- Agriculture, Food and Nutrition Security (AFNS) Program, African Centre for Technology Studies, Nairobi, Kenya

Initiatives to address food loss and waste (FLW) are gaining attention especially in smallholder-dominated food systems in developing regions. This is in effort to meet some of the Sustainable Development Goals (SDGs) targets. Countries are seeking innovative solutions to address the FLW challenge to contribute food and nutrition security and to reduce environmental impacts of greenhouse gas emissions through food waste. The lack of effective sustainable cold chain targeting smallholders is a key gap and driver of this challenge. There are gaps in system diagnostic of key factors and practices related to value preservation of food loss but is equally important in capturing value in market opportunities for smallholders and other value chain actors that can guide structuring of such cold chain investments. This article provides findings from a diagnostic study conducted to understand these factors and practices in smallholder focused horticultural value chains in Kenya. The mixed-method study collected quantitative and qualitative data through a household survey of 460 farmers and 25 key informant interviews. Results showed that postharvest loss (PHL) is a major challenge affecting all horticultural crops but with different magnitude. Despite the high PHL experienced, most farmers (96%) don’t undertake any postharvest management measures during and/or after harvest. Market related challenges were rated as the most (85%) causes to PHL followed by pest and disease (56%), weather impacts (24%), lack of storage facilities (17%), and damage during harvest (8%). Most smallholders sell to brokers at farm gate, capturing a small share of the value that is linked to lack of aggregation, gaps in cold chain infrastructure along value chain and the transactions costs of marketing. Results showed that other market outlets other than brokers offered higher prices linked to quality and safer product handling. Thus, integrating end-to-end cold chain solutions in smallholder systems through inclusive business models will shape interactions with markets and enable farmers to tap into new opportunities. Enhancing access to cold chain is key to supporting farmers and other value chain actors reduce PHL and facilitate better market integration, contribute to profitability of smallholder farming enterprises and improve socio-economic development.

1 Introduction

Food loss and waste (FLW) is a critical threat to agri-food systems accounting for almost one-third of the food produced globally, equivalent to about 1.3 billion tonnes annually. This significantly contributes to the food shortage, where 830 million people are notably hungry (Gustavsson et al., 2011). Initiatives to address FLW are gaining much attention, especially regarding smallholder-dominated food systems in developing regions, reinforced by the need to meet some of the Sustainable Development Goals (SDGs) targets. Reducing FLW is the focus of SDG 12, which explicitly includes a target (12.3) to halve per capita global food waste at the retail and consumer levels and reduce food loss along production and supply chains (United Nations, 2015). To achieve this, countries are seeking innovative solutions to address FLW that is critical to food and nutrition security and to reduce environmental impacts associated with greenhouse gas emissions through food waste, currently estimated to be 8% of total emissions. Furthermore, reducing FLW can enhance incomes and economic sustainability and profitability of farming (Guo et al., 2020; IPCC, 2019; Kikulwe et al., 2018).

The lack of effective cold chain is notably a key gap and driver of this challenge and is estimated to contribute to twelve per cent loss of the total food produced (UNEP and FAO, 2022). Access to cold chain, particularly in a warming world, is on the agenda of food systems transformation policies and investments, especially in developing countries where there is a glaring gap. Cold chain development in this context has remained exclusive infrastructure for export–oriented food supply chains, leaving behind many smallholders who focus on domestic value chains with limited support for such critical infrastructure (Peters and Sayin, 2021; Nuthalapati et al., 2022). However, deploying cold chain can further exacerbate the climate change challenge linked to the use of high-global warming refrigeration and the high energy demand of cooling (UNEP and FAO, 2022). Thus, there is need for sustainable cold chain in developing countries that consider the socio-economic and environmental dimensions of cooling. These need to be delivered as an integrated system that consider that the challenges faced in developing countries food systems dominated by many smallholders is not only at one node but is a farm to fork connectivity issue (Peters and Sayin, 2021; Nuthalapati et al., 2022).

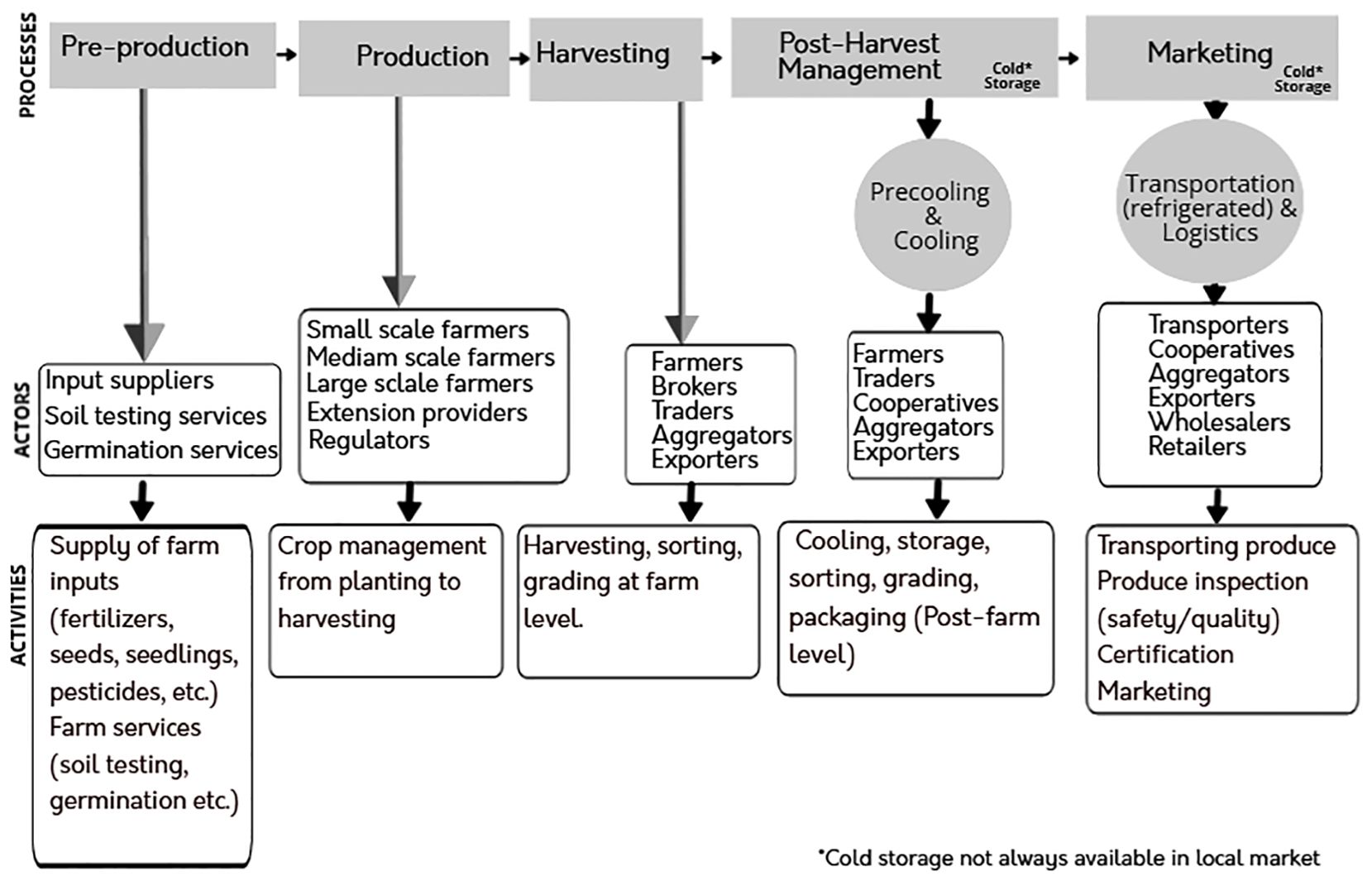

In Kenya, like other developing countries, smallholder-based food supply chains especially for fruits and vegetables have glaring gaps in cold chain resulting in estimated postharvest losses (PHL) of between 40% to up to 80% in some instances (Ambuko and Owino, 2023). As Gema et al. (2018) note, the Kenyan horticultural sector has developed over the years moving towards structured market and sophisticated value chains (Figure 1), especially for the export market. However, the local market, which presents significant opportunity for growth, remains fragmented and dominated by informal market systems. Nonetheless, shifts are happening through various differentiated market segmentation as well as regulatory advances to enhance quality and safety. In this context many actors including the government, development agencies and private companies are keen on investing in cold chain solutions. Many scholars have argued that investing in integrated cold chain infrastructure targeting smallholder farmers and their related supply chains is not only to address food loss but equally important to unlock market opportunities (Debnath et al., 2021). However, there is limited understanding of factors that can inform how to best structure cold chain deployment for the many smallholders’ producers and make a good business case for such high-cost investments (Singhal and Saksena, 2018). Most interventions for addressing food loss, especially in temperature sensitive value chains such as horticulture, comprising fruits and vegetables are structured purely as a technical challenge. As such they fail to consider the market dynamics and other crucial factors such as the socio-economic feasibility that underly gaps in such critical infrastructure (Peters and Sayin, 2021).

Unraveling the supply and demand dynamics of smallholder focused food value chains like horticulture is an important entry point to tailor sustainable cold chain infrastructure and close the gaps that contribute to food loss in these food supply chains. Such diagnostics can inform viable business models needed to correct the lopsided development of current cold chain infrastructure that is not accessible to most smallholders in developing countries.

This article presents findings from a need assessment conducted as a diagnostic to contribute to knowledge gap in understanding postharvest loss factors and practices in smallholder-focused horticultural value chains and the link with cold chain and the effects on market access. The study was conducted as part of the entry point to inform a proof-of-concept investment in cold chain infrastructure as part of the African Centre for Sustainable Cooling (ACES) program. The program takes a data-driven approach to structure a pilot that will deploy socio-technical and business models to inform the deployment of sustainable cold chain to smallholder farmers in Kenya engaged in horticultural value chains.

