- 1Automotive Engineering Department, Military Technical College, Cairo, Egypt

- 2Mechatronics Engineering Department, Military Technical College, Cairo, Egypt

Introduction: This study explores the optimization of Electric Bus (EB) performance by integrating predictive maintenance strategies, utilizing real-time data and advanced modeling techniques.

Methods: The study involves installing measurement sensors to capture dynamic behavior and energy consumption during actual road trips, analyzing the collected data to refine vehicle dynamics models and assess battery degradation under various operational conditions, and employing a multi-objective optimization framework to minimize battery degradation while ensuring efficient energy use and maintaining operational requirements.

Results and Discussion: The study offers valuable insights into battery management strategies, revealing that battery degradation can be reduced by 25% through optimum driving behavior, which can be achieved in real driving conditions by avoiding aggressive driving. This research supports the broader goal of promoting sustainable public transportation solutions through the effective use of electric buses, enabling operators to extend battery longevity and enhance overall vehicle performance by implementing the identified strategies.

1 Introduction

The transportation sector is a significant contributor to global Greenhouse Gas (GHG) emissions, accounting for approximately 24% of global CO2 emissions from fuel combustion (IEA, 2021a). Road transport is the main source of these emissions, driven primarily by the widespread use of Internal Combustion Engine (ICE) vehicles. Electric Vehicles (EVs) have emerged as a promising solution to mitigate the environmental impacts of road transport by producing zero tailpipe emissions. This transition is essential for reducing pollutants like CO2, Nitrogen Oxides (NO

Public buses, especially electric ones, offer a highly efficient mode of transportation due to their ability to carry many passengers, thus distributing energy consumption more effectively. Studies show that public transportation reduces GHG emissions compared to private vehicles. For example, a diesel transit bus emits around 33% lower GHGs per passenger mile than single-occupancy vehicles, and this percentage rises to 82% when the buses are fully occupied (Hodges, 2010). EBs can reduce emissions even further if their source of electricity comes from a renewable source. In addition, EBs are more efficient than gls*ice in converting energy to motion, i.e., less tank-to-wheel fuel consumption (Dimitrova and Maréchal, 2015), with energy consumption ranging from 1.0 to 3.5 kWh per kilometer based on factors such as bus technology and traffic conditions (Pamuła and Pamuła, 2020). This makes EBs a sustainable and energy-efficient alternative, contributing to a reduction in urban air pollution and lower operational costs (Borén, 2020).

The efficient deployment of EBs necessitates optimizing bus routes and strategically placing charging stations. This optimization minimizes the downtime for recharging, ensures smooth operations, and maximizes the benefits of EB technology (Zhong et al., 2024). Recent studies have proposed integrated optimization models that consider both route design and charging station placement to minimize infrastructure costs and travel time (Su et al., 2023). For example, advanced techniques such as variable neighborhood search effectively address the simultaneous planning of charging stations and vehicle scheduling, improving both energy efficiency and service reliability (Olsen et al., 2022).

However, despite the benefits of EBs, they come with some trade-offs, mainly the high initial cost compared to the conventional gls*ice ones (Johnson et al., 2020). The high voltage battery pack is the most expensive component. The battery degrades gradually over the time (years) and over distance (mileage) as well. The degradation of Electric Vehicle (EV) battery packs significantly affects both the performance and the economic viability of these vehicles. As EV batteries undergo a natural capacity reduction process, their ability to store and deliver energy decreases, leading to a decrease in driving range and overall efficiency. This degradation results in reduced power delivery and a reduction in State of Health (SOH) of the battery pack. Consequently, EVs may experience a decrease in the vehicle’s range, necessitating more frequent charging and potentially altering driving habits to avoid range anxiety. Economically, this degradation results in increased maintenance costs and potentially shorter vehicle lifespans, which can offset the initial cost savings associated with EV ownership. Furthermore, accelerated degradation due to factors such as high temperatures, extreme state of charge, and fast charging can lead to premature battery replacement. This eventually increases the overall life cycle cost of EVs (Noura et al., 2020; Laadjal and Cardoso, 2021; Ou, 2023; Zekry et al., 2023; Etxandi-Santolaya et al., 2024). Understanding these adverse effects is crucial for developing strategies to mitigate battery degradation, ensuring long-term performance and economic sustainability of EVs.

Since public transit buses by nature of operation cover considerably long distances quickly over time, it is important to optimize the operation of EBs to minimize battery degradation and maximize its life. Moreover, other regular maintenance costs increase over the lifetime of the bus as it ages (C.A.R.B., 2018). Therefore, as more EBs are entering service, there is a need to achieve two objectives: 1) optimize their performance and 2) reduce their maintenance costs.

The first objective can be achieved by optimizing the bus routes and strategically placing charging stations. This optimization minimizes the downtime for recharging, ensures smooth operations, and maximizes the benefits of EBs technology (Zhong et al., 2024). Recent studies have proposed integrated optimization models that consider both route design and charging station placement to minimize infrastructure costs and travel time (Su et al., 2023). For example, advanced techniques such as variable neighborhood search effectively address the simultaneous planning of charging stations and vehicle scheduling, improving both energy efficiency and service reliability (Olsen et al., 2022).

However, accurate energy consumption estimation is critical for optimizing EB operations, as it influences route planning, charging infrastructure, and battery management. Traditional energy consumption models fall into three main categories: analytical, statistical, and computational (Qi et al., 2018). Analytical models are based on physics-based equations to describe the forces acting on the vehicle (Fiori et al., 2016). Statistical models use historical data to identify patterns in energy use (De Cauwer et al., 2017; Zhang and Yao, 2015). Finally, computational models, which often incorporate machine learning and simulations, handle complex data to provide detailed predictions (Montazeri-Gh and Fotouhi, 2011; Alvarez et al., 2014). These models vary in complexity and computational demand, but each offers valuable insights into energy consumption.

Recent researches have introduced hybrid models that combine data-driven and physics-based approaches to improve the accuracy of energy consumption predictions. For example (Pan et al., 2024), employed a hybrid model to optimize energy consumption in urban transit systems, demonstrating significant improvements in efficiency. Similarly (Jiang et al., 2024), developed a trip-level prediction model that integrates factors such as weather conditions and driving patterns, achieving high accuracy in predicting the energy consumption (Ali et al., 2023).

