- 1Department of Food Science and Technology, School of Food and Nutritional Sciences, Jomo Kenyatta University of Agriculture and Technology, Nairobi, Kenya

- 2Department of Agricultural and Resource Economics, School of Agriculture and Environmental Sciences, Jomo Kenyatta University of Agriculture and Technology, Nairobi, Kenya

The sustainability of fresh fruits and vegetables value chains is challenged by high levels of food loss and waste (FLW) in resource-limited economies. In Kenya, where smallholder farmers dominate the food production sector, FLW in fruits and vegetables is estimated at 30-40%. This study investigated the ecosystem of FLW solution providers in Kenya, examining the challenges faced in developing and scaling interventions, and identifying successful strategies to overcome these barriers. A qualitative approach was employed. Primary data on FLW was obtained from solution providers through key informant interviews. The FLW solution providers were categorized as either successful or partially successful based on their commercial viability and operational tenure. The study utilized purposive sampling and a structured interview guide. The study identified several key challenges faced by FLW solution providers which comprised insufficient technical knowledge in food processing and machine operation, limited financial capacity for both operation and scaling, inconsistent supply of raw materials due to seasonality, competition from established companies and artificial products, slow market penetration, and low product acceptability (for partially successful providers). Successful solution providers employed various strategies to overcome these challenges including partnering with universities, governmental and non-governmental organizations for research, development, and initial financing; undertaking comprehensive technical and commercial viability assessments before scaling; adopting product differentiation to capture diverse markets; utilizing preservation techniques like drying and establishing off-take contracts to counter supply inconsistencies and establishing stable external markets and reliable business to business models. The study also revealed the potential for gender-inclusive impact, as many solution providers tend to employ more women due to the nature of the work. The findings highlight the critical role of partnerships, comprehensive market research, and adaptive strategies in developing successful FLW solutions. The contrast between successful and partially successful solution providers underscores the importance of comprehensive planning, technical expertise, and market-oriented approaches. By learning from successful solution providers and addressing key challenges, stakeholders can create more sustainable and effective interventions to reduce FLW and improve food security and nutrition status, and enhance the livelihoods of smallholder farmers.

1 Introduction

There is push to adopt sustainable foods systems. An important component of such systems is increasing the production and consumption of plant-based foods like fruits and vegetables as they are environmentally friendly and nurture human health. Inclusion of Fruits and vegetables in the diet is crucial as they contain essential nutrients for normal body functioning as well as nutraceutical compounds which when regularly consumed lead to better health outcomes by abating development of chronic lifestyle diseases (Clark et al., 2020; Willett et al., 2019). As a result, daily per capita consumption of 300 to 600 g of fruits and vegetables has been proposed (Harris et al., 2023). Despite this recommendation, low fruit and vegetable consumption persists in 93% of Sub-Saharan African countries (Harris et al., 2023; Mason-D’Croz et al., 2019). Supporting these findings, a survey conducted in East Africa, including Kenya, reported per capita consumption levels ranging from 4 to 135 grams for fruits and 84 to 184 grams for vegetables (Sarfo et al., 2023).This is a paradox as the production of fruits and vegetables has risen in Kenya. For example, mango and avocado production tripled and doubled, respectively, between the years 2005 and 2014 (Ridolfi et al., 2018). It is possible that the low consumption of fruits and vegetables can be partly attributed to high postharvest losses (Schreinemachers et al., 2022).

In Kenya, food loss and waste (FLW) in fruits and vegetables value chains average estimates are between 30-40% with reported upper limits being as high as 70% (Mugao, 2023; Ntawuruhunga et al., 2020; Gogo et al., 2018; Ridolfi et al., 2018). Fruits and vegetables are highly perishable requiring proper postharvest management (Beausang et al., 2017). Adoption of low-cost postharvest management practices and technologies is low in Kenya. This is because 80% of fruits and vegetables are produced, distributed and marketed by small holder farmers, aggregators and traders who experience financial and behavioral constraints (Ridolfi et al., 2018). The underlying drivers of FLW established by Flanagan et al. (2019) are consistent with what has been observed in Kenya (Mugao, 2023; Ntawuruhunga et al., 2020; Gogo et al., 2018) and can be clustered into four categories. ‘The first category, the technological drivers, include poor infrastructure, inadequate handling or processing equipment and improper packaging among others. Second category are those drivers that are managerial in nature encompassing inadequate food processing skills and knowledge, poor supply and demand forecasting, inadequate planning and marketing strategies. Third category of factors are behavioral and entails consumer norms and attitudes, lack of awareness and concerns about possible risks of FLW. The fourth category include structural drivers such as demographics, climate change effects, economics, finances, policies and regulations’ (Flanagan et al., 2019).

The United Nations SDG 12.3 underpins halving global per capita FLW at the retail and consumer levels by 2030 (Nicastro and Carillo, 2021). Therefore, reducing FLW is becoming an important motivation of an increased number of enterprises which have tailored an extensive array of services and products. Understanding the methodologies used in developing services and products that are effective in reducing FLW, i.e., successful solutions, is critical. Generally, promoting the widespread adoption of the successful solutions could have a significant impact on the livelihoods resulting in improved food and nutrition security of small-scale farmers and other low-income consumers especially in developing countries (Nicastro and Carillo, 2021; Hanson et al., 2016). Specific benefits that can be indirectly accrued from solutions that reduce FLW include salaries for workers, returns on assets (profits) to entrepreneurs and asset owners, revenues to the government, a better food supply to consumers and a positive impact on the environment in the short and long term (Schuster and Torero, 2016; Swinnen, 2015).

The main objective of the study was to assess the methodologies or pathways used to develop successful solutions to FLW in Kenya. This led to a summation of the challenges faced by solution providers in reducing FLW and the strategies employed to overcome these challenges.