1.1 Smallholder food systems loss and value and role of sustainable cold chain development

Studies note that improving access to proper cooling facilities is vital in helping farmers avoid food loss. Horticultural crops are particularly affected by lack of cold chain, including pre-cooling and storage and distribution. These crops have more field heat at harvest that needs to be removed to avoid physiological and pathological effects resulting from respiration, ethylene production, and mechanical injury (Makule et al., 2022). The high perishability in horticultural value chains requires a holistic approach to delivering end to end cold chain and not cold storage that has been the dominant focus in research in developing countries (Rutta, 2022). The argument for integrated cold chain infrastructure targeting smallholder farmers and their related supply chains is not only to address the food loss challenge, thus preserving the food value including from a quality, safety and resource use perspective. But equally important is to capture value through unlocking different market opportunities in various ways and increasing incomes of smallholder farmers (Sheahan and Barrett, 2017). The value capture is unpinned by evolving and emerging diverse business models including specialized retail stores, online trading platforms among others. Sustainable cold chain integration can enable farmers to access these different structured, high value domestic and export markets for their current or new crops (Debnath et al., 2021). Singhal and Saksena (2018) argue that the lack of cold chain has structured how smallholders dependent value chains are organized and their underlying practices, thus constraining the possibilities for value preservation and capture starting at the farmer level. In the horticulture sector, access and availability of cold chain infrastructure for smallholder supply chains is an essential element for maintaining quality and freshness of harvested produce from the farm to different markets given the specific biological characteristics of the crops. Additionally, postharvest food loss is noted to be about inadequate food distribution (Stathers et al., 2020). Studies have assessed low consumption of horticultural produce in developing countries pointing to various barriers spanning socio-economic factors, consumer behavior, environmental conditions, and other macro-system level drivers including those linked to the food environment (Kaur, 2022). All these barriers provide opportunities, but an important one that is linked to food loss that is increasingly receiving attention is on the food environment and the limitations of adequately distribute quality horticultural produce to all markets including in remote non-producing, rural regions (Dean and Sharkey, 2011)

Looking at these interrelated factors provides a framework to understand practices and factors on how to structure interventions and investment in integrated cold chain to addressed postharvest loss in the horticultural value chain, with emphasis on addressing the market drivers in that make a case for sustainable cooling and cold chain

2 Materials and methods

2.1 Study site

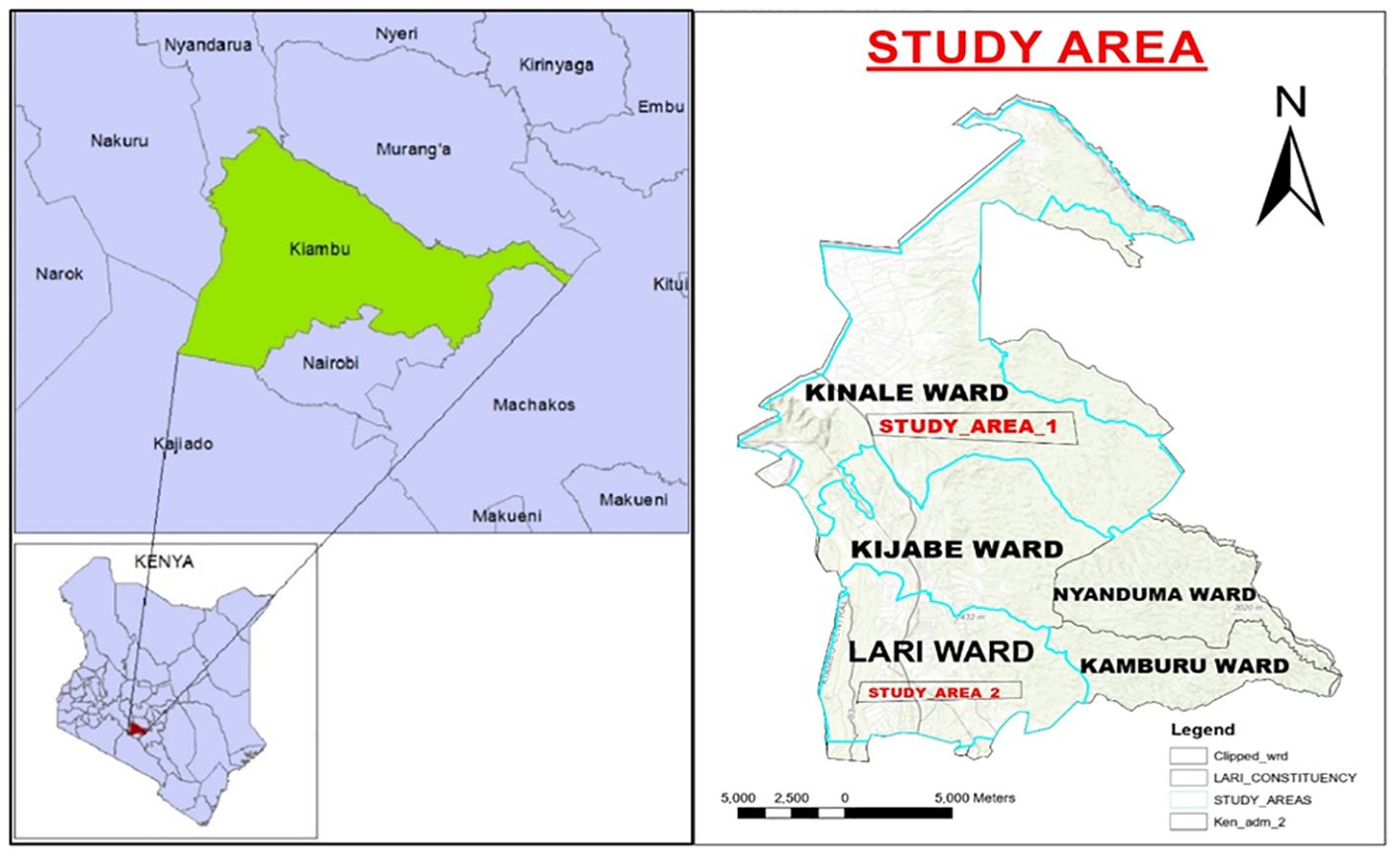

The study was conducted in Lari Subcounty, located in Kiambu County, Kenya, which, according to the 2019 KNBS census, comprises 38,592 households (KNBS, 2019). Agriculture is the leading economic activity, contributing about 17% of the sub-county’s income. The area under agricultural production is 1880 ha, which is 74% of the total land area (MoALFC, 2021). Lari Subcounty was purposively selected from among the 12 sub-counties as shown in Figure 2, due to its significant agricultural activity, with 62% of its households engaged in crop production (KNBS, 2019). The research specifically targeted two main agricultural wards within Lari Subcounty, Kinale and Lari-Kirenga, which together represent 44% of the sub-county’s population, accounting for approximately 17,034 households (KNBS, 2019).

The climatic conditions of Lari subcounty are characterized by a mean annual temperature between15-23°C though warming trends are being observed and projections indicating continued increases in the future. The rainfall is a bimodal pattern distributed in two rainy seasons with the long rainy season running between March and May being wetter than the short season experienced between October and December. The annual average precipitation in the sub-county is 600-1300 mm with the highest rainfall (200mm) recorded in April (KMD, 2024). The two wards were selected as they are part of a pilot intervention seeking to integrate sustainable cold chain in smallholder horticultural value chains. The pilot is part of The Africa Centre of Excellence for Sustainable Cooling and Cold-chain (ACES) that aims to promote access to resilient, efficient and climate-friendly cooling and cold-chain technologies with a focus on smallholder producers. The initiative seeks to strengthen local and global food systems, with an emphasis on achieving food and nutrition security goals enabled through integration of sustainable cold chain as critical infrastructure (Peters and Sayin, 2023).

2.2 Sampling procedure

Sampling involved identifying and listing administrative units (locations, sub-locations, and villages) within Lari-Kirenga and Kinale wards. List of villages were used as the sampling frame for the survey in which approximately half of the villages in each ward were randomly selected. Village elders, who assisted in the mapping process, indicated that each village typically consisted of 50-100 households.

In Lari-Kirenga and Kinale wards a total of 62 and 80 villages were identified and listed, after which 31 and 40 villages were randomly selected for sampling in each ward respectively. To ensure diverse representation of farming households during data collection, systematic random sampling was used to select every 7th household in each village as guided by village elders. This approach resulted in a total sample of 460 households being interviewed: 234 from Kinale and 226 from Lari-Kirenga.

2.3 Determination of sample size

To determine the sample size, the study utilized Kothari’s (2004) formula for a finite population. The sample was later adjusted to meet the desired requirement. The formula is expressed as follows:

Where:

is the initial sample size,

Z is the Z-score corresponding to the desired confidence level, (1.96)

N is the population size (Households N=17034)

is the estimated population proportion of farming household (0.62)

δ is the margin of error (0.05).

Formula for adjusted sample size using actual population size was adopted (Hasan and Kumar, 2024).

Adjusted sample to cater for non-response 10%, Oversample of 30% to strengthen the robustness of the results to allow the sample to accommodate any quality issues

*As stated in the sampling procedure above, utilization of the systematic sampling approach resulted in a total sample size of 460 households which accounts for 96% of the computed adjusted sample size.

2.4 Data collection

The study used a mixed-method approach integrating quantitative and qualitative data from primary and secondary sources. Primary data was obtained through a household survey and key informant interviews (KIIs). The survey was administered by trained enumerators and data was collected using Survey CTO platform.

The household level data included socio-economic characteristics of respondents and their households such as family size, gender, level of education, size of land produced, types of crops produced, postharvest management practices, loss and market information. Size of land was estimated in acres and transformed into M2 by equivalent of 1 acre=4046.86M2. Data on loss at farm level was based on farmers estimation through recall of the losses incurred during the last harvesting cycle. Farmers used diverse units such as number of bags, crates, buckets etc. This data was later standardized into kilograms and extrapolated annual loss. However, using such self-reported data has limitation as noted by (Kitinoja and Fonseca, 2018).

