94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Nucl. Eng., 20 January 2025

Sec. Radioactive Waste Management

Volume 3 - 2024 | https://doi.org/10.3389/fnuen.2024.1433247

This article is part of the Research TopicEURAD: State of the Art in Research and Development on Radioactive Waste Management and DisposalView all 6 articles

Within the framework of the European Joint Programme on Radioactive Waste Management, the work package ACED–Assessment of chemical evolution of intermediate level (ILW) and high level (HLW) waste at disposal cell scale–used combined experimental and modelling methods in a multi-scale approach with process integration to improve the long-term modelling and assessment of the chemical evolution at the disposal cell scale. Part I provides the relevance of the assessment of the chemical evolution for safety, performance, and optimization. It further describes the main characteristics of disposal cells for ILW and vitrified HLW waste in European disposal programmes. From that, a number of interfaces between different types of material are identified that are highly relevant for many national disposal programs: glass-steel, steel-concrete, steel-clay, steel-crystalline, concrete-clay, and concrete-crystalline. Based on literature review, the main processes and consequences occurring at these interfaces are described. The key element is the narrative of the evolution at the disposal cell scale based on process understanding. In part II, tools to obtain process understanding–experiments, analogues, modelling–are discussed in detail.

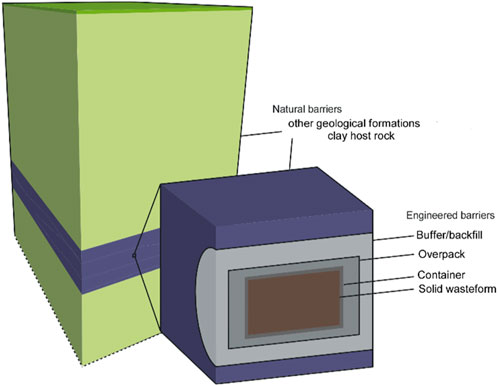

The most safe and sustainable option for the end point management of high-level (HLW) and (long-lived) intermediate-level (ILW) radioactive waste is to isolate the waste and contain the radionuclides in a system of engineered barriers and natural barriers. The waste packages are to be emplaced in a deep (several hundreds of meters) repository that is constructed in a stable geological formation (a natural barrier). After closure of this facility, the isolation of the waste and containment of radionuclides is controlled by natural processes (passive safety), i.e., the waste is no longer managed. The depth of the disposal facility determines the vulnerability of its barriers to climate change. The multiple barriers (see Figure 1) are assumed to be deep enough to neglect climate change for their evolution.

Figure 1. The general concept of the multibarrier system for geological disposal of radioactive waste—the waste package (solid waste form, container, overpack), the host rock (blue) and other geological formations (green) (adapted from Chapman and Hooper, 2012).

All EU countries need to have a national program to deal with radioactive waste. In general terms, the engineered barrier system consists of a solid waste form in a (backfilled) disposal container that is placed in a sometimes backfilled and/or lined disposal gallery. Several materials coexist in the engineered barrier system such as glass, cementitious materials or bitumen in the waste form, concrete and steel of containers, and cementitious materials or clay (bentonite) as buffer or backfill and concrete or steel as liner material. In addition, different types of host rocks, i.e., the stable geological formation, are envisaged with a clayey or a crystalline type of rock being the most common host rock types in Europe. The geological environment provides isolation of the waste. The effects of climate change in the next million year are included in the depth of the underground facility. For example, surface areas can be covered with ice sheets during ice ages. The erosion potential of streams of melting water associated with the retreat of these ice sheets may be small for crystalline rock due to its hardness but this potential is considered high for clay rock. Clay host formations are therefore below several other geological formations (see Figure 1).

The engineered barriers (see Figure 1) provide containment of the radionuclides in various functions:

• The solid waste form has a very low solubility in order to limit the radionuclide release rates; the solid waste form is in a thin walled container;

• The metal overpack–in which the solid waste form with the container is to be encapsulated - prevents contact between the waste form and groundwater for thousands till hundreds of thousands years after closure of the disposal facility;

• The buffer or backfill can provide beneficial physical and chemical conditions to the overpack to limit corrosion of the overpack.

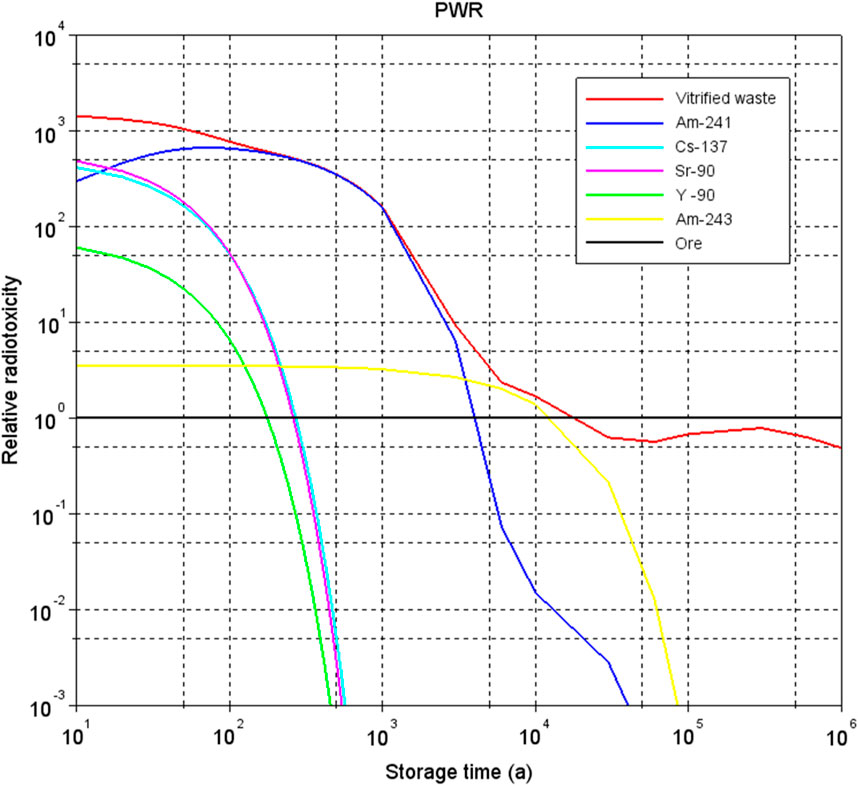

These functions are just a few examples of safety functions of the engineered barriers and described here in order to introduce the reader into the multiple barrier system. Each barrier can also have multiple functions that contribute to the containment of radionuclides (Chapman and Hooper, 2012). The engineered barriers to contain radionuclides can be different for ILW and HLW. Some safety functions can be time-dependent. The required time depends on the radiotoxicity of the waste. This radiotoxicity decreases by decay of radionuclides. Figure 2 shows that it takes about 25,000 years for vitrified HLW to decrease to the same radiotoxicity as the amount of uranium ore that was originally used to manufacture nuclear fuel.

Figure 2. Relative radiotoxicity of vitrified HLW from reprocessing of spent nuclear power fuel from a pressurized water reactor (PWR) when all radionuclides are released from the glass and the uranium ore, radiotoxicity of uranium ore to manufacture fuel is here set as 1. Calculations performed by Professor Jan Leen Kloosterman from Delft University of Technology in the Netherlands in 2017.

The americium isotopes are mainly responsible for the radiotoxicity of vitrified HLW and heat generation in the long-term. The ultimate goal of a geological disposal system is long-term (post-closure) safety for people and the environment. To assess the long-term safety and performance, analyses at the disposal system scale as a whole including the engineered barriers, the host rock and the geological environment are required. To scientifically underpin such analysis, many additional aspects are studied experimentally and numerically, ranging from the repository scale (or disposal facility, including mainly engineered barriers) to more detailed scales (e.g., interfaces between materials).

A particular scale between repository scale and detailed scale is the scale that represents the waste packages, the gallery and a few meters of the host rock around the gallery. This scale is called the disposal cell scale in this review paper. The disposal cell scale consists of several different types of materials with different geochemical properties. As such, all these materials will evolve geochemically and also physical and mechanical properties will vary over long time scales. These alterations are driven by chemical gradients between the materials and disequilibrium with their environment. The performance of the engineered barriers will change by these chemical alterations and associated changes in physical and mechanical properties. Ultimately, the prevailing time-dependent geochemical, physical and mechanical conditions of the waste form, other engineered barriers and the host rock will influence radionuclide release, fate and transport.

The chemical evolution at the disposal cell scale, even it is only a part of the repository, forms a highly relevant input to the assessment of many safety- and performance-related aspects such as waste form degradation, material alteration, source term evolution (radionuclide release), and radionuclide speciation, fate, and transport but also to scenarios describing the evolution of the repository. Important aspects to which a scientific-based description of chemical changes contributes are, amongst others:

• Waste package (for HLW consisting of a container/canister encapsulated in an overpack is embedded in a buffer) evolution and integrity–The geochemical conditions in the materials of waste packages and the interactions at different interfaces within a waste package are an important factor in the durability, performance and life time assessment of waste packages. Crucial is the impact of these geochemical transformations on the evolution of porosity (including clogging phenomena), as porosity represents the primary affected physical variable determining radionuclide migration and fluid flow. In addition, elements in the metallic and cementitious components in waste packages will have an influence on the geochemical conditions in other components.

• Radionuclide release–The geochemical evolution influences degradation/corrosion of different waste immobilisation matrices (vitrified waste, cemented waste) and metallic wastes as function of the evolving conditions imposed by different materials and geometrical features. Experimental and modelling studies concerning waste form alteration provide essential information on the mechanisms and kinetics of radionuclide release.

• Near field evolution–Specifically, feedbacks between the transport of reactive species and/or other drivers for geochemical alterations are important. The geochemical evolution is inevitable linked with the Thermal-Hydraulic-Mechanical (THM) processes at the disposal cell scale.

This is relevant with respect to safety assessments, implementation and optimization (specifically within national programs):

• The assessment and quantification of containment of the radionuclides which is one of the principal objectives of a multiple barrier system in a repository, obtained via attributing various safety functions to the system, structures and components (SSCs). It is to be expected that, at least for some SSCs, geochemical changes will be relevant, i.e., they affect a given safety function of a SSC in its foreseen timeframe. Differences in chemical conditions between different materials induce diffusive transport, changing geochemical conditions and, most likely, geochemical alterations of the barriers. These alterations may influence the lifetime of a barrier, including the waste package, and change the mobility of radionuclides as they effect solubility and sorption.