2 Methodology

2.1 Selection of fruits and vegetables processors

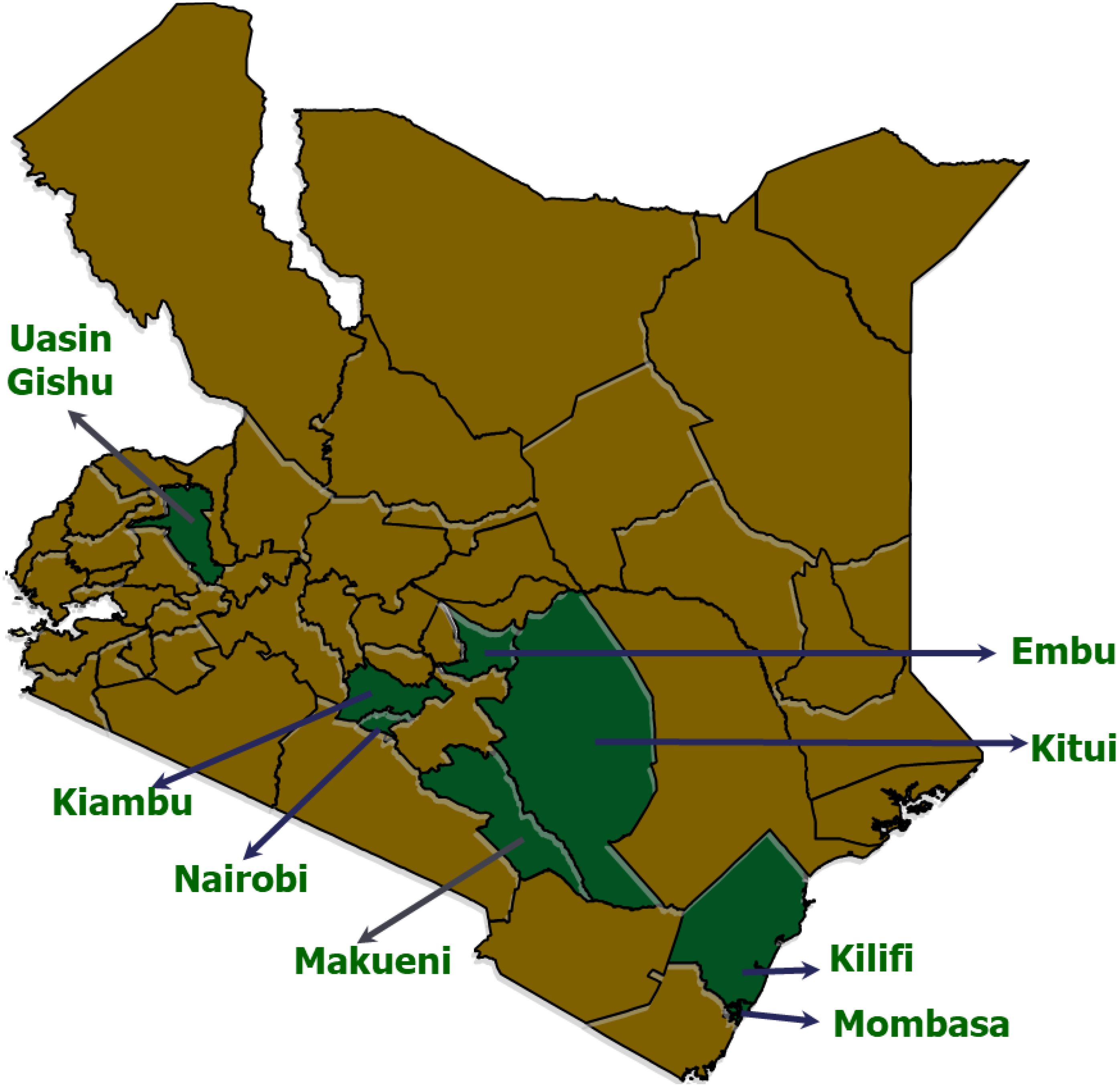

In 2022 and 2023, TechnoServe Inc. carried out an overview of the fruits and vegetable landscape in Kenya. This included reviewing secondary sources of data and conducting expert interviews. One of the results, was a comprehensive list of thirty-seven solution providers to FLW undertaking aggregation, off-take, value addition and recycling of wastes. From this list, purposive sampling was employed to select solution providers focusing on aggregation, value addition and offtake. These categories represented up to 95% of solutions undertaken in Kenya to manage fruit and vegetable loss and waste aimed at delivering foods for direct human consumption. As a result of the foregoing rationale, solution providers downcycling wastes into end products such as bioethanol, fertilizer and use as feed for black soldier fly larvae which are not directly consumed as foods were left out. Twelve solution providers, accounting for 38% of those carrying out aggregation, value addition and off-take, were selected. These solution providers were situated in different regions of the country as shown in Figure 1 representing a diverse pool of agro ecological and socio-economic characteristics.