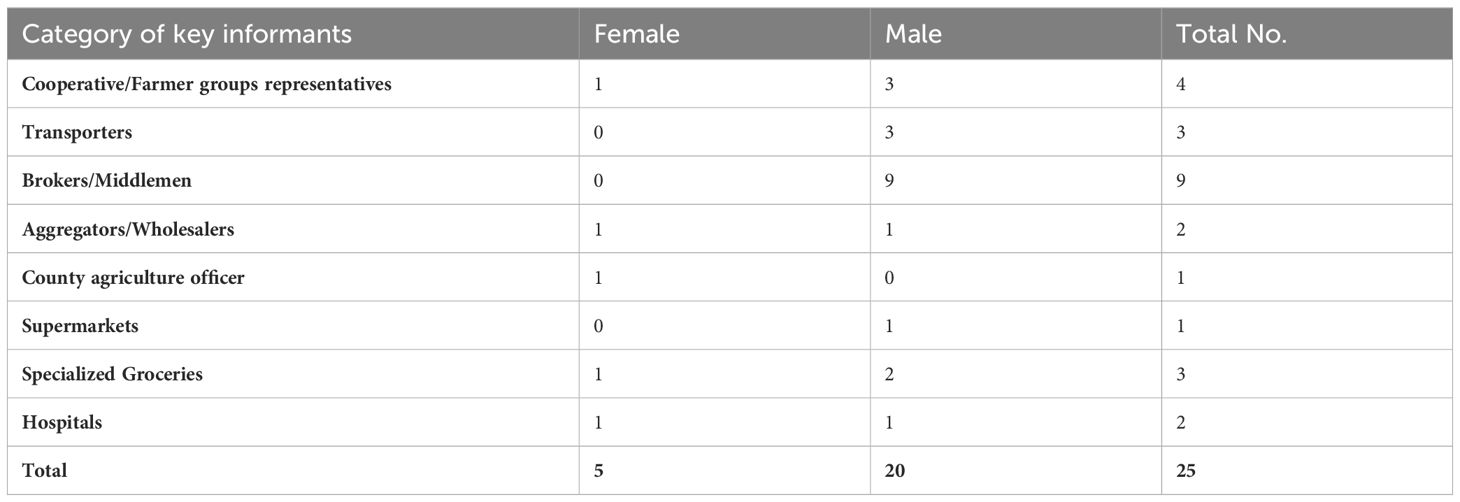

25 KIIs were conducted with various actors along the value chain as summarized in Table 1.

2.5 Data analysis

Household survey quantitative data was cleaned and analyzed using Excel 2016 and Stata software version 18. This included descriptive and inferential analysis. Production, postharvest data and product marketing units were standardized into kilograms, converting units such as bags, bunches, bucket, net, crates, and pieces. This standardization process was validated by cross-referencing with other value-chain actors, such as brokers, and traders, who predominantly sell their products in kilograms. Food loss was assessed based on farmer estimates of produce lost at farm level in the previous production season.

The qualitative data from the survey was extracted and coded. KIIs were transcribed and the data coded guided by the key analytical concepts then subjected to thematic analysis using MAXQDA version 24.

3 Results

3.1 Farmers’ demographics and socio-economic characteristics

The findings showed that majority of the respondents were male (52%), while female constituted 48%. The average age of both men and women farmers was 47 years. The majority (57%) of the farmers are aged 45 years and above, while the youth farmers (aged below 35years) represented 21% of the respondents. Additionally, majority of households’ heads were male (80%) while female-headed households represented 20% with an average household size of 4.2 persons. The households owned an average of 6,070.29M2 of land, with around 29% leasing an average of 4046.86M2.

3.2 Types of farming systems

The findings show that over 99% of the households engaged in crop farming, out of which 76% practiced mixed farming, combining both crops and livestock, whereas 23% of the households engaged exclusively in crop farming. About 76% of the households reported keeping some type of livestock, with the majority (82%) engaged in dairy production.

3.2.1 Horticultural production

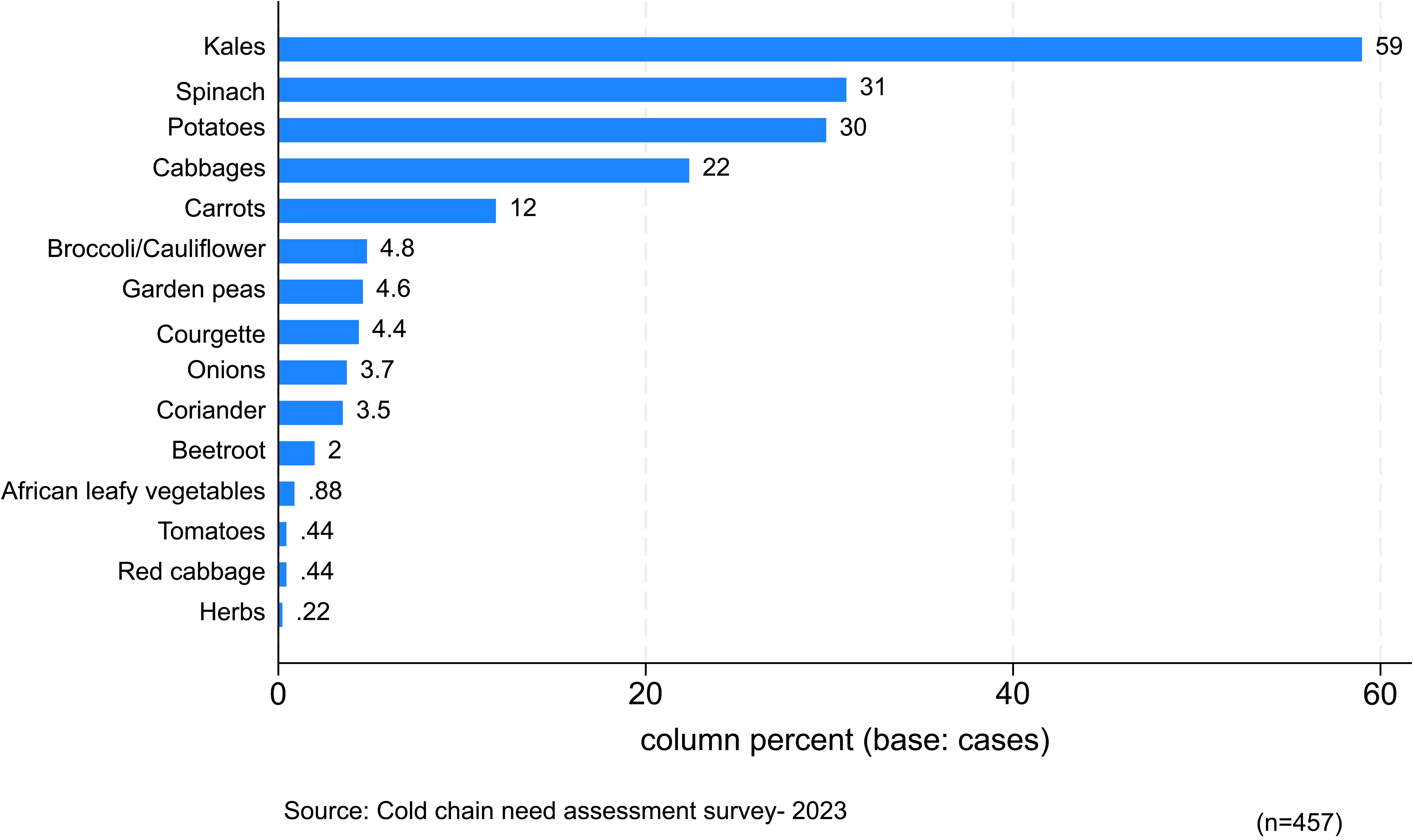

The findings show that most (99%) crop farming households cultivate horticulture crops, followed by maize (25%), fruits (17%), and beans (10%). Results showed that a wide range of horticultural crops are produced in the area with kales emerging as the most produced by 59% of farmers over the past year. Other horticultural crops grown included spinach (31%), Irish potatoes (30%), cabbage (22%), carrots (12%) (Figure 3). Others horticultural crops that were listed are grown by fewer farmers.

Most farmers (60%) practiced mixed horticultural farming, producing more than one crop per season, of which about 46% typically cultivate two different crops. Cabbage, kales, and spinach were most produced, with each farmer achieving an average production of over 33 and 29 tons per year as shown in Table 2. The land allocated for these crops is also significantly larger compared to other crops. Although only small percentage of farmers (3.7%), grow onions, they allocated the highest portion of land, averaging almost (2833M2) per production season as shown in Table 2.

The main horticultural crops are produced all year round with some months considered the peak for harvest as shown in Figure 4. Typically these main horticultural crops are grown and harvested around the same time. Farmers and some of the KIIs noted that this results in cycles of glut and scarcity, that has effected on pricing. Kales and spinach which have multiple and shorter harvesting cycles implies more farmers are able to supply throughout the year.

3.3 Harvesting and Postharvest management practices and value loss

Postharvest loss (PHL) was noted as a major challenge affecting all horticultural crops but with differentiated magnitudes. Among the 457 crop farmers sampled, 295 (female 122, male 173) reported experiencing some PHL with losses of 12% for courgettes and garden peas to as high as 29% for carrots and onions as summarized in Table 3. The reported PHL translates to notable economic loss but also contributes to food shortage and resultant effects on nutrition. Most farmers (78%) reported that they used the wasted produce to feed their livestock while 26% reported that they decomposed the waste into manure (26%) or left in the farm to rot. On the other hand, (20%) used it for home consumption, others recycled it as seed for the next season (common for Irish potatoes), 12% gave it to their neighbors, while 4% simply threw it away. There were no significant differences between genders in the reporting of PHL. However, this is area that would need further interrogation in subsequent assessment considering the different roles that women and men play in agricultural systems.

