Abstract

Introduction:

This study was undertaken to evaluate a value-added innovative buttermilk biscuit made from orange flesh sweet potato (OFSP) flour, infused with coconut. It underscores the importance of food utilisation through alternatives to wheat flour contributing to food and nutrition security amidst evolving global challenges. The objectives of this study were: to investigate the effect of different levels of OFSP flour with and without shredded coconut on the physical, microbiological, nutritional and sensory properties of buttermilk biscuits. The hypotheses were: Ho: There is no effect of different levels of OFSP flour and shredded coconut on the physical, microbiological, nutritional and sensory properties on buttermilk biscuits at ∝ = 0.05 and Ha: There is an effect of different levels of OFSP flour and shredded coconut on the physical, microbiological, nutritional and sensory properties on buttermilk biscuits at ∝ = 0.05.

Methods:

OFSP flour was produced and combined with wheat flour at different ratios and infused with desiccated shredded coconut to produce six formulations of buttermilk biscuits: 100% wheat flour + 5% coconut (control 1), 100% wheat flour (control 2), 70% wheat flour + 30% OFSP flour + 5% coconut, 70% wheat flour + 30% OFSP flour, 50% wheat flour + 50% OFSP flour + 5% coconut and 50% wheat flour + 50% OFSP flour. The study followed a randomised 3 × 2 factorial design where each treatment was replicated four times giving 24 treatments. Physical, nutritional, sensory, microbiological and shelf-life analyses were determined for each buttermilk biscuit treatment.

Results:

The study’s findings revealed that buttermilk biscuits formulated with 30% OFSP flour received the highest (p < 0.05) sensory evaluation scores for the majority of attributes and overall acceptability while the 100% wheat flour formulations received the lowest scores according to the 9-point hedonic scale. Notably, the inclusion of shredded coconut did not improve sensory attributes or overall acceptance of the buttermilk biscuits. The OFSP flour buttermilk biscuits contained protein, fat, fibre, moisture and ash. The 100% wheat flour treatments contained significantly higher levels of proteins and moisture than the OFSP flour buttermilk biscuits. The colour L* of the OFSP flour treatments were significantly lower than the 100% wheat flour treatments. There were no significant changes in spread-ratio, diameter and thickness of the buttermilk biscuits during storage. Furthermore, the microbiological quality was maintained as no growth of bacteria, yeasts and molds were observed.

Discussion:

The OFSP flour with and without desiccated coconut produced acceptable buttermilk biscuits with less reliant on wheat flour. It is noteworthy that the protein content of the OFSP flour buttermilk biscuits was at an acceptable level even though it was lower than that in 100% wheat flour buttermilk biscuits. Food safety was maintained throughout storage which is crucial in the elimination of food borne diseases. The use of different baking parameters can be used for future studies to assess the effect of temperature on the quality of buttermilk biscuits.

1 Introduction

Food insecurity and undernutrition have been increasing globally, especially in developing countries. In 2019, 8.9% of the total 7.68 billion population of the world was reported as undernourished and in 2020, globally 155 million people were intensely food insecure (von Grebmer et al., 2021). These problems are further exacerbated by climate and economic shocks, population growth, the recent COVID-19 pandemic and the armed conflict that commenced in 2022 between Russia and Ukraine. Both Russia and Ukraine are known to be major producers of essential food commodities such as sunflower food products, maize and especially wheat (FAO, 2022). Wheat in particular, plays a pivotal role in global food and nutrition security (Shiferaw et al., 2013). In 2020, at least 179 countries imported wheat to meet their domestic demand (FAOSTAT, 2022). Thus, a reduction in this vital food commodity, can cause significant negative consequences on global food security especially for developing countries that rely heavily on imported wheat to meet domestic demand. Recognizing the dependence on food imports, this current study underscores the urgency and importance of food utilisation through alternatives to wheat flour to produce value added products to aid with food and nutrition security amidst these evolving global challenges.

One of the ways to address food and nutrition security is through the increased use of underutilized food commodities such as sweet potato (Ipomoea batatas L.). Sweet potato (Ipomoea batatas L.) is ranked as the seventh most important crop in the world with a total production of 103 million tonnes in 2013. It is readily available, versatile in food product development and has immense nutritional properties. Various cultivars have been identified in the Caribbean region: Chicken foot-yellow and pink flesh, Centennial- orange flesh, orange skin, St. Vincent variety-yellow flesh, purple skin, TIS 9191 white flesh, light purple skin, TIB 8-21-1- white flesh, light purple skin and Carrot-deep orange flesh and skin (Alam, 2021). Of particular interest are the Orange-flesh sweet potatoes, which are a good source of carbohydrates, fibre and have “antidiabetic” properties (Anbuselvi et al., 2012). They are also a significant source of Vitamin A carotenoids and non-pro Vitamin A carotenoids (Mohammad et al., 2016) and contain nutritional components with anticarcinogenic and cardiovascular disease (CVD)-preventing attributes (Chandrasekara and Joseph Kumar, 2016; Jung et al., 2011) unlike wheat flour. Composite flours play a pivotal role in various baked products by substituting the conventional wheat flour either fully or partially. They are derived from roots, tubers and even legumes which enhances both nutritional value of food products and also aligns with economic benefits by encouraging the use of locally grown crops (Noorfarahzilah et al., 2014; Julianti et al., 2020; Roshana et al., 2019). However, OFSP, has been underutilized due to the highly perishable nature of the roots because of high moisture content, low mechanical strength as well as high susceptibility to microbial decay (Sugri et al., 2017). Thus, processing it into flour will expand its utility and extend its shelf -life. This has been demonstrated in various scientific studies such as in the production of biscuits (Mridula, 2011; Srivastava et al., 2012; Roger et al., 2022; Kausar et al., 2023) and breads (Greene and Bovell-Benjamin, 2004; Kidane et al., 2013; Torbica et al., 2019; Fayaz et al., 2021; Oyinloye et al., 2022).

Buttermilk biscuits, unlike regular biscuits, are savoury, soft, fluffy and produced generally with 100% wheat flour. They have a tangy flavour, tender texture, and delicate layers which has more sensory appeal. To the best of our knowledge, there is no peer reviewed evidence for innovative formulation of this type of biscuit made with mainly wheat flour and is a commercial staple in many restaurants internationally. Inclusion of OFSP flour at the correct ratio can improve the sensory and nutritive value of buttermilk biscuits. The production of an innovative and versatile buttermilk biscuit enriched with sweet potato flour and shredded desiccated coconut can have the potential as a healthier addition to meals compared to 100% wheat flour products (Bovell-Benjamin, 2007). Coconut, (Cocos nucifera Linnaeus) is a very important well-adapted crop of the tropics and is readily available. Moreover, this crop is one of the richest natural plant sources of nutritional and medicinal components. It is an indispensable food item as it provides required and essential nutrients such as protein, fat, vitamins, and minerals (USDA Data, 2018). Notably, evidence supports the concept that coconut may be beneficial in the treatment of obesity, dyslipidaemia, elevated LDL, insulin resistance and hypertension (Divya et al., 2023). Coconut has extensive use in confectioneries, puddings and many other food preparations as a substitute to raw grated coconut (Pandiselvam et al., 2019; Bitto and Devi, 2019). A such, for all these pivotal reasons, desiccated shredded coconut was used in this study by being infused with the OFSP flour buttermilk biscuit.

Additionally, these value-added OFSP flour buttermilk biscuits can help address the evolving issues of food and nutrition security as countries ca produce them as a source of nutritive food with less reliant on what flour. As such, the objectives of this study were: 1) To investigate the effect of different levels of orange flesh sweet potato flour on the physical, microbiological, nutritional and sensory properties of innovative buttermilk biscuits and 2) To determine the effect of the addition of shredded coconut on orange-flesh sweet potato enriched buttermilk biscuits. The hypotheses were: Ho: There is no effect of different levels of orange-flesh sweet potato flour and shredded coconut on the physical, microbiological, nutritional and sensory properties on buttermilk biscuits at ∝ = 0.05 and Ha: There is an effect of different levels of orange-flesh sweet potato flour and shredded coconut on the physical, microbiological, nutritional and sensory properties on buttermilk biscuits at ∝ = 0.05.

2 Materials and methodology

2.1 Experimental design

The experiment followed a randomised 3 × 2 factorial design where each treatment was replicated four times giving 24 treatment combinations. Buttermilk biscuits were produced by the enrichment of wheat flour with OFSP flour at various levels with and without shredded coconut. Six variations of buttermilk biscuits were prepared as follows: 100% wheat flour + 5% desiccated coconut (T1, control), 100% wheat flour + 0% coconut (T2, control), 70% wheat flour: 30% OFSP flour + 5% desiccated shredded coconut (T3), 70% wheat flour: 30% OFSP (T4), 50% wheat flour: 50% OFSP + 5% desiccated shredded coconut (T5) and 50% wheat flour: 50% OFSP flour (T6) (Table 1).