2.2 Categorization of solution providers

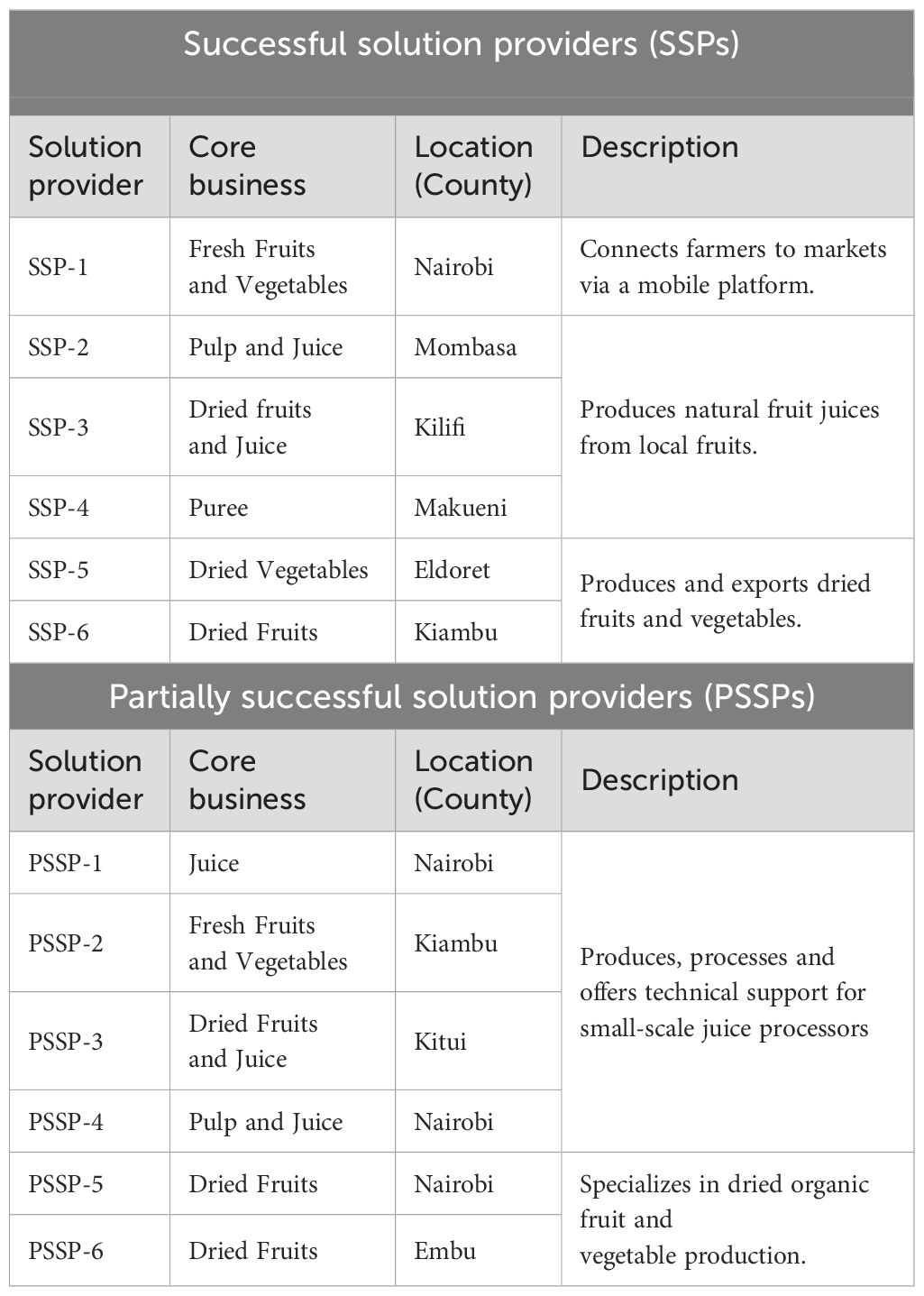

The service providers were further categorized as successful or partially successful based on two observations. The first was the presence or absence of solutions in the formal market and the second was the period of operation. Solution providers access to the well-regulated formal markets implies fulfillment of all legal and consumer related requirements which further adds value to the solution. In addition, operational tenure gives an indication of product or service lifecycle. It can be assumed that the longer the product or service life cycle, the more successful the solution. The successful solution providers, herein referred to as SSPs, were those that had solutions in the formal market and had been operational for more than 2 years. The partially successful solution providers, denoted as PSSPs, were those with commercially viable products in either formal or informal markets and had been existence for less than two years or solutions providers that only had products in the informal markets and have been operating for more than two years.

2.3 Data collection and management

The present work was based on only qualitative data obtained from key informant interviews. Representatives of the solution providers including founders and senior managers involved in daily operations were considered as key informants. A cross-sectional survey was carried out in October 2023 with the view of obtaining descriptive data. An unstructured in-depth guide was used to collect data from the key informants through in-person interviews. The key informant interview guide covered the motivations for solution development, characteristics of solutions, feasibility assessments undertaken and the involvement of end-users during solution development, the challenges faced and the strategies adopted to overcome the challenges. The interviews were recorded and data stored using the open data kit (ODK) configured to pick location coordinates to ensure the authenticity of the data. The outputs were transferred into excel worksheet to allow for data cleaning and analysis.

2.4 Data analysis

Data was analyzed using the general inductive approach according to Thomas (2006). The data obtained was transcribed and summarized into texts from which patterns were identified and assigned themes which were linked to the objective of the study. Recurring themes were grouped under different topics in a table. The information in the table was the basis upon which the challenges and success strategies adopted by solution provided were derived. Behavior mapping which is a deductive method (Zhang et al., 2021) was also implemented using the Nvivo version 13 Software. The solution provider categorizations as SSP and PSSP were considered the spaces under which methodologies used in solution development were assessed. The use of both inductive and deductive approaches in analyzing qualitative data strengthens the validity of findings.

2.5 Ethical concerns

Permissions to carry out the research was obtained from the National Commission of for Science, Technology and Innovation, Kenya. Verbal consent was also sought from the representatives of solution providers prior to commencing the interviews.

3 Results

3.1 Description of the solution providers surveyed

The solution providers surveyed were from the counties of Kiambu, Nairobi, Makueni, Embu, Uasin Gishu, Kitui, Kilifi and Mombasa. Table 1 shows the specific solution providers involved in the study, their classification (successful or partially successful), core business which means the solutions provided. Most of the solution providers reported that they understood the importance for reducing food waste and food loss. They reported that reducing food waste and loss would result in sustainable food systems, enhanced profitability and food security. The solutions being undertaken to address FLW included providing farmers with market access by creating online platforms where consumers could order fresh produce, transforming fresh fruits and vegetables into intermediary i.e., pulps and end-products i.e., juices, jams and a variety of dried products. The products were marketed locally and internationally and consumed mainly by women, children and the youth and institutions.

The solution providers had attempted to develop an extensive range of products some of which became successful. The unsuccessful solutions had either been developed but not taken to market because their production costs were too high or were products that had gone to market and completely failed and thus removed from the solution providers’ portfolio. These unsuccessful solutions included Chili oil, Tomato paste, Vegetable powder, Mango sweets, Mango nectar, Mango pulp, Mango jam, Banana puree and Tomato puree.

3.2 Challenges faced by the solution providers

3.2.1 Inadequate and inconsistent supply of raw materials

The SSPs and PSSPs both reported inadequate and inconsistent all-year round availability of raw materials, i.e., fruits and vegetables. SSP-5 and SSP-2 mentioned the following: “One of our greatest challenges is that there are seasons when we are oversold. We are not able to meet the market demand which is a good problem” and “We realized there are times in a season you will not even find a single mango in the market”. SSPs could not meet demand in the export market even during peak produce seasons which was as a result of low supply of good quality raw materials in the case of SSP-5. On the one hand, SSPs consistently obtained raw materials all year round but in insufficient quantities. On the other hand, PSSPs struggled to find adequate raw materials off-season, especially mangoes. PSSP-3 and PSSP-5 reported that they were unable to get mangoes during the off season leading to temporary closures of the plants. These different experiences could be attributed to the ability of SSPs to source raw materials from diverse localities around the country where the harvest of fruits and vegetables occurs at different times of the year while the PSSPs only source fruits and vegetables locally with one harvest season a year.

3.2.2 Insufficient finances

The solution providers, both SSPs and PSSPs, experienced limited access to financing options. The SSPs required finances to scale to enable export to external markets in Europe and the US. SSP-2 had an export order from Denmark, but did not have the equipment that would enable them to produce end-products with the required high-quality standards. The PSSPs needed finances for initial processing and operating costs. PSSP-3 stated “Financing is a major problem and just getting someone to finance you a particular machine such as a vegetable washer is very difficult”. PSSP-2, establishing cold storage units for fresh fruits and vegetables, also mentioned the high cost of equipment. “A processing unit is very expensive, so at some point capital would be a challenge”. These findings illustrate that solutions need funding not only at the start but also during the course of development to reach as many more beneficiaries.