3.3.1 Practices and factors influencing postharvest loss

The findings show that most farmers (96%) did not undertake any practice during harvesting that can be considered as PHL management measure which was a major contributing factor to the observed PHL. Whereas losses were mentioned to happen at harvest, losses could be attributed to some factors during crop growth mainly associated with poor farming practices such as poor soil and seed quality, inconsistent moisture levels as well as pest infestations and diseases. Inability to implement proper crop management practices could be linked to limited knowledge and advisory support that notably emerged as a significant challenge. It is thus imperative to have support strategies through farmer training and extension support, particularly during crop production and on postharvest management practices, which are crucial for reducing PHL. Findings show that over the past one year, only 15% of farmers reported having received agricultural-related training, while only 5% had accessed extension services. Limited access to farmers extension and advisory services in Kenya is a glaring gap in smallholder dominated agricultural innovation system (Kilelu et al., 2011)

However, most farmers (85%) attributed PHL to market related challenges linked to market integration dynamics. Factors ranged from aspects of produce quality that did not match market requirements (e.g. undersize), delays from buyers resulting in overgrown produce, poor price offers that made some farmers opt not to sale (Figure 5). Other noted factors were the effects of pests and diseases during crop production (56%), weather effects (frost, heavy rains and drought) (24%), lack of storage facilities (17%) resulting in rotting, withering etc. and damage during harvest (8%) were also notable factors. On harvesting practices, farmers and brokers indicated that the arrangement is usually the buyer, typically a broker is responsible for harvesting the crop. The casual laborers employed by the broker to harvest are usually not careful, or do not use appropriate tools resulting in damage to a proportion of the crops.

Lack of adequate packaging was noted as part of the practice in handling the horticultural produce that contributed to spoilage and loss. Sacks or gunny bags were the main form of packaging used to carry all produce as noted by over 97% of the farmers, but also observed by the different key informants. Less than 2% of farmers used other packaging options such as baskets or crates. Additionally, traders and transporters interviewed as key informants noted post-farm loss due to spoilage as a key challenge. This was due to a combination of factors including poor roads and, especially during the rainy season and mechanical breakdowns of vehicles that caused delays. One pointed out that the lack of refrigerated trucks in this context resulted in spoilage of produce that needs to be transported over long distances.

3.3.2 Markets and marketing dynamics

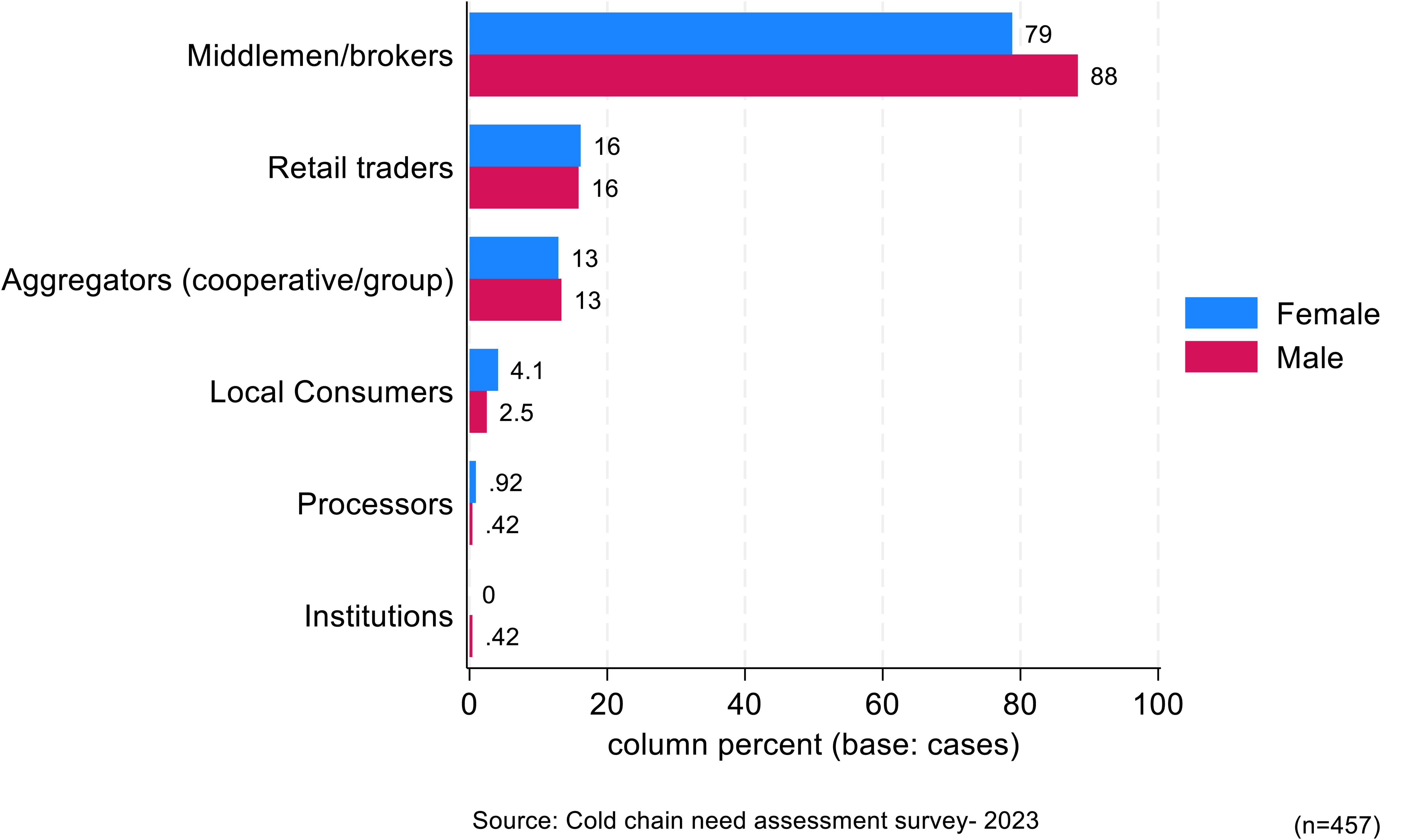

Most of the farmers in the area are commercially oriented with (99%) indicating that most of what they produced was sold. Most of these farmers relied on middlemen or brokers as their main buyers selling at farm gate, with some differences between men (88%) and (79%) women as shown in Figure 6. Farmers noted that their preference for such spot marketing was to avoid transactions costs such as transportation and market search. There were few farmers that sold their produce directly to other outlets such as wholesaler markets or retail traders. Majority farmers (64%) noted that they used motorbike as the main mode of transporting the produce from the farms, followed by donkey carts (23%), motor vehicles (15%) and bicycles (4%).

Middlemen or brokers play a crucial role in the food supply chain aggregating and delivering food produce to other supply actors such as wholesalers and retailers thus ensuring that the food reaches diverse and distant markets. Many aggregators dealing with horticultural produce were involved in trading with distant markets across the country. Notable market destinations included Nairobi (40km), Mombasa (524), Kilifi (580km), Malindi (639km), Kisumu (306km), and Garissa (406km). The distribution and marketing chain thus form a comprehensive network, with farmers, brokers, aggregators, playing distinct roles seamlessly to ensure supply of horticultural produce to both local and distant markets as one aggregator noted below.

“There are retailers and wholesalers. We sell to markets in … Mombasa, Voi, Kisumu and Eldoret. There are around five lorries that go to Mombasa daily, carrying potatoes, carrots, Sukuma, and cabbages.” Vegetable aggregator.

3.3.2.1 Market outlets, Pricing structure, aggregation and value distribution

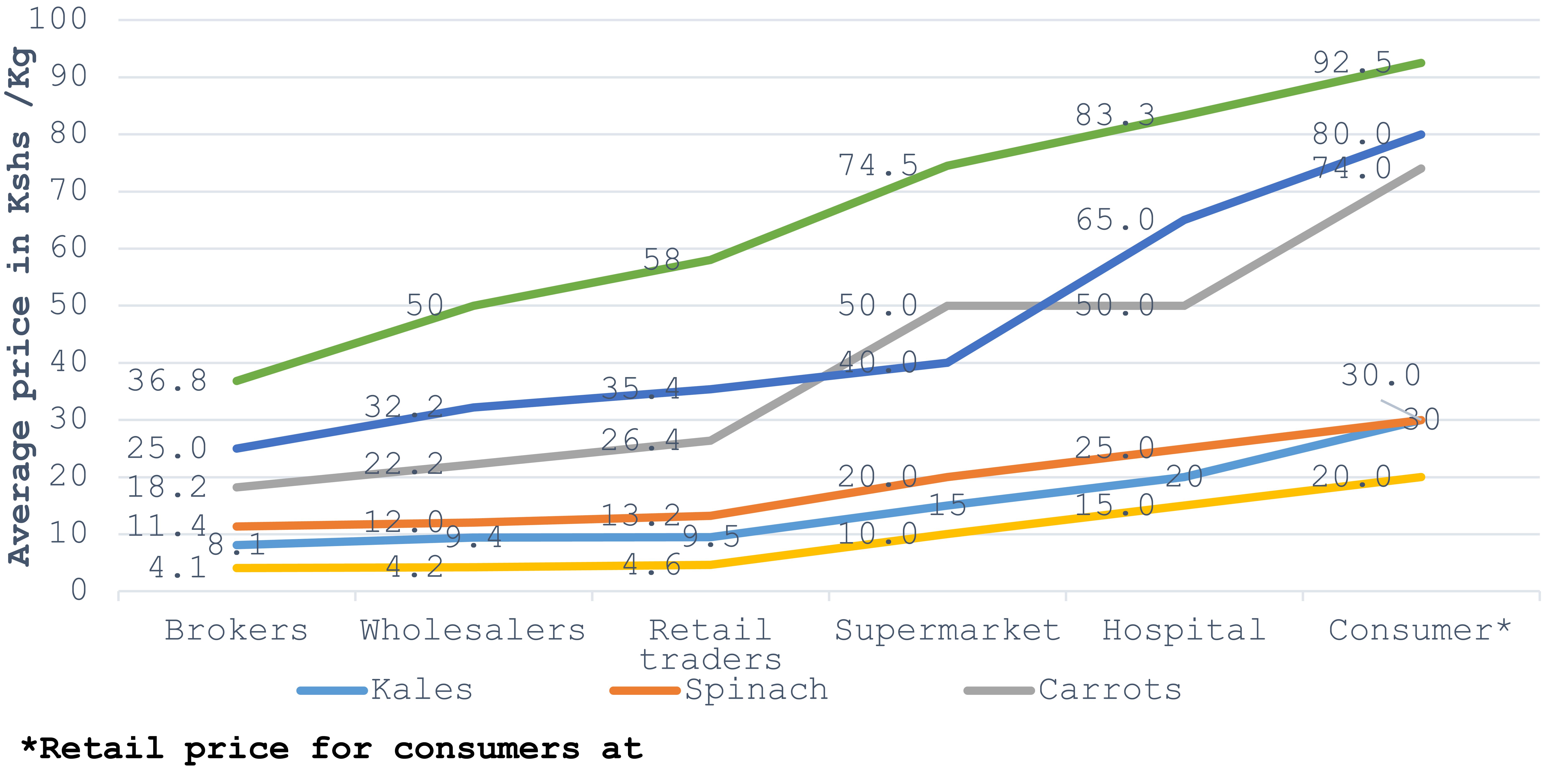

Selling at farm gate which is the main outlet for most farmers attracted the least price for their produce. As the farmers noted, at this point they were price takers. The price offered to farmers increased as you move away from spot farmgate selling. As Figure 7 shows, for each of the produce where pricing data was available, it can be noted that formal markets like supermarkets, specialized grocery stores and institutions such as hospitals offered the highest prices, peaking at the retail price in supermarket for the end consumer.