Incorporating vehicle dynamics into these models provides a more detailed understanding of energy consumption (Fiori et al., 2016). Developed a model that accounts for factors such as aerodynamics and mass, validated with real-world driving cycles (Vepsäläinen et al., 2018). Investigated the uncertainty in the estimates of energy consumption due to varying driving conditions. These studies highlight the need for accurate models that reflect the real-world performance of EBs, considering both environmental and operational conditions.

The second objective can be achieved by preventive maintenance. Predictive maintenance is a technique in which maintenance is conveniently scheduled according to the condition of a machine in terms of its degree of degradation and probability of failure (Levitt, 2011; K, 2002). This contrasts with preventive maintenance, where maintenance is performed periodically or by time intervals. This conventional maintenance approach requires that some components can be needlessly replaced despite Remaining Useful Life (RUL). On the other hand, preventive maintenance estimates RUL based on predictive models using accurate historical operational data. To ensure accurate prediction, it is important to measure and collect meaningful and relevant data as much as possible. This has been made possible by the advancement of data measurements, collection, and storing technologies. Predictive maintenance has been shown to lead to a reduction in maintenance costs (Ambriško and Teplická, 2021). A recent study investigated the proper way to implement predictive maintenance in a local public transport company (Grimaldi, 2022). It showed that optimization can be used as a tool to optimize the operation and reduce maintenance costs of the mixed fleet of both diesel and electric buses (Ayman et al., 2021). Recent studies showed that preventive maintenance can be used to effectively minimize maintenance costs (Arena et al., 2021; Kamel, 2022; Arévalo et al., 2024; Dui et al., 2023; Ekici et al., 2023; Martyushev et al., 2023; Massaro et al., 2020; Wieczorek et al., 2024)

However, the challenge lies in creating an efficient tool that can manage a fleet of buses under real-world operational conditions while minimizing system complexity and resource requirements. This paper presents a unified framework for predictive maintenance and optimization. It seamlessly combines experimental measurements, vehicle dynamics modeling, and optimization algorithms in order to achieve the two objectives of optimizing battery performance and reducing degradation to minimize maintenance costs. A case study of an EB is presented to demonstrate the practical applicability of this approach in real-world conditions.

The remainder of the paper is structured as follows. In Section 2, we describe our methodology and how it is applied to the EB case study. Section 3 presents the experimental work and the measurement system used to capture its dynamic behavior and energy consumption. Section 4 presents the longitudinal dynamic model and the battery degradation model, using a multi-objective optimization technique to minimize battery degradation. Section 5 discusses the results of the simulation, experimental work, and model validation. Finally, Section 6 concludes and discusses future work.

2 Methodology

The methodology is centered on accurately estimating the amount of electric energy consumed during a trip that accurately resembles real operating conditions. This included selecting a route that fits these conditions as closely as possible. The bus was fitted with measurement sensors and data recording devices. The data were then used to fine-tune the parameters of a vehicle dynamics model using numerical optimization. The model was then used to calculate the amount of energy consumption, which was used as input to a model that calculated the amount of battery degradation. Multi-objective optimization was applied to the battery degradation model to find the optimum operating conditions to minimize battery degradation. The methodology can be summarized in the following step:

1. Set up EB with measurement and data recording devices.

2. Measure the Center of Gravity (C.G) of the EB.

3. Select a representative route of the real operating conditions.

4. Conduct a real-world driving experiment that measures the energy consumption of the EB and dynamic parameters.

5. Develop a vehicle dynamics model.

6. Use the value of measured consumed energy to fine-tune the dynamics model.

7. Develop a battery degradation model.

8. Integrate the battery degradation model with the vehicle dynamics model.

9. Apply optimization to find the optimal conditions to minimize battery degradation.

10. Use the results to recommend the operating policies for preventive maintenance.

A battery electric bus was used as our case study. The bus is designed for public city transit. It is fully electric with a battery pack capacity of 345 kWh. It is equipped to accommodate 36 seated, 40 standees and a wheelchair. It is driven by a permanent magnet synchronous electric motor rated at delivering 195 kW up to a maximum of 350 kW. Its rated toque is 3,200 N.m and maximum is 3,500 N.m. Its payload is 5,800 kg.

3 Experimental work

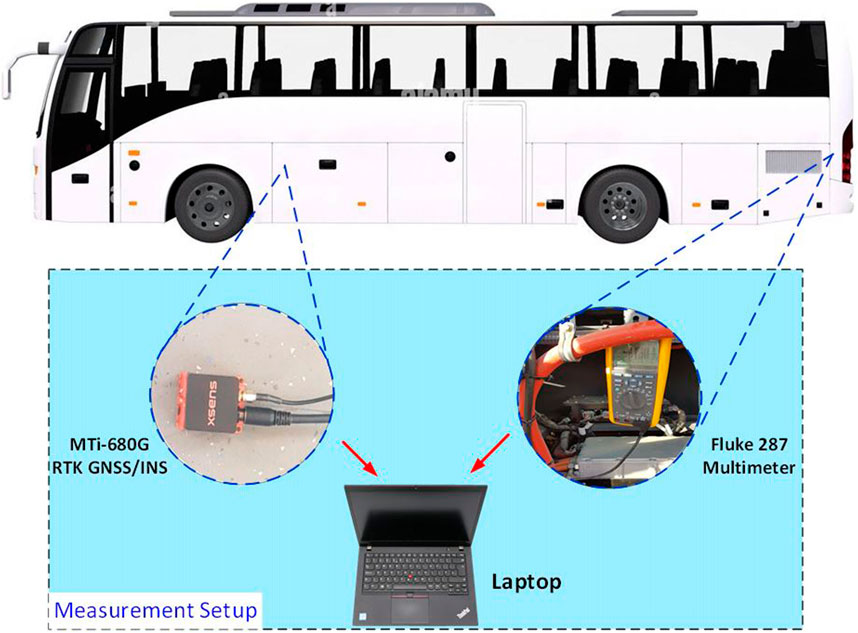

The experimental setup employed a combination of advanced measurement devices to capture the dynamic behavior and energy consumption of the EB. As shown in Figure 1, the Xsense MTi-680G RTK GNSS/INS was used to accurately measure linear accelerations, linear and angular velocities, orientations, altitude, longitude and latitude. This high-precision sensor system provided comprehensive data on the vehicle’s motion and positioning during the trip. Additionally, a Fluke 287 True-RMS Electronics Logging Multimeter, equipped with a Fluke 325 True RMS Clamp Meter (Fluke 289 IMSK Industrial Multimeter), was used to measure and record the current drawn by the electric motor from the battery pack. This setup enabled for precise monitoring of the electric power consumption, allowing for detailed analysis of the energy usage patterns and their impact on battery health. The meter was calibrated and certified according to ISO 17025 standard. It scored 99.9% accuracy.