3.2.3 Competition

The SSPs and PSSPs faced competition from companies that produced juices made largely using artificial ingredients and sold at cheaper prices. Other than lower prices, the competition was also attributed to the fact that customers struggled to differentiate between juices made from real fruits and those made from only artificial ingredients. Representatives from PSSP-3 and PSSP-4 reported that, “Juice from a certain competitor comes with 0% fruit content but the consumer is unable to discern this” and “People do not realize the difference between a mango juice and a mango drink because the colors of both are the same”. Furthermore, PSSPs struggled to compete with already established large-scale companies. PSSPs processed mango juices with higher contents of pulp in comparison to the already established companies. One of the respondents of PSSP-4 indicated that “For instance one large scale company processes juice with 11% fruit pulp and the remaining 89% is mostly water. While our ready-to-drink juice is made with a pulp to water ratio of 60:40 but we are expected to compete on the market”.

3.2.4 Slow market penetration and product acceptability

Some of the SSPs and PSSPs brought new products into the markets such as mango pulp processed from the improved Apple variety and the use of dried mango flakes to make juices for uptake by processing companies and restaurants, respectively. These solution providers could not easily find a receptive market and had to take on additional marketing and demonstration costs to prove that the pulp and dried mango flakes could be reformulated into juices that were acceptable by consumers. PSSP-4 reported that “Convincing the consumers on the quality of new products we have manufactured was a big challenge.” It was also observed that consumers had negative attitudes towards processed foods and preferred fresh fruits and vegetables. The slow uptake of the new solutions led to cash flow bottlenecks which negatively affected talent acquisition and eventually likelihood of success of the solution.

3.2.5 Technical challenges

SSPs reported inadequate specialized capacity to calibrate and operate machines. SSP-2 had installed artisan large-scale equipment which was difficult to calibrate and operate at precise conditions, consequently affecting the consistency of the final products in an undesired manner. The PSSPs had limited knowledge in food science and technology which also contributed to production of inconsistent end products. The employees were reported to have difficulties in using equipment such as dryers and pasteurizers. PSSP-4 engaged small-holder farmer cooperatives in drying mango fruits to be reconstituted into juice conveyed the following statement. “Trying to change processes from being done informally to formally was a big challenge.” The technical challenges mentioned caused solution providers to withdraw one or more of their products from the market.

3.2.6 Distribution challenges faced by PSSPs

PSSPs reported that they encountered high cost of distribution to reach underserved markets such as low-income construction workers. PSSP-4 embraced a B2B marketing model using on-foot distribution partners. Juice dilution which involves the mixing of dried mangoes and water was carried out at the premises of the PSSP using documented procedures in the mornings and the resultant juice would be packed into specialized backpacks imported from Germany. The backpacks would be given to the distributors who sold the juice to underserved low-income consumers. This PSSP reported incidents in which some of the distributors further diluted the juices with water lowering quality of the juice. This behavior among distributors caused distrust.

3.3 Strategies adopted to overcome challenges

3.3.1 Feasibility assessments and consumer research

The SSPs involved financial modeling, marketing and food science experts in the initial stages to carry out consumer research and intensive technical, financial and commercial viability assessments prior to product launch. This led to the development of robust business plans which enabled the access of financing to start off the solution. In addition, market trials were undertaken before and iteratively during the product development cycle to meet consumer requirements. SSP-4 and SSP-5 statements were captured as follows; “We commissioned a market study which was done alongside procurement of the equipment to process ready to drink juice, so that the market would be ready once the equipment was installed” and “Product development was a step-by-step transition from the first market trial and afterwards several other assessments were done. The market trials included both financial and commercial aspects of launching the product”, respectively. Furthermore, consumer research led to obtaining specific insights on potential customer bases for SSP-5 that dried indigenous leafy green vegetables. The previously mentioned SSP indicted that “School feeding programs exhibited a preference for exotic vegetables over indigenous ones.”

The PSSPs largely focused on consumer research and conducted limited financial or commercial viability assessments, with rare involvement of experts. PSSP-1 reported the following actions. “Direct interaction with consumers, including vendors and shoppers, played a role in product development. We had to identify what are the customer needs and come up with a suitable solution. Several trials were done on the pack size, the user friendliness of the packaging and labelling. In the end the design of the solution was influenced by the demands and preferences of the end-users”. PSSP-1 consumer research also resulted on insights on the potential buyers and consumers of mango juice as depicted in the following accounts. “According to the survey, only few men buy mango juice for themselves. Men mostly buy mango juice for the children”. Also, exhibitions were one of the platforms PSSPs used to undertake consumer research. PSSP-3 reported “I went to an exhibition with about 200 packs of my products and I sold all of them. When I came back home customers were already calling me for more products”.