As noted in section 3.2.1 seasonality shapes horticultural produce availability. This affects prices. According to KII with market actors, the price of different commodities fluctuated according to seasons. For example, cabbage and kale prices ranged from 0.08USD to 0.19USD per kg whereas carrot prices fluctuated from 0.6 to 0.62USD during glut and scarce periods respectively. Furthermore, interviews with various market actors including specialized grocery stores, supermarkets and aggregators selling to supermarkets and other clients including restaurants, revealed that their target customers are increasingly quality conscious and concerned with food safety. Driven by these demands, the markets are restructuring their procurement process and supply chains to ensure quality assurance which results in high prices. This context is stimulating investments in cold chain infrastructure, though many smallholder producers are not being reached hence the gap persists. The study assessed farmers willingness to pay for cold chain services to maintain the quality of their produce from farm to the market. The results indicate that farmers are willing to utilize cooling services, however, willingness to pay was only considered by most when the cost is almost negligible. This may be linked to the low value that farmers get from selling their produce.

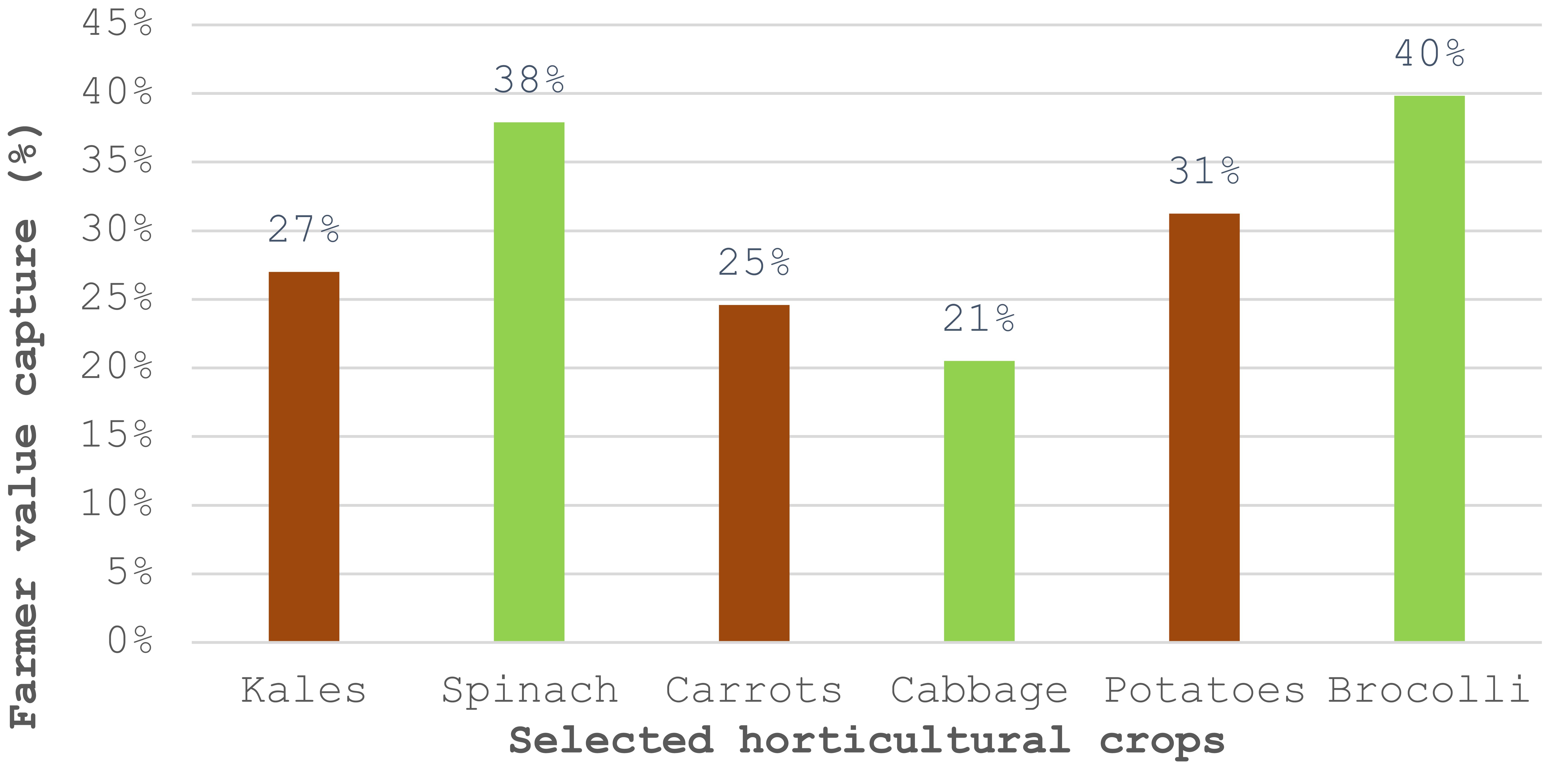

Analysis of price data from the survey and the interviews with KIIs showed that for most horticultural produce, farmers capture below 30% of the value, since they sell mainly at farm gate (Figure 8). Farmers targeting markets other than brokers generally received slightly higher average prices for most of the produce.

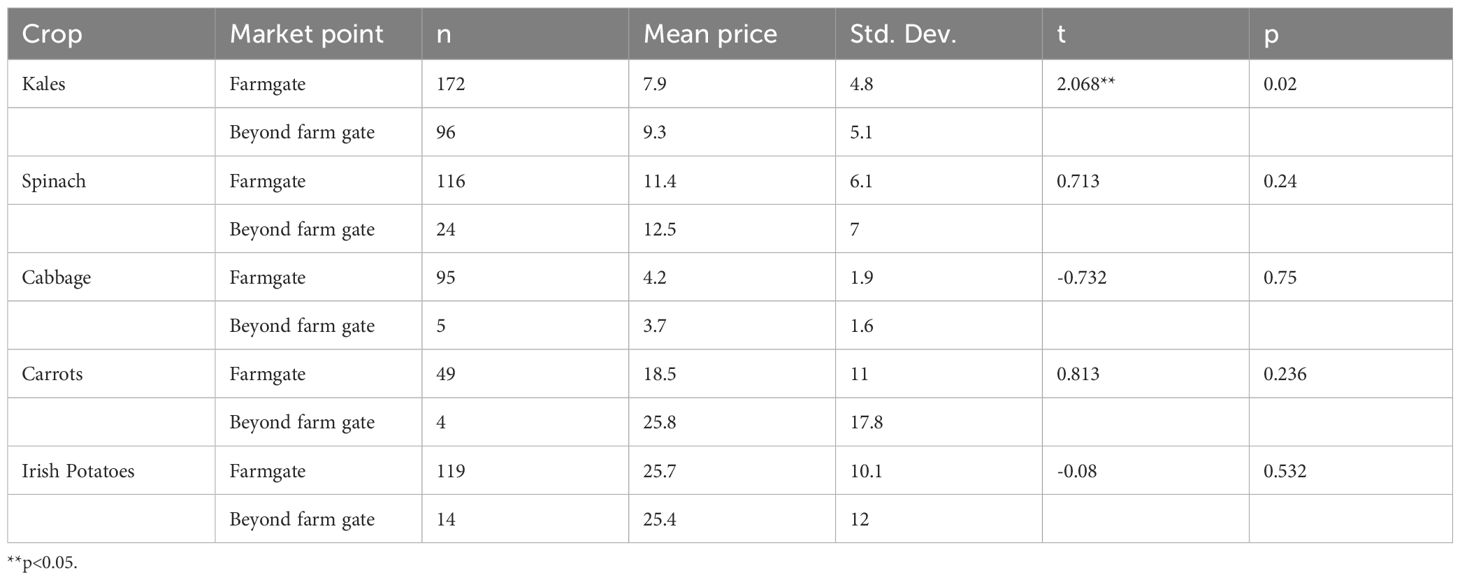

However, t-tests results as summarized in Table 4 comparing the mean prices farmers get of the five most grown and sold horticultural crops at farm gate and when marketing beyond the gate, shows no significant differences (p=0.05), except for Kales. The average Kale price at farmgate was M=7.9, SD=4.8, while beyond the farmgate it was M=9.3, and SD=5.1 indicating significant difference, t (188) =2.07, p<0.05, and a Satterthwaite’s degrees of freedom of 187.99.

Even though farmers felt exploited by brokers they persisted in selling their produce at farm gate owed to the fact that brokers paid them on delivery and the fact they provided a ready market for their produce thus saving them from the hustle of searching for markets. Most of the farmers indicated that they engaged with markets individually, with no structured relations with buyers. This was confirmed by the findings that showed that only less than 1% of the farmers were involved in any form of contract farming, as a model that can better structure their marketing and relations with buyers. This can mitigate market fluctuations, uncertainty and price volatility hence stabilize incomes.

