- 1GfL Gesellschaft für Lebensmittel-Forschung mbH, Berlin, Germany

- 2Biotechnical Faculty, University of Ljubljana, Ljubljana, Slovenia

Alternatives to the conventional thermal processing (TT) of food are an area of research that has grown tremendously in recent decades. The impact of these alternative techniques on the sensory profile of fruit juices has been discussed in the literature but only in a fragmented manner. This review takes a macroscopic approach to discuss the influence of emerging thermal and non-thermal techniques currently used by industries on a commercial scale, like high-pressure processing (HPP), ohmic heating (OH), and pulse electric field processing (PEF), on certain sensory characteristics of fruit juices and beverages. A sensory impression of a product is a result of a complex mixture of several compounds. The sensory profile varies with the type of processing technique due to differences in intensities and the inactivation mechanism for enzymes. Heat plays a role in the generation of flavor and odor-active compounds; hence, a different sensory profile is expected with alternative techniques that operate at ambient temperatures (HPP and PEF) or have short treatment time due to rapid heating (OH). HPP, OH, and PEF positively influence the retention of compounds that contribute to a fresh-like sensory experience. However, enzyme inactivation is often challenging with alternative techniques resulting in higher residual activity, affecting sensory quality during storage. Nevertheless, there is evidence in the literature of products with stable sensory properties during storage after processing with alternative techniques. Additionally, some residual enzyme activity may play a role in flavor enhancement during storage, i.e., the release of aglycones from glycoconjugates by pectolytic enzymes. Multiple factors like fruits’ cultivar, way of cultivation, external growth conditions, and maturity stage at the time of harvest influence its sensory quality and, subsequently, the products derived from them. The review concludes with the impression that there is extensive literature on the effects of HPP on the sensory properties of fruit juices. However, the research is limited in discussing the influence of OH and PEF. Additionally, it is difficult to make a fair and systematic comparison among the different preservation technologies because of the lack of standardization and comprehensive sensory evaluation in the studies in the literature.

1 Introduction

The main objective behind processing a food commodity is to kill pathogenic bacteria and reduce the load of spoilage microorganisms to extend shelf life. However, good quality encompasses not only safety but also nutrition and sensory properties. It is imperative to minimize or, if possible, eliminate enzyme activity with processing as they can adversely affect sensory properties like odor, flavor, and color during storage. A food business operator strives to implement processing technology that minimizes the impact on the desired sensory and nutritional properties while producing a product safe for consumer consumption. Fruit juices are traditionally subjected to thermal processing (TT). While TT does help achieve shelf-stable products, the product does suffer from major quality losses. There is ample evidence in the literature that TT often results in the loss of valuable components of food, such as phenolic compounds, anthocyanins, vitamins, volatile odor-active compounds, and other bioactive compounds (Odriozola-Serrano et al., 2008; Cao et al., 2011; Rupasinghe and Yu, 2012; Santhirasegaram et al., 2015; Petruzzi et al., 2017). Although better variants of TT have been developed, such as high-temperature short-time pasteurization and ultrahigh temperature treatments, which have shown to be less invasive than the TT, the detrimental effects of thermal treatments on food quality have still not been marginalized to a significant extent (Perez-Cacho and Rouseff, 2008; Petruzzi et al., 2017).

The impaired sensory quality in TT-treated products can be compensated for by adding artificial flavor and odor compounds, but these products have poor perceived naturalness, and customers prefer minimally altered products with no additives (Román et al., 2017; Martins et al., 2019). Emerging thermal and non-thermal food processing technologies have been demonstrated to provide natural and safe food products with higher nutritional and sensory qualities than TT-treated foods (Shao et al., 2021; Cheng et al., 2022; Pinto et al., 2022). Alternative to the TT treatment of food is an area of research that has grown tremendously in recent decades. Generally, these new technologies operate at ambient or moderately high temperatures to eliminate pathogenic/spoilage microorganisms and inactivate enzymes. Several alternatives to TT have been developed. However, adopting the emerging techniques on a commercial scale is hindered by several barriers. Although the emerging processing technologies are more energy efficient and, therefore, more environmentally friendly and cost-effective in the long run, they have significantly higher initial capital investment than TT, leading to a higher price of the treated commodity (Rastogi et al., 2007). Moreover, the industry can benefit from ample literature on the optimization of TT treatment for a variety of food products, but there still exist significant gaps of knowledge in the literature when it comes to the optimization of emerging preservation techniques (Priyadarshini et al., 2018). Additionally, consumers lack information about non-traditional food technologies and often have false negative assumptions about their effect on human health (Junqueira-Gonçalves et al., 2011). The adoption rate of emerging food processing technologies, however, has improved over the years as the advancement in technology and design of the equipment continues to drive down the production cost, and the consumers’ perception of the new technologies continues to improve as a result of increased awareness (Martins et al., 2019; Houška et al., 2022; Rocha et al., 2022). The fruit juice and beverage industry has been more open to the adoption of new processing technologies compared to other food sectors (Martins et al., 2019). The emerging technologies such as high-pressure processing (HPP), ohmic heating (OH), and pulse electric field (PEF) have been successfully applied on a commercial level for fruit juice and beverages preservation and continue to strengthen their presence in the global food market (Morales-de La Peña et al., 2016; Alkanan et al., 2021).

The sensory impression of a food product is an intricate and complex concept constituting different senses, their non-linear way of interaction with each other, and several cross-modal phenomena (Negoias et al., 2008). The main sensory characteristics include taste, odor, texture, and color. The term “flavor” is predominantly used synonymous with the sensory perception of a product in literature and will also be used in the review as such. The flavor of a fruit juice and beverage is the result of an amalgamation of several chemical compounds that are either endogenously present or produced through different chemical pathways. Certain taste and odor compounds have a stronger influence on the overall flavor profile compared to others due to the difference in their potency, i.e., different odor thresholds. Moreover, the flavor compounds often interact to contribute to a particular odor note in a food matrix; hence, a small change in the concentration of one compound can potentially have a large effect on the overall sensory experience. Most of the chemical pathways that result in the production of organoleptically relevant compounds in food matrices are catalyzed by enzymes. Depending on the intensity of processing, a food product will vary in residual enzyme activities. Henceforth, it is intuitive that products subjected to different processing conditions may differ in their sensory properties, especially after mid- or long-term storage. Furthermore, it has been reported in the literature that many compounds that actively contribute to the flavor of fruit juices and beverages are produced through thermal processing (Perez-Cacho and Rouseff, 2008; Liang et al., 2020). The extensive research and discussion on the use of emerging thermal and non-thermal processing techniques as a means of producing fruit juices and beverages with high nutritional value in an environmentally sustainable manner merit the question of their influence on the sensory profile of the treated food products.

The impact of novel food processing technology on the sensory profile of fruit juices has been discussed in the literature, but only in a fragmented manner, i.e., specific to a particular fruit type or processing technique (Oey et al., 2008; Caminiti et al., 2011; Terefe et al., 2013; Terefe et al., 2014; Khandpur and Gogate, 2015; Morales-de La Peña et al., 2016; Sulaiman et al., 2016). To the best of our knowledge, only one other review by Rocha et al. (2022) talks about the impact of emerging thermal and non-thermal technologies on the sensory characteristics of food products in general. In this review, we attempt to take a macroscopic approach to discuss the influence of emerging alternative techniques currently used by industries on a commercial scale (HPP, PEF, and OH) on the main sensory characteristics of fruit juice and beverages, i.e., color, taste, texture, and odor. The review targets the latest studies, i.e., in the last 10–15 years, and specifically the ones that investigate the change in sensory properties in treated products during storage, which has been lacking in previous review studies. The odor is found to be the dominant sensory property, especially for fruit juice and beverages, since humans have a high number of odor receptors that are capable of distinguishing among a wide range of odors (Nicolaï et al., 2008; Bushdid et al., 2014). Moreover, the taste of food products is mostly associated with non-volatile compounds in the concentration of parts per hundred, which is significantly higher than the odorant volatile compounds that exist in parts per trillion concentrations. Therefore, small changes in odor-active compounds will strongly influence the overall sensory impression compared to small changes in non-volatile compounds responsible for taste, i.e., sugars and organic acids (Fructuoso and Cortada, 2010). Henceforth, the discussion presented in this review is dominated by odor-active compounds and how they are affected by processing technologies. The review begins with a basic overview of the compounds that actively contribute to the sensory impression of fruit juices and beverages. It is then followed by a brief description of TT, HPP, PEF, and OH treatments including their underlying inactivation mechanisms for enzymes and their influence on different sensory properties of fruit juices and beverages. The review uniquely discusses the influence of TT, HPP, OH, and PEF treatment on the sensory properties of fruit juices after treatment and during storage in a single study. Factors that affect the sensory properties of fruits and, subsequently, the products derived from them are also briefly touched on in the review. The knowledge gaps in the available literature related to the effect of TT and other alternative technologies on the sensory impression of fruit juices and beverages are also brought under discussion.

2 Sensory active compounds and metabolites in fruit juices and beverages

The sensory profiles of fruit juices and beverages are not based on a single characteristic sensory-active compound but on a complex mixture of several chemical compounds. All these compounds are mainly derived from the endogenous nutrients present in the fruit, such as carbohydrates, fatty acids, and amino acids. These nutrients are fed as substrates into biochemical pathways involving several different enzymes that convert them into sensory-active metabolites.