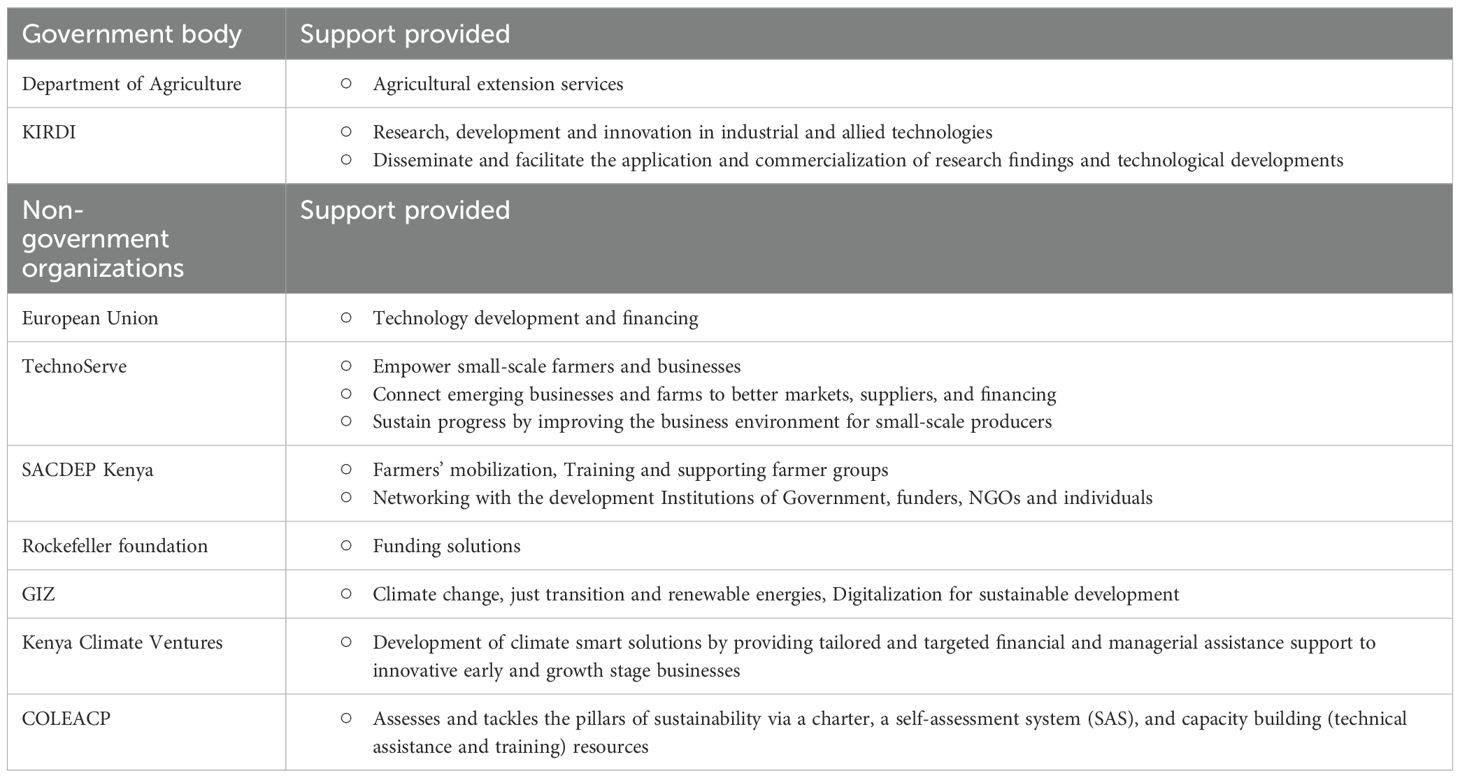

3.3.2 Partnerships

The SSPs and PSSPs partnered with universities, governmental and non-governmental organizations (NGOs) which are listed in Table 2. SSPs sought support from government institutions and obtained a number of benefits including political good will, extension services, technical expertise and incubation spaces. The success of SSPs underscores the importance of government involvement in reducing FLW of fruits and vegetables. SSP-3 received significant financial support as they reported “We work with various collaborators and suppliers. Among these, development partners like the EU have assisted us in the establishment of a juice processing line”. SSP-4 situated in Makueni County submitted that “The county leadership established the Makueni County Food Development and Marketing Authority which is an act of the county assembly to operationalize the food processing plant and run it sustainably”. It was also observed that SSP-4 received financial support from both the EU and county government as they mentioned that “In the year 2018/2019, the EU and county government agreed to finance 60% and 40% of the company’s start-up costs”. SSP-5 also received financial support as the solution provider said that “We received a loan from Kenya Climate Ventures at a friendly interest rate. They also financed a large part of machinery and gaining technical knowledge”. SSP-5 also worked with the Kenya Bureau of Standards (KEBS) to improve the quality of their end products. “We worked closely with KEBS to develop a standard suitable for dried vegetables”.

PSSPs did not mention that they had obtained financial support from governmental organizations, only technical support. Nevertheless, PSSPs reported to have received short term financial and technical support from NGOs. PSSP-5 and PSSP-6 stated that “We have received technical support from TechnoServe, COLEACP, SACDEP Kenya, KIRDI and Ministry of Agriculture” and “Rockefeller foundation and TechnoServe funded us through the University of Nairobi”, respectively.

Furthermore, the partnerships also aided in research and development. Partnerships with universities enabled innovation of new and acceptable product variants and support in research and development (R&D) to improve the existing products. Partnering with governmental regulatory bodies such as Kenya Bureau of Standards (KEBS), Kenya Revenue Authority (KRA) and Ministry of Public Health helped to ensure compliance to legal and consumer standards. Partnering with NGOs was significant as they provided free training for contracted farmers, processing machinery and ideas that led to new products.

3.3.3 Product differentiation

SSPs and PSSPs developed a range of products such as dried tomato powder to serve as condiments, mango pulp, ready-to-drink mango juice, dried mango flakes, mango leather and dried Chilies’. The SSPs strived to bring the best products to the markets thereby effectively addressing competition. SSP-2 stated “Our products are natural and organic”. SSP-3 also said “We have made sure that our products are conforming to the best quality standards in the country and region and this makes us stand out”. SSP-4 realized they needed to further diversify their product offering to increase revenues. “After extracting puree from mangoes, we further process the puree into ready-to-drink juice which is of higher value”. It was also noted that SSP-5 used one processing line to produce a range of products. “We are very versatile in the sense that we are able to make different products in the same product line including vegetables in different pack sizes”. The previously quoted SSP also carries out contract packaging which involves packing their products in the brands of their clients. This has been proven to be an effective approach for them to indirectly increase their market share.

One distinguishing observation between SSPs and PSSPs is that the former diversified products for the mass markets whereas the latter diversified products for niche markets. PSSP-4 developed dried mango pulp for conversion into juices at restaurants. Furthermore, PSSP-5 who targeted international food processors mentioned that “We have placed the tomato powder, which is a component that is used as a condiment by manufacturers, on the international markets”. PSSP-3 that processes a variety of products from dried mango including pulp, ready-to-drink juice and jam stated that “We can dry mango and store them and make many other products from them”.

3.3.4 Harnessing renewable energy

Due to the high moisture content of fruits and vegetables, they tend to be highly perishable. This can limit year-round availability of such produce especially because they are harvested during specific months in a year. To counter low supply, the solution providers embraced the use of renewable energy to preserve mangoes. SSP-3 employed freezers powered by solar energy to preserve mango pulp while PSSP-3 and PSSP-4 dried mango fruit using greenhouse solar dryers. Both of these strategies help to cut on the high operational cost of electricity as well as ensure constant availability of fruits for processing.

3.3.5 Off-take contracts with farmers

This was another strategy used to ensure consistent supply of raw materials. SSP-1 reduced raw materials costs by eliminating middlemen during acquisition. “Previously we would buy from brokers but now we buy directly from farmers.” To add on SSP-6 insists that having direct linkages to farmers aids in traceability. “Our procurement guidelines stipulate that the company should get produce directly from the farmers for purposes of traceability in case of fruit diseases”. SSP-2 stated that “We contract farmers and register them on our digital application. So far 6,000 farmers have been registered. We intend to group them together and train them”. Furthermore, SSP-4 works with farmer cooperatives who aggregate and transport their produce to factory premises. This eases the burden of raw material acquisition as farming in Kenya is fragmented as it is mostly carried out by small-scale farmers.

3.3.6 Human centered designs

Seeking frequent customer feedback and ensuring consistent product quality helped SSPs to be competitive. SSPs reported engaging some form of customer feedback mechanism like regular customer surveys that helped them identify flaws in the solutions as well as trends in consumer behavior such as packaging preference. “We have an ERP system that keeps a database of consumer feedback which we monitor frequently” was stated by SSP-5. The SSPs reported that they capitalized on this as a competitive advantage. The SSPs also invested in high level operational standards including deploying and implementing standard operating procedures (SOPs) that enabled them to further create a strong brand and market their products based on quality. SSP-4 stated, “We have implemented the best manufacturing practices here as we adhere to ISO”. PSSPs adopted strong messaging such as “nutritious” and ‘organic’ on their packaging materials.