Most of the key market actors indicated that they didn’t have any agreed contracts but only informal mutual agreements with farmers. Findings show that only 11% of the farmers belonged to a farmer group or cooperative, indicating limited aggregation or collective marketing of horticultural produce. About 25% of the farmers indicated that some factors they considered as key motivator in joining a farmer group or cooperative is effective leadership and management characterized by qualities like honesty, transparency, trustworthiness, inclusivity, and accountability. Some farmers (26%) expressed interest in joining a cooperative if it could offer better market opportunities possibly enabled by cold storage coupled with new knowlegde sharing and market information.

According to one of the aggregators, the horticultural value chains are dynamic with comprehensive distribution and marketing networks of farmers, brokers, aggregators, and farmers’ groups playing distinct roles in catering to both local and distant markets.

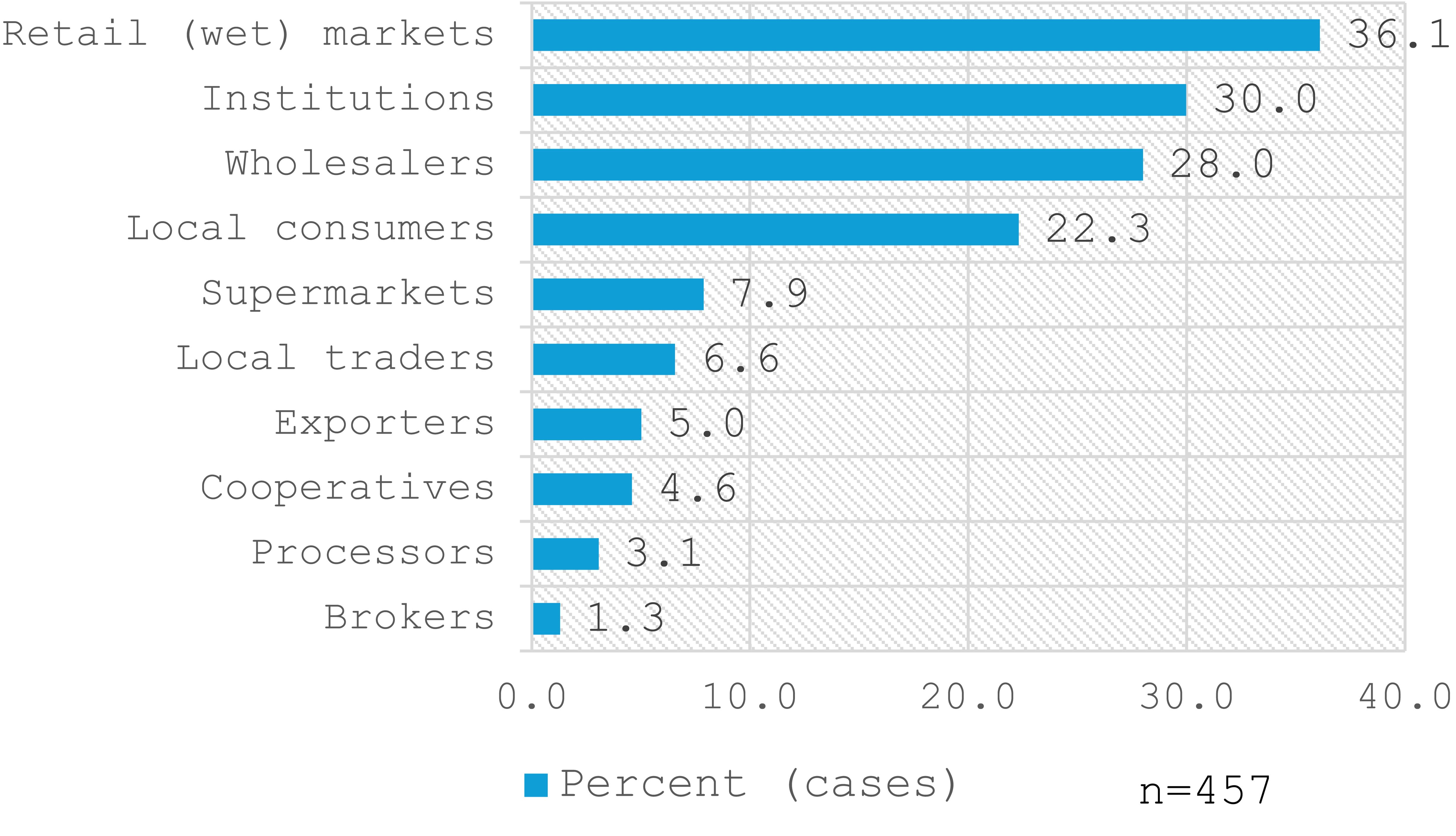

However, as some of the key informants noted, lack of storage and aggregation points and access to cold chain affects seamless operations of horticultural value chains that results in significant losses. Farmers expressed a desire to engage with markets that would offer them better prices (Figure 9). Approximately 36% of the farmers interviewed indicated a preference for selling directly to wet markets in the country's major cities. Another 30% expressed an interest to sell to institutional markets, including hospitals, hotels and hospitals, as shown in Figure 9. Interestingly, supermarkets and export markets were not mentioned as highly desired by many farmers. Discussions with key informants showed that this was linked to the terms of payment offered by the institutional markets and the stringent requirements for accessing the supermarkets and export markets.

3.4 Diversification to high value horticultural crops

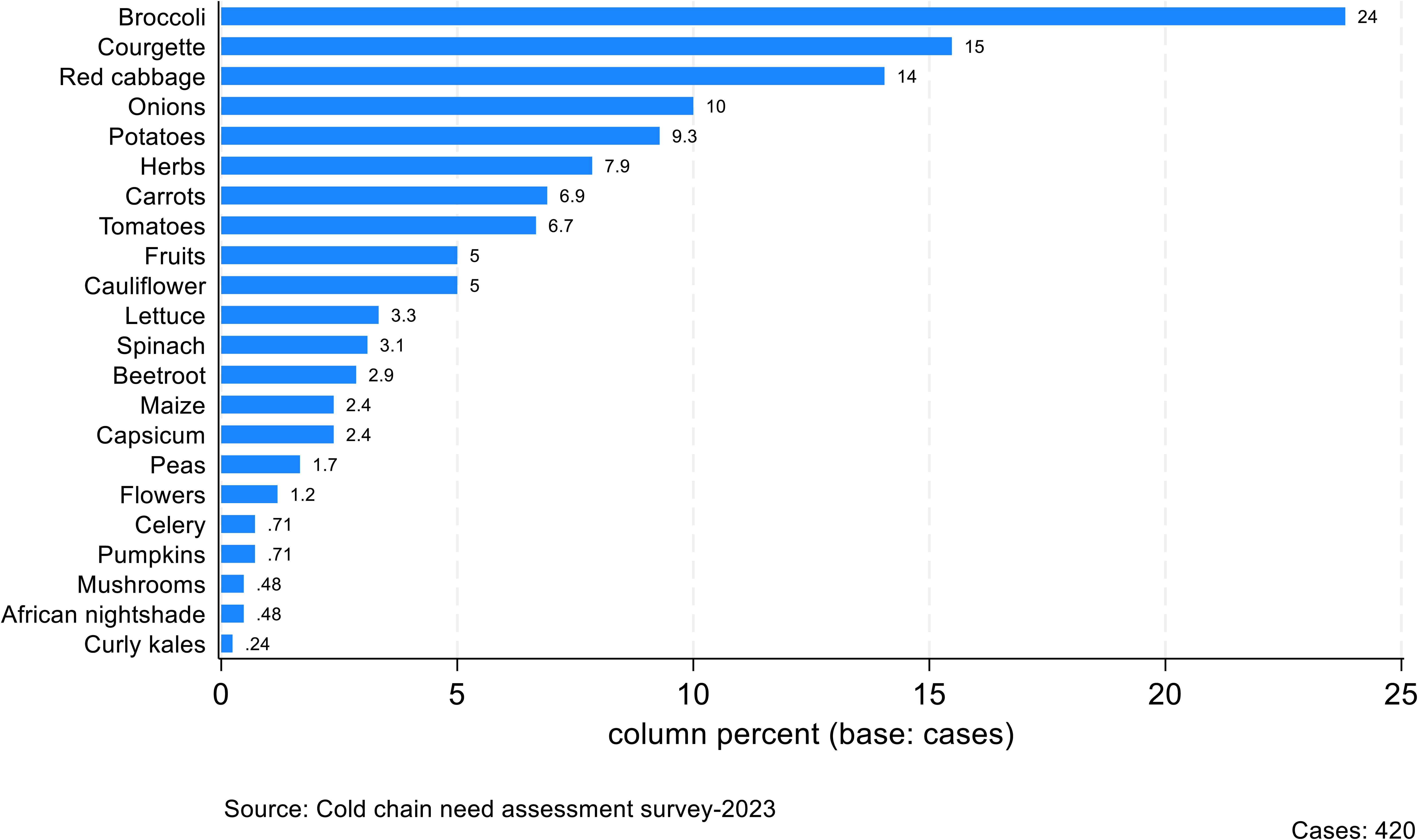

The sampled farmers were asked to list crops they considered as high value, in terms of economic return, that they were currently not growing but would be willing to grow (Figure 10). The crops mentioned were broccoli (24%) courgetti (15%), cabbage (12%), and onions and potatoes (10%). Other crops mentioned by less than 10% of the farmers included carrots, herbs and spices, lettuce, colored capsicum and fruits such as strawberries and tree tomato.

Farmers identified several factors that hindered their ability to cultivate high-value crops. The main hindrance was the high cost of production attributed to the high cost of inputs including seeds, fertilizers, pesticides and other agricultural inputs. Water scarcity, particularly for irrigation, was another key factor influencing the production of high-value crops, as noted by 18% of respondents. Land availability and marketing were also quoted as other factors restricting the expansion of the production of high-value crops by 12% and 6% of the respondents respectively.