Figure 1. Measurement setup: the MTi-680G RTK GNSS/INS is placed on the bus floor, GPS antenna is on the bus roof, Fluke 287 multimeter with Fluke 325 clamp are placed at bus back for measuring the current and voltage drawn by the electric motor.

Data from The MTi-680G and the Fluke system are collected by a laptop which formed a robust data acquisition system, ensuring accurate and reliable data collection for model development and validation.

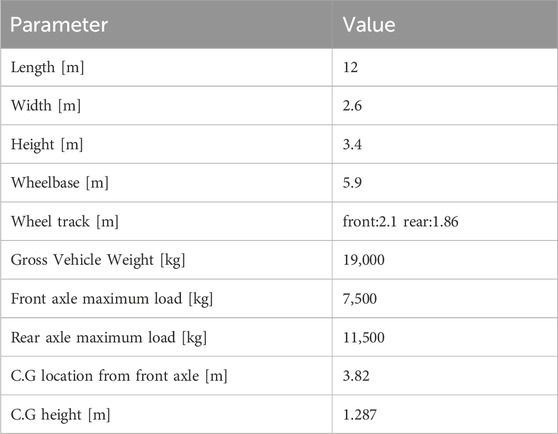

For estimating the position of C.G, the bus was loaded with dummy weights to reach the value of Gross Vehicle Weight (GVW) and proper load distribution on the front and rear axles according to the manufacturer’s specifications. This was followed by an experiment to determine the position of the C.G as shown in Figure 2. The data is shown in Table 1.

Figure 2. Tilting the bus to measure the difference in weight on front axle to determine the position of C.G.

3.1 Road selection

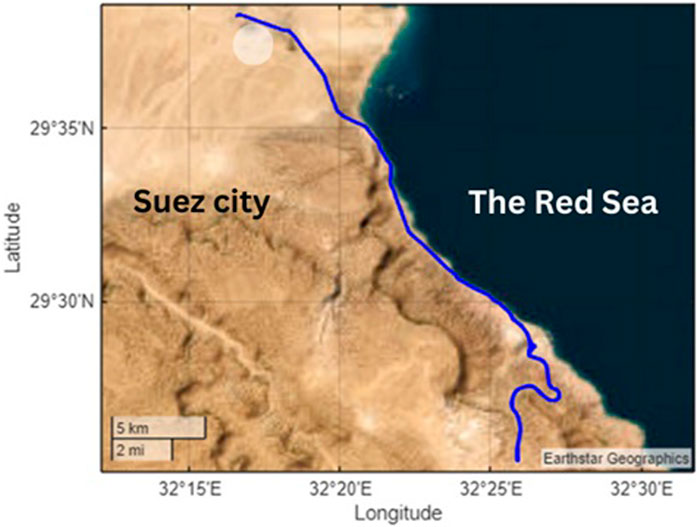

The objective is to select a route that can represent a real route as accurately as possible. Based on the given and available data from end-user requirements, a route was selected as shown in Figure 3.

It should be noted that the investigated vehicle in this study is assumably considered for intra-city reciprocals without allocated stops in-between (except for unforeseen traffic conditions). Therefore, the influence of repeating acceleration/deceleration on battery degradation has been precluded from our scope at this stage.

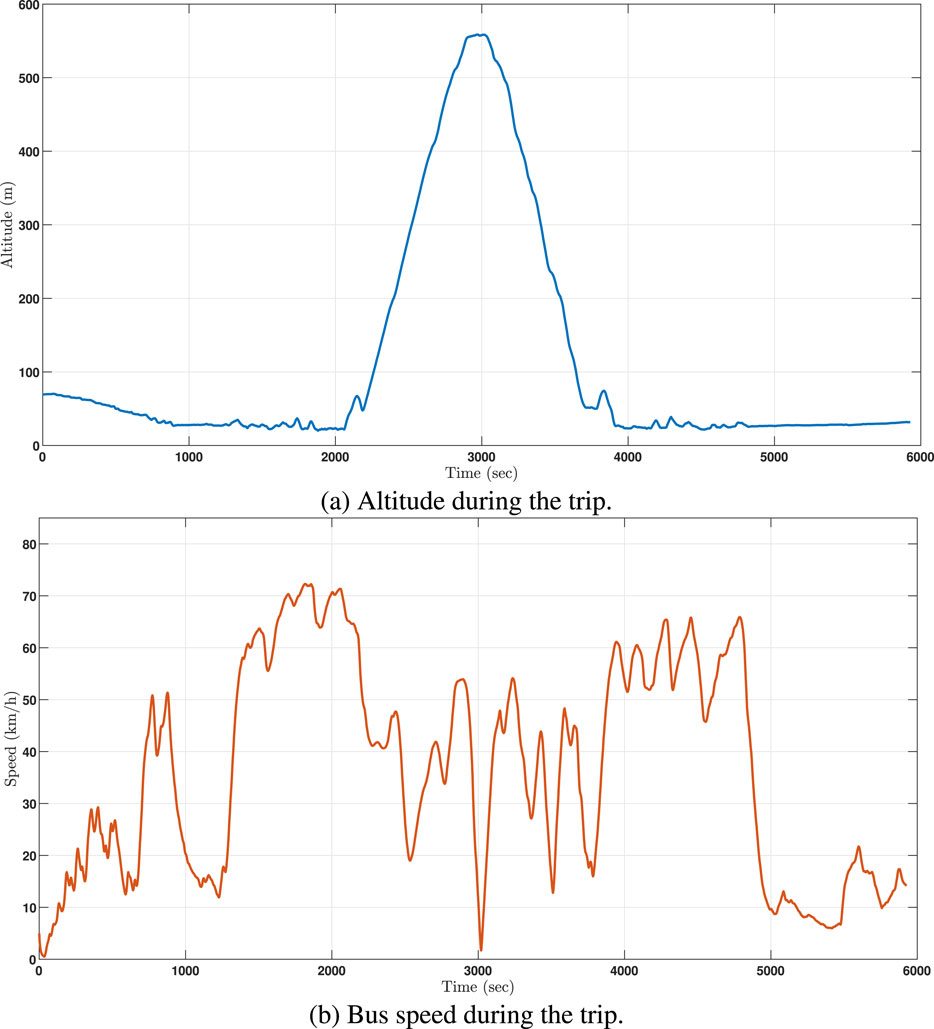

This route constitutes a combination of asphalt, concrete, gravel, and unpaved road surfaces which matches the real conditions where the bus will be operated. In addition, the route included a moderately steep mountainous segment to an elevation of approximately 500 m from sea level as shown in Figure 3. The total travel distance was 67.8 km which lasted for 98.8 min.