TABLE 1

| Treatments | Wheat flour (%) | Orange flesh sweet potato flour (%) | Butter (%) | Buttermilk (%) | Desiccated coconut (%) | Sodium benzoate (%) |

|---|---|---|---|---|---|---|

| T1 | 100 | 0 | 5 | 5 | 5 | 1 |

| T2 | 100 | 0 | 5 | 5 | 0 | 1 |

| T3 | 70 | 30 | 5 | 5 | 5 | 1 |

| T4 | 70 | 30 | 5 | 5 | 0 | 1 |

| T5 | 50 | 50 | 5 | 5 | 5 | 1 |

| T6 | 50 | 50 | 5 | 5 | 0 | 1 |

Formulations of buttermilk biscuit treatments with varying levels of orange flesh sweet potato flour and desiccated shredded coconut.

2.2 Production of OFSP flour

Orange flesh sweet potato (variety: Ipomoea batatas carrot) was purchased from a registered farmer who cultivates sweet potatoes in Endeavour, Chaguanas, Trinidad and Tobago. The raw produce was weighed, washed and sorted before processing in the laboratory. Thereafter, they were sanitized with a 5.2% chlorine sanitizing solution. This process ensured that any undesirable microorganisms were removed before peeling, eliminating the occurrence of contamination of the exposed peeled flesh. The peeled tubers were weighed, washed, and shredded using a Hobart Food Processor (model: FP100 ML-38962, Ohio 45374-0001) with a ⅝ “shredding disc. The shredded sweet potatoes were then placed on racks on a TSDM-Stainless Steel Commercial Food Dehydrator (D-14 Digital Touch Screen, The Sausage Maker) for 12 h at a temperature of 60°C. There are various studies on sweet potato drying, but they lack collective information that would help researchers to conduct more research. Several factors such as equipment used and method of drying, thickness of slices and variety of sweet potato all influence the drying temperature selected. Due to these myriad factors, there is no single specific temperature that can be adopted for the drying process. Several studies reported that a drying temperature of 60°C was favourable (Santi et al., 2022; Korese et al., 2021; Srivastava et al., 2012). As such, the temperature of 60°C was used for our study in the drying process of OFSP. After the dehydration process was completed, the dried shreds were milled/ground using a 3000 A High speed commercial Comminutor Grinder (ALD Professional Kitchen, model: A-S3000, China). The ground sweet potato flour was then sieved through a 710 µm sieve and stored at 4°C for further use.

2.3 Formulations of OFSP flour buttermilk biscuits infused with desiccated coconut

The buttermilk biscuits were produced with various formulations using different levels of flour and desiccated shredded coconut (A-plus Industries Ltd. Montrose, Chaguanas, Trinidad) and other ingredients according to each treatment (Table 1). Each treatment also included buttermilk, butter and sodium benzoate. All dry ingredients were mixed thoroughly and then the buttermilk (Yumma Buttermilk, cultured and unsweetened, Yumma Products, Hillview Drive, Arouca, Trinidad) was added while mixing with an electric mixer to form a slightly “sticky” dough texture. The dough was then transferred to a lightly floured surface and manually sheeted to a thickness of 31.75 mm. After, the dough was then cut into circles using a three-inch diameter biscuit cutter. These were then transferred onto a lined sheet pan and baked in a pre-heated oven for 15 min at 190.5°C. From previous studies, a range of temperature has been used for baking cookies such as 170°C for 11 min (Korese et al., 2021), 200°C for 10 min (Srivastava et al., 2012) and 165°C for 20 min. The making parameter thus, is influenced by materials used, dough formulation among other factors. Since there is no prior published evidence for baking parameters of OFSP flour buttermilk biscuits, based on those aforementioned studies, an average temperature of 190°C for 15 min was used and a buttermilk biscuit sample was tested by removing a sample and observing for thorough cooking. The buttermilk biscuits were allowed to cool for about 5 min on a sterile cooling rack after baking followed by sensory evaluation, microbiological analyses and physico-chemical analyses. Some biscuits were stored at 4°C for shelf-life evaluation.

2.4 Sensory evaluation of OFSP buttermilk biscuits

The various formulations of buttermilk biscuits were sensory assessed. The 9-point hedonic scale is the most widely used scale for testing consumer acceptance of food globally. A sensory panel consisting of n = 81 assessors (Females = 31, Males = 50) was randomly selected to evaluate the sensory attributes of the treatments. The sensory scores were based on appearance, colour, aroma, texture, and overall acceptability using a 9-point hedonic scale in the range of 9 for like extremely, 5 for neither like nor dislike and 1 for dislike extremely. The treatments were coded with 3 digits random numbers and presented to each participant along with a structured score sheet, plain crackers and water. The crackers and water were used for palate cleaning between sensory evaluation of each sample. The buttermilk biscuits were kept warm in a hot holding tote to ensure the biscuits were not exposed to the external environment which could have affected the quality of the biscuits.

2.5 Proximate analyses of OFSP buttermilk biscuits

The proximate analyses of moisture, crude protein, crude fat, crude fibre, ash and total solids were assessed according to the Standard Methods of the Association of Official Analytical Chemists (AOAC, 2002). For determining moisture content, a Thermo Scientific-UT 6200 hot air oven was employed to subject a 1–2 g sample to consistent drying at a temperature of 102°C ± 2°C for a duration of 3–5 h. The moisture content was computed after the sample was placed in a desiccator for approximately 15 min to cool. The crude fat content analysis was conducted using the ANKOM XT15 Automated Crude Fat Extraction machine. Fat content analysis was achieved using petroleum ether. A well-defined and weighed amount (1–2 g) of the ground and well mixed samples were taken, and placed in a pre-weighed filter bag, then encapsulated. The samples were then dried in a drying oven for 3 h at 102°C. Automatic extraction was carried out for 60 min at 60°C, with petroleum ether as extraction solvent. After the extraction the samples were dried for 30 min at 105°C, cooled in a desiccant pouch at room temperature and weighted. The fat content was calculated as follows: 100 × (pre dried sample weight–sample weight after extraction)/wet sample weight = fat % solvent extraction method. The determination of crude protein content was accomplished utilising the micro-Kjeldahl method, wherein each sample’s percentage of protein was calculated by multiplying its nitrogen value by a factor of 6.25. Meanwhile, the ash content was determined as a percentage of the samples’ weights. Porcelain crucibles were dried overnight at 105°C, and then cooled to room temperature. Oven dried crucibles were weighed (Wt) then approximately 2 g of ground sample were added to it. To achieve the ash value of the samples the dry matter was ignited overnight at 550°C in a muffle furnace then cooled to room temperature. The crucibles and the samples were then weighed (Wa) and the % ash was calculated using the following equation:

2.6 Microbiological analyses

Microbiological evaluation was conducted directly after production of the buttermilk biscuits and for each subsequent week during the 2–3 weeks of storage. The evaluation was done to determine the presence of total colony forming units (CFUs) of aerobic bacteria (AOAC, 1999), yeasts and molds (AOAC, 1997). The pour plate and spread plate techniques were utilized in this evaluation. Plate Count Agar (PCA; Oxoid, Wade Road, Basingstoke, Hants, RG24 8PW, United Kingdom) and Potato Dextrose Agar (PDA; Wade Road, Basingstoke, Hants, RG24 8PW, United Kingdom) were the media used for enumeration of total aerobes and fungi (yeasts and moulds) respectively. All materials were sterilised using a Tuttnauer -Steam autoclave (Tuttnauer USA Co. Ltd.) at 121C, 15psi for 15 min and the analyses was conducted under sterile environmental conditions in an Envirco Laminar Flow Hood (Envirco Corporation; Albuquerque, New Mexico, United States). Representative composite samples of all treatments were obtained using a sterile spatula to make 10 g which were aseptically weighed and subjected to stomaching at high speed for 60 s using a Seward Stomacher to ensure the treatments were thoroughly homogenised. A series of serial dilutions were done: 10−1 to 10−4 for all treatments. The PCA Petri dish treatments were incubated at 35°C for 48 h for bacterial growth while the PDA plates were incubated at 25°C for 48 h for yeasts and mold growth. After, all Petri-dishes were examined for colony forming units for a countable plate of 30–300 colony forming units.