As some key informants noted, a key challenge for farmers is that their production is not always guided by market demand. A supply driven approach to production is a driver of postharvest loss, especially when the farmers produce the same thing resulting in a glut especially during high seasons. Limited access to cold storage was mentioned to hinder production of some of the high value crops which are temperature sensitive and highly perishable. The informants noted that some of the product target niche markets that would require careful handling.

4 Discussion

4.1 Significance of PHL in smallholder horticultural value chains

The study confirmed that horticulture value chain is a key economic activity and a source of livelihood for many smallholder households and a wide network of value chain actors in Kiambu County. The value chain comprises a variety of horticultural crops cultivated in small sized farms. The susceptibility of horticultural crops to PHL reported at farm level was further confirmed by the findings of other researchers (Ambuko and Owino, 2023; Sibanda and Workneh, 2020). PHL as value loss is a significant challenge demonstrated by the fact that 65% of the farmers reported having experienced postharvest losses. Despite PHL being a challenge in the study area, the majority (96%) of farmers reported that they had not taken any postharvest management measure to avert the PHL, a factor which further aggravates the problem. This is mainly due to the fact that farmers sell at the market gate, where the brokers played a big role in harvesting, and are not always careful in the process. This is also linked to limited extension support offered to farmers as was noted in the study findings. The study further provided analysis to demonstrate the differences in PHL by produce. While the challenge of such self-reported data is acknowledged (Kitinoja and Fonseca, 2018), it shows the complexity and diversity of the horticultural value chain that should inform how to structure solutions including cold chain that factor these differences. Further considerations are needed as the producing regions are experiencing climate change risks including erratic rainfall patterns, temperature variability with increasingly high temperatures leading to even quicker deterioration and adverse effects on the product quality and increase losses. The occurrence of pests and disease was cited as a major contributor to PHL which compounded with other factors such as poor farming practices including use of poor-quality seeds, poor soils, coupled with pre-mature harvesting exposes produce to the risk of quality deterioration. This thus calls for the need to adopt sustainable good agricultural practices which are a prerequisite to a shift towards high-value crops that present an opportunity for enhanced incomes amongst smallholder farmers. Effective training programs and services are crucial for disseminating knowledge, providing technical assistance, and supporting farmers in adopting best practices to reduce losses. Low access rate of such services highlights a significant gap in support to smallholder farmers, which has a ripple effect along the value chains. The bias of delivering extension services mainly toward productions issues has resulted in limited investment in PHL extension (Kitinoja and Fonseca, 2018). Thus, enhancing farmers’ capacity on good agricultural practices, PHL coupled with technology access and adoption by smallholder farmers is needed.

4.2 Understanding PHL through market structures

The findings show that PHL is a factor in how markets function and are structured, influenced by limited investment in the requisite infrastructure especially at the domestic level. Access to reliable infrastructure such as roads, cold chain including storage and transportation is critical to getting produce from farm to the markets in an efficient way thus minimizing loss and related impacts. Results of the study show that such infrastructure is not within the reach of the smallholder farmers, and they mostly depend on third parties for these kinds of services. This prevents farmers and other value chain actors from capturing value from the farm produce. Only 17% of the farmers interviewed had access to storage facilities. This is a key driver for farmers selling their produce immediately after harvest at the farm gate to brokers. Typically, harvesting occurs when these buyers are present on the farm. In most cases the horticultural produce that is ready for harvest can spoil if the buyers don’t show up at the right time or at all, especially in periods of glut production, and especially when farmers lack other alternative market options. In cases where the buyers don't show up, some farmers opt to leave the produce on farm for as long as they can, and others opt to use it as animal feed. The implications are high losses in volumes and quality in these supply chains. These losses are discounted from the farm-gate prices offered by the off-takers. Thus, the lack of required infrastructure is a direct contributor to PHL and loss of incomes for farmers.

Thus, PHL is both a factor and an effect of how smallholder farmers engage with the market dynamics. Results from the study showed that most farmers (85%) attributed PHL to market related challenges and dynamics. Whereas aggregation and transport facilities at the farm gate are key to expanding the market reach, most of the farmers indicated that they relied on the capacity of the brokers/middlemen to offer market linkages of their produce by buying at farm gate. However, the farmers indicated that the brokers offered low prices which limits their potential to reap full benefits and profitability of their farm enterprises.

This lack of significant price variation can be attributed to the informal market structures in Lari sub-county, which do not show substantial price differences between selling at the farm gate and beyond. This situation is exacerbated by individual marketing practices, which diminish farmers’ bargaining power, even when they transport their produce to farther markets. Additionally, the lack of a cold chain means that farmers are often forced to accept the prices offered at the market, even if they are not better than those at the farm gate. As other studies have shown, the supply chain inefficiencies are passed on to the farmer (Roy, 2015). The dominance of an informal horticultural value chain is characterized by low integration of quality and safety standards that shape practices around production, harvesting, handling, and marketing which are key drivers of PHL. Scholars (Mvumi and Stathers, 2020; Islam et al., 2022) note the challenge of most smallholder horticultural farmers inability to adhere to local and global standards (e.g. GlobalGap) in the horticultural value chains is tied to the informality in their operations and transactions, coupled with lack of requisite infrastructure such as storage and transportation that contributes to high PHL.

On the other hand, membership to producer organizations gives farmers bargaining power that can facilitate efficient marketing and reduced exploitation by middlemen. Results indicate that only 11% of the farmers belonged to a farmer group or cooperative, which clearly depicts that there is limited aggregation or collective marketing which further exposes the farmers to exploitation by middlemen. This justifies the report by (UNEP and FAO, 2022) which indicates that to enhance productivity, and profitability of smallholder farming enterprises calls for development of aggregation facilities near farms with transport services which would facilitate farmers’ market connectivity and direct access to far and high-end markets which offer better prices.

4.3 Investment in cold chain to address PHL and value creation

Although farmers reported that most of the PHLs are experienced at farm level during harvesting, significant losses occur due to inefficient arrangements across the entire value-chain including lack of postharvest technologies such as cold chain facilities. There is need to integrate cold chain storage solutions across the entire postharvest processes including sorting, grading and packing, transportation, and marketing. Enhancing access to the cold chain is key to supporting farmers and other agro-entrepreneurs to reduce PHL and increase product shelf-life which would eventually facilitate better and higher prices.

Investments in cold chain can potentially improve the distribution of temperature sensitive horticultural produce to smaller and distance markets whilst enhancing farmer benefits. The findings confirm that there is need for investment in cold chain for smallholder driven horticultural value chains targeted as a way of structuring the domestic market supply chains to become more efficient. This needs to be considered especially because of consumption gaps of vegetables and even fruits in Kenya, with a skew against regions with limitations in production and certain urban populations (Holdsworth et al., 2020; Li et al., 2024). There is a need to stimulate investment in cold chains for domestic markets as an important element in improving the effective handling and marketing of the horticulture value chains to reduce losses that will also affect prices. This can improve on the retaining of nutritive value and food safety while increasing availability, access and affordability of the horticultural produce for the local populations (Holdsworth et al., 2020; Kitinoja and Njie, 2021). The investment in such infrastructure should be driven by the goal of linking the smallholders to well-paying markets. As Islam et al. (2022) have noted, cold chain not only reduces the economic and opportunity costs of food loss but supports in positioning farmers in markets. In addition, enabling the restructuring of the currently fragmented and inefficient domestic focused horticultural supply chain, which is the focus form most smallholder farmers. Therefore, cold chain access can unlock the discriminatory prices farmers are getting for their produce and may be enabled through access to structured markets. However, the guiding principle for considering such investments is the opportunities presented for inclusive business models that will make cold chain accessible to all smallholder producers and enterprises, including for marginalized groups such as women and youth but also enable them to derive the value from such infrastructure.

5 Conclusion

The study took a needs assessment approach to understand postharvest challenges facing smallholder farmers engaged in diverse horticultural value chains as a combination of many factors that relate to value preservation and value capture. The temperature sensitive nature of horticultural produce makes them highly perishable, resulting in high losses. While there are some differences between different crops, the points of loss are similar and occur during harvest, marketing, transporting and storage. For many smallholder farmers, a combination of limited knowledge and extension support and gaps in access to necessary technology including cold chain are key drivers. This is affecting the availability of horticultural produce that affects food and nutrition security and the resultant loss of income for farmers. However, important drivers for high PHLs in horticulture are the market dynamics and the inefficiencies along the supply chain. The findings highlight drivers including insufficient logistics and limited infrastructure including cold chain as critical gaps in the horticultural value chain that have disadvantaged many smallholder farmers in Kenya.

The focus therefore is beyond cold storage that has been the dominant area of focus of research and investment. However, the cost of cold chain infrastructure is notably high which has been a constraint for government investments. As the findings of this study, there are various drivers that are presenting more opportunities in evolving domestic markets and expansion into export for the private sector to invest. However, given the magnitude of the needs, including the imperative to reduce food loss to address food and nutrition challenges and the opportunity to enhance livelihoods of smallholders and other small agro-enterprises, public-private partnership (PPP) business models may present viable options for enabling investment at scale. There is need to develop these models and test how they contribute to bringing the smallholder dominated horticultural sector in developing countries like Kenya into a systematic supply chain that can enable value preservation and capture for its growth and development.

