94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mar. Sci. , 30 September 2024

Sec. Ocean Solutions

Volume 11 - 2024 | https://doi.org/10.3389/fmars.2024.1455522

Ports are of great significance in processing cargo containers and facilitating global marine logistics. Nevertheless, the susceptibility of the container shipping network for hazardous cargo is likely to intensify in the event of a significant disruption at a major port, such as adverse weather conditions, inadequate management practices, or unforeseen catastrophes. Such situations require the deployment of port protection emergency response and prevention in advance. This study proposes a digital twin (DT) model that employs extensive and trajectory data within containers to comprehensively analyze the occurrence of hazardous cargo failures within the port storage process. The virtual models of physical entities in the port are created through a data-driven approach, and the behavior of these entities in a port environment with big data is then simulated. A combination of a convolutional neural network (CNN) and a long short-term memory (LSTM) algorithm is employed to provide predictions for the service layer of the DT system. The predicted correlation coefficients of temperature and humidity in the container reach 0.9855 and 0.9181, respectively. The developed system driven by DT models integrated with a CNN and the LSTM algorithm can more effectively assist the safety manager in achieving prevention in port operations. This study enables marine authorities and decision-makers to optimize emergency procedures, thereby reducing the probability of accidents in port operations and logistics.

The global containership fleet is set to exceed the 30 million twenty-feet equivalent unit (TEU) mark for the first time in history in 2024, as the ships larger than 15,000 TEU are dominating deliveries in ports. The ports of China have officially solidified their position as premiere builders of containerships, accounting for approximately 55% of capacity delivered in 2023. The increase of shipping container throughput continues to break through an innovative pattern, which puts forward new requirements for port operation capacity and safety management efficiency. Moreover, the intelligent unmanned operation mode, gradually implemented in large ports, has emerged as the mainstream mode of new-type port operation and management (Alimam et al., 2023). Under the port operation mode, monitoring and control of status of dangerous cargoes in the process of shipping container operation and storage have become an important direction of smart port safety management. There are still many deficiencies in traditional monitoring, early warning, and disposal methods of the marine container storage process, which are highlighted by poor real-time monitoring system, failure to integrate multi-source data, imperfect digital early warning system, and failure to match the prediction results to the requirements of rapid emergency response (Lim et al., 2019). Meanwhile, the use of digital technology to assist accurate safety management in the current development of smart ports remains to be improved (Yang et al., 2023). With the rapid development in the Yangtze River basin and delta region of China, the trend of industrial agglomeration with petrochemical parks as the carrier appears obvious and the demand for chemical materials in Shanghai have increased by more than 10% in recent years. Nearly 90% of dangerous chemical cargoes are loaded, unloaded, stored, and circulated through the Shanghai Port by marine transportation. The import and export of dangerous cargoes at the Shanghai Port account for approximately 50% of the country’s total. More than 6,600 business units of various types have declared the import of dangerous cargoes at the Shanghai Port, and the annual throughput of dangerous cargoes in port storage has reached 42.62 million tons. The safety problems of dangerous cargoes with inflammable and explosive properties are becoming increasingly prominent in the container storage process. Because of the large-cluster, large-scale, and large-circulation characteristics of the marine industry, an accidental explosion of dangerous cargoes in containers may lead to massive casualties and major property losses (Chang and Zhang, 2023). In recent years, fire and explosion accidents caused by container operation and logistics in ports have frequently occurred across the globe, such as the 12 August 2015 Tianjin Port fire and explosion, the 21 March 2019 Xiangshui explosion, the 4 August 2020 Beirut Port explosion (Boeck and Mahan, 2022), and the 2022 Jeddah Port fire and explosion. The abovementioned accidents occur in the operation and storage process of dangerous cargoes, which gives a warning to the safety management of containers in developing port. Moreover, the emergency response to accidents caused by dangerous cargoes is difficult, and the emergency response force may result in further damage. In this context, it is imperative to formulate targeted accident emergency countermeasures based on intelligent methods.

As an emerging technology, digital twin (DT) technology helps to promote high integration of digital technology and real economy (Grieves and Vickers, 2017). In the Industry 5.0 era, most studies on marine logistics management came from China and the United States, where marine logistics was developing towards informatization (Zhou et al., 2024). DT-driven management is devoted to enhancing the operational efficiency, safety, and sustainability of the marine transportation sector through integration of data intelligence and Internet of Things (IoT). The safety performance of DT in the marine transportation system based on IoTs was explored, providing an extraordinary basis for intelligent and secure marine transportation towards intelligence (Liu J. et al., 2023). The innovation of DT technology was used to promote the change of elements, organization, innovation system, and business mode of the shipping industry and the marine logistics industry chain. Kinaci et al. have established a ship DT concept in terms of navigation autonomy (Liu et al., 2024), representing the physical ship by a mathematical model in one computer and control algorithms on the other. Meanwhile, automatic data integration between these two computers ensured the DT (Kinaci, 2023). A DT-driven fault diagnosis approach was developed based on a graphical model and an extended Kalman filter algorithm, which successfully provided evidence of the reliability in detecting actuator faults for autonomous surface vehicles (Bhagavathi et al., 2023). In the marine sector, the DT failed to offer a wide selection of standards to support interoperability of systems, undermining the ship managers’ ability to create a cohesive DT that combines multiple data sources (Aragao et al., 2023). The challenges anticipated in scaling the DT framework toward marine industrial applications were discussed in terms of standards’ capabilities, compatibility, and data governance (Wang et al., 2022; Yang and Lin, 2023). The DT framework for autonomous marine surface ships had four layers, and the system platform for DT application was equipped with trolling electric motor, camera, LiDAR (Chen et al., 2023), inertial navigation system, and GPS, providing a proof of DT-based concept (Raza et al., 2022). To improve the performance of DT’s prediction, future work could focus on developing a more robust parameter model by employing interpretable machine learning methods (Hasan et al., 2023). DT can be regarded as an analog technology integrating multiple physical quantities and scales. A DT was proposed for fuel consumption and carbon footprint, aimed to predict the hybrid propulsion system of ocean-going patrol ships under the aggregate effect of operational and environmental uncertainty. This work developed a method for the evaluation of alternative design options for ships with a similar operating profile (Vasilikis et al., 2023). DT-driven safety management creates virtual models of physical entities in the port in a digital way and simulates the behavior of physical entities in the real environment with big data. DT for the decision support system of real-port application has two modules (recovery and resilience), and this approach enabled the inclusion of operational uncertainties within smart port resilience evaluation (Zhou et al., 2021). The DT-driven decision support approach serves the life cycle of physical entities through virtual and real interactive feedback, data fusion analysis, decision iterative optimization, and other means. A DT model was presented based on data structure and backbone scheduling algorithm for the Busan New Port, and the DT port improved the predictions of ships’ arrival time and carbon emission (Eom et al., 2023). The process of developing a DT-based numerical tool was designed for shipboard cranes, based on co-simulation using the Functional Mock-up Interface standard. This tool was validated by data from a real-time monitoring sensor. It was worth noting that the data acquisition benefited to some extent from the offshore state (Liu Z. et al., 2024). The operation and storage processes of containers in ports have always been crucial in real-time monitoring due to various risk factors.

Although the abovementioned works offered insights into the potential benefits arising from the DT applications to optimize the management strategy in the marine industry under the port mechanical operation and vessel navigation monitoring, some expanded aspects remained unexplored and should be investigated in depth. In particular, the current research only established virtual models and addressed adjusting some parameters of the management policy among risk value or range, and they did not consider to develop an integrated DT platform related to port operations (e.g., hazardous cargo status, container storage status, and marine environment). This study attempts to combine the DT concept with the safety management of the dangerous cargo container storage process in ports, and integrate the system platform for the safety management of port operation and logistics in terms of demand analysis, three-dimensional modeling, data fusion, data-driven models, algorithm iteration, and result prediction. The DT-driven management platform uses information technology to monitor data flow inside dangerous cargo containers, builds a high-precision synchronous model with real scenes, and obtains prediction results through optimization algorithms to assist on-site decision-making. The main contributions of this study are twofold: (1) It proposes a novel implementation of the five-layer DT model that combines a dynamic model with a data-driven model fitted on real-world shipping port operation data. This significantly differentiates from previous works in the domain of numerical models that often used simulation data. Previous scaled experiments did not complete synchronization over time-varying real input. (2) The developed DT-driven platform outperforms state-of-the-art approaches in predicting the accuracy of marine container behavior and yields significantly improved predictions for the hazardous cargoes in the port. This study effectively combines the virtual and real interactive feedback and decision iteration functions of DT to gradually transform the approach of traditional ports from having an emergency response after accidents to planning ahead and implementing prevention measures, and reduces the likelihood of accidents during port operation and logistics from source. With an effort to improve the accuracy of risk assessment in the operation and storage of dangerous cargoes in containers in ports, this study hopes to improve the safety management of smart ports and provide accurate emergency work.