• The quantification of safety margins and the decrease in conservatism and uncertainty.

• To definition of the requirements for materials, including the robustness of allowable tolerances. The specifications, including dimensioning, of the packages and disposal cell(s) can be influenced based on the calculations of the geochemical evolution. The geochemical evolution can be one of the factors for defining acceptance criteria for varying wastes and stabilization materials.

Crucial elements to assess the geochemical evolution are a good scientific understanding of processes that will influence the chemical evolution and tools to extrapolate the understanding to relevant time scales. Understanding is mostly based on observations obtained from dedicated experiments (mostly limited in time and scale) or natural analogues (can give information over long time scales). Extrapolation is based on numerical modelling tools. The challenges to assess the chemical evolution at the disposal cell scale are how scientific understanding and knowledge on individual materials or processes and the conceptual and mathematical models can be integrated at a disposal cell scale, and how these complex integrated models can be simplified to obtain model descriptions with a complexity appropriate for a given application in the safety and performance assessments. Crucial points are thus to:

• describe which processes are influencing the chemical evolution at the disposal cell scale (narrative of chemical evolution);

• understand the chemical processes within and at the interface between materials;

• integrate the scientific knowledge into conceptual and mathematical models for simulating the long-term large-scale evolution;

• simplify–abstract these models to allow sensitivity and uncertainty calculations or optimisation.

Furthermore, as processes and features on small scales may affect the chemical evolution at a disposal cell scale, studies at different scales are required. It is important that scales here do not refer to its meaning in some multi-scale studies looking at molecular, pore-, meso- and macro-scale, but to looking at less or more different materials in less or more complex geometries. Assessing the geochemical evolution could study following scales:

• Interface scale: The focus of the interface scale is on two materials in contact with each other to obtain information on the geochemical evolution close to an interface in terms of changes in aqueous composition and alteration in solid phase composition at, typically, a detailed small scale.

• Waste package scale: The key feature of the waste package scale is that several materials are present in a specific configuration and are interacting with each other under chemical and possible other gradients. Here, interactions with host rocks or other waste packages are not considered. For HLW disposal cells, in which the chemical evolution of the waste package is governed to a very high degree by the integrity of the canister, mainly the small-scale evolution of the system glass, iron corrosion products and part of adjacent backfill material (clay/cement) after canister breaching is of interest to assess the evolution of the glass and cement alteration zones when the materials are in contact via a perforated stainless steel barrier.

• Disposal cell scale: The disposal cell scale consists of waste packages and their immediate surrounding being other waste packages or other near field components including the host rock.

To develop integrated models for assessing the chemical evolution at different scales, two main methodological routes are possible being process integration and model abstraction:

• Process integration: This concerns the integration of scientific knowledge, conceptual and mathematical models on individual or selected processes into an integrated, usually simplified, model. The integration will increase the understanding of the system behaviour and evolution, helps identifying key processes or parameters, or enables transfer of information from a more detailed scale to a larger scale.

• Systematic abstraction: Model complexity is reduced in a systematic way such that (i) an acceptable description of the chemical evolution is preserved during model abstraction, and/or (ii) differences in some key variables of the chemical evolution can be described qualitatively and/or quantitatively. This leads to a better representation of the expected evolution in safety or performance models, thus helping in reducing and quantifying conservatism and uncertainty and thus directly impacts the definition of safety margins.

This two-part overview focusses on process integration and provide the state-of-the-art of building blocks of the geochemical assessment. The overview focuses solely on waste placed in deep geological repositories with consideration of following waste forms:

• For HLW, only vitrified waste forms, typically originating from reprocessing activities, are considered. This overview does not examine disposal cells with waste packages containing spent fuel.

• For ILW, the focus is on waste that is conditioned in a cementitious matrix. Cementitious waste forms are common conditioning material in many countries (IAEA, 2013; Abdel Rahman et al., 2014; Ojovan and Lee, 2014; Rahman and Ojovan, 2021). However, there exists a large variety of other conditioning matrices including for example, bitumen (Millot et al., 2024), but they are outside the scope of this study. Intermediate level waste have much more origins compared to HLW resulting in a larger variety of waste types. The overview considers here only waste with organics and metallic elements that have been processed with cementitious materials.

The first part describes the various components and characteristics of a disposal cell commonly found in the main European programs (section 2). State-of-the-art scientific knowledge on processes occurring on common interfaces in most disposal cells are discussed in detail in section 3. Based on the information presented in section 2, the following interfaces have been selected: glass-steel, cement/mortar-crystalline, cement/concrete-clay, steel/iron-bentonite, steel/iron-cement/concrete, and steel/iron-crystalline. Based on this scientific understanding, a description is given in section 4 of the space-time evolution of different generic disposal cells. The second part of this overview focusses on how the scientific understanding of processes at different spatial and temporal scales can be obtained and how quantitative assessments can be made. Information is given on experimental studies at laboratory scale or in-situ, on available natural or archaeological analogues, and on coupled reactive transport models for quantitative assessment.

The conceptualisations of the chemical evolutions require the radiological, chemical, and physical properties of the engineered barriers and natural barriers and the potential microbial activity in these barriers. The radiological properties determine the classification of waste.

• HLW has a very high activity content and also generates heat in such amounts that special measures for sufficient heat dissipation need to be made during storage and disposal of this waste. Examples of HLW are vitrified waste forms from the reprocessing of spent fuel and spent nuclear fuel. As described in section 1.3, only vitrified HLW is considered in this paper.

• HLW and ILW both require shielding during transport and storage of this waste, but no additional measures for heat dissipation need to be made for ILW. An example of ILW are the compacted metallic parts of spent fuel that arise during the reprocessing process of spent fuel. Also sources with alpha-emitting radionuclides with smaller half-lives than naturally occurring uranium isotopes such as plutonium and americium can be ILW.

HLW and long-lived ILW are disposed of at larger depth than LLW and short-lived ILW. Usually, the depth of the disposal facility is so large that reducing chemical conditions are present in the virgin clayey and crystalline host rock. The diversity in the chemical composition of the waste forms generally decreases with increasing radioactivity of the waste:

• HLW: Spent fuel has currently always uranium oxide as a waste matrix and the HLW arising from reprocessing of this fuel results into a vitrified waste form. The chemical alteration rate of these waste forms is very small and generally well understood for example, by studying natural analogues or modelling (see Part II, Deissmann et al. (2024)). These analogues do however not have complementary materials such as steel that might alter the chemical process on a small scale.

• ILW: The chemical nature of the waste considered in this review is metallic or organic. Radiation resistant resins (organic) are used to absorb radionuclides from water used in operation and maintenance of nuclear reactors. The volume of waste is reduced since the radionuclides are concentrated in these resins and the cleaned water can be re-used. Metallic waste can be compacted Zircaloy hulls from spent nuclear power fuel but also stainless steel that has been neutron irradiated in nuclear plants. There are several reasons why these metallic materials (Zircaloy and stainless steel) have been chosen to use in nuclear plants and one of them is their high corrosion resistance. The chemical alteration rate associated to both resins and these metallic materials can also be very small but only for resins evidence from natural analogues are available.

• LLW: The chemical nature of the waste can also be metallic and organic, but the diversity in organic material arising from nuclear power plants is generally larger for LLW than for ILW. Exceptions are the waste arisings from research and reprocessing plant dismantling operations; a similar diversity in the chemical nature of the waste forms may be for LLW and ILW. Everything that people use in ordinary life such as cloths, paper (tissues), rubber, steel, aluminium can also become contaminated with radionuclides and become waste. Also LLW is often conditioned into cementitious materials. Substantiation of the chemical alteration process and the prediction of the chemical alteration rate of some specific waste forms is still investigated since degradation of these waste forms can enhance the transport of radionuclides into our living environment.

The waste forms for HLW and ILW (glass, metal) have such a low porosity that the presence of the pores within these waste forms is neglected in the chemical evolution. The alteration rate of these waste forms depends on the physical properties that interface these waste forms. These properties having an impact on the chemical evolution at disposal cell scale are the porosity, the pore size distribution and the presence of cracks in the engineered materials and host rocks. These two properties and the water content in the pores and cracks of these materials determine the potential exchange of chemical species and microbial activity. The potential diffusional pathways of dissolved species in materials increase with increasing saturation degree. The interfacing materials are not in equilibrium and a new precipitated material between the interfacing materials may arise. This new material can also have physical properties that impact the chemical evolution.

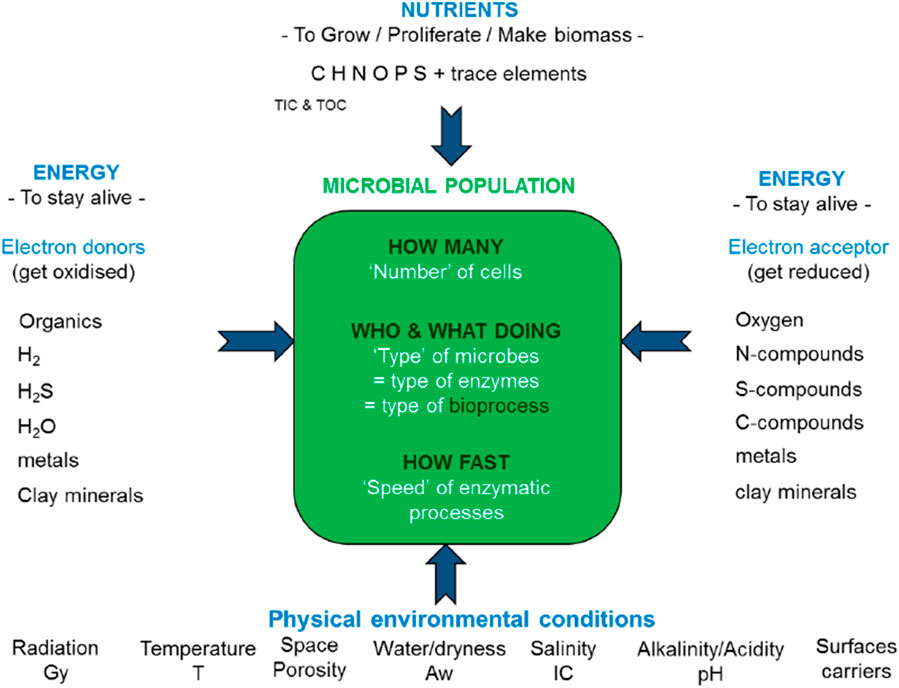

Microbial activity enhances chemical processes, for example, the microbially induced corrosion rate of steel is larger than the pure chemically induced steel corrosion rate. Microbes are always present but there is no microbial activity if these microbes are in a dormant phase. The microbial activity depends on various factors that can be generalized (see Figure 3) and these factors need to be taken into account in the selection of (the combination of materials for) the engineered barriers. Preferably, microbial activity is minimized by design, especially for HLW, in order to be able to reduce the uncertainty in the prediction of the chemical evolution. There are also very different types of microbes but the alteration of a material may require specific microbes. Microbes require organic matter as a food source but also other nutrients to build their DNA and proteins. Organic matter can be present in the waste forms of ILW but not in a HLW waste form.