The study points to areas for further research. These include exploring the types of models needed to deliver knowledge, capacity support coupled with the requisite cold chain infrastructure and market connectivity to address food loss through efficient horticulture supply chains. There are knowledge gaps in understanding the opportunities presented by aggregation and collective action of smallholder farmers. Additionally, there is still limited understanding of some of the gender equity and social inclusion considerations to enable inclusive business models for market-led PHL reduction. There is need to interrogate the role of policies as enablers for accelerating investments in restructuring the horticulture supply chains that consider value preservation and creation, and the price effects on horticultural products that are especially important for nutrition. Further, there is need to understand the influence of the food environment, especially the dynamics and the spatial distribution of markets and the effect on food loss. This can inform how best to strategically plan for and invest in cold chain deployment including integration of inclusive business models that can work best for smallholder-dominated horticultural value chains.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

The study was approved by the African Centre for Technology Studies (ACTS) – Research Ethics committee. The study was conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

CK: Conceptualization, Methodology, Project administration, Supervision, Validation, Writing – original draft, Writing – review & editing. DM: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Validation, Writing – original draft, Writing – review & editing. DK: Project administration, Supervision, Validation, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. The study was undertaken building on methodology developed by University of Birmingham and Heriot Watt University for cold chain needs assessment. Special appreciation to the UK government Department of Environment, Food and Rural Affairs (DEFRA) for funding this work through the United Nations Environment Program (UNEP) under the African Centre of Excellence for Sustainable Cooling and Cold Chain (ACES). This is part of the Clean Cooling Network.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fhort.2024.1474056/full#supplementary-material

References

Ambuko J., Owino W. (2023). “Toward sustainable transformation through postharvest management: Lessons from Kenya's mango value chain,” in Food Systems Transformation in Kenya. Eds. Breisinger C., Keenan M., Mbuthia J., Njuki J. (International Food Policy Research Institute, Washington, DC, USA), 433–459.

Dean W. R., Sharkey J. R. (2011). Rural and urban differences in the associations between characteristics of the community food environment and fruit and vegetable intake. J. Nutr. Educ. Behav. 43, 426–433. doi: 10.1016/j.jneb.2010.07.001

Debnath K. B., Wang X., Peters T., Menon S., Awate S., Patwardhan G., et al. (2021). Rural cooling needs assessment towards designing community cooling hubs: case studies from Maharashtra, India. Sustainability 13, 5595–5617. doi: 10.3390/su13105595

Gema J., Keige J., Chemeltorit P., Ngetich T., Moreno Echeverri I., Saavedra Gonzalez Y., et al. (2018). Catalysing food safety in the domestic horticulture sector in Kenya: The potential link between export production and evolving domestic supply chains. (Wageningen: Wageningen Centre for Development Innovation, Wageningen University & Research). Available at: https://edepot.wur.nl/468643.

Guo X., Broeze J., Groot J. J., Axmann H., Vollebregt M. (2020). A worldwide hotspot analysis on food loss and waste, associated greenhouse gas emissions, and protein losses. Sustainability 12, 7488. doi: 10.3390/su12187488

Gustavsson J., Cederberg C., Sonesson U., van Otterdijk R., Meybeck A. (2011). Global Food Losses and Food Waste: Extent, Causes and Prevention (Rome: FAO). Available at: https://www.fao.org/3/i2697e/i2697e.pdf.

Hasan M. K. H., Kumar L. K. (2024). Determining adequate sample size for social survey research: sample size for social survey research. J. Bangladesh Agric. Univ. 22, 146–157. doi: 10.3329/jbau.v22i2.74547

Holdsworth M., Pradeilles R., Tandoh A., Green M., Wanjohi M., Zotor F., et al. (2020). Unhealthy eating practices of city-dwelling Africans in deprived neighbourhoods: evidence for policy action from Ghana and Kenya. Global Food Secur. 26, 100452. doi: 10.1016/j.gfs.2020.100452

IPCC. (2019). Climate change and land: an IPCC special report on climate change, desertification, land degradation, sustainable land management, food security, and greenhouse gas fluxes in terrestrial ecosystems. eds. Shukla P. R., Skea J., Calvo Buendia E., Masson-Delmotte V., Pörtner H.-O., Roberts D. C., et al. [In press]. Available online at: https://www.ipcc.ch/site/assets/uploads/2019/11/SRCCL-Full-Report-Compiled-191128.pdf.

Islam M., Mukherjee D., Jena L. K., Chakraborty S., Hasan K. K., Debnath R. (2022). Antecedents of livelihood development using cold chains in the horticultural sector of the emerging markets: A systematic literature review. Horticulturae 8, 1196. doi: 10.3390/horticulturae8121196

Kaur S. (2022). Barriers to consumption of fruits and vegetables and strategies to overcome them in low-and middle-income countries: a narrative review. Nutr. Res. Rev. 36, 420–447. doi: 10.1017/S0954422422000166

Kikulwe E. M., Okurut S., Ajambo S., Nowakunda K., Stoian D., Naziri D. (2018). Postharvest losses and their determinants: A challenge to creating a sustainable cooking banana value chain in Uganda. Sustainability. 10, 2381. doi: 10.3390/su10072381

Kilelu C. W., Klerkx L., Leeuwis C., Hall A. (2011). Beyond knowledge brokering: an exploratory study on innovation intermediaries in an evolving smallholder agricultural system in Kenya. Knowledge Manage. Dev. J. 7, pp.84–pp108. doi: 10.1080/19474199.2011.593859

Kitinoja L., Fonseca J. M. (2018). “Enhancing postharvest capacity in national extension systems and advisory services,” in Postharvest Extension and Capacity Building for the Developing World (CRC Press), 41–53. Available at: https://dokumen.pub/qdownload/postharvest-extension-and-capacity-building-for-the-developing-world-9781315115771-1315115778-9781351631617-1351631616-9781351631624-1351631624-9781138069282.html.

Kitinoja L., Njie D. (2021). “Policy, strategies, investments and action plans for cold chain development,” in Cold Chain Management for the Fresh Produce Industry in the Developing World (CRC Press), 219–230. Available at: https://api.pageplace.de/preview/DT0400.9781000473988_A41993600/preview-9781000473988_A41993600.pdf. doi: 10.1201/9781003056607

KMD. (2024). Kiambu County Seasonal Climate Forecast Valid March-April-May (MAM) 2023. Available online at: https://t.ly/zMp1n (accessed June 12, 2024).

KNBS. (2019). 2019 Kenya population and housing census volume 4: Distribution of population by socio-economic characteristics. Available online at: https://www.knbs.or.ke/wp (accessed May 19, 2024).

Kothari C. R. (2004). Research Methodology: Methods and Techniques. New Delhi-India: New Age International (P) Ltd Publishers.

Li J., Gonzalez W., Monterrosa E., Gómez M. I., Nicholson C. F. (2024). Choice experiments and value-chain modeling of attribute improvements to increase vegetable consumption in Kenya. Food Policy 127, 102682. doi: 10.1016/j.foodpol.2024.102682

Makule E., Dimoso N., Tassou S. A. (2022). Precooling and cold storage methods for fruits and vegetables in Sub-Saharan Africa—A review. Horticulturae 8, p.776. doi: 10.3390/horticulturae8090776

Mvumi B. M., Stathers T. (2020). Supporting smallholder farmers in developing countries to improve postharvest management of staple grains: the role of loss reduction technologies. In Advances in postharvest management of cereals and grains (pp. 389–444). Burleigh Dodds Science Publishing.

Nuthalapati C. S., Dev S. M., Sharma R. (2022). Supply-side problems in food loss and waste. Economic Political Weekly 57, 51–61.

Peters T., Sayin L. (2021). “Sustainable cold chain development,” in Cold Chain Management for the Fresh Produce Industry in the Developing World. (CRC Press), 55–68. doi: 10.1201/9781003056607

Peters T., Sayin L. (2023). Developing a sustainable, resilient, and equitable global cold-chain. Fletcher F. World Aff 47, 19–33.

Roy T. N. (2015). “Supply chain management of horticultural crops,” in Value Addition of Horticultural Crops: Recent Trends and Future Directions. (New Delhi: Springer). 293–314.

Rutta E. W. (2022). Understanding barriers impeding the deployment of solar-powered cold storage technologies for post-harvest tomato losses reduction: insights from small-scale farmers in Tanzania. Front. Sustain. Food Syst. 6. doi: 10.3389/fsufs.2022.990528

Sheahan M., Barrett C. B. (2017). Food loss and waste in Sub-Saharan Africa: A critical review. Food Policy 70, 1–12. doi: 10.1016/j.foodpol.2017.03.012

Sibanda S., Workneh T. S. (2020). Potential causes of postharvest losses, low-cost cooling technology for fresh produce farmers in Sub-Sahara Africa. Afr. J. Agric. Res. 16, 553–566. doi: 10.5897/AJAR2020.14714

Singhal R., Saksena S. (2018). Role of Cold Chain in fostering Agribusiness in India: Prospects and Policy Insights. Available online at: https://mpra.ub.uni-muenchen.de/id/eprint/87138 (accessed June 23, 2024).

Stathers T., Lamboll R., Mvumi B. (2020). “Challenges and initiatives in reducing postharvest food losses and food waste: sub-Saharan Africa,” in Preventing food losses and waste to achieve food security and sustainability. London: Burleigh Dodds Science Publishing. 729–786. doi: 10.1201/9780429266621

UNEP, FAO. (2022). Sustainable Food Cold Chains: Opportunities, Challenges and the Way Forward (Nairobi: UNEP and Rome, FAO). doi: 10.4060/cc0923en

United Nations. (2015). Transforming our world: The 2030 agenda for sustainable development. Available online at: https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed April 22, 2024).

Keywords: cold chain, sustainable, value preservation, post-harvest management, value capture, market integration, inclusive business model

Citation: Kilelu CW, Musyoka DM and Kalele DN (2024) Unraveling smallholder food loss and value for sustainable cold chain investments: a case of horticultural value chains in Kiambu County, Kenya. Front. Hortic. 3:1474056. doi: 10.3389/fhort.2024.1474056

Received: 31 July 2024; Accepted: 18 October 2024;

Published: 29 November 2024.

Edited by:

Peninah Yumbya, International Center for Evaluation and Development, KenyaReviewed by:

Gordana Popsimonova, Saints Cyril and Methodius University of Skopje, North MacedoniaArnold Opiyo, Egerton University, Kenya

Copyright © 2024 Kilelu, Musyoka and Kalele. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dorcas N. Kalele, ZC5rYWxlbGVAYWN0cy1uZXQub3Jn

Catherine W. Kilelu

Catherine W. Kilelu Daniel M. Musyoka

Daniel M. Musyoka Dorcas N. Kalele

Dorcas N. Kalele