingyu Han

Lingyu Han Bing Hu

Bing Hu