Figure 3. Generalized overview of restricting and enhancing parameters for microbial life (Wouters et al., 2016).

Radiation There is a wide diversity of values considering the radiation resistance of microbes. It is the hydroxyl radical that is formed during irradiation of water and water containing media that is the most damaging agent since this radical oxidises DNA, RNA, proteins and lipids (Brown, 2013). The upper limit of the radiation dose of microbes is 30 kGy (Wouters et al., 2016). For example, microbes that can enhance corrosion of steel and have been added to steel lose their activity after 100 days irradiation at dose rates of 2.1 Gy per hour, i.e. 5 kGy (Bruhn et al., 2009). Figure 8 shows the expected radiation dose rates for steel interfacing buffers (see Section 4.1). Some elements determining the activity of the microbes are shortly described below.

Temperature The diversity in the denaturation resistance of microbes is large and can range from −20°C till 122°C (Wouters et al., 2016). The optimal activity of sulphate reducing bacteria1, i.e., bacteria mainly responsible for microbial induced corrosion, is 28°C–30°C, but these bacteria can tolerate a temperature as high as 75°C (Virpiranta et al., 2019). Buffers usually have a limit of 100°C (see Section 2.1.3.3).

Space/porosity A microbial cell should have a certain minimal size in order to harbour all essential proteins and nucleic acids to maintain life. The range in diameters of microbes is between 0.2 µm and 2 µm. The connecting pore throats in clayey host rocks such as Boom Clay are smaller than 10–50 nm. The microbial activity is restricted in space in these clayey rocks not only because they are not mobile but also because the transport of electron donors and acceptors and carbon sources is very slow (Wouters et al., 2016). The best natural analogue to illustrate negligible microbial activity in clays is the Dunarobbe forest in Italy in which 2 million year old trees had been preserved in compacted clay. These trees were protected against microbial degradation and therefore had cellulose contents similar to present-day wood (Lombardi and Valentini, 1996; De Putter et al., 1997)). Manufactured concrete can also have pores with a maximum in diameter till 50 nm but that requires very well engineering. A maximum in 100 nm (0.1 µm) is not uncommon for concrete by which it can also be assumed that the potential microbial activity is limited due to space restriction in concrete. Dormant microbes can become activated when cracks in clayey rock or concrete appear.

Water/dryness Most microbes require water activities larger than 0.9 in order to be active (Swanson et al., 2018), i.e., a relative humidity of 90%. However, there is also a wide diversity in the desiccation resistance of microbes. Sulphate reducing bacteria have been experimentally examined to require a minimum in water activity of 0.96 (Stroes-Gascoyne and West, 1997; Stroes-Gascoyne et al., 2007). Lower relative humidities can be present during storage of the waste, in the operational phase of the disposal facility and early in the post-closure phase for HLW disposal cells, when the waste emits heat and drying occurs.

Salinity Salinity has a similar effect as drying, i.e., the water activity is reduced with increasing salinity. A water activity of 0.90 is equal to ≈2.7 M NaCl solution or ≈1.4 M MgCl2 solution (Swanson et al., 2018).

pH Microbial life in high pH environments requires a mechanism to keep a neutral cellular life and a proton motive force across the cell membrane to preserve proteins and produce adenosine triphosphate (ATP), a carrier of energy. The concentration of H+ is very small at high pH and an upper limit of 12 is generally assumed, although microbial communities have been described also to grow up till a pH of 13.2 (Wouters et al., 2016). These microbes have been found in a lake in which steel slag had been dumped (Roadcap et al., 2006).

Although the HLW and ILW disposal cells have country or program-specific features and specifications, it is possible to group them into different classes with respect to the different components, structures, interfaces etc. The following sections describe this grouping and the main characteristics of the HLW and ILW disposal cells in European countries/programs. The section starts with the characteristics of the waste and the engineered barriers. Construction and operation of the disposal facility can have an impact on the clayey and crystalline host rock and affect both ILW and HLW disposal cells and are described at the end of this section.

Vitrified HLW results from the reprocessing of spent nuclear fuel from which uranium and plutonium have been extracted. The pretreated High-Level Liquid Waste (HLLW) is melted with a glass frit and poured into a stainless steel container (Baehr, 1989). This waste processing ensures that the radionuclides are homogeneously distributed in a borosilicate glass matrix. This matrix contains traces of plutonium and uranium, other actinides that have not been extracted such as americium and fission products. These vitrified waste products have been made in Sellafield (UK) and are still being made in La Hague (France). The largest amount comes from France and therefore frequently, the French abbreviation for this waste product is used: Conteneur Standard de Déchets vitrifiés, CSD-V. The vitrified waste product is made in two batches with each of 200 kg of molten glass (Moncouyoux et al., 1991) – typical dimensions of CSD-V are found in CEA (2009). The thermal power as a function of time and other properties of a CSD-V with a high actinide content can be found in the (Supplementary Materials Section 1). Vitrified waste was also produced in a few other countries United Kingdom and Belgium (Thorpe et al., 2021; Ojovan and Yudintsev, 2023).

The number of cracks that are present within this waste form after pouring into the canister and subsequent cooling may be limited, but a tomographic or X-ray image of a canister with processed waste to deduce the cracks within the waste form has not been found. The experimental studies performed in the nineties for the 3rd framework (RTD) programme to characterize radioactive waste forms have demonstrated that it is possible to produce homogeneous glass blocks by applying appropriate cooling procedures even with non-radioactive simulate HLW, as has been observed with tomograms (Reimers, 1992). Full-scale tests with non-radioactive simulants without appropriate cooling procedures show large glass shrinkage cavities (Moncouyoux et al., 1991) as the inner part solidifies last. Rapid cooling also generates a large number of circumferential cracks due to the stress associated with the large thermal gradient (Reimers, 1992). The temperature of the waste will remain several hundreds of degrees after the vitrified waste form is transferred to the storage facility. The size of the glass specimen and cooling rate are essential in order to determine which experimental results are representative for disposal of waste. The ‘so-called’ reference blocks with a controlled cooling rate of 2.8°C per hour (Moncouyoux et al., 1991) may therefore provide the best estimate for the determination of a cracking factor but the time at which the package is removed from the casting station at which molten vitrified waste is poured in the canister is an essential feature. This cracking factor (or fracturation factor) is a parameter that is used in performance assessment studies to determine the alteration/dissolution rate of glass and radionuclide release rate. The cracking factor can be best estimated from the actual measured surface area. For the block with the controlled cooling rate of 2.8°C per hour: the outer surface of a glass block would be 1.781 m2, assuming the surfaces at top and bottom to be flat. After the reference block of 391 kg was taken out of the canister, it was broken into 11 pieces: one weighing 250 kg, another 80 kg and nine pieces with a weight of less than 10 kg. The outer surface was 2.787 m2 as measured by wrapping all the faces in aluminum foil. The cracking factor then becomes 1.56. Even if the 400 kg poured glass was removed 2.5 h after pouring and left to naturally cooling, the cracking factor only increases till less than one order in magnitude: 14.5 (Moncouyoux et al., 1991). Please note that this cracking factor is smaller than average in cracking factor of 40 obtained from leaching experiments with another experiment with inactive glass blocks at full-scale. This factor is reduced during the leaching experiment until an average in cracking factor of 5 due to alteration of glass by which the small cracks were closed (Ribet et al., 2009).

The presence of radionuclides within glass has some beneficial characteristics to prevent or heal cracks. The thermal power source and the radioactivity work as glass network modifier by producing ionization rays. Cooling (passive) systems are needed in order to store these vitrified waste forms. The thermal power is so large that it can take 65 years in order to have a sufficient heat loss for disposal. The α-decay of actinides present in waste diminishes slightly the glass density and its mechanical properties and appreciably improves, especially its resistance to cracking (Ribet et al., 2009). The evolving helium diffuses through the glass at such a high speed at room temperature that helium implantation below room temperature is necessary to make helium observations within glass using neutron activation analysis (Chamssedine et al., 2010). Consequently, defects generated by stopping the highly energetic alpha particles within the waste form are annealed at room temperature by which helium trapping by defects within the waste form glass does not occur at temperature conditions representative for storage and disposal.

For disposal, the stainless steel canister with vitrified waste is envisaged to be put in a carbon steel overpack (see Figure 1) in many national programmes (e.g., France, Switzerland, Belgium and Netherlands) (Neeft et al., 2020). This steel has predictable corrosion kinetics; general corrosion is considered the predominant mechanism rather than localised corrosion processes such as pitting. In all programmes, the safety function of the overpack is to prevent contact between the vitrified waste form and groundwater but the required periods for this physical containment are different. These differences are caused by the used safety concepts.

• In the French concept, there should be no contact between pore water and vitrified waste until the temperature of the core of the vitrified waste form is lower than a certain temperature. This temperature is determined by the advances in knowledge about the behaviour of vitrified waste forms and radionuclides in solution. The required period for containment is envisaged to be less than 500 years.