To generate a smart port, port authorities exert significant effort on modernizing infrastructure and optimizing operations with a reliable network. The container ports are constantly faced by forces of change, uncertainty, and stiff competition (Cuong et al., 2021). Thus, managing these operations is a complex task for port management, as they require an estimate for future container throughput to be handled in ports (Sanguri et al., 2022). Overall container throughput data of a port can be arranged into diverse hierarchical dimensions. The container drayage operators play an important role in port drayage operations. The target of container port operators is to efficiently manage operations in the terminal, thereby alleviating traffic problems and preventing yard congestion (Chen et al., 2022). A quantitative analysis is implemented (Wang et al., 2022), where the data are collected through evidence-based practice techniques with the participation of safety management experts. It indicates that the low safety management ability of labor service enterprises causes frequent unsafe incidents. The above theoretical and practical research shows that the risk factors affecting the whole process of port operation mainly involve four aspects: personnel, equipment, environment, and management. The risks include accidents during lifting and transportation, collisions, falls, and risks associated with working at heights. In terms of routing decision, the existing efficiency-oriented approaches tend to neglect the risk objectives associated with the transportation network conditions (Tarhan et al., 2023). In related literatures and accident reports, the decision-making panel determines a group of 20 risk factors involving environment, human, management, and cargo aspects. One major cause of significant losses is accidents from fires, explosions, and the resultant adverse impacts from dangerous cargoes (Tseng and Pilcher, 2023). The main causes of human factors might be complex, such as the lack of risk perception, the lack of occupation safety education training, unsafe working behavior, and personal physical or psychological factors, which can then result in port accidents (Liou and Tseng, 2024). Therefore, the port operation requires project planning. It is essential for the operators to provide education and training for accident prevention, evacuation, disaster relief, and danger reporting for port operating processes (Lin and Lu, 2023). The application of risk management in daily operations of ports is becoming increasingly widespread. Construction of smart ports requires a large amount of capital and manpower support; however, it is subject to deficiencies due to the limited development time and the immature technology of the safety management system (Cui et al., 2023). Tools are directly applicable in ports with forecast weather variables as input and will support operational decision-making based on risks that stakeholders assume. It can also be enhanced by extending the database for both downtime and weather variables or by including new data such as the period of container ship movements (Costas et al., 2023). Since the development of industrial trade has led to large-scale hazardous cargo operations in ports, it is essential to conduct management of port safety and prevent the occurrence of accidents (Ma et al., 2024). To ensure port safety, the related requirements and guidelines regarding operations of hazardous cargo in ports have been issued by the International Maritime Organization (IMO). Meanwhile, the rapid development of shipping trade should inspire automated container terminals to become smart and safe ports. The efficiency of smart container ports primarily depends on the synchronization of an automated guided vehicle (AGV) (Chen et al., 2024) and an automated crane (Chen et al., 2020). The interaction process between the AGV and the yard crane in the side-loading block differs from that in the end-loading block, as illustrated by a case in the Yangshan Port in China (Yue et al., 2023). The optimization of the AGV path is a key step for promoting container terminals, which ensures the safety of the AGV path and the necessary conditions for efficient operation of ports (Chen et al., 2024a). In Cai et al.’s (2024a) research, a novel U-shaped layout and double-cycling operation mode have been developed, and they indicate that it is capable of generating a robust pre-scheduling plan with a reduced makespan, along with a higher number of gap time slots between operations and a more uniform distribution of these gap time slots. Moreover, Cai et al. (2024b) propose a novel multi-objective solution algorithm, featured with a dynamic fitness evaluation method that incorporates two operators (crowding distance operator and fuzzy correlation entropy coefficient operator). For the operators of a port, providing suitable port facilities, flexible support decisions, and contingency plans are also critical. A port represents an interchange node between land and maritime transport systems. Gattuso et al. address the problem by using optimization algorithms to support the decision-making approach, such as advanced metaheuristics and DT (Gattuso and Pellicanò, 2023; Almeida and Okon, 2024). It is evident that the safety of containers in port areas cannot be overlooked. This study examines a multitude of potential risk factors that could contribute to accidents in these marine environments, as well as the potential benefits of adopting the new intelligent digital technologies to enhance the management and control of the container operations in port areas.

There are many barriers in port logistics that restrict the effective operation of port logistics (Shen et al., 2022). Subsequently processing and managing the data is a difficult task, yet it is necessary to do so since it has a significant impact on port logistics (Kuakoski et al., 2023; Rajak et al., 2024). In smart ports, safety domain within the logistics sector refers to traditional safety and cybersecurity problems that involve ports (Pu et al., 2023; Liu M. et al., 2024). The domain to act on is identified, including safety, mobility, environment, economy, telecommunications, government, and community. Sustainable development and digitalization are designated as the purposes for smart logistics in ports (Belmoukari et al., 2023; Yang et al., 2023). By analyzing the storage and risk factors of the port container yard for dangerous cargo and evaluating the hidden danger of accidents and their impact scope (Wang and Wang, 2023), it is found that the main risk factors of dangerous goods involve seven aspects: inherent dangerous characteristics of dangerous cargoes, improper storage methods, unqualified packaging, inadequate implementation of port operators’ main responsibilities, weak safety awareness of practitioners, inadequate safety supervision, and inadequate emergency response (Verschuur et al., 2023). The aforementioned results demonstrate that the risk factors associated with the shipping container storage process are inextricably linked to the safety awareness and behavior of personnel, the safe operation of equipment, the enhancement of management systems, and the stability of the surrounding environment. The underlying cause of this maladministration appears to be a dearth of regulatory oversight from the government, as there is a lack of legislation that provides guidance on best practices or minimum requirements to be met. The government is reticent about sharing information, which presents a transparency barrier that hinders the development of a unified information system for all entities to expedite nationalization processes and negatively impacts transparency country indicators (Numa-Navarro et al., 2023). Sarantakos et al. (2024) propose a model that ensures feasible port logistics operation for all uncertainty realizations defined by robust optimization, while minimizing operational costs. The findings of their study indicate that the likelihood of a network constraint violation may reach as high as 70% in the context of an electrified port, in the absence of consideration for uncertainty in port logistics. This poses a significant risk of disruption to port activities, which is unacceptable. A three-stage digital maturity model has been developed, which effectively measures digital readiness in port logistics (Hamidi et al., 2024). The technology, leadership, and operations dimensions are in the best state, respectively. The results indicate the need for an office and process automation in the logistics supply chain of port. The field of port logistics has enabled a reduction in transportation costs, which, in turn, has facilitated the growth of the shipping industry through the utilization of logistics networks and platforms. The implementation of blockchain platforms in port logistics domains (such as port logistics and mobility) has led to the development of more efficient systems based on digital automation (Pesquera, 2024). In the conventional port, video surveillance is employed to ensure the security of the container storage area. This entails the deployment of multiple monitoring probes within the port premises, with the safety of container stacking operations being overseen through manual observation and monitoring (Park et al., 2023). The monitoring method in question is limited in its capabilities, as it can only query the basic information, quantity, and location of dangerous cargo containers. Furthermore, it relies on an administrator to monitor the process, which not only is single and inefficient, but also lacks the capacity for real-time monitoring (Ding et al., 2023). The monitoring method in question is limited in its capabilities, for it can only query the basic information, quantity, and location of dangerous cargo containers. Concurrently, incidents resulting from administrator negligence underscore the constraints of these approaches. Furthermore, the storage requirements of all-weather surveillance video can be considerable, leading to data accumulation and increased difficulty in performing queries (Chen et al., 2024b). In the context of logistics management and intelligent construction in ports, the introduction of the IoT is a key aspect of Industry 4.0, as discussed by Zhang Z. et al. (2024). The utilization of IoT data for real-time interactive chains, particularly in the domains of logistics, safety, technology, and the economy, is a significant and invaluable application. Presently, port surveillance video is primarily utilized for post-accident investigation, lacking the capacity to facilitate functions such as prevention and auxiliary decision-making in advance. In light of such deficiencies, the deployment of cutting-edge digital technologies to bolster the management of shipping containers has been repeatedly advocated.

The development of global ports is predicated on the integration of information technology, automation, and artificial intelligence, which collectively facilitate the transformation of port operations into a more intelligent and efficient system. The Port of Rotterdam in the Netherlands (Nadi et al., 2021), the Port of Hamburg in Germany (Molavi et al., 2020), and the modern ports represented by the United Kingdom, the United States, and Japan (Wang et al., 2021) are gradually promoting intelligent monitoring systems. Researchers from various countries actively explore new methods to assist in monitoring the status of containers. Merino et al. (2022) conducted a project involving an ongoing trial applied to monitor the condition of quay cranes using IoT sensors communicating via 5G technology and employ artificial intelligence to identify pre-incident trigger conditions in the port. Without a time tamp reference, data lose its meaning because they cannot be matched with the real operation of monitored asset in ports. An algorithm framework for real-time tracking and berthing aid system using three-dimensional LiDAR data was established in Chen C. et al.’s (2023) study. An on-site monitoring experiment of the “Yukun” training ship in Dalian Port was conducted, and the results demonstrated the feasibility and effectiveness of the method in the application of ship dynamic target tracking and safe ship berthing. Nadales et al. (2023) presented a proposed monitoring strategy for the observation of vessel movement in the Guadalquivir River. The monitoring system employs a real-time trajectory comparison with the actual trajectory provided by the AIS system. This comparison considers a range of parameters, including position, arrival delay, and vessel speed, to identify potential incidents (Trujillo-González et al., 2022; Liu Z. et al., 2023; Bi et al., 2024). There is an increasingly internal requirement to pursue large-scale power projects that incorporate physical systems in order to investigate the potential of wide-area monitoring, protection, and control strategies. It is necessary to transfer physical power systems from the offline software environment to a real-time port environment. Thanks to AIS data, a real-time monitoring system for port container operations is established (Chen W. et al., 2023), which can effectively monitor and evaluate port status and support decision-making efforts of all parties on the shipping supply chain (port, ship enterprise, cargo owner, shipping agent, etc.). A case study was conducted for the ultralarge Yangshan Deepwater Automated Container Terminal Phase IV in Shanghai, China. The experimental results demonstrated that the proposed DT-based monitoring tool can assist port operators in evaluating vessel service through optimized resource allocation plans and operations (Wang et al., 2022). A case study of the Shenzhen port was then presented, with the objective of conducting a regional collision risk analysis and developing a safety management plan for ports. The findings demonstrated that a real-time monitoring and risk assessment system, which integrates data on accidents and traffic patterns, can effectively identify high-risk areas and facilitate improvements in the safety of vessel traffic in these locations (Li et al., 2023). As Hydro-Québec is engaged in the development of simulation tools, the potential for software-related issues and challenges is inherent to the process. The specifics of the activities required for wide-area control explorations at a large-scale port were outlined in this document (Le-Huy et al., 2023) to further strengthen the link between big data of environmental contributors and human factors, as well as to establish a more integrated model for ports. Commercial sensor networks can be found in Muuga Port, Townsville Port, Freemantle Port, Hedland Port, Bilbao Port, Balearian Port, and Tianjin Port (López et al., 2024). The digitalization system for port management integrates traditional operational processes with data, algorithms, and computing, thereby enhancing the comprehensive capacity for innovation in port management. Moreover, the digitalization system enables the investigation of novel models and the restructuring of the ecosystem (Xu et al., 2024). Shanghai Port is intensifying its endeavors to facilitate an intelligent transformation, having successfully completed the construction of an ultra-long-distance intelligent command and control center (Zhang D. et al., 2024). Real-time monitoring networks of non-conventional container storage require high-end instrumentation, typically designed for short-term monitoring, and able to provide high-quality real-time data at high temporal resolution (Zhang Z. et al., 2024). Real-time monitors tend to be applied to renewable or alternative cargoes, including lithium batteries and their associated accessories. Consequently, ports engaged in international trade are confronted with intricate complexities and challenges pertaining to compliance.