The conducted driving experiment along the coastal side of the Red Sea and uphill Northern Galala Plateau reflects the actual speed and altitude profile of the actual trip under study as shown in Figure 4. In this context, the acquired measurements of energy consumption and deducted battery degradation are directly related to the actual driving conditions.

Figure 4. Altitude vs. bus speed during the typical road trip. (A) Altitude during the trip. (B) Bus speed during the trip.

The data collected during this typical road trip included a comprehensive set of measurements that captured both the dynamic behavior of the bus and the corresponding energy consumption. Using the Xsense MTi-680G RTK GNSS/INS, data on linear accelerations, angular velocities, linear velocities, orientations, altitude, and geographical coordinates were recorded throughout the trip. This information was crucial for developing the longitudinal dynamics model of the bus, as it accurately represented the vehicle’s motion under real-world driving conditions. Simultaneously, the Fluke 287 True-RMS Electronics Logging Multimeter, paired with the Fluke 325 True RMS Clamp Meter, measured the current drawn by the electric motor. These measurements provided insights into the power consumption and its variations over the trip, forming the basis for the battery degradation model.

Acquisition of experimental measurements has been conducted using Movella MT Software and Fluke Firmware, while all numerical simulations of the vehicle model and relevant optimization procedures in the sequel have been carried out in MATLAB-Simulink environment. Together, the collected data facilitated the development of accurate models that reflect the impact of driving conditions on the bus’s energy usage and battery health.

4 Vehicle model

This section introduces the dynamic model of the EB and the battery degradation model. Optimization was applied to both models. Firstly, we estimate the values of some of the parameters of the dynamic model. Secondly, multi-objective optimization was applied to the battery degradation model to identify the optimal settings that minimize battery degradation.

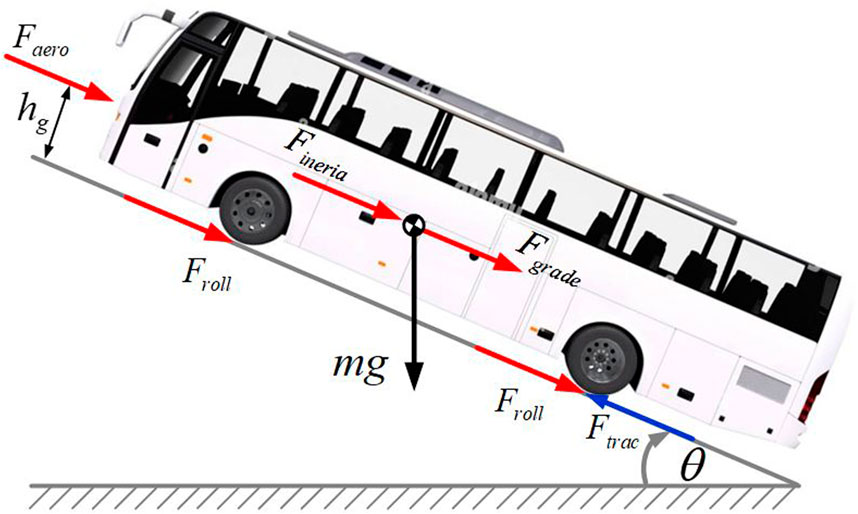

4.1 Longitudinal vehicle dynamics

An analytical model was chosen to calculate the amount of energy consumption due to its simplicity and its ability to account for the physical factors that contribute to energy consumption. The model is based on the longitudinal vehicle dynamics (Wong, 2022). The analysis of forces exerting on the vehicle in longitudinal direction is illustrated in Figure 5 and formulated as

where the rolling resistance force from tire road interaction is denoted as

Therefore, Equation 1 can be expressed as follows:

where

The energy is calculated by adding these forces in Equation 2 and multiplying the sum by the average velocity to obtain the power consumption as shown in Equation 3. Hence, the energy is obtained by multiplying the power by the total time of the bus trip as shown in Equation 4.

where

However, the remaining model variables (

4.1.1 Optimization of dynamic model parameters

Optimization was applied to find the optimum values of the model variables (

This can be formulated in a mathematical form as an optimization problem as follows in Equation 5:

The upper and lower limits on f and

4.2 Battery degradation model

Modeling the degradation of EV batteries is crucial for predicting their lifespan and optimizing their performance. The different approaches to modeling battery degradation can be categorized as follows:

1. Empirical Models: These models rely on historical data to establish relationships between operating conditions and battery degradation. They are relatively simple and computationally efficient, but may lack accuracy under varying conditions (Das and Kumar, 2023).

2. Semi-Empirical Models: These models combine empirical data with theoretical insights, offering a balance between simplicity and accuracy. They incorporate specific degradation mechanisms, such as Solid Electrolyte Interphase (SEI) layer growth and lithium plating, to improve predictive capabilities (Ji et al., 2024).

3. Physics-Based Models: Also known as mechanistic models, these delve into the electrochemical processes within the battery. Models like the Doyle-Fuller-Newman (DFN) model simulate the internal states of the battery, providing detailed insights into the degradation mechanisms. However, they are computationally intensive and require extensive parameterization (O’Kane et al., 2022).

4. Data-Driven Models: With the advent of machine learning techniques, these models analyze large datasets to identify complex patterns in battery behavior, enhancing the accuracy of degradation predictions. Machine learning algorithms, such as neural networks and support vector machines, can model nonlinear relationships and adapt to new data, making them highly effective for real-time battery management (Preis and Biedenbach, 2023).

5. Hybrid Models: These models integrate physics-based and data-driven approaches, leveraging the strengths of both methodologies. They use physical insights to guide the learning process and improve the robustness of the model (Kong et al., 2022).

In this work, the Semi-Empirical model was selected for its simplicity and accuracy to model the degradation of the battery. The battery degradation model received input values from the vehicle dynamics model in terms of required torque

where

The amount of electric current

where

where

The battery and electric drive model employ a second-order Thevenin representation to accurately capture the relationship between voltage, resistance, and SoC. The battery’s SoC is monitored using the Coulomb counting method, which calculates the current that flows into and out of the battery over time. The output variables of the battery model are directly linked to the electric motor model, ensuring that the voltage and current parameters are synchronized.