• The temperature of the host rock is considered as a criterion in other programmes for this physical containment, for example, in the Belgian and Dutch programme. The heat dissipation to the host rock should be declined to negligible. If that is achieved, radionuclide migration data obtained in laboratory experiments performed at room temperature or the radionuclide migration data extracted from the site, can be used to calculate the transport of the released radionuclides in the clay formation. The required period for integrity of the steel container and carbon steel overpack is envisaged to be more than 1,000 years.

The Czech and Spanish programmes do not consider vitrified HLW but they do consider these steel overpacks for physical containment of spent nuclear power fuel and spent fuel also generates heat like vitrified waste Such programmes therefore also contributed to understanding of chemical evolution under temperature gradients as long as overpacks are intact. This steel overpack is in contact with an engineered buffer in their programmes and has the same purpose as disposal cells with vitrified waste Many other programmes also envisage an overpack interfacing an engineered buffer (Neeft et al., 2020).

Bentonite and concrete are envisaged as interfacing materials for the carbon steel overpack. Bentonite buffers are considered in the Czech, English, German, Spanish and Swiss programmes and concrete buffers are considered in Belgian and Dutch programmes. These engineered buffers are carefully designed to meet specific criteria. The work performed on bentonite in the Swedish and Finnish programmes has been carefully looked at to extract its characteristics.The bentonite interfaces copper in these Scandinavian programmes instead of steel. In this paper, interfacial reactions between copper and bentonite are not considered, only those between bentonite (clay) and steel.

Bentonite has a high smectite content of which montmorillonite is the most abundant mineral. These minerals can swell and therefore induce a large impact on the distribution in size of pores, its consequent connecting pore throats and hydraulic conductivity. The smectite content can be 88 wt% as used in the Czech and 75 wt% in the Swiss programme, in which smectite is further specified as Na-montmorillonite in Wyoming MX-80 bentonite (Müller-Vonmoos and Kahr, 1983). Wyoming MX-80 bentonite is also used in the Swedish programme (Wanner et al., 1983). Please note that these clay contents are higher than the clay contents of around 60 wt% in any clay host rock considered in the national programmes (see Supplementary Materials). The bentonite is compacted to an optimum in density and its resulting swelling pressure. The density and swelling pressure should be high enough to reduce microbial activity and resulting swelling pressure, prevent movement (sinking) of the overpack, and limit advective transport (Hedin et al., 2011). There is much evidence indicating that microbial activity will not occur in compacted bentonite with a dry density exceeding 1,600 kg/m3, either because of low water activity or because of the effect of swelling pressures in excess of 2 MPa on the physiology of the microbes (Johnson and King, 2008). There are a number of interface locations such as placement gaps, contact regions with materials of different densities and contact points with water carrying fractures in the crystalline rock by which the dry density can become smaller than 1,600 kg/m3 upon expansion of compacted bentonite into a void. The reduction in dry density can stimulate or restore the cultivability of indigenous microbes which would increase the possibility for in-situ microbial activity. Reductions in dry density should therefore be minimized or eliminated by adequate design (Stroes-Gascoyne et al., 2011). The density and resulting swelling pressure should also be low enough to prevent damage to the metal overpack and host rock (Hedin et al., 2011).

Bentonite buffers are usually ‘dry’ emplaced. Dry can mean for bentonite buffers a water content of 17 wt% (e.g., Johannesson et al. (2020) or 10% (e.g;, Atabek et al., 1991). The saturation of these dry blocks with which the buffer is constructed is between 50%–60% (Johnson and King, 2008). The pore water chemistry of this engineered barrier is therefore determined by the inflow of host rock water and establishment of equilibria between dissolved species present in this host rock water and minerals present in bentonite, i.e., there is no initial pore water chemistry as in concrete.

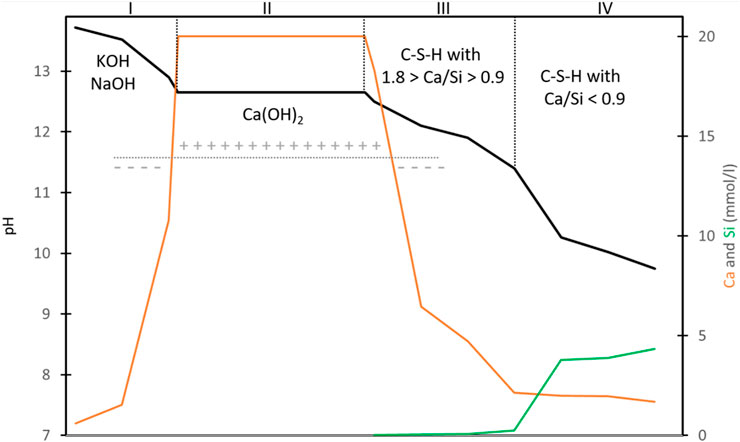

Cementitious materials, a material omnipresent in many disposal systems (Jacques et al., 2021a), are a chemically reactive material in many environments and could be subject to several chemical ageing and processes (Jacques et al., 2021b; Rahman and Ojovan, 2021). Therefore, the characteristics of concrete are of uttermost importance for its long-term chemical durability. The required strength of concrete, environmental class, fluidity during pouring and distribution in size of aggregates have all been defined before fabrication of any cementitious material. The strength of concrete is determined by the strength of aggregates and the attachment of the aggregates with the cementitious phase in concrete. Choices in concrete recipe and type of mixing of ingredients follow from these requirements and available knowledge. This available knowledge is integrated in standards for civil engineering. These standards are regularly updated. The European standard EN 206 divides the potential degradation of concrete or the reinforcement inside the concrete into 18 exposure classes. There are three exposure classes for ranges in dissolved sulphate content, pH, amount of dissolved CO2, dissolved ammonium and magnesium content. All dissolved species are also present in the pore water of clay and crystalline host rock except for dissolved ammonium, which is characteristic for polluted groundwater. Polluted groundwater may not be relevant for disposal studies. The pH of concrete pore water is high after fabrication of concrete, around 13 (see Supplementary Material Section 2). The ingress of CO2 can lower the pH of the concrete pore water, which can be detrimental to the steel used for the reinforcement, i.e., ingress of CO2 may not be detrimental to concrete itself. The resulting calcite precipitation within concrete results in a porosity reduction that can decrease the permeability of concrete. The environmental class determines many requirements. For example, concrete being exposed to the highest magnesium concentration (XA3) requires:

• the smallest water to cement ratio since this ratio has an impact on the permeability of concrete and thereby ingress rate of dissolved magnesium. A small permeability is characteristic for a concrete with a high strength and has the smallest ratio in water to cement;

• the largest cement content in order to buffer the ingress of magnesium;

Superplasticisers are used to achieve a well mixing and processability of cementitious fluid with a reduced water content. There are chemical alterations in which the mechanical strength of fabricated concrete is too early too much decreased in the operational phase of the disposal facility or in the post-closure phase of the disposal system. These alterations can be prevented with a proper choice in cement, content of cement in concrete and a proper choice in combination of cement and aggregates. For example, sulphate resistant cement is used to prevent Delayed Ettringite Formation (DEF). DEF can be caused by:

• an internal sulphate attack, when the temperature during hydration is too high;

• an external sulphate attack by ingress of dissolved sulphate species reacting with tri calcium aluminate (C3A).

The hardened cement paste between the aggregates is cracked when DEF occurs. Both cases of DEF can be prevented by limiting the C3A concentration. A Portland cement blended with microsilica, fly ash or slag also reduces the temperature for hydration by which internal sulphate attack is prevented. These blended cements can be called sulphate resistant cements for example, CEM III/B.

Another example of a proper choice to prevent chemical alteration in which the mechanical strength of fabricated concrete is too early too much decreased is using calcite or quartz aggregates instead of aggregates with silica polymorphs that have a higher reactivity with alkalis in the concrete pore water. These silica polymorphs change into silica gels; cracks become present through the reactive siliceous aggregates. The use of blended cements also reduces the probability of the alkali silica reaction (ASR) due its low permeability at an ordinary engineering time scale of about 100 years. Concrete made with blended cements are called low-permeability concretes, due to their more refined pore structure compared to concrete made with Portland cement (Atabek et al., 1991; Atkins et al., 1991; Mulcahy et al., 2017). A porosity between 10 and 15 vol% is a good estimate for the concrete buffer.

Both bentonite and concrete buffers have small connecting pore throats by which two beneficial physical conditions are provided for the durability of the carbon steel overpack:

• the transport of dissolved chemical species is dominated by predictable slow diffusional processes;

• microbial activity is limited.

The corrosion of many metals is determined by the solubility of the metal-oxide that is formed, the diffusion of species through this metal-oxide and the concentration of dissolved species near this metal-oxide. In case of carbon steel, the anaerobic corrosion rate is controlled by the formation of magnetite. These dissolved species have a larger diffusional speed in stagnant groundwater than in these buffer materials, by which the removal speed of these dissolved species is larger. The concentration of dissolved species near the metal-oxide can however also be reduced, if the buffer adsorbs the dissolved species. The microbial corrosion rate is usually larger than the chemical corrosion rate (e.g., Swanton et al. (2015)), but the initiation of microbial corrosion does not take place when the microbial activity is absent. This absence may be possible by space restriction in both buffers. The high pH for the concrete buffers is also limiting the microbial activity.

Both buffers have a temperature limit of 100 °C in many disposal programmes. One of the reasons for this temperature constraint is to limit degradation or mineral alteration of the bentonite buffer for bounding the uncertainty in the long-term predictability of this buffer. For the concrete buffer, this temperature constraint has been set to limit the formation of a gaseous phase.