The literature review above reveals that the risk factors associated with shipping container storage are inextricably linked to the safety awareness and behavior of personnel, the safe operation of equipment, the improvement of management systems, and the stability of the surrounding environment. In traditional ports, video surveillance is used to monitor container storage area, and the safety management of container stacking operations is carried out by manual viewing and monitoring. The storage of certain dangerous cargoes is contingent upon the maintenance of specific temperature and humidity conditions. Failure to do so may result in chemical reactions and the potential for explosion accidents. In the event of elevated temperatures, failure to implement cooling measures in a timely and efficacious manner can result in the expansion and rupture of dangerous cargoes within a tank in a container, ultimately leading to leakage. The conventional monitoring techniques employed at ports are unable to provide real-time observation of the changes occurring within the container and its surrounding environment. The packaging of dangerous cargo may be compromised as a result of impact during the shipping process. The exposed dangerous cargoes may spontaneously ignite during storage in containers, resulting in large-scale fire and explosion accidents. The tragedies caused by the 12 August 2015 explosion at Tianjin Port and the explosion at Beirut Port are still fresh in our memories. The reasons can be attributed to outdated on-site monitoring methods, inadequate safety management, and inaccurate on-site emergency response methods. As port scale and complexity of business operations increase, large ports should strive to become smart ports. This is occurring concurrently with an increasingly advanced demand for port security management. The rapid development of Industry 4.0 technology represented by a cyber physical system (CPS) and DT technology, the continuous improvement of port equipment automation, and the popularity of data sensing methods have catalyzed the application of DT technology to build intelligent port auxiliary emergency response. The DT technology facilitates the fusion of information and physical processes, thereby enabling the implementation of a holographic visual management and control mode. This, in turn, serves to advance the transformation of port operations towards an intelligent operational framework. Table 1 highlights some frameworks and relevant models based on DT technology by various researchers.

Extensive literature reviews above provided various approaches for safety management in port operation, logistics, and monitoring, based on specific tools and models. It identified that DT can be used for demand forecasting and the creation of port virtual models. However, as all the literatures described show, there are few relevant works in the dynamical DT model for shipping containers and their hazardous cargo. Moreover, most of the published works refer to specific high-risk scenarios in ports and aim to evaluate impacts rather than proposing DT platform for a systematic risk analysis. Based on this, the current study is conducted to improve the application of DT-driven safety management and a decision support approach for hazardous cargo container operations and logistics in ports. The operation and storage process of containers in ports has consistently been a primary area of monitoring due to its inherent risk factors. Information technology is employed to monitor the data flow within the body of dangerous cargo containers, construct a high-precision synchronous model based on the actual scene, and obtain predictions through optimization algorithms to facilitate on-site decision-making. The effective combination of virtual and real-time interactive feedback and decision-making functions of DT technology will assist ports in transitioning from a reactive approach to an emergency response following incidents to a proactive strategy of prevention and preparedness. In addition, it serves to diminish the likelihood of mishaps during the handling and storage of hazardous materials in containers at the source, while enhancing the precision of risk assessment for the operation and storage of such materials in ports. To this end, the objective is to provide more scientific means for improving the safety management of smart ports and provide accurate emergency planning.

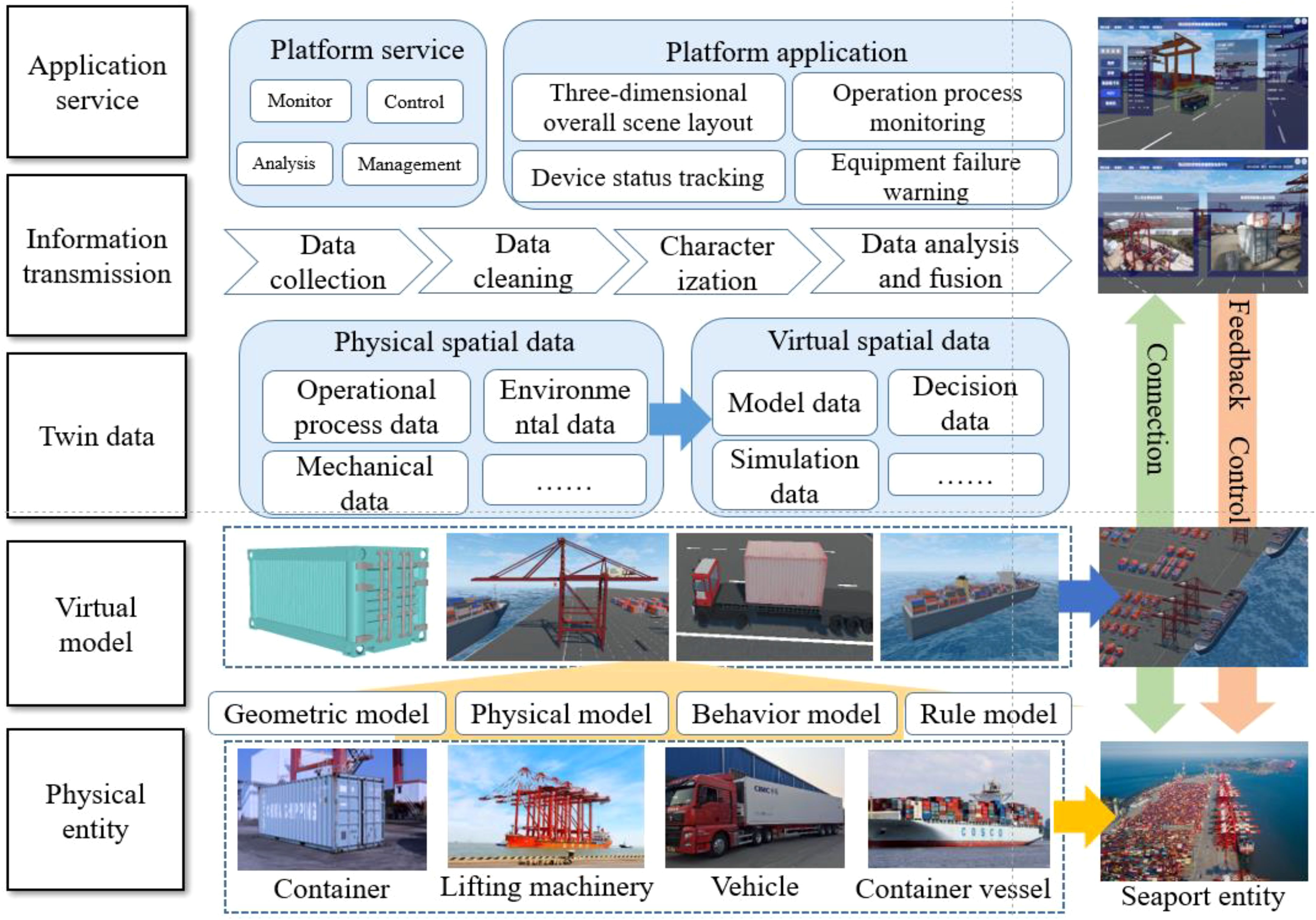

The necessity for specific DT frameworks arises from the need to address the unique needs or challenges of particular scenarios or objects in ports. It thus follows that a comprehensive DT framework for onshore spaces must encompass five critical elements. In order to reflect the complex dynamic process of a variety of integrated technologies, this study proposes a five-layer DT model to divide digital intelligence emergency platform into hierarchical structures: the physical entity, virtual model, twin data, information transmission and application services, and realized data information interaction by connecting each layer for iterative mapping. The novel implementation of the five-layer DT model structure combines a dynamic model with a data-driven model fitted on real-world shipping port data. This significantly differentiates from previous works in the domain of numerical models that often used simulation data. The proposed DT framework for port operations and logistics is illustrated in Figure 1.

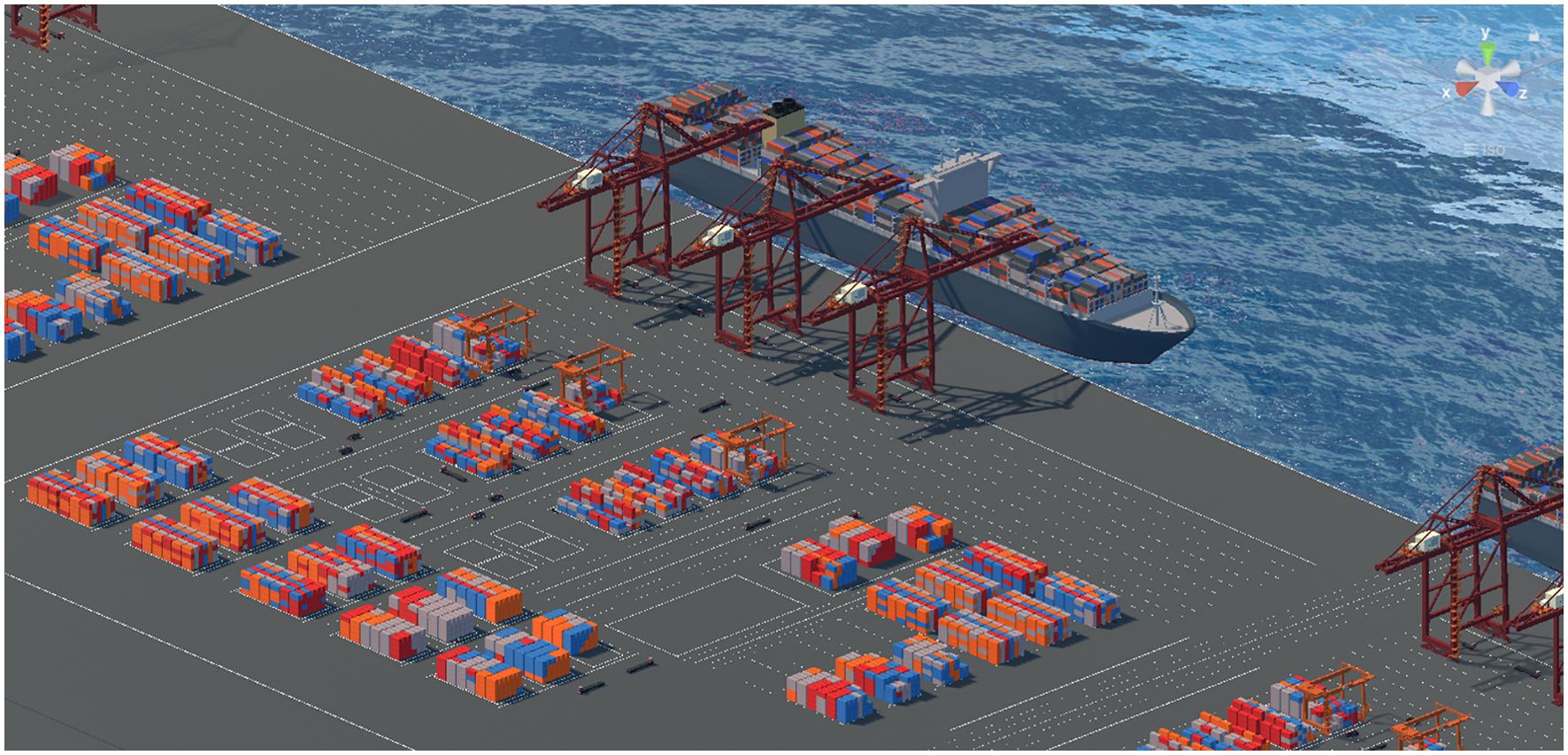

Figure 1. The five-layer model of dangerous cargo container operations and logistics in the port. Source: Models created with Unity, by the authors.