The battery degradation model quantifies the capacity loss of the battery over time due to various operational factors. This model utilizes a semi-empirical approach based on damage accumulation, linking the end-of-life (EoL) of the battery to the accumulated charge throughput

4.2.1 Minimization of battery degradation and charge depletion

The amount of battery degradation can now be calculated for any given bus route. This helps the EB operator in predictive maintenance as: 1) planning well ahead the schedule for battery replacement based on the level of accepted degradation, 2) reassigning buses that lost enough battery storage capacity to less energy demanding, for example, shorter routes. 3) In addition, we can find the best (optimal) settings in terms of the amount and rate of change of the drawn current to minimize the degradation of the battery

Find

where.

where

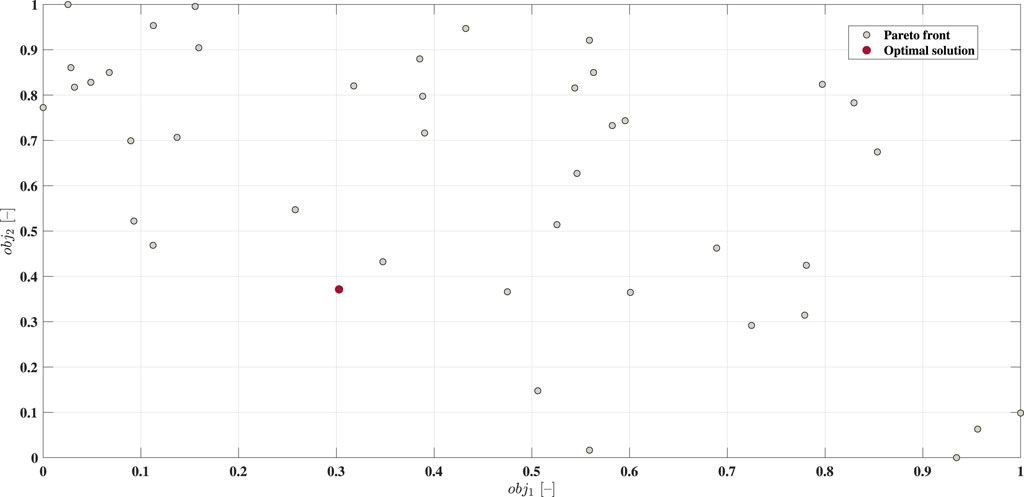

The Non-dominated Sorting Genetic Algorithm II (NSGA-II) was used to solve the multi-objective optimization problem. The NSGA-II algorithm is a widely recognized evolutionary algorithm designed to address multi-objective optimization problems. Developed by Deb et al. (2002). NSGA-II enhances the traditional genetic algorithm framework by incorporating mechanisms for non-dominated sorting and a crowding distance assignment, which together ensure a diverse and well-distributed set of Pareto-optimal solutions. The algorithm’s ability to simultaneously optimize multiple conflicting objectives makes it particularly suitable for complex engineering and scientific applications where trade-offs between objectives must be carefully balanced. NSGA-II’s elitist approach, which retains the best solutions across generations, and its computational efficiency further contribute to its popularity and effectiveness in solving multi-objective optimization problems (Ma et al., 2023). These features make NSGA-II a suitable tool for solving multi-objective optimization problems.

5 Results and discussion

In this section, we present the findings from the case study. We explore the bus’s energy consumption patterns and provide an estimation of battery health over time. Furthermore, the results are used to predict battery maintenance intervals based on its degradation rate. This analysis offers valuable information for optimizing electric bus performance and extending its battery life through data-driven predictive maintenance strategies.

5.1 Comparison with WLTP-LOW driving cycle

Standard driving cycles testing is essential in order to evaluate the energy consumption measures in a widely-comprehensive way. To this aim, the scalable WLTP driving has been implemented for the comparative evaluation of power consumption, SoC drop, and battery degradation.

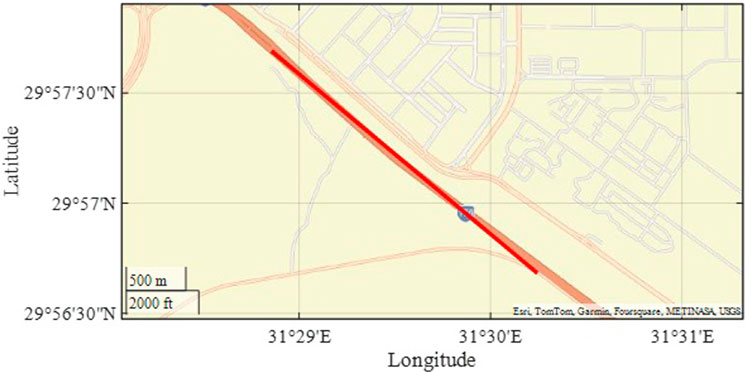

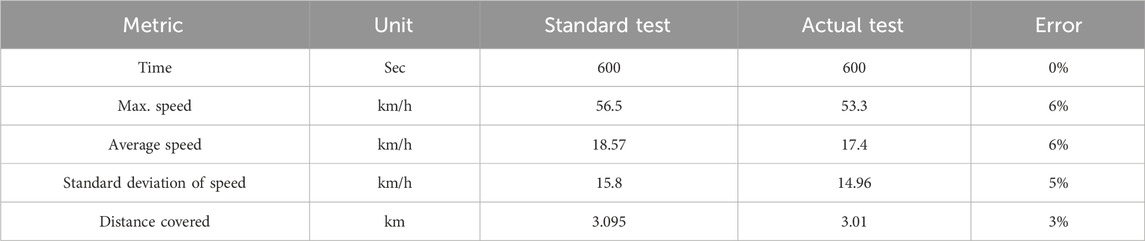

A road test was conducted according to the standard for measuring energy consumption, WLTP-LOW driving cycle (Schmidt, 2015). The test was conducted two times by a professional driver to drive the bus on a road as shown in Figure 6. To familiarize the driver with the test, the test speed profile was plotted and presented on a tablet so the driver can follow the desired profile as shown in Figure 7. The driver was trained several times before conducting the main test. The test lasted for 600 s and covered a total distance of 3.095 km. Table 2 presents a comparison between standard and actual tests. It shows that the actual test adhered as closely as possible to the standard requirements. The measured energy consumption was then estimated and the data was then used to compare with the value calculated from the vehicle dynamics model in Section 4.