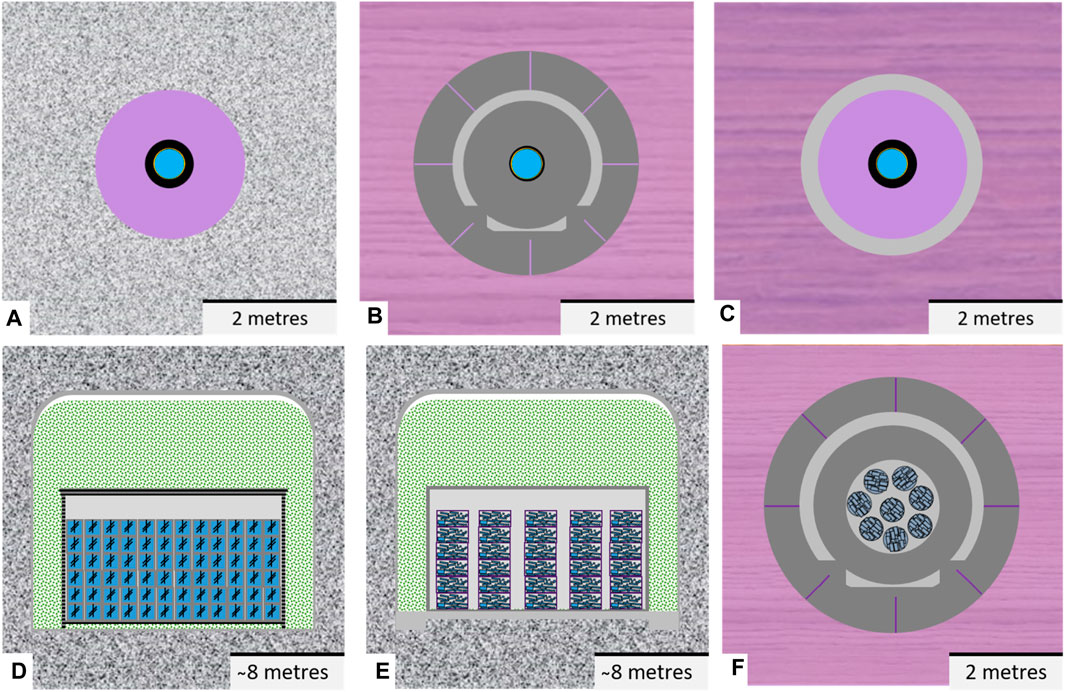

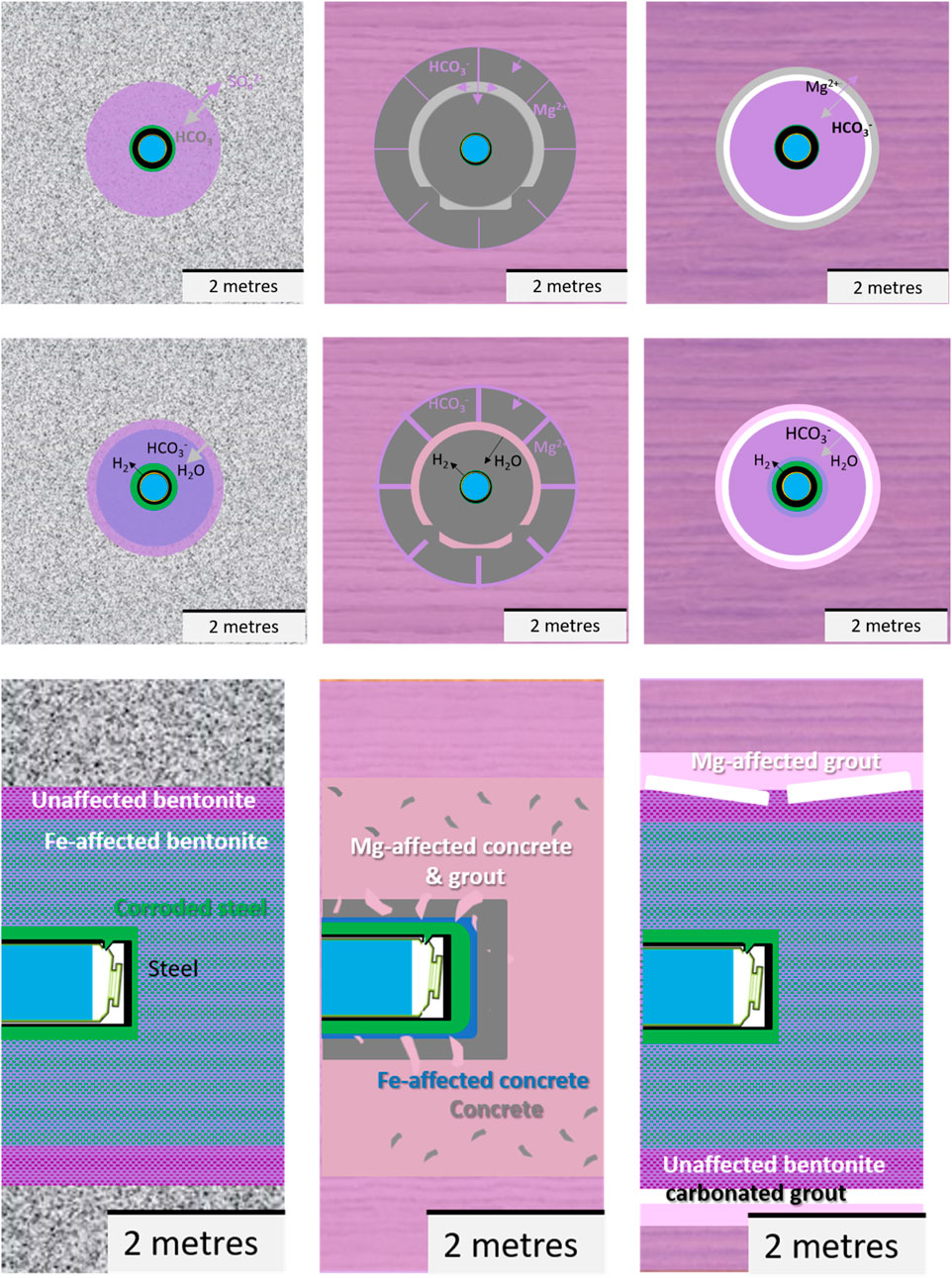

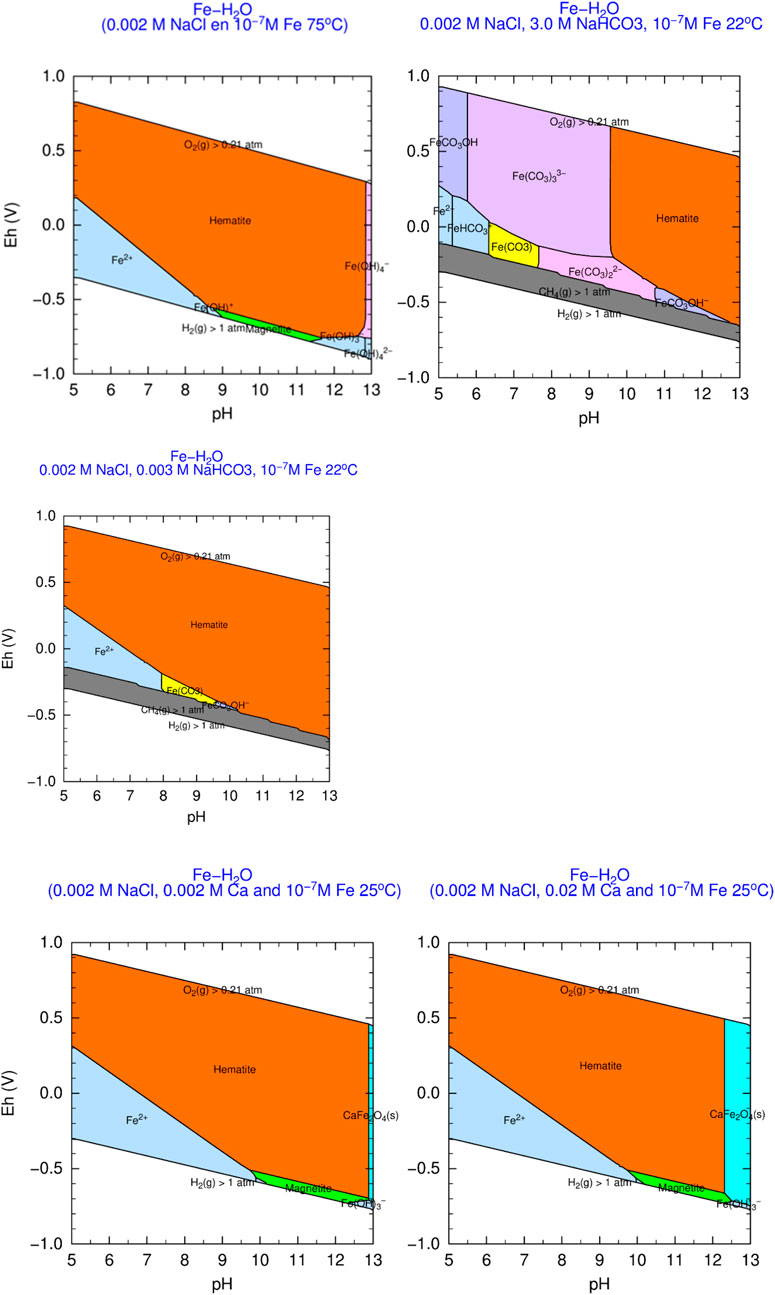

Figure 4 shows an abstraction of the disposal cells considered in Europe for the following host rocks: granite (e.g., Czech Republic2), poorly indurated clay (e.g., Figure 4B, Belgium and Netherlands with the supercontainer concept (Bel et al., 2006)) and indurated clay (e.g., Switzerland and France, Figure 4). The disposal concept of compacted clay buffer bricks surrounding vitrified waste in granitic host rocks has been studied earlier in Europe (e.g., Atabek et al., 1991) but these studies were without a carbon steel overpack. Please note that the thickness of the carbon steel overpack considered for concrete buffer is thinner (about 3 cm (Neeft et al., 2020)) than considered for this overpack for bentonite buffers (about 14 cm, e.g., in the Swiss programme (Leupin et al., 2016). The reason for this difference in thickness is the higher corrosion rate foreseen for steel interfacing bentonite compared to concrete.

Figure 4. (Top) Abstracted disposal cells containing vitrified HLW considered in Europe for the host rocks: crystalline (A), poorly indurated clay (B) and indurated clay (C). Blue = vitrified HLW, black = steel overpack, bentonite (purple) or concrete buffer (grey) surrounds the overpack, grout = light grey and purple both clay host rocks. (Bottom) Abstracted disposal cells containing cemented ILW considered in Europe for the host rocks: crystalline (D, E) and poorly indurated clay (F). Blue = ILW or cemented ILW, black = steel, green = crushed crystalline rocks, grey = concrete, light grey = mortar or shotcrete and purple = poorly indurated clay.