This study has constructed a DT-driven framework system, enabling the creation of a five-layer model structure of DT for container storage safety in ports. Meanwhile, this study presents expressions for the model, as illustrated in Equation 1. The DT-driven frame model is suitable for analyzing safety problems in port container operation. Meanwhile, the framework is easy to improve and promote the application to solve safety problems of other port equipment, such as ship docking operation, yard crane/quay crane operation, and container transport vehicles.

where Cpr is the physical entity model, Cve is the DT virtual model, Ctd is the twin data center, Cin is the information transmission and interaction, and Cse is the application service system.

The physical layer encompasses the entirety of the marine operation, and the tangible physical model serves as the foundation for the DT system. The foundation of DT is the physical model of reality, and the objective is to facilitate the interaction between physical and informational entities. It is essential that the physical model incorporates a temporal and spatial decomposition, allowing for the adaptation of the model according to varying requirements and management granularity. For this purpose, a mathematical statement is shown in Equation 2. In order to ensure the safety of marine ports from a physical operation standpoint, it is essential to consider the varying time periods of the day and different seasons of the year in the temporal dimension. Furthermore, it is crucial to prepare for the importation of the DT model as pre-data. Based on it, the life cycle and the whole process of the call are realized. In the process of operational unit decomposition, the container port places particular emphasis on a number of items that are considered to be high risk, including dangerous cargo containers, container transport ships, lifting machinery, and transport vehicles. The interaction and coupling between each sub-unit collectively constitute a comprehensive, DT-driven physical model of the port operation process.

where Cnm represents the different temporal dimensions and operational units of container ports.

The data layer is founded upon the aggregation of real-time sensor data and historical data, which are then utilized to construct a DT model within the model layer. As the fundamental driving force of the DT system, the virtual twin model represents a basic core component that enables the realization of a multitude of DT functions. Its mathematical expression is shown in Equation 3. Geometric models are used to represent a variety of geometric parameters and relationships in physical reality, including, but not limited to, location, size, shape, model, appearance, and connection. The container serves as an illustrative example, delineating the positioning of each component, the dimensions of each section, and the mode of connection. Furthermore, the CAD drawings of the standard container provide information that describes the geometric model. In DTs, the Autodesk Maya platform is used for geometric modeling to transform 2D relationships into three-dimensional visualizations. Vp is built by combining geometric models and adding various physical properties, boundary conditions, load action, environmental information, and so on in physical reality. The combination of the physical model and the finite element theory can facilitate the generation of a substantial corpus of simulation data for analytical purposes. This includes the thermal response of the dangerous cargo tanks, temperature distribution in containers, and port wind field analysis. The accuracy of the DT model can be improved by comparing the data collected by the simulation and sensor system in real physics, the dynamic response and behavioral change of the behavioral model to real physical processes under the influence of external random factors, and the action of internal operating mechanisms in different time and space contexts. The process of container storage is subject to the influence of the port environment, which may include conditions such as high temperatures, strong winds, and heavy precipitation. These external factors can affect the parameters of a hazardous cargo container, leading to observable changes in its behavior. The rule model is composed of the historical data and industry standards involved in the container operation process in the port and is implemented on the basis of machine learning algorithms. As a result, the DT continues to intelligently analyze, predict, and self-update the rule model over time.

where Vg denotes the parameters and relationships of related geometric models in physical reality; Vp indicates the various physical properties, boundary conditions, and environmental information; Vb is the behavior model; and Vr is the rule model.

The twin data layer is an important driving force of the DT-driven system, and it is also the data concentration, storage, and backup center of the whole system. The twin data layer is tasked with making decisions regarding the data fusion and regression prediction for all datasets, and is responsible for providing data support for application function services, as shown in Equation 4. The data generated by the physical entity is collected by sensors that have been installed in the hazardous cargo container. This study encompasses an examination of the temperature, humidity, wind velocity, and the gas concentration of chemical reaction products. The data are utilized as the fundamental dataset for the DT-driven system, and the requisite sample size is contingent upon specific criteria. The data pertaining to DT are derived from a virtual model that has been constructed based on the results of numerical simulations. While the sample size is adequate for the DT data, it is necessary to confirm the accuracy of the results through comparison with data obtained from physical entities’ data. The experiential knowledge data are based on the historical statistics of marine industry in which the port is located, as well as executive data of industry experts and managers. The fusion of decision data and regression prediction data constitutes the comprehensive derived data, which are formed after the deep learning of basic data using an optimization algorithm. The accuracy of the data is contingent upon the selection of the algorithm and the model training, and the data shared in the system are utilized for the port operations.

where Dg is the data on physical entities in reality, Dp is the data from the DT model, Dk is the empirical knowledge data, Df is the fusion decision data, and Dr is the regression prediction data.

The information transport layer functions to realize the real-time sharing and effective feedback of data and information among subsystems in the DT system. The efficacy of the information transmission layer is contingent upon the configuration of the perception system, network system, and protocol system arranged in the port. The sensing system consists of the radio frequency identification (RFID) on the container surface, the sensor inside the container, and the positioning system. The network system comprises a wireless local area network (LAN), a 5G communication network, and mobile internet. The communication protocol system is based on application programming interfaces (APIs) and ASCII code standards. The equation of information transfer layer can be shown in Equation 5.

The application services layer encompasses the provision of the cloud-based services offered by DT, including the monitoring of operational status pertaining to vessels and ports, the classification and risk classification of accident types, the issuance of accident risk warnings, and the formulation of accident handling recommendations. The applications and services represent the primary drivers of DT, providing a foundational guidance for the remainder of the DT system. The ultimate value of the DT system is reflected through functional application, which can be classified into two principal aspects: the function-oriented service and the application-oriented service. The function-oriented services tend to fall into three categories: the basic services, model services, and data services. As a highly effective instrument within the DT ecosystem, a single application-oriented service may necessitate the involvement of numerous function-oriented services to ensure its optimal functioning. The application-oriented services are classified into four distinct categories, each designed to cater to the specific needs of different computer users. The categories include the process visualization, key component intelligent identification, structural behavior intelligent prediction, and random influence factor analysis.

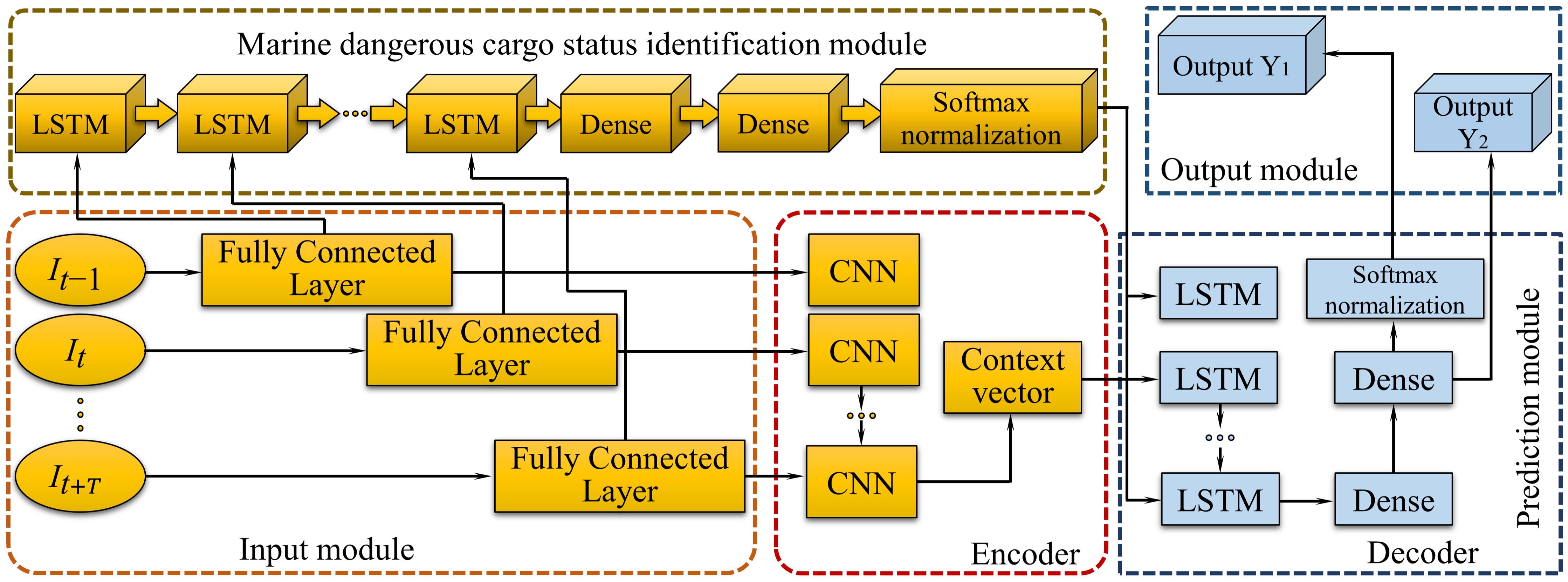

The advent of deep learning has precipitated a revolutionary transformation in the domain of artificial intelligence, culminating in the attainment of cutting-edge performance on an array of tasks, encompassing image classification and natural language processing, among others (Al-Selwi et al., 2024). In the DT-driven system, a fusion algorithm is embedded in the DT management platform of port dangerous cargo containers. This study selects seven models, namely, convolutional neural network (CNN), long short-term memory (LSTM), bidirectional LSTM (BiLSTM), recurrent neural network (RNN), gated recurrent unit (GRU), the combination of CNN and BiLSTM, and the combination of CNN and LSTM. The experimental tests of different models have yielded discernible discrepancies in the temperature predictions of each model for the hazardous cargo container. The evaluation of these models is based on a comprehensive assessment of various statistical metrics, including the mean squared error (MSE), root mean squared error (RMSE), and mean absolute error (MAE). Additionally, the mean absolute percentage error (MAPE) and coefficient of determination (R2) are also considered. The results of the evaluation demonstrate that the predictions of the combination of CNN and LSTM algorithm for the temperature within a hazardous cargo container exhibit an MSE of 19.37%, an RMSE of 4.4%, an MAE of 2.58%, and an MAPE of 7.3%. These values indicate the lowest values in the comparison results for the selected models. In addition, the R² demonstrates a value of 0.981, which reveals the highest level of predictive accuracy among the models under consideration. The results demonstrate the superior predictive capability and high precision of the combination of a CNN and the LSTM algorithm in estimating the parameters required for this study. Based on the comparison, the combination of a CNN and the LSTM algorithm is ultimately identified as the embedded deep learning model of the DT-driven system in the current study.