3.3.7 Strategic business models

SSPs established stable external markets and reliable B2B business models operating in the formal sector. SSP-5 reported the following; “In 2020, we were exporting to Salt Lake City in Utah, USA”. Additionally, SSP-2 stated, “Our business models target supermarkets where there is guaranteed sales”. While PSSPs relied more on the mass market, trade fairs and restaurants which are highly involving and costly business strategies.

3.4 Gender inclusivity in solution provision

All the solution providers employed a labor force that was gender leaning based on primary tasks. Solution providers tended to employ more women than men due to the nature of work such as plucking and washing vegetables and fruits. Also, the solution providers attributed preference to work with women over men since women tend to be more family oriented and have low turnover (stay in the company for longer periods). This could imply that this business segment offers an opportunity for impact targeting women. SSP-1 reported that the nature of their business automatically made them work with more women than men. Similarly, PSSP-1 indicated that they had more women members in the company.

4 Discussion

4.1 Raw material availability

The overall production of fruits and vegetables increased by 43% and 36%, respectively, in Sub-Saharan Africa between 2010 and 2020 (Reardon et al., 2024). This increase is owed to a number of factors including availability of improved seeds, irrigation systems that increase quality and quantities of produce, improved farmers’ access to training opportunities and technologies, infrastructure such as roads to transport produce to markets, electrification and agricultural extension services (Reardon et al., 2024; Sonka et al., 2023; Liverpool-Tasie et al., 2020; Khapayi et al., 2018);. In turn this increased production of fruits and vegetables and their availability in markets have led to the development of a large number of micro, small, medium enterprises within these food value chains (Reardon et al., 2024). The higher the availability of fruits and vegetables on the market the lower their prices, the more affordable it is for the enterprises to operate. The production of fruits and vegetables in Kenya is rain fed which results in seasonal cycles of glut and scarcity. Furthermore, during the glut seasons high post-harvest losses of 30 to 40% are observed, poor road infrastructure and limited cold storage capacity led to low levels of aggregation and lowering supply to market (Onyango et al., 2023; Shiundu and Oniang’o, 2007).

The availability of fruits and vegetables can be enhanced through contractual farming, cold storage and drying of produce. Contractual farming is an agreement between producers, who are expected to embrace good farming practices for the provision of high quality and pre-determined quantities of raw materials, and a buyer, who is expected to purchase the produce at a fixed price. This can be good as it assures the buyer of availability of produce and the farmers are guaranteed income. The conditions that would justify contractual farming include large scale buyer, quality variations and perishability of the products among others (Minot, 2011). Khapayi et al. (2018) carried out a survey involving 70 small scale farmers and 15 key informant agri-business firms. The aforementioned study observed that participation in contract farming depended on farm assets such as availability of irrigation systems which allowed for off-season farm production, young age and literacy which enhanced sustainable partnerships and distance to market which lowered transportation costs. Cold storage entailing the use of CoolBot™, evaporative coolers (active or passive) and cold rooms can generate high relative humidity and low temperature suitable for the short-term storage of fruits (Jarman et al., 2023). Cold chains were also reported to reduce the postharvest losses of ILGs (Elolu et al., 2023). Due to its simplicity and low investments costs, drying fruits and vegetables is the most widely adopted means of ensuring their availability (Sarfo et al., 2023). Sun drying, chimney solar drying, greenhouse solar drying together with storage of dried fruits and vegetables in hermetic bags can be effective in preventing product decay and profitable in markets where dried products are sold at a premium (Jarman et al., 2023).

4.2 Product development

Dried fruits and vegetables seem to dominate among the downstream solutions of postharvest handling of fruits and vegetables in African countries. Mhazo et al. (2015) reported that enterprises processed jams/jellies/marmalades, dried vegetables, dried fruits and vegetable soups/piccalilli/chutneys. Musebe et al. (2017) also observed that due to ready availability of solar energy, sun drying technique was widely used to process indigenous leafy greens (ILGs) which were high in demand during dry seasons. Drying is also considered to be a minimal processing technique that produces products with wide acceptability among rural women (Sarfo et al., 2023). However, it has been noted that although blanching, solar drying and fermentation are the most applied methods to ILGs, large quantities of homogenous end-products cannot be achieved using these methods (Elolu et al., 2023). This calls for training on more ways of differentiating products alongside investment in processing equipment to meet the demands of different types of consumers (Mujuka et al., 2020; Musebe et al., 2017; Mhazo et al., 2015). Furthermore, more knowledge on what influences demand would enable developers of solutions to respond to the needs of different types of consumers (Horton et al., 2023). This highlights the critical role of market information. The more upstream market information on product attributes requested reaches solution developers, the more heterogeneous markets can be served (Hawkes and Ruel, 2011). In addition, business management skills, branding/certification and open access to market information is necessary to develop competitive market strategies that combine affordability and high product quality (Ruben, 2024; Danse et al., 2020).

4.3 Partnerships with governments and NGOs

Developing FLW mitigation solutions involves significant financial investments on technology, management systems and a range of legal and consumer standards required by importers and exporters (Temu and Temu, 2005). Without partnerships, solution providers in developing countries can be likely forced to adopt high-touch, expensive models that entail training and financing suppliers, technology deployment through research and development to create value as well as creating awareness among consumers. To lessen this burden NGOs and governments step in to form private-private and private-public partnerships, respectively (Danse et al., 2020).

4.4 Ecosystem: political, socio-economic and behavioral factors

It has been previously suggested that successful methodologies in solution development and deployment are possibly anchored on the following precepts; (i) improving product quality to compete effectively, (ii) increasing systems’ efficiency by lowering transaction costs, (ii) developing differentiated products in response to consumers’ demand and (iv) creating an enabling business environment (Musebe et al., 2017; Danse et al., 2020; Ruben, 2024). The need for inclusive solution development also arises from the fact that most fruits and vegetables in sub-Saharan Africa is produced by small-scale farmers, many of whom are women and living in poverty (Ingutia and Sumelius, 2022; Mukasa and Salami, 2015).

The ability of solution providers to meet legal regulations is a determining factor in their access of formal markets which deliver greater profits than informal markets (Mhazo et al., 2015). Governments need to foster sustainable business practices and inclusive value chains characterized by “shorter and circular in nature (reducing transaction costs), sharing of best practice technologies, open access to markets, governance and mutual trust” (Ruben, 2024). In addition to trust as a behavioral factor, there is need for creation of awareness of solutions availability among consumers (Danse et al., 2020).