In this step, we expect the calculated value of the energy consumption

5.2 Simulation and experimental results

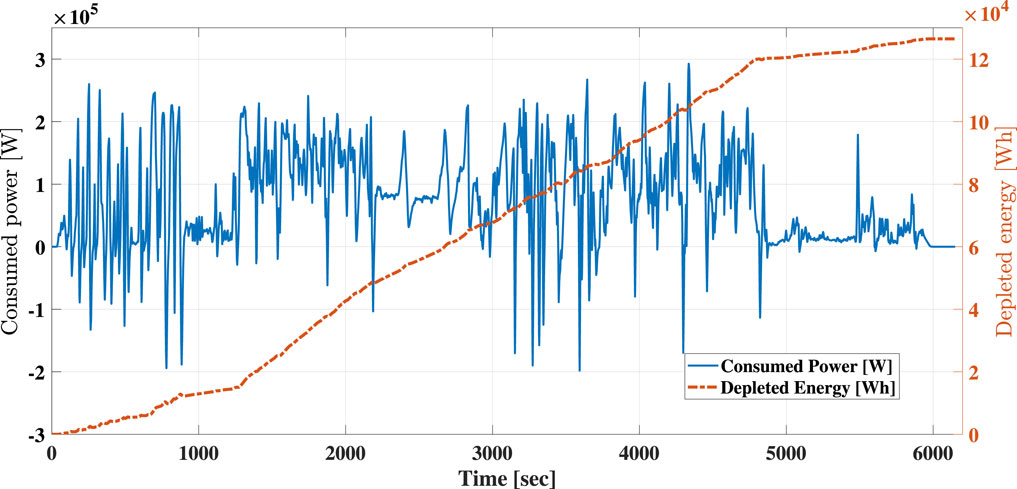

Figure 8 shows the simulated instantaneous power consumption and the accumulated energy depleted from the battery. The total depleted energy was 126 kWh. This value is in good agreement with the measured 122 kWh during the road trip illustrated in Section 3.

The Negative values of power consumption indicate the activation of regenerative braking during the deceleration and stopping phases. Recuperation of propulsion energy through regenerative braking flattens the increasing rate of accumulated energy at the corresponding time intervals as shown in Figure 8.

Figure 9 shows the simulated battery SoC and the associated capacity loss over time during the road trip. It shows a drop of the battery SoC by approximately

The multi-objective optimization problem in Section 4.2 is solved using the NSGA-II and it converged to a solution after 2500 iterations. The final result is the Pareto set of non-dominated solutions, which for three normalized objectives

By considering both real and synthetic driving conditions, this study aims to give a clear insight into the factors affecting the energy consumption and battery degradation.

The findings of this study offer several practical implications for public transit authorities, EV operators, and manufacturers, emphasizing the potential of predictive maintenance and data-driven energy consumption models to enhance the operational efficiency of EB fleets. These can be summarized as follows:

1. Optimized Route Planning and Charging Infrastructure: Accurate energy consumption forecasts, based on real-world driving data and vehicle dynamics, enable public transit authorities to optimize route planning. This ensures that EBs operate within their energy limits, reducing the likelihood of unexpected downtime due to depleted batteries. Strategic placement of charging stations, guided by these energy consumption models, minimizes infrastructure costs and improves route efficiency, allowing buses to remain in service longer while reducing charging interruptions.

2. Reduced Operational Costs: Predictive maintenance strategies allow operators to identify potential mechanical or electrical problems before they escalate, reducing breakdowns and expensive repairs. Accurate estimation of battery degradation further improves the maintenance planning and extends the battery life, a significant cost driver for EBs. In addition, optimized energy use reduces operational costs, as buses are deployed under conditions that minimize energy waste and battery wear.

3. Improved Fleet Reliability: Ensuring reliable bus operation is critical for transit operators to maintain public trust. The proposed framework improves fleet reliability by optimizing energy consumption based on variables such as passenger load, traffic, and environmental conditions. The integration of real-time data allows operators to dynamically adjust schedules and routes in response to unexpected challenges, such as traffic congestion or weather changes, while maintaining energy efficiency.

4. Extended Battery Life: The battery degradation modeling provided in this study has important implications for EB manufacturers. Understanding how driving patterns, charging habits, and environmental factors affect battery life enables manufacturers to design more robust vehicles. This leads to longer battery life, fewer replacements, and a reduced total cost of ownership for bus operators. In addition, smart battery management systems that use predictive analytics can be incorporated to optimize charging cycles and monitor battery health in real-time.

5. Sustainability Goals: Public transit authorities are increasingly focused on reducing their carbon footprint. Predicting and optimizing energy consumption ensures that EBs operate sustainably, minimizing energy waste and maximizing battery efficiency. This contributes to meeting environmental goals, such as reducing GHG emissions and urban air pollution. Improved route optimization and vehicle scheduling further support these sustainability efforts by ensuring that buses follow energy-efficient routes.

6. Scalability and Real-Time Application: The presented framework is scalable and adaptable to various regions, climates, and fleet sizes. As EB fleets expand, this model allows transit authorities to continuously optimize operations in real-time, adjusting to changes in passenger demand, traffic and energy costs. This scalability is essential for cities aiming to increase their electric public transportation systems while maintaining high levels of efficiency.

The afore-discussed results give clear insights into the significant influence of the operational variables of electrified fleets on achievable energy efficiency and lifetime prolongation of the battery. These key-variables can be pointed out, namely, as: allowable power throughput, SoC, and DoD of the battery, trip duration, road grade, and ambient temperature. Conscious tuning of these variables using different optimization methods can be beneficial to minimize operational cost of electric buses. Besides, the outcomes of this study can be used as guidelines for industry experts and policymakers during planning and sizing of case-oriented electric transportation. Furthermore, it should mentioned that the proposed study and methodology are applicable for intra-city public transportation, which might produce different results when considered for other case-sensitive types of transportation.

6 Conclusion

This study successfully developed and implemented a framework to optimize the energy consumption and overall performance of electric buses (EBs) through predictive maintenance. The approach effectively integrates experimental testing, modeling, and numerical optimization. By selecting a real-world road scenario for testing, the research achieved a more accurate estimation of energy consumption, emphasizing the importance of using realistic conditions over standard driving tests, which can underestimate energy use and battery life.