where sct-1 is the state of the tuple received by the Inputgate and Forgetgate at the previous time instant and sct is the current status of the tuple as received by the Outputgate. Upon receipt of the requisite input data, each gate proceeds to perform the necessary computations. The activation function determines whether to initiate the activation process and simultaneously generates the corresponding output; bct is the sct memorized output of cell tuples after combining nonlinear computation with output gate morphology at time t; at is the input of each unit structure; bt is the output of each unit structure; W is the weight matrix; Wi is the weight matrix that connects input signals; Wj is the weight matrix that connects output signals of hidden layer; and Wk is the connection tuple activation function that outputs the vector sct-1, the diagonal matrix sct, and gate functions.

The LSTM has been specifically designed to address the issue of vanishing gradients, which renders vanilla CNN unsuitable for learning long-term dependencies. The output of a traditional CNN node is determined by the weight, bias, and activation function. The input to a CNN is a set of related sequence data that are recursively calculated in the direction of sequence progression and all neurons are linked by a chain. The LSTM is a temporal recurrent neural network that has an ability to remember information over a certain length of time. Concurrently, the incorporation of the prediction performance into the design of a DT-driven system for port operation has become a pivotal aspect that is taken into account. The combination of a CNN and the LSTM algorithm, with its sensitivity to marine environmental response characteristics and the ability to generalize hazardous cargo properties, represents a promising tool for risk assessment. The main reason why the LSTM neural network can solve the long-term dependence problem is that the Gate mechanism is added on the basis of the CNN, which controls the flow and loss of parameters. Each memory unit consists of a tuple (Cell) and three gates, ensuring that the gradient can go through many time steps without disappearing. For each time t, the state accepted by the memory unit consists of xit at the current time and bht-1 at the hidden unit at the previous time. The expressions of the tuple of three gate control units are shown in Equations 6-9.

In this study, the Softmax function is selected for normalization processing; therefore, the output value Yn of the LSTM neural network is statistically significant, and its probability value expression can be presented by Equation 10. Determining the number of Softmax classifiers depends on the specific application scenario and the characteristics of the dataset. In the neural network classifiers, the Softmax function is used as an activation function for the output layer. The number of classifiers depends on the number of output categories required for the task. In the classification task of parameters affecting hazardous cargo container operations in the port, it is necessary to recognize the multiple different object categories. Consequently, the number of output nodes of the Softmax layer is equal to the number of categories.

where Yi is the input vector, given by (Y0, Y1,…, Yn); n is the number of classes for the multi-class classifier, and the range of values for n is from 0 to 20.

The basic LSTM network model framework is updated, and a prediction model for the dangerous cargo container built by the combination of a CNN and the LSTM unit is proposed in the current study. The framework includes five modules, namely, the input module, the dangerous cargo status identification module, the encoder, the decoder, and the output module, as shown in Figure 2.

Figure 2. Framework of the hazardous cargo status prediction model based on the CNN and LSTM neural network.

Safety management is important for the operation of shipping containers carrying dangerous cargoes. The primary factors influencing the safety of operations at ports include the personnel, equipment (goods), environment, and management. To guarantee operational safety, it is imperative to implement real-time monitoring and early warning systems for the operational processes in ports. The digital intelligence emergency platform, developed with these objectives in mind, encompasses a comprehensive range of monitoring components, including the equipment status within the port, operational data, personnel supervision, container yard observation, internal container status monitoring, and environmental information surrounding the port.

The implementation of this digital intelligence emergency platform, however, presents a number of challenges, which can be broadly classified into the following aspects:

i. It is necessary to construct a physical entity image model. The operational process of a marine dangerous cargo container encompasses a range of activities, including the loading and unloading of containers, the lifting of mechanical equipment, the horizontal transportation of vehicles, and other related behaviors. It is essential to construct a highly accurate virtual model of the port in a digital three-dimensional space. In order to achieve three-dimensional visualization of the container operation process, it is consistent with the real port in terms of equipment operating status data.

ii. A compilation of distinctive parameters is assembled within the shipping container. The status of dangerous cargoes may undergo alteration during the course of their operation and storage. The temperature and humidity sensors are installed in containers to collect relevant parameter data and facilitate a synchronous display on the monitoring platform, which enables administrators to ascertain the status of the hazardous cargo containers at any given moment.

iii. The system is designed to facilitate the integration of disparate systems. The monitoring process of the automatic container loading and unloading in ports is the primary focus. The real-time monitoring of the operating status of port operating equipment and the synchronous characterization of status information inside containers are realized in digital three-dimensional space through scene visualization, data processing, data analysis, and data fusion. Furthermore, a deep learning algorithm is developed to predict the status of containers based on the historical and real-time data, thereby facilitating digital intelligent monitoring and assisting port safety managers in promptly identifying and responding to abnormal conditions.

The DT virtual model is a high-fidelity dynamic model of physical entity in information space, simulating the real port in the physical space to achieve a multi-area, multi-equipment, multi-type of work environment. The system can facilitate a dynamic simulation environment for operational and storage processes within a real port container, thereby enabling the monitoring and management of the container’s internal status and aiding the operator in making emergency decisions. A virtual model of the entire port area scene has been constructed using modeling technology. The model has been developed from four levels: geometry, physics, behavior, and rules. The geometric shape, material texture, and behavior rules of the physical entities such as containers, quay cranes, and yard cranes should be considered in the modeling process. The hazardous cargo container is transported horizontally from the hands of the cargo owner to the site, where it is then lifted by a center dispatching yard crane and conveyed to the storage yard. This action completes the establishment of a three-dimensional model and movement trajectory of the entire lifting process, thereby ensuring consistency with a real port and facilitating the integration of virtual and real elements. In this study, the physical entity model is drawn in Maya and 3dMax, and after exporting fbx files, each model is built in Unity 3D to completely describe the container handling process. The construction of a virtual scene is composed of three primary processes: the creation of a geometric model, the development of the scene, and the mapping of real-time data. The geometric model is the foundation of virtual scene construction, and scene construction is the improvement of the geometric model. The construction of an entire port scene can be completed by establishing a single geometric model of the port, comprising the relevant equipment and facilities. It includes the yard cranes, quay cranes, containers, container trucks, forklifts, storage yards, berths, street lamps, gates, and other facilities. The scene construction includes adding the physical attributes, colliders, scene lights, and actual materials to the geometric model to make the virtual port scene more real. Real-time data mapping is carried out to realize the container operation process of a physical port in a virtual scene by collecting the operation data, equipment information, container status, and other information corresponding to the physical port on the basis of completion of port scene construction. The objective of this study is to collate and present a visual representation of the status data pertaining to dangerous cargo containers.