5 Conclusions

The comparison between the solution development processes adopted by SSPs and PSSPs brings to light factors critical to the ability of a solution to reduce post-harvest losses in fruits and vegetables in Kenya. There is need for comprehensive planning including consumer research and feasibility studies prior to solution development. In addition, consumer research needs to be continuous to aid in the iterative improvement of product or service during development and deployment in the market. Also, important value propositions for the Kenyan market are that fresh fruits and vegetables and their processed counterparts should be natural, organic and of the highest quality. Moreover, partnerships should be encouraged, particularly due to the role of government and non-governmental organizations in accessing financing and technical know-how or expertise in the establishment of processing facilities and meeting product standards. Financing for start-up and scaling up are both needed for the success of a solution. The ability to ensure all year-round availability of raw materials through partnerships with farmers and/or leveraging technology is vital for continuous production. Creating consumer awareness and pushing for behavioral change that will increase consumption of processed fruits and vegetables would add to the success of many solutions. The SSPs have better managed to consider these factors in solution development than the PSSPs. The findings of this study can be used as a guide for organizations or individuals seeking to reduce postharvest losses in Kenya using for-profit business establishments.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

Research permit was acquired from the National Commission for Science and Technology (NACOSTI). The concerned County authorities also granted permission to carry out the survey. For the purpose of participating in this study, the participants gave their written informed permission.

Author contributions

WO: Conceptualization, Funding acquisition, Investigation, Project administration, Supervision, Writing – original draft, Writing – review & editing. PK: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Writing – original draft, Writing – review & editing. EW: Data curation, Formal Analysis, Investigation, Methodology, Visualization, Writing – original draft, Writing – review & editing. GO: Investigation, Resources, Validation, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The funding for this research article was provided jointly by the Bill and Melinda Gates Foundation (BMGF) and the UK Foreign, Commonwealth and Development Office (FCDO) through TechnoServe. The opinions and findings presented here are however those of the authors and do not represent those of BMGF, FCDO or TechnoServe.

Acknowledgments

We would like to express our appreciation to our field enumerators for their assistance in carrying out this survey. We are also appreciative of the respondents (Joles farm, Twiga Foods, Association of Kenya Mango Traders (AKMT), Milly Fruit processors Ltd, Pwani Magic Fresh Juice, Mace Foods Ltd, Karurumo Horticulture SHG/Fruit Processors, and Kitui fruit processors), whose data forms the core of our study. We also acknowledge persons who made invaluable contributions that made this research article possible. These include; Carolyne Maina, Project Director; Daniel Waigwa, MEL Specialist; Ismail Ahmed, Public Health Nutrition Manager; Ronald Gichuki, Innovation Manager; Matt Foerster, Director, Agricultural Markets; Caitlin Nordehn, Global Gender Manager; Kris Ansin, Country Director, TechnoServe Kenya and David Hale, Director, TechnoServe Labs.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Beausang C., Hall C., Toma L. (2017). Food waste and losses in primary production: Qualitative insights from horticulture. Resources Conserv. Recycling 126, 177–185. doi: 10.1016/j.resconrec.2017.07.042

Clark M., Macdiarmid J., Jones A. D., Ranganathan J., Herrero M., Fanzo J. (2020). The role of healthy diets in environmentally sustainable food systems. Food Nutr. Bull. 41, 31S–58S. doi: 10.1177/0379572120953734

Danse M., Klerkx L., Reintjes J., Rabbinge R., Leeuwis C. (2020). Unravelling inclusive business models for achieving food and nutrition security in BOP markets. Global Food Secur. 24, 100354. doi: 10.1016/j.gfs.2020.100354

Elolu S., Byarugaba R., Opiyo A. M., Nakimbugwe D., Mithöfer D., Huyskens-Keil S. (2023). Improving nutrition-sensitive value chains of African indigenous vegetables: current trends in postharvest management and processing. Front. Sustain. Food Syst. 7. doi: 10.3389/fsufs.2023.1118021

Flanagan K., Robertson K., Hanson C. (2019). Reducing Food Loss and Waste: Setting a Global Action Agenda (Washington, DC, USA: World Research Institute). Available at: https://wriorg.s3.amazonaws.com/s3fs-public/reducing-food-loss-waste-globalaction-agenda_0.pdf.

Gogo E. O., Opiyo A., Ulrichs C., Huyskens-Keil S. (2018). Loss of African indigenous leafy vegetables along the supply chain. Int. J. Vegetable Sci. 24, 361–382. doi: 10.1080/19315260.2017.1421595

Hanson C., Lipinski B., Robertson K., Dias D., Gavilan I., Gréverath P., et al. (2016). Food Loss and Waste Accounting and Reporting Standard. WRI: World Resources Institute. United States of America

Harris J., de Steenhuijsen Piters B., McMullin S., Bajwa B., de Jager I., Brouwer I. D. (2023). Fruits and vegetables for healthy diets: priorities for food system research and action. Sci. Innov. Food Syst. Transformation 87, 88–132. doi: 10.1007/978-3-031-15703-5_6

Hawkes C., Ruel M. T. (2011) February. Value chains for nutrition. In 2020 Conference Paper International Food Policy Research Institute (IFPRI) 2020 International Conference “Leveraging Agriculture for Improving Nutrition and Health,” (New Delhi, India). 4, 10–2.

Horton D., Devaux A., Bernet T., Mayanja S., Ordinola M., Thiele G. (2023). Inclusive innovation in agricultural value chains: lessons from use of a systems approach in diverse settings. Innovation Dev. 13, 517–539. doi: 10.1080/2157930X.2022.2070587

Ingutia R., Sumelius J. (2022). Determinants of food security status with reference to women farmers in rural Kenya. Sci. Afr. 15, e01114. doi: 10.1016/j.sciaf.2022.e01114

Jarman A., Thompson J., McGuire E., Reid M., Rubsam S., Becker K., et al. (2023). Postharvest technologies for small-scale farmers in low-and middle-income countries: A call to action. Postharvest Biol. Technol. 206, 112491. doi: 10.1016/j.postharvbio.2023.112491

Khapayi M., Van Niekerk P., Celliers P. R. (2018). Agribusiness challenges to effectiveness of contract farming in commercialization of small-scale vegetable farmers in Eastern Cape, South Africa. J. Agribusiness Rural Dev. 50 (4), 375–384. doi: 10.17306/J.JARD.2018.00429

Liverpool-Tasie L. S. O., Wineman A., Young S., Tambo J., Vargas C., Reardon T., et al. (2020). A scoping review of market links between value chain actors and small-scale producers in developing regions. Nat. sustainability 3, 799–808. doi: 10.1038/s41893-020-00621-2

Mason-D’Croz D., Bogard J. R., Sulser T. B., Cenacchi N., Dunston S., Herrero M., et al. (2019). Gaps between fruit and vegetable production, demand, and recommended consumption at global and national levels: an integrated modelling study. Lancet Planetary Health 3, e318–e329. doi: 10.1016/S2542-5196(19)30095-6

Mhazo N., Hanyani-Mlambo B., Nazare R. M., Mupanda K., Masarirambi M. T. (2015). Small-and medium-scale production and marketing of processed fruits and vegetables in Zimbabwe. UNESWA J. Agric. (UJA). 18, 37–48.