Battery degradation accelerates with higher discharge currents. Therefore, it is advisable to avoid aggressive driving whenever possible. The results indicate that optimal driving can extend battery life by up to 25

The case study demonstrated that the proposed methodology significantly reduced battery degradation and extended the service life of EBs. These results are particularly beneficial for fleet operators, as they provide strategies to minimize both operational and maintenance costs. Overall, this research underscores the potential of predictive maintenance and optimization techniques to improve the efficiency and sustainability of electric bus operations.

For future work, implementing the optimization results in an experimental road test will provide valuable real-world data. In addition, investigating the sensitivity of the optimal solution to factors such as gross vehicle weight, temperature, driving behavior, and road conditions will help to understand the robustness and applicability of the proposed methodology under varying conditions.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

HI: Conceptualization, Formal Analysis, Investigation, Methodology, Project administration, Supervision, Writing–original draft, Writing–review and editing. AA: Data curation, Formal Analysis, Investigation, Software, Validation, Visualization, Writing–original draft, Writing–review and editing. TA: Data curation, Formal Analysis, Investigation, Methodology, Software, Visualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ali, A. M., Moulik, B., and Söffker, D. (2023). Intelligent real-time power management of multi-source HEVs based on driving state recognition and offline optimization. IEEE Trans. Intell. Transp. Syst. 24 (1), 247–257. doi:10.1109/TITS.2022.3215607

Alvarez, A. D., Garcia, F. S., Naranjo, J. E., Anaya, J. J., and Jimenez, F. (2014). Modeling the driving behavior of electric vehicles using smartphones and neural networks. IEEE Intell. Transp. Syst. Mag. 6, 44–53. doi:10.1109/mits.2014.2322651

Ambriško, L., and Teplická, K. (2021). Proactive maintenance as a tool of optimization for vehicle fleets, in terms of economic and technical benefits. Acta Polytech. Hung. 18, 235–249. doi:10.12700/aph.18.8.2021.8.13

Arena, F., Collotta, M., Luca, L., Ruggieri, M., and Termine, F. (2021). Predictive maintenance in the automotive sector: a literature review. Math. Comput. Appl. 27 (2), 2. doi:10.3390/mca27010002

Arévalo, P., Ochoa-Correa, D., and Villa-Ávila, E. (2024). A systematic review on the integration of artificial intelligence into energy management systems for electric vehicles: recent advances and future perspectives. World Electr. Veh. J. 15, 364. doi:10.3390/wevj15080364

Ayman, A., Sivagnanam, A., Wilbur, M., Pugliese, P., Dubey, A., and Laszka, A. (2021). Data-driven prediction and optimization of energy use for transit fleets of electric and ICE vehicles. ACM Trans. Internet Technol. TOIT 22, 1–29. doi:10.1145/3433992

Borén, S. (2020). Electric buses’ sustainability effects, noise, energy use, and costs. Int. J. Sustain. Transp. 14, 956–971. doi:10.1080/15568318.2019.1666324

Das, K., and Kumar, R. (2023). Electric vehicle battery capacity degradation and health estimation using machine-learning techniques: a review. Clean. Energy 7, 1268–1281. doi:10.1093/ce/zkad054

Deb, K., Pratap, A., Agarwal, S., and Meyarivan, T. (2002). A fast and elitist multiobjective genetic algorithm: nsga-ii. IEEE Trans. Evol. Comput. 6, 182–197. doi:10.1109/4235.996017

De Cauwer, C., Verbeke, W., Coosemans, T., Faid, S., and Van Mierlo, J. (2017). A data-driven method for energy consumption prediction and energy-efficient routing of electric vehicles in real-world conditions. Energies 10, 608. doi:10.3390/en10050608

Dimitrova, Z., and Maréchal, F. (2015). Techno-economic design of hybrid electric vehicles using multi objective optimization techniques. Energy 91, 630–644. doi:10.1016/j.energy.2015.08.073

Dui, H., Dong, X., Chen, L., and Wang, Y. (2023). IoT-enabled fault prediction and maintenance for smart charging piles. IEEE Internet Things J. 10, 21061–21075. doi:10.1109/jiot.2023.3285206

Ekici, Y., Akdağ, O., Aydin, A., and Karadağ, T. (2023). A novel energy consumption prediction model of electric buses using real-time big data from route, environment, and vehicle parameters. IEEE Access 11, 104305–104322. doi:10.1109/access.2023.3316362

Etxandi-Santolaya, M., Mora-Pous, A., Canals Casals, L., Corchero, C., and Eichman, J. (2024). Quantifying the impact of battery degradation in electric vehicle driving through key performance indicators. Batteries 10, 103. doi:10.3390/batteries10030103

Fiori, C., Ahn, K., and Rakha, H. A. (2016). Power-based electric vehicle energy consumption model: model development and validation. Appl. Energy 168, 257–268. doi:10.1016/j.apenergy.2016.01.097

Hodges, T. (2010). Public transportation’s role in reducing greenhouse gas emissions. U. S. Dep. Transp., 1–20.

IEA (2021a). “Global energy review: CO2 emissions in 20212021 – analysis - IEA,” Tech. Rep. International Energy Agency.

IEA (2021b). “Policies to promote electric vehicle deployment – global EV Outlook 2021 – analysis - IEA,” Tech. Rep. International Energy Agency.

Ji, C., Dai, J., Zhai, C., Wang, J., Tian, Y., and Sun, W. (2024). A review on lithium-ion battery modeling from mechanism-based and data-driven perspectives. Processes 12, 1871. doi:10.3390/pr12091871

Jiang, Y., Song, G., Wu, Y., Lu, H., Zhai, Z., and Yu, L. (2024). Impacts of cold starts and hybrid electric vehicles on on-road vehicle emissions. Transp. Res. Part D Transp. Environ. 126, 104011. doi:10.1016/j.trd.2023.104011

Johnson, C., Nobler, E., Eudy, L., and Jeffers, M. (2020). enFinancial Analysis of battery electric transit buses. Tech. Rep. nrel/tp-5400-74832. doi:10.2172/1659784

Kamel, H. (2022). Artificial intelligence for predictive maintenance. J. Phys.: Conf. Ser. 2299 (1). doi:10.1088/1742-6596/2299/1/012001

Komnos, D., Broekaert, S., Grigoratos, T., Ntziachristos, L., and Fontaras, G. (2021). In use determination of aerodynamic and rolling resistances of heavy-duty vehicles. Sustainability 13, 974. doi:10.3390/su13020974

Kong, J.-Z., Cui, D., Hou, B., Liu, X., and Wang, D. (2022). New short-long-term degradation model for precise battery health prognostics. IEEE Trans. Industrial Electron. 70, 9527–9537. doi:10.1109/tie.2022.3212365

Laadjal, K., and Cardoso, A. J. M. (2021). Estimation of lithium-ion batteries state-condition in electric vehicle applications: issues and state of the art. Electronics 10, 1588. doi:10.3390/electronics10131588

LaClair, T. J. (2005). “Truemner; russell,” in Modeling of fuel Consumption for heavy-duty Modeling of fuel Consumption for heavy-duty: SAE technical papers, 01–3550.