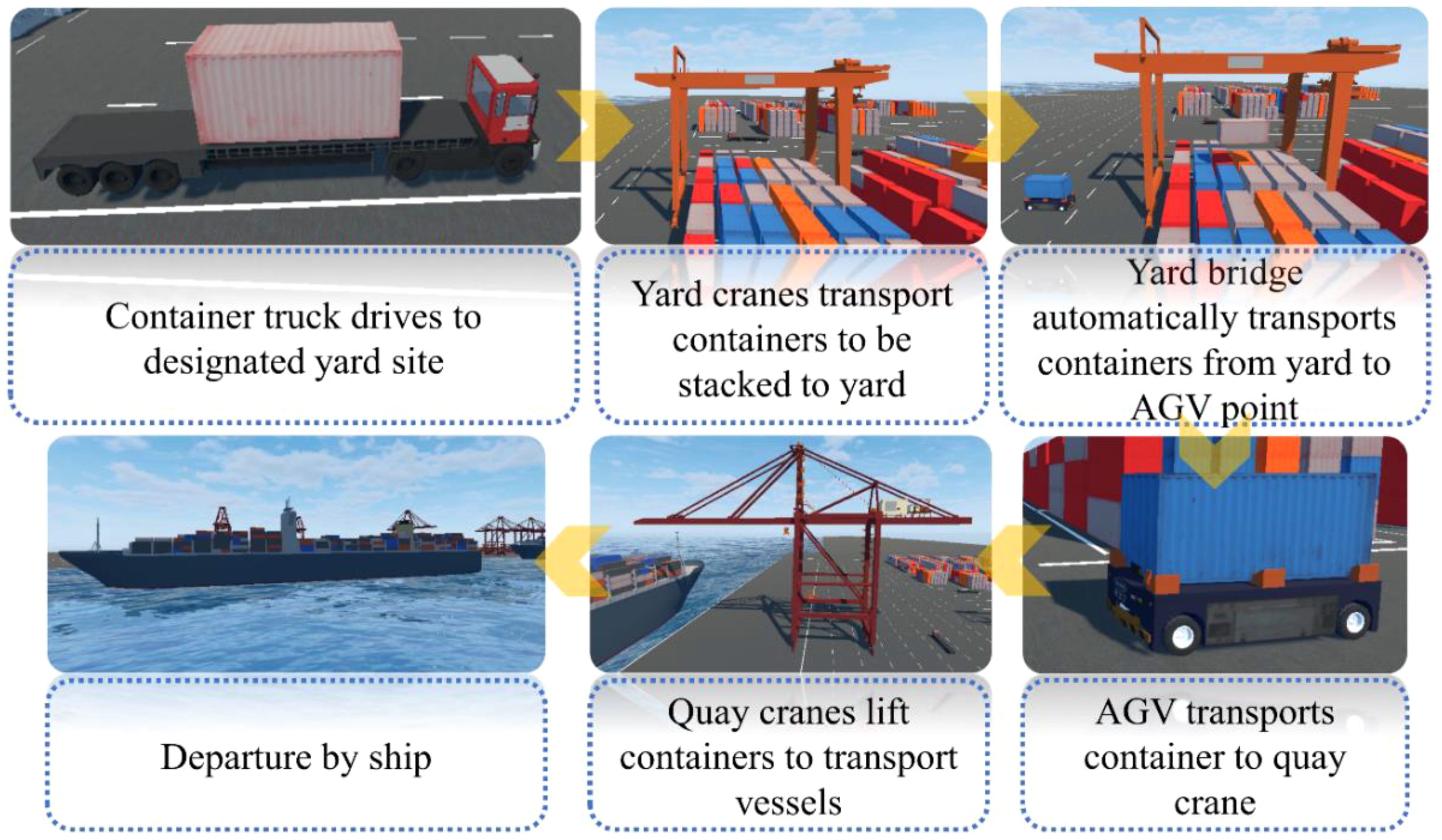

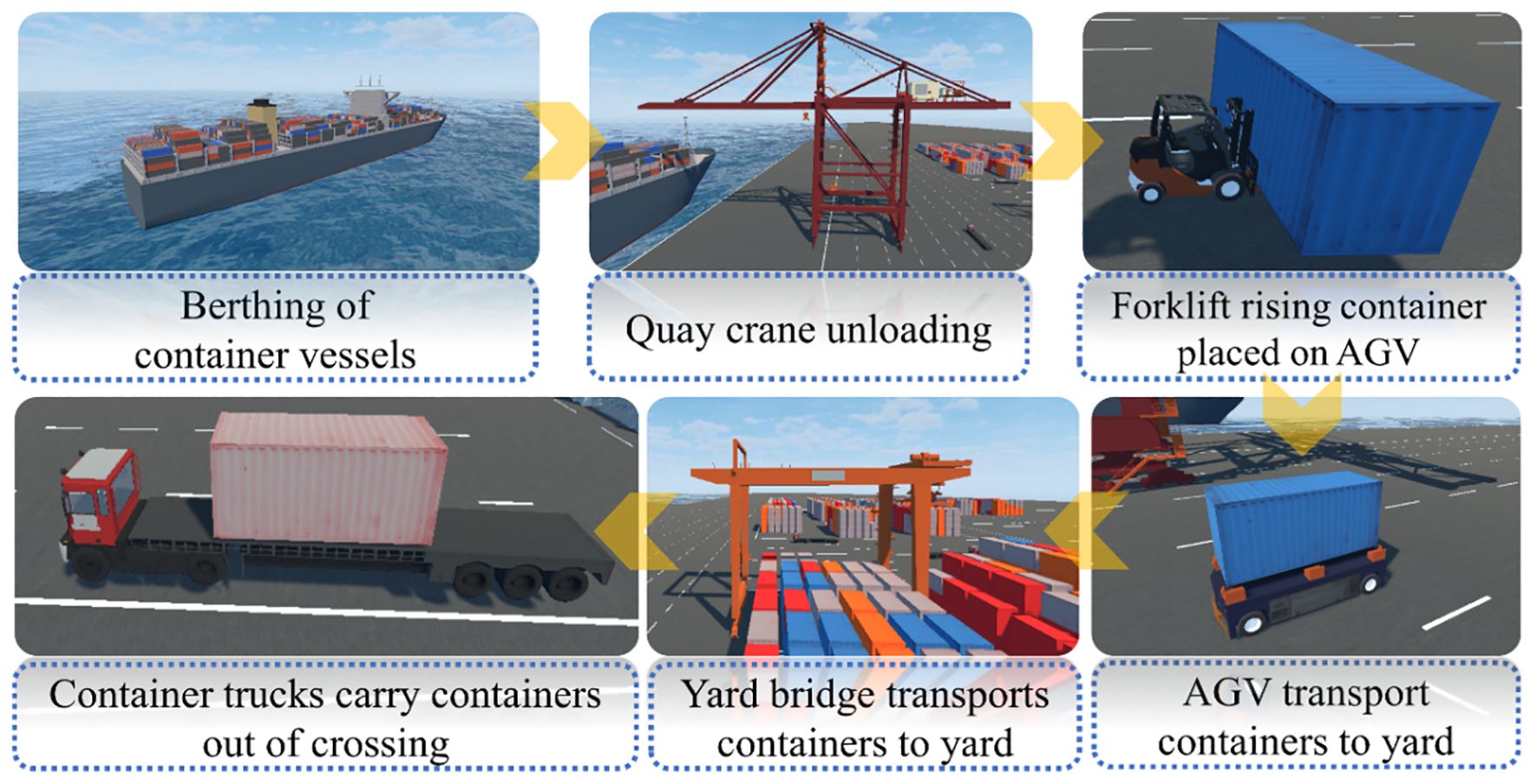

To illustrate the operational and storage procedures for the hazardous cargo containers at the Shanghai Port, a three-dimensional computer-generated model was constructed using Unity 3D. In this study, the operation process of the containers is constructed. Figures 3, 4 illustrate the operational processes involved in the import and export of the shipping dangerous cargo containers, respectively. The operation scenario of the port container includes model resources such as a yard crane, a quay crane, a container truck, a forklift truck, AGVs, a container ship, and a container, which matches the real operation scenario. It aims to complete the export process of containers from the storage yard, truck collection transportation, yard crane transportation, AGV transportation, and, finally, quay crane loading. The import process, on the other hand, entails quay crane unloading, forklift container raising, AGV transportation, yard crane transportation, and truck collection transportation. In essence, the system is designed to comprehensively control the import and export operations of dangerous cargo containers, thereby ensuring the safe movement of such cargo. The objective is to enhance the safety management of the operations pertaining to the transportation of dangerous cargo containers in ports. The operation process of exporting containers from the storage yard in the port is illustrated in Figure 3.

Figure 3. The process and the virtual model of hazardous cargo container exports in the port. Source: Models created with Unity, by the authors.

Figure 4. The process and the virtual model of hazardous cargo container imports in the port. Source: Models created with Unity, by the authors.

The hazardous cargo container import operation process in ports is as follows:

i. Upon arrival at the port, the container ships are equipped with quay cranes that facilitate the lifting and placement of containers at the shore crossing.

ii. A forklift is utilized to elevate a container containing a potentially hazardous material and subsequently deposit it onto an AGV plane.

iii. The control room is responsible for the operation of the AGV transport container, which is connected to the bridge crane via remote control.

iv. Upon arrival at the designated location, the AGV is remotely operated by the dispatch center to lift containers and transport them to the container yard.

v. A container truck driver proceeds to the designated storage yard, loads the container, and subsequently transports it to the crossing in order to complete the import container process.

Figure 5 shows the virtual model of the container operation and logistics process in the port constructed by Unity 3D. In order to achieve the action unity between virtual models and physical entities, the principle of geometric variation plays a pivotal role in the Unity 3D visualization scenes. For ensuring the seamless integration of all models, the scripts are developed and implemented based on geometric transformation technology, which governs matching the motion and scene roaming. This study uses the matrix transformation to realize the free transformation of the model in three-dimensional space, which is the basic tool for manipulating the graph element. The geometric transformation of the model is achieved by modifying the spatial position of pixels and displaying the coordinates of the original points in the new spatial position, including the translations, rotations, and scaling. In Unity 3D, every GameObject has a Transform property that implements object shift, rotation, and scaling. The hierarchy of the transform property can be observed in the Unity 3D Hierarchy panel. The transform is a matrix operation encapsulated in Unity 3D that enables the realization of a range of 3D model operations, including translation, rotation, and scaling, among others. In other words, the matrix operations constitute the fundamental basis for the realization of model actions within a virtual scene. The transform component has three properties: position, rotation, and scale. By binding the parent relationship to the model moving parts, mount scripts to moving parts and call transform.position or transform.Translate() methods to realize the translation transformation of model objects. Then, rotate the model through the transform.Rotate() and transform.Rotation functions. The rotation is achieved by calling the update function, which rotates each frame in accordance with the desired orientation. The rotation method circumvents the issue of universal joint deadlock that is inherent to the Euler angle method, which relies on the selection of three axes. Ultimately, the virtual model can be scaled using transform.Scale().

Figure 5. DT-based virtual model of port operation and logistics process. Source: Models created with Unity, by the authors.