2.7 Determination of physical properties of the buttermilk biscuits

Buttermilk biscuits measurements of thickness, diameter spread ratio and weights of each of the 4 replicated treatments were carried out after production and during the storage period up to week 3. Determination of each sample weight was completed using the Mettler Toledo precision balance scale (MS8001TS, Mettler Toledo, Ohio, United States). Dimensions, which included diameter and thickness, were determined using an electronic digital Vernier calliper (Fowler 54-100-112-2, Newton, MA). The spread ratio was determined by dividing the average diameter with the average thickness of each sample separately according to Levent and Bilgiçli (2012). The colour of the treatments was assessed numerically using a Konica Minolta Chroma Meter CR-400 on the basis of the chromaticity of L∗, a∗ and b∗ coordinates. The colorimeter was calibrated with the standard black and white plate to set zero. Different places on the surface of samples were given four exposures by the 8 mm-diameter measuring port of the colorimeter. The “a” value indicates the redness to greenness, the “b” value measures the blueness to yellowness, while the “L” value ranges from 0 (black) to 100 (white) which indicates the measure of lightness.

2.8 Statistical analyses

Statistical analyses for measured variables were performed using Minitab Statistical Software (Version 21.4), Minitab Statistical Software, Minitab Inc., Enterprise Drive State College, PA, United States) for Microsoft Windows. The results were analysed using the ANOVA with significant treatment effects separated by Tukey Pairwise Comparisons (p < 0.05).

3 Results and discussion

3.1 Sensory evaluation

3.1.1 Texture

Buttermilk biscuits texture differed significantly (p < 0.05) among all treatments except for T1 and T2 which both contained similar amounts of wheat flour with and without desiccated shredded coconut respectively (Table 2). Additionally, the highest scores for texture, 8.82 and 8.46 (like very much) were assigned to T3 and T4, the formulations that included 30% orange flesh sweet potato flour with and without coconut respectively. However, as the OFSP flour content increased to 50% in T5 (with coconut) and T6 (without coconut), the scores for texture reduced significantly to 5.76 and 6.10 respectively resulting in the lowest scores for this sensory attribute. Increasing the amount of OFSP flour resulted in the non-favourable sensory response for texture. In studies conducted by Oyinloye et al. (2022) and Srivastava et al. (2012) the scores for texture were most acceptable with the inclusion of sweet potato flour at higher levels of 50% which contrasted this current study. A possible reason for this variation on acceptability of levels of sweet potato flour could have been due to differences in formulations as this current study did not contain any leavening agents such as yeast or baking powder as the case in those studies. Leavening agents lead to the development of bakery products such as breads and biscuits with increased porous, sponge-like structure thus enhancing textural properties (Garcia- Hernandez et al., 2022) even up to the higher levels of sweet potato flour which can make the products denser with increased fibre (Dogan, 2006). Additionally, demographic factors such as ethnicity may also play a role.

TABLE 2

| Treatments | Overall Acceptability | Texture | Aroma | Taste | Colour | Appearance |

|---|---|---|---|---|---|---|

| T1 | 5.91E | 7.76C | 8.49D | 6.07B | 4.16D | 6.29B |

| T2 | 5.63E | 7.92C | 8.60 CD | 5.82B | 4.11D | 5.61C |

| T3 | 8.58A | 8.82A | 9.01A | 8.67A | 8.62B | 8.78A |

| T4 | 8.20B | 8.46B | 8.93AB | 8.84A | 8.54 BC | 8.67A |

| T5 | 7.02C | 5.76E | 8.65 CD | 5.94B | 8.97A | 8.52A |

| T6 | 6.59D | 6.10D | 8.76 BC | 6.04B | 8.27C | 8.58A |

Mean score for sensory attribute including overall acceptability for six buttermilk biscuits treatments.

Means with different superscript letters within the same column are significantly different (p < 0.05).

T1 = 100% wheat flour + 5% shredded coconut; T2 = 100% wheat flour + no coconut; T3 = 70% wheat flour + 30% OFSP flour + 5% shredded coconut; T4 = 70% wheat flour + 30% OFSP flour no coconut; 50% wheat flour + 50% OFSP flour + 5% shredded coconut; T6 = 50% wheat flour + 50% OFSP flour no coconut.

Like extremely-9, like very much- 8, like moderately- 7, like slightly- 6, neither like nor dislike- 5, dislike slightly- 4, dislike moderately- 3, dislike very much- 2, dislike extremely- 1

3.1.2 Aroma

Table 2 presents sensory scores for aroma with mean separators. Aroma is another attribute that influences the acceptability of baked good products even before they are tasted. All buttermilk biscuits received acceptable sensory scores for aroma that were either “like very much” or “like extremely” even without or with the OFSP flour and coconut. However, Treatments 1 and 2 formulations with 100% wheat flour without and with desiccated coconut respectively, differed significantly (p < 0.05) in aroma from T3 and T4, (treatments formulated with OFSP flour without and with desiccated coconut respectively). Furthermore, it was notable that the innovative buttermilk biscuits formulated with OFSP flour with and without desiccated coconut received higher scores for aroma compared to the 100% wheat flour controls. Similarly, in a study conducted by Kausar et al. (2023), the inclusion of sweet potato flour produced higher sensory aroma scores than the wheat flour treatments. According to Tsai et al. (2021), the volatile flavour constituents in sweet potato during cooking causes characteristic flavour and enzyme reaction that influence aroma thus appealing to consumers. Additionally, Liu et al. (2022) reported that, 2-acetyl-1-pyrroline (2AP) is the most significant aroma formed during Maillard reactions, and imparts a roasted, cracker-like aroma that can influence the panellists. These compounds have low odour thresholds, meaning that it does not take a lot of them for their scent to be detectable. Even though coconut is known for its strong characteristic “coconut” aroma, the inclusion of the coconut did not affect the aroma scores of the buttermilk biscuits but the OFSP flour did. A reason for this could have been due to the coconut being desiccated as the drying process before use and even applying heat in baking would have reduced the volatile oils making it less pronounced in aroma. As such, a higher level than 5% could be required to cause any distinct effect on aroma.

3.1.3 Taste

The sensory scores for taste varied from 5.95 (dislike slightly) to 8.84 (like extremely) for the buttermilk biscuits (Table 3). Scores for tastes of T3 and T4 were significantly higher (p < 0.05) than T1, T2, T5, and T6. However, there was no significant difference (p > 0.05) in taste scores between T3 and T4, neither between T1 and T2 nor between T5 and T6 which implied that the infused desiccated coconut did not significantly affect the taste of the buttermilk biscuits but rather the OFSP flour. The treatments with 100% wheat flour (T1 and T2) and the higher level (50%) of OFSP flour (T5 and T6) received significantly lowest scores for taste compared to T3 and T4. Treatments, T3 and T4 that contained 30% OFSP flour with and without shredded coconut respectively, scored the highest for taste. As such, the addition of the OFSP flour up to 30% had a positive effect on taste of the buttermilk biscuits compared to the controls and higher level of OFSP flour in this current study. Regarding the taste of baked products with the inclusion of sweet potato flour, studies by Kindeya et al. (2021), Afework et al. (2016) also reported that inclusion of 30% sweet potato flour was most acceptable for taste but not at higher levels. Another study by Srivastava et al. (2012), reported similarly that taste scores were highest at the inclusion of both 20% and 40% sweet potato flour but not at higher levels. Thus, the higher preference for taste of T3 and T4 buttermilk biscuits in this current study could have been attributed to the sweetness imparted by the 30% level of OFSP flour from the extraction of more sugars during baking (Maaruf et al., 2011) in comparison to the 100% wheat flour buttermilk biscuits. A possible reason why the taste of buttermilk biscuits with the inclusion of the 50% OFSP flour was not acceptable in the current study could be because, the texture at this level was also not liked and texture of food products could also play a crucial role as a taste influencer (Korese et al., 2021).

TABLE 3

| Treatment | Weight (g) | Diameter (mm) | Thickness (mm) | Spread ratio (mm) | Colour L* | a* | b* |

|---|---|---|---|---|---|---|---|

| T1 | 22.70C | 45.25BC | 24.92E | 3.77BC | 73.46A | 0.77C | 25.33B |

| T2 | 23.12C | 44.26C | 25.48E | 3.68C | 73.65A | 0.01C | 25.72B |

| T3 | 43.09A | 50.91A | 33.73A | 4.24A | 65.08B | 6.11B | 29.02A |

| T4 | 43.10A | 52.24A | 32.25B | 4.35A | 65.03B | 5.80B | 31.25A |

| T5 | 39.25B | 50.00A | 28.13D | 4.16A | 63.06C | 8.26A | 31.16A |

| T6 | 42.74A | 47.18B | 30.88C | 4.13A | 62.94C | 8.25A | 30.86A |

The effect of OFSP flour and desiccated coconut on physical properties of buttermilk biscuits right after production.

Means with different superscript letters within the same column are significantly different (p < 0.05).

T1 = 100% wheat flour + 5% shredded coconut; T2 = 100% wheat flour + no coconut; T3 = 70% wheat flour + 30% OFSP flour + 5% shredded coconut; T4 = 70% wheat flour + 30% OFSP flour no coconut; 50% wheat flour + 50% OFSP flour + 5% shredded coconut; T6 = 50% wheat flour + 50% OFSP flour no coconut.

3.1.4 Colour

The sensory scores for colour (Table 3) differed significantly between the treatments with 100% wheat flour (T1 and T2) and all the OFSP flour treatments (T3, T4, T5 and T6). All the OFSP flour treatments scored significantly higher scores in the “like very much” – “like extremely range” of 8–8.9 than the wheat flour treatments that received the lowest scores of 4.16 and 4.11 meaning “dislike moderately” No significant difference (p > 0.05) was observed in colour between T1 and T2 (100% wheat flour with and without shredded coconut respectively). Additionally, there was no significant difference in colour between T3 and T4. The participants’ preference for the colour of the buttermilk biscuits with the OFSP flour as opposed to those that contained only the wheat flour could have been attributed to the bright orange-yellow colour imparted by the OFSP flour also reported by Srivastava et al. (2012), Afework et al. (2016), Kausar et al. (2023). The enhanced Maillard and other browning reactions chiefly due to baking temperature as well as addition of OFSP flour that contained beta-carotene, could be responsible for development of the attractive color (Lindenmeier and Hofmann, 2004) that influenced the high sensory scores for colour. In this current study, it was also demonstrated that, the infused coconut did not affect the sensory scores for colour as the white colour of the coconut could have been masked by the stronger golden orange colour of the OFSP flour making it not visible enough to influence sensory evaluation for colour. Moreover, since the natural white colour of the 100% wheat flour treatments were disliked, it can be deduced that, this colour was not attractive to the sensory participants. Colour is a key component that increases the ultimate appetizing value and consumer acceptance towards foods such as coloured biscuits (Kindeya et al., 2021) and thus has the potential to increase the purchasing power of consumers.

3.1.5 Appearance

Appearance refers to the visual characteristics and properties of a food product and plays a crucial role in the perception and evaluation of food products by consumers. Sensory scores for appearance of T3, T4, T5 and T6 were significantly (p < 0.05) higher than T1 and T2 (Table 3). The treatments with the highest appearance ratings were T3 with a mean score of 8.78 (like very much) followed closely by T4, T6 and T5 with similar mean scores of 8.67, 8.58 and 8.52 respectively. Treatment 2 had the lowest score for appearance with a mean score of 5.61 (dislike). The appearance of all the buttermilk biscuits formulated with a blend of OFSP flour and wheat flour, with and without desiccated coconut (T3, T4, T5, T6), all obtained high scores in the category of 8 of like very much, but lower scores of like slightly and neither like nor dislike were given to the two 100% wheat flour buttermilk biscuits. This implies that the panellists had a greater preference for the appearance of the treatments formulated with composite flours that included the OFSP flour rather than the controls produced with 100% wheat flour. Similar findings were also reported in studies conducted by Onabanjo and Ighere (2014), Afework et al. (2016), Fayaz et al. (2021). However, as with other sensory attributes in this current study, the infused coconut also did not influence appearance as no significant difference was exhibited in appearance scores between treatments with and without desiccated coconut. It is noteworthy that, the appearance sensory scores were similar to the colour sensory scores which could imply that colour also influenced appearance of the buttermilk biscuits.

3.1.6 Overall acceptability

The overall acceptability was significantly different (p < 0.05) among all treatments (Table 3). Among the six treatments, T3, obtained the highest overall acceptability mean score of 8.58, like very much. This was followed with a mean overall acceptability score also of like very much, 8.20 by T4, the treatment with the same flour ratios as T3 but without the shredded coconut. In a study conducted by Lalitha and Sinthuja (2013), the use of coconut in the form of flour, had no significant effect on the sensory scores of biscuits. A thorough literature review revealed no published scientific evidence for use of infused desiccated shredded coconut in buttermilk biscuits nor similar baked food products but as “fresh” toppings on already prepared foods or desserts. In this current study, desiccated shredded coconut was used as this form is similar to a powdery consistency which gives the smooth texture that was desired. In addition, with the removal of moisture, the shelf life would be increased. Generally, coconut has a strong and distinct “coconut” flavour that can add a tropical touch to various recipes. However, in the case of desiccated coconut, the drying process removes some of the natural oils from the coconut, resulting in a less pronounced effect on taste, texture and aroma which would have been responsible for the non-significant effect of the desiccated coconut on the buttermilk biscuits.

The two treatments, T5 and T6 were liked moderately (7.02) and slightly (6.59) respectively. T1 and T2 which were formulated with 100% wheat flour had the lowest significant overall acceptability scores of 5.63 and 5.91 (dislike slightly) respectively. Overall acceptability increased within inclusion of OFSP flour up to 30% and then decreased significantly to 7.02 and 6.59 for T5 and T6 respectively as the OFSP flour increased to 50%. Despite this decrease in scores, the scores on the Hedonic scale for this sensory attribute in this current study, were still within the “like” ratings for all OFSP flour buttermilk biscuits with and without desiccated coconut. While the researchers (Singh et al., 2007; Oyinloye et al., 2022; Kindeya et al., 2021) reported a similar finding of a reduction in overall acceptability of baked products as the sweet potato flour increased, the reduction scores were not within the “like” ratings but rather “dislike”. It was clearly demonstrated in the other sensory attributes scores in this current study, that all the buttermilk biscuits formulated with OFSP flour (either at the 30% level, 50% level or both levels) with and without desiccated coconut were most acceptable for all sensory attributes examined compared to those formulated only with 100% whole wheat flour. As such, they could have directly influenced the overall acceptability scores. Hence, our study revealed that, acceptable buttermilk biscuits can be produced from both 30% and 50% OFSP flour with or without shredded coconut based on the sensory evaluation.

3.2 Proximate analysis of buttermilk biscuits

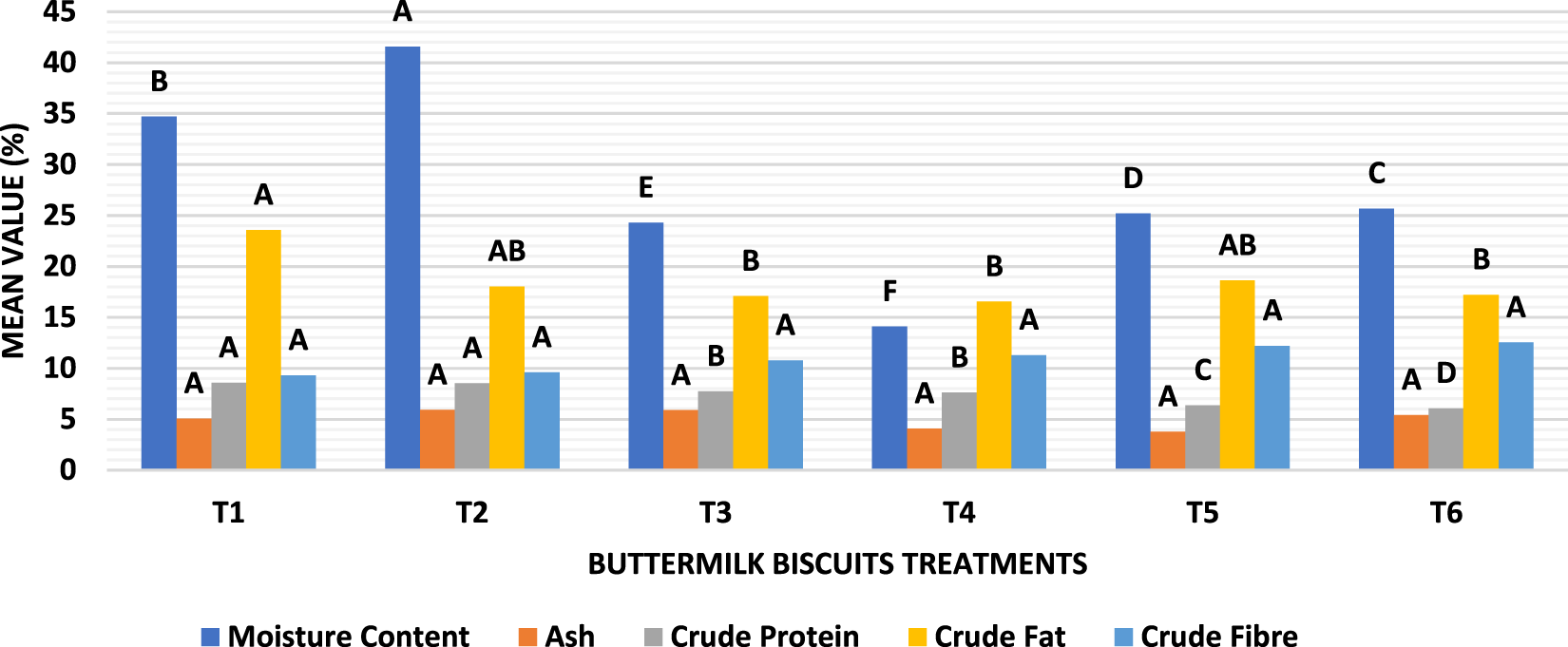

3.2.1 Crude protein

The crude protein content of all six buttermilk biscuit treatments is shown in Figure 1. The protein content of T1 and T2 with 100% wheat flour did not differ significantly (p > 0.05) from each other. However, their protein content was significantly higher compared to all other treatments. Similarly, both T3 and T4, which were formulated with sweet potato flour and wheat flour, with and without shredded coconut showed no significant difference in their protein levels; but were significantly higher than (p < 0.05) T5 and T6. It is noteworthy that as the levels of OFSP flour increased, the protein content decreased significantly. Researchers (Afewak et al., 2016, Oyinloye et al., 2022; Kidane et al., 2013) reported similar findings. The higher content of protein in wheat flour than in sweet potato flour is largely due to the presence of gluten in wheat flour but absent in sweet potato flour (Greene and Bovell-Benjamin, 2004). Thus, the reduction in crude protein of the buttermilk biscuits with increasing OFSP flour is attributed to a dilution effect on the gluten from the wheat flour. Additionally at 50% inclusion of OFSP flour, the infusion with coconut resulted in a significantly higher crude protein content (T5) than T6, that was formulated with the same level of OFSP flour but without the coconut. Furthermore, all buttermilk biscuits infused with coconut (T1, T3, T5) had a slightly (but not significant) higher crude protein content than those treatments with same level of flour but without the infused coconut. Alternatively, this is likely attributable to the protein content of coconut meat (Sinaga et al., 2015). Despite the lower levels of protein in the OFSP flour buttermilk biscuits, the protein content of T3 and T4 were at a level greater than 7%, corresponding to the minimum requirement for individuals set by the Codex Alimentarius, 1990.

FIGURE 1

The effect of OFSP and desiccated coconut on proximate analysis: moisture, ash, crude protein crude fat and crude fibre of buttermilk biscuits Columns that do not share a letter are significantly different (p < 0.05). T1 = 100% wheat flour + 5% shredded coconut; T2 = 100% wheat flour + no coconut; T3 = 70% wheat flour + 30% OFSP flour + 5% shredded coconut; T4 = 70% wheat flour + 30% OFSP flour + no coconut; 50% wheat flour + 50% OFSP flour + 5% shredded coconut; T6 = 50% wheat flour + 50% OFSP flour + no coconut.

3.2.2 Crude fat

The crude fat content in T1 differed significantly (p < 0.05) from T3, T4 and T6 which were formulated with the inclusion of OFSP flour (Figure 1). However, there was no significant difference (p > 0.05) in the fat content among T2, T3, T4, T5 and T6. The fat content was highest, 23.57% in T1 and observed to be lowest, 16.54% in T4, with 30% OFSP flour without shredded coconut. The general trend was that the fat content was generally lowest in buttermilk biscuits infused with OFSP flour either with or without infused desiccated coconut. This trend was also reported in studies conducted by Roger et al. (2022), Afework et al. (2016), Dako et al. (2016), Srivastava et al. (2012), Kidane et al. (2013), Kindeya et al. (2021). In a study conducted on nutritional analysis of both wheat and sweet potato flour by Dako et al. (2016), it was revealed that, sweet potatoes have a lower fat content than wheat flour. This is attributed to the lipolytic activity of enzymes in the OFSP flour as reported. Hence, these findings explain the generally low levels of fat in the OFSP flour buttermilk biscuits.

3.2.3 Moisture

The moisture percentage was significantly different (p < 0.05) across all buttermilk biscuits (Figure 1). Notably, the two treatments (T1 and T2) formulated with 100% wheat flour had significantly highest moisture contents of 35% and 41% respectively than those formulated with different levels of OFSP flour (T3, T4, T5 and T6) either with or without desiccated coconut. For the OFSP flour treatments, moisture content ranged from 25.7% to 14.1%. Additionally, the infused desiccated coconut had no significant effect on the moisture content of the buttermilk biscuits because, probably because moisture was removed in the desiccation process. Furthermore, the moisture content of the buttermilk biscuits became significantly (p < 0.05) lower as the OFSP flour increased. This finding contrasts a number of studies that reported, the moisture content increased significantly with increasing levels of sweet potato flour due to higher fibre content and hence higher water absorption capacity than wheat flour (Srivastava et al., 2012; Kindeya et al., 2021; Korese et al., 2021; Roger et al., 2022; Oyinloye et al., 2022). However, in this current study, even though the fibre content in OFSP flour buttermilk biscuits, was slightly higher than those formulated with only wheat flour, they were not significantly higher to cause a higher moisture absorption by the OFSP buttermilk biscuits. In addition, a study by Roger et al. (2022) reported that, due to the hydrophilic carbohydrates and higher amounts of functional groups of proteins (due to the presence of gluten) in wheat flour compared to sweet potato flour, they play a pivotal role in forming more hydrogen bonds in water than in sweet potato flour (Roger et al., 2022). Hence in this current study, both the level of fibre and protein content affected the moisture content of the buttermilk biscuits. Moisture content in baked products such as buttermilk biscuits is of great importance as it influences quality properties and shelf life. Hence, in this current study, the OFSP flour buttermilk biscuits with a lower moisture content will have a longer shelf life than the 100% wheat flour buttermilk biscuits.

3.2.4 Ash

The ash content was not significantly different (p < 0.05) among all treatments (Figure 1). However, T2 and T3 exhibited the highest ash content of 5.92% and 5.87% respectively while treatment 5, had the lowest ash content of 3.77%. Ash contents provide insight into the amount of minerals contained in a food sample (Olaoye and Beatrice, 2011). The ash values in this study, were higher than those reported in similar wheat-sweet potato flour baked products by Srivastava et al. (2012), Afework et al. (2016), Oyinloye et al. (2022), Roger et al. (2022). Since there were no significant differences in ash content between the 100% wheat flour and OFSP flour treatments, it can be deduced that, the OFSP flour buttermilk biscuits can also provide essential minerals necessary for the body.

3.2.5 Fibre

There were no significant differences in fibre content across the six buttermilk biscuits treatments (Figure 1). The fibre content ranged from 9.32% being lowest for the 100% wheat flour treatments to 12.54% (T6) being the highest for the OFSP flour treatments with the higher level of OFSP flour. Even though there was a small increasing trend in the fibre content of the buttermilk biscuits as the OFSP flour increased, they did not differ significantly among each other. This finding contrasts a number of studies that reported, significantly higher fibre contents as sweet potato flour increased (Srivastava et al., 2012; Afework et al., 2016; Dako et al., 2016; Kindeya et al., 2021; Malavi et al., 2022; Oyinloye et al., 2022; Roger et al., 2022). Moreover, the fibre contents in this current study, were much higher than those other studies. A possible explanation for these findings could be due to differences in sweet potato cultivars from the Caribbean compared to those in other regions. Also, the infused desiccated coconut did not cause any significant effect on the fibre content of the buttermilk biscuits probably because the amount of coconut added was not sufficient to cause any pronounced effect. In addition, wheat flour and OFSP flour is known to have higher levels of fibre than coconut.

3.3 Physical properties of buttermilk biscuits after production

The weights of the buttermilk biscuits after production are presented in Table 3. There was no significant difference (p > 0.05) in weights between T1 and T2 that was formulated with 100% wheat flour with and without shredded coconut respectively. These two treatments also had the lowest weights of 22.70 g (T1) and 23.12 g (T2). Additionally, the weights of all the OFSP flour treatments (T3, T4, T5 and T6) were significantly higher (p < 0.05) than T1 and T2. Similar findings were reported by Dako et al. (2016) and Mridula (2011). A possible explanation for this is, the starch polymer molecules in plain wheat are more tightly bound with granules and swelling is limited in the biscuits formulated with more wheat flour when baked than sweet potato flour (Agu et al., 2007). This is attributable to the reduced gluten protein in OFSP flour buttermilk biscuits which makes it difficult to form a strong three-dimensional network structure inside the dough to hold the air resulting is a tighter tissue structure, less porosity, increase hardness and thus greater weight (Cao et al., 2019). There was no apparent effect of the infused desiccated coconut on weight probably because the quantity was too low.

Similar to weights, the mean diameter of T1 and T2, did not differ significantly (p > 0.05) from each other but they differed significantly (p < 0.05) from T2, T3, T4 and T5 (Table 3). The lowest mean diameter observed was 45.25 and 44.26 mm for T1 and T2 respectively while the highest diameters were observed among the formulations that contained the OFSP flour. However, the mean thickness differed significantly (p < 0.05) among T3, T4, T5 and T6. There was no significant difference (p > 0.05) between T1 and T2 also for thickness. The highest thickness was observed generally for the treatments with OFSP flour and the lowest for the treatments formulated with only wheat flour. The mean spread ratio values between T1 and T2 exhibited no significant difference (p > 0.05) for this parameter. In addition, the mean spread ratio for T3, T4, T5 and T6 were not significantly different from each other but significantly different (p < 0.05) from T1 and T2.

Lower values were seen in the wheat flour buttermilk biscuits (T1 and T2) than the buttermilk biscuits produced with OFSP blends regarding diameter, thickness and spread ratio after production. This finding however, contradicts the report of Srivastava et al. (2012) as they reported an opposite trend whereas as the sweet potato flour increased, the diameter decreased. This contrasting result could have been due to a difference in sweet potato variety that was used. It is important to note that, spread factor is strongly influenced by the properties of the raw materials used in the formulation of biscuits. Another possible explanation for the significantly lower spread factor of the wheat flour buttermilk biscuits compared to the buttermilk biscuits formulated with OFSP flour can be due to, higher protein content of wheat flour that affected the formation of the gluten web, increasing the viscosity thereby stopping the dough flow, and therefore the biscuits made from wheat flour had a significantly lower spread factor (Noor Aziah et al., 2012). The infused coconut had no effect on the spread ratio of the buttermilk biscuits probably because, the amount used was too low to cause any significant effect.

The lightness of colour, colour L* did not differ significantly within treatment for the infusion of coconut (Table 3). However, the lightness of colour was significantly different (p < 0.05) among the 100% wheat flour treatments, T1 and T2 and all the OFSP flour treatments, T3, T4, T5 and T6. Furthermore, the treatments with the higher level of OFSP flour (T5 and T6) differed significantly (p < 0.05) from T3 and T4 in colour L*. Moreover, the lightness of colour decreased as the OFSP flour level increased. The highest values were exhibited by T1 and T2 with values of 73.46 and 73.65 respectively and lowest by T5 and T6 with values of 63.06 and 62.94 respectively. As the concentration of OFSP flour increased, the L* values decreased significantly indicating they became darker. The reduction in colour L* is due to a higher degree of browning via the Maillard reaction, which was influenced by the water distribution and the reduction of amino acids and sugars (Greene and Bovell-Benjamin, 2004).

For the colour a* numerical value, +a represents redness and -a represents greenness of treatments while for the b* values, + b represents yellowness and - b represents blueness of colour. There was no significant difference (p > 0.05) between T1 and T2 (100% wheat flour treatments) for the a* value. A similar pattern was observed for the treatments with OFSP flour where there was no significant difference between T3 and T4 and also T5 and T6. However, colour a* for both treatments formulated with 100% wheat flour (T1 and T2) differed significantly (p < 0.05) from T3, T4, T5 and T6. In addition, the b* values showed no significant difference (p > 0.05) among all the OFSP flour treatments. However, there was a significant difference (p < 0.05) between the two 100% wheat flour treatments (T1 and T2) and the OFSP flour treatments (T3, T4, T5 and T6). The colour parameters a* and b* were evident in the treatment as a direct result of the biofortified beta carotene and anthocyanin in the OFSP flour. Similar findings were also revealed by Srivastava et al. (2012), Fayaz et al. (2021) and Korese et al. (2022) regarding colour of sweet potato baked products.

3.4 Microbiological analyses of buttermilk biscuits after production

No colony forming units for aerobic bacteria, yeasts and molds were observed on the PCA and PDA plates after the products were produced. Hence, the sterile conditions that were maintained during the production and storage of the buttermilk biscuits at 4°C as well as the use of the sodium benzoate would have preserved the products and maintained food safety. According to World Health Organization Food Safety (2022), food is a key transmission channel for more than 200 diseases in people. The significance of safe food is crucial in eliminating contamination with pathogenic microorganisms and serious illness to humans as well as a preventable burden of disease. Thus, this current study demonstrate that the buttermilk biscuits are safe to consume.

3.5 Effect of storage on physical and microbiological characteristics of buttermilk biscuits

The colour laboratory parameters L∗, a∗, and b∗ mean values among the buttermilk treatments were assessed during storage for 3 weeks (Table 4). For all treatments, the highest L* value was observed in week 1 which then decreased in week 2. For T1 (100% wheat flour) the L* value varied from 77.91 to 70.78 (week 2) and 71.69 (week 2) during storage period. The L* value at week 1, differed significantly (p < 0.05) from weeks 2 and 3 values for all treatments. There was a significant (p < 0.05) increase in colour a* values for Treatments 1, 2, 3 and 6 from week 1 to week 2. All other treatments 2, 3, 5 and 6 at week 3 had lower colour a* values than the initial start at week 1. Additionally, all treatments exhibited significant decrease in b* values from week 1 to week 3 where the yellowness continually decreased over the storage period. Determining colour change in baked products during storage is crucial as colour change affects sensory appeal (Kindeya et al., 2021).

TABLE 4

| Treatments | Colour L* | Colour a* | Colour b* | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Week 1 | Week 2 | Week 3 | Week 1 | Week 2 | Week 3 | Week 1 | Week 2 | Week 3 | |

| T1 | 77.91A | 70.78B | 71.69B | −0.28G | 2.51F | 0.09G | 29.58B | 23.68DE | 23.38DE |

| T2 | 77.92A | 71.32B | 71.73B | −0.46G | 0.51FG | −0.03G | 29.83B | 23.96DE | 22.43E |

| T3 | 70.56B | 62.72DEF | 64.12DE | 5.72CDE | 7.69BC | 4.93E | 36.94A | 25.54BCDE | 24.57CDE |

| T4 | 69.35BC | 62.47DEF | 63.28DEF | 5.31DE | 4.79E | 7.29BCD | 38.87A | 29.27BC | 25.60BCDE |

| T5 | 66.35CD | 59.99FG | 62.85DEF | 8.71AB | 7.79B | 8.27AB | 38.35A | 27.73BCD | 27.39BCDE |

| T6 | 69.01BC | 57.85G | 61.96EF | 7.49BC | 9.93A | 7.33BCD | 41.84A | 25.54BCDE | 25.21BCDE |

Effect of different levels of OFSP flour and shredded coconut on colour L*, a* and b*of buttermilk biscuits during storage.

Means with different superscript letters within the same rows and same colour category are significantly different (p ≤ 0.05).

T1 = 100% wheat flour + 5% shredded coconut; T2 = 100% wheat flour + no coconut; T3 = 70% wheat flour + 30% OFSP flour + 5% shredded coconut; T4 = 70% wheat flour + 30% OFSP flour no coconut; 50% wheat flour + 50% OFSP flour + 5% shredded coconut; T6 = 50% wheat flour + 50% OFSP flour no coconut.

Comprehensive research of the scientific literature did not reveal any information regarding storage effect of wheat flour and OFSP flour buttermilk biscuits. In this current study, during the 3 weeks storage, the buttermilk biscuits formulated with only wheat flour recorded the highest value of L* and this result indicates the intensity of whiteness synonymous to wheat which when milled is white in colour (Kamil et al., 2011). Nevertheless, generally, the lightness of colour for all treatments decreased significantly with time which is indicative of the buttermilk biscuits becoming darker. The treatments with the highest b* values for yellowness over time were all those that included the OFSP flour blends with and without desiccated coconut. Possible reasons for this are due to colour degradation and the breakdown of sugars and amino acids resulting in the Maillard reaction during storage (Fayaz et al., 2021).

The other physical parameters-weights, diameter, thickness and spread ratios of the buttermilk biscuits of each treatment generally showed no significant difference (p > 0.05) in changes during the storage period (Table 5). This implied that, the innovative golden OFSP flour buttermilk biscuits can maintain their integrity even up to 3 weeks after production. This information is crucial especially for packaging purposes and consumers’ acceptability.

TABLE 5

| T | Weight (g) | Diameter (mm) | Thickness (mm) | Spread ratio | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Week 1 | Week 2 | Week 3 | Week 1 | Week 2 | Week 3 | Week 1 | Week 2 | Week 3 | Week 1 | Week 2 | Week 3 | |

| T1 | 23.50E | 22.00E | 22.62E | 46.30CDEFG | 45.93DEFG | 43.52FG | 25.27G | 25.20G | 24.29G | 3.85CDEFG | 3.82DEFG | 3.62FG |

| T2 | 23.52E | 22.72E | 23.12E | 46.22CDEFG | 44.20EFG | 42.37G | 25.80G | 25.54G | 25.10G | 3.85CDEFG | 3.68EFG | 3.53G |

| T3 | 45.72A | 41.77BC | 41.77BC | 51.75AB | 50.77ABCD | 50.21ABCD | 34.05A | 34.00A | 33.13AB | 4.31AB | 4.23ABCD | 4.18ABCD |

| T4 | 46.00A | 42.12BC | 41.17BCD | 54.13A | 51.75AB | 50.83ABC | 32.64ABC | 32.31BCD | 31.80BCDE | 4.51A | 4.31AB | 4.23ABC |

| T5 | 39.45CD | 40.12CD | 38.20D | 52.31AB | 49.35ABCD | 48.35BCDEF | 28.03F | 28.34F | 28.02F | 4.35AB | 4.11ABCD | 4.02BCDEFG |

| T6 | 43.92AB | 42.20BC | 42.10BC | 49.03BCDE | 46.54CDEFG | 45.95DEFG | 31.28CDE | 30.97DE | 30.39E | 4.08BCDE | 3.87CDEFG | 3.82DEFG |

Effect of different levels of OFSP flour and shredded coconut on physical parameters of buttermilk biscuits during storage.

Means with different superscript letters within the same rows and same physical parameters are significantly different (p ≤ 0.05).

T1 = 100% wheat flour + 5% shredded coconut; T2 = 100% wheat flour + no coconut; T3 = 70% wheat flour + 30% OFSP flour + 5% shredded coconut; T4 = 70% wheat flour + 30% OFSP flour no coconut; 50% wheat flour + 50% OFSP flour + 5% shredded coconut; T6 = 50% wheat flour + 50% OFSP flour no coconut.

Moreover, during the storage period of 3 weeks, no colony forming units for aerobic bacteria, yeasts and molds were observed on the PCA and PDA plates. Hence, the sterile conditions that were maintained during the production and storage of the buttermilk biscuits at 4°C as well as the use of the sodium benzoate would have preserved the products. Thus, it can be inferred that food safety was maintained. Safe food is imperative as it enhances individuals’ health and is critical for economic viability of the food industry.

4 Conclusion

The production of OFSP buttermilk biscuits with desiccated shredded coconut in this study is an innovative product as no previous scientific work was reported for this formulation. The findings of this research reject the null hypothesis (p < ∝) while the alternative hypothesis is supported. The most acceptable buttermilk biscuits based on sensory attributes were the two buttermilk biscuits with 30% OFSP flour with 5% desiccated coconut and without the coconut (T3 and T4). The inclusion of shredded coconut did not improve sensory attributes or overall acceptance of the buttermilk biscuits. Furthermore, the OFSP flour buttermilk biscuits can be considered nutritious as they contained moisture, fat, crude protein, fibre and ash. Even though the protein content was reduced with the addition of the OFSP flour, it is noteworthy that the protein content was at an acceptable level. During the shelf-life period, all physical parameters (except colour) and food safety were maintained. Therefore, OFSP flour either with or without desiccated coconut showed promising potential in the formulation of OFSP flour buttermilk biscuits that can be used as healthy options in diets instead of the 100% wheat flour products and can also help address the issue of food security globally.

Statements

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

RR: Writing–original draft, Investigation, Visualization, Validation, Resources, Methodology. VD: Writing–review and editing, Writing–original draft, Visualization, Validation, Supervision, Software, Project administration, Methodology, Investigation, Formal Analysis, Data curation, Conceptualization. GE: Writing–review and editing, Validation, Formal Analysis.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This study has been financially supported by The University of the West Indies, St. Augustine Campus.

Acknowledgments

We are grateful for this support. We are also appreciative for the assistance provided by the Food Production, Microbiology and Food Biology laboratories in the Department of Food production, Faculty of Food and Agriculture, The UWI. St. Augustine Campus.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

Afework K. A. Mezgebe A. G. Abadi G. M. (2016). Development of provitamin A and energy-rich biscuits: blending of orange-fleshed sweet potato (Ipomoea batatas L.) with wheat (Triticum Vulgare) flour and altering baking temperature and time. Afr. J. Food Sci.10, 79–86. 10.5897/ajfs2015.1403

2

Agu H. O. Ayo J. A. Paul A. M. Folorunsho F. (2007). Quality characteristics of biscuits made from wheat and African breadfruit (Treculia africana). Niger. Food J.25 (2), 19–27. 10.4314/nifoj.v25i2.50827

3

Alam M. K. (2021). A comprehensive review of sweet potato (Ipomoea batatas [L.] Lam): revisiting the associated health benefits. Trends Food Sci. Technol.115, 512–529. 10.1016/j.tifs.2021.07.001

4

Anbuselvi S. Kumar M. S. Selvakumar S. Rao M. R. K. Dash A. (2012). A comparative study on biochemical constituents of sweet potatoes from Orissa and Tamilnadu and its curd formation. J. Chem. Pharm. Res.4 (11), 4879–4882. Available at: www.jocpr.com.

5

AOAC (2002). Official methods of analysis of AOAC international. 17th ed.Washington, DC: Association of Official Analytical Chemists.

6

Aoac A. (1997). “Official Method 997.02 for yeast and mold count in foods,” in Official methods of analysis (Washington, DC: Association of Official Analytical Chemists), 14.

7

Aoac A. (1999). “Official Method 999.08 Aerobic plate count in foods,” in Official methods of analysis (Washington, DC: Association of Official Analytical Chemists), 14.

8

Bitto P. Devi P. (2019). Consumer’s perception about desiccated coconut- A value added product of coconut. Central Eur. Manag. J.30 (2).

9

Bovell-Benjamin A. C. (2007). Sweet potato: a review of its past, present, and future role in human nutrition. Adv. Food Nutr.52, 1–59. 10.1016/S1043-4526(06)52001-7

10

Cao Y. Zhang F. Guo P. Dong S. Li H. (2019). Effect of wheat flour substitution with potato pulp on dough rheology, the quality of steamed bread and in vitro starch digestibility. LWT–Food Sci. Technol.11, 527–533. 10.1016/j.lwt.2019.01.034

11

Chandrasekara A. Josheph Kumar T. (2016). Roots and tuber crops as functional foods: a review on phytochemical constituents and their potential health benefits. Int. J. food Sci.2016 (1), 3631647. 10.1155/2016/3631647

12

Dako E. Retta N. Desse G. (2016). Effect of blending on selected sweet potato flour with wheat flour on nutritional, anti-nutritional and sensory qualities of bread. Global Journal of Science Frontier Research: D Agriculture and Veterinary. 16 (4).

13

Divya P. M. Roopa B. S. Manusha C. Balannara P. (2023). A concise review on oil extraction methods, nutritional and therapeutic role of coconut products. J. Food Sci. Technol.60 (2), 441–452. 10.1007/s13197-022-05352-0

14

Dogan I. S. (2006). Effect of oven types on the characteristics of biscuits made from refrigerated and frozen dough. Food Technol. Biotechnol.44 (1), 117–122.

15

FAO (2022). Impact of the Ukraine-Russia conflict on global food security and related matters under the mandate of the Food and Agriculture Organization of the United Nations. FAO: Rome.

16

FAOSTAT (2006). Trade: crops and livestock products [WWW document]. Food agric. Organ: United Nations. Available at: https://www.fao.org/faostat/en/#data.

17

Fayaz U. Dar A. H. Kumar N. Junaid P. M. Shams R. Khan S. A. (2021). Formulations and quality characterization of low salt flat bread: effects on functionality, rheological and sensory properties. Appl. Food Res.1 (1), 100005. 10.1016/j.afres.2021.100005

18

Garcia-Hernandez A. Roldan-Cruz C. Vernon-Carter E. J. Alvarez-Ramirez J. (2022). Effects of leavening agent and time on bread texture and in vitro starch digestibility. J. Food Sci. Technol.59, 1922–1930. 10.1007/s13197-021-05206-1

19

Greene J. L. Bovell-Benjamin A. C. (2004). Macroscopic and sensory evaluation of bread supplemented with sweet-potato flour. J. Food Sci.69 (4), SNQ167–SNQ173. 10.1111/j.1365-2621.2004.tb06359.x

20

Julianti E. Lubis Z. Limanto S. (2020). Utilization of purple sweet potato flour, starch, and fibre in biscuits making. IOP Conf. Ser. Earth Environ. Sci.443 (1), 012047. 10.1088/1755-1315/443/1/012047

21

Jung J. K. Lee S. U. Kozukue N. Levin C. E. Friedman M. (2011). Distribution of phenolic compounds and antioxidative activities in parts of sweet potato (Ipomoea batata L.) plants and in home processed roots. J. Food Compos. Anal.24 (1), 29–37. 10.1016/j.jfca.2010.03.025

22

Kausar S. M. Anil B. Neeti Harshitha M. (2023). Preparation and quality evaluation of sweet potato (Ipomoea batatas) flour biscuits. Int. J. Agric. Food Sci.5 (2), 20–24. 10.33545/2664844x.2023.v5.i2a.141

23

Kidane G. Abegaz K. Mulugeta A. Singh P. (2013). Nutritional analysis of vitamin A enriched bread from orange flesh sweet potato and locally available wheat flours at Samre Woreda, Northern Ethiopia. Curr. Res. Nutr. Food Sci. J.1 (1), 49–57. 10.12944/CRNFSJ.1.1.05

24

Kindeya F. Hailu W. Dessalegn T. Kibr G. L. (2021). Effect of blending ratio of wheat, orange fleshed sweet potato and haricot bean flour on proximate compositions, β-carotene, physicochemical properties and sensory acceptability of biscuits. F1000Research10, 506. 10.12688/f1000research.52634.2

25

Korese J. K. Chikpah S. K. Hensel O. Pawelzik E. Sturm B. (2021). Effect of orange-fleshed sweet potato flour particle size and degree of wheat flour substitution on physical, nutritional, textural and sensory properties of cookies. Eur. Food Res. Technol.247 (4), 889–905. 10.1007/s00217-020-03672-z

26

Lalitha R. Sinthuja R. (2013). Preparation of bakery products using coconut flour and glycemic response on normal healthy adults. Cord29 (1), 10. 10.37833/cord.v29i1.94

27

Levent H. Bilgiçli N. (2012). Evaluation of physical, chemical and sensory properties of Turkish flat breads (bazlama and yufka) supplemented with lupin, buckwheat and oat flours. Int. J. Food Sci. Nutr. Eng.2 (5), 89–95. 10.5923/j.food.20120205.04

28

Lindenmeier M. Hofmann T. (2004). Influence of baking conditions and precursor supplementation on the amounts of the antioxidant pronyl-L-lysine in bakery products. J. Agric. Food Chem.52 (2), 350–354. 10.1021/jf0346657

29

Liu S. Sun H. Ma G. Zhang T. Wang L. Pei H. et al (2022). Insights into flavor and key influencing factors of Maillard reaction products: a recent update. Front. Nutr.9, 973677. 10.3389/fnut.2022.973677

30

Maaruf A. G. Linforth R. S. Taylor A. J. (2011). Interaction of temperature/time and humidity on the generation of wheat bread flavor. University Kebangsaan Malaysia and University of Nottingham Research.

31

Mohammad K. Ziaul H. Sheikh N. (2016). Comparison of the proximate composition total carotenoids and total polyphenol content of nine varieties of orange fleshed sweet potato grown in Bangladesh. Institute of Nutrition and Food Science, University of Dhaka: Dhaka, Bangladesh.

32

Mridula D. (2011). Physico-chemical and sensory characteristics of β-carotene rich defatted soy fortified biscuits. Afr. J. Food Sci.5 (5), 305–312. 10.5897/AJFS.9000223

33

Noor Aziah A. A. Mohammad Noor A. Y. Ho L. H. (2012). Physicochemical and organoleptic properties of cookies incorporated with legume flour. Int. Food Res. J.19 (4), 1539–1543.

34

Noorfarahzilah M. Lee J. S. Sharifudin M. S. Mohd Fadzelly A. B. Hasmadi M. (2014). Applications of composite flour in development of food products. Int. Food Res. J.21 (6).

35

Olaoye O. A. Beatrice I. O. A.-O. (2011). Composite flours and breads: potential of local crops in developing countries. Flour Breads Fortification Health Dis. Prev., 183–192. 10.1016/B978-0-12-380886-8.10017-0

36

Onabanjo O. O. Ighere D. A. (2014). Nutritional, functional and sensory properties of biscuit produced from wheat-sweet potato composite. J. Food Technol. Res.1 (2), 111–121. 10.18488/journal.58/2014.1.2/58.2.111.121

37

Oyinloye O. D. Akande N. Osinubi O. B. Ajani A. A. Abdulkareem S. A. Oyinloye F. F. (2022). Evaluation of bread made from wheat and composite flours of sweet potato. Int. J. Sci. Eng. and Environ. Technol. (IJOSEET)7 (14), 128–136.

38

Pandiselvam R. Manikantan M. Ramesh S. Beegum S. Mathew A. (2019). Adulteration in coconut and virgin coconut oil: implications and detection methods. Kasaragod, India: ICAR-Central Plantation Crops Research Institute.

39

Roger P. Bertrand B. M. M. Gaston Z. Nouhman B. Elie F. (2022). Nutritional composition of biscuits from wheat‐sweet potato‐soybean composite flour. Int. J. Food Sci.2022 (1), 7274193. 10.1155/2022/7274193

40

Roshana M. R. Mahendran T. Chathuranga H. G. S. (2019). Effect of replacement of wheat flour with sweet potato flour on quality characteristics of muffins. SLAAS2 (1), 12–20.

41

Santi E. N. Murdianto W. Ahmadi N. R. Sulistyaningrum A. (2022). Physicochemical characteristics of three local sweet potato flour from east Kalimantan. Earth Environ. Sci.1024 (2022), 012037. 10.1088/1755-1315/1024/1/012037

42

Shiferaw B. Smale M. Braun H. Duveiller E. Reynolds M. Muricho G. (2013). Crops that feed the world 10. Past successes and future challenges to the role played by wheat in global food security. Food Secur.5, 291–317. 10.1007/s12571013-0263-y

43

Sinaga S. M. Margata L. Silalahi J. (2015). Analysis of total protein and non-protein nitrogen in coconut water and meat (Cocos nucifera L.) by using Kjeldahl method. Int. J. Pharm. Tech. Res.8, 551–557. Available at: http://sphinxsai.com/2015/ph_vol8_no4/1/(551-557)V8N4PT.pdf.

44

Singh S. Riar C. S. Saxena D. C. (2007). Effect of incorporating sweet potato flour to wheat flour on the quality characteristics of cookies. Afr. J. food Sci.2 (6), 65–72. Available at: http://www.academicjournals.org/ajfs.

45

Srivastava S. Genitha T. R. Yadav V. (2012). Preparation and quality evaluation of flour and biscuit from sweet potato. J. Food Process Technol.3 (12), 1–5. 10.33545/2664844X.2023.v5.i2a.141

46

Sugri I. Maalekuu B. K. Francis K. Gaveh E. (2017). Quality and shelf-life of sweet potato as influenced by storage and postharvest treatments. Trends Hortic. Res.7 (1), 1–10.

47

Torbica A. Belović M. Tomić J. (2019). Novel breads of non-wheat flours. Food Chem.282, 134–140. 10.1016/j.foodchem.2018.12.113

48

Tsai Y.-J. Lin L.-Y. Yang K.-M. Chiang Y.-C. Chen M.-H. Chiang P.-Y. (2021). Effects of roasting sweet potato (Ipomoea batatas L. Lam.): quality, volatile compound composition, and sensory evaluation. Foods.10 (11), 2602. 10.3390/foods10112602

49

USDA Data (2018). Coconut products - food composition database: United States department of agriculture. Agric. Res. Serv.

50

von Grebmer K. Bernstein J. Delgado C. Smith D. Wiemers M. Schiffer T. et al (2021). 2021 global hunger index: hungerand food systems in conflict settings. Dublin: Bonn.

51

World Health Organization Food Safety (2022). World health organization food safety. Available at: https://www.who.int/news-room/fact-sheets/detail/food-safety (accessed on March 28, 2022).

Summary

Keywords

buttermilk biscuits, orange-flesh sweet potato, wheat flour, sensory evaluation, nutritive value, shelf-life, microbiological quality

Citation

Ramsaran R, de Gannes V and Eudoxie G (2024) Quality evaluation of innovative buttermilk biscuits produced from orange-flesh sweet potato flour infused with coconut. Front. Food. Sci. Technol. 4:1467839. doi: 10.3389/frfst.2024.1467839

Received

21 July 2024

Accepted

23 October 2024

Published

05 November 2024

Volume

4 - 2024

Edited by

Oladipupo Adiamo, The University of Queensland, Australia

Reviewed by

Saleha Akter, The University of Queensland, Australia

Olumide Fawale, The University of Queensland, Australia

Updates

Copyright

© 2024 Ramsaran, de Gannes and Eudoxie.

This is an open-access article distributed under the terms of the Creatindive Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Vidya de Gannes, vidya.degannes@uwi.edu

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.