Minot N. (2011). Contract Farming in Sub-Saharan Africa: Opportunities and Challenges. International Food Policy Research Institute, Prepared for the (IFPRI), Policy Seminar titled: Smallholder-Led Agricultural Commercialization and Poverty Reduction: How to Achieve It? 18-22 April 2011: Kigali, Rwanda.

Mugao L. G. (2023). Factors influencing tomato postharvest losses in Mwea, Kenya. Int. J. Multidiscip. Res. Growth Eval. 4, 41–48. doi: 10.54660/.IJMRGE.2023.4.4.41-48

Mujuka E., Mburu J., Ogutu A., Ambuko J. (2020). Returns to investment in postharvest loss reduction technologies among mango farmers in Embu County, Kenya. Food Energy Secur. 9, e195. doi: 10.1002/fes3.195

Mukasa A. N., Salami A. O. (2015). Gender Productivity Differentials Among Smallholder Farmers in Africa: A Cross-Country Comparison. Vol. 231 (Abidjan: African Development Bank., African Development Research group), 45.

Musebe R., Karanja D., Rajendran S., Kessy R., Kansiime M., Marandu D., et al. (2017). Development of market opportunities through post-harvest processing of the African indigenous vegetables in Tanzania. Afr. J. Business Manage. 11, 426–437. doi: 10.5897/AJBM2017.8286

Nicastro R., Carillo P. (2021). Food loss and waste prevention strategies from farm to fork. Sustainability 13, 5443. doi: 10.3390/su13105443

Ntawuruhunga D., Affognon H. D., Fiaboe K. K., Abukutsa-Onyango M. O., Turoop L., Muriithi B. W. (2020). Farmers’ knowledge, attitudes and practices (KAP) on production of African indigenous vegetables in Kenya. Int. J. Trop. Insect Sci. 40, 337–349. doi: 10.1007/s42690-019-00085-8

Onyango K., Bolo P., Ndiwa A., Wanyama R., Chege C. G. (2023). A Rapid Agroecological Mango Value Chain Analysis in Kenya. (Nairobi, Kenya: Consultative Group on International Agricultural Research (CGIAR) Initiative on Agroecology report). 40.

Reardon T., Liverpool-Tasie L. S. O., Belton B., Dolislager M., Minten B., Popkin B., et al. (2024). African domestic supply booms in value chains of fruits, vegetables, and animal products fueled by spontaneous clusters of SMEs. Appl. Economic Perspect. Policy 46, 390–413. doi: 10.1002/aepp.13436

Ridolfi C., Hoffmann V., Baral S. (2018). Post-Harvest Losses in Fruits and Vegetables: The Kenyan Context. (Washington, DC: International Food Policy Res Inst.Research Institute (IFPRI)).

Ruben R. (2024). From market-based development to value chain transformation: What markets can (not) do for rural poverty alleviation? J. Rural Stud. 109, 103328. doi: 10.1016/j.jrurstud.2024.103328

Sarfo J., Pawelzik E., Keding G. B. (2023). Fruit and vegetable processing and consumption: Knowledge, attitude, and practices among rural women in East Africa. Food Secur. 15, 711–729. doi: 10.1007/s12571-022-01343-3

Schreinemachers P., Ambali M., Mwambi M., Olanipekun C. I., Yegbemey R. N., Wopereis M. (2022). The dynamics of Africa’s fruit and vegetable processing sectors. Annual Trends and Outlook Report. (No. WorldVeg Staff Publication). AKADEMIYA 2063.

Schuster M., Torero M. (2016). “Toward a sustainable food system: Reducing food loss and waste,” in 2016 Global Food Policy Report. Chapter 3 (International Food Policy Research Institute (IFPRI, Washington, D.C), 22–31. Available at: http://www.Tanzaniagateway.org/docs/HighValAgricProdsforSmallholdermkts.pdf.

Shiundu K. M., Oniang’o R. K. (2007). Marketing African leafy vegetables: Challenges and opportunities in the Kenyan context. Afr. J. food agriculture Nutr. Dev. 7, 1–17. doi: 10.18697/ajfand.15.IPGRI2-8

Sonka S., Lee H., Shah S. (2023). The yieldWise approach to post-harvest loss reduction: creating market-driven supply chains to support sustained technology adoption. Agriculture 13, 910. doi: 10.3390/agriculture13040910

Swinnen J. (2015). Value Chains, Agricultural Markets and Food Security. Available online at: http://www.fao.org/3/a-i5226e.pdf. (Accessed on July 30, 2024).

Temu A. E., Temu A. A. (2005). High Value Agricultural Products for Smallholder Markets in Sub-Saharan Africa: Trends, Opportunities and Research Priorities (Cali, Combodia: International Center for Tropical Agriculture).

Thomas D. R. (2006). A general inductive approach for analyzing qualitative evaluation data. Am. J. Eval. 27, 237–246. doi: 10.1177/1098214005283748

Willett W., Rockström J., Loken B., Springmann M., Lang T., Vermeulen S., et al. (2019). Food in the Anthropocene: the EAT–Lancet Commission on healthy diets from sustainable food systems. Lancet 393, 447–492. doi: 10.1016/S0140-6736(18)31788-4

Keywords: food loss and waste, markets, nutrition, scaling intervention, solution providers

Citation: Owino WO, Kahenya P, Wafula E and Otieno G (2024) Challenges and effective strategies for developing and scaling solutions to reduce food loss and waste in Kenya’s fruit and vegetable sector. Front. Hortic. 3:1489192. doi: 10.3389/fhort.2024.1489192

Received: 31 August 2024; Accepted: 31 October 2024;

Published: 21 November 2024.

Edited by:

Vijay Yadav Tokala, The Postharvest Education Foundation, United StatesReviewed by:

Khursheed Hussain, Sher-e-Kashmir University of Agricultural Sciences and Technology, IndiaGhulam Khaliq, Lasbela University of Agriculture, Water and Marine Sciences, Pakistan

Olubukola Odeyemi, Federal University of Agriculture, Abeokuta, Nigeria

Copyright © 2024 Owino, Kahenya, Wafula and Otieno. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Willis O. Owino, d2lsbGlzQGFnci5qa3VhdC5hYy5rZQ==

Willis O. Owino

Willis O. Owino Peter Kahenya

Peter Kahenya Elizabeth Wafula

Elizabeth Wafula Geoffrey Otieno2

Geoffrey Otieno2