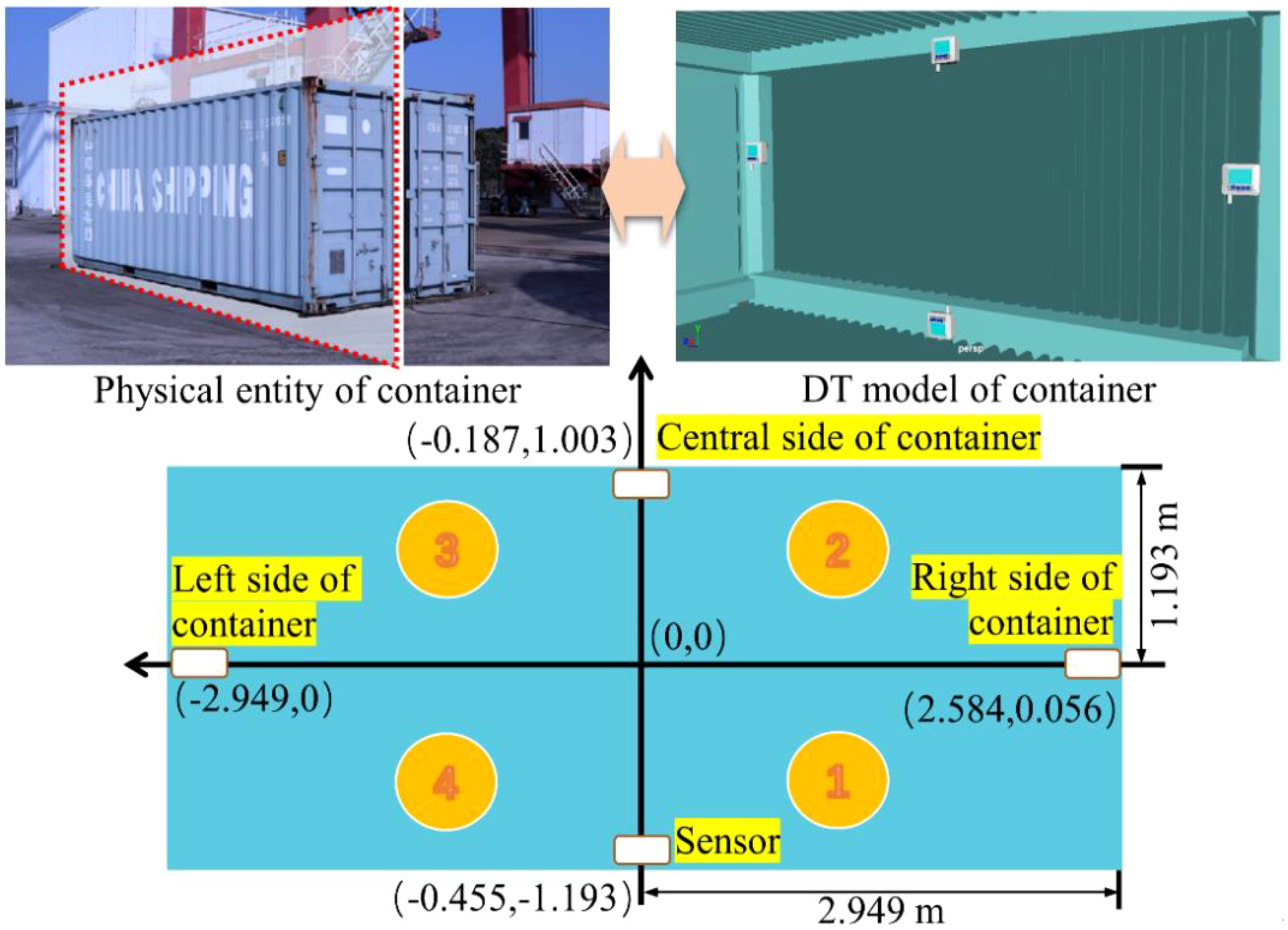

The data are the core driving force of the DT-based platform. This study collects the data through sensors installed in the container operation and storage area in the port, and realizes the real-time data display on the virtual model side of the DT platform. The status of dangerous cargo containers may change in the process of import and export, loading and unloading, and storage. The status of the dangerous cargo is generally related to its current temperature, humidity, vibration, location, and tilt, and the temperature inside the container determines the storage conditions of dangerous cargo. The remote monitoring of container working status (mainly temperature and humidity) has become the consensus of the port management. By monitoring temperature and humidity data in different locations of a fixed container, this study explores the temperature and humidity differences in various locations of the container. Furthermore, a full-scale shipping container is selected for experimental testing in port operation and storage site. The hazardous cargo container is a standard 20 feet, with an inner size of 5.898×2.352×2.385 m (length×width×height). The volume of the testing container is 28 m2, and the load is 18 T. A total of four temperature and humidity sensors are arranged on the hazardous cargo container wall in axisymmetric mode. The left middle sensor is placed on the left side of the container, and the sensor is applied to monitor the change of characteristic parameters near the innermost side wall of the container. The sensor is placed in the middle upper part of the container, in order to monitor the characteristic parameter changes of the uppermost side of the hazardous cargo container. The sensor placed in the lower middle part of the container is designed to monitor the change of the characteristic parameters at the lowest point. The right middle sensor of the container is closest to the container door to monitor the impact of external sunlight from onshore environment. The data acquisition and sensor layout of the testing hazardous cargo container is illustrated in Figure 6.

Figure 6. Schematic diagram of data collection in the actual container and digital model conversion. Source: Models created with Unity, by the authors.

The sensor used in this experiment is RS-WS-WIFI-6, which is an industrial temperature and humidity transmitter using WIFI for wireless data transmission. The device makes full use of the established WIFI communication network to achieve data acquisition and transmission, so as to realize centralized monitoring of temperature and humidity data. The twin data are the link between the physical entity and the virtual model, and the dispatch, operation, and environmental data related to the real container operation process are collected by distributing sensors throughout the port area. It involves the production business data, machinery data, and other environmental data. The communication interface is developed by using communication protocols. The communication connection between the system platform and field operation equipment, the terminal operation system (TOS), equipment management system, truck dispatching system, truck positioning system, and other relevant systems of the port is established, and the twin data of physical container in the port are collected.

i. Communicate with TOS to obtain the overall port operation plan, ship information, operation task list of each container lifting and transportation equipment, container distribution in the storage yard, container type, and container number.

ii. Communicate with the equipment management system to obtain the real-time location and operating speed of the lifting equipment such as a quay crane and a field crane, spreader expansion size and load condition, container quality under spreader, equipment fault information, and other data.

iii. Communicate with the collection truck positioning system to obtain the real-time location of the operation collection truck and field crane, quay crane, and other information of the current service.

The data acquisition in real time serves as the foundation for the transition from the physical to the digital space. In this study, real-time data represent the fundamental building block for the construction of a DT Ad Hoc network model. During the course of container operations within the port, the sensors generate a substantial quantity of streaming data. However, the overall quality of streaming data is inadequate, resulting in a considerable amount of the noise data and redundant data in real-time data collection. The construction of a DT Ad Hoc network model is contingent upon the availability of high-quality, real-time data from the port DT Ad Hoc network. This study uses a methodology that processes the aforementioned real-time data, which have been collected from the port. Non-local means the denoising algorithm is developed for the purpose of removing the noise data. In the initial stage, the target denoising point x and the search point y are selected to construct the neighborhood window. The degree of the similarity between the target denoising point x and the search point y is illustrated in Equation 11. A smaller distance between the target denoising point x and the search point y indicates a higher degree of similarity between them.

where S(x, y) is the similarity between the target denoising point x and the search point y; L is the distance between the search window ψ(x) and the neighborhood window ψ(y); α is the smoothing parameter.

In order to calculate the similarity between all data points y in the search window, it is necessary to apply Equation 11 to all of the data points. The neighborhood weight value of the target denoising point x is calculated based on the results obtained. Non-local means the denoising algorithm is developed to process the target denoising point x, resulting in the expression shown in Equation 12.

where V(x) is the real-time data of an Ad Hoc network following the removal of noise and ω is the neighborhood weight value of the target denoising point.

Equation 12 is used for the processing of all data collected by the port. Following the removal of noise, a self-assembled real-time dataset of the DT-based system can be obtained, resulting in V={V1,V2,⋯,Vt}. In this study, the Kalman filter algorithm is utilized once more for the processing of the redundant data. The real-time dataset V of an Ad Hoc network can be processed to yield a real-time dataset of the same network that is free of noise and redundancy. Accordingly, the dataset is provided for the construction of the DT Ad Hoc network model of the subsequent port operation and logistics. The DT Ad Hoc network model is composed of three distinct networks, including an Ad Hoc network, a twin network, and a service system. The twin network is a highly realistic replication network that is established on the basis of real-time data. It is achieved through the implementation of entity modeling, rule modeling, service modeling, and behavior modeling, which, in turn, facilitate the realization of the Ad Hoc virtualization based on a cloud platform. Additionally, the data acquisition module has been incorporated into the service system to facilitate the integration of the multi-source data.

Information transmission is the operation support of the whole DT system, which transmits, iterates, and maps the data of each layer in real time, including the control instruction data generated in the life-cycle process. These data cover the user interaction data, job management data, equipment traffic scheduling data, as well as the relevant data generated by iterative and real-time mapping with the data of each layer. In this study, the twin data are cleaned, processed, and fused, and the database table is established according to the logical relationship of data for the unified storage and management. By leveraging advanced sensing, signal transmission, and storage technology, the system can obtain data with a greater speed, precision, and completeness. It enables the elimination of the issue of the information islands and data non-interaction at the container operation site in the port, facilitating the centralized management and control of container operations. The system can also monitor and manage the entire process in the port, providing the personnel with real-time visibility into the operating status of equipment and the internal situation of containers. It guarantees the intelligent monitoring and management of the dangerous cargo containers in the port.

As the foundation of the DT-driven platform, the data baseboard must integrate and manage all stages, all elements, and all business information throughout the entire life-cycle process of port operations and logistics. It is achieved through the use of multi-source data fusion. In accordance with the DT Ad Hoc network model developed in this study, the multi-source data gathered from the service system are loaded, and the multi-source data features are extracted through the region-based CNN. The high feature dimension of the multi-source data extracted by the region-based CNN presents a significant challenge for the conventional models attempting to achieve a rapid data fusion. Accordingly, this study develops the creation of a bilinear model. The bilinear pool is an effective method for capturing the relationship between the features of the multi-source data and for achieving the fusion of the multi-source data by incorporating a substantial number of parameters. The multi-source data collected during the container operations and logistics in the port is input into the region-based CNN to extract data features, and the output is the result of the multi-source data fusion. In addition, unmanned aerial vehicles (UAVs) and the on-site monitoring camera are used for image acquisition. The internal processing of the acquired images, and files such as index, coordinate system, and open scene graph binary data are generated, respectively. According to the processed data and coordinate system file, slice cache is carried out to generate the image configuration file matching the type. This study releases the video picture service of the hazardous cargo container operation and storage in the port and invokes it in the DT models and scenario platform.

According to statistics on accidents regarding dangerous cargo in the port, the probability of accidents in conveying machinery and loading and unloading machinery is higher accordingly. The unsafe state of the machinery and equipment in the process of dangerous cargo container operation is mainly analyzed from the safety and reliability of the port machinery and equipment, storage facilities, loading and unloading technology, safety facilities, and the dangerous cargoes’ characteristics. The failure of port machinery and equipment covers the failure of fixed devices, parts falling, equipment overturning, equipment breaking, leakage, etc., which cause lifting injuries, object strikes, and other accidents. Therefore, real-time monitoring of the environmental wind velocity and air humidity in the port is extremely important, and these parameters directly affect the performance instability of the machinery and equipment during the port operation process. On the other hand, the focus of this study is on the dangerous cargoes’ characteristics. Because of unknown situations inside the hazardous cargo container, the data presented by the DT are essential. Statistics on the causes of port accidents (Hou et al., 2021; Khan et al., 2022, 2023) revealed that due to the packaging breakage of dangerous cargoes stored in containers, spontaneous combustion caused by thermal runaway and moisture caused by dangerous substances accounted for a high proportion. For the current deficiency of real-time monitoring inside containers, this study attempts to use the temperature and humidity sensors to synchronize data to DT-driven system. The deep learning algorithm in the DT-driven system is used to analyze a large amount of temperature and humidity data to identify the potential risk of spontaneous combustion accidents of dangerous cargoes in containers.