Ma, H., Zhang, Y., Sun, S., Liu, T., and Shan, Y. (2023). A comprehensive survey on nsga-ii for multi-objective optimization and applications. Artif. Intell. Rev. 56, 15217–15270. doi:10.1007/s10462-023-10526-z

Martyushev, N., Malozyomov, B., Sorokova, S., Efremenkov, E., Valuev, D., and Qi, M. (2023). Review models and methods for determining and predicting the reliability of technical systems and transport. Mathematics 11, 3317. doi:10.3390/math11153317

Massaro, A., Selicato, S., and Galiano, A. (2020). enPredictive maintenance of bus fleet by intelligent smart electronic board implementing artificial intelligence. IoT 1, 12. doi:10.3390/iot1020012

Montazeri-Gh, M., and Fotouhi, A. (2011). Traffic condition recognition using the -means clustering method. Sci. Iran. 18, 930–937. doi:10.1016/j.scient.2011.07.004

Noura, N., Boulon, L., and Jemeï, S. (2020). A review of battery state of health estimation methods: hybrid electric vehicle challenges. World Electr. Veh. J. 11, 66. doi:10.3390/wevj11040066

O’Kane, S. E., Ai, W., Madabattula, G., Alonso-Alvarez, D., Timms, R., Sulzer, V., et al. (2022). Lithium-ion battery degradation: how to model it. Phys. Chem. Chem. Phys. 24, 7909–7922. doi:10.1039/d2cp00417h

Olsen, N., Kliewer, N., and Wolbeck, L. (2022). A study on flow decomposition methods for scheduling of electric buses in public transport based on aggregated time–space network models. Central Eur. J. Operations Res. 30, 883–919. doi:10.1007/s10100-020-00705-6

Ou, S. (2023). Estimate long-term impact on battery degradation by considering electric vehicle real-world end-use factors. J. Power Sources 573, 233133. doi:10.1016/j.jpowsour.2023.233133

Pamuła, T., and Pamuła, W. (2020). Estimation of the energy consumption of battery electric buses for public transport networks using real-world data and deep learning. Energies 13, 2340. doi:10.3390/en13092340

Pan, Y., Fang, W., Ge, Z., Li, C., Wang, C., and Guo, B. (2024). A hybrid on-line approach for predicting the energy consumption of electric buses based on vehicle dynamics and system identification. Energy 290, 130205. doi:10.1016/j.energy.2023.130205

Preis, V., and Biedenbach, F. (2023). Assessing the incorporation of battery degradation in vehicle-to-grid optimization models. Energy Inf. 6, 33. doi:10.1186/s42162-023-00288-x

Qi, X., Wu, G., Boriboonsomsin, K., and Barth, M. J. (2018). Data-driven decomposition analysis and estimation of link-level electric vehicle energy consumption under real-world traffic conditions. Transp. Res. Part D Transp. Environ. 64, 36–52. doi:10.1016/j.trd.2017.08.008

Schmidt, H. (2015). “Worldwide harmonized light-vehicles test procedure (wltp) und real driving emissions (rde)–aktueller stand der diskussion und erste messergebnisse,” in Internationales stuttgarter symposium: automobil-und motorentechnik (Springer), 1403–1411. 15.

Su, X., Jiang, L., and Huang, Y. (2023). Design of electric bus transit routes with charging stations under demand uncertainty. Energies 16, 1848. doi:10.3390/en16041848

Vepsäläinen, J., Ritari, A., Lajunen, A., Kivekäs, K., and Tammi, K. (2018). Energy uncertainty analysis of electric buses. Energies 11, 3267. doi:10.3390/en11123267

Veza, I., Asy’ari, M. Z., Idris, M., Epin, V., Fattah, I. R., and Spraggon, M. (2023). Electric vehicle (ev) and driving towards sustainability: comparison between ev, hev, phev, and ice vehicles to achieve net zero emissions by 2050 from ev. Alexandria Eng. J. 82, 459–467. doi:10.1016/J.AEJ.2023.10.020

Wieczorek, A., Stecuła, K., and Grebski, W. (2024). Methods and techniques supporting energy and media savings in maintenance of public transport buses—state of the art and recommendations. Energies 17, 2051. doi:10.3390/en17092051

Zekry, O. H., Attia, T., Hafez, A. T., and Ashry, M. M. (2023). “PID trajectory tracking control of crazyflie nanoquadcopter based on genetic algorithm,” IEEE Aerospace Conference, Big Sky, MT, 1–8. doi:10.1109/AERO55745.2023.10115538

Zhang, R., and Yao, E. (2015). Electric vehicles’ energy consumption estimation with real driving condition data. Transp. Res. Part D Transp. Environ. 41, 177–187. doi:10.1016/j.trd.2015.10.010

Keywords: predictive maintenance, electric buses, energy consumption optimization, battery degradation, sustainable transportation, industrial informatics

Citation: Ibrahim H, Ali AM and Attia T (2025) Optimizing electric bus performance via predictive maintenance: a combined experimental and modeling approach. Front. Future Transp. 5:1506866. doi: 10.3389/ffutr.2024.1506866

Received: 09 October 2024; Accepted: 16 December 2024;

Published: 07 January 2025.

Edited by:

Cheng Siong Chin, Newcastle University, United KingdomReviewed by:

Xuanyu Wu, Hefei University of Technology, ChinaLoshaka Perera, University of Moratuwa, Sri Lanka

Copyright © 2025 Ibrahim, Ali and Attia. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hisham Ibrahim, aGlzaGFtLmthbWVsQG10Yy5lZHUuZWc=

Hisham Ibrahim

Hisham Ibrahim Ahmed M. Ali

Ahmed M. Ali Tamer Attia

Tamer Attia