Lining material to support the rock is not needed and used for crystalline host rocks. Pre-fabricated concrete segments are needed to construct a disposal gallery in poorly indurated clay. These hardened segments need to be directly applied against the fast convergence of this clay. There is more time to apply a lining in indurated clay for example, when excavation has been finished. The lining is made by in-situ curing of shotcrete (grout). Grouts are sprayed against the surface of excavated rock in a disposal gallery for indurated clays. Chemical interactions between the cementitious fluid and the clay host rock take place before hardening. Reaction rims between shotcrete and clay may have been formed in order to enhance the bonding of the shotcrete with the clay host rock.

The porosity of the pre-fabricated concrete segments is similar to the concrete buffer, i.e., between 10 and 15 vol%. The porosity for the backfill grout and shotcrete is larger between 25 and 35 vol%.

If further specified, the metallic ILW considered in this review was Zircaloy, stainless steel and carbon steel (Neeft et al., 2020). Metallic radioactive waste is mainly generated by reaction with neutrons and elements within these metals.

Stainless steel and carbon steel arise from the maintenance and dismantling of nuclear reactors. Metallic waste also arises from reprocessing spent fuel from nuclear plants: Compacted waste Standard Residues (Collis Standard de Déchets Compatés: CSD-C). It comprises metal parts from the spent fuel assemblies that have been cut off to extract the spent fuel, then rinsed and dried. A canister of about 170 L internal volume is filled with either hulls or end pieces. The hulls are made of Zircaloy; other metal parts are usually made of Inconel. End pieces are solid stainless steel sections. Drums with other waste arising from reprocessing fuels, such as pumps, stirrers and filters, are primarily made of stainless steel. All drums are compacted to produce pucks that are loaded into CSD-C canisters with similar outer dimensions to those used for vitrified waste, which are welded closed. The void space is about 20% in the canisters. CSD-C canisters can later be encapsulated in concrete containers (see Figure 4). Another example of pure metallic ILW is activated steel (e.g., Stein, 2014). Frequently, however, radioactive steel is processed with organic ILW (e.g., Uras et al., 2021).

If further specified, the organic ILW in this review were spent resins, but the French programme noted a special interest in PVC and cellulose since degradation of both polymers lead to complexing agents for radionuclides (Neeft et al., 2020). The amount of cellulose based material identified in the ILW inventory in the French programme is 25 wt% (Altmaier et al., 2021). Experiments with cellulose have been made and described e.g., in Blanc et al. (2024) and Altmaier et al. (2024) but are not treated in this paper.

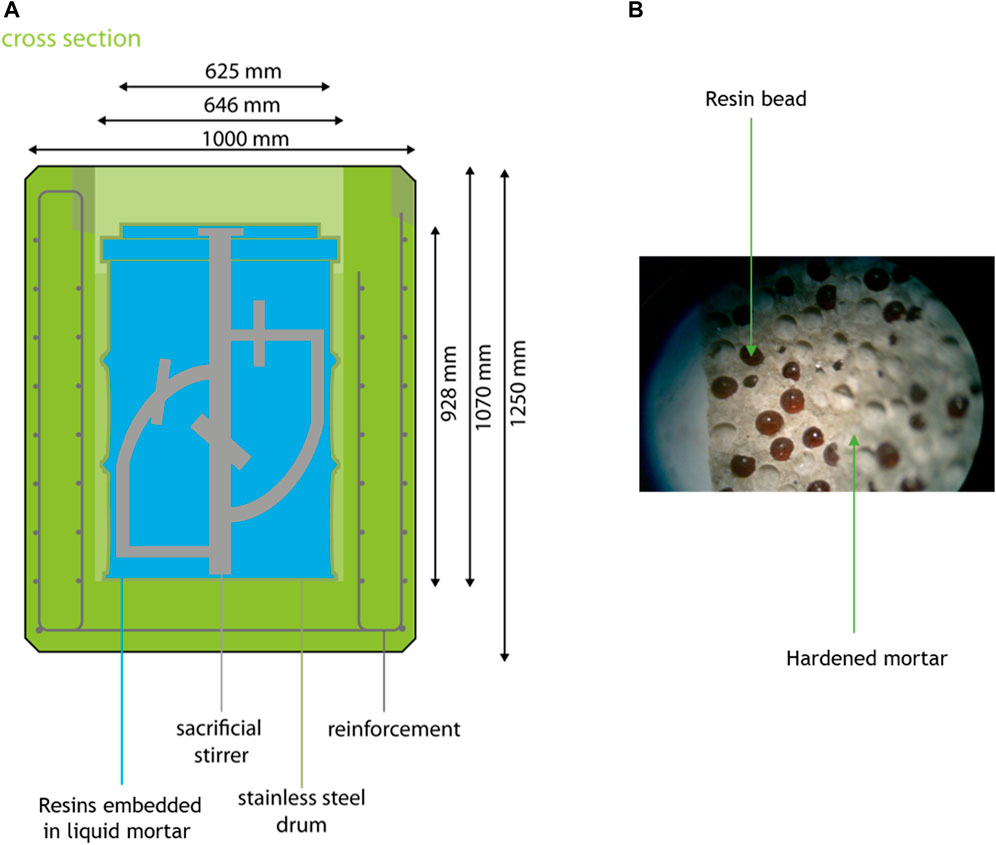

Resins purify reactor coolant water and other types of water used during operation and maintenance of nuclear reactors. The most common form of synthetic ion exchange resins is polystyrene divinylbenzene in powdered form with diameters from 5 to 150 µm or in beads from 0.5 to 2 mm. The resins have functional groups that are to be exchanged with a radionuclide in cationic form such as 60CoOH+ or in anionic form such as H14CO3−. Spent resins are mixed with a waste matrix that can be a cementitious matrix. Figure 5 shows the schematics of this waste with an example showing a detail with the embedding of resin beads in a cementitious matrix (blue). This matrix is fabricated without siliceous aggregates. This type of waste is a so-called homogeneously mixed cemented waste (Uras et al., 2021).

Figure 5. (A) Schematics of processed resins (adapted from Verhoef et al. (2016)). Magnetite aggregates are used for the fabrication of the concrete in reinforced concrete container in order to contribute to shielding. (B) Detail with the resin beads embedded in a cementitious matrix.

An image of a heterogeneously cemented waste is compacted plutonium contaminated material generated at the Sellafield site in the United Kingdom that contains halogenated plastics (PVC) and non-halogenated plastics, is available in the MIND project from the Horizon 2020 programme. These compacted plastics have been enclosed in an annulus of cement grout (Abrahamsen et al., 2015).

Cementitious materials are used to condition the ILW but can also be used as a backfill. The dimensions of a disposal gallery for ILW are usually larger than those of galleries constructed for disposal of HLW. Figures 4D,E shows an abstraction of the ILW disposal cells considered in Europe for the following host rocks: crystalline (Figure 4d,e, e.g., Sweden) and poorly indurated clay (Figure 4f, e.g., Belgium). The ILW disposal cells in crystalline rocks consist of vaults that are lined with shotcrete to stabilise the rock in the operational phase and caissons in which the waste containers are emplaced.

The types of waste drawn in Figures 4D,E are processed spent ion exchange resins with a sacrificial stirrer for each package and metallic waste arising from the maintenance of a nuclear reactor and being mostly steel (both disposed in granitic rock). As an example, processed resins have been drawn within reinforced concrete caissons and metallic waste in unreinforced concrete caissons. The coverage of concrete in well-engineered reinforced concrete depends on the environmental class, for example, 40 mm for the highest environmental class XA3 in the European standard EN 206. For reinforced concrete, the attachment between steel and the cementitious phase is important. Steel rebars have usually ribbons and are commonly oxidised in air before concrete pouring in order to obtain a good attachment between concrete and steel. Gaps between steel and the cementitious phase of concrete may arise due to shrinkage of the cementitious phase during hardening, when polished and smoothend steel is used. Oxygen in air can increase the corrosion rate of steel. The corrosion rate of steel is minimized if steel is exposed to reducing, alkaline conditions, since a passivation layer on the steel surface that limits corrosion is stable at these chemical conditions. Consumption of oxygen by corrosion of steel can deplete oxygen in the vicinity of the steel bar by which aerobic corrosion is followed by a lower anaerobic corrosion rate. High aerobic corrosion rates caused by the insufficient coverage of the steel bar by concrete may result into the spallation of concrete during the operational phase of the disposal facility. Especially if carbonation of the concrete cover has occurred by which the alkaline environment is no longer provided. So far, only cracking of concrete by aerobic corrosion of rebars has been known with characteristic orange-brown corrosion products with minerals such as hematite and lepidocrocite. Anaerobic corrosion of rebars is characterised by dark-brown to black corrosion products with minerals such as magnetite (Argo, 1981).

For granitic rocks, also shotcrete or a grout can be applied sometime after excavation as previously explained for the HLW disposal cells constructed in indurated clay. The caissons are backfilled with cementitious grout after completion of emplacement of waste packages. The empty volume between the caissons and shotcrete is backfilled with crushed granitic rock to control the waterflow in the disposal gallery. Granitic rock is easily available from the excavation activities.

Hardened concrete segments need to be immediately applied after excavation of poorly indurated clay as previously explained for the HLW disposal cells constructed in poorly indurated clay. A cylindrical concrete disposal package containing eight canisters CSD-C is envisaged to be emplaced in this disposal gallery. This gallery is backfilled with mortar.

Usually, the depth of the disposal facility is so large that reducing conditions are dominant for clayey and crystalline host rocks. Determination of the chemistry of the porewater is not always possible by measurements, modelling needs to be used especially for clayey host rocks. The pore water chemistry of the virgin host rock and how this chemistry has been determined and the mineralogy and its impact on the pore water chemistry are described in the Supplementary Materials.

The properties of the host rock in the vicinity of the engineered materials change during excavation of the host rock and may change during the operation of the facility. There will be some fractures generated in the host rock and the size and density of the cracks depends on the excavation technique, size of excavated volume and type of host rock. The disposal galleries to emplace HLW packages are usually smaller in diameter than the disposal galleries to emplace packages containing ILW and the excavation procedure can be different. The outcome of both features is that the Excavation Damaged Zone (EDZ) is smaller for galleries to dispose HLW than for galleries to dispose ILW. The required time to heal or seal these fractures is host-rock dependent.

Crystalline rock specific excavation procedures have been defined in Finland and Sweden to make galleries to dispose of HLW with an acceptable limited water inflow through fractures to emplace the engineered material bentonite in the operational phase (e.g., Baxter et al., 2018). The water flow from the host rock into the disposal cells needs also to be limited for the post-closure phase to limit ingress of species from shallow and deep ground water (Vieno et al., 2003) and bentonite erosion (Baxter et al., 2018). Excavation of rock to construct disposal galleries is performed by drilling and blasting. Rock support are bolts and shotcrete; the density of applied bolts as well as non-reinforced or reinforced shotcrete is determined by the fracture extent of the rock (e.g., Carlsson and Christiansson, 2007). Shotcrete hardens in-situ and chemical interactions between the cementitious fluid and crystalline host rock can take place before hardening. Reaction rims between shotcrete and crystalline may have been formed in order to enhance the bonding of shotcrete with the crystalline host rock.

Decades of experience is available for operating a disposal facility for LLW and short lived ILW in Hungary, Sweden and Finland. Pumps are needed to keep the disposal facility dry. The main inflow of water into this facility in Sweden is, however through, the access tunnels and not the disposal galleries (Carlsson and Christiansson, 2007; Vahlund and Andersson, 2015). The permeability of the shotcrete lining is smaller than the permeability of the crystalline rock. The same accounts for the bentonite buffer that is emplaced in HLW disposal cells. Consequently, the concrete lining and bentonite buffer acts as a barrier for further transport of water into the facility. Potential healing of fractures can take place by precipitation of minerals, e.g., calcite, chlorite and clay minerals (Drake et al., 2006).

Also, the ingress of dissolved species from the host rock pore water that can alter the cement mineralogy of the lining in ILW disposal cells starts in the operational phase. The shotcrete used for disposal cells in crystalline rock can become atmospherically carbonated due to ventilation air. The fractures in crystalline rock give a heterogeneous influx of granitic pore water into the shotcrete. The ingress of bicarbonate, sulphate and dissolved magnesium (depending on the host rock geochemistry) may precipitate into minerals that replace the calcium-containing cement minerals. There can therefore be a loss in strength of shotcrete liner in the operational phase since the calcium-containing minerals provide the binding and strength of the shotcrete.

Special tunnel boring machines are used to construct galleries in poorly indurated clays. Concrete segments are immediately applied after excavation of the clay with these machines. The stability of the lining is caused by the use of a wedge block. The block is emplaced between concrete segments. Concrete interfacing clay in the HLW and ILW disposal cells (Figure 4) is the external diameter of the gallery. The diameter of the excavated clay is slightly larger than the envisaged external diameter of the gallery. This so-called overcut is needed in order to be able to emplace the concrete segments. So far, the EDZ has been measured by the larger hydraulic conductivity compared to virgin clay. The larger hydraulic conductivity is attributed to the presence of cracks. The hydraulic conductivity of clay interfacing the concrete liner is the largest measured hydraulic conductivity. Further away from this interface, the hydraulic conductivity diminishes and approaches the virgin hydraulic conductivity.

The cracks induced by excavation revoke the limitations for microbial activity that were initially present in the virgin host rock. Active microbial communities present in various boreholes demonstrate that only providing space is sufficient to initiate the establishment of an active microbial community (Wouters et al., 2013; Wouters et al., 2016). The smectite content of poorly indurated clay is more than 20 wt% (see Supplementary Material Section 3.1). The dominant process for closure of cracks is self-healing by swelling clay minerals (Bernier et al., 2007). The decrease in hydraulic conductivity by self-healing of cracks will limit the transport of cells and nutrients. This excavation induced microbial activity is therefore envisaged to be only temporarily present.

The concrete segments are usually manufactured with a so-called engineered impermeability; envisaged porosities are between 10% and 15%. This limits the diffusional exchange between the dissolved species in the concrete segments and clay but also dehydration of the clay; the Boom Clay surface - at emplaced concrete segments that had been removed for experimental reasons - felt wet. The flow of water into the disposal facility is so small that ventilation is sufficient to keep the facility dry. The salts that have been deposited at the intrados of the concrete liner especially at joints between concrete segments indicate the preferential flow of clay pore water (Levasseur et al., 2021). The concrete lining acts as a barrier for further transport of water into the facility by which sufficient access of water is present in the operational phase to seal the fractures. The sealing of these cracks takes place by swelling of clay minerals such as smectite. This process can be very fast. No difference in hydraulic conductivity has been found for galleries constructed with an external diameter of 2.5 m (Dizier et al., 2017). The overcut during the construction of the gallery was minimized. In the SELFRAC project from the FP5 programme, the hydraulic conductivity in clay surrounding a gallery with an external diameter of 4.6 m was studied. This gallery was constructed with a larger overcut. After a few months, the hydraulic conductivity at 1.5 m from the interface with concrete was measured to be 3 times larger than the virgin hydraulic conductivity (Bernier et al., 2007) and two times this hydraulic conductivity after 8 years (NIROND, 2013). The virgin vertical hydraulic conductivity is about 1.7 × 10−12 m/s for Boom Clay, i.e., a poorly indurated clay (NIROND, 2013; Levasseur et al., 2021).

Atmospheric carbonation of the concrete segments from the intrados towards the extrados is expected but the small porosity and the engineered water tightness of the concrete segments prevents carbonation. Carbonation of well-engineered buildings at the surface exposed to the atmosphere for more than 100 years have measured carbonation depths smaller than 1 cm (Mallinson and Davies, 1987). This carbonation depth is very small. Above all, carbonation may not necessarily be a problem for the performance of unreinforced concrete. Spallation of concrete from reinforced concrete can occur especially if sufficient ingress of oxygen takes place for aerobic corrosion of the rebars.

The thermal impact on the damaged zone in poorly indurated (and indurated clays) has been investigated in the 6th framework programme TiMoDaz. There will be an increase in temperature in the host rock due to the conduction of the emitted heat by HLW for the HLW disposal cells. This 6th framework programme provided the evidence that the thermal-induced plasticity, swelling and creep of clay are likely beneficial for the sealing of fractures and recovery of the permeability of the EDZ to the original state of the clay host rock (Li et al., 2010).

Road headers and tunnel boring machines are used to construct the excavation rooms in indurated clay. The lining does not need to be applied immediately. The virgin vertical hydraulic conductivity for indurated clay can be more than 10 times smaller than in poorly indurated clays, for example, 1 × 10−13 m/s for Callovo-Oxfordian clay and 10–14 m/s for Opalinus Clay (Levasseur et al., 2021). The excavation has a higher impact on the transport properties of indurated clay surrounding the lining than for poorly indurated clay. The fractures generated in clay host rocks are believed to have an atmospheric pressure immediately after excavation. The driving forces to close these cracks are compressive load or confining pressure and access to water. The smectite content of indurated clays can be less than 2 wt% (see Supplementary Material Section 3.1). The dominant process for closure of fractures is cementation, i.e., precipitation of minerals (self-sealing). This precipitated phase has a smaller tensile strength than the surrounding restored clay host rock. The closure of cracks can be measured as the increase in pore water pressure; equilibrium is achieved when the formation pressure is achieved (Alcolea et al., 2014). The EDZ is characterised in clay host rocks as a zone with a larger porosity and permeability than the virgin host rock. The values for hydraulic conductivity or permeability are largest near the interface between concrete and clay. These values asymptotically decrease as a function of the radial distance till the values measured for the virgin host rock after about 6 m from this interface.

The necessary ventilation in the operational phase may have an impact on the clay host rock at the start of the post-closure phase. The lining of a facility built in indurated clay decreases further drying by ventilation; the associated formation of drying shrinkage cracks of this clay host rock is limited but the porosity of the shotcrete is larger than that of clay, so further drying cannot be prevented. The formation pressure is therefore expected to be achieved in the post-closure phase and not in the operational phase. After recovery of the formation pressure, the modelled variation in hydraulic conductivity has decreased by less than 2 orders in magnitude (Alcolea et al., 2014).

After the concrete of the lining has hardened (in the case of a lining made with in-situ curing), the clay may be too dry for dissolved species in the clay pore water to enter the lining in the operational phase. Any chemical alteration of the lining before emplacement of the waste is expected to be mainly caused by ingress of carbon dioxide from the ventilation air.

The long-term safety of the geological disposal of radioactive wastes is based on a multi-barrier concept combining man-made engineered barriers (such as waste form, waste canister, backfill and sealing materials) with a suitable geological barrier (i.e., the host rock). The prediction of the evolution of the waste matrices, the waste canisters and overpacks, the engineered barriers (e.g., bentonite or cementitious backfill) with time in response to physical and chemical perturbations is an important aspect with respect to the performance and long-term safety of a repository. The introduction of “foreign materials” such as borosilicate glasses, metallic canisters, and cementitious materials will induce chemical gradients across the repository components, which can induce perturbations such as pH and redox changes, or changes in mineralogy and microstructure that may alter the performance of the barriers over time (e.g., NAGRA, 2002). Dissolution and precipitation processes occurring in this context can be associated with modification of porosity and pore architecture, thus affecting permeability and diffusivity of porous media and consequently transport of solutes or transfer of gases. Predicting the interactions between the different materials entails understanding and evaluating the pertinent coupled thermal, hydraulic, mechanical, and (radio and/or bio)geochemical processes. A number of studies on deep geological disposal of nuclear wastes showed that chemical and physical interactions are focused on interfaces between the different barrier materials, due to the prevailing chemical gradients (e.g., Claret et al., 2018; Bildstein et al., 2019). In this context, the nature and the extent of the alteration within the different materials, the progress of the perturbations with time and the evolution of the material properties are essential to evaluate the impact on the overall performance of the disposal system.

A valid starting point is using the knowledge available at the scale of interfaces between two materials in order to build models for assessing the chemical evolution at the disposal cell scale. This section describes the state-of-the-art on the phenomenological chemical processes occurring at the interface between two materials for the combinations relevant for European repository concepts (cf. section 2.1; see also Neeft et al. (2020)). For each interface, a short description of the phenomenology is given together with references to studies that give evidence for these processes. A comprehensive and structured overview of existing information and data on relevant processes occurring at the interfaces, including natural/archaeological analogues that may provide insight/data for long-term processes relevant to the chemical evolution of the disposal cells, as well as on conceptual and numerical models used to describe the processes at the interfaces has been compiled in Deissmann et al. (2021).

This interface is related in particular to the disposal of vitrified HLW and has been investigated in the context of the disposal concepts of countries where spent nuclear fuels have been or are reprocessed or form part of the waste inventory, as, e.g., in France, Belgium, Russia, Japan, Germany, the Netherlands, the UK or the United States of America (Gin et al., 2013). The glasses developed for this purpose (i.e., in particular borosilicate glasses) are contained in stainless steel canisters, which are placed usually in carbon steel overpacks prior to disposal (cf. section 2.1.1). However, it should be noted that in recent years some preliminary studies conducted, e.g., within the frame of the European collaborative project THERAMIN, investigated also vitrification of ILW (e.g., Clarke et al., 2020; Scourfield et al., 2020), where the treated product may also be packed in steel containers.

The main physico-chemical interactions at the glass-steel interface will start once the overpack and the canister are breached due to corrosion and/or lithostatic pressure and water can enter the canister. Thus, besides metallic iron/steel, corrosion products from the metal containers will also be present as surrounding materials close to the glass-steel interface. Corrosion products formed during anaerobic corrosion of low-alloy steel disposal containers are mainly composed of iron oxides such as magnetite (Fe3O4), or iron carbonates such as siderite (FeCO3) or chukanovite (Fe2(OH)2CO3) (e.g., Honda et al., 1991; Taniguchi et al., 2004). Localised variations in pH and in concentrations of carbonates may favour the formation of the one or other corrosion products (Michelin et al., 2015). In some cases, FeIII oxy-hydroxides were detected; they may have formed during the initial period of the corrosion test with remaining traces of oxygen (e.g., Kursten and Van Iseghem, 1999; Leon et al., 2017).

The glass-steel interface is only relevant at the later stages of the repository (i.e., after canister failure). A distinction needs to be made with respect to corrosion products formed in a first phase, in which the steel container or overpack corrodes in the groundwater until its failure, where the corrosion products formed are characteristic of corrosion in the host rock medium and some residual metallic iron remains in the system. In a subsequent phase, the disposal container continues to corrode in parallel to the alteration of the glass, i.e., the nature of the corrosion products forming may then be influenced by the solution chemistry at the glass/iron interface, including elements released by the glass.

The alteration and dissolution of nuclear waste glass in contact with water is controlled by several inter-related processes at the glass surface. Independent of the glass composition and the alteration conditions, the most important processes comprise (e.g., Ferrand et al., 2006; Gin et al., 2013; Marcial et al., 2024):

• Water diffusion into the glass,

• Ion exchange between hydrogenated species and alkalis (interdiffusion),

• Hydrolysis of covalent and iono-covalent bonds in the glass matrix,

• Formation and evolution of a surface alteration layer (gel layer),

• Silica saturation of the solution,

• Precipitation of secondary phases,

• Retention of radionuclides in the gel layer and secondary phases,

• Removal of silicon from the solution by sorption, chemical reaction or transport.

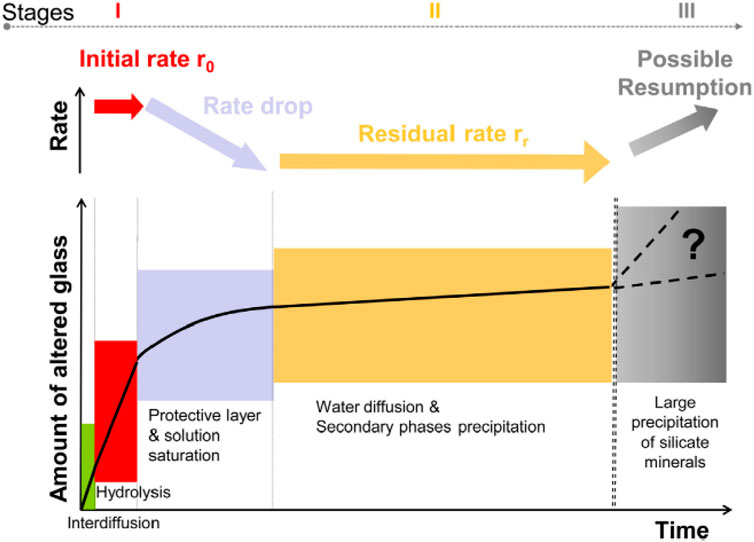

Based on extensive studies on the dissolution of nuclear waste glasses and in particular simulated HLW borosilicate glasses, a general picture on the typical dissolution behaviour of HLW borosilicate glasses under conditions representative for geological disposal environments has been established (Figure 6, cf. van Iseghem et al. (2006); Gin et al. (2013); Gin (2014)).

Figure 6. Stages of nuclear glass corrosion and related potential rate-limiting mechanisms (Gin et al., 2013).

Understanding the glass/steel interactions and their consequences on the long-term behaviour of nuclear waste glasses requires knowledge regarding the main processes controlling the aqueous alteration of glass. According to Vienna et al. (2013) and Gin et al. (2015), glass alteration leads to the formation and dissolution of an alteration film layer, which is likely to incorporate chemical elements from the solution and acts as a diffusion barrier for reactive species. The effectivity of this barrier depends primarily on the concentration of silicon in solution in the vicinity of the glass, with glass dissolution rates increasing when the activity of Si decreases. Other parameters affecting the glass alteration and its rate are (local) solution pH and solution composition, since some elements may stabilise (e.g., calcium (Paul, 1977; Gin et al., 2012) or destabilise (e.g., magnesium (Aréna et al., 2016)) the hydrated glass layer. Glass alteration rates are lowest at circumneutral pH and increase both under acidic and alkaline conditions.

Generally, the presence of iron and iron corrosion products (from steel canisters and/or overpacks) has been found to increase glass alteration by maintaining high alteration rates over longer periods than in the same leaching solution without iron or corrosion products (Martin, 2021). However, this impact is only perceptible at local scale, and seems to be significantly attenuated as the distance between glass and the iron source increases. There are four possible mechanisms that are discussed in literature to explain the increase in glass alteration rates due to the presence of iron or iron corrosion products (Rebiscoul et al., 2015):

• silicon sorption at surface sites of corrosion products, or silica precipitation at the iron source;

• formation of iron silicates;

• retention of iron in the gel layer, which could modify its structure and its protective properties;

• increase in pH due to iron corrosion.

The first two mechanisms both lead to the consumption of cross-linking elements, in particular silicon, leading to either (i) a depletion of the concentration of silicon in solution, which increases glass dissolution rates, or (ii) the formation of a gel depleted in silicon which is, therefore, less protective (Lemmens, 2001). These effects both hinder the formation of a protective layer, delaying saturation of the aqueous solution needed for its formation. In the first case, the effect works by making the initial rate phase (r0) last longer, and, in the second case, by slowing down the rate drop (cf. Figure 6).

The sorption of species like silicon produced by glass alteration on steel corrosion products close to the glass/steel interface can delay the beginning of the rate drop. This effect has been demonstrated in the presence of steel corrosion products such as magnetite (Bart et al., 1987; Grambow, 1987; Grambow et al., 1987), goethite (Bart et al., 1987; Grambow, 1987; Grambow et al., 1987), and siderite (Michelin et al., 2013a). Since the number of surface sites on the corrosion products available for sorption is finite, the effect of silicon sorption on glass alteration lasts for a period that is proportional to the sorption capacity of the corrosion products. The higher the sorption capacity of the corrosion products, which is dependent on their amounts and their specific surface areas, the longer it takes to reach silicon saturation in solution, which in consequence delays the rate drop. However, the results from different glass alteration experiments carried out in the presence of corrosion products seems to indicate that the sorption of silicon to corrosion products does not prevent a slowing of the alteration rate over time. Studies on silicon sorption on steel corrosion products (magnetite, siderite, goethite) indicate (i) that the maximum sorption occurs at pH values between 6 and 9 and decreases, both under more acidic and alkaline conditions, and (ii) that silicon sorption by steel corrosion products will be maintained for a relative short period of time compared to the time scales relevant for geological disposal (Philippini et al., 2006; Philippini et al., 2007).

Sorption of silicon on corrosion products alone seems not to be sufficient to explain the quantities of altered glass in experimental tests since even after saturation of the sorption sites, glass alteration rates in the presence of steel and corrosion products remained higher than the residual rate (rr) observed in the absence of steel and corrosion products over longer periods. Thus, other mechanisms such as the formation of silicates may prolong the consumption of silicon in the longer-term. Most studies performed in this context suggest the formation of various ferrosilicates (e.g., McVay and Buckwalter, 1983; Shade et al., 1983; Björner et al., 1987; Grambow, 1987; Grambow et al., 1987; Werme et al., 1990; Shanggeng et al., 1995; Kim et al., 1997; Michelin et al., 2013a; Godon et al., 2013; Dillmann et al., 2016), sometimes in nano-colloidal form. The precipitates formed may incorporate other elements in addition to iron, such as magnesium, aluminium, sodium and calcium, depending on solution chemistry (e.g., Burger et al., 2013). The silicates formed in this context may include trioctahedral serpentines (e.g., greenalite, berthierine, cronstedite), trioctahedral smectites (e.g., hectorite, saponite) or dioctahedral smectites (e.g., nontronite). The (Fe + Mg)/Si ratio of the silicates formed can vary, especially depending on the distance from the iron source. Moreover, the nature of the precipitated silicates highly depends (i) on temperature (e.g., favouring the formation of serpentines at higher temperature), and (ii) on local pH, since iron/magnesium silicates can only be precipitated above a certain pH, which is a function of the silicon activity imposed by glass alteration.