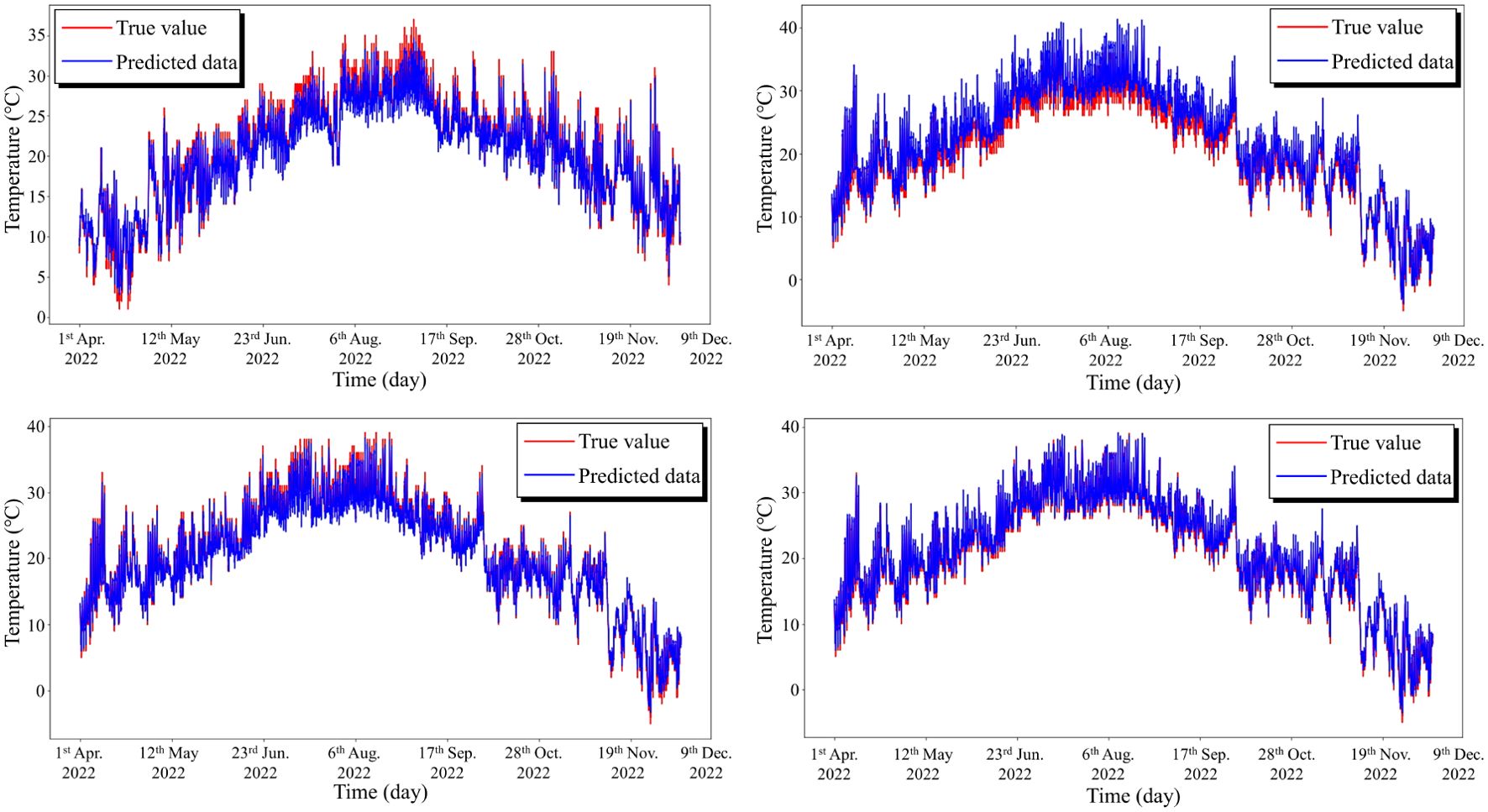

The input module tracks the information of the target container and the surrounding environment information (e.g., temperature, humidity, and wind velocity) of the port into the fully connected layer (FCL) with 128 nodes. The FCL compiles the data information of each hazardous cargo container at every moment into a strip vector. In preparation for the data entry into the compiler and dangerous cargo status identification module, the ReLU function is used as the activation function in FCL. In the module, the results obtained after the training test set are output through the output module. Output one is a two-dimensional vector composed of temperature (°C) and humidity (%RH) in the target hazardous cargo container, and output two is a vector composed of probabilities of the different states such as spontaneous combustion of dangerous cargoes. This study selects the temperature, humidity, and pressure collected in a fixed hazardous cargo container in the Shanghai Port from March 2019 to January 2023. The offshore wind velocity and dew point temperature within the Shanghai Port are subject to monitoring data. The dataset is divided into three distinct subsets: a training set, a verification set, and a test set. The training set is developed for the purpose of training the model, the verification set is utilized for the evaluation of the model, and the test set is utilized for the determination of the accuracy of the final predictions. The data sampling process is conducted on a 30-min time scale, resulting in the acquisition of a total of 65,529 data points in the present work. The ratio of the training set to the test set is 8:2. The correlation coefficient is calculated to assess the precision of the forecast derived from the combination of a CNN and the LSTM algorithm. Figure 7 shows the predicted results of the temperature change in a hazardous cargo container by using the combination of a CNN and the LSTM algorithm. The blue dots represent the predictions of the optimization algorithm in a DT-driven system, while the red dots depict the actual data collected by the sensor inside the target container. Through the comparison between data, one can observe the predictions of status change of the dangerous cargoes in containers under the influence of different environmental factors in the port. Figure 7A indicates the temperature change in a hazardous cargo container when considering the factors of the humidity and atmospheric pressure in the Shanghai Port. In the case of an independent variable comprising the two highly correlated factors, namely, humidity and pressure, the predicted correlation coefficient reaches up to 0.9868. The results reveal that the integrated combination of a CNN and the LSTM algorithm can precisely forecast the temperature within a hazardous cargo container in the port storage process. This approach can be utilized to generate the precise prediction data for the service layer of the developed DT-driven system in the current study.

Figure 7. Influence of different independent variables on temperature prediction inside the container.

Figure 8 presents the monitoring data and change trend of the last 10 days in 2022 when considering the humidity and atmospheric pressure in the Shanghai Port. The training results using the combination of CNN and LSTM algorithm are highly accurate. This not only provides a more precise prediction of the temperature change trend within the hazardous cargo container but also generates the data with greater accuracy regarding both the value and the occurrence time of the peak temperature. Figure 7B shows the predictions of the combination of a CNN and the LSTM algorithm on the temperature inside a hazardous cargo container when considering the factors of humidity, wind velocity, and atmospheric pressure comprehensively. The findings indicate that as the independent variable, namely, the factor influencing the environmental wind condition in the port, increases, the correlation coefficient reaches a value of 0.9817. The environmental wind conditions in the port are a significant factor that is highly correlated with the forecasted temperature within the hazardous cargo container. Figure 7C presents the predictions of the combination of a CNN and the LSTM algorithm on the temperature inside a hazardous cargo container when considering the factors of humidity, dew point temperature, and atmospheric pressure. Upon transforming the independent variables into units of humidity, pressure, and dew point temperature, the resulting correlation coefficient reaches 0.9853. In comparison to the independent variables of humidity and pressure, the predicted correlation coefficient is diminished. Nevertheless, in comparison with the independent variables of humidity, pressure, and wind velocity, the predicted correlation coefficient is observed to be augmented. The results suggest that the environmental wind conditions in the port have a stronger correlation with the temperature of hazardous cargo containers than the dew point temperature. Figure 7D indicates the predictions of the combination of a CNN and the LSTM algorithm on the temperature inside a hazardous cargo container when the factors of humidity, wind velocity, dew point temperature, and atmospheric pressure are considered. Upon modifying the independent variables to include humidity, pressure, wind velocity, and dew point temperature, the predicted correlation coefficient is 0.9855. The findings demonstrate that the combined impact of the environmental wind conditions and dew point temperature of the port on the temperature prediction in the hazardous cargo container is more precise than that of a single factor.

In addition to the temperature data obtained from the hazardous cargo container, the combination of a CNN and the LSTM algorithm is used to predict the parameter of the humidity inside the hazardous cargo container. Similarly, the corpus of reading data contained within the collection spans the period between 2019 and 2023. Figure 9 presents the real-time monitoring humidity data inside the container in 2022 and the predicted results using the combination of a CNN and the LSTM algorithm. The humidity value within a hazardous cargo container plays a pivotal role in the self-heating and spontaneous combustion of specific dangerous cargoes that have absorbed water, particularly when the packaging of such cargoes has been damaged. In order to analyze the accuracy of port environmental factors in the combination of a CNN and the LSTM algorithm to predict humidity data in hazardous cargo containers, this study conducted the training and prediction of data samples respectively by using the control group. Figure 9A shows the prediction result of the optimization algorithm in the DT-driven system on the humidity inside the hazardous cargo container when considering the factors of temperature and atmospheric pressure in the Shanghai Port. Figure 9 illustrates the predictions of the combination of a CNN and the LSTM algorithm, represented by blue dots, and the humidity data obtained by sensors in the hazardous cargo container, represented by red dots. In comparison, the projected outcomes of the embedding algorithm in the DT system with respect to the humidity within the hazardous cargo container are in alignment with the actual monitoring data. Considering the variables of temperature and atmospheric pressure in port conditions, the predictive efficacy of the optimization algorithm utilized in this study is evidenced by a correlation coefficient of 0.9332. Figure 10 reveals the comparison between humidity monitoring data in the hazardous cargo container and predictions by the combination of a CNN and the LSTM algorithm within 10 days, and the data collection time is 1 April to 11 April 2022. The results demonstrate that the embedding algorithm of the DT system is capable of accurately predicting the change trend in the humidity data within a hazardous cargo container. Furthermore, for instances where the humidity peak did not occur within the specified time frame, an augmented training set comprising a greater number of samples can be employed to facilitate the incremental enhancement of the predicted outcomes through the implementation of a modified CNN and LSTM combination.