2.1 Fatty acids

Fatty acids are one of the prominent classes of non-volatile precursors for several volatile metabolites, such as aliphatic unsaturated and saturated alcohols, acids, esters, aldehydes, and ketones. These volatile compounds are primarily derived via two metabolic pathways: β-oxidation and lipoxygenase. The unsaturated or saturated C6 or C9 odor-active aldehydes, such as 2-(E) Hexenal and 3-(E) Hexenal, that are widely found in fruits and derived products and are associated with a fresh-green-like taste and odor, are mainly produced via lipoxygenase pathway (Baysal and Demirdöven, 2007). The primary metabolites of fatty acid metabolism may undergo other enzyme-catalyzed chemical reactions leading to the formation of other odor-active compounds. For example, aldehydes derived from the lipoxygenase pathway can undergo a reduction reaction catalyzed by alcohol dehydrogenase to produce alcohol (Siegmund, 2014). The alcohols can participate in esterification reactions, typically with acetyl-CoA moieties, to produce odor-active esters (González et al., 2009). The flavor- and odor-active esters form the most important class of compounds contributing to the characteristic sensory impression of fruit and, subsequently, fruit juices and derived products (Hadi et al., 2013). For example, ethyl butanoate is responsible for the characteristic strawberry odor, ethyl hexanoate contributes to the distinguish pineapple odor and C9 esters contribute strongly to the melon odor (Parker, 2014; Wu et al., 2021).

2.2 Amino acids

Amino acids like alanine, leucine, isoleucine, and aspartic acid are other important non-volatile substrates for the formation of flavor compounds in fruits. The typical steps in the metabolism of amino acids to produce flavor compounds are deamination and decarboxylation. The metabolites can further undergo chemical reactions to produce other flavor compounds. For example, the deamination of phenylalanine leads to the formation of cinnamic acid, and it can further esterify to form ethyl cinnamate, an active odorant abundant in sour cherries, cranberries, pineapples, and strawberries (Siegmund, 2014). The amino acids also serve as a precursor for a range of phenylpropanoid and benzenoid compounds, which are non-volatile, but they can undergo further chemical conversion, i.e., reduction, alkyl addition to hydroxyl or carboxyl group, and become volatile to contribute to the chemosensory properties in fresh fruits. For example, benzenoid derivatives like methyl salicylate and methyl benzoate significantly contribute to floral odor notes in tomatoes, papaya, strawberry, mango, and citrus fruits (Osorio et al., 2010).

2.3 Terpenoids and furanones

Terpenoid and furanone are two groups of volatile compounds derived from carbohydrate metabolism. Terpenes are mainly produced from carbohydrates via the mevalonic pathway or the 2-C-methyl D-erythritol-4-phosphate pathway, with the reaction steps catalyzed by a large group of enzymes called terpene synthases (Degenhardt et al., 2009). Monoterpenes and sesquiterpenes have been identified in fruits as the main terpenoids contributing to odor and taste, i.e., oxygenated monoterpenes contribute to the characteristic flavor of citrus fruits (Reineccius, 2006). Terpenes like α-pinene and linalool are an abundant part of the flavor profile of strawberries, contributing to sweet and floral flavor, and nerolidol contributes to rose and green-like flavor notes (Aharoni et al., 2004; Aguiló-Aguayo et al., 2009b). Furanones are mainly produced as a result of carbohydrate metabolism via the Maillard reaction pathway. These compounds usually have a pleasant, sweet odor note. Two prominent examples of furanone that contribute to the flavor and odor of fruits are 2,5-dimethyl-4-hydroxy-3(2H)-furanone (DMHF, known as furaneol) and 2,5-dimethyl-4-methoxy-3(2H)-furanone (known as mesifuran) (Schwab, 2013; Siegmund, 2014). For example, these compounds are a significant part of the flavor profile of fruits like strawberries, pineapple, and passion fruit and are responsible for sweet, fruity, caramel-like, and floral odor notes (Montero-Calderon et al., 2010; Narain et al., 2010; Kallio, 2018).

2.4 Color pigments

Color is also an important sensory property. There is a wide range of compounds that are associated with imparting characteristic fresh-like color to fruits and the products derived from them, i.e., juices. Chlorophyll is the most dominant color pigment in unripe fruits imparting green color (Kapoor et al., 2022). Carotenes and xanthophylls, which belong to the group of carotenoids, are color pigments responsible for yellow, orange, and red hues in fruits (Ghosh et al., 2022). Betalains are tyrosine derived nitrogen containing color pigments that are found in a limited number of fruit species like red dragon fruit, red pitaya fruit, and prickly pear (Calva-Estrada et al., 2022). The yellow-orange betaxanthin and red-violet betacyanin make up the two major classes of betalains that are present in the fruits (Sadowska-Bartosz and Bartosz, 2021). Anthocyanins are another important class of compounds that impart red, yellow, and blue colors in fruits (Lu et al., 2021). The stability of color pigments in a matrix depends on various factors such as pH, temperature, light, heat, dissolved oxygen, metal ions, and co-pigments (Enaru et al., 2021; Calva-Estrada et al., 2022; Ghosh et al., 2022). The color of a processed food product may change during processing by accelerated non-enzymatic browning at elevated temperatures or during storage mainly by enzymatic browning, i.e., due to the residual activity of the peroxidase (POD) and polyphenol oxidase (PPO) (Mannozzi et al., 2019; Wibowo et al., 2019).

2.5 Pectin

The texture of the food product, another type sensory property, is also affected by the residual activity of the enzymes during storage. Texture is more important as a sensory property in the case of whole fruits, but it is still a relevant sensory property to discuss when talking about fruit juices and beverages. Phase separation in cloudy fruit juices is a major textural defect that is observed due to the residual activity of pectin methylesterase (PME) and polygalacturonase (PG) and has a direct effect on the appearance and mouthfeel (Sila et al., 2009; Hurtado et al., 2019). Pectin, a heteropolysaccharide present in the cell wall of the plant cell, is majorly responsible for the texture of fruit and the consistency of derived products. The molecule is composed of units of galacturonic acid with its carboxylic acid group esterified with methyl groups. PME causes the de-esterification of the methyl groups, leading to the formation of pectate, which causes the cross-linking of polymer chains via interaction with calcium ions (Sila et al., 2009). PG enzyme triggers the depolymerization of the unmethylated pectin chain (Sila et al., 2009). These actions consequently lead to the disintegration of the fruit juice cloud stability in the case of non-clarified fruit juices and beverages and can also decrease the viscosity of fruit juices (Umair et al., 2022). The change in texture can also influence taste and odor profile as texture influences the relative vapor pressure of volatiles and, consequently, the odor release (Tournier et al., 2009).

2.6 Sugars and organic acids

Taste is another important sensory property that affects the sensory impression of fruit juice. Sweet and sour are the dominant sensations used to describe the taste of the fruits, and the sensations are mainly associated with the presence and concentration of sugar, i.e., glucose and fructose, and organic acids, i.e., citric, malic, and tartaric acids, respectively (Sanz and Perez, 2010). Other descriptors like bitterness, astringency, and saltiness have also been used to describe certain taste sensations in fruits and are associated with minor components, i.e., tannins (Brandão et al., 2020). The taste perception of juices and beverages is strongly dictated by the ratio of fruit sugars to the organic acids rather than their absolute content (Boylston, 2010). Changes in taste due to processing have scarcely been reported in the literature (Chang et al., 2017; Aaby et al., 2018; Wibowo et al., 2019; Doan et al., 2023).

3 Fruit juice and beverage processing

3.1 Conventional thermal processing

TT treatment of juices is typically carried out at temperatures between 84°Cand 88°C with a treatment time of 15–45 min (Škegro et al., 2021). TT treatment of fruit juices triggers a series of chemical reactions involving the different components of fruit like peel oils, phenolic compounds, lipids, ascorbic acid, sugars, amino acids, and sulfur-containing compounds, and lead to the production of metabolites that influence the sensory properties. The majority of the key oxygenated volatile odor compounds, such as alcohols, ketones, and aldehydes, are formed at elevated temperatures. For example, heating of juice increases the rate of acid-catalyzed hydration of terpenes present in the matrix to generate aromatic alcohols like α-terpineol, breakdown of cinnamic acids to aromatic aldehydes and alcohols, and degradation of carbohydrates to furan aldehydes, and furanone (Perez-Cacho and Rouseff, 2008). C6 aldehydes such as hexanal are compounds that play a vital role in the odor of sweet cherries and are produced during TT treatment (Sun et al., 2010). Heat also facilitates the metabolism of sulfur-containing amino acids like methionine to aromatic compounds, namely, dimethyl sulfide (cabbage-like odor), dimethyl disulfide (onion-like, cabbage-like odor), methanethiol (cabbage-like odor), and dimethyl trisulfide (cabbage-like odor), which are responsible for the undesirable flavor notes in fruit juices (Perez-Cacho et al., 2007; Maoz et al., 2022).

The Maillard reaction, another heat-induced chemical reaction between sugar and amino acids, also leads to the production of important flavor-active compounds such as diacetyl, 2-acetyl-1-pyrroline, 2-acetyl-3,4,5,6-tetrahydropyridine and furaneol (Deblander et al., 2015). The profile of the odor-active Maillard reaction products (MRP) may vary with the temperature-time profile during the treatment, potentially influencing the perceived flavor (Lund and Ray, 2017). The sensory profile of apple juice improved after TT treatment mainly due to enhanced levels of aromatic esters (Šimunek et al., 2013). Moreover, high temperatures typically result in accelerated ascorbic acid (AA) oxidation to produce dehydroascorbic acid (DHA). The DHA compound can readily participate in the formation of odor-active Strecker aldehydes such as ethanal (fruity, sweet odor), methylpropanal (malty odor), and 2-phenyl ethanal (floral/honey-like odor) and can influence the odor profile of a product (Bharate and Bharate, 2012). Heat also accelerates the hydrolysis of flavorless glycosides, a conjugated structure between a flavor-active compound (aglycone) and a sugar moiety (glycone), to release flavor-active compounds hence improving the sensory profile (Liang et al., 2020). These glycosides play a crucial role in the sensory profile of almost all fruits, especially in grapes (Rocha et al., 2000), raspberries (Vrhovšek et al., 2014), and pineapple (Steingass et al., 2015) since the volatiles in these fruits majorly exist in bound form as glycosides than in free form.

