94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Food. Sci. Technol., 27 February 2025

Sec. Food Packaging and Preservation

Volume 5 - 2025 | https://doi.org/10.3389/frfst.2025.1520532

In 2021, the packaging sector emerged as the largest source of plastic waste in Europe, accounting for about 40% of the total demand for plastics. On average, an EU citizen produced 35.9 kg of waste from plastic packaging, with a 27% increase over the last 10 years. Despite advances in material efficiency and sustainability efforts, the average recycling rate of plastic packaging in the EU was around 40% in 2022, significantly lower than that of paper and cardboard packaging (83.2%) and metals (76.9%). The Food and Beverage (F&B) sector is an extensive user of packaging, driving the demand for innovative solutions to maintain food quality and safety while minimizing environmental impact. In light of these challenges, this comprehensive review examines the expanding use of packaging within the F&B sector and the management of post-consumer plastic waste at the EU level. It scrutinizes the technical, economic, and regulatory trade-offs in packaging deployment and disposal, emphasizing the need for supply chain collaboration to devise effective solutions. The study provides an overview of EU regulations on health and safety, sustainability, and labeling requirements for F&B packaging materials and products. It also explores the optimization of packaging for food business operators and supply chain management practices as well as current waste management strategies for post-consumer plastic waste, focusing on mechanical and chemical recycling and adherence to regulatory targets. Additionally, it identifies barriers to adopting sustainable packaging alternatives and discusses the impact of packaging design on recyclability and consumer acceptance. The study concludes with future research and industry opportunities, highlighting innovative packaging solutions that balance health and safety, sustainability, and cost-effectiveness.

Global food consumption has been steadily increasing since 2015 (Statista, 2022), with projections indicating that food demand will grow by at least 35% between 2010 and 2050 (Van Dijk et al., 2021). It is estimated that the average individual consumes food three times per day (Ada et al., 2023), and, in the large majority of cases, this food comes with packaging. Packaging serves different functions, including containment, protection, handling, transport, storage, convenience, information and presentation (Robertson, 2005; ISO/IEC, 2018) and it is therefore widely used in many industries. In developed countries, packaging constitutes approximately 2% of the gross national product, with most packaging materials being utilized in the food industry (Ncube et al., 2021). This underscores the integrated nature of foods and their packaging, a concept frequently addressed in the literature as the “product-package” perspective (Rezaei et al., 2019).

In the EU, the packaging industry is a significant economic sector, with the market valued at approximately EUR 153 billion in 2024 and expected to grow to EUR 186 billion by 2029 (Fachpack, 2024). The Food and Beverage (F&B) sector drives this growth, carrying a demand for innovative solutions to maintain food quality and safety while minimizing impact on natural resources. According to the EU’s Packaging and Packaging Waste Directive (PPWD) (European Parliament, 2018), packaging consists only of:

⁃ Primary packaging, or sales packaging, is the packaging conceived so as to constitute a sales unit to the final user or consumer at the point of purchase.

⁃ Secondary packaging, or grouped packaging, is intended to group a certain number of sales units, either for sale to the final user or consumer. This type of packaging can be removed from the product without affecting its characteristics.

⁃ Tertiary packaging, or transport packaging, is designed to streamline the handling and transportation of multiple sales units or grouped packages, thereby mitigating the risk of physical damage during transit. It does not include containers used for road, rail, ship, or air transport.

A wide range of materials are used for packaging, including glass, paper and cardboard, metals such as steel and aluminum, plastics, and wood; more than two-thirds of all packaging materials are used in the F&B sector alone (Ncube et al., 2020). Each material offers unique properties that make it suitable for different types of packaging needs and food to be packed. Secondary and tertiary packaging are generally made up of homogenous materials, making them easier to collect, reuse and recycle (Sæter et al., 2020). This contrasts with primary packaging, which can come in more complex combinations, since in F&B applications it must guarantee optimal performance in protecting foodstuffs. In addition, secondary and tertiary packaging solutions are commonly used across various sectors–and mainly in logistics operations–while primary packaging tends to be more specific to certain industries in terms of technical and regulatory requirements. In the context of this manuscript, primary packaging is also referred to as food packaging.

Among the other materials used, plastics have a critical importance in primary packaging, fulfilling the need of different stakeholders and accommodating a wide range of products. Their versatility is widely recognized, and they are extensively employed in the F&B sector as well as across multiple market segments, including building and construction, automotive, electrical, and electronic. Among the fossil-based plastics, polypropylene (PP), polystyrene (PS), polyvinylchloride (PVC), polyethylene (PE) and polyethylene terephthalate (PET) have been extensively used for food packaging (Ncube et al., 2021). In the last decades, bio-based polymers such as polylactic acid (PLA) also entered the market. Table 1 represents packaging materials widely used in F&B, with examples of applications.

Although the contribution of plastic packaging production to the total life cycle GHG emissions for most food products is less than 10% (Kan and Miller, 2022), plastic waste can persist and accumulate in the environment (Guillard et al., 2018), especially in marine ecosystems where it harms the wildlife and leads to long-term ecological damage (Gündoğdu et al., 2024). As of today, it is estimated that at least 5 billion tons of plastic waste are dispersed in the environment globally (Geyer et al., 2017; Sonke et al., 2022), with debris residence times that can range from hundreds of years to millennia (Chamas et al., 2020; Sonke et al., 2022; Dey et al., 2024). The F&B sector is a significant contributor to this pollution (Phelan et al., 2022), and single-use plastics employed to pack beverages, fresh meats, fruits, and vegetables are of particular concern (Dey et al., 2021). The extensive use of packaging in the F&B sector is raising concerns also in the European Union, where the packaging sector is the major source of plastic waste (European Environment Agency, 2023b). In the attempt to address these concerns, the EU issued stringent regulations to reduce pollution as well as increase customer expectations, thus rendering traditional packaging insufficient for current time (Schaefer and Cheung, 2018). However, despite the efforts to increase the circular use of packaging materials, the average recycling rate for plastic packaging in the EU is not increasing at the rate required by its increasing production volumes (Eurostat, 2023). This highlights the need to identify the current gaps preventing a wider adoption of circular strategies in the use of food plastic packaging as well as the trends and opportunities to enhance waste management and reverse the growing trend of plastic waste volume.

This comprehensive review examines the dual focus of the use of packaging by operators in the F&B sector on one side, and the management and recycling of post-consumer waste on the other, with the aim of promoting circularity within EU systems. It evaluates the trade-offs among technical, economic, and regulatory factors related to packaging use and disposal, and identifies barriers that currently hinder the adoption of sustainable packaging alternatives or processes for end-of-life management. These trade-offs are addressed with a supply chain perspective—rather than focusing on isolated businesses—emphasizing that this approach is essential to generating benefits for all stakeholders, including consumers. Hence, the review discusses how packaging optimization should involve collaboration among supply chain actors to develop solutions that are not only effective but also facilitate recycling and promote closed-loop systems. Key areas of focus are packaging use and waste management. For the former, this manuscript analyzes the key aspects involved in the optimization of packaging for food business operators, for instance considering material selection, design, and functionality to enhance food protection and preservation. The second focus area is addressed by exploring current strategies for managing post-consumer plastic waste, including the existing recycling alternatives, and identifying barriers to the adoption of sustainable alternatives. By adopting this dual focus, the review aims to provide an understanding of the challenges and opportunities in achieving a circular economy for food packaging. It highlights the need for innovative solutions that not only meet regulatory requirements but also promote sustainability and consumer acceptance.

This manuscript is structured as follows. Section 2 delineates the methodology utilized to conduct the comprehensive literature analysis, aimed at achieving the objectives of this review. This section elaborates on the conceptual framework of the packaging value chain and introduces the key stakeholders within the F&B sector addressed in this study. Section 3 provides an overview of the regulations on packaging materials and products in force in the EU. Health and safety requirements, sustainability, and labeling are discussed as the three main areas of food packaging regulations together with their implications on the development of new solutions. Section 4 examines packaging use by food businesses from production to retail, delving into the specific needs of various stakeholders concerning packaging. It highlights the factors that should be considered when optimizing packaging, distinguishing between primary, secondary, and tertiary packaging. Collaboration is emphasized as a prerequisite for effective supply chain management, guiding packaging optimization towards shared benefits for all stakeholders. Section 5 delves into waste management and recycling of post-consumer waste, with a focus on plastic packaging, which poses severe challenges for ecosystems and human health. After reviewing the state of the art of recycling methods, the impact of packaging design on recyclability and consumer acceptance is discussed as a key enabler of circularity, helping to maintain the value of packaging materials and products for as long as possible. Both Sections 4, 5 identify the barriers limiting packaging use and plastic recycling, respectively. Finally, Section 6 discusses opportunities and future directions for research and industry, presenting examples of innovations in food packaging that ensure health and safety, sustainability, and cost-effectiveness in implementation.

This review was produced within the framework of the MAGNO project (grant number “101135258”), funded by the EU under the Horizon Europe programme. MAGNO aims to enhance packaging effectiveness, sustainability, efficient usage, and end-of-life processes (reuse and recycling). It also promotes innovative business practices in EU food systems through novel strategies, such as efficient recycling and reuse of packaging solutions, as well as the adoption of new circular business practices aligned with the Circular Economy Action Plan’s (CEAP) mission. Building on these objectives, this review investigates packaging intended for F&B applications, with a particular focus on plastics. The packaging value chain is conceptualized as comprising four stages: design, manufacturing, use, and waste management. Within the use stage, a packaging product comes into contact with a food product, forming the “product-package” system (Rezaei et al., 2019). This study specifically addresses the use of packaging by food operators and the management of post-consumer packaging waste at the EU level. Regarding packaging use, these research questions were investigated: a) What factors are currently driving F&B actors in the adoption of packaging solutions?; b) What are the current barriers and challenges faced by these actors? For post-consumer packaging waste, the following questions were investigated: c) What is the current state of recycling systems in the EU?; d) What are the current barriers and challenges in the end-of-life management of post-consumer packaging waste? The interrelation of these stages with packaging design and manufacturing is also considered, as they significantly influence the safety, quality, sustainability, cost-effectiveness, and regulatory compliance of packaging solutions. By addressing these aspects, this review highlights the current knowledge gaps in EU food systems and identifies areas where improvements are needed to achieve circularity.

The results would be beneficial to industry professionals in the F&B sector and the broad academic audience dealing with advancements in packaging sustainability and innovation. To address the research questions, a semi-systematic approach was adopted (Snyder, 2019), with the research framework including regulatory analysis, literature search, qualitative analysis, snowballing approach, clustering and writing, depicted in Figure 1.

First, to identify relevant regulations for packaging in F&B applications, a study of the EU regulatory landscape was conducted. This involved consulting institutional websites of the EU, including those dedicated to press communications, to determine the regulatory compliance prerequisites for packaging in this specific context and general regulatory decisions. The search encompassed various legislative acts (frameworks, directives, regulations, strategies) applicable to different types of packaging and materials, excluding those addressing specific packaging solutions such as active and intelligent packaging materials. Three overarching topics emerged from the selected EU laws and policies: safety, sustainability, and labeling. The findings were synthesized in a hierarchical tabular format to enhance clarity, presenting overarching frameworks first, followed by directives, strategies, and regulations (more detail in Section 3). The identified regulatory themes informed the initial keywords for the subsequent literature search, which included terms such as “safety”, “food safety”, “traceability”, “consumer awareness”, “labeling”, “sustainability”, “single-use plastics”, and “contamination”.

The literature search was divided into two areas of investigation: Packaging use in F&B and post-consumer packaging waste management. This division reflects the scope of packaging use by food operators and the disposal of packaging waste. Keywords identified from the regulatory analysis were combined with terms such as “technical”, “economic”, “challenges”, “hurdles”, “barriers”, “market”, “prices”, “incentives”, “innovations”, and “opportunities”, which are relevant to the research questions and the objectives sought. The initial criteria for article selection included: a) only peer-reviewed articles, book extracts, and conference proceedings in English; b) preference for articles published from 2020 onwards; and c) articles with more than 20 citations. Articles on specific packaging solutions or targeting precise environmental issues were excluded to focus on common issues for different operators in the F&B sector, including primary producers, processors, logistic providers, and retailers, as well as the end-of-life operators of packaging waste. Therefore, the search queries included combinations such as “Food AND packaging AND (Barriers OR hurdles)”, “F&B AND packaging AND Challenges”, and “Plastic AND Waste AND Management AND (Challenge OR Challenges)”, adding to these queries the keywords emerging from the regulatory analysis and those pertaining to technical and economic aspects, as needed. This literature search yielded an initial batch of 50 articles. Articles meeting the criteria were documented, and a summary of their main findings was drafted. From this qualitative analysis, it emerged that the most recurrent thematic areas were packaging optimization, focusing on packaging performance and functions, supply chain management, focusing on collaboration among stakeholders, packaging recyclability, focusing on extending the lifecycle of products, and consumer acceptance toward innovative packaging. Subtended in these areas, different packaging solutions are mentioned (i.e., smart packaging, nanopackaging), as well as different technologies, materials and related performance encompassed in recycling systems (i.e., NIR scanning, manual sorting, performance degradation).

At this stage, it was deemed necessary to deepen these aspects. Hence, the snowballing approach was adopted to identify additional relevant papers by reviewing the references of the initially selected articles. In this case, primary criteria b) and c) were not strictly adopted, while still considering criterion a). Indeed, a secondary criterion was considered: d) articles that may not meet the primary criteria but are deemed highly relevant due to i) the number of citations (>100), such as older foundational studies or ii) articles with fewer citations but promising contributions to the field in light of innovative packaging solutions or approaches addressed. Around 250 articles were considered and divided according to the two areas of investigation (i.e., packaging use in F&B and post-consumer packaging waste management). The articles were analyzed in scope, goal, and results, and a summary of their findings was drafted. Subsequently, articles were further clustered according to the main thematic areas that emerged during the first literature search (i.e., packaging optimization, supply chain management, packaging recyclability, and consumer acceptance). These clusters were linked to the relevant F&B stakeholders or end-of-life operators. This provided the foundation for the manuscript.

The manuscript was drafted with regulatory requirements as the backbone of the discussion, as these are obligations that must be fulfilled by packaging materials and products. The description was enriched with technical and economic challenges and opportunities found within the two areas of investigation with the previous literature searches, thereby addressing multiple topics and perspectives. This approach highlighted the complex trade-offs between regulatory, economic, and technical aspects for a variety of stakeholders, comprehensively reflecting major trends, needs, gaps, and opportunities.

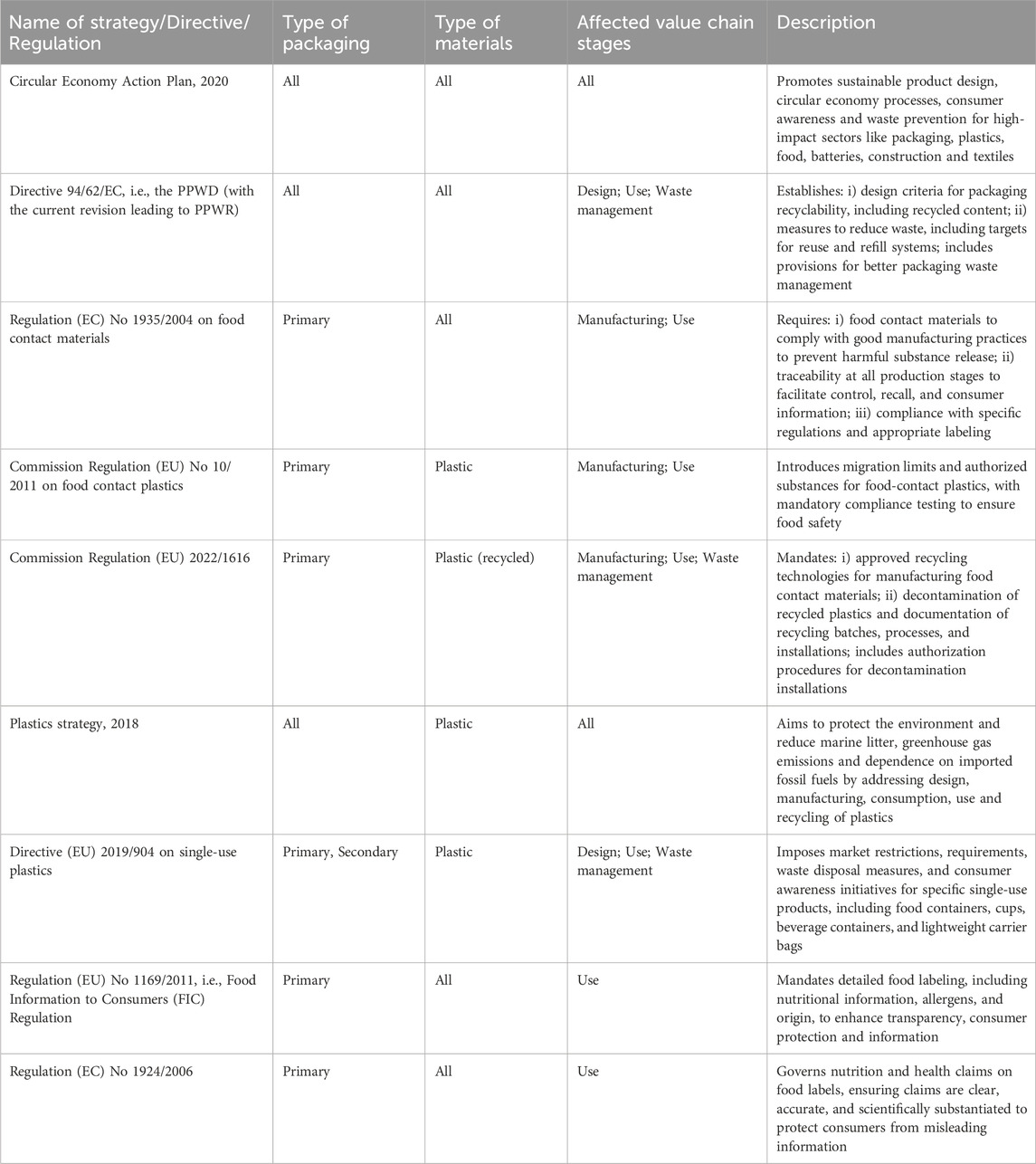

In line with the European Green Deal and the ambition to achieve climate neutrality by 2050, the Circular Economy Action Plan (European Commission, 2020) was implemented in March 2020 to promote sustainable growth by transitioning the EU to a circular economy. The sectors of plastics, packaging, and food have been identified as key for this transformation given their intensive resource use and potential for circularity, offering significant opportunities for improvements and potential benefits (European Commission, 2020; European Parliament, 2024b). CEAP addresses products placed on the EU market by incorporating sustainability throughout their whole lifecycle, aiming to prevent and reduce waste and alleviate pressure on natural resources. Concurrently, the action plan promotes a culture of sustainability for EU consumers, empowering them to make environmentally conscious choices when purchasing goods. The EU regulatory landscape on packaging materials and products, with the CEAP as its overarching framework, addresses packaging at every stage of the value chain, from design to post-consumer waste management, and for all types of materials used as well as packaging types. This regulatory landscape includes directives, regulations and strategies, among other instruments. Directives are legislative acts that establish objectives for member states to achieve, while allowing flexibility in the methods of implementation at the national level–i.e., national laws. In contrast, EU regulations are binding legislative acts that are directly applicable and enforceable in their entirety across all member states (European Union, 2024). Strategies, on the other hand, are broader plans that outline the EU’s long-term goals and priorities in a specific area. These are not legally binding but provide guidance and direction for future legislations and policy actions. Table 2 presents the EU regulatory landscape for packaging materials and products relevant to the F&B sector, with a focus on legislations and plans governing packaging use and waste management addressed in this manuscript. Directives, regulations, and strategies are categorized by the type of packaging concerned, the materials involved, and the stages of the value chain addressed. It is worth noting that all these legislative instruments can also cover stages of the packaging value chain not within the scope of this manuscript, such as packaging design and manufacturing, which are nonetheless coherently reported.

Table 2. EU strategies, directives and regulations in force on packaging materials and products relevant to the F&B sector.

Packaging waste directives and regulations are a clear example of the practical implementation of the CEAP objectives. These have evolved significantly over time so as to achieve circular systems for packaging in the EU. The PPWD (Directive 94/62/EC), firstly established in 1994, is the centerpiece of packaging waste legislation, setting mandatory targets for member states, yet allowing flexibility in implementation. The directive emphasizes proper packaging life cycle management, addressing design, use, and waste management across all materials and applications, from industrial to household. However, its transposition into national laws has led to uneven application in the EU, creating disparities. To address these, the Packaging and Packaging Waste Regulation (PPWR) has been currently agreed by the European Parliament after being proposed on 30 November 2022, to amend the PPWD. This transition marks a fundamental change, promoting consistent rules across the members. The PPWR goes beyond the scope of the PPWD, introducing specific measures to tackle urgent challenges such as excess packaging and insufficient recycling. Key advances include mandatory recyclable design requirements by 2030, large-scale recyclability by 2035 and reducing excess packaging through reuse strategies (more detail in Section 5). In addition, the PPWR requires the incorporation of minimum recycled content into packaging products, promoting closed-loop recycling systems and aligning with the mission of CEAP (European Council, 2024). These measures aim to address the 20% increase in packaging waste mass observed in the EU between 2009 and 2020 (European Parliament, 2024a). The PPWR represents a step forward in promoting a circular economy for packaging in a cost-efficient way (European Council, 2024) by setting specific requirements for sustainable packaging design and integrating objectives for large-scale recycling and reuse. As stated by the European Commission, the objective of the PPWR is to ensure that “all packaging on the EU market is reusable or recyclable in an economically viable way by 2030” (European Commission, 2023).

In the F&B sector, EU regulations on packaging materials and products are essential to safeguard consumer health and safety. Around 8,000 substances are permitted for use in food packaging production (Catherine et al., 2016; Gündoğdu et al., 2024). The safety of packaging is strictly controlled to prevent the release of harmful chemicals into food until it is consumed (Wrona and Nerin, 2019). Additionally, sustainability has become a critical aspect of packaging, with efforts focused on reducing environmental impacts while preserving functionality and ensuring economic viability (Pauer et al., 2019). Food packaging that is not designed to be environmentally friendly throughout its life cycle significantly contributes to sustainability issues (Hussain et al., 2024), particularly when its disposal is not properly managed (De Pilli et al., 2021). Furthermore, the disclosure of information regarding food and packaging is imperative for ensuring health and safety, as well as promoting awareness of sustainable consumption and disposal practices. In the following sections, the main EU regulations addressing health and safety, sustainability and labeling of food packaging are discussed.

Regulation (EC) No 1935/2004 (Regulation EC No, 1935/2004 of the European Parliament and of the Council, 2021) establishes the fundamental principles and requirements for materials and articles intended to come into contact with food and drinks, known as food contact materials (FCMs). The regulation requires that FCMs do not release substances in quantities that could endanger human health or alter the food’s composition, taste, or odor. It applies to all materials used for food contact, including plastics, metals, and paper. Key requirements include proper labeling, the safety assessment of substances used in FCMs, and full traceability and documentation of packaging materials and products throughout the supply chain. FCMs may contain around 352 chemicals classified as carcinogenic, mutagenic, or toxic to reproduction (Zimmermann et al., 2022) by the Globally Harmonized System of Classification and Labelling of Chemicals (UNECE, 2023). Empirical evidence confirms the presence of 127 of these chemicals in FCMs, with 85 of them having a known potential to migrate into foodstuffs (Zimmermann et al., 2022).

The regulation on FCMs also mandates that these materials and articles be manufactured in a way that does not compromise food safety and quality, in accordance with Commission Regulation (EC) No 2023/2006 (Commission Regulation (EC), 2008) on good manufacturing practices.

Plastics dominate the market share among all FCMs for F&B applications (Kan and Miller, 2022) due to their versatility, good performance, including durability, and cost-effectiveness (Navarre et al., 2022). The Commission Regulation (EU) No 10/2011 establishes specific technical requirements for food contact plastics. This regulation imposes measures, controls, and monitoring to ensure food safety. It mandates the authorization of substances used in plastic packaging products, adherence to both specific (i.e., targeting individual substances) and overall migration limits, as well as compliance testing. In a recent review by the EFSA Panel on Food Contact Materials, Enzymes and Processing Aids requested by the European Commission (EFSA Panel on Food Contact Materials, Enzymes and Processing Aids (CEP), 2020), specific migration limits for substances were re-examined and proposed. Notably, three substances were identified as having significant potential health risks: salicylic acid, styrene, and vinyl laurate.

Finally, Commission Regulation (EU) 2022/1,616 (Commission Regulation (EU), 2022) has been recently established to address the safety requirements for recycled plastics intended for food contact, as contamination can hinder the reuse of materials after recycling. Recycling processes must employ approved technologies that are designed to decontaminate used plastics to a safe level. The full approach to decontamination is governed by the European Food Safety Authority. This regulatory framework ensures that FCMs meet stringent safety requirements, thereby promoting public health in the food packaging industry (Commission Regulation (EU), 2022).

The sustainability impacts of food packaging are a critical area of concern, particularly regarding waste generation. Food packaging, while essential for preserving product quality and extending shelf life, often results in significant waste. Among various materials used, plastic packaging stands out due to its widespread use and the challenges it presents in waste management. If not properly managed, this waste can enter the environment, causing harmful impacts on both ecosystems and human health (Navarre et al., 2022). Single-use plastics (SUP), in particular, have been identified as a significant contributor to pollution, especially in marine environments. As the food and beverage sector is one of the main users of single-use packaging (Phelan et al., 2022), the resulting environmental impacts are aggravated, emphasizing the urgency of adopting sustainable practices to reduce waste and promote a circular economy.

In response to these concerns, the EU adopted the Plastic Strategy in 2018 (European Commission, 2018), which is now integrated into the CEAP. This strategy aims to protect the environment and reduce marine litter, greenhouse gas emissions and dependence on imported fossil fuels by promoting more sustainable design, manufacturing, consumption, use and recycling of plastics. To reinforce this commitment, the EU implemented the SUP Directive (Directive (EU), 2019), targeting specific plastic products frequently found in litter and that have viable, more sustainable alternatives. This directive significantly impacts plastic products used in F&B applications. It bans the market placement of items such as straws, expanded polystyrene food containers and cups. Moreover, it mandates that member states adopt measures for a sustained reduction in the consumption of other SUP products. The directive also introduces measures such as design requirements to ensure caps and lids remain attached to containers, labeling requirements to inform consumers about proper disposal, and extended producer responsibility schemes to manage waste and clean-up efforts.

Labeling is essential for providing consumers with critical information about food products, while also promoting sustainability and ensuring health and safety. Accurate labeling encompasses details about contents, nutritional value, and potential allergens, thereby facilitating informed purchasing decisions. Additionally, clear labeling supports environmental and social sustainability by encouraging responsible consumption and proper disposal of packaging materials.

Regulation (EU) No 1169/2011 (Regulation EU No 1169/2011 of the European Parliament and of the Council, 2018), known as the Food Information to Consumers (FIC) regulation, mandates comprehensive labeling requirements to enhance transparency and consumer protection. It sets mandatory information on food labels, including the name of the food, origin, ingredients list, allergens information, date of minimum durability, any special storage conditions and/or conditions of use. The regulation also requires a standardized format for nutrition information. Complementing the FIC regulation, Regulation (EC) No 1924/2006 (Regulation EC No, 1924/2006 of the European Parliament and of the Council, 2014) governs the use of nutrition and health claims on food labels. Its primary goal is to ensure a high level of consumer protection by preventing misleading claims and harmonizing regulations across member states. The regulation covers both nutrition claims, such as “low fat” or “high fiber,” and health claims, which link food to health benefits. Claims must be clear, accurate, and scientifically substantiated. Health claims, in particular, require authorization from the European Food Safety Authority and must meet specific nutrient profiles to prevent misleading information on foods. Non-compliance can result in penalties, including fines and product removal. In summary, both regulations promote responsible food consumption by utilizing packaging as a medium to convey essential information to consumers. Labels may also include details about the environmental impact of food production, such as carbon footprint, water usage, and sustainable farming practices, encouraging consumers to choose products with lower environmental impacts. Similarly, by knowing the origin of food, consumers can decide to support local and sustainable food systems, reducing the carbon footprint associated with long-distance transportation. As discussed by (Steenis et al., 2017), labeling is part of the verbal design features of packaging, which consumers rely on when making their decisions, along with structural features (shape, size, material type, etc.) and graphical features (colors, imagery, graphics, etc.), as well as beliefs and other associations forming judgments. Packaging can play a significant role in implicitly cueing sustainability, with labels acting in the cue utilization process, thereby leading to more sustainable choices.

Furthermore, the EU’s increasing focus on plastic packaging recyclability is evident through the introduction of labels under the CEAP, which indicate the recyclability of packaging and provide guidance on proper material separation, thereby encouraging environmentally responsible consumer choices (Sazdovski et al., 2022). The EU has also introduced a voluntary ecolabel scheme for packaging to identify products that meet specific environmental criteria (Tobi et al., 2019). However, the adoption and implementation of these ecolabels can vary significantly among EU countries (Albu and Chitu, 2012; Kijek, 2015). For instance, while countries like France and Italy have developed their own distinct recycling logos—such as the Triman logo in France—other nations may not have harmonized labeling standards in place (Albizzati et al., 2023). This inconsistency can lead to consumer confusion and hinder effective recycling practices, highlighting the need for a unified approach to packaging labels across the EU.

Food Business Operators (FBOs) are the natural or legal persons responsible for ensuring that the requirements of food law are met within the activities performed throughout the production, processing, and distribution of food (Regulation (EC), 2002). In the following, FBOs are defined as any organization (i.e., legal person) in the food industry–from ingredient production to finished products, including primary production–logistics, retail, e-commerce and food service. This section explores the aspects related to the use of packaging as means for these actors to fulfil roles and responsibilities within the supply chain.

FBOs rely on packaging to contain, protect, store, transport, and distribute F&B products. They are driven by the need to find and use optimal packaging solutions to support these operations (Dörnyei et al., 2023). The range of materials available for packaging production is increasing due to the advancement of research, carrying many differentiations. Consequently, this progress has led to a variety of packaging solutions with unique characteristics, providing FBOs with a broad spectrum of options depending on diverse products and considering technical issues, shelf life, environmental impact, cost, consumer acceptance, and regulatory compliance (González-López et al., 2023). Furthermore, the integration of smart and innovative technologies in the packaging industry is on the rise and provides new solutions, such as freshness indicators and interactive labels for a better consumer experience (Halonen et al., 2020; Abekoon et al., 2024), which lastly enhances packaging attributes. All these factors help define the “optimal” packaging choices for FBOs, making this dependent on business and supply chain contexts. Packaging optimization involves balancing functionality, cost, and environmental impact along with consumer preferences, experience, and acceptance (Agarwal et al., 2023; Nair et al., 2023).

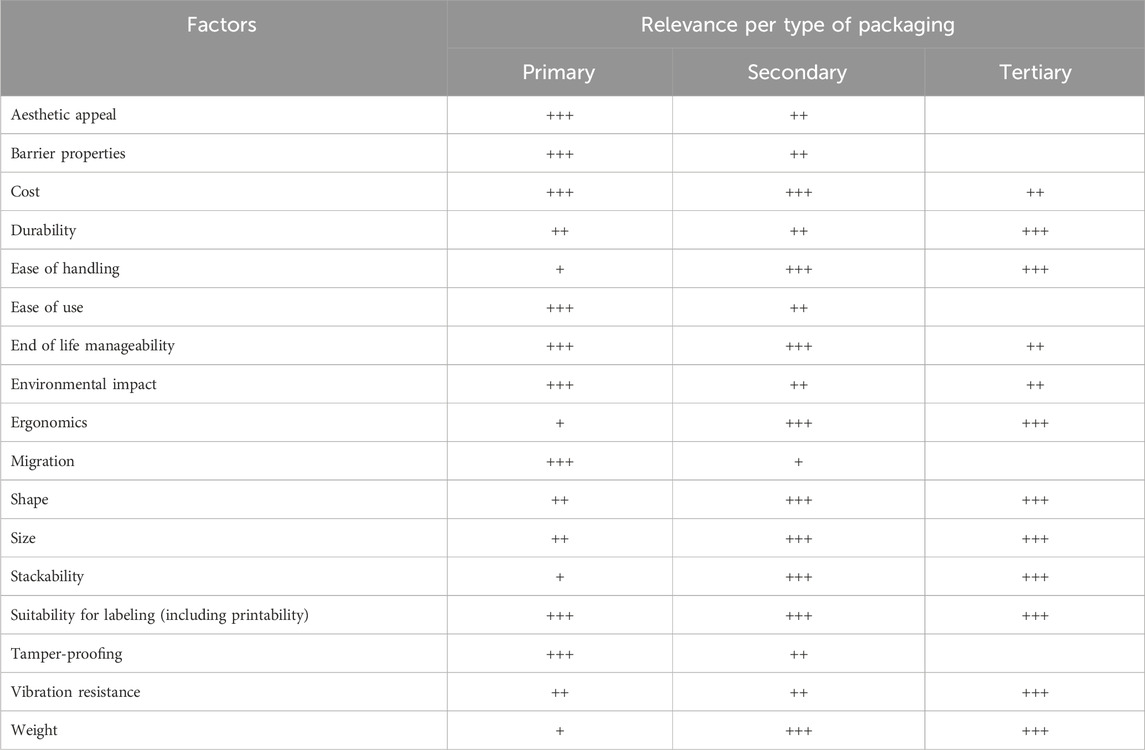

Food protection and preservation are the primary functions that packaging serves (Lindh et al., 2016; Schmidt and Schmidt, 2019; Garba, 2023). According to (Lindh et al., 2016), the function of protection, which includes preservation, unfolds several features or properties (i.e., prominent or distinctive qualities or characteristics) of packaging, such as mechanical, barrier, thermal and sealing properties. These features can also indirectly contribute to sustainable development. For instance, enhanced barrier properties of packaging can reduce the risk of human health hazards, while optimized mechanical properties may decrease food waste. In this regard, packaging optimization seeks to accommodate these requirements as effectively as possible. This applies regardless of packaging type, as protection and preservation enable retaining the safety and market value of food until it reaches the consumer. Primary packaging, in particular, is subject to more stringent requirements regarding materials that can be used and technical specifications in F&B applications. Nevertheless, protection is cumulative and relies on the combined action of primary, secondary, and tertiary packaging (and even beyond), depending on the external conditions that foods encounter along the supply chain. For example, strawberries can be packed with plastic clamshell containers with ventilation holes to allow air circulation, reducing moisture buildup and preventing mold growth; cardboard boxes can be used to host multiple clamshell containers, providing an additional layer of protection against impacts during handling and transportation; wood pallets can be used to stack cardboard boxes, securing the whole content against dust and temperature fluctuations with shrink wraps, further providing stability for long distance transportation. If any of these packaging solutions is not optimized for food protection and preservation, the results can include reduced nutritional value due to decay or spoilage, poor food attractiveness, or worse, food waste and economic losses, as damaged products may be rejected by customers (Versino et al., 2023). Therefore, FBOs have a strong interest in considering food protection and preservation when optimizing packaging (Sarkar and Aparna, 2020), as they must address potential shocks, damage, or any other externalities that may alter food characteristics and/or possibly be a source of health risks. Besides this, packaging serves many other functions, from traceability to advertisement and warranty (Schmidt and Schmidt, 2019). Table 3 outlines the factors that FBOs should consider in optimizing packaging for F&B applications. It specifies the relevance of these factors to primary, secondary, and tertiary packaging, denoted as low (+), medium (++), or high (+++). A blank cell indicates negligible or null relevance.

Table 3. Factors that FBOs should take into account when optimizing packaging solutions for F&B applications (Marsh and Bugusu, 2007; Svanes et al., 2010; Lindh et al., 2016; Sohrabpour et al., 2016; Siracusa and Rosa, 2018; Fadiji et al., 2019; Gardas et al., 2019; Wang et al., 2019; Ozcan and Arman Kandirmaz, 2020; Sarkar and Aparna, 2020; Vermeir and Roose, 2020; Alamri et al., 2021; Ilhan et al., 2021; Mesa et al., 2022; Yang et al., 2022; Versino et al., 2023). The relevance of each factor toward each packaging type is indicated as low (+), medium (++) or high (+++). A blank cell denotes negligible or null relevance.

As a general observation, the relevance of these factors varies depending on specific products, sales methods (e.g., single package, multiple subpackages grouped in a single package), and sales channels (e.g., retail, e-commerce, local markets). While factors such as cost are universally considered across all types of packaging and determine their affordability for both FBOs and consumers (Popovic et al., 2019; Stoica et al., 2020), other factors may exhibit higher variability and should be carefully evaluated on a case-by-case basis. Some of those are relevant for specific food products based on their peculiarities. For example, ease of handling (i.e., the ability of a package to be easily moved from one location to another) is particularly important for bulky products, such as a leg of cured ham contained in a cardboard box, whereas it is less relevant for smaller products. Similarly, ease of use (i.e., the easiness in accessing and utilizing the product, especially for end-users) is critical for liquids, where the primary packaging must be designed and optimized for convenient and/or repeated access, while it may be less relevant for solids packaged in single-use solutions. Finally, other factors may exhibit relevance to food products in general, as packaging plays a primary role in ensuring the safety of food products and protect them against contamination. For this reason, factors such as durability (i.e., the ability of packaging to perform its own functions at the anticipated performance level under expected conditions of use) (Mesa et al., 2022) or migration (i.e., the transfer of chemical compound between the package and the product it contains) (Alamri et al., 2021) are crucial in the design and optimization of food packaging. When considering sales methods and channels, some factors may be addressed by multiple packaging types simultaneously or transferred among packaging types, typically primary and secondary. Aesthetic appeal, for example, is often optimized in primary packaging for F&B applications (e.g., a single package of snacks) but can also be served by secondary packaging (e.g., small carton case containing stacked snacks sold individually, frequently contained in a primary package made by plastic materials). In other cases, both packaging types are designed to be appealing (e.g., single packages of chips grouped with display packaging). Furthermore, it is worth noting that the factors in Table 3 are interdependent, and optimizing for some may influence others, even at different stages of the supply chain. For instance, the shape of the packaging affects stackability, which is crucial for efficient logistics operations (Han, 2013). However, the shape also impacts the aesthetic appeal of packaging, influencing consumer choice and brand differentiation (Vermeir and Roose, 2020). These trade-offs underscore the necessity of a supply chain perspective for packaging optimization.

In addition to the factors in Table 3, further needs are considered when optimizing different packaging solutions based on the intended use. For example, breathability is crucial for the primary packaging of fresh produce, as controlling oxygen and gas exchange between the food and the external environment is necessary to prevent spoilage (Robertson, 2005; Bishop and Hanney, 2008). Similarly, leak resistance is essential for packaging jams or beverages and is addressed by primary packaging. Once leak resistance is ensured, secondary packaging should focus on shock and vibration resistance to protect primary packages during transportation and handling (Coles et al., 2003). To conclude, packaging optimization in F&B applications requires a comprehensive evaluation of multiple factors and needs. While Table 3 offers generally applicable insights, it is essential to adopt a tailored approach when developing specific solutions for F&B products. This ensures that all relevant factors are considered, leading to optimized packaging that meets the unique requirements of each product and its supply chain.

Packaging is a critical determinant of global supply chain efficiency, influencing operational costs and performance (Sohrabpour et al., 2016; Molina-Besch et al., 2019) across various segments, including inventory management, warehousing, and transportation operations (Morashti et al., 2022). The environmental and societal impacts of packaging are increasingly garnering stakeholder interest, necessitating collaboration among supply chain actors to adopt innovative solutions (Morashti et al., 2022). The evolution of Supply Chain Management (SCM) as a discipline highlights a shift from isolated business operations to interconnected networks, emphasizing the benefits of collaboration among stakeholders (Chen et al., 2020). Modern global supply chain strategies aim to integrate circular economy principles into traditional business operations and management (Solomon et al., 2024), addressing resource recovery, efficient use, and waste reduction from product design and manufacturing to distribution, consumption, and end-of-life management. Therefore, effective packaging strategies must adopt a supply chain perspective to advance sustainability while maintaining competitiveness for supply chain actors (Sohrabpour et al., 2016). In the F&B sector, integrating packaging strategies in SCM should support product safety, quality, and compliance with regulations and standards in addition to supply chain efficiency (i.e., food loss reduction) and sustainability (i.e., food waste reduction, packaging recycling, etc.). Recent studies focus on the development and optimization of sustainable packaging alternatives to achieve these objectives.

Abbate et al. (2023) examined the environmental benefits and social implications of using recyclable and biodegradable plastic packaging in the Italian egg industry. The study addressed the supply chain stages associated with the packing, inner and outer logistics, and distribution operations. By using a bio-based material (e.g., PLA) that met both regulatory requirements (i.e., food contact materials) and company needs (i.e., packaging transparency), a 14% decrease in GHGs emission was observed. Zambujal-Oliveira and Fernandes (2024) explored sustainable packaging in the circular food supply chain using the multi-criteria decision-making (MCDM) approach. Criteria such as recyclability, food safety, packaging material, and environmental impact are used to study sustainable product-package designs that minimize food losses at each stage of the supply chain. Conversely, Rezaei et al. (2019) examined the influence of sustainable packaging criteria, derived from an extensive supply chain analysis, on packaging design within a specific food company. Their criteria encompassed environmental, social, and economic performance, addressing the diverse needs and perspectives of producers, distributors, and consumers. Utilizing the MCDM approach, the study focused on three products to determine optimal packaging designs.

In logistics, the number of studies focusing on sustainable packaging systems is similarly increasing as global trade and e-commerce drive up the volume of packaged goods (Escursell et al., 2021; Cano et al., 2022; Morashti et al., 2022). Sustainable packaging must take into account handling methods, transport modes, facility dimensions, and communication needs to optimize the system, presenting high complexity (Coles et al., 2003). Innovation in this area requires internal (i.e., company level) transformations, such as adopting new packaging materials and processes, and external transformations, such as collaborating with supply chain partners to ensure compatibility and efficiency (García-Arca et al., 2014; García-Arca et al., 2017). Smart packaging solutions have been shown to enhance sustainability and efficiency in logistics. They provide real-time data on product conditions, enabling managers to make informed decisions (Johansson, 2009; Kabadurmus et al., 2023). Technologies such as time-temperature indicators (TTIs) and radio frequency identification (RFID) devices help extend the shelf-life of products and maintain their freshness, increase food safety, and facilitate the exchange of quality information with consumers (Kaushani et al., 2022; Ganeson et al., 2023; Chen et al., 2020) highlighted that the adoption of TTIs and RFID reduces food loss and waste along the supply chain by enhancing product traceability. Nonetheless, smart packaging adoption requires cross-collaboration to enable real-time monitoring and data collection; these solutions must leverage SCM principles to ensure an effective implementation into the food system. However, the costs associated with their manufacturing technologies and limited marketing strategies currently impact their market penetration.

The integration of packaging solutions promoting efficiency and sustainability in logistics can lead to significant improvements also in retail (Saghir, 2002; García-Arca et al., 2014), for instance by facilitating the exchange of relevant information on the package itself or enhancing the sustainability of packaging logistics. Retail serves as the interface between the upstream stages of the food supply chain and consumers. It holds demand information (Lemos and Castro, 2021) and manages contracts with suppliers, hence playing a primary role in collecting the needs of both producers and consumers and fostering a collaborative approach to adopt packaging solutions that meets both upstream and downstream necessities. Furthermore, the increasing presence of e-grocery and e-commerce is exacerbating the challenges of last mile deliveries and the atomization of parcel flows (Morganti et al., 2014), increasing sustainability concerns and fostering the adoption of sustainable packaging, as consumers’ demand and willingness to pay for eco-friendly options are increasing (Singh et al., 2018).

FBOs face difficulties in adopting sustainable packaging, given its higher uncertainty on costs and benefits and generally requires more investment compared to conventional options (Afif et al., 2022). A systematic review by (Afif et al., 2022) underscored the complex trade-offs between environmental, logistical, and marketing requirements of sustainable packaging, which complicate the decision-making process for optimal solutions. Firms must develop packaging that is both attractive and environmentally friendly, while still being able to protect and promote the product. Large firms are more likely to address this multi-criterion decision-making due to their substantial financial resources, awareness of regulations, and understanding of consumer preferences compared to small firms (De Koeijer et al., 2017). also examined these trade-offs in packaging development, focusing on the need to balance sustainability with other critical indicators such as costs and technical challenges. The authors discuss the interrelations among stakeholders involved in the development process and the responsibilities they bear in ensuring sustainable product-packaging solutions. In most cases, marketing actors are reported to lead the decision-making processes for sustainable packaging as the main intermediaries between development teams in the business context (De Koeijer et al., 2017).

On top, effective SCM emerges as of concern to the F&B sector as an integrated supply chain approach can significantly improve the performance of food chains of fresh produce (Veena et al., 2011). Sharing information and improving logistics efficiency throughout the supply chain is crucial as the perishability of food products requires timely fulfillment of operations among a large number of intermediaries. Temperature-controlled supply chains for fresh produce face infrastructural deficiencies (roads for transport, facilities for food storage) in many areas of the world (Bharti, 2020; Kitinoja et al., 2021; Olowosoke, 2022), failing to maintain food quality and safety. This is noticeable in developing countries, while developed countries experience food loss due to inefficiencies in post-harvest management processes and operations relating to pre-cooling, packing, transportation and storage (Onwude et al., 2020; Stellingwerf et al., 2021) rather than infrastructural challenges. Additionally, fresh produce supply chains face seasonality (De Castro Moura Duarte et al., 2024), labor shortages and foreign competition (Chanda et al., 2021), and adverse effects imposed by climate change (García-Flores et al., 2022), thus needing adaptability to a series of unfavorable conditions and cumulated uncertainties. According to literature studies, losses throughout these supply chains can be attributed to a lack of coordination in matching supply and demand between actors (Mason et al., 2015; Song and He, 2018), and, in turn, losses create an imbalance between demand and supply (Anand and Barua, 2022) in a feedback loop.

Coordination among FBOs from production to distribution is at the center of the challenges for effective SCM in the F&B sector. Optimal food product-package systems are essential to maximize revenues and ensure food is consumed and marketed effectively. In this regard, food waste is the predominant issue in developed countries including the EU (Gheorghescu et al., 2019; Jeremić et al., 2024), with poor coordination among supply chain stakeholders as a relevant cause. Stellingwerf et al. (2015) demonstrated that logistics collaboration in the Dutch food retail sector can enable high-frequency supply instead of large, infrequent batches. As a result, the food quality increases and food waste decreases, achieving environmental and economic benefits. Similarly, Pérez Mesa and Galdeano-Gómez (2015) discussed the positive benefits of coordination strategies of horticultural exporting firms in Spain - among the main suppliers of European markets - whose primary customers are retailers. These latter, serving as intermediaries between upstream supply chain actors and consumers, must balance various requirements and preferences concerning the adoption and optimization of sustainable packaging. Leveraging their insights into consumer preferences and sales data, retailers can influence and support upstream practices. However, the potential environmental and economic benefits of sustainable packaging may be compromised if retailers compel suppliers to “overpack” products based solely on shelf-life considerations, as discussed by Dörnyei et al. (2023).

Finally, consumer attitudes influence the adoption of sustainable packaging by FBOs (Siddiqui et al., 2022). Although many consumers are aware of the benefits and environmental impact of sustainable packaging, this awareness does not consistently translate into purchasing behavior (Orzan et al., 2018; Hamid et al., 2022). Negative consumer attitudes shaped by motivational (i.e., personal and ethical identification), cognitive (driven by the information on the product), and behavioral (involving trade-offs regarding time, cost, and others), barriers (Boz et al., 2020) hinder the implementation of sustainable packaging, in addition to value chain complexity. Factors such as price, quality, convenience (e.g., ease of food preparation), appearance, and brand often drive consumers’ decision-making (Rai et al., 2023). Additionally, consumers, irrespective of their country of origin, often lack understanding of the sustainability impacts associated with the production, transportation, and retail stages of packaging (Boz et al., 2020; Dörnyei et al., 2023). This lack can hinder the acceptance of innovative solutions, such as nano packaging (Siddiqui et al., 2022), which hold promise for addressing issues such as food waste. Therefore, it is necessary to enhance consumer awareness and education about sustainable packaging through public awareness campaigns, labeling initiatives, and by stakeholders of the food and packaging value chains as well as policymakers (Boz et al., 2020). These efforts can help overcome the challenge of creating a “sustainability culture” among the general public, encompassing both packaging and food as well as their interrelationship.

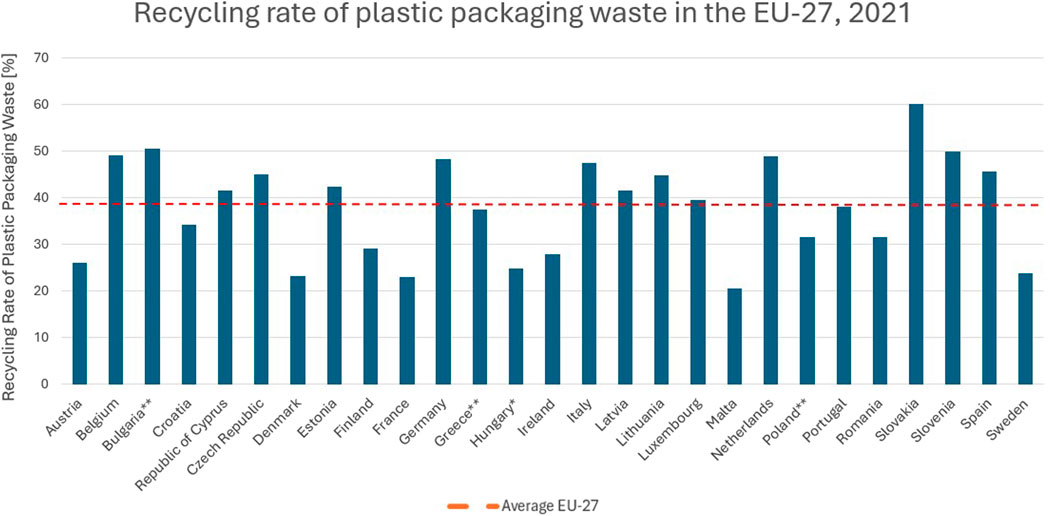

The widespread use of plastic has raised growing concerns about its environmental impact and the complex challenges associated with managing its end-of-life (Thompson and Pahl, 2018). In 2021, the packaging sector emerged as the largest source of plastic waste in Europe, accounting for about 40% of the total demand for plastics (European Environment Agency, 2023b), and contributing substantially to the generation of plastic waste. In that year, each EU citizen produced an average of 35.9 kg of waste from plastic packaging. Over the last 10 years, this amount has increased by 27%, with an increase of 7.5 kg per capita between 2011 and 2021 (Eurostat, 2023). However, this increase in plastic waste volume has not been accompanied by a corresponding rise in recycling rates, despite advances in material efficiency and sustainability efforts within the sector. In the EU, the average recycling rate of plastic packaging was around 40% in 2022 (Statistics Eurostat, 2024d). In comparison, the recycling rates for paper and cardboard packaging reached 83.2% (Statistics Eurostat, 2024c), metallic packaging achieved around 76.9% (Statistics Eurostat, 2024a), while glass packaging stopped at 75.6% (Statistics Eurostat, 2024b). Although plastic packaging does not constitute most of the total waste, the significant per capita increase over the years, combined with low recycling rates, underscores the urgent need to enhance waste management systems within the EU, as remarked by the growing regulatory pressure. Figure 2 shows the variability in plastic recycling rates across EU countries: Slovakia, Germany, and Slovenia lead with rates exceeding 50%, whereas France, Denmark, and Malta lag behind with rates below 30% (Eurostat, 2023).

Figure 2. The recycling rate of plastic packaging waste in the EU-27 in 2021 (Eurostat, 2022; Eurostat, 2024).

These disparities show that, while some countries have developed more effective recycling systems, others still face significant challenges that must be addressed to reduce these disparities. This requires targeted actions, as highlighted by the European Environment Agency (European Environment Agency, 2023a). The agency points out that many EU member states face challenges in meeting recycling targets due to insufficient infrastructure, inconsistencies in waste collection systems, and a lack of economic incentives for recycling. Furthermore, it emphasizes the need for harmonized approaches across countries, including investments in advanced sorting technologies, stronger enforcement of Extended Producer Responsibility (EPR) schemes, and policies that promote the design of more recyclable packaging materials.

One of the significant challenges facing the packaging industry delves around the concept of recyclability. Recently, the PPWR introduced specific criteria for packaging to be deemed recyclable, providing an initial definition to guide manufacturers in developing sustainable packaging solutions. According to the PPWR (Proposal for a revision of EU legislation on Packaging and Packaging Waste, 2022), packaging can be considered recyclable if:

1) It is designed for recycling.

2) It is efficiently collected.

3) It is sorted into defined waste streams without affecting the recyclability of other waste streams.

4) The resulting recyclates are of sufficient quality to substitute the primary raw materials.

5) It can be recycled at scale

The ability of recyclates—particularly plastics—to replace primary raw materials is often limited by their quality. During the recycling process, plastics are exposed to heat, pressure, and mechanical stress, which can degrade their physical properties. According to (Golkaram et al., 2022), the properties of recycled materials are heavily influenced by factors such as plastic-type, recycling method, and contamination levels in the waste stream. As a result, these material changes often restrict the use of recyclates to lower-performance applications, as the higher quality required for more demanding uses, such as in automotive or construction, cannot be achieved. Recyclability, however, extends beyond mere technical feasibility. There must be consumer access to recycling programs, recyclers must be capable of processing the material, there must be a market for the recycled product, and the performance of recyclates must be comparable to that of virgin materials. Furthermore, innovative materials need to demonstrate that they can be collected and sorted in sufficient quantities and must be compatible with existing recycling systems. The product must be made from plastic that is collected for recycling, has market value, and/or is supported by a legislatively mandated program.

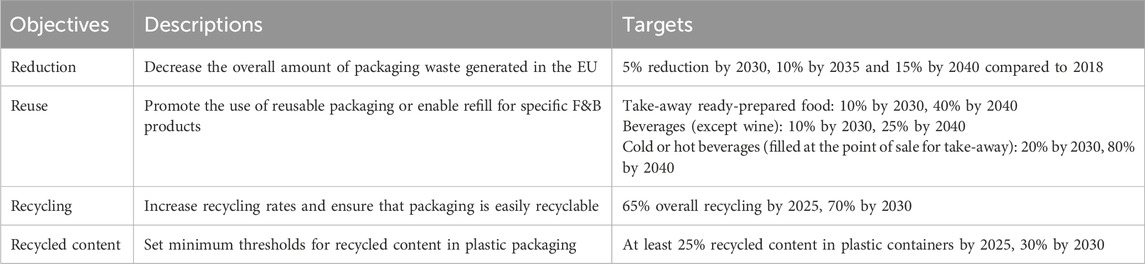

In response to escalating environmental challenges, the EU has intensified its efforts to advance the circular economy and boost plastic recycling rates. The European Green Deal and the CEAP are central to reducing plastic waste and improving recycling infrastructure across member states. These policies aim to curb the use of virgin plastics and foster innovation in recycling systems, driving cross-sectoral collaboration towards ambitious sustainability goals. They gained further momentum after the Chinese government implemented the “National Sword” policy in 2018, which effectively banned the import of plastic waste from foreign countries. This decision marked a turning point in global waste management, forcing developed nations, including European countries, to reconsider their reliance on waste exports. Between 2016 and 2018, plastic waste exports from the EU to China plummeted by around 95% boiling down to about 50 thousand tons (Brooks et al., 2018; Eurostat, 2020). This sudden shift put immense pressure on European recycling systems, exposing their limitations and accelerating the adoption of increasingly ambitious circular economy policies. In this regard, the PPWR aims to significantly reduce the environmental footprint of packaging, with an emphasis on plastic packaging. The regulation sets out targets for the reduction of packaging waste, reuse of materials, improvement of recycling rates, and increased recycled content in packaging products, as shown in Table 4.

Table 4. Targets for reduction, reuse, recycling, and recycled content in the PPWR (Proposal for a revision of EU legislation on Packaging and Packaging Waste, 2022).

Moreover, recycling targets for packaging waste with specific additional targets for materials contained in packaging waste are defined in the PPWR. These targets are shown in Table 5.

Table 5. Recycling targets in the PPWR for packaging waste and specific materials contained in packaging waste (Proposal for a revision of EU legislation on Packaging and Packaging Waste, 2022; European Commission, 2024). Targets are expressed in percentages by weight.

Reaching these targets is inherently demanding, and several member states have been identified as at risk of missing them (Amicarelli et al., 2024). In this context, Amicarelli et al. (2024) investigated the waste management of water-packaging in Italy, which has the largest consumption in the EU and the second largest worldwide, generating 1,311 kt of water-packaging waste per year. Beyond the environmental concerns raised, the authors emphasized that additional strategies must be implemented to meet regulatory requirements, such as replacing heavy bottles with lighter ones, particularly in the glass sector. Furthermore, the study highlights the role of public authorities in promoting tap-water programs, as replacing packaged water with tap water is the only effective strategy to eliminate material consumption and waste production, thereby aiding the country in achieving these targets.

After food plastic packaging materials have fulfilled their purpose, they are discarded and become post-consumer waste (PCW). Managing this waste stream is complex, primarily due to the wide variety of plastic types and the specialized processes required for their effective recovery and reuse. PCW is far more complex than post-industrial waste, which is generated during production and is typically more homogeneous, higher-quality grades, and easier to recycle (Ragaert et al., 2017; Schmidt et al., 2021). PCW consists of a diverse range of materials collected after product use, making it significantly more challenging to process (Lange, 2021). This challenge is further compounded by contamination, polymer degradation, the presence of additives, and the mixture of immiscible polymers, which negatively affect key properties like color, odor, and mechanical performance of the recycled material (Schmidt et al., 2021). European countries have developed different PCW management systems, which can vary significantly from country to country and internally between regions/municipalities of the same country (Ahmad et al., 2018; Tsimnadis and Kyriakopoulos, 2024). These variations in collection models, regulations, and infrastructure lead to inconsistencies in recycling rates and the quality of recovered materials (Tsimnadis and Kyriakopoulos, 2024). Addressing these issues requires effective collaboration among governments, municipalities, industries, experts, and the public, ensuring that all parties work together to improve the overall management of municipal solid waste (Soltani et al., 2015).

Recycling of post-consumer plastic packaging waste is conducted in three steps: collection, sorting, and reprocessing. The first step, collection, involves gathering plastic waste via different schemes, typically through “drop-off systems” or curbside collection programs (Ncube et al., 2021). The effectiveness of separate collection is significantly influenced by consumer participation (Thoden van Velzen et al., 2019). High response rates, driven by convenience, awareness, and incentives, are essential for achieving accurate sorting of waste and maximizing the efficiency of recycling systems. Collection rates exhibit high variability among EU countries. For instance, Lombardi et al. (2021) reported a difference in separate collection rates between Italy (53%) and the Netherlands (25%), highlighting the need for the expansion and qualitative improvement of packaging waste collection systems, especially in light of the increased recycling targets mandated by the EU.

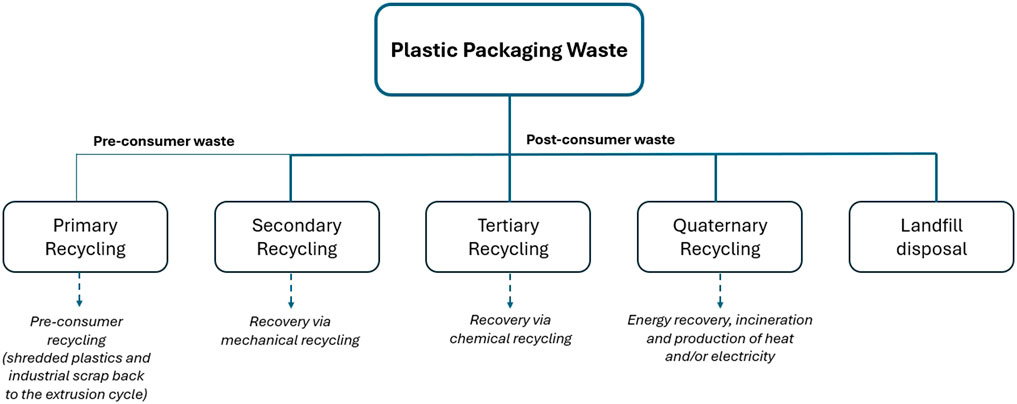

Sorting follows as a distinct and challenging phase, requiring the categorization of materials based on type and quality, often hindered by a lack of specific waste streams according to the origin of packaging materials. Currently, plastic sorting relies on a combination of automated systems and manual intervention. Near-infrared (NIR) scanning is used to identify different polymer types, while optical systems separate plastics based on transparency and color. Effective sorting is vital, as contamination of key polymers like PET and HDPE with incompatible materials can severely hinder closed-loop recycling (Lange, 2021). Such contaminants lower the quality of recycled plastics, making it difficult to reuse them in new packaging or other food-grade products (Lange, 2021). To enhance sorting accuracy, complementary techniques such as X-ray scanning, density-based separation, electrostatics sorting, melting point detection, and fluorescent dye systems are also employed, with manual sorting playing a role in fine-tuning the process (Schyns and Shaver, 2021). It is estimated that the absence of dedicated material streams during collection and inadequate sorting limits the recycling industry’s efficiency, with operations running at only 40% of their potential capacity (Ncube et al., 2021). After collection and sorting, plastic materials are sent to specialized recycling plants for further processing. The existing recycling methods for plastics are typically categorized into four main types (Beghetto et al., 2021; Conesa et al., 2021; Ncube et al., 2021) as shown in Figure 3. Landfill disposal adds to these management pathways for plastic packaging waste.

Figure 3. Management pathways for plastic packaging waste, from recycling (primary to quaternary) to landfill disposal.

Primary recycling involves reintroducing pre-consumer waste, such as shredded plastics and industrial scrap, back into the extrusion cycle to produce new products made from the same material. This method allows manufacturers to reuse plastic waste from their production processes, leveraging uncontaminated, single-type polymers with properties close to virgin material (Singh et al., 2017), potentially supporting the circular economy by reducing the demand for new raw materials. For instance, both PET and HDPE are often recycled into new bottles or containers that serve the same purpose as those made from virgin plastic (Ncube et al., 2021). However, the efficiency of primary recycling still depends on careful sorting and cleaning of materials to ensure the quality of the recycled product.

Secondary recycling, or mechanical recycling, is the main and most widely used technology for plastic packaging (food and non-food) recycling and is focused on the three dominant packaging polymers: PE, PP, and PET (Lange, 2021). It consists of several steps: collection, screening, automatic or manual sorting, washing, shredding, extrusion, and granulation. This method enables the recycling of plastics waste for its use in various applications. Typically, due to the heterogenous composition as well as polymer degradation during its lifetime and reprocessing, these recycled plastics are used in lower-grade products (Lange, 2021). As an example, recovered HDPE from milk bottles can be repurposed to make items like crates and bins, while PP from yogurt containers can be recycled into consumer products such as toothbrushes (Ncube et al., 2021). PET has historically been an extensively studied polymer in the field of mechanical recycling, with a substantial body of research focused on enhancing its recyclability and recovery potential. The study of La Mantia and Vinci (1994) established a comprehensive understanding of PET’s behavior and properties throughout the recycling and recovery processes. The authors examined the maximum number of extrusion cycles PET can endure before becoming unsuitable for further reuse, revealing significant degradation in its mechanical properties over multiple recycling cycles. Their work also identified key factors limiting the long-term recyclability of PET, such as polymer chain degradation and contamination. Building on these insights, recent scientific efforts have been directed toward improving the mechanical and functional properties of mechanically recycled PET, particularly in food packaging applications. Masmoudi et al. (2020) explored the potential of blending virgin and recycled PET to achieve an optimal formulation for use in food contact materials. Their study demonstrated that a blend containing 30% recycled PET, and 70% virgin polymer exhibited the best balance between sustainability and performance (mechanical and thermal properties). Additionally, migration tests performed on the final product confirmed its compliance with EU regulations, validating its suitability for use in food packaging (Masmoudi et al., 2020). Research is also focusing on advancements in sorting, cleaning, and processing techniques. These innovations aim to further enhance PET’s recyclability, improve its circularity, and boost its performance in recycled applications, ensuring a more sustainable future for this material.

Tertiary recycling, or chemical recycling, is an advanced method for recycling plastic packaging, particularly useful for heterogeneous, complex, and contaminated plastic materials like multilayer packaging (Ragaert et al., 2017). It enables the production of high-purity polymers, making it a viable option for closed-loop recycling of post-consumer food packaging. Chemical recycling encompasses processes that alter the polymer chains to recover monomers or molecules with a low molecular weight (Dogu et al., 2021). These processes modify the polymer structure typically converting it into liquids and gases that can be used as feedstock for the production of new petrochemicals or plastics that are chemically identical to the replaced products (Meys et al., 2020). Chemical recycling avoids the performance degradation typically associated with mechanical recycling of plastics (Meys et al., 2020). Technologies like solvolysis, dissolution/precipitation, and pyrolysis, offer greater flexibility because they can handle difficult-to-recycle plastics. However, these technologies face several challenges. The efficiency of chemical recycling methods is significantly influenced by both the processing conditions and the nature of the feedstock (Dogu et al., 2021). Pyrolysis and gasification are energy-intensive processes that often rely on part of the feedstock as fuel to maintain the necessary reaction conditions, which reduces the overall yield of reusable materials and limits the efficiency of these technologies (Mong et al., 2022). In addition, the effectiveness of these processes depends on the cleanliness and sorting of the feedstock, as the presence of impurities can lower product quality, increase operational costs, and produce hazardous byproducts (Dogu et al., 2021; Shah et al., 2023).

In recent years, chemical recycling has gained momentum, drawing increasing attention from both researchers and industry leaders. Its potential to overcome the limitations of conventional mechanical recycling has made it a focal point for development, especially given its ability to handle complex, hard-to-recycle plastics and to face increasingly stringent sustainability targets such as the recycling rates of 55% imposed by the European Commission (Meys et al., 2020). Despite its potential, in 2022, chemical recycling accounted for just 0.1% of Europe’s total plastics production, highlighting its minimal contribution compared to the 13.2% achieved by mechanical recycling of post-consumer plastics (Plastics Europe, 2024). It is important to note that chemical recycling processes generally require a well-defined, pre-sorted feedstock, which presents a challenge regarding the waste streams they can effectively process. This dependence further limits the scalability and cost-effectiveness of chemical recycling, compared to more established mechanical methods.

In addition to efficiency, recycling systems must be evaluated from an environmental perspective to assess their sustainability. The scientific community remains uncertain about the environmental benefits that chemical recycling may provide compared to mechanical recycling and other waste management strategies, such as energy recovery, depending on the processed plastics. Current evaluations reveal a disconnection between the expected environmental benefits and the actual outcomes associated with chemical recycling, highlighting the need for further investigation. For instance, Shen et al. (2010) indicate that linear recycling pathways for PET through mechanical means present greater environmental advantages than circular pathways involving chemical recycling to convert plastics back into feedstock monomers. Even when mechanically recycled PET is ultimately incinerated, the overall mechanical recycling process tends to have a lower impact on greenhouse gas emissions and energy consumption. Moreover, studies demonstrated that a significant volume of well-sorted plastic waste can be efficiently processed through mechanical recycling, retaining properties that are sufficient to substitute for virgin polymers (AITEC, 2008). Thus, while chemical recycling may present advantages in managing challenging materials, the environmental efficacy of this approach should be evaluated case by case. Thus, both mechanical and chemical recycling should be viewed as complementary approaches, with the optimal choice contingent on the specific characteristics of the waste stream and the materials involved.

Quaternary Recycling, also known as energy recovery, involves incinerating plastic waste to produce energy, typically in the form of heat or electricity. While this approach reduces the amount of waste sent to landfills, it is not considered a sustainable option since the plastic materials are not recovered but instead used to produce energy with the consequence of emitting CO2 and other harmful substances. However, waste-to-energy is often used for plastic materials that cannot be recycled through mechanical or chemical methods.

Despite all the options discussed, the dominant form of waste disposal is landfill. Landfilling is the worst waste management option, although it is considered indispensable for accommodating nonrecyclable and noncombustible waste (Ncube et al., 2021). Due to its cost-effectiveness, around 60% of plastic waste ends up in landfills (Hoornweg and Bhada-Tata, 2012), contributing to long-term environmental damage. Landfilling rates for plastic waste exhibit significant disparities across Europe (Ragaert et al., 2017). In nations where landfill bans are enforced, such as Belgium, Luxembourg, the Netherlands, Germany, Denmark, Switzerland, Austria, Norway, and Sweden, less than 10% of plastic waste is directed to landfills. Conversely, in countries like Spain and Greece, over 50% of plastic waste is still disposed of in landfills.

In an era where environmental sustainability and circular economy principles are at the forefront of global and EU policies, companies are increasingly urged to redesign their products to reduce environmental impact while adapting to shifting consumer expectations. The design phase plays a pivotal role in this process, influencing the recyclability and overall environmental footprint of the product. Moreover, product design can significantly shape citizen behavior, encouraging more sustainable consumption patterns and proper waste disposal, informing consumers, and facilitating separation and sorting of packaging waste (Nemat et al., 2020). The introduction, in 2021, of the EPR principle has marked a significant shift in this direction (Directive (EU), 2018). This regulation extends the responsibility of “producers” beyond just manufacturing, requiring them to ensure the sustainability of their products throughout the entire lifecycle, from design to disposal (Directive (EU), 2018). Notably, the definition of “producer” includes not only manufacturers but also those who first introduce a product into the European market, such as e-commerce platforms, marketplaces, and importers. This increase further the relevance of the design phase, as it must consider recyclability and minimize environmental impact right from the outset. According to Ahmad et al. (2018), the design phase determines about 80% of the environmental impact, being the most influential phase of the entire life cycle. Sustainable design not only facilitates proper waste management and recycling but also helps reduce costs, which are shared among different stakeholders under the EPR framework. Food plastic packaging represents a particularly challenging case, as it is designed to meet strict requirements aimed at extending the shelf life of products while ensuring high standards of quality, safety, and hygiene (Hahladakis and Iacovidou, 2018).