The different examples described above demonstrate that heat plays an imperative role in the development of sensory profiles. However, the prolonged TT treatment of fruit juices has been shown to impact the sensory properties of fruit juices negatively. Compared to the color of the untreated counterpart, a loss of color or discoloration was observed in different types of fruit juices and beverages after TT treatment (Tribst et al., 2011; Uckoo et al., 2013; Andrés et al., 2016). The TT treatment of citrus juices often results in increased bitterness, mainly attributed to the accelerated rate of closing of the aromatic ring of limonoate A-ring lactone to form limonin (Zhang et al., 2024). Several MRPs like 2-furfuryl, 2-furaldehyde, and 5-hydroxymethyl-2- furaldehyde produced during TT treatment also negatively impact the taste of the product (Sönmez et al., 2017). TT treatment has been reported to result in an increase in the viscosity of carrot juice (Chen et al., 2012) and mango nectar (Liu et al., 2014), possibly due to increased solubilization of the pectin in the cell wall. A comprehensive review by Petruzzi et al. (2017) summarizes the possible detrimental effects of TT treatment on the sensory properties of fruit juices and beverages.

3.2 High-pressure processing

HPP is a promising non-thermal processing technology that is already been used on a commercial scale for the processing of fruit juices and beverages. HPP uses a liquid medium like water to apply specific pressure to the pre-packaged food products in a closed compartment. HPP has been shown to reduce the microbial load of bacteria, yeast, and mold and extend the shelf life of products under cold storage (Hu et al., 2020; Podolak et al., 2020). The most common inactivation mechanism of HPP for microorganisms is the damaging of the cellular barrier, such as cell wall and membrane, under high pressure (Georget et al., 2015). Similarly, high pressure can disrupt the tertiary and quaternary structure of proteins, which is then followed by the penetration of water into the deformed proteins leading to the loss of interaction between the non-polar domains and eventually to conformational changes or partial unfolding causing enzymes to become non-functional or acquire altered functionalities (van Loey et al., 2003; Georget et al., 2015). While there are several different factors that can influence the efficacy of HPP treatment, applied pressure and treatment time are the main operating parameters (Podolak et al., 2020). Generally, a high pressure between 300–600 MPa is applied to the food for 5–15 min (Houška et al., 2022). Although indirect heating is involved due to adiabatic heating, there is an immediate step of decompression to minimize the thermal effects. The temperature rise and exposure time are low, so the nutritional and sensory properties of HPP-treated fruit juices and beverages are close to those of fresh products, and in some cases, the properties are even improved compared to fresh products (Barba et al., 2010; Huang H.-W. et al., 2020).

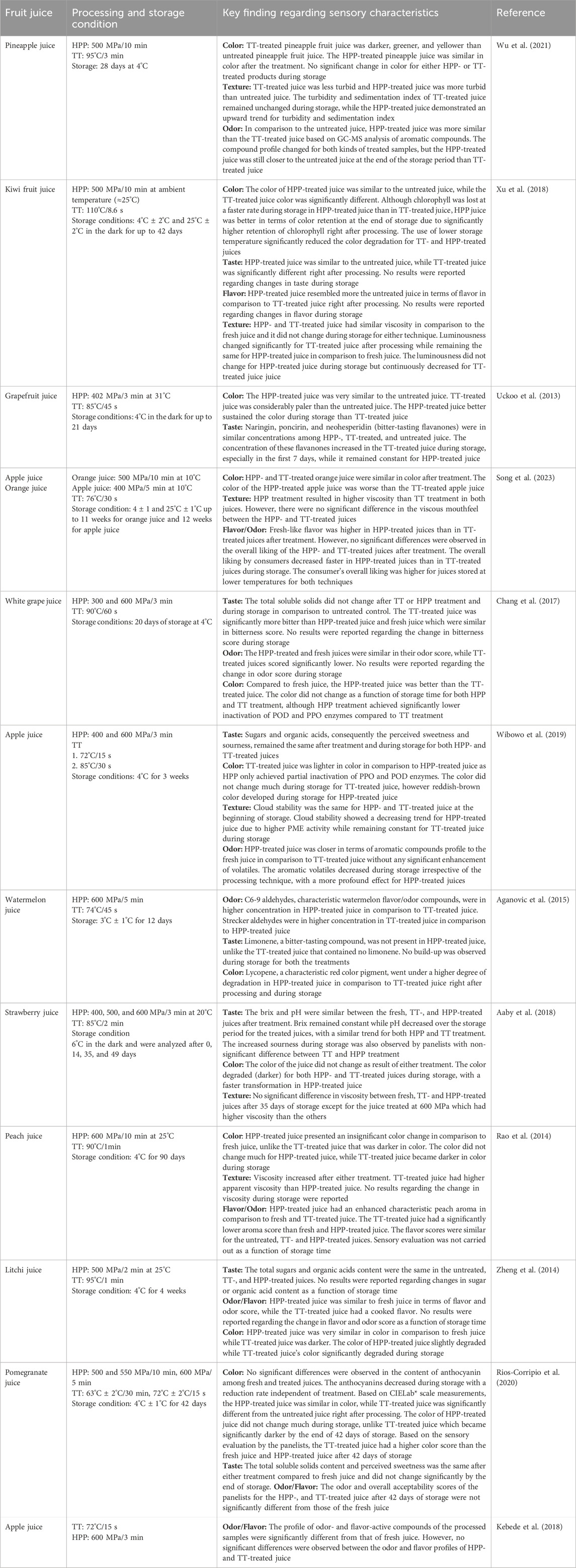

HPP treatment has also been reported to reduce the bitter/grapefruit-like flavor notes that are often perceived to a higher degree in TT-treated juices (Baxter et al., 2005; Hu et al., 2020). The bitter/grapefruit-like flavor and odor notes have been attributed to the thermally induced production of limonin and volatile sulfur compounds like one-p-menthene-8-thiol from sulfur-containing amino acids like methionine (Perez-Cacho et al., 2007; Zhang et al., 2024). HPP has been reported to have little to no effect on the covalent bonds of the pigment compounds responsible for the coloration of fruits, such as chlorophyll, carotenoids, and anthocyanins (De Ancos et al., 2000; Butz et al., 2002; Garcia-Palazon et al., 2004; Oey et al., 2008; Houška et al., 2022). The magnitude of the applied pressure and not the treatment time affects color during HPP treatment, if at all (Ahmed et al., 2005). Cold pasteurization techniques like HPP contribute to better retention of color after processing because the non-enzymatic browning reaction is significantly slowed. The better color properties may also be due to the higher retention of AA at low temperatures. AA is a heat-labile compound that easily oxidizes to DHA, and this oxidation reaction is significantly accelerated at elevated temperatures. The DHA can degrade to 2,3-diketogulonic acid following further degradation to xylosone, furfural, and reductones. These compounds can react with the free amino acids in the matrix to form brown pigments that cause the loss of fresh-looking color in fruit juices (Bharate and Bharate, 2012). HPP can even enhance the color of processed foods by releasing pigments from the cellular compartments into the extracellular spaces of the plant matrix under pressure (Dörnenburg and Knorr, 1993; De Ancos et al., 2000; Oey et al., 2008). Table 1 summarizes the main findings from different studies reported in recent years that investigated and compared the sensory properties of fruit juices subjected to TT and HPP.

Table 1. The table describes the main findings of selected studies in the recent years comparing the sensory properties of fruit juices processed with two different processing techniques: conventional thermal processing (TT) and high-pressure processing (HPP).

3.3 Ohmic heating

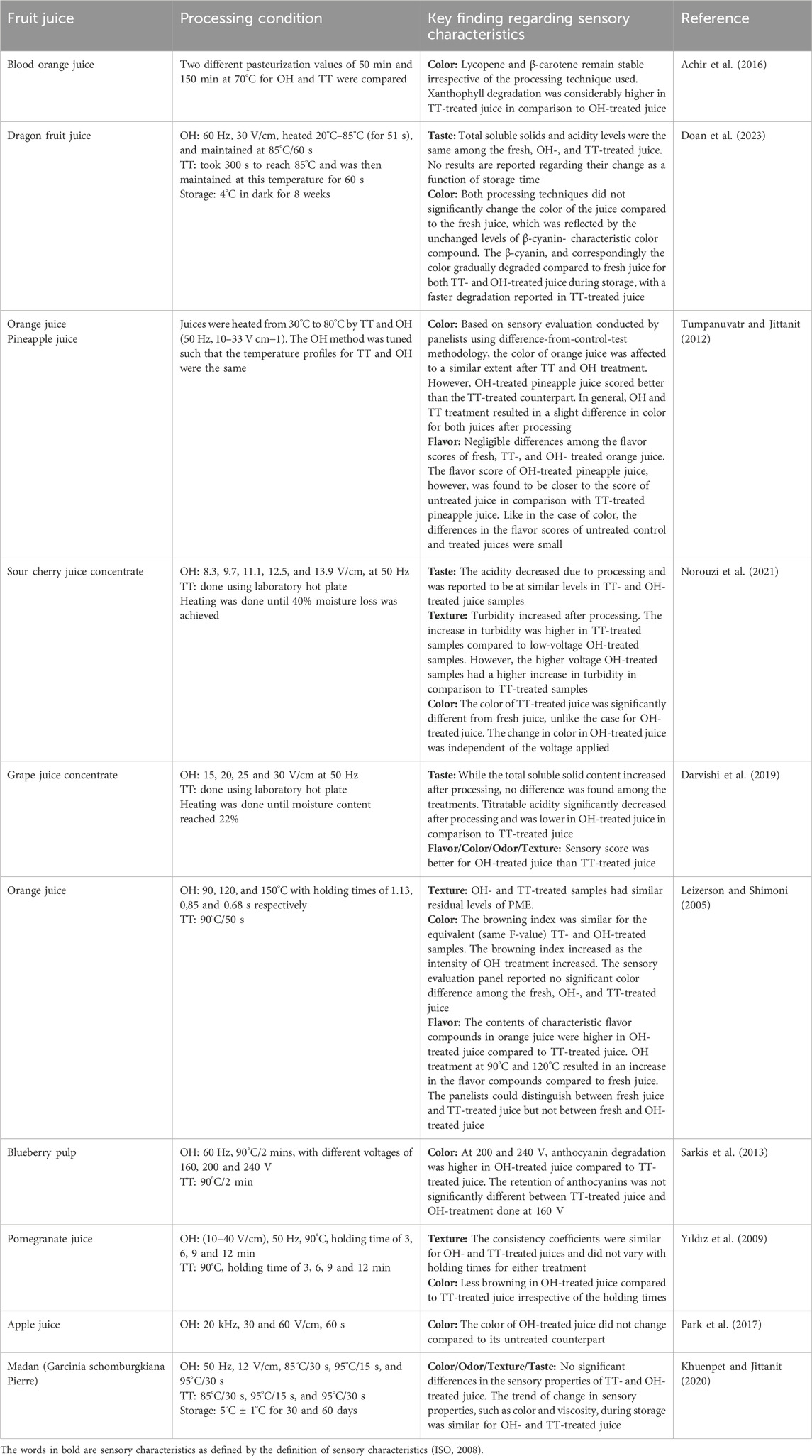

OH is an emerging thermal processing technique that uses electric current to generate heat inside the food. OH is an eco-friendly alternative to TT and provides faster and uniform heat treatment, resulting in shorter treatment times (Darvishi et al., 2013; Fadavi and Salari, 2019). Heating rates as different as 80°C/min for OH treatment and 2°C/min for TT treatment in orange juice have been reported (Achir et al., 2016). The intensity of the OH treatment depends on the applied voltage gradient and the electrical conductivity of the food but is also affected by other factors like the size of suspended particles, solid-liquid ratio, ion content, and current frequency (Doan et al., 2022). OH has been reported to be quite effective in processing fruit juices, as they contain a higher proportion of water and ionic salts, which provide high electrical conductivity (Millers and Silva, 2012). OH involves two inactivation mechanisms: electroporation and heating. OH has been shown to be more efficient than TT treatment in terms of inactivating pathogens, and this additional antimicrobial effect is attributed to electroporation (Park and Kang, 2013). The OH-treated foods resemble fresh and minimally processed food products regarding their nutritional and sensory properties mainly due to short treatment time (Leizerson and Shimoni, 2005; Petruzzi et al., 2017). For example, OH treatment resulted in processed orange juice with a higher concentration of important desired odor-active volatiles like decanal, octanal, limonene, pinene, and myrcene than the TT-treated juice and fresh orange juice (Leizerson and Shimoni, 2005). The OH treatment also enables higher retention of characteristic color compounds in fruit juices, which includes carotenoids like cis-violaxanthin, lutein, zeaxanthin, cis-antheraxanthin, and β-cryptoxanthin, compared to TT treatment for the same pasteurization effect (Achir et al., 2016). Sarkis et al. (2013) reported a higher degree of degradation of anthocyanins in blueberry pulp treated with TT treatment in comparison with OH at low voltage (160 V). However, at such low voltage, there was no considerable difference in the heating time between the OH and TT treatments. With higher voltages for OH treatment, the treatment time could be significantly reduced, but the degradation of anthocyanins was higher in comparison to TT treatment due to electrochemical degradation effects (Sarkis et al., 2013). Darvishi et al. (2019) also reported potential electrochemical degradation of organic acids in grape juice after OH treatment. The non-thermal effects due to the applied electric field need to be considered when talking about the effect of OH on food quality as they can cause electrochemical degradation of compounds contributing to the sensory properties (Kaur et al., 2016). The main results from studies that investigated and compared the influence of OH and TT treatment on the sensory properties of fruit juices and beverages are presented in Table 2.

Table 2. The table summarizes the key findings from selected studies in the last 10–15 years that studied the influence of ohmic heating (OH) and conventional thermal processing (TT) on different aspects of sensory quality of fruit juices.

3.4 Pulse electric field

PEF uses electrical pulses for a short period to treat food products. Typically, a field intensity of 25–85 kV/cm, and an exposure time of a few milliseconds, or in some cases, nanoseconds is used (Jadhav et al., 2021). The effectiveness of PEF treatment depends on the energy of the applied pulses (electric field strength and frequency) and the exposure time. Depending on the intensity of electric pulses used, PEF treatment can be categorized as low-intensity, moderate-intensity, and high-intensity PEF (Timmermans et al., 2019). The inactivation mechanism involved in PEF treatment is the perforation of the cell membranes of contaminating microorganisms when they are exposed to an external electric field, a phenomenon known as electroporation (Demir et al., 2023). Electroporation induced by the electric field can be reversible or irreversible depending on the intensity of PEF treatment (Timmermans et al., 2019). The inactivation of enzymes by PEF treatment can be explained by the unfolding of proteins and the redox reaction induced by the electric field, which then alters the surface configuration of enzymes (the tertiary and quaternary structure) and affects their ability to bind the substrate at their active site (Zhao et al., 2012; Salinas-Roca et al., 2017). The thermal effect due to ohmic heating, especially in the case of high-intensity PEF, also contributes to enzyme inactivation (Jaeger et al., 2010). Due to the short treatment time, any adverse effects of heating are minimized, resulting in PEF-treated products having higher retention of bioactive compounds compared to TT treatment (Morales-de La Peña et al., 2016). Although OH and PEF are, in principle, two different processing techniques, with the introduction of high-intensity PEF treatment, the difference between the two is diminishing. In OH, an electric field strength of less than 0.5 kV/cm is used, and the current flows directly through the food to be treated, with inactivation happening mainly by Joule heating and to some extent by electroporation (Timmermans et al., 2019). On the other hand, high-intensity PEF uses high-intensity electrical pulses at an electric field strength of 10 kV/cm or higher with a pulse width of 2 μs that result in significant temperature rise due to Joule heating (Timmermans et al., 2019). For example, a 40 kV/cm high-intensity PEF treatment resulted in a 15°C increase in the temperature of apple juice (Ertugay et al., 2013). Inactivation occurs not only by electroporation, as in the classical case of PEF, but also by heat generated due to the application of high-intensity pulses (Timmermans et al., 2019).

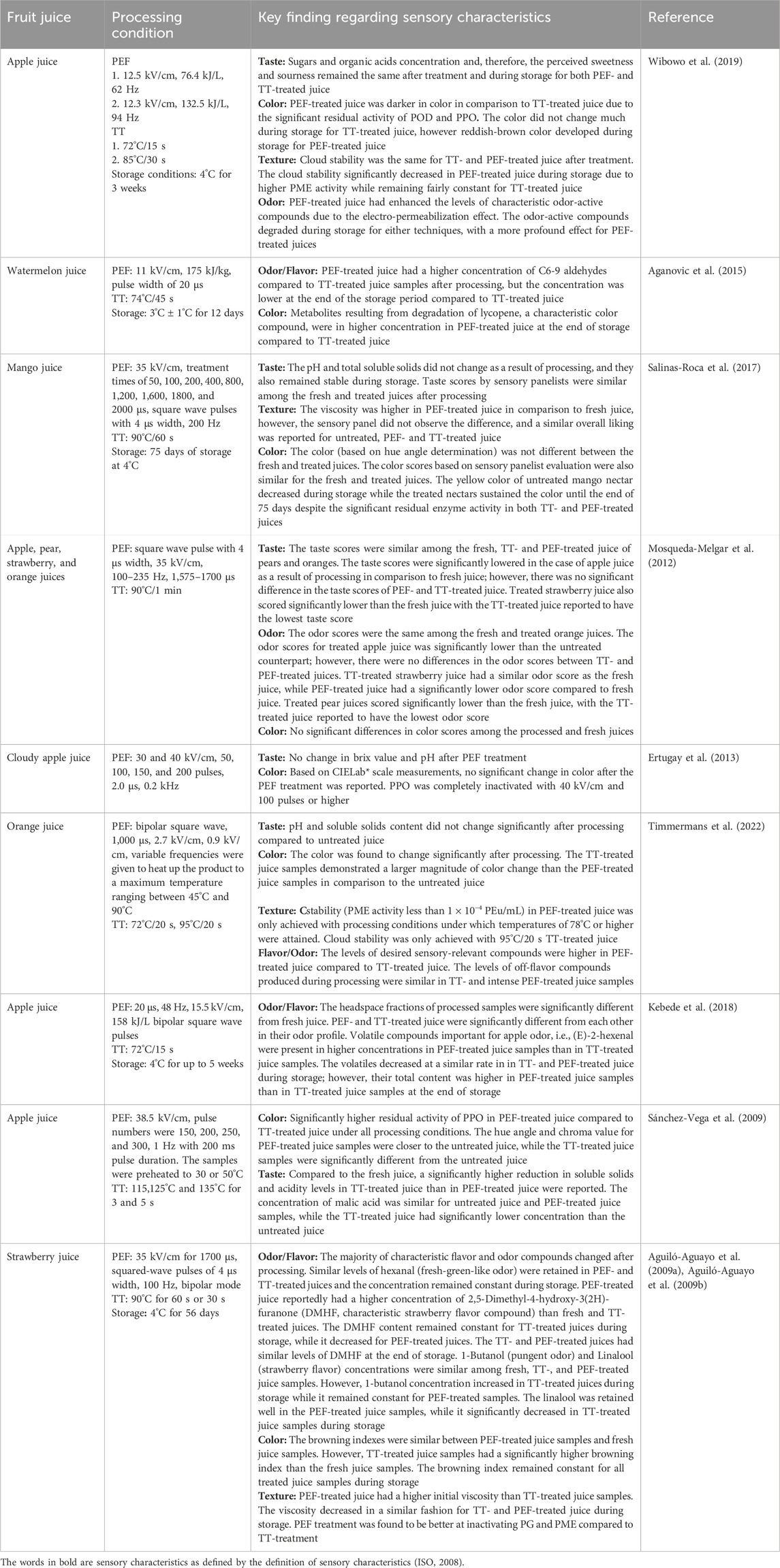

Like HPP, PEF has been reported to affect covalent bonds in the pigment compounds minimally. As PEF predominantly operates at ambient temperatures, the non-enzymatic browning reaction is significantly retarded, enabling better retention of color in fruit juices and beverages (Sánchez-Vega et al., 2009; Timmermans et al., 2022). PEF also helps in better retention of AA and prevents its oxidation to DHA, which can contribute to the deterioration of the color of the product, as explained previously. PEF treatment has also been reported to enhance desirable color characteristics of processed foods by facilitating the release of color compounds outside of the cell due to the electroporation effect (Dörnenburg and Knorr, 1993; Elez-Martínez et al., 2005; Aguiló-Aguayo et al., 2009a; Ghosh et al., 2022). However, this is not always the case, as Plaza et al. (2011) did not report any change in the carotenoid or xanthophyll content in orange juice after PEF treatment compared to fresh juice. Some studies reported to have found the PEF- and TT-treated juice to be similar in color retention after treatment (Mosqueda-Melgar et al., 2012; Salinas-Roca et al., 2017; Mannozzi et al., 2019). Contrary to most findings in the literature, Wibowo et al. (2019) found the PEF-treated apple juice to be darker in color compared to its TT-treated counterpart due to the high residual activity of color-degrading enzymes such as PPO and POD. Table 3 presents the major findings from recent studies on the comparison of the influence of PEF and TT treatment on the sensory properties of fruit juices and beverages.

Table 3. The table presents the main findings from selected studies in the last few years that studied the effect of pulse electric field (PEF) and conventional thermal processing (TT) on the sensory characteristics of fruit juices.

4 Sensory stability of processed fruit juices and beverages

While OH treatment can achieve comparable levels of enzyme inactivation as in TT treatment (Umair et al., 2022), the inactivation of enzymes using HPP and PEF treatment is challenging since the process occurs at ambient temperatures. In general, higher pressure in HPP and higher intensity of pulses in PEF treatment have been reported to result in a significant reduction of enzyme activities in fruit juices (Espachs-Barroso et al., 2003; Garcia-Palazon et al., 2004; Salinas-Roca et al., 2017). However, the typical operating range of 400–600 MPa pressure in HPP (Houška et al., 2022) and 10–20 kV/cm electric field strength in PEF (Toepfl, 2012) that are used in the industry leaves behind a significant residual enzyme activity consequently leading to a limited shelf life under cold storage (Espachs-Barroso et al., 2003; Houška et al., 2022). Fruit juices and beverages treated with cold pasteurization techniques like HPP and PEF may potentially undergo color and flavor changes during storage due to significant residual enzyme activity. The endogenous enzymes like lipoxygenase (LOX), β-glucosidase (B-GLU), peroxidase (POD), pectin methylesterase (PME), hydroperoxide lyase (HPL), polygalacturonase (PG), acyltransferase alcohol (AAT), polyphenol oxidase (PPO), and cysteine lyase play an important role in affecting the appearance and flavor of a food product derived from fruits (Garcia-Palazon et al., 2004; Rodrigo et al., 2007; Schiller et al., 2015). While LOX and HPL significantly contribute to the “fresh” flavor of fruits and fruit-derived products through the formation of C-6 aldehydes from polyunsaturated fatty acids, the concentration of these flavor compounds above a certain threshold level leads to undesirable taste and odor notes (Aguedo et al., 2004). In a study by Polydera et al. (2005), HPP-treated orange juice was found to be more susceptible to the deterioration of color during storage due to a higher rate of enzymatic browning reaction than in the TT-treated counterpart. The residual enzyme activity of PPO in HPP-treated banana and peach puree resulted in significant browning during storage (Khalil et al., 2011). Discoloration in smoothies containing orange, papaya, and melon juices was observed during storage (4°C for 45 days) after HPP treatment (450 and 600 MPa, 3 min at 20°C) and was attributed to residual enzymatic activity (Andrés et al., 2016). PEF and OH treatment did not provide sufficient inactivation of the POD in carrot and apple juices, resulting in a higher browning index compared to TT treatment (Mannozzi et al., 2019).

The magnitude of change in sensory properties during storage after treatment with alternative technologies varies with the type and cultivar of fruit, as the degree of inactivation of an enzyme after processing depends on the matrix. B-GLU from strawberries showed a 41% decrease in activity, while B-GLU sourced from raspberries decreased by only 10% after being treated at 600 MPa for 15 min (Houška et al., 2022). Different enzymes have different susceptibilities toward processing conditions. For example, PME found in mangoes is more resistant to high pressure than PPO and POD (Kaushik et al., 2015). On the contrary, PPO is more resistant to high pressure than POD and PME in strawberries (Chakraborty et al., 2015) and pineapple (Chakraborty et al., 2014). In another study on the effects of HPP on enzymes in strawberries, POD was found to be more resistant than PPO (Garcia-Palazon et al., 2004). The difference in results regarding the susceptibilities of PPO and POD in strawberries could be due to the different cultivars investigated in the respective studies, and this further corroborates the theory that matrix has a strong influence on enzyme stabilization. Different susceptibilities of enzymes to PEF treatment in different matrices have also been reported in the literature. PPO in apple juice was found to be more resistant to PEF than POD (Schilling et al., 2007). On the other hand, the POD in white grapes was more resistant to PEF compared to PPO (Marsellés-Fontanet and Martín-Belloso, 2007). PG was found to be more resistant to PEF than PME in strawberry (Aguiló-Aguayo et al., 2009a) and watermelon juice (Aguiló-Aguayo et al., 2010).

There is some evidence in the literature of stable sensory properties of fruit juices and beverages during storage after processing with emerging thermal and non-thermal processing techniques. Fresh mango juice subjected to HPP treatment (550 MPa for 1 min) was stable in terms of pH, total soluble solids, and color for up to 60 days at three different storage temperatures of 4, 12, and 20°C (Hiremath, 2005). The author also reported that the mango juice treated at 400 MPa demonstrated significant color degradation during storage at all three temperatures, with the most drastic decrease at 20°C. However, Hiremath (2005) did not offer the comparison of HPP-treated mango juice with a TT-treated counterpart to see which technique offered a longer shelf life with better sustenance of sensory quality. Additionally, the author did not explore the changes in other sensory properties like taste, odor, and texture during storage for HPP-treated juice, which is an important dimension to explore to ensure consumer acceptance of the product. In another study by Baxter et al. (2005), comparable levels of key aromatic compounds were found in TT-treated (85°C for 25 s) and HPP-treated (600 MPa for 60 s) orange juice after processing. The HPP-treated juice stored at 4°C was acceptable to the consumer for up to 4 weeks, while the TT-treated juice could be stored at 10°C and was still acceptable to the consumer after 4 weeks of storage (Baxter et al., 2005). Grape juice also showed good overall flavor stability over a storage period of 30–60 days at 4°C after HPP treatment (Daoudi et al., 2002). In orange juice, cloud stability was observed despite significant residual PME activity after HPP treatment (Nienaber and Shellhammer, 2001; Lacroix et al., 2005). This peculiar behavior could be explained by the smaller size of the suspended cloud particles or by structural changes in the pectin molecules due to shear forces generated under high pressure, which prevents them from being used as a substrate by PME that causes phase settling issues (Terefe et al., 2013). Despite incomplete inactivation of PME in orange juice after PEF treatment, no viscosity change was reported during storage at 4°C and 22°C for 2 months (Elez-Martínez et al., 2005). The authors also reported better color retention for the PEF-treated orange juice than for TT-treated juice under both storage conditions. However, there were no sensory tests performed to determine if this resulted in higher consumer acceptance for PEF-treated juice in comparison to TT-treated juice and if there was deterioration in sensory properties other than color during storage (Elez-Martínez et al., 2005). PEF treatment (4.8 kV/cm, 60 pulses, 169 ms treatment time) of apple juice resulted in a residual activity of 17.7% for PPO after processing compared to only 3.2% after TT treatment (75°C, 20 min), but the color change was similar in both cases after processing and during storage at 3°C for 30 days (Sulaiman et al., 2016). The storage of juice at such low temperatures, however, is not economically feasible and it would have been more practical to investigate how the sensory quality changed when stored at ambient temperature.

The presence of residual enzyme activity in fruit juices and beverages is not always detrimental to the sensory quality, as some enzymes may continue to play their role in flavor enhancement during storage. The aromatic compounds in fruits can exist as flavorless glycoconjugates that are non-volatile and are referred to as glycosidic odor precursors (Liang et al., 2020). The contents of the glycosidically bound flavor and aroma compounds are typically higher than the free volatiles in fruits making them an indispensable source for further flavor and odor generation (Hadi et al., 2013). Residual pectolytic enzyme activities such as those of β-glucosidase and malonylesterase may facilitate the release of aglycones from these glycoconjugates and improve the flavor profile (Orruno et al., 2001; Pogorzelski and Wilkowska, 2007; Wang et al., 2023). DMHF, an important odor-active compound that is widely present in fruits, often exists as glucosides in matrices, and pectolytic enzymes can generate free DMHF from these glucosides to further enhance the odor (Yang et al., 2020; Yokoyama et al., 2020). Residual PPO activity can have a positive effect on the flavor and odor profile by co-oxidization of carotenoids in the presence of polyphenols and, subsequently, result in various odor compounds like ionones (Aguedo et al., 2004). HPP can also lead to increased activity of enzymes like β-glucosidase that influence the organoleptic properties of fruit juices, as described earlier. A 76% increase in activity was observed for the β-glucosidase present in strawberries when subjected to 400 MPa pressure for 15 min (Garcia-Palazon et al., 2004). Sumitani et al. (1994) reported an increased amount of benzaldehyde (a common aromatic compound in fruits) in peaches treated at 400 MPa for 10 min at 20°C and this effect was attributed to enhanced β-glucosidase activity. There are several different reasons described in the literature for the enhanced activity of enzymes after HPP treatment. The most common explanation is the disruption of cells under pressure, which releases membrane-bound enzymes and allows the free movement of substrates, ions, and enzymes located in different compartments in the cell (Terefe et al., 2013). Another plausible explanation is the activation of the latent form of the enzyme due to structural modification in proteins under pressure (Buckow et al., 2009; Terefe et al., 2013; Rao et al., 2014).

5 Other miscellaneous factors affecting sensory quality

While processing is a major factor influencing the sensory quality of fruit juices and derived products, the sensory quality of the fruit before processing also has a significant impact. Several factors, such as cultivar, environmental conditions, cultivation method, the maturity stage of the fruits at harvest, and postharvest handling, influence the sensory characteristics of the fruits and, subsequently, the sensory traits of the products derived from them, i.e., juices and beverages.

5.1 Cultivar

The content and the profile of the taste, flavor, and odor compounds in fruits can vary with the cultivar due to differences in the genetic makeup (Hadi et al., 2013; Li et al., 2021). The differences in the sensory profile among the cultivars are significant enough to result in differential consumer preferences based on sensory tests (Xi et al., 2016; Karabulut et al., 2018). The difference in the types and concentration of sensory-related compounds can also be used for the classification of different cultivars of a fruit (Sung et al., 2019; Wu et al., 2022). The knowledge of the sensory quality among different cultivars of fruit is important for designing breeding programs and developing cultivars with superior sensory properties for fresh consumption as well as for the commercial market for processing into further products (Sung et al., 2019; Drkenda et al., 2021).

5.2 Ripening stage

The sensory quality of individual fruit also changes significantly with the different stages of maturity. There is a significant change in the color, taste, texture, and odor of the fruit. The major change in taste is brought by the change in the ratio of sugars, such as glucose, fructose, and sucrose, to organic acids, such as citric acid and malic acid. As the fruit progresses in ripening there is a gradual increase in the content of sugars, especially sucrose. The sucrose serves as a signaling molecule to trigger different ripening processes within the fruit such as inducing ethylene biosynthesis, a ripening hormone, in climacteric fruits (Fei et al., 2020). Abscisic acid (ABA) is an important ripening hormone in non-climacteric fruits, and the level of ABA increases in the presence of increased sucrose levels (Durán-Soria et al., 2020). The organic acids content seems to follow an overall decreasing trend during the ripening process which further contributes to the ripe fruit becoming sweeter (Xi et al., 2016). As the fruit progresses in the ripening stage, there is a continuous loss of green color that is associated with unripe fruit due to chlorophyll degradation, and there is an accumulation of non-green color pigments which gives the fruit their bright color (Kapoor et al., 2022). The literature also describes a strong correlation between high sugar levels and high content of color-imparting phenolic compounds, and carotenoids (Heng et al., 2019; Nardozza et al., 2019). The odor compounds profile also change as the fruit progresses through the different ripening stages. Initially, the profile is dominated by aldehydes like hexanal and (E)-2-hexenal and terpenes such as linalool and nerolidol, which impart a fresh-green-like flavor and odor, a characteristic property of unripe fruits, and they continuously decrease in content as the fruit ripens (Hadi et al., 2013; Karabulut et al., 2018). As the fruit matures, there is an accumulation of compounds like esters and lactones which contribute to the strong fruity flavor and odor (Xi et al., 2016). The ripeness stage of fruit at the time of harvest is critical for the sensory quality of the products derived from it since it affects the ratio of sugar to organic acids, flavor and odor compounds, and the pigment profile (Milic et al., 2016).

5.3 Environmental conditions

The sensory properties of a cultivar of fruit can also vary with season and geographical location due to the difference in the growth conditions. Different cultivars of blueberries grown and harvested in two different years had different sensory properties owing to differences in rainfall, average temperature, and solar radiation between the 2 years (Vilela et al., 2016). The authors reported higher sweetness levels in blueberries associated with higher temperatures during the growing season, and this was true for multiple cultivars of the fruit (Vilela et al., 2016). A study by Sater et al. (2021) also reports higher sweetness levels in different cultivars of southern highbush blueberry when the growth temperatures were higher. There is contradictory evidence regarding how rainfall can affect fruit sweetness levels. Vilela et al. (2016) reported that a higher level of precipitation during the ripening of the blueberry fruit resulted in lower sweetness levels. However, in another study, the blueberries had a higher sweetness level despite a strong precipitation event about a week before the harvest compared to the year when the precipitation event did not occur before the harvest time (Sater et al., 2021). While the differences of the blueberry cultivars in the two studies might potentially explain the contradictory results, it could also be that the timing of precipitation events may be more crucial than the absolute level of precipitation received during the growth period. The inevitable natural variability in the quality of the fruits is a major hurdle for food business operators to produce juices and beverages of homogenous quality, and they should integrate flexibility within their manufacturing processes to adjust accordingly (Riddick et al., 2016). A common approach to adjust the quality of the product is to blend it with the same product obtained from fruits from a different harvest season (Borghoff et al., 2023).

5.4 Cultivation method

The cultivation systems used for the production of the fruit also influences the sensory properties significantly. The organically produced strawberries were found to be sweeter, have better flavor, and have higher overall consumer preference compared to conventionally cultivated strawberries (Reganold et al., 2010). The authors attributed the difference in the quality of fruit to the difference in microbial properties of the soil in organic and conventional cultivation systems, which is due to a combination of factors like the use of synthetic pesticides and fumigation in the conventional systems and higher use of compost in the organic system (Reganold et al., 2010). A significant reduction in characteristic flavor and odor compounds was seen in strawberries when grown under substrate cultivation in comparison to conventional soil cultivation, i.e., the concentration of sensory-active esters was around 74% higher in conventional soil cultivation in comparison to substrate cultivation (Li et al., 2021). The differences in sensory properties arise due to differences in the microbial and nutritional composition between the soil and matrix used in substrate cultivation (Li et al., 2021). The authors also demonstrate the magnitude of difference in sensory properties grown under the two different cultivation system varied significantly with the cultivar (Li et al., 2021). The effect of the cultivation method on the sensory quality of fruit, however, is not as strong as that of the cultivar and the environmental conditions during the growth period (Rocchetti et al., 2022).

5.5 Growth regulators

Fruit drop is a major cause of produce loss; up to 30% produce loss is reported for apples (Arseneault and Cline, 2016). It is a common practice to use natural or synthetic growth regulators to modulate the rate of ripening of fruits by influencing the biosynthesis of growth hormones like ethylene and, therefore, controlling the rate of fruit drop (Rademacher, 2015). The use of such growth regulators, however, also influences the sensory properties of fruits. It is possible to use multiple growth regulators to reduce fruit drop and also optimize the content of desired sensory properties of the produce. A study by Schultz et al. (2022) investigated the effect of naphthalene acetic acid (NAA), aminoethoxyvinylglycine (AVG), and 2-chloroethylphosphonic acid (ethephon) as growth regulators on the rate of fruit drop and sensory quality. Flavor- and odor-active esters like hexyl acetate and alcohols like 1-butanol are the main contributors to the sensory impression of apples and these compounds were present in significantly higher quantities after the application of NAA and ethephon (Schultz et al., 2022). However, their application also resulted in a higher rate of fruit drop. The authors reported that using AVG and NAA in combination was the most efficient in reducing fruit drop and maintaining desired sensory properties (Schultz et al., 2022). The use of NAA and Paclobutrazol improved the level of sweetness, firmness and overall sensory score in mangoes than the control condition where no regulators were used (Naleo et al., 2018). The use of growth regulators influenced the physical and chemical properties of sour cherries, like the total soluble solid-to-acid ratio, color, and firmness (Correia et al., 2019). However, the effect of the growth regulators was found to be cultivar- and season-specific (Correia et al., 2019). This demonstrates that there is an interaction between the applied growth regulators and other factors like the genetic makeup of the plant and the growth conditions that discern the overall effect on fruit sensory quality.

5.6 Postharvest handling

Postharvest handling of fruit is also crucial as it also has a significant effect on sensory traits. Storage temperature is a major factor that affects the sensory quality of fruit after harvesting. The characteristic mandarin flavor was significantly higher for a storage temperature of 8°C as compared to storage under 2°C, and the difference was attributed mainly to the difference in terpene profiles under different storage temperatures (Tietel et al., 2012). The effect of storage temperature on the sensory traits of mandarin also varied significantly with the cultivar (Tietel et al., 2012). The storage temperature and time for apple fruit post harvesting played a crucial role in the cloud stability of acquired fresh apple juice as the storage conditions had a direct influence on the type and the quantity of substances that are susceptible to precipitation, such as starch, total phenolics, soluble protein and pectin (Wang et al., 2022).

5.7 Packaging material

Apart from the type of technology employed for preservation, the type of packaging material can also play an important role in influencing the sensory profile of fruit juices and beverages during storage. The ultrasound-treated sweet lime juice had a higher overall sensory score for the juice stored in multilayered polyethylene terephthalate pouches than in coextruded ethylene vinyl alcohol copolymer pouches due to better barrier properties against oxygen and moisture (Shaik and Chakraborty, 2023). Youssef (2013) demonstrated that retention of typical orange juice flavor and color and reduced off-flavor production could be better achieved using Tetra Pak boxes than PET bottles at 4°C for up to 75 days. The Tetra Pak boxes are significantly better at preventing oxygen from diffusing across the packaging material and into the headspace of the juice container which facilitates better retention of sensory properties (Youssef, 2013). The aluminum cans were found to better retain the color of sour cherry nectar than 6-layered carton boxes (Bakan and Ekşi, 2014). Hydroxyl methyl furfural (HMF) is an intermediate Maillard reaction product and is often used as an indicator of quality deterioration in food products (Wibowo et al., 2015). Interestingly, the authors also report a significantly higher accumulation of HMF in sour cherry nectar stored in aluminum cans than in the cartons due to the migration of metal ions from the aluminum cans to the fruit juice, which alters the rate of Maillard reaction (Bakan and Ekşi, 2014). The prickly pear juice stored in vacuum-sealed polyamide/polyethylene pouches better retained sensory characteristics like taste and flavor than in air-packed pouches at 4°C storage (Karabagias et al., 2019).

6 Sensory evaluation methods

While reviewing studies on the impact of processing technologies on the sensory properties of fruit juices and beverages, it is also important to shed light on how the sensory evaluation is conducted. There are several different ways of conducting sensory evaluation.

6.1 Qualitative methods

The most common approach used in the literature is using trained panelists to assess sensory quality (Giménez et al., 2012; Djekic et al., 2021). The panelists can use discriminative or intensity scales to record their evaluations as a degree of difference between the control samples and test subjects. This methodology is called the difference-from-control test. While this methodology accurately identifies differences in sensory properties, the evaluation does not necessarily inform how consumer preference is influenced. Another approach, referred to as descriptive analysis, involves the panelist providing a numerical response using a scale corresponding to the intensity of some sensory properties integral to the product. The studies using trained panelists to carry out sensory evaluation need to ensure that they recruit an optimal number of panelists, i.e., in the range of 8–12, the panelists are well trained, the training procedure is documented, and the performance of the trained panelists is validated before the final evaluation is carried out (Djekic et al., 2021). The studies should also provide data regarding panelists’ demographic characteristics, selection and training criteria, and performance analysis results (Djekic et al., 2021). ISO 11132 provides guidelines on how to validate the performance of trained panelists (ISO, 2021). Sensory evaluation can also be based on consumer liking/preference data collected using a hedonic scale. While it is easier to conduct such an evaluation since the participants need not be trained, using consumer-liking data to conduct sensory evaluation requires many participants, i.e., 100 people or more (Mammasse and Schlich, 2014; Yang and Lee, 2019). The requirement for many participants also makes it hard to repeat sensory evaluation to increase the confidence in results. Traditional sensory evaluation methods like difference-from-control, description analysis, and consumer tests are subjective due to highly variable human responses (Torrico et al., 2023). Typical psychological biases in traditional sensory evaluation are the halo/horn and dumping effect (Kappes et al., 2006). Depending on the sensory evaluation technique used, the effect on the cognitive bias can vary, but generally, the consumer tests are susceptible to a higher degree of bias than other techniques (Torrico et al., 2023). Multiple ways are reported in the literature to minimize such biases, for example, using advanced statistical knowledge to manage the variability in the responses (Yu et al., 2018) and improving experimental design (Jirangrat et al., 2013). However, the results still carry significant bias.

6.2 Quantitative methods

Modern instrumental techniques offer an unbiased quantitative-based approach to sensory evaluation. Different instrumental techniques exist for analyzing different sensory parameters like a rheometer and texture profile analyzer to study texture, a refractometer to estimate sweetness level, a pH meter or automatic titrator to estimate the acidity levels, and color analyzers based on CIELAB color space. There exists an array of techniques for analyzing the flavor and odor compounds, such as gas chromatography olfactometry (GC-O), gas chromatography–mass spectrometry (GC–MS), and solid phase microextraction-gas chromatography–mass spectrometry (HS-SPME-GC–MS). The instrumental techniques for sensory evaluation provide a higher degree of sensitivity, objectivity, accuracy, and consistency of results compared to traditional sensory evaluation methods involving human testers (Gao et al., 2024). However, a major drawback of these instrumental techniques is that the data is purely analytical and does not necessarily inform how the sensory traits measured influence consumer responses (Giménez et al., 2012). More advanced instrumental techniques have been developed to facilitate quantitative-based sensory evaluation by providing better insight into human perception, like e-nose and e-tongue, and biosensors to monitor involuntary/subconscious reactions during evaluation like heart rate, skin conductance, and body temperature (Wasilewski et al., 2019; Torrico et al., 2023; Tibaduiza et al., 2024). These novel techniques, however, come with their own set of drawbacks, like complex data cleaning skills are required when monitoring involuntary responses, and the performance of sensors used in e-tongue and e-nose can vary considerably with external factors like temperature, humidity, and matrix (Tan and Xu, 2020; Torrico et al., 2023). Additionally, considering the nuanced nature of human sensory perception, techniques like e-nose and e-tongue can not fully reproduce the perception that the brain generates as a response to sensations (Torrico et al., 2023; Gao et al., 2024). In the context of the alimentary industry, the integrated use of human testers and instrumental techniques like e-nose and e-tongue is recommended to get a reliable and comprehensive understanding of sensory quality (Tibaduiza et al., 2024).

7 Knowledge gaps in the literature

There are several studies reported in the literature that compare emerging thermal and non-thermal technologies with TT treatment in terms of their influence on the sensory properties of fruit juices and beverages. However, there exist knowledge gaps that warrant attention.

7.1 Stability of sensory quality during storage

The sustenance of the sensory quality of a treated product during storage needs to be studied to make a fair and holistic comparison among the preservation technologies. A significant number of studies reported in the literature, however, do not address the important dimension of storage time while conducting the comparison. The application of heat-based treatments like TT and OH treatments successfully lead to the inactivation of the majority of quality-related enzymes (Umair et al., 2022) compared to only partial inactivation achieved with HPP (Terefe et al., 2013; Wibowo et al., 2019) and PEF (Elez-Martínez et al., 2005; Sánchez-Vega et al., 2009; Terefe et al., 2014; Sulaiman et al., 2016). As mentioned in section 7, the residual enzyme activity can have both positive and negative impacts on the sensory quality during storage. The studies reported in Tables 1–3 offer insight into how the sensory property of fruit juices changes over time after HPP, OH, and PEF processing compared to TT treatment.

7.2 Enzyme sensitivity towards non-thermal treatments

There also exists a lack of knowledge and rather contradictory evidence regarding susceptibilities of enzymes relevant to the sensory quality of fruit juices and beverages towards HHP and PEF treatment, as highlighted in section 4. In the case of TT treatment, POD is considered to be the most heat-stable enzyme, and it serves as a marker for determining the efficiency of the applied treatment (O’Donnell et al., 2010). Unlike in the case of TT treatment, it is hard to generalize which enzymes in fruit juices are more resistant to PEF and HPP. The scarcity of information on this topic adds to the challenge of optimizing the non-thermal treatments like HPP and PEF to extend the shelf life of the treated product under cold storage.

7.3 Standardized treatments

Another important observation regarding the studies reported in the literature comparing sensory properties of fruit juices and beverages after TT treatment and non-traditional processing is the lack of standardization in the way TT treatment is conducted. The equipment used in the studies to conduct OH, HPP, or PEF treatment is designed to conduct laboratory-scale experiments and emulate the processing conditions that are present at the industrial scale. However, the TT treatment is conducted in a variety of significantly different ways in the literature: water bath (Yıldız et al., 2009; Rao et al., 2014; Chang et al., 2017; Aaby et al., 2018; Darvishi et al., 2019; Rios-Corripio et al., 2020; Wu et al., 2021; Doan et al., 2023), oil bath (Sánchez-Vega et al., 2009; Achir et al., 2016), tubular heat exchanger (Aguiló-Aguayo et al., 2009a; Aguiló-Aguayo et al., 2009b; Zheng et al., 2014; Kebede et al., 2018; Xu et al., 2018), heating coil system immersed in a water bath (Mosqueda-Melgar et al., 2012; Salinas-Roca et al., 2017; Timmermans et al., 2022), a plate heat exchanger (Leizerson and Shimoni, 2005; Aganovic et al., 2015), steam/hot water jacketed kettle (Sarkis et al., 2013; Uckoo et al., 2013), hot plate stirrer (Tumpanuvatr and Jittanit, 2012; Norouzi et al., 2021), and microwave heating (Mannozzi et al., 2019). The most common approach adopted in studies to mimic TT treatment is heating a pre-weighted sample of fruit juice or beverage in a centrifuge tube immersed in static water or oil bath. The surface area to volume ratio is low in the case of a water bath and oil bath, leading to a slow heat transfer and potential uneven treatment of the sample, i.e., over-treatment of the sample near the surface of the container with cold spots in the center. Lalwani et al. (2021) recently described an additional non-ideal effect that occurs in a tube-fluid system heated in static water and oil bath for low-viscosity fluids like fruit juices related to overheating of samples at the surface due to convection currents. Just like the heating of samples in water or oil baths, the cooling down of samples in static ice baths is also non-optimal due to slow and uneven heat transfer, leading to over-treatment (Greiby et al., 2017; Lalwani et al., 2021). The TT treatments at an industrial scale are conducted using tubular and plate heat exchangers. They offer a high surface area to volume ratio, facilitating faster and uniform heating up of the sample product, which eventually results in shorter come-up and residence time (Huang B. et al., 2020). The way of carrying out the TT treatment significantly affects the heat transfer rate during processing and, therefore, the acquired results. For example, Achir et al. (2016) reported a significantly higher degradation of xanthophyll in orange juices after TT treatment conducted using an oil bath in comparison to OH-treated juice. However, in another study, an insignificant difference in browning index and overall color was observed between orange juice treated with OH treatment and TT treatment done using a plate heat exchanger (Leizerson and Shimoni, 2005). Several other studies reported in the literature that used tubular heat exchangers or pilot scale equipment to conduct TT treatment, interestingly, present conclusions that are contrary to the popular opinion that juices processed with alternative techniques perform better in terms of sensory quality in comparison to TT treatment (Wibowo et al., 2019; Khuenpet and Jittanit, 2020; Song et al., 2023). Wibowo et al. (2019) reported a lighter color in TT-treated apple juice than HPP-treated juice. There was no evidence of better color retention in HPP-treated orange juice than in TT-treated juice (Song et al., 2023). The authors also report no difference in terms of consumer preference based on sensory tests between HPP- and TT-treated orange juice (Song et al., 2023). There was no evidence of a significant difference in the sensory properties of Madan fruit juice after TT and OH treatment (Khuenpet and Jittanit, 2020).

The literature also lacks a systematic comparison of preservation technologies that involves normalization of the used processing conditions, i.e., processing conditions resulting in the same log reduction of a chosen reference microorganism (Petruzzi et al., 2017; Ağçam et al., 2019; Houška et al., 2022). In most of the studies, the processing conditions for the TT and alternative processing techniques do not have the same pasteurization effect since the TT treatment typically targets not only a specific log reduction of the pathogen but also the inactivation of other spoilage microorganisms and enzymes. Additionally, the majority of the studies that investigate and compare the influence of PEF and TT treatment on the sensory quality of fruit juices use electric field strength in the range of 25–85 kV/cm, which is much higher than what is viable at commercial scale (Jadhav et al., 2021). An electric field strength between 10 and 20 kV/cm is used commercially to strike a balance between the effectiveness of PEF treatment and the operation cost (Toepfl, 2012). The use of economically non-viable PEF conditions in studies decreases the relevance of the results for industry.

7.4 Systematic and comprehensive sensory evaluation

The majority of studies reported in this review use trained panelists to carry out a qualitative sensory evaluation. However, the studies lacked the necessary information regarding the panelists’ demographics, training, and validation of their performance. Additionally, the studies that used consumer tests recruited fewer participants than the recommended number (Yang and Lee, 2019). Among the quantitative techniques for sensory evaluation, HS-SPME-GC–MS, rheometer, and CIELAB color analyzer were the most common choices for analyzing odor, texture, and color, respectively. The literature is lacking in studies that conduct systematic and comprehensive sensory analysis using both qualitative and quantitative evaluation methods when comparing different preservation technologies in terms of their influence on the sensory quality of fruit juices and beverages. Although the intent of most studies is to use sensory evaluation data as a tool to demonstrate the stability of a product during storage, it is imperative to implement good practices and standard protocols when conducting such evaluation to acquire accurate information, especially when it has to be used to estimate the food product’s shelf life.

8 Conclusion

Given the growing evidence regarding the positive impact of emerging thermal and non-thermal processing on food quality and the environment, the market for products treated with these technologies has grown significantly. The increasing use of alternative processing techniques for fruit juice and beverage processing warrants attention, as heat has been shown to affect flavor development. Alternative techniques like HPP and PEF that operate at ambient temperature or OH, which is less invasive due to its rapid uniform heating, could result in different sensory experiences in the treated products. This topic has been well studied in the literature, but the information is fragmentary and sometimes contradictory. It is evident that HPP, OH, and PEF can positively influence the retention of compounds that contribute to fresh-like sensory properties in fruit juices and beverages, especially color. A major drawback of non-thermal techniques like HPP and PEF is the significant residual activity of enzymes, which can adversely affect sensory characteristics and the overall quality of the treated product during storage. It was discussed, however, that the residual enzyme activity does not always result in deterioration of the sensory quality and can potentially also have a positive impact. Moreover, it can be established from the literature that the degree of inactivation of an enzyme depends on the type of fruit, the variety, and the physiochemical properties of the matrix. Hence the change in sensory properties during storage of fruit juices after non-thermal treatment varies greatly and cannot be generalized.

The review also concludes with the impression that there is extensive literature on the effects of HPP on the sensory properties of fruit juices; however, the research is limited when it comes to discussing the influence of OH and PEF. Additionally, the literature lacks in conducting a fair and reliable comparison between the different preservation technologies (TT, HPP, PEF, and OH). The reported studies vary in types and cultivars of fruit, processing conditions, and equipment used to undertake TT processing. The lack of standardization in studies is a major reason for contradictory evidence in the literature regarding comparing the influence of TT, HPP, PEF and OH on the sensory quality of food products. For a fair and reliable characterization of the effects of different preservation technologies on the sensory properties of fruit juices and beverages, it is essential to perform studies under comparable conditions, such as the same raw material, normalizing processing conditions by ensuring the same log reduction of a chosen microorganism and use of pilot scale equipment to undertake processing. Additionally, a comprehensive sensory evaluation using a combination of qualitative and quantitative sensory evaluation methods conducted in a standardized manner is crucial. The results of such studies will facilitate precisely elucidating the influence of emerging thermal and non-thermal processing techniques on the sensory quality of fruit juices and beverages in a holistic manner.

Author contributions

HZ: Methodology, Writing–review and editing, Writing–original draft, Project administration, Investigation, Data curation, Conceptualization. AS: Supervision, Funding acquisition, Writing–review and editing. TK: Writing–review and editing. MK: Writing–review and editing, Conceptualization, Supervision.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The project has received funding from European Union’s Horizon 2020 research and innovation program under the Marie Sklodowska-Curie grant agreement No. 956257.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aaby, K., Grimsbo, I. H., Hovda, M. B., and Rode, T. M. (2018). Effect of high pressure and thermal processing on shelf life and quality of strawberry purée and juice. Food Chem. 260, 115–123. doi:10.1016/j.foodchem.2018.03.100

Achir, N., Dhuique-Mayer, C., Hadjal, T., Madani, K., Pain, J.-P., and Dornier, M. (2016). Pasteurization of citrus juices with ohmic heating to preserve the carotenoid profile. Innovative Food Sci. Emerg. Technol. 33, 397–404. doi:10.1016/j.ifset.2015.11.002

Aganovic, K., Grauwet, T., Siemer, C., Toepfl, S., Heinz, V., Hendrickx, M., et al. (2015). Headspace fingerprinting and sensory evaluation to discriminate between traditional and alternative pasteurization of watermelon juice. Eur. Food Res. Technol. 242, 787–803. doi:10.1007/s00217-015-2586-8

Ağçam, E., Dündar, B., Polat, S., and Akyildiz, A. (2019). “Recent studies on healthy nutrients changing in fruit juices processed with non-thermal technologies,” in Health and safety aspects of food processing technologies. Editors A. Malik, Z. Erginkaya, and H. Erten (Switzerland: Springer Nature Switzerland AG), 235–271. doi:10.1007/978-3-030-24903-8_9

Aguedo, M., Ly, M. H., Belo, I., and Teixeira, J. A. (2004). The use of enzymes and microorganisms for the production of aroma compounds from lipids. Food Technol. Biotechnol. 42, 327–336. Available at: https://www.ftb.com.hr/archives/1047-table-of-contents-octoberdecember-2004.

Aguiló-Aguayo, I., Oms-Oliu, G., Soliva-Fortuny, R., and Martín-Belloso, O. (2009a). Changes in quality attributes throughout storage of strawberry juice processed by high-intensity pulsed electric fields or heat treatments. LWT - Food Sci. Technol. 42, 813–818. doi:10.1016/j.lwt.2008.11.008

Aguiló-Aguayo, I., Oms-Oliu, G., Soliva-Fortuny, R., and Martín-Belloso, O. (2009b). Flavour retention and related enzyme activities during storage of strawberry juices processed by high-intensity pulsed electric fields or heat. Food Chem. 116, 59–65. doi:10.1016/j.foodchem.2009.02.007

Aguiló-Aguayo, İ., Soliva-Fortuny, R., and Martín-Belloso, O. (2010). Color and viscosity of watermelon juice treated by high-intensity pulsed electric fields or heat. Innovative Food Sci. Emerg. Technol. 11, 299–305. doi:10.1016/j.ifset